Patents

Literature

96results about How to "Avoid size errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

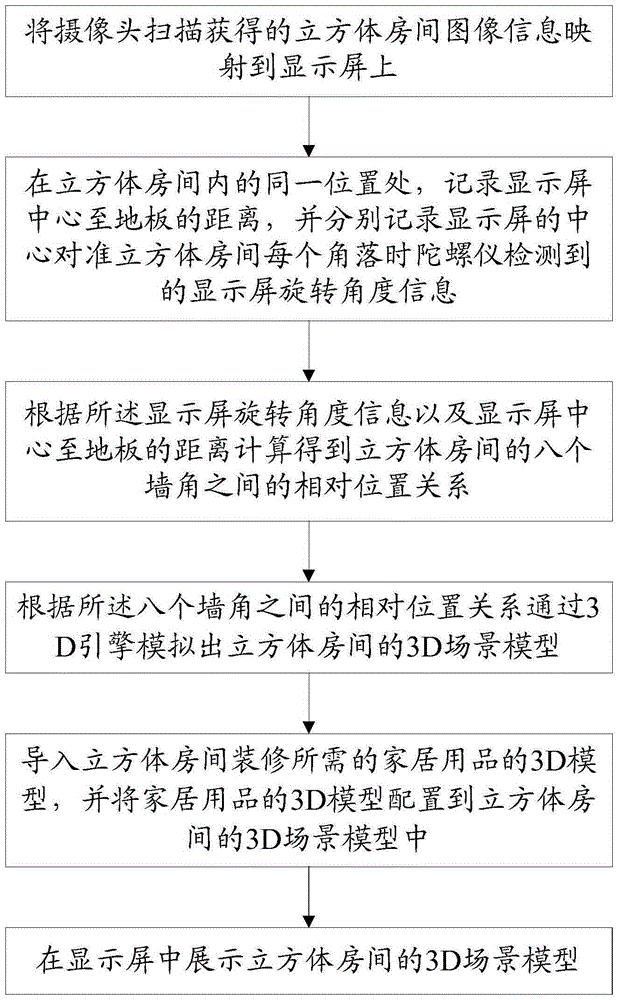

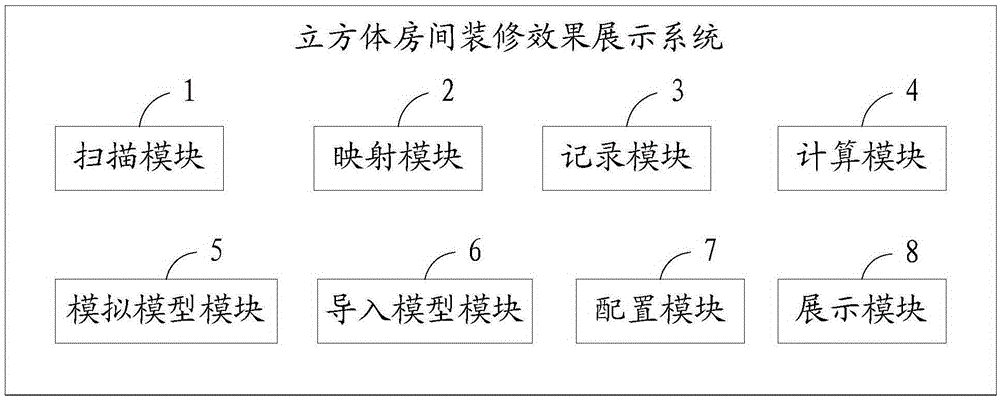

Decoration effect displaying method and system of cubic room

The invention provides a decoration effect displaying method and system of a cubic room. The method comprises: image information, obtained by scanning by a camera, of a cubic room is mapped to a display screen; a distance between the center of the display screen to a floor is recorded at a same position inside the cubic room, display screen rotation angle information that is detected by a gyroscope when the center of the display screen is aligned at each corner of the cubic room is recorded respectively; according to the display screen rotation angle information as well as the distance between the center of the display screen and the floor, calculation is carried out to obtain relative position relations between the eight corners of the cubic room; on the basis of the relative position relations of the eight corners, a 3D scene model of the cubic room is simulated by using a 3D engine; a 3D model of a household item needed by decoration of the cubic room is introduced and is configured into the 3D scene model of the cubic room; and the 3D scene model of the cubic room is displayed on the display screen. With the method and system, a room dimension can be measured on site and a room decoration effect can be displayed.

Owner:FUJIAN TQ DIGITAL

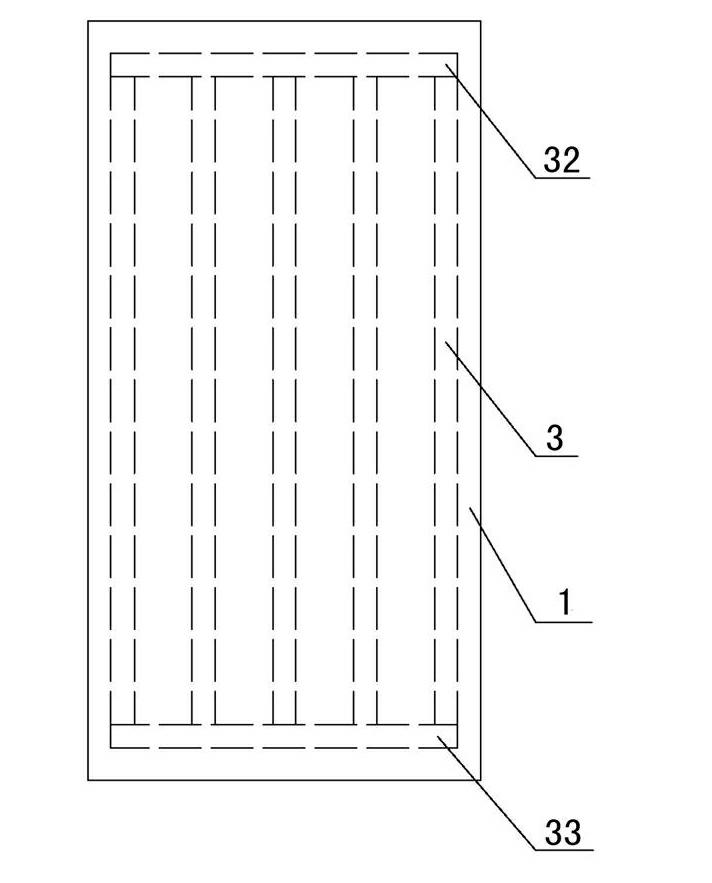

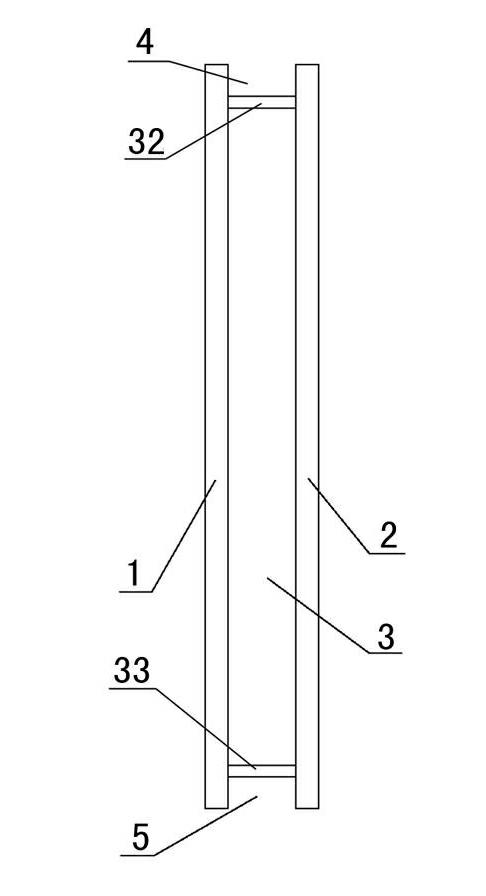

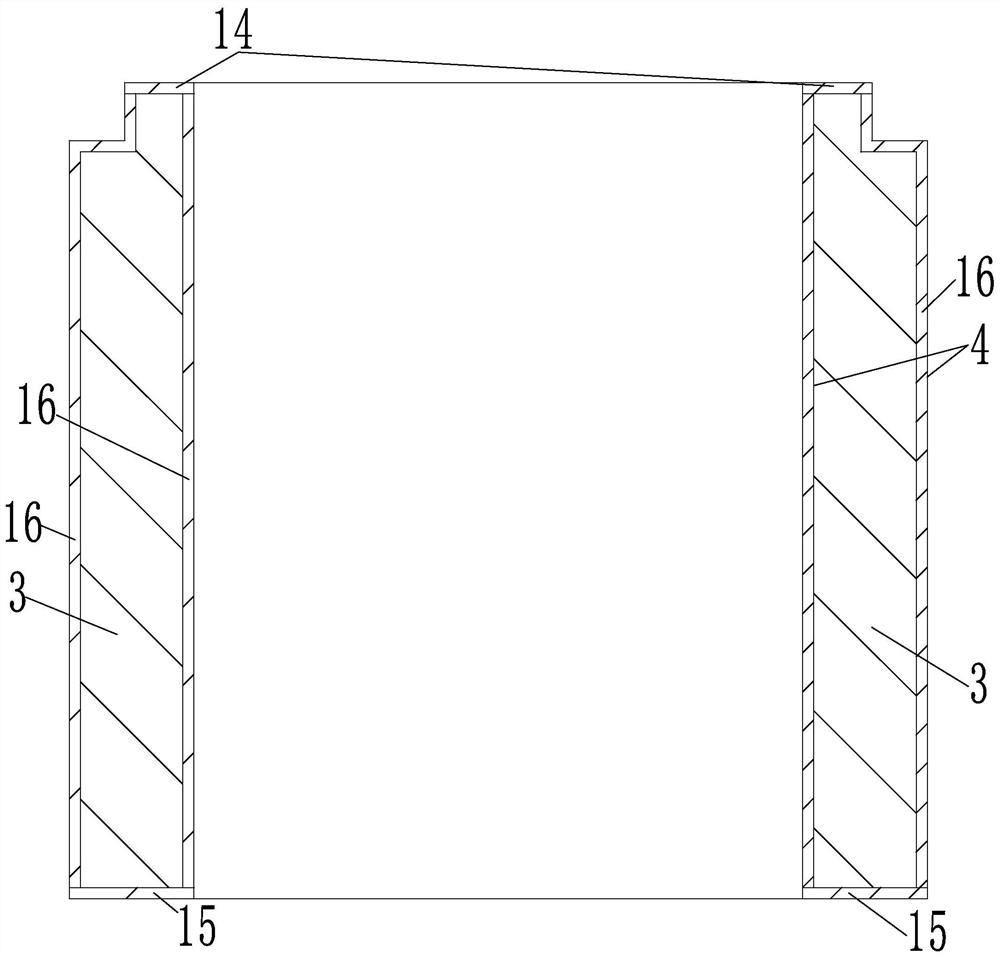

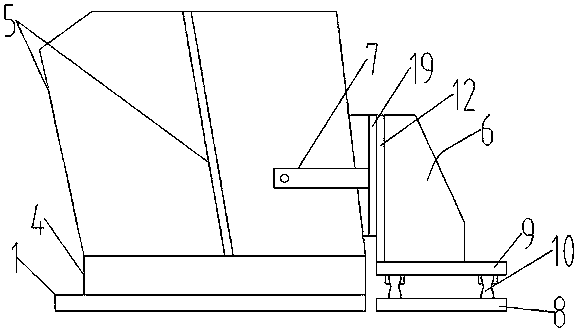

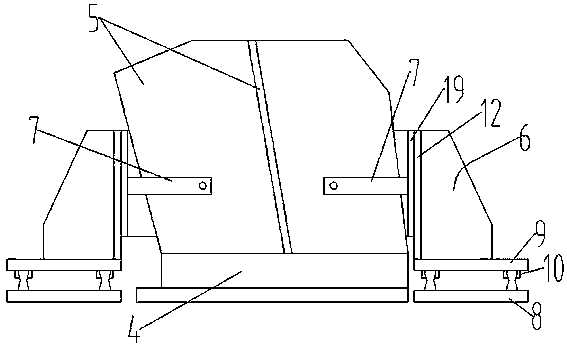

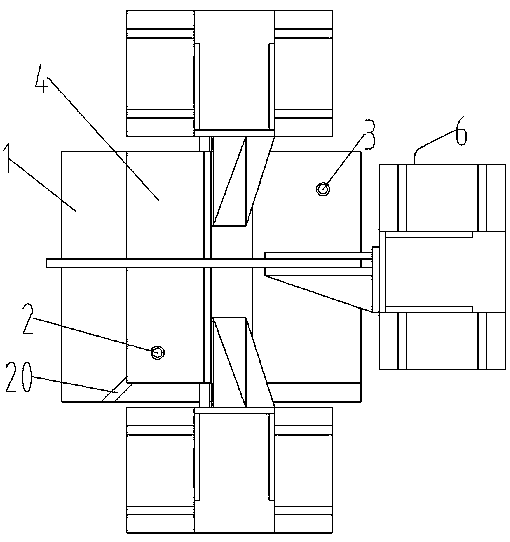

Two-storey modular villa building and construction method thereof

ActiveCN102587693ASimple installation and constructionNo pollution in constructionBuilding material handlingDwelling buildingSeismic resistanceGable

Disclosed is a two-storey modular villa building and a construction method thereof. The villa building comprises a foundation, structural upright columns, a gable wall, longitudinal walls, floors and a roof. The structural upright columns are connected with the foundation, the gable wall and the longitudinal walls are connected with the structural upright columns, the floors and the roof are connected with the gable wall and the longitudinal walls, the gable wall comprises a first-storey gable wall and a second-storey gable wall, modular square plate walls are pieced together to form the first-storey gable wall, modular square plate walls and modular triangular plate walls are pieced together to form the second-storey gable wall, each longitudinal wall comprises a first-storey longitudinal wall and a second-storey longitudinal wall, modular square plate walls are pieced together to form the first-storey longitudinal walls and the second-storey longitudinal walls, each modular square plate wall comprises a square external inorganic plate, a square internal inorganic plate and vertical inorganic plate strips parallelly distributed between the square external inorganic plate and the square internal inorganic plate. The modular square plate walls are pieced together to form the first-storey walls and the second storey walls of the villa building, the first-storey walls and the second-storey walls are connected with the floors, so that a firm integral frame is formed and has quite high seismic resistance, and the integral weight of the villa building is greatly reduced.

Owner:沈汉杰

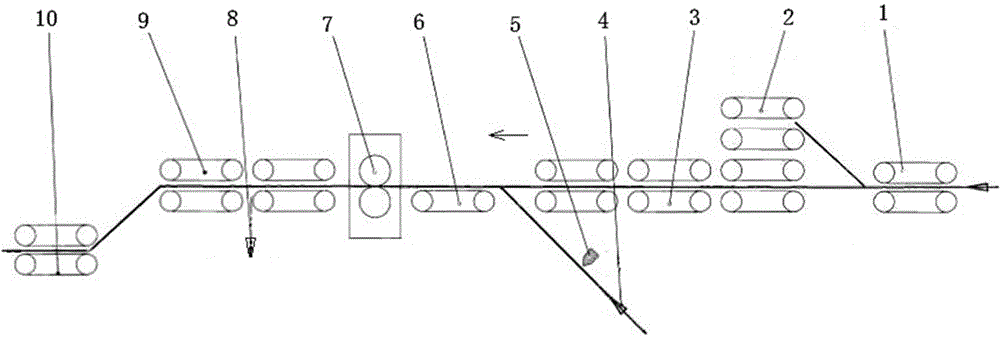

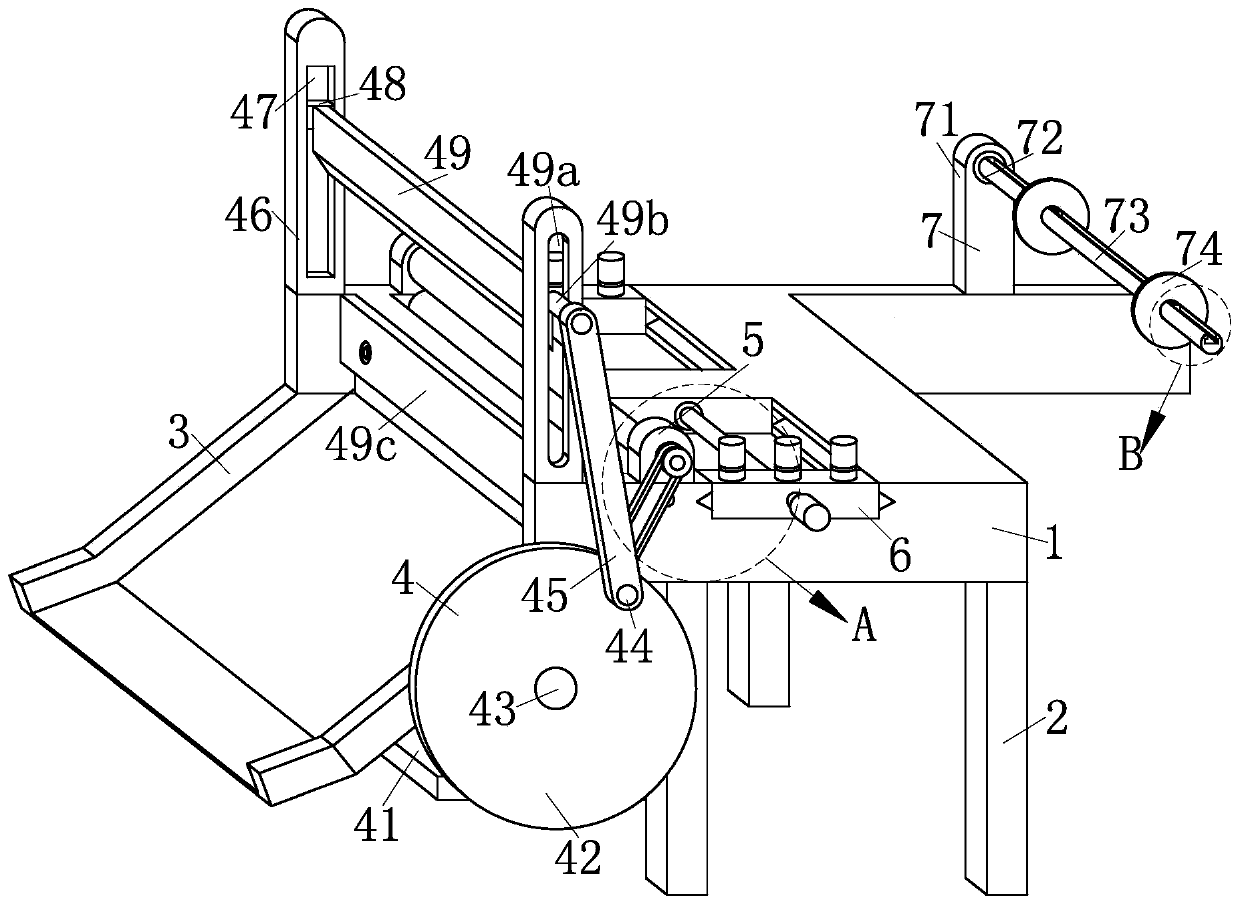

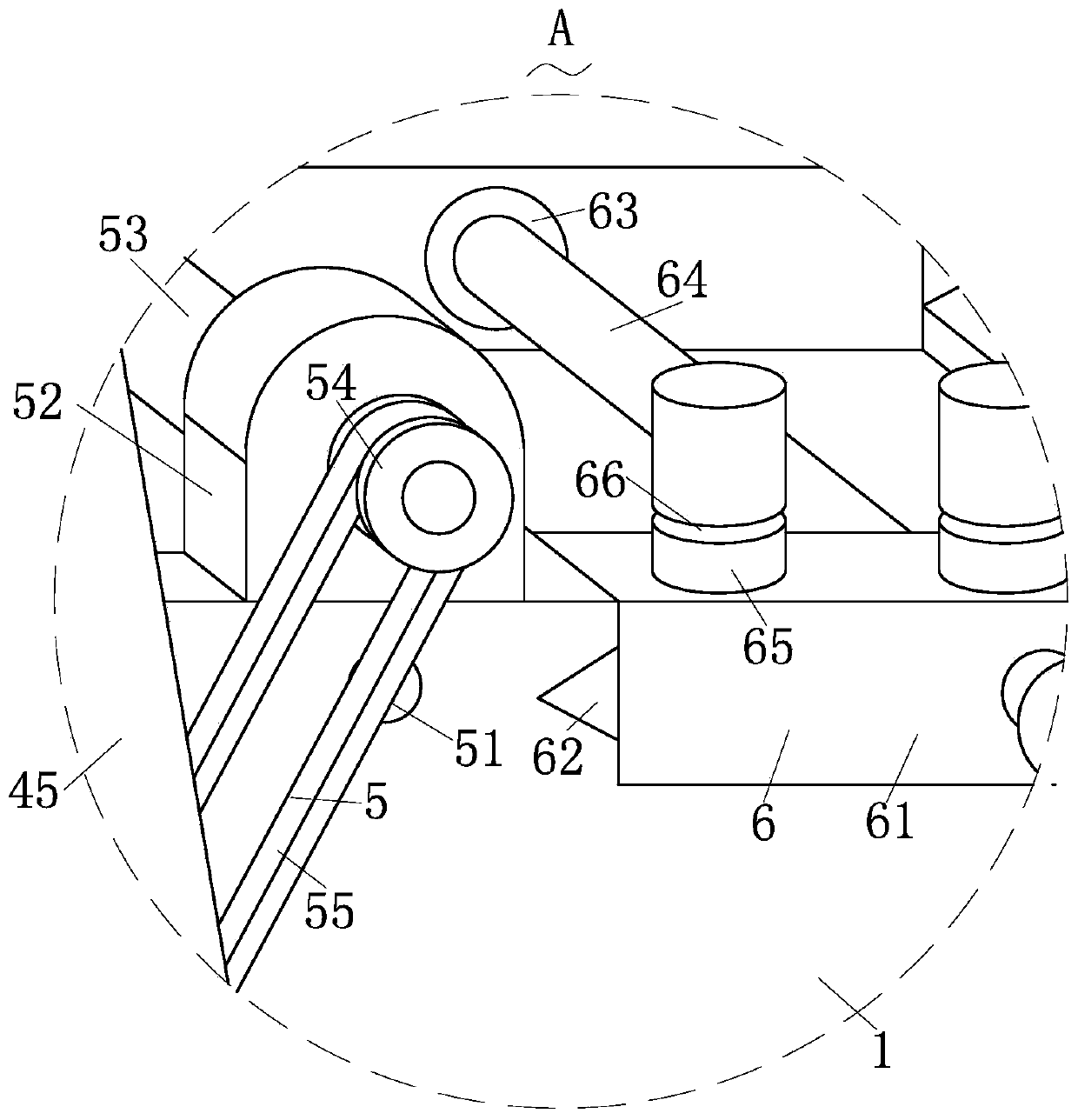

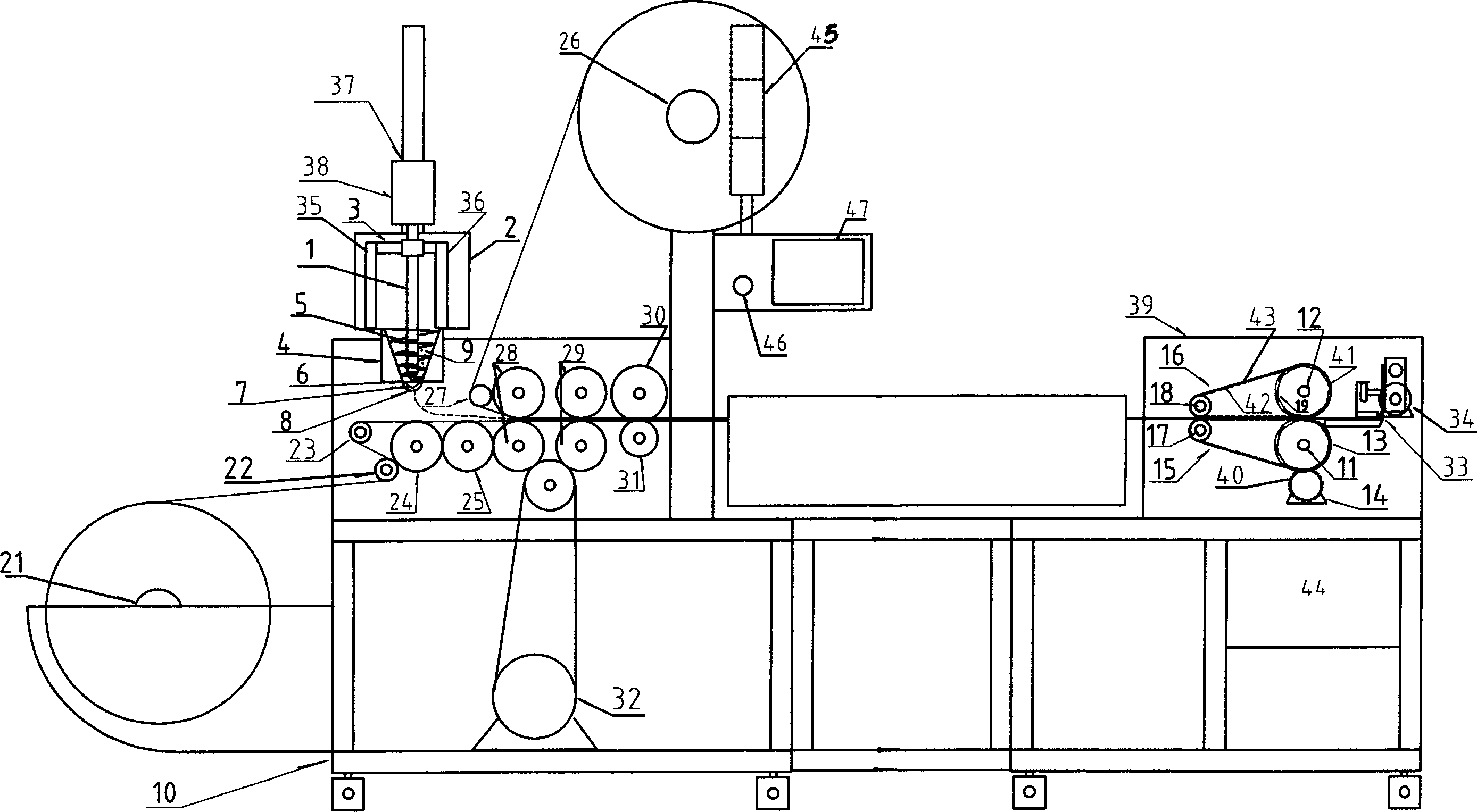

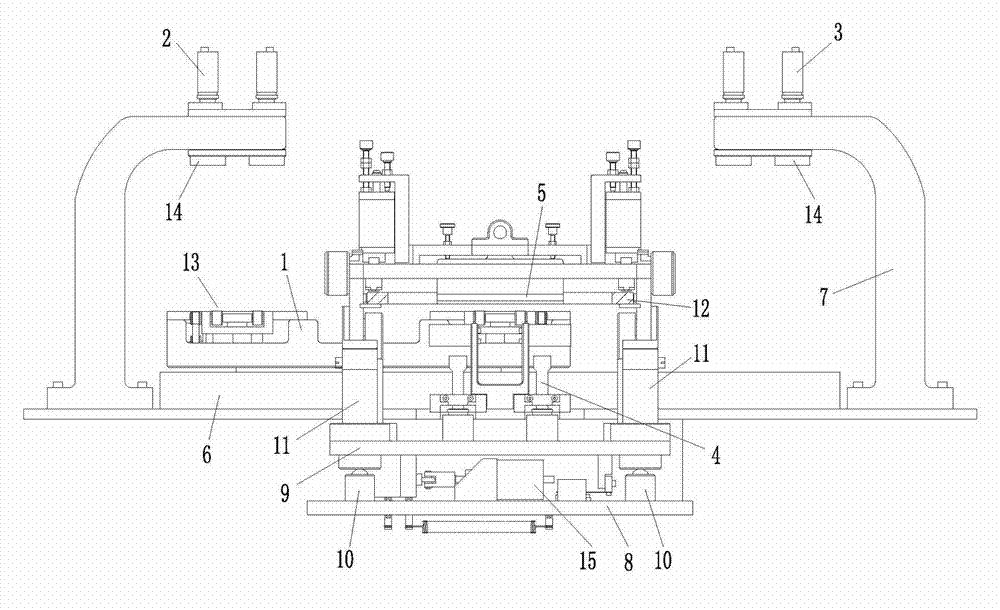

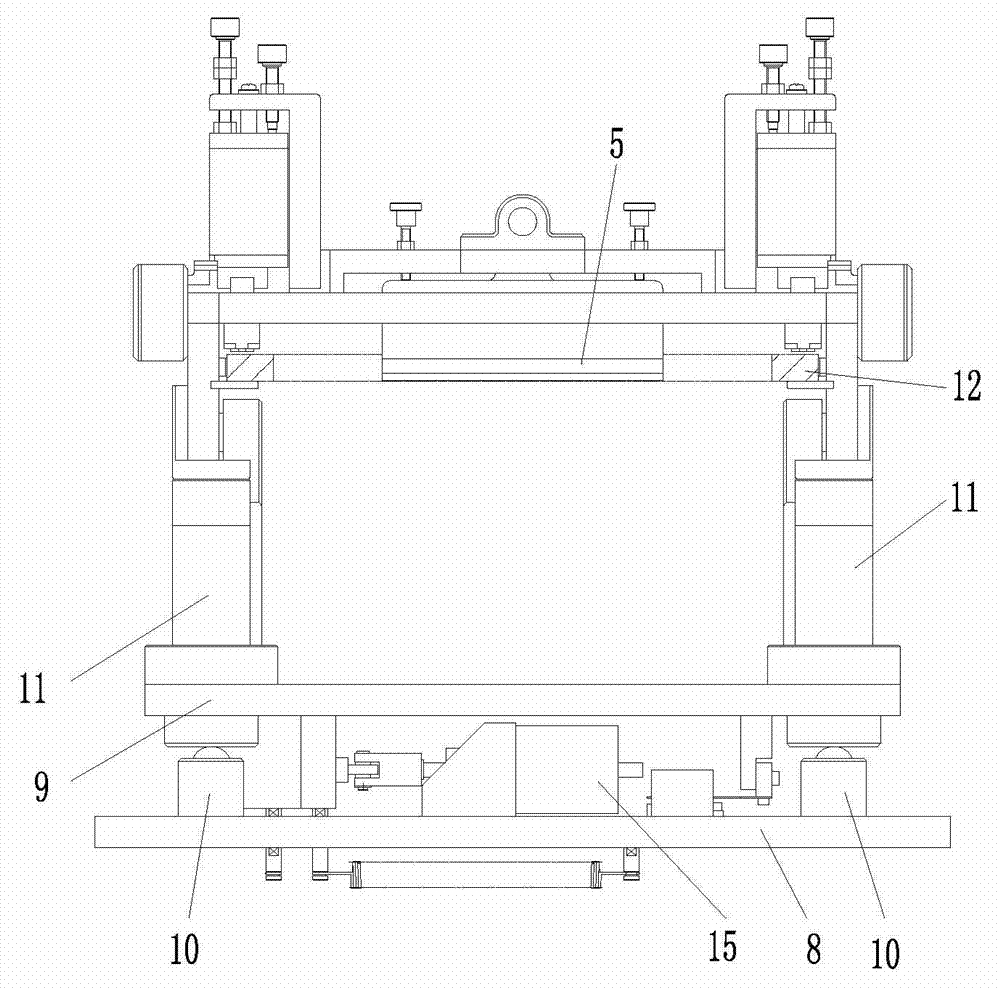

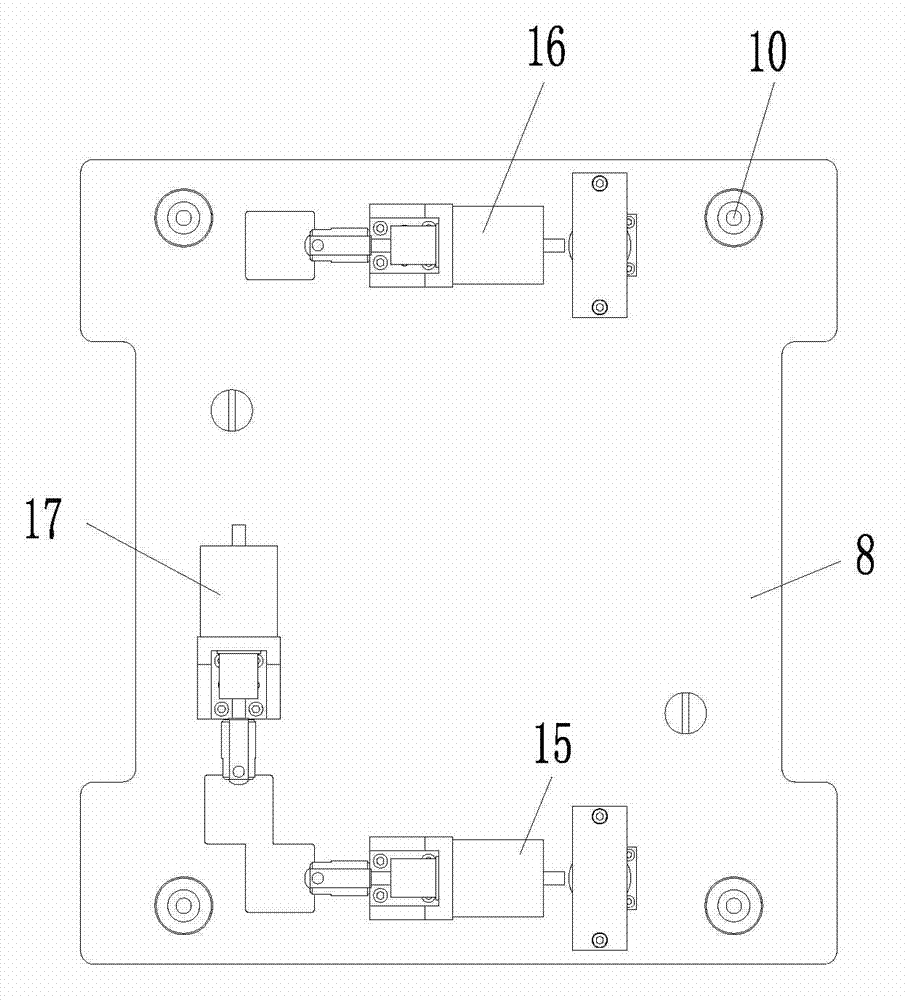

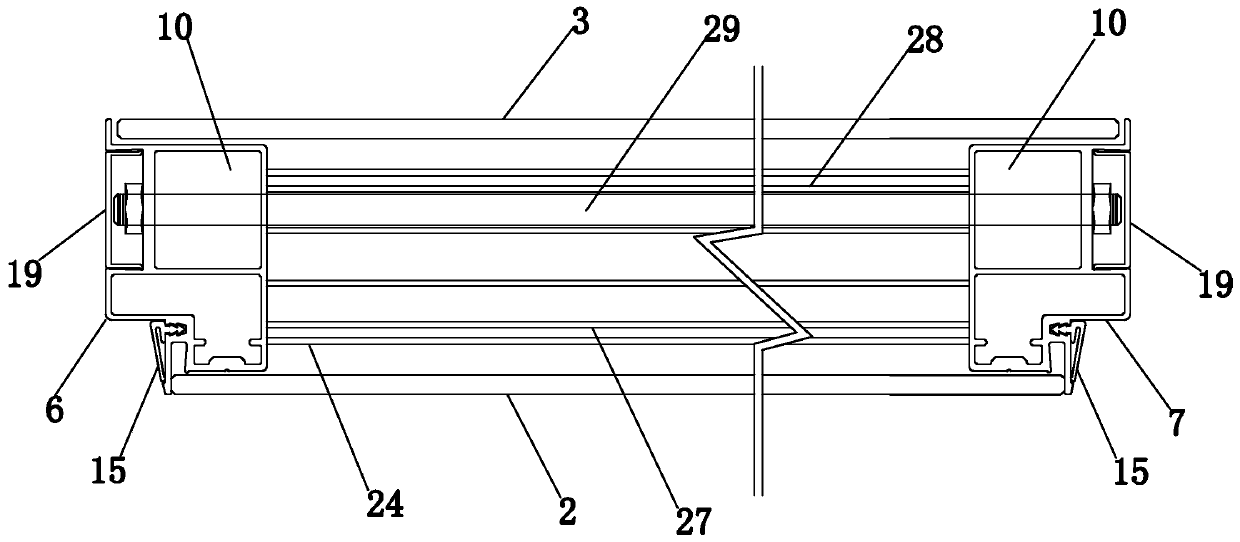

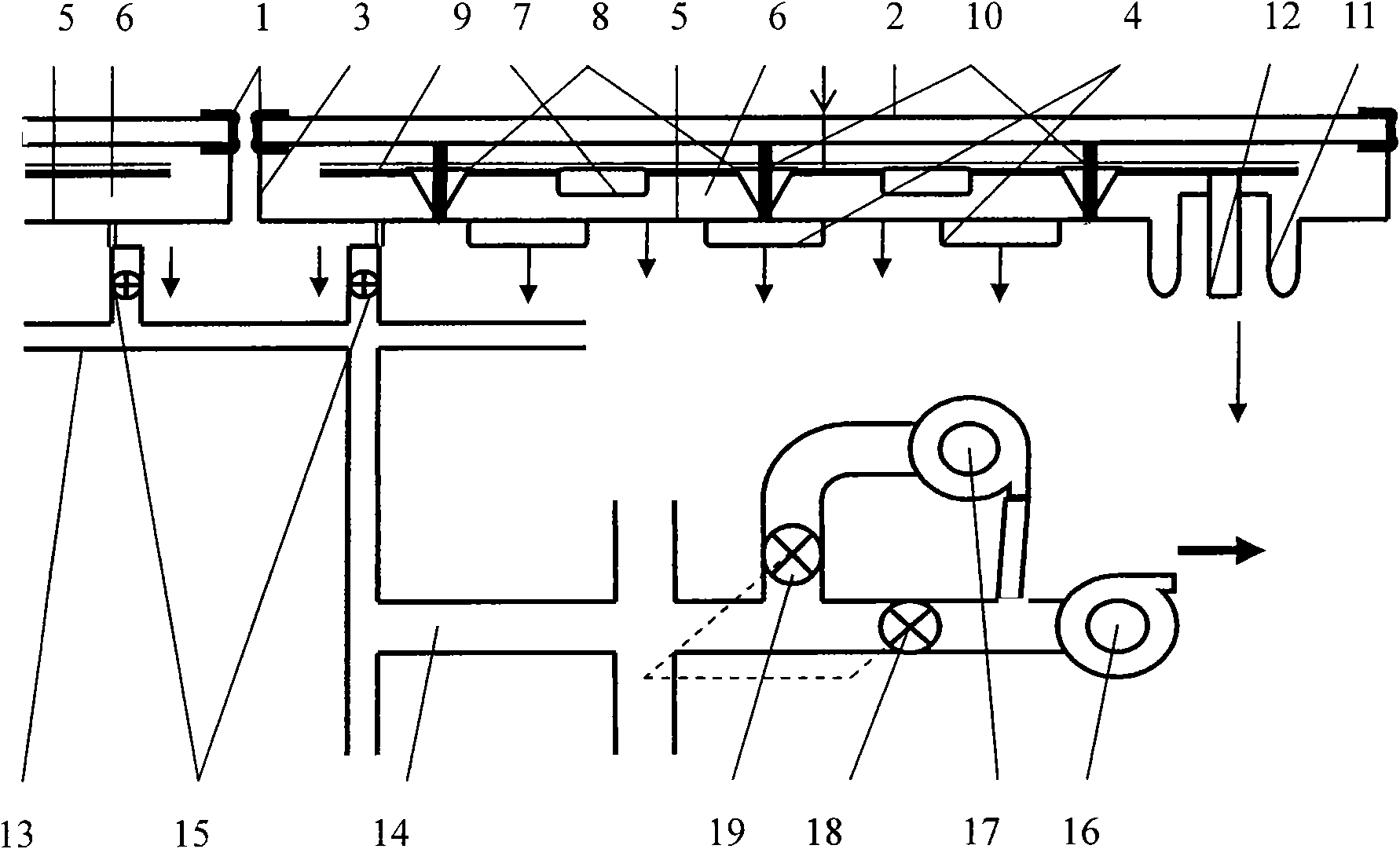

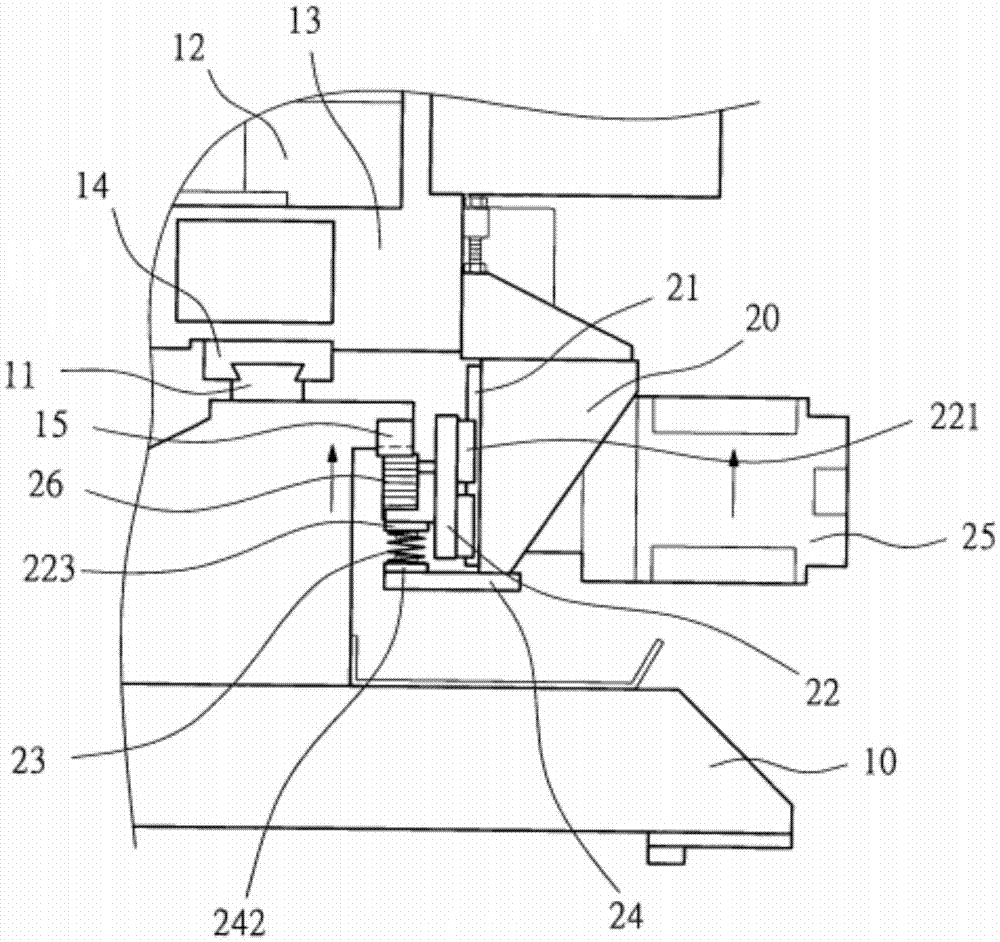

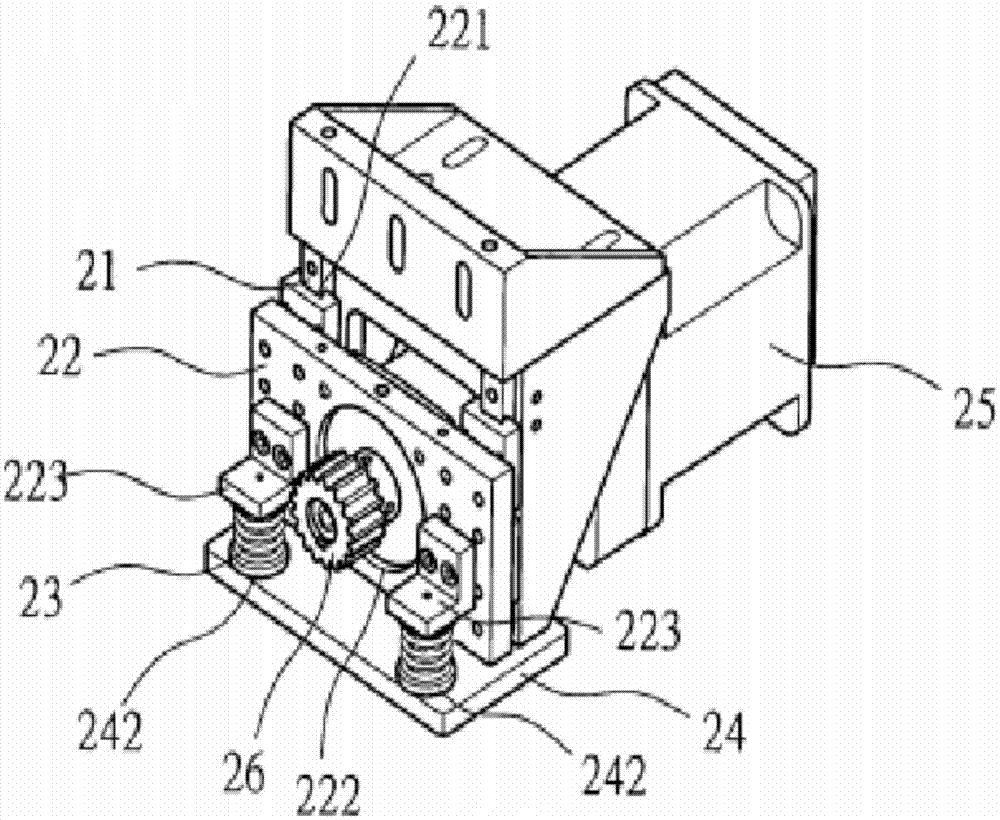

Automatic packaging mechanism for single-piece absorptive hygienic product

ActiveCN105083629AAdjust intervalImprove pass ratePaper article packagingWrappingMechanical engineeringFast speed

The invention belongs to the technical field of production equipment of absorptive hygienic products, and discloses an automatic packaging mechanism for a single-piece absorptive hygienic product. A packing system is sequentially provided with a multi-stage conveying unit, a film packaging and folding device and a heat sealing and cutting combination unit in the conveying direction. The multi-stage conveying unit sequentially comprises a front portion conveying unit, a middle conveying unit in the middle and a rear portion conveying unit which are operated independently. The middle conveying unit is provided with a synchronous conveying belt, baffles which protrude out of the surface of the conveying belt are evenly arranged on the surface of the conveying belt at intervals, and the hygienic product is conveyed on the portion, between the adjacent baffles, of the synchronous conveying belt. The automatic packaging mechanism for the single-piece absorptive hygienic product can be applied to single-piece packaging of the larger and thicker hygienic product such as sweat pants, has the beneficial effects of being high in packaging yield, low in size deviation, high in production speed and the like, and can adapt to high-speed development requirements of the hygienic products.

Owner:ZUIKO (SHANGHAI) CORP

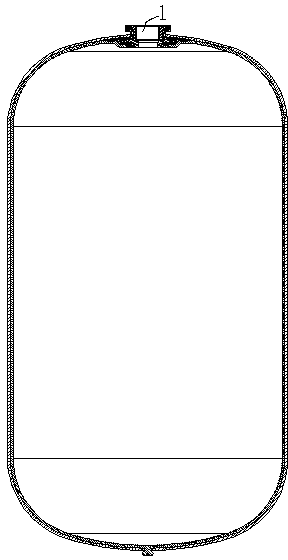

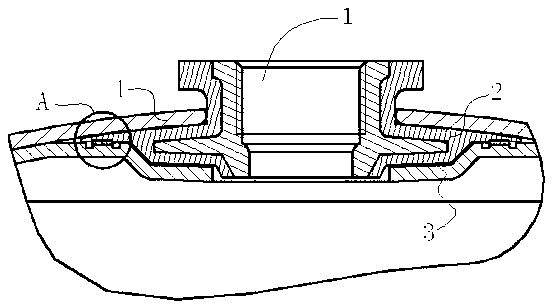

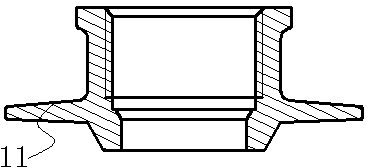

Plastic liner wound cylinder and manufacturing process

ActiveCN102840440AFew accessoriesNot easy to leakVessel mounting detailsPressure vesselsBlow moldingBottle

The invention relates to a plastic liner wound cylinder for liquefied petroleum gas, in particular to a plastic liner wound cylinder and a manufacturing process. The plastic liner wound cylinder comprises a metal bottle opening. An injection molding piece is arranged outside the metal bottle opening. The metal bottle opening and the injection molding piece are identical in vertical height. A circular bump is arranged outside the lower of the metal bottle opening. The upper surface of the circular bump is a downwards-inclined surface. The injection moulding piece is circular. The shape of the inner side of the circle is matched with that of the outer side of the metal bottle opening. The position of the injection molding piece, relative to the circular bump, is provided with an outer edge body. The upper surface of the outer edge body is a downwards-inclined surface. The thickness of the outer edge body is radially and gradually reduced to 3-20mm. An embedded ring is arranged on the lower surface of the outer edge body. Seal rings are arranged on both sides of the embedded ring. The outer side surface below the outer edge body of the injection molding piece is a blow molding plastic liner. A winding layer is arranged above the outer edge body. The winding layer is distributed at the outer side of the plastic liner to fasten the plastic liner and the metal bottle opening.

Owner:艾赛斯(杭州)复合材料有限公司

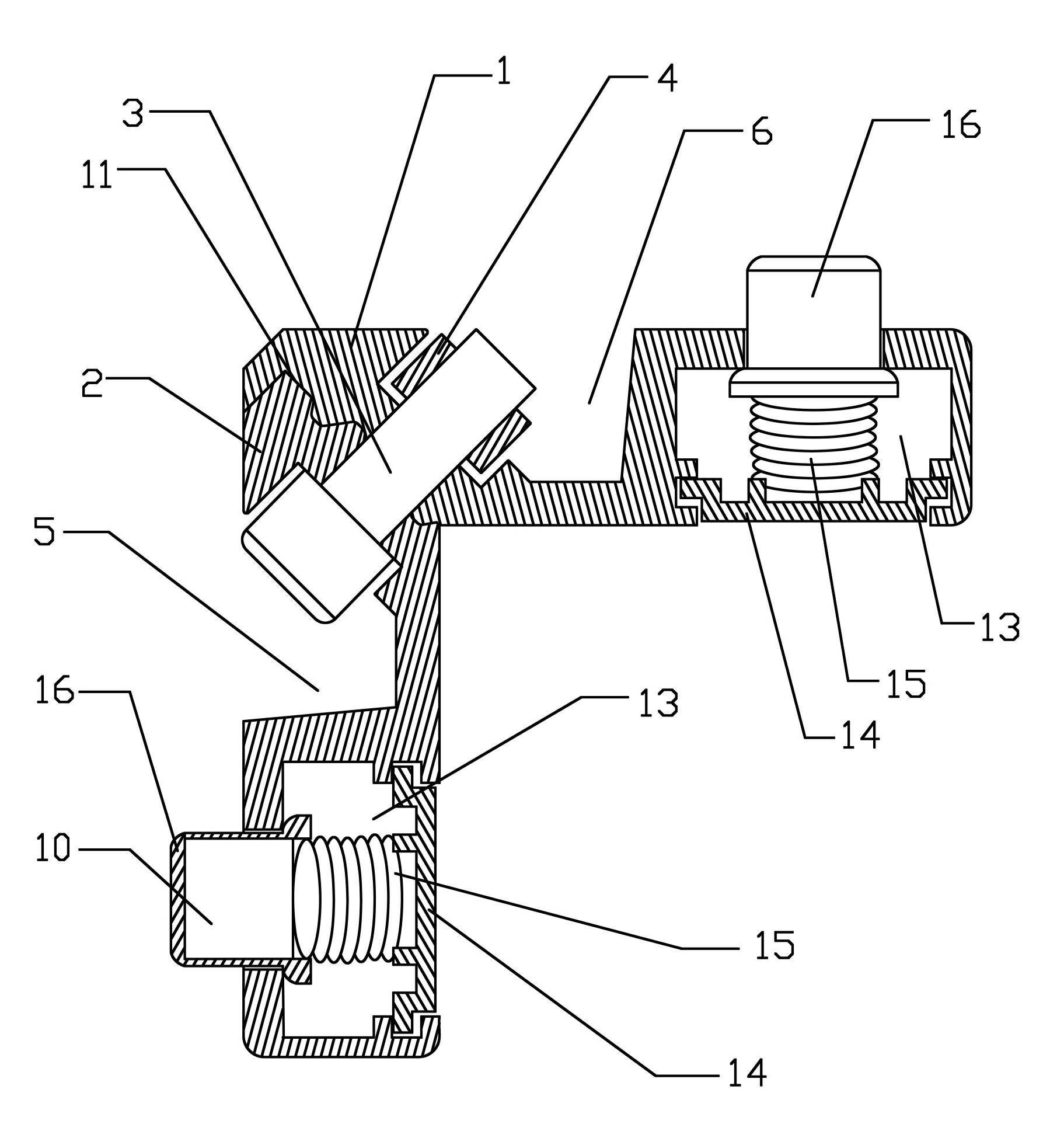

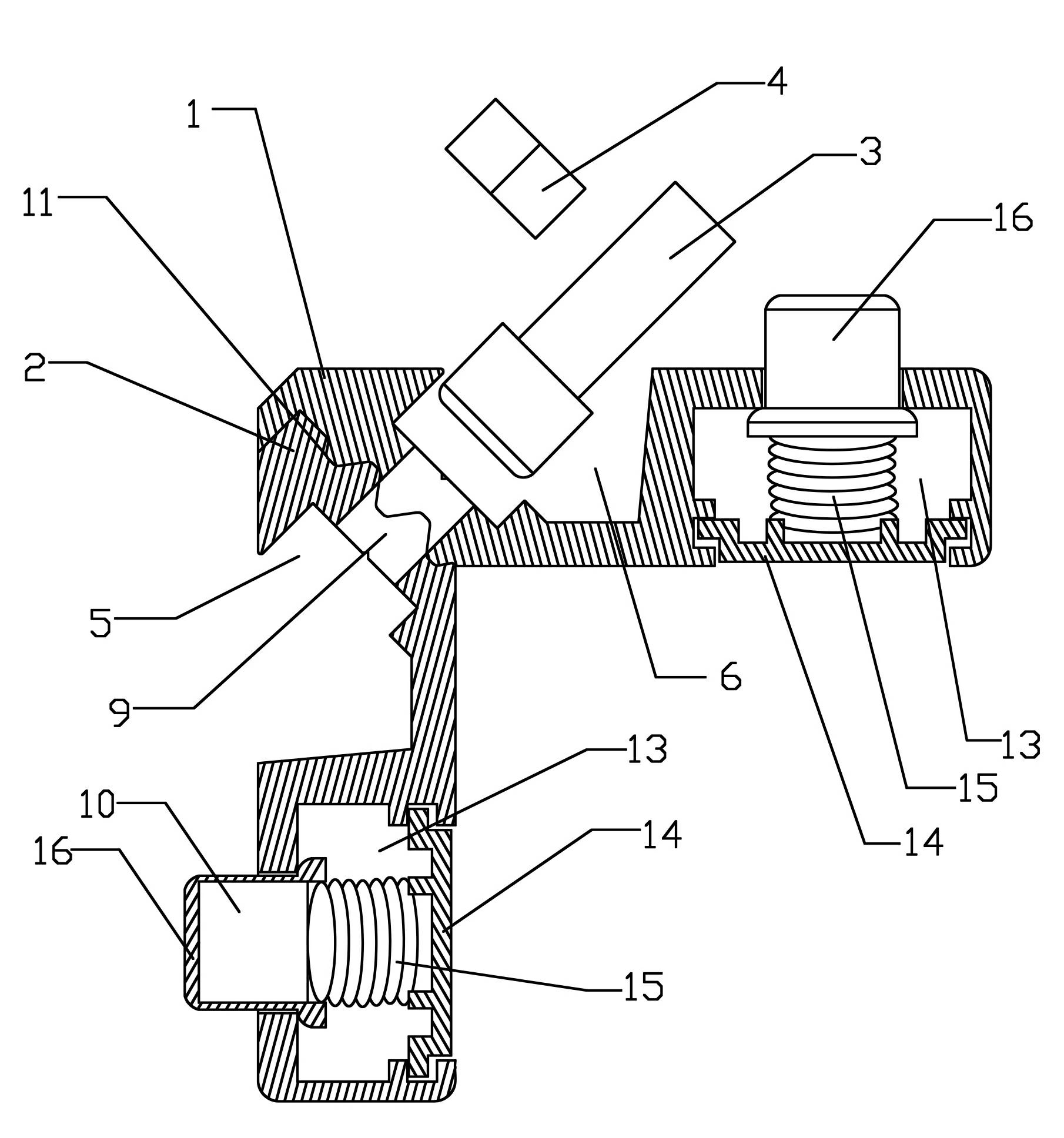

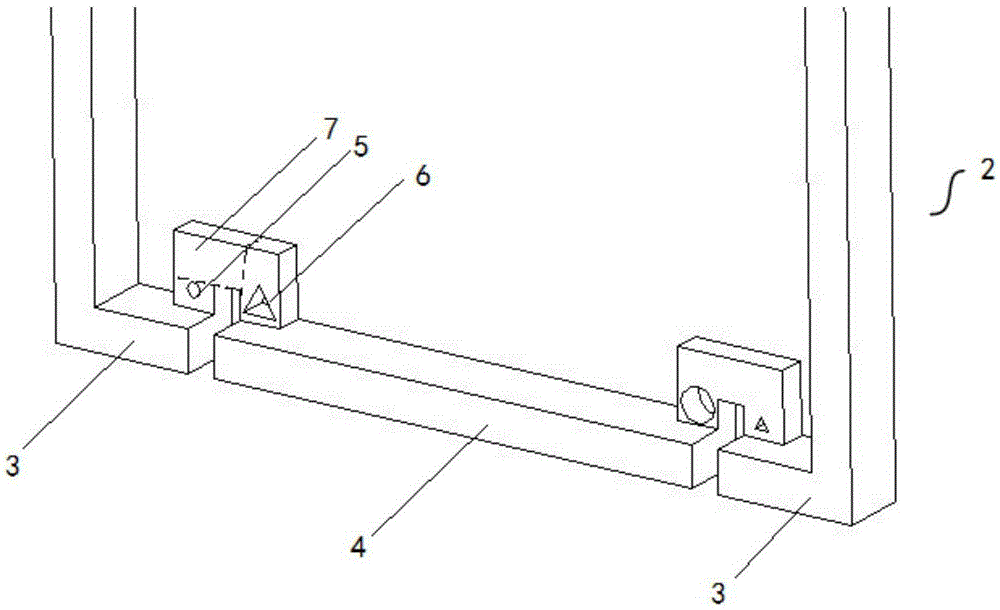

Corner connector for movable connection

InactiveCN102182386AAdjustable tightnessAvoid size errorsCorner/edge jointsManufacturing cost reductionEngineering

Owner:广东顺德兴益康金属科技股份有限公司

Cutting machine with guiding function for gauze element production and processing

ActiveCN110861132AAvoid creasesAvoid offsetMetal working apparatusWebs handlingMechanical engineeringIndustrial engineering

The invention relates to the field of gauze element production and processing devices, in particular to a cutting machine with a guiding function for gauze element production and processing. The cutting machine comprises a base, supporting legs, a discharge sleeve, a cutting structure, a feeding structure, a guiding structure and a discharging structure; the cutting structure can synchronously drive the feeding structure to work while the cutting structure is working, through the setting of the feeding structure, the feeding operation can be automatically conducted on a gauze element, the workintensity of manual feeding is reduced, the cut gauze element can further be leveled and limited, namely the wrinkle of the gauze element during cutting is avoided, the deviation of the gauze elementcaused by difficult fixation of the gauze element during cutting is also avoided, the guiding structure is arrange at the top end, close to one end of the feeding structure, of the base, the gauze element entering the feeding structure can be guided, the gauze element of the feeding structure is prevented from wrinkling and deviating, the guiding structure can be adjusted, and thus gauze elementswith different width can further be guided.

Owner:LIXIN FUYA GAUZE CO LTD

Traditional Chinese medicine oniment shaping equipment

InactiveCN1596869AQuantitative cutting is accurateAvoid sticking to each otherPharmaceutical product form changeDrive shaftEngineering

Owner:孙永俊 +1

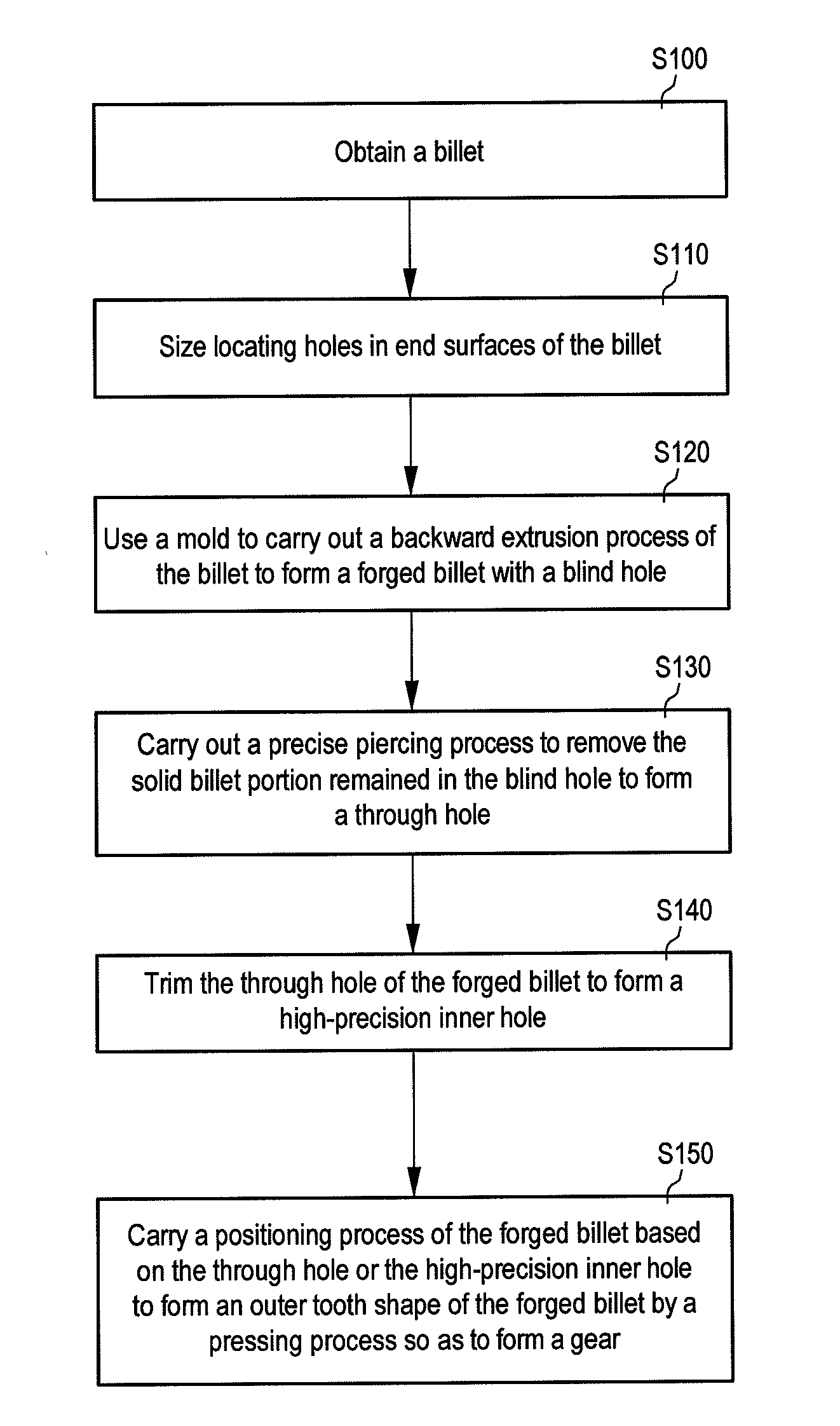

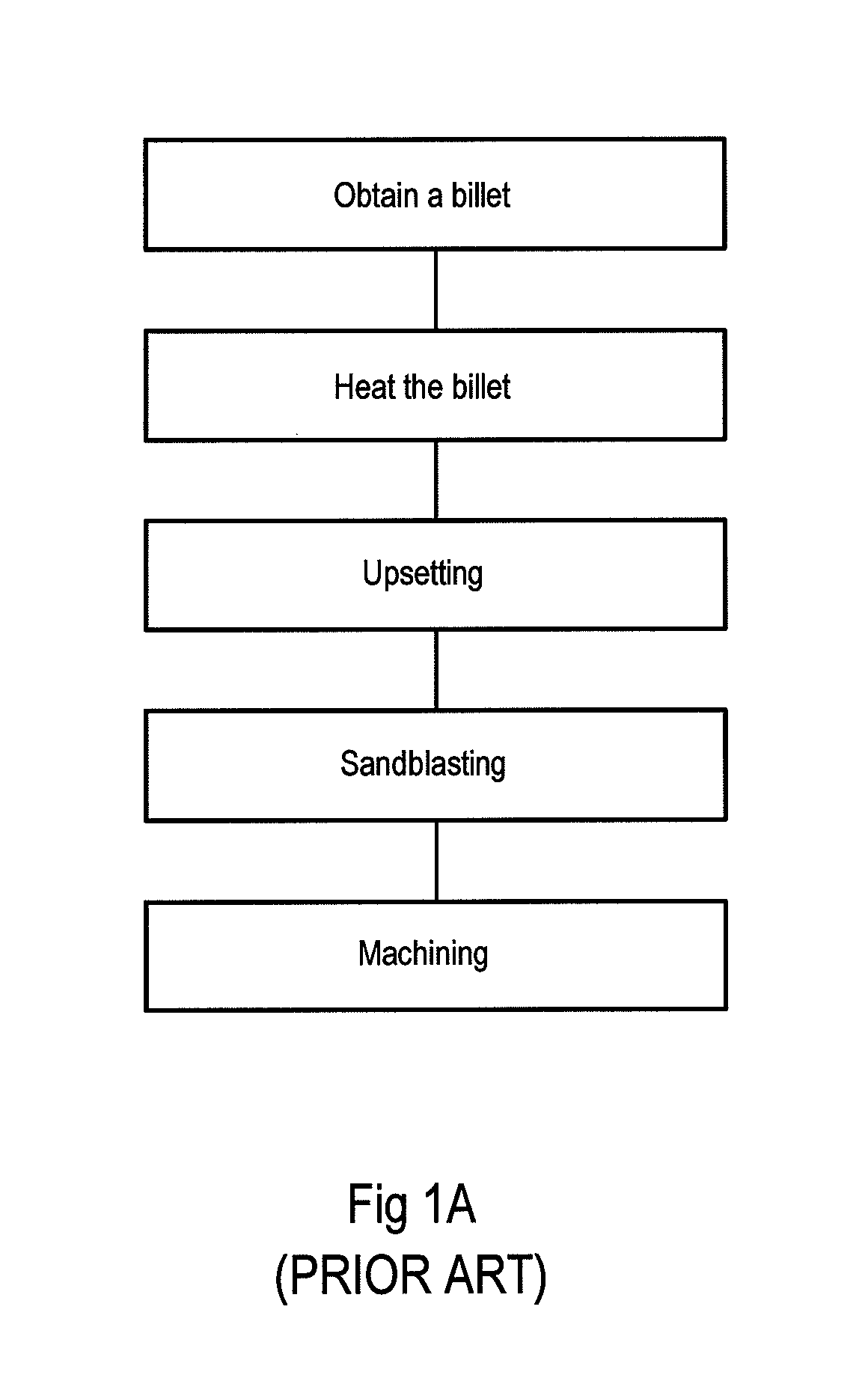

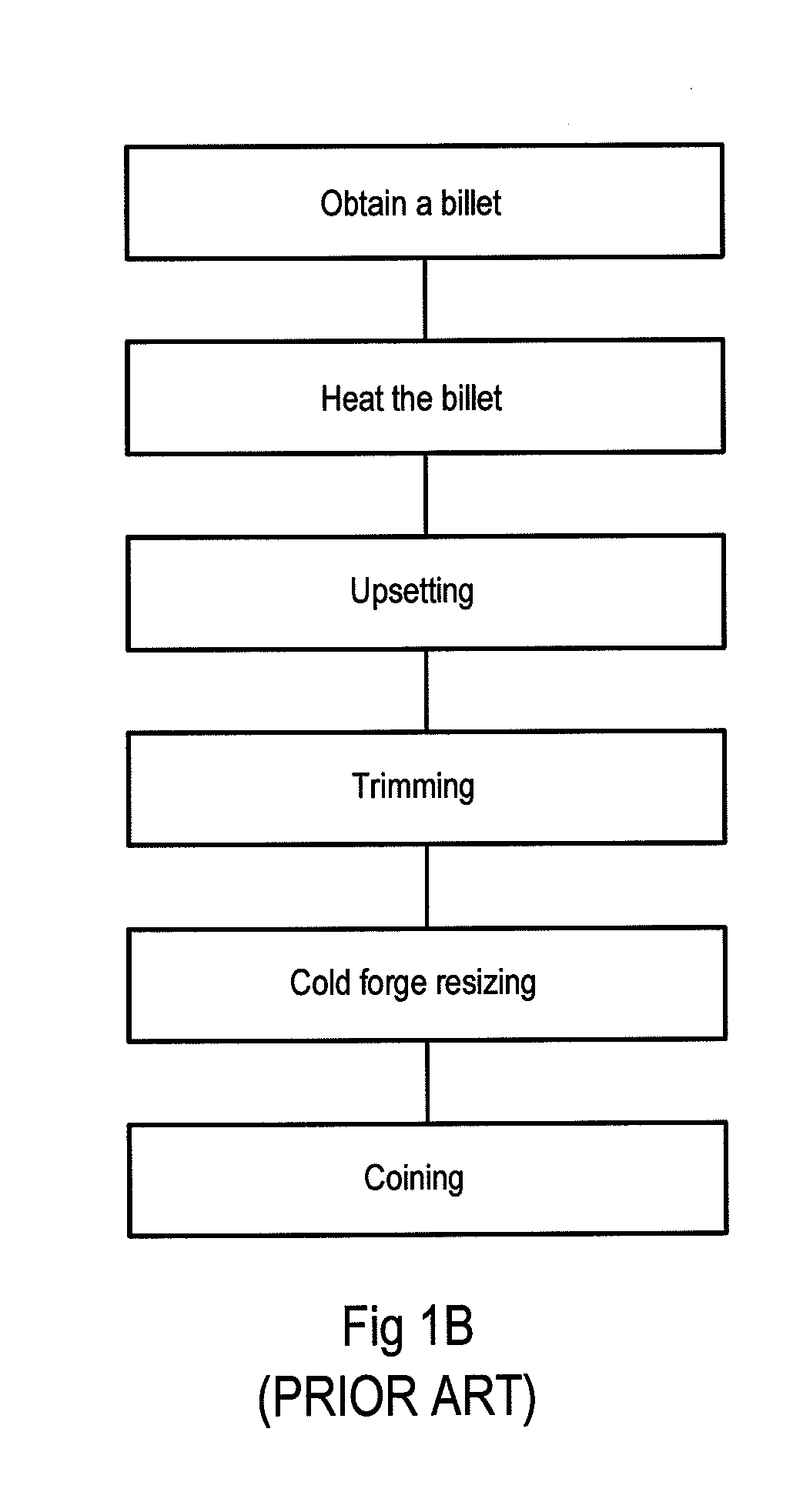

Method for forming a gear

InactiveUS20100299925A1Reduce loadExtension of timeMetal-working apparatusPortable liftingEngineeringBlind hole

A method for forming a gear, including the following steps: first obtaining a billet, then carrying out a backward extrusion process of the billet to form a forged billet with a blind hole by using a mold, and the forged billet has an appropriate axial length and an appropriate radial length. Then, a precise piercing process is carried out to remove the solid billet portion remained in the blind hole of the forged billet to form a through hole. Then, trimming of the through hole is carried out to form a high-precision inner hole, and positioning is carried out based on the high-precision inner hole to implement a pressing process of an outer tooth shape of the forged billet to form the gear.

Owner:METAL INDS RES & DEV CENT

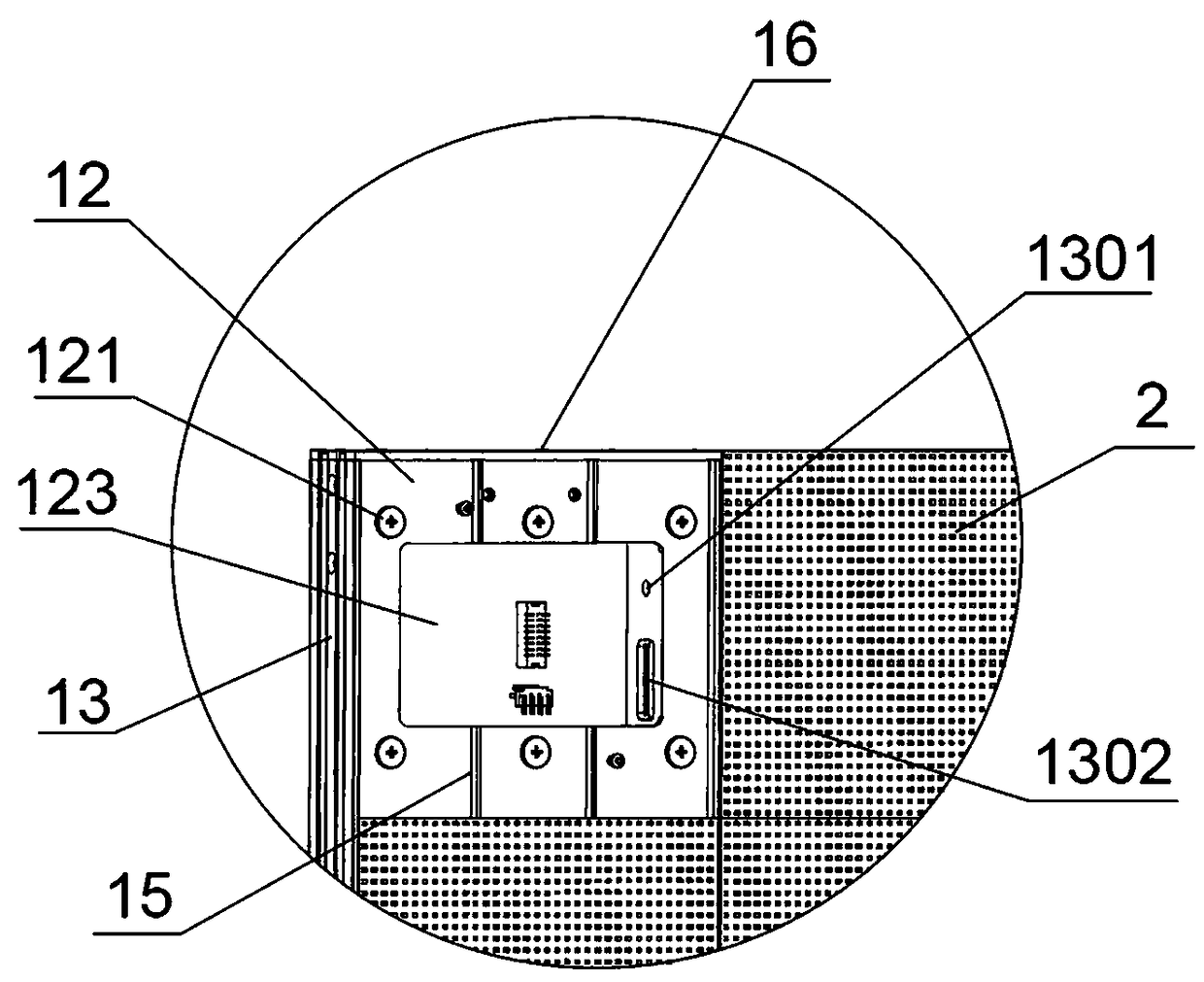

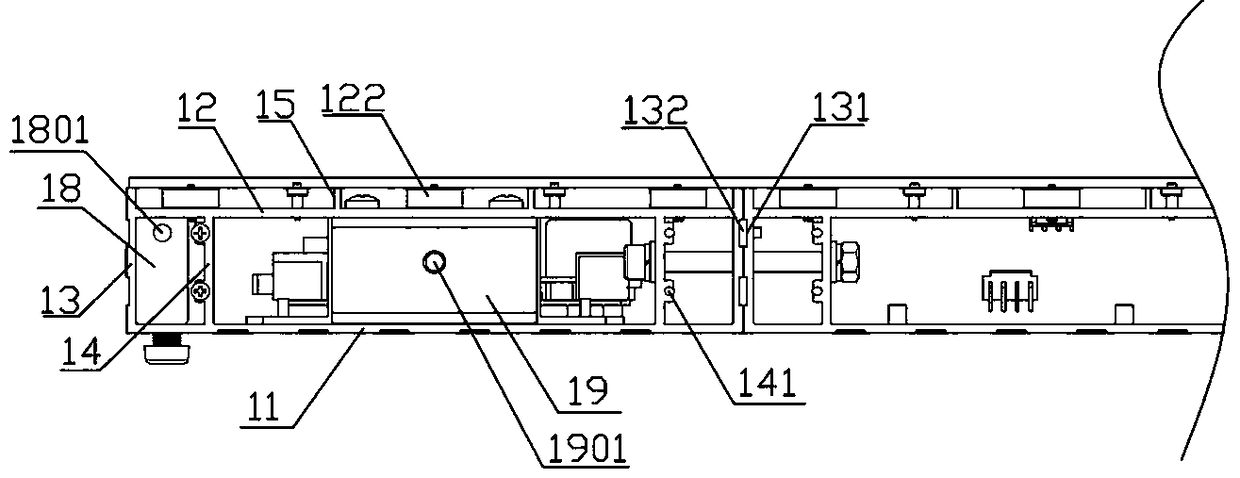

LED display cloud media capable of realizing seamless splicing

PendingCN108766271AQuality improvementStable structureIdentification meansLED displayComputer module

The invention provides an LED display cloud media capable of realizing seamless splicing, and belongs to the technical field of LED display. The LED display cloud media comprises a plurality of display modules and a reference plate, wherein the reference plate is connected with the plurality of display modules; at least one positioning pin is arranged on the display modules; a plurality of positioning holes or a plurality of groups of positioning holes at the same intervals are formed in the reference plate; each display module comprises a frame body, a plurality of LED display units arrangedon the frame body, a adapter plate and a power supply; corresponding position limiting grooves are formed in the connecting surface of the adjacent frame bodies; a position limiting block is arrangedbetween the two corresponding position limiting grooves; a plurality of magnet blocks are arranged on one side surface of each frame body; a plurality of suction grooves matched with magnet blocks areformed in the LED display units. The dismounting, the mounting and the maintenance are convenient and efficient; the quality of the whole display screen is high.

Owner:浙江威谷光电科技有限公司

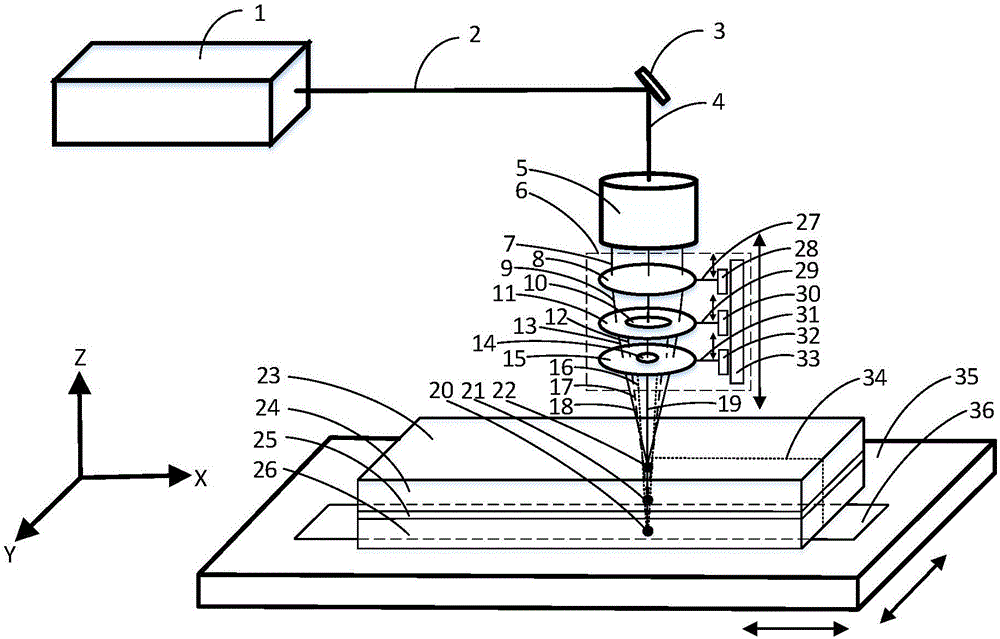

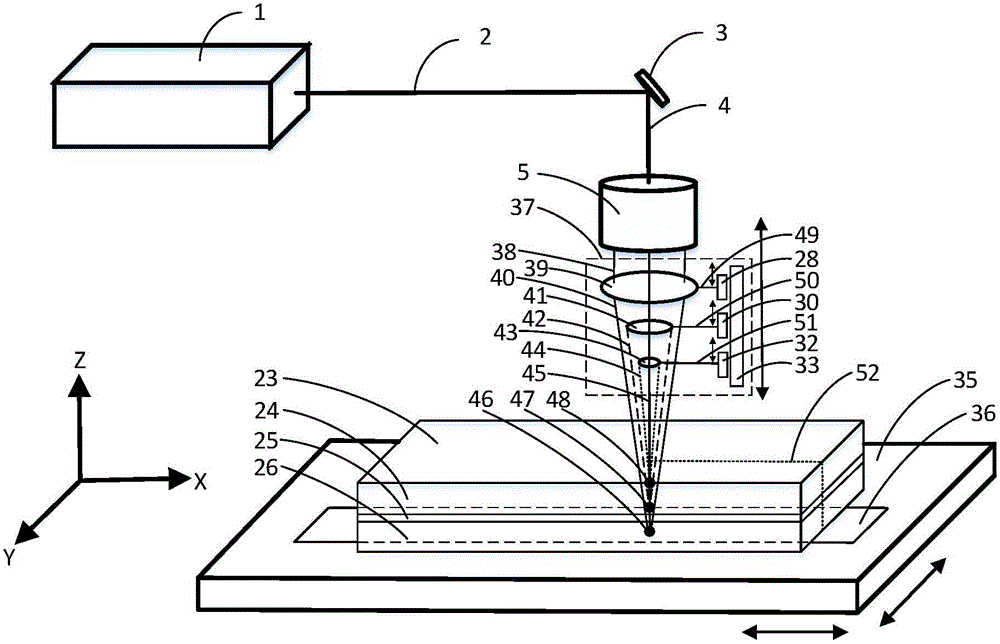

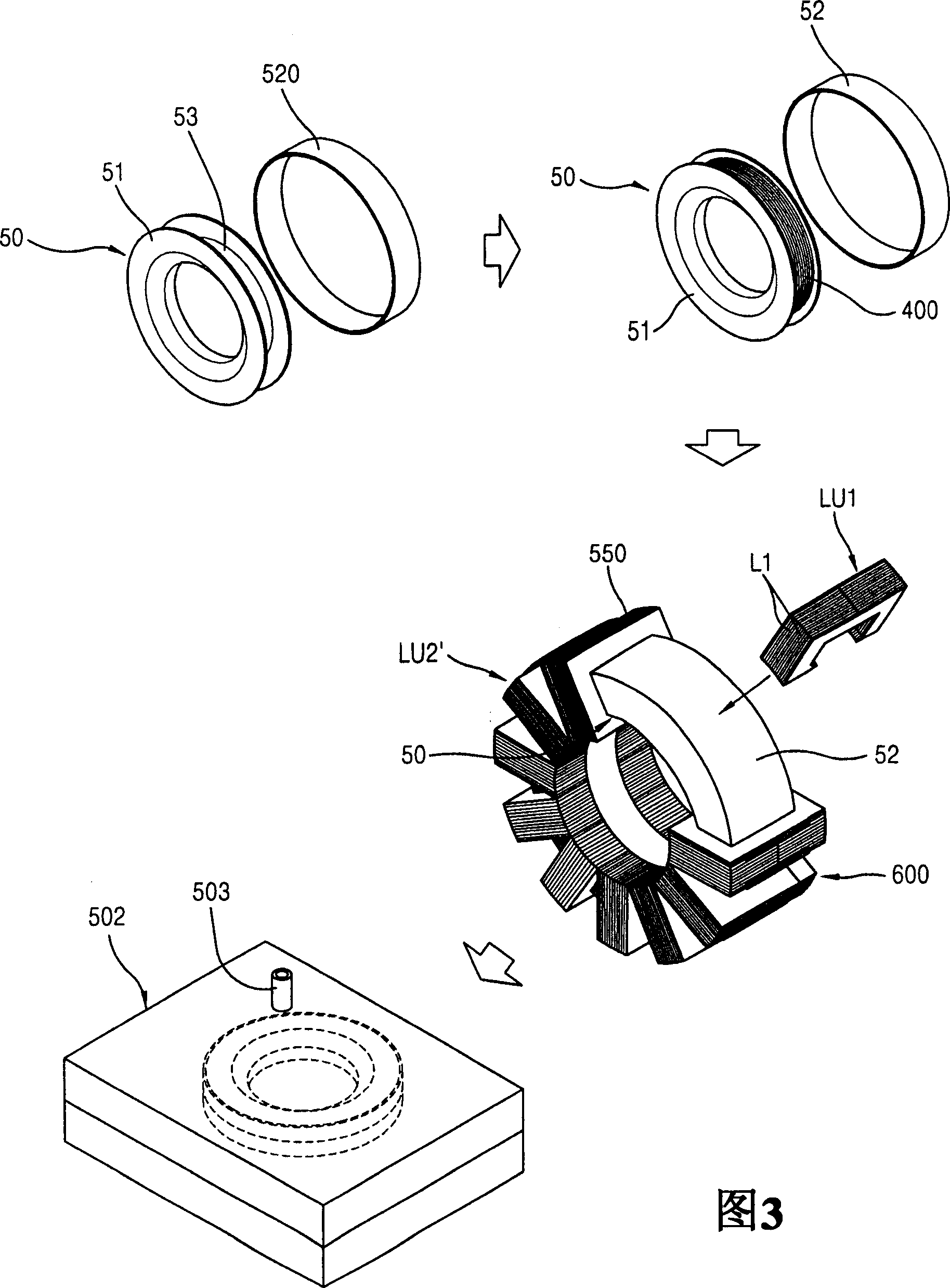

Multi-focus laser laminated glass separating method and device

ActiveCN106271111ASimple processIncrease productivityWelding/soldering/cutting articlesLaser beam welding apparatusOptoelectronicsBeam collimation

The invention discloses a multi-focus laser laminated glass separating method and device. According to the method, a laser beam with transmissivity on laminated glass is adopted; by means of a multi-focus lens set, the laser beamproduces a plurality of focuses to enter the laminated glass, and each layer of glass and each glueing material layer of the laminated glass are provided with at least one laser focus; under the action of the laser focuses, the glass layers and the glueing material layers are separated, the glass layers and the glueing material layers of the laminated glass are cut and separated at the same time through multiple laser focuses moving along the separating direction, and the whole laminated glass is cut and separated at the same time. The device comprises a two-dimensional working platform, a laser, a reflector, an expanded beam collimation lens and the multi-focus lens set, wherein the laser, the reflector, the expanded beam collimation lens and the multi-focus lens set are sequentially located on the same light path. By means of the multi-focus laser laminated glass separating method and device, follow-up manual piece breaking is not needed, and the cutting speed is greatly improved; the multi-focus laser laminated glass separating method and device have the advantages of being simple in separation procedures, high in separation speed, good in separation quality, capable of achieving special-shaped separating and mechanization and the like and are especially suitable for cutting and separating the laminated glass for buildings and automobiles.

Owner:HUAZHONG UNIV OF SCI & TECH

Pattern contraposition method based on double printing stations and device thereof

The invention discloses a pattern contraposition method based on double printing stations and a device thereof. The pattern contraposition method comprises the following steps of: printing three reference points on a printing stock printed for the first time, and preparing three reference points on a silk screen in the overprinting process; in the follow-up overprinting process, collecting the coordinates of the reference points on the printing stock on a left part delivery station or a right part delivery station through a camera, and simultaneously collecting the coordinates of the reference points on the silk screen on a middle printing station; and comparing the deviation of the two coordinates by using a controller, and further controlling U, V and W motors to drive the silk screen to carry out movement adjustment. The pattern contraposition method has the advantages that the contraposition printing is carried out on the printing stock by adopting a pattern contraposition manner, the errors of the size and shape existing in the printing stock are overcome, the error accumulation is avoided, the contraposition accuracy of grid lines on the printing stock is effectively increased, and the high quality of silk screen printing is ensured. According to the pattern contraposition method, the charging is carried out at two sides, sheet delivery and printing are simultaneously finished, and the whole printing cycle period is substantially shortened, thereby increasing the productivity of equipment.

Owner:S C NEW ENERGY TECH CORP

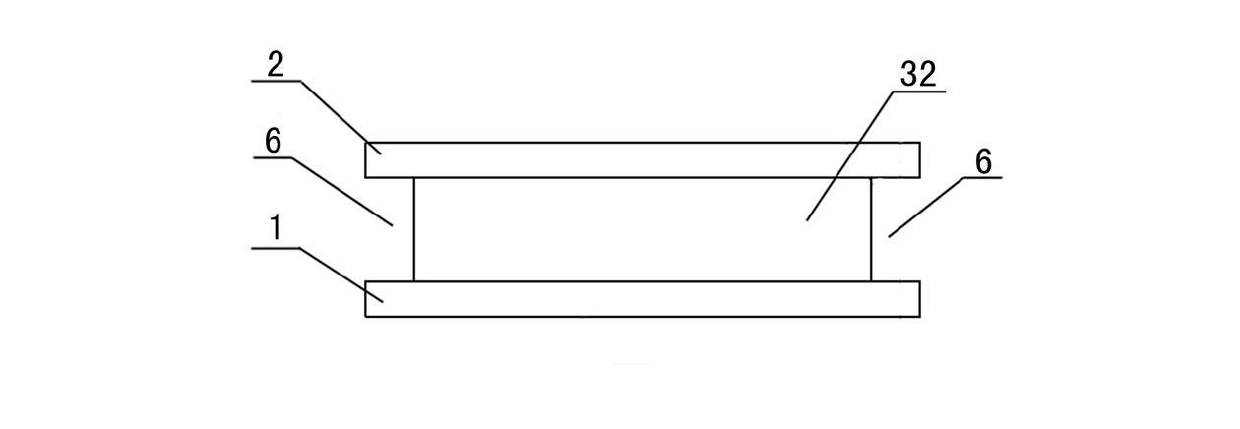

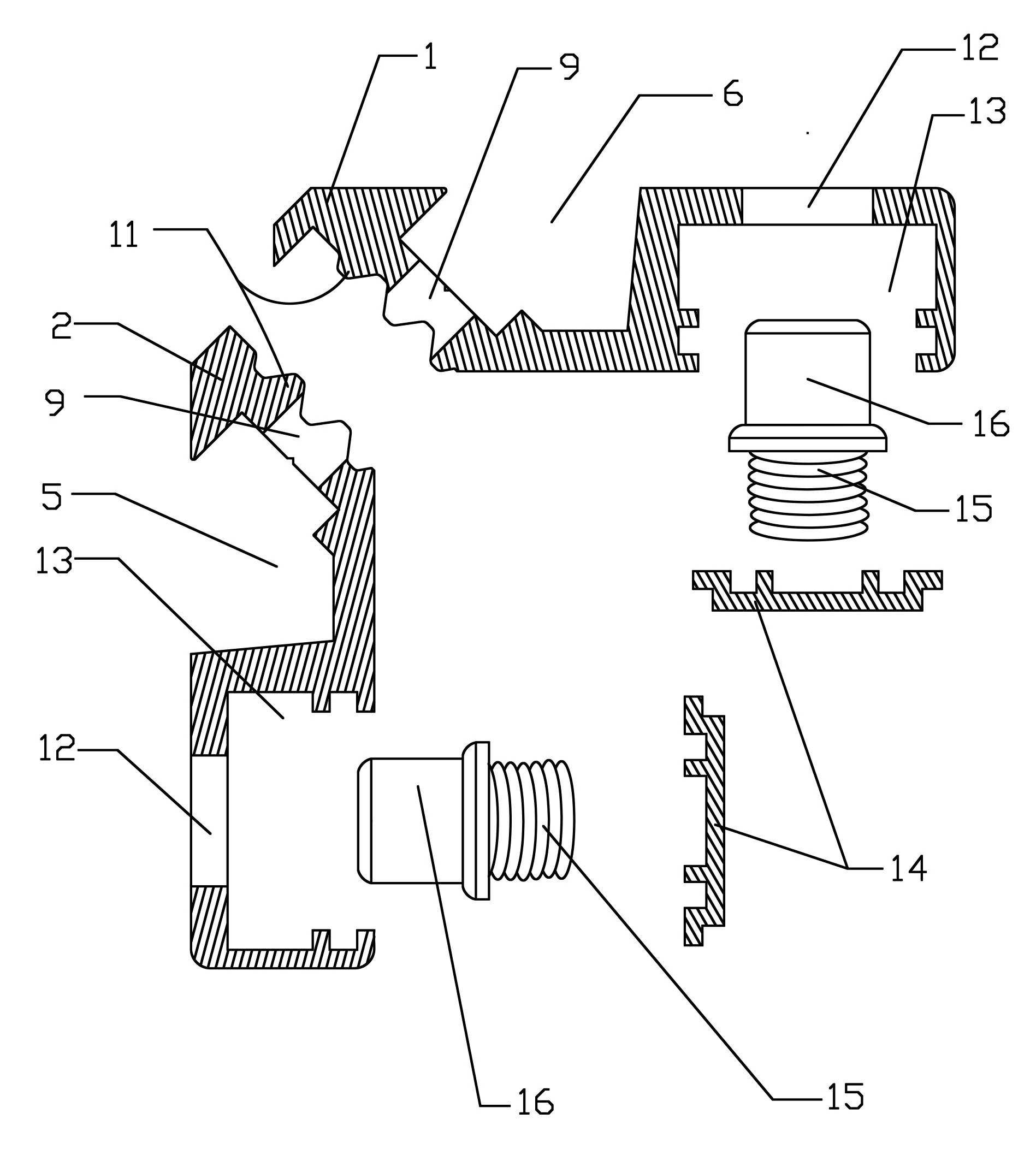

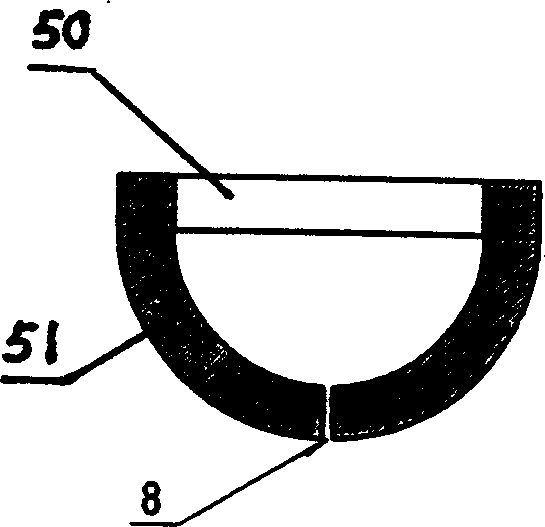

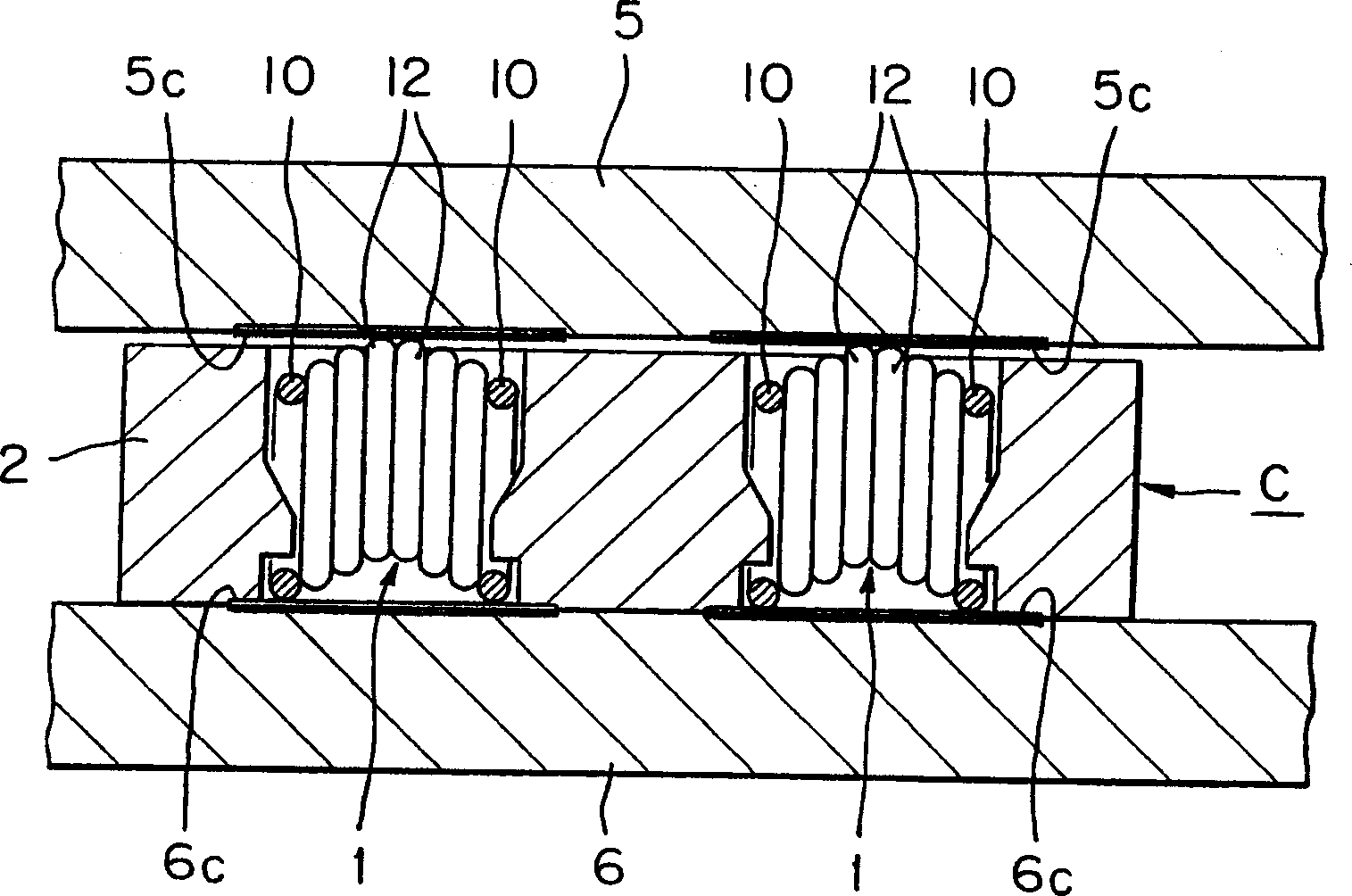

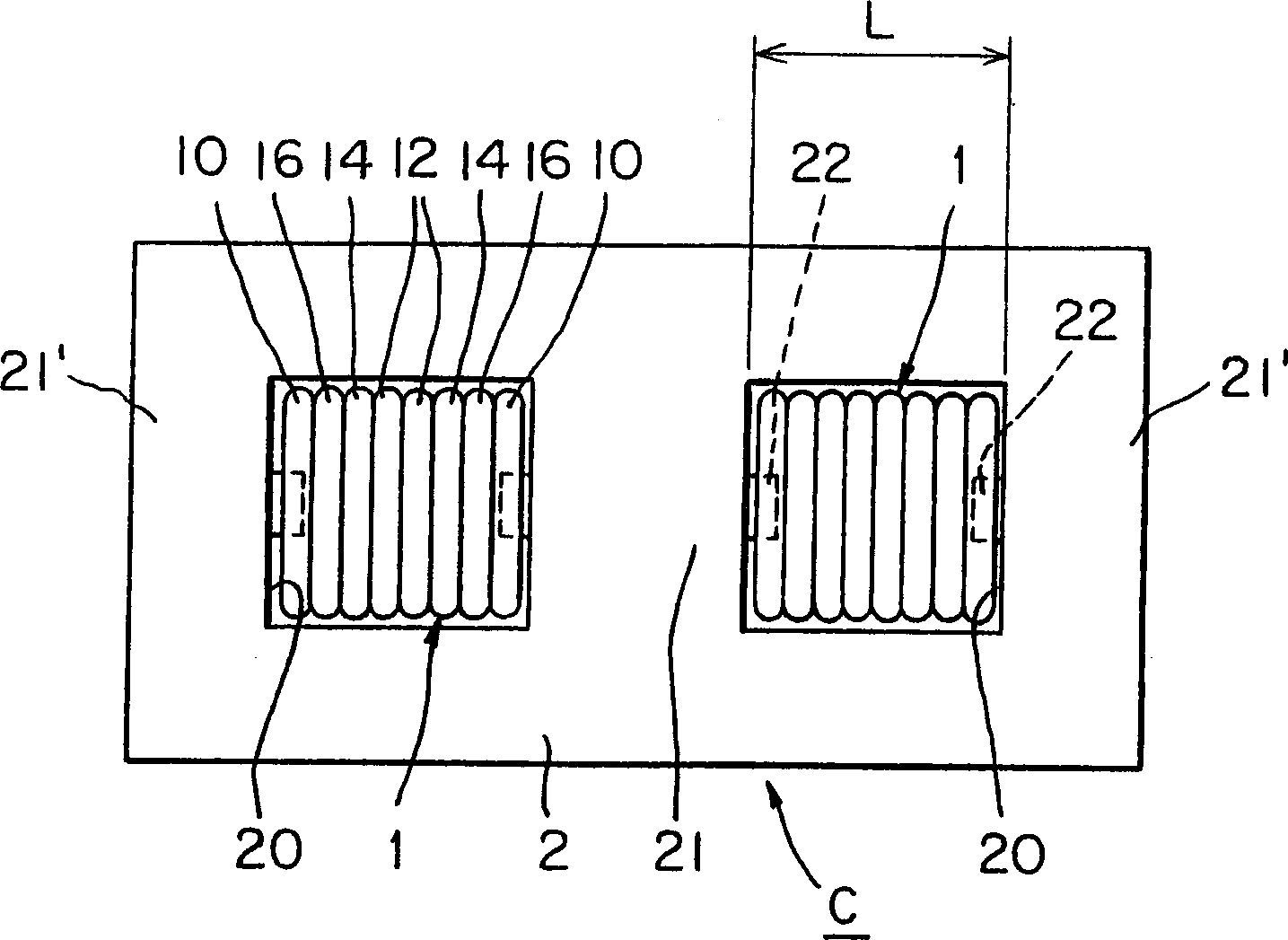

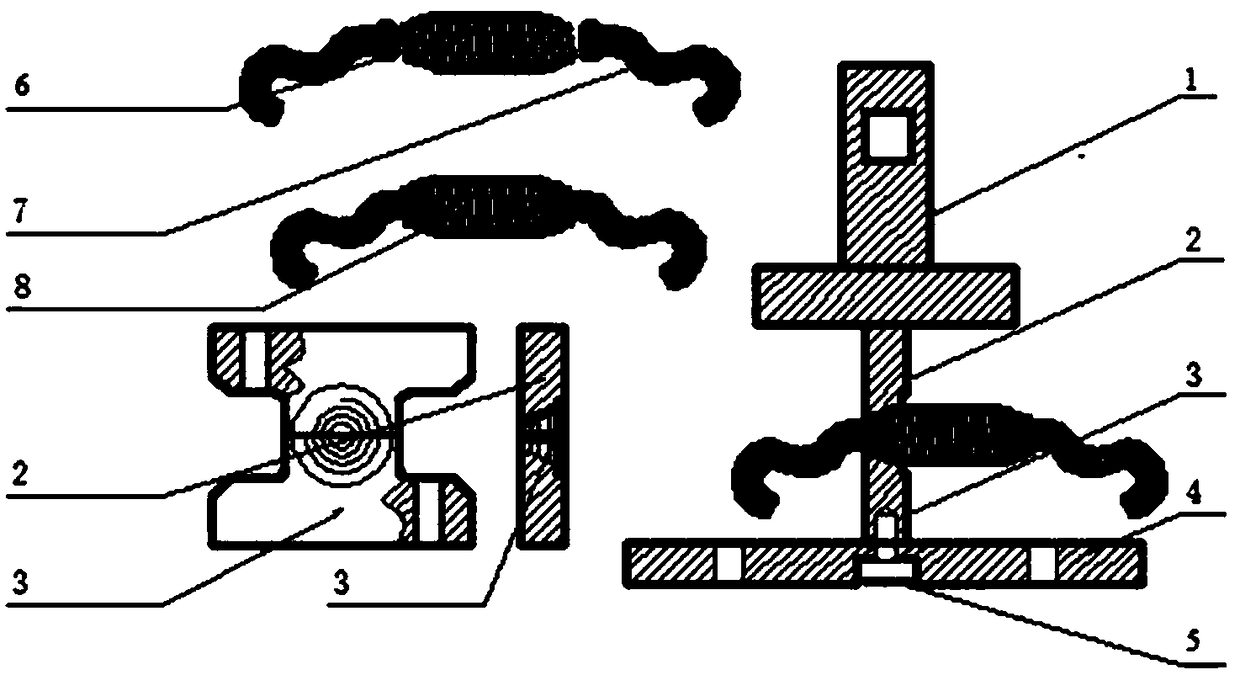

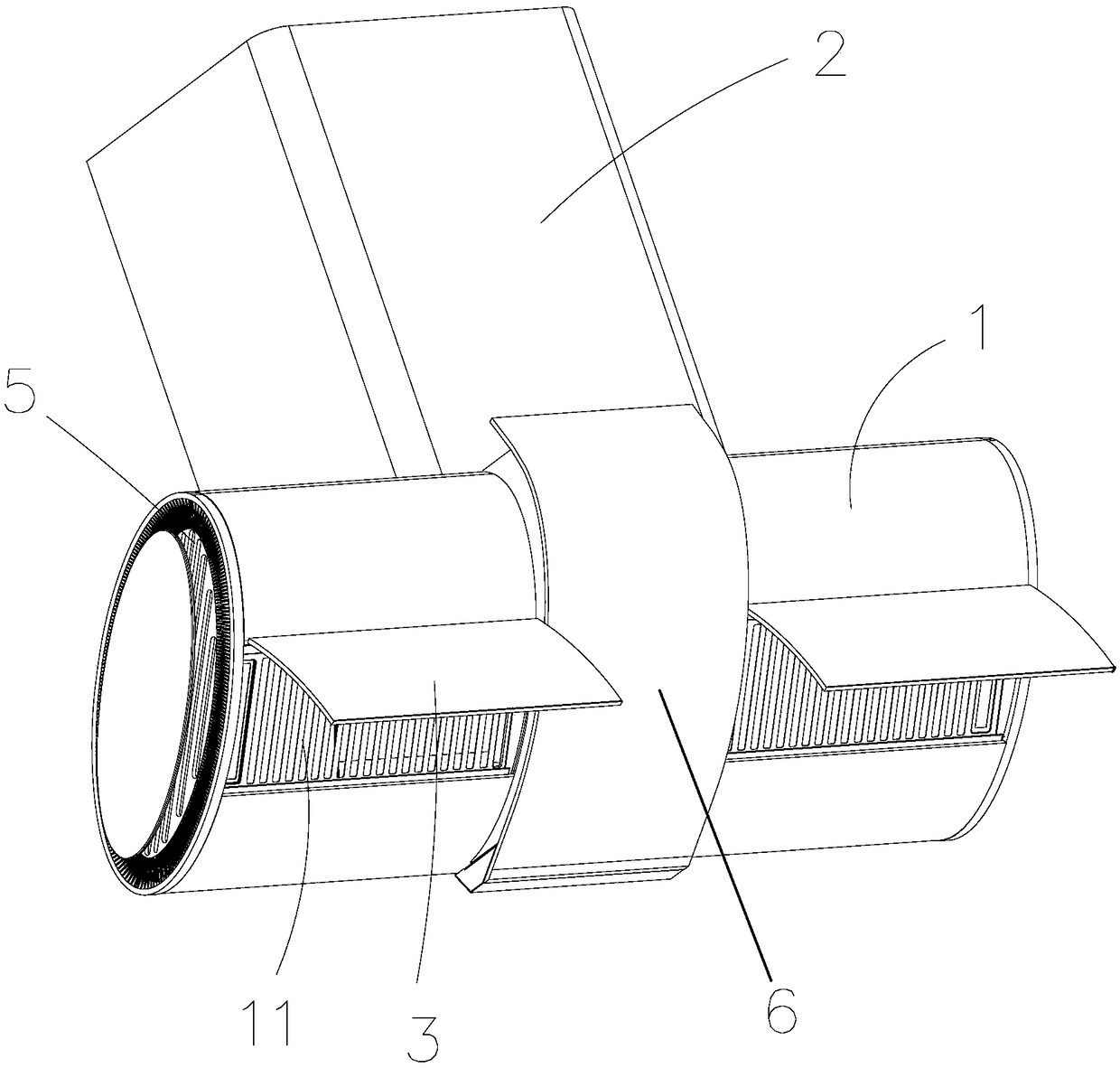

Coil spring contact type connector

InactiveCN1426615AAvoid size errorsHigh precisionCoupling contact membersElectric connection structural associationsCoil springElectrical and Electronics engineering

A coil spring contact connector (C) includes a plurality of coil spring contacts (1) and an insulating holder (2) holding the coil spring contacts arranged at intervals. Each coil spring contact has a pair of end contact coils (10) to be brought into contact with a terminal electrode (6c), and middle contact coils (12) radially offset relative to the end contact coils (10) so as to be brought into contact with another terminal electrode (5c). The holder is provided with openings through which contact parts of the end and the middle contact coils project outside, respectively, restrains each coil spring contact (1) from axial deformation and axial movement, and allows each coil spring contact (1) to be deformed in an offset direction thereof.

Owner:YOKOWO CO LTD

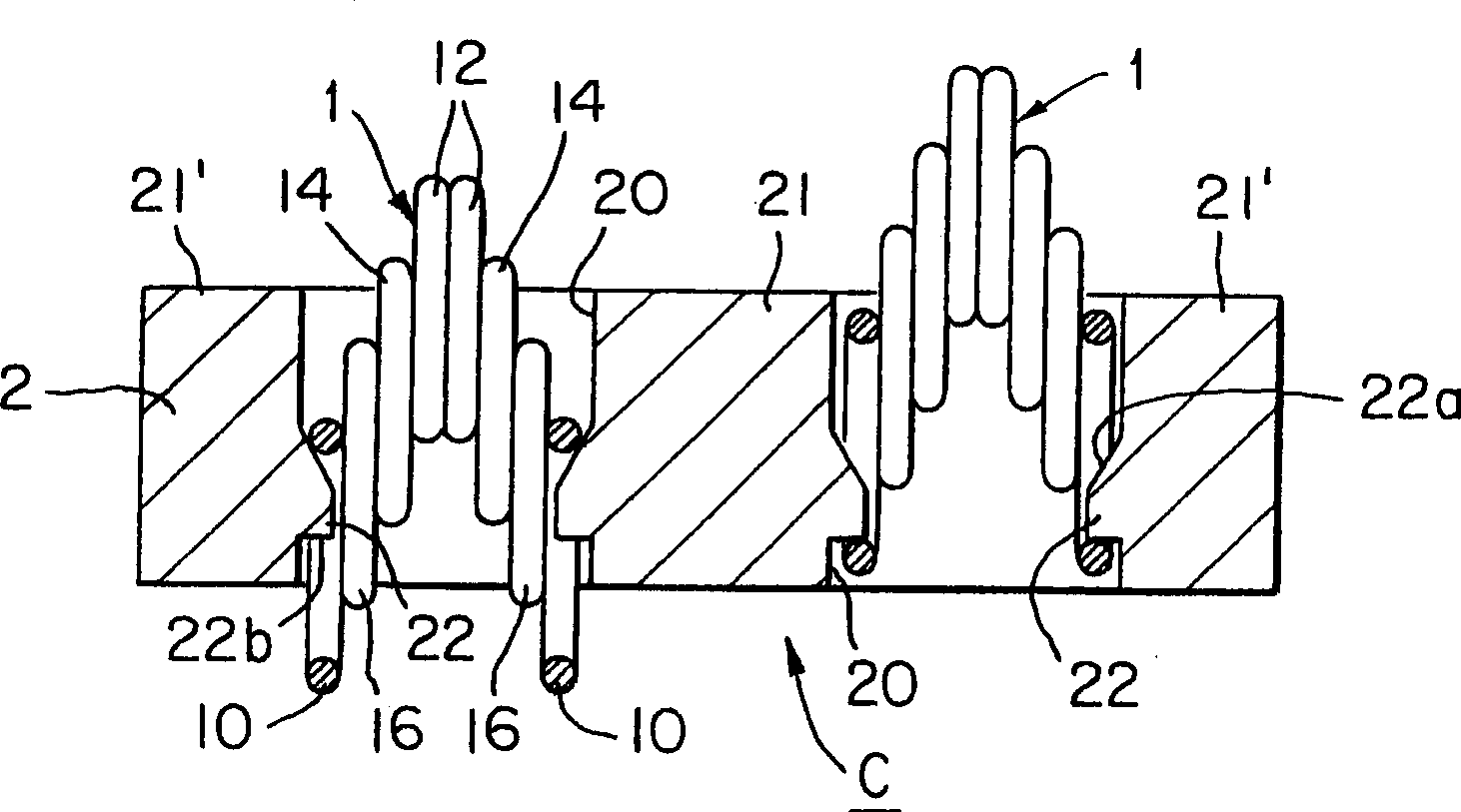

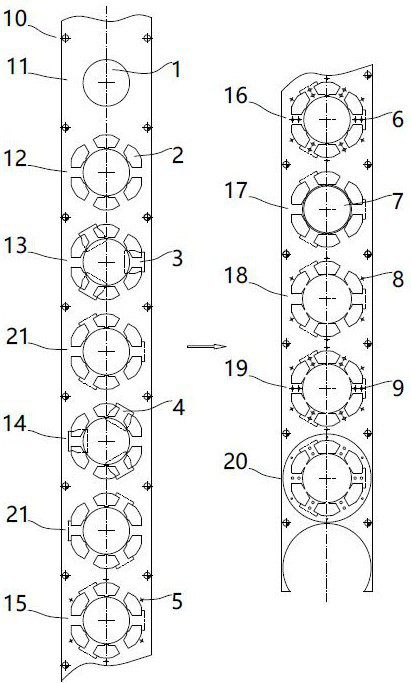

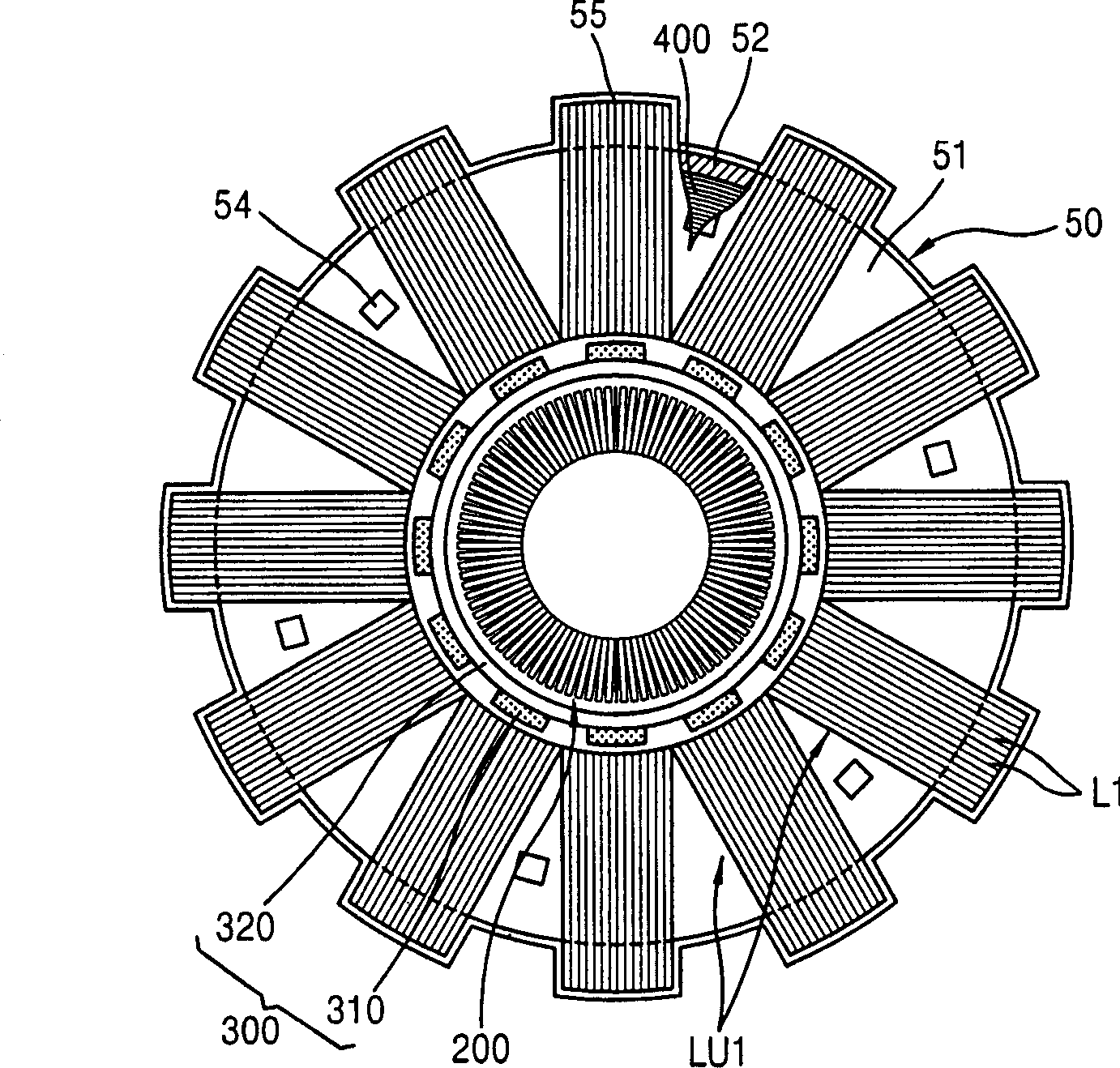

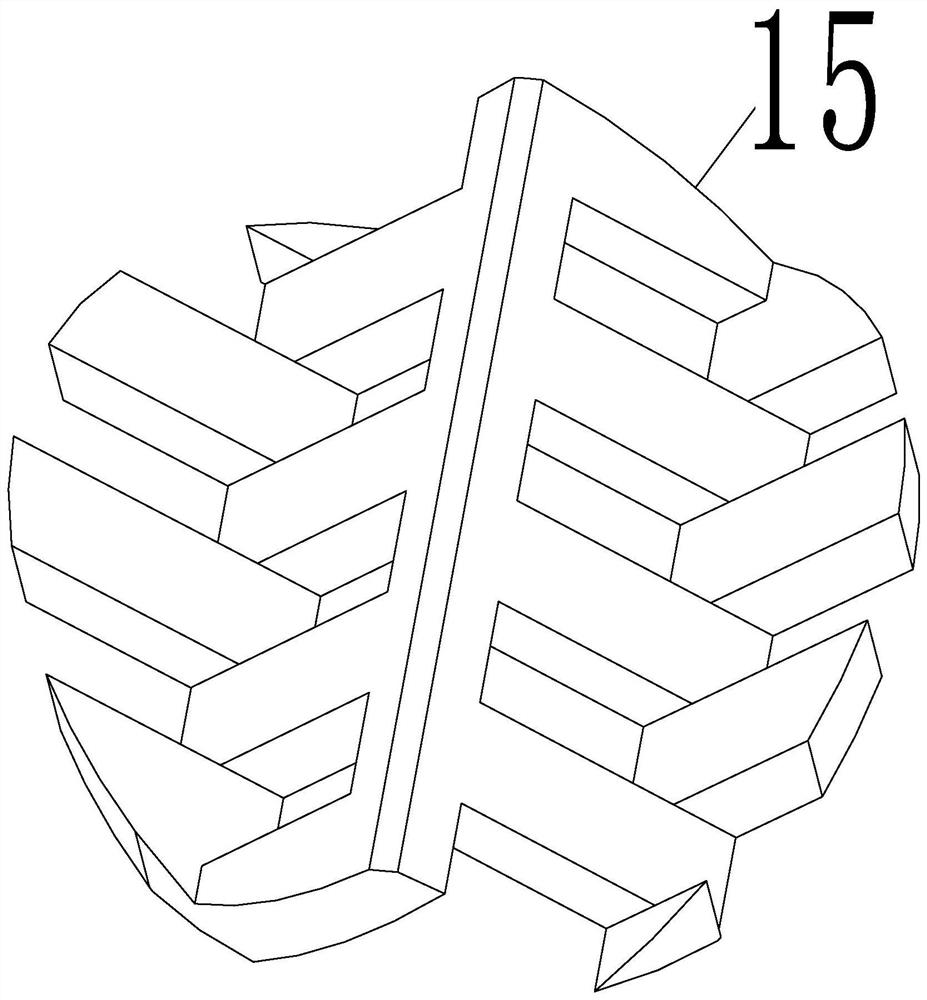

Manufacturing process of motor stator with locally separated tooth yokes

ActiveCN112366905AAvoid size errorsReduce scrap rateManufacturing stator/rotor bodiesManufacturing technologyElectric machine

The invention discloses a manufacturing process of a motor stator with locally separated tooth yokes. The manufacturing process comprises the following process steps: A, feeding; B, punching a windingslotted hole; C, notching the splicing surface of tooth yokes; D, punching a metering hole; E, punching an inner hole; F, punching a buckling point; G, blanking: obtaining a stator iron core; H, performing separation: separating the stator iron cores to obtain two stator iron core single blocks; I, winding: separately winding the two stator iron core single blocks separated in the step H; and J,performing combination: recombining the two stator iron core single blocks wound in the step I along the original separation position to obtain a motor stator finished product. The process has the advantages that the size error is small when all parts are assembled, the rejection rate of products is low, the performance of a motor using the process stator is good, and the working efficiency is high.

Owner:NINGBO ZHENYU TECH

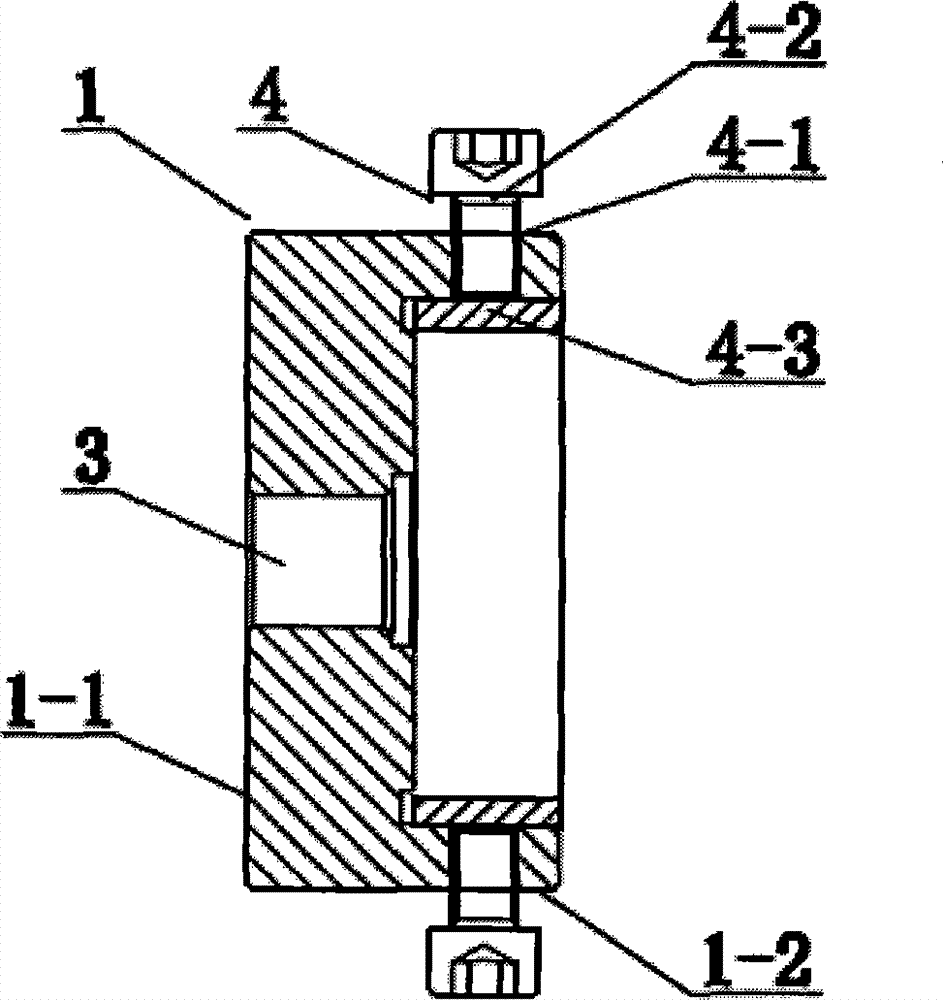

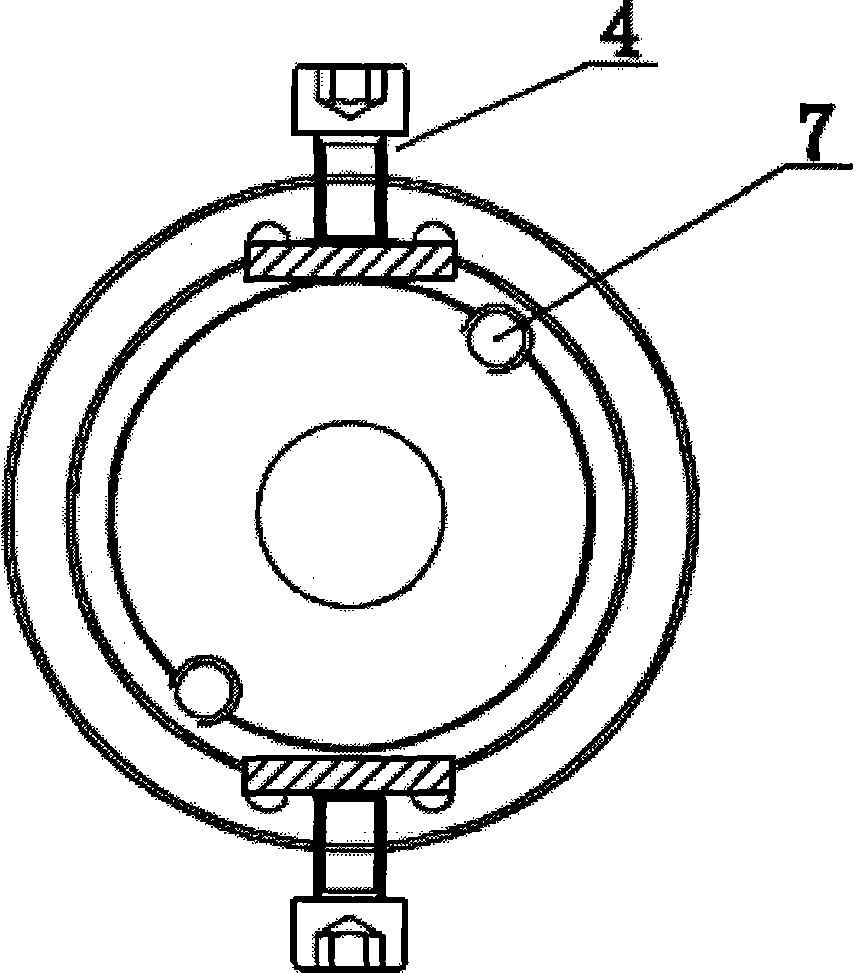

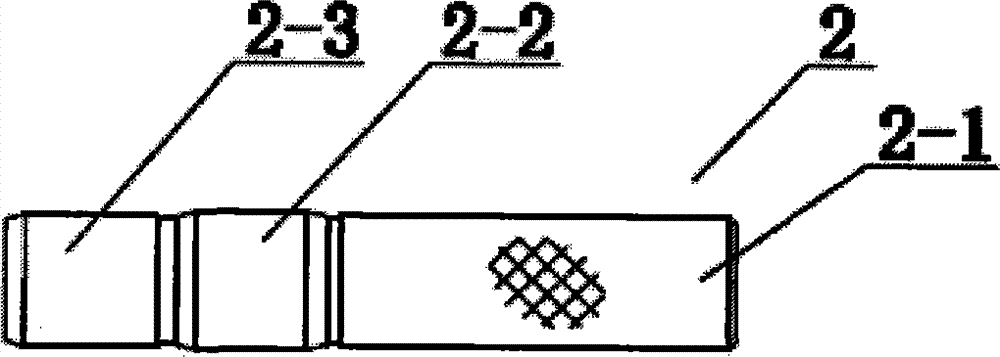

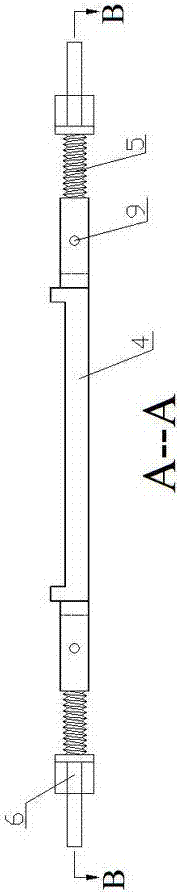

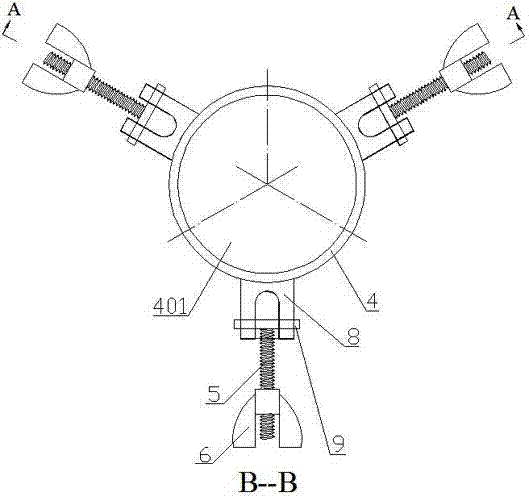

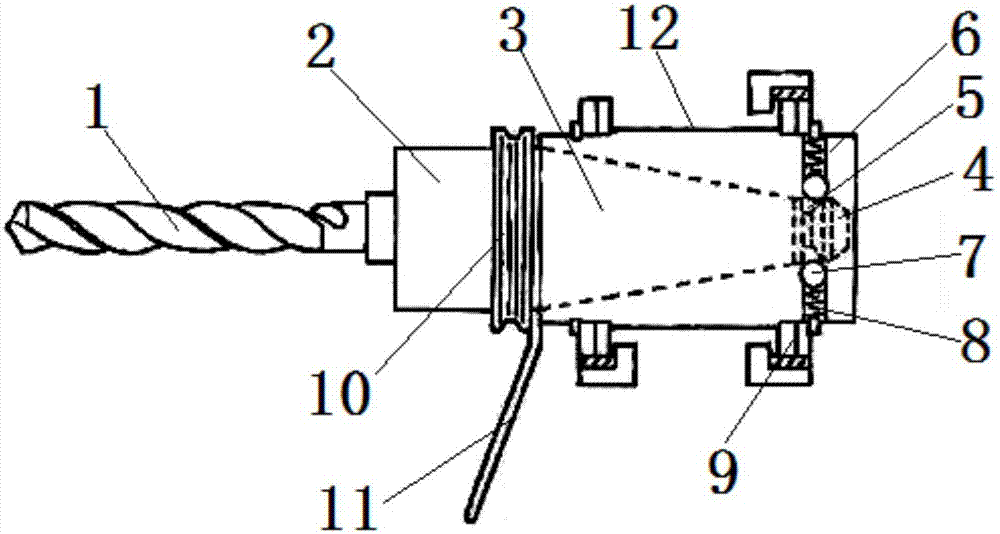

Inner hole re-machining tool for workpieces with asymmetric contours

InactiveCN102814676AImprove processing efficiencyImprove machining accuracyPositioning apparatusMetal-working holdersLocking mechanismEngineering

The invention relates to a machining tool, in particular to an inner hole re-machining tool for workpieces with asymmetric contours. The inner hole re-machining tool comprises a cylindrical tool body and a positioning hinge pin. The tool body comprises a cylindrical wall and a cylindrical bottom, a hinge pin hole is arranged in the center of the cylindrical bottom, the positioning hinge pin is inserted in the hinge pin hole, and at least two position adjusting locking mechanisms are arranged on the cylindrical wall. Each position adjusting locking mechanism comprises a threaded hole, a bolt and a clamping plate, the threaded hole is arranged on the cylindrical wall, a platform is arranged around the threaded hole on the inner side of the cylindrical wall, the clamping plate is embedded in the platform, and the bolt penetrates through the threaded hole to be in pressed connection with the clamping plate. A gland is further arranged on the upper portion of the tool body. The inner hole re-machining tool has the advantages that by the tool, a workpiece with an asymmetric contour can be clamped on a lathe in a manner the same with a manner that a rotating piece is clamped on the lathe, machining efficiency and machining precision of batch products are improved, and machining cost is greatly lowered as compared with machining cost of a machining center.

Owner:YANTAI EDDIE HYDRAULIC TECH

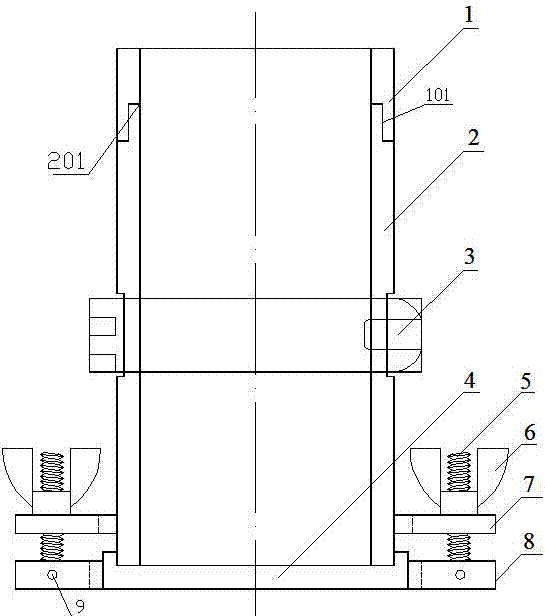

Device and method for preparing cylindrical standard test pieces of filling bodies

ActiveCN107063827AImprove clamping effectSo as not to damagePreparing sample for investigationStructural engineeringSlurry

The invention relates to a device and a method for preparing cylindrical standard test pieces of filling bodies, and belongs to the field of mine filling theories and technologies. The device comprises a bottom mold, a side mold and a float mold. A groove which is of a circular structure is formed in the center of the bottom mold and is filled with the bottom of the tubular side mold, the side mold comprises three identical arc-shaped split structures, a convex edge structure is arranged at the upper end of the side mold, the tubular float mold sleeves the convex edge structure, and the convex edge structure is embedded in a concave edge structure on the float mold. The method includes filling the assembled device with slurry by means of pouring at one step; detaching the float mold after 6 hours, scraping redundant filling bodies which exceed the height of the side mold and enabling test pieces and the side mold to be positioned at the same height; detaching the side mold and the bottom mold after 24 hours, taking out the test pieces, numbering the test pieces and maintaining the test pieces according to requirements to completely prepare the test pieces. The device and the method have the advantages that the side mold comprises the three identical arc-shaped split structures, and accordingly the test pieces can be prevented from being damaged and can be conveniently released from the molds; the float mold is connected with the upper end of the side mold, and accordingly the prepared test pieces can be assuredly completely prepared by means of pouring at one step.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

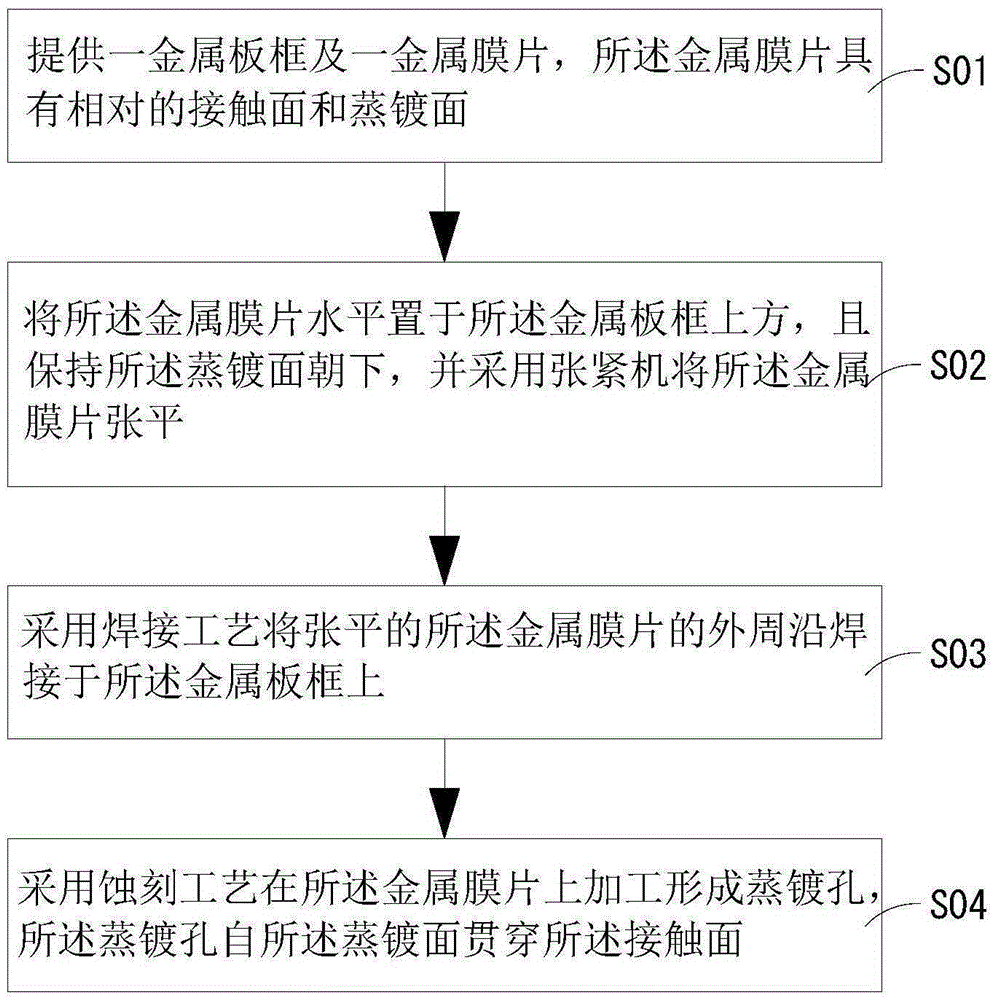

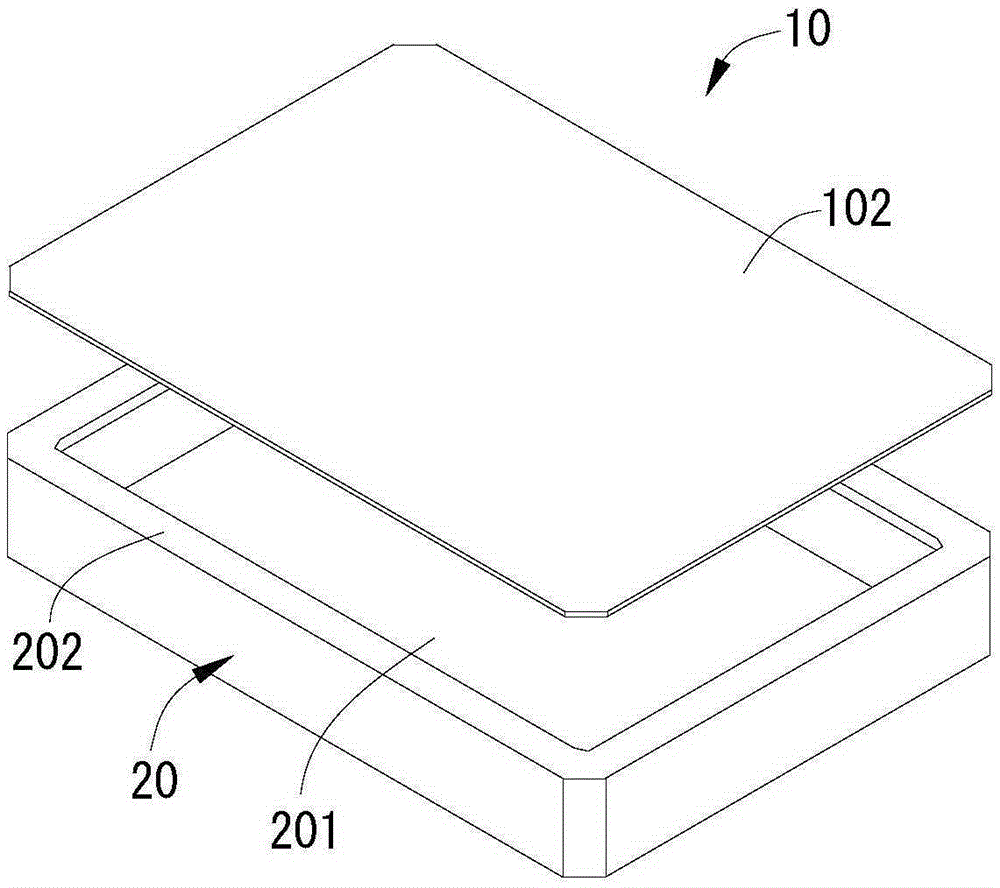

Machining method for high-accuracy metal mask plate

ActiveCN105349947AHigh dimensional accuracyReduce defect rate and scrap rateVacuum evaporation coatingSputtering coatingMetal membraneMaterials science

The invention relates to a machining method for a high-accuracy metal mask plate. The machining method includes the steps that a metal plate frame and a metal membrane are provided, wherein the metal membrane has a contact face and an evaporation face which are opposite; the metal membrane is horizontally arranged above the metal plate frame, the evaporation face is kept downward, and the metal membrane expands to be flat through a tensioning machine; the peripheral edge of the metal membrane expanding to be flat is welded to the metal plate frame through a welding process; and evaporation holes are machined in the metal membrane through an etching process and penetrate the contact face from the evaporation face. By means of the machining method, the size accuracy of the formed evaporation holes can be improved obviously, the reject ratio and the condemnation factor can be reduced, and meanwhile the production cost is greatly reduced.

Owner:深圳浚漪科技有限公司

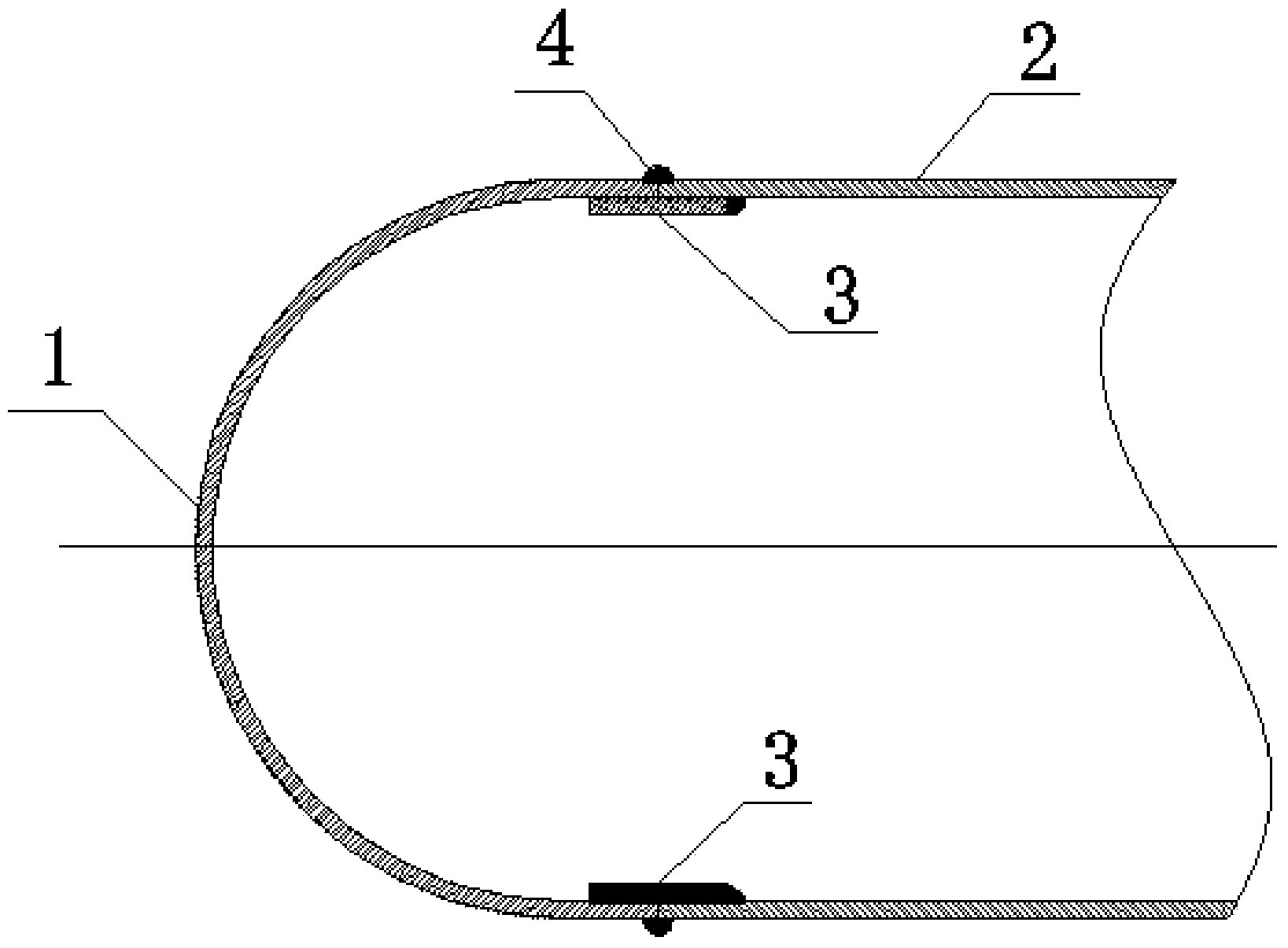

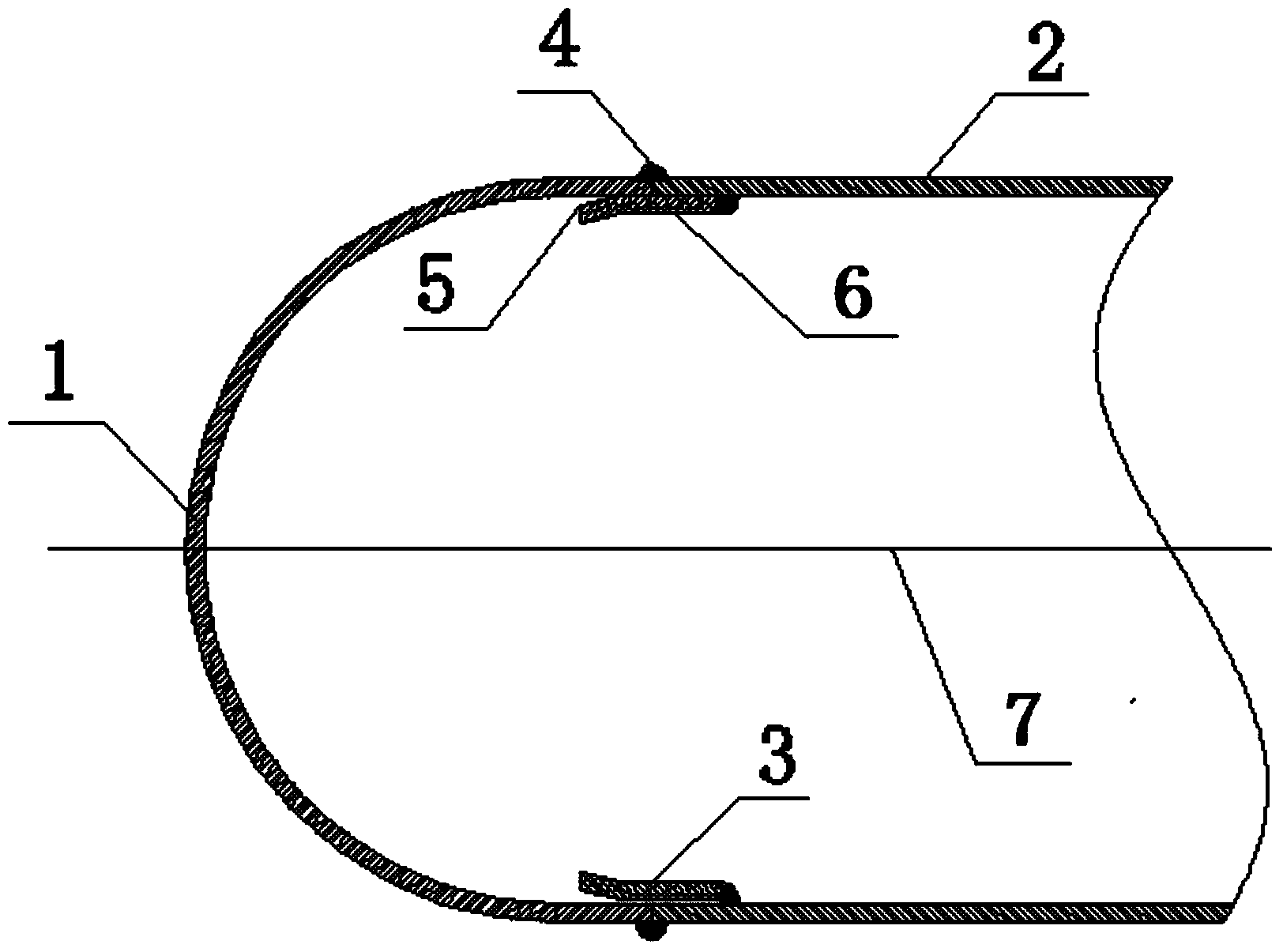

Circumferential weld structure of water heater water tank liner and welding method

ActiveCN103521992AEasy dockingOvercoming error dockingWelding/cutting auxillary devicesArc welding apparatusButt jointEngineering

The invention provides a circumferential weld welding method for a water heater water tank liner. A water tank end socket is welded with a liner body of a water tank. The method comprises the steps that firstly, a lining is welded to the edge of an opening of the liner body of the water tank, the shape of the longitudinal section of the lining is formed by combining a panel and an inclined plane, the panel is provided with two end faces, the inclined plane is connected with a first end face of the panel, the included angle between the inclined plane and the first end face of the panel ranges from 160 degrees to 175 degrees, the thickness of the lining accounts for 80%-150% of the thickness of the liner body, the lining is made of materials same as the materials of which the liner body is made, the lining is welded to the edge of the liner body of the water tank, a second end face of the lining faces the bottom of the liner body, and the inclined plane faces a central axis of the liner body; secondly, the edge of the end socket slides to the position where the edge of the end socket is connected with the liner body in a butt joint mode along the outer side of the lining; thirdly, the outer side of the connecting position of the water tank end socket and the water tank liner body is welded. The lining is arranged on the inner side of the connecting position of the liner body and the end socket, the end socket can slide into the butt joint position along the side face of the lining when the end socket is connected with the liner body welded, and the problem that due to the fact that the butt joint is not even, the subsequent welding quality is affected cannot occur.

Owner:HUNAN EWAVV NEW ENERGY TECH

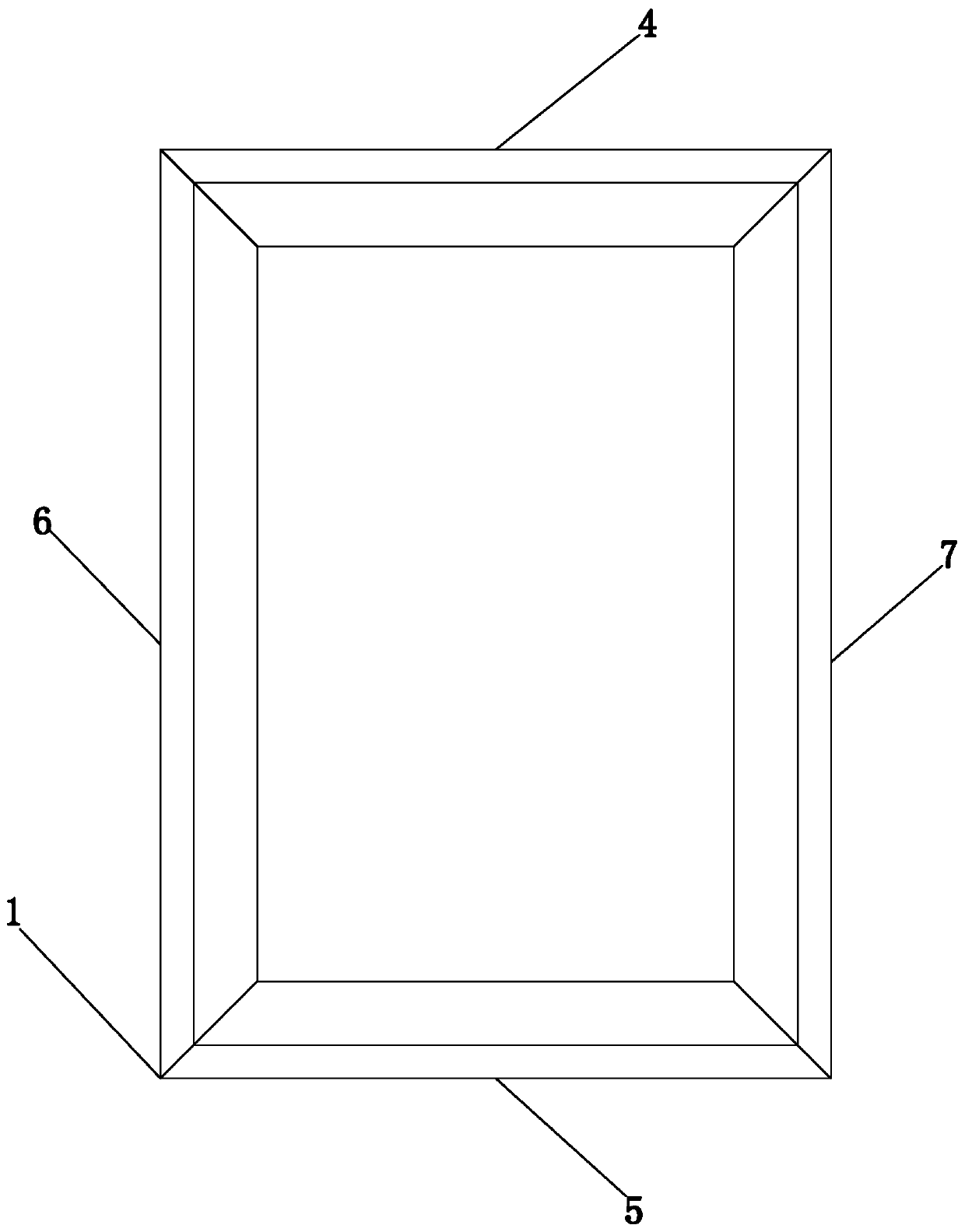

Quick-assembling combined door plate

PendingCN110513008AShort cycleIncrease productivityFireproof doorsBuilding braking devicesButt jointAdhesive

The invention discloses a quick-assembling combined door plate. A fabricated process is adopted, the production efficiency is high, the processing procedures are less, environmental protection is achieved, the service life is long, recycling and disassembling can be achieved, reutilization is achieved, a panel with a special shape and a matching structure is adopted to be combined with a bolt, a horizontal keel, a screw rod and a door frame keel, the door frame keel comprises a front plate butt-joint block and a rear plate butt-joint block, thus a front decoration panel and a rear decoration panel are tightly and firmly combined with a keel frame, the overall structure is stable, matching is ingenious, details are perfect, all parts are tightly combined in all directions, thus the four sides of the door plate can be flexibly and fine adjusted, the size error caused by the actual installation of the door frame is overcome, the adaptation is high, when the door plate is in contact with the door frame, an anti-collision sealing adhesive strip provides buffer protection, the protective performance is good, the gap formed under the door plate is always sealed by a closing adhesive stripat a lower mouth, dust, insects and ants are avoided entering, and the sound insulation performance is good.

Owner:艺墙之格建筑发展(上海)有限公司

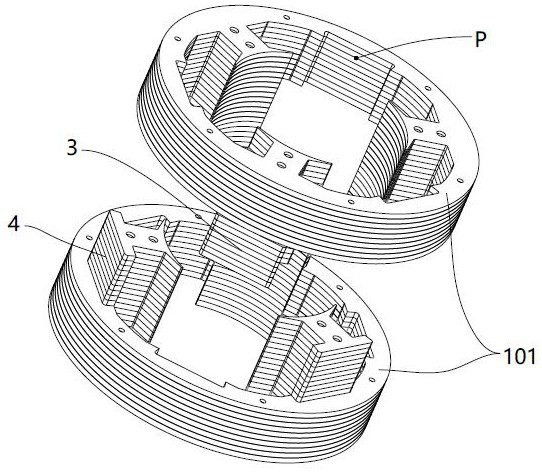

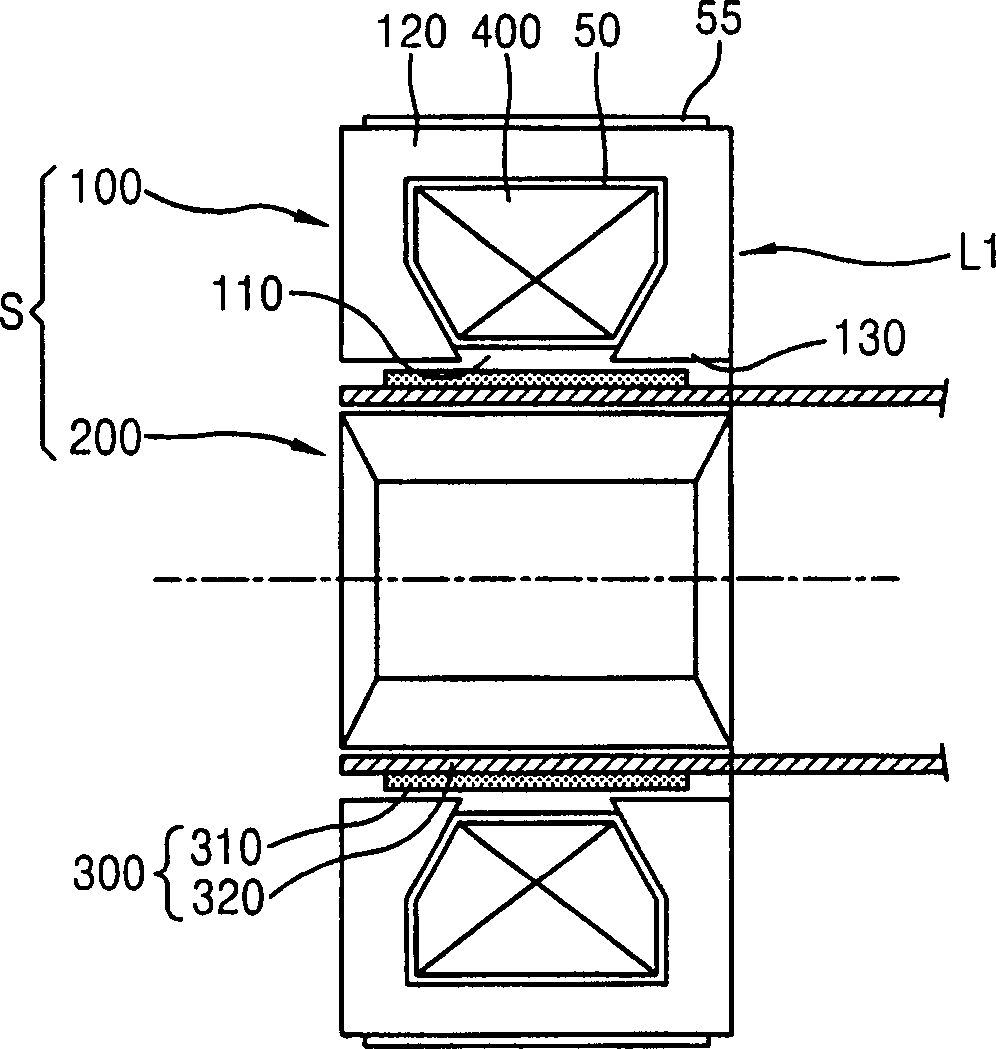

Stator for reciprocating motor and fabrication method thereof

InactiveCN1805242ASimple manufacturing processAvoid size errorsLacing hooksMagnetic circuit stationary partsBobbinBand shape

A stator for a reciprocating motor includes a coil winding in which a coil is wound plural times, and fixed and insulated with a bonding material distributed between gaps of the wound coil, an insulation band formed in a circular band shape along an outer circumferential surface of the coil winding, an annular bobbin coupled to both side surfaces of the coil winding and covering the coil winding together with the insulation band, a plurality of core blocks coupled on the bobbin in a circumferential direction, and an inner core inserted with a certain interval from the circular inner circumferential surface formed by the bobbin and the plurality of core blocks.

Owner:INTELLECTUAL DISCOVERY CO LTD

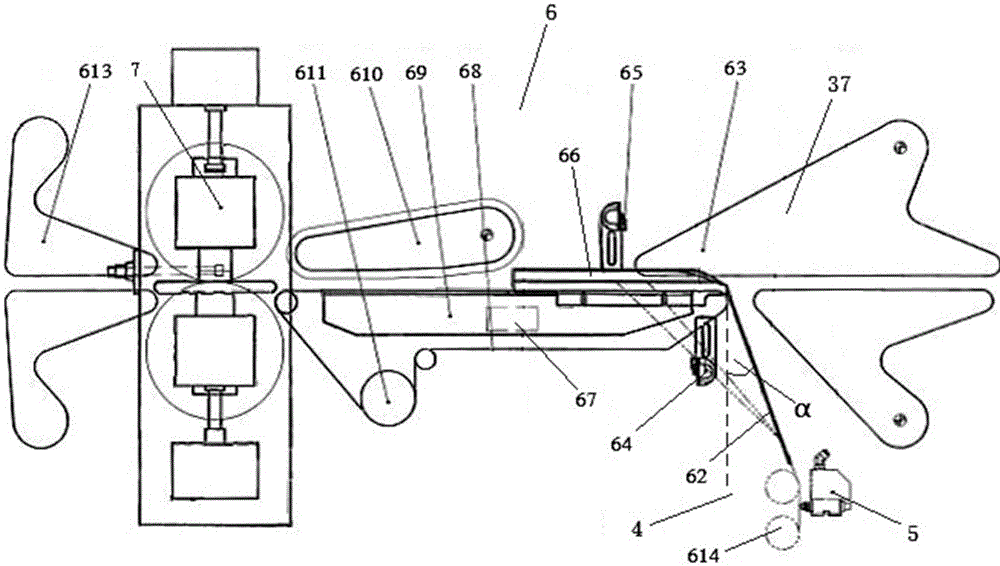

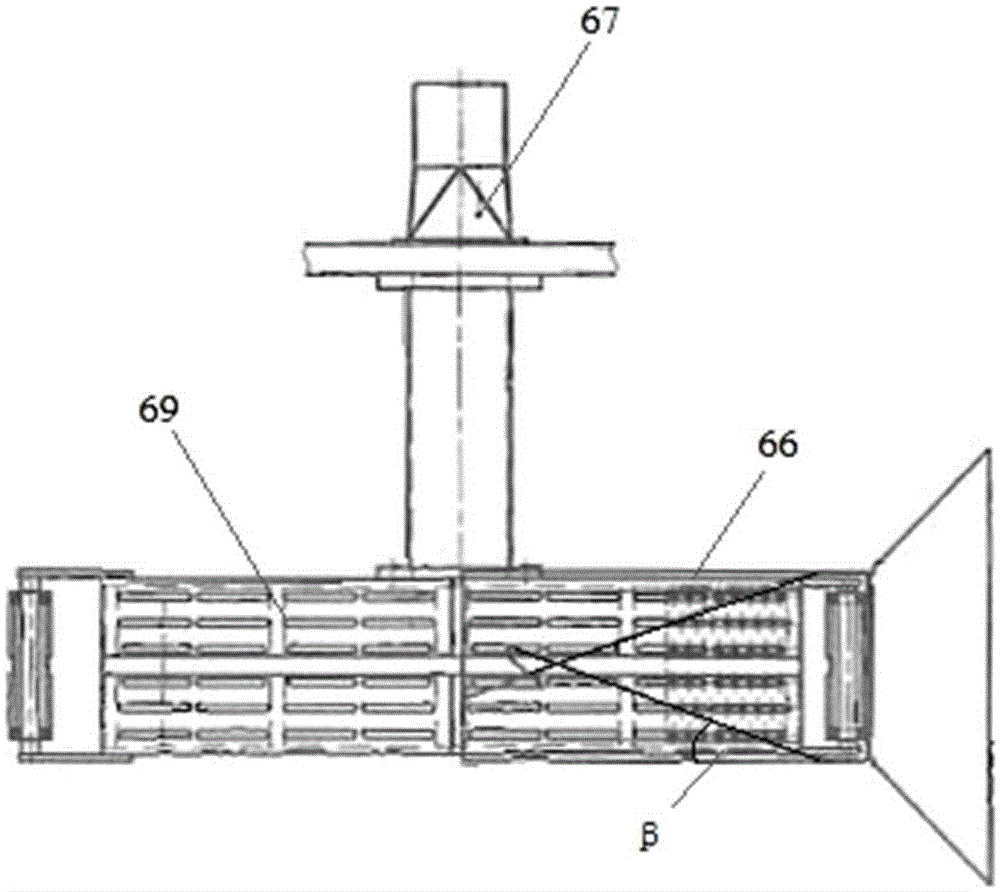

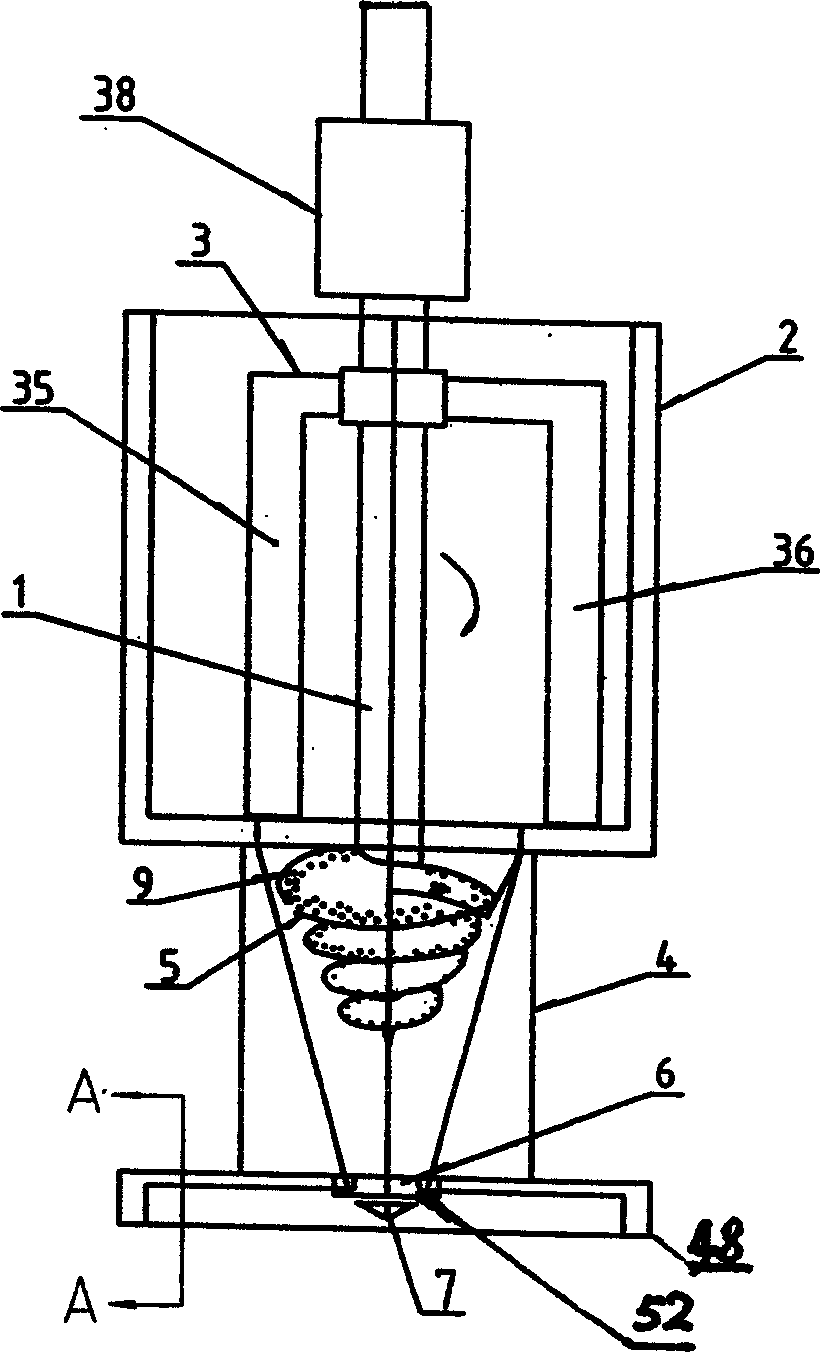

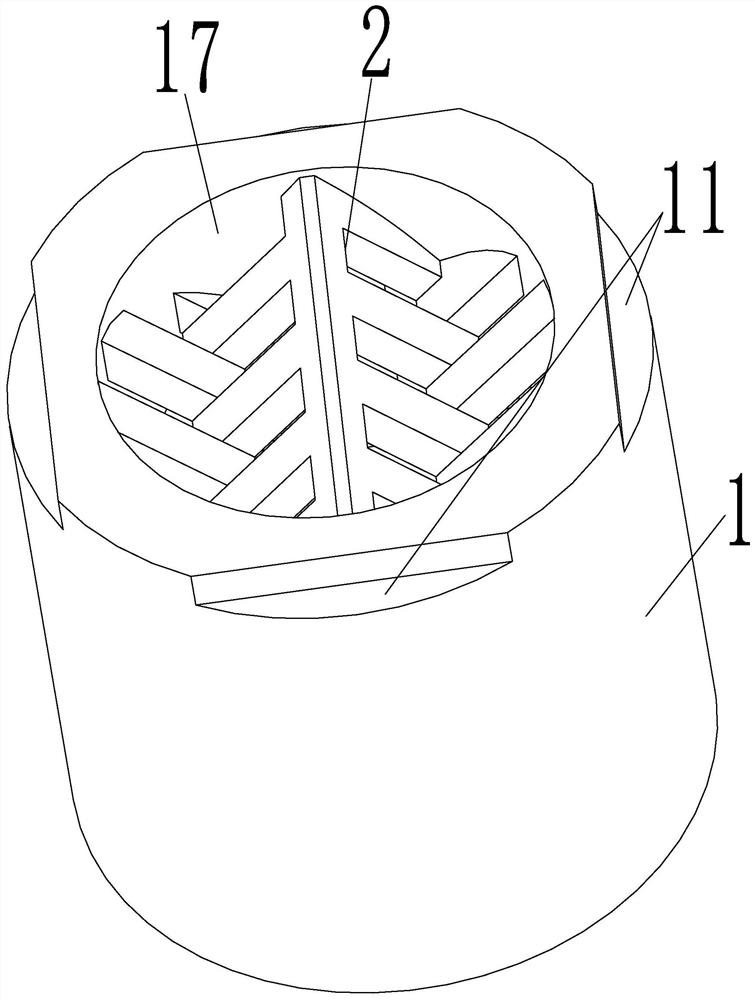

Laser additive manufacturing forming method of static mixer

PendingCN114012106AGood molding effectAvoid size errorsAdditive manufacturing apparatusIncreasing energy efficiencyManufactured formEngineering

The invention discloses a laser additive manufacturing forming method of a static mixer. A shell is included, a penetrating through hole is formed in the shell, and a plurality of locking grooves are formed in one end of the shell in the circumferential direction. A plurality of W-shaped elements are fixedly connected in the through hole. The shell and each W-shaped element each consist of an inner core and an outer shell. The overall model of the static mixer is decomposed into an outer shell and an inner core, different printing parameters are adopted for printing the upper surface, the lower surface, the main body and the contour, and the printing efficiency can be considered while low-angle and cantilever structure printing is met. A second phase material is added into a metal powder material according to a certain proportion, so that the material forming performance is improved, the precision of the product is improved, and meanwhile, the strength, hardness and wear resistance of the product are enhanced.

Owner:宁波中乌新材料产业技术研究院有限公司 +1

Special die for assembling tower legs of iron tower

InactiveCN111055070AGuaranteed accuracyGuaranteed uniformityWelding/cutting auxillary devicesAuxillary welding devicesTowerMechanical engineering

The invention discloses a special die for assembling tower legs of an iron tower. The die comprises a tower leg base fixing plate, wherein a tower leg bottom plate positioning component for positioning a tower leg bottom plate is arranged on the tower leg base fixing plate; and a plurality of groups of three-dimensional adjustable tower leg vertical plate assembling dies for clamping a tower leg vertical plate and positioning the tower leg vertical plate are arranged outside the tower leg base fixing plate. The special die has simple operation, assembly of a plurality of tower legs and nodes can be quickly completed by only one person, and the special die has high reliability, few faults, safety and reliability, and does not discharge any solid, liquid, gas or other wastes which can causeenvironmental pollution, so that human resources can be saved to the maximum, and labor intensity of assembly workers and welding workers is greatly reduced.

Owner:于千斐

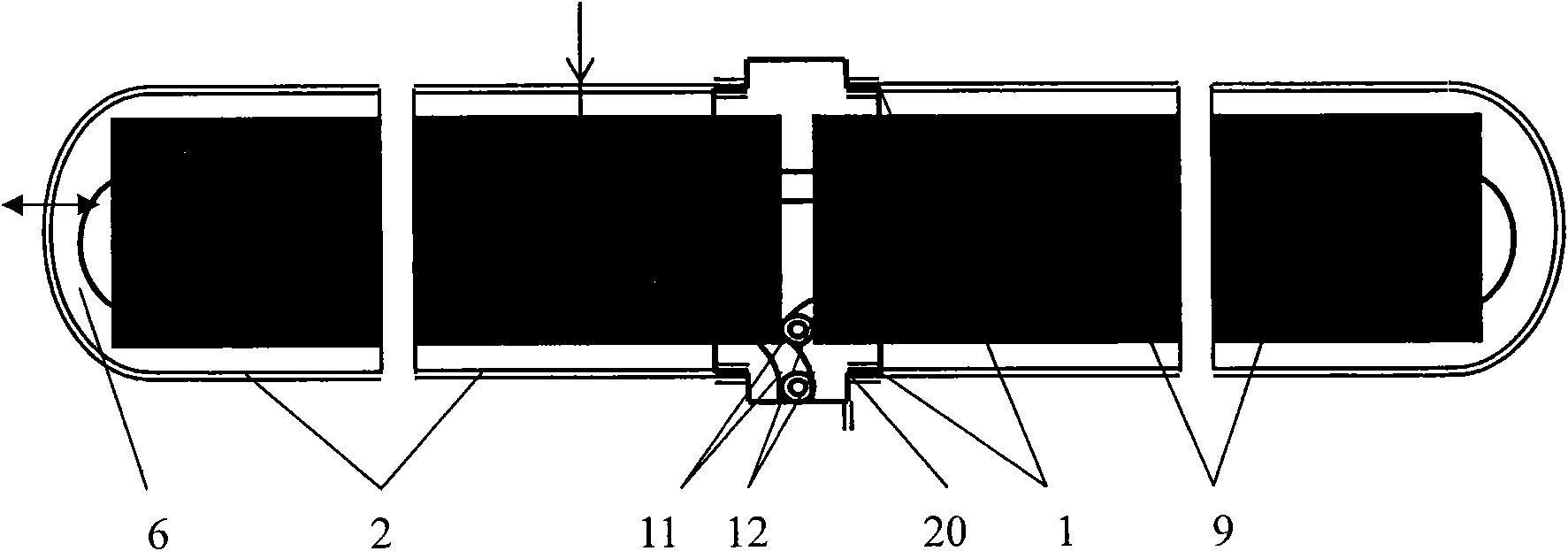

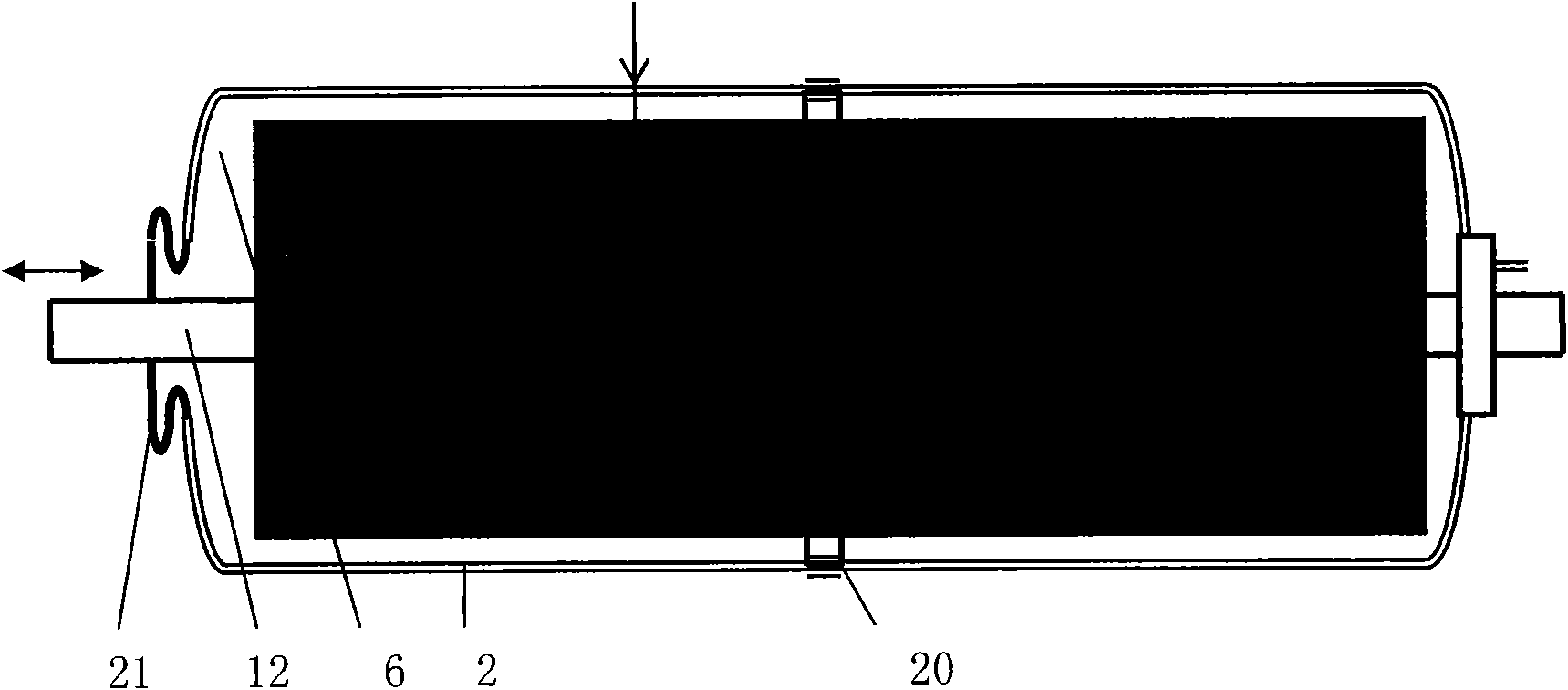

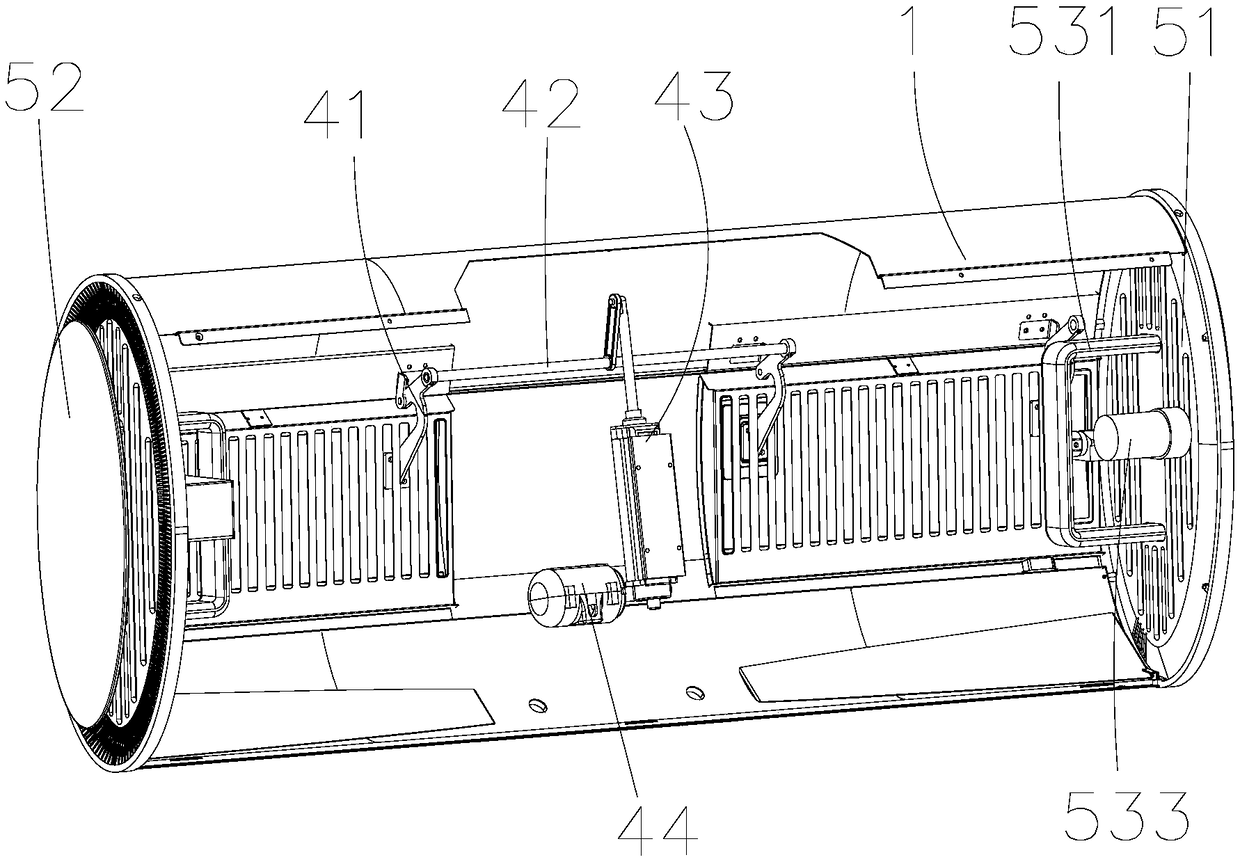

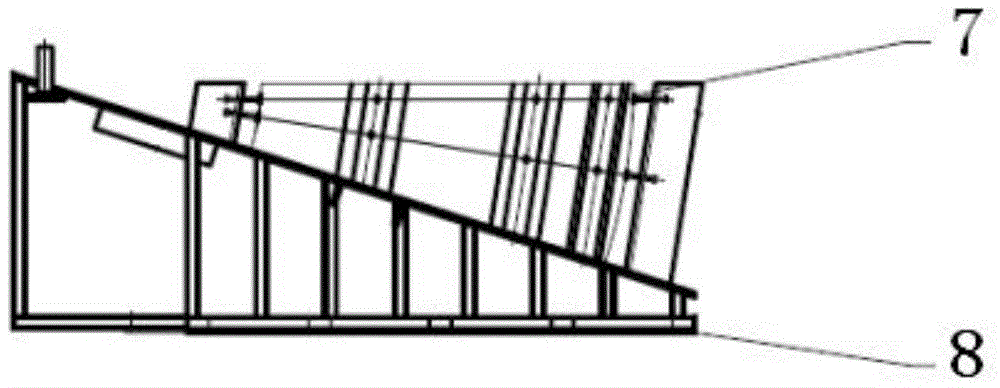

Method and equipment for providing vacuum heat insulation for solar system by negative pressure source

InactiveCN101603737AAvoid size errorsExpand the scope of selectionSolar heating energyRoof covering using slabs/sheetsInsulation layerControl system

The invention relates to a method for providing vacuum heat insulation for a solar system by a negative pressure source. A transparent closed container, a solar energy collecting and utilizing device, a measurement and control system and the negative pressure source are utilized to form an active vacuum solar energy collecting and utilizing system, and the negative pressure source and the closed container are communicated to form a vacuum heat insulation layer. The active vacuum solar energy collecting and utilizing system of the method comprises the transparent closed container, the solar energy collecting and utilizing device, the measurement and control system and the negative pressure source and is characterized in that an exhaust channel is arranged between the transparent closed container and the negative pressure source. The method can solve the problem of vacuum degree reduction because of material exhaust and helium permeation. A common sealing technology can be used for manufacturing various new vacuum solar energy collecting and utilizing products, thereby enlarging the selection range of materials and processes. The service life of the products can be synchronized with buildings, and the heat energy cost is low. A jacket is adopted so as to be helpful to solve the problem of size errors of glass tube plates, and the closed container made of a thin curtain wall glass sheet has good heat insulation and convenient use. Five embodiments are given by combining attached pictures.

Owner:余仁素

Forming tool for draw spring mouth closing

PendingCN109226604AReduce physical exertionDimensionally stable overall lengthWire springsPunch pressEngineering

The invention discloses a forming tool for draw spring mouth closing. The tool comprises a mold handle, an upper module, a lower module, a template and a fixing screw; the lower module is fixed to thetemplate by the fixing screw, the upper module is arranged on the lower module, and the mold handle is fixed to the upper module; during working, a draw spring before the draw spring to be processedis combined is placed on the lower module, the punching machine drives the mold handle, thereby driving the upper module to move up and down, the draw spring before combination is closed and processed, a hook of the draw spring is processed, and the combined draw spring is processed. The tool improves the dimensional stability of produced draw spring parts and improves work efficiency.

Owner:南京弹簧有限公司

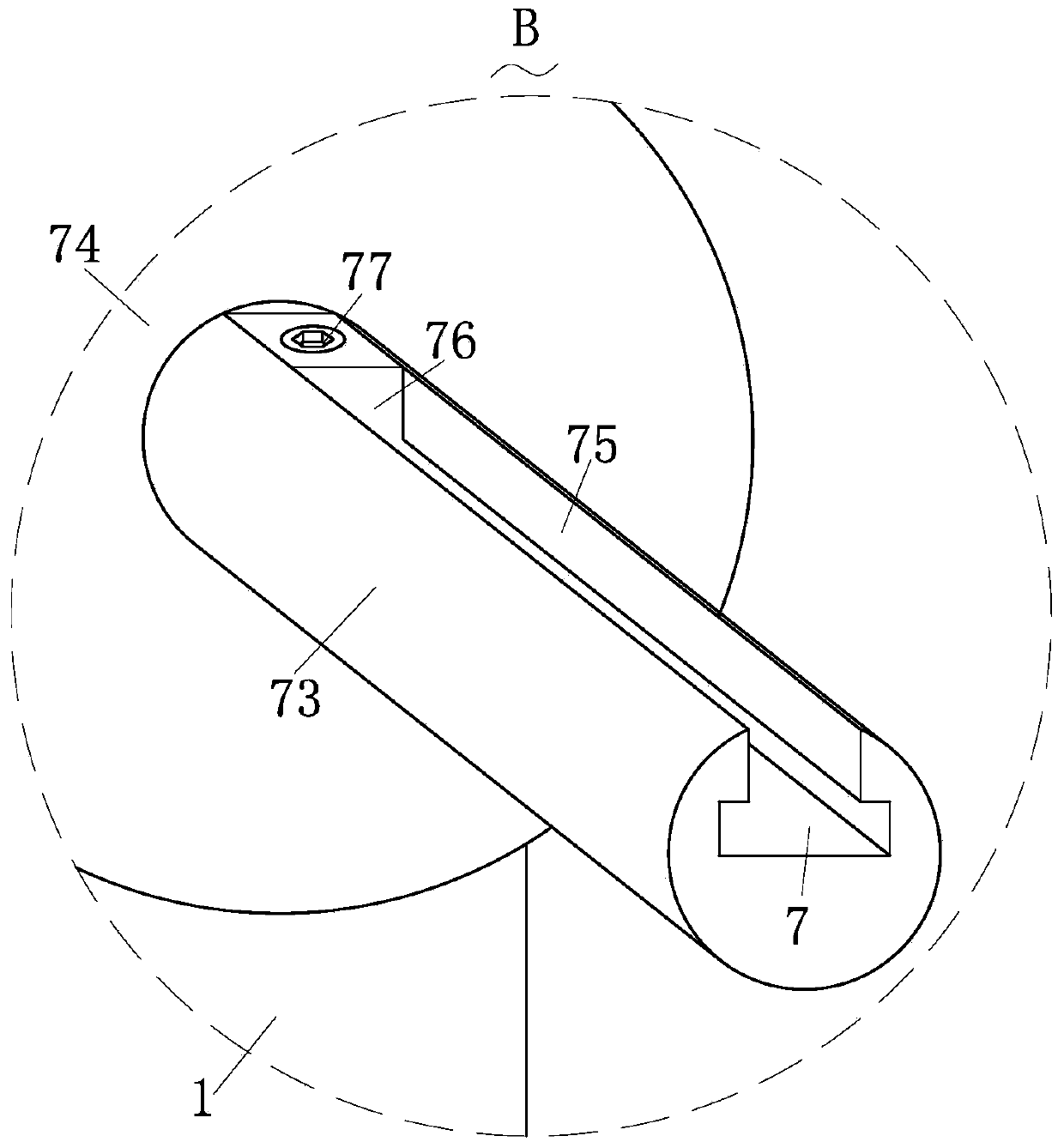

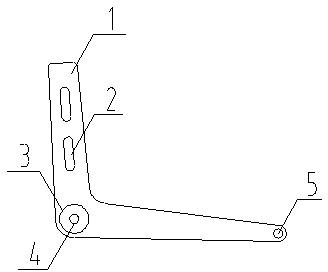

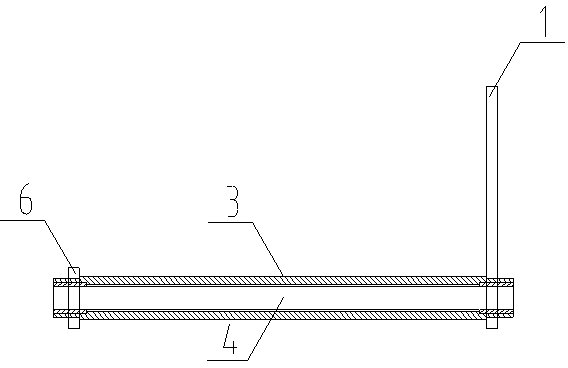

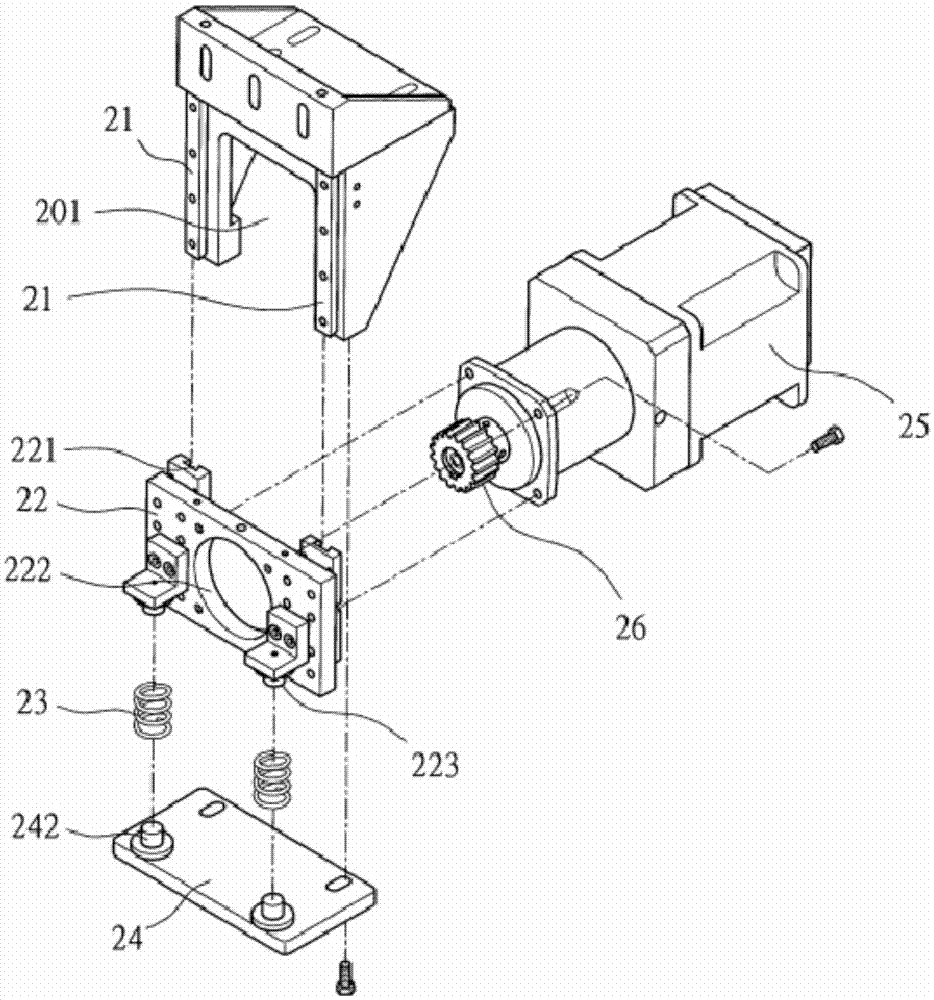

Driving swing arm rack

InactiveCN104192455AWith fine-tuning functionAvoid size errorsLarge containersDrive shaftEngineering

The invention discloses a driving swing arm rack which comprises a swing arm rack body. The driving swing arm rack is characterized in that two kidney-shaped holes are formed in the upper end of one side of the swing arm rack body, a driving shaft is connected to the part of the rotating shaft of the swing arm rack body in the Z-axis direction, the driving shaft is provided with a fixing shaft hole, the other end of the swing arm rack is provided with a connecting hole, the driving shaft is provided with a locating plate, and the swing arm rack body is of an L-shaped structure. The driving swing arm rack has the advantages that the arm swing action around the driving shaft on the single aspect is achieved in an optimized mode, meanwhile, the driving shaft is used for driving other connecting mechanisms to run, the structure has the fine adjustment function, the size error in the mounting process is avoided, the structure is simple, mounting is convenient, production efficiency is improved, and production cost is reduced.

Owner:HEFEI SANGUAN PACKING SCI & TECH

Glass mold machining cutter placement device

PendingCN107186545AAvoid size errorsSmall size errorProtection and storage accessoriesTool bitEngineering

The invention relates to a glass mold machining cutter placement device which is simple in structure and facilities placement and takeout of a machining cutter. The glass mold machining cutter placement device comprises the cutter formed by a cutter head, a cutter base and a connecting piece, the cutter head is installed on the cutter base, the connecting piece is installed on the cutter base, a round head is connected to the tail end of the connecting piece, and connecting grooves are formed in the round head and the tail end of the connecting piece; the connecting piece is sleeved with a containing barrel, other containing barrels are symmetrically installed at the position, on the other side of an opening of the containing barrel, in the containing barrel, balls and a spring are installed in an installing pipe, and the balls are located at an opening of the installing pipe and are limited in the installing pipe; the spring is located on the inner side of the installing pipe; when the tail end of the connecting piece goes deep into the installing pipe, the balls are embedded into the connecting groove in the tail end of the connecting piece; when the cutter needs to be drawn out, the balls compress the spring, move to the interior of the installing pipe, and break away from the connecting groove, and therefore the cutter is drawn out, size errors caused by friction and the like caused by random placement of the cutter are prevented, and the glass mold machining accuracy is improved.

Owner:常熟市兄弟玻璃模具有限公司

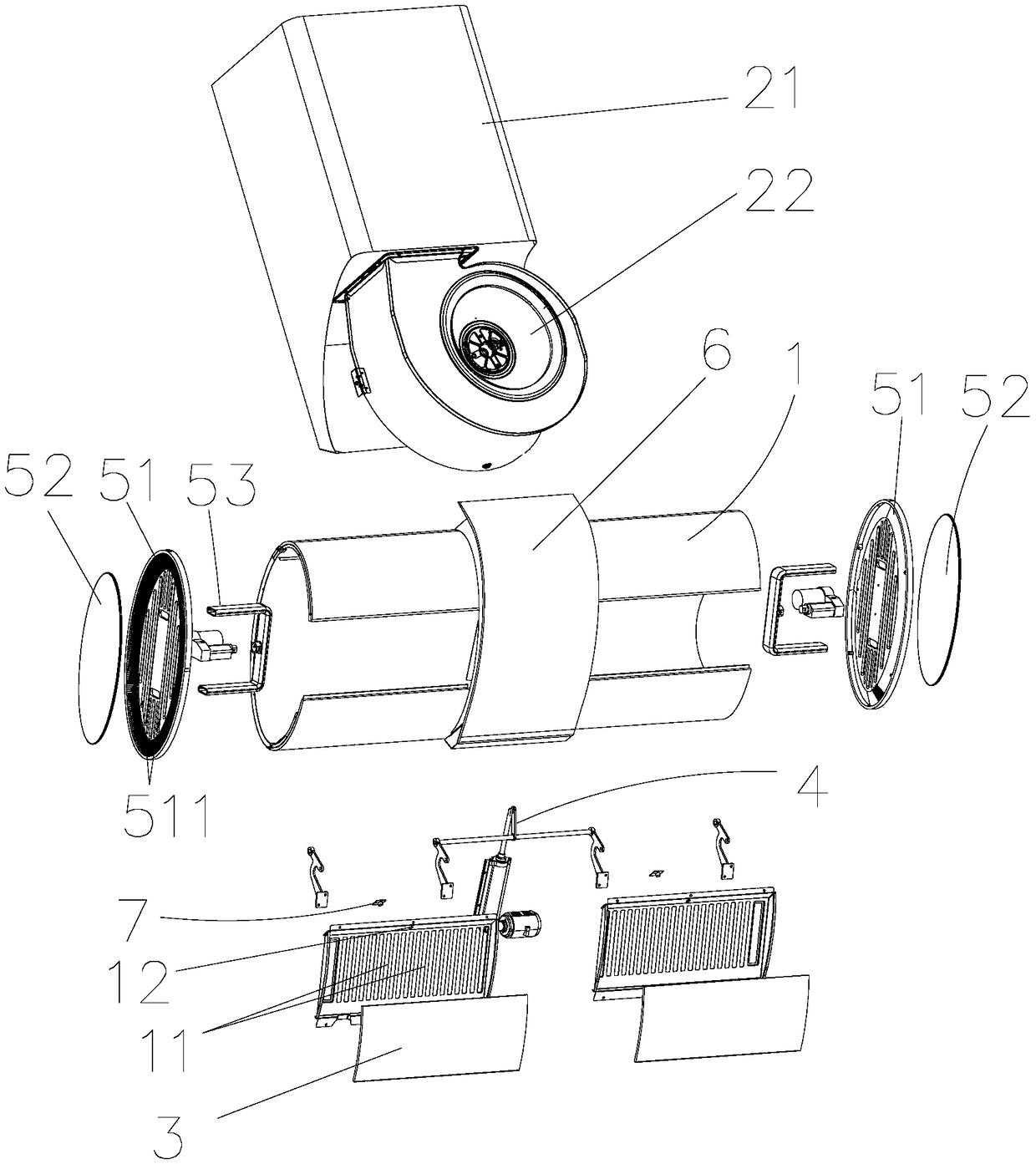

Multi-directional air inlet extractor hood structure

PendingCN108826411ASolve the escapeNice appearanceDomestic stoves or rangesLighting and heating apparatusControl systemEngineering

The invention discloses a multi-directional air inlet extractor hood structure. The multi-directional air inlet extractor hood structure comprises an extractor hood box and an air cabinet assembly arranged above the extractor hood box, a control system is arranged on the extractor hood box, a main air inlet is formed in the extractor hood box, a smoke gathering plate and a swing assembly for driving the smoke gathering plate to open and close are arranged at the main air inlet, and a side air inlet assembly is arranged on the extractor hood box; and the side air inlet assembly comprises a sideplate arranged on the side face of the extractor hood box, a side air inlet is formed in the side plate, and a cover plate and a driving device for driving the cover plate to open and close are arranged at the side air inlet. By means of the multi-directional air inlet extractor hood structure, lampblack on the front face can be absorbed to the maximum degree, secondary suction and discharge arecarried out through the side air inlet assembly on the side even though a small quantity of lampblack escapes on the left and right sides, two times of lampblack suction and discharge basically solvethe problem of lampblack escaping, the appearance is attractive, and the practicability is high.

Owner:ZHONGSHAN INSE GROUP

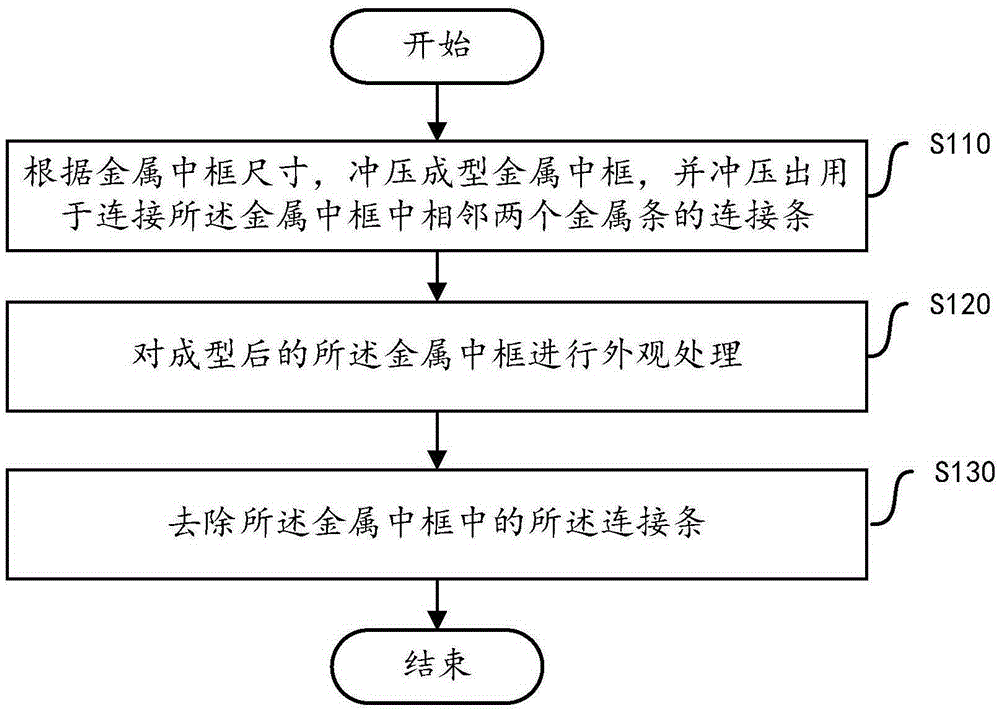

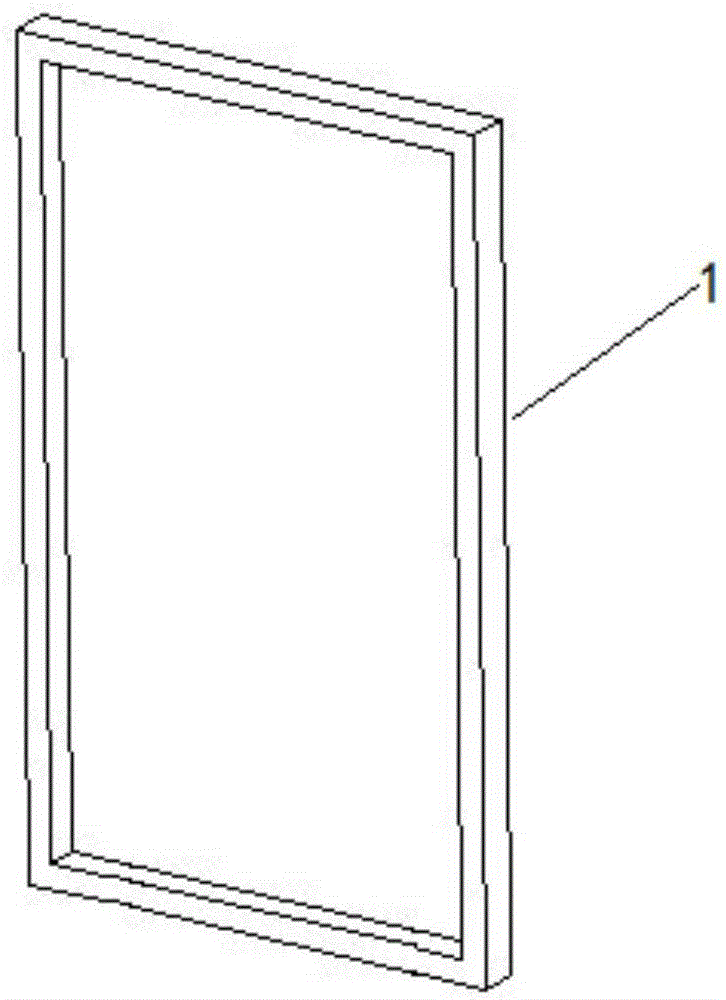

Metal frame and manufacturing method

InactiveCN106816708AAvoid size errorsAvoid chromatic aberrationMetal casingsAntenna equipments with additional functionsPunchingEngineering

The invention discloses a metal frame and a manufacturing method thereof. The metal frame manufacturing method comprises steps: according to the size of the metal frame, the metal frame is punched and formed and a connection bar for connecting adjacent two metal bars in the metal frame is punched; appearance processing is carried out on the formed metal frame; and the connection bar in the metal frame is removed. The punching mode is adopted, all metal bars are together processed and formed, size errors to the metal bars can be avoided, and compared with a CNC metal bar processing mode, the method of the invention reduces the manufacturing cost; and the metal bars are connected through the connection bars, the whole appearance processing is carried out, and color difference among the metal bars can be avoided.

Owner:DONGGUAN COOLPAD SOFTWARE TECH

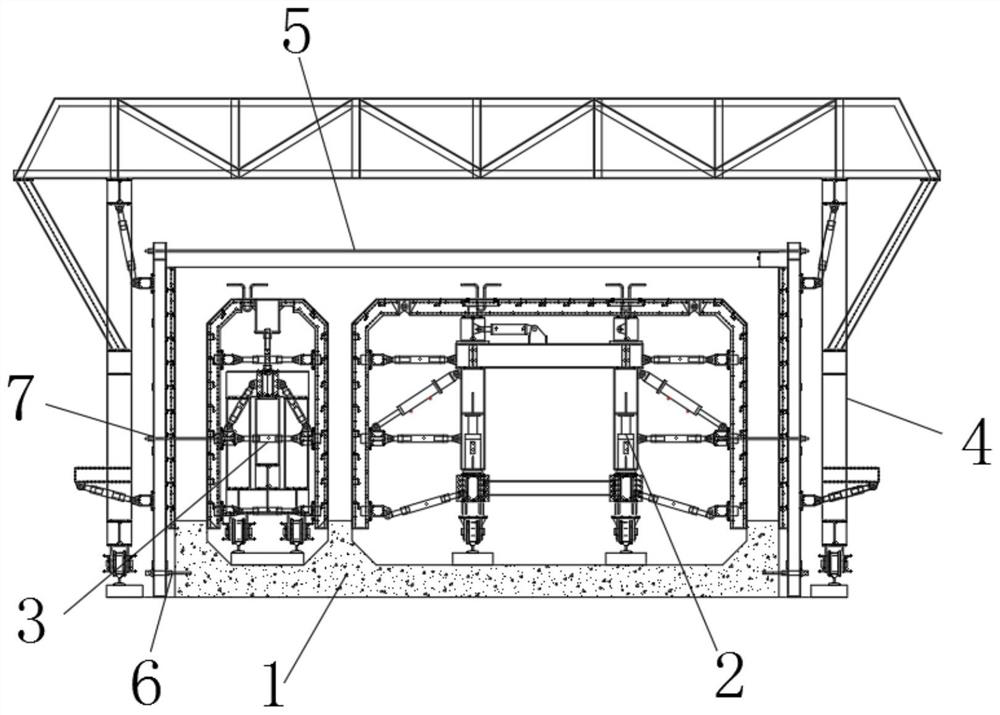

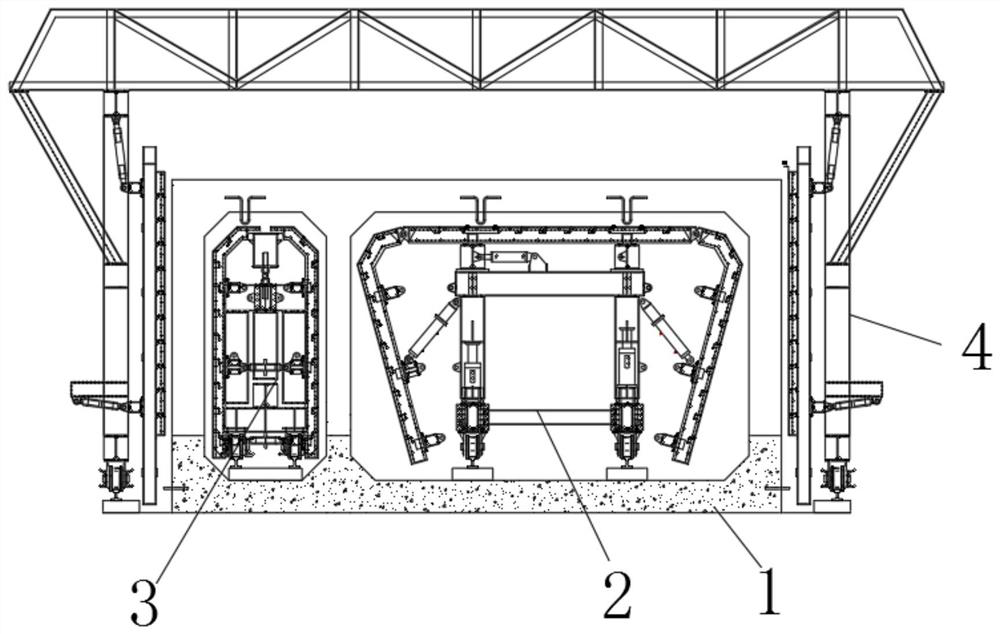

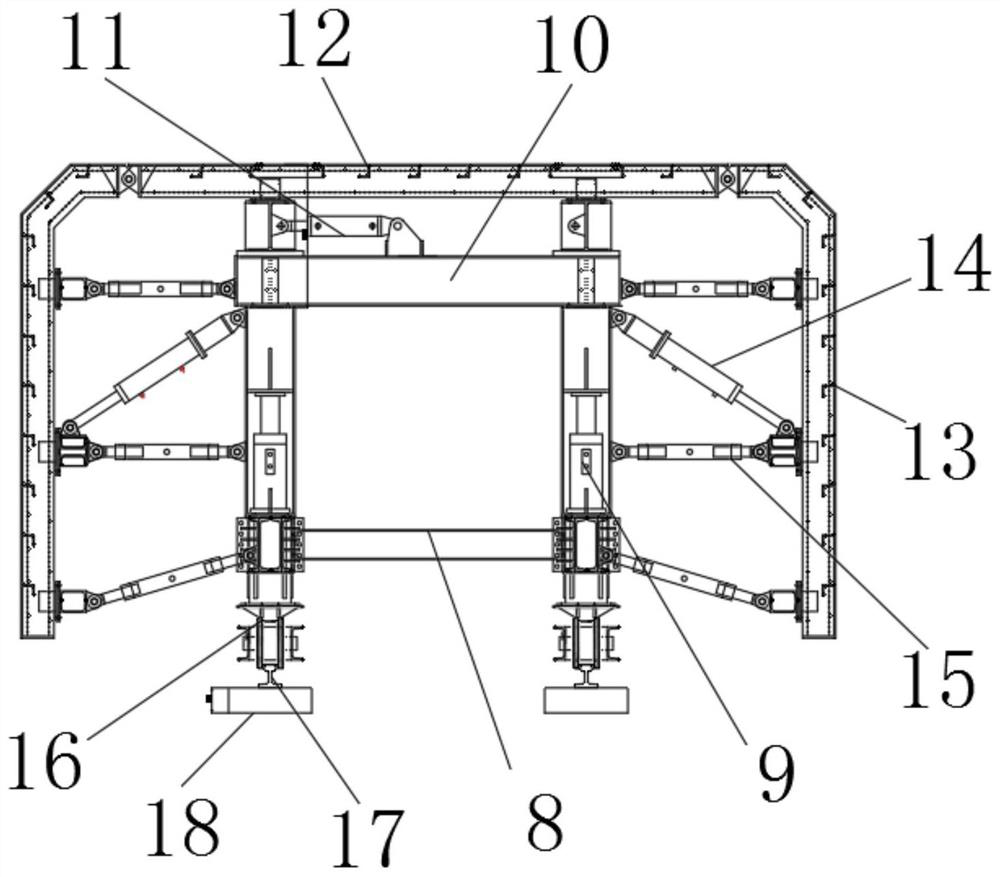

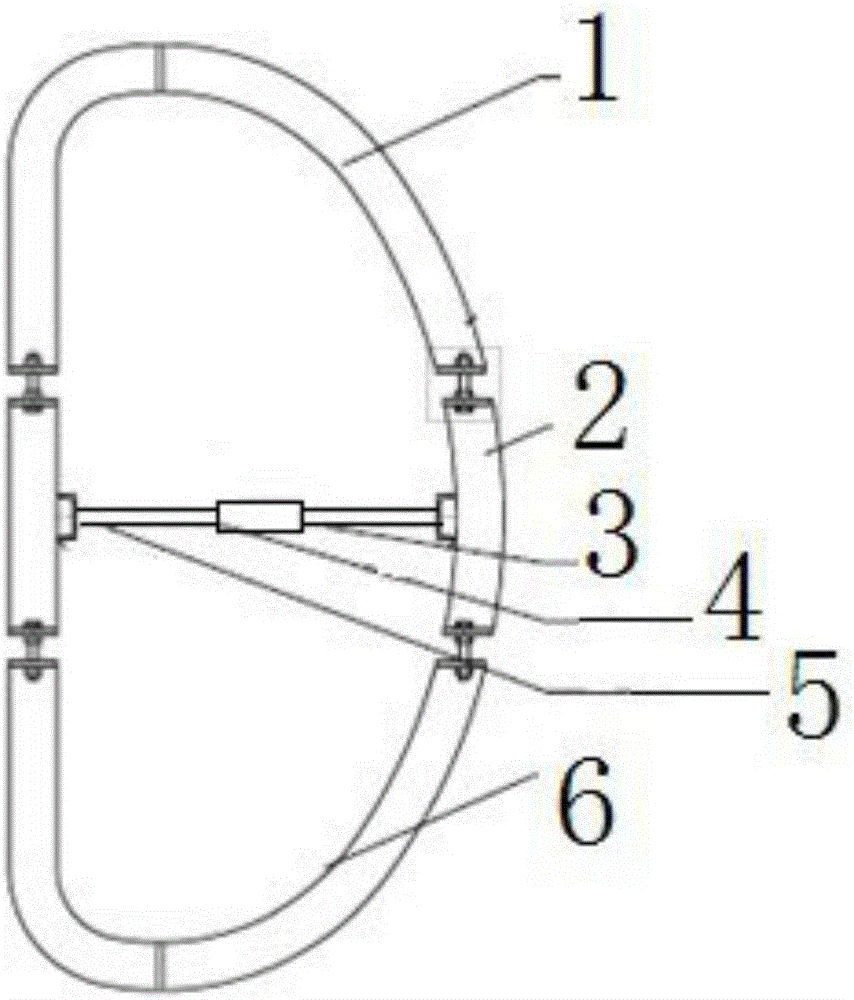

Double-pipe-rack slip form trolley and double-pipe-rack construction method

PendingCN113463683AGuaranteed stabilityEasy constructionArtificial islandsUnderwater structuresDouble tubeArchitectural engineering

The invention discloses a double-pipe-gallery slip form trolley and a double-pipe-gallery construction method, and relates to the field of constructional engineering equipment.The double-pipe-gallery slip form trolley comprises a bottom plate, an inner form trolley is installed at the top of the bottom plate, and a gas cabin trolley installed on the bottom plate is arranged on one side of the inner form trolley. According to the construction method, a pouring cavity of an M structure can be defined through the arrangement of the gas cabin trolley, the outer mold trolley and the inner mold trolley, so that the pipe gallery can be poured out, the stability of the gas cabin trolley, the outer mold trolley and the outer mold trolley during pouring can be guaranteed through the arrangement of the pull rod, the bottom pull rod and the top pull rod, and construction is facilitated. The construction method is simple in operation and convenient to construct, loss of redundant formworks and use of sporadic materials are avoided in the construction process, material cutting, waste and the like caused by wood formwork construction are avoided, and meanwhile environmental pollution caused by dust raising and formwork explosion caused by wood formwork cutting, supporting, demolding and the like is controlled.

Owner:重庆川九建设有限责任公司

Machining method for large double-layer thin-walled D-shaped section vacuum chamber fan-shaped section end face

The invention belongs to the technical field of nickel base alloy double-layer thin-walled structural component machining, and particularly relates to a machining method for a large double-layer thin-walled D-shaped section vacuum chamber fan-shaped section end face. According to the machining method, firstly, a tool is adopted for positioning, the forming error of high-strength alloy panels is effectively avoided, and rigidity is increased through an inner supporting tool; and a circle of waist line is drawn through a platform, and the size error of all spliced sections of a D-shaped section is solved. The influence of the outer arc forming error of the D-shaped section on the 18-degree section is solved through machine tool line drawing. A mold is fixed, a workpiece is positioned and clamped, a base plate is adopted for a force exerting point, and therefore a positioning contact face during machining is enlarged; and meanwhile, a stainless steel plate of a similar shape is manufactured on the positioning contact face to be cushioned at the force exerting point, the contact area is enlarged, and deformation of the product is reduced to the maximum extent. Due to the adoption of the method, the problems that double-layer thin-walled pieces are twisted and folded after being machined, the end face flatness is quite poor and metal fillings fall into interlayer runners can be well solved.

Owner:西安核设备有限公司 +1

Gear transmission structure

The invention discloses a gear transmission structure. The gear transmission structure comprises a main frame, wherein a bottom plate is arranged on the main frame, two first convex bases are arranged on the bottom plate, and two limiting holes are formed in the bottom plate; a sliding plate is arranged on the bottom plate, two embedding grooves are formed in one end face of the sliding plate, a through hole is formed in the middle of the sliding plate, and the radius of the through hole is 10cm; the through hole is located between the two embedding grooves, and the other end face of the sliding plate is provided with two second convex bases; and the two first convex bases are connected with the two second convex bases through springs respectively. According to the gear transmission structure, gaps between transmission gears and row teeth are eliminated, and the size error of the material part is effectively avoided. The gear transmission structure has the beneficial effects of being low in transformation cost, long in service life, improving the product percent of pass and the like.

Owner:重庆智成友和会计服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com