Double Servo Plunger Dosing Machine

A plunger-type, double-servo technology, applied in the field of double-servo plunger-type dosing machines, can solve the problems of high labor intensity for operators, low product yield, and low production efficiency, and achieve high labor intensity and improved mixing. Sufficiency, avoiding the effect of poor bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In the traditional production process, artificial glue mixing is mainly used. The operator needs to pour the filling A glue and B glue into the glue mixing cup in a specified proportion, and then mix the glue fully through the continuous stirring of the glue mixing stick, and then use the dispensing stick to mix the glue. The mixed AB glue is applied to the parts. However, since the setting time of AB glue after mixing is usually short, in order to avoid the waste of glue, the operator can only mix the amount of glue that can be used up within a certain period of time, which results in a high labor intensity for the operator, and it is easy to cause mixing. The glue ratio and sufficiency are unstable (especially when the amount of glue used is relatively large), which eventually leads to poor bonding of product parts, low production efficiency, and reduced product yield.

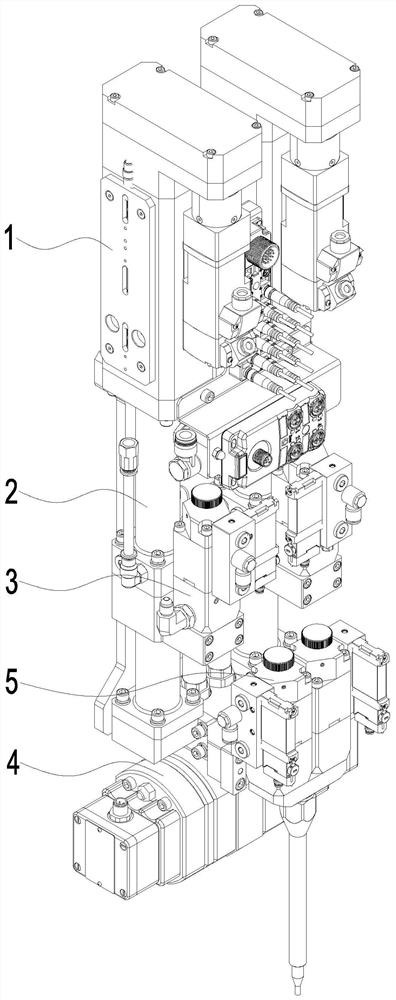

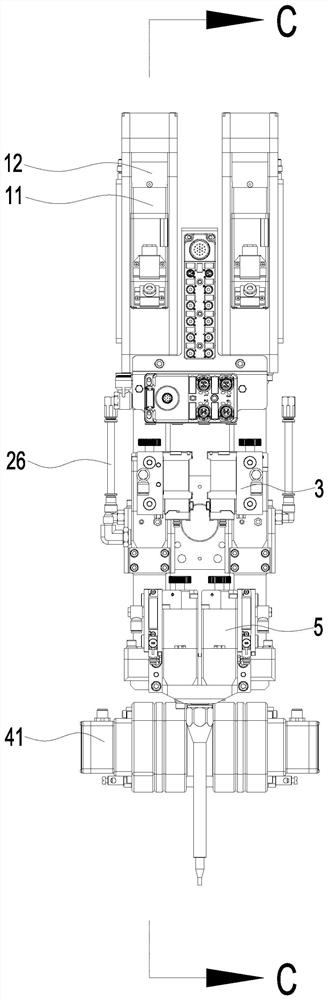

[0042] In order to solve the problem in the prior art that the use of artificial glue mixing resul...

Embodiment 2

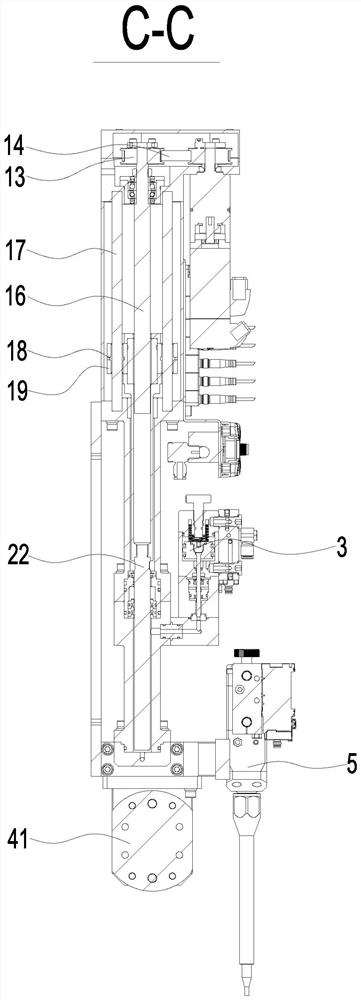

[0055] In order to facilitate the precise control of the amount of glue, the proportion of glue and the speed of glue discharge from the feeding valve 3, further, such as Figure 8-Figure 12 As shown, the feed valve 3 includes a cylinder body 31 and a solenoid valve 32; the cylinder body 31 and the solenoid valve 32 are in an integrated structure; the cylinder body 31 and the metering mechanism 2 are communicably arranged. Through the design of the integrated solenoid valve 32, the solenoid valve 32 and the cylinder body 31 have an integrated structure, that is, there is no air pipe connected between them, thereby avoiding the delay problem when the cylinder is opened and closed. 3 The precise control of the amount of glue, the proportion of glue and the speed of glue provides the basis.

[0056] At present, the valve needles 33 used for the feed valve 3 on the market are all tie rod type or V-shaped at the end, and these types of valve needles 33 will discharge more fluid dur...

Embodiment 3

[0060] On the basis of Example 2, as Figure 13-Figure 16 As shown, the mixing valve 5 is an integrated design of a plurality of feeding valves 3 . The mixing valve 5 in this embodiment is specifically designed by integrating two feeding valves 3. The mixing valve 5 obtained by integrating the two feeding valves 3 can be used independently, or can be used in combination with any two-component static mixing system. It can be used in combination according to actual usage scenarios and conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com