Assembly type skirting line internal and external corner closing-up mounting structure

A technology of installation structure and skirting, applied in building structure, construction and other directions, can solve problems such as affecting the closing process, and achieve the effects of improving worker efficiency, tight closing effect, and high material utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

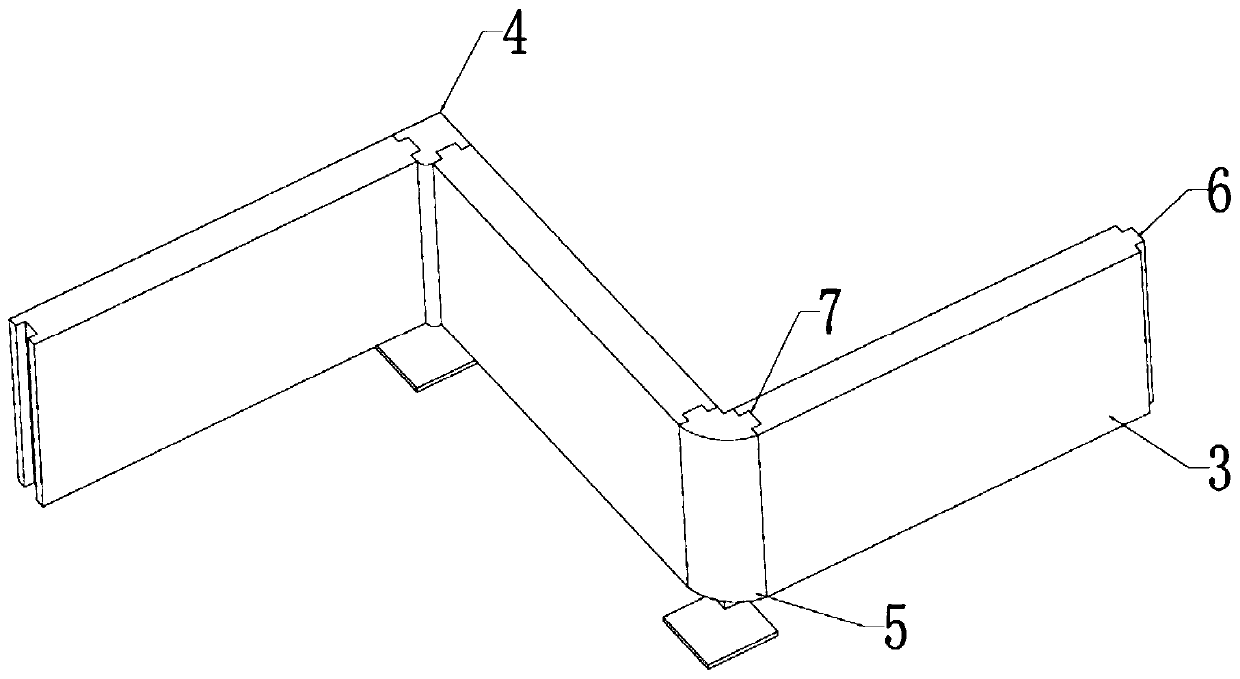

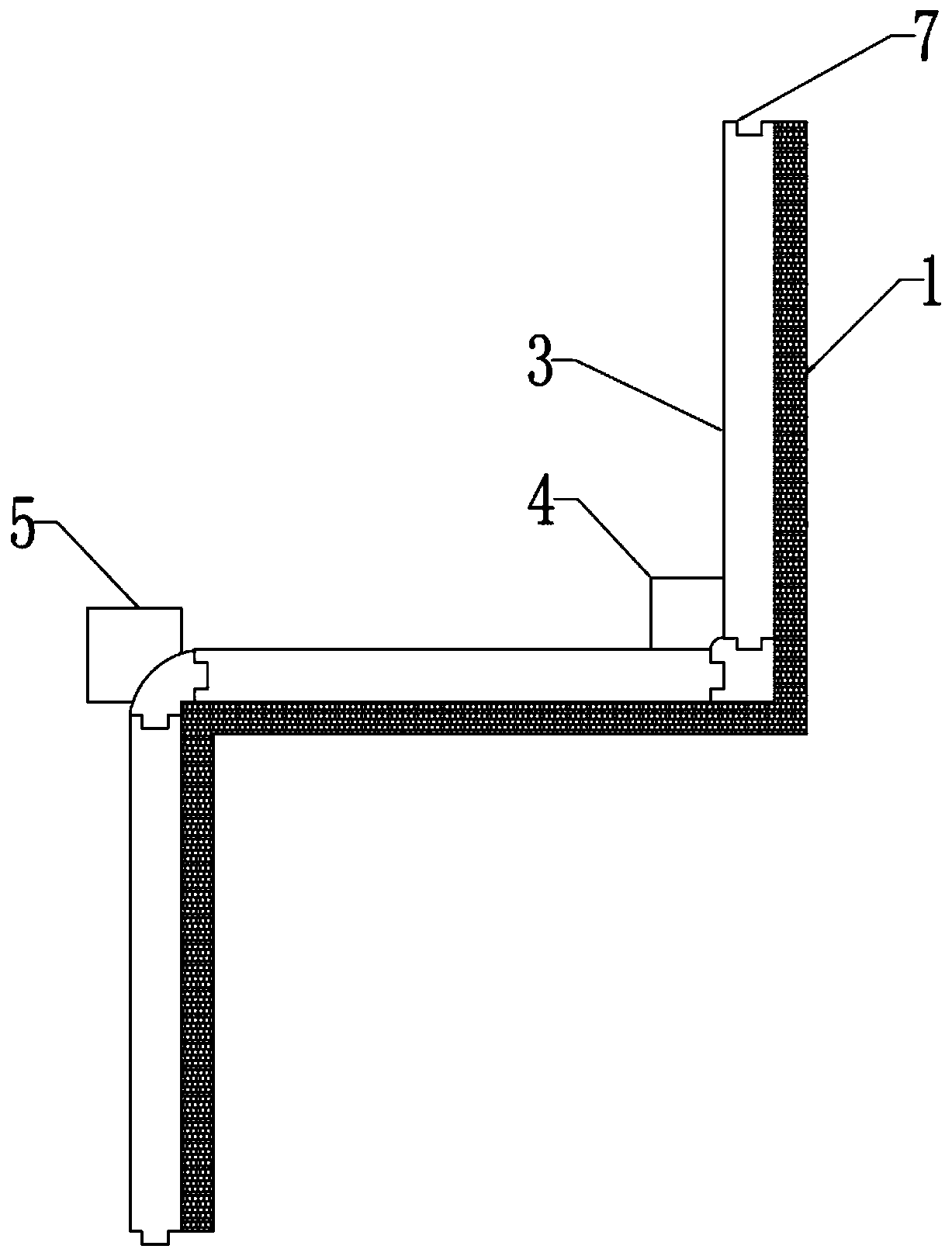

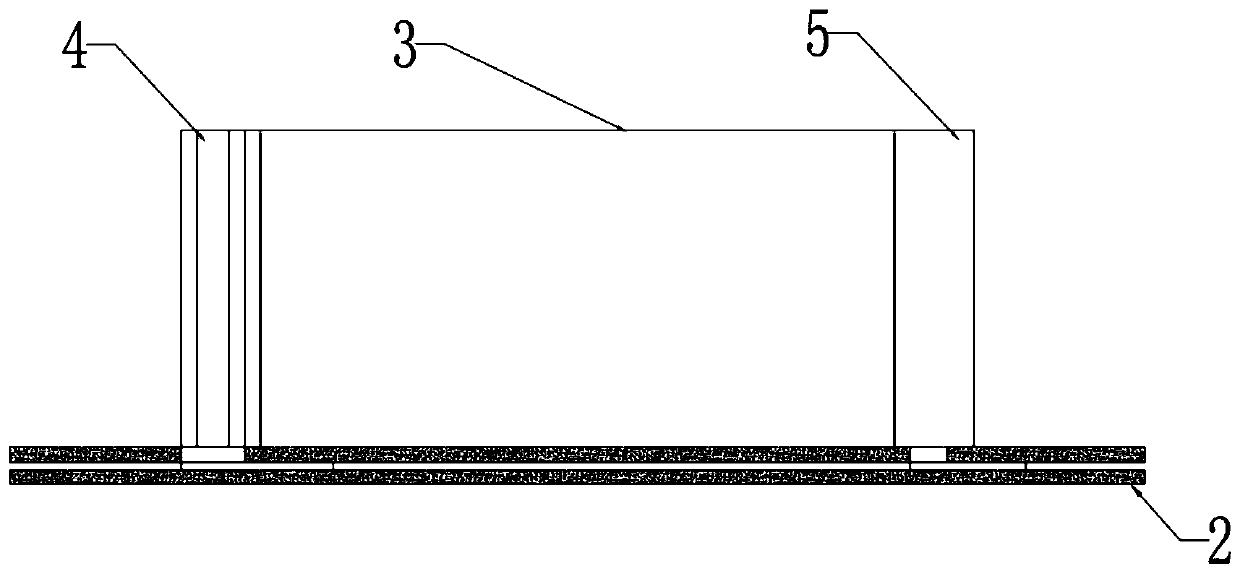

[0025] see Figure 1 to Figure 5 , the present embodiment provides an assembly type skirting line 3 yin and yang corner installation structure, wherein, firstly set the wall 1, the ground 2, the skirting line 3, the inner corner mechanism 4 and the outer corner mechanism 5, the ground 2 and the wall The body 1 is vertically connected, the baseboard 3 is set on the side of the wall 1, the inner corner mechanism 4 is set at the inner corner of the wall 1, the male corner mechanism 5 is set at the outer corner of the wall 1, the inner corner mechanism 4 and the male corner The mechanisms 5 are fixedly connected to the ground 2, one end of the baseboard 3 has a boss 6, and the other end of the skirting 3 has a groove 7, and the boss 6 is engaged and connected to the inner corner mechanism 4 at the inner corner of the wall 1 , the groove 7 is engaged and connected to the male corner mechanism 5 at the outer corner of the wall body 1 .

[0026] see Figure 1 to Figure 5 Specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com