Patents

Literature

34results about How to "Improve mixing adequacy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

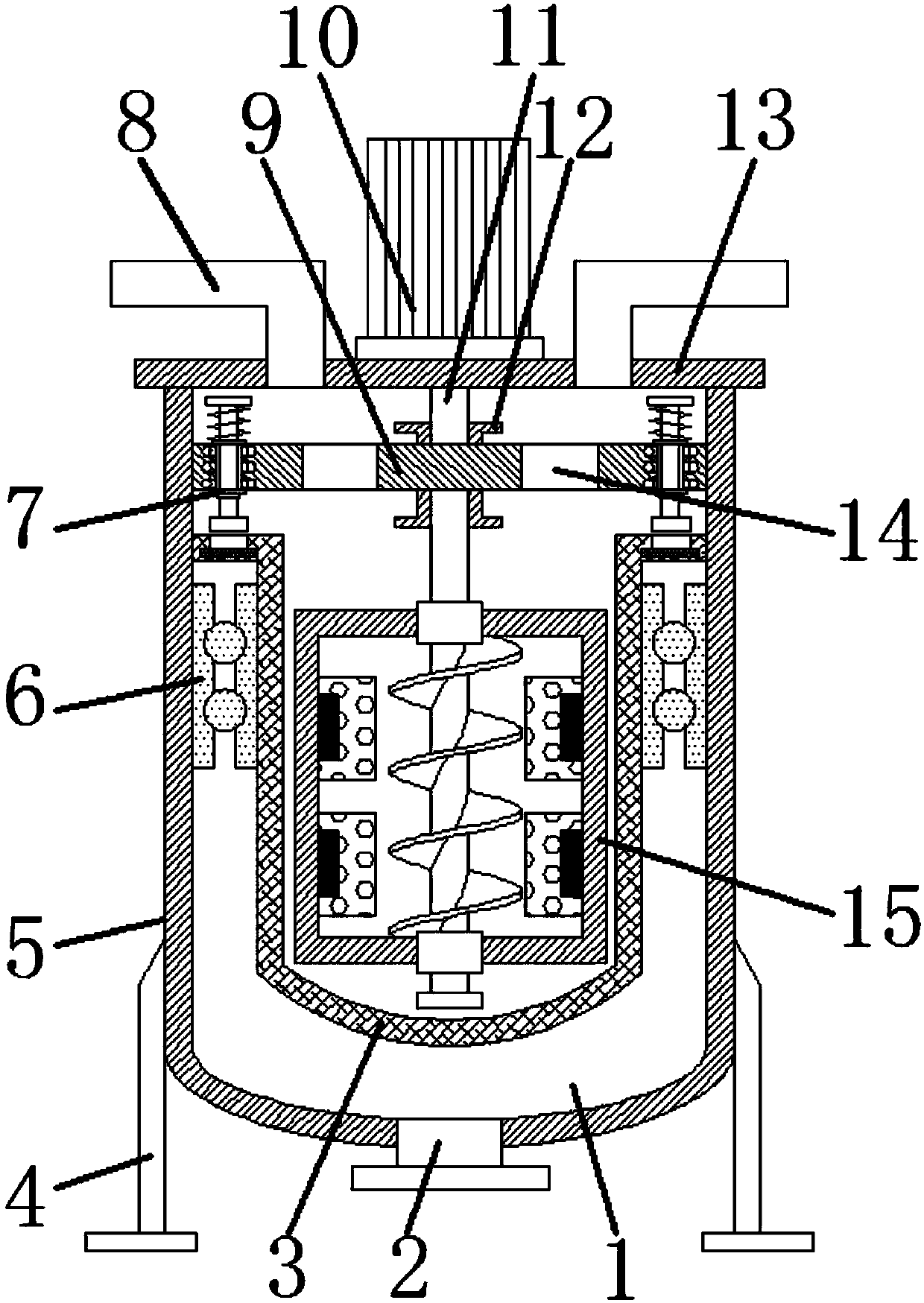

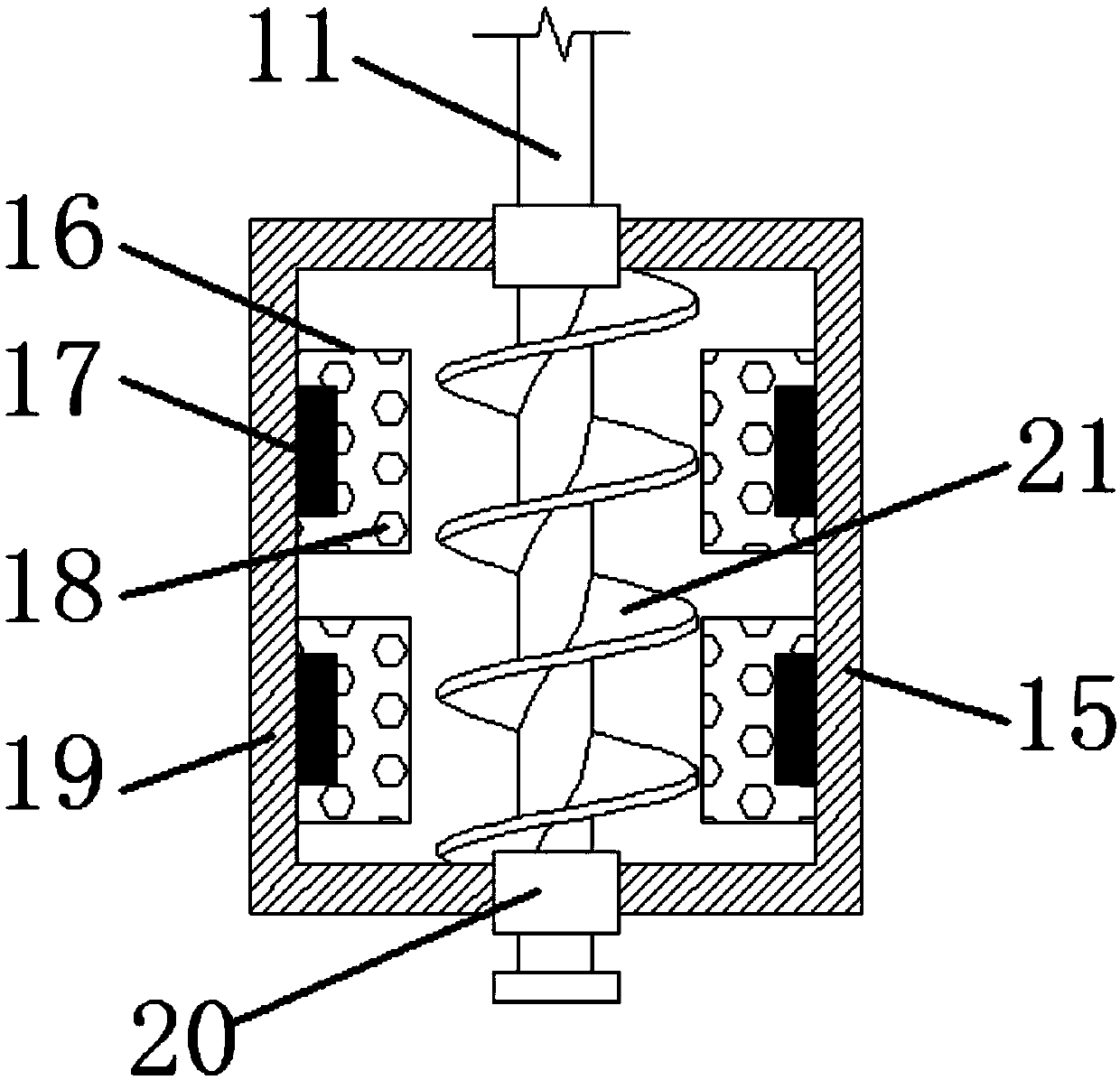

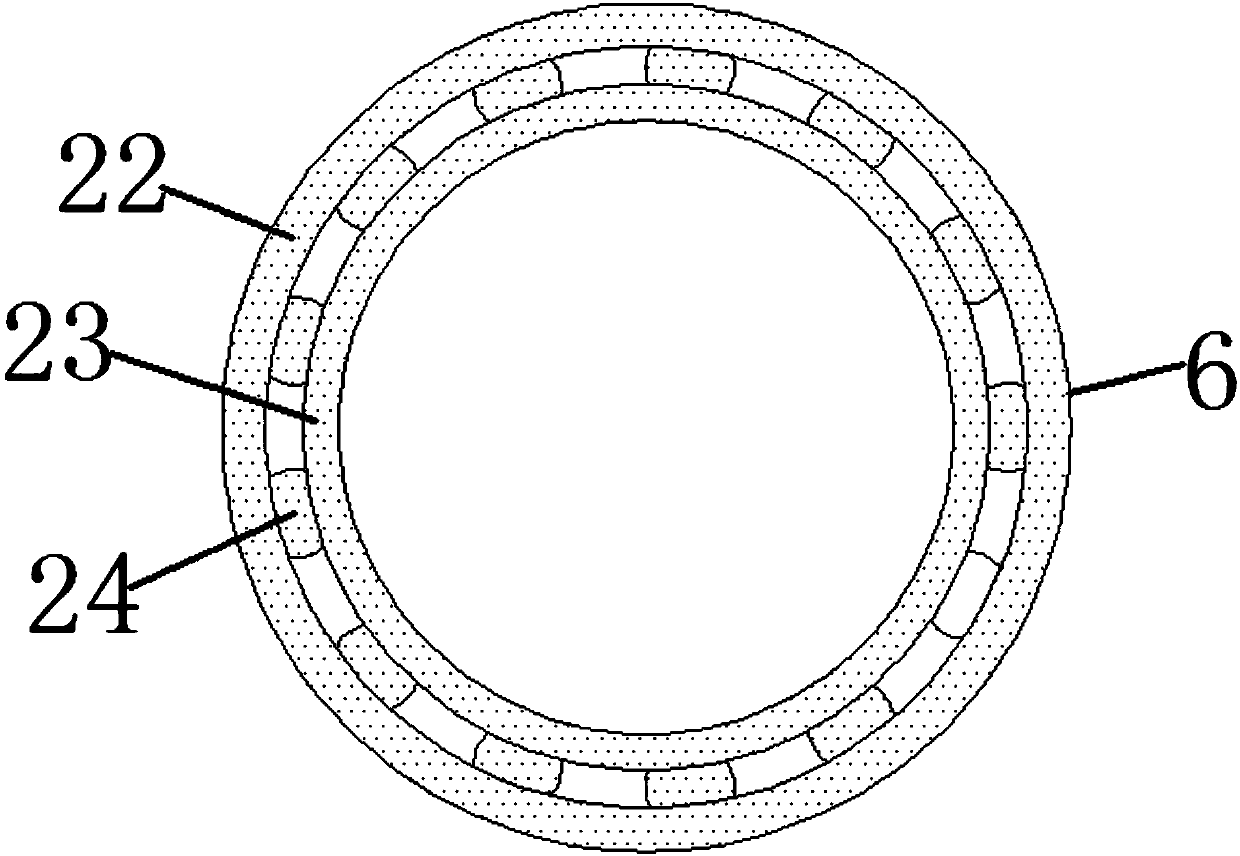

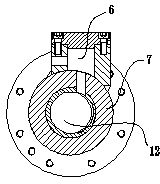

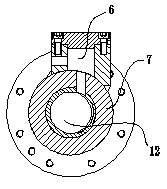

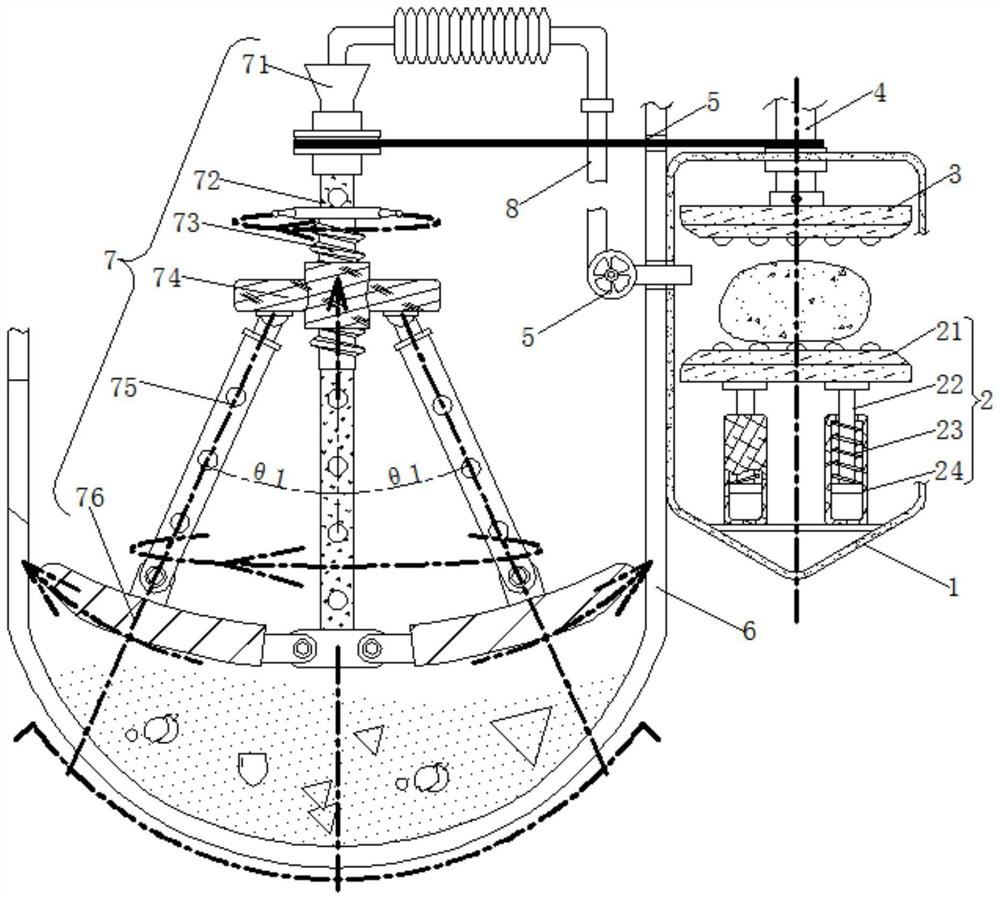

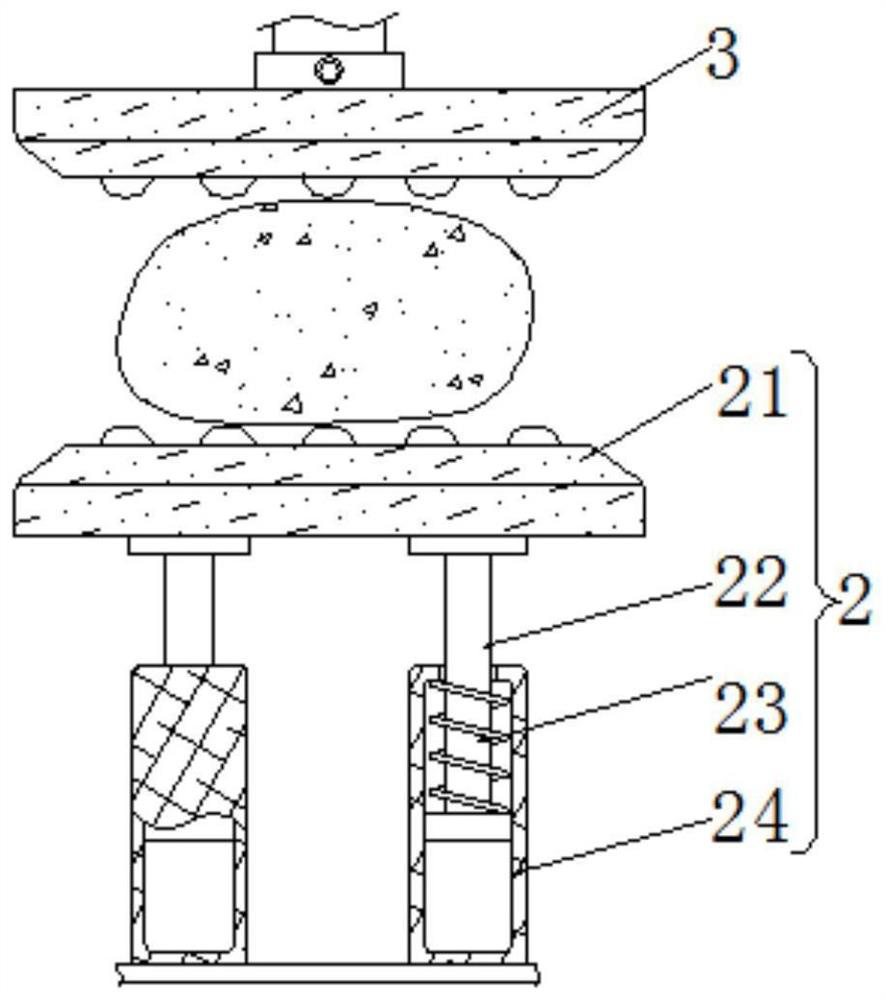

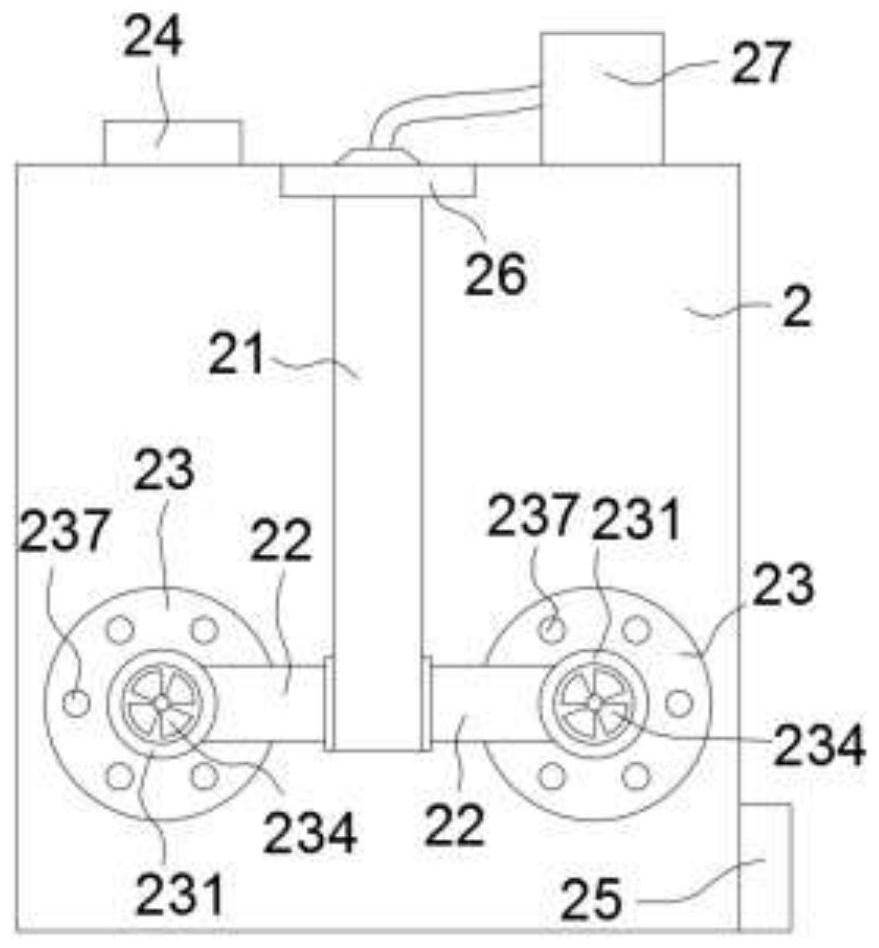

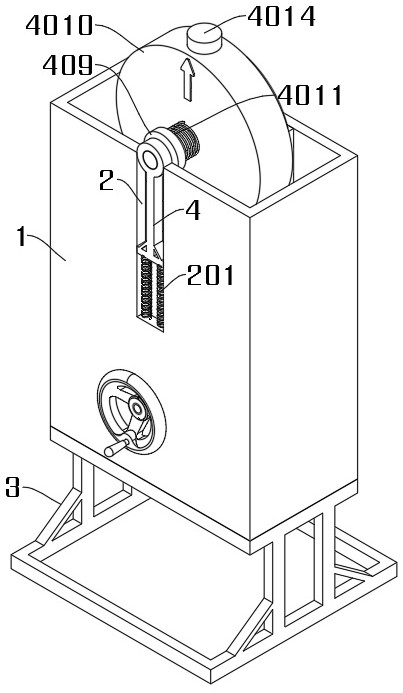

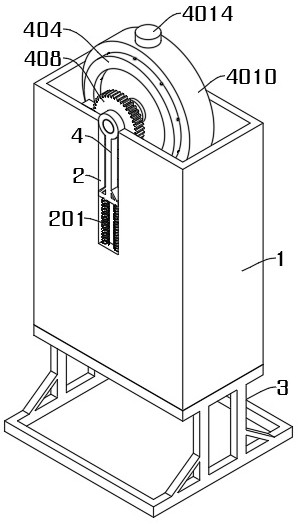

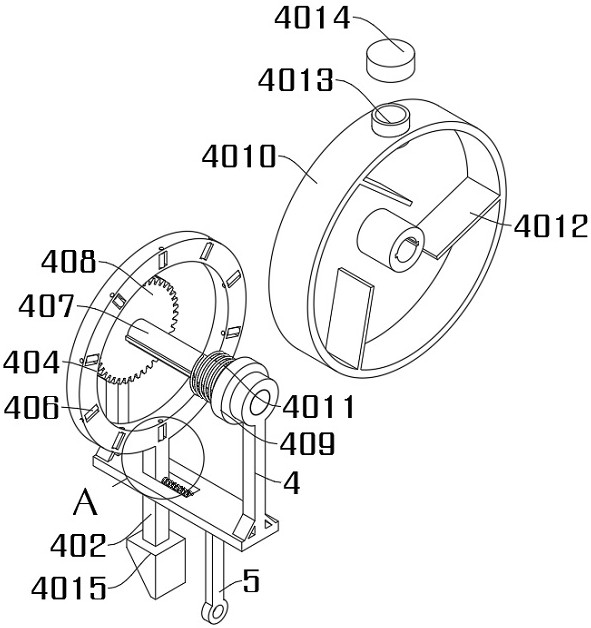

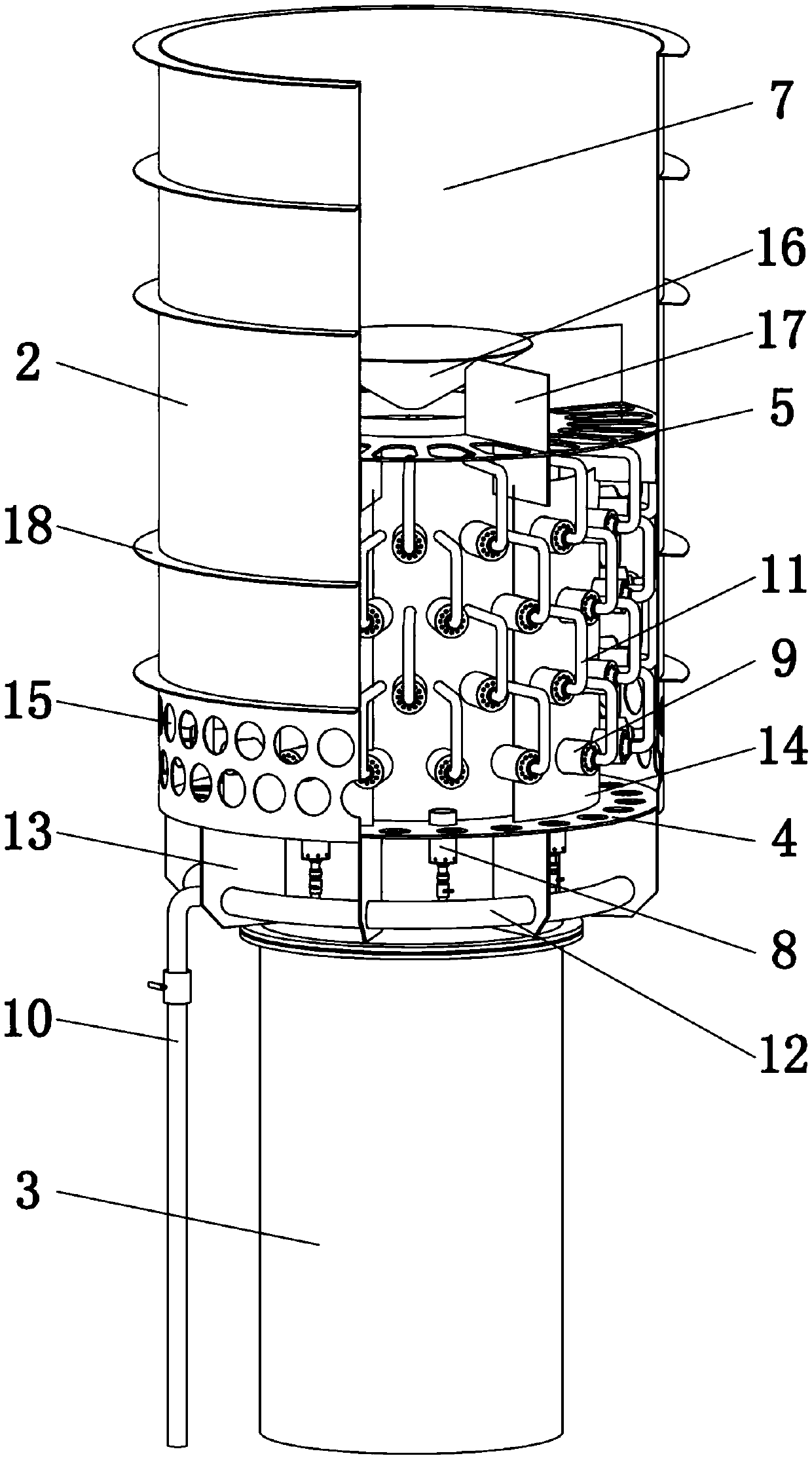

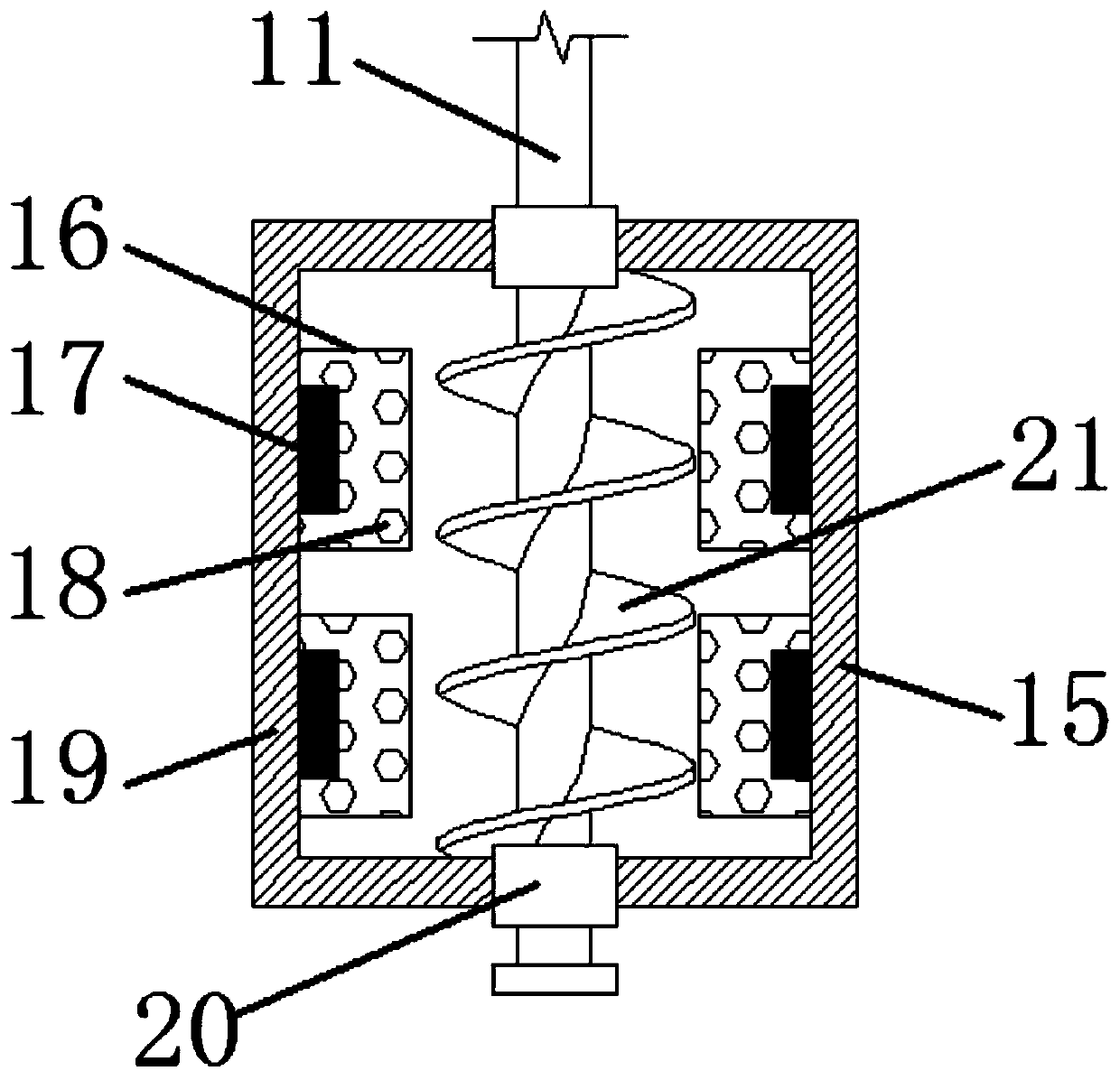

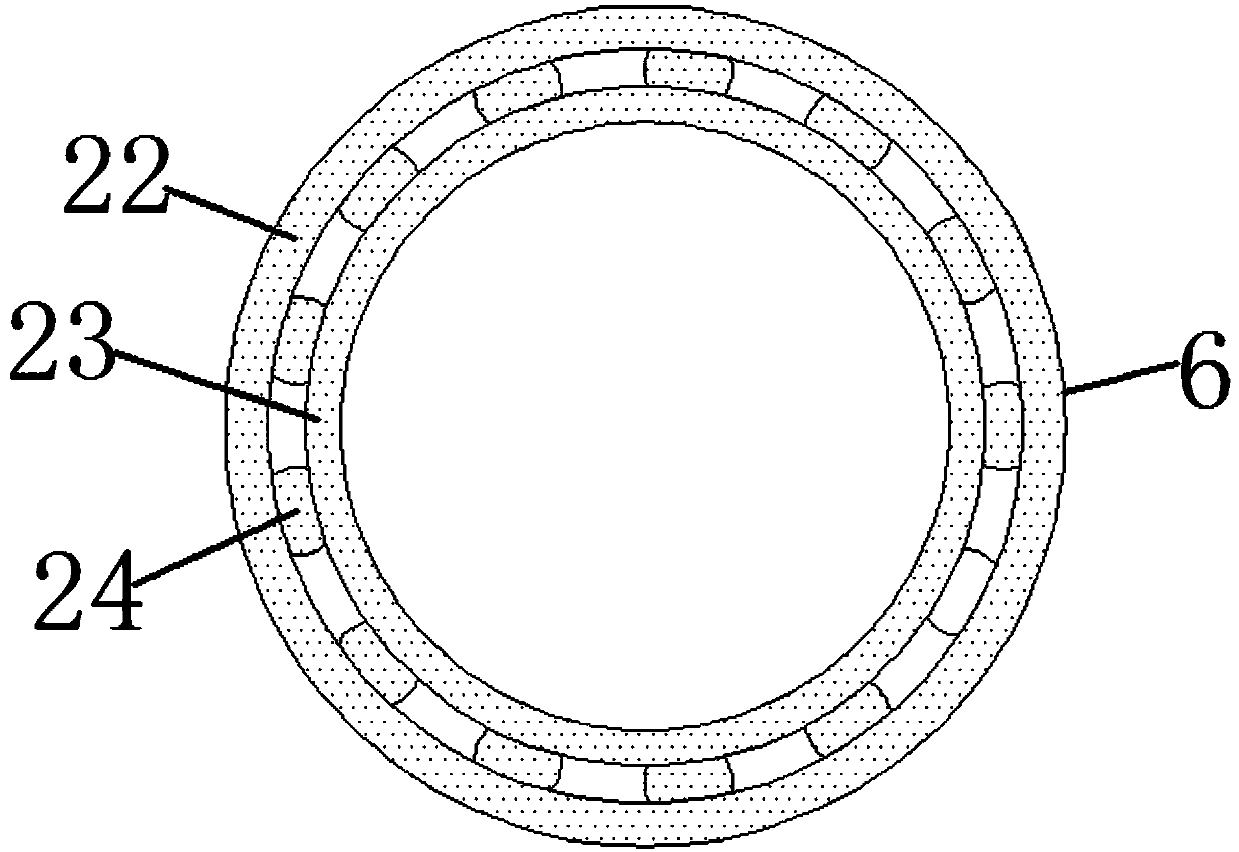

Building coating stirring and centrifugal separating device capable of removing ferromagnetic material

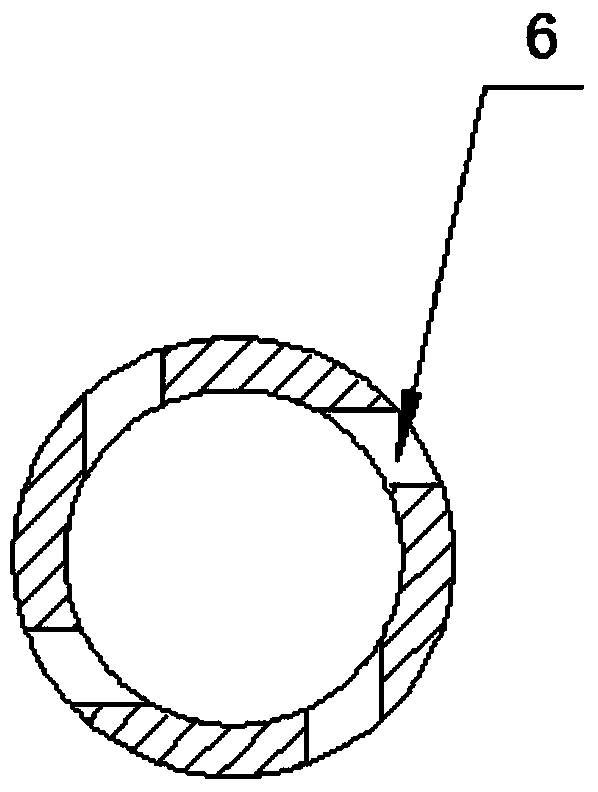

InactiveCN107866334AStable structureEasy to addRotary stirring mixersTransportation and packagingBall bearingArchitectural engineering

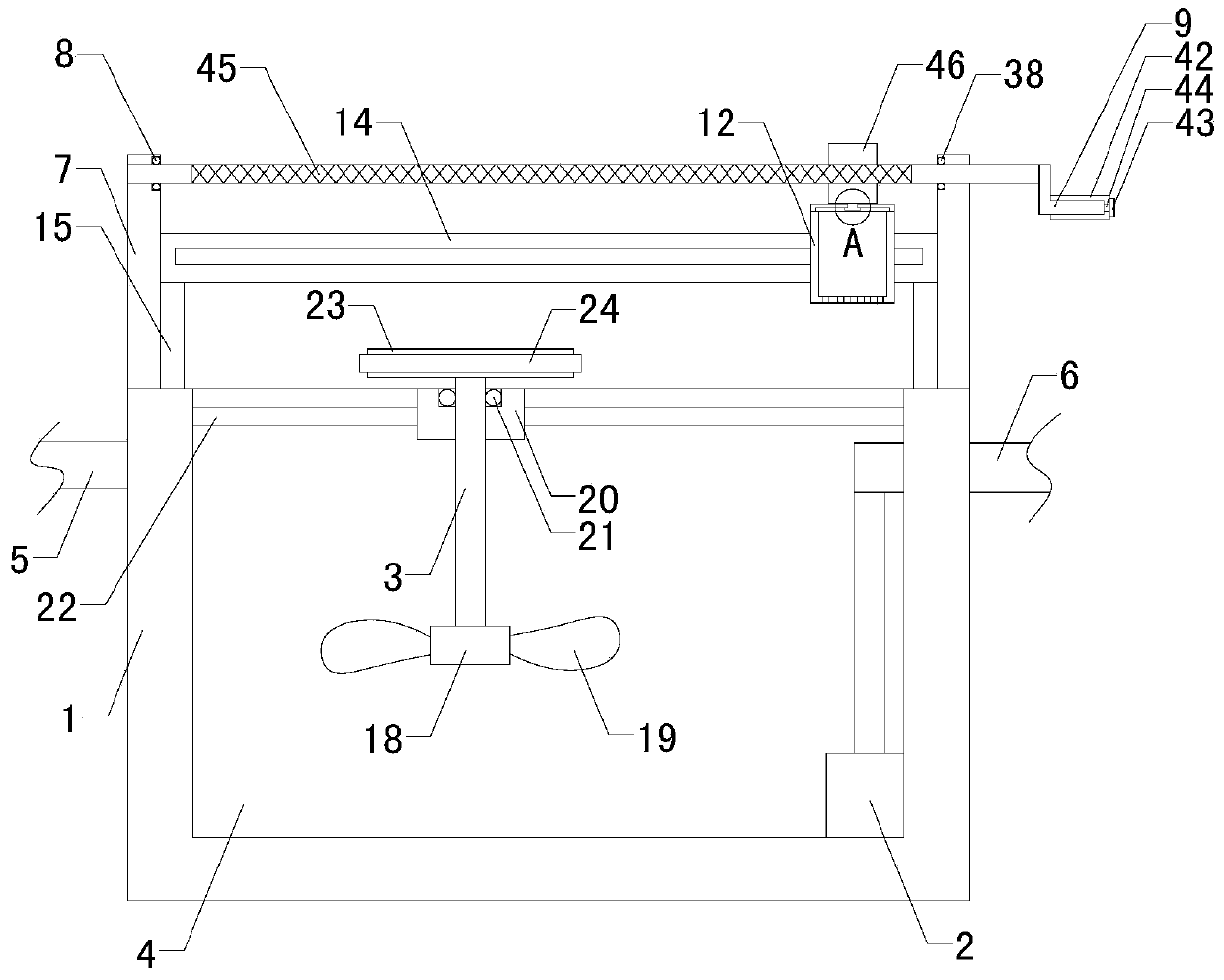

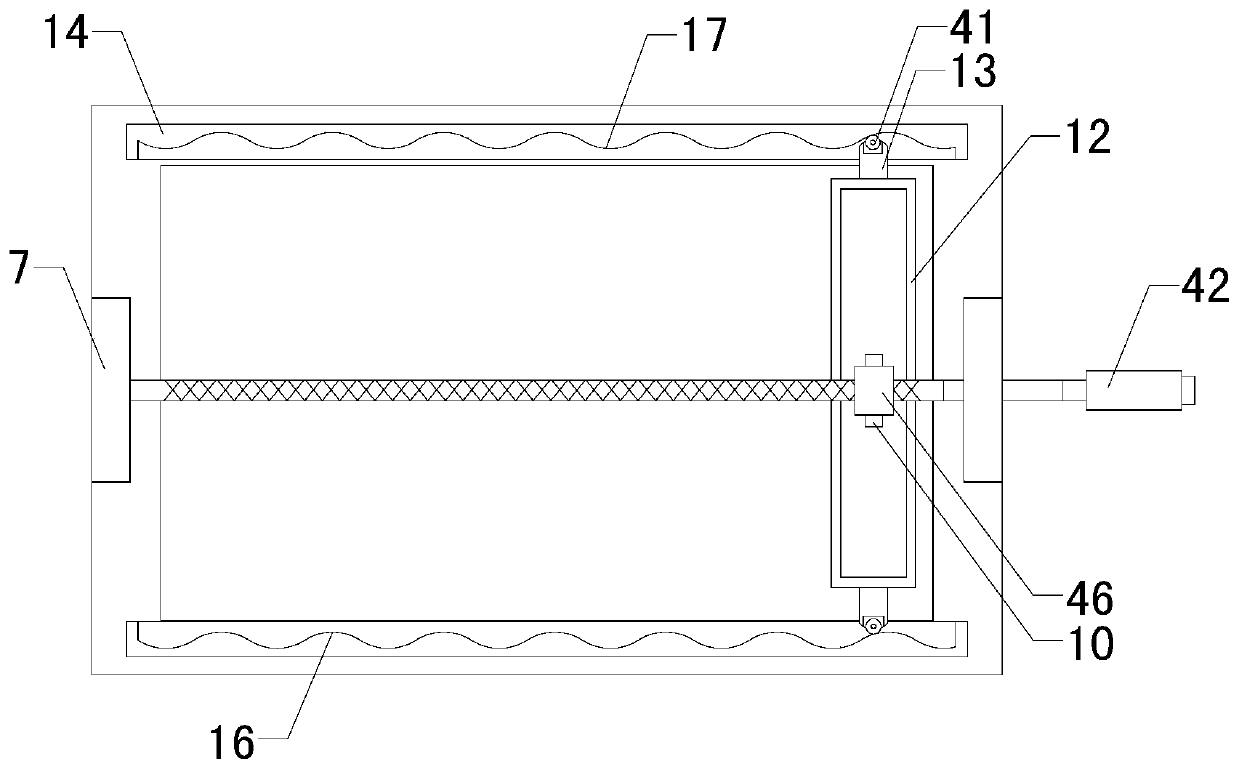

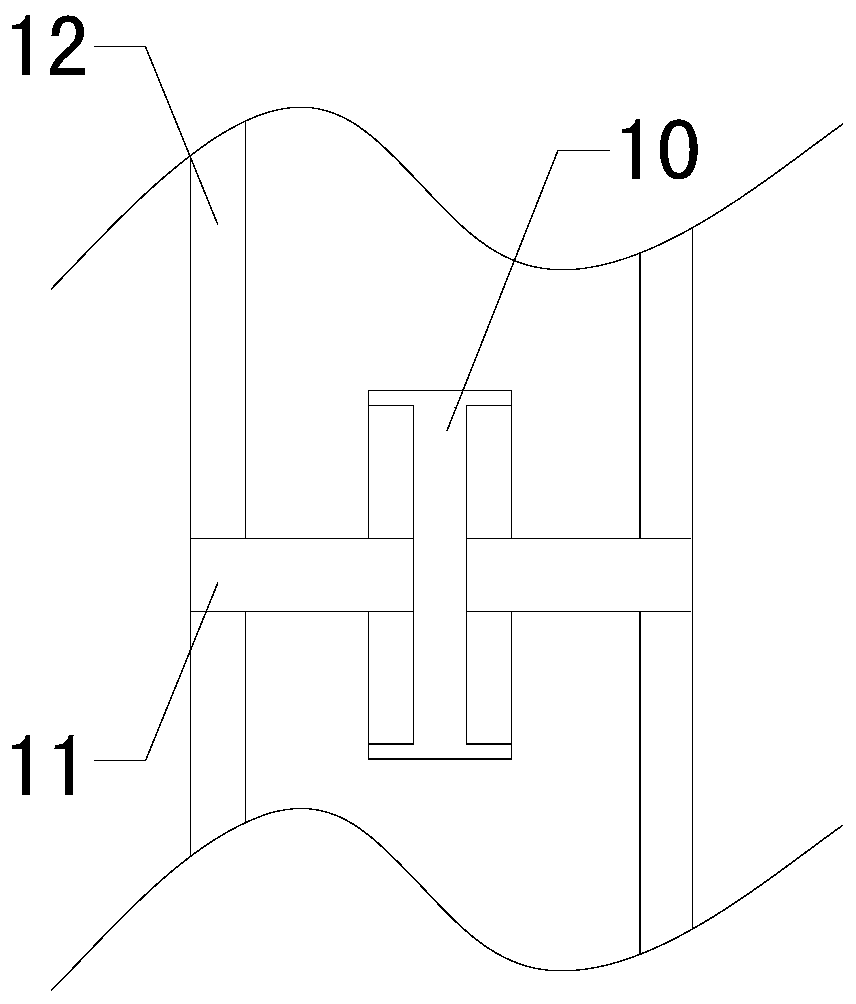

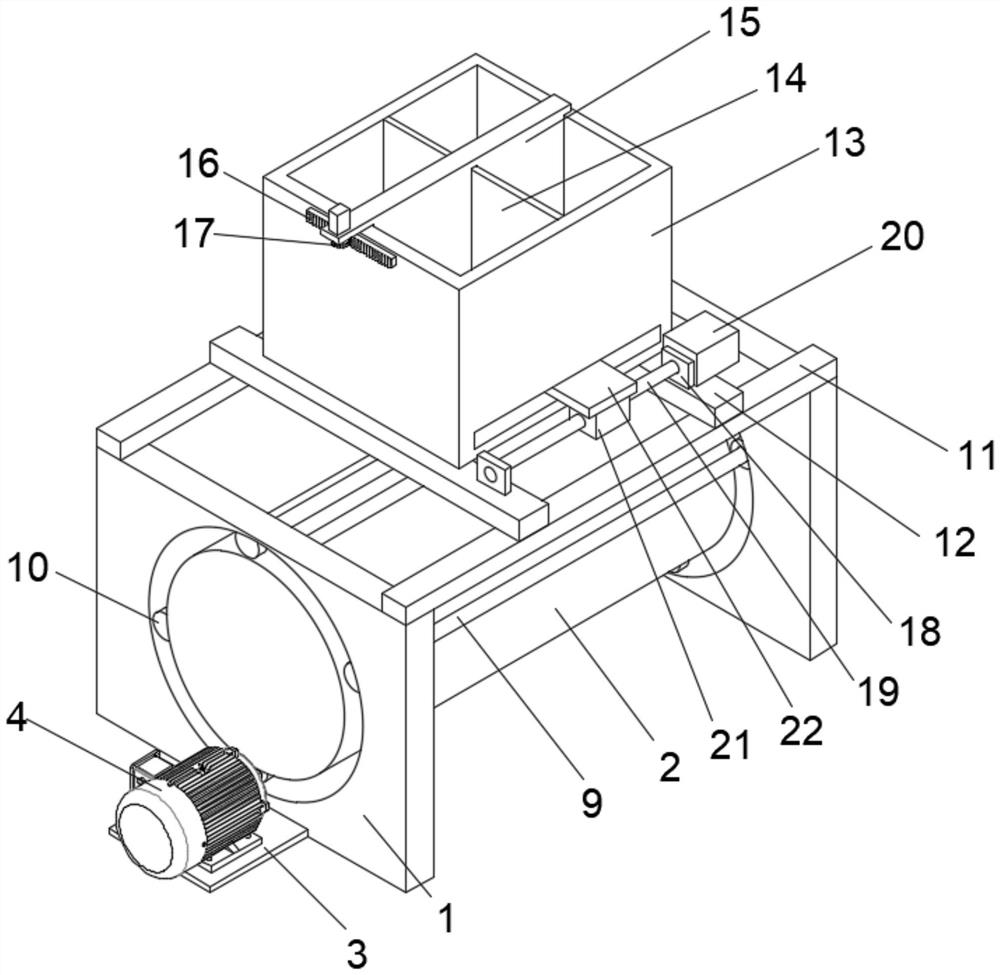

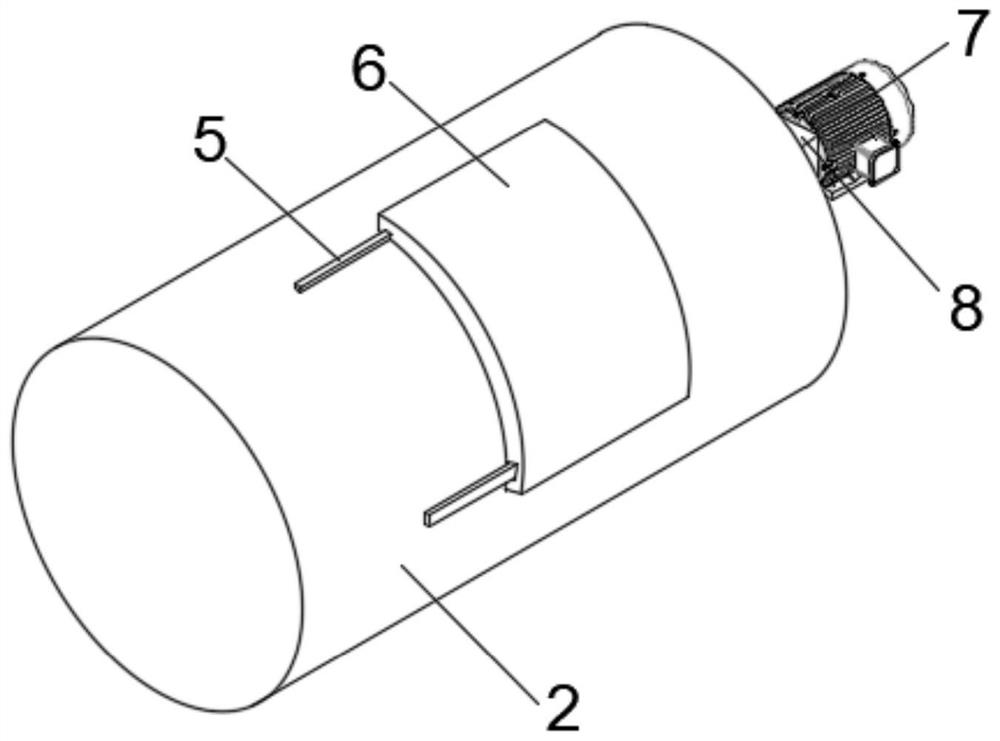

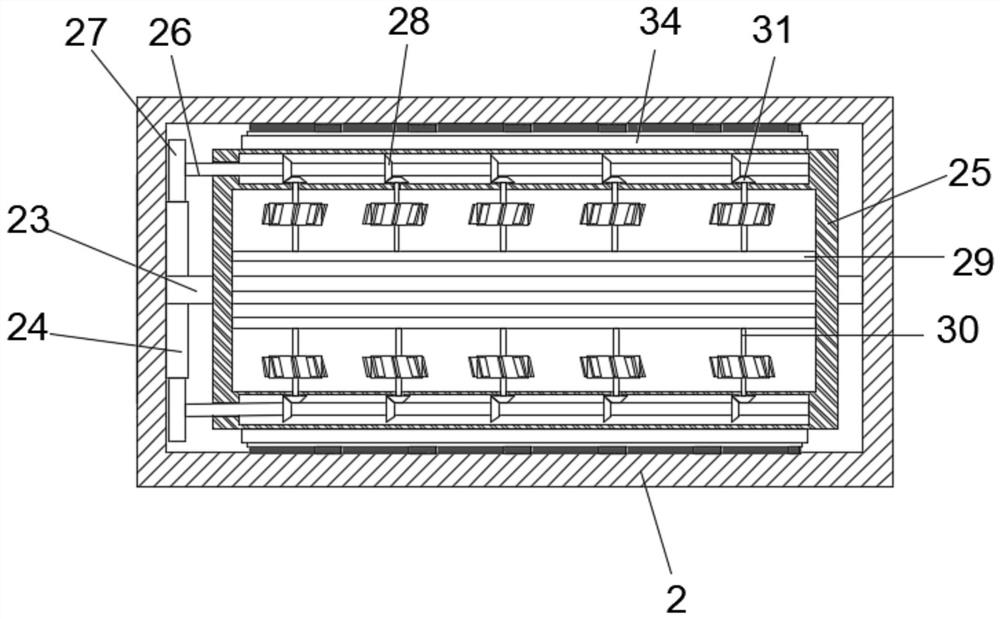

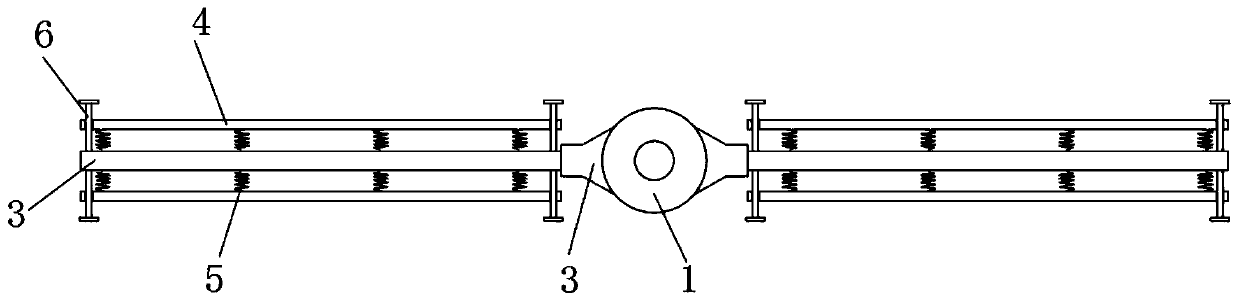

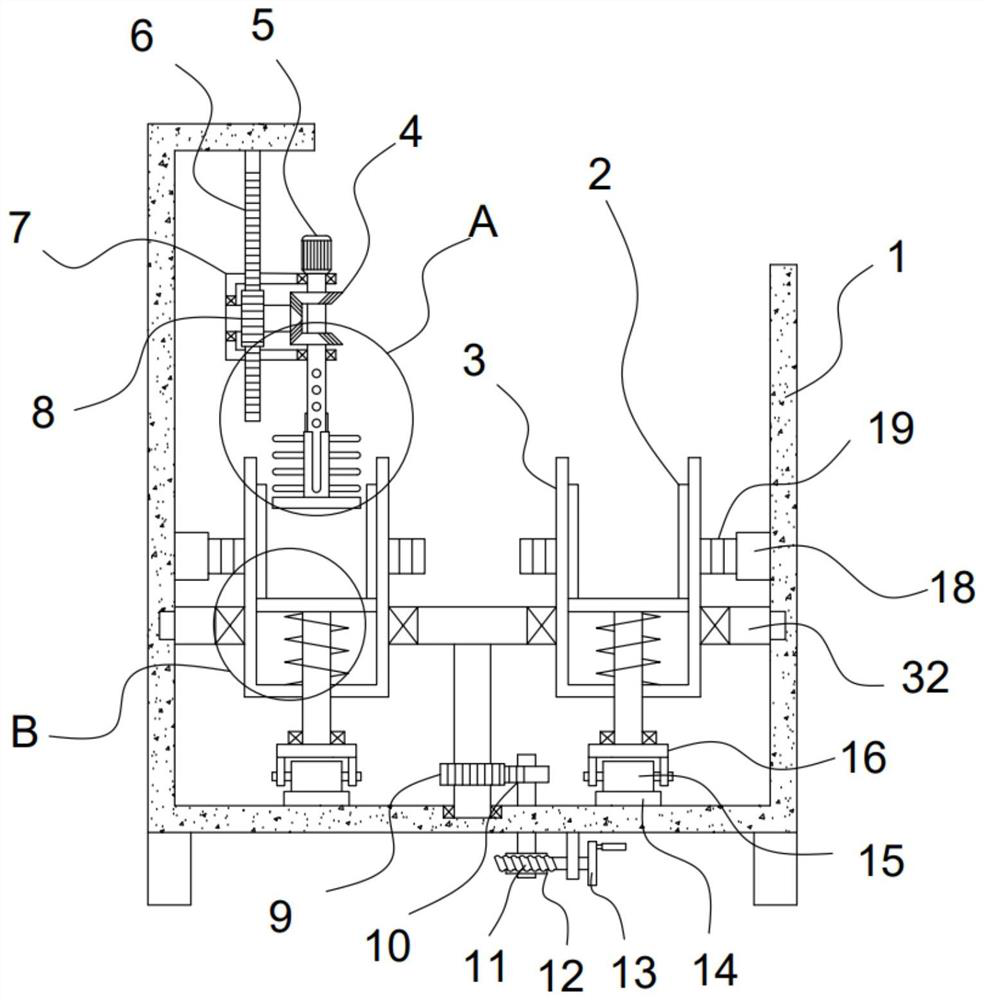

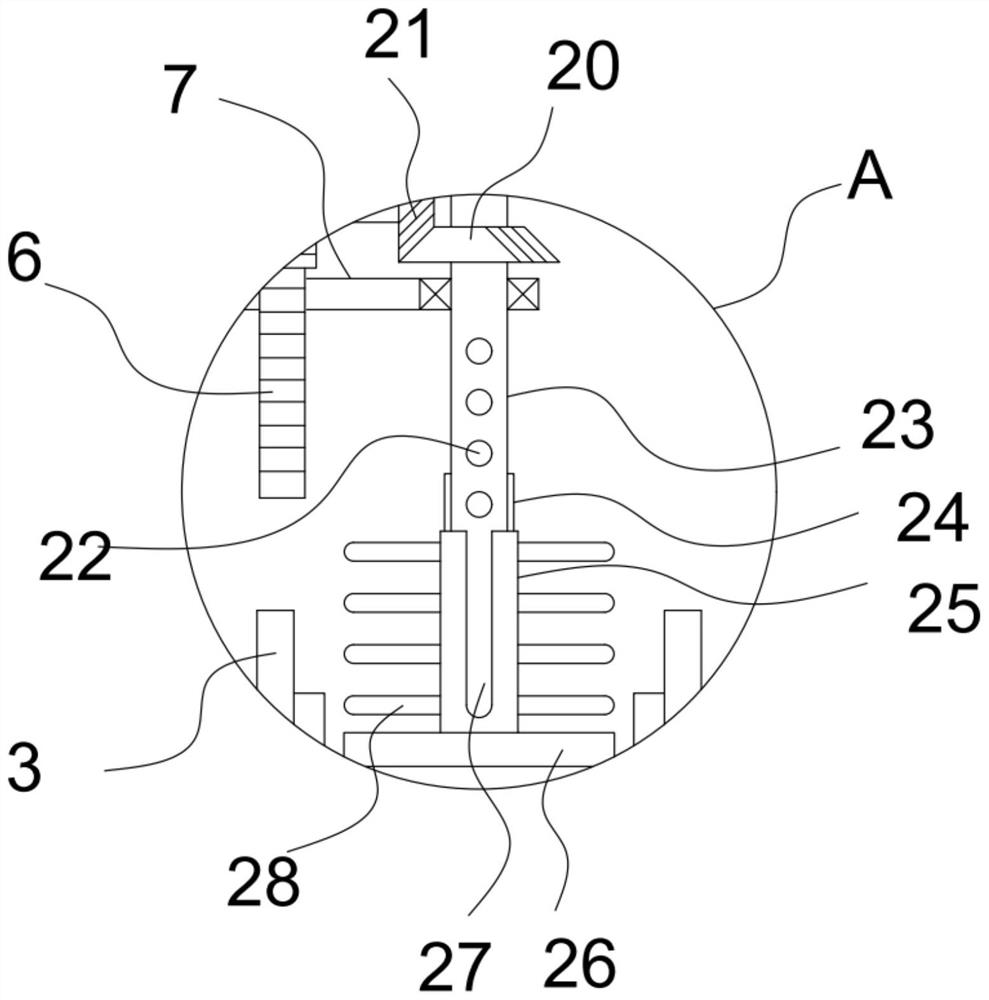

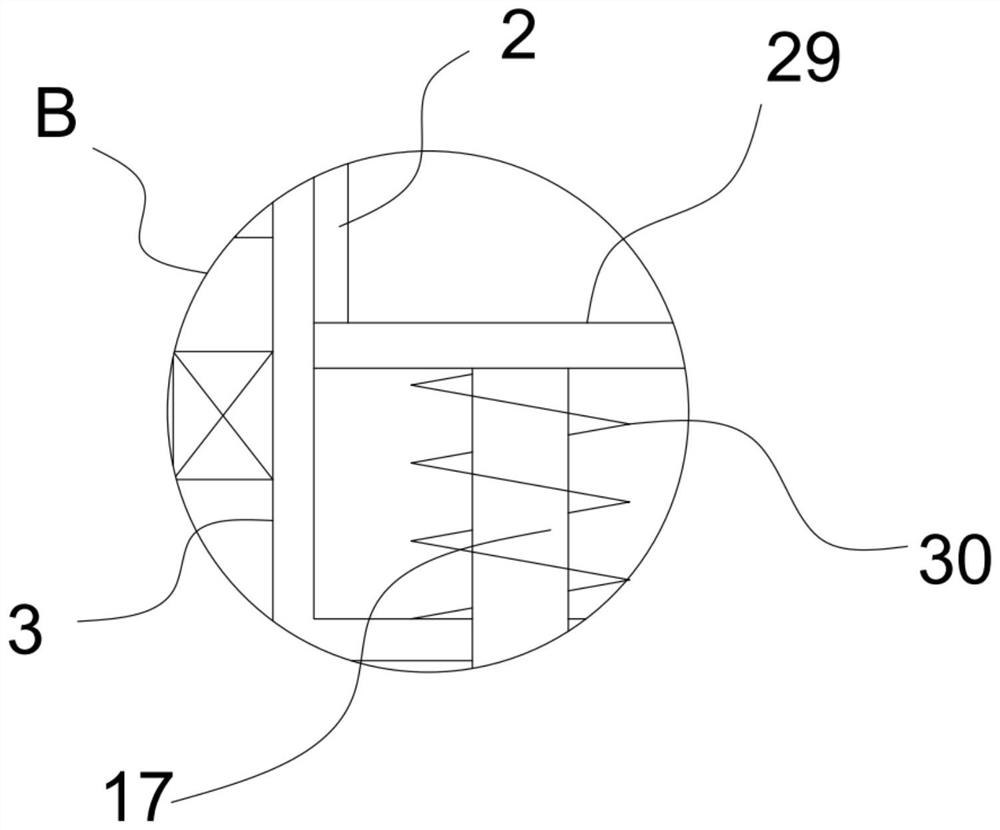

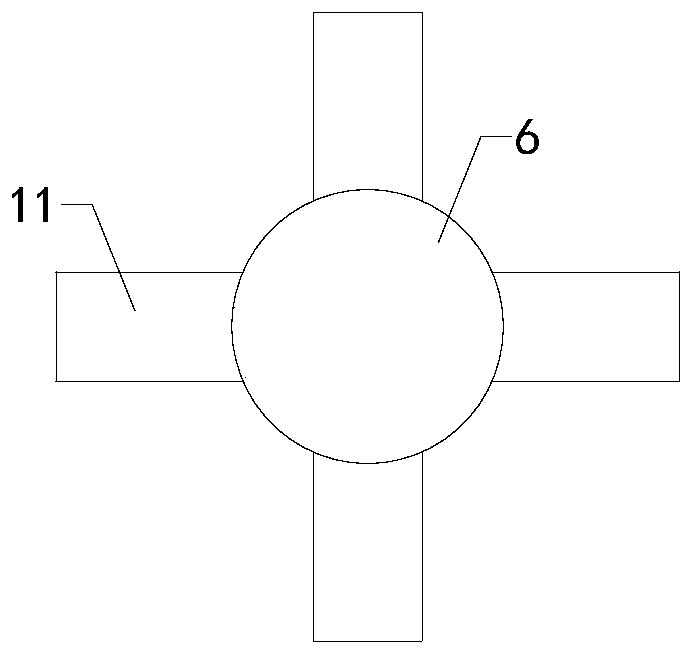

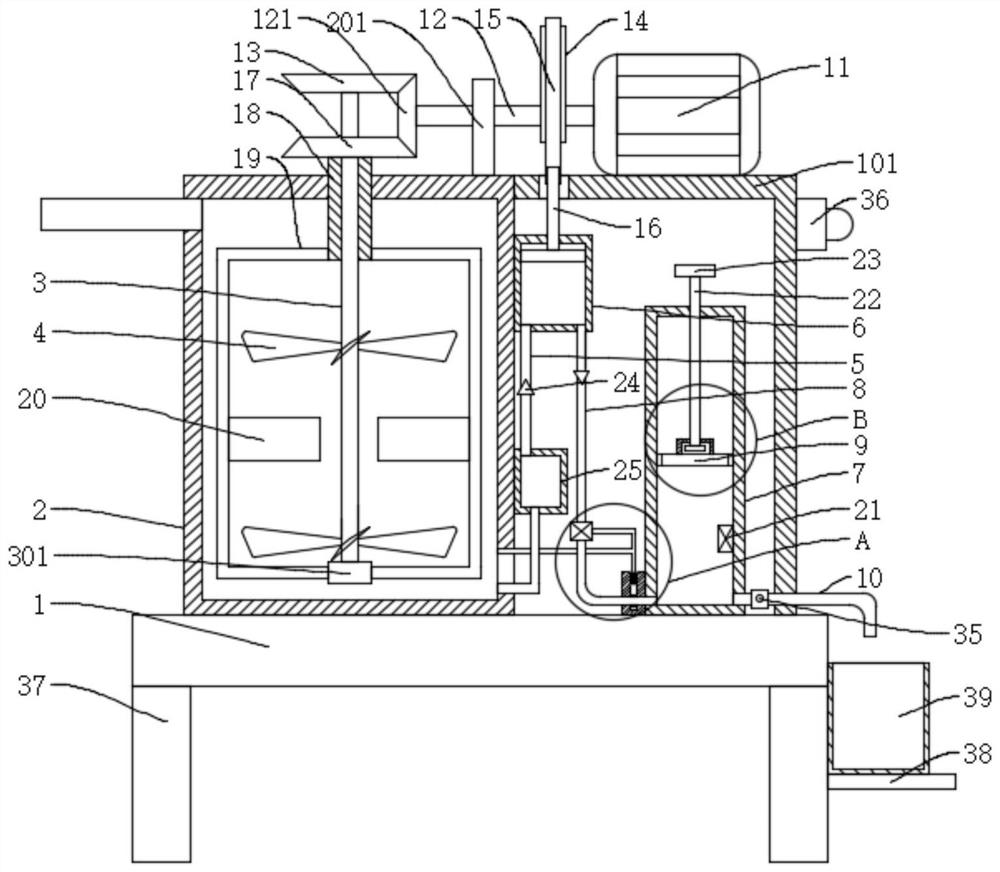

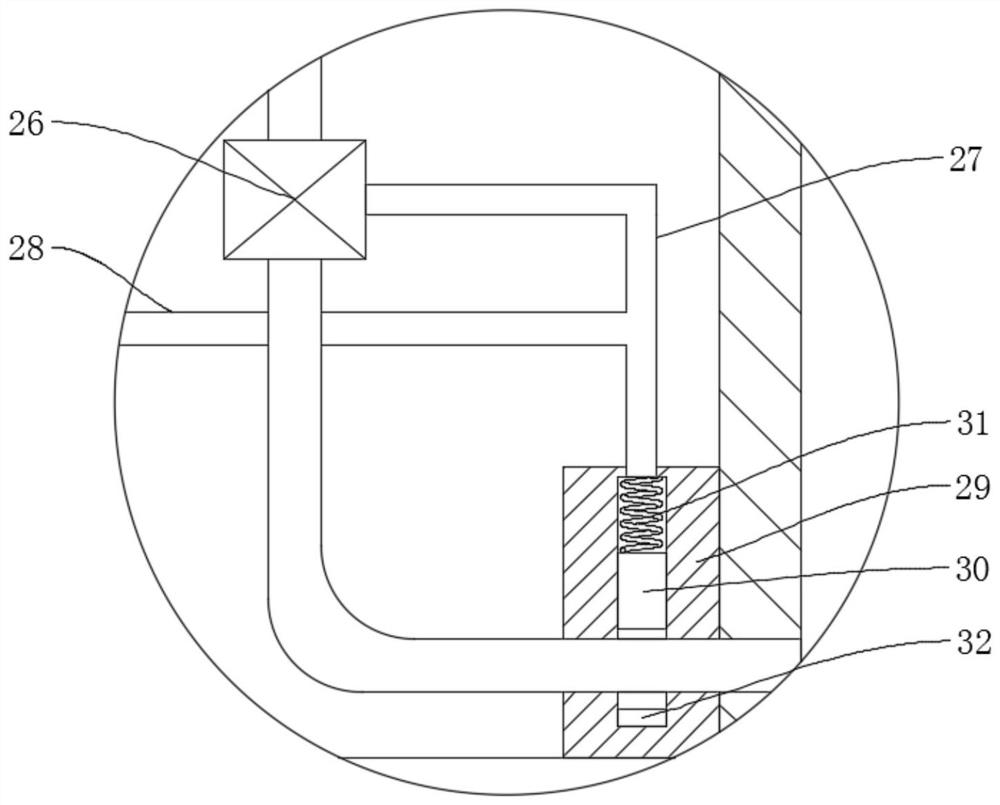

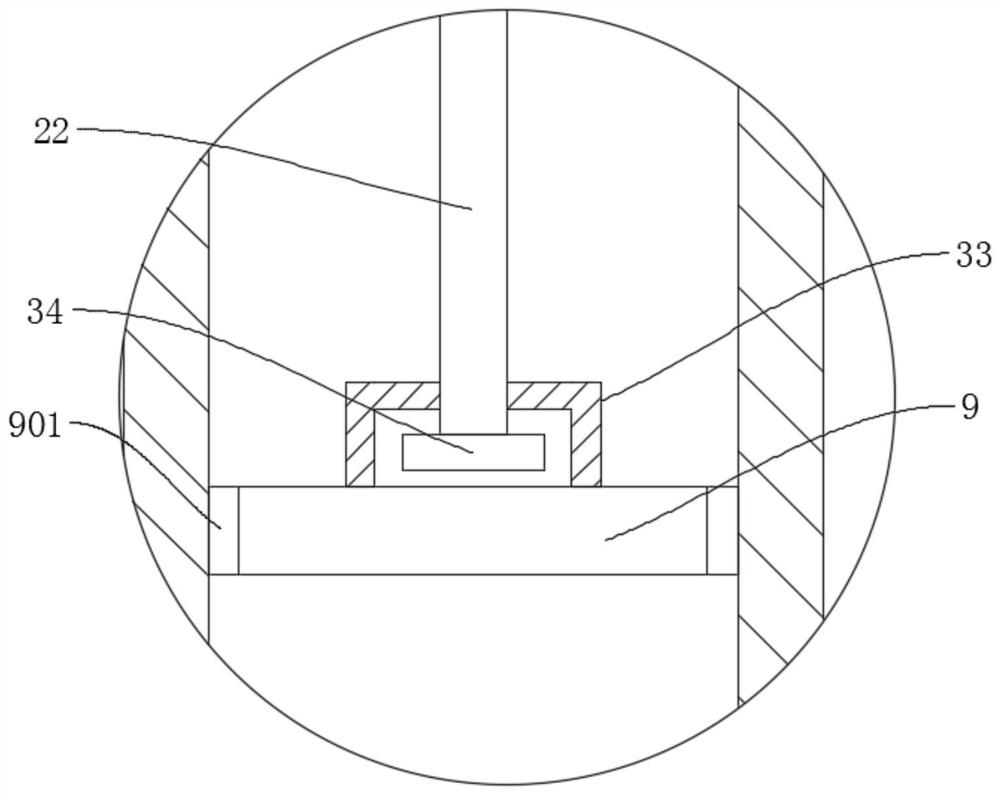

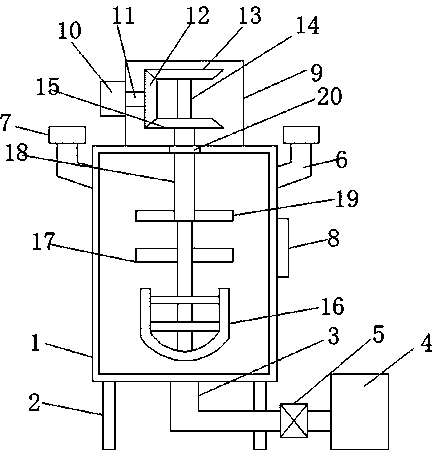

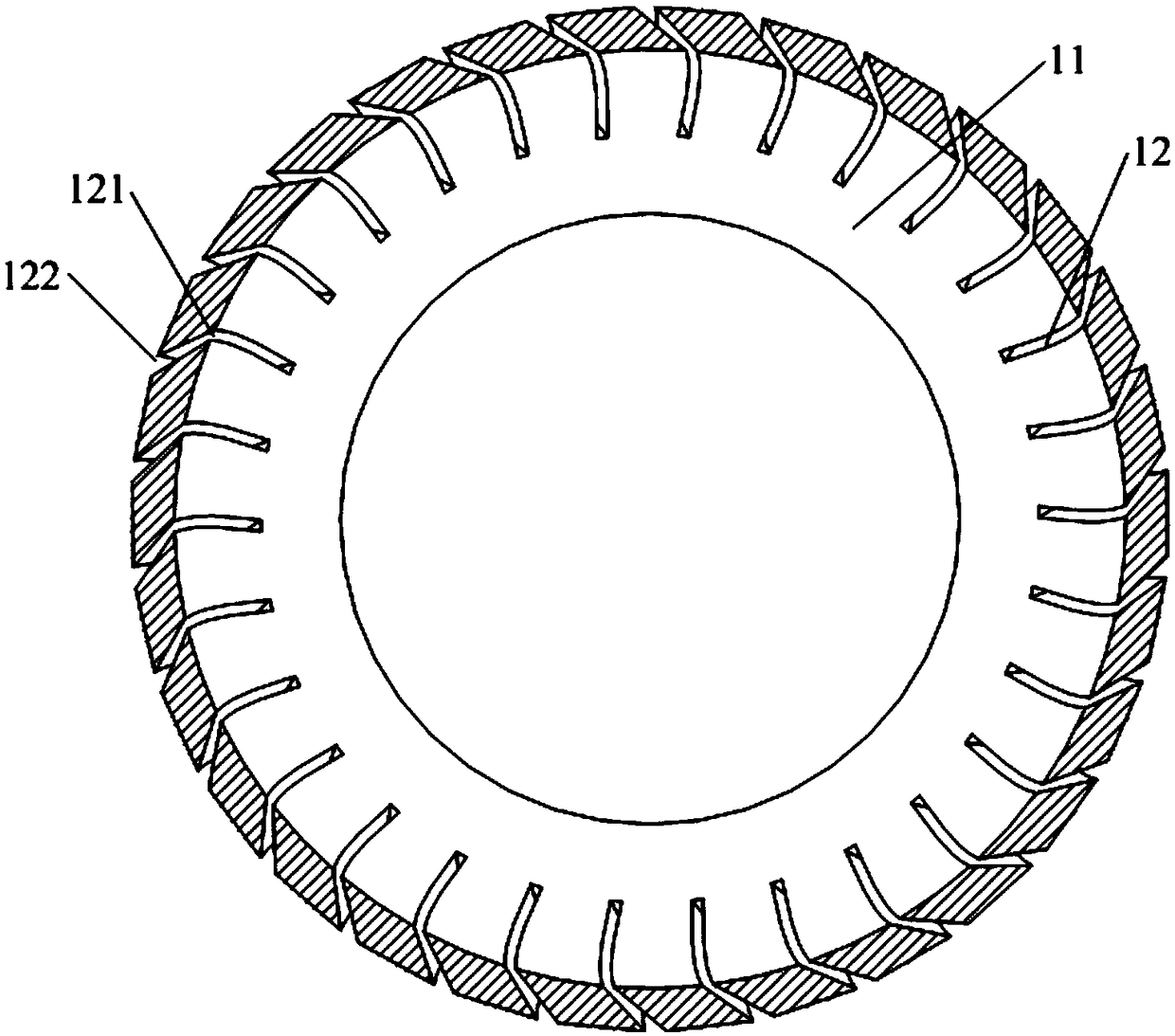

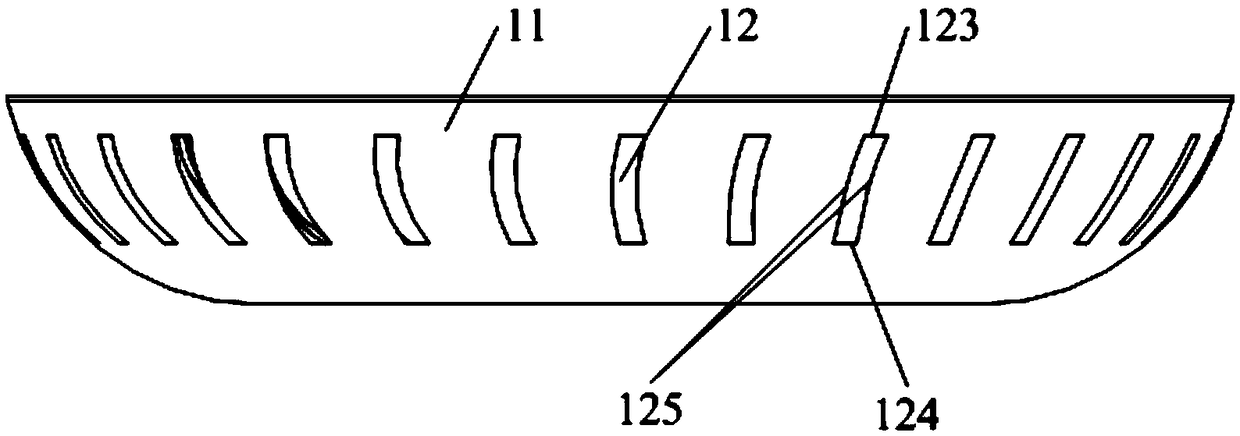

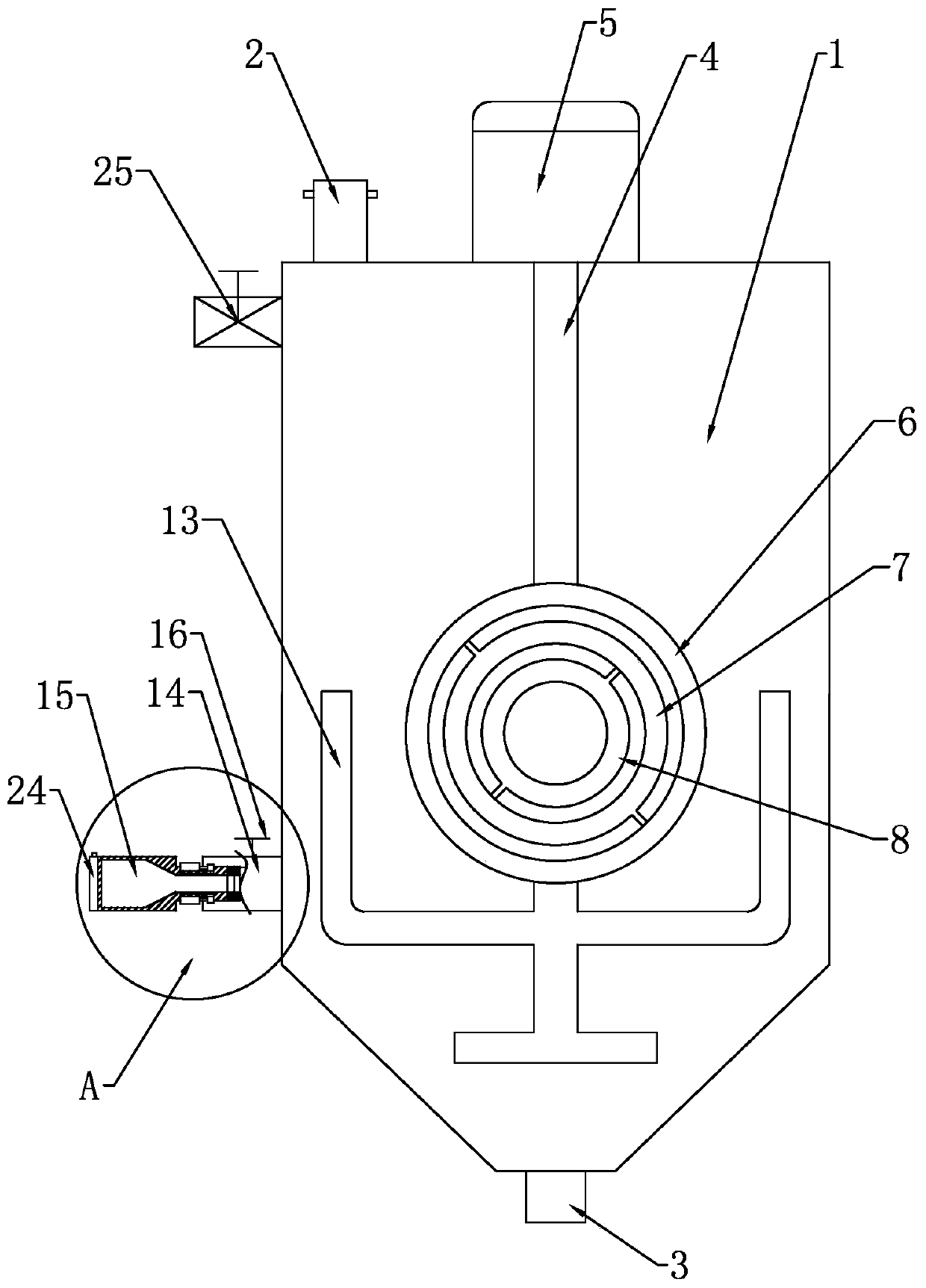

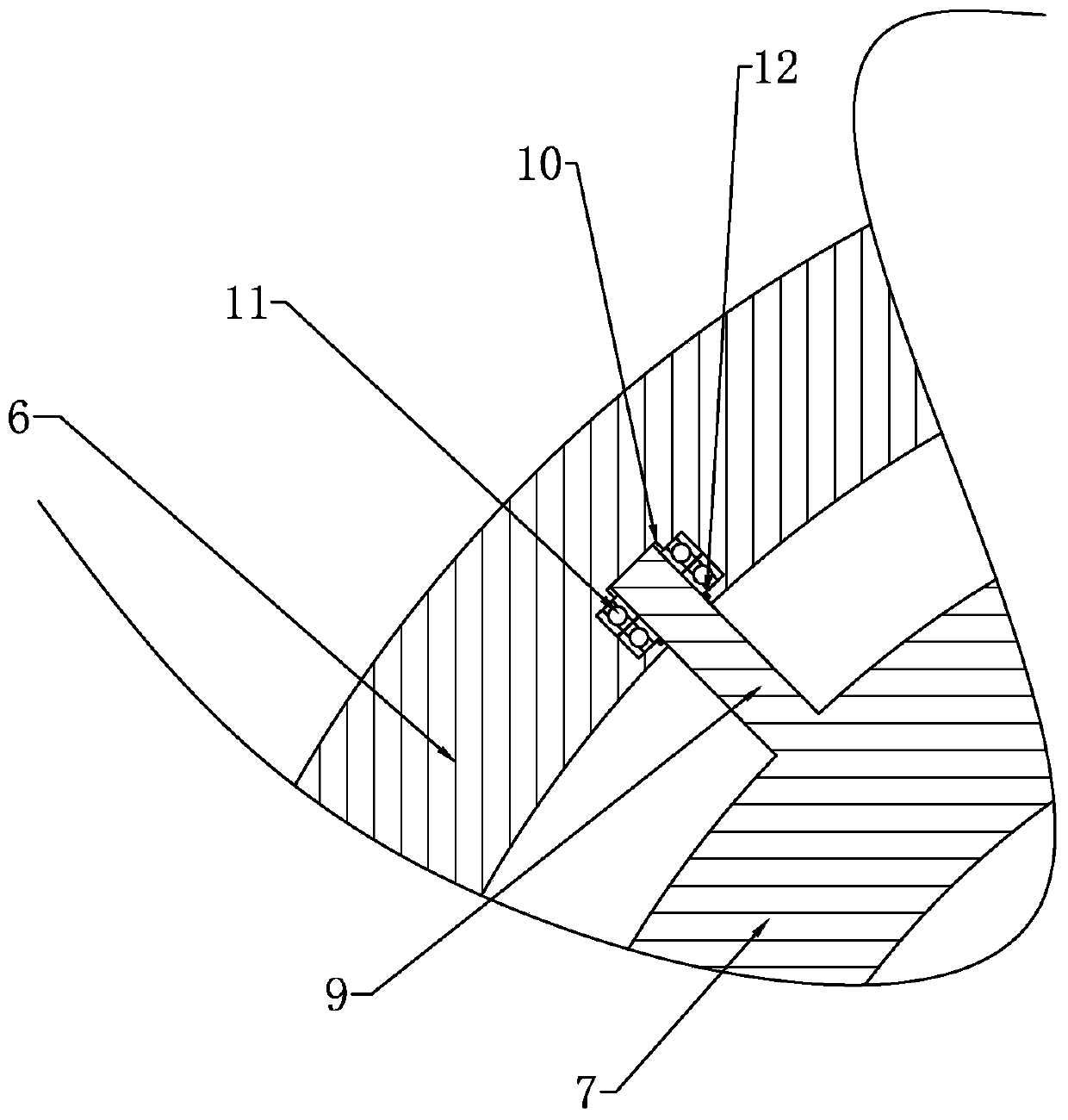

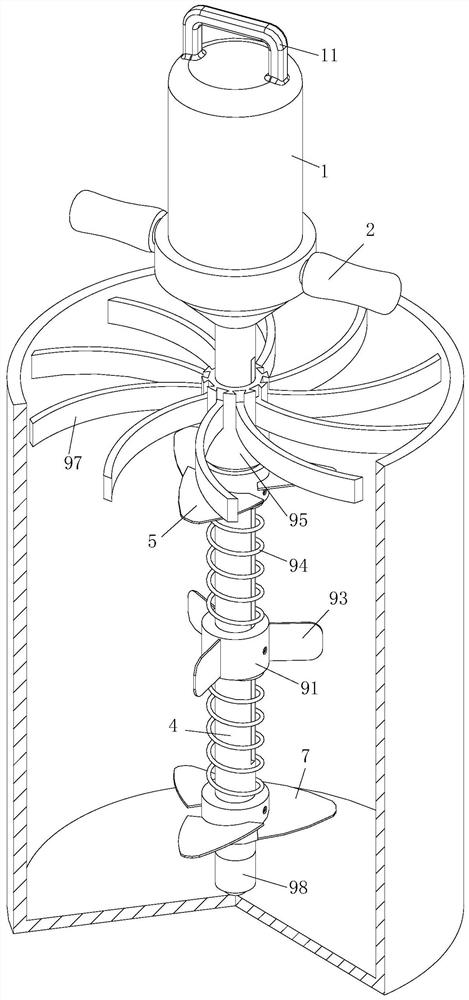

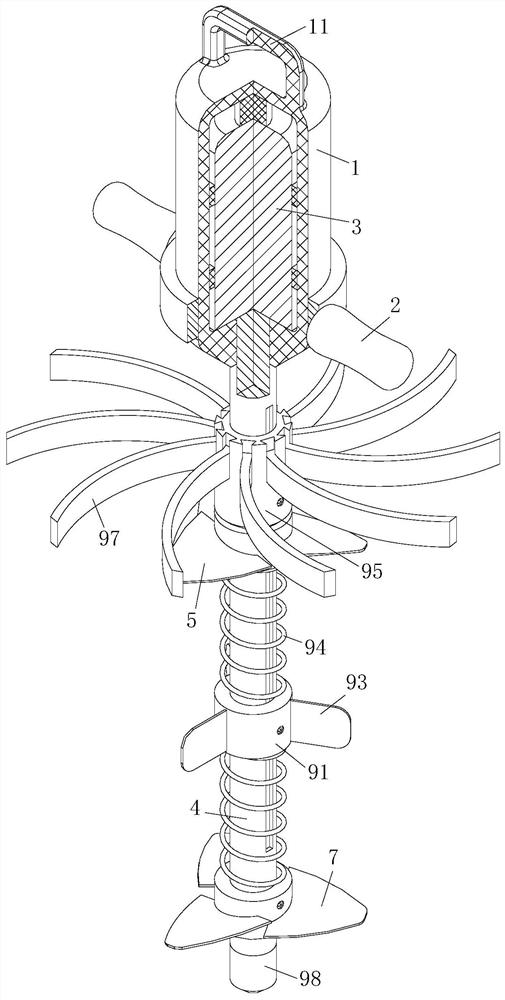

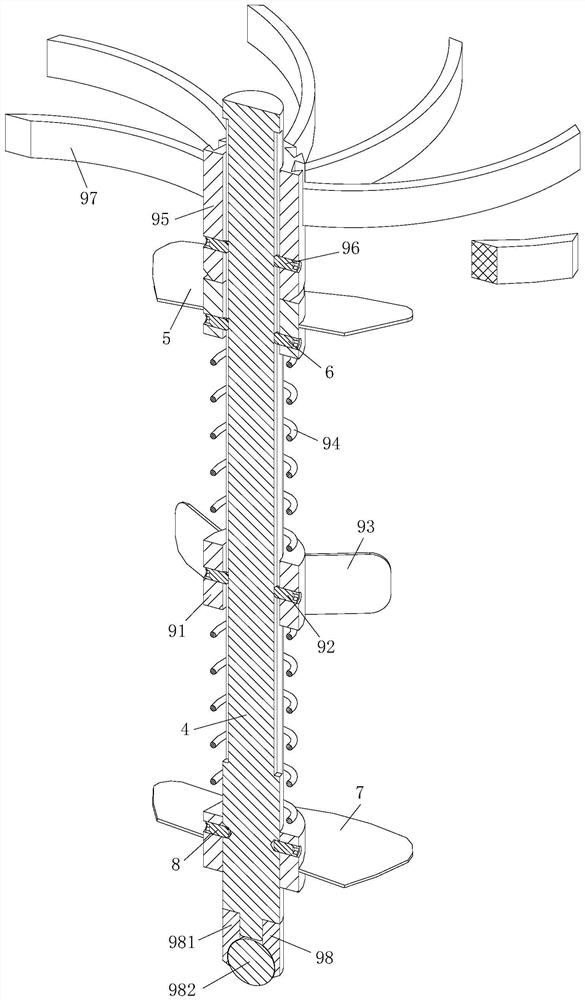

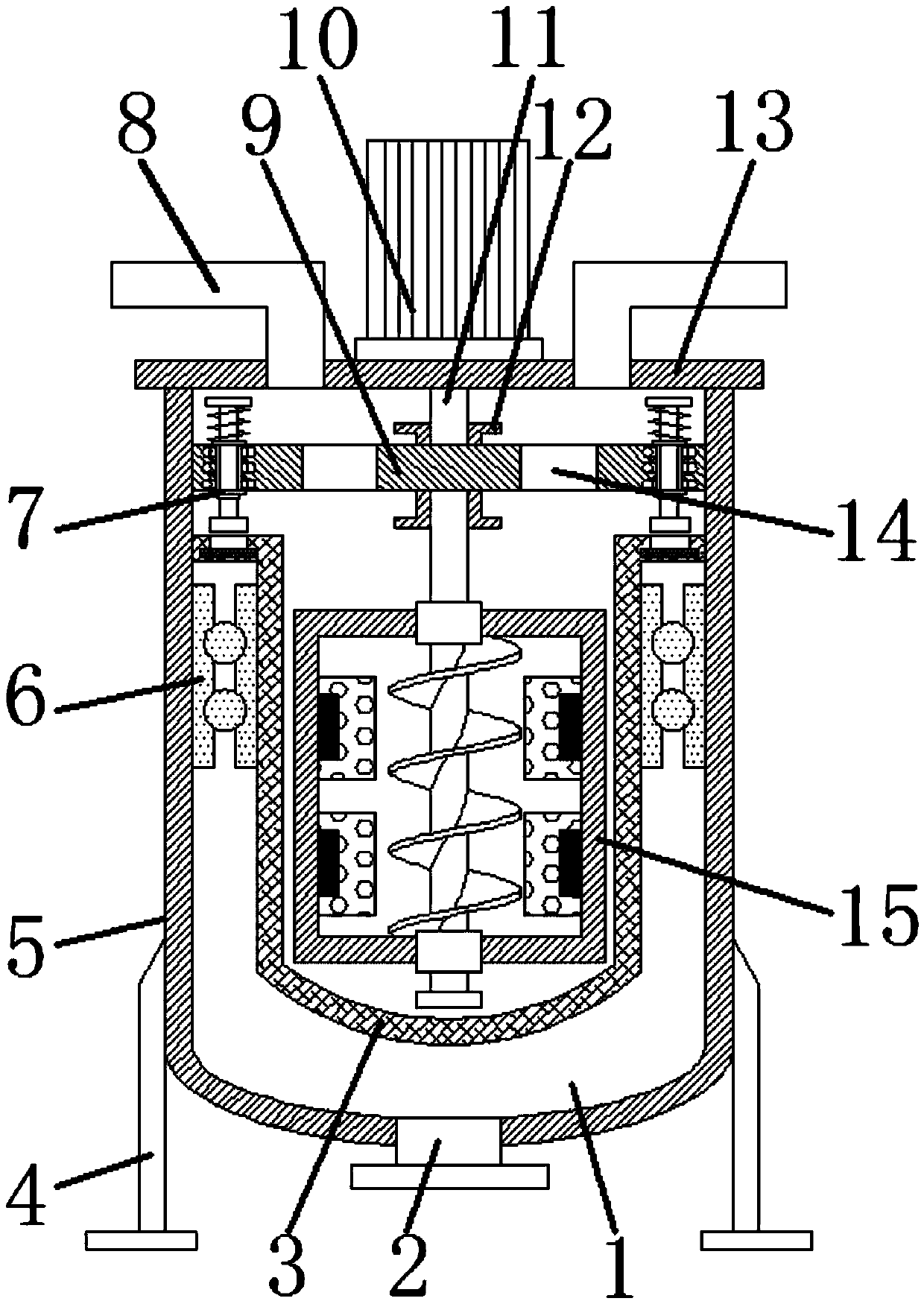

The invention discloses a building coating stirring and centrifugal separating device capable of removing ferromagnetic material. The building coating stirring and centrifugal separating device capable of removing the ferromagnetic material comprises a centrifugal separating barrel body, a building coating tank body, a ball bearing, electromagnetic driving mechanisms, a rotating disc and a rotating shaft, the bottom of the building coating tank body is installed on a machine frame, and the ball bearing is installed on the inner wall of the building coating tank body; the centrifugal separatingbarrel body is arranged in the ball bearing, a stirring machine is arranged in the centrifugal separating barrel body, and the stirring machine is arranged at the bottom of the rotating shaft; and the rotating disc is installed on the rotating shaft which is positioned above the centrifugal separating barrel body, a plurality of material guiding holes are formed in the rotating disc, and the electromagnetic driving mechanisms are arranged on the rotating disc. According to the building coating stirring and centrifugal separating device capable of removing the ferromagnetic material, rotatingstability of the centrifugal separating barrel body is improved, stirring sufficiency of building coating is improved, and impurities of the ferromagnetic material in the building coating can be effectively adsorbed and removed; and the centrifugal separating barrel body is driven by iron core rods to rotate under the rotation of the rotating disc, so that the centrifugal separating barrel body can be conveniently rotated to carry out centrifugal treatment on the building coating.

Owner:湖北屹峡峰建设工程有限公司

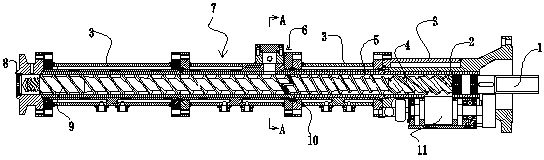

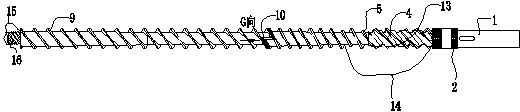

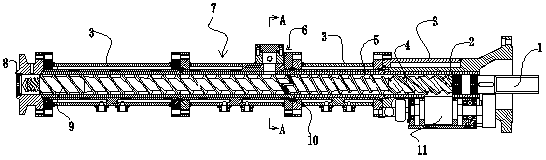

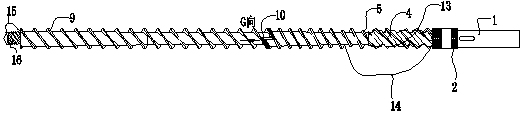

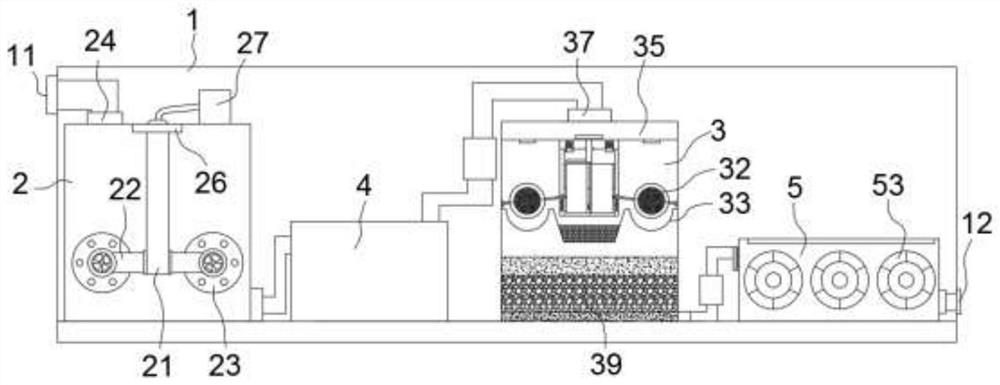

Single-screw extruder

The invention provides a single-screw extruder, which comprises a shell and a screw, wherein the screw is rotationally arranged in a rotating cavity of the shell; a main push plate is arranged on the peripheral surface of the screw, and the main push plate is spirally extended on the peripheral surface of the screw; the shell is provided with a feeding hole and a discharge hole; the screw is provided with a feeding part and a discharge part, the feeding part of the screw is positioned at the feeding hole of the shell, and the discharge part of the screw is positioned in the discharge hole of the shell; a spiral structure extended spirally is arranged on the peripheral surface of the feeding part of the screw, and the pitch of the spiral structure is different from the pitch of the feeding part of the screw; and the spiral structure is crossed with the main push plate once at least, so that a sharp angular shearing structure is formed at the crossed part of the spiral structure and the main push plate. Through the extruder, the gaps of the extruded granules are small, the quality of subsequent injection molding pieces can be ensured, and the advancing smoothness of the granules on the screw is good.

Owner:浙江百纳橡塑设备有限公司

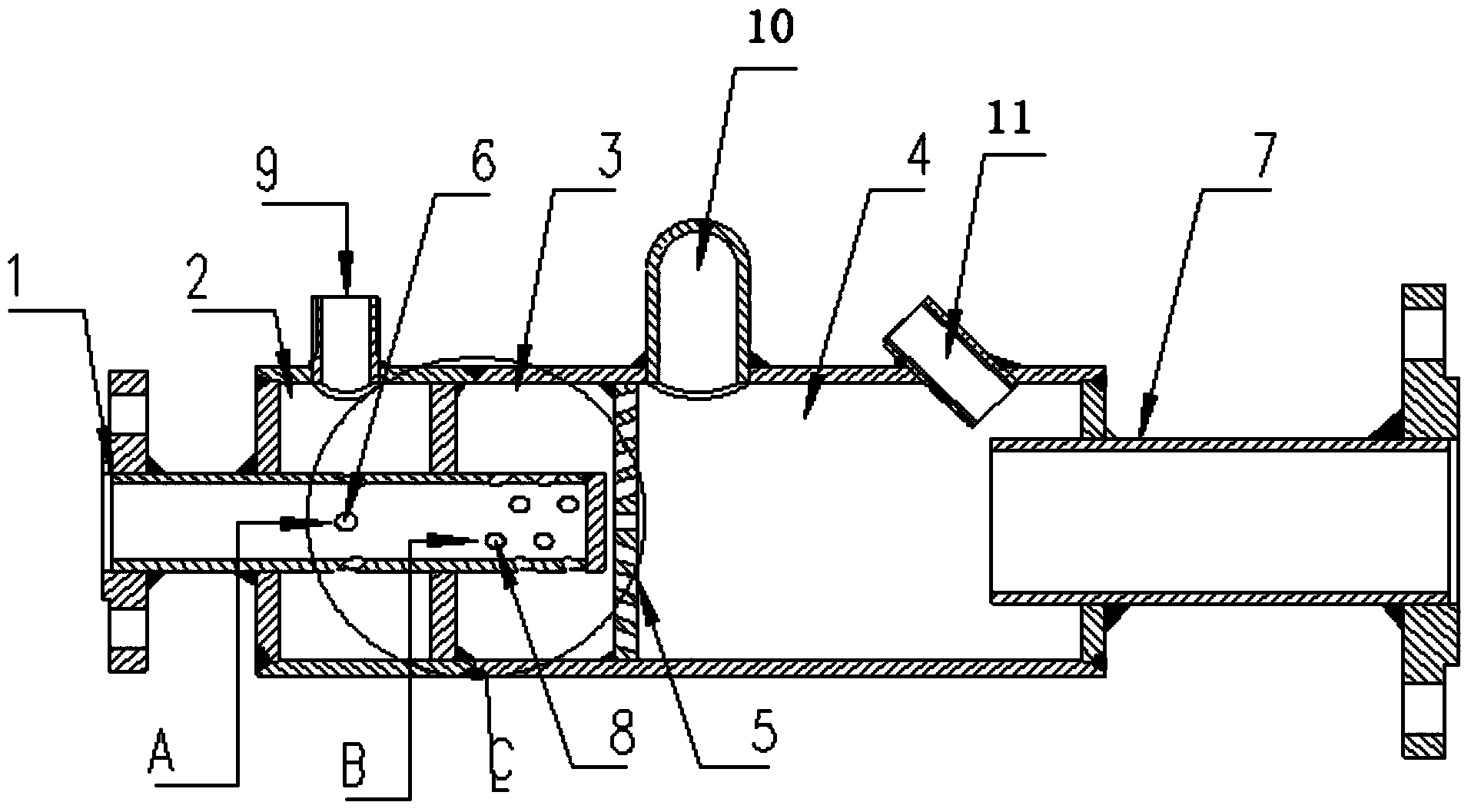

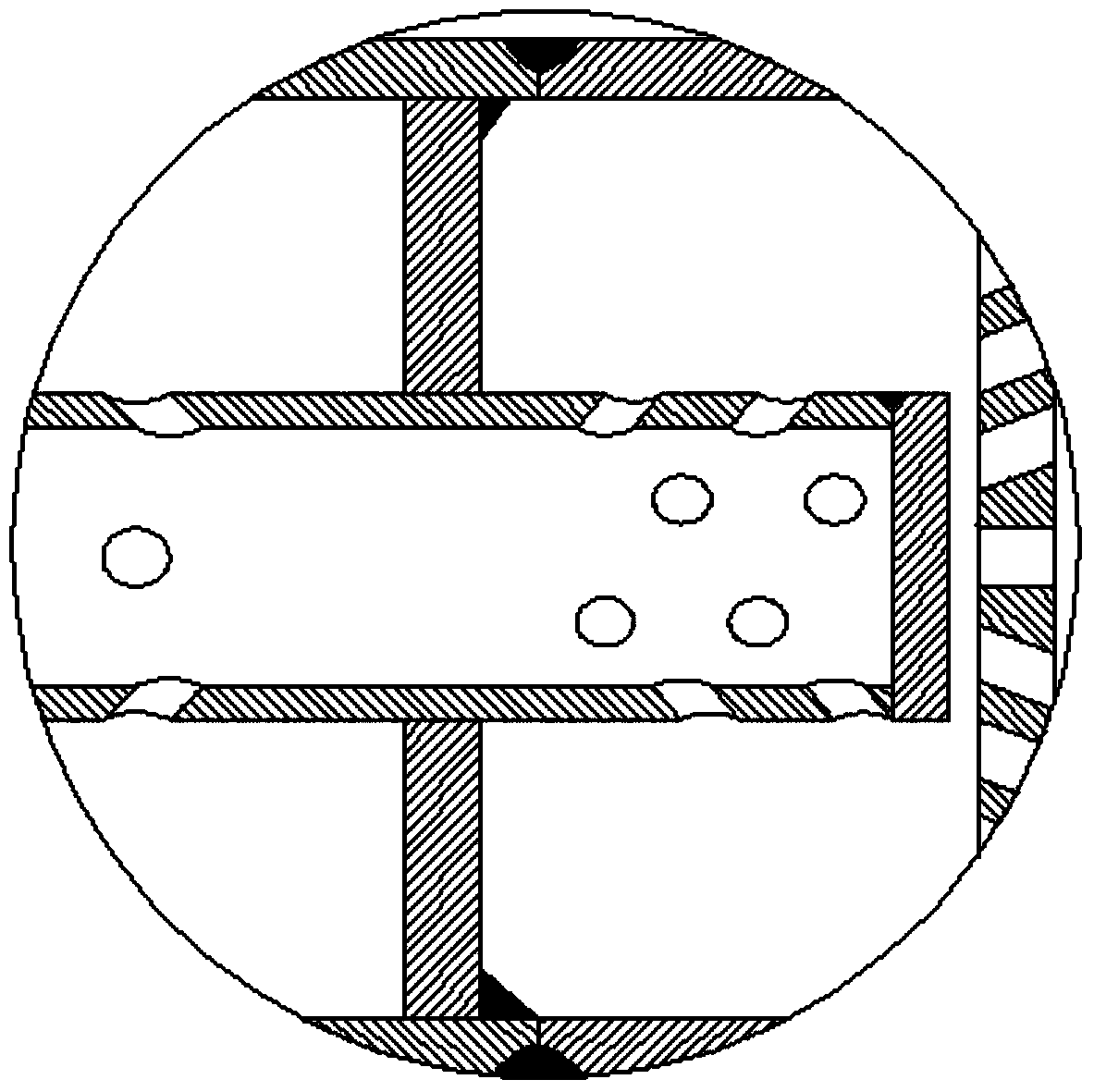

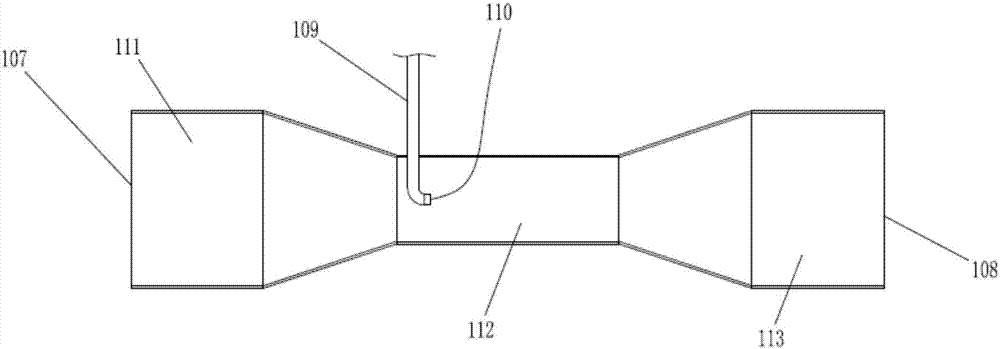

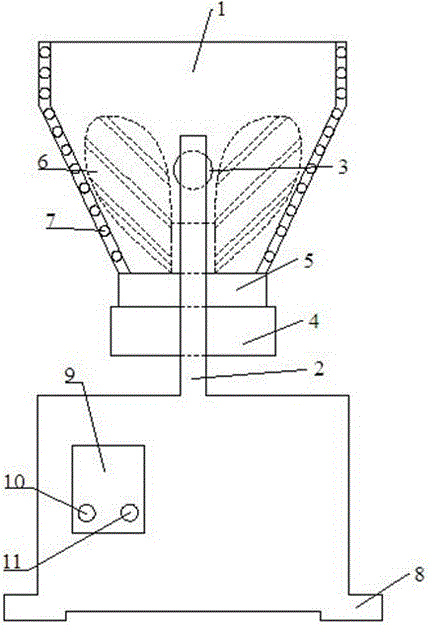

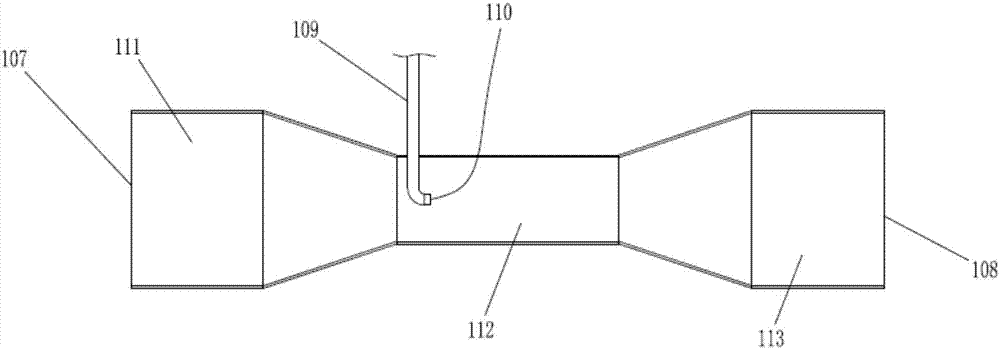

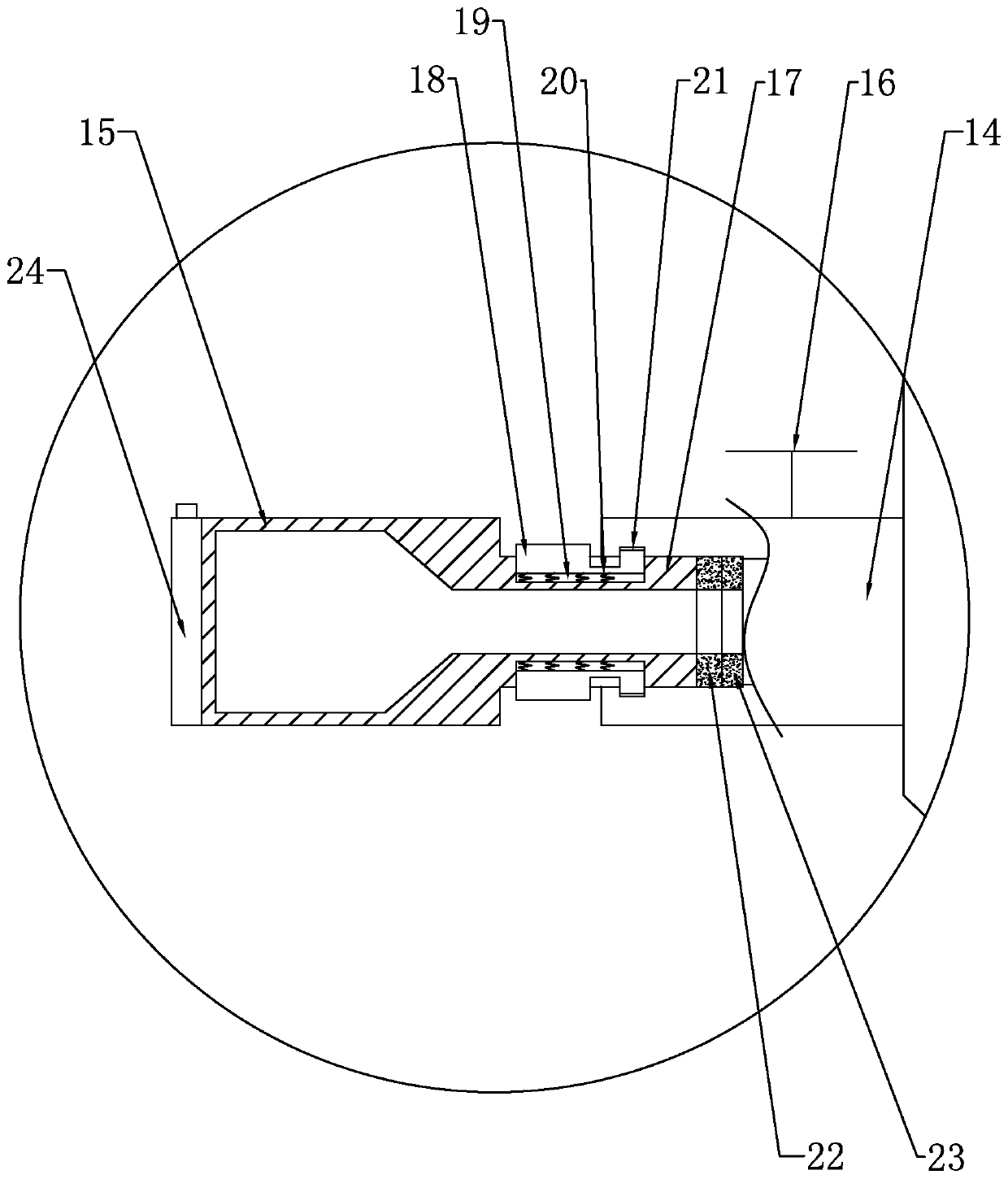

High-mixing-ratio ignition tank

InactiveCN104061573AInto the uniformImprove mixing adequacyGaseous fuel burnerSolid removalEngineeringGas chamber

The invention discloses a high-mixing-ratio ignition tank, and belongs to the technical field of boiler soot blowing. The ignition tank comprises an air inlet connecting pipe, a gas chamber, a mixing chamber, an ignition chamber and a flame outlet pipe, wherein the gas chamber, the mixing chamber and the ignition chamber are arranged in the ignition tank in sequence according to a gas inlet direction; the air inlet connecting pipe is communicated with the gas chamber and the mixing chamber; a secondary mixed gas shunt plate is arranged between the mixing chamber and the ignition chamber; a gas mixing inclined hole is formed in the middle part of the air inlet connecting pipe; primary mixed gas outlet inclined holes are formed in the tail part of the air inlet connecting pipe; a plurality of vertical first through holes and inclined second through holes are uniformly formed in the secondary mixed gas shunt plate; the flame outlet pipe is communicated with the ignition chamber. According to the high-mixing-ratio ignition tank, mixed gas can uniformly enter the ignition chamber by improving the structure of the air inlet connecting pipe and arranging the shunt plate between the mixing chamber and the ignition chamber, so that the mixing full degree of air and gas is greatly improved.

Owner:BEIJING GUANGHUA TEXTILE GRP +1

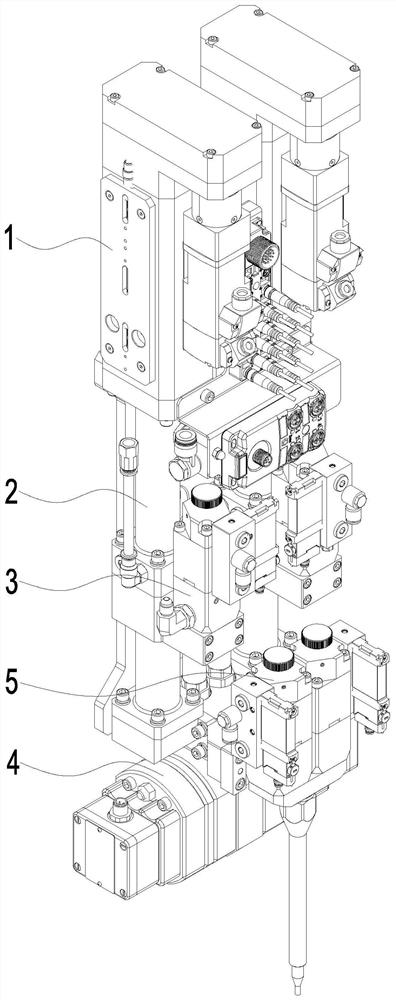

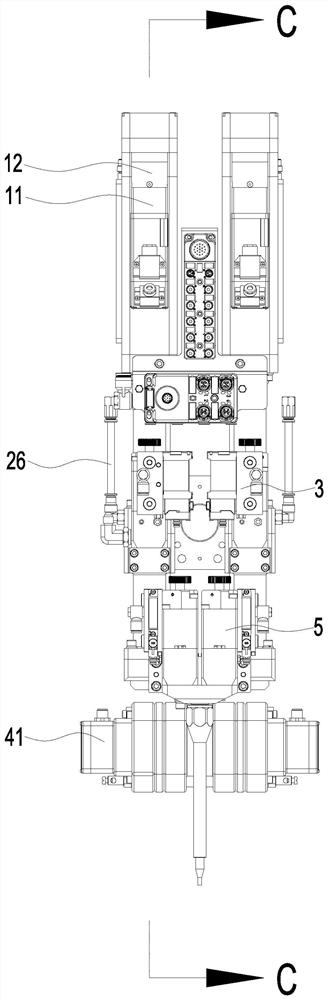

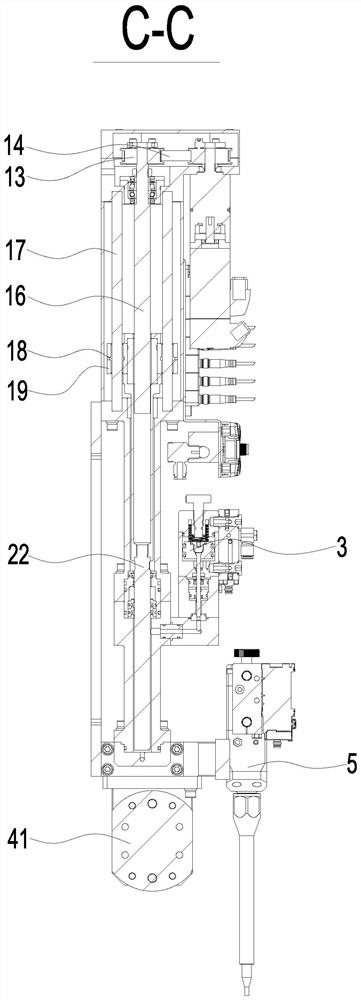

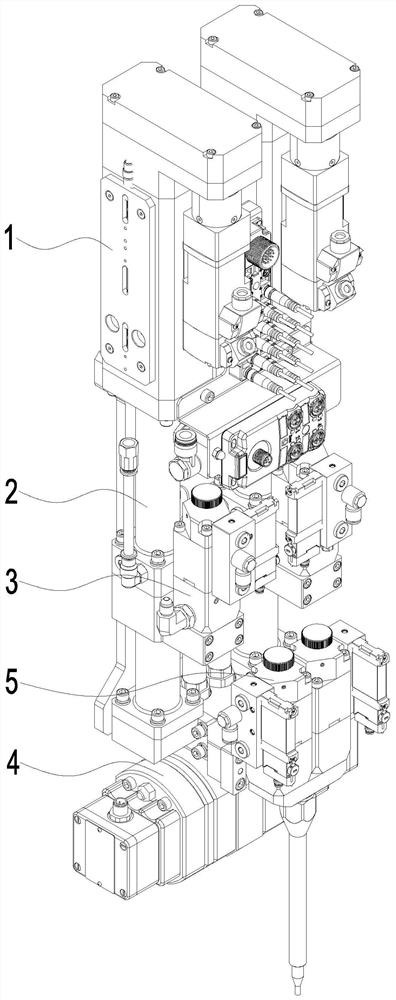

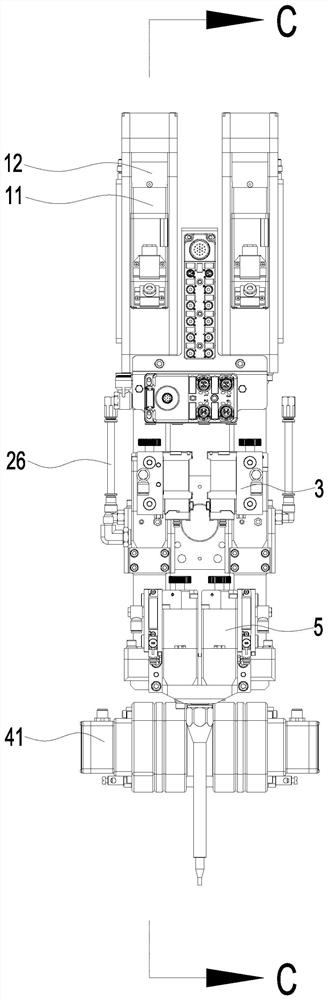

Double-servo plunger type quantifying machine

ActiveCN111842028AGood bondingSolve the problem of labor intensityLiquid surface applicatorsCoatingsControl engineeringAdhesive glue

The invention relates to the field of quantifying equipment, in particular to a double-servo plunger type quantifying machine. The quantifying machine comprises a power mechanism, a metering mechanism, a feeding valve, a flow monitoring system used for monitoring various parameters of fluid and a mixing valve; the metering mechanism is movably arranged on the power mechanism; the feeding valve communicates with the metering mechanism; the flow monitoring system communicates with the metering mechanism; the mixing valve is communicably disposed with the flow monitoring system. According to thequantifying machine, on one hand, the flow monitoring system and the quantifying machine are integrally designed, so that no pipeline needs to be arranged between the whole quantifying machine and theflow monitoring system, namely, no pressure loss is generated when fluid flows, and the flow monitoring system can monitor technological parameters such as the glue outlet proportion, the glue outletamount and the glue outlet speed in real time, and therefore the accuracy and sufficiency of glue mixing can be improved; and on the other hand, the automatic operation level of glue injection and glue mixing is improved, and the problems that the labor intensity of manual glue mixing is high, and the production efficiency is low are solved.

Owner:存融流体设备(无锡)有限公司

Beverage wastewater treating equipment

PendingCN109911999AEvenly distributedImprove uniformityWaste water treatment from food industryWater/sewage treatment by neutralisationFixed bearingPh control

The invention relates to the technical field of accessory devices of wastewater treating equipment, in particular to beverage wastewater treating equipment. The beverage wastewater treating equipmentis characterized in that the uniformity of PH controlling agent powder in sewage is improved by additionally arranging a PH controlling agent powder scattering device; in addition, a sewage stirring device is additionally arranged for reducing the influence of human factors on the stirring process of sewage, so that the stirring efficiency and the stirring adequacy are improved; the beverage wastewater treating equipment comprises a pond body, a draining mechanism and a stirring rod; an accommodating cavity is formed inside the pond body; the beverage wastewater treating equipment further comprises two groups of supporting plates, a locating bearing, a reciprocating screw, a rotating handle, a limiting plate, two groups of driving rods, a charging box, two groups of sliding rods, two groups of limiting plates and four groups of supporting rods; the reciprocating screw is provided with a reciprocating screw rod and a reciprocating sliding block; and the beverage wastewater treating equipment also comprises a mounting block, three groups of stirring blades, a moving plate, fixed bearings, two groups of limiting rods, a driven chain wheel, a chain, a fixed plate, a motor, a driving chain wheel, a limiting spring, a sliding block, a fastening chain wheel, a supporting rod and radial journal bearings.

Owner:山东中科贝特环保装备股份有限公司

Full mixing device for alloy material production and processing

InactiveCN112717826AMixing volume controlImprove efficiencyRotating receptacle mixersTransportation and packagingRotational axisVertical plane

The invention discloses a full mixing device for alloy material production and processing. The full mixing device comprises a mixing barrel, a transfer material box is arranged over the mixing barrel, the transfer material box is fixedly connected with a longitudinal mounting rod, and a fixed partition plate and a movable partition plate are arranged in the transfer material box; by arrangement of the transfer material box, the fixed partition plate and the movable partition plate are arranged in the transfer material box, and the movable partition plate is moved by utilizing an adjusting motor, so that the material mixing proportion of each time is controlled, and the efficiency of the mixing device is improved; the stirring frame is arranged in the mixing barrel, and the rotating shaft is driven to move through meshing transmission of the fixed gear and the rotating gear, so that stirring blades on the outer side of the mounting shaft rotate, the stirring frame stirs in a vertical plane, and meanwhile, the stirring blades also stir and mix alloy raw materials in the horizontal direction; the mixing efficiency and the mixing sufficiency of the materials are greatly improved, the phenomenon that the materials are layered is avoided, and the yield is increased.

Owner:安徽众成合金科技有限公司

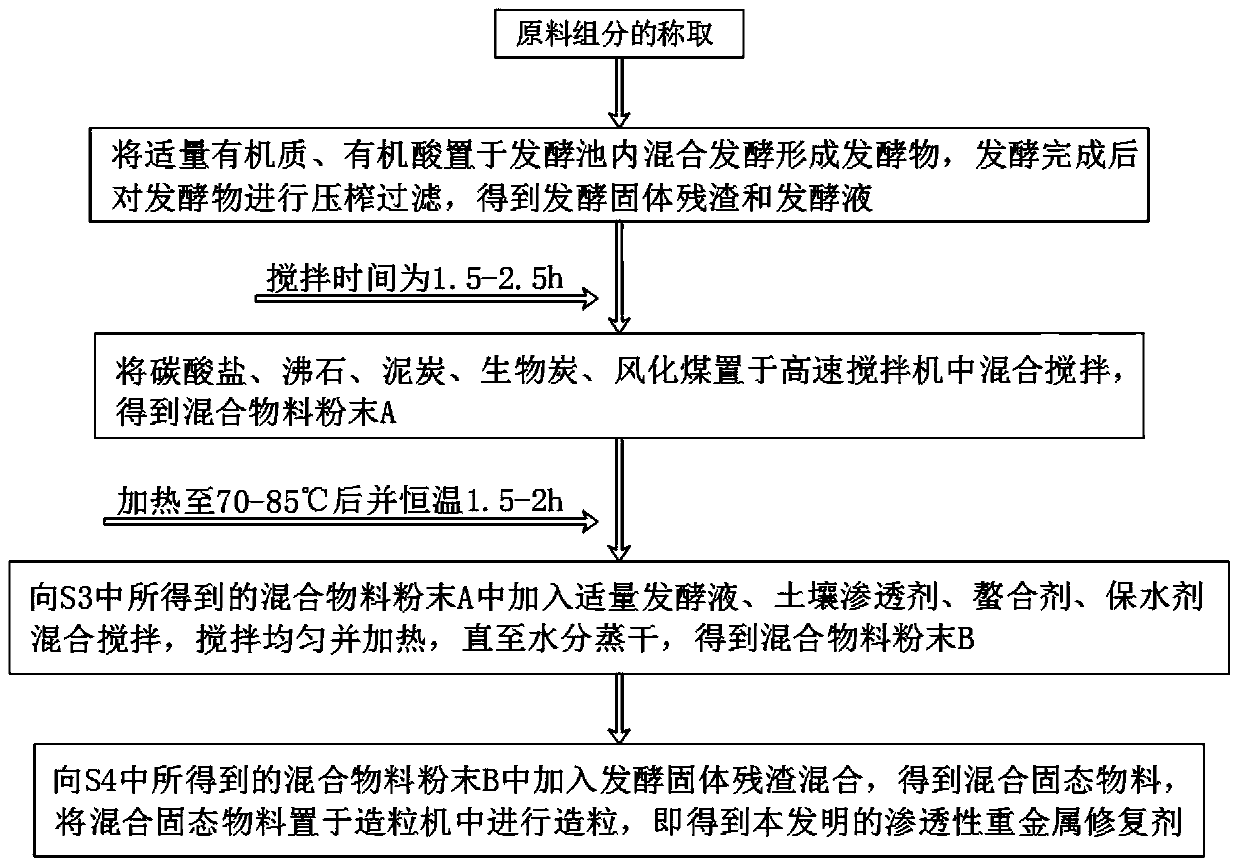

Self-permeating type soil heavy metal repair agent and preparation method thereof

InactiveCN110591719AGood physical propertiesImprove fat retention capacityAgriculture tools and machinesRotary stirring mixersFood chainIon exchange

The invention discloses a self-permeating type soil heavy metal repair agent and a preparation method thereof, and belongs to the technical field of repair agent preparation. According to the self-permeating type soil heavy metal repair agent and the preparation method thereof, organic matter is mixed with a base material of organic acid, the promoting property of the repair agent on growth and development of plants is effectively improved, physical properties of repaired soil are improved, activities of microorganisms and soil organisms are promoted, nutrient elements in the soil are promotedto be decomposed, and meanwhile, air permeability, permeability and adsorbability of the soil are changed; by addition of mineral improvers such as zeolite, peat, charcoal, weathered coal and the like, on one hand, reaction performance such as adsorption, ion exchange and the like of heavy metal elements is improved, heavy metal pollutants such as cadmium, chromium, lead and the like in soil canbe cured and passivated, bio-availability of the heavy metal pollutants and mobility in soil are reduced, risks that the pollutants are absorbed by crops and transferred to food chains are reduced, and on the other hand, physical and chemical properties of the soil are improved.

Owner:杨涛

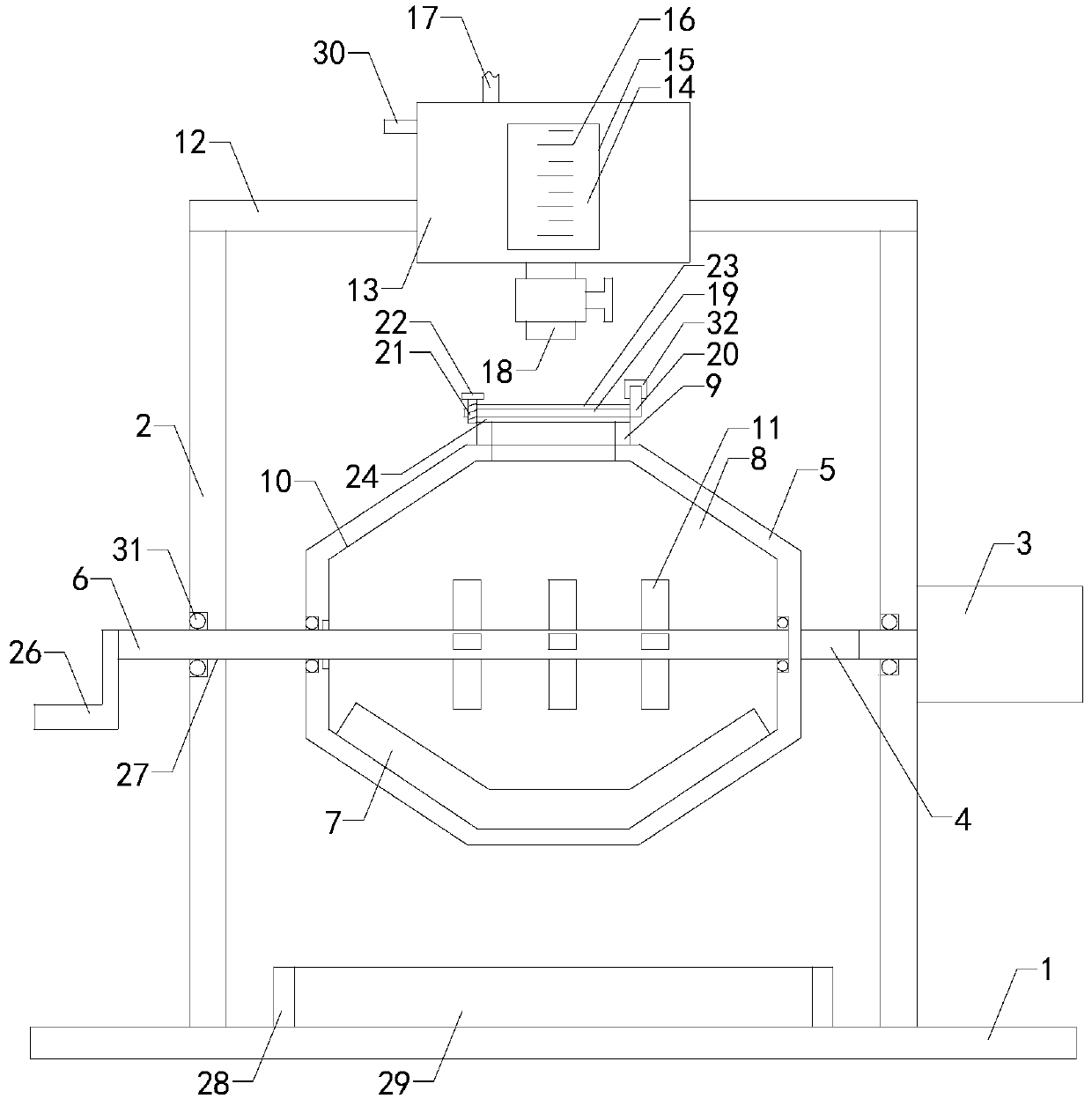

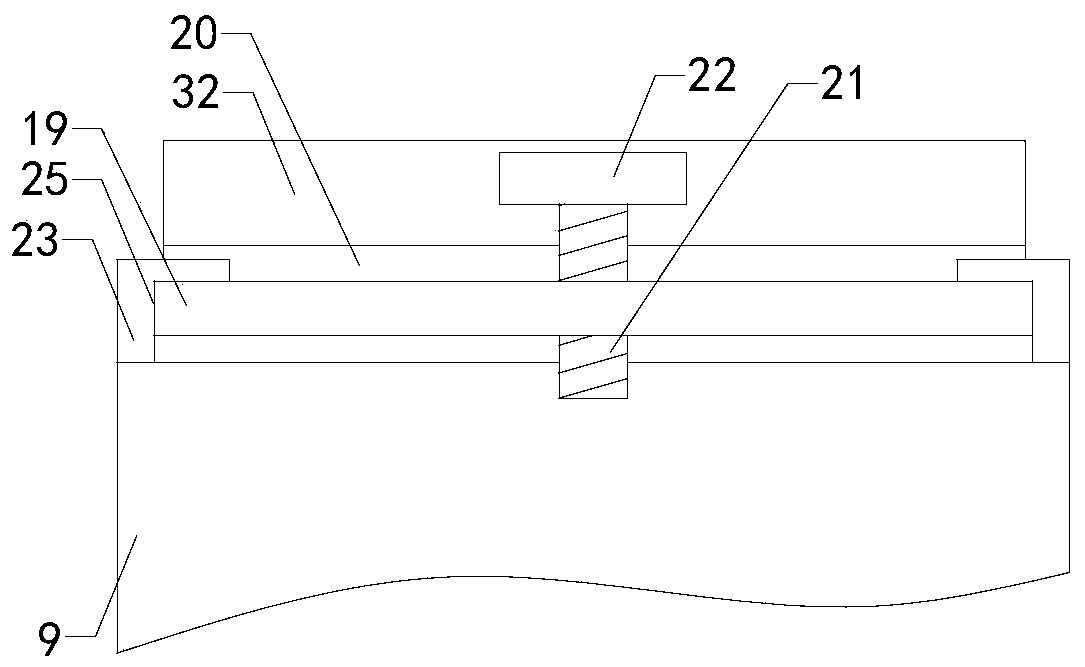

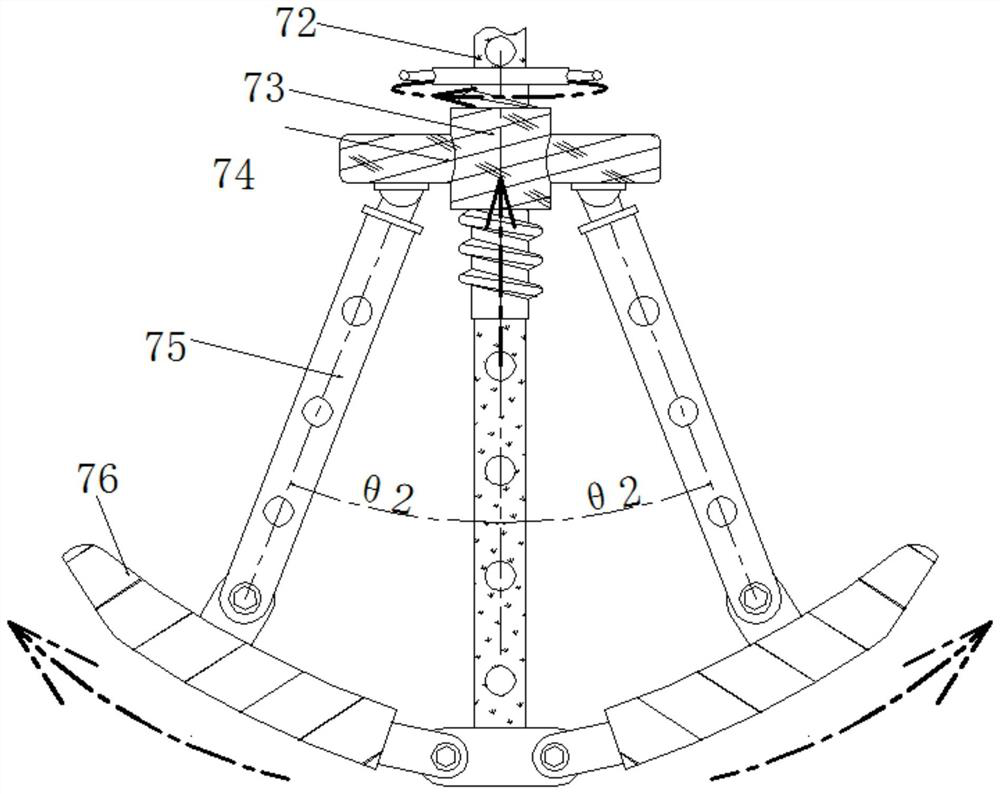

Concrete rotary stirring and mixing device for building construction

InactiveCN112519002AFull rotation and stirring effectAchieving stirring one by oneCement mixing apparatusArchitectural engineeringMechanical engineering

The invention discloses a concrete rotary stirring and mixing device for building construction, and relates to the technical field of concrete stirring. The concrete rotary stirring and mixing devicecomprises a fixing frame, wherein a rotating plate is rotatably mounted on the fixing frame, a plurality of rotatably arranged stirring barrels are annularly and uniformly mounted on the rotating plate, and a vertical rack is vertically fixed on the fixing frame. According to the concrete rotary stirring and mixing device, the rotating plate is driven by an arranged stepping driving mechanism to rotate in a stepping manner, at the moment, the stirring barrels on the rotating plate can rotate to vertically correspond to a stirring mechanism after being adjusted, the arranged stirring mechanismrotates in the lifting process of a lifting frame and meanwhile performs sufficient rotary stirring on concrete in the stirring barrels, and an arranged bottom scraping plate can ascend and descend vertically in the adjusting process to make the concrete shake up and down, so that the concrete stirring sufficiency can be effectively improved. The device allows the concrete to be separately placedin the multiple stirring barrels and realizes one-by-one stirring of the concrete in the stirring barrels, so that the stirring process is more sufficient and efficient.

Owner:李宁宁

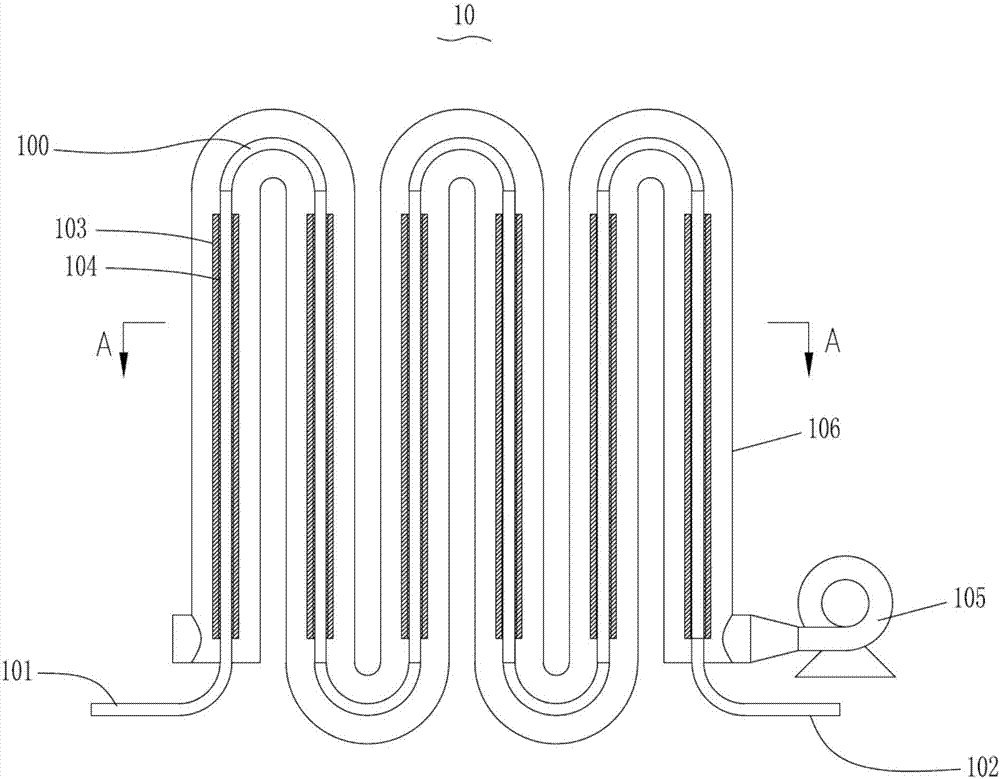

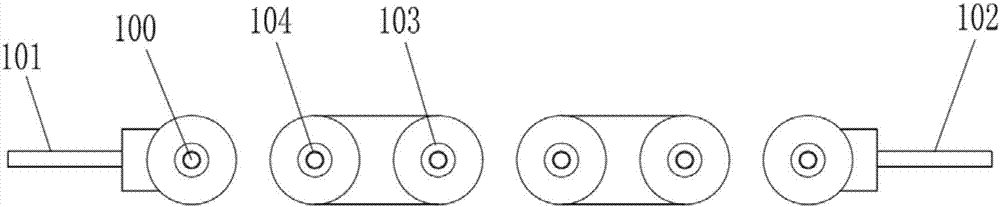

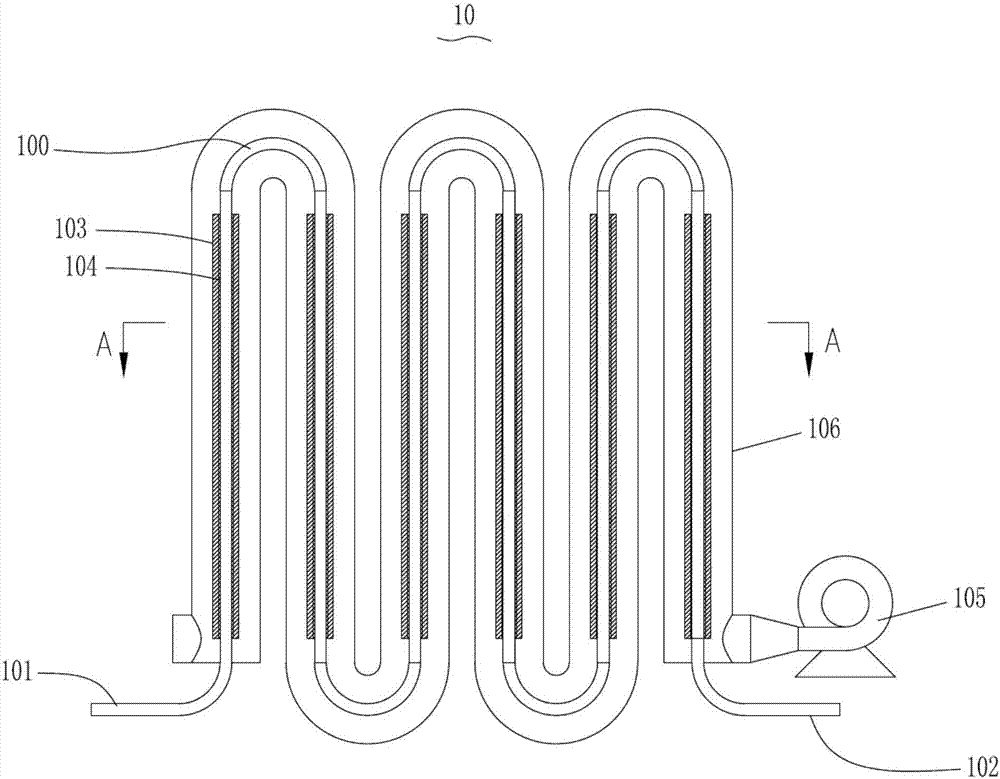

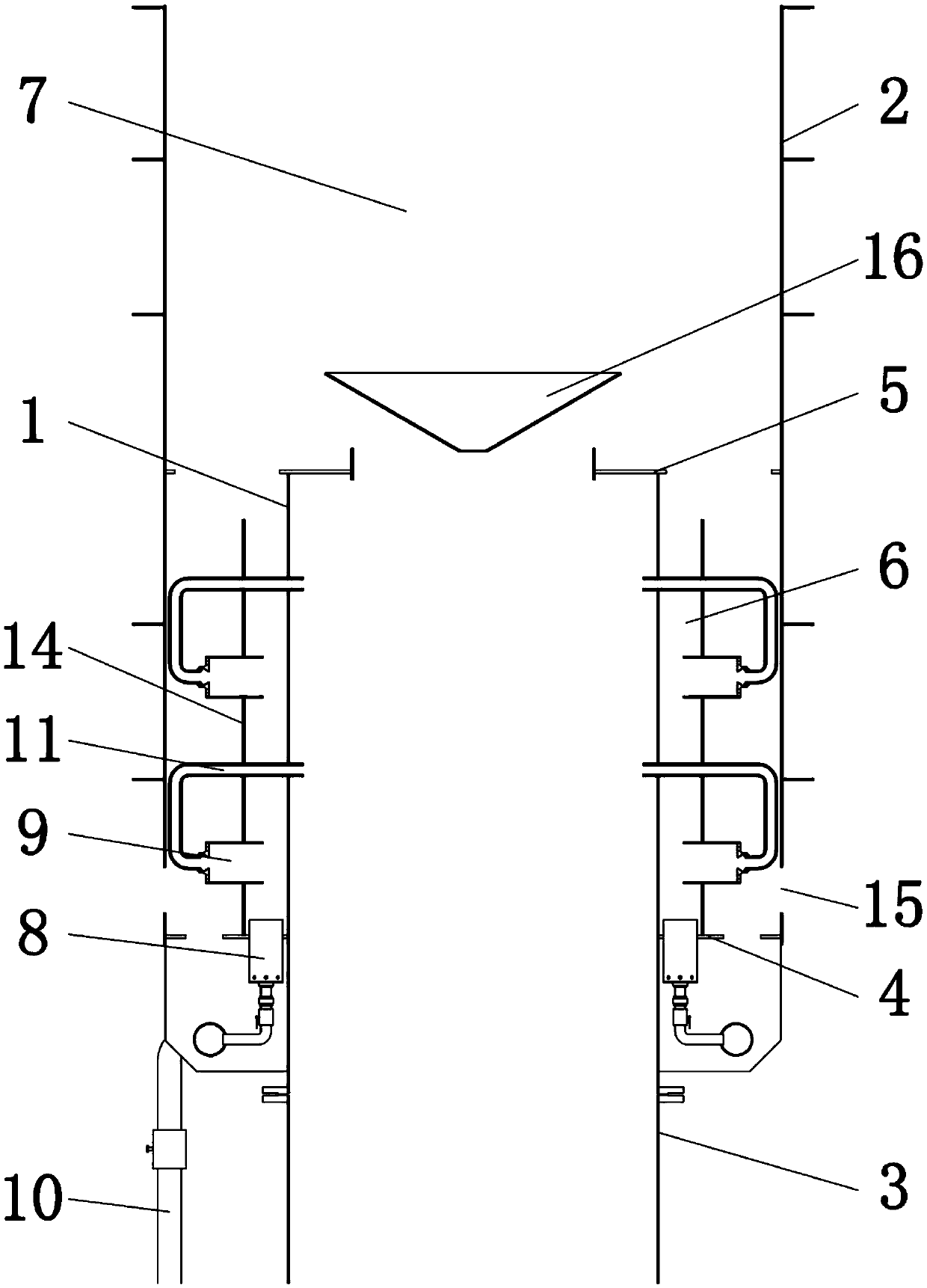

Liquid ammonia evaporator for denitration device line

PendingCN107126714AIncrease the heat exchange areaImprove mixing adequacyGas treatmentDispersed particle separationNitrogen oxidesLiquid ammonia

The invention relates to the technical field of air pollution prevention of environmental protection industries, in particular to a liquid ammonia evaporator for a denitration device line. The liquid ammonia evaporator comprises a liquid ammonia conveying pipe, one end of the liquid ammonia conveying pipe is a liquid ammonia inlet end connected with a liquid ammonia source, the other end of the liquid ammonia conveying pipe is an ammonia outlet end, and a plurality of radiating fins are arranged outside the liquid ammonia conveying pipe. According to the liquid ammonia evaporator, the radiating fins are arranged outside the liquid ammonia conveying pipe, the heat exchange area between the liquid ammonia conveying pipe and outer space is enlarged, so that liquid ammonia can be more completely gasified to form ammonia in the conveying process of the liquid ammonia, the gasification rate of the liquid ammonia is increased, so that the mixed sufficiency of the ammonia and flue gas is improved, on one hand, denitration efficiency is improved, the removal rate of nitric oxide in the flue gas is increased, on the other hand, and the liquid ammonia evaporator solves the problem that the ammonia escapes as the ammonia cannot completely react.

Owner:CHENGDU GUOHUA ENVIRONMENTAL TECH

Single-screw extruder

Owner:浙江百纳橡塑设备有限公司

Cement stirring device for house construction engineering

InactiveCN110936498AReduce the waste of manpowerImprove stirring efficiency and stirring adequacyCement mixing apparatusLiquid ingredients supply apparatusPhysicsHouse building

The invention relates to the technical field of accessory devices of stirring equipment, in particular to a cement stirring device for house construction engineering, and the device can be used to automatically mix and stir cement raw materials, greatly reduce labor cost and improve the stirring efficiency and sufficiency. The stirring device comprises a base, two groups of supporting plates, a speed reducing motor, a power shaft, a stirring cylinder, stirring rods, a driving plate and a cover plate assembly; the left and right sides of the top end of the base are connected with the bottom ends of two supporting plates; the left end of the speed reducing motor is connected with the middle of the right end of the right supporting plate; a rotating hole penetrates the middle of the right endof the right supporting plate and sleeves a bearing at the output end of the speed reducing motor; the right end and the left end of the power shaft are concentrically connected with the output end of the speed reducing motor and the middle of the right end of the stirring cylinder respectively; a working cavity is formed in the stirring barrel; the top end of the working cavity is provided witha material taking and placing pipe in a communicating mode; and the left area and the right area of the inner side wall of the working cavity are conical surfaces respectively.

Owner:盐城市权航科技有限公司

Metering and detecting device for liquid taking and metering

InactiveCN112857502APrevent precipitationImprove uniformityTransportation and packagingRotary stirring mixersControl engineeringLiquid storage tank

The invention discloses a metering and detecting device for liquid taking and metering, and belongs to the field of metering and detecting. A metering detection device for liquid taking and metering comprises a workbench, a liquid storage tank and a metering cylinder are fixedly connected to the workbench, a stirring rod is rotatably connected to the liquid storage tank, a stirring fan is fixedly connected to the stirring rod, a piston cylinder is fixedly connected to the liquid storage tank, the liquid storage tank is fixedly connected with the piston cylinder through a liquid inlet pipe, the piston cylinder is fixedly connected with a metering cylinder through a liquid outlet pipe, an adjusting plate is connected to the metering cylinder in a sliding mode, and a driving mechanism is fixedly connected to the workbench. The device is easy to use, liquid precipitation is reduced, the uniformity of the liquid is improved, the accuracy of detection data is improved by stirring the liquid in advance, meanwhile, the accuracy of the taking amount of the liquid is improved by controlling the using amount of the taken liquid, meanwhile, the labor intensity of taking a large amount of liquid is reduced, and the working efficiency of taking the liquid is improved.

Owner:刘三凤

Biopharmaceutical stirring device

InactiveCN108905741AEasy to useImprove mixing adequacyRotary stirring mixersTransportation and packagingDrive wheelDrive shaft

The invention discloses a biopharmaceutical stirring device which comprises a stirring shell. A support frame is arranged at the bottom of the stirring shell. A discharge pipe is arranged at the bottom of the stirring shell. A storage tank is arranged at one side of the discharge pipe. Feeding pipes are arranged at both sides of the top of the stirring shell, a transmission box is arranged at thetop of the stirring shell, one side of the transmission box is provided with a driving motor, and one side of the driving motor is provided with a driving shaft which runs through the transmission boxand is connected with a driving wheel located in the transmission box. One side of the top of the driving wheel is provided with a driven wheel I, and the bottom of the driven wheel I is provided with a rotating shaft. Beneficial effects are that: The design is reasonable, the structure is simple and the use is convenient. Compared with a traditional biological pharmaceutical stirring device, thestirring effect is effectively improved, and the drug efficacy is effectively ensured.

Owner:合肥七小俊生物科技有限公司

Constant-temperature mixer

InactiveCN105926414ASimple structureEasy to operateRoads maintainenceReduction driveElectric machinery

The invention discloses a constant-temperature mixer. The constant-temperature mixer comprises a hopper and a bracket. The hopper is installed on the bracket. A rotating device is installed between the hopper and the bracket. A motor is installed at the bottom of the hopper. A reducer is installed between the motor and the bottom of the hopper. A mixing propeller is installed on the reducer. The hopper is of a two-layer structure. Constant-temperature pipes are installed in the two-layer structure of the hopper. A stable block is installed on the bottom surface of the bracket. A control module is installed on the bracket. By means of the mode, the constant-temperature mixer is simple in structure and convenient to operate, and not only is the mixing sufficiency of the equipment improved, but also constant-temperature mixing can be conducted; and thus, the viscosity of asphalt is not too high, and the effect that the asphalt can be sufficiently mixed and blended is ensured.

Owner:SUZHOU HAOSHUN PLASTIC RUBBER CO LTD

Flue gas denitrification equipment line

PendingCN107138042AIncrease gasification rateSolve the escapeGas treatmentDispersed particle separationPtru catalystNitrogen oxides

The application relates to the technical field of air pollution control in the environmental protection industry, in particular to a flue gas denitrification equipment line. The flue gas denitrification equipment line comprises a flue gas conditioning assembly and at least one denitrification tower, wherein the denitrification tower comprises a tower body; at least one catalyst assembly is arranged in the tower body; the catalyst assembly comprises at least two silk screen assemblies; a third sealing plate is connected between opposite edges of the silk screen assemblies; the silk screen assemblies and the third sealing plate are enclosed into a second cavity for charging or discharging flue gas; first cavities of the silk screen assemblies are filled with a denitrification agent. In the flue gas denitrification equipment line disclosed by the application, the conditioning assembly and the denitrification tower with the catalyst assembly are provided, so that the denitrification efficiency in a flue gas denitrification process is increased greatly, the removal rate of nitrogen oxide in the flue gas is increased greatly, and the problem of ammonia escape due to incomplete reaction of ammonia gas is solved.

Owner:CHENGDU GUOHUA ENVIRONMENTAL TECH

Multifunctional chemical experiment connecting device

InactiveCN112371201AImprove mixing adequacyImprove efficiencyRotating receptacle mixersHeating or cooling apparatusChemical solutionElectric machinery

The invention discloses a multifunctional chemical experiment connecting device, and relates to the technical field of chemical experiment appliances. The multifunctional chemical experiment connecting device comprises a support frame, a stirring tank is fixed in the support frame, an output shaft of a driving motor is in driving connection with a driving shaft, a servo motor is in driving connection with a support mechanism for supporting a beaker, and a clamping mechanism for clamping and fixing a test tube is arranged above an alcohol lamp. A chemical solution in the stirring tank can be rotationally stirred through an arranged stirring device, and an arranged stirring frame can rotate and revolve around a rotating plate, so that the stirring sufficiency and efficiency of the chemical solution are remarkably improved, an arranged rotating table can drive a beaker on the rotating table to rotate, the position of the beaker can be flexibly adjusted, a stirred solution can be conveniently added into the beaker, the arranged clamping mechanism can well clamp a test tube, and meanwhile, the clamping mechanism can drive the test tube to achieve a steering adjustment effect, so that the test tube is inclined and is fully heated by the alcohol lamp.

Owner:河南财政金融学院

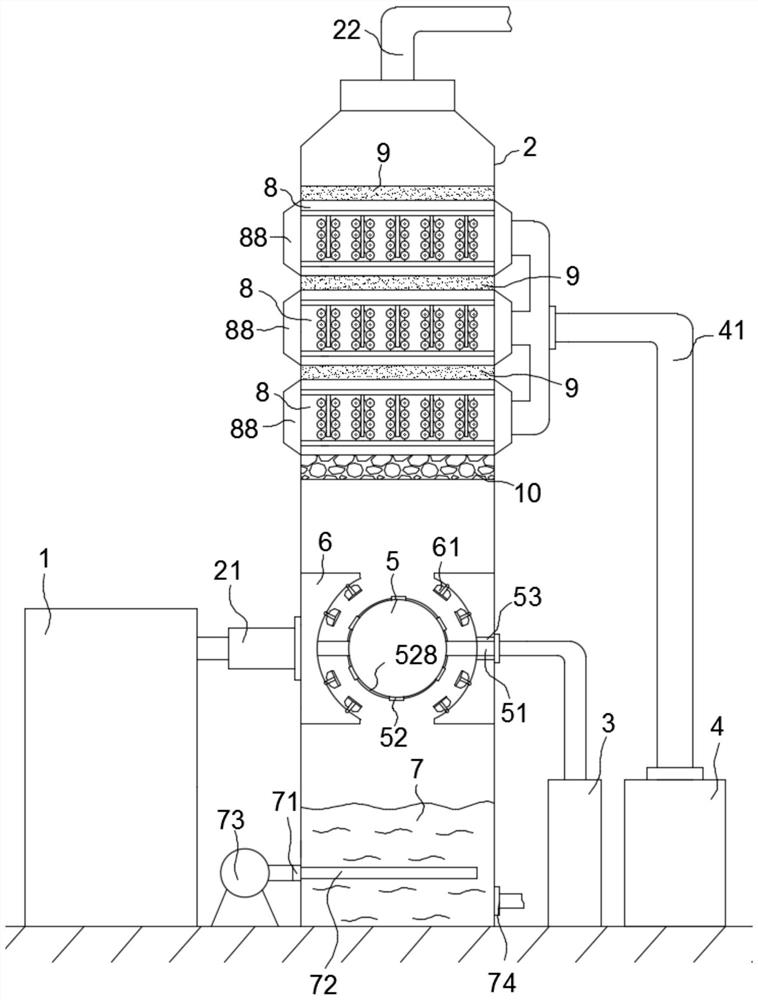

A combined desulfurization and denitrification device and process

ActiveCN110038409BGood removal effectCombined desulfurization and denitrification efficiency is highGas treatmentDispersed particle separationFlue gasEnvironmental engineering

The invention discloses a combined desulfurization and denitrification device and process, which mainly includes a dust removal system, a desulfurization and denitrification tower, an ammonia water tank, and an ozone tank; Gas port, the interior of the desulfurization and denitrification tower is divided into a desulfurization section and a denitration section from bottom to top; the dust removal system is connected to the smoke inlet; the desulfurization section includes a spray ball, a flue gas dispersion ring, and an oxidation pool; The denitration section includes a mixer and a denitration packing layer. The combined desulfurization and denitrification device and process of the present invention, through the structural design of the combined multi-stage desulfurization and denitrification device, has high desulfurization and denitrification efficiency and good use effect.

Owner:无锡市道格环保科技有限公司

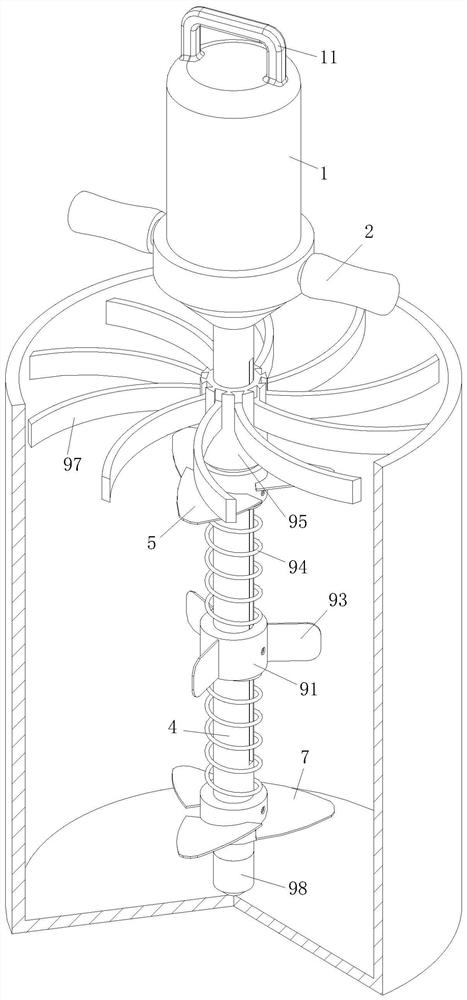

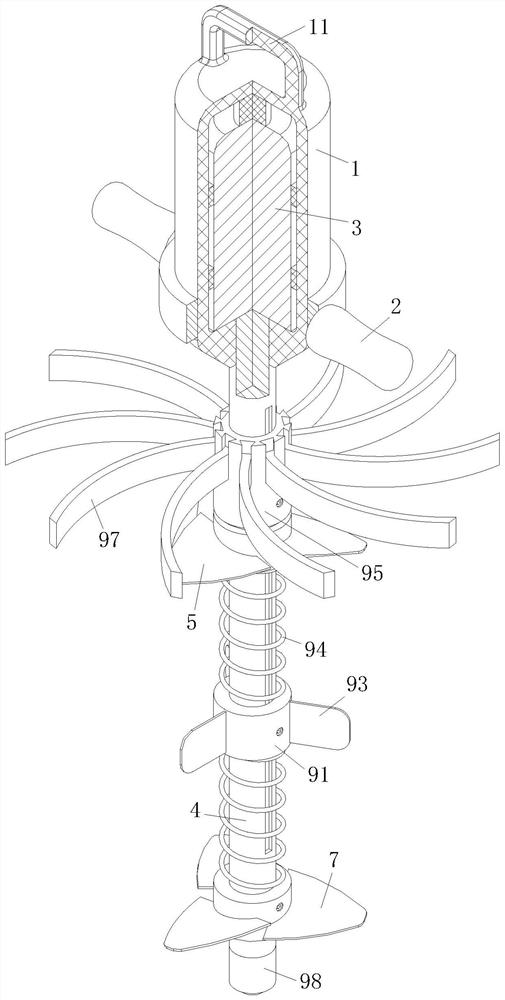

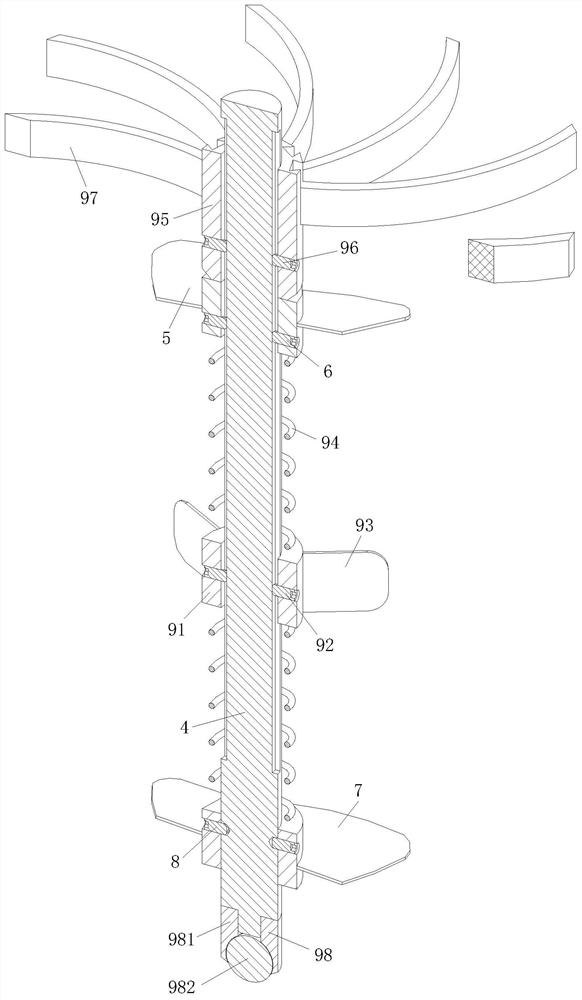

Stirring device for fully stirring catalyst and degraded plastic organisms

InactiveCN113457538AImprove finenessGuaranteed frictionRotary stirring mixersMixer accessoriesPtru catalystEngineering

The invention relates to the technical field of bio-based materials, and discloses a stirring device for fully stirring a catalyst and degraded plastic organisms. The stirring device comprises a stirring mechanism, a funnel is movably mounted above the stirring mechanism, and a main rod is movably mounted below the funnel. By using the catalyst of a lower grinding disc, the weight is reduced, the gravity is reduced, the elastic force of a spring pushes a piston rod to move upwards in an air cylinder and drives the lower grinding disc and the catalyst to move upwards. Friction force between an upper grinding disc and the lower grinding disc is kept, the fineness of the catalyst is improved, and then powder of the catalyst falls into the periphery of a stirring box through vent holes by means of wind power of a fan. The sufficient stirring rate between the catalyst and the biological plastic is improved. A threaded rod rotates to drive a connecting block to move upwards, so that a support shaft pulls a supporting rod to be folded. At the moment, the stirring mechanism is shrunk, the bioplastics are prevented from being stacked above the stirring mechanism when being fed, the stirring time is shortened, and the stirring efficiency is improved.

Owner:杭州麦铺网络科技有限公司

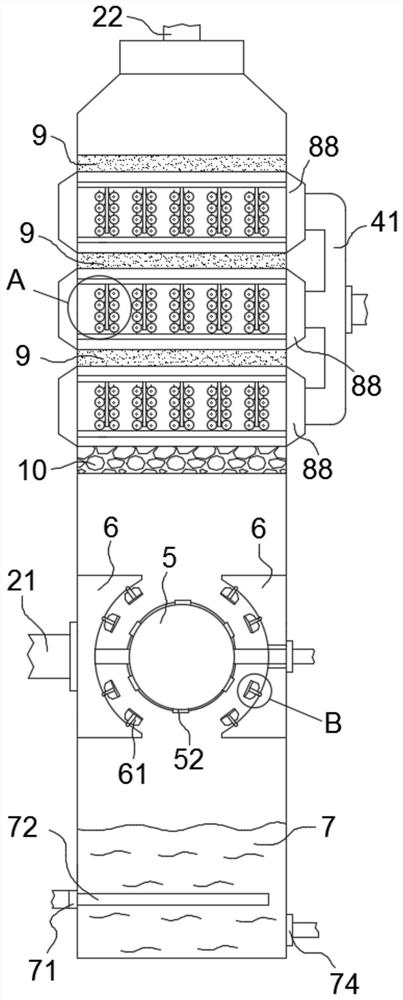

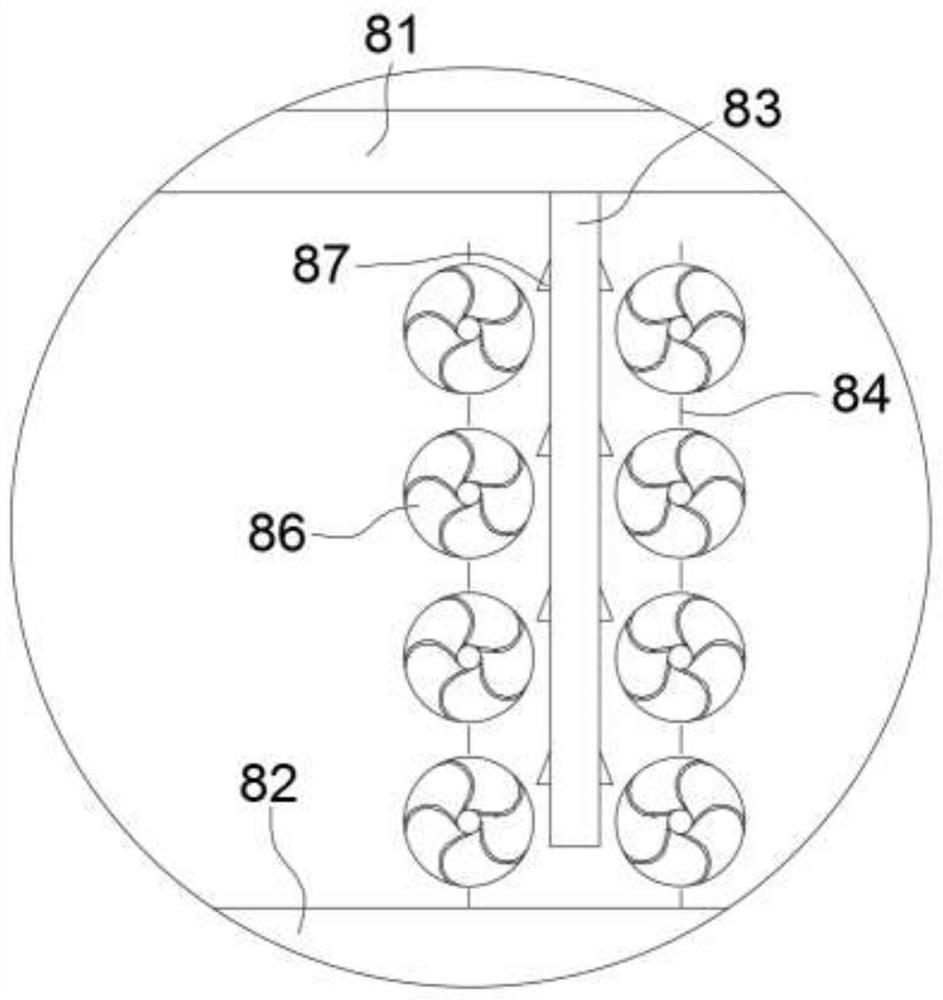

A multi-stage high-efficiency purification device and purification method for mineral water containing iron and manganese

ActiveCN110759558BImprove filtering effectPrevent compactionWater/sewage treatment by irradiationSpecific water treatment objectivesPurification methodsManganese

The present invention disclosed a multi -level high -efficiency purification device and purification method of iron -manganese mineral water, including the main body of the device, the aeing warehouse, the iron -manganese filter, the sedimentation warehouse, and the sterilization device.Inlet, the water outlet is provided at the lower part of the main body of the device.The ingredients are connected to the water inlet and outlet.The present invention effectively uses water flow to convert it into the power of device operation. The power utilization is low, the purification effect is strong, the energy conservation and environmental protection can be quickly and efficiently purified to obtain mineral water that meets national standards.

Owner:LINYI UNIVERSITY

A preparation device for ophthalmic drug modulation and mixing

ActiveCN114307780BWell mixedEfficient mixingShaking/oscillating/vibrating mixersTransportation and packagingOphthalmologyPharmaceutical drug

Owner:AFFILIATED HOSPITAL OF WEIFANG MEDICAL UNIV

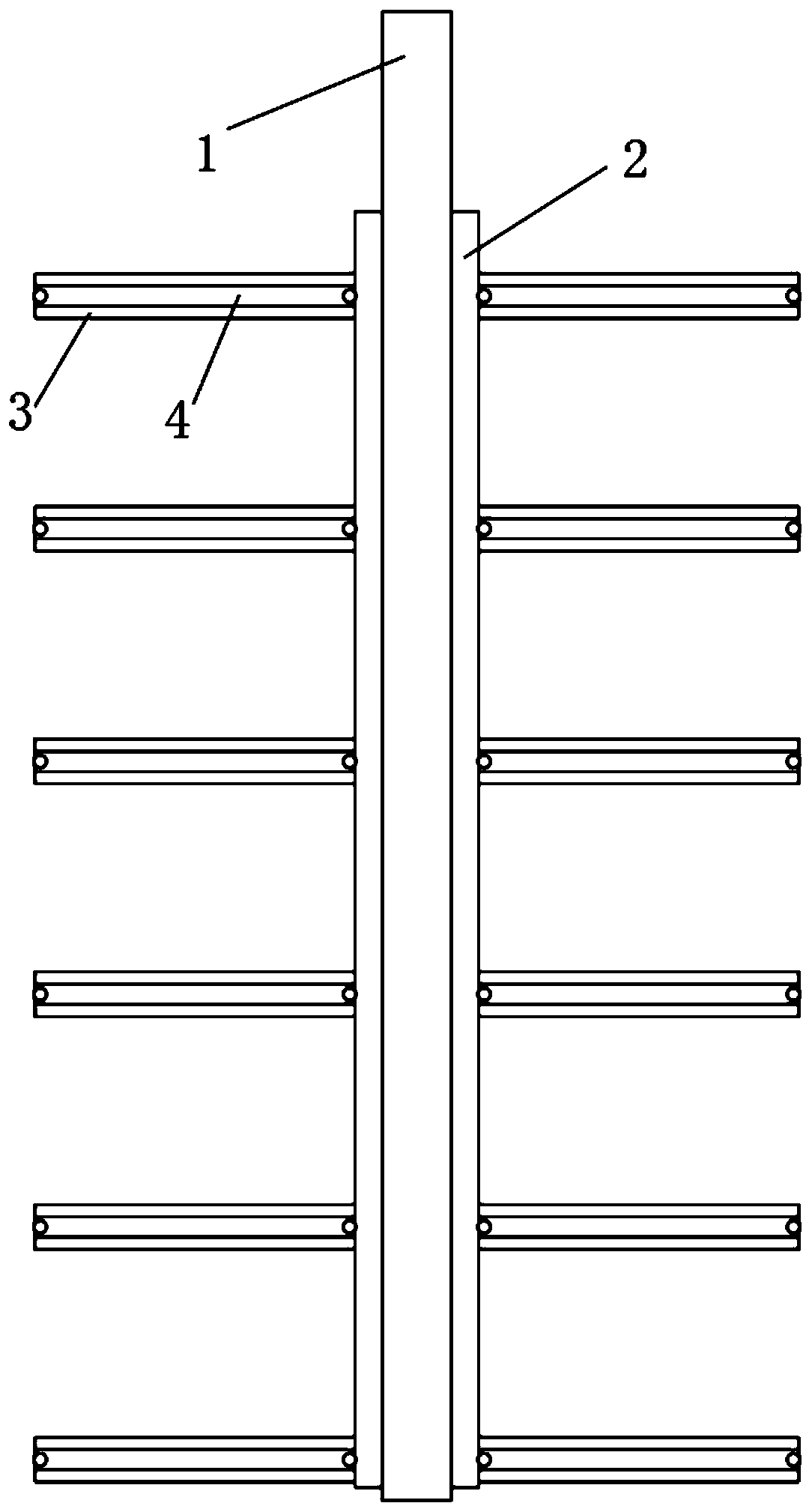

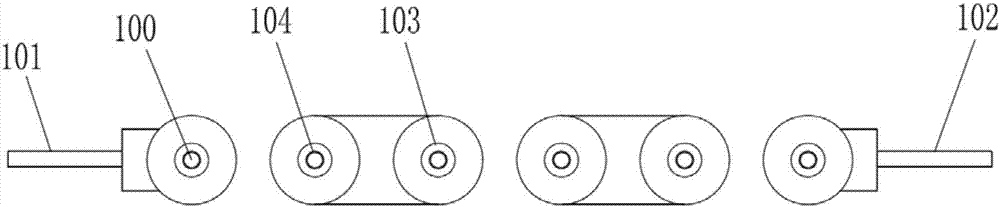

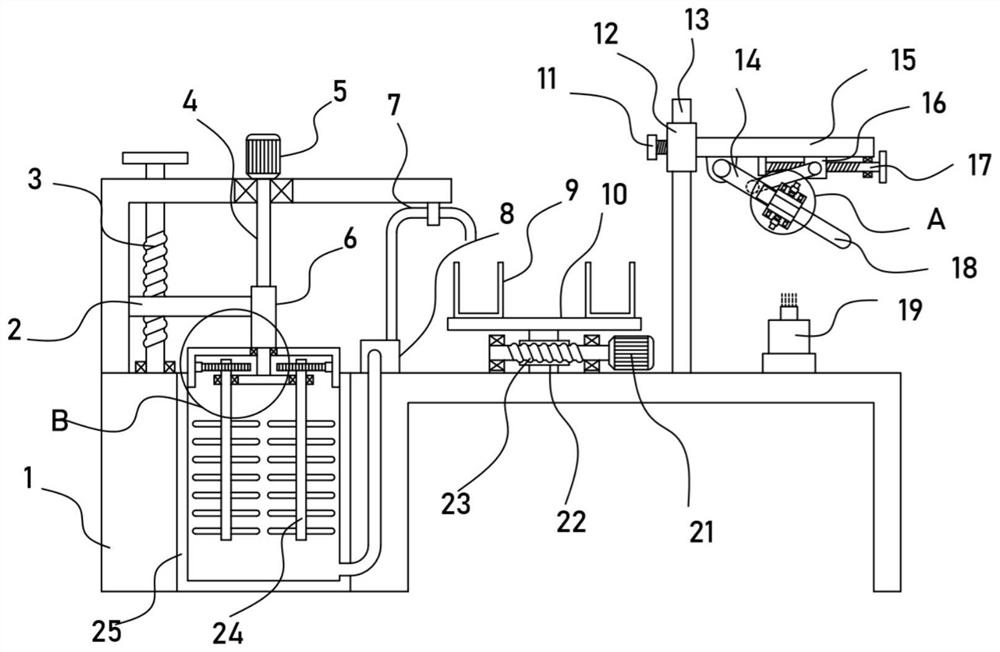

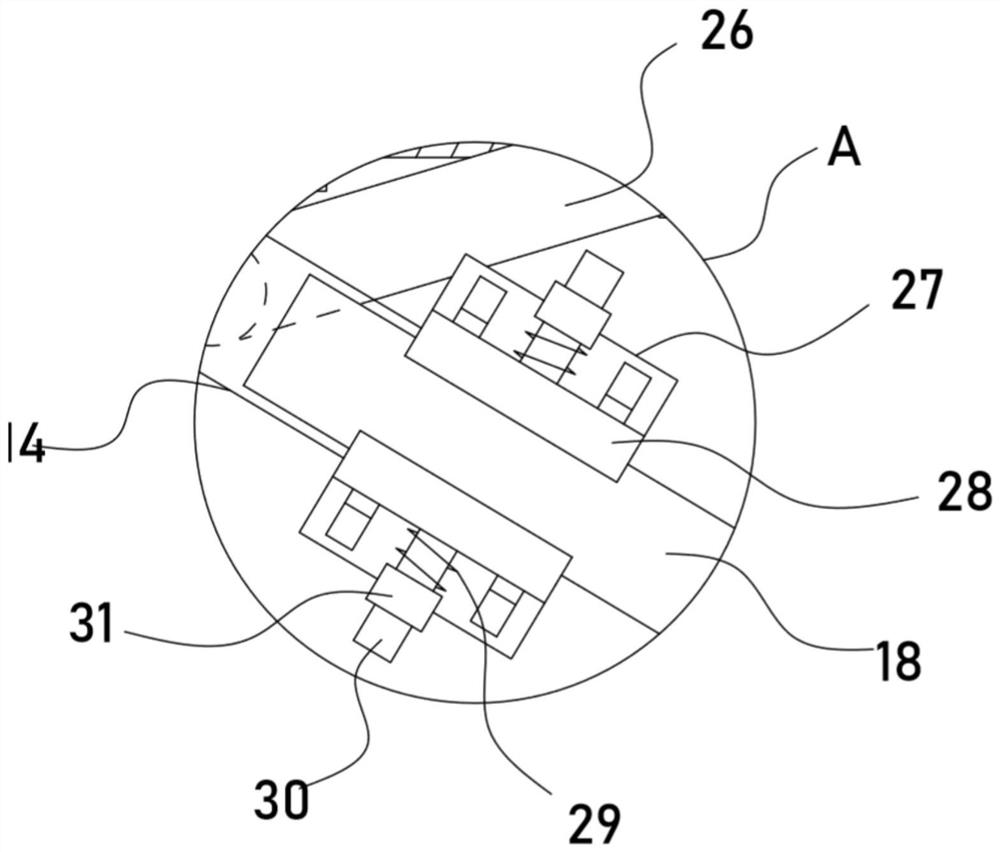

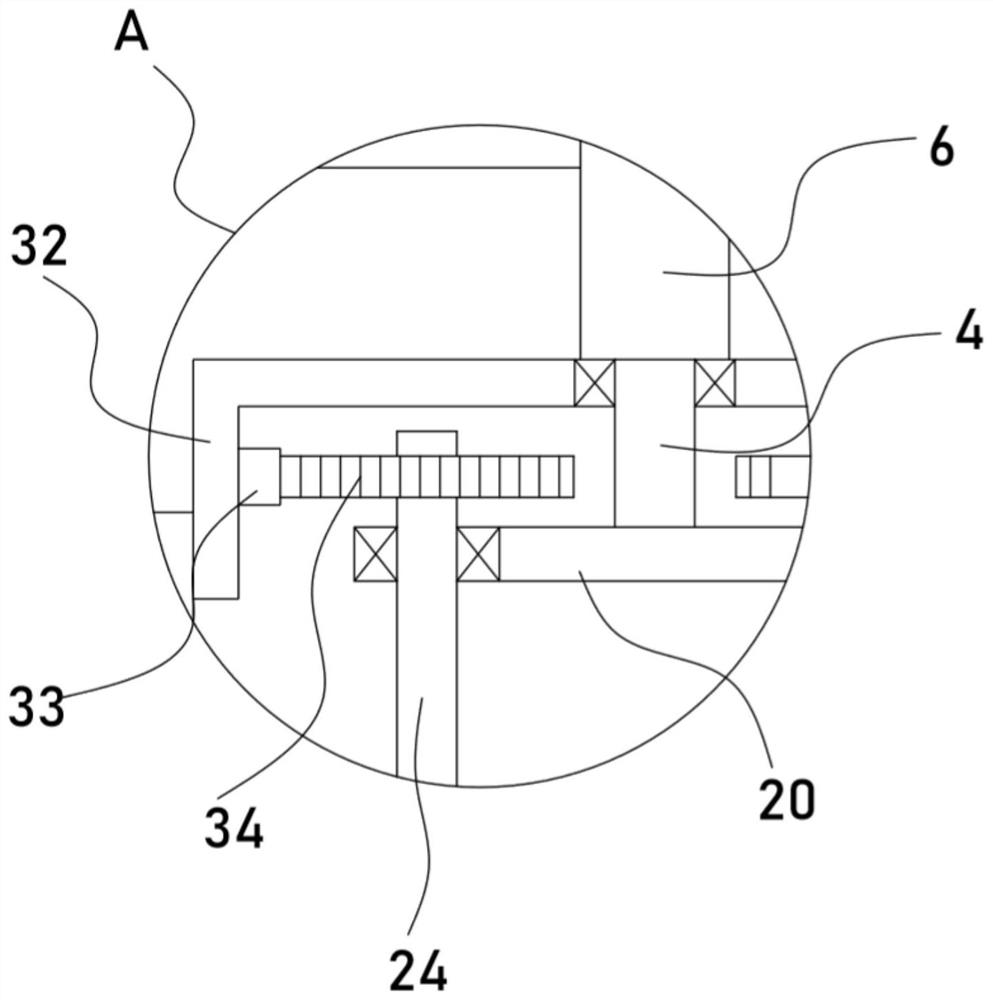

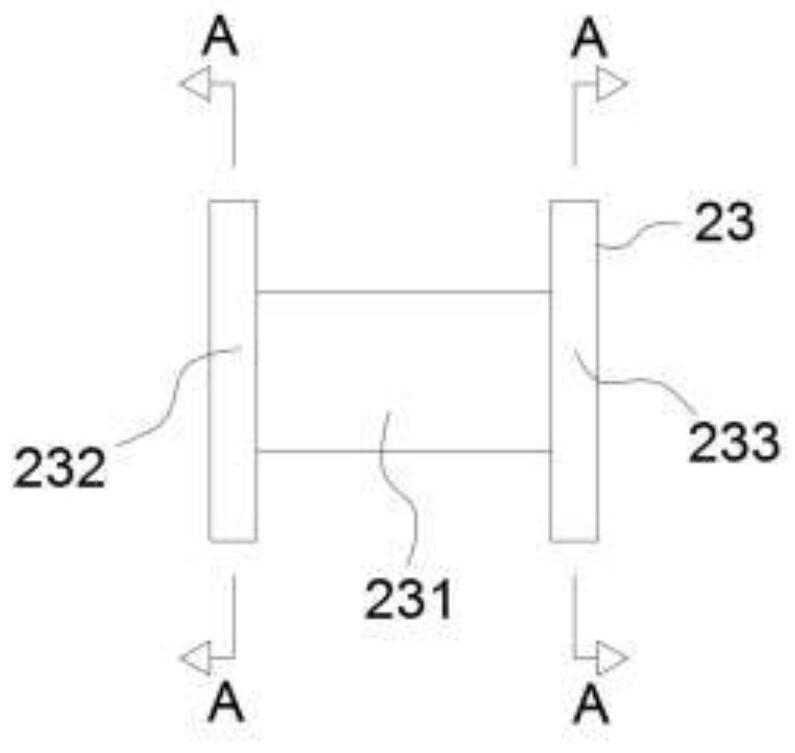

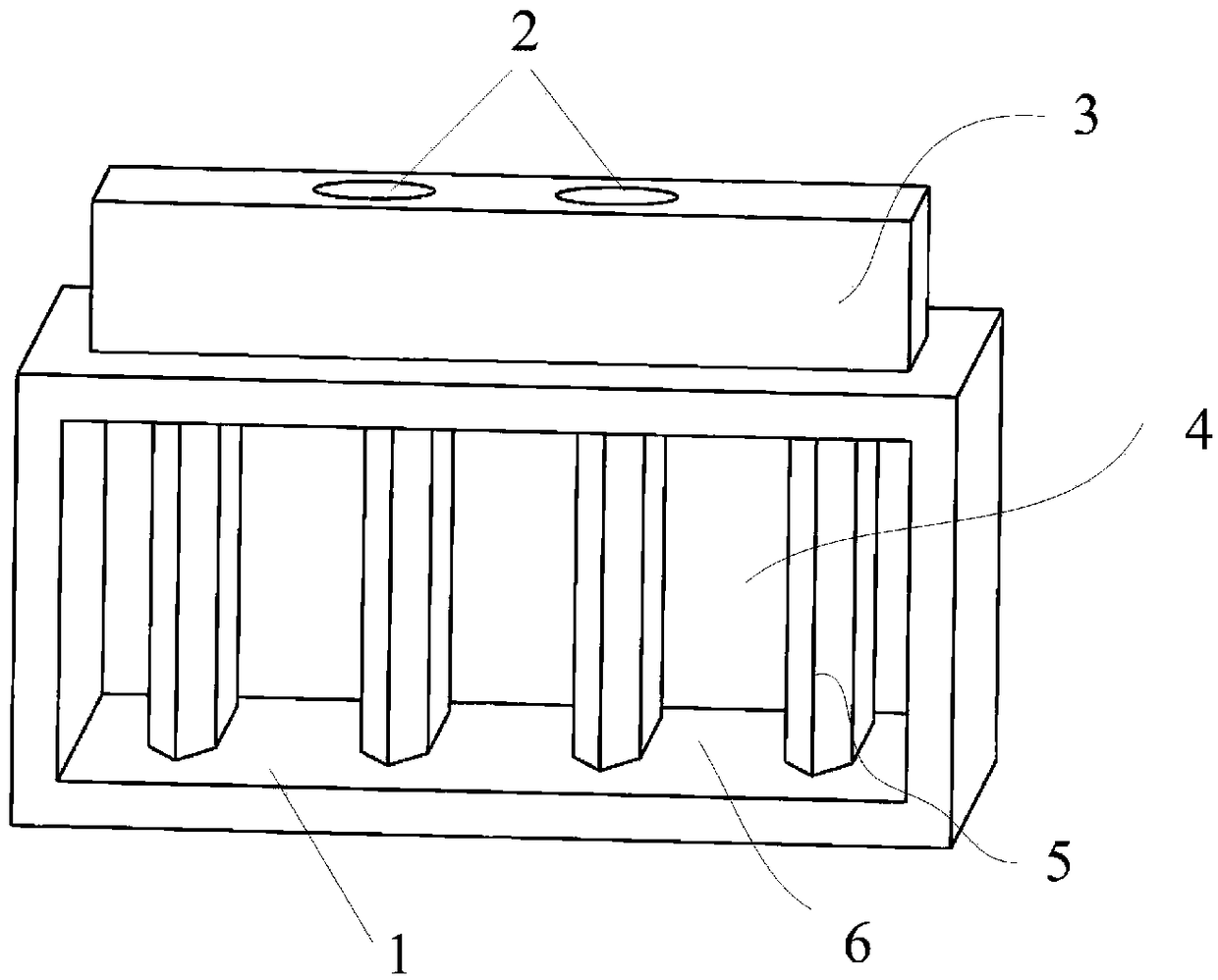

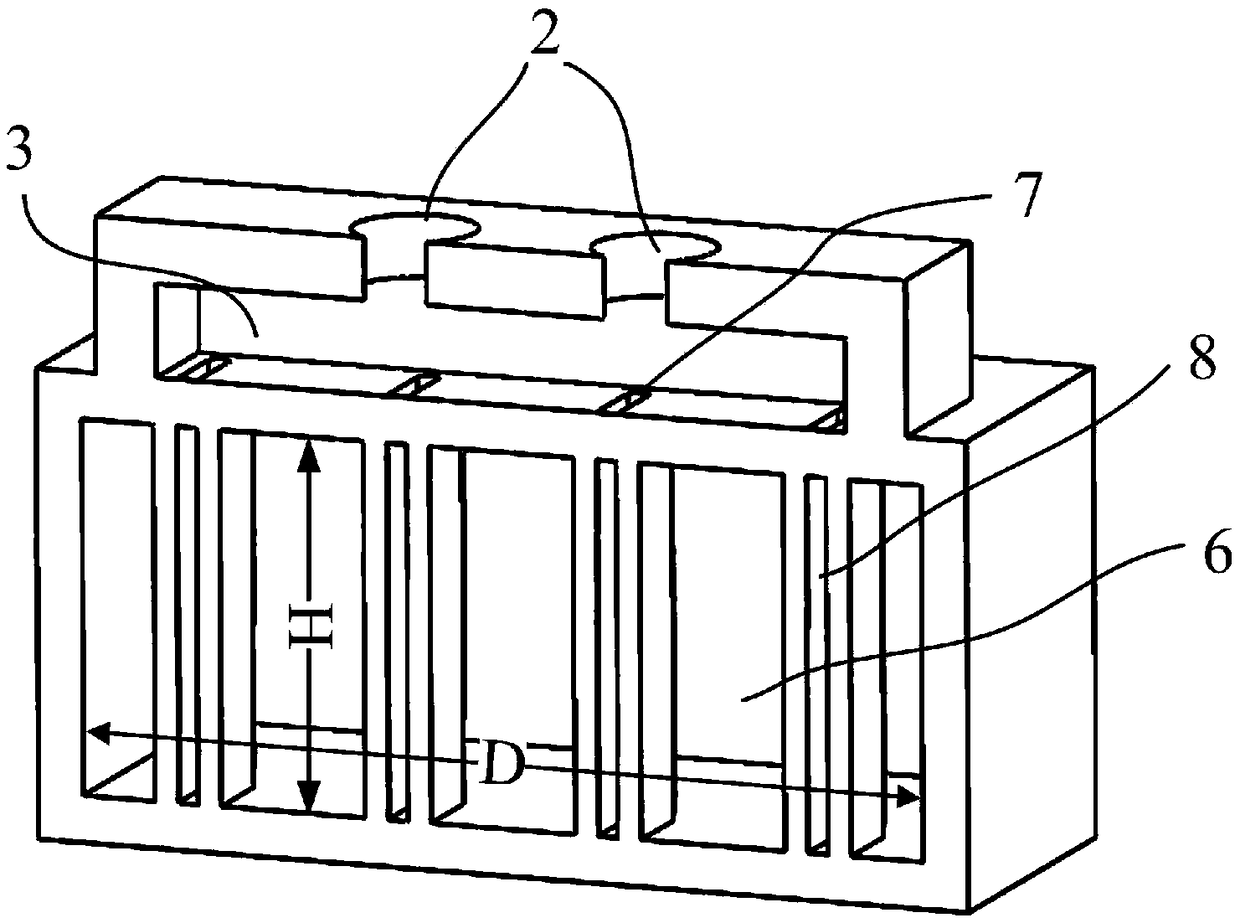

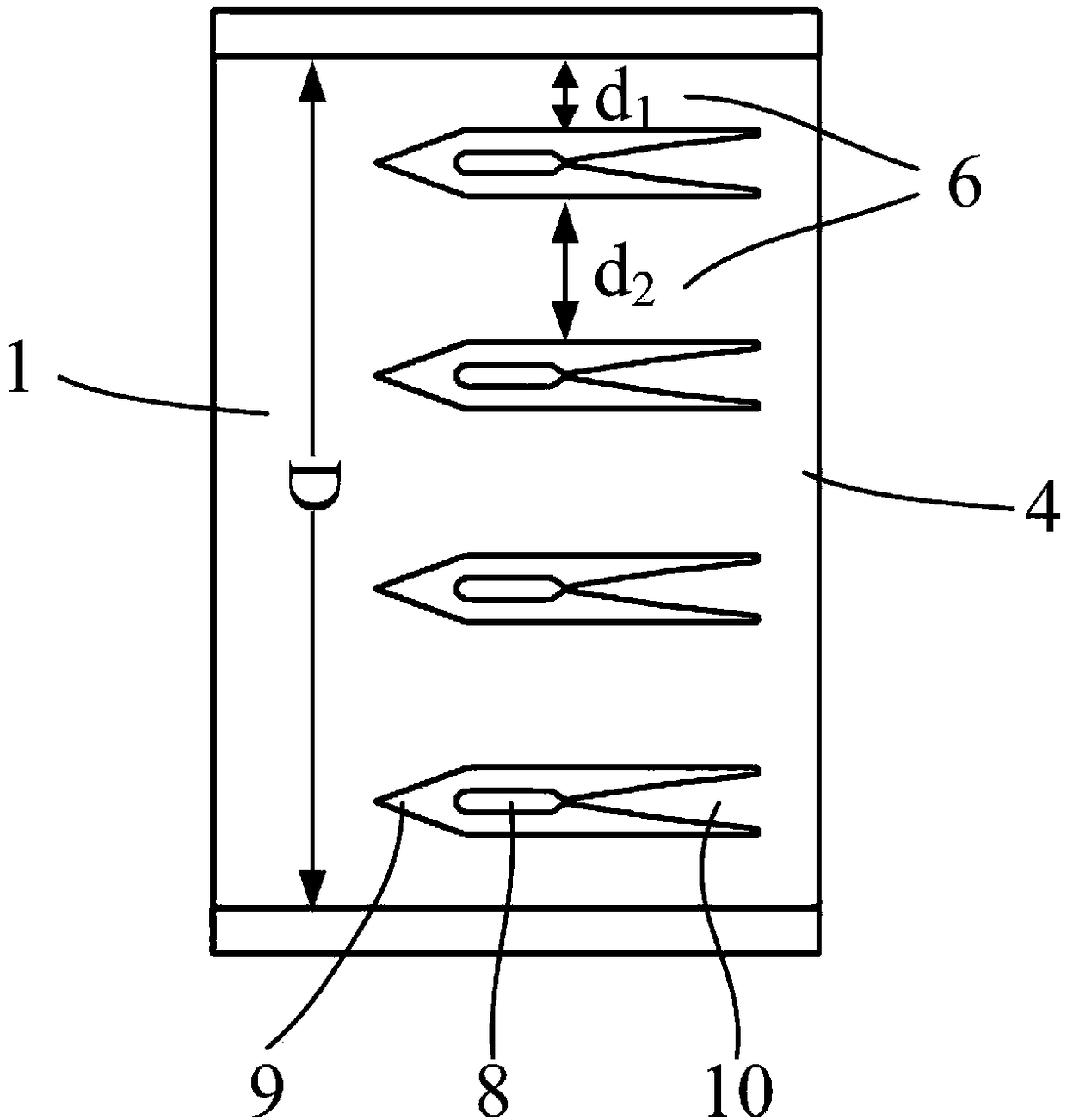

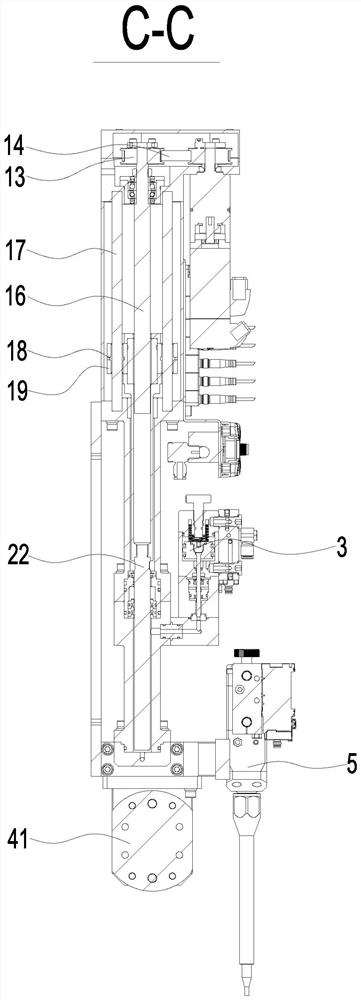

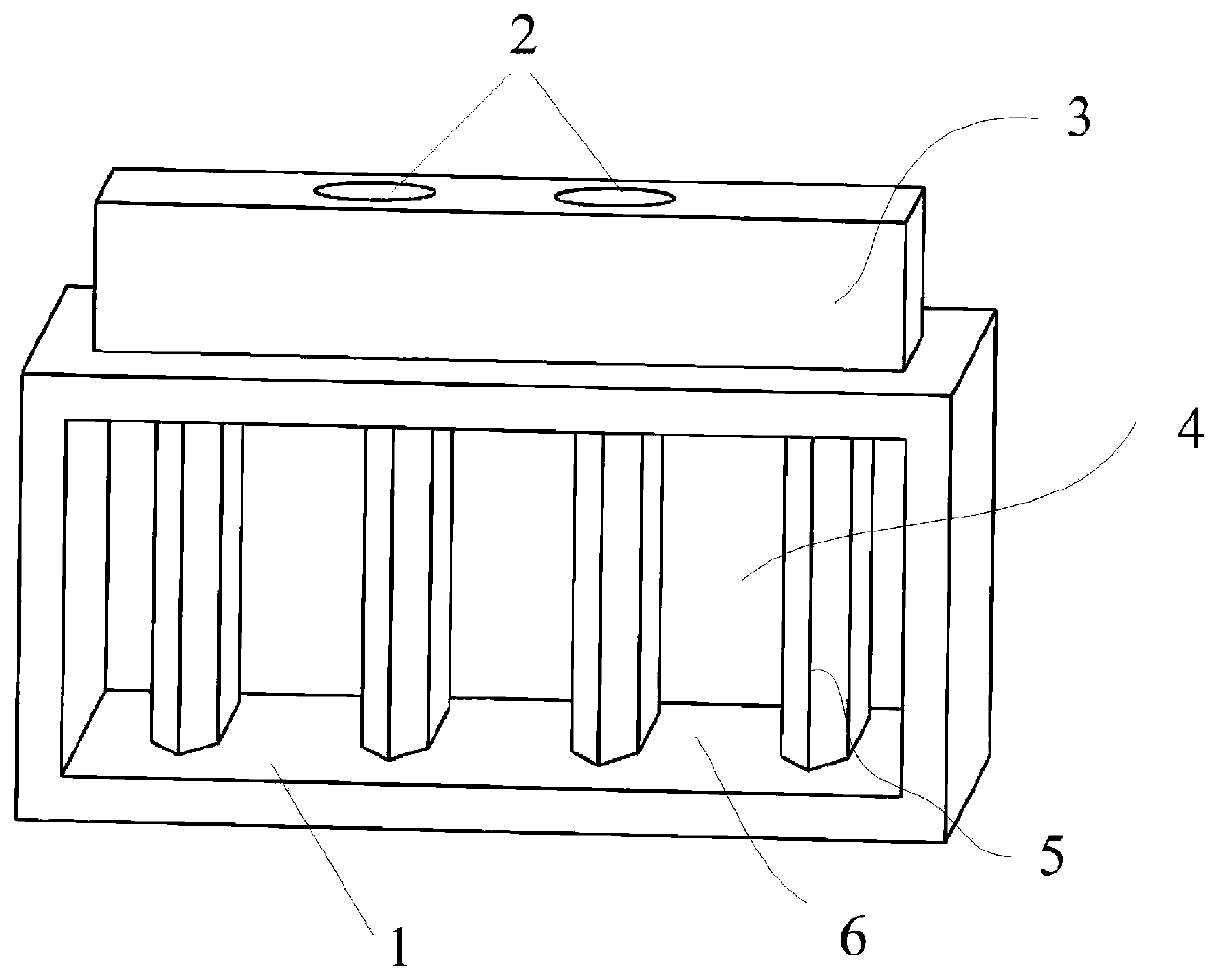

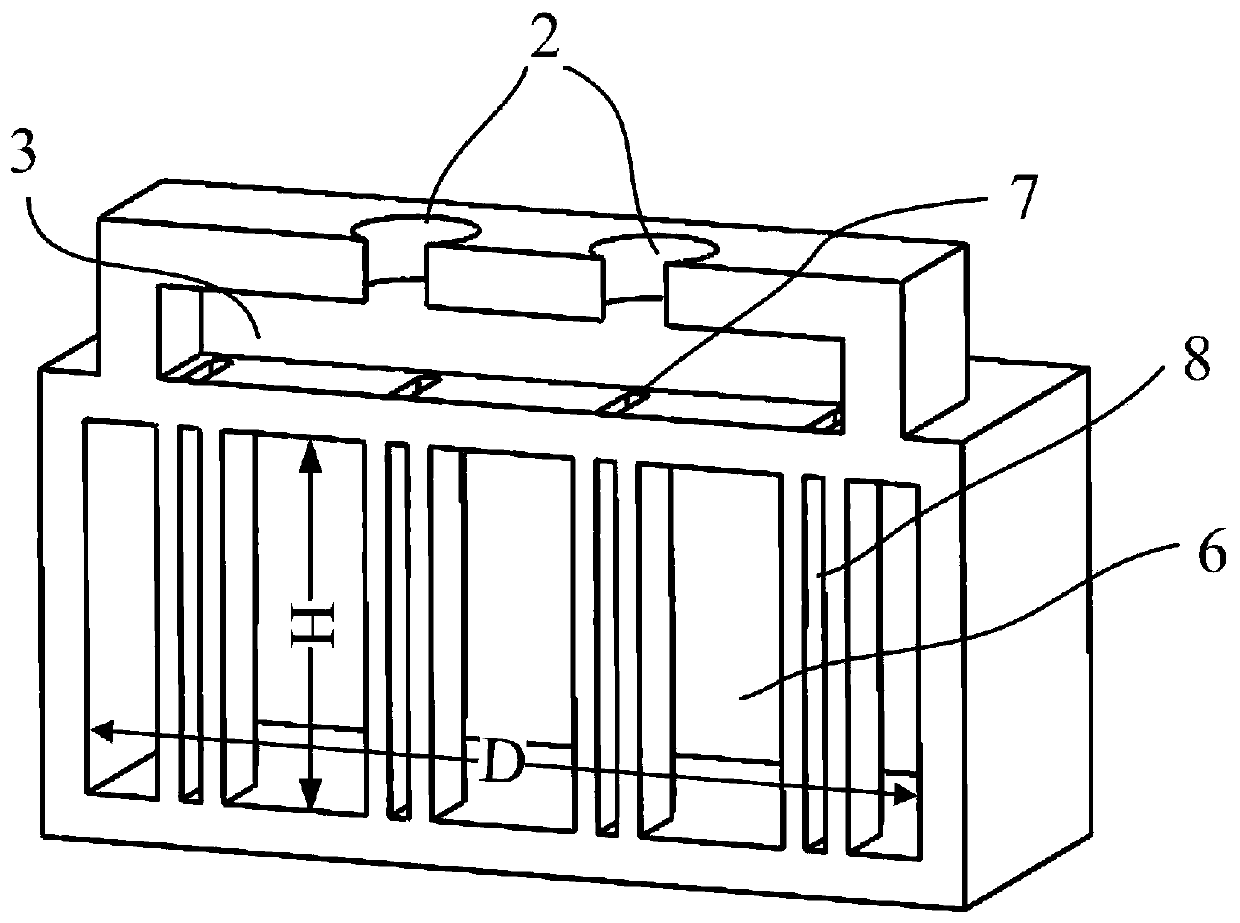

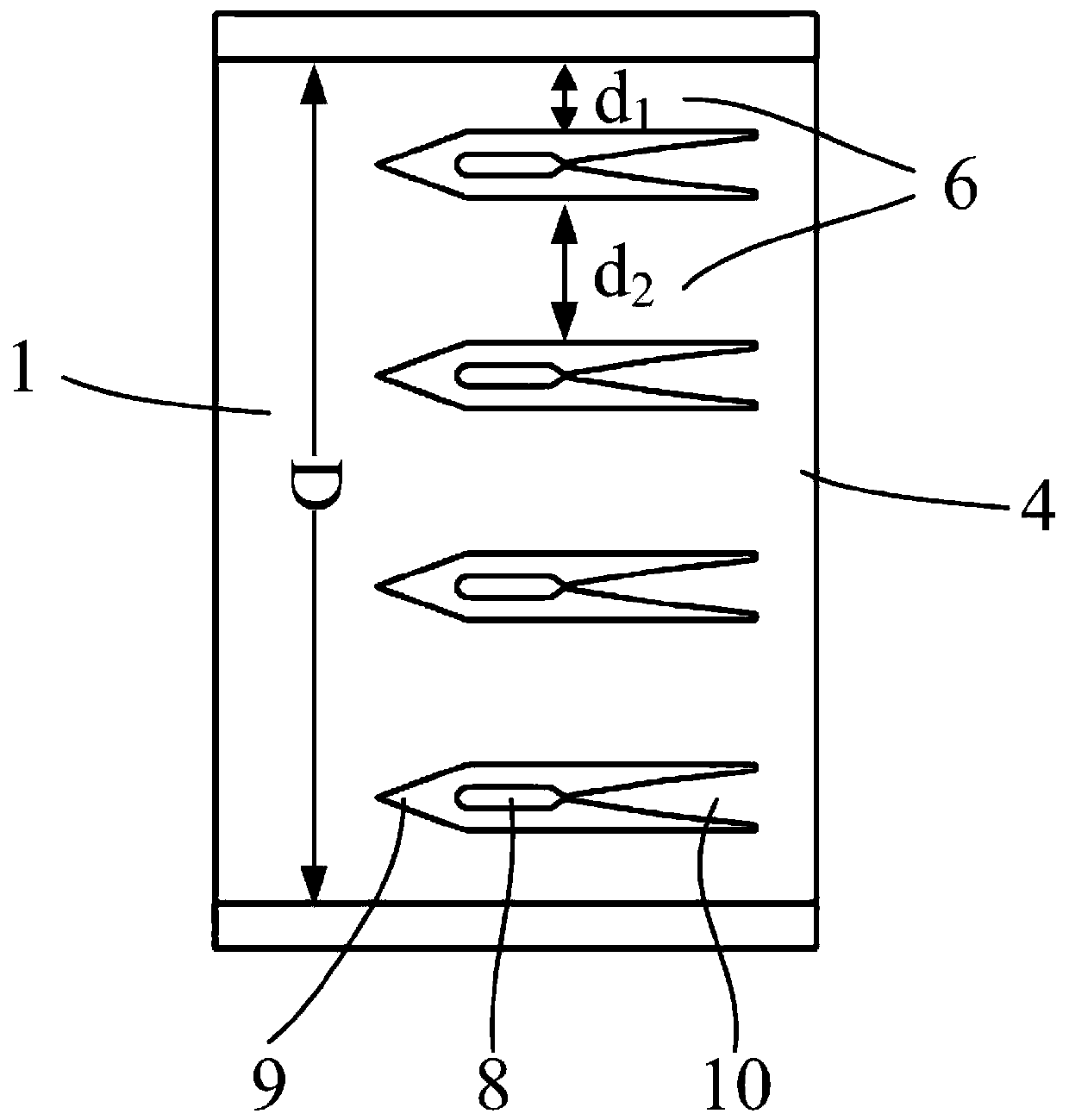

Two-dimensional construction multi-support-plate ejector structural design

ActiveCN108757591ACompact structureImprove ejection abilityJet pumpsMachines/enginesShock waveEngineering

The invention provides two-dimensional construction multi-support-plate ejector structural design and belongs to the technical field of ejector structural design. Multiple sets of support plates for dividing ejecting airflow and ejected airflow are arranged in an ejector. Flow guide sections are arranged at the front ends of the support plates, and spraying tube air guide cavities and two-dimensional laval jet tubes are arranged in the support plates. The ejecting airflow is divided into multiple streams of uniform airflow by the two-dimensional laval jet tubes in the support plates. The ejected airflow is divided into multiple streams of uniform airflow by ejected airflow subchannels between the support plates, then the contact area between the ejecting airflow and the ejected airflow isincreased, and a better mixing effect is achieved. Through the two-dimensional construction multi-support-plate ejector structural design, shock wave loss is lowered effectively while mixing adequacyof the ejecting airflow and the ejected airflow is enhanced, and then ejecting performance of the ejector is improved.

Owner:NAT UNIV OF DEFENSE TECH

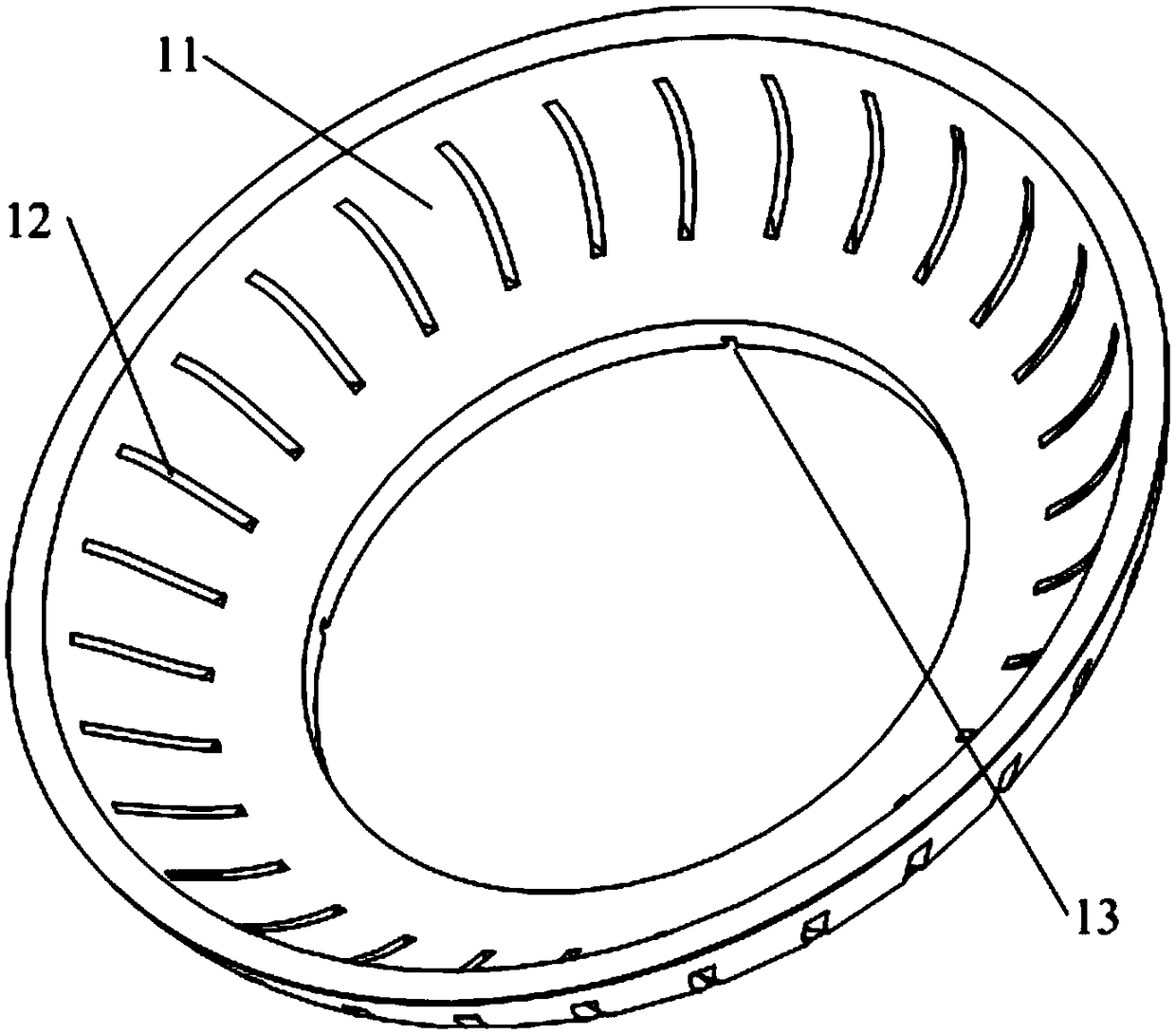

Focus rings and gas hobs

ActiveCN106152202BImprove sufficiencyImprove mixing adequacyDomestic stoves or rangesLighting and heating apparatusProcess engineeringFuel gas

Owner:GREE ELECTRIC APPLIANCES INC

Preparation method of BMC mould pressing resin

InactiveCN111250022AImprove quality stabilityHigh strengthChemical/physical/physico-chemical stationary reactorsPolyesterVacuum pumping

The invention relates to a preparation method of BMC mould pressing resin. The preparation method comprises the following steps: feeding materials according to a feeding sequence; after the feeding isfinished, adding corresponding auxiliary agents and small materials, slowly opening a heating oil valve, and starting to raise the temperature; heating a first material to effluent, slowly heating from the temperature of the effluent, introducing nitrogen in the heating process, sampling, measuring the acid value, and cooling; after the material is cooled, adding a second material and an auxiliary agent; after the second material is fed, heating to discharge water, keeping the temperature for reaction after discharging water, heating and keeping the temperature, introducing nitrogen in the heating process, keeping the temperature, and measuring the acid value; after the acid value reaches the standard and the polyester 150 DEG C lamina viscosity reaches the standard, starting vacuum pumping, cooling after the product is detected to be qualified, adding JQ and PQ hydroquinone, continuing to cool the material, and diluting; adding DQ and T50 small materials in advance before dilution; and cooling after dilution, adding copper naphthenate, carrying out vacuum dehydration, continuing cooling, sampling, detecting, filtering after the product is detected to be qualified, and packaging.Compared with the prior art, the quality stability of the BMC mould pressing resin is improved, and the strength and hardness of the BMC mould pressing resin are improved.

Owner:浙江新纪化工有限公司

Gas diffusion device

ActiveCN109519939AReliable ignitionReduce consumptionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberFlameout

The invention discloses a gas diffusion device. The gas diffusion device comprises an inner cylinder and an outer cylinder surrounding the periphery of the inner cylinder. Spacing exists between the inner wall of the outer cylinder and the outer wall of the inner cylinder, and a first annular partition plate and a second annular partition plate in the circumferential direction of the inner cylinder are arranged on the outer wall of the inner cylinder at intervals in the axial direction from bottom to top. The circumferential peripheries of the first partition plate and the second partition plate are connected to the inner wall of the outer cylinder, and the first partition plate and the second partition plate are provided with through holes. A first combustion chamber is arranged at an area between the first partition plate and the second partition plate, and a second combustion chamber is arranged at the position, above the second partition plate, in the outer cylinder. The first combustion chamber is internally provided with first burners and second burners at intervals from bottom to top in the axial direction of the inner cylinder, the first burners are connected with a blast furnace gas pipe and maintained in a normally open flame state, and the second burners are in communication with the inner cylinder through branch pipes. The gas diffusion device can enable diffused gas to be reliably ignited, can preheat the gas and air, improves the sufficiency of combustion, and avoids the situations of flame lifting and flameout.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Handheld stirrer for building construction

The invention belongs to the technical field of stirring devices, and particularly discloses a handheld stirrer for building construction. The handheld stirrer comprises a housing, handles, a stirringmotor, a stirring shaft, first blades, first sliding screws, second blades and set screws. According to the handheld stirrer, to-be-stirred solutions at the upper layer and the lower layer in a barrel are conveyed to the middle layer in the simultaneous rotating process of the first blades and the second blades, and then the to-be-stirred solutions in the barrel are fully mixed through the constant convection of the to-be-stirred solution at the upper layer and the to-be-stirred solution at the lower layer; besides, the to-be-stirred solutions gathering at the middle layer gradually flow to the side wall of the barrel after completing convection, then two circulating fluids are formed in the barrel, then no stirring dead corner will exist in the barrel, and thus the stirring uniformity isguaranteed; and the solutions with different level heights are stirred by adjusting the distance between the first blades and the second blades, and thus the application range of the stirrer is expanded.

Owner:郑州领翔环保科技有限公司

Starch adhesive paste preparation method

InactiveCN112480842AImprove mixing adequacyHigh bonding strengthNon-macromolecular adhesive additivesStarch adhesivesPolymer sciencePtru catalyst

The invention relates to the technical field of adhesive manufacturing, in particular to a starch adhesive paste preparation method which comprises the following specific steps: (1) sieving granular components by a 1000 to 1200-mesh sieve one by one; (2) fully mixing and uniformly stirring all the raw materials sieved in the step (1); (3) adding a hydrophilic agent, a gelatinizing agent, a preservative and a catalyst into distilled water, and fully stirring until the components are completely dissolved; (4) adding a mixture obtained in the step (2) into an aqueous solution obtained in the step(3); (5) heating a stirred mixed product to 60-80 DEG C, and continuously stirring in the heat preservation process; and (6) naturally cooling to room temperature to obtain the pasty starch adhesive.According to the starch adhesive paste preparation method, the powder is fully mixed, the auxiliaries are dissolved in the water, and then mixing and paste preparation are performed, so that the mixing sufficiency is greatly improved, the bonding strength of the product is improved, and the starch adhesive paste preparation method is more environmentally friendly and low in cost.

Owner:桐乡迅捷包装有限公司

Double Servo Plunger Dosing Machine

ActiveCN111842028BGood bondingSolve the problem of labor intensityLiquid surface applicatorsCoatingsControl engineeringAdhesive glue

The invention relates to the field of quantitative equipment, in particular to a double-servo plunger type quantitative machine, comprising a power mechanism, a metering mechanism, a feed valve, a flow monitoring system for monitoring various parameters of a fluid, and a mixing valve; On the mechanism; the feeding valve and the metering mechanism can be set in communication; the flow monitoring system and the measuring mechanism can be set in communication; the mixing valve and the flow monitoring system can be set in communication. On the one hand, the present invention adopts the integrated design of the flow monitoring system and the dosing machine, so that there is no need to set up any pipeline between the whole dosing machine and the flow monitoring system, that is, there is no pressure loss generated when the fluid flows, and the flow monitoring system can monitor the glue in real time. Process parameters such as proportion, glue output and glue output speed can improve the accuracy and adequacy of glue mixing; on the other hand, the invention also improves the automatic operation level of glue injection and glue mixing, and solves the labor of manual glue mixing. The problem is that the strength is large and the production efficiency is low.

Owner:存融流体设备(无锡)有限公司

Structural design of a two-dimensional multi-plate ejector

ActiveCN108757591BCompact structureImprove ejection abilityJet pumpsMachines/enginesShock waveEngineering

The invention provides two-dimensional construction multi-support-plate ejector structural design and belongs to the technical field of ejector structural design. Multiple sets of support plates for dividing ejecting airflow and ejected airflow are arranged in an ejector. Flow guide sections are arranged at the front ends of the support plates, and spraying tube air guide cavities and two-dimensional laval jet tubes are arranged in the support plates. The ejecting airflow is divided into multiple streams of uniform airflow by the two-dimensional laval jet tubes in the support plates. The ejected airflow is divided into multiple streams of uniform airflow by ejected airflow subchannels between the support plates, then the contact area between the ejecting airflow and the ejected airflow isincreased, and a better mixing effect is achieved. Through the two-dimensional construction multi-support-plate ejector structural design, shock wave loss is lowered effectively while mixing adequacyof the ejecting airflow and the ejected airflow is enhanced, and then ejecting performance of the ejector is improved.

Owner:NAT UNIV OF DEFENSE TECH

A hand-held mixer for construction

The invention belongs to the technical field of agitating devices, in particular to a hand-held agitator for building construction, including a casing, a handle, an agitating motor, an agitating shaft, a No. 1 fan blade, a No. 1 sliding screw, a No. 2 fan blade and a tight Set screws; in the present invention, the solution to be stirred in the upper layer and the lower layer in the barrel is transported to the middle layer during the simultaneous rotation of the No. Continuous convection realizes sufficient mixing of the solution to be stirred in the material tank; and the solution to be stirred in the middle layer gradually flows to the side wall of the material tank after convection, and then forms two circulating fluids inside the material tank, and then There will be no stirring dead angle in the material tank, thereby ensuring the uniformity of stirring; by adjusting the distance between the No. The scope of application of the device.

Owner:郑州领翔环保科技有限公司

A stirring and centrifugal separation device for removing ferromagnetism architectural paint

InactiveCN107866334BStable structureEasy to addTransportation and packagingRotary stirring mixersRotational axisBall bearing

The invention discloses a stirring and centrifuging device for removing ferromagnetism building paint, which comprises a centrifugal separation cylinder, a building paint tank, a ball bearing, an electromagnetic drive mechanism, a rotating disk and a rotating shaft. The bottom of the building paint tank is installed on On the frame, a ball bearing is installed on the inner wall of the building paint tank, a centrifugal separation cylinder is placed inside the ball bearing, an agitator is installed inside the centrifugal separation cylinder, and the agitator is installed at the bottom of the rotating shaft. A rotating disk is installed on the rotating shaft above the body, and a number of material guide holes are arranged on the rotating disk, and an electromagnetic drive mechanism is installed on the rotating disk; the stability of the rotation of the centrifugal separation cylinder is improved, and the protection against architectural coatings is improved. Stirring is sufficient to effectively absorb ferromagnetic impurities in architectural coatings. Under the rotation of the rotating disc, the iron core rod drives the centrifugal separation cylinder to rotate, which is convenient to realize the centrifugal treatment of architectural coatings by the rotation of the centrifugal separation cylinder.

Owner:湖北屹峡峰建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com