New structure fixing fixture for metal irregular workpiece machining

A technology for special-shaped workpieces and fixtures, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of poor stability and adaptability, narrow use range, etc., to improve the stability of use, improve adaptability, Improve the effect of clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

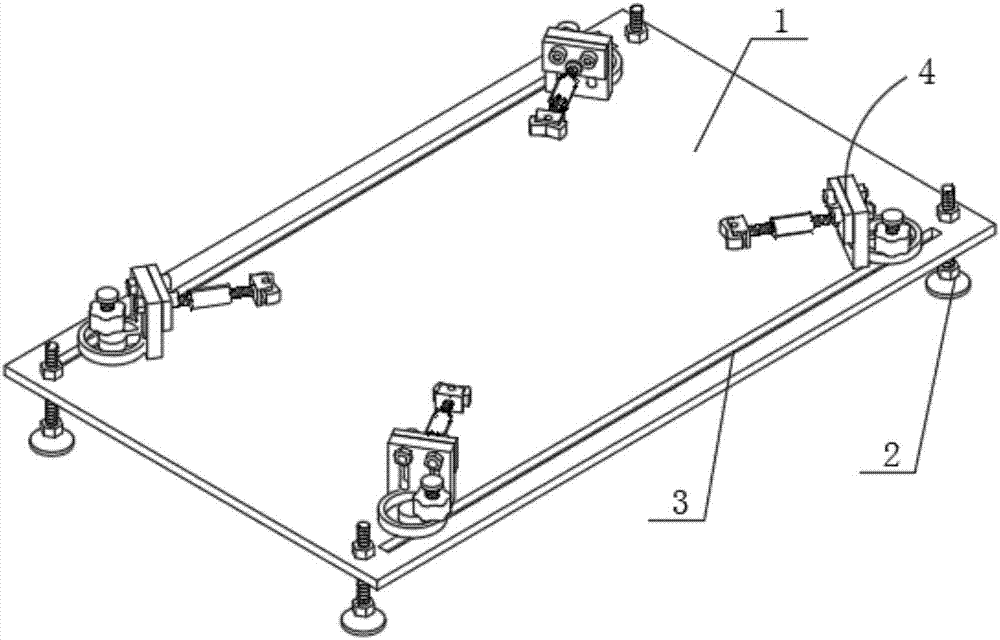

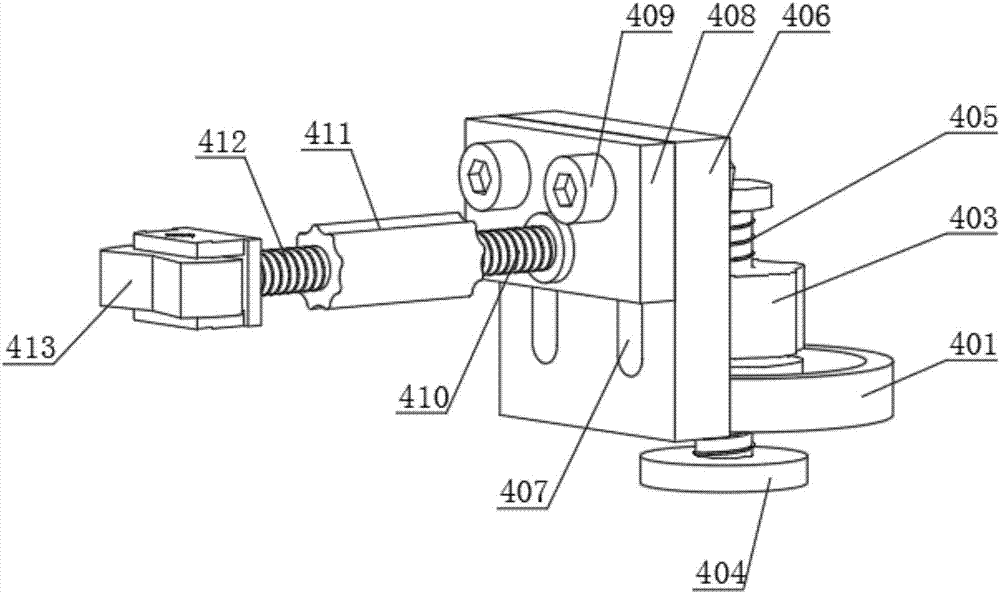

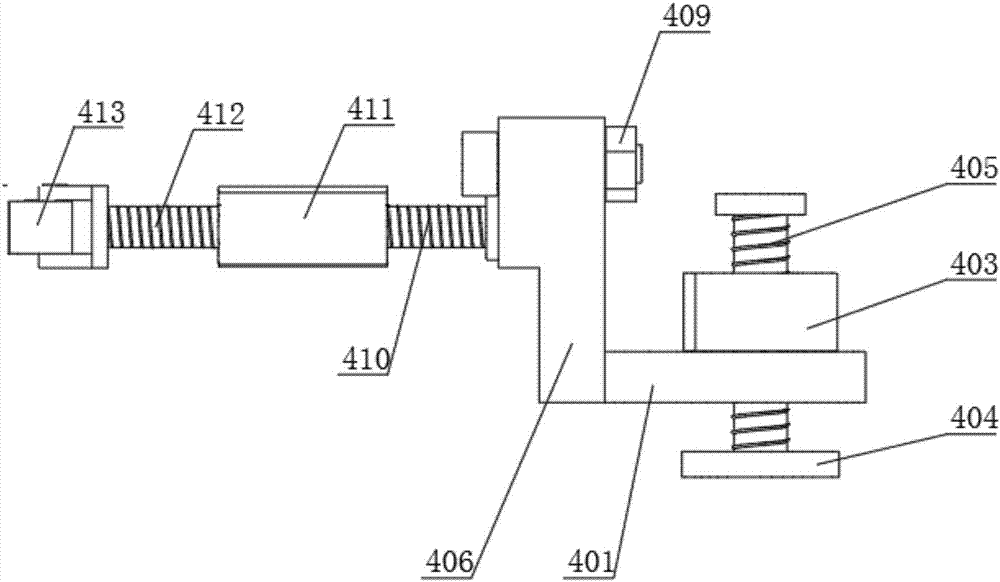

[0023] as attached figure 1 to attach Figure 5 Shown:

[0024] The invention provides a new structure fixing fixture for processing metal special-shaped workpieces, which includes a workbench 1, a foot 2, an adjustment chute 3, a clamping device 4, a turntable 401, a ring groove 402, a locking block 403, a pressing block 404, an adjustment Screw rod 405, mounting seat 406, height adjustment groove 407, sliding seat 408, locking bolt 409, first stud 410, adjusting screw sleeve 411, second stud 412, clamping block 413, jacket 414 and rotating shaft 415; The four corners of the workbench 1 are supported by four legs 2; the two sides of the workbench 1 are provided with two adjustment chute 3; the clamping device 4 is installed on the adjustment chute 3; each adjustment There are two clamping devices 4 on the chute 3; the clamping device 4 includes a turntable 401, a ring groove 402, a locking block 403, a pressing block 404, an adjusting screw 405, a mounting seat 406, a chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com