Stone crushing machine for civil engineering

A technology of civil engineering and stone crushers, which is applied in cleaning methods and appliances, dust removal, and dispersing particle filtration, etc. It can solve the problems of difficult loading and unloading and transportation of stones, and low efficiency of crushing stones, so as to reduce labor intensity and improve The effect of safety and convenient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

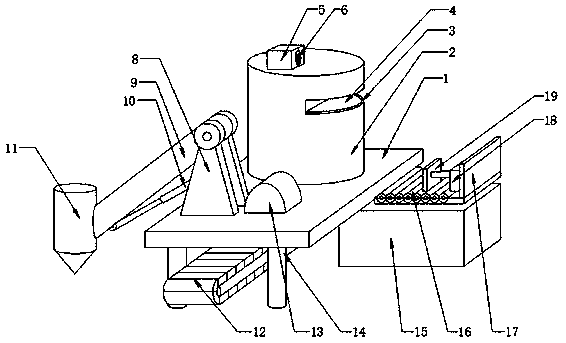

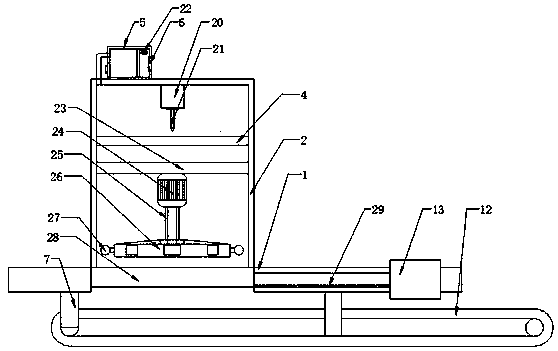

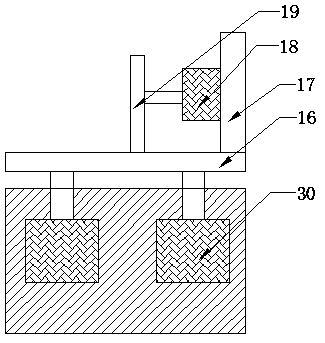

[0030] like Figure 1-5As shown, a rock crusher for civil engineering of the present invention comprises a platform 1, one side of the top of the platform 1 is fixed with a crushing barrel 2, one side of the crushing barrel 2 is provided with a feed port 3, and the feed port 3 The load-bearing plate 4 provided at the place is installed on the inner wall of the gravel barrel 2, the second hydraulic press 20 is provided on the top of the load-bearing plate 4, and one end of the hydraulic rod of the second hydraulic press 20 is fixedly connected with one end of the crushed stone 21, and the crushed stone is The inner walls on both sides of the tube 2 are fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com