Multi-directional air inlet extractor hood structure

A range hood, multi-directional technology, applied in the direction of oil fume removal, heating method, household heating, etc., can solve the problems of limited enhancement of smoking effect, loss of air volume of condensing oil guide plate, cost consumption, space occupation, etc., to achieve Good smoking effect, solve the problem of oil fume escape, high practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

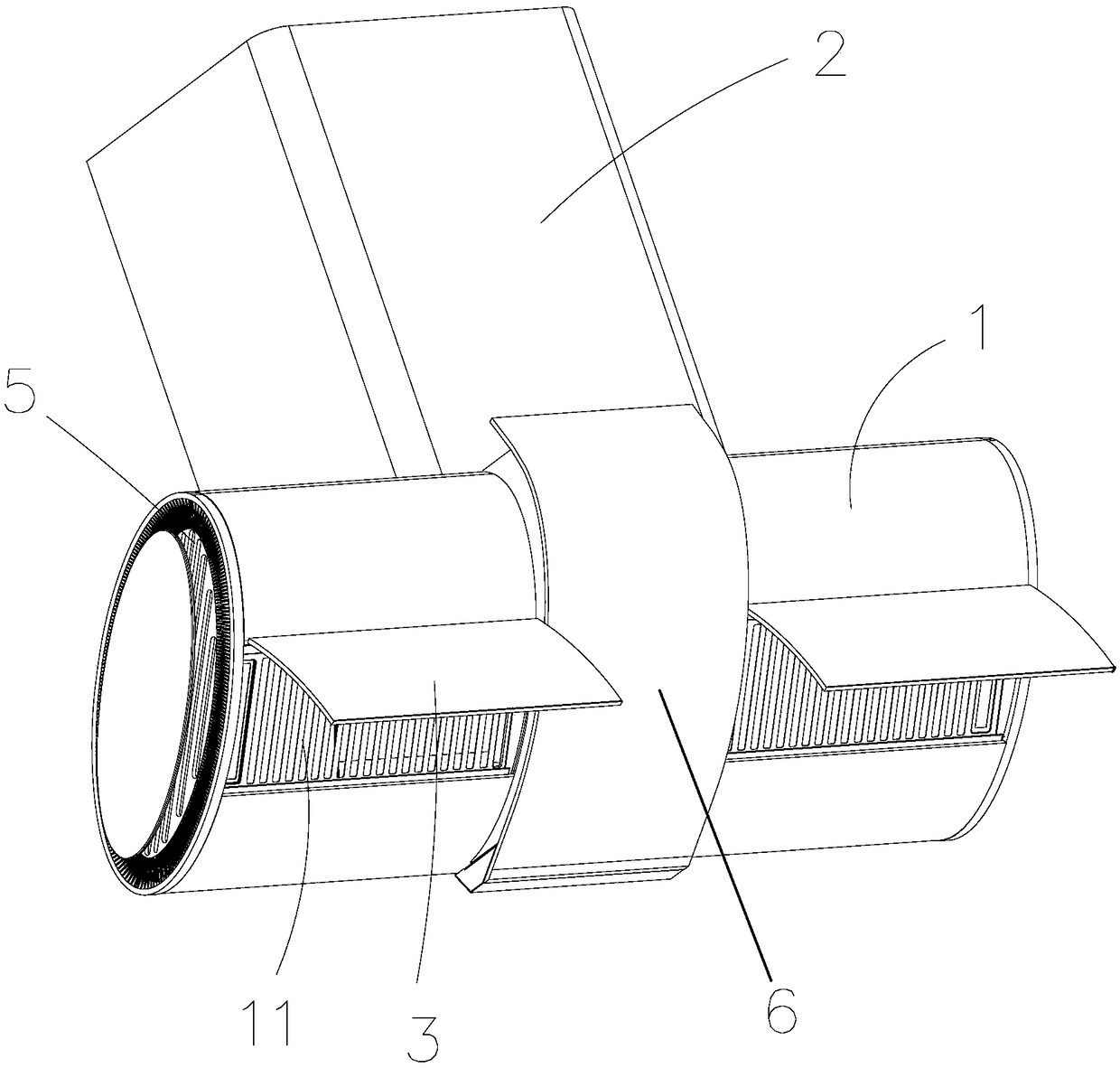

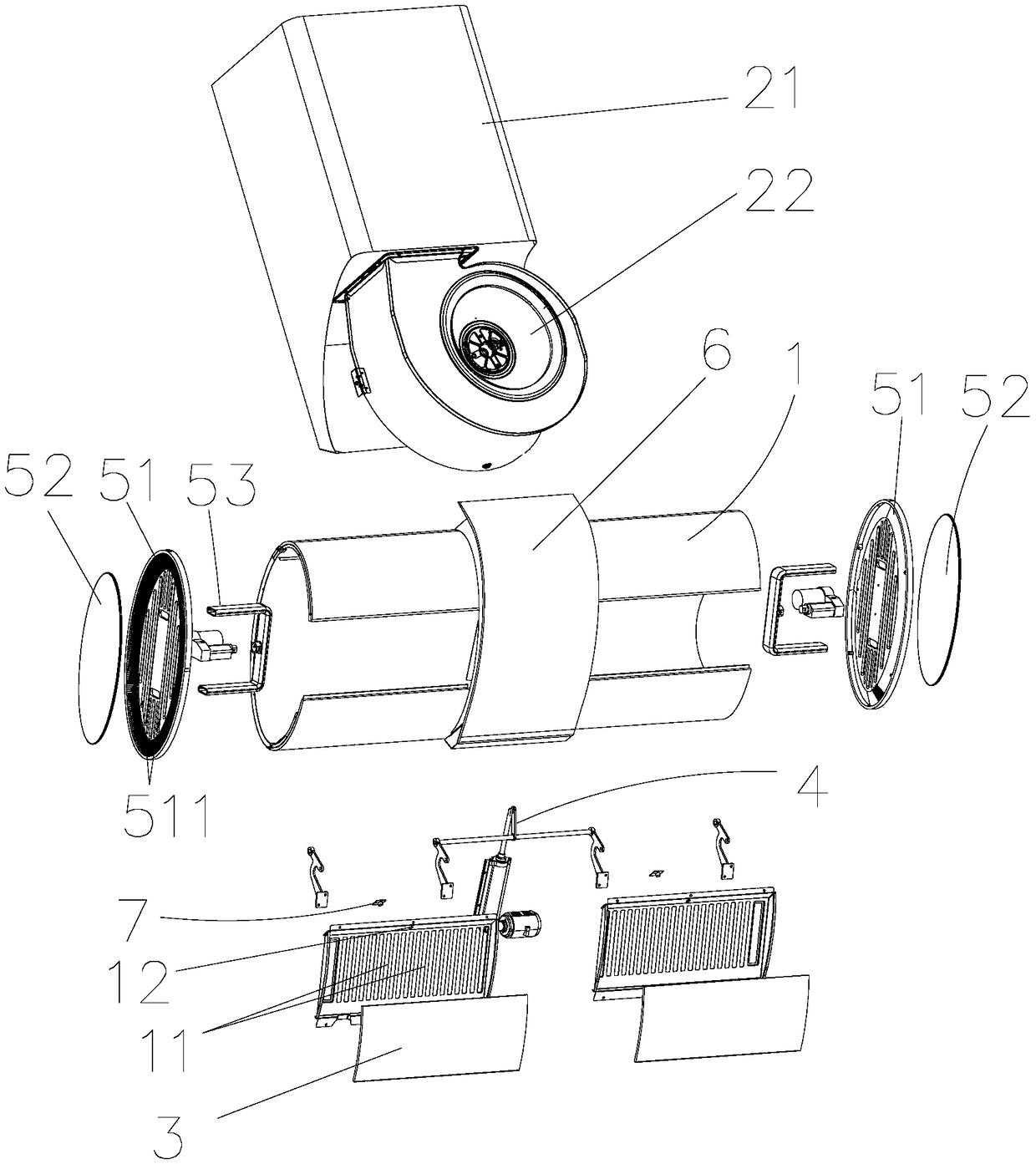

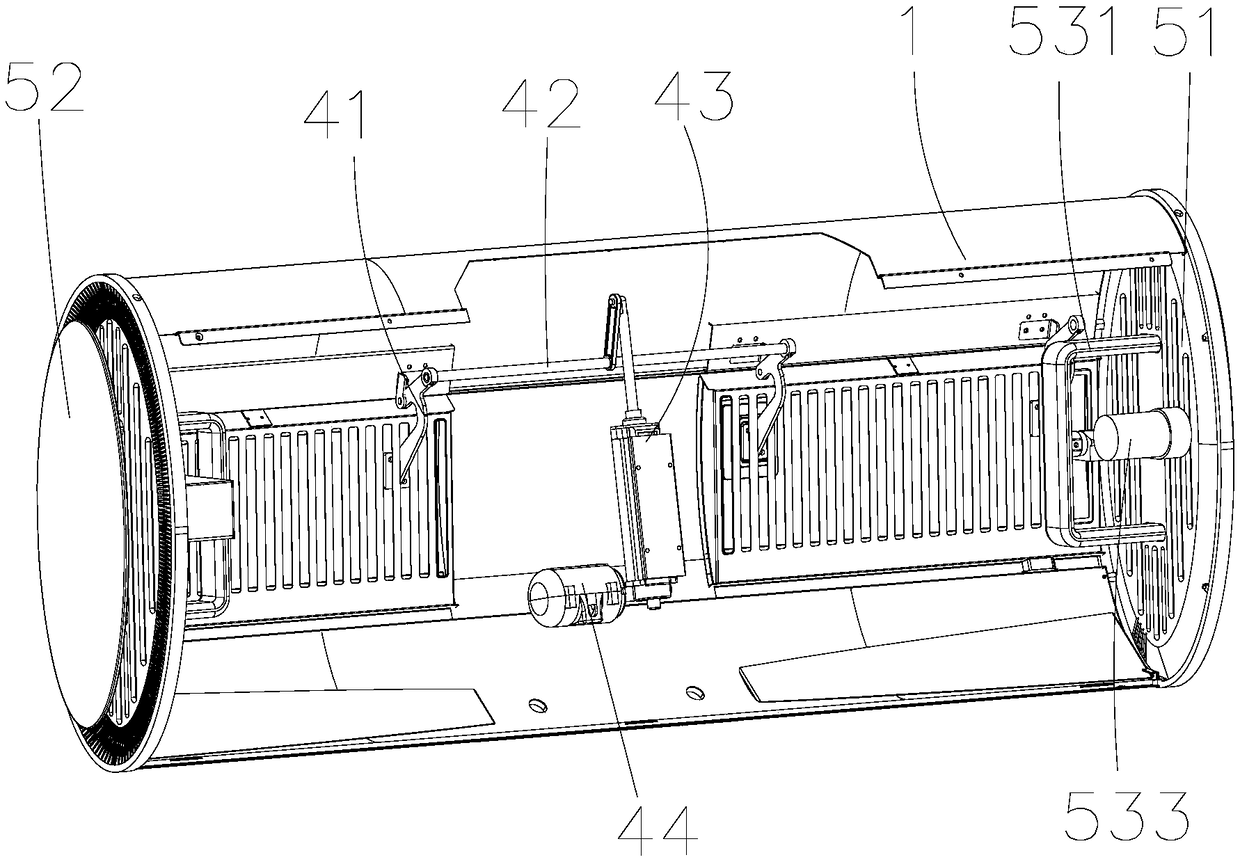

[0033] Such as Figure 1 to Figure 5 As shown, a range hood structure with multi-directional air intake includes a range hood casing 1 and a wind cabinet assembly 2 arranged above the range hood casing 1, and the range hood casing 1 is provided with Control system 6, the range hood casing 1 is provided with a main air inlet 11, and the main air inlet 11 is provided with a smoke collecting plate 3 and a swing assembly 4 that drives the smoke collecting plate 3 to open and close, and the range hood cabinet The body 1 is also provided with a side air intake assembly 5; the side air intake assembly 5 includes a side plate 51 arranged on the side of the range hood cabinet 1, and a side air intake 511 is opened on the side plate 51, and the side air intake 511 A cover plate 52 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com