High-mixing-ratio ignition tank

A high mixing ratio, ignition tank technology, applied in the field of boiler soot blowing, can solve the problems of insufficient deflagration, carbon accumulation and water blockage, weak soot blowing effect, etc., and achieve the effect of improving the mixing adequacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

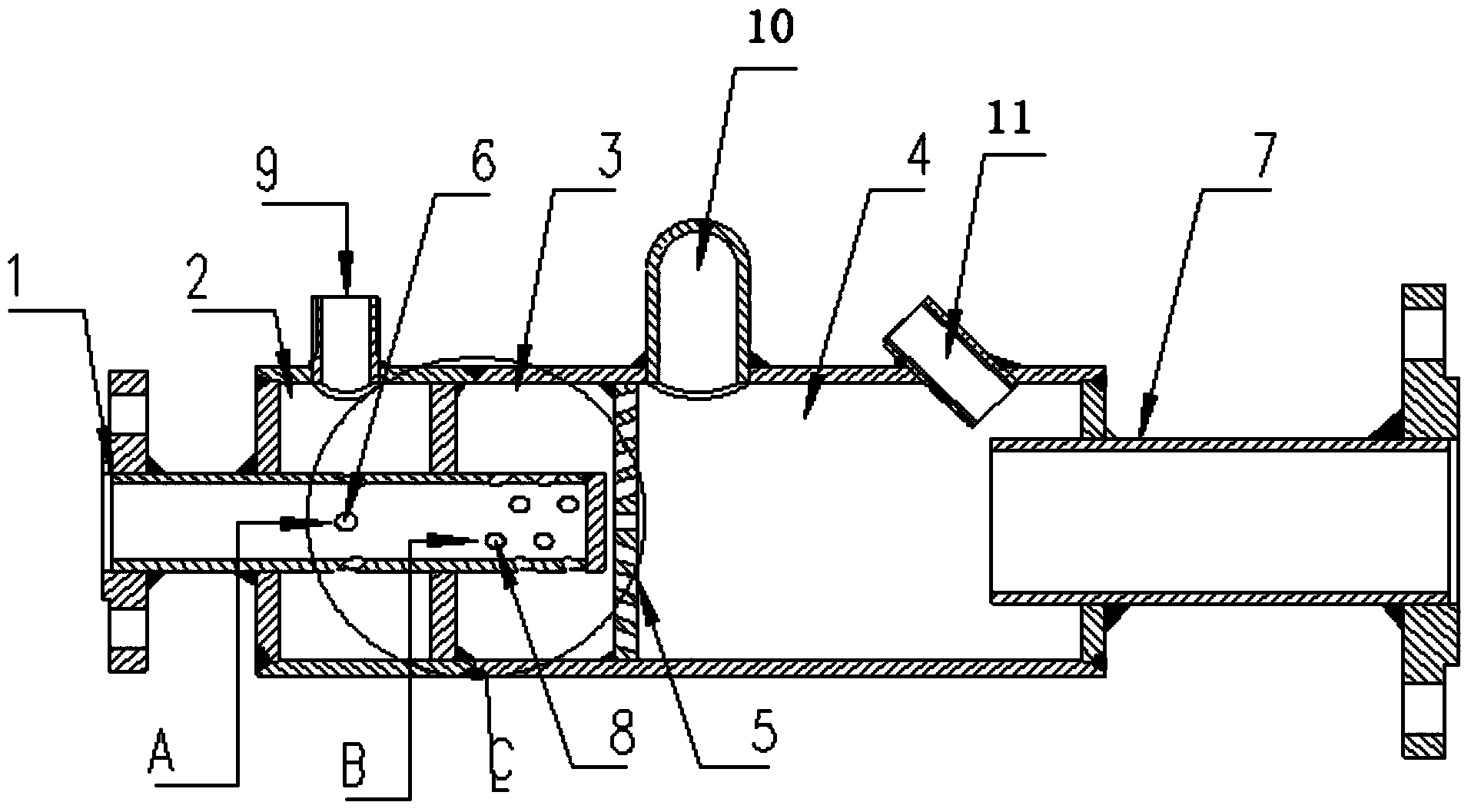

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

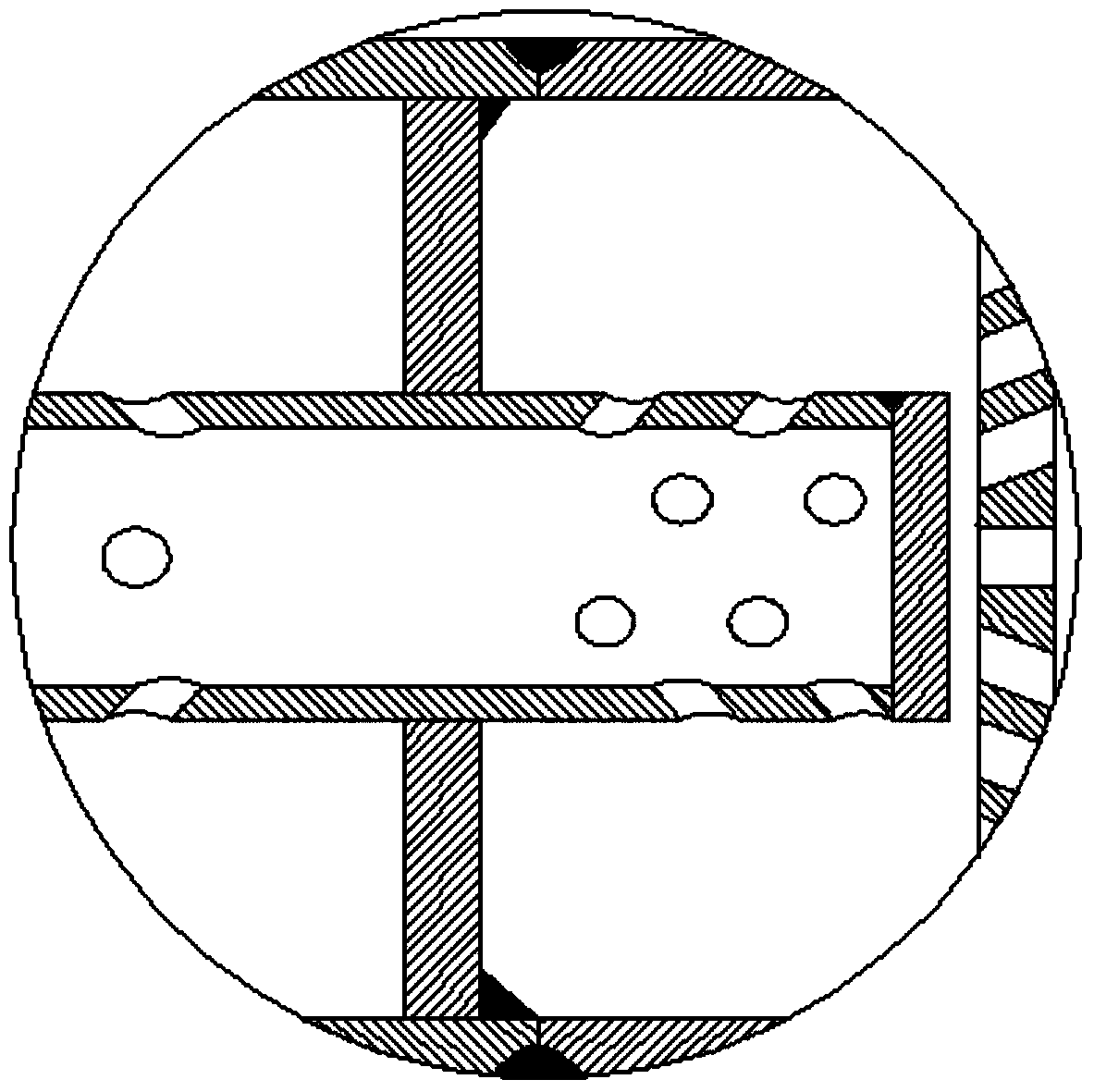

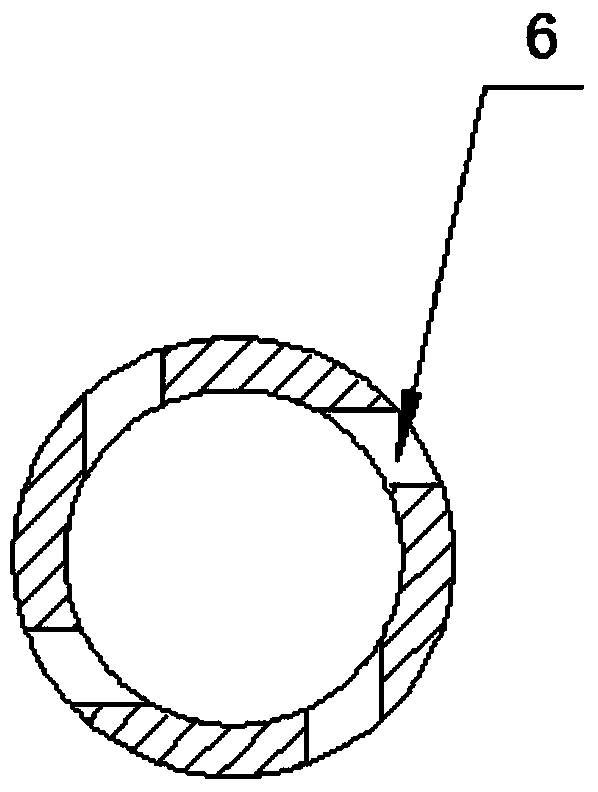

[0017] see figure 1 , the embodiment of the present invention provides a high mixing ratio ignition tank for the mixing and detonation of gas and air, the air inlet connecting pipe 1, the gas chamber 2, the mixing chamber 3, the ignition chamber 4 and the flame outlet pipe 7. Among them, the gas chamber 2, the mixing chamber 3 and the ignition chamber 4 are sequentially arranged inside the ignition tank according to the air intake direction; the air inlet connecting pipe 1 communicates with the gas chamber 2 and the mixing chamber 3; the mixing chamber 3 and the ignition chamber 4 is provided with a secondary mixed gas splitter plate 5, and the secondary mixed gas splitter plate 5 separates the mixing chamber 3 from the ignition chamber 4; the middle part of the air inlet connecting pipe 1 is provided with a gas mixing incline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com