Energy-saving type submerged combustion gasifier

A technology of submerged combustion and gasifier, which is applied in the field of energy-saving submerged combustion gasifier and low-temperature liquid gasification submerged combustion gasifier, which can solve the problem of high cost and large footprint of submerged combustion gasifier , Material selection requirements and other issues, to achieve the effect of reducing material selection requirements, reducing size, and improving heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

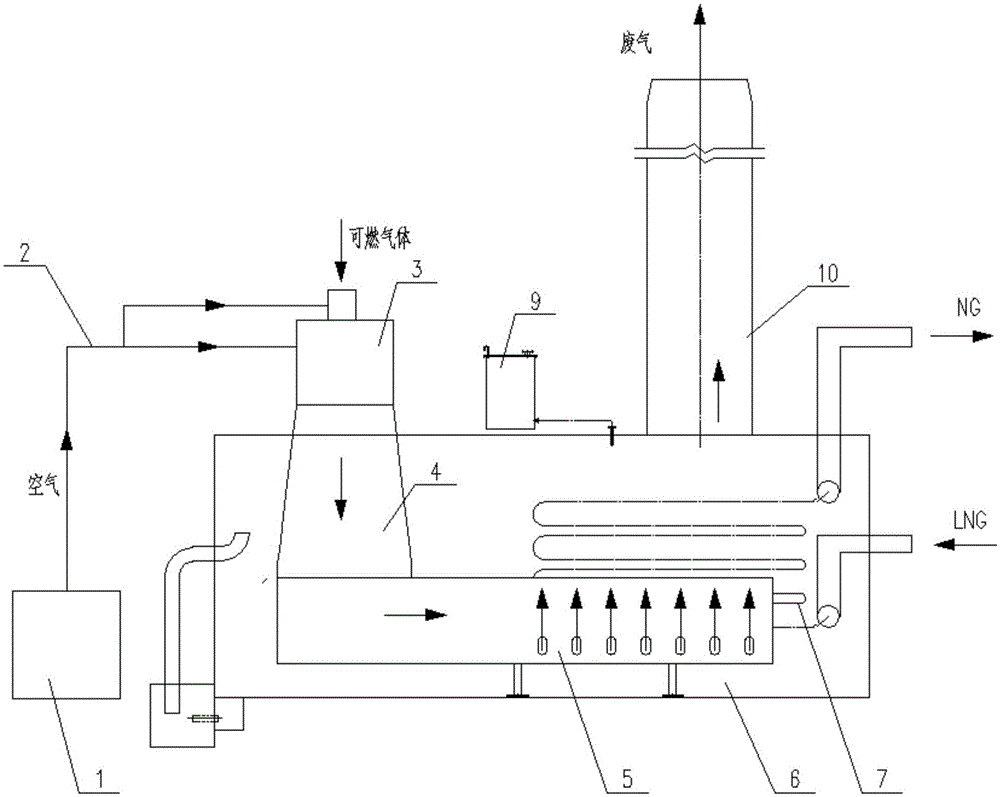

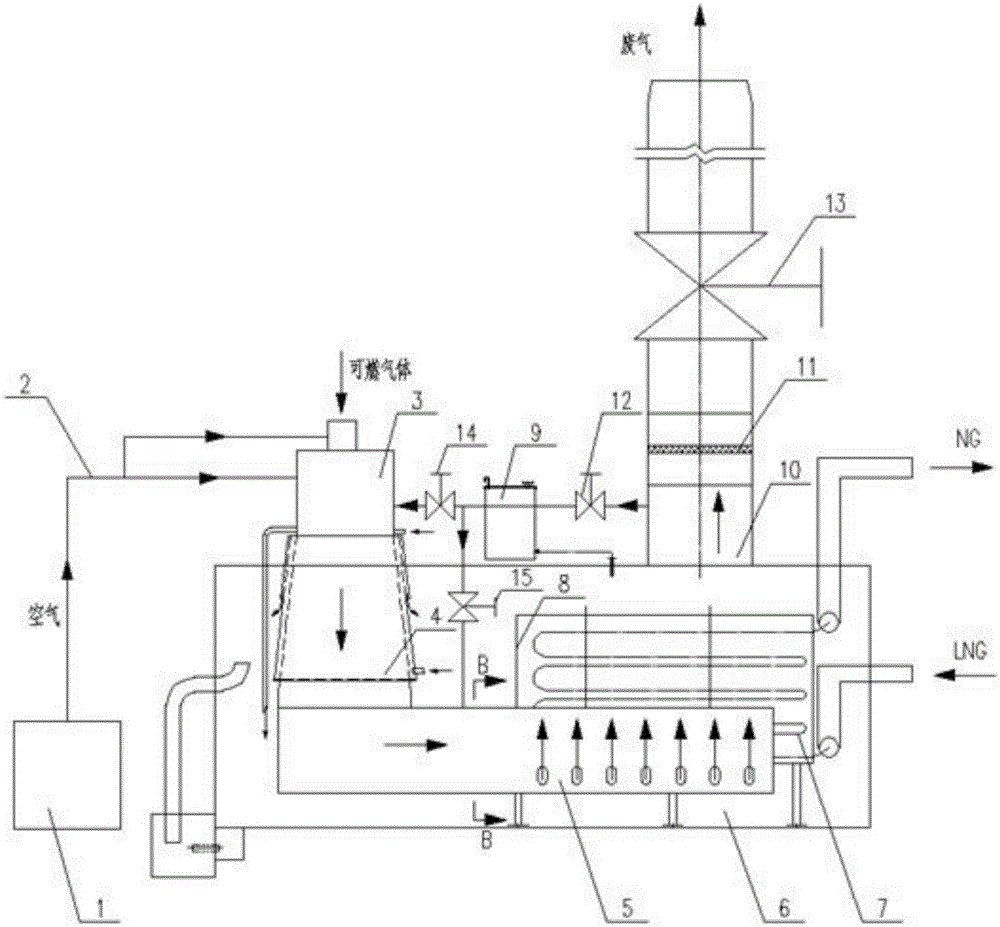

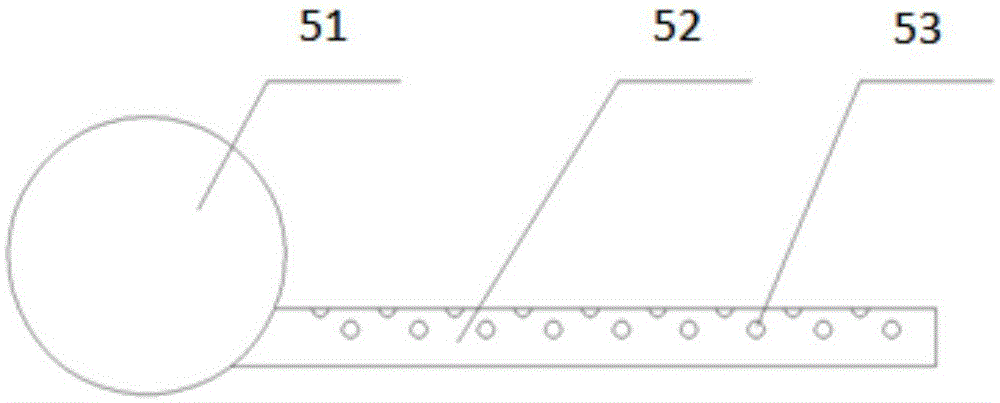

[0029] Such as figure 2 , 3As shown in and 4, an energy-saving submerged combustion gasifier includes a blower 1, an air duct 2, a burner 3, a combustion chamber 4, a flue gas distributor 5, a water tank 6, a heat exchange tube bundle 7, and a weir flow box 8, lye tank 9, chimney 10, gas-liquid separator 11, chimney regulating valve 13; described blower 1 links to each other with the air inlet of burner 3 through air duct 2, the outlet of described burner 3 and The combustion chamber 4 located on one side of the water tank 6 is connected, and the air in the burner 3 is fully mixed with the combustible gas entering from the gas inlet of the burner 3, and enters the combustion chamber 4 after ignition to generate high-temperature flue gas; The periphery of the combustion chamber 4 is provided with a water jacket 43, the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com