Circuit protector

A circuit protector and protector technology, applied in the direction of electric thermal protection switch, heating/cooling contact switch, etc., can solve the problems of uneven shunt of parallel circuits, irregular rising trend, difficult parallel circuits, etc., to reduce material selection requirements, The effect of wide selection of materials and low production level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

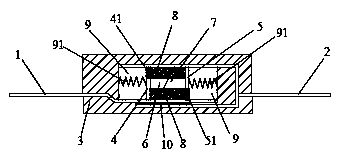

Embodiment 1

[0031] Product A1 structure: shell, first lead-out end, second lead-out end, switch assembly, heating element and two sets of protective bodies; the protective body is high-expansion filler. The switch assembly includes a first conductive part, a first connecting body, a second conductive part and a second connecting body that are electrically connected in sequence, and one end of the first conductive part electrically connected to the first connecting body is also provided with a first insulating part; A second insulating part is provided at one end of the conductive part electrically connected to the second connecting body, and cavities are provided between the first conductive part and the casing, and between the second conductive part and the casing. The cavity is filled with elastomer.

[0032] The material of each part: shell: alumina ceramics, size 12mm×8mm×6mm; heating element: CPTC, size 6mm×4mm×0.3mm, room temperature resistance 5Ω, working voltage 2-30V; first lead-...

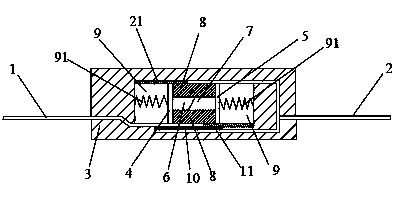

Embodiment 2

[0034] Product A2 is prepared according to the structure and materials of Example 1, the difference is that: the cavity is a low-expansion filler; the low-expansion filler is insulating ceramics; the shell is zirconia ceramics; the high-expansion filler: chlorinated polyethylene; The first insulating part and the second insulating part: zirconia ceramics; the first conductive part and the second conductive part: tin bronze; the first connecting body and the second connecting body: tin bronze.

Embodiment 3

[0036] Product A3 was prepared according to the structure and materials of Example 1, the difference is that there is no filler in the cavity; the shell is made of zirconia ceramics; the high-expansion filler: polyethylene glycol; the first insulating part and the second insulating part: zirconia Ceramic; the first conductive part and the second conductive part: nickel; the first connecting body and the second connecting body: nickel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com