Device and method for preparing cylindrical standard test pieces of filling bodies

A standard test piece and preparation device technology, which is applied to the filling body cylindrical standard test piece preparation device and the field of mine filling theory, can solve the problems of destroying the integrity of the test piece, the influence of mechanical parameters, and the damage of the test piece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

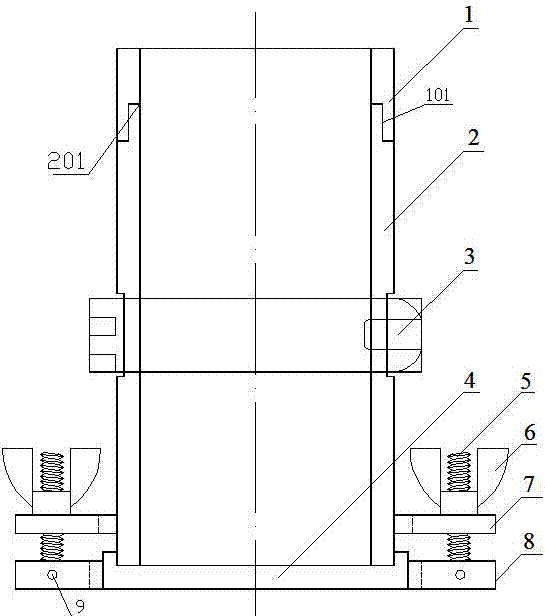

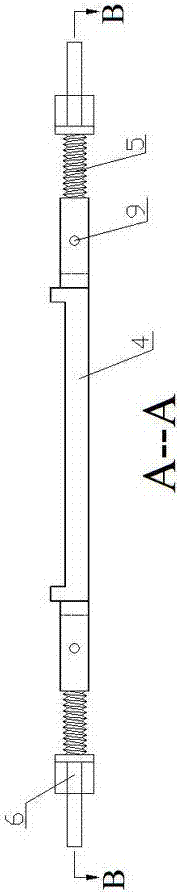

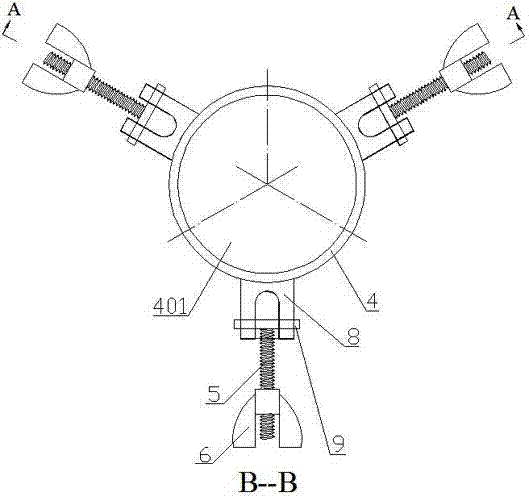

[0035] A kind of filling body cylindrical standard test piece preparation device, refer to the attached figure 1 to attach Figure 11 , in the figure: floating mold 1, concave edge structure 101, side mold 2, convex edge structure 201, positioning groove structure 202, clamp 3, bottom mold 4, circular groove structure 401, screw rod 5, wing nut 6 , U-shaped groove structure 7, U-shaped groove 8, horizontal axis 9.

[0036] In this embodiment, the center of the bottom mold 4 is provided with a circular structure groove 401, and the bottom of the cylindrical side mold 2 is housed in the circular structure groove 401. The side mold 2 is composed of three identical arc-shaped split structures. Three arc-shaped split structures with the same structure can be (such as Figure 11 As shown) along the axial direction, one end has a dovetail groove, and the other end h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com