Structural design of a two-dimensional multi-plate ejector

A two-dimensional configuration and ejector technology, which is applied in the directions of jet pumps, mechanical equipment, machines/engines, etc., can solve the problems of large flow loss of the ejected airflow, complex nozzle arrangement, and affecting ejection performance. Achieve the effect of improving ejection performance, compact structure and reducing shock loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

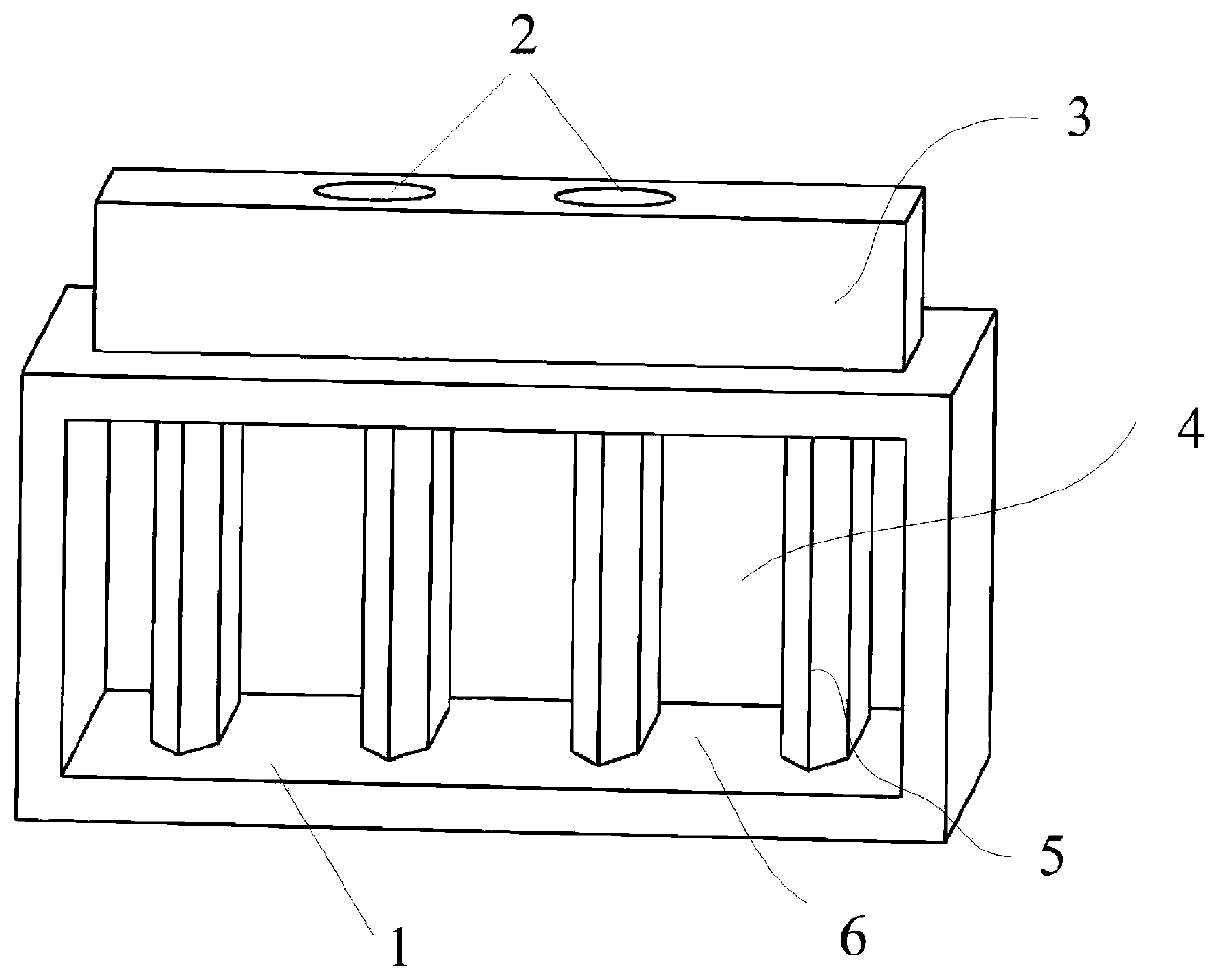

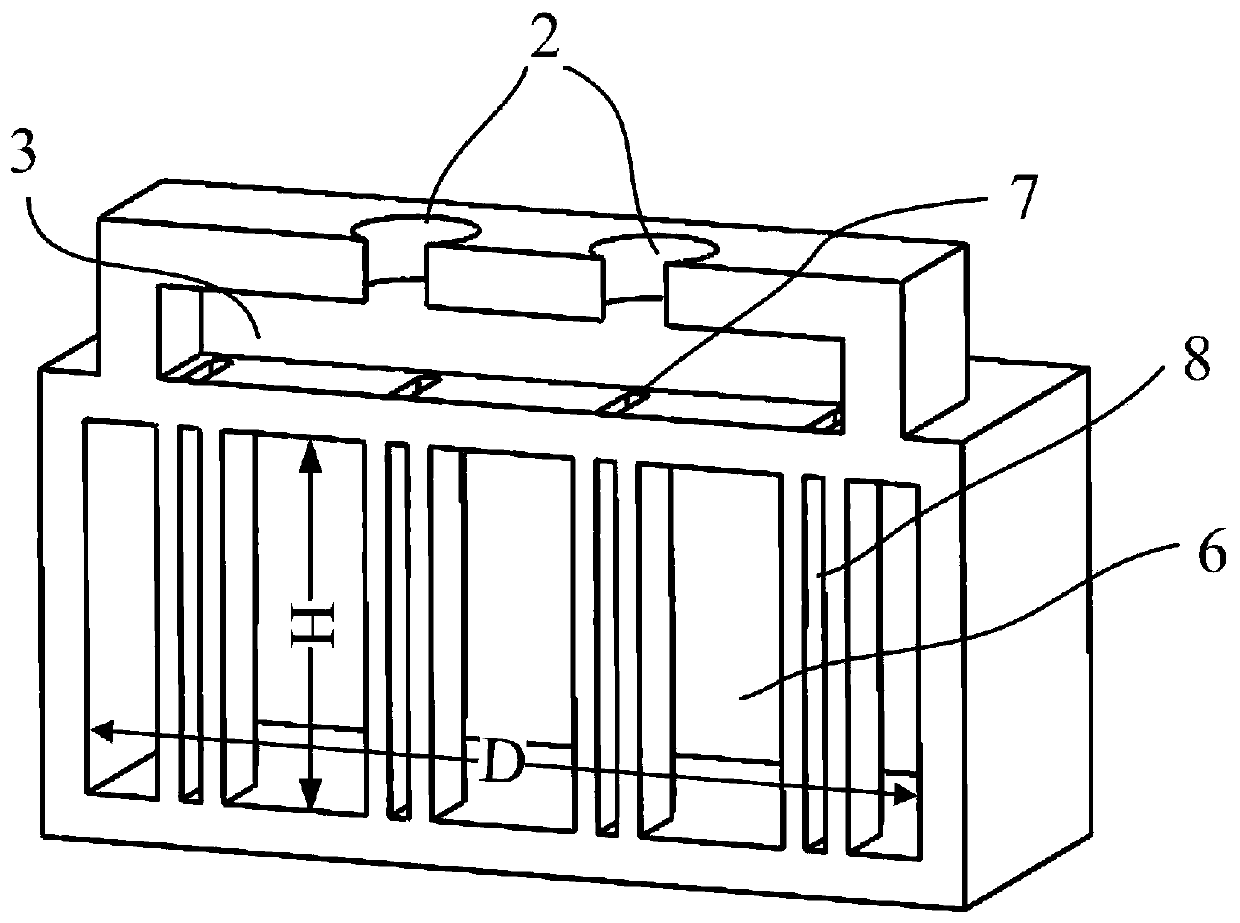

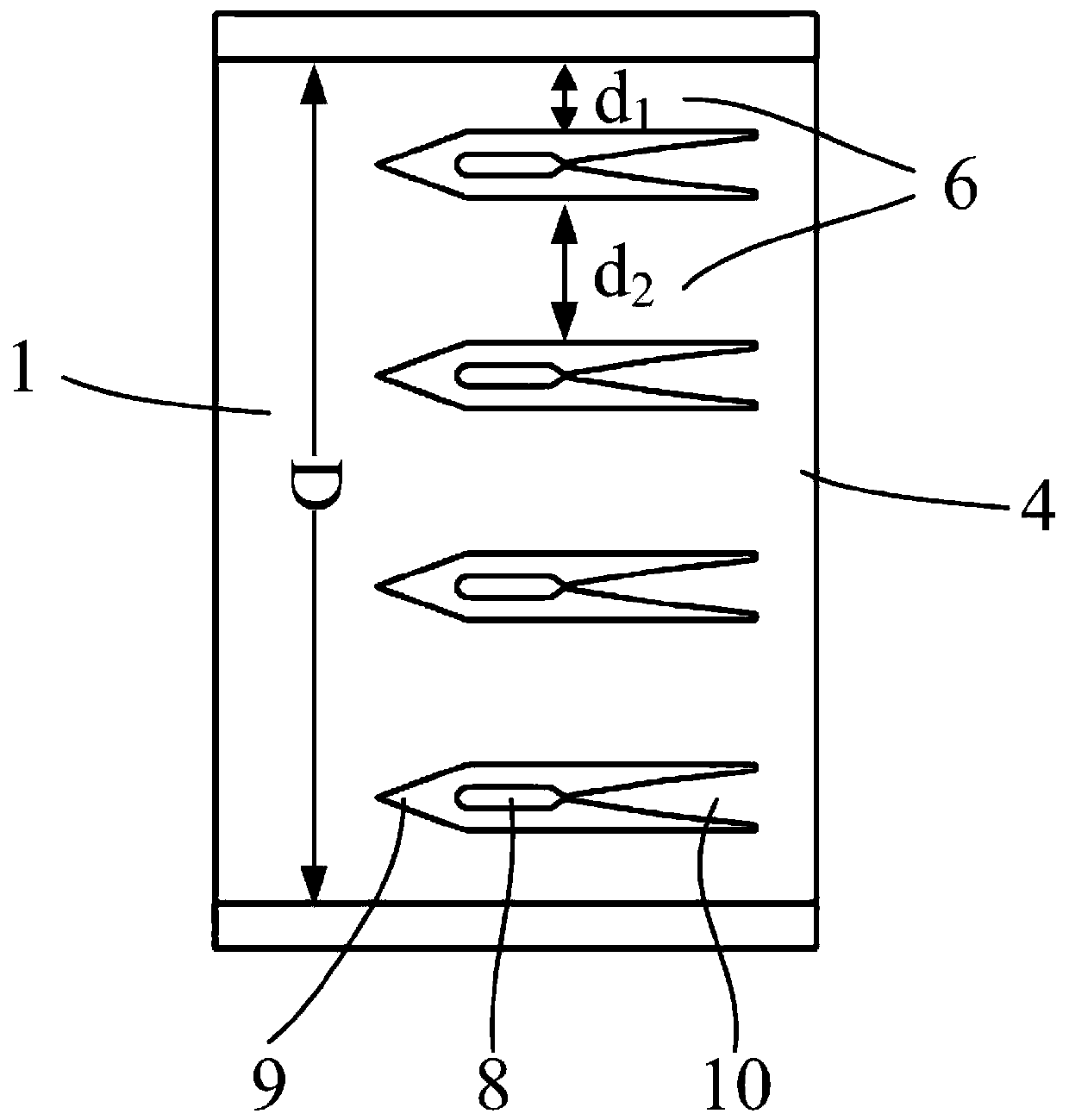

[0029] As shown in the accompanying drawings, the present invention proposes a two-dimensional multi-branch ejector structure design, which is characterized in that the interior of the ejector is provided with multiple sets of splitters for the ejected airflow and the ejected airflow Support plate, one end of the ejector is provided with an ejected air inlet for introducing the ejected airflow, the side wall of the ejector is provided with an air collection chamber, and the air collection chamber is provided with an ejected airflow for introducing the ejected airflow Inlet, the inside of the support plate is provided with a nozzle air guide chamber, the nozzle air guide chamber and the gas collection chamber are connected through the air inlet of the nozzle air guide chamber, and the inside of the support plate is provided with a two-dimensional Laval nozzle, a two-dimensional Laval nozzle The inlet of the nozzle is connected to the air guide cavity of the nozzle, and the outle...

Embodiment 2

[0041] As shown in the accompanying drawings, the present invention proposes a two-dimensional configuration of multi-branch ejector structure design, and the design steps of the ejector are as follows:

[0042] S1, determining airflow parameters;

[0043]According to the physical parameters and performance requirements of the ejected airflow and the ejected airflow, the physical parameters include specific heat ratio and viscosity, etc., and the performance requirements include the ejection coefficient and pressurization ratio, and the ejector airflow is determined through the one-dimensional design theory of the ejector The parameters of the ejected airflow, where the Ma number of the ejected airflow is 4, the total pressure is 3MPa, the Ma number of the ejected airflow is 0.4, and the total pressure is 12kPa;

[0044] S2, setting the inner channel size of the ejector;

[0045] Set the width of the inner cavity of the ejector to be D=850mm, the height to be H=350mm, the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com