Patents

Literature

62results about How to "Avoid cropping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

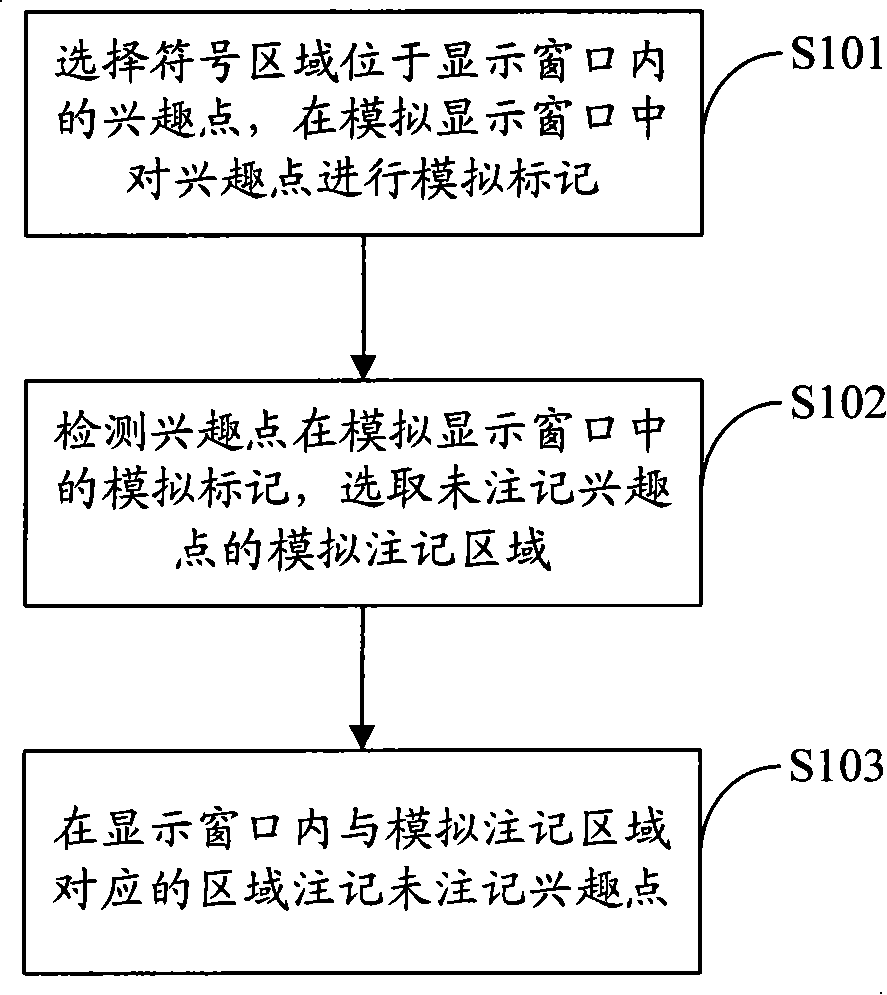

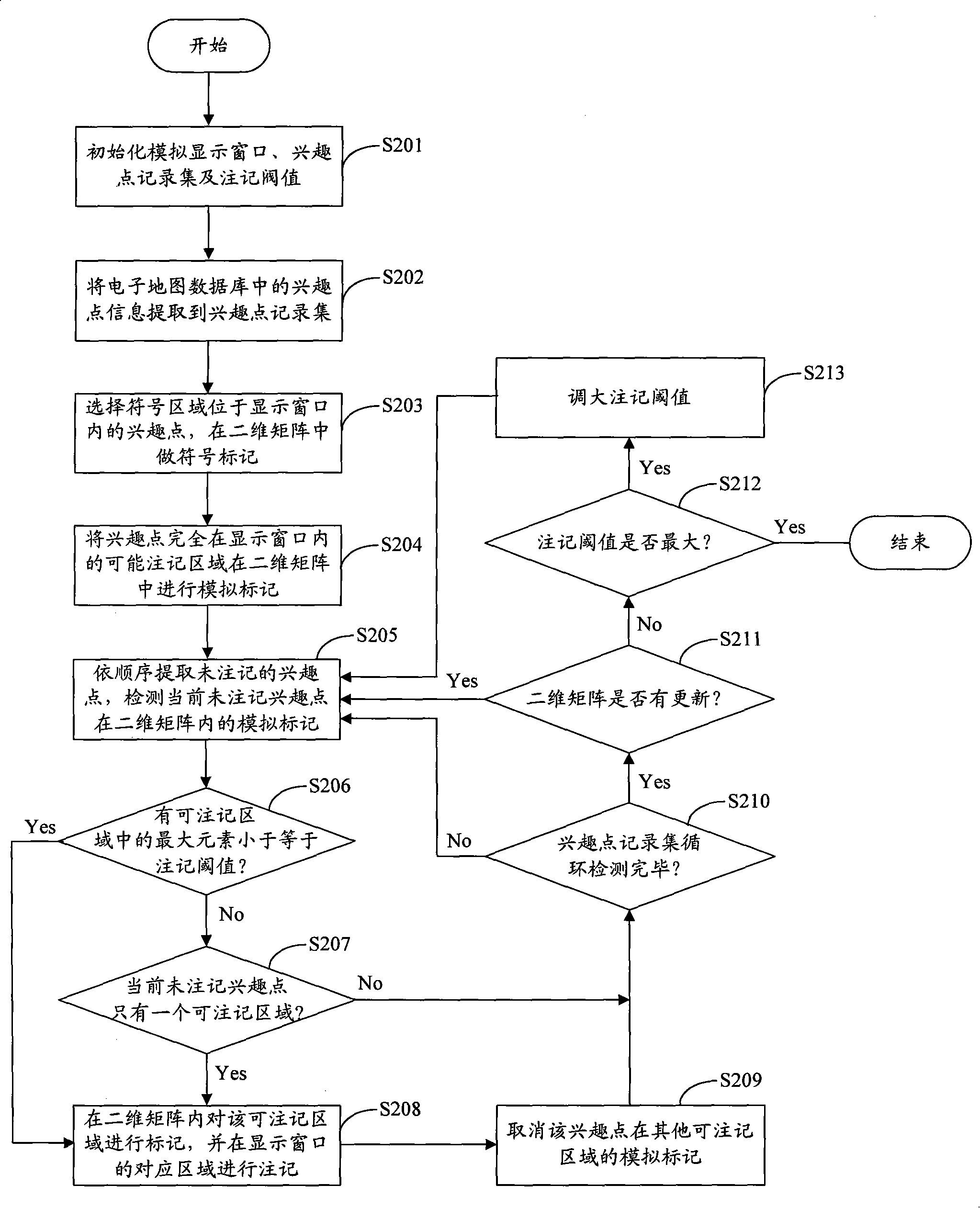

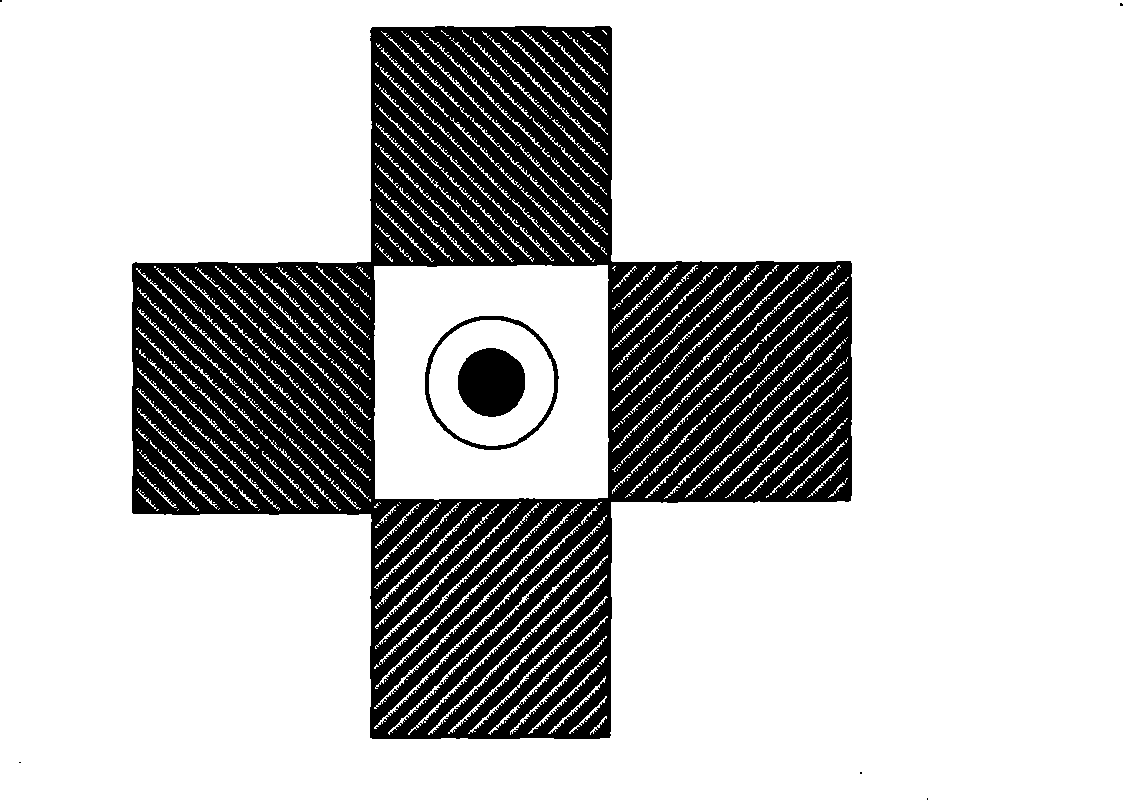

Electronic map interest point marking method, system and equipment

The invention suitable for the electronic map field provides a method for marking an electronic map interest point, a system and a device; the method comprises the following steps that: an interest point with a sign region in a display window is selected; the interest point is carried out by simulation marking in the simulated display window; a simulated marker of the interest point in the simulated display window is detected; a simulated marking region of an unmarked interest point is selected; the unmarked interest point is marked in the region of the display window corresponding to the simulated marking region. The method for marking an electronic map interest point, a system and a device can optimize and arrange the marking region of the interest point on the whole, can avoid the marking of the interest point being cut by window boundary and remove the phenomena of superposition and occupancy between the markers of the interest points or between the marker and the sign of the interest point in order that more interest points can obtain markers.

Owner:SHENZHEN DAIWEN TECH

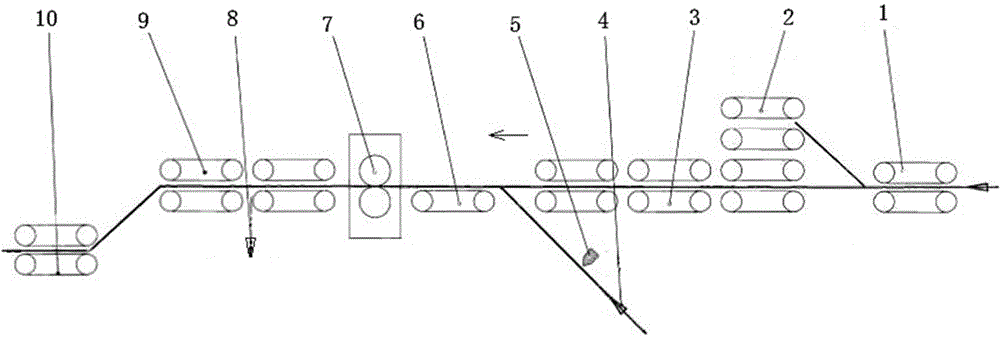

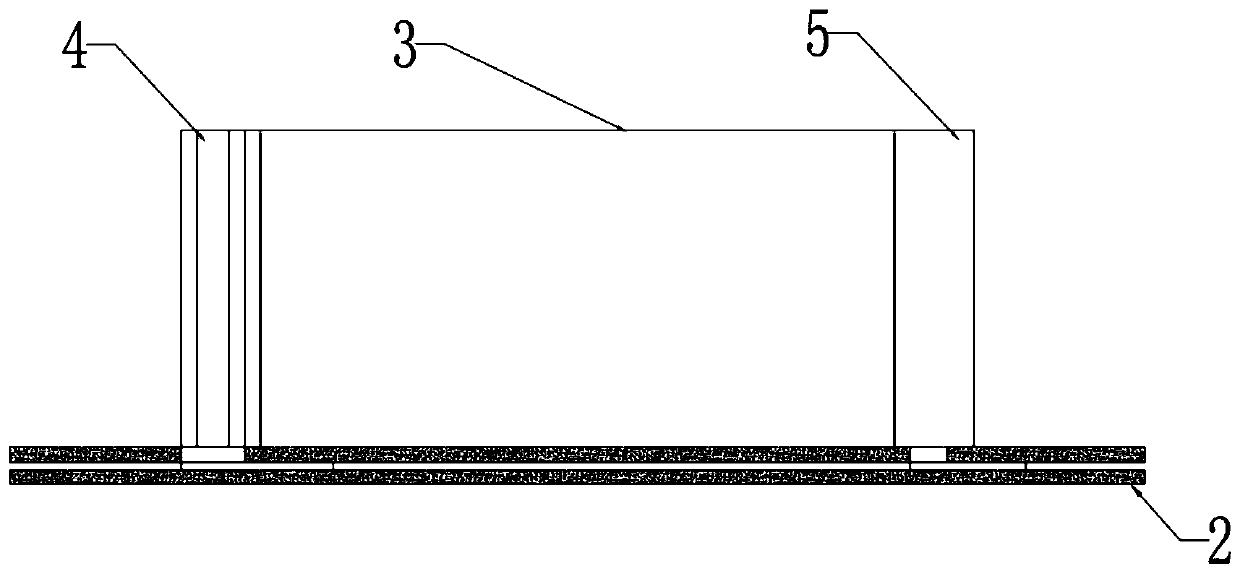

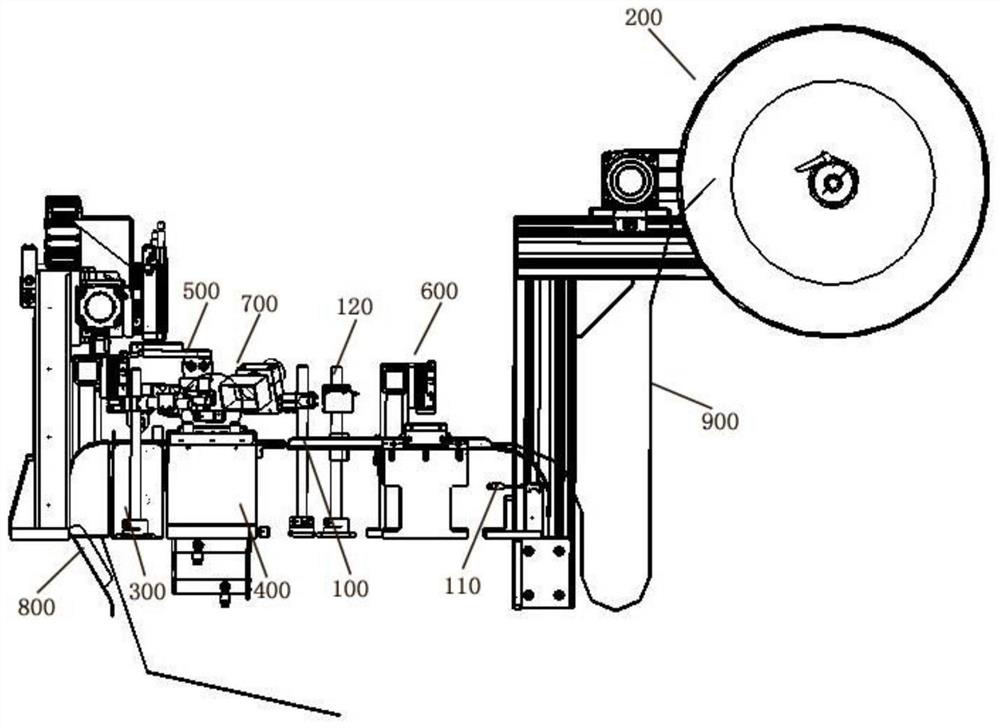

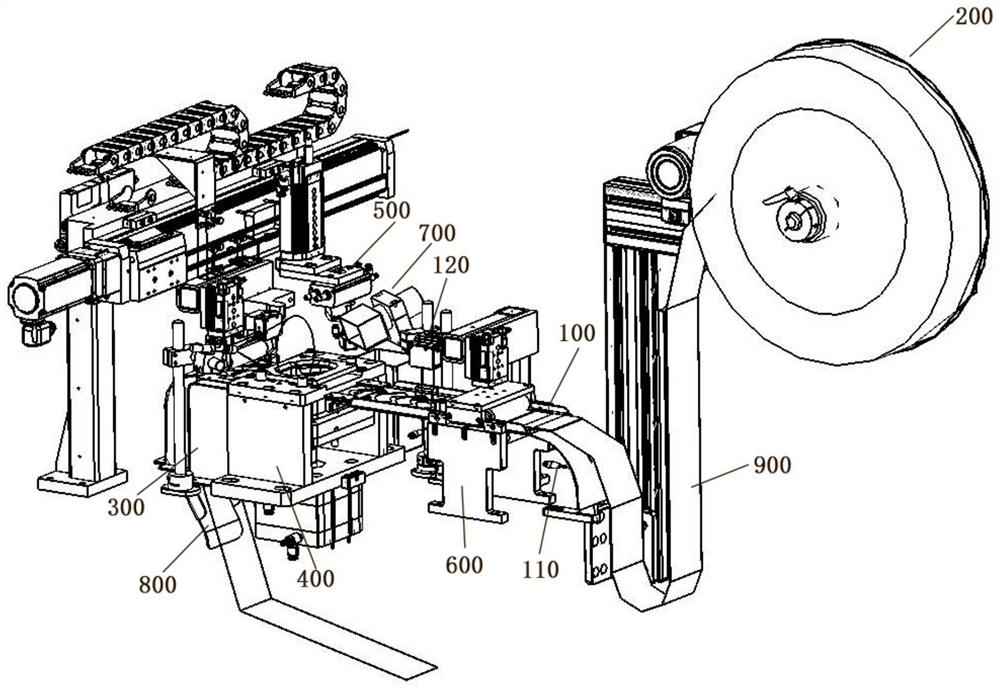

Automatic packaging mechanism for single-piece absorptive hygienic product

ActiveCN105083629AAdjust intervalImprove pass ratePaper article packagingWrappingMechanical engineeringFast speed

The invention belongs to the technical field of production equipment of absorptive hygienic products, and discloses an automatic packaging mechanism for a single-piece absorptive hygienic product. A packing system is sequentially provided with a multi-stage conveying unit, a film packaging and folding device and a heat sealing and cutting combination unit in the conveying direction. The multi-stage conveying unit sequentially comprises a front portion conveying unit, a middle conveying unit in the middle and a rear portion conveying unit which are operated independently. The middle conveying unit is provided with a synchronous conveying belt, baffles which protrude out of the surface of the conveying belt are evenly arranged on the surface of the conveying belt at intervals, and the hygienic product is conveyed on the portion, between the adjacent baffles, of the synchronous conveying belt. The automatic packaging mechanism for the single-piece absorptive hygienic product can be applied to single-piece packaging of the larger and thicker hygienic product such as sweat pants, has the beneficial effects of being high in packaging yield, low in size deviation, high in production speed and the like, and can adapt to high-speed development requirements of the hygienic products.

Owner:ZUIKO (SHANGHAI) CORP

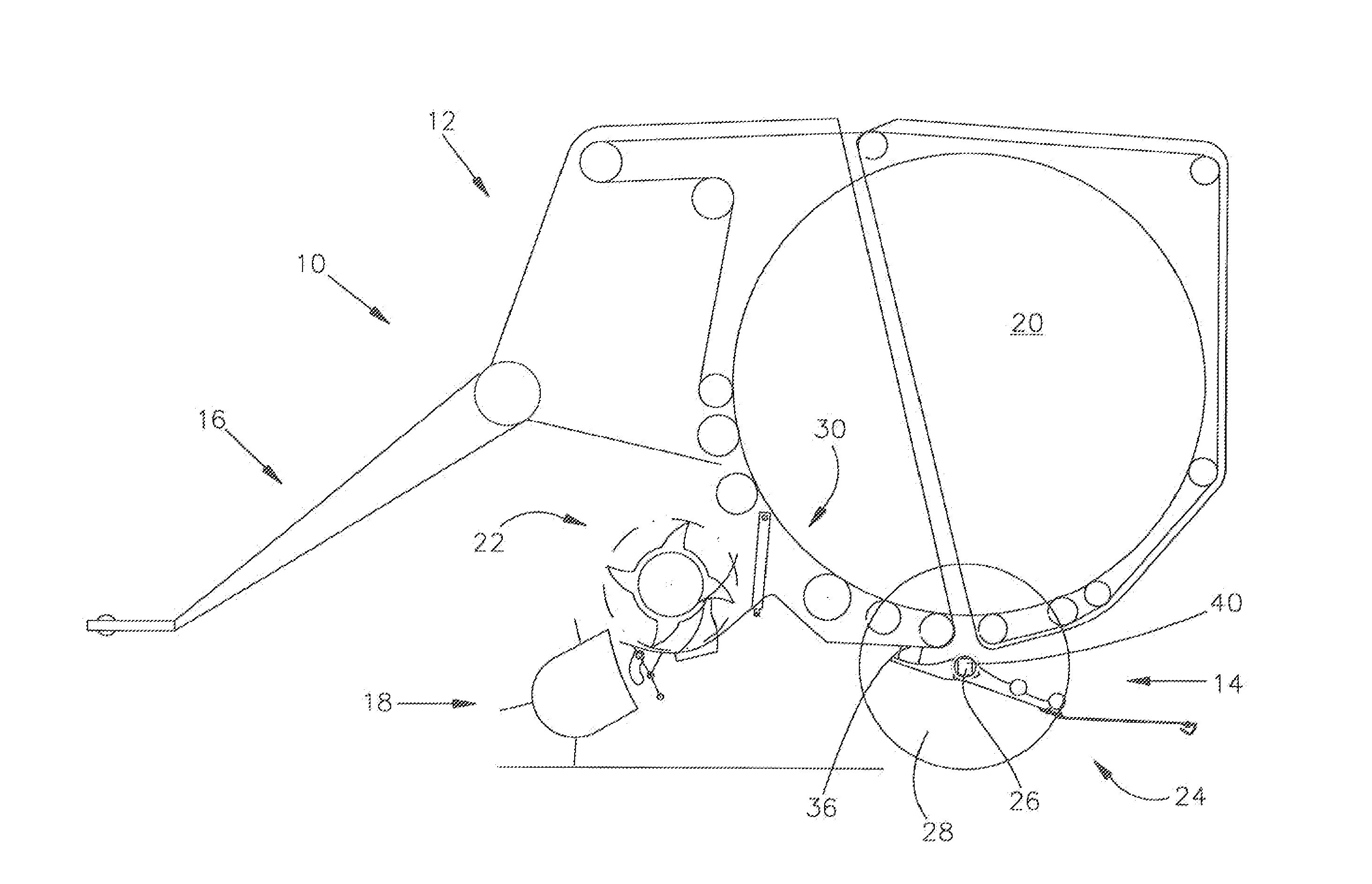

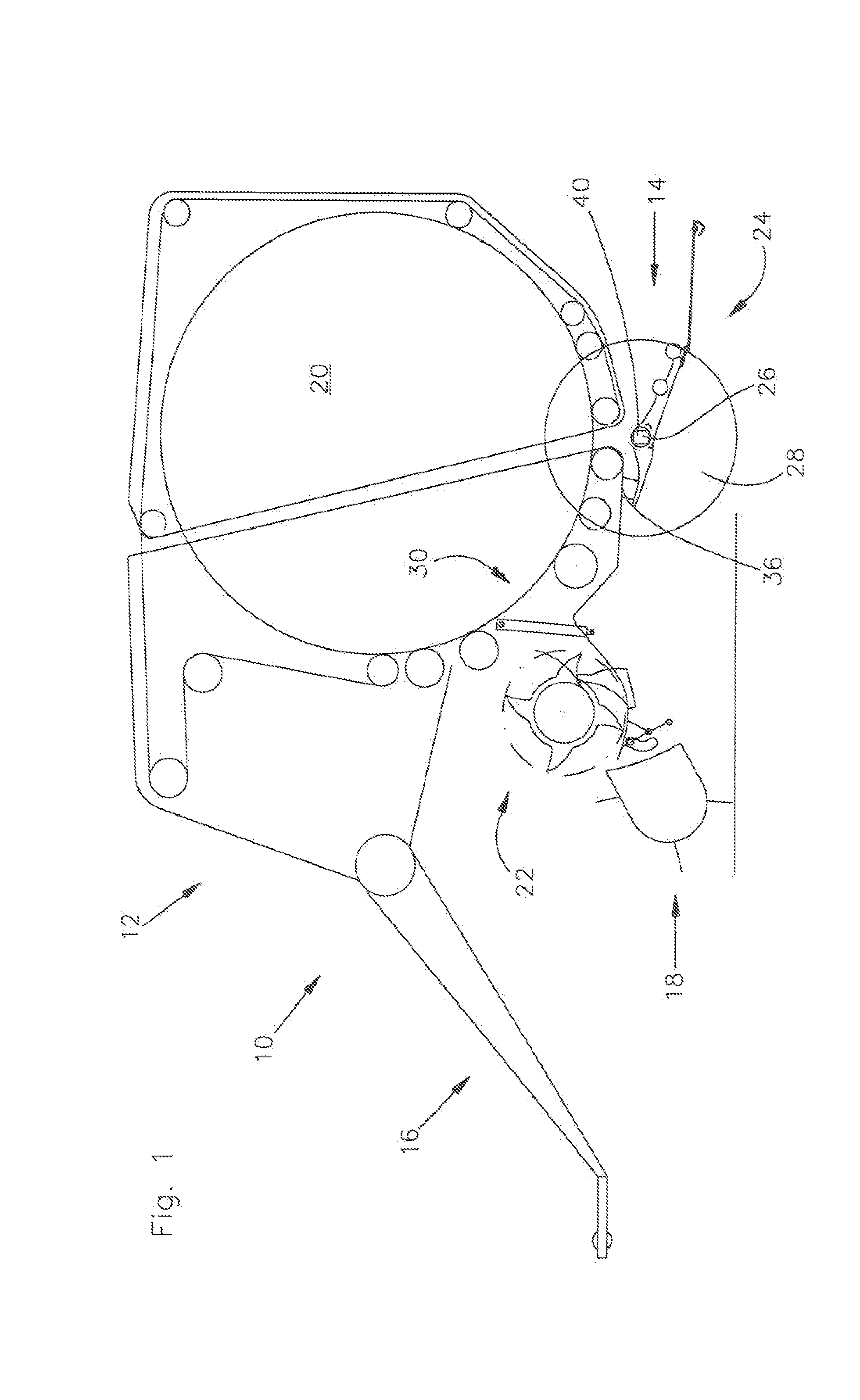

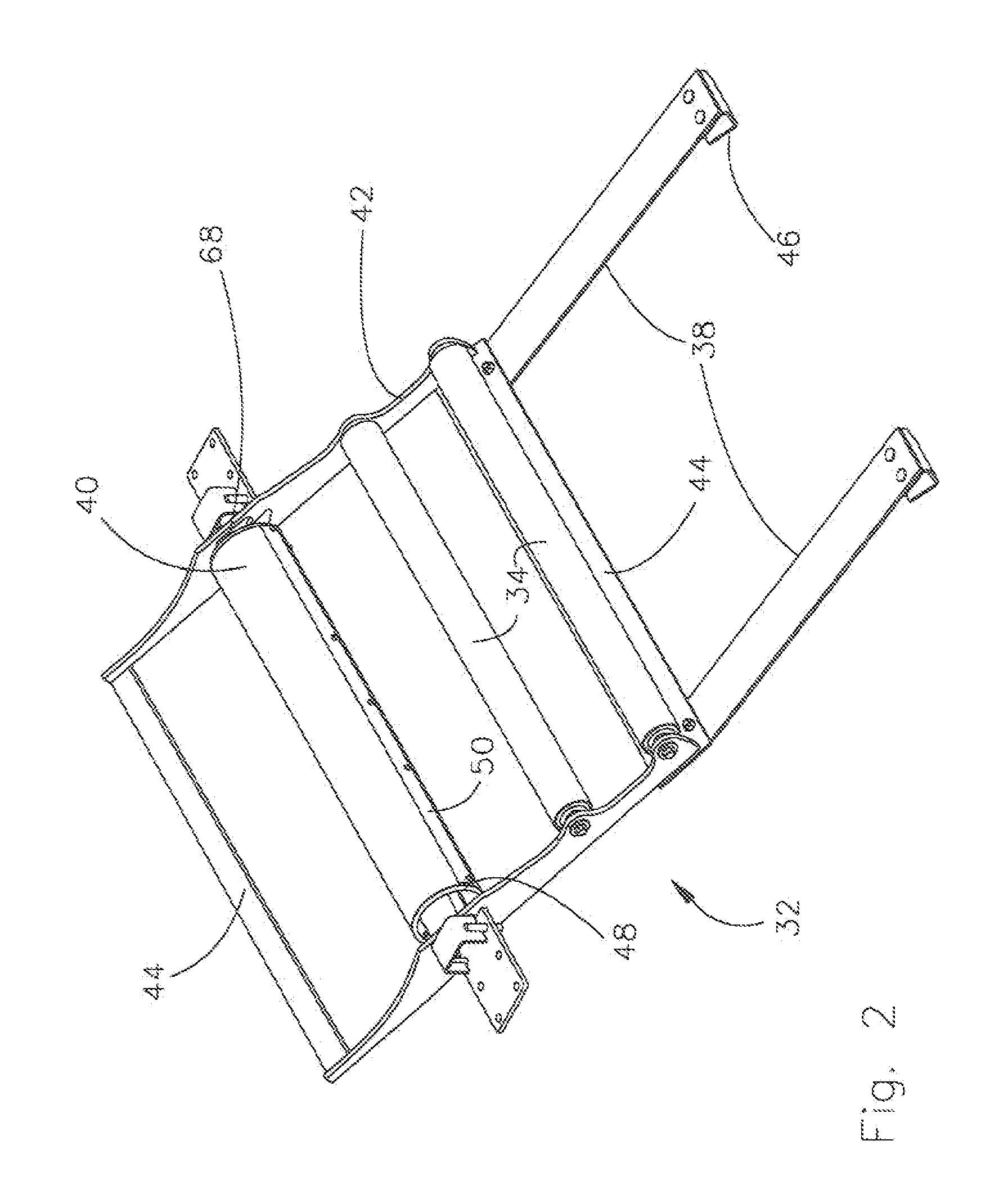

Round Baler

A round baler has an unloading apparatus downstream of a bale chamber provided with movable carrying elements, for example rollers, belts, etc., so that a round bale discharged in rotating motion from the bale chamber is able to maintain its spin and twine wound onto it does not fall off again. To prevent the rotary motion of the round bale from being slowed or even terminated upon transfer to the unloading apparatus, stationary portions of a superstructure of the round baler, for example, a cross-stay serving as an axle, are covered by a movable cover.

Owner:DEERE & CO

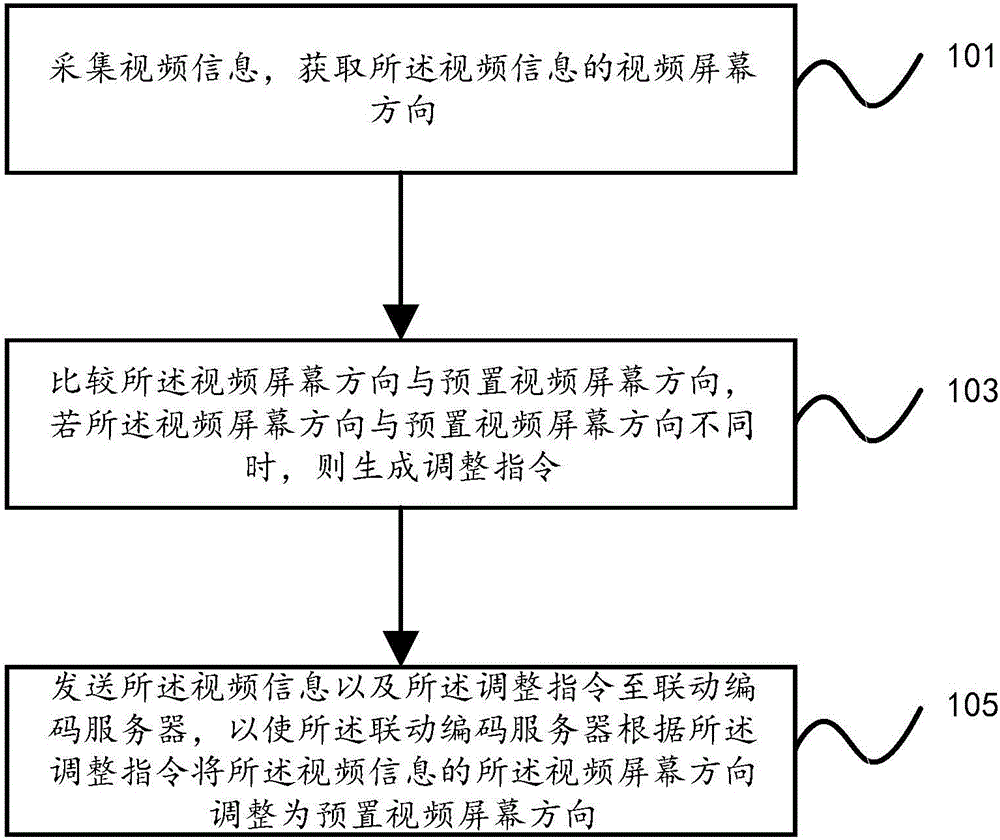

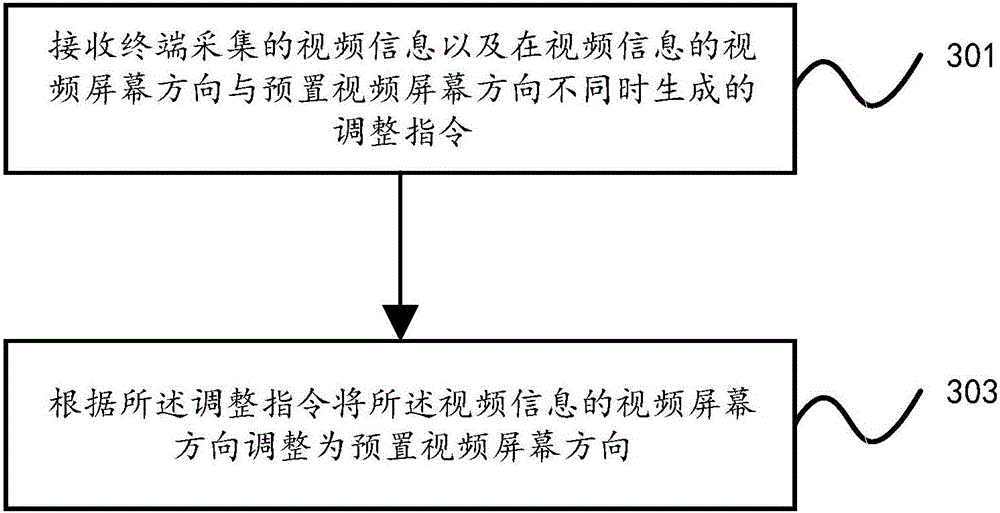

Method, device and system for live broadcast coding, and terminal and linkage coding server

InactiveCN106506554AAvoid croppingImprove the display effectTransmissionSelective content distributionVideo screen

The invention discloses a method, a device and a system for live broadcast coding, and a terminal and a linkage coding server. The method for live broadcast coding comprises the following steps of collecting video information and obtaining a video screen direction of the video information; comparing the video screen direction and a preset video screen direction, and generating an adjusting instruction if the video screen direction is different from the preset video screen direction; and sending the video information and the adjusting instruction to the linkage coding server in order to make the linkage coding server adjust the video screen direction of the video information to the preset video screen direction according to the adjusting instruction. Through adjusting the video screen direction of the collected video information, so that the video screen direction is consistent to the preset video screen direction, and thus the video screen direction of the collected video information is unified, the clipping of the video information is avoided, and the viewing experience of a user is improved to a certain extent.

Owner:GUANGZHOU HUADUO NETWORK TECH

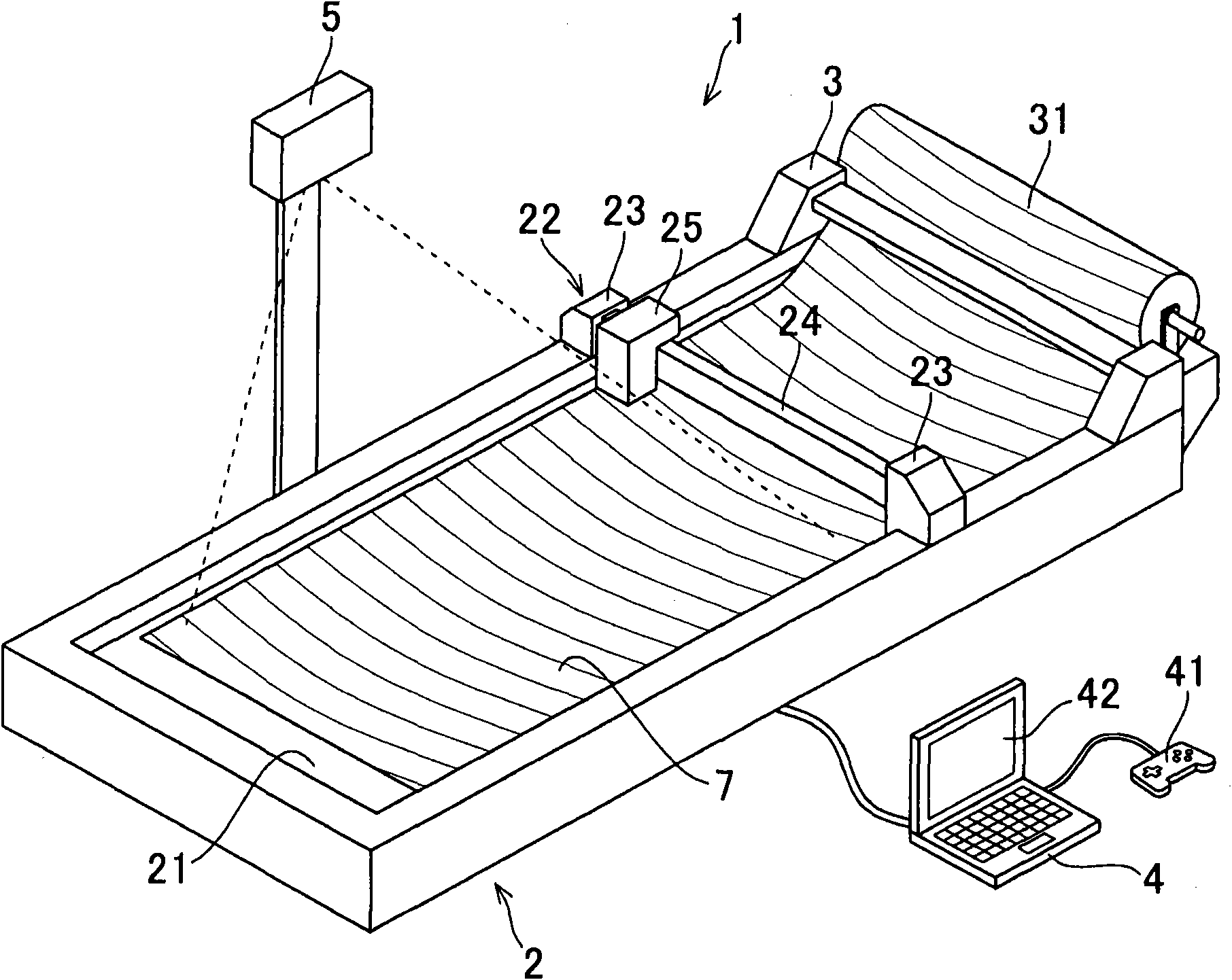

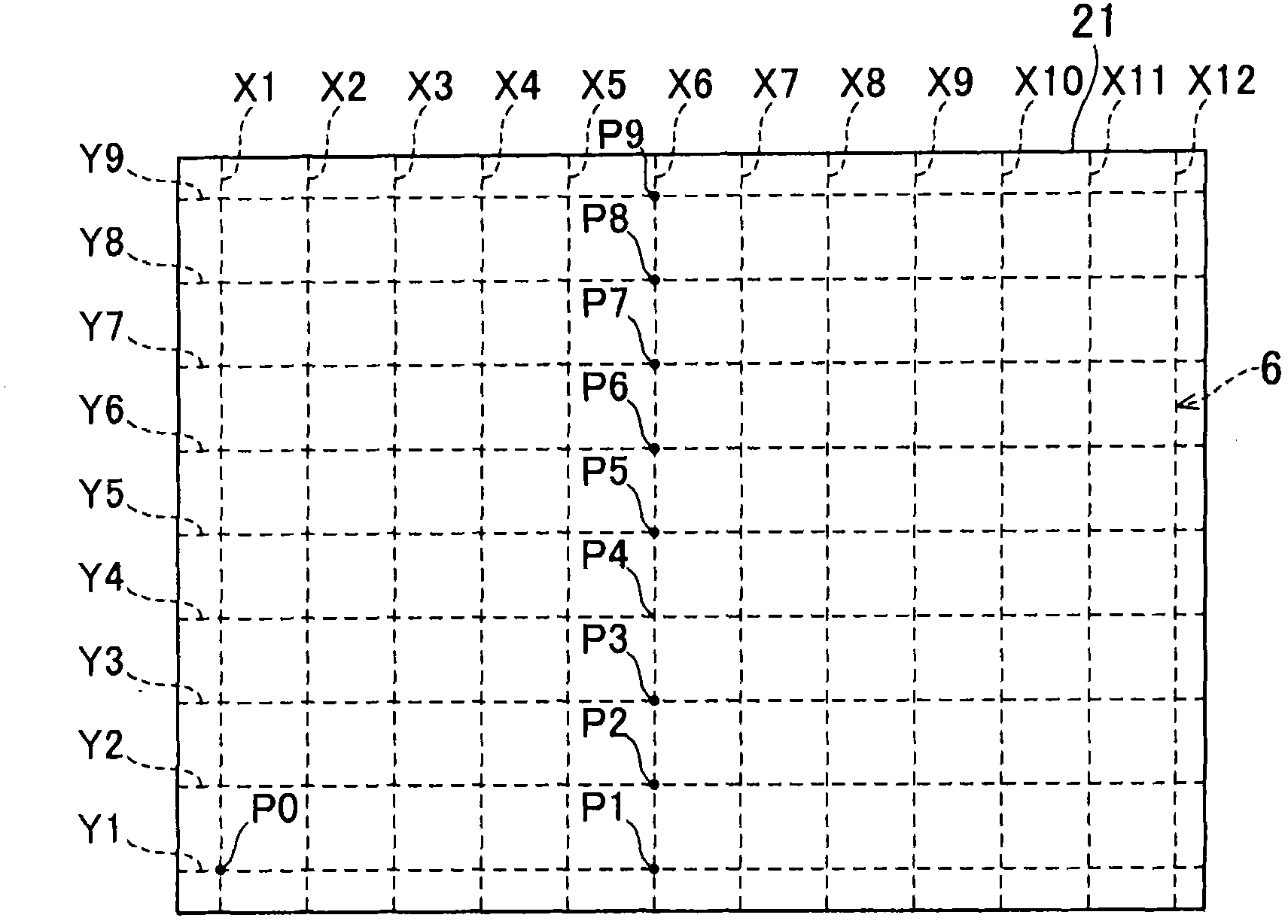

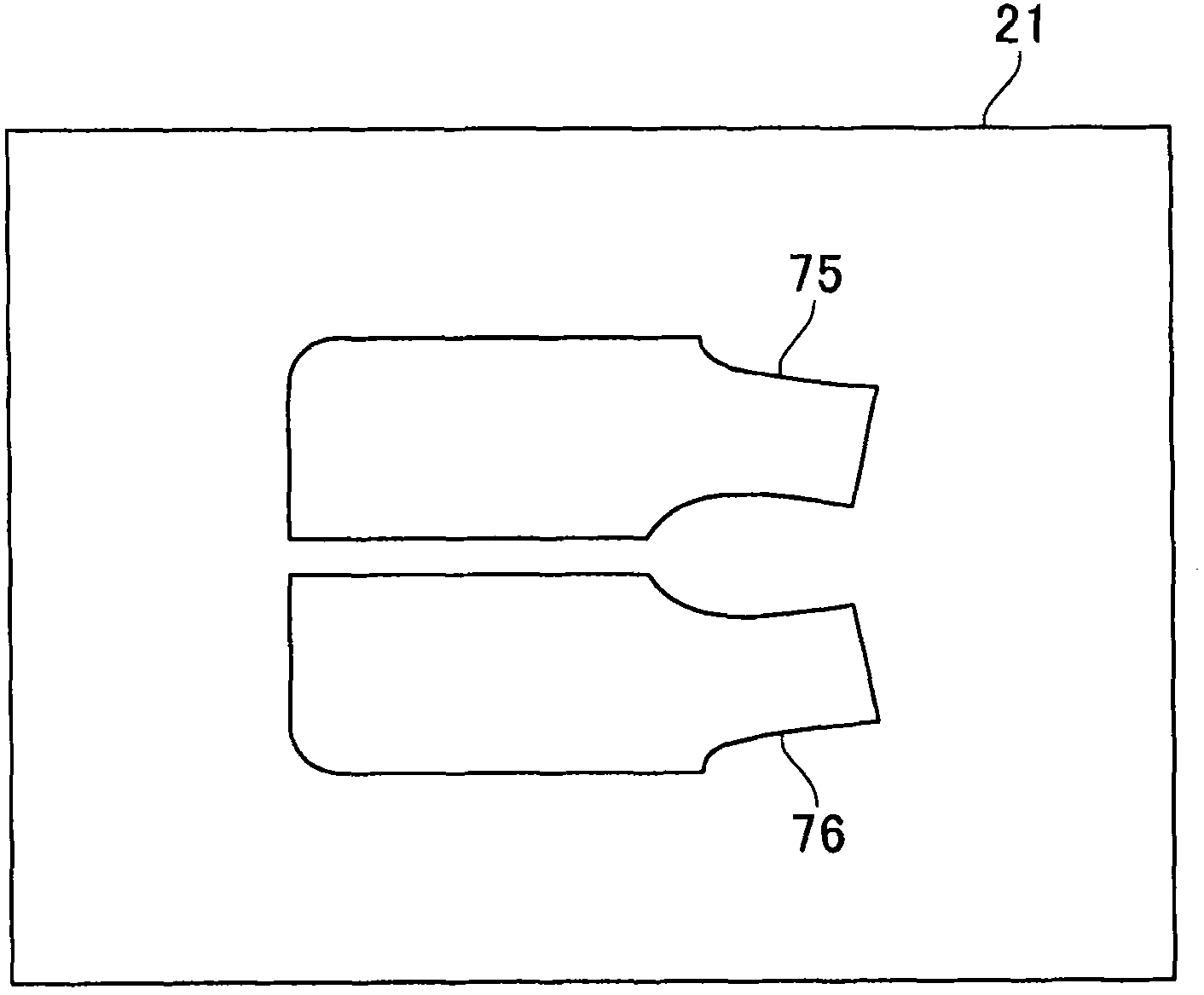

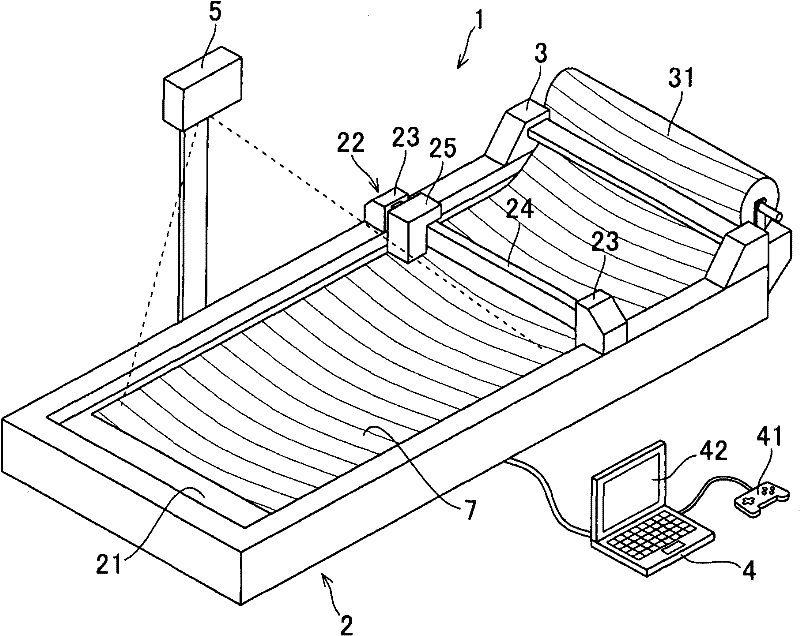

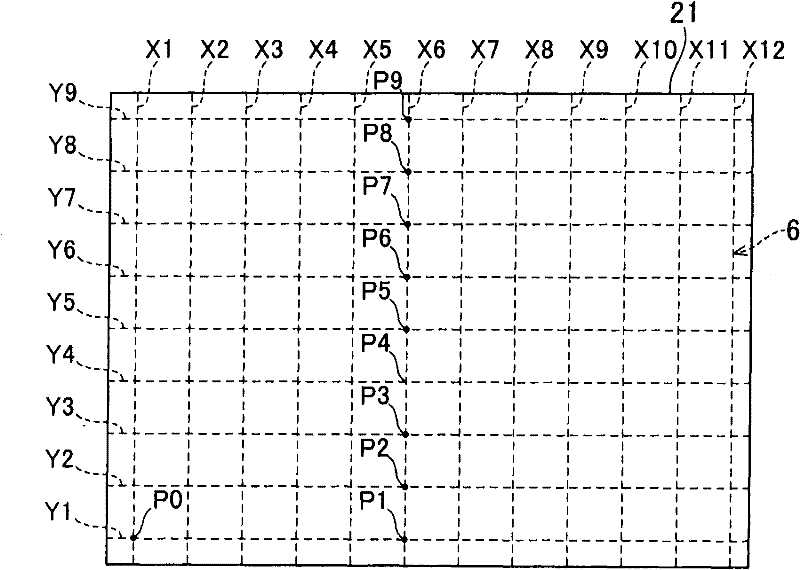

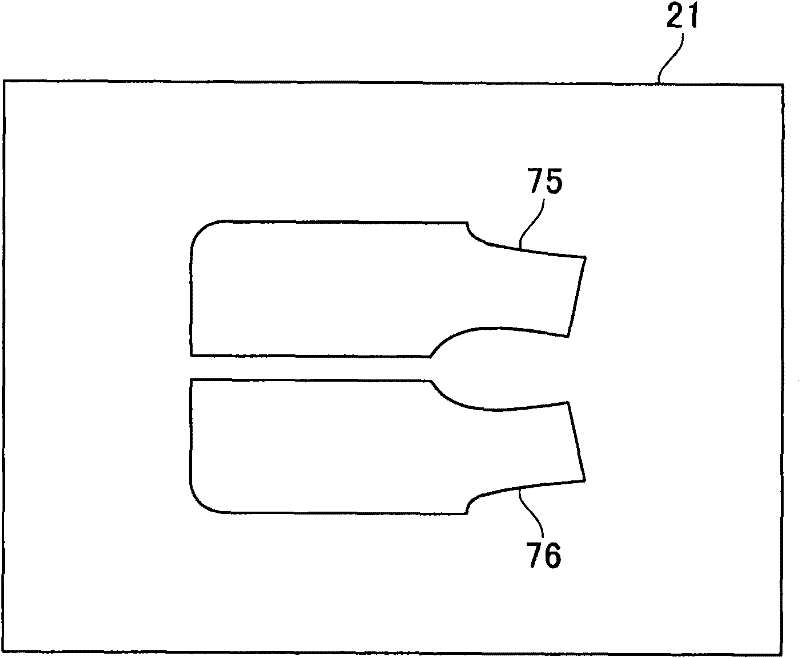

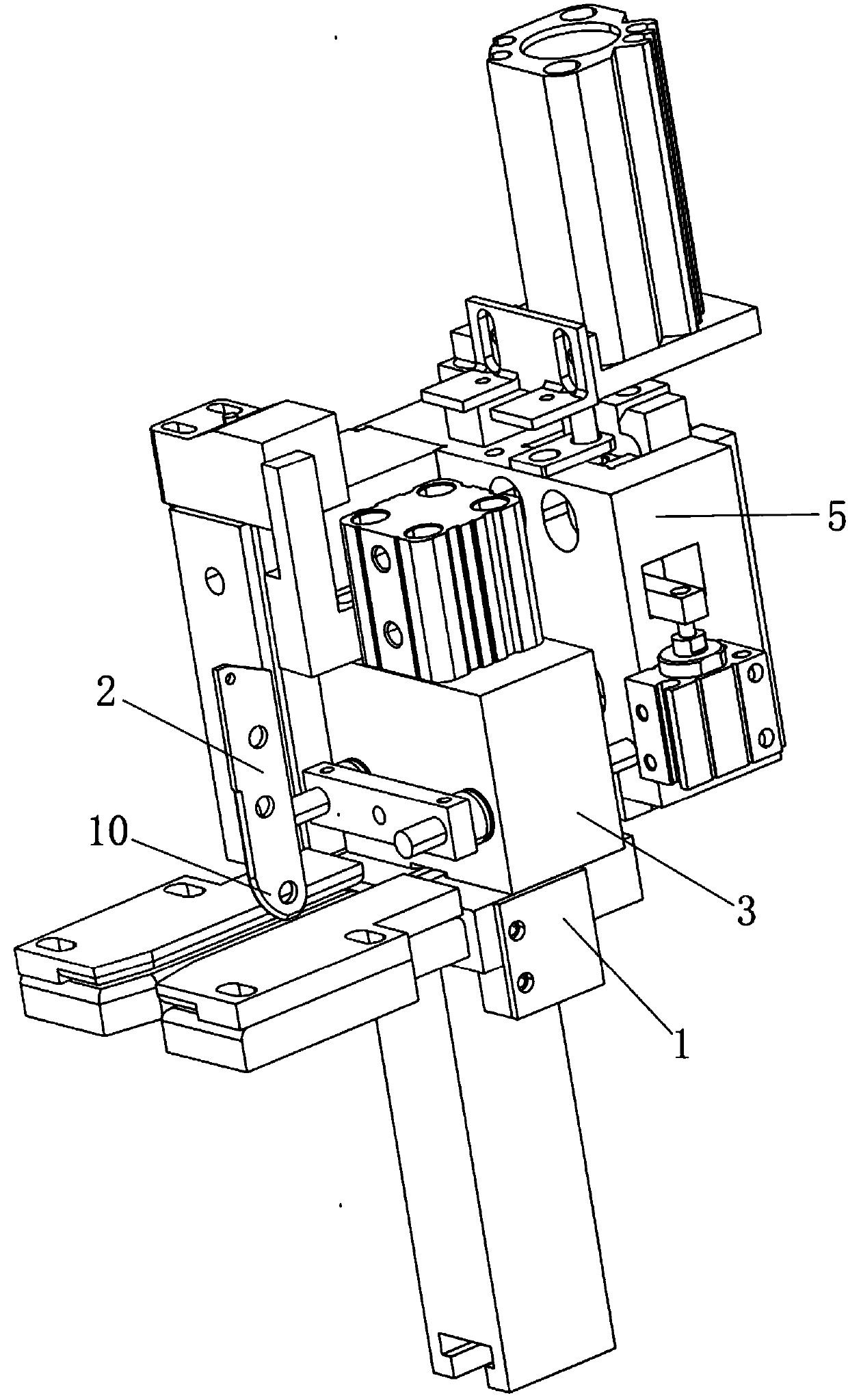

Cutting device

The invention provides a cutting device, capable of enable an operator to correctly identify the distortion of sheet materials, so that the operator can cut the sheet materials along the cutting patterns corresponding to the distortion of the sheet materials, as a result, the pattern sheets with less distortion can be obtained. The cutting device (1) has a cutting workbench(2), a stretching device (3), a projection controlling device (4) and a projector(5). A grid (6) is projected on the surface of a cloth (7) arranged on a bearing surface (21) of the cutting workbench (2) by the projector (5). An operator visually identifying the grid (6) operates a controller (41) to adjust the position of the adjusting points (P1 to P9) of the grid (6), so that the grid (6) is deformed along the patterns of the cloth (7). The cutting patterns (75,76) are deformed correspondingly to the deformed grid (6), and the deformed grid is projected on the surface of the cloth (7). The position and angle of the cutting patterns (75,76) are adjusted, and the cloth (7) is cut into a shape along the cutting patterns (75,76).

Owner:那姆克斯有限公司

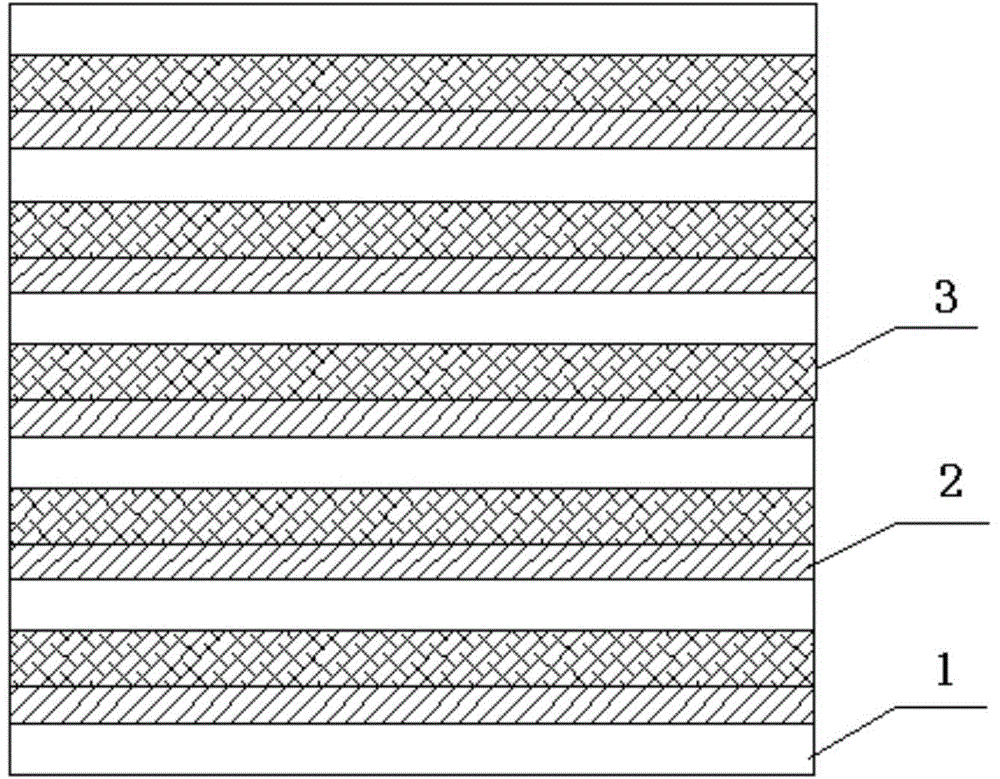

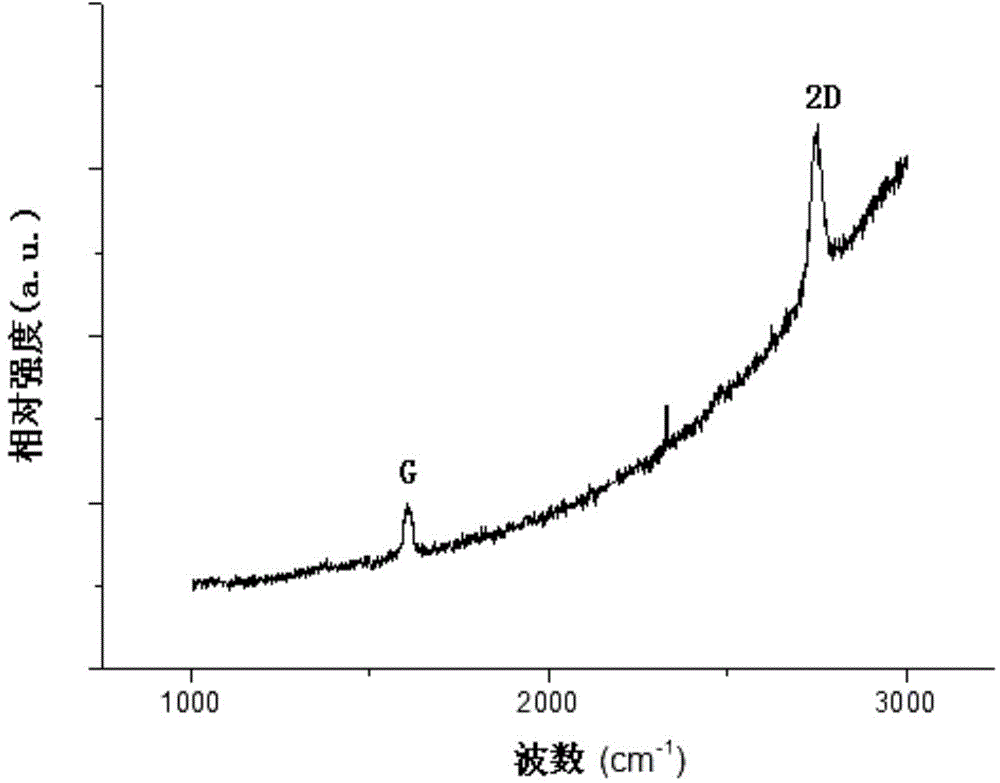

Graphene film, and making method and use thereof

The invention relates to a making method of a graphene film. The method comprises the following steps: 1, preparing a carrier for growing the graphene film, wherein the carrier is a multilayer separator plate-metal substrate structure formed by superposing separator plates and metal substrates at intervals; 2, placing the carrier in a reaction furnace, and heating under a vacuum condition or in an inert gas and reducing gas mixture; 3, introducing the inert gas and reducing gas into the reaction furnace when the temperature reaches 900-1100DEG C, carrying out heat insulation annealing, introducing a carbon source, and forming graphene films on the metal substrate; 4, separating the separators from the metal substrates; and 5, separating the graphene films from the metal substrates. The invention also relates to the graphene film made through the method, and a use of the graphene film as a transparent conductive electrode.

Owner:2D CARBON CHANGZHOU TECH INC

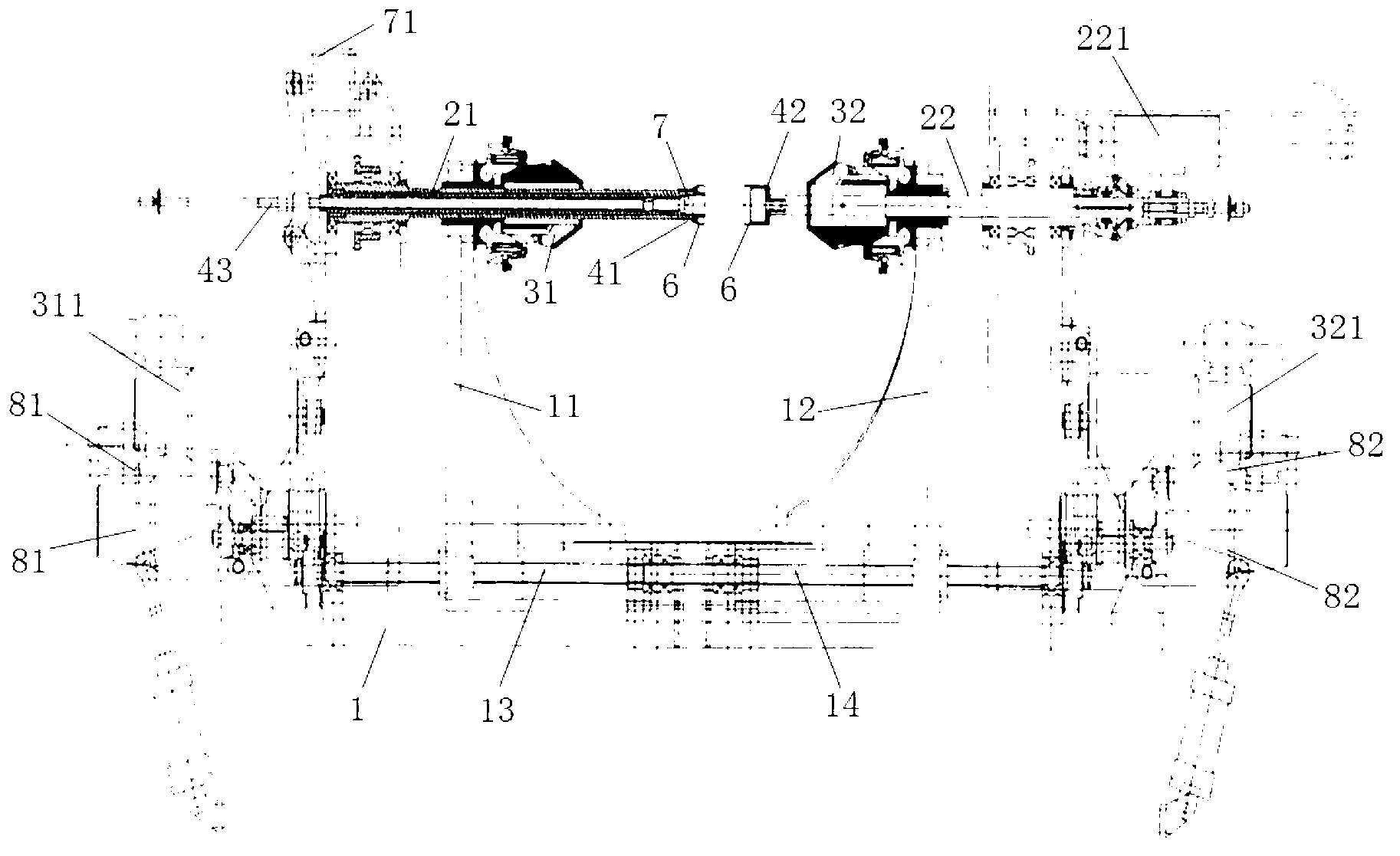

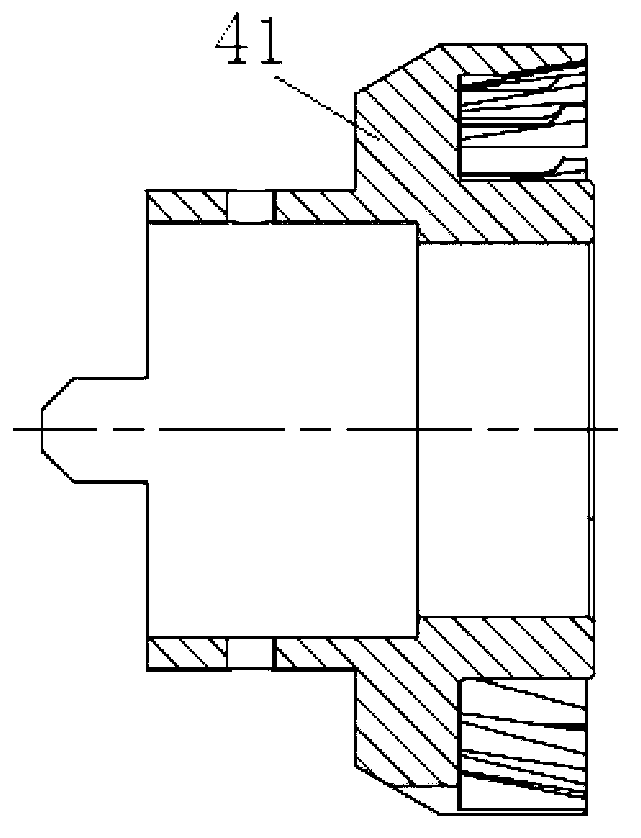

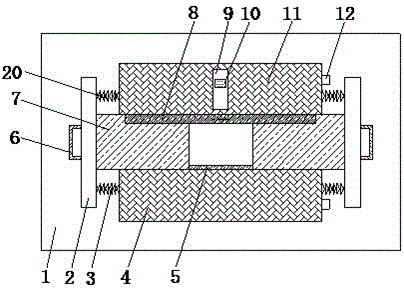

Winding device and method of armature winding

ActiveCN102843004AShorten the timeIncrease productivityManufacturing dynamo-electric machinesEngineeringConductor Coil

A winding device of an armature winding is provided with a support frame. A left fixed axle and a right shifting axle are arranged on the support frame; a left wire pressing device is sleeved on the left fixed axle; a left rotational head is installed at the end of the left fixed axle; a right wire pressing device is sleeved on the right shifting axle; a right rotational head is installed at the end of the right shifting axle; the left rotational head and the right rotational head share the same diameter as an armature, and are provided with wire fastening grooves thereon with consistent width with a groove on the armature. The technical scheme disclosed by the invention has the beneficial effects that full automatic mechanical control is adopted for winding; the time required is short and the production efficiency is high; corresponding pressing treatment is conducted for each winding; the external force required for the pressing maintains balanced, so that the winding is tight and uniform; after the termination of the winding, the exposed conductor connectors have the same length, thus subsequent operations are convenient. The force applied for the winding is uniform, thus material cutting during post-welding is avoided and the material is saved.

Owner:马勒电驱动(太仓)有限公司

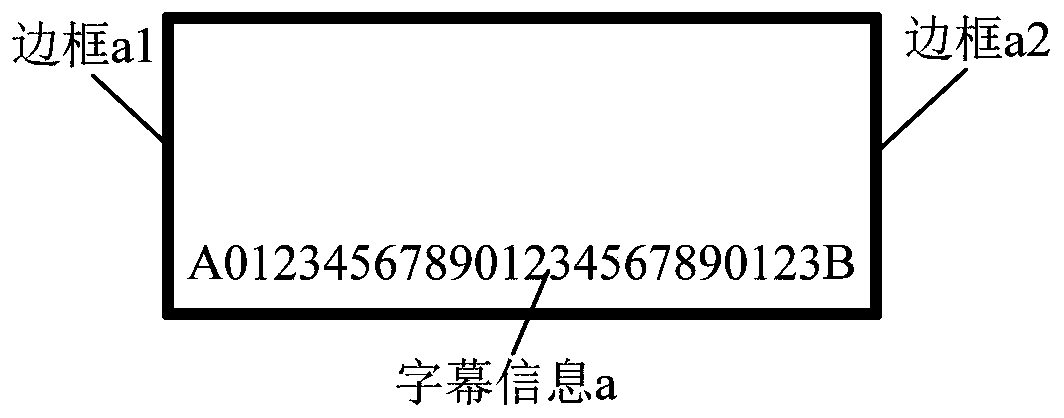

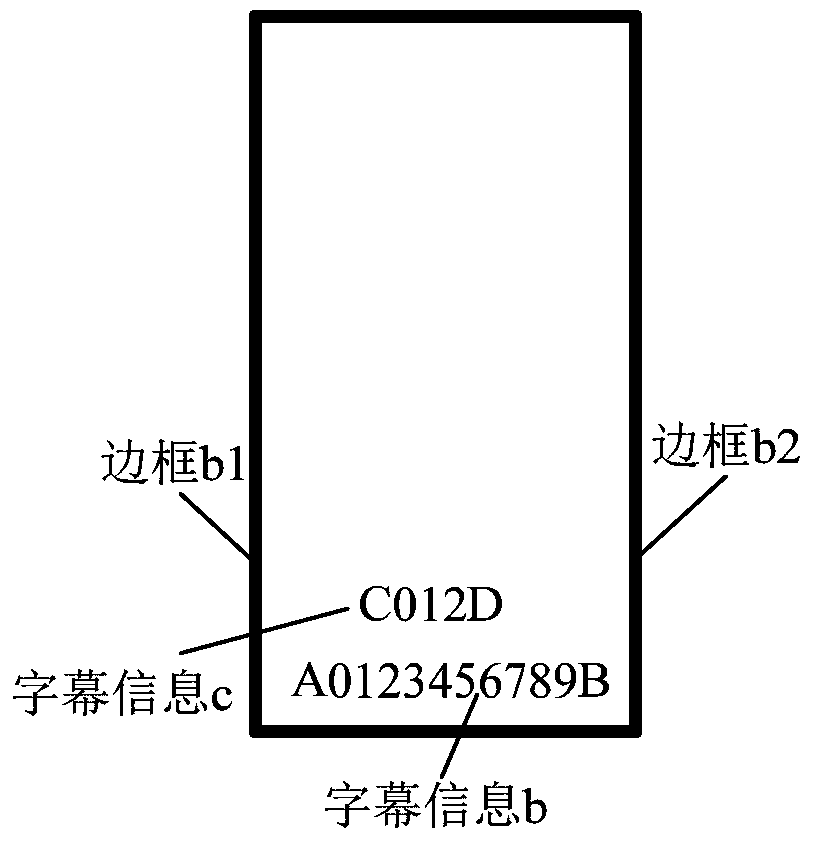

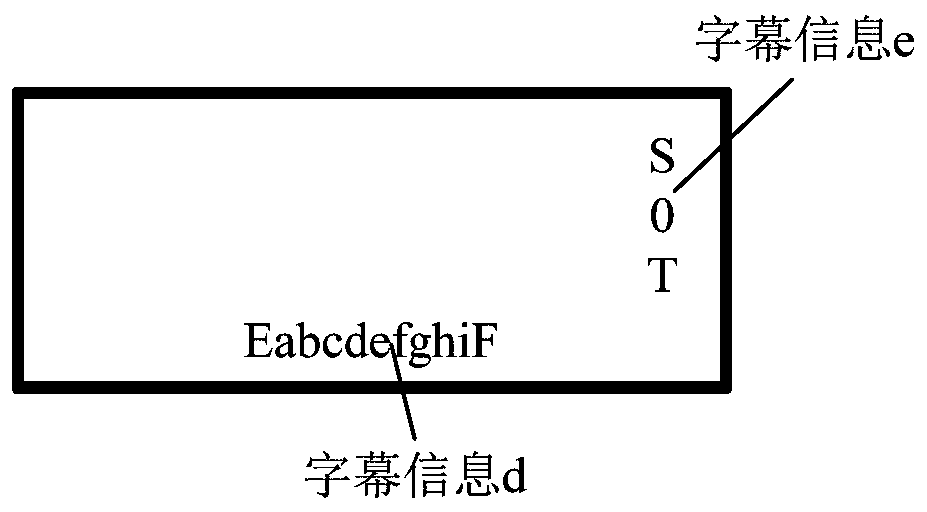

Video scaling method and device, server, client and storage medium

ActiveCN110381353ASolve the problem of poor viewing effectAvoid croppingSelective content distributionComputer graphics (images)Client-side

The invention relates to a video scaling method and device, a server, a client and a storage medium. The scheme comprises the following steps: a server acquiring a to-be-processed video, wherein a video frame of the to-be-processed video comprises subtitle information; calculating subtitle proportion values of the subtitle information of the to-be-processed video in a plurality of preset directions; and sending the plurality of caption proportion values to the client; and the client performing scaling processing on the video frame of the to-be-processed video when the plurality of caption proportion values are all greater than or equal to a preset proportion threshold, and determining a target video frame. By applying the technical scheme provided by the embodiment of the invention, the problem that when the screen of the equipment is filled with the video frame, the video frame comprises all or part of caption information which is cut off, so that the video watching effect is poor issolved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Method for preparing carbon/carbon composite material profile by slurry casting

The invention relates to a method for preparing a carbon / carbon composite material profile by slurry casting. The method comprises the following steps: 1, mixing phenolic resin with chopped carbon fiber so as to prepare a mixed material, and mixing the mixed material with water so as to prepare slurry, wherein the mass percentage of the chopped carbon fiber in the mixed material is no greater than 70%; 2, pouring the slurry into a plaster mold, and removing the water in the slurry so as to obtain a blank; 3, performing preoxidation treatment on the blank so as to obtain oxysome; 4, performing carbonization treatment on the oxysome so as to obtain a carbonized body; and 5, performing densification treatment on the carbonized body so as to obtain the carbon / carbon composite material profile. The mixed material and water are prepared into the slurry, the slurry is further introduced into the plaster mold, and the moisture in the slurry is adsorbed and removed by plaster, so that the blank is rapidly obtained; after the blank is pre-oxidized, carbonized and densified, the profile of an approximate net size is obtained; the profile can be made into a component without subsequent machining or only slight machining is needed, and thus the method is particularly applicable to preparation of the carbon / carbon composite material profile which is complex in structure.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Cutting device

Owner:那姆克斯有限公司

Length-adjustable road traffic stone mold

The invention discloses a length-adjustable road traffic stone mold. The length-adjustable road traffic stone mold comprises a bottom plate, a first fixed block and a second fixed block are fixedly connected to the top of the bottom plate and are parallel, the outer side surface of the first fixed block is fixedly connected to two symmetric first springs, the outer side surface of the second fixed block is fixedly connected to two symmetric second springs, a sliding way is formed in the top of the second fixed block, a gap is formed in the side surface, close to the first fixed block, of the second fixed block and communicates with the sliding way, and a sliding strip is fixedly connected to the inner bottom wall of the gap. According to the length-adjustable road traffic stone mold, resource waste is avoided, time and labor are saved, the production efficiency is high, the flexibility is good, and the practicality is high. The mold can be effectively adjusted, suitable road traffic stone can be manufactured according to the length of roads, and therefore the applicability is good, and the problem that the length of traditional road traffic stone molds cannot be adjusted is effectively solved.

Owner:WUXI DONGBEITANG YONGFENG RUBBER FACTORY

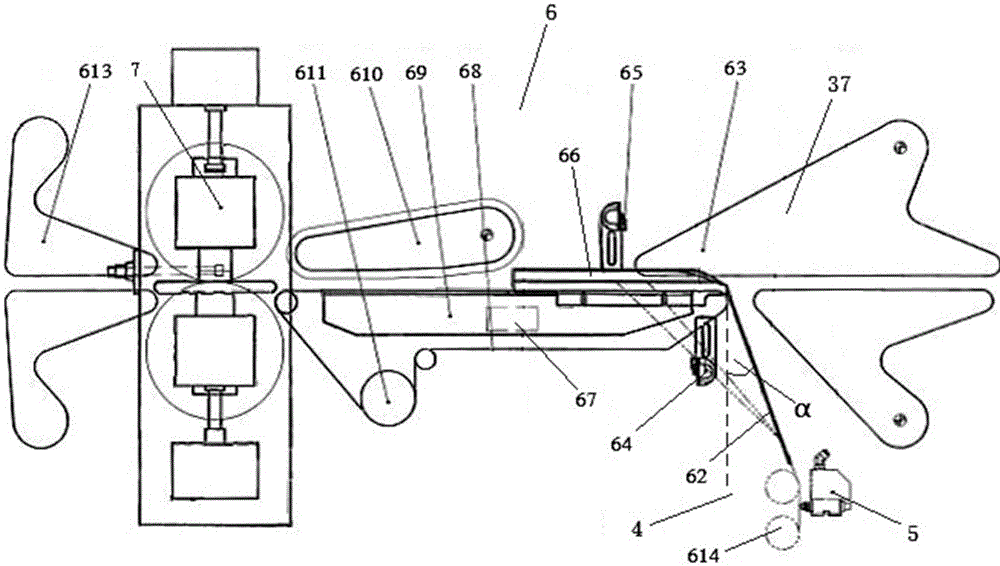

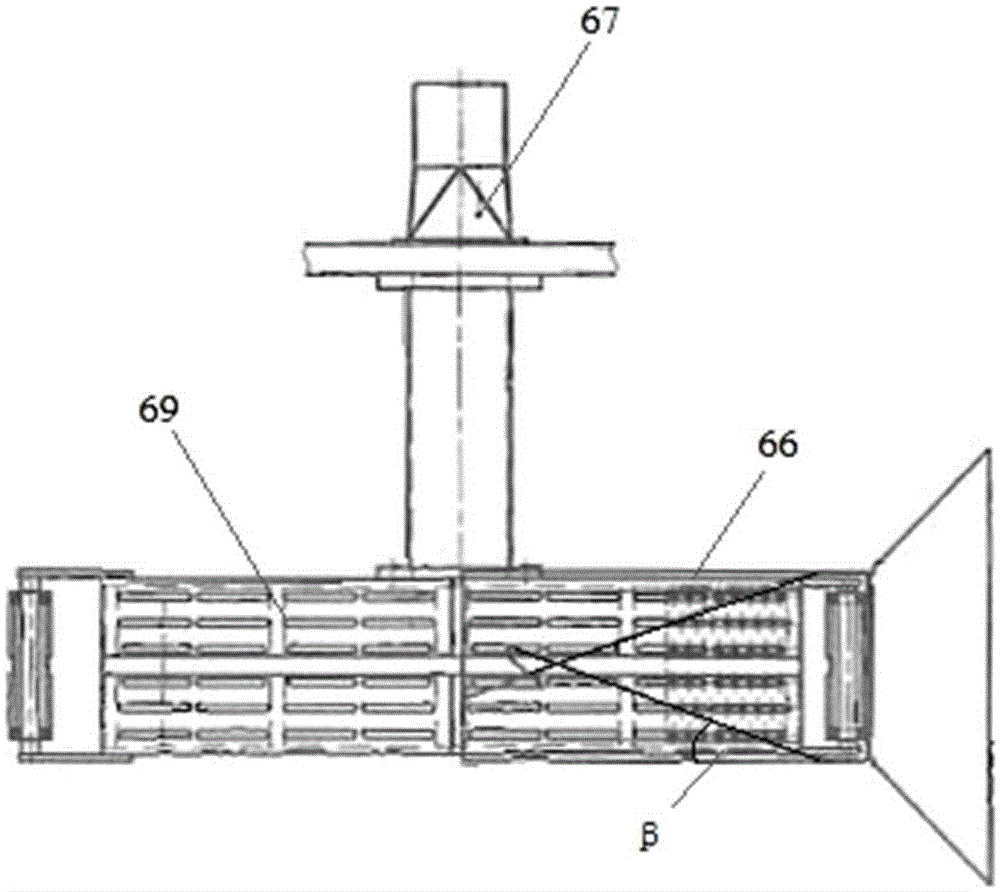

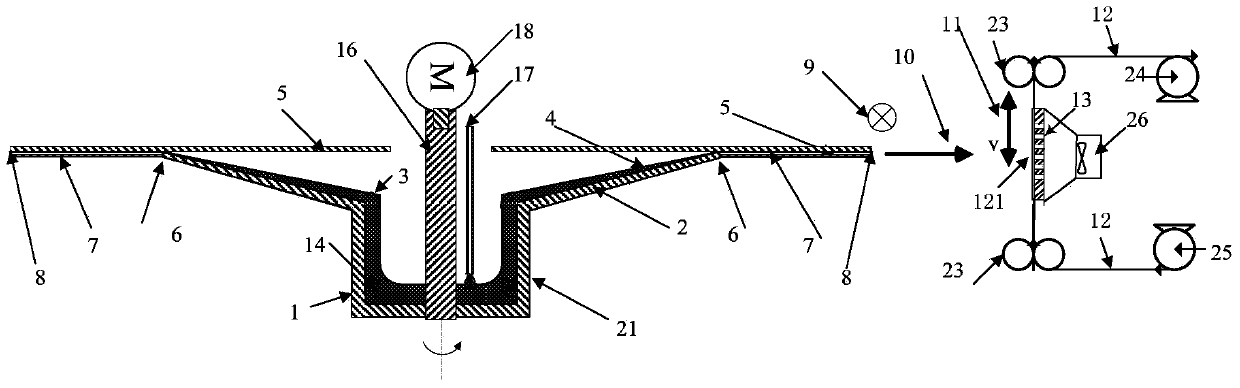

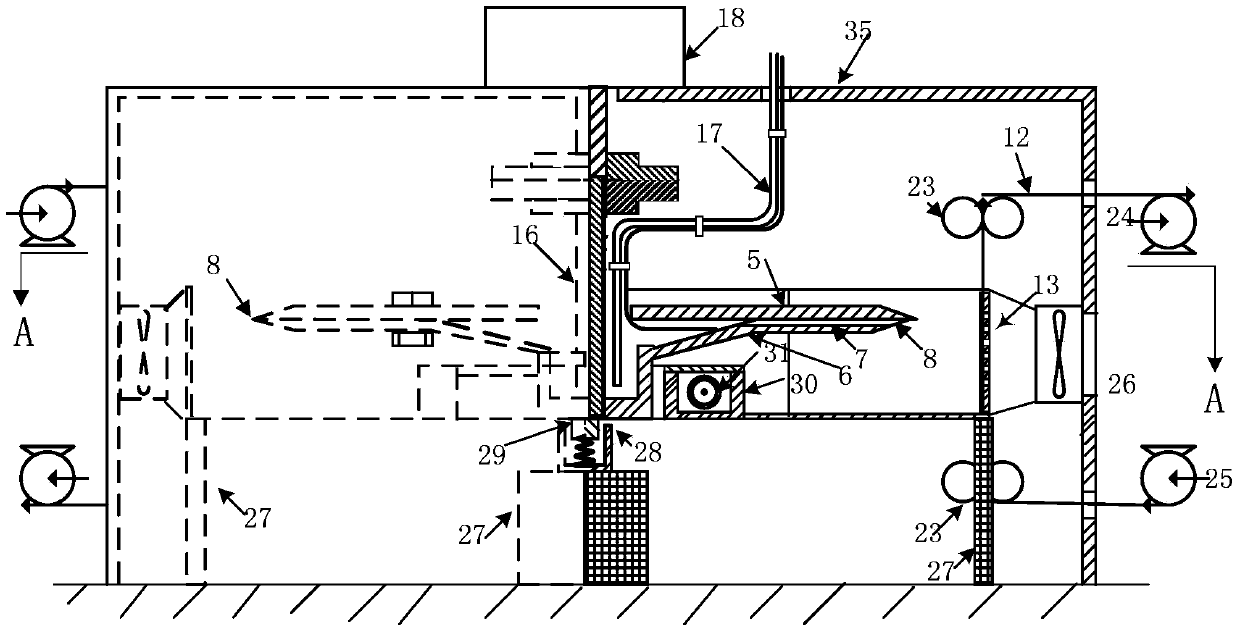

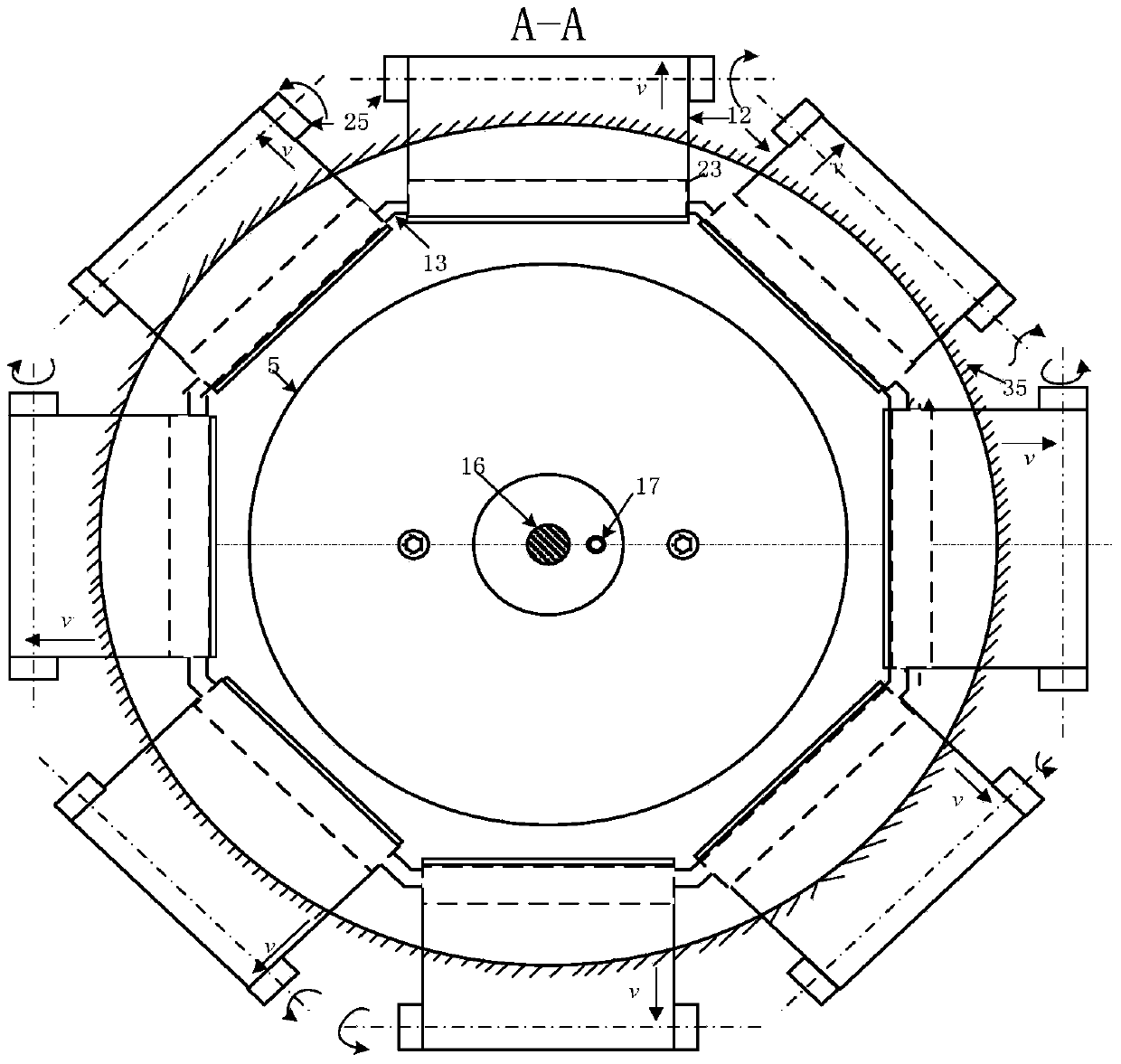

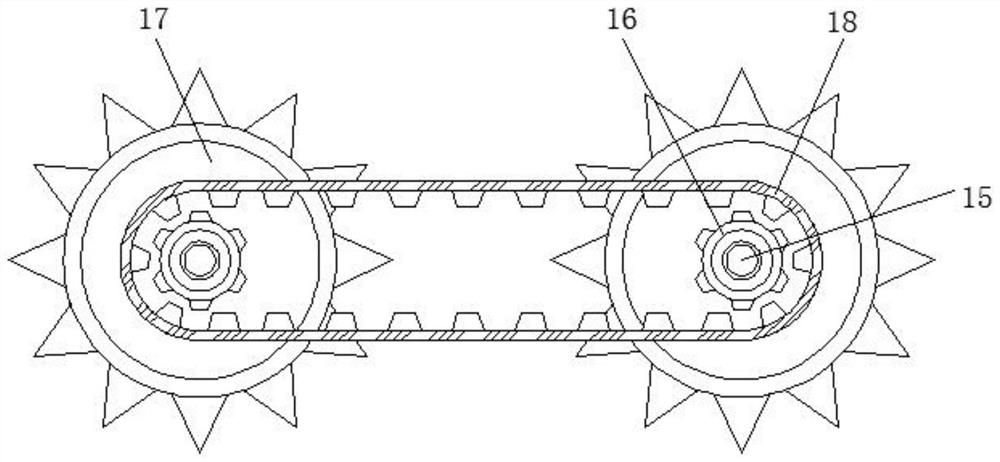

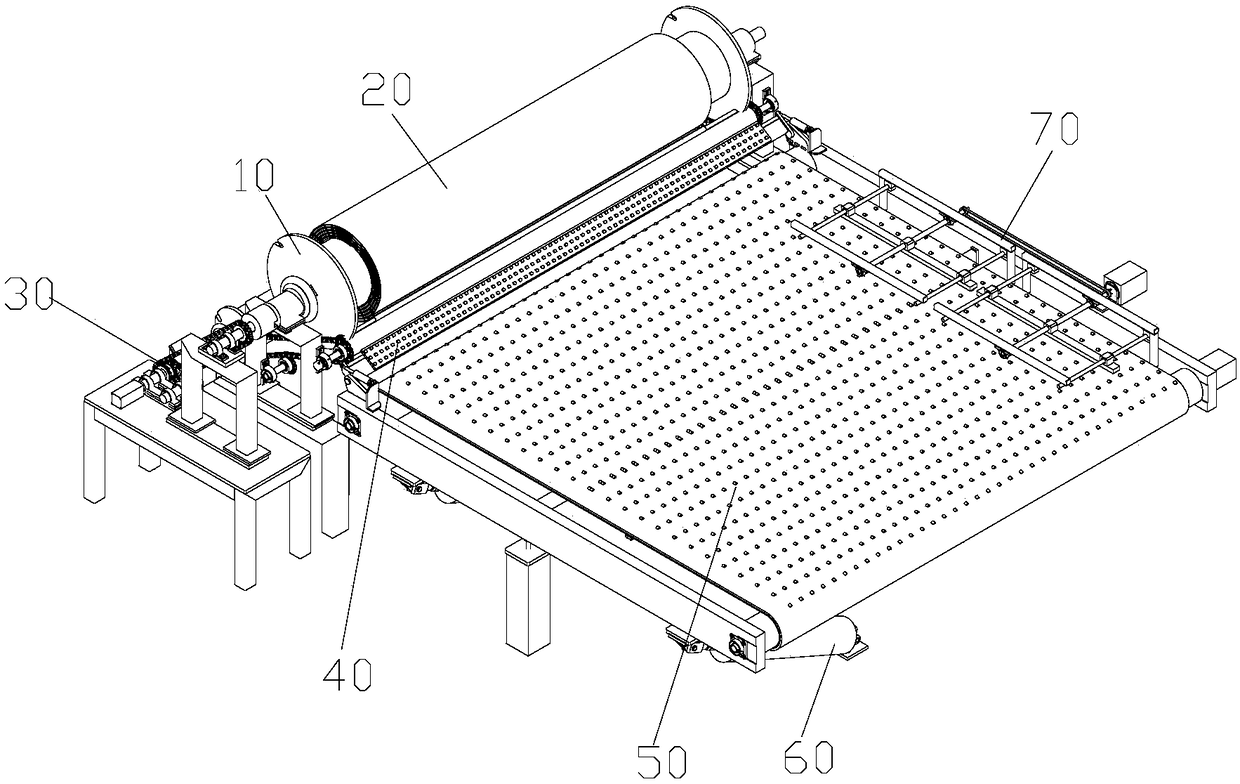

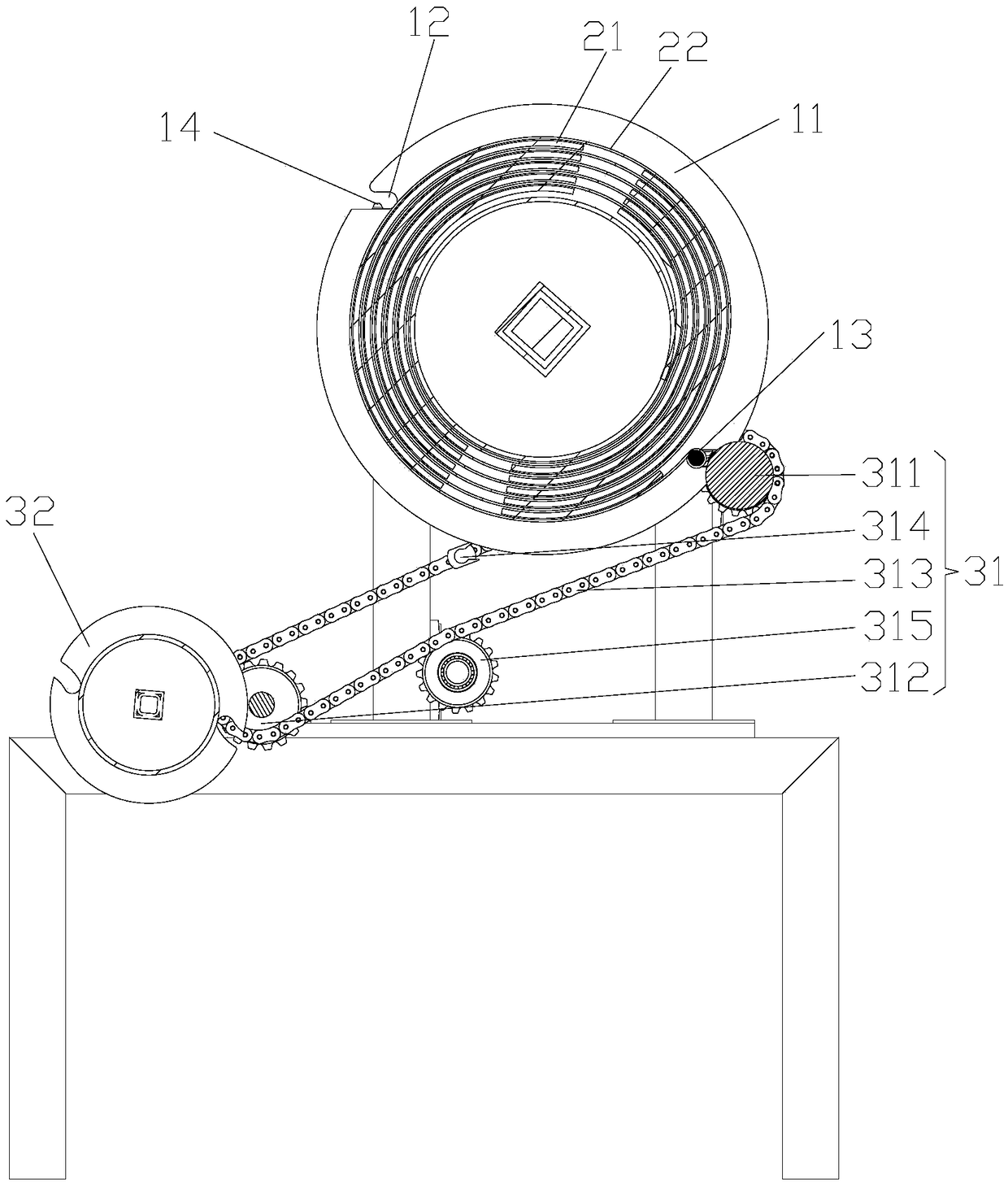

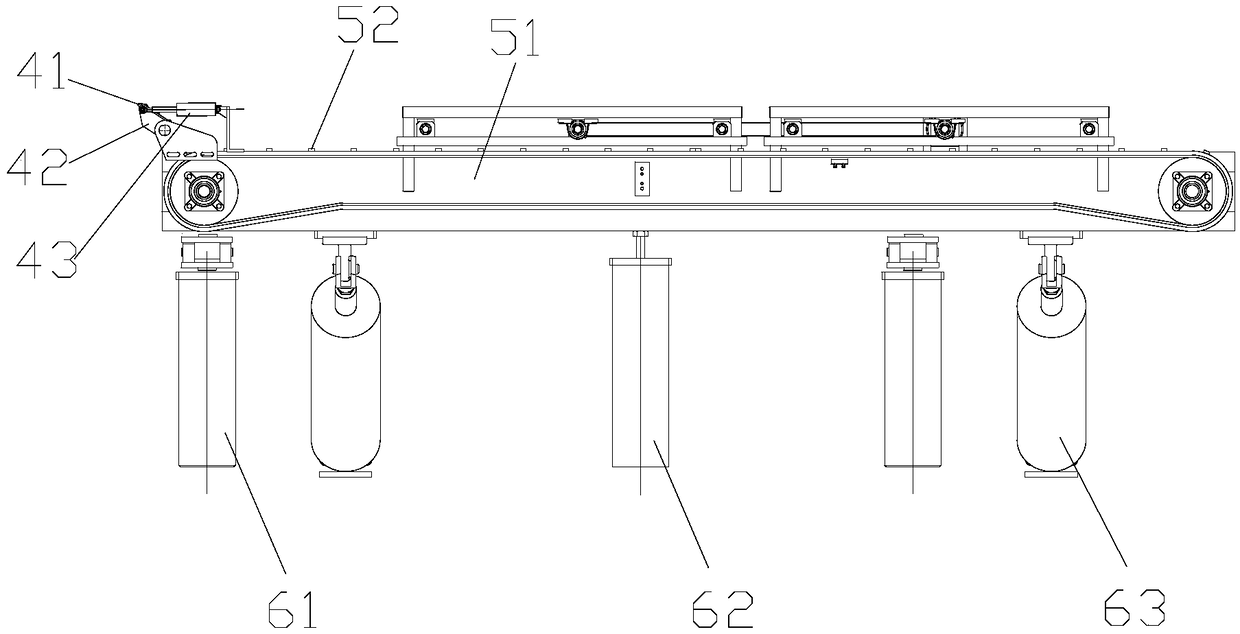

Continuous collection device for nanofibers spun through centrifugation and static electricity

ActiveCN104178830AAvoid croppingHigh material utilizationNew-spun product collectionFilament/thread formingPhysicsRotational axis

The invention relates to a continuous collection device for nanofibers spun through centrifugation and static electricity. The continuous collection device is characterized by comprising multiple sets of collection mechanisms uniformly distributed on the periphery of a nanofiber spinning mechanism, wherein each set of the collection mechanism comprises a collecting strip driven by a transmission mechanism; the part, corresponding to a melted material outlet in the nanofiber spinning mechanism, of each collection strip is a main collecting part; the included angle alpha between the plane surface, where the main collection parts are positioned, and the rotary axis of the a rotary cup in the nanofiber spinning mechanism is not less than 0 degree and not greater than 45 degrees. The continuous collection device has the benefits as follows: the collection strips are vertically arranged on the periphery of the rotary cup, so that fiber fabrics with the same thicknesses can be collected, clipping is avoided, and the utilization ratio of material can be increased. A centrifugal spinning technology and an electrostatic spinning technology are combined organically, so that the advantage of high efficiency of the centrifugal spinning and the advantages of controllable order degree and nanofiber collection of are also achieved.

Owner:ZHEJIANG HUAYUAN ELECTRIC HEAT

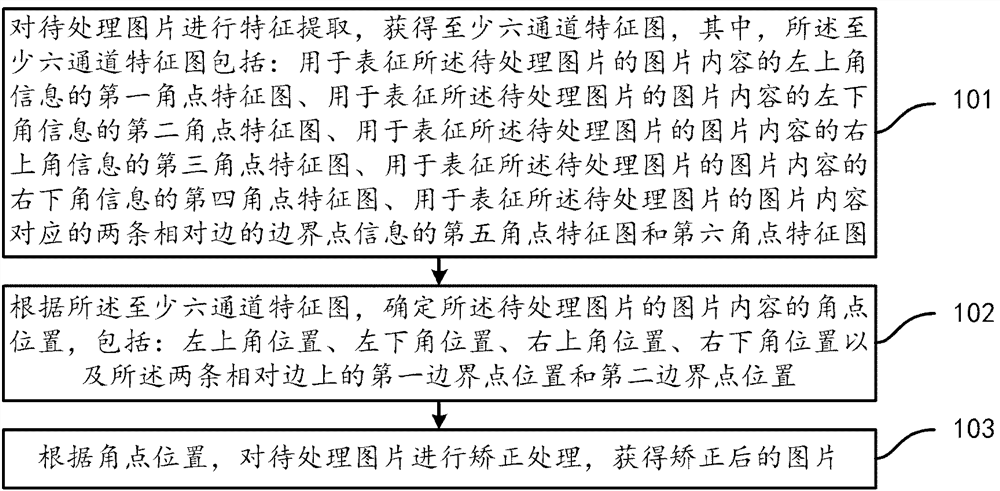

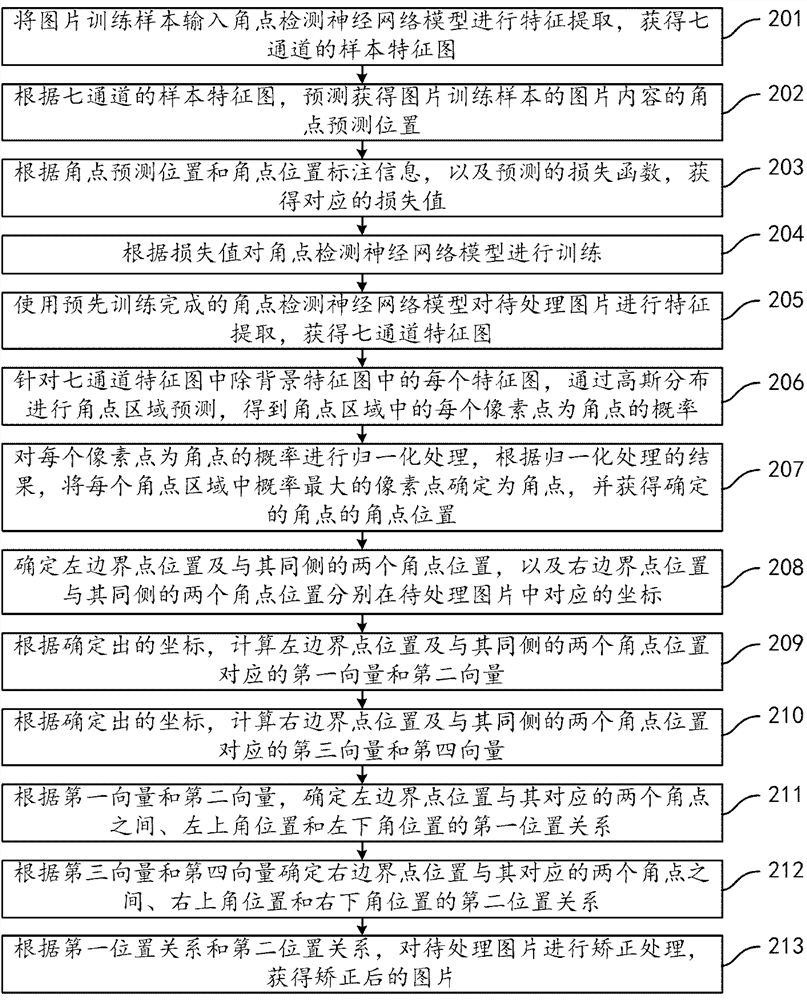

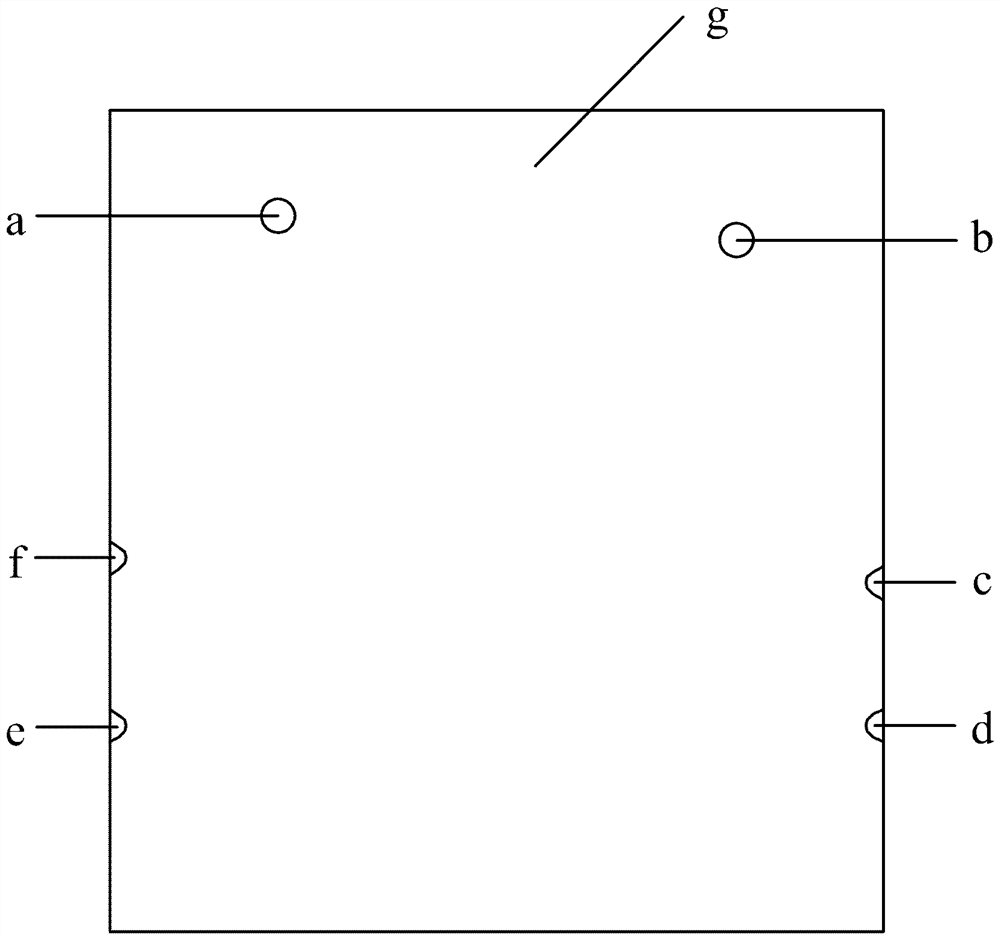

Picture processing method and device, electronic equipment and computer storage medium

PendingCN112906708AAvoid croppingEasy to keepCharacter and pattern recognitionNeural architecturesEngineeringAlgorithm

The embodiment of the invention provides a picture processing method and device, electronic equipment and a computer storage medium, and the method comprises the steps: carrying out the feature extraction of a to-be-processed picture, obtaining a first angular point feature map for representing top left corner information of picture content of a to-be-processed picture, a second angular point feature map for representing bottom left corner information of the picture content, a third angular point feature map for representing top right corner information of the picture content, a fourth angular point feature map for representing bottom right corner information of the picture content; and a fifth corner feature map and a sixth corner feature map which are used for representing two opposite sides corresponding to the picture content; determining an upper left corner position, a lower left corner position, an upper right corner position, a lower right corner position, a first boundary point position and a second boundary point position of the picture content according to the at least six-channel feature map; and correcting the to-be-processed picture according to the angular point position to obtain a corrected picture. According to the scheme, the original content in the picture can be better reserved.

Owner:BEIJING CENTURY TAL EDUCATION TECH CO LTD

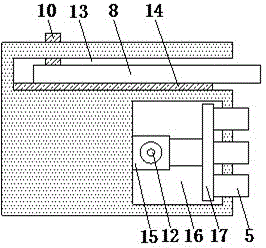

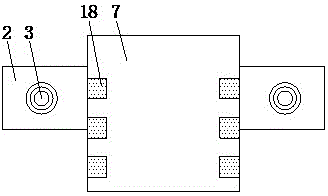

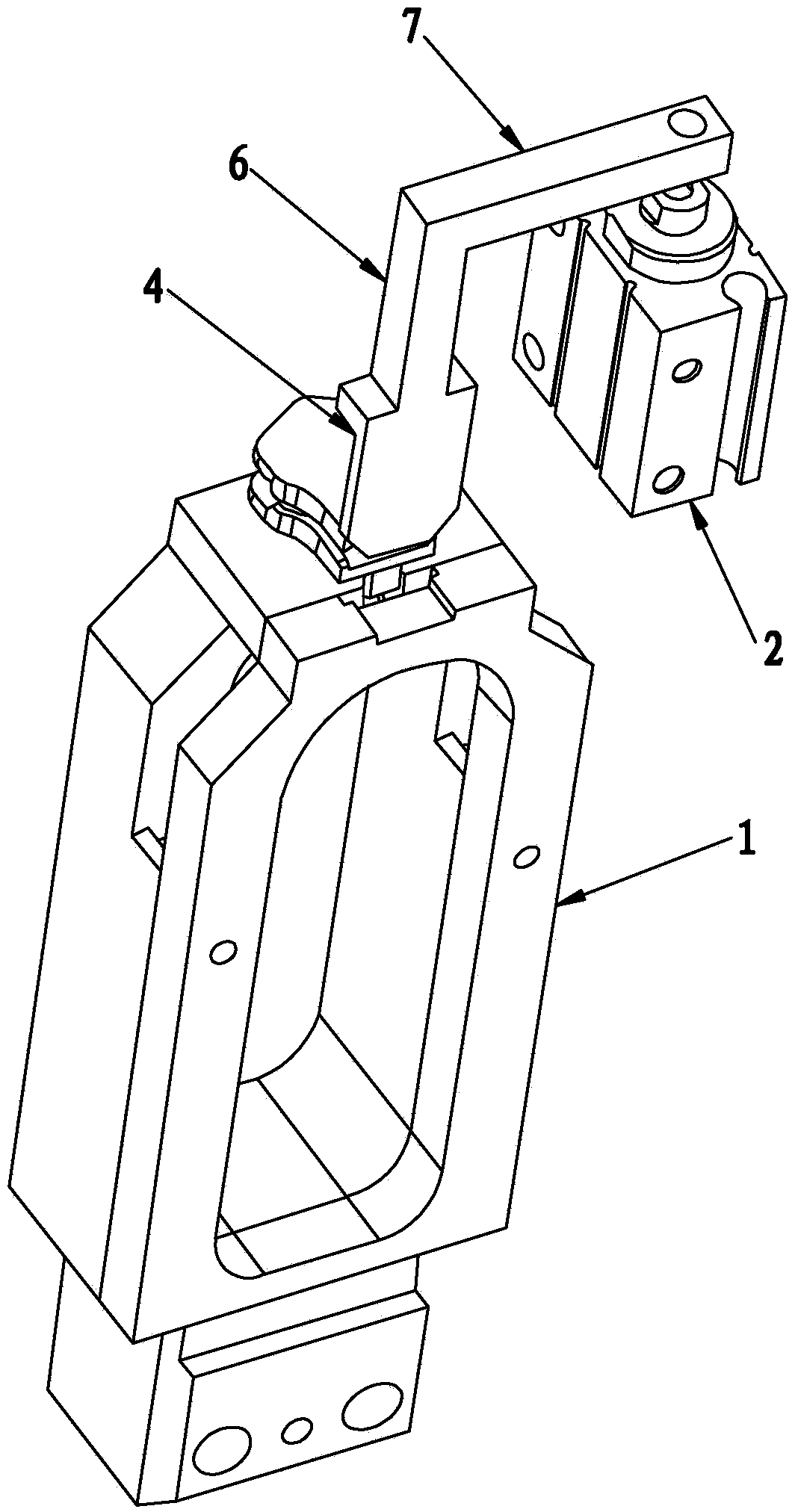

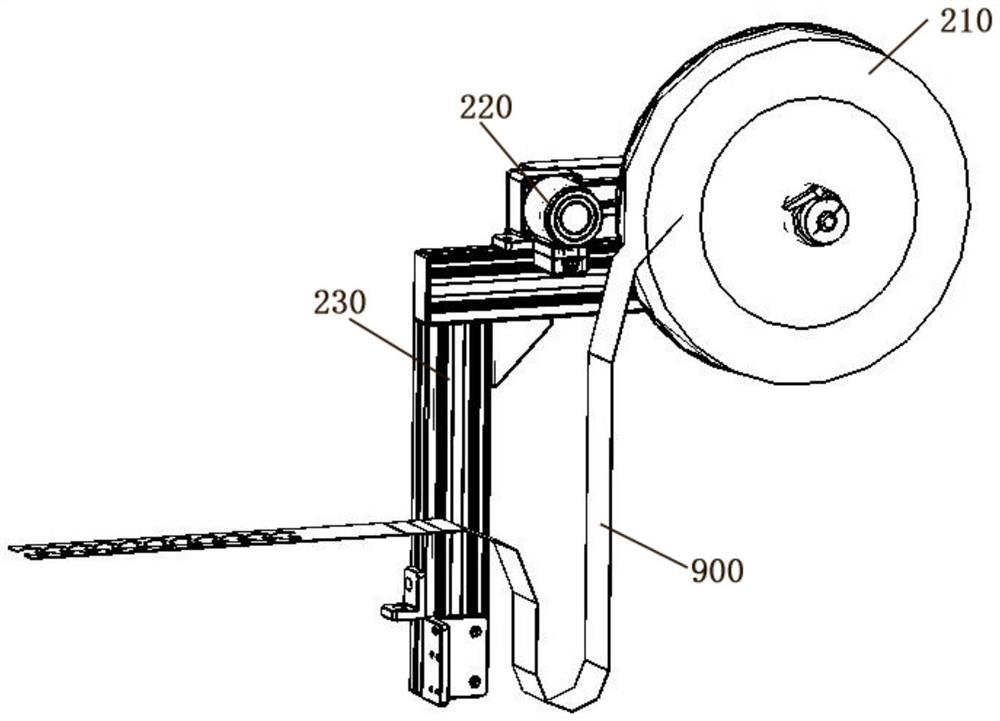

Pull head mounting machine

PendingCN107713194APrevent movementSolve the problem of easy falling offSlide fastenersEngineeringMechanical engineering

The invention belongs to the field of zipper equipment and in particular relates to a novel pull head mounting machine. The pull head mounting machine comprises a zipper stripping device, wherein thezipper stripping device comprises a zipper stripping platform, a sensing piece is arranged in front of the zipper stripping platform, a sliding block which can move along a zipper conveying directionis arranged on the upper surface of the zipper stripping platform, a first stripping needle is arranged in the sliding block, a fixation frame is arranged at the rear of the zipper stripping platform,a second stripping needle is arranged in the fixation frame, a pull head conveying device comprises a pull head mould, a pull head fixation position is moulded on the pull head mould, the pull head mould rises to a set position, and the pull head fixation position is located between the zipper stripping platform and the second stripping needle; and a stop block is arranged on the zipper strippingplatform, a first reset spring is arranged between the bottom of the stop block and the bottom of a stop slot, space between the stop block and the fixation frame is equal to width of the sliding block, and a first reset device used for driving the sliding block to be far away from the fixation frame is arranged on the sliding block. The pull head mounting machine has the advantages of simple structure, convenience in use, high pull head mounting efficiency, conservation of labor cost and high degree of automation.

Owner:温州宏业精机有限公司

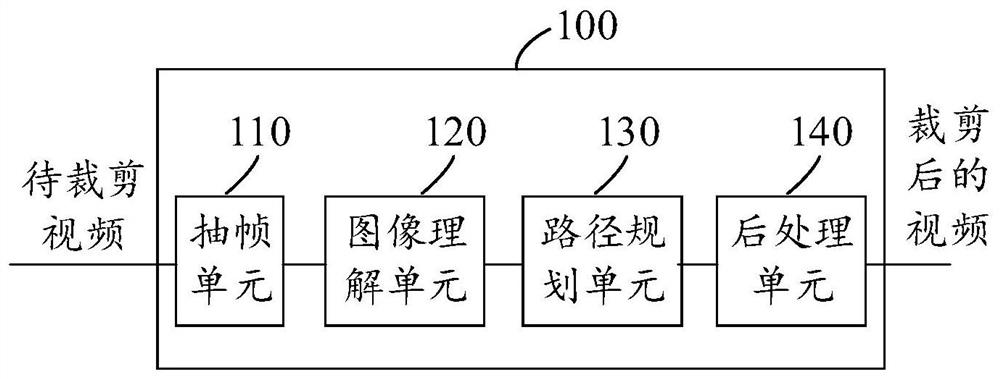

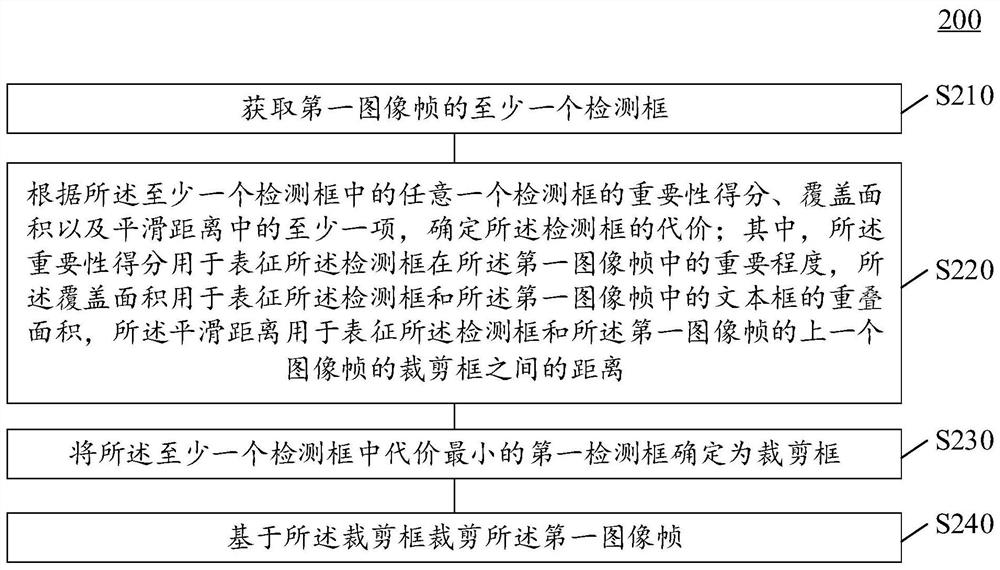

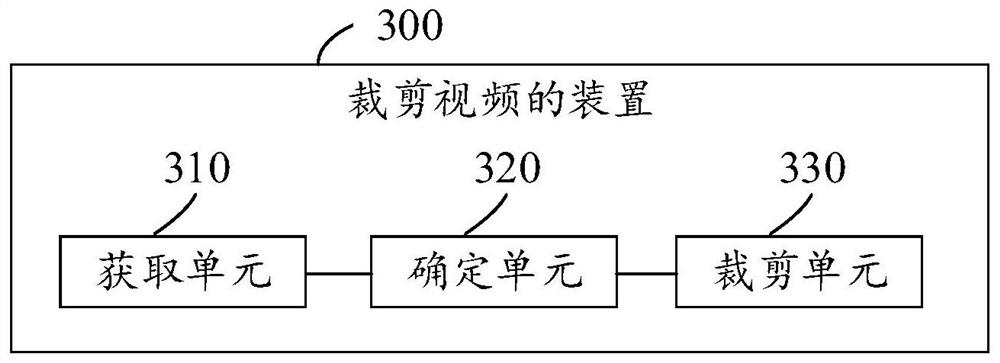

Video cropping method and device, equipment and storage medium

ActiveCN112188283AAchieve croppingIncrease flexibilitySelective content distributionImage enhancementAgricultural engineeringEngineering

The invention provides a video cropping method and device, equipment and a storage medium. The method comprises the following steps: acquiring at least one detection box of a first image frame; determining the cost of the detection box according to at least one selected from the importance score, the coverage area and the smooth distance of any detection box in the at least one detection box; determining the first detection box with the lowest cost in the at least one detection box as a cropping box; and cropping a first image frame based on the cropping frame. Based on the cost of each detection frame, the first detection frame with the minimum cost in the at least one detection frame is determined as the cropping frame so as to crop the first image frame, thereby improving the flexibility of video cropping and enhancing the cropping effect under the condition of ensuring the simplification of a video cropping process.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

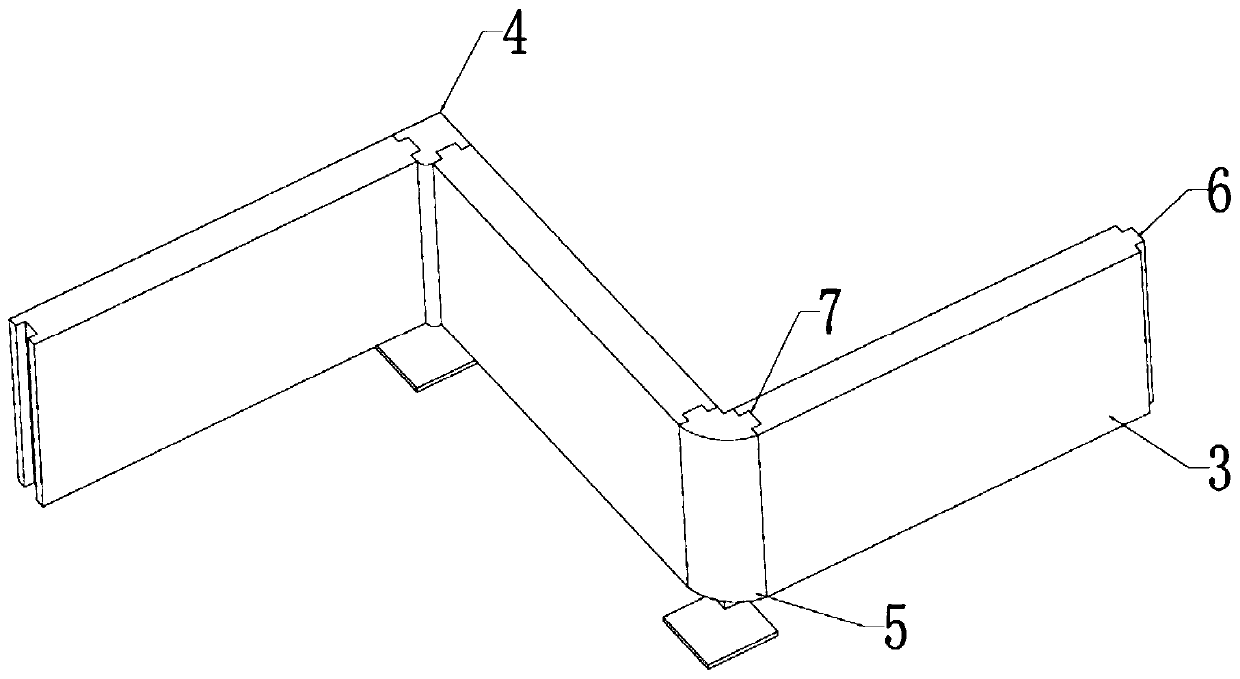

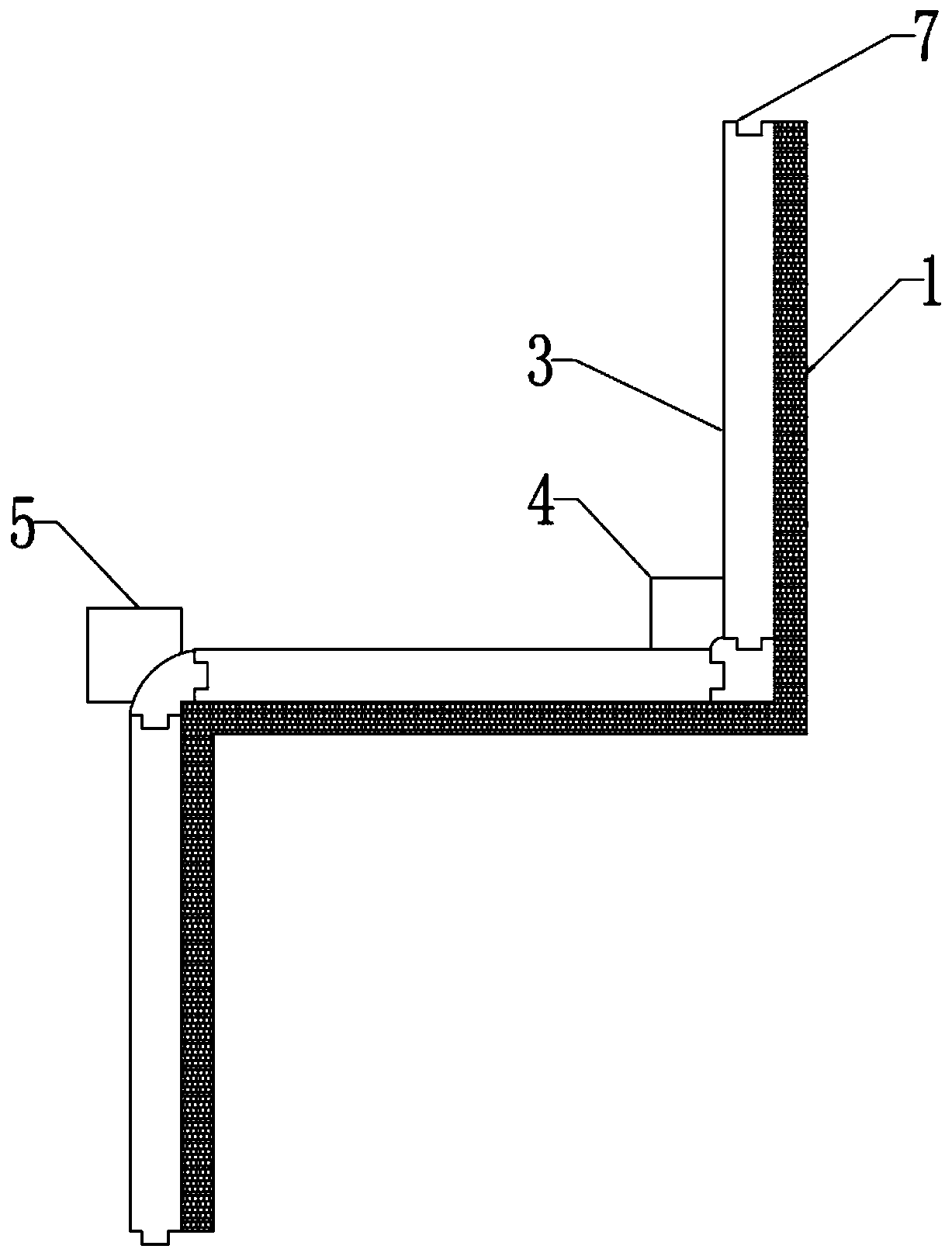

Assembly type skirting line internal and external corner closing-up mounting structure

PendingCN111502190AEasy to installAvoid croppingBuilding constructionsMechanical engineeringAccident risk

The invention provides an assembly type skirting line internal and external corner closing-up mounting structure. The assembly type skirting line internal and external corner closing-up mounting structure comprises a wall body, a ground, a skirting line, an internal corner mechanism and an external corner mechanism, wherein the ground is perpendicularly connected with the wall body; the skirting line is arranged on the side face of the wall body; the internal corner mechanism is arranged at the internal corner of the wall body; the external corner mechanism is arranged at the external corner of the wall body; the internal corner mechanism and the external corner mechanism are both fixedly connected to the ground; a boss is arranged at one end of the skirting line; a groove is formed in theother end of the skirting line; the boss is connected to the internal corner mechanism in a clamped mode at the internal corner of the wall body; and the groove is connected to the external corner mechanism in a clamped mode at the external corner of the wall body. Through the internal and external corner closing-up mounting design of the assembly type skirting line, mounting of an internal and external corner line and the skirting line is facilitated, line cutting is avoided, the efficiency of workers is improved, the closing-up effect is compact, and accident risks are avoided; and by dividing the form of the skirting line, the assembly type process of factory prefabrication and on-site direct assembly is implemented, construction is accurate, and the material utilization rate is high.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

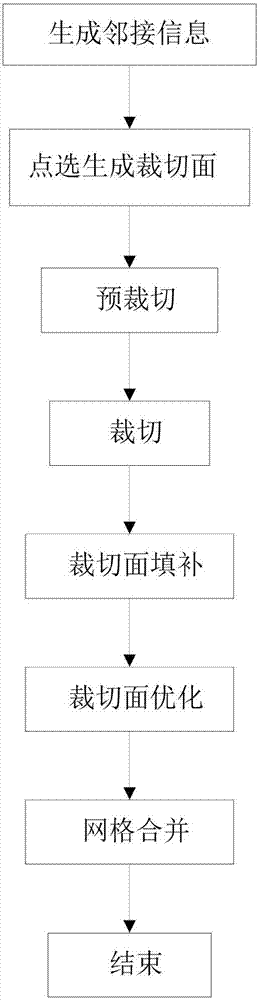

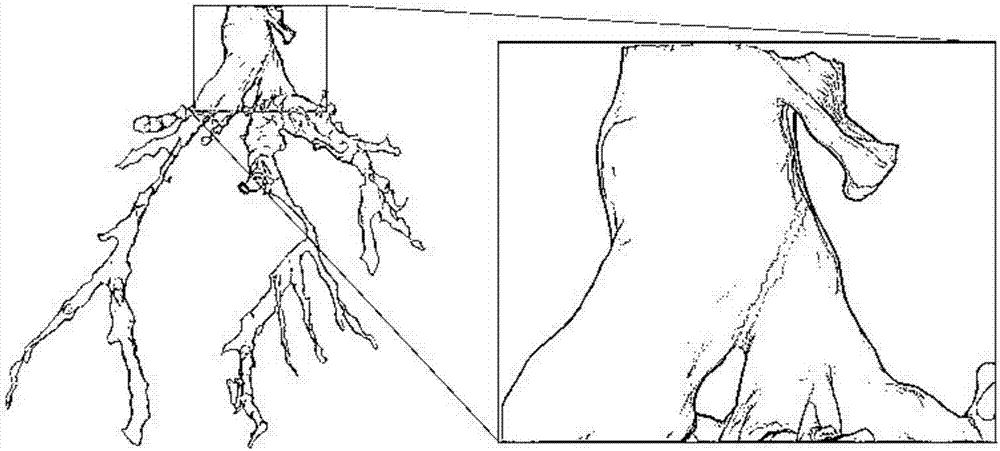

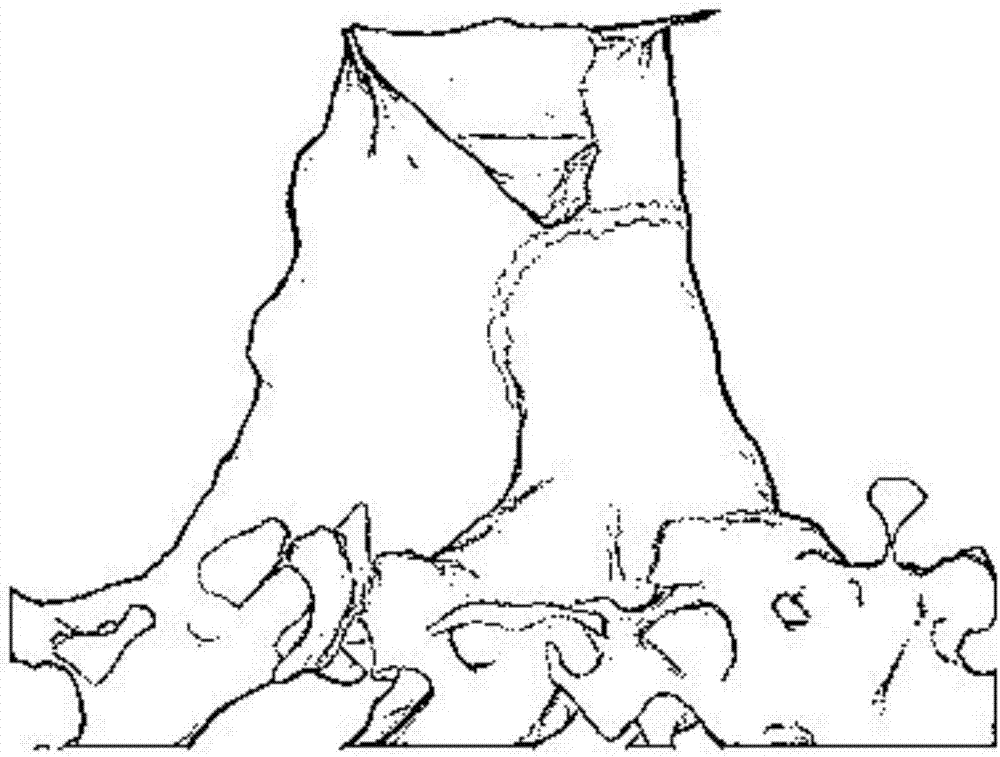

Two-point grid model cutting method

ActiveCN107967682AGuaranteed closureImprove operational efficiencyImage enhancementImage analysisEngineering

The invention discloses a two-point grid model cutting method. The method comprises steps that an organ three-dimensional grid model is constructed; a mouse is operated to select two points of to-be-cut partial points to generate an expression of a cutting surface; any point is selected, a triangle patch where the point is located is calculated and acquired as a seed triangle; in adjacent surfacesof the seed triangle, a triangle intersecting with the cutting surface is searched, the acquired triangle is taken as a new seed triangle until no new seed triangle generation position exists, and the triangle band grid is acquired; the triangle band grid is divided into two upper and lower sub-grids separated by the cutting surface, and edges generated by cutting are acquired; a set of polygonswhich do not communicate with each other is acquired; the three-dimensional grid model is divided into upper and lower parts according to a cut surface, and cut parts do not stick any more. The methodis advantaged in that improvement of the grid processing speed and improvement of computer auxiliary diagnosis efficiency are facilitated, and easy operation and accurate result are realized.

Owner:深圳市一图智能科技有限公司

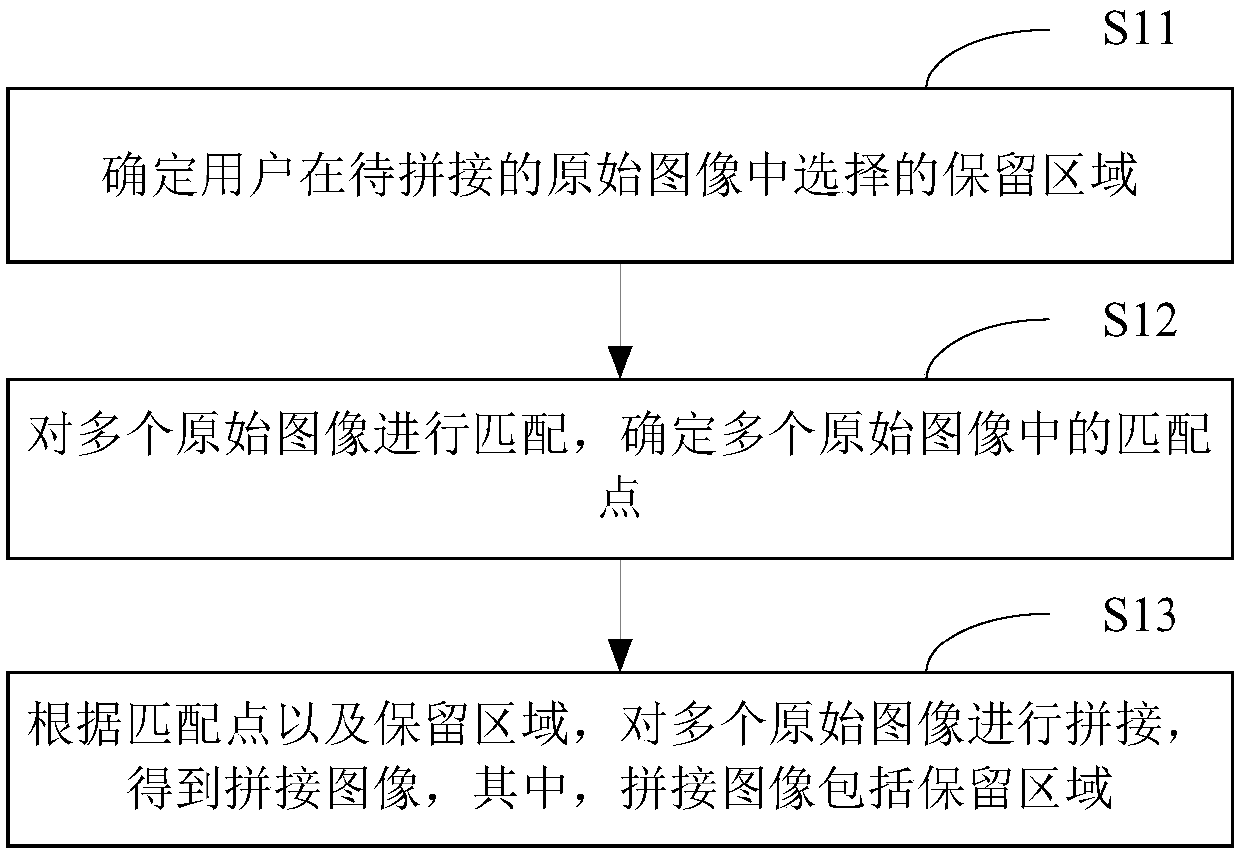

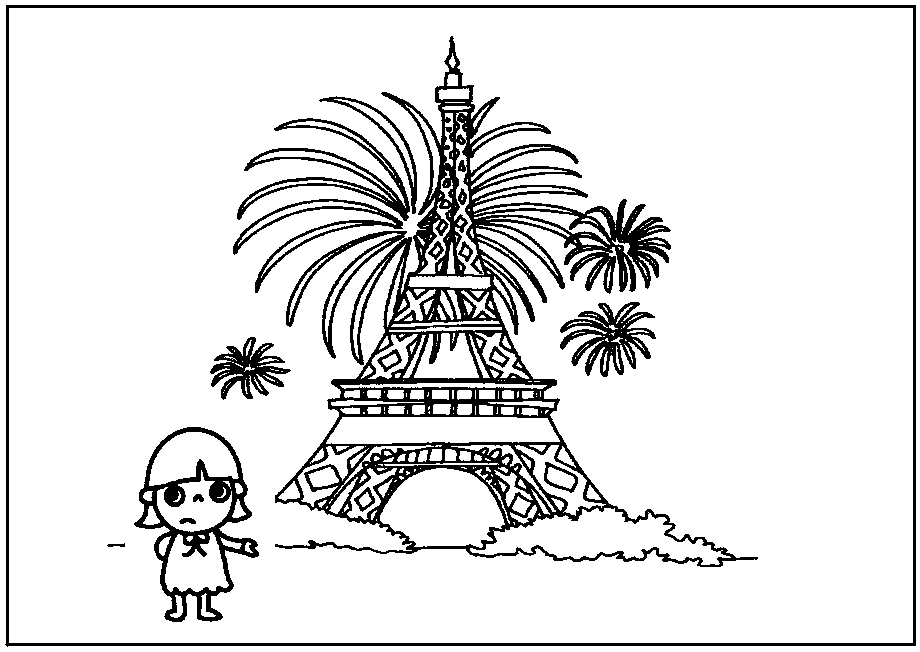

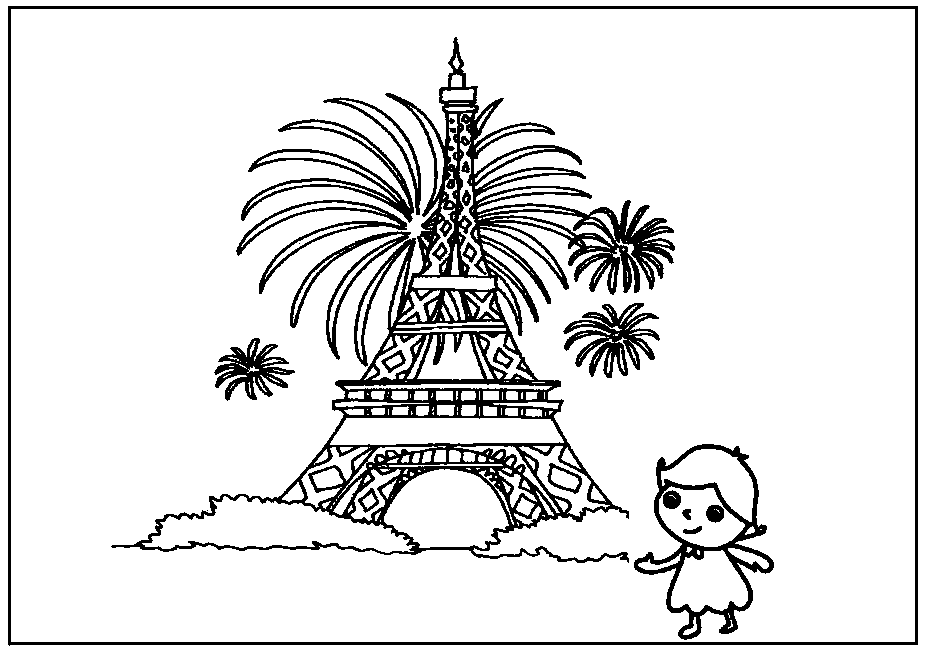

Image stitching method and device

ActiveCN107730452AMeet the needs of image stitchingGuaranteed retentionImage enhancementImage analysisImage stitching

The invention relates to an image stitching method and device. The method comprises the steps that reserved regions selected by a user from multiple original images are determined; the original imagesare matched, and matching points in the original images are determined, wherein the matching points are overlapping points in at least two original images; and according to the matching points and the reserved regions, the original images are stitched to obtain a stitching image, wherein the stitching image comprises the reserved regions. According to the image stitching method and device, the reserved regions selected by the user from the original images are determined, the original images are matched, the matching points in the original images are determined, and according to the matching points and the reserved regions, the original images are stitched to obtain the stitching image, wherein the stitching image comprises the reserved regions. In this way, it can be guaranteed that the images needed by the user are partially reserved in the stitching image, the situation that the image parts needed by the user are clipped out in the image stitching process is avoided, and therefore the image stitching demand of the user can be met.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

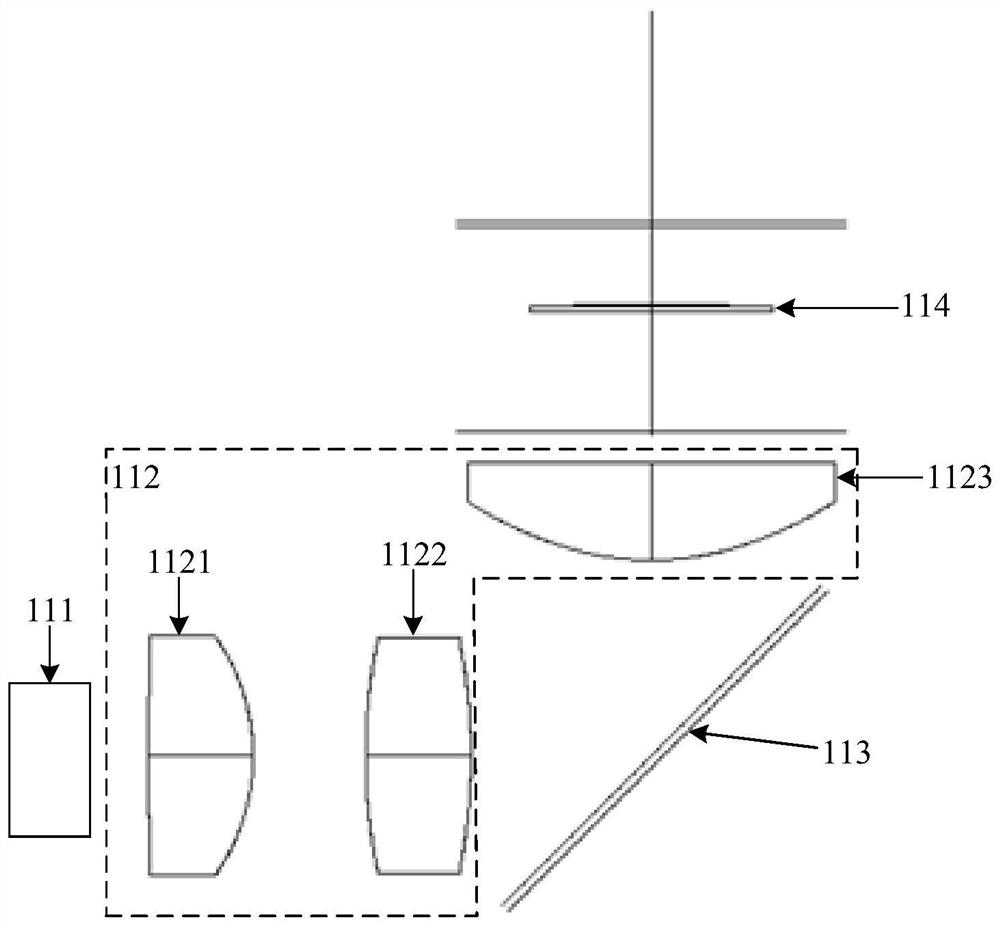

Optical machine illumination system and laser projection equipment

PendingCN112835257ASimplify the manufacturing processLow manufacturing costProjectorsLighting systemPrism

The invention discloses an optical machine illumination system, and belongs to the field of laser projection. The optical machine illumination system comprises an illumination mirror group and a light valve. The illumination mirror group comprises a dodging assembly, a collimating lens group, a rectangular reflector and a total internal reflection prism, the collimating lens group comprises at least three lenses, and the at least three lenses are spherical lenses; and an included angle is formed between each of two adjacent sides of the rectangular reflector and the display surface of the light valve. According to the optical machine illumination system provided by the invention, the rectangular reflecting mirror is rotationally placed to avoid other structures in the light machine illumination system, the rectangular reflecting mirror is prevented from being cut, and the lenses are spherical lenses which are relatively easy to process, so that the problem that the manufacturing process of the light machine illumination system is relatively tedious in the related technology is solved; and the effect of simplifying the manufacturing process of the light machine lighting system is achieved, and meanwhile the manufacturing cost of the light machine lighting system is reduced.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

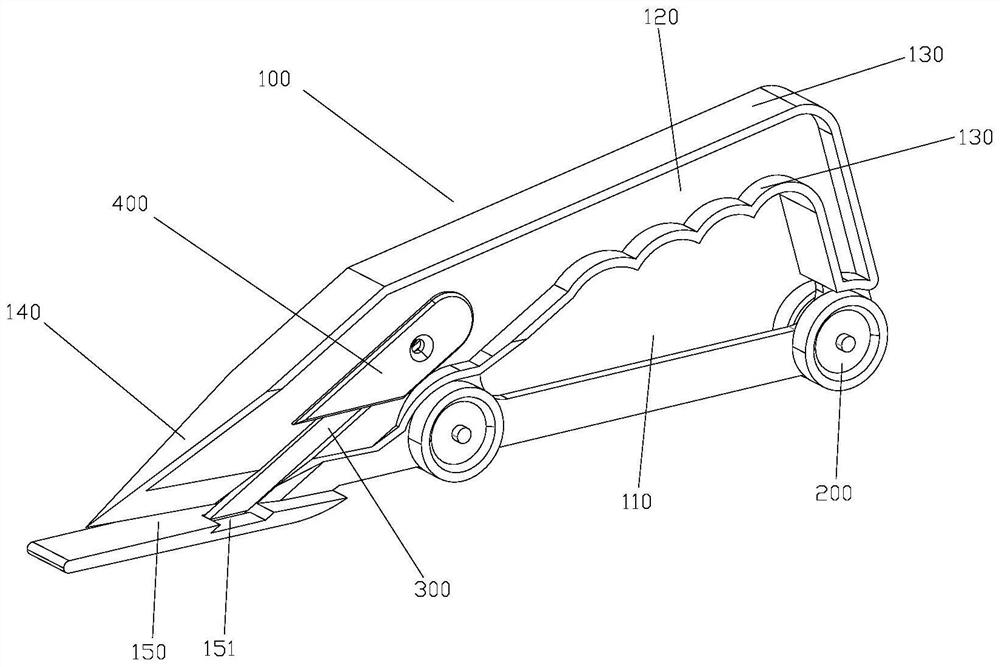

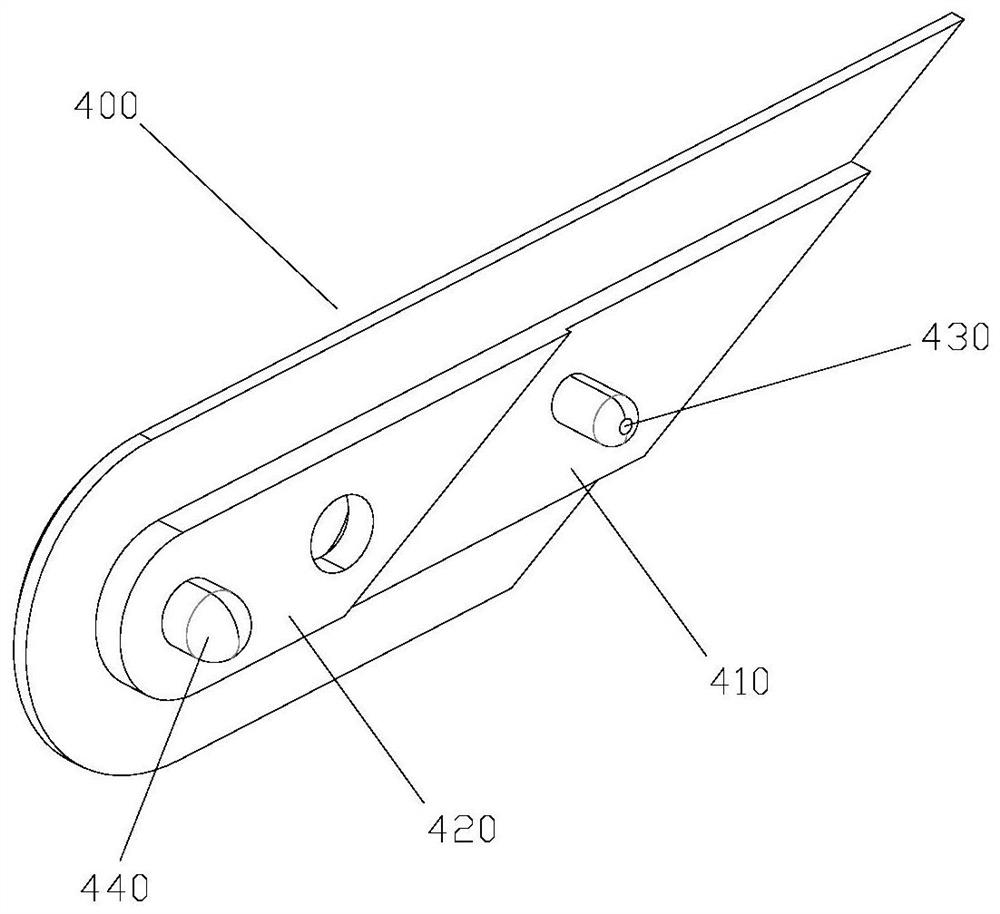

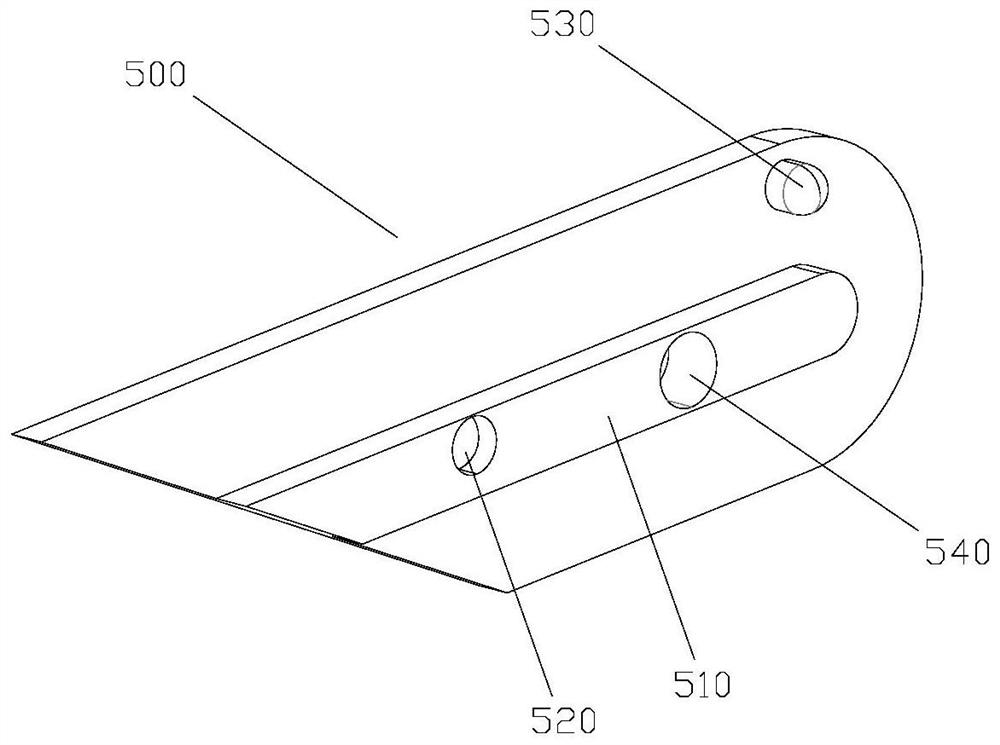

Cloth cutter

The invention discloses a cloth cutter. The cloth cutter comprises a cutter holder and a blade, A pair of pressing wheels are installed at the lower side of the tool apron, a holding hole is formed inthe rear portion of the tool apron, and a holding handle is formed at the portion, located at the upper side of the holding hole, of the tool apron; a blade installation groove extending obliquely downwards is formed in the front portion of the tool apron, the blade is a long blade, the shape of the blade is matched with that of the blade installation groove, the blade is installed in the blade installation groove obliquely downwards through a pair of fixing pressing blocks, and a tool edge of the blade faces forwards; a base plate is fixedly connected to the lower end face of the tool apron,a gap is formed between the base plate and the front end of the tool apron, and a containing groove is formed in the base plate; and the front end of the blade penetrates through the gap and extendsinto the containing groove in the base plate. The cloth cutter is simple in structure, convenient to use and not prone to deviating in the cutting process, and a table top below cloth cannot be scratched.

Owner:SHOW SHOP DISPLAY CO LTD

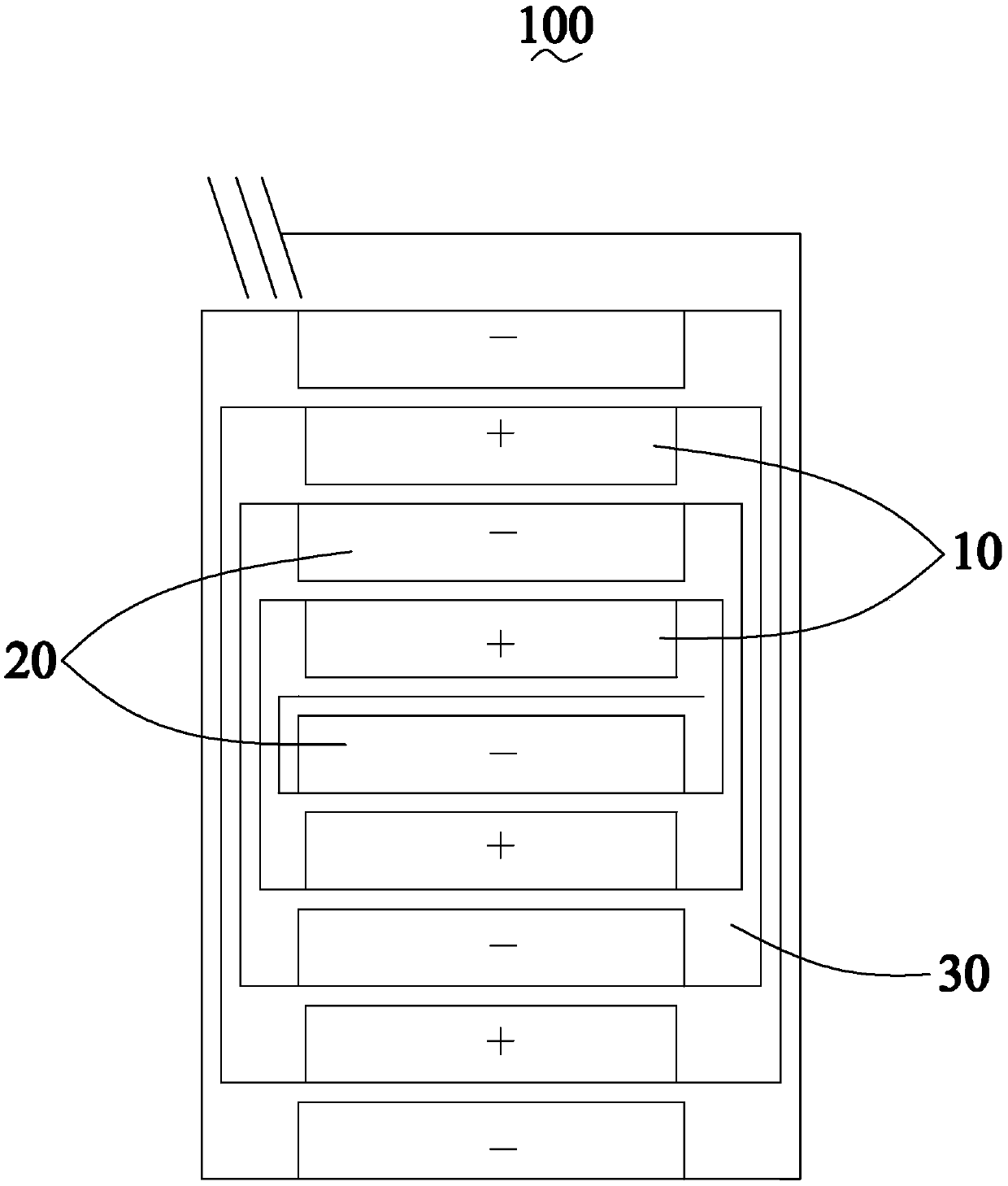

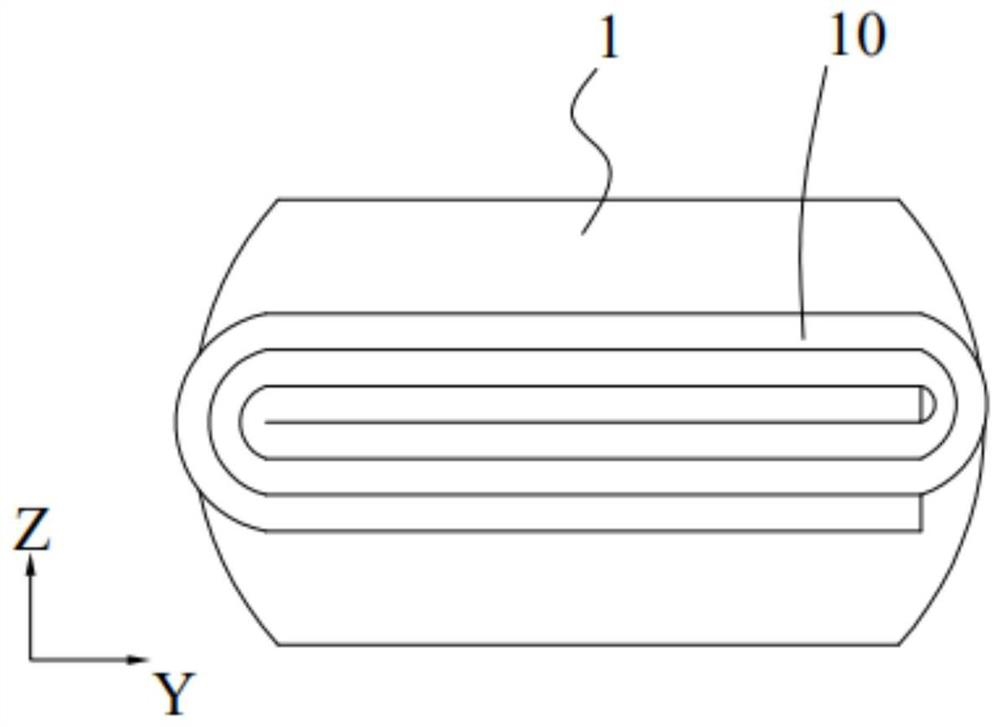

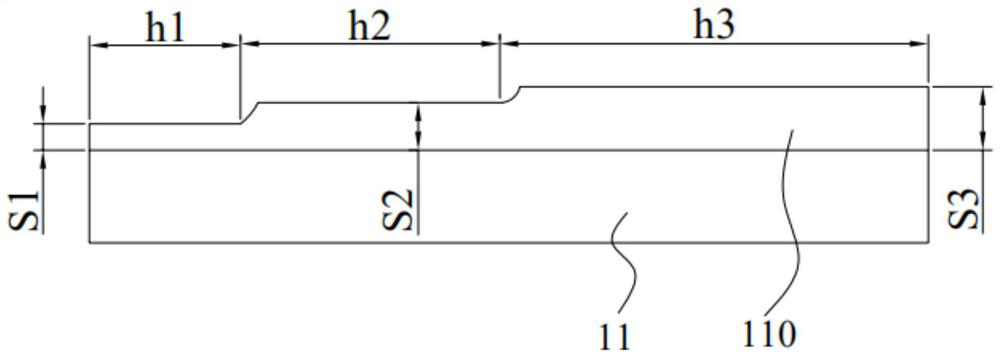

Square battery cell

PendingCN107732280AImprove securityAvoid croppingFinal product manufactureWound/folded electrode electrodesEngineeringBattery cell

The invention provides a square battery cell. The square battery cell comprises multiple unit positive plates, multiple unit negative plates and a diaphragm, wherein the diaphragm comprises a reservezone and a winding zone, and the winding zone is used for arranging the unit positive plates and the unit negative plates; the quantity of the unit negative plates is one more than the quantity of theunit positive plates; the unit positive plates and the unit negative plates are cyclically arranged in the winding zone in a sequence of the unit negative plate, the unit positive plate, the unit positive plate and the unit negative plate, the reserve zone covers a first unit negative plate in the winding zone, and the first unit negative plate is sequentially and cyclically wound with the adjacent unit positive plate, unit positive plate and unit negative plate; or the unit positive plates and the unit negative plates are cyclically arranged in the winding zone in a sequence of the unit positive plate, the unit negative plate, the unit negative plate and the unit positive plate, the reserve zone covers the first unit positive plate in the winding zone, and the first unit positive plate is sequentially cyclically wound with the adjacent unit negative plate, unit negative plate and unit positive plate.

Owner:OPTIMUM BATTERY CO LTD

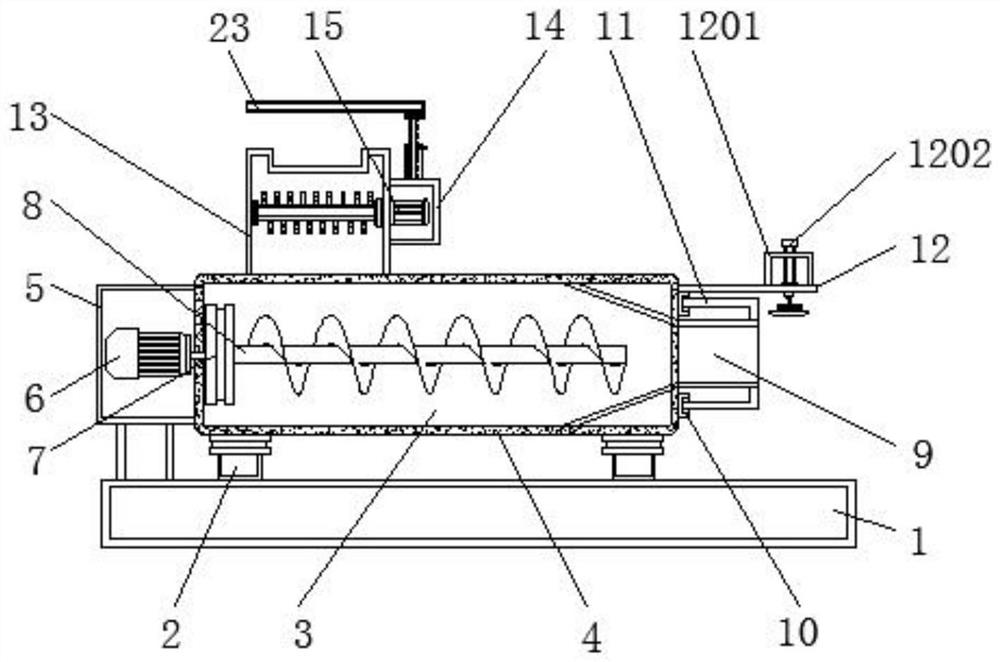

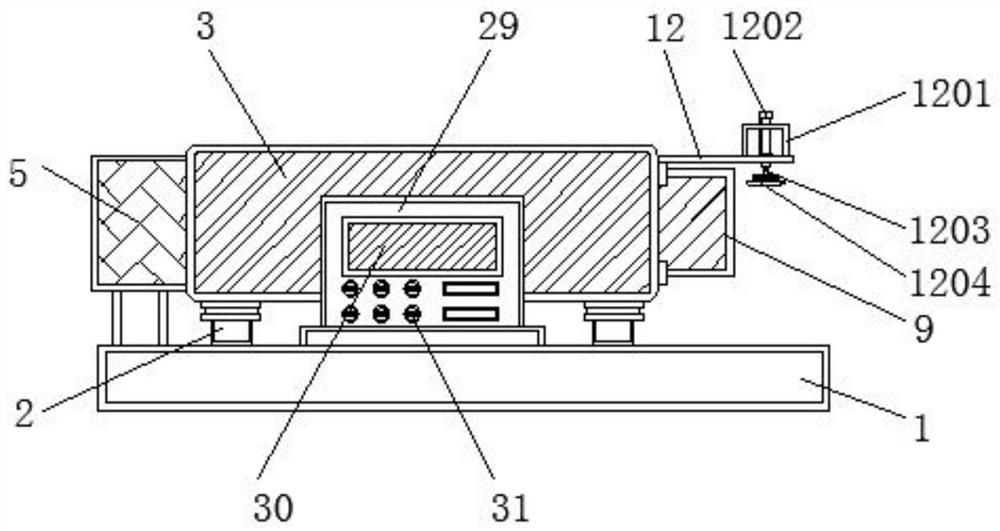

Raw material melting process and equipment for production of PVC foam core material for fan blade

PendingCN112223713AReduce use costAvoid croppingDomestic articlesMetal working apparatusElectric machineEngineering

The invention belongs to the technical field of PVC foam, and particularly relates to a raw material melting process and equipment for production of a PVC foam core material for a fan blade. The equipment comprises a base and a cutting mechanism, wherein support frames are arranged above the outer side of the base, a barrel body is mounted at the top ends of the outer sides of the support frames,an electric heating plate is arranged on the inner side of the barrel body, a machine box is installed on one side of the barrel body, a first driving motor is installed in the machine box, a rotary disc is arranged in front of the outer side of the first driving motor, meanwhile, the rotary disc is connected with a screw rod, a discharging port is formed in the other side of the barrel body, andclamping grooves are formed in the other side of the barrel body. By arranging the cutting mechanism, when raw material is extruded after being melted and reaches a certain amount, a pneumatic rod anda cutting knife are driven by a pneumatic cylinder to cut the raw material, the situation that an individual cutting device needs to be used for cutting is avoided, and therefore the work efficiencyof the device is improved, and meanwhile the use cost of the equipment is reduced.

Owner:戴铂新材料(张家港)有限公司

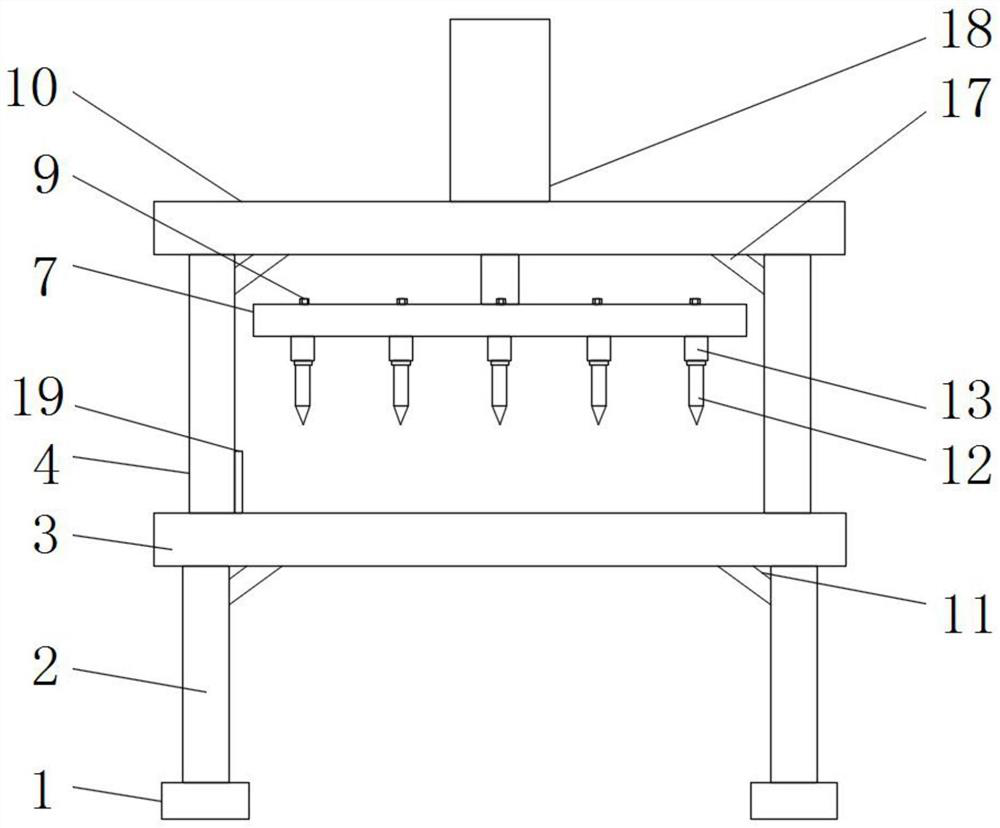

Cutting device for PVA collodion heads

InactiveCN112776036AAdjustable distanceAvoid croppingMetal working apparatusEngineeringMaterials science

The invention discloses a cutting device for PVA collodion heads, and relates to the technical field of PVA collodion head processing equipment. The cutting device specifically comprises a cutting table, multiple supporting columns are fixedly connected to the lower surface of the cutting table, and a top plate is fixedly connected to the upper surface of the cutting table through multiple supporting rods. When the cutting device is used, locking bolts are unscrewed, first sliding blocks are horizontally moved, horizontal movement of the first sliding blocks drives horizontal movement of second sliding blocks through connecting blocks, horizontal movement of the second sliding blocks drives horizontal movement of mounting plates, and therefore horizontal movement of cutting tools is driven, the distance between the cutting tools can be adjusted, the cutting tools are fixed through the locking bolts, an adjusting plate is pushed to move downwards through an air cylinder, PVA collodion strips placed on the upper surface of the cutting table are cut, and therefore PVA collodion heads of different sizes can be obtained through cutting, the situation that multiple cutting devices need to be used for cutting is avoided, and therefore the production cost is reduced.

Owner:湖北魔洗高新材料制品有限公司

Filter screen assembly production method and injection molding device

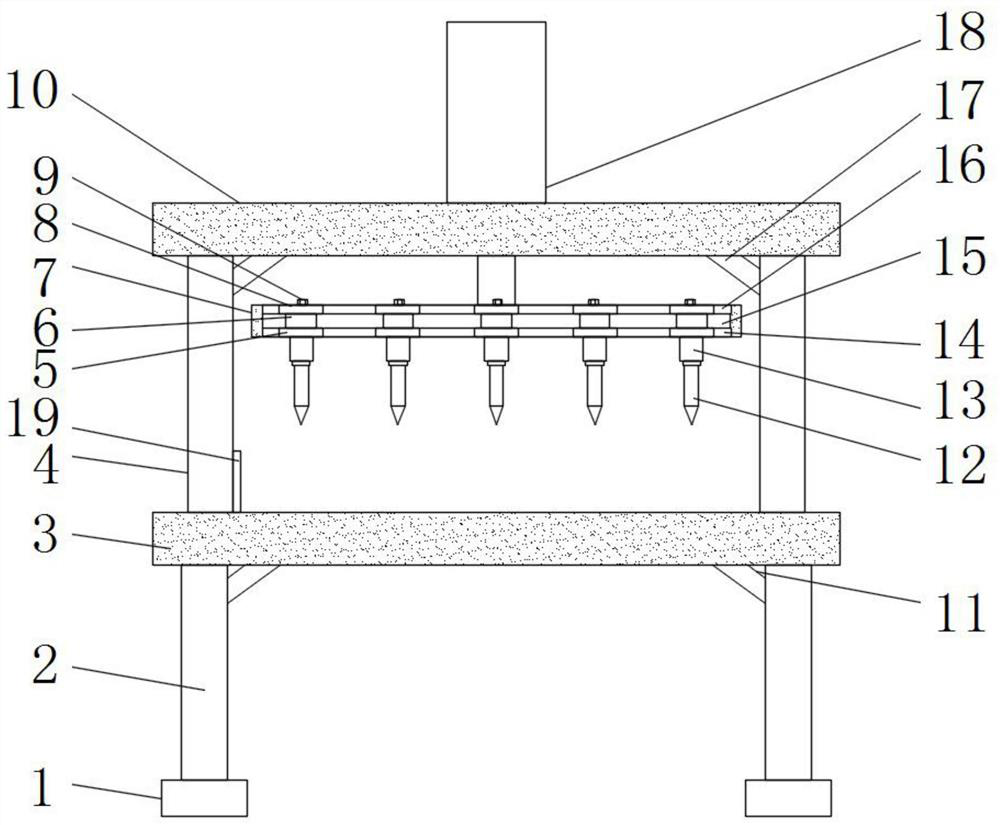

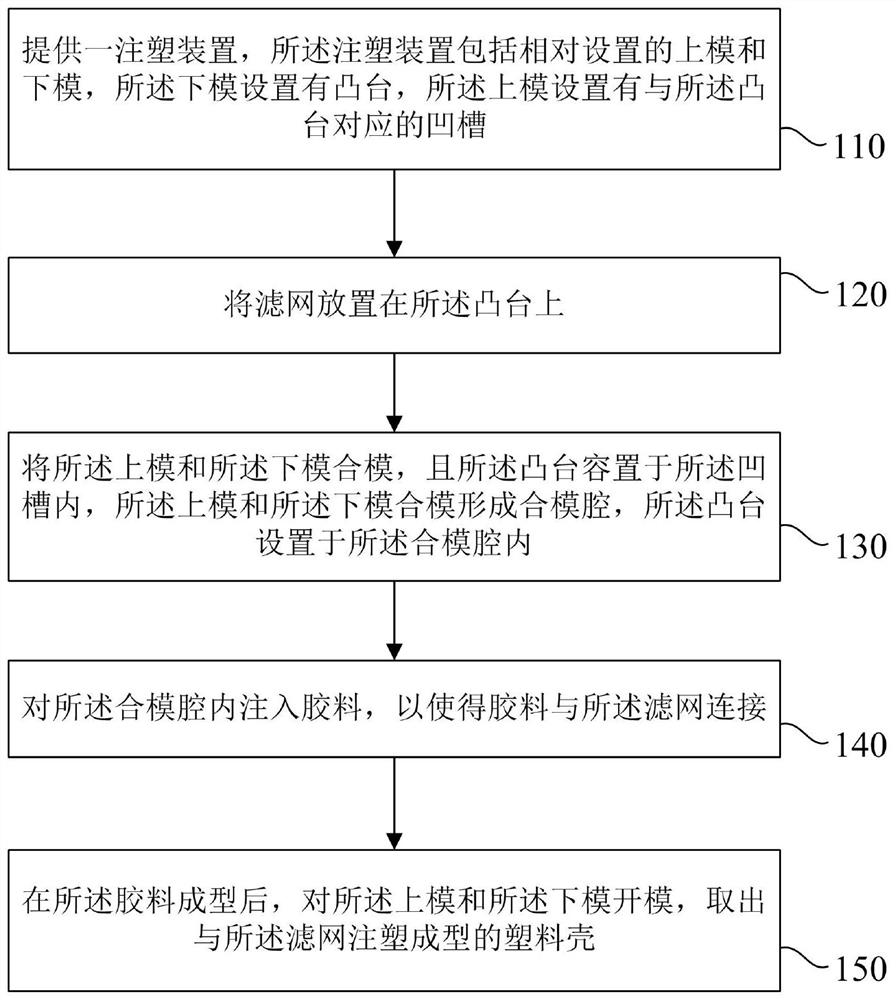

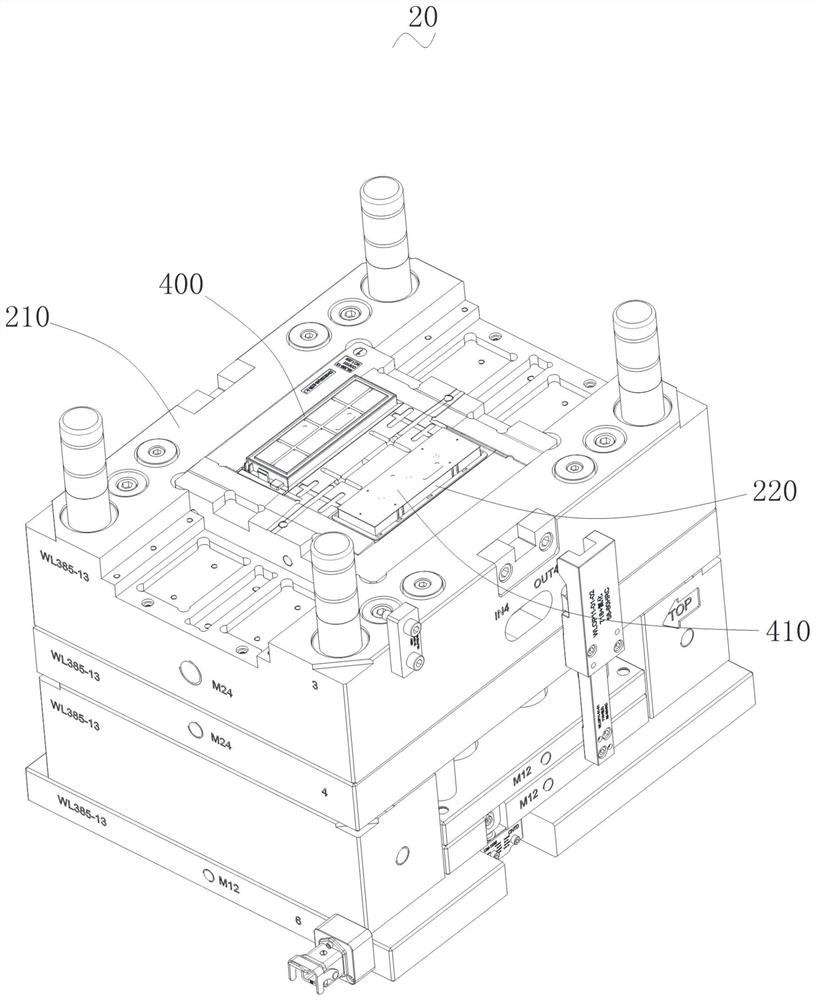

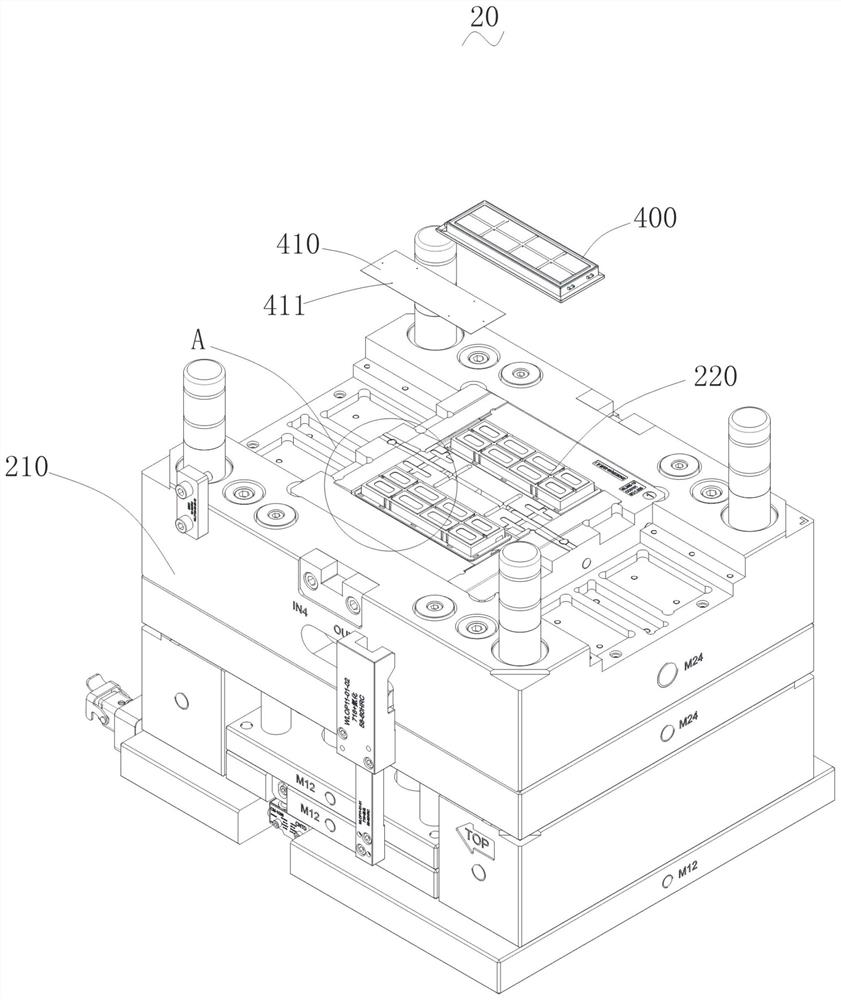

InactiveCN111619069AFirmly connectedAvoid croppingDomestic articlesMechanical engineeringScreen filter

The invention relates to a filter screen assembly production method and an injection molding device. The method comprises the following steps: 1, the injection molding device is provided, the injection molding device comprises an upper die and a lower die which are oppositely arranged, the lower die is provided with a boss, and the upper die is provided with a groove corresponding to the boss; 2,a filter screen is placed on the boss; 3, the upper die and the lower die are closed, the boss is arranged in the groove in an accommodated mode, the upper die and the lower die are closed to form a die closing cavity, and the boss is arranged in the die closing cavity; 4, sizing material is injected into the die closing cavity, so that the sizing material is connected with the filter screen; and5, after the sizing material is formed, the upper die and the lower die are opened, and a plastic shell formed with the filter screen by injection molding is taken out. By placing the filter screen inthe injection molding device to carry out injection molding together with the plastic shell, the filter screen can be directly connected with the plastic shell, the connection between the filter screen and the plastic shell is more stable, the subsequent cutting of the filter screen is avoided, and the installation of the filter screen and the plastic shell is simpler and more convenient.

Owner:GUANGDONG WELL TECH

Feeding device

PendingCN109263108ASolve the uniformity requirementReduced uniformity requirementsTyresState of artRubber material

The invention provides a feeding device. The feeding device comprises a material roll device provided with pre-treated materials; an unwinding device connected with the material roll device to conveya material on the material roll device to the unwinding device; a stripping device for stripping the material on the unwinding device to separate a rubber material of the material from a material lining; a conveying platform connected with the discharging end of the stripping device to convey the stripped rubber material; a swinging device connected with the conveying platform and used for controlling overall swinging inclination of the conveying platform, so that the rubber material slides along the inclined surface under the action of gravity; a rectifying device, wherein at least a part ofthe rectifying device is movably connected with the conveying platform and blocks sliding of the rubber material on the inclined surface to align one side edge of the rubber material. The feeding device solves the problem in the prior art that the existing feeding device cannot meet the use requirement, is inconvenient to operate and has low efficiency when applied to large-size feeding.

Owner:MESNAC

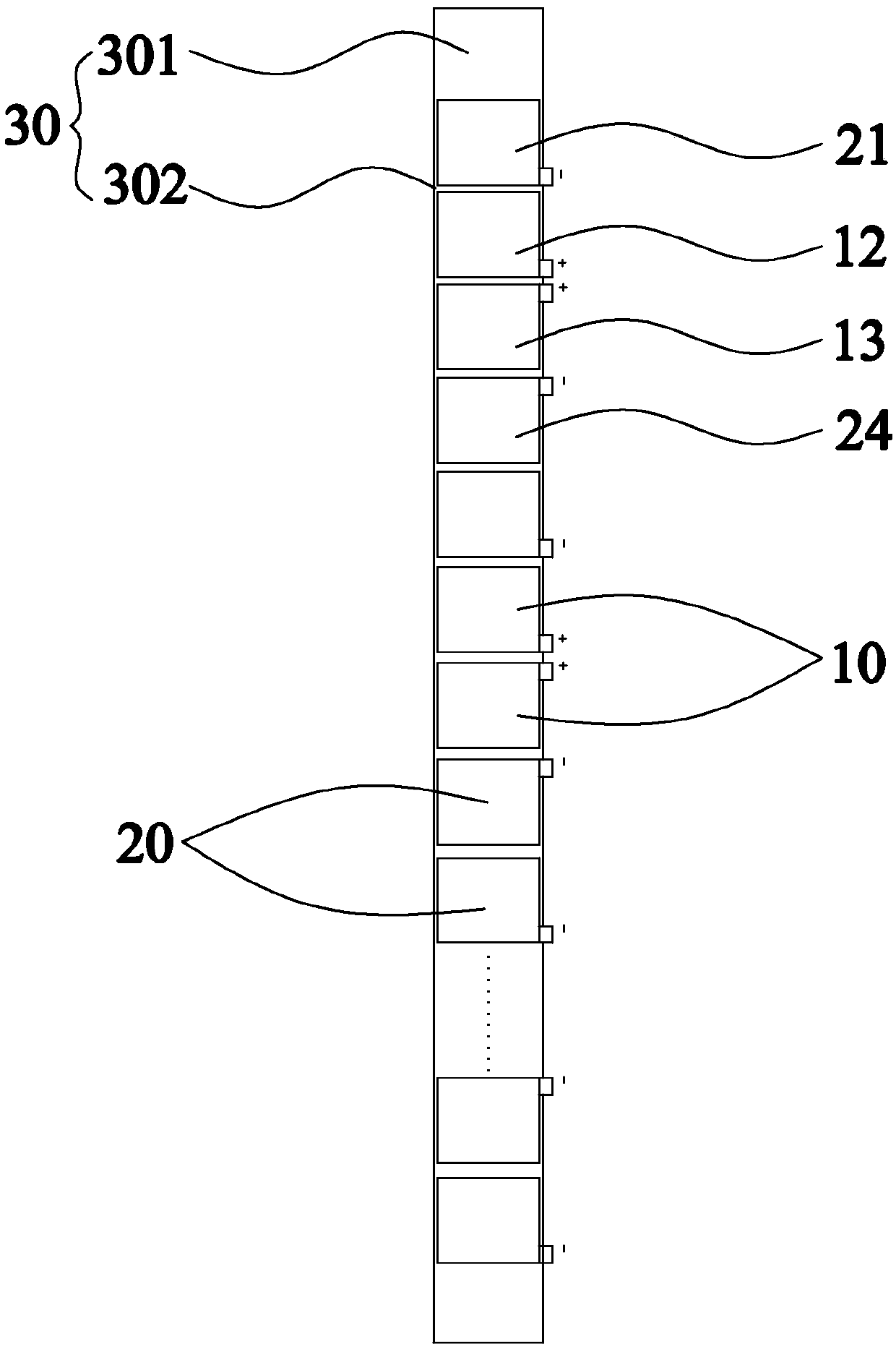

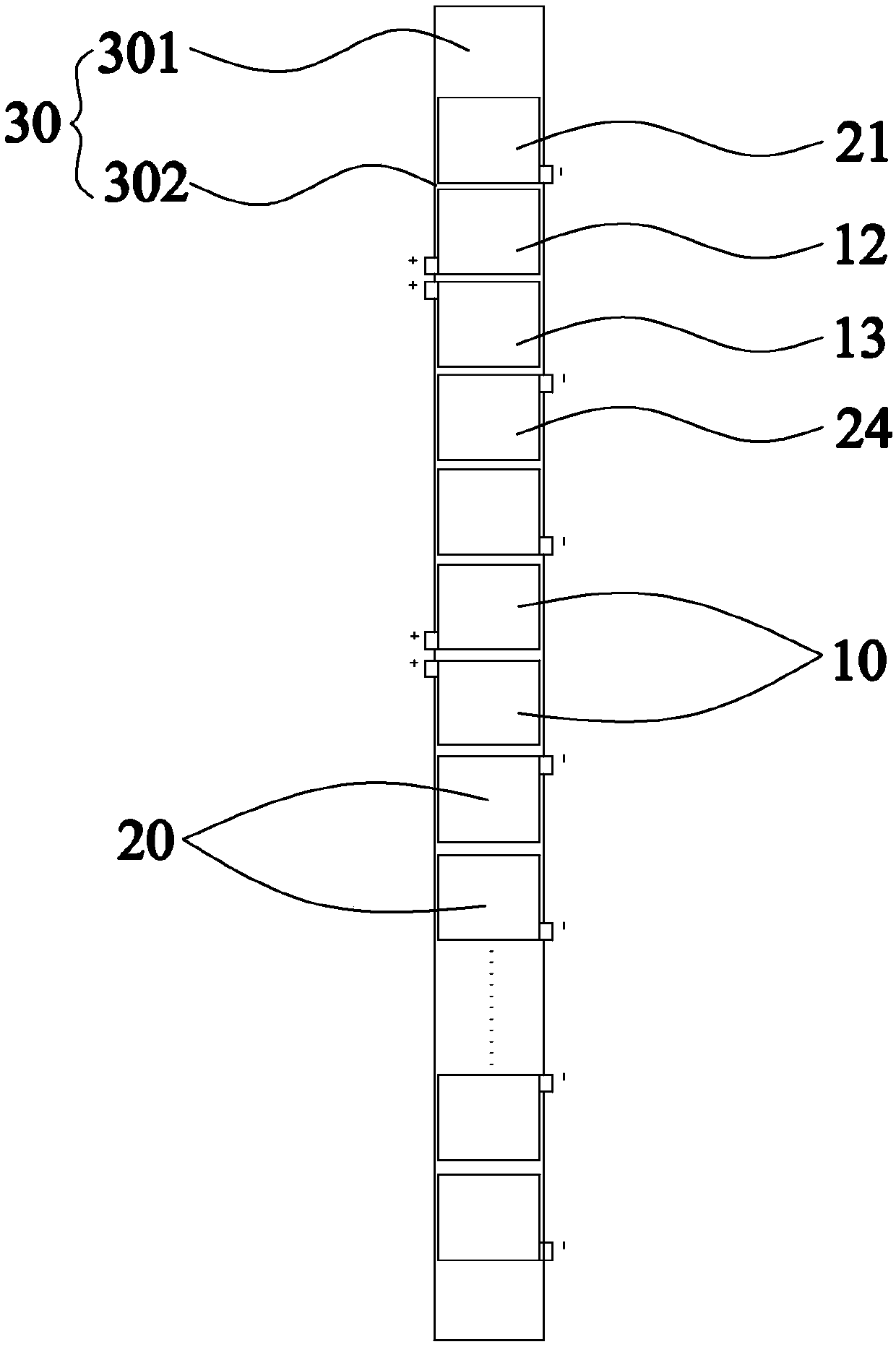

Manufacturing method of winding type battery cell, winding type battery cell and lithium battery

InactiveCN112117498AAvoid safety hazardsImprove product qualityNon-aqueous electrolyte cellsFinal product manufactureComposite materialStructural engineering

The invention relates to a manufacturing method of a wound battery cell, the wound battery cell and a lithium battery. The method comprises the steps: providing a positive plate, a negative plate anda diaphragm, and enabling one side of the positive plate and one side of the negative plate to extend to form a positive empty foil area and a negative empty foil area, wherein the positive empty foilarea and the negative empty foil area are provided with a plurality of positive empty foil area sections and negative empty foil area sections in the first direction; enabling the lengths of the anode empty foil region sections and the cathode empty foil region sections to be different; stacking and winding the positive plate, the diaphragm and the negative plate according to a set sequence to form a battery cell, wherein the positive empty foil area and the negative empty foil area are respectively positioned at two ends of the battery cell; respectively shaping the positive empty foil areaand the negative empty foil area to enable the positive empty foil area sections and the negative empty foil area sections to be respectively stacked together, enabling the ends, far away from the centers of the positive pole piece and the negative pole piece, of the positive empty foil area sections and the negative empty foil area sections to be flush, and respectively welding all the positive empty foil area sections and the negative empty foil area sections to form positive tabs and negative tabs. The method has the characteristics of simplifying the process flow and improving the batteryproduction quality.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

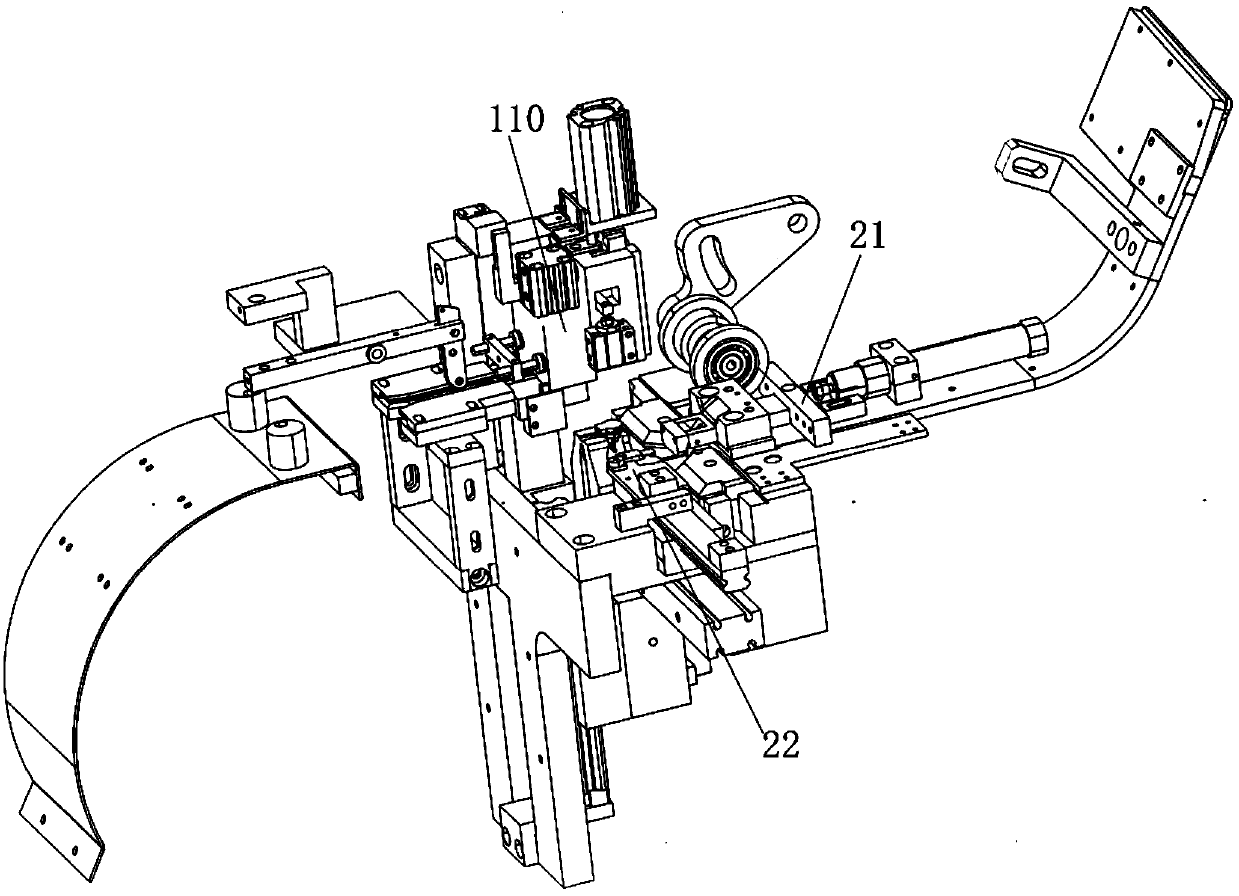

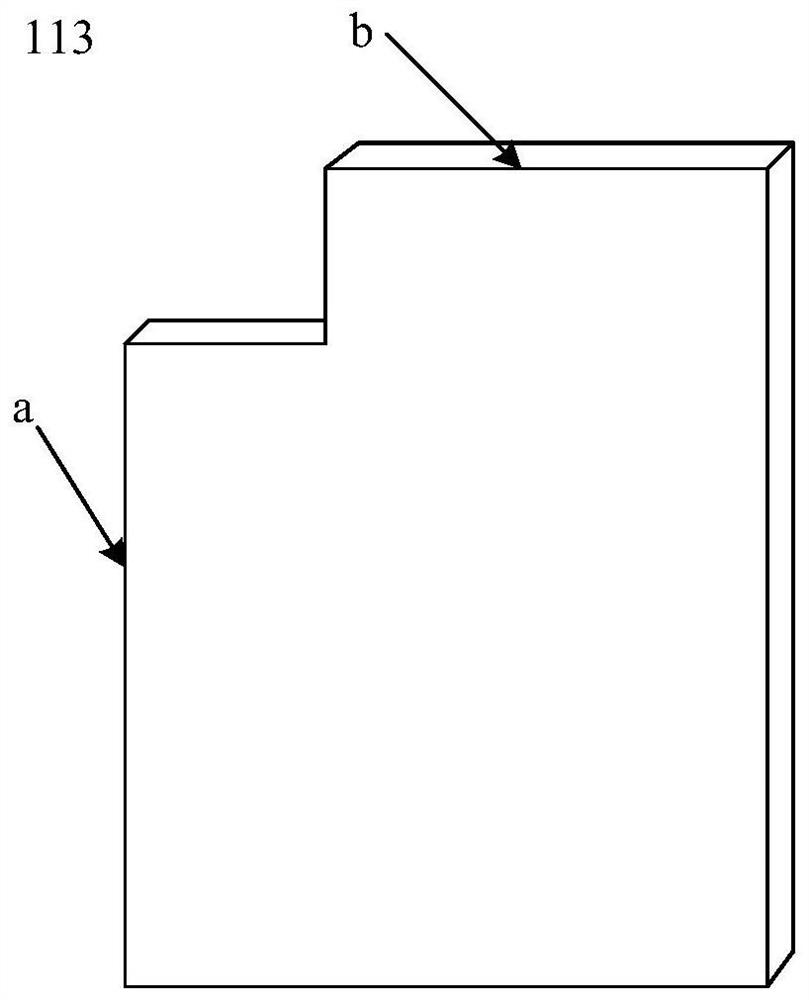

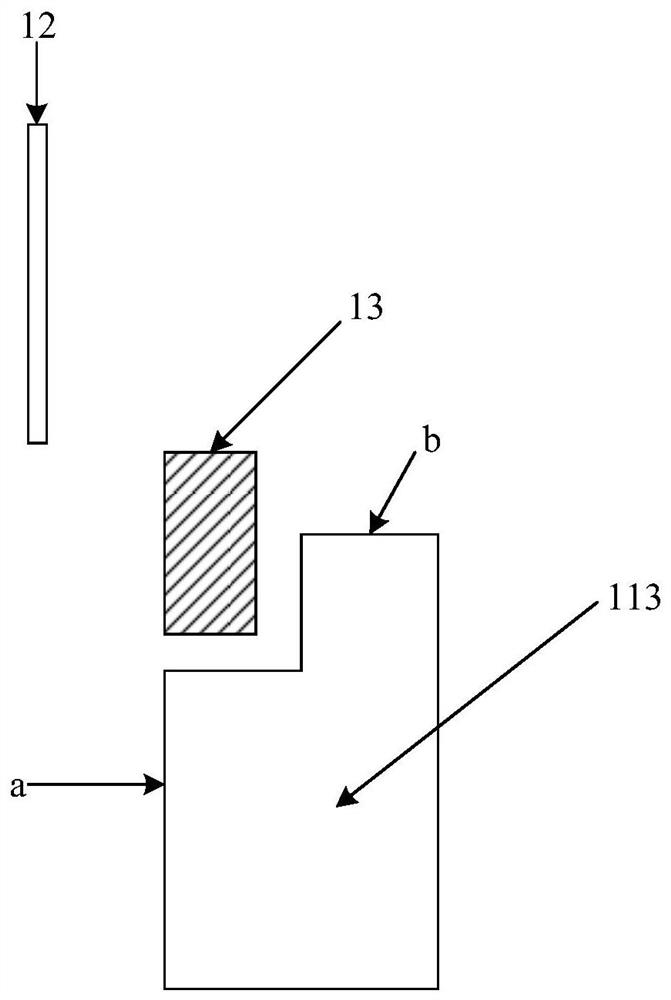

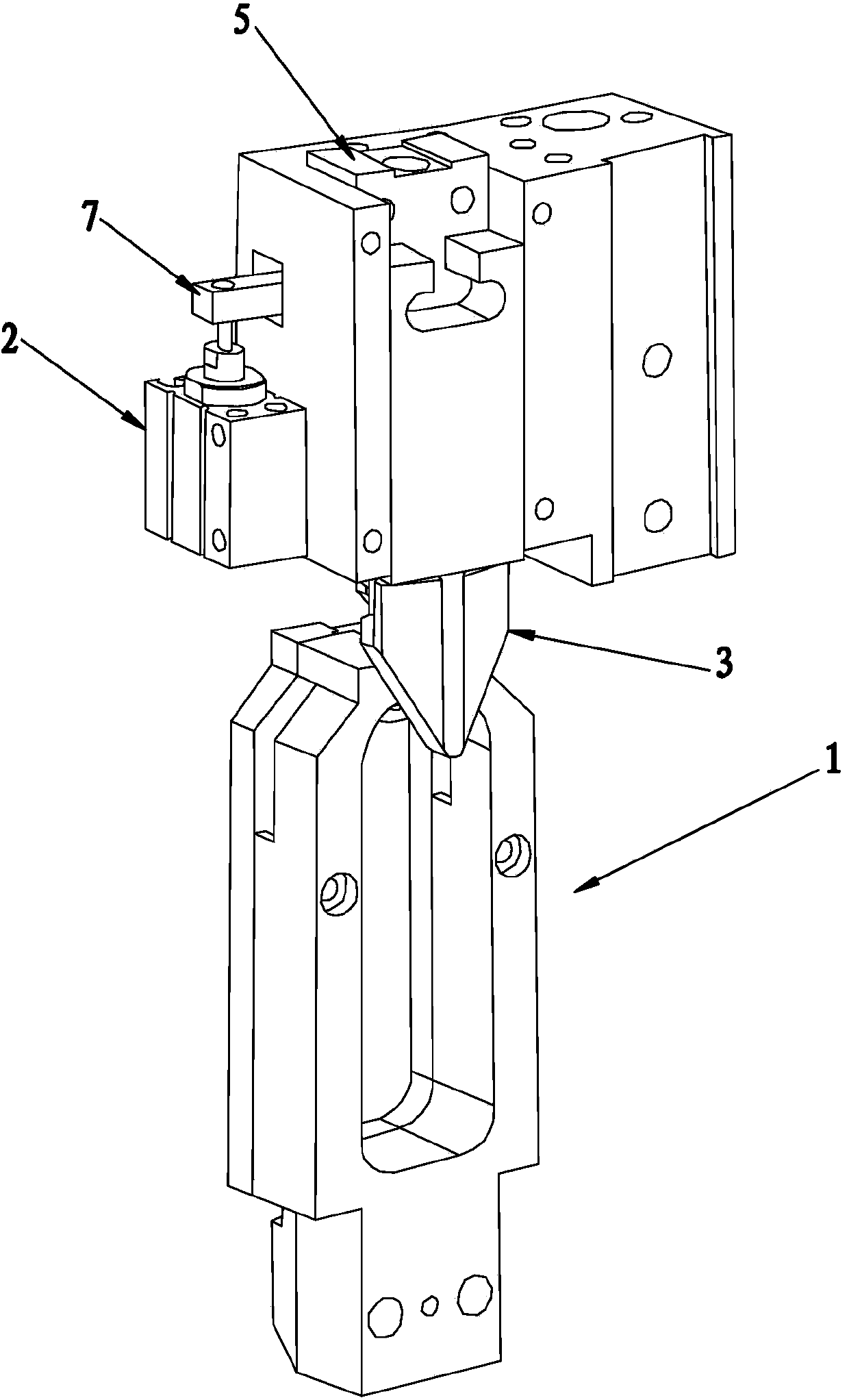

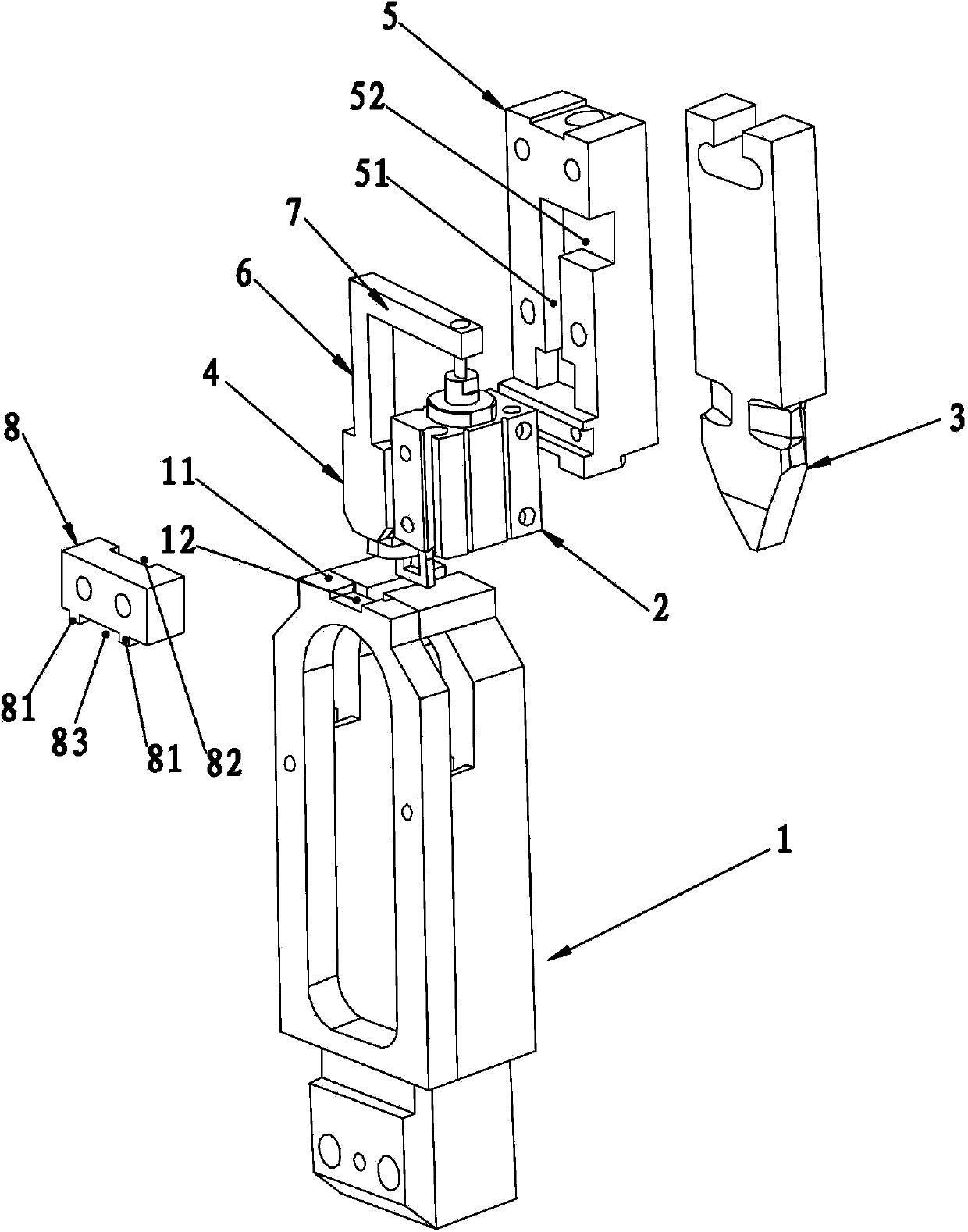

Strap splitting device arranged on zipper machine and used for zipper head installation

The invention relates to a zipper machining device, in particular to a zipper head installation device of a zipper machine. According to the technical scheme, the strap splitting device arranged on the zipper machine and used for zipper head installation comprises a zipper head insurance opening installation rack, an installation platform allowing a zipper head to be placed thereon and an accommodating space allowing a zipper to pass through are arranged on the insurance opening installation rack, and a strap splitting head which is capable of sliding towards the accommodating space in a reciprocating mode and is driven by a driving mechanism, and a strap splitting press shovel which moves together with the strap splitting head are erected on the insurance opening installation rack. According to the device, the distance between different zipper sections is shortened, materials are saved, strap splitting can be achieved conveniently, and the structure is simple.

Owner:温州宏业精机有限公司

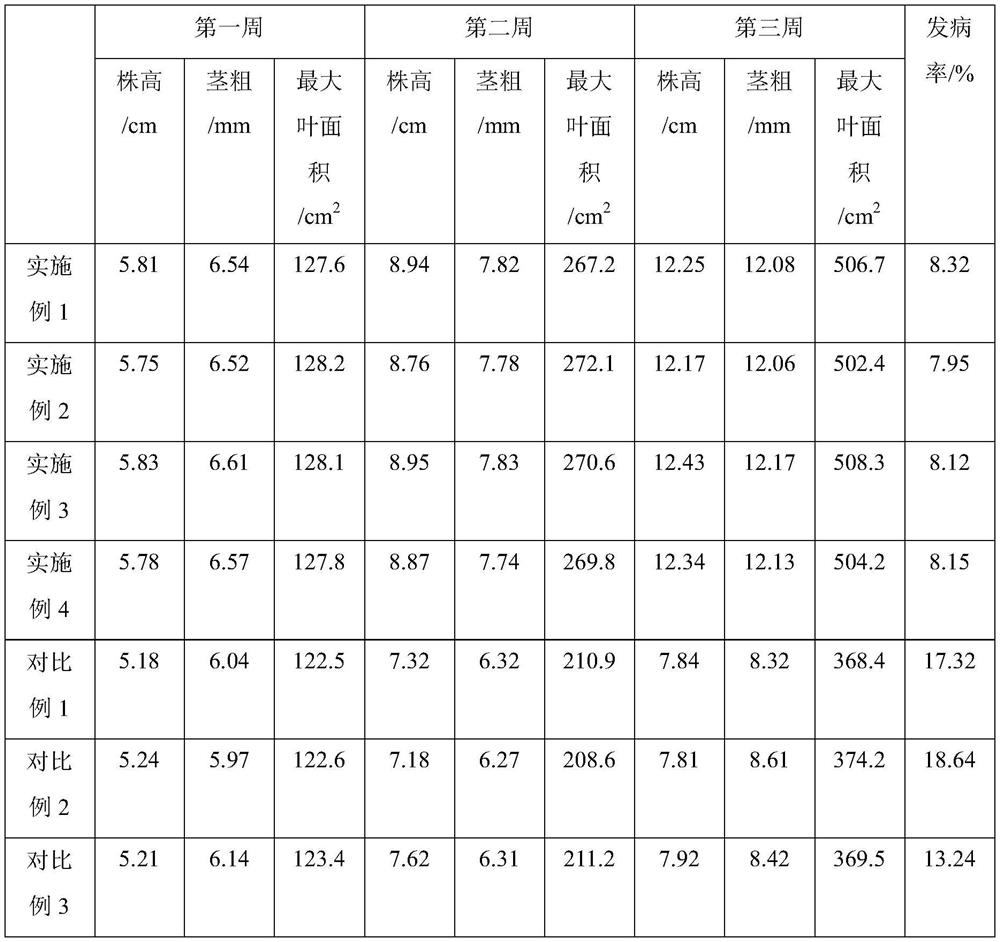

Anti-continuous-cropping cultivation method for eucheuma melons

InactiveCN112703979AReduce adverse effectsAvoid croppingCalcareous fertilisersGrowth substratesContinuous croppingNutrition

The invention discloses an anti-continuous-cropping cultivation method for eucheuma melons. The device comprises the following steps of selecting an eucheuma melon variety, drying seeds in the sun, soaking the seeds, sowing the seeds into a nutrition pot filled with nutrient soil, raising seedlings in cold frames, taking out the seedlings from the soil, removing caps, and irrigating with biological agent fertilizer; ploughing the field to be planted in late autumn of the previous year, ploughing again in January to March of the next year, applying mixed fertilizer, ploughing, bedding, laminating, punching by a puncher, transplanting into holes, applying biological bacterial fertilizer liquid, and taking soil on site to seal roots tightly; building a shed frame, pulling seedlings after field planting to the shed frame, uniformly separating melon vines on the shed frame in a vine growing period, performing artificial supplementary pollination in a flowering period, applying fruit fertilizer when young fruits are born, and stopping irrigation in 1-2 weeks before melon picking; and performing pest control. The method is simple to operate, can prevent and treat adverse effects caused by continuous cropping of the eucheuma melons, improves the yield and quality of the eucheuma melons, and effectively solves the problems that in the prior art, the eucheuma melons are not resistant to continuous cropping, large in chemical agent dosage, poor in yield and quality and the like.

Owner:BEIJING PLANT PROTECTION STATION

Cutting device for special outline of non-woven fabric and using method thereof

PendingCN111945412ARealize automatic controlReduce labor costsSevering textilesAutomatic controlNonwoven fabric

The invention provides a cutting device for a special outline of non-woven fabric and a using method thereof The cutting device comprises a conveying frame used for bearing and conveying the non-wovenfabric, a feeding module arranged at one side of the conveying frame, a material pulling module arranged at the other side of the conveying frame and away from the feeding module, a cutting module used for cutting the non-woven fabric into a special outline, and a material taking module used for transferring the cut non-woven fabric to a next station. The problems existing in existing non-woven fabric cutting are solved, a high-precision cutting die is designed according to the cutting requirement, automatic control is achieved, the labor cost is saved, the machining cost is greatly reduced,meanwhile, the combinability with other procedures is improved, and the production efficiency is improved.

Owner:苏州凌创科技发展有限公司

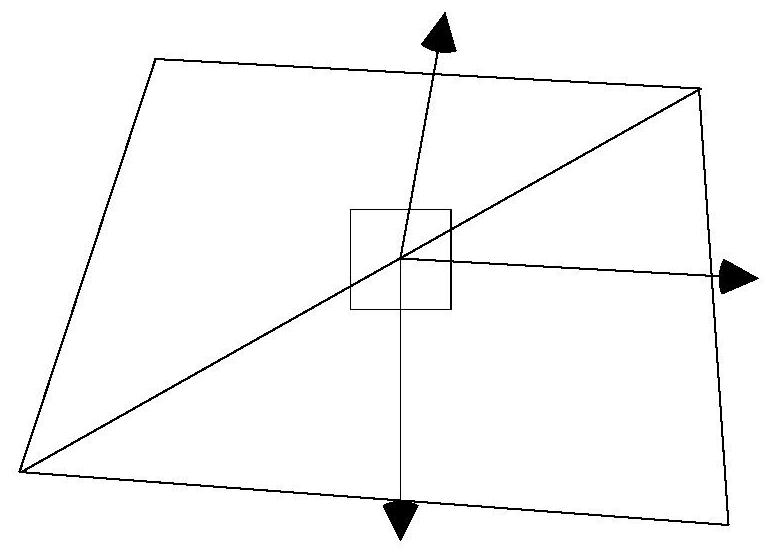

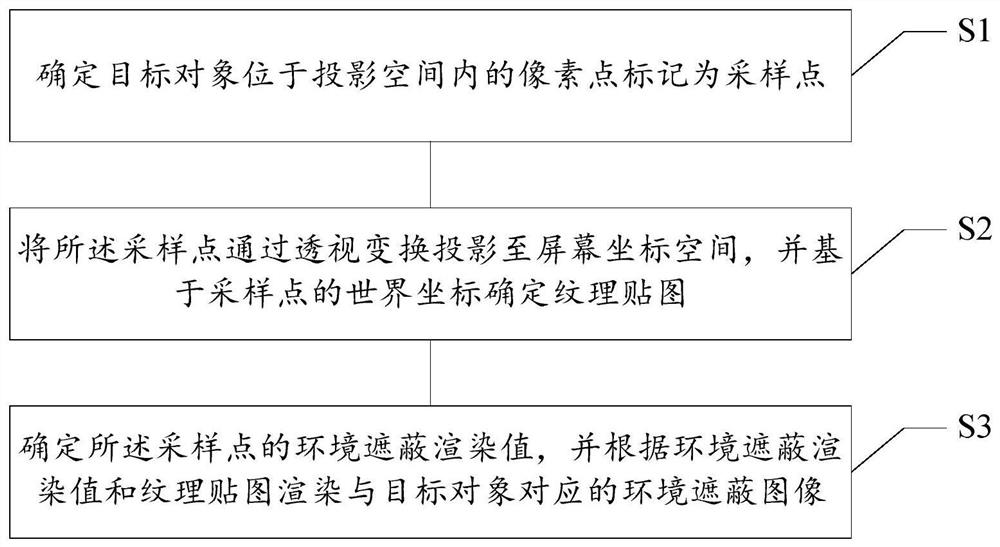

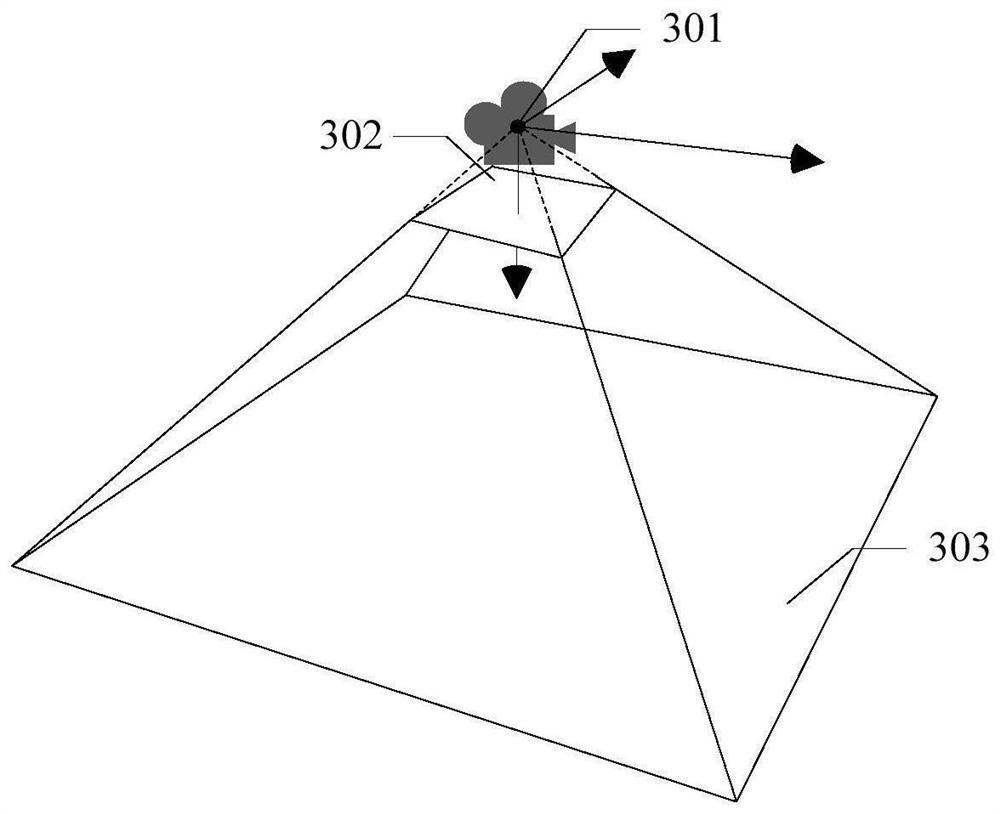

Environment shielding rendering method, environment shielding rendering device, computer readable storage medium and electronic equipment.

PendingCN112734896AGuaranteed ambient occlusionSave CPU calculationReconstruction from projection3D-image renderingProjection spacePerspective transformation

The invention relates to the field of image processing, in particular to an environment shielding rendering method, an environment shielding rendering device, a computer readable storage medium and electronic equipment. The environment shielding rendering method comprises the steps of determining and marking pixel points, located in a projection space, of a target object as sampling points; projecting the sampling points to a perspective space through perspective transformation, and determining a texture map based on world coordinates of the sampling points; and determining an environment shielding rendering value of the sampling point, and rendering an environment shielding image corresponding to the target object according to the environment shielding rendering value and the texture map. According to the environment shielding rendering method, the expenditure of the CPU can be reduced while the environment shielding effect is simulated.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com