Patents

Literature

35results about How to "Solve the filling problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

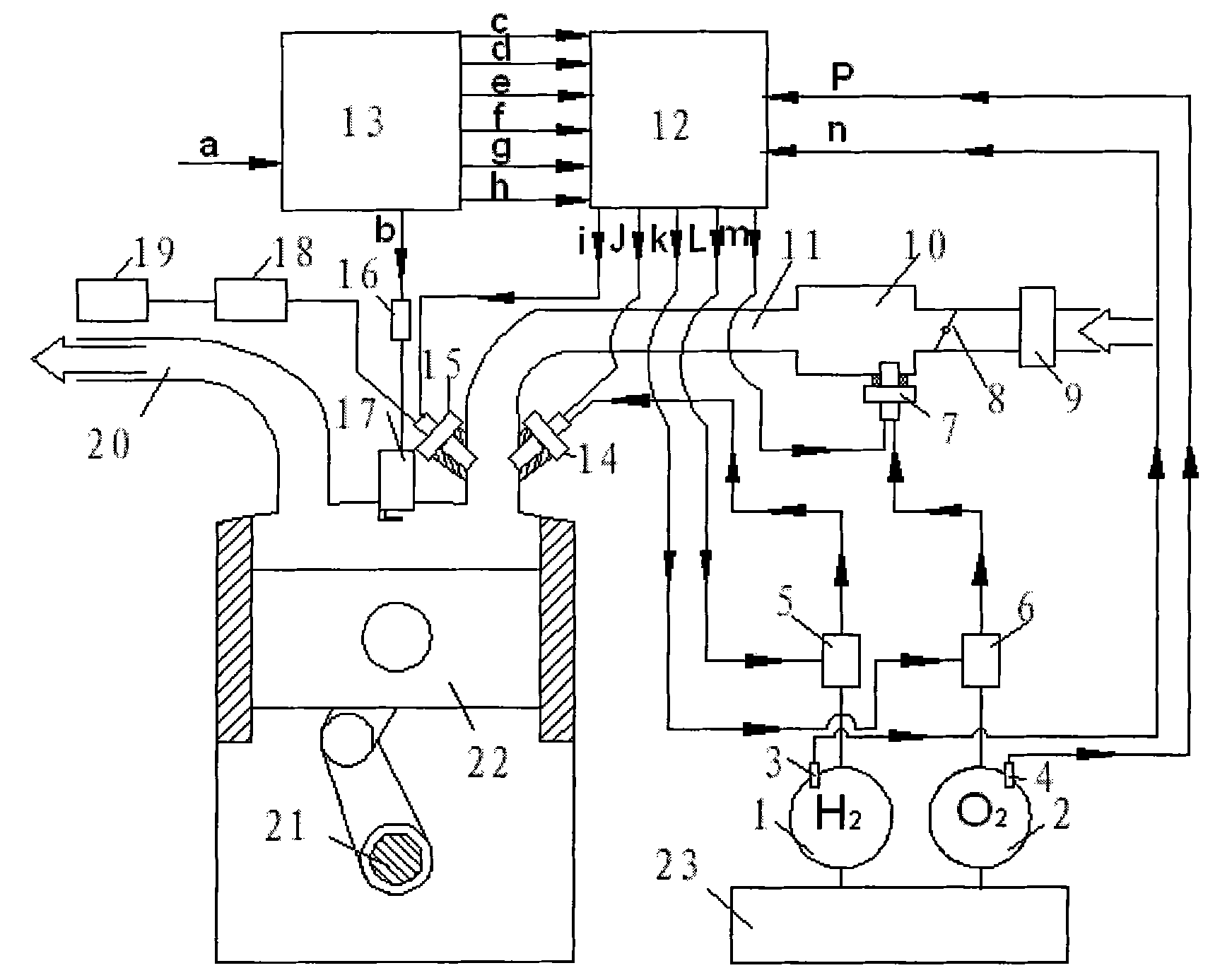

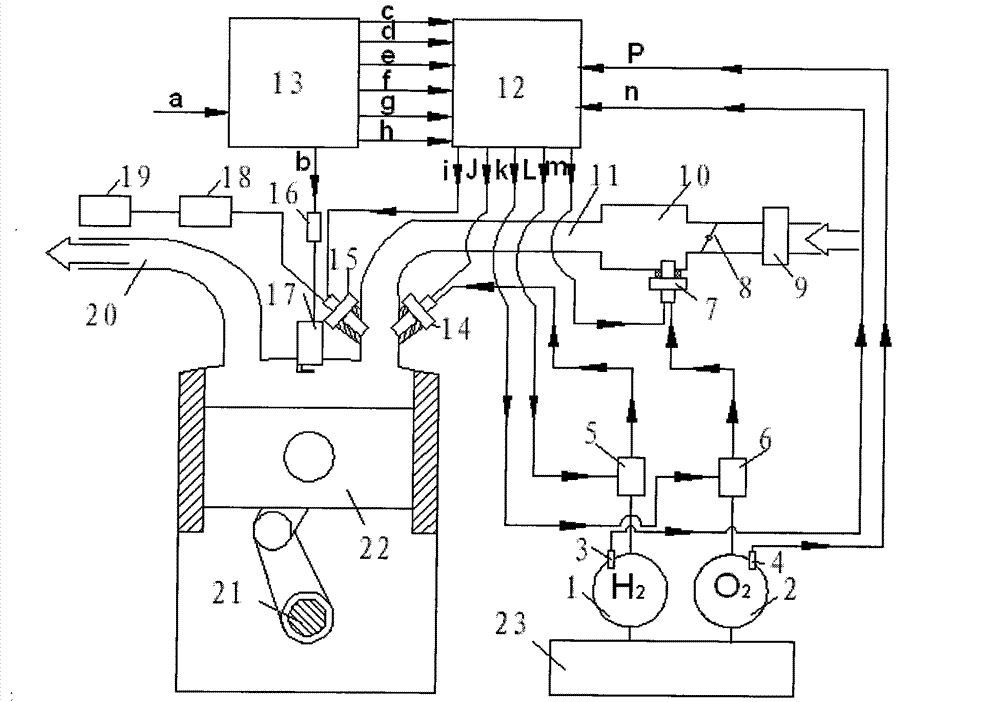

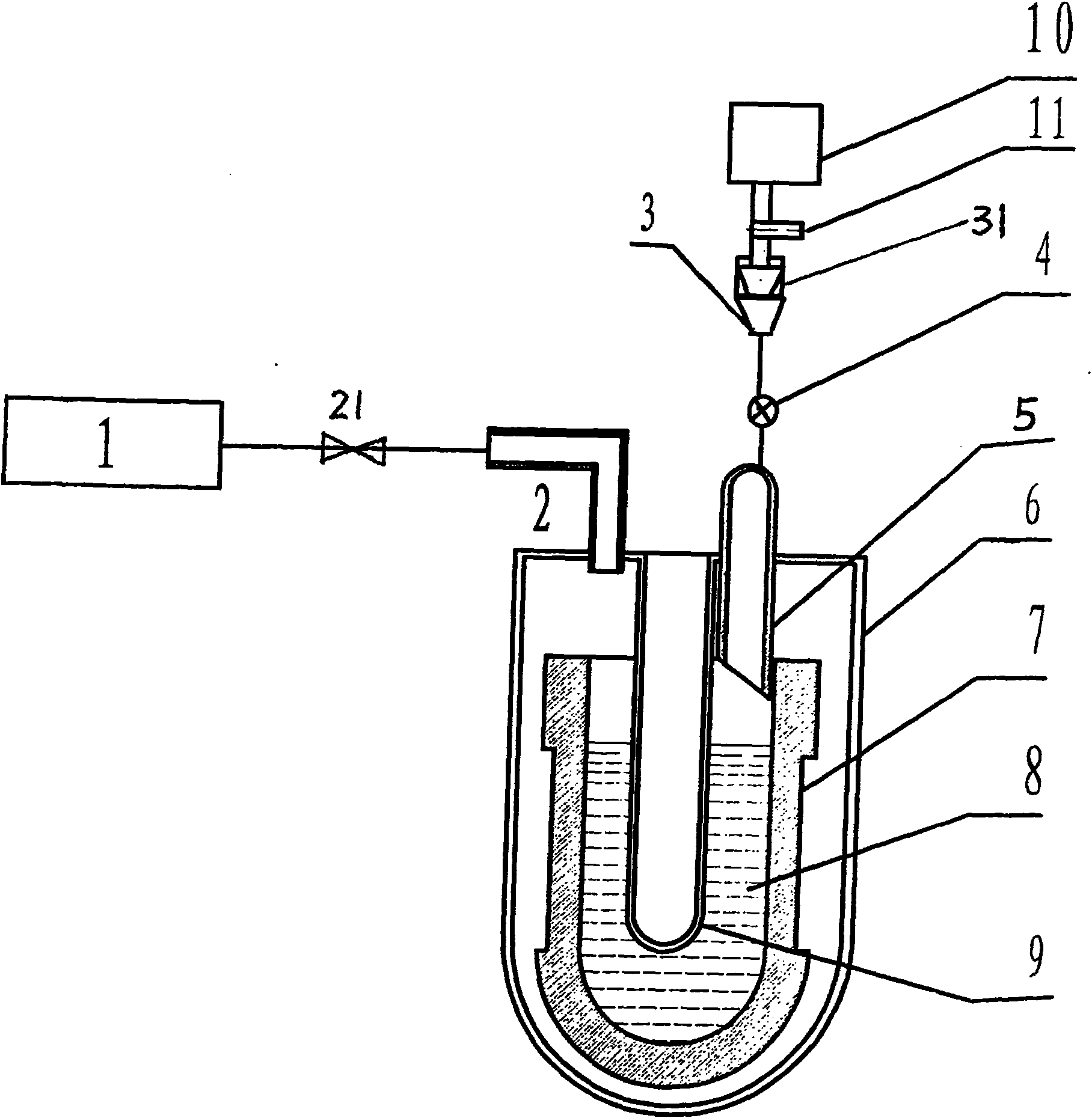

Hydrogen-oxygen-mixed high-octane fuel ignition combustion engine and control method thereof

ActiveCN101975108AReduce consumptionImprove economyElectrical controlInternal combustion piston enginesOn boardLow load

The invention provides an ignition combustion engine by the mode of mixing hydrogen and oxygen with high-octane fuel and a control method thereof, and particularly relates to a fuel storage and supply system of the ignition combustion engine by the mode of mixing the hydrogen and the oxygen with the fuel, fuel proportional distribution and combustion process control, wherein, a set of on-board hydrogen and oxygen production, a storage and supply device is added to the system on the basis of retaining main parts and an electronic control unit of the original engine. The hydrogen and oxygen mixed fuel electronic control unit (12) can control the opening and closing of a hydrogen nozzle and an oxygen nozzle according to sensor signals c-h so that the engine can run in three combustion modes such as pure hydrogen and oxygen mixed gas, hydrogen-oxygen-high-octane fuel mixed gas and pure high-octane fuel according to different operating conditions, thus greatly lowering HC and CO emission in the case of cold starting and idling of the high-octane fuel combustion engine and improving the thermal efficiency and emission level of the high-octane fuel combustion engine in middle and low load stages.

Owner:BEIJING UNIV OF TECH

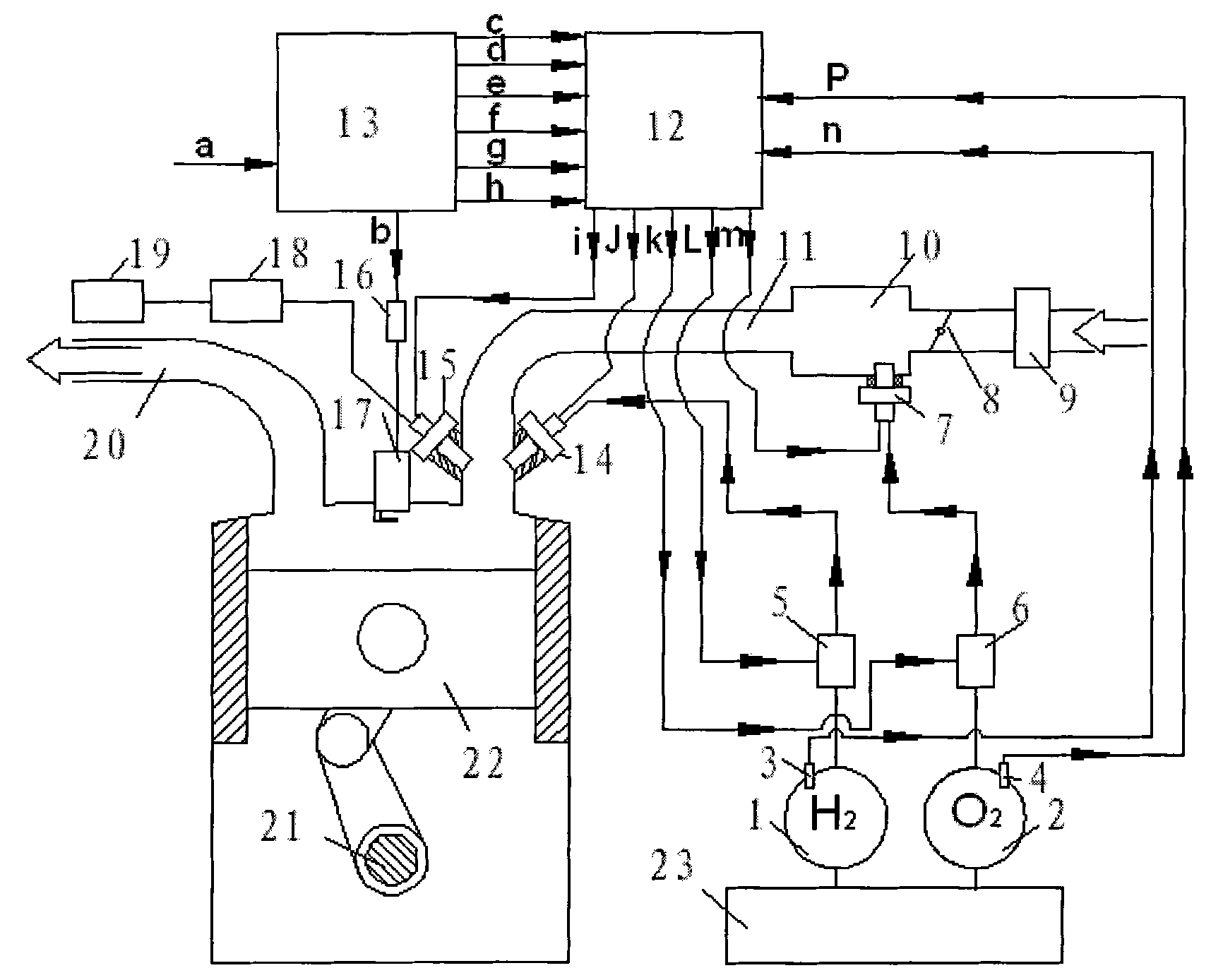

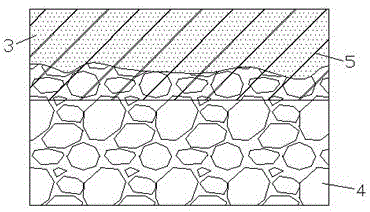

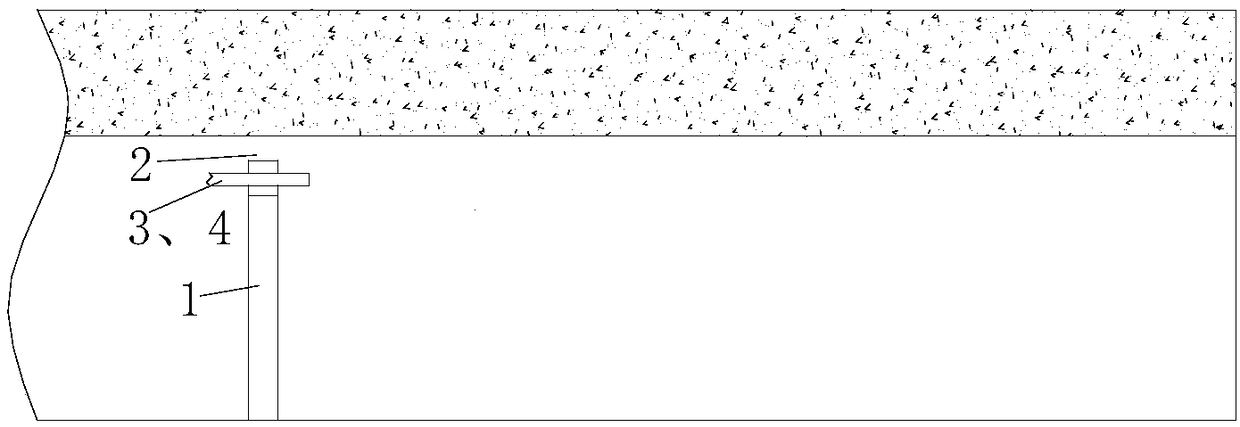

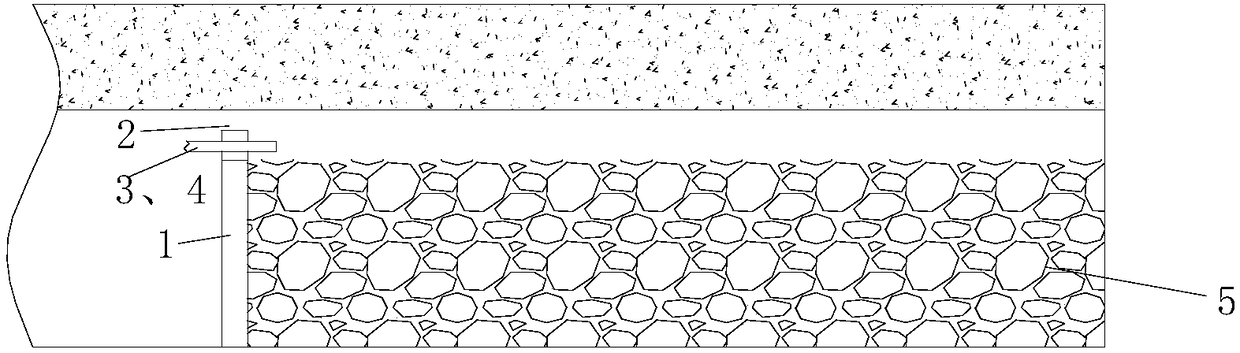

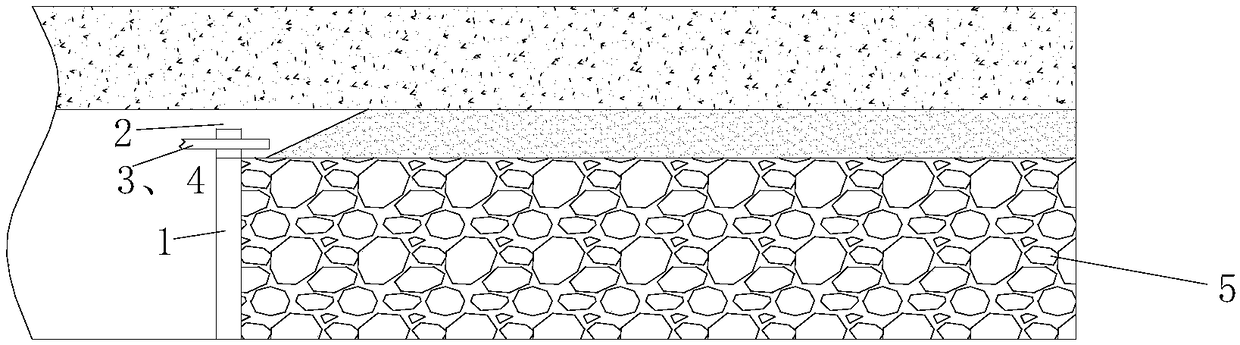

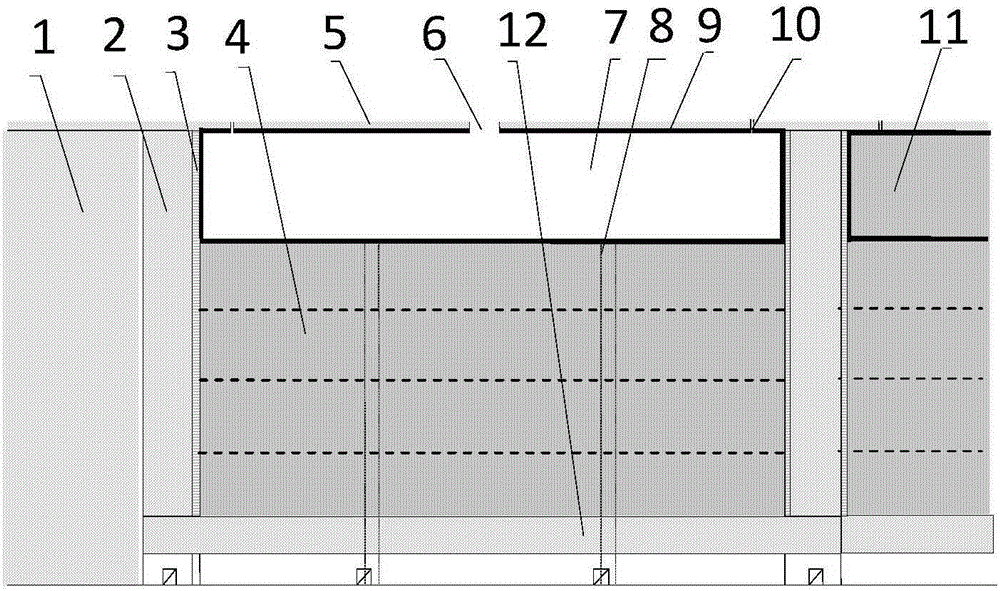

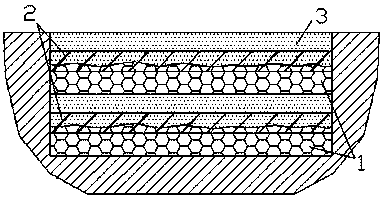

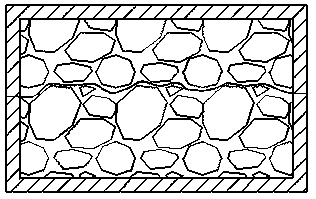

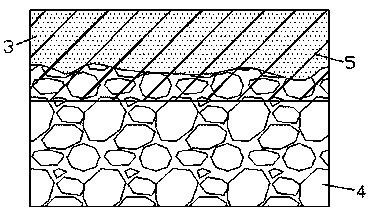

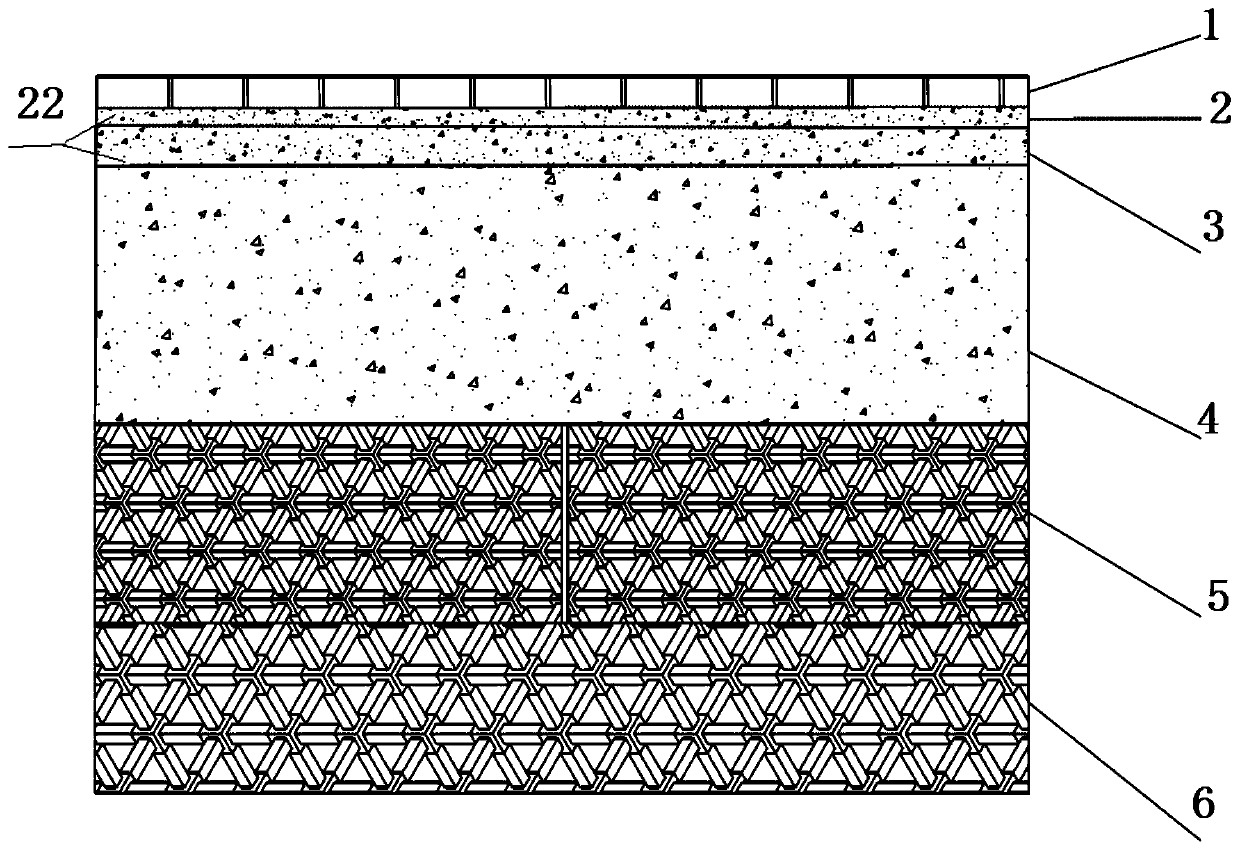

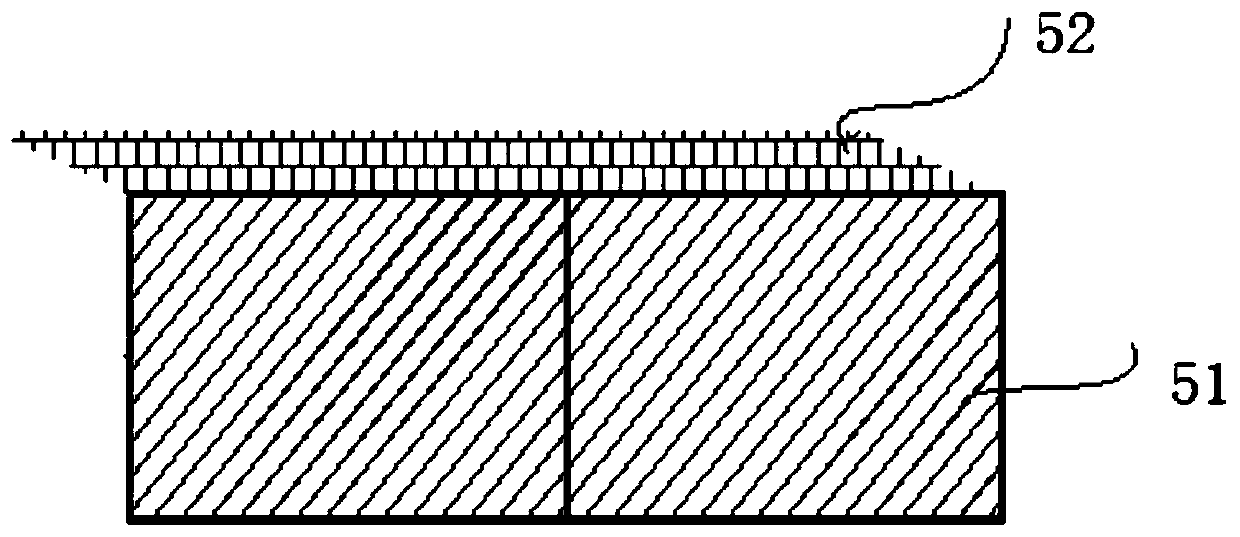

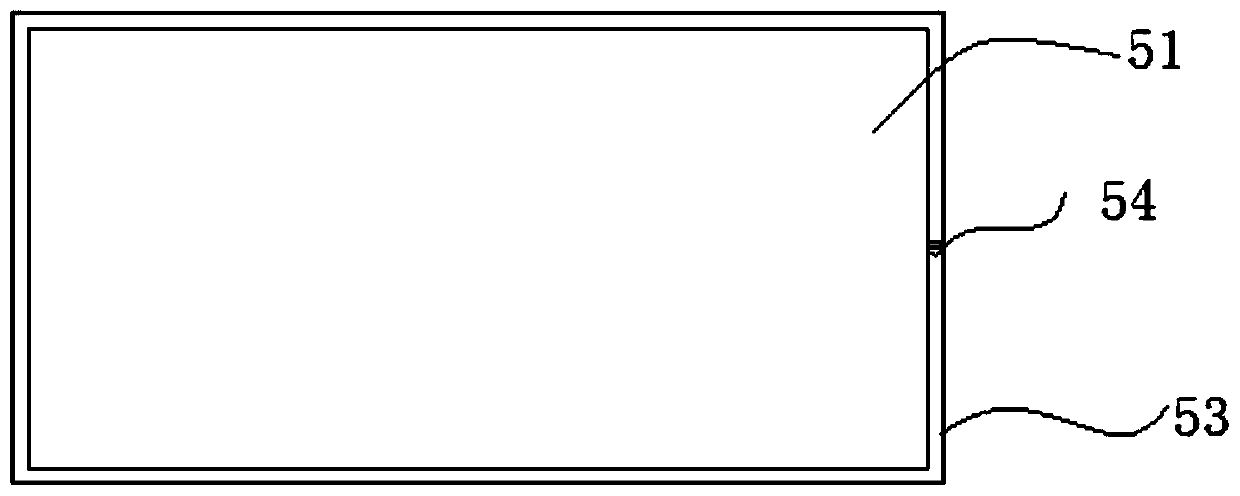

Building waste-doped geogrid cell reinforced sand blanket and construction method

The invention discloses a building waste-doped geogrid cell reinforced sand blanket and a construction method. The geogrid cell reinforced sand blanket mainly consists of a plurality of building waste layers and reinforced structure layers which are crossly arranged in a ground foundation from bottom to top; each building waste layer is formed by compacting and paving the crushed waste concrete; each reinforced structure layer is a geogrid cell; the bottom part of each geogrid cell is partially crossed with the building waste layer thereunder, sand is charged to the middle part and upper part of each geogrid cell, and a sand layer is formed above each geogrid cell; another building waste layer is arranged on each sand layer. The geogrid cell reinforced sand blanket has the advantages that the main body materials are building wastes and geogrid cells, so that the problem of building waste filling is solved, the resource is saved, and the manufacturing cost of project is reduced; the building waste is compacted, and a tight engaged skeleton is formed and is combined with the three-dimensional geogrid cells, so that the bearing capacity of the ground foundation is improved, and the damage due to overlarge deformation of the ground foundation is overcome.

Owner:HUBEI UNIV OF TECH

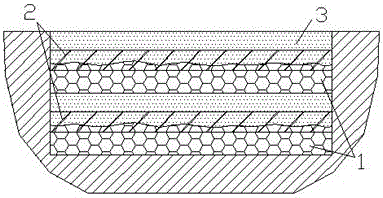

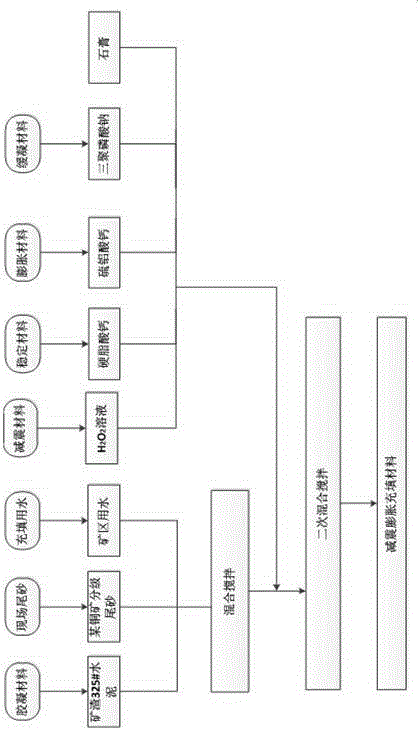

Shock-absorption expansion filling material used for filling deep goaf and preparation method

InactiveCN105152595AStress Migration ReliefPrevention and Control of RockburstsGypsumCalcium aluminates

The invention discloses a shock-absorption expansion filling material used for filling a deep goaf and a preparation method in order to solve the problem that filling cannot realize roof contact after the underground goaf is filled with a conventional filling material. The shock-absorption expansion filling material is composed of a base material and other material, and the base material comprises, in percent by mass, 53.60%-64.89% of mine tailings, 7.44%-14.60% of a gelling material, and the balance water. The other material is prepared from the following raw materials in percent by mass: 3.75%-8.75% of hydrogen peroxide, 2.00%-6.00% of a stabilizing material, 8.00%-12.00% of calcium sulphoaluminate, 1.00%-3.00% of a retarding material, and 2.00%-4.00% of gypsum. The preparation method comprises selection of the materials, proportioning of the ingredients, molding and molding maintenance. Because of the special pore structure, the shock-absorption expansion filling material possesses the advantages of obvious shock absorption performance, relatively good fluidity, excellent expansion performance and the like, and is especially applicable to filling of the metal mineral deep goaf.

Owner:LANZHOU ENG & RES INST OF NONFERROUS METALLURGY

High-early-strength low-expansibility filling material and filling method thereof

PendingCN108439910AWeak expansibilityImprove liquidityMaterial fill-upCeramicwareFoaming agentMaterials science

The invention discloses a high-early-strength low-expansibility filling material and a filling method thereof. The filling material comprises a matrix component and an admixture component; the matrixcomponent comprises an inert material, a cementing material and water; the admixture component comprises, by mass of the inert material, 3-10% of a foaming agent, 3-5% of a foam stabilizing agent and0.1-0.8% of a retarder. The high-early-strength low-expansibility filling material has advantages of high fluidity, long initial setting time, high early strength and low expansibility, the expansionrate is 20-50%, a high tight-filling ratio of 100% can be realized in application to mining filling, and effective support for roofs of goafs or roadways can be formed.

Owner:CHINA UNIV OF MINING & TECH

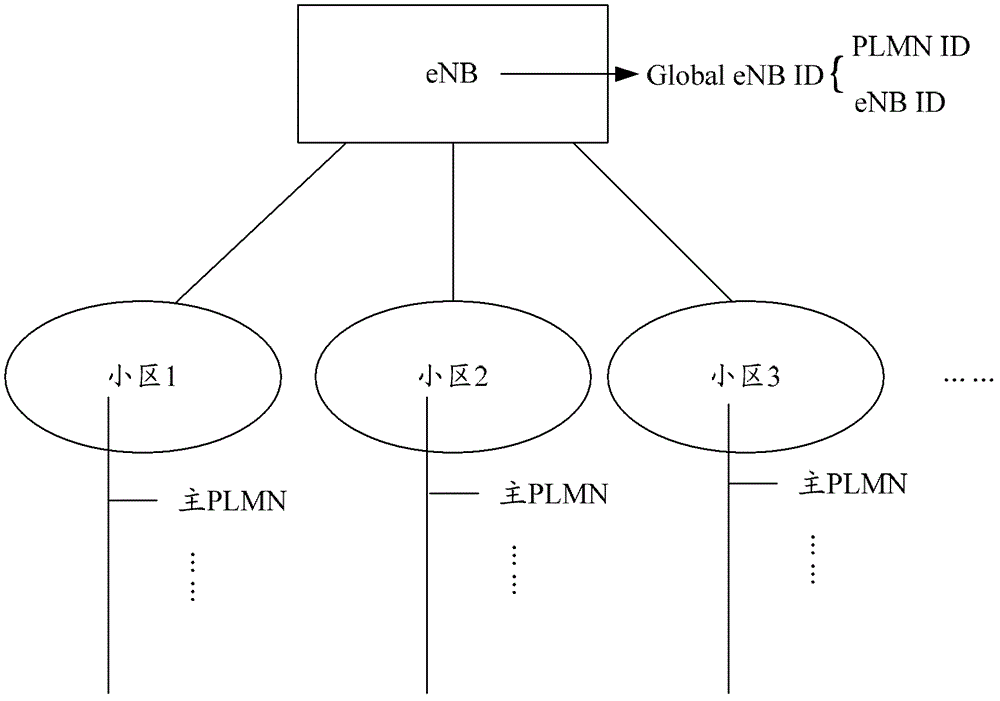

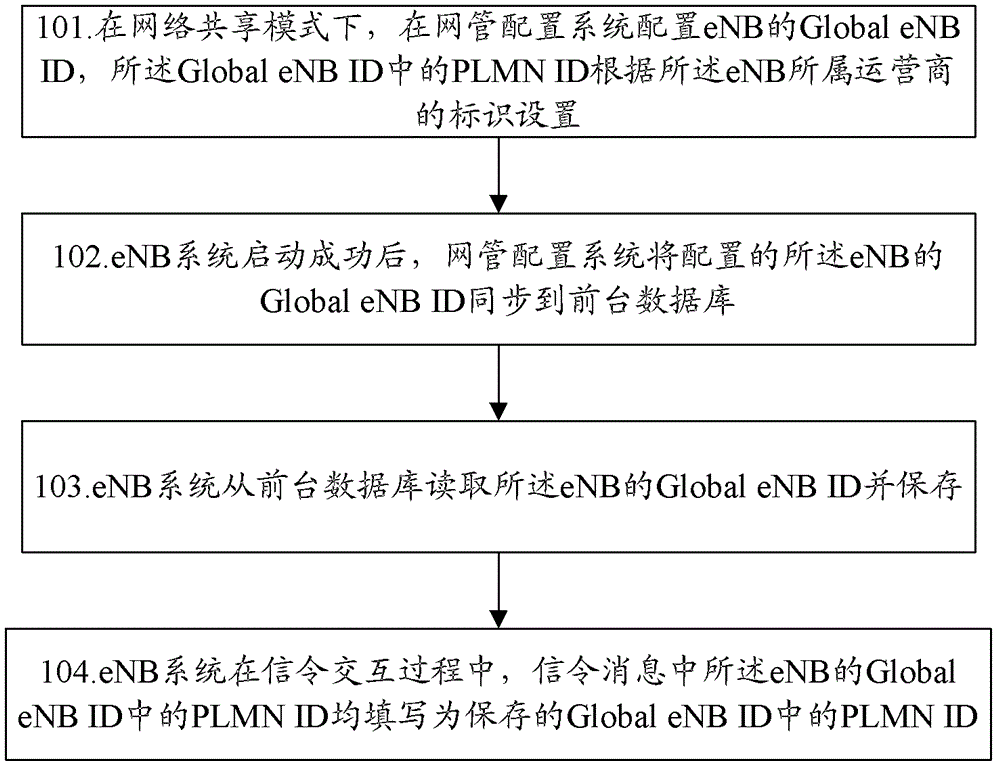

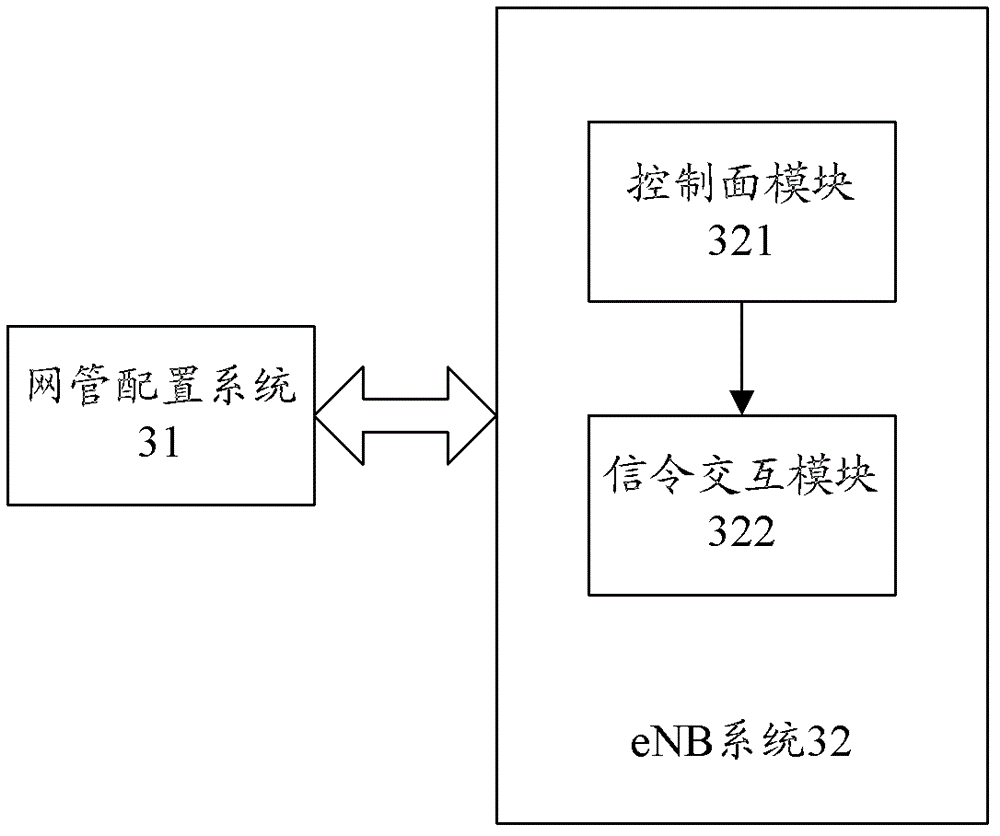

Method and system for effective noise bandwidth (eNB) global identification configuration and eNB system

ActiveCN103067912ASolve the filling problemNetwork data managementNoise bandwidthPublic land mobile network

The invention discloses a method for effective noise bandwidth (eNB) global identification configuration. Under a network sharing mode, the global eNB identification (ID) of eNB is configured in a web master configuration system. The public land mobile network (PLMN) ID of the global eNB ID is set according to the identification of a service provider, and the eNB belongs to the service provider. When an eNB system is successfully started, the global eNB ID of the eNB is sent to a foreground data base in a synchronous mode through the web master configuration system. The eNB system reads the global eNB ID of the eNB and stores the global eNB ID of the eNB. During a signal interactive process, the PLMN ID in the global eNB ID of the eNB of signal information is filled as the PLMN ID of the stored global eNB ID. The invention further discloses a system for eNB global identification configuration and an eNB system. The eNB can be accurately and uniquely identified under the network sharing mode, and a filling problem of the PLMN ID in the global eNB ID is solved.

Owner:ZTE CORP

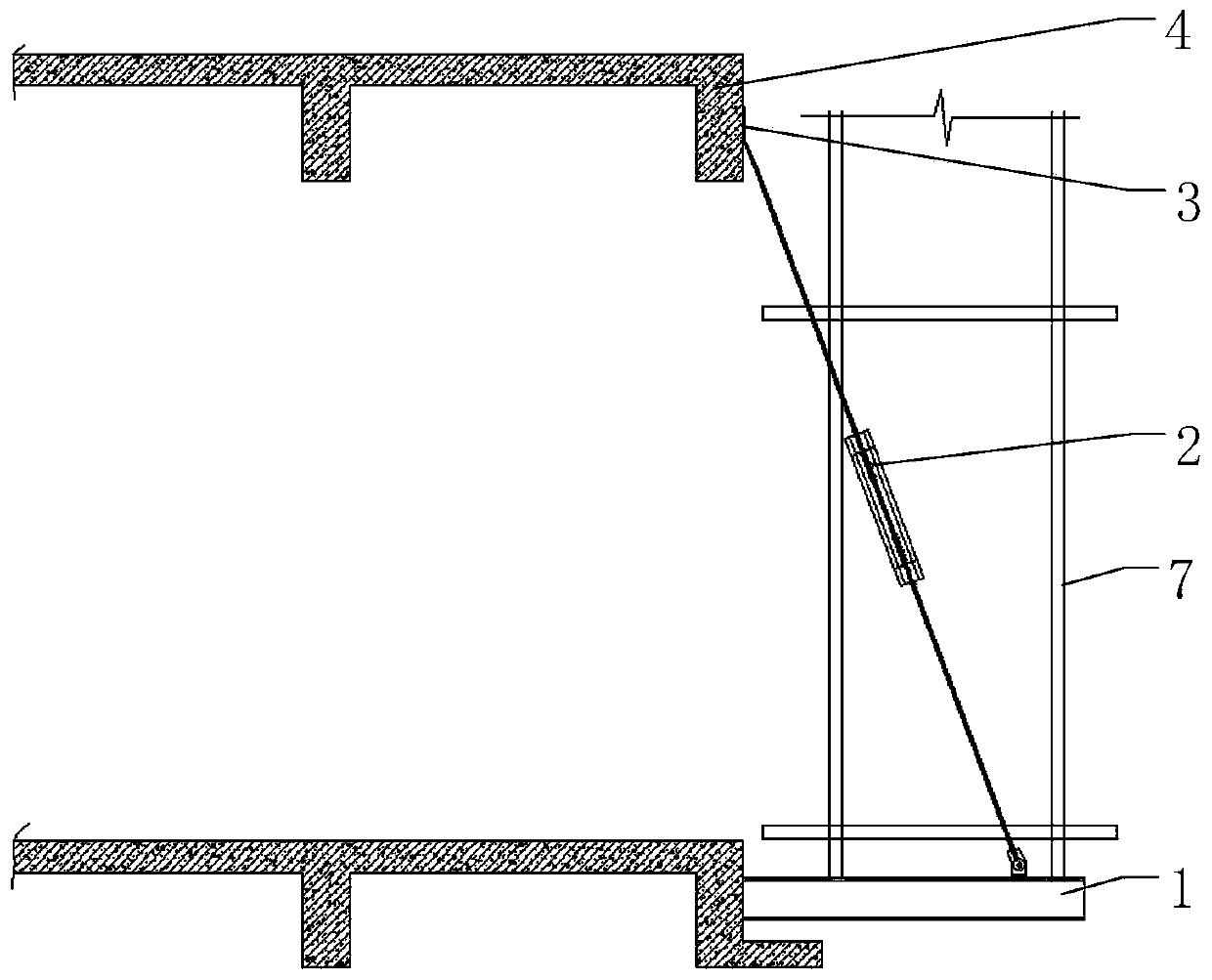

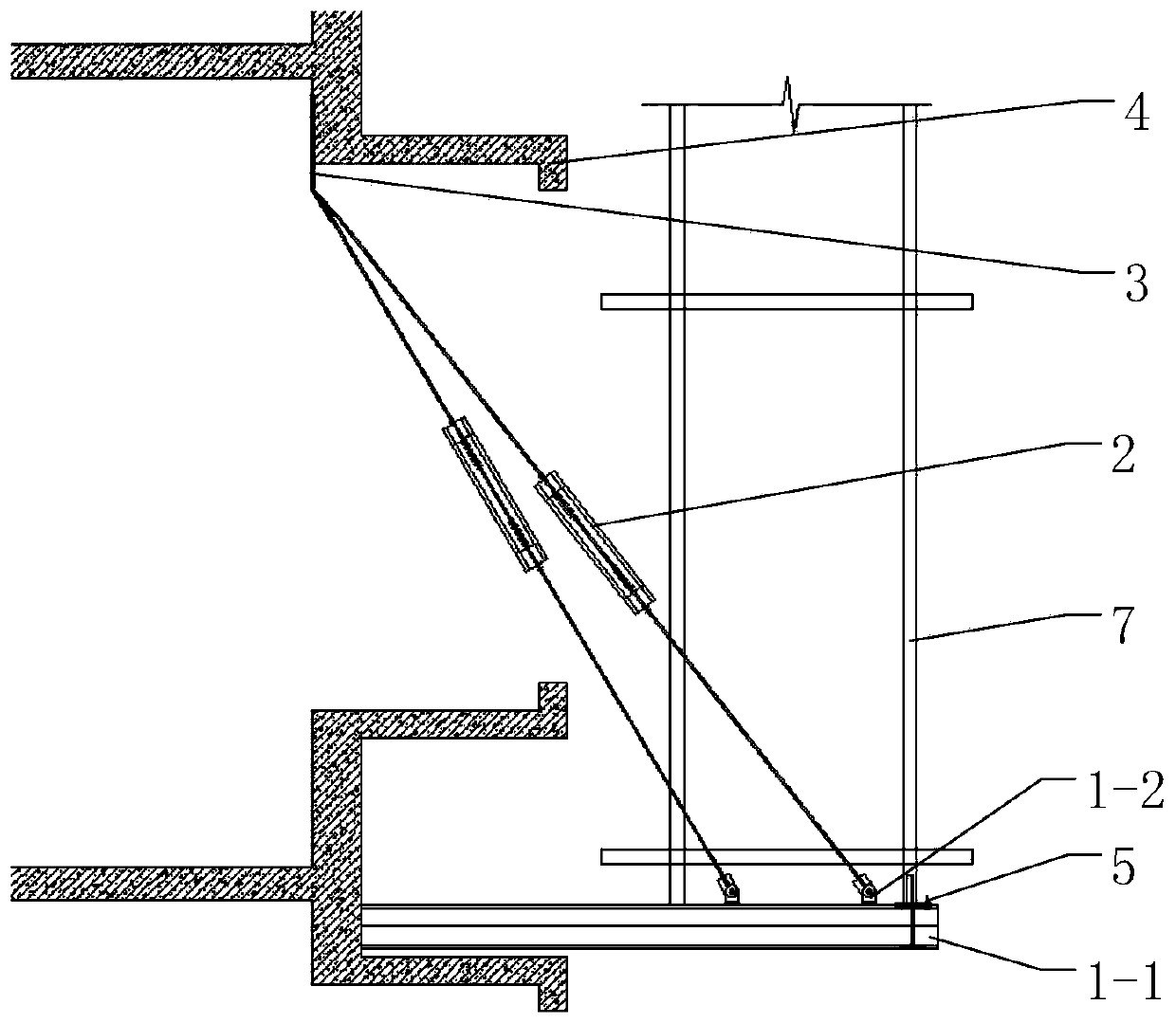

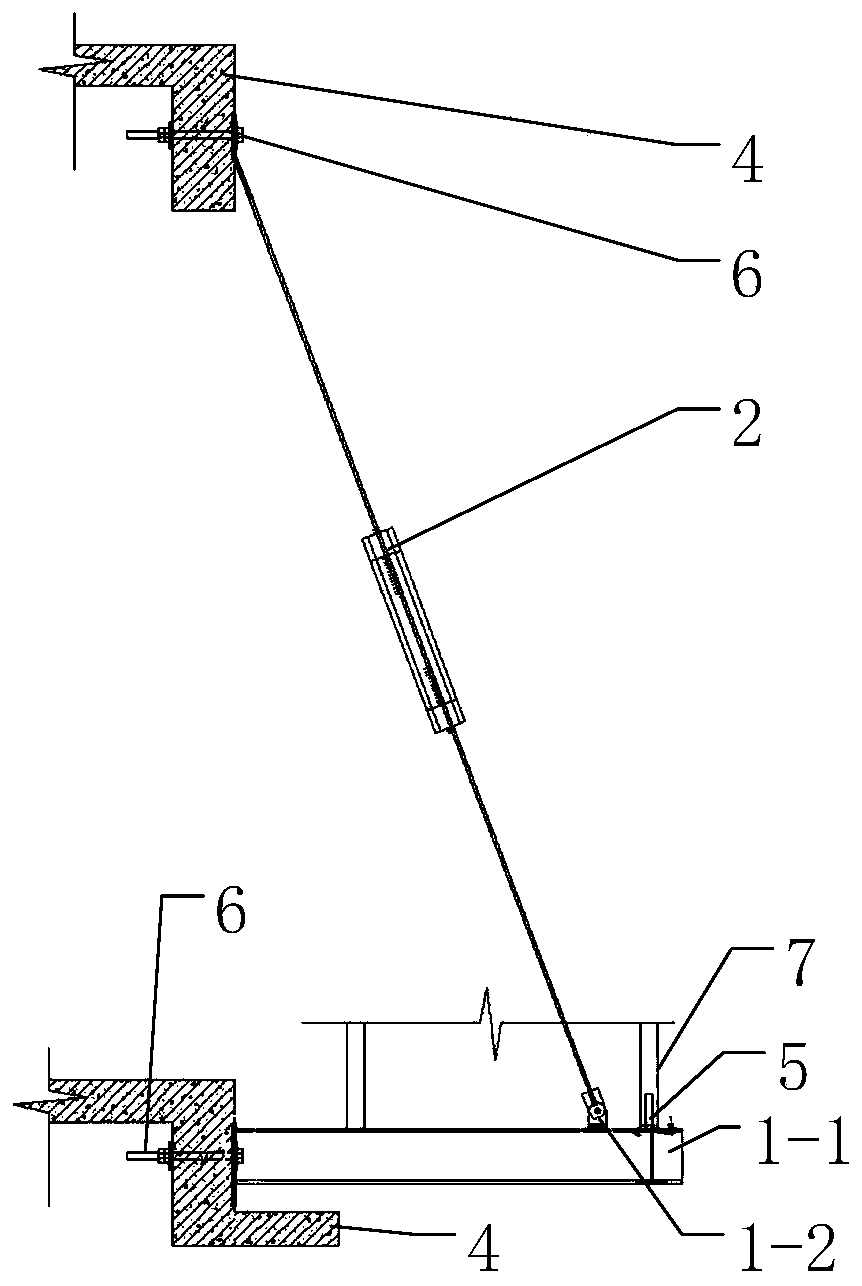

Flower basket tie rod I-steel cantilever bearing frame for construction engineering and installation method thereof

PendingCN111472530ASimple structureFlexible structureBuilding material handlingScaffold accessoriesFalseworkArchitectural engineering

The invention discloses a flower basket tie rod I-steel cantilever bearing frame for construction engineering and an installation method thereof, belonging to the field of cantilever bearing frames. The invention provides a flower basket tie rod I-steel cantilever bearing frame with convenient construction, no damage to the floor structure, convenient disassembly and reusability and an installation method thereof. In the flower basket tie rod I-steel cantilever bearing frame, a cantilever frame bearing beam is cantilevered on the side of an embedded part, and a connecting plate is arranged onthe side of the embedded part above the cantilever frame bearing beam; lugs are fixed on the I-steel; flower basket bolts are fixed between the lugs and the connecting plate; and a mobile positioningpile is installed on the I-steel. The installation method of the flower basket tie rod I-steel cantilever bearing frame comprises the following steps: pre-burying a plurality of embedded parts of a main structural beam in the wall; cantilevering the I-steel on the side of any embedded part; making the I-steel, the wall space and the flower basket bolts form a triangular shaped steel load-bearing system; and sleeving an upright tube steel pipe on the mobile positioning pile. The invention is mainly used for the design, construction and use of cantilevered steel pipe scaffolding.

Owner:INSTALLATION BRANCH WEIHAI CONSTR GRP CO LTD +1

Expansion filling method based on gangue filling

The invention discloses an expansion filling method based on gangue filling. The expansion filling method comprises the following steps that after coal cutting is completed, a separation wall is arranged in a goaf in the direction of a working face, the upper end of the separation wall is close to the top of the goaf, a passageway opening is reserved between the upper end of the separation wall and the top of the goaf, and filling space is formed between the separation wall and the goaf; the goaf is filled with gangue through the passageway opening, a feeding installation hole is formed in theupper end of the separation wall, a distributing material pipe group is installed on the feeding installation hole, and the distributing material pipe group is formed by distributing a plurality of first distributing material pipes and a plurality of second distributing material pipes at intervals; and expansion agent fluid is supplied to the filling space by switching between a first feeding pump and a second feeding pump. According to the expansion filling method, the expansion characteristic of an expansion agent is utilized on the basis of the gangue to fill the goaf in a short time, thencertain stress is produced on surrounding rocks under the condition of limited expansion, and the full range compaction of a gangue filling body is achieved.

Owner:SHANDONG UNIV OF SCI & TECH

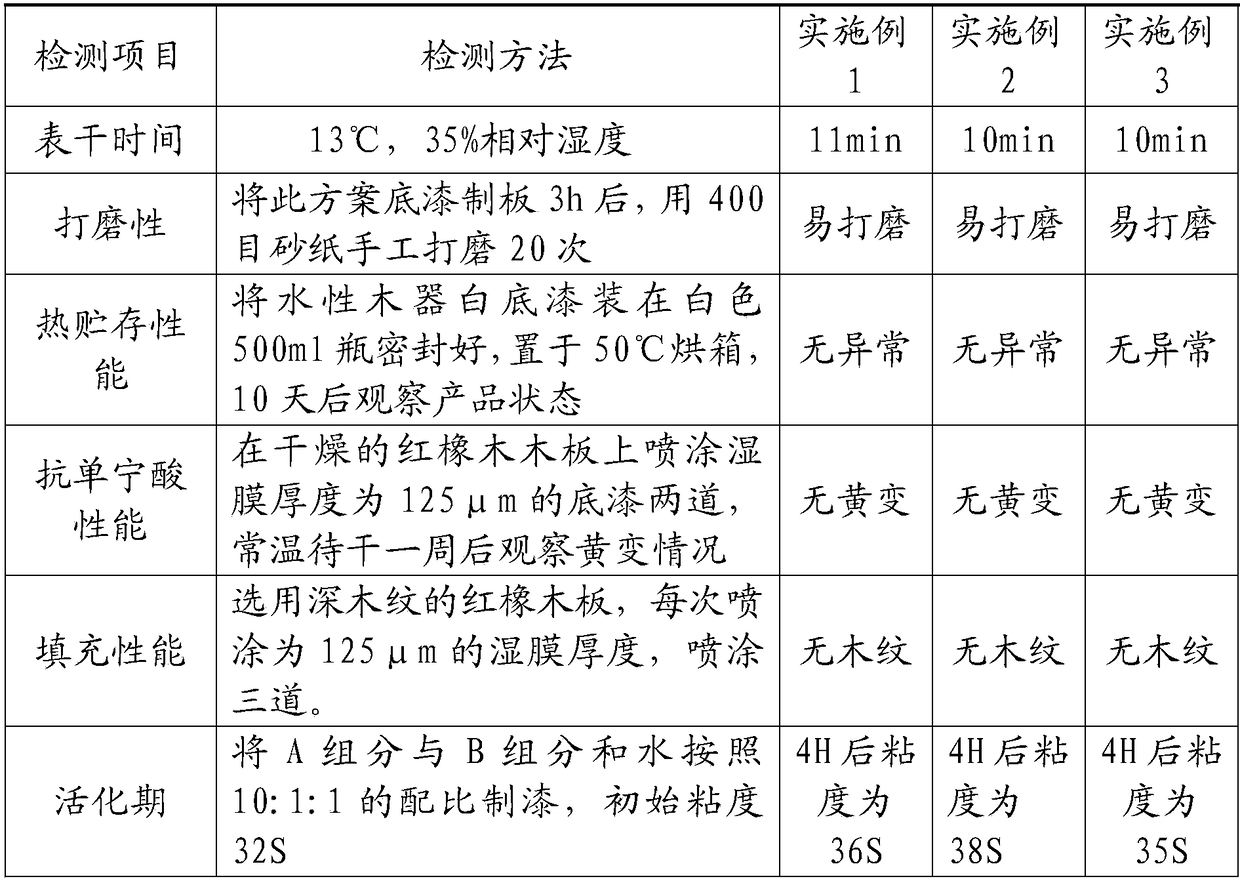

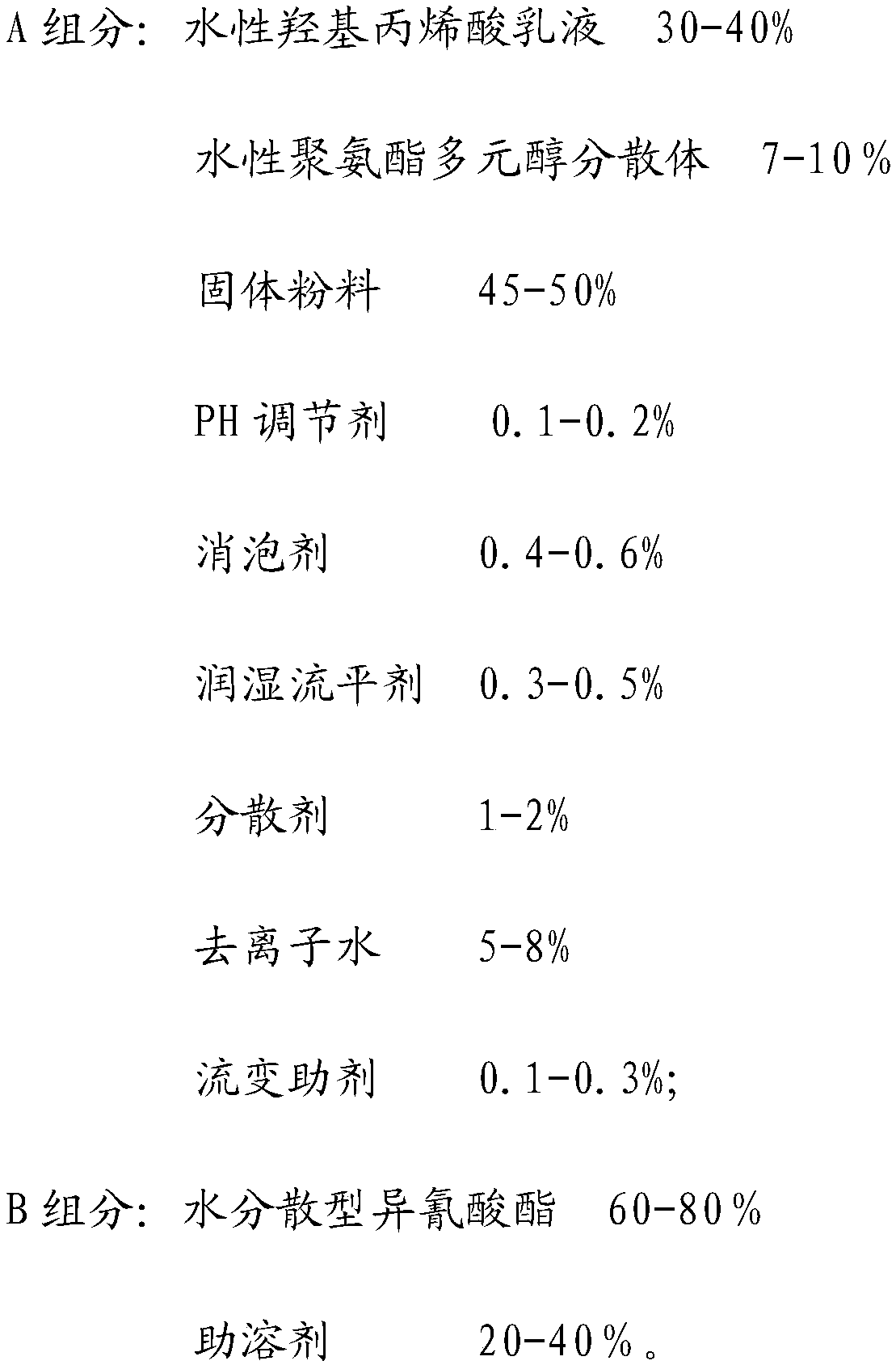

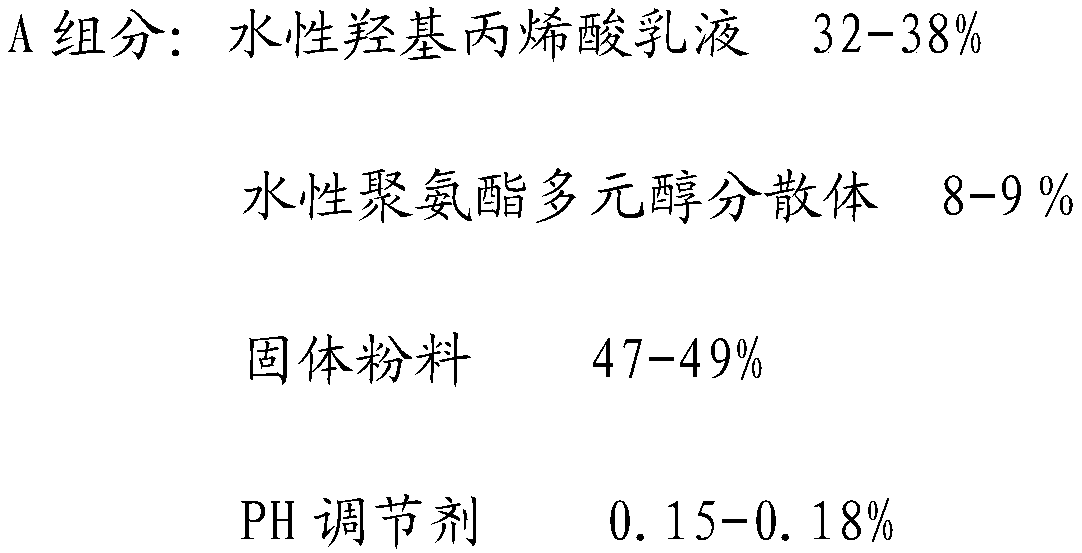

High solid content and economical tannic acid resistant two-component white environment-friendly waterborne primer

InactiveCN108948992AGood recombinationImprove water resistancePolyurea/polyurethane coatingsPriming paintsWater basedPolyol

The invention discloses a high solid content and economical tannic acid resistant two-component white environment-friendly waterborne primer. The preparation method includes: adding a dispersant intodeionized water and performing dispersion, then adding a PH regulator, then adding a defoamer and conducting high speed dispersion, then adding solid powder and performing high speed dispersion; adding a water-based hydroxyl acrylic emulsion and a waterborne polyurethane polyol dispersion into another new material preparation pot, and adding a mixture of a neutralizer and deionized water at an intermediate speed to obtain an emulsion; adding a defoamer and a wetting leveling agent into the emulsion and performing high speed dispersion so as to obtain a mixed solution c for standby use; addinga prepared white pulp into the mixed solution c, then adding deionized water and a rheological assistant to obtain a component A; mixing water dispersed isocyanate and a cosolvent evenly to obtain a component B; and mixing the component A and the component B evenly in a proportion of 10:1, thus obtaining the environment-friendly waterborne primer. The waterborne primer prepared according to the invention has the advantages of low cost, good environmental protection effect, good stability and strong practicability.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

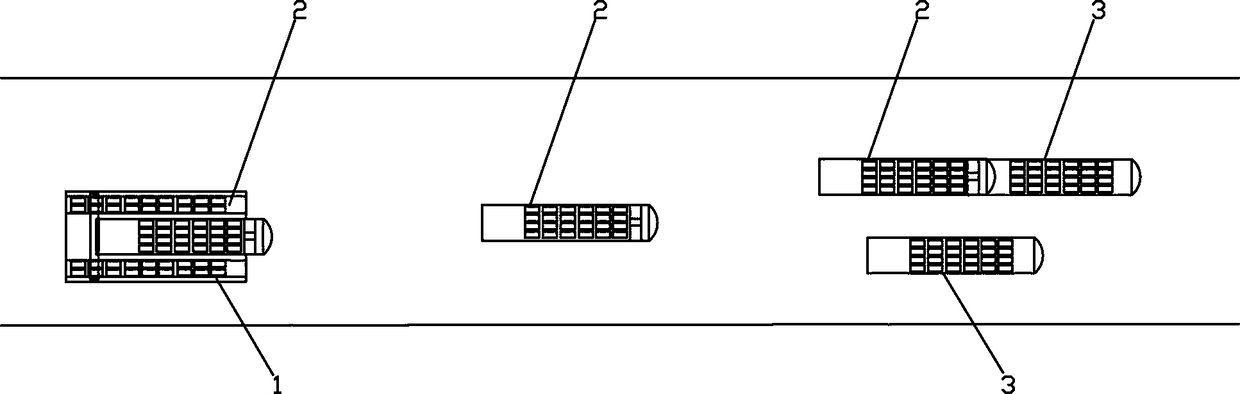

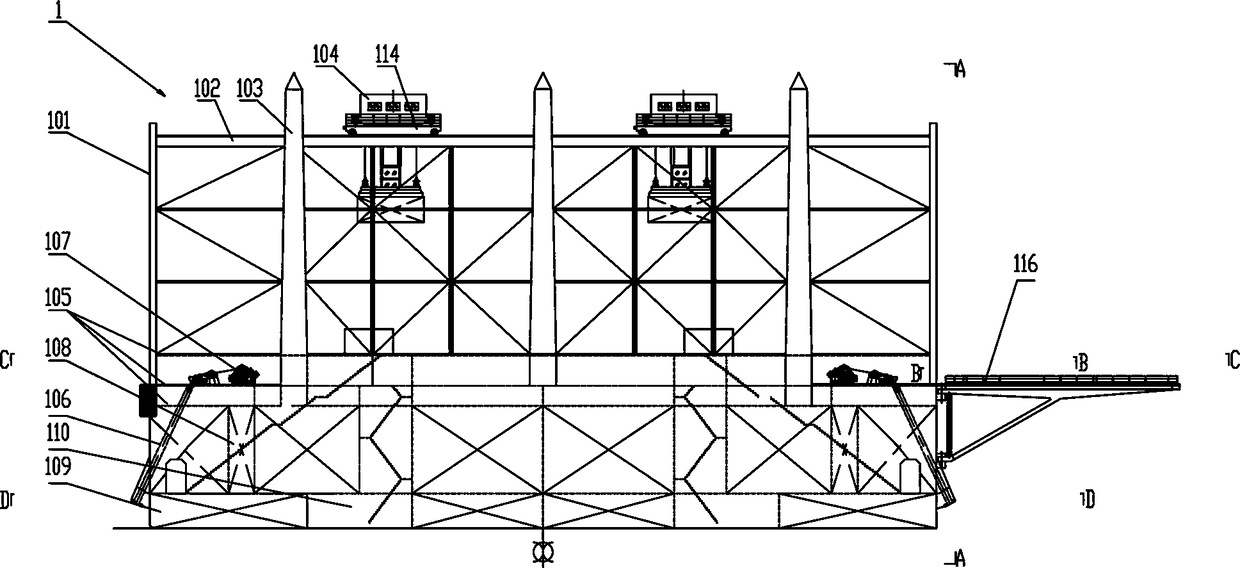

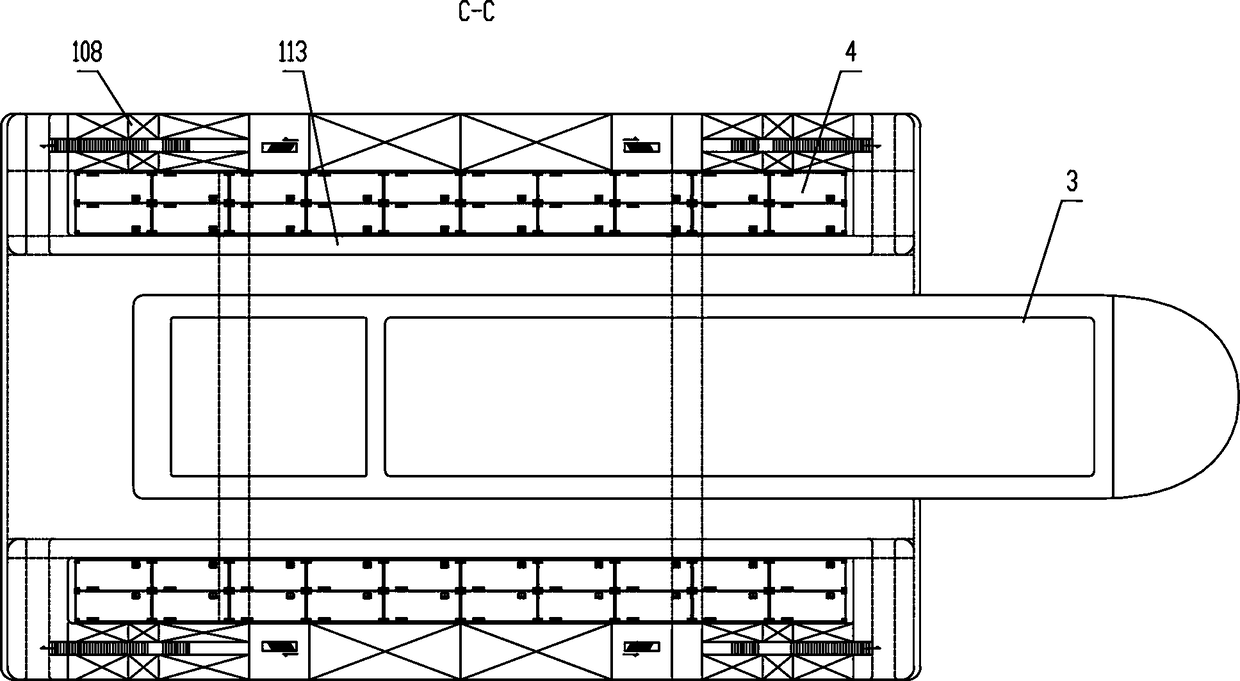

Semi-submersible LNG replacement shipment and marine LNG shipment application method

PendingCN109110049ALow costSimple and efficient operationCargo handling apparatusPassenger handling apparatusMarine engineeringWater level

The invention provides a semi-submersible LNG replacement shipment and a marine LNG shipment application method. The cross section of the ship hull is of a frame structure, the middle of the frame structure forms a space for accommodating the ship to sail in, and a lifting device is arranged at the top of the ship hull. A plurality of semi-submersible LNG replacement ships are arranged along the river, so that the floating tank deck of the semi-submersible LNG replacement ship is located below the water level, the LNG tanker or container ship using LNG tanker as fuel enters the frame structurespace of the semi-submersible LNG replacement ship and replaces the LNG tanker for the LNG fuel tanker or loads and unloads the LNG tanker from the container ship by using the lifting device at the top of the semi-submersible LNG replacement ship. By adopting a semi-submersible frame structure, a water-stable semi-permanent operating platform is obtained at a lower cost, which facilitates the replacement of LNG tank containers for ships using LNG tank containers as fuel, or the docking of container ships carrying LNG tank containers for loading and unloading LNG tank containers.

Owner:YICHANG DONGJIANG SHIPBUILDING CO LTD

Closed type capping method by upward filling mining

InactiveCN105178960AAvoid dischargeMaintain volumeUnderground miningSurface miningSlurryMechanical engineering

The invention discloses a closed type capping method by upward filling mining. The method is characterized in that after stoping the last layer, four gas vent holes are drilled in four side corners of a roof by use of a drilling machine, and then, partition walls are built at the periphery of a mined-out area for processing the bottom of the mined-out area and the roof to be flat; waterproof materials are paved and pasted on the partition walls at the periphery of the mined-out area, the bottom of the mined-out area and the roof for enclosing the mined-out area into a closed type filling space; by virtue of a filling raise, a filling material is injected into the closed type filling space; when the filling material runs out of the gas vent holes, filling is stopped; and after the closed type filling space is filled up with the filling material, a layer of waterproof materials covers the four gas vent holes and the filling raise, and cement is used for sealing. The closed type capping method prevents water in filling slurry from discharging, and keeps the volume and the shape of the filling slurry; after the filling material is condensed, a completely roof-contacted filling body is formed, so that a filling roof-contact problem is solved. The closed type capping method is simple in process, safe and reliable, simple and easy to perform, and relatively low in cost.

Owner:UNIV OF SCI & TECH LIAONING

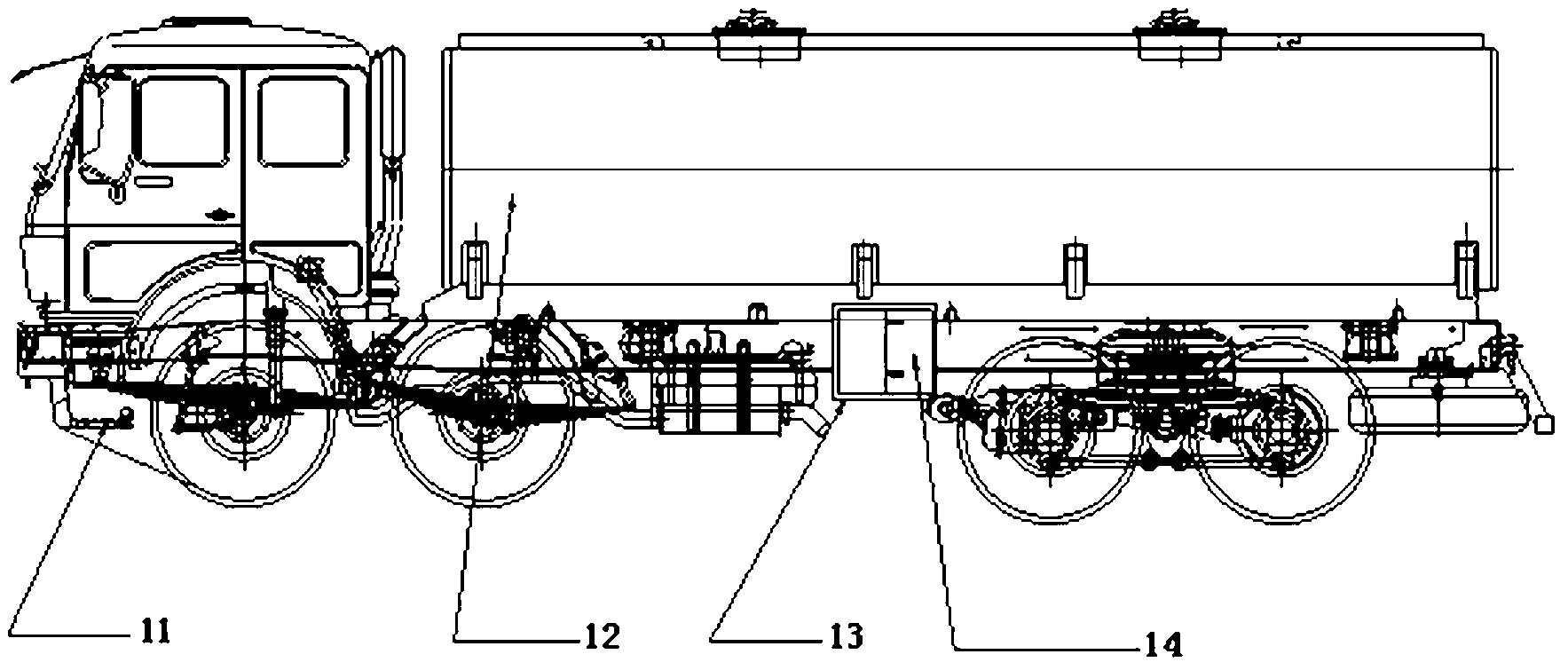

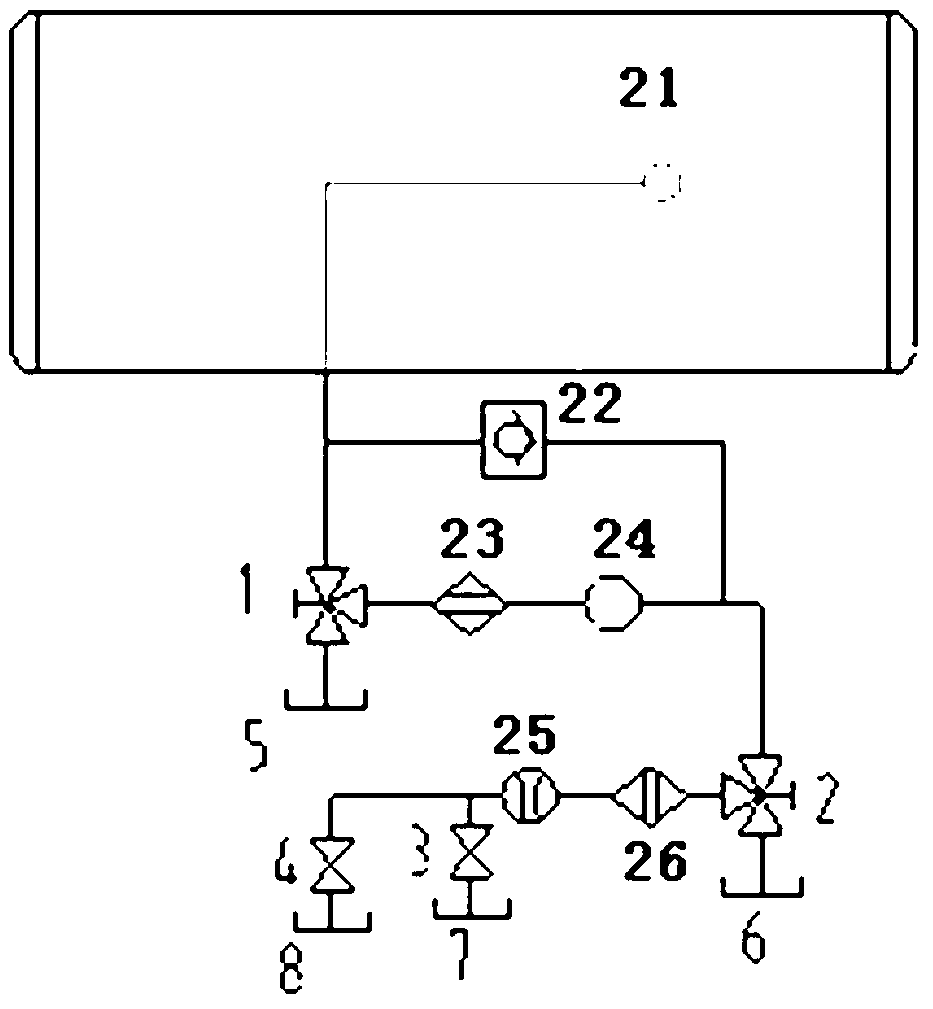

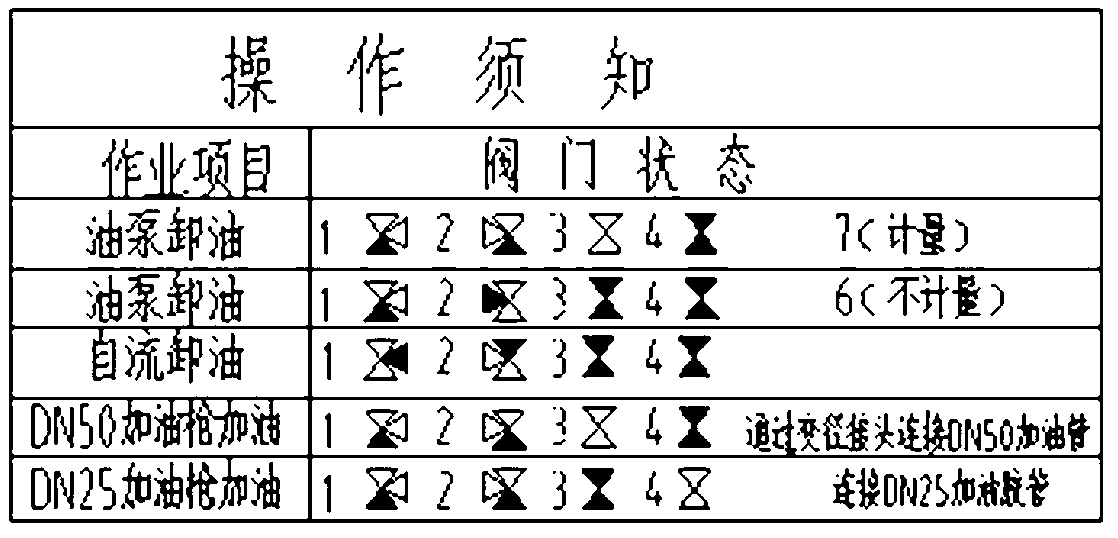

Transport and refueling truck for mining area

InactiveCN102795147ASolve the filling problemReduce purchasesTank vehiclesLiquid transferring devicesTruckRoad condition

The invention discloses a transport and refueling truck for a mining area, comprising an underpan system (11), an oil tank system (12), a maneuvering box (13) and a pump oil pipeline system (14). The pump oil pipeline system is internally provided with three pipelines and joints with different apertures and refueling guns matched with the pipelines and joints, wherein the three pipelines and joints can be conveniently and rapidly connected and have apertures DN80, DN50 and DN25, and different equipment and vehicles in the mining area can be refueled respectively or simultaneously through the refueling pipelines and joints as well as the refueling guns. The transport and refueling truck for the mining truck is mainly designed for the condition that the common transport and refueling truck cannot fully meet the requirement for the apertures of various equipment and engineering vehicles in the mining area during refueling, is large in underpan power, strong in bearing capacity and suitable for various road conditions such as roads, mountain roads, rugged and bumpy roads and the like in the mining area. On the premise of ensuring low cost, the oil consumption requirements of all the equipment and vehicles in the mining area are ensured, and potential safety hazards are reduced.

Owner:XINXING HEAVY IND GRP

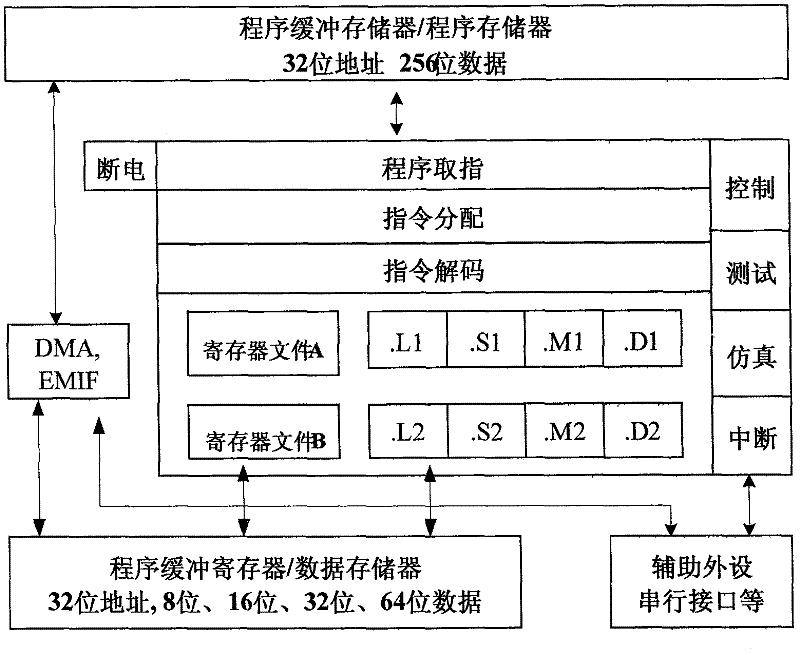

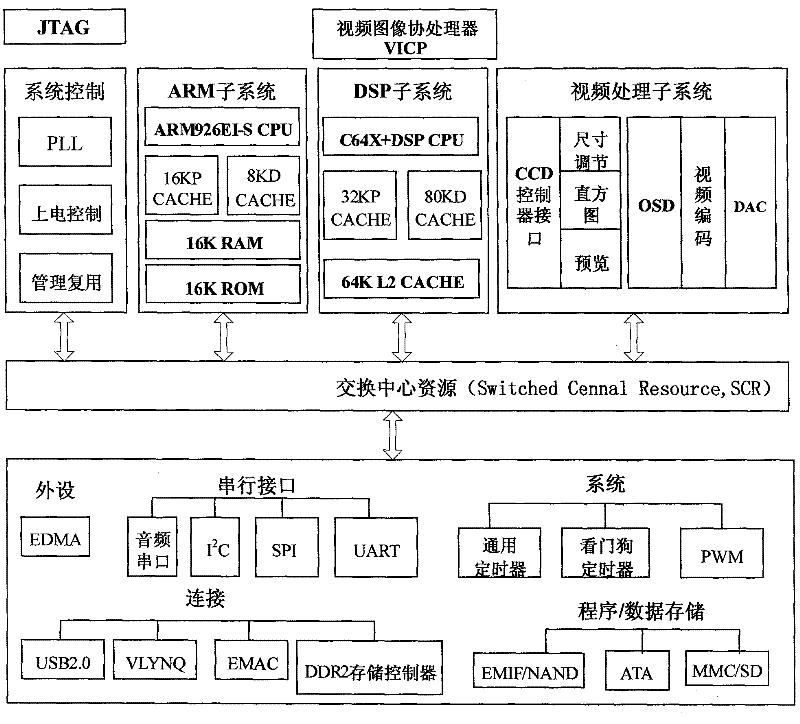

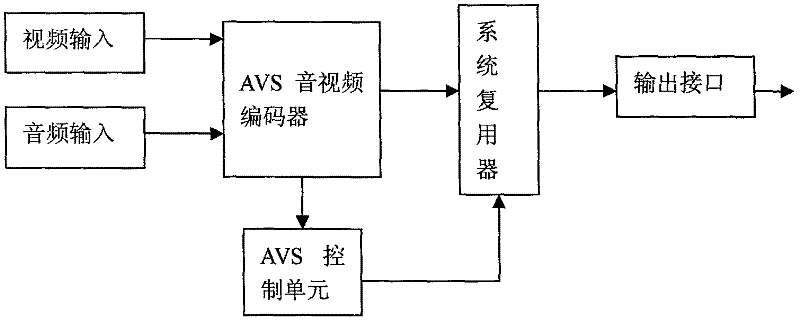

Audio video coding standard (AVS) video coder adopting high speed multi-core digital signal processor (DSP) platform

InactiveCN102244781AEasy to operateSolve the need to re-emptyTelevision systemsDigital video signal modificationDigital signal processingComputer architecture

The invention provides an audio video coding standard (AVS) video coder adopting a high speed multi-core digital signal processor (DSP) platform. The AVS video coder provided by the invention has a built-in high speed multi-core signal processing chip which adopts a multiprocessor system, and the multiprocessor system consists of a universal processor kernel and a high-performance application-specific processor, thereby forming the high speed multi-core DSP platform. The DSP platform has the operational capability of 500 billion times per second, so that the AVS video coder provided by the invention realizes multi-thread, multi-core and multi-task digital signal processing capability, the real-time compression processing and transmission of video data and the high-speed real-time processing of video signals, and finishes AVS-based real-time high-definition signal coding.

Owner:苏州汉辰数字科技有限公司

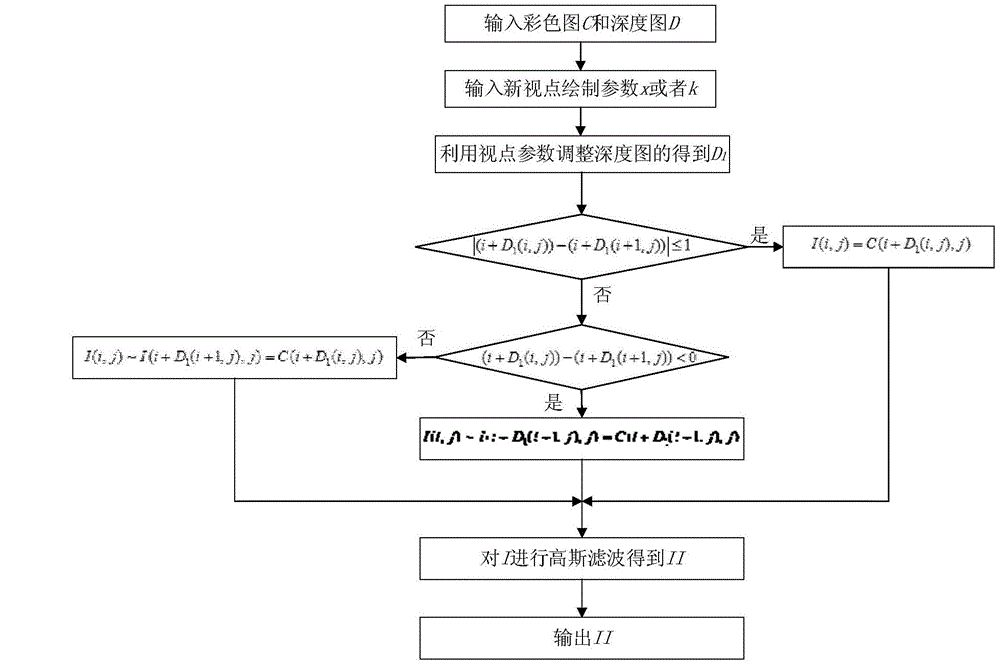

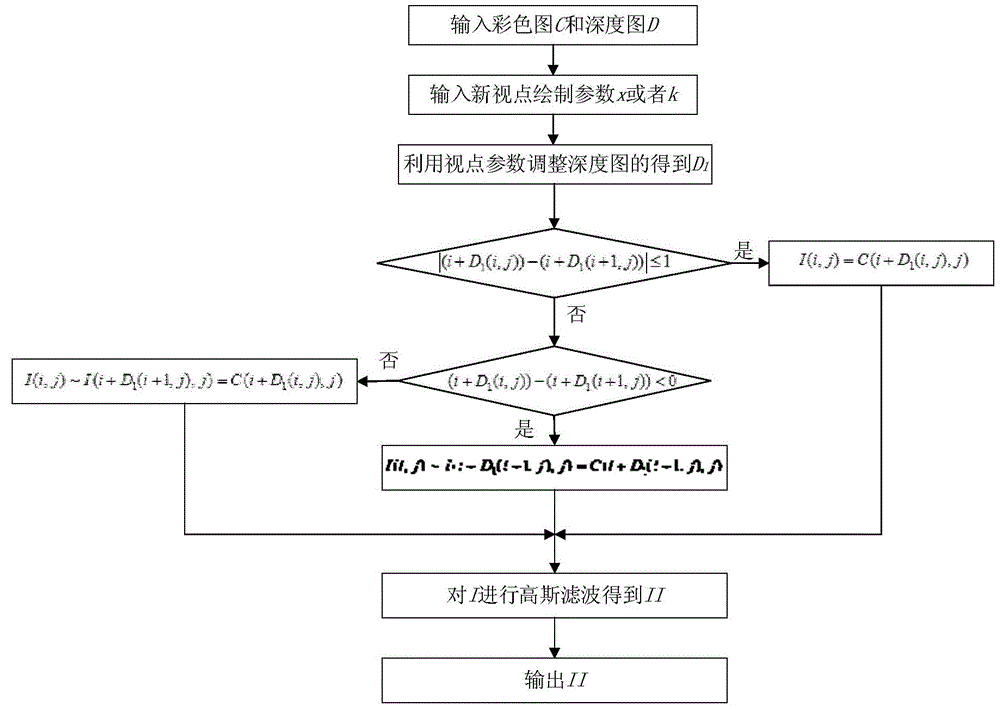

Image rendering method by utilizing depth image

ActiveCN103916656AReduce time complexityQuality improvementSteroscopic systemsViewpointsTime complexity

The invention relates to an image rendering method by utilizing a depth image. The image rendering method is characterized by comprising the following steps of (1) inputting a color image and the corresponding depth image, (2) inputting rendering parameters of a new viewpoint, (3) rendering the new viewpoint by utilizing the color image and the depth image to obtain a color image I, (4) performing post treatment on the color image I to obtain an image II and (5) outputting the obtained image II. According to the image rendering method, the process of image rendering and the process of hole filling are combined, and therefore the problem of hole filling is directly solved in the process of image rendering. In this way, the method not only can lower the time complexity of an algorithm but also can improve the quality of image rendering.

Owner:HUAZHONG UNIV OF SCI & TECH +1

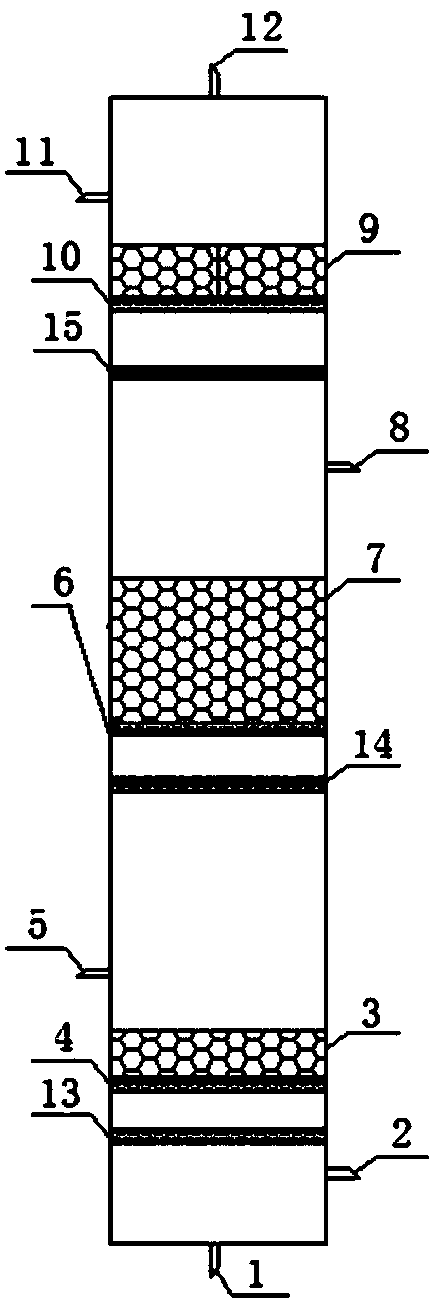

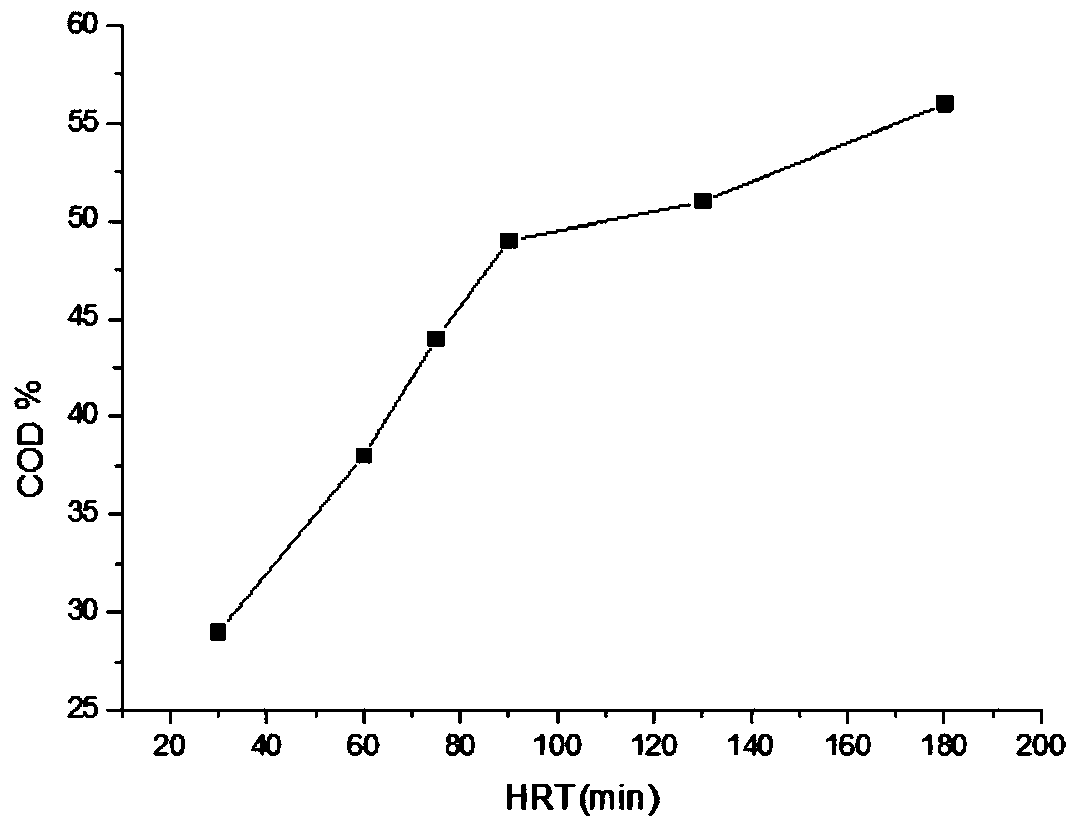

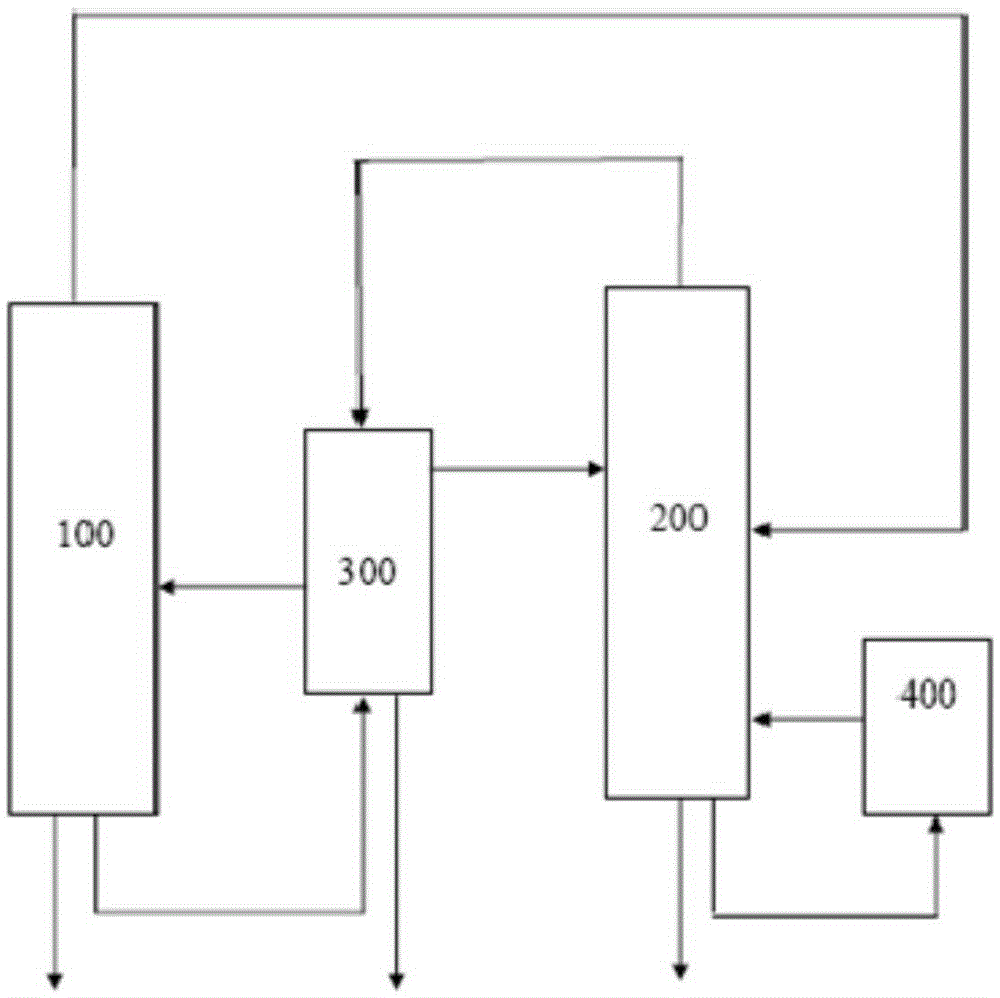

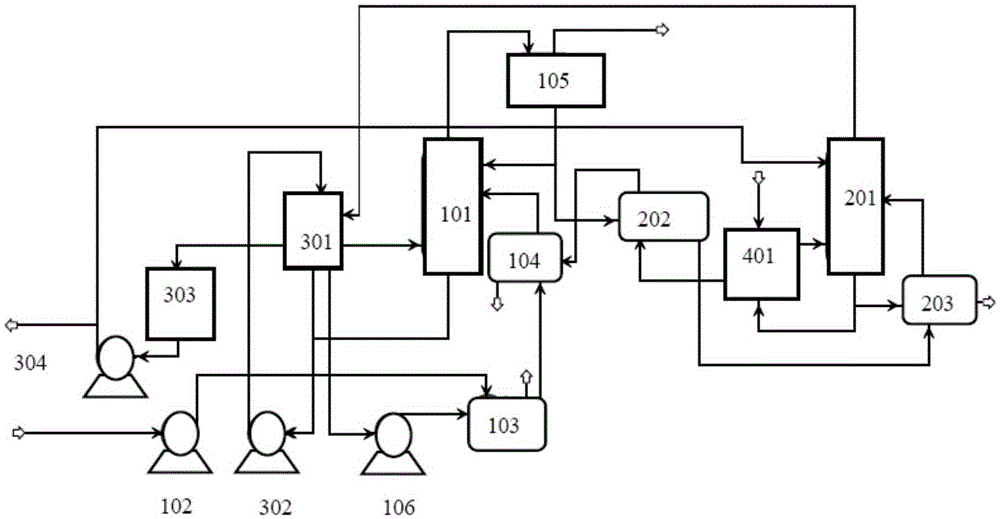

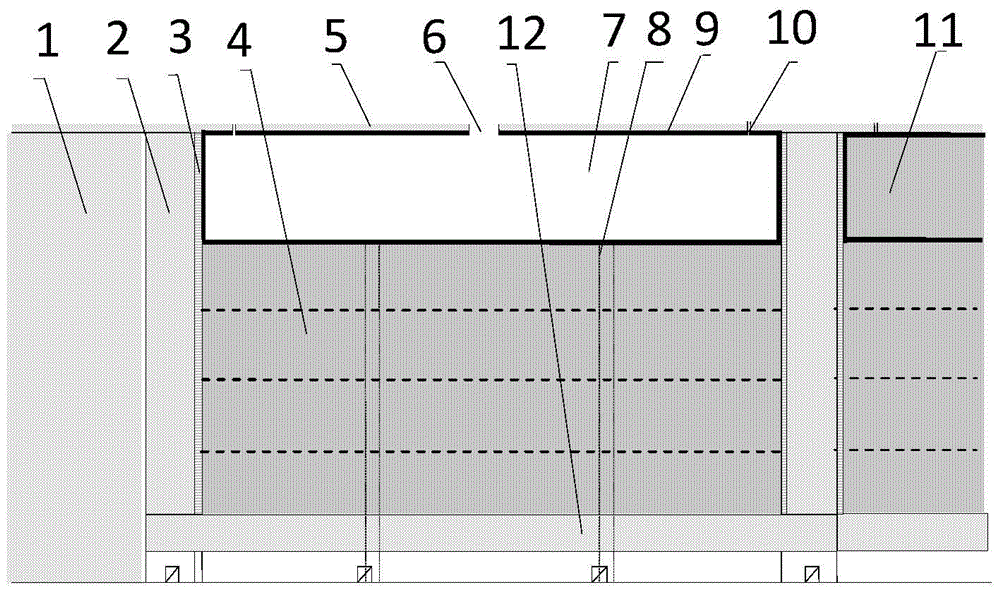

Heterogeneous catalytic ozonization pharmaceutical wastewater treatment device and process

InactiveCN109081421AStrong resistance to water erosionAvoid breakingNon-contaminated water treatmentWater/sewage treatment by oxidationPtru catalystCatalytic oxidation

The invention relates to a heterogeneous catalytic ozonization pharmaceutical wastewater treatment device and process. The heterogeneous catalytic ozonization pharmaceutical wastewater treatment device comprises a catalytic ozonization reactor; the catalytic ozonization reactor is composed of a first-layer reactor, a second-layer reactor and a third-layer reactor which are sequentially connected from bottom to top, wherein the bottom of the first-layer reactor is provided with an air inlet 1, the side bottom of the first-layer reactor is provided with a water inlet 2, and the top of the third-layer reactor is provided with a tail ozone outlet 12; inside every reactor, a gas distributing plate, a catalyst bed and a catalyst support plate are arranged, and every catalyst bed is provided witha water outlet. When applied to treating pharmaceutical wastewater, the heterogeneous catalytic ozonization pharmaceutical wastewater treatment device and process can prolong the service life of catalysts; meanwhile, applied catalyst medium ceramic pellets are low in price and easy to acquire and can form a catalytic oxidation system together with ozone to effectively improve the utilization rateof ozone and reduce the production cost.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Separating and recycling method and device for solvent-water mixture containing impurities prone to scale formation

ActiveCN105348043ANot easy to scaleReduce foulingOrganic compounds purification/separation/stabilisationOrganic compound preparationWastewaterSolvent

The invention relates to a separating and recycling method and device for a solvent-water mixture containing impurities prone to scale formation. The method comprises the following steps that 1, decompression stripping operation is performed on the solvent-water mixture containing the impurities prone to scale formation; 2, rectification operation is performed on a product obtained through decompression stripping operation to obtain a solvent product with the mass percent more than 80%. The impurities prone to scale formation in the solvent-water mixture containing the impurities prone to scale formation comprise proteins and salts. According to the method and device, the problem that the impurities in the material liquid are prone to scale formation to block a column plate or packing is successfully solved, and the cleanliness of the interior of a rectifying column is guaranteed; the steam using amount is decreased; meanwhile, the wastewater draining amount is decreased, and high efficiency, energy conservation and environmental protection are achieved.

Owner:HEBEI UNIV OF TECH

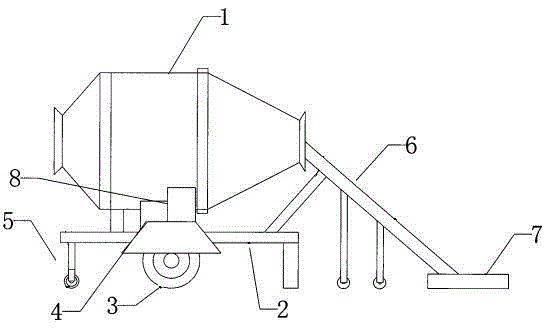

Concrete mixer

InactiveCN106182415AFlexible moving processSolve the problem of manually filling the feed portCement mixing apparatusStructural engineeringSmall range

The invention relates to the field of construction machinery, in particular to a concrete mixer. The concrete mixer provided by the invention moves flexibly in a small range and can save manual labor. The concrete mixer moves flexibly in the small range, the problem that filling to a feed inlet is conducted through manual work is solved, and thus the labor cost is reduced greatly.

Owner:CHANGGE TENGDA PRECISION IND BUILDING MACHINERY FACTORY

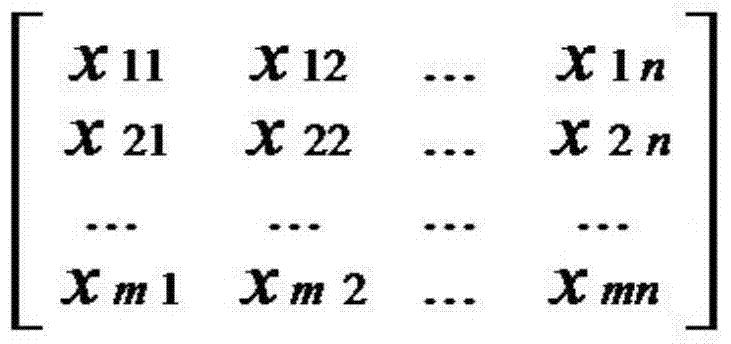

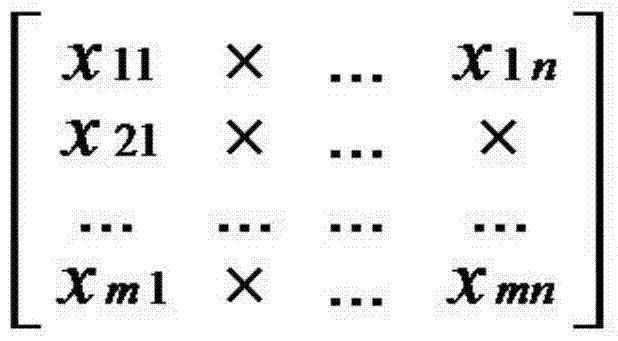

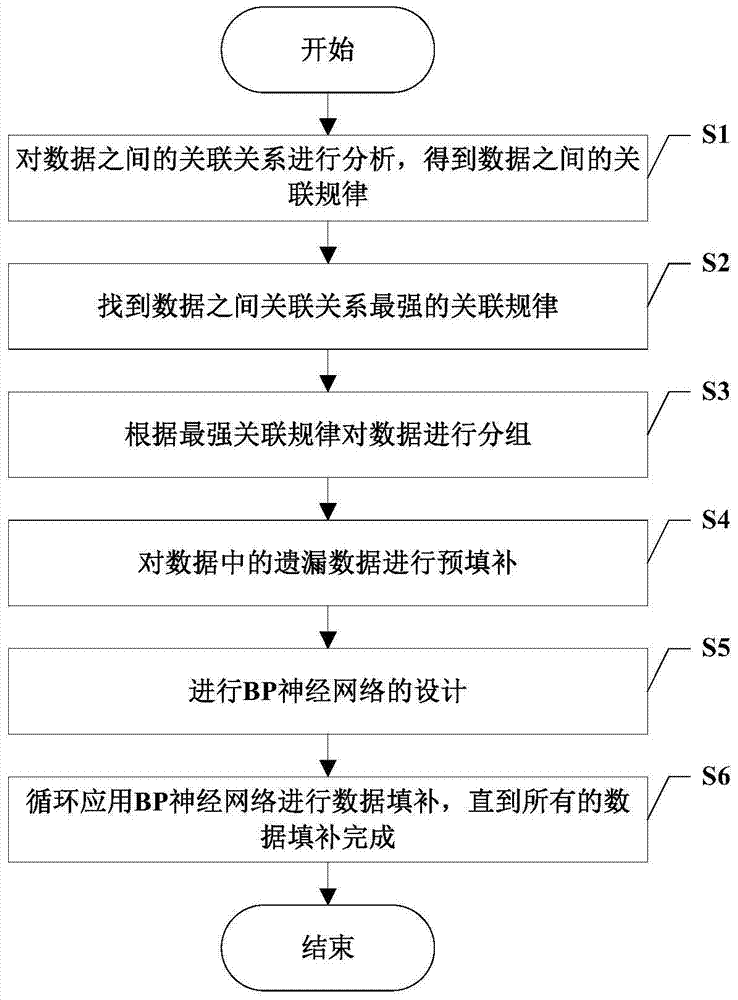

A Filling Method for Missing Data Based on Correlation Between Data

ActiveCN104679868BSolve the filling problemQuality improvementBiological neural network modelsSpecial data processing applicationsMissing dataAnalysis data

The invention discloses a method for filling missing data based on the correlation between data, which comprises the following steps: S1, analyzing the correlation between data, and obtaining the correlation law between the data; S2, finding the best correlation between the data Strong association law; S3, grouping data according to the strongest association law obtained in step S2; S4, pre-filling the missing data in the data; S5, carrying out the design of BP neural network; S6, cyclic application in step S5 The obtained BP neural network is filled with data until all the data is filled. The invention solves the problem of filling missing data by utilizing the correlation between data and designing a BP neural network, provides high-quality data for later data analysis, and has the advantages of simplicity, high efficiency, and accuracy.

Owner:UESTC COMSYS INFORMATION

Hydrogen-oxygen-mixed high-octane fuel ignition combustion engine and control method thereof

ActiveCN101975108BReduce consumptionImprove economyElectrical controlNon-fuel substance addition to fuelOn boardLow load

The invention provides an ignition combustion engine by the mode of mixing hydrogen and oxygen with high-octane fuel and a control method thereof, and particularly relates to a fuel storage and supply system of the ignition combustion engine by the mode of mixing the hydrogen and the oxygen with the fuel, fuel proportional distribution and combustion process control, wherein, a set of on-board hydrogen and oxygen production, a storage and supply device is added to the system on the basis of retaining main parts and an electronic control unit of the original engine. The hydrogen and oxygen mixed fuel electronic control unit (12) can control the opening and closing of a hydrogen nozzle and an oxygen nozzle according to sensor signals c-h so that the engine can run in three combustion modes such as pure hydrogen and oxygen mixed gas, hydrogen-oxygen-high-octane fuel mixed gas and pure high-octane fuel according to different operating conditions, thus greatly lowering HC and CO emission in the case of cold starting and idling of the high-octane fuel combustion engine and improving the thermal efficiency and emission level of the high-octane fuel combustion engine in middle and low load stages.

Owner:BEIJING UNIV OF TECH

A geocell reinforced sand cushion mixed with construction waste and its construction method

The invention discloses a building waste-doped geogrid cell reinforced sand blanket and a construction method. The geogrid cell reinforced sand blanket mainly consists of a plurality of building waste layers and reinforced structure layers which are crossly arranged in a ground foundation from bottom to top; each building waste layer is formed by compacting and paving the crushed waste concrete; each reinforced structure layer is a geogrid cell; the bottom part of each geogrid cell is partially crossed with the building waste layer thereunder, sand is charged to the middle part and upper part of each geogrid cell, and a sand layer is formed above each geogrid cell; another building waste layer is arranged on each sand layer. The geogrid cell reinforced sand blanket has the advantages that the main body materials are building wastes and geogrid cells, so that the problem of building waste filling is solved, the resource is saved, and the manufacturing cost of project is reduced; the building waste is compacted, and a tight engaged skeleton is formed and is combined with the three-dimensional geogrid cells, so that the bearing capacity of the ground foundation is improved, and the damage due to overlarge deformation of the ground foundation is overcome.

Owner:HUBEI UNIV OF TECH

Manufacturing method of multi-layer copper-based sandwich bent plate

PendingCN111295048AAvoid croppingSave the placement processInsulating layers/substrates workingConductive material chemical/electrolytical removalMechanical engineeringElectroplating

The invention discloses a manufacturing method of a multilayer copper-based sandwich bent plate. The method comprises the steps of sandwich copper base and FR4 board cutting, FR4 board inner layer circuit manufacturing, high-temperature glue pasting, press fit, drilling, copper deposition plate electroplating, outer layer circuit manufacturing, pattern electroplating, outer layer etching, outer layer A01 detection, soldermask process, forming, high-temperature glue tearing, FQC1, tin deposition, copper base bending, FQC2 and final packaging process. According to the manufacturing method, the cost of an FR4 plate is reduced; the production efficiency and yield of the plate are improved; production cost is reduced; and the manufacturing process of the sandwich copper-based bent plate is simplified.

Owner:黄石星河电路有限公司

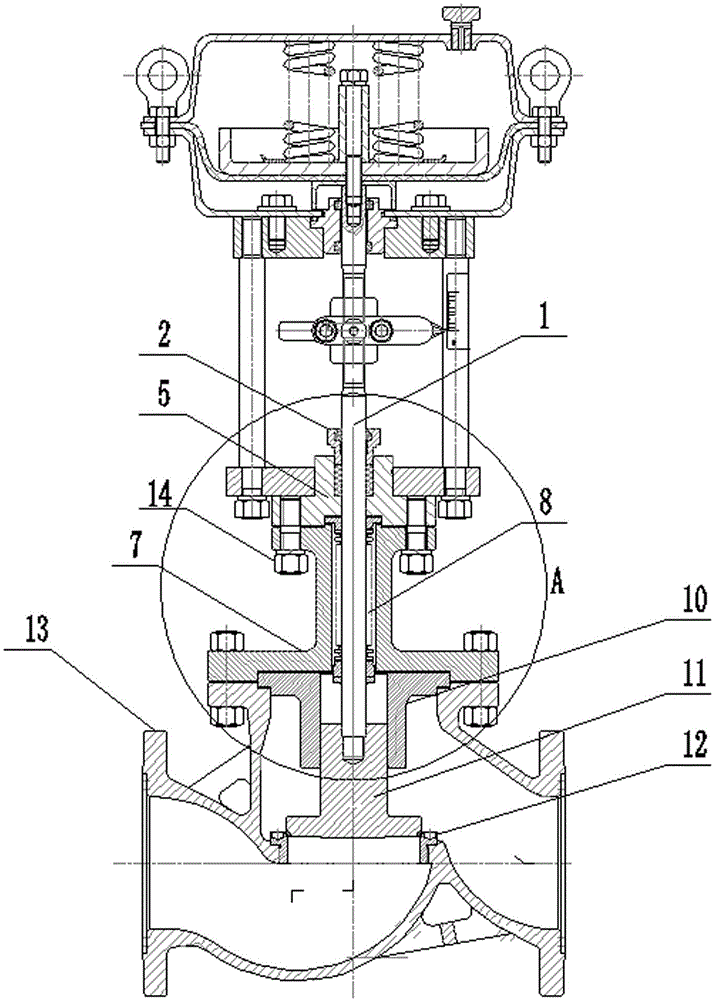

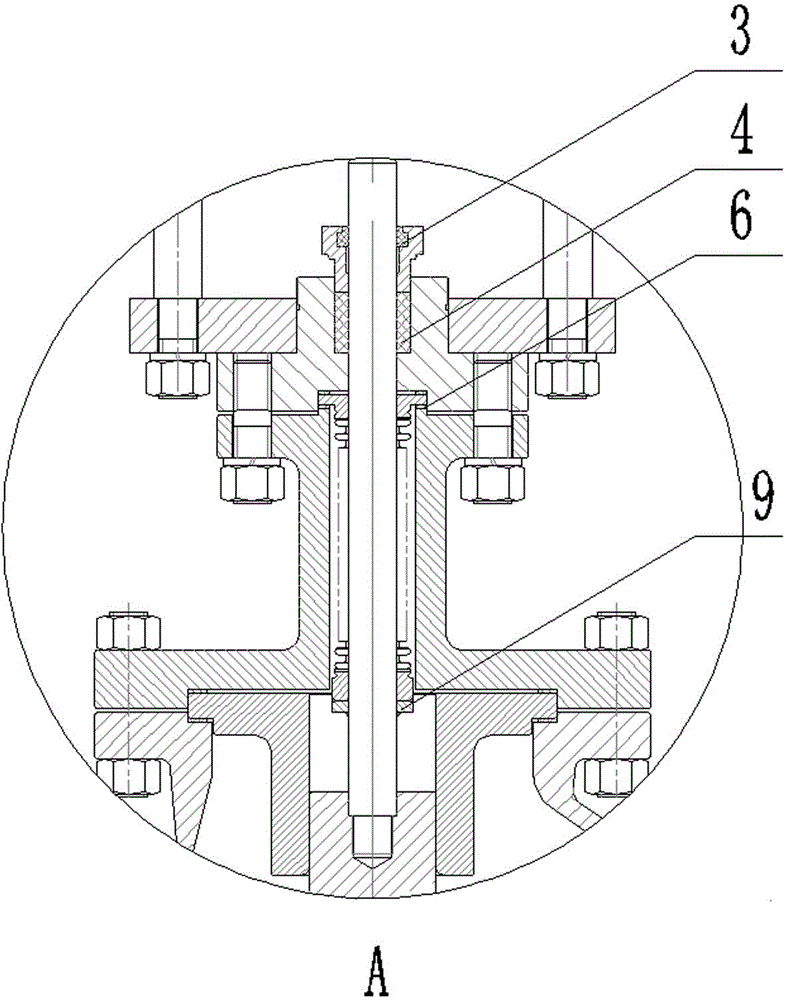

Detachable chlor-alkali special valve having leakage preventing device

InactiveCN104896107ASolve worn valve stemSolve the filling problemSpindle sealingsLift valveEngineeringFlange

The invention discloses a detachable chlor-alkali special valve having a leakage preventing device. The special valve is characterized by comprising a special valve body, the leakage preventing device and a control device, wherein the special valve body comprises a valve part, a valve base and a valve body; the valve body is fixedly connected with the leakage preventing device; the control device comprises a valve rod; the leakage preventing device comprises a gland, an upper valve cover, a lower valve cover and a corrugated pipe inserted through by the valve rod in sequence; the upper and lower valve covers are fixedly connected; the gland is positioned at the upper end of the upper valve cover; a sealing filler is arranged in a filler cavity defined by the gland, the upper valve cover and the valve rod; the upper end of the corrugated pipe is pressed and fixed by the upper and lower valve covers; and the lower end of the corrugated pipe is fixedly connected with a flange fixedly connected to the valve rod. As the valve rod is welded with the flange, the reshaping is convenient; the lower end of the corrugated pipe is welded on the flange, so that the valve rod is not liable to deform; and the upper end of the corrugated pipe is pressed and fixed through the upper and lower valve covers, so that a traditional welding structure is broken through, the disassembly among parts is easy, and the cleaning, the checking and the maintenance are convenient.

Owner:江苏明江阀业有限公司

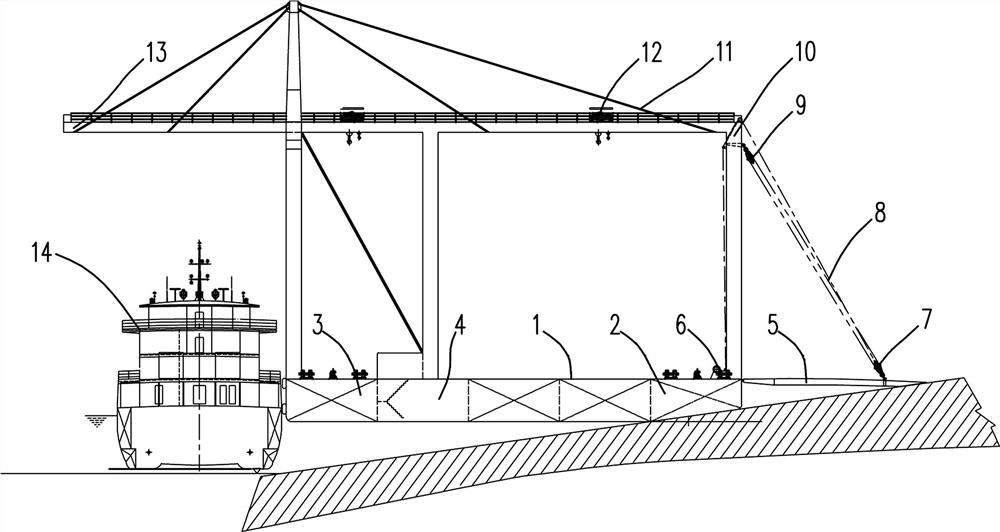

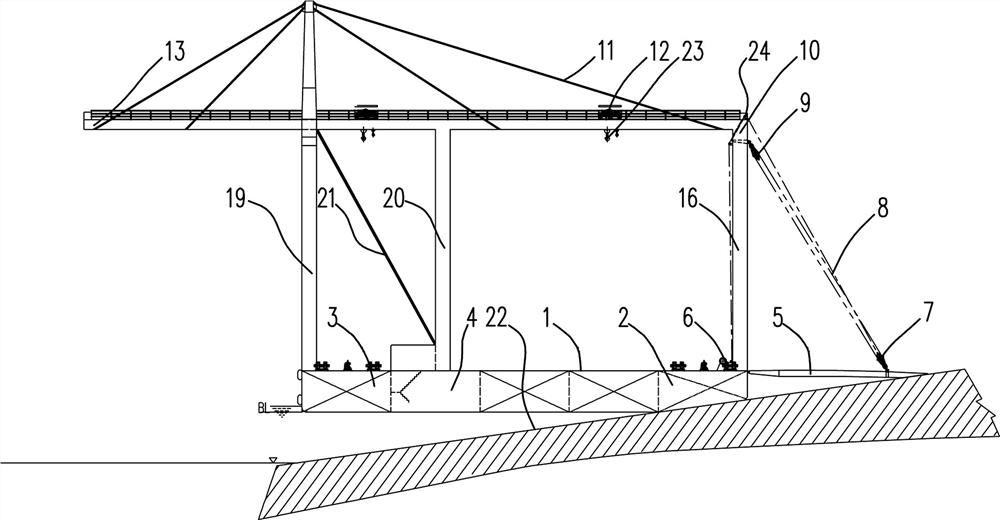

Amphibious lng tank container reloading ship and reloading method

ActiveCN110498020BSolve the filling problemIncrease supplyCargo handling apparatusAuxillariesTank containerStern

The invention provides an amphibious LNG reloading ship, which includes a hull, a lifting device is arranged on the hull, a first ballast tank is arranged at one end of the hull, the bottom of the first ballast tank is provided with an inclined surface in contact with the ramp lane, and There is a pump room for adjusting the load in the first ballast tank; there is a driving springboard at the end of the hull close to the first ballast tank. When in use, the hull is towed to an appropriate position on the ramp lane, and the load is increased by injecting water into the first ballast tank through the pump room, so that the bottom of the first ballast tank is in contact with the ramp lane; the figure-eight cables between the stern and the shore foundation are fastened, and the vehicle puts the LNG tank The LNG tank container is transported from the shore to the hull, and the LNG tank container is hoisted from the vehicle to the deck of the hull by the lifting device to realize the replacement of the LNG tank container. The invention overcomes the fluctuation of the water level and realizes the replacement of the tank container from the land to the LNG ship on the water by only occupying relatively small shoreline resources, and the operation speed is fast and the safety efficiency is high.

Owner:YICHANG DONGJIANG SHIPBUILDING CO LTD

A Closed Capping Method for Up-fill Mining

The invention discloses a closed roof capping method for upward filling mining. The characteristic of this method is that after mining the last stratification, use a drilling rig to drill four exhaust holes at the four corners of the roof, and then build partition walls around the goaf to level off the bottom of the goaf and the roof. The partition walls around the goaf, the bottom of the goaf and the roof are pasted with waterproof materials to enclose the goaf into a closed filling space, and the filling material is injected into the closed filling space through the filling patio. When the filling material overflows, the exhaust When filling holes, stop injecting, and after the filling material fills the closed filling space, cover the four vent holes and the filling patio with a layer of waterproof material, and seal them with cement. The invention prevents the discharge of water in the filling slurry, maintains the volume and shape of the filling slurry, and forms a completely top-connected filling body after the filling material condenses, thus solving the problem of filling and top connection. The process of the invention is simple, safe, reliable, easy to implement and low in cost.

Owner:UNIV OF SCI & TECH LIAONING

A Method for Image Rendering Using Depth Map

ActiveCN103916656BQuality improvementSolve the filling problemSteroscopic systemsColor imageViewpoints

Owner:HUAZHONG UNIV OF SCI & TECH +1

A method for subsequent filling of closed open field mining

InactiveCN105041318BAvoid dischargeMaintain volumeUnderground miningSurface miningFilling materialsBody contact

The invention discloses a method for filling after closed open space mining. The method is characterized by excavating a filling patio on the roof, using a drilling rig to drill four exhaust holes at the four corners of the roof, building partition walls around the goaf, and leveling the bottom and roof. Pave waterproof materials on the partition wall, bottom plate and top plate, and form a closed filling space surrounded by the partition wall, bottom plate and top plate. Fill the filling material into the closed filling space through the filling patio. When the filling material overflows the vent hole, stop the injection and start filling. After the material fills the closed filling space, the four vent holes and the filling patio are covered with a layer of waterproof material and sealed with cement. The invention maintains the volume and shape of the filling slurry, and forms a completely top-connected filling body after the filling material is solidified, thus solving the problem of filling and top-connection.

Owner:UNIV OF SCI & TECH LIAONING

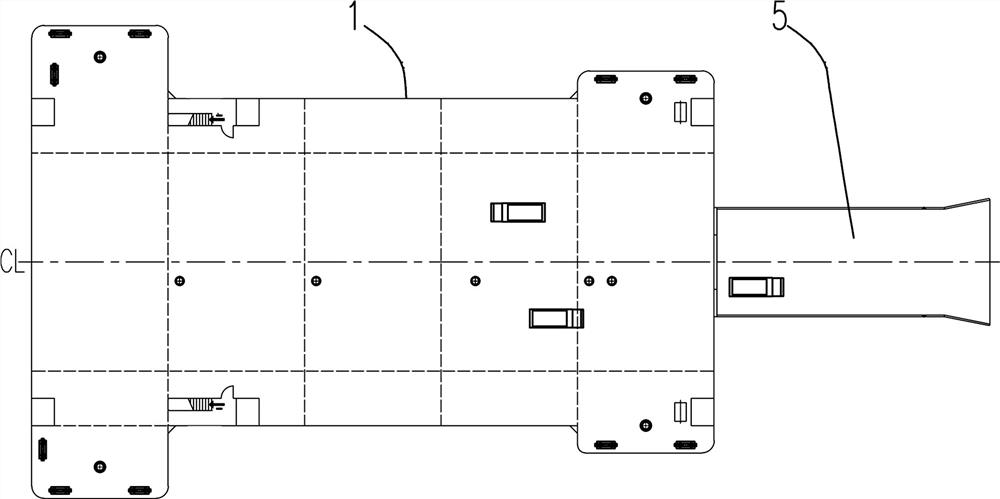

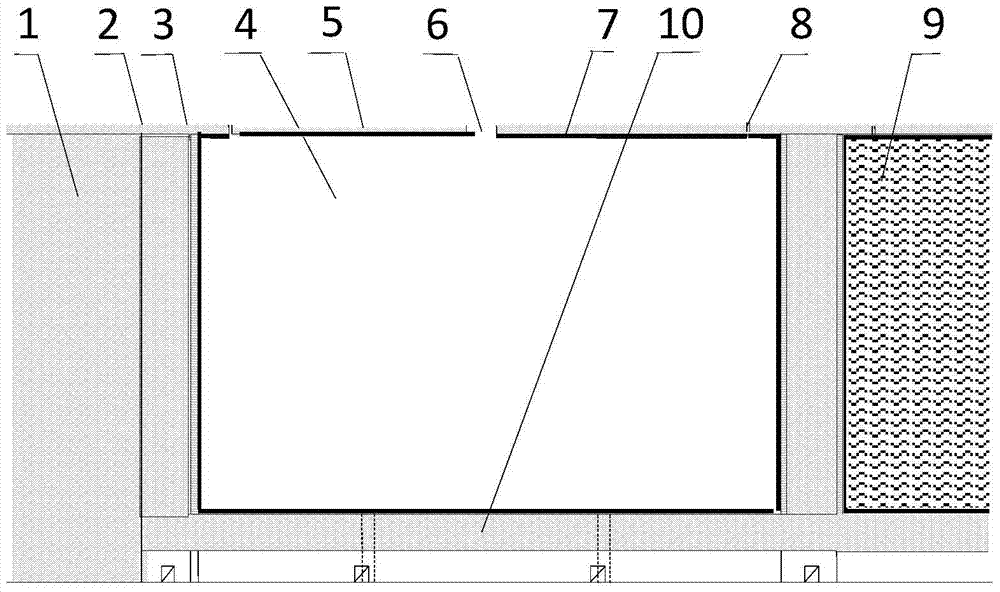

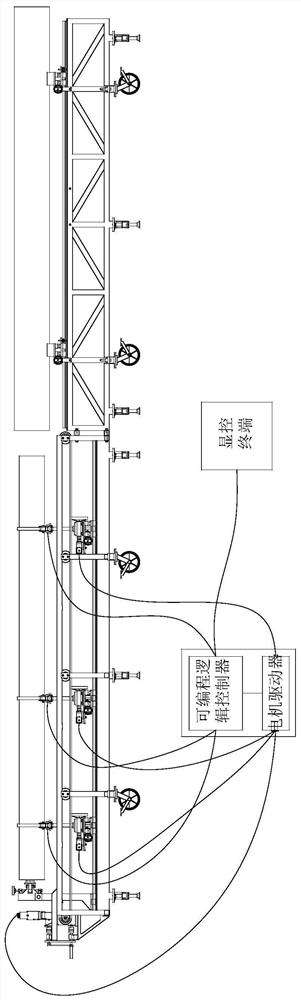

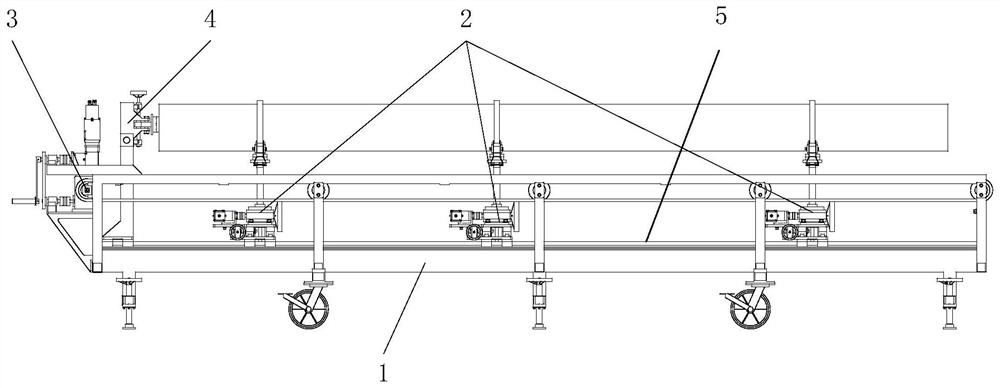

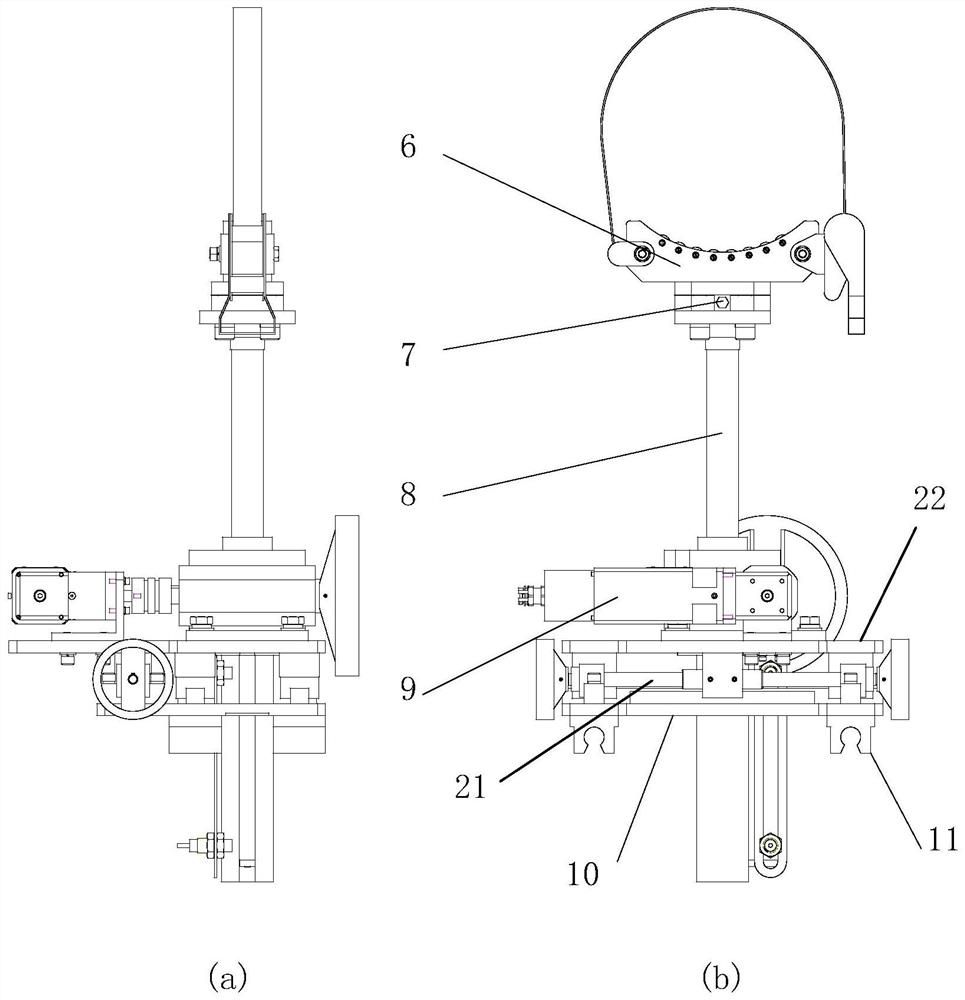

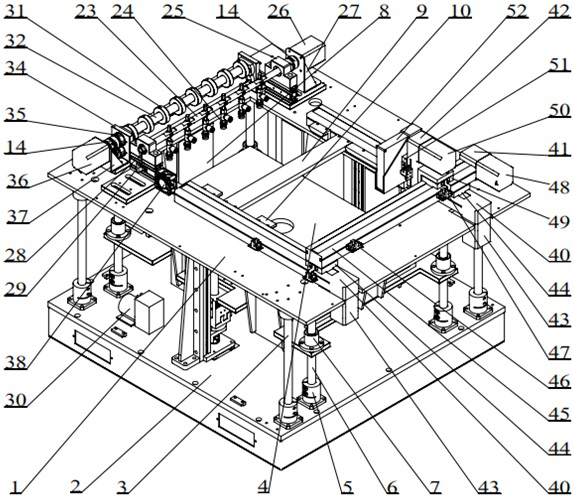

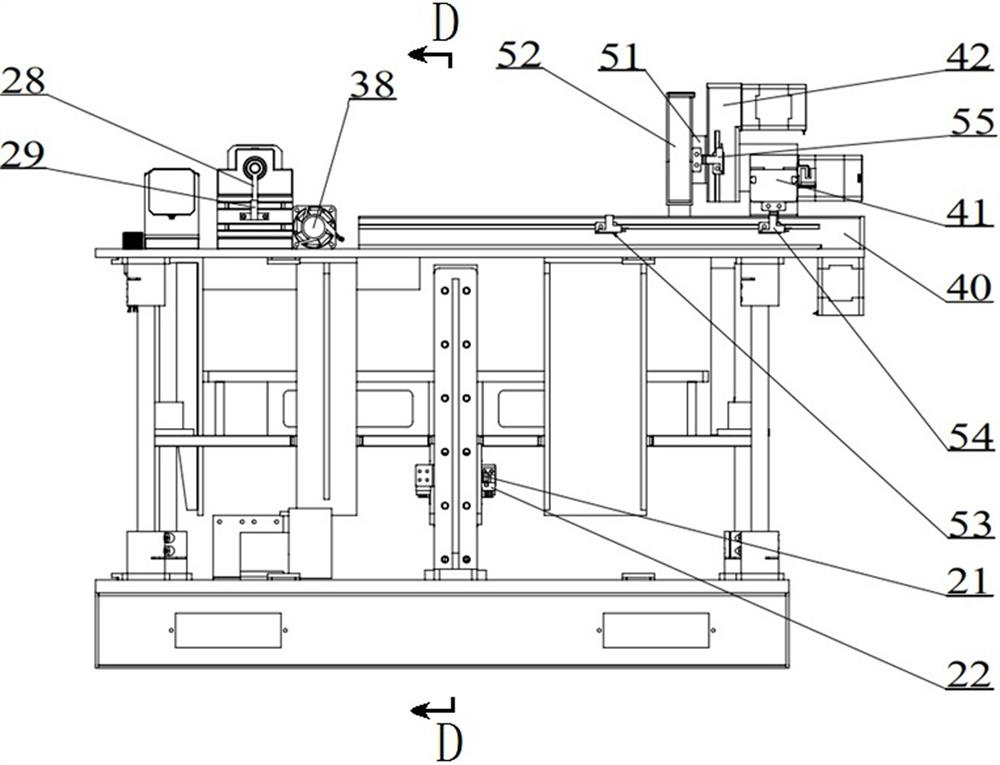

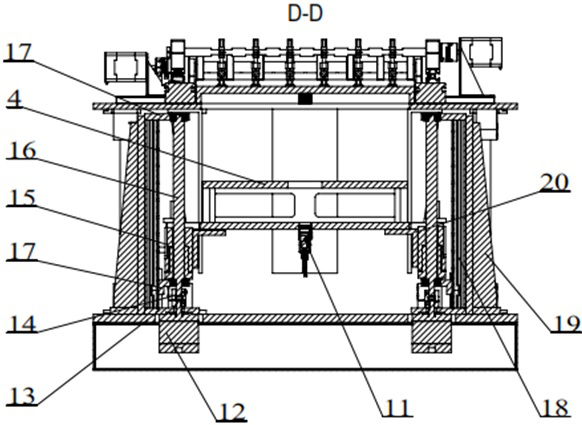

Automatic loading and unloading equipment for compartment products

ActiveCN110125634BSolve the filling problemRealize filling automationLaunch systemsCosmonautic partsControl systemControl engineering

The equipment for automatically entering and exiting the tank for cabin products of the present invention includes a cabin product platform, a tank platform and a control system; the cabin product platform is mechanically connected to the tank platform; the cabin product platform includes a structural platform, A lifting bracket, a chain drive system and a push-pull device; the structural platform is provided with a first guide rail, and the lift bracket and the push-pull device are installed on the first guide rail; the chain drive system is installed on the On the structural platform, the push-pull device is connected to the chain drive system; the control system is electrically connected to the lift bracket to adjust the height of the lift bracket; the control system is electrically connected to the chain drive system , which drives the chain drive system to move, thereby pushing the push-pull device. Cabin products automatically enter and exit the barrel equipment.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

File envelope filling printer

PendingCN112776477ASolve the filling problemWork reliablyPower drive mechanismsOther printing apparatusComputer printingSoftware engineering

The invention relates to the field of printers, in particular to a file envelope filling printer which is a printer with special paper and printing modes. The file envelope filling printer is composed of a printer body, a paper storage bin, a paper feeding mechanism, a writing and printing mechanism and a paper taking and moving-out mechanism. The paper storage bin is arranged in the middle of the printer body and used for storing file envelope paper. The paper feeding mechanism is arranged in the middle of the printer body and is a file envelope paper feeding and conveying part; The writing and printing mechanism is arranged on the upper portion of the printer body and is a printing component with the function of moving in the X-axis direction, the Y-axis direction and the Z-axis direction. The paper taking and moving-out mechanism is arranged on one side of the upper portion of the printer body and is a file envelope paper taking-out component. The file envelope filling printer is simple in structure, reliable in work and convenient to use, a pickup roller does not need to be replaced frequently, the working intensity is reduced, and the working efficiency is improved.

Owner:南京激扬智慧信息技术研究院有限公司

A sponge city permeable pavement suitable for prefabricated roadbed

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

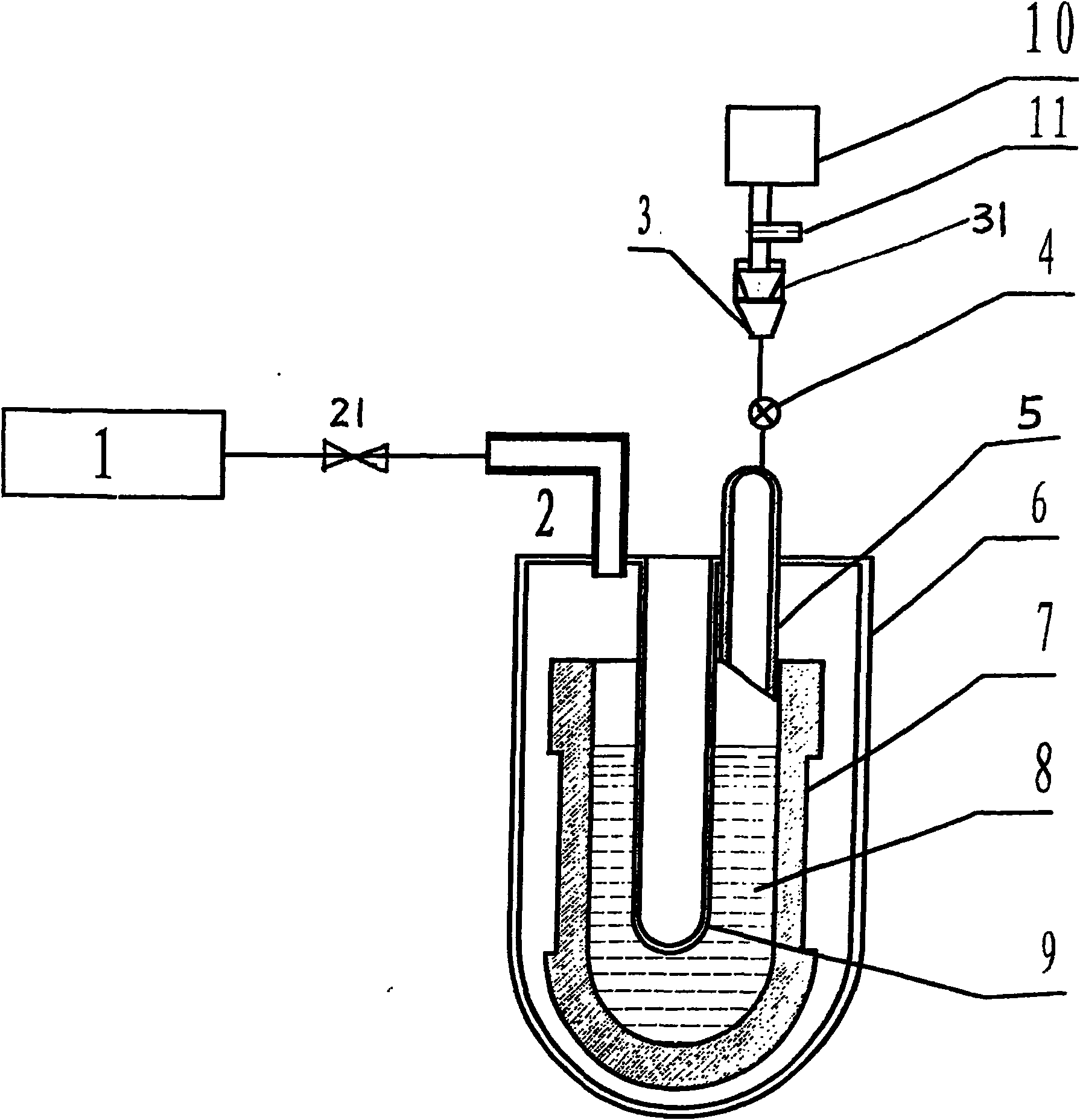

Pressure filling device and method of molten metal

InactiveCN101507906BLow viscositySolve the filling problemPressure/vacuum vesselsPressure vessels for chemical processTriple pointPositive pressure

Owner:BEIJING ALLWELLTECH

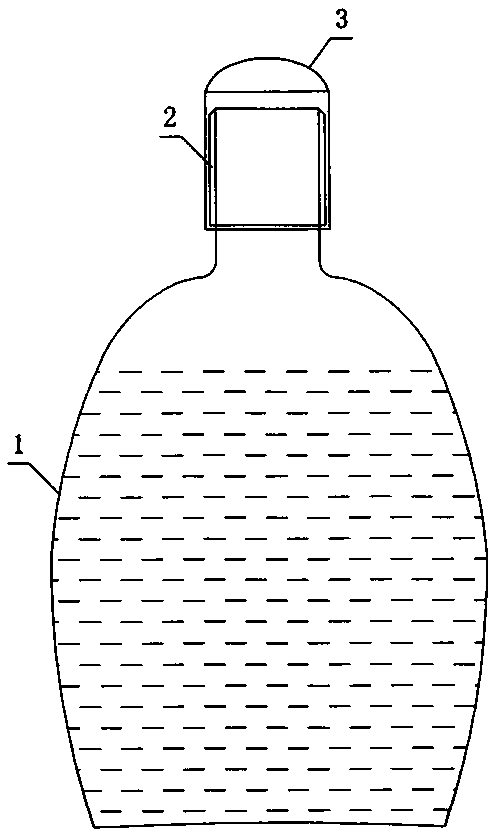

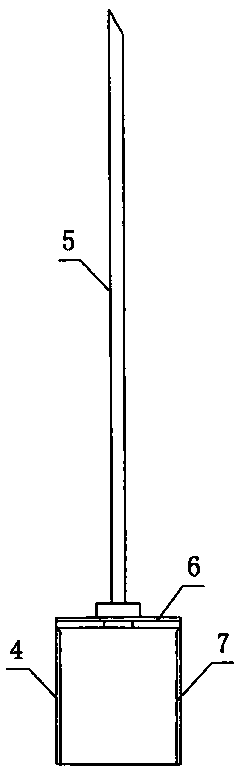

Ink filler for fountain pen core

The invention discloses an ink filler for a fountain pen core. A bottleneck is arranged at the upper end of an ink bottle; outer threads are arranged on the outer edge of the bottleneck; an ink filling needle is arranged on the outer threads of the bottleneck; inner threads are arranged in a needle body of the ink filling needle; a long needle head is arranged at the upper end of the needle body;in use, a bottle cover is dismounted, the needle body of the ink filling needle is mounted and connected onto the outer threads of the ink bottleneck through threads, the needle head is inserted intoa to-be-used-out pen core, and the ink bottle is extruded for filling ink into the pen core. The ink filler is simple in structure, is reasonable in design, is low in processing and production cost, and is good in energy-saving environment-friendly benefit.

Owner:刘晨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com