Patents

Literature

94results about How to "Easy to discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

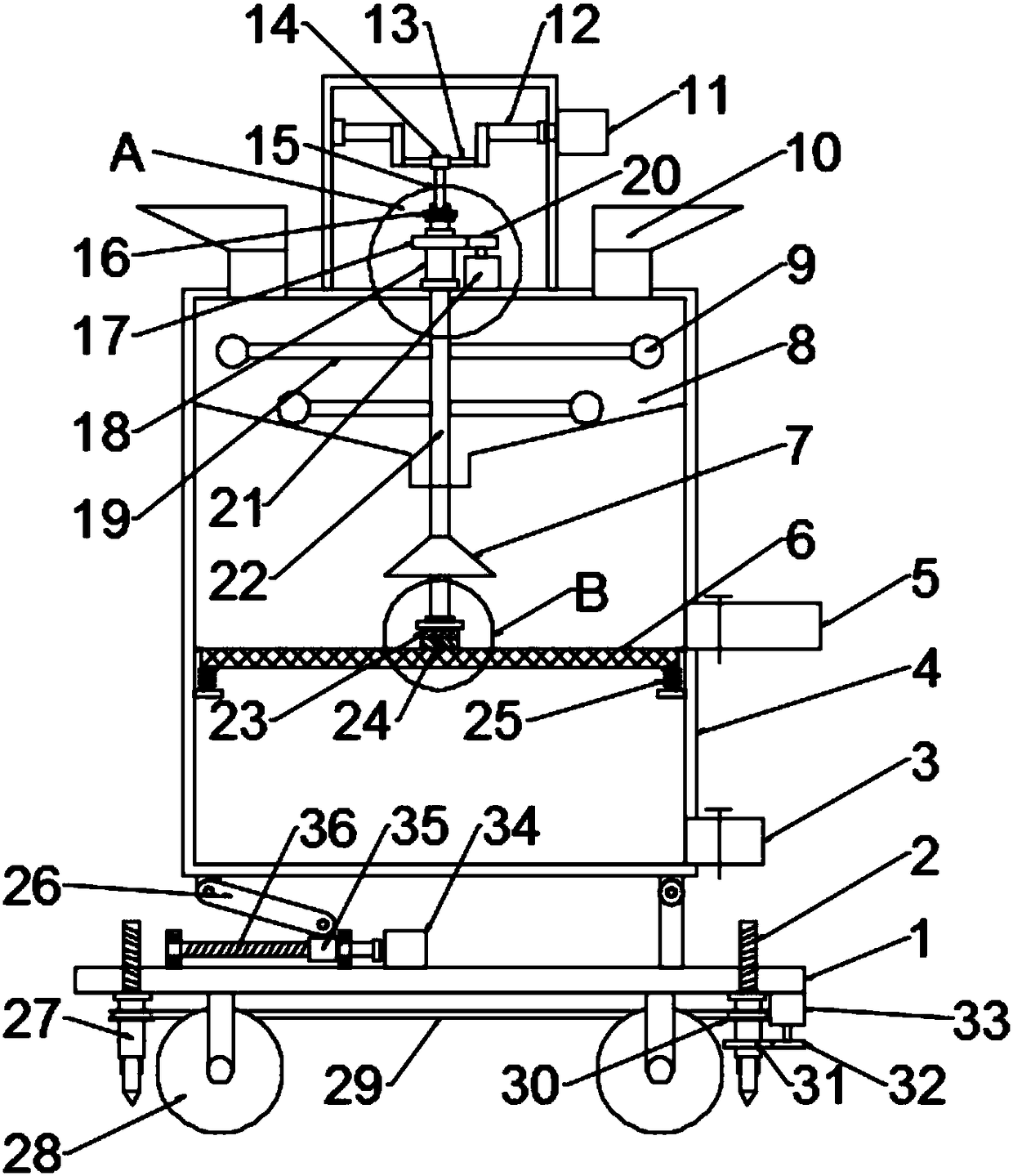

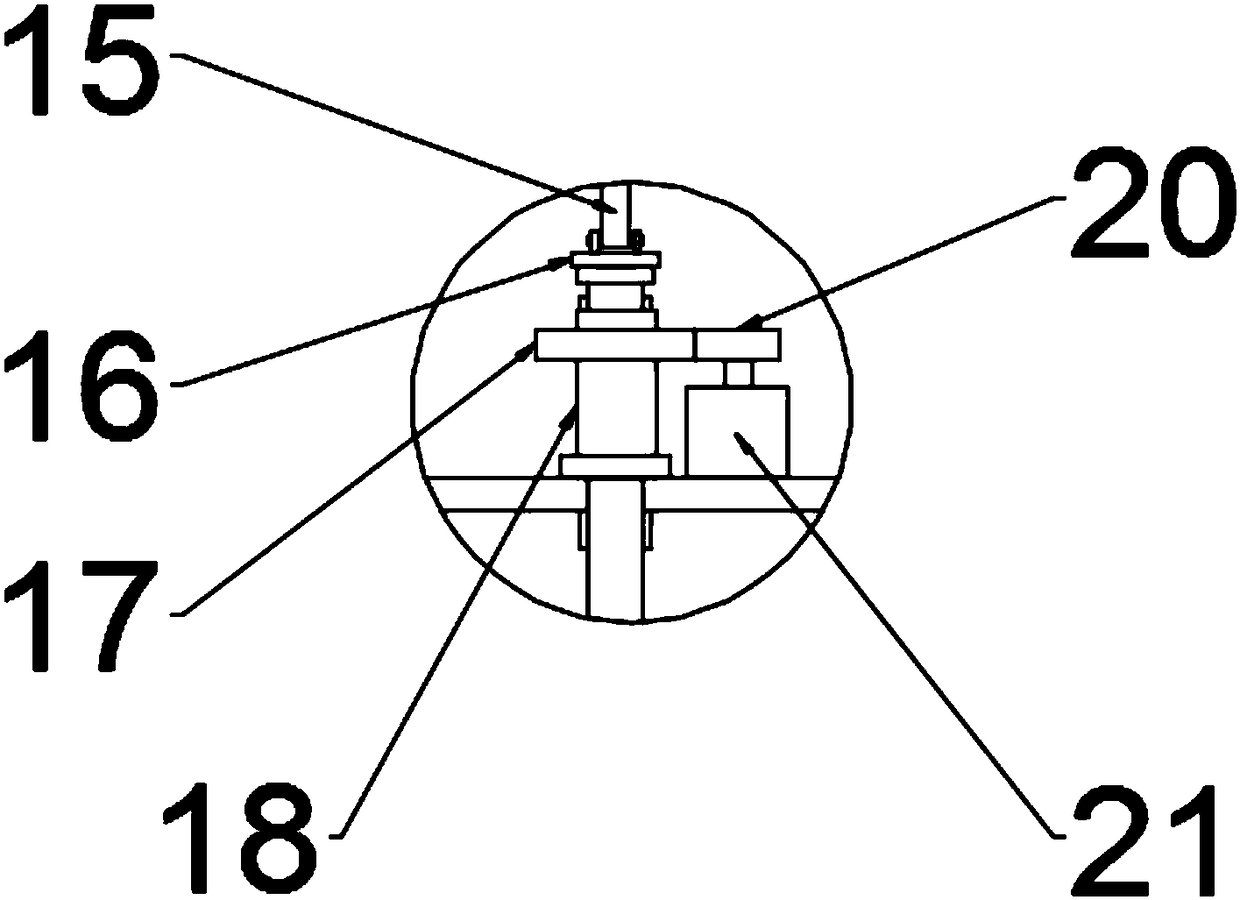

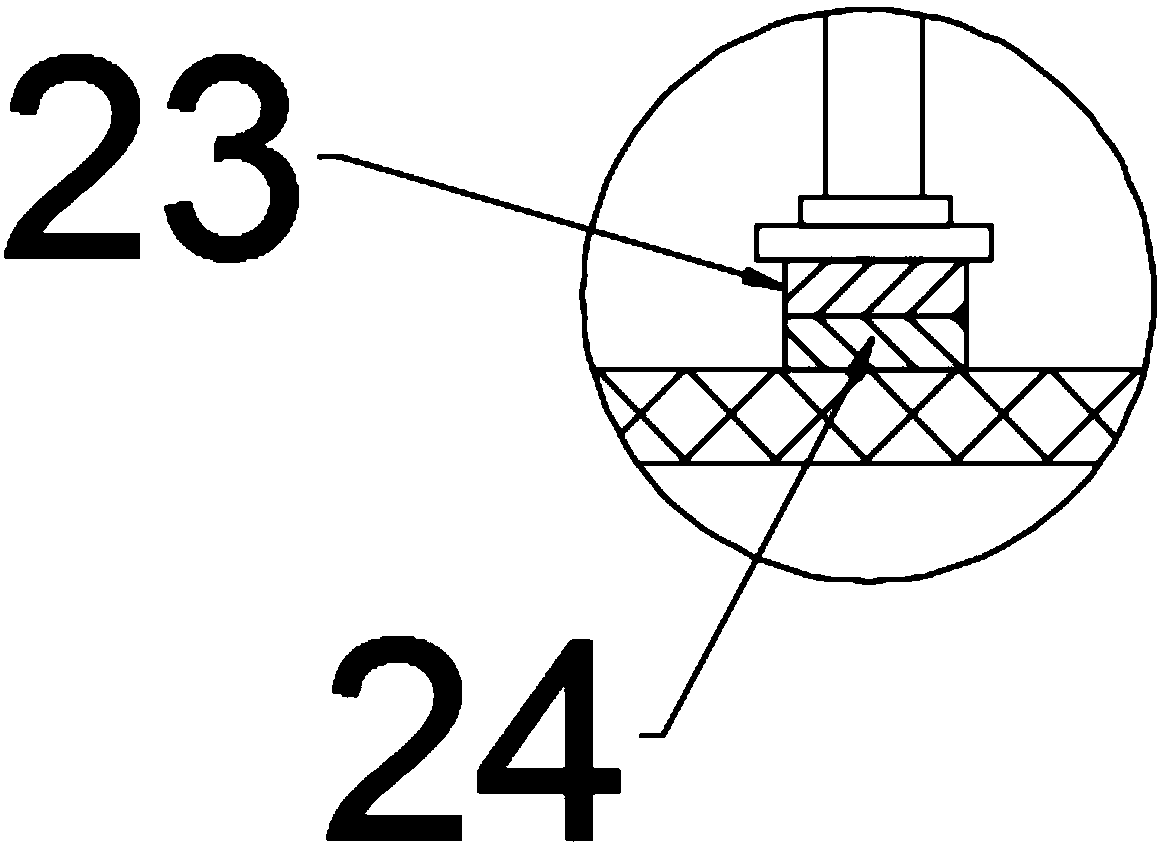

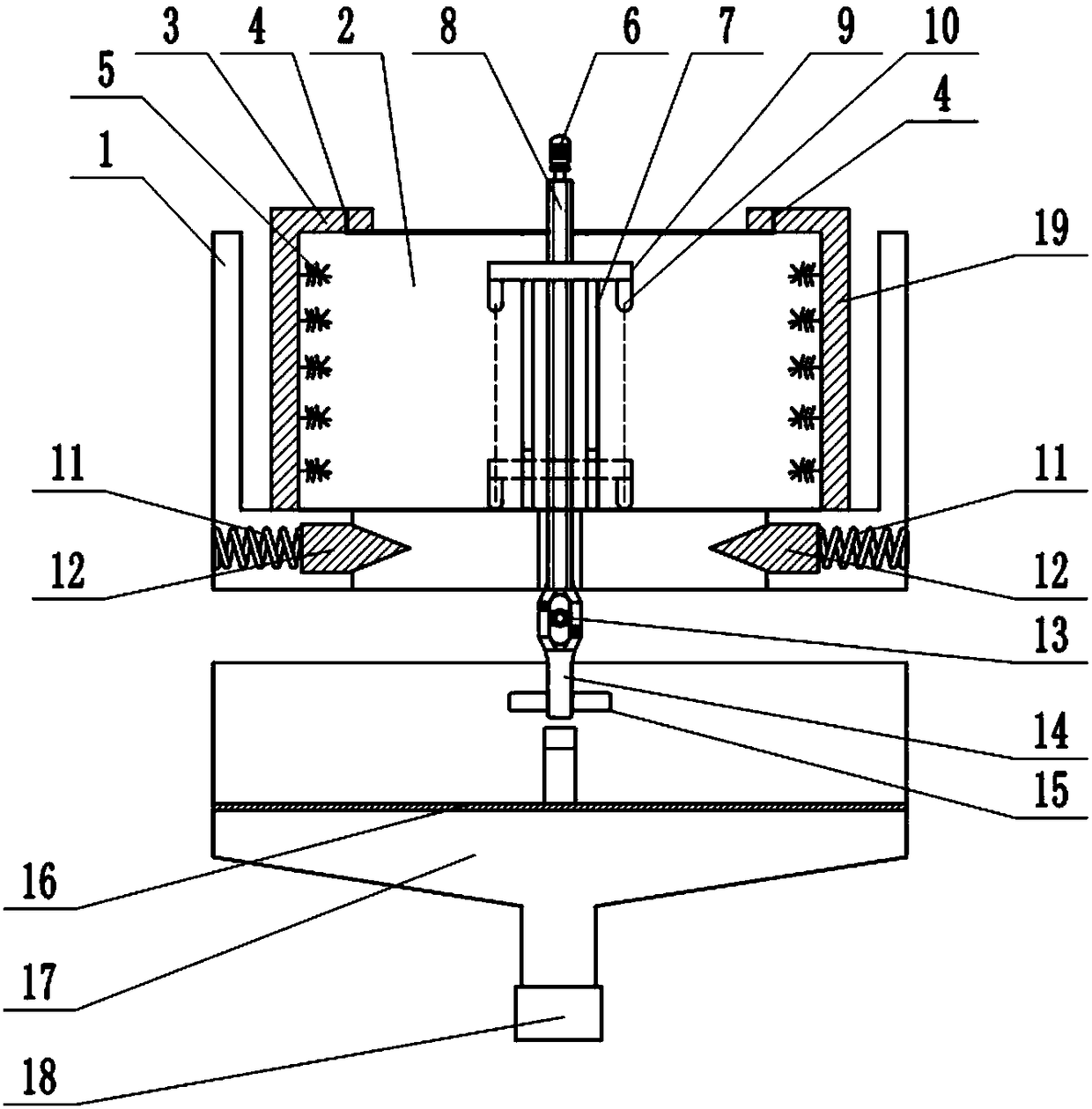

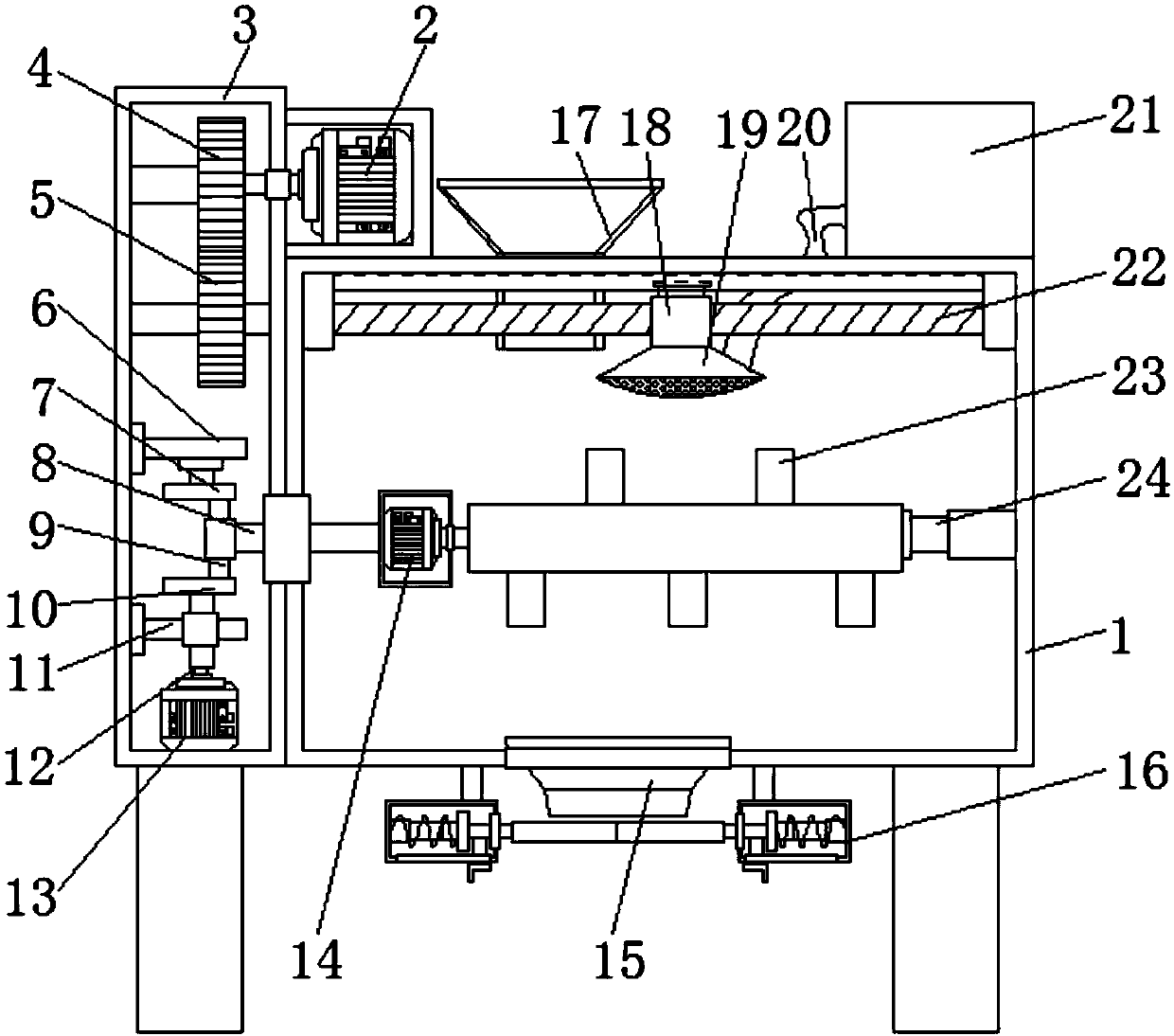

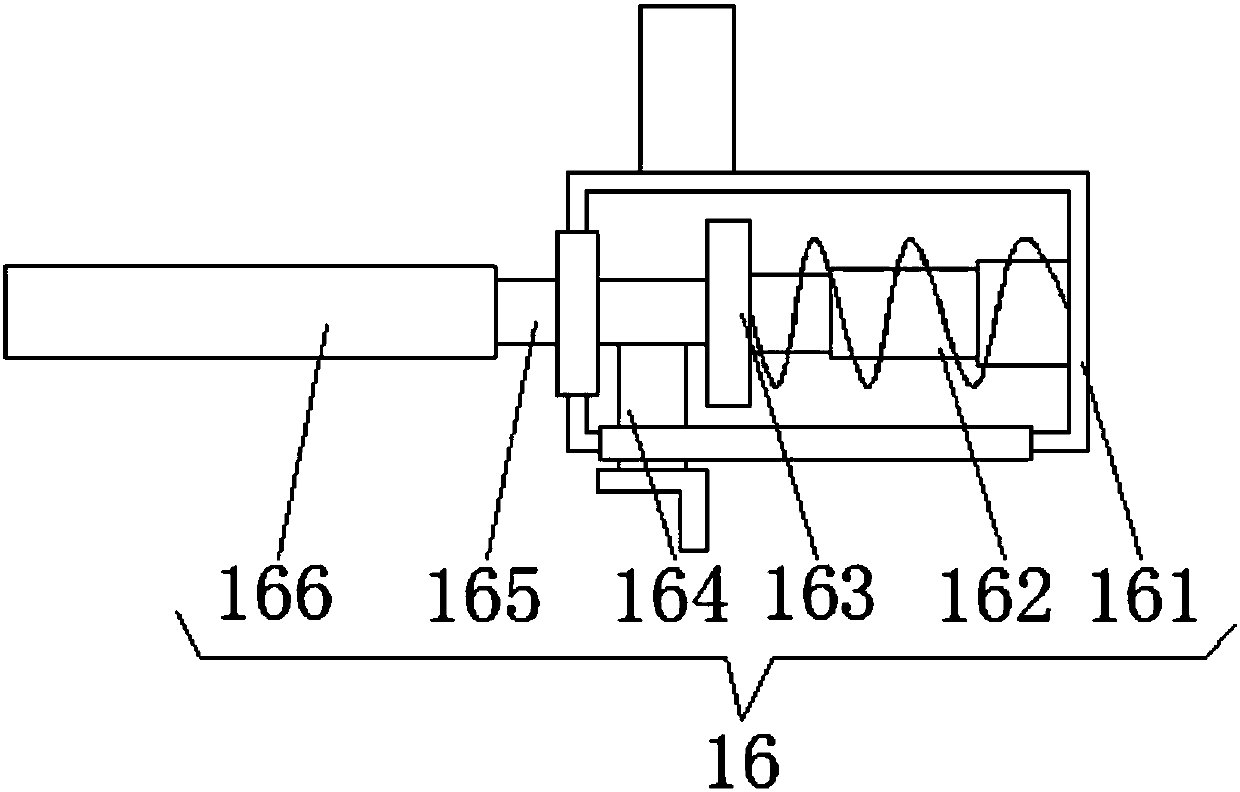

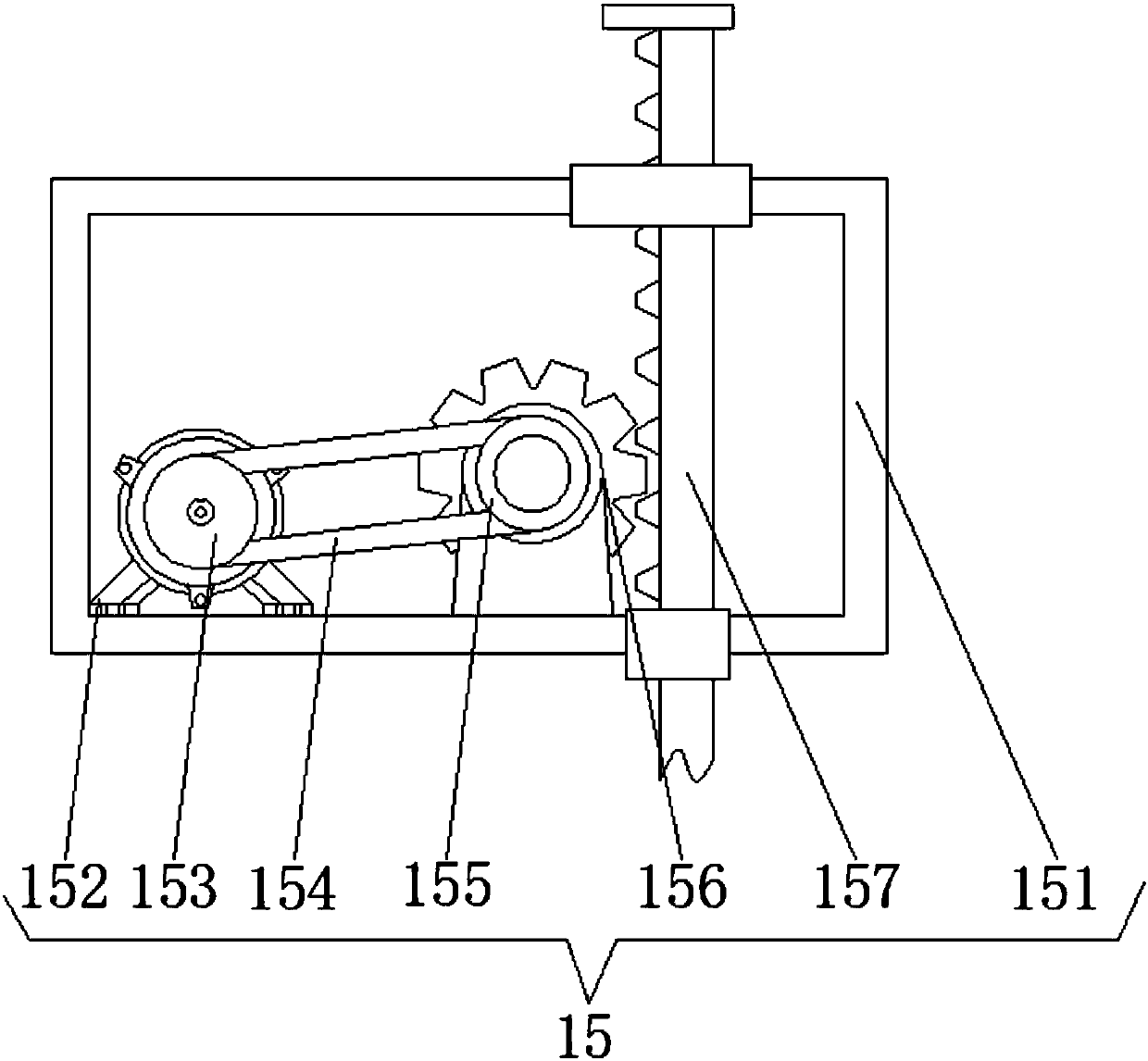

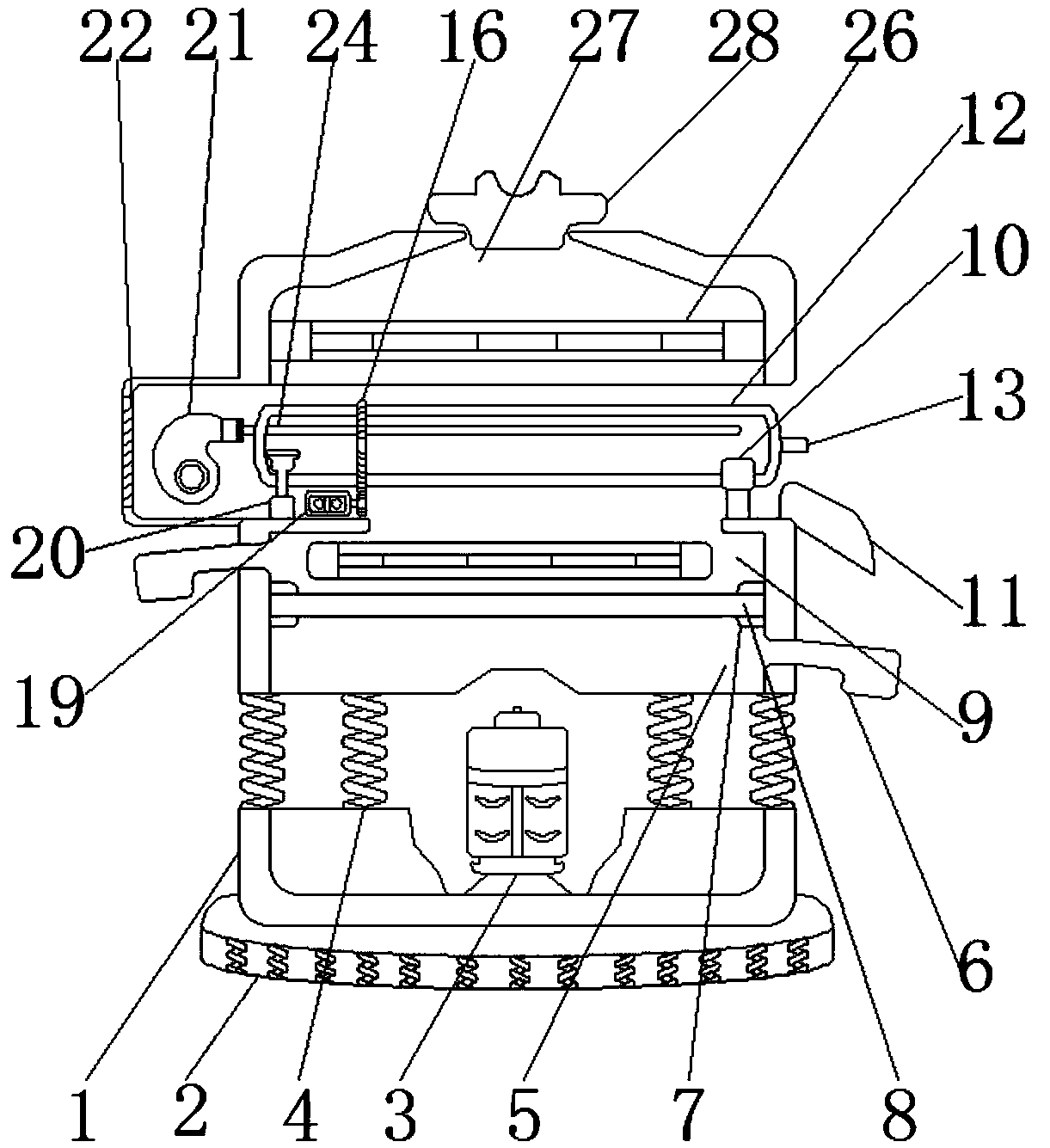

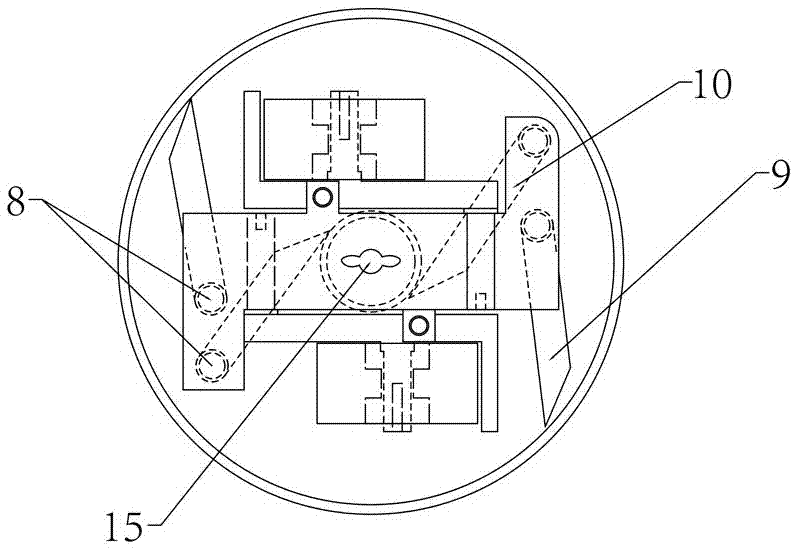

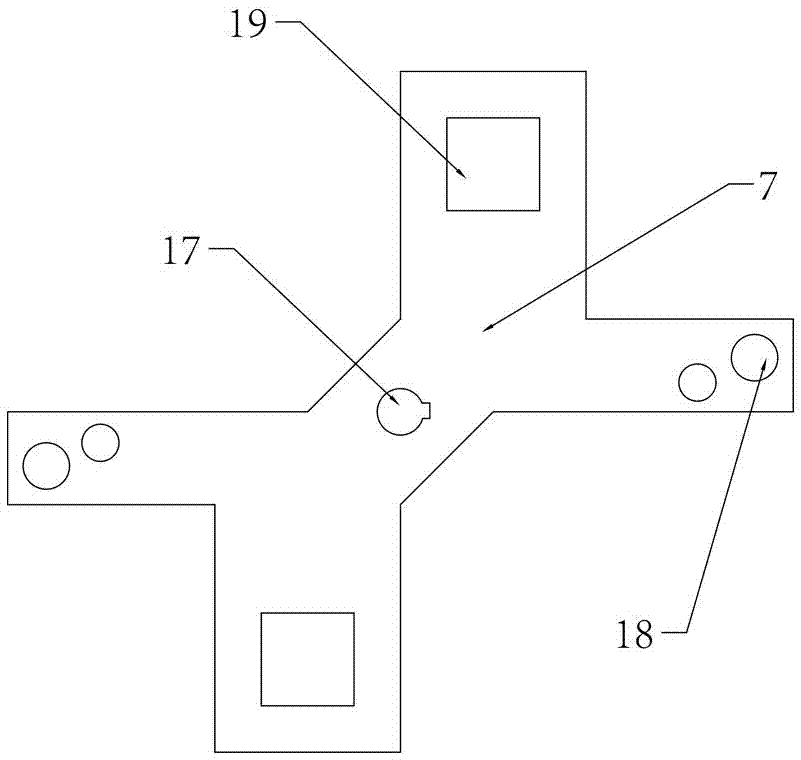

Sand screening device for constructional engineering

The invention discloses a sand screening device for constructional engineering. The sand screening device for the constructional engineering comprises a bottom plate, a screen net, a sand screening box, a second motor, a second threaded rod, a second sleeve, a connection rod, a third motor, a crankshaft, a linking rod, a rotating shaft, a fourth motor, a third gear, a fourth gear, a spring, a stirring rod, a shredding ball, a conical material dividing plate, a magnet and an iron sheet. The sand screening device for constructional engineering is provided with a first motor, a first gear, firstsleeves and first threaded rods, the whole device is fixed, and equipment damage and a safety accident caused by toppling and falling of the device are avoided; the second motor, a second sleeve, a second threaded rod and the connection rod are arranged, the sand screening box is made to incline, discharging is facilitated, sand which cakes because of moisture is smashed, and it is avoided that the screening efficiency is affected; meanwhile, falling sand is uniformly thrown to the periphery through the conical material dividing plate, sufficient and uniform screening is performed, and it is avoided that the sand is accumulated at one position of the screen net and the screening speed is decreased; and the magnet, the iron sheet and a spring are arranged, the screen net is made to shake violently, and the screening efficiency is improved.

Owner:河北地质大学

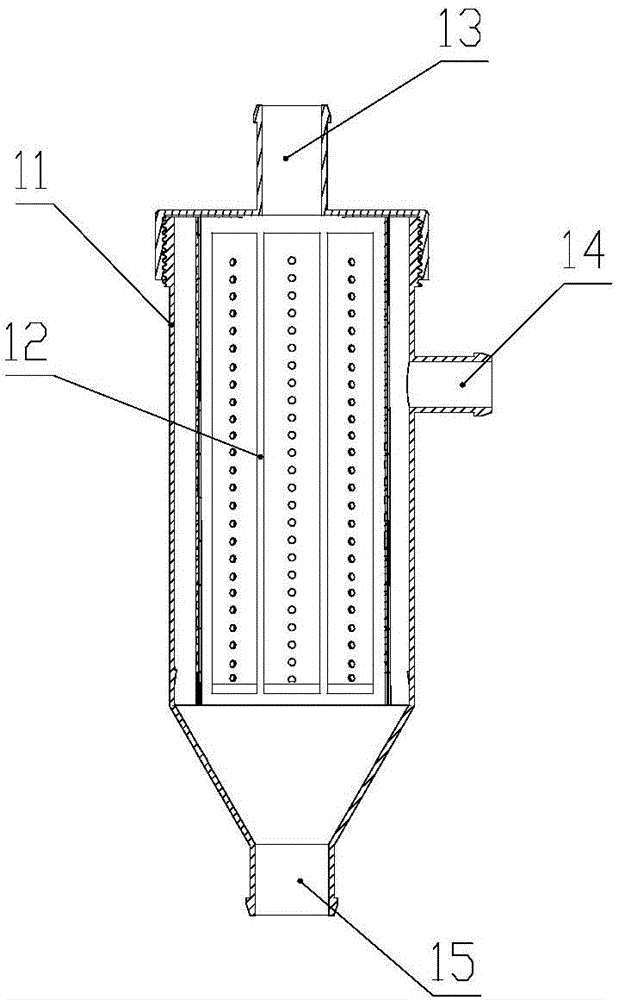

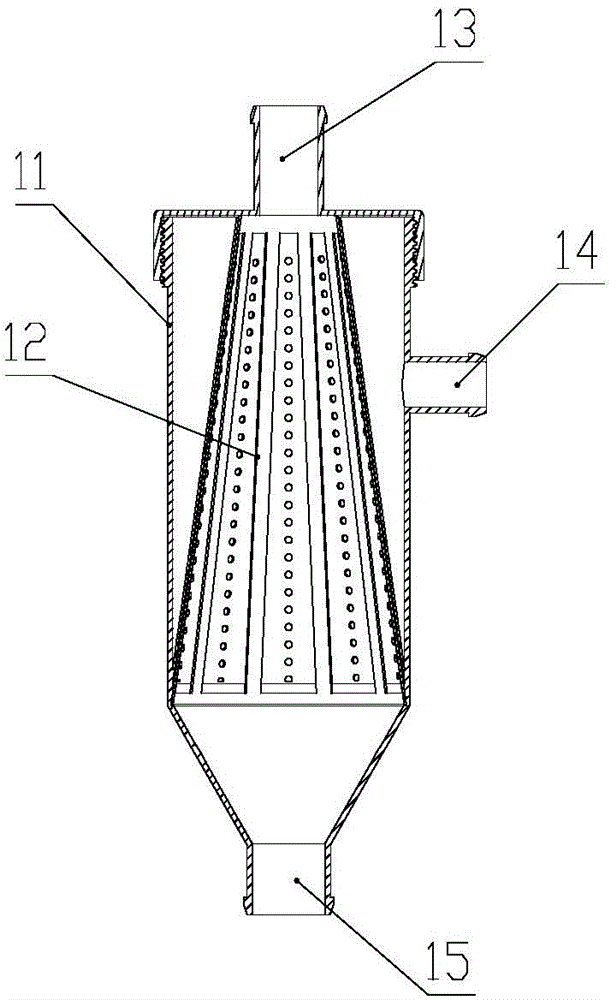

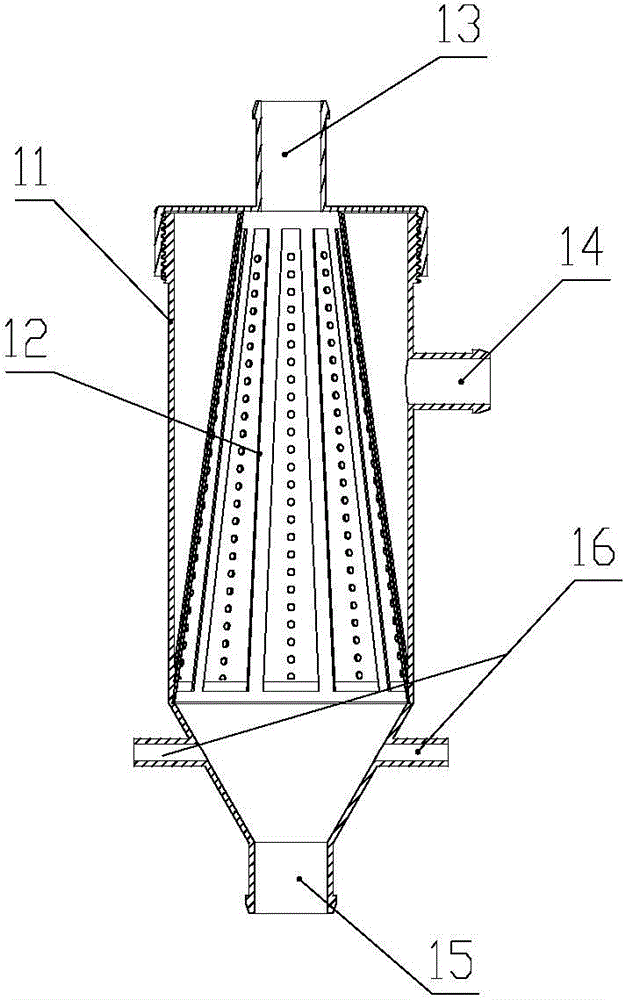

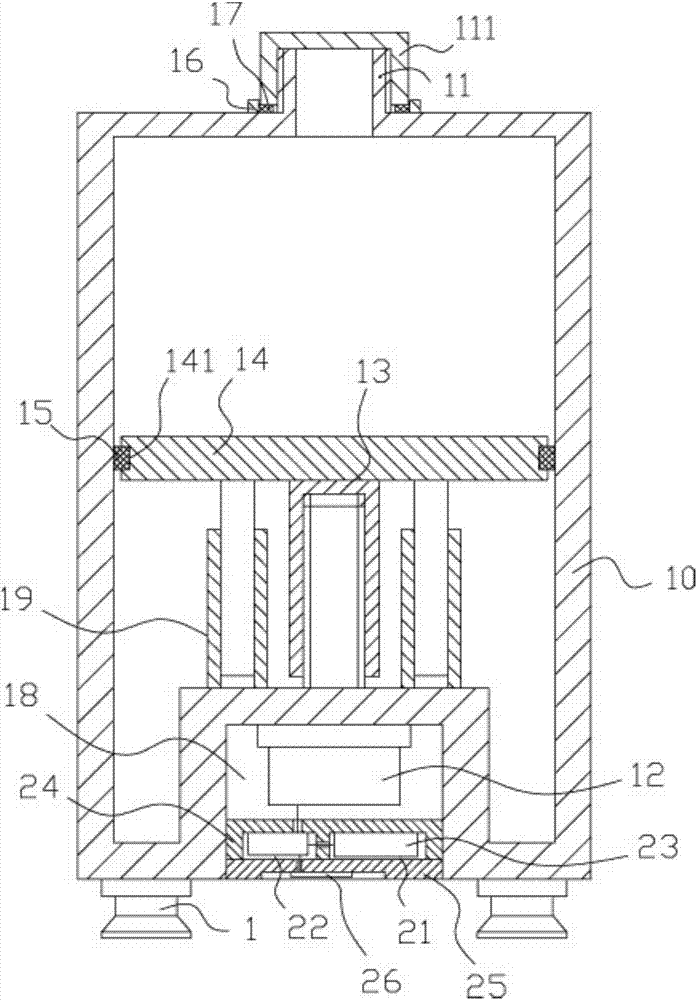

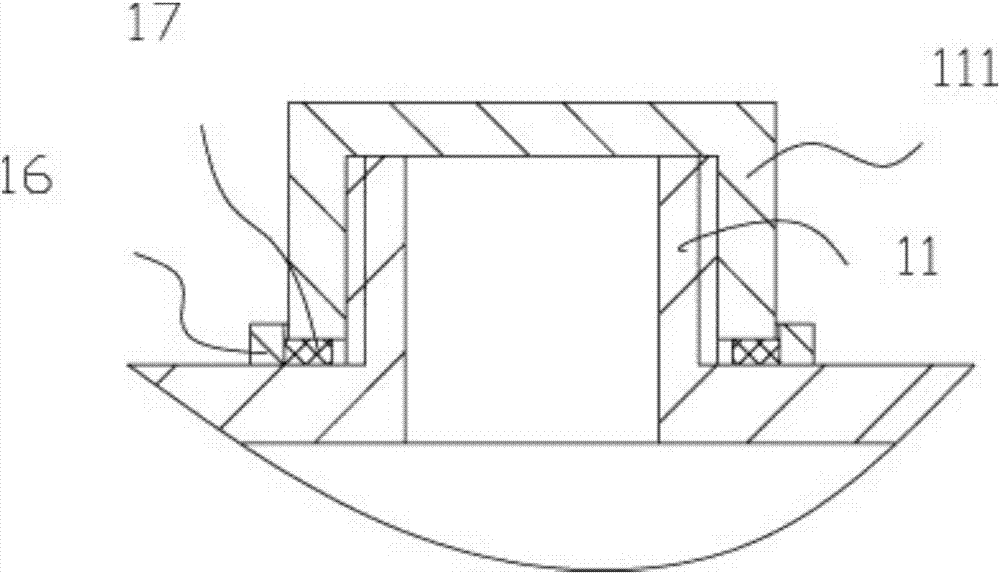

Filter and washing machine

ActiveCN104674517AEasy to dischargeGood recyclingOther washing machinesWashing machine with receptaclesWater resourcesFiltration

The invention discloses a filter and a washing machine. The filter and the washing machine are designed for solving the problems that the existing filters are not even in filtration and cannot be cleaned automatically, and the like. The filter comprises a filter cylinder body and a filter screen. The cylinder body is provided with a water inlet, a water outlet, and a sewage discharge port. The filter screen is installed inside the cylinder body and the filter screen separates the inner cavity of the filter cylinder body into two portions including an internal containing cavity and an external containing cavity. The upper end of the internal containing cavity is connected with the water inlet; the lower end is connected with the sewage discharge port. The external containing cavity is connected with the water outlet. Sewage flows into the internal containing cavity from the water inlet, and then enters the external containing cavity after being filtered by the filter screen; and then the sewage is discharged through the water outlet. The filtered impurities are discharged through the sewage discharge port. The filter is even in filtration, and easy to deposit the impurities. The washing machine having the filter is able to filter the water for washing clothes in circulation, and is able to discharge the filtered impurities automatically, thus saving plenty of water resources.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

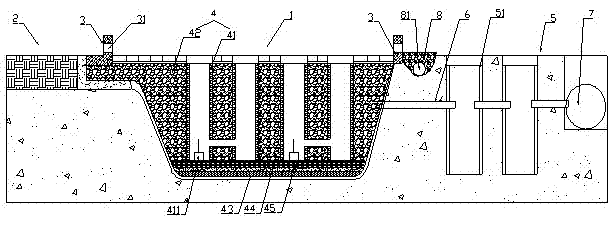

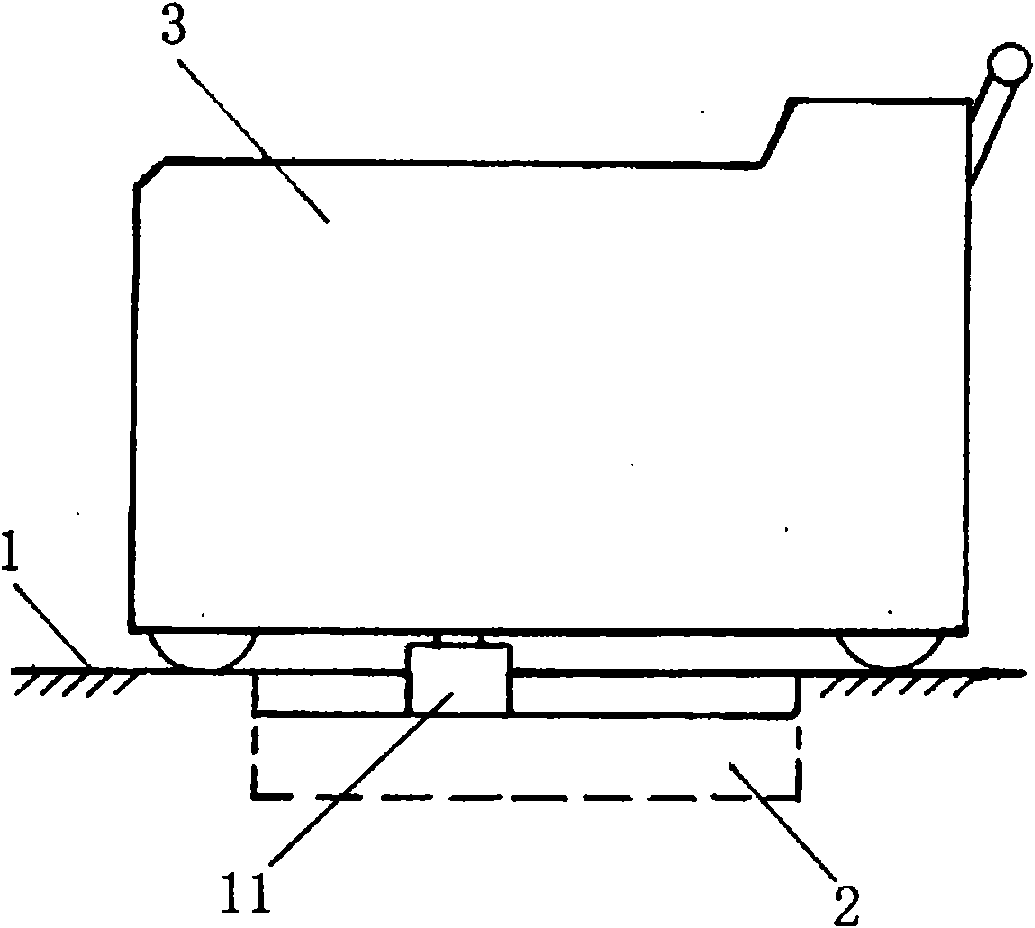

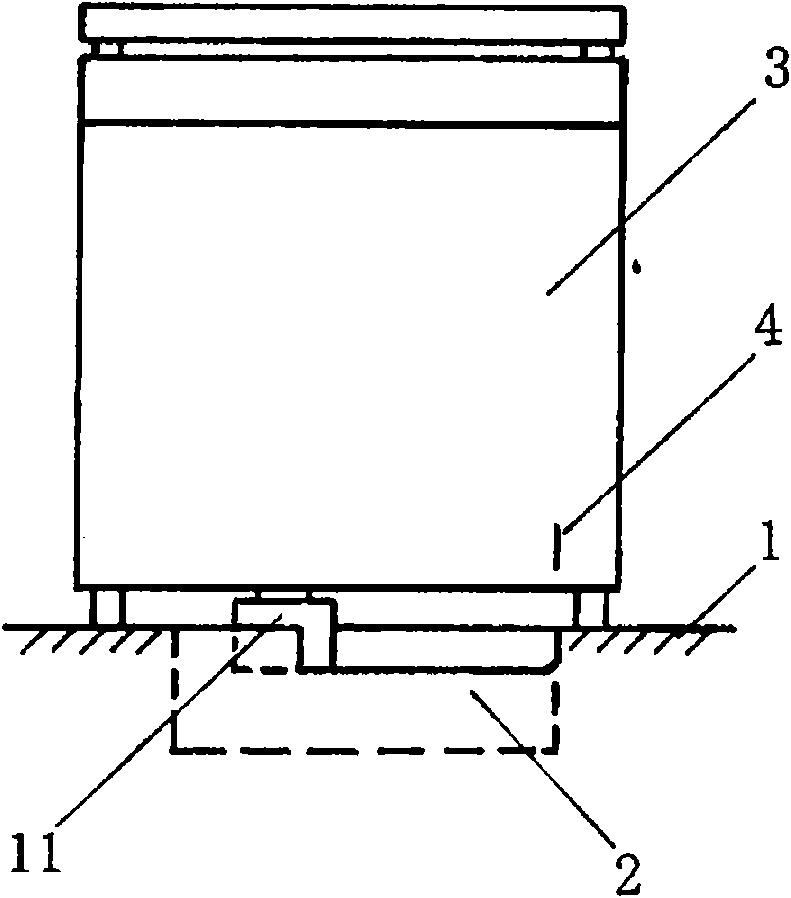

Road rainwater collecting system for preventing surface gathered water

ActiveCN103174079AEasy to dischargeReduce Waterlogging ProblemsGround-workPaving detailsWater storageWater storage tank

The invention discloses a road rainwater collecting system for preventing surface gathered water. The road rainwater collecting system comprises a sidewalk surface (1) made of a seepy material, water drainage road side stones (3) arranged between the sidewalk surface (1) and a motor vehicle surface (2), and water storage tanks (4) arranged on the lower sides of the sidewalk surface (1) and the water drainage road side stones (3), wherein the sidewalk surface (1) is lower than a motor vehicle surface (2) or parallel to the motor vehicle surface (2). By utilizing the rainwater collecting system, the technical problem that water can be accumulated on the conventional road surface, particularly a motor vehicle surface, can be solved.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

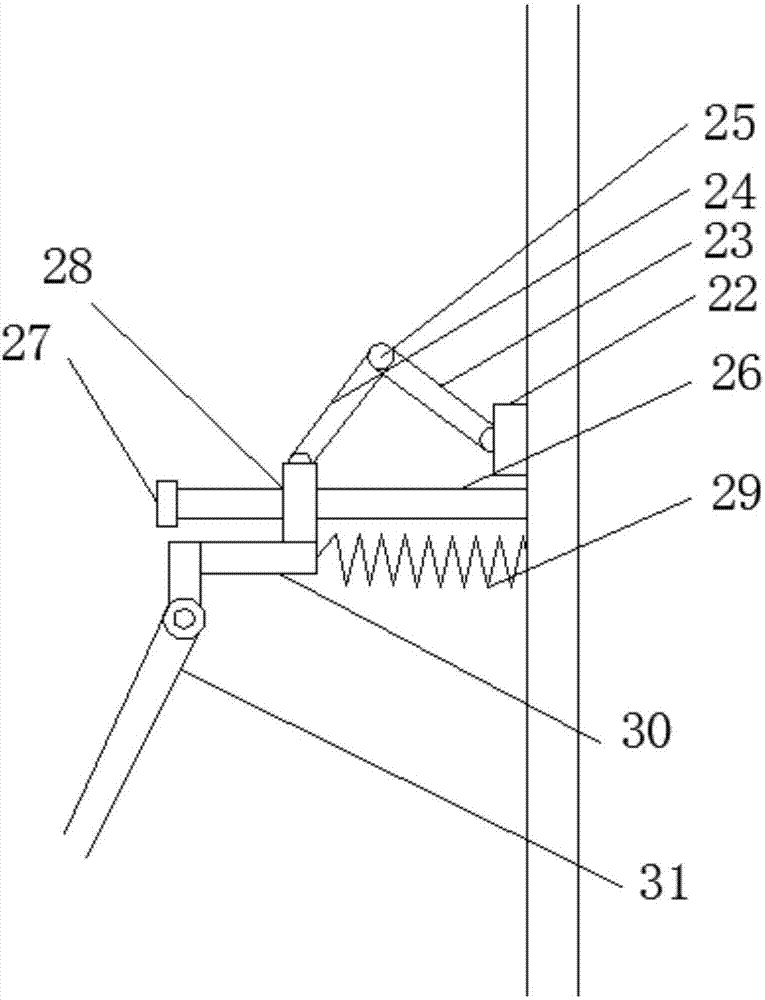

Fruit cleaning device

InactiveCN108125260AEasy to dischargeIncrease productivityFood treatmentBatch productionAgricultural engineering

The invention belongs to the technical field of fruit processing, and particularly discloses a fruit cleaning device. The fruit cleaning device comprises a machine frame and a cleaning mechanism, wherein the cleaning mechanism comprises an outer cylinder and an inner roller; a plurality of vertical rods and a plurality of horizontal rods are arranged on the side wall of the inner roller; magnets are respectively arranged on the outer cylinder and the vertical rods; a plurality of brushes are respectively arranged on each of the vertical rods; a rotating shaft is connected to a driving mechanism; a transmission shaft is connected to the bottom of the rotating shaft through a universal joint; a push rod is in threaded connection to the rotating shaft; a guide rail is connected to the push rod; a telescopic rod is arranged at the bottom of the guide rail; press blocks are symmetrically arranged at two ends of the push rod; an annular door is arranged at the bottom of the outer cylinder; ablind hole is formed in the bottom of the outer cylinder; a tapped block is connected to the blind hole through a spring; a groove is formed in the annular door; a lug is arranged at the bottom of the transmission shaft; a discharging mechanism is arranged just below the cleaning mechanism; a feeding opening is formed in the top of a discharging cavity of the discharging mechanism; a mesh screenis arranged at the middle part of the discharging cavity; and a water collecting tank is connected to the bottom of the discharging cavity. Through adoption of the technical scheme of the fruit cleaning device disclosed by the invention, the problems of being poor in fruit cleaning effect, low in efficiency and not suitable for batch production are solved.

Owner:重庆市长寿区石猫儿农业有限公司

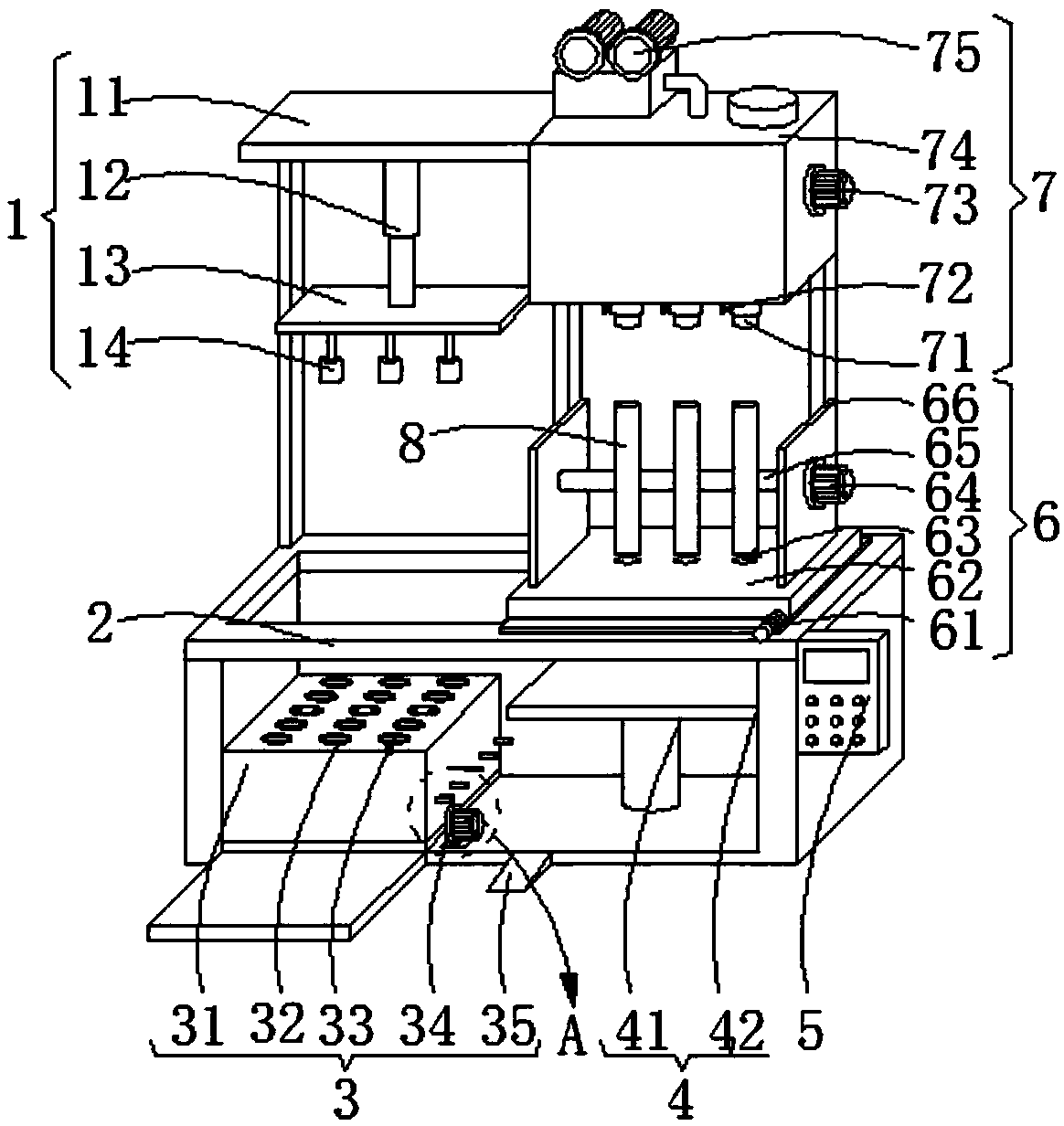

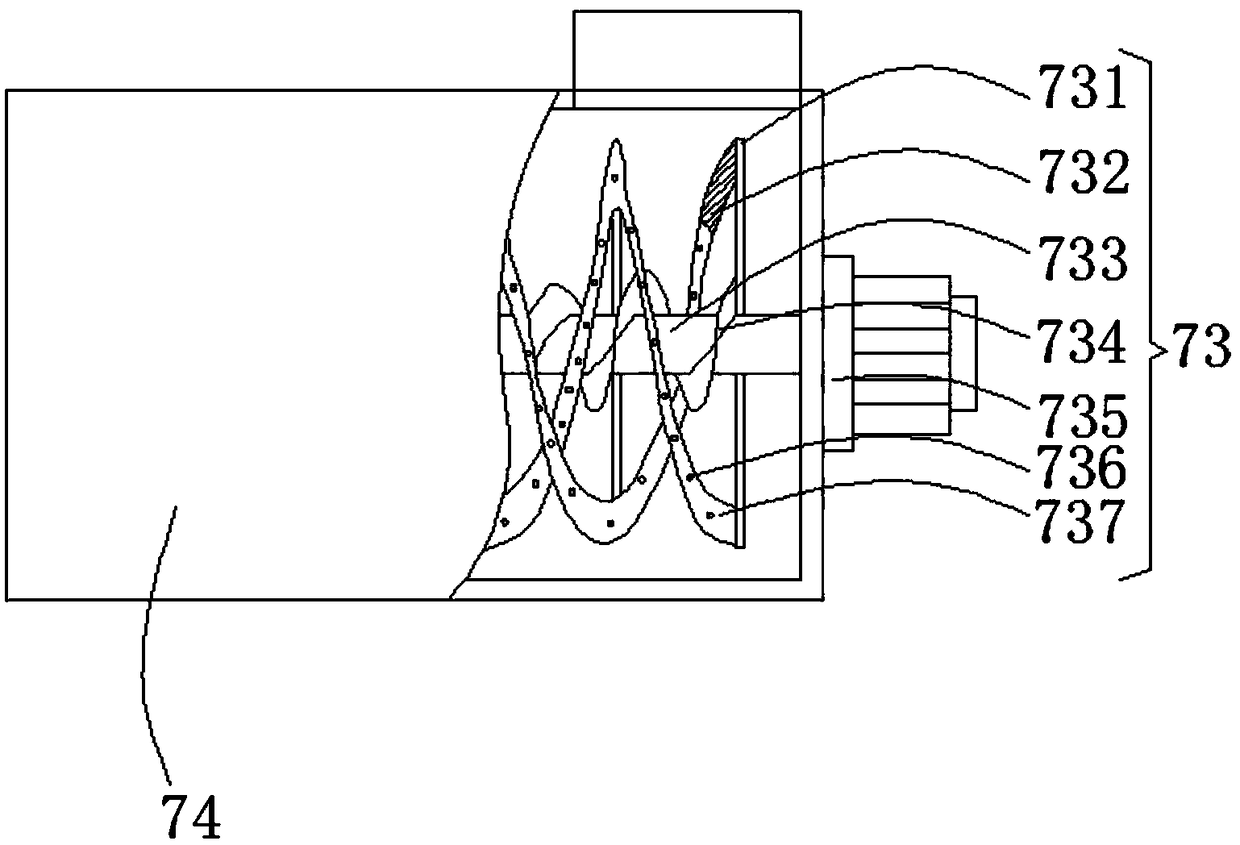

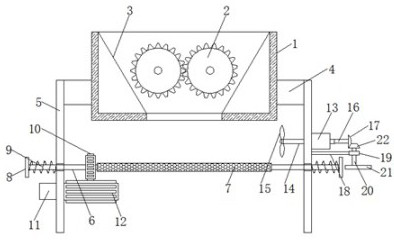

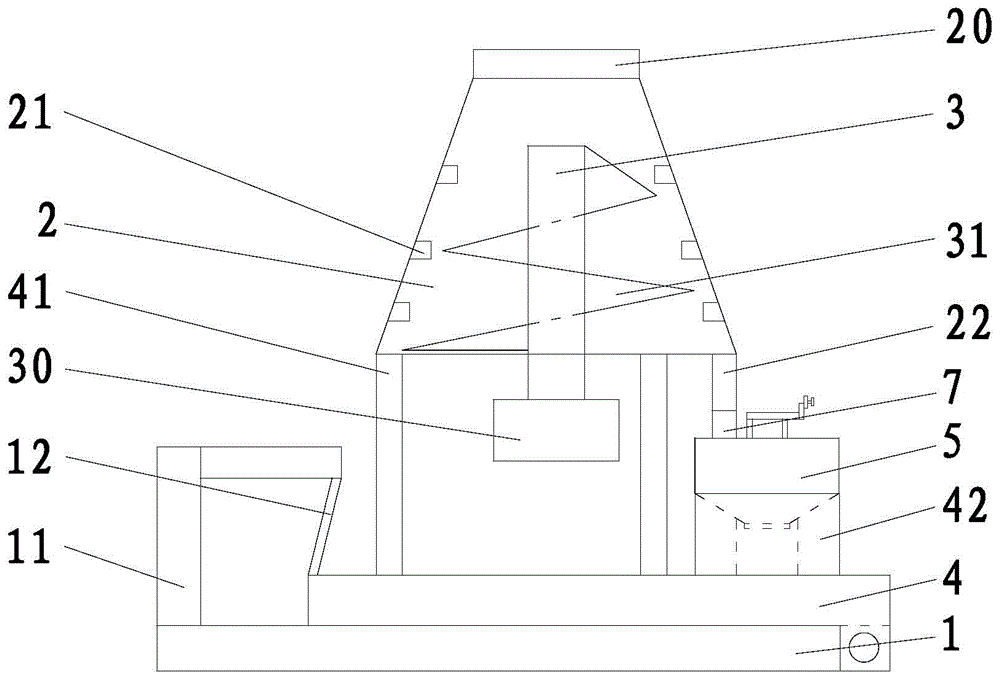

Seed dressing machine based on crop planting

The invention discloses a seed dressing machine based on crop planting. The seed dressing machine comprises an outer frame, wherein the left side of the outer frame is fixedly connected with a side frame, the left side of the top of the outer frame is fixedly connected with a first motor, one end of an output shaft of the first motor penetrates through the side frame and extends into the side frame, the output shaft of the first motor is positioned at one end inside the side frame and fixedly connected with a first gear, the bottom of the first gear is meshed with a second gear, and a screw rod is fixedly connected at an axis center of the second gear through a center shaft. The invention relates to the technical field of agricultural production machinery. The seed dressing machine for planting based on crops achieves the purpose of uniformly spraying a liquid pesticide, enables the liquid pesticide and seeds to be mixed more uniformly, prevents the liquid pesticide from pouring directly into the outer frame directly, avoids adhesion of the seeds, enables the liquid pesticide and the seeds to contact uniformly, ensures a seed germination rate in a later period, avoids the loss caused by non-uniform mixing of the liquid pesticide, is easy to operate and convenient for people to use, and reduces the waste of time.

Owner:浙江两山信息科技有限公司

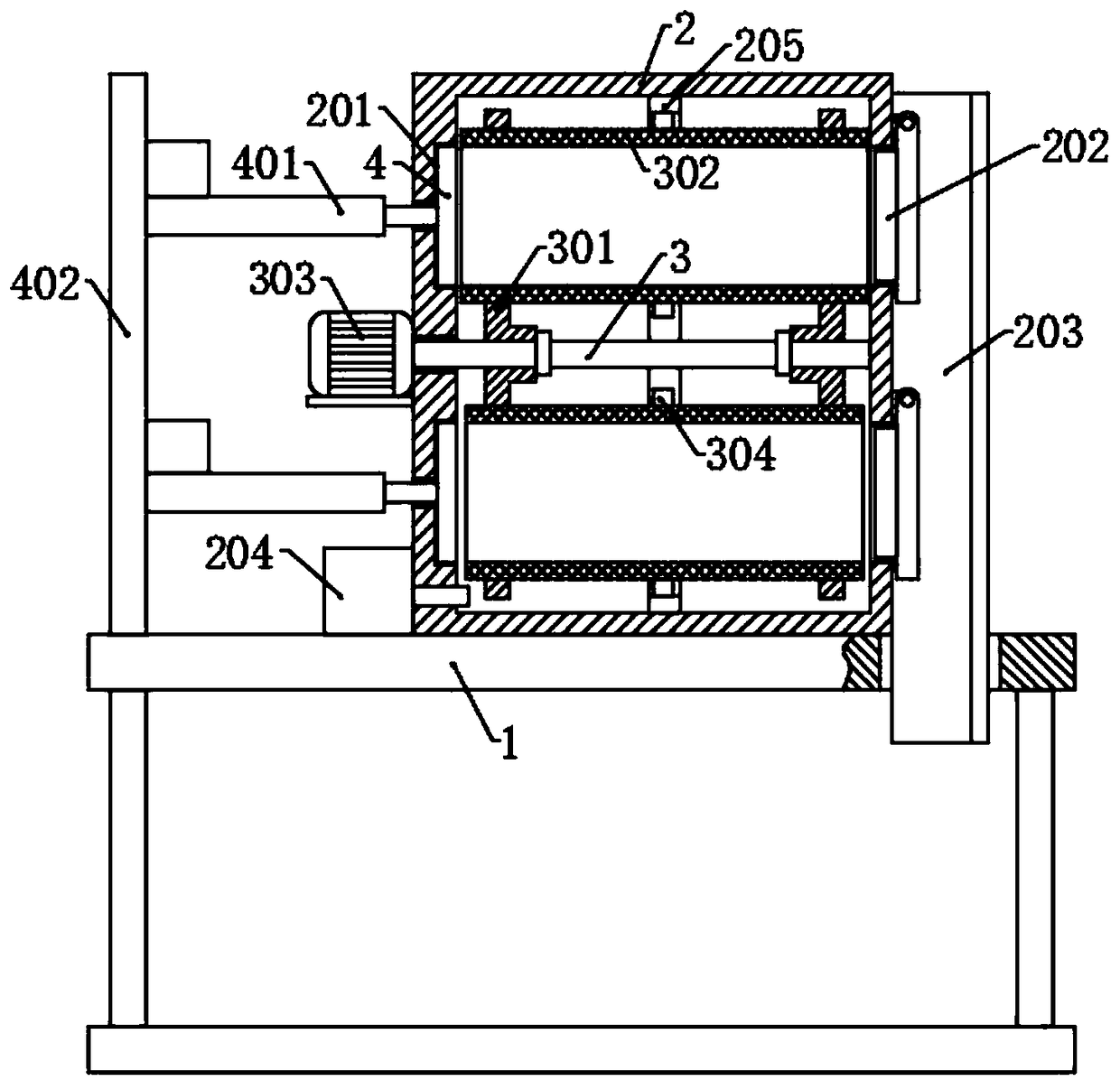

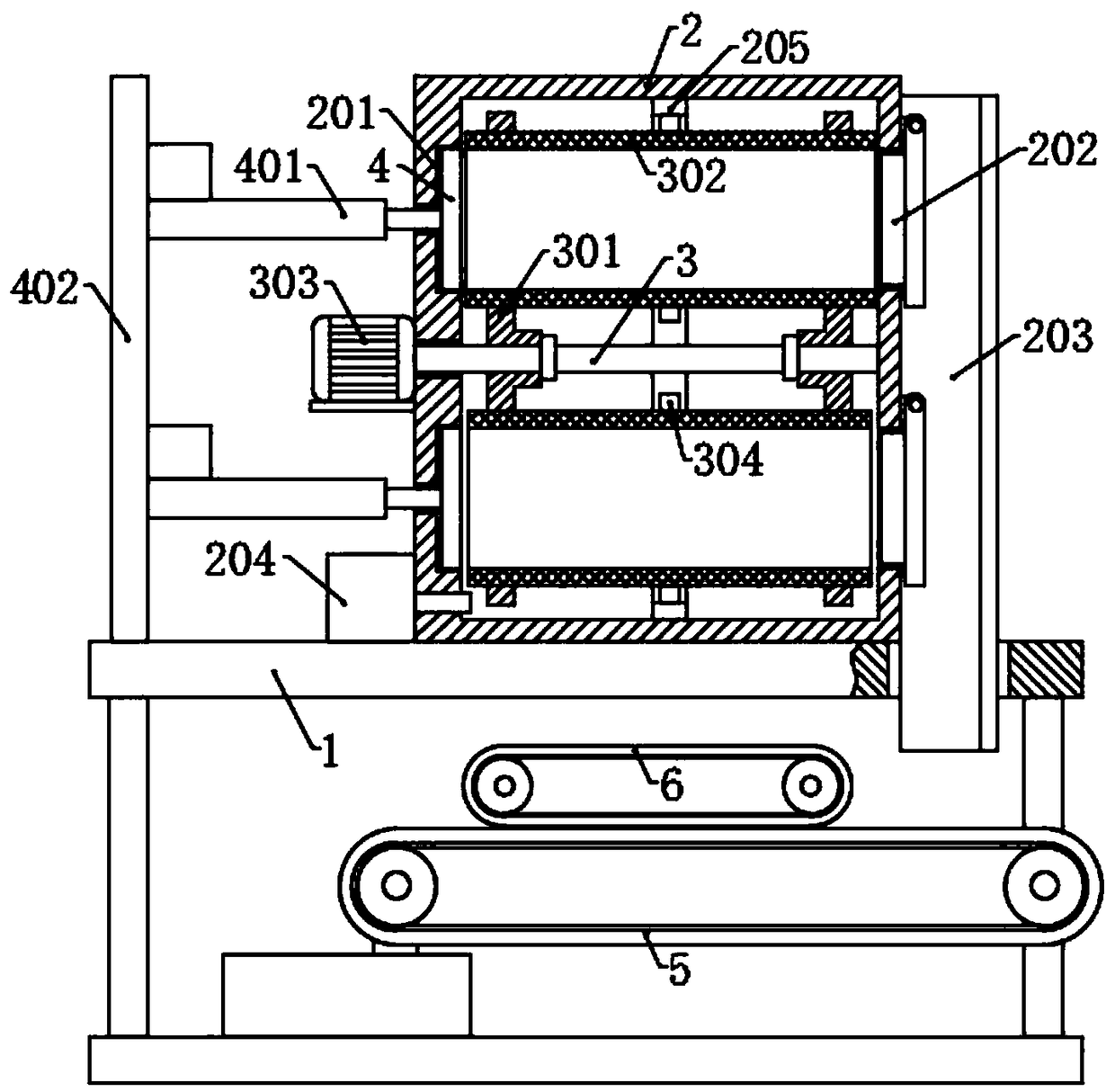

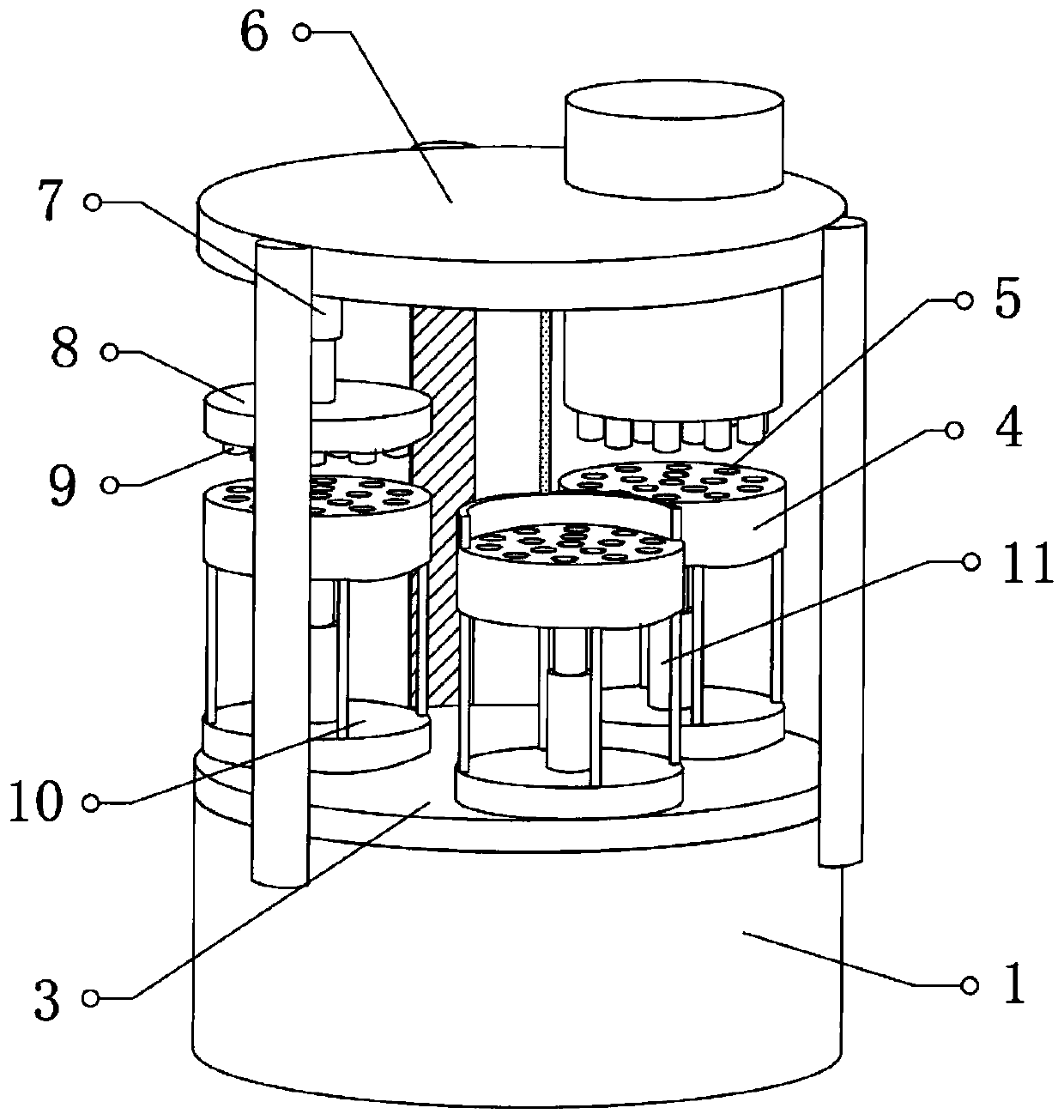

Cleaning device for traditional Chinese medicinal material production and processing

ActiveCN109013522AGood cleaning effectEasy to dischargeDrying solid materials without heatDrying machines with progressive movementsPush outGradual increase

The invention discloses a cleaning device for traditional Chinese medicinal material production and processing, and belongs to the technical field of traditional Chinese medicinal material processing.The cleaning device comprises a supporting frame, a cleaning tank, a pushing mechanism, an upper conveying mechanism, a lower conveying mechanism and a squeezing mechanism. According to the cleaningdevice, traditional Chinese medicinal materials are placed into screen cylinders, a rotary shaft and rotary plates drive the screen cylinders to rotate around the rotary shaft, and the screen cylinders also rotate automatically, so that the traditional Chinese medicinal materials are stirred and cleaned in the screen cylinders, and the cleaning effect is good. After cleaning, the traditional Chinese medicinal materials are pushed out of the screen cylinders through electric hydraulic push rods and pushing plates and then fall onto a guide plate via outlets, and thus, the traditional Chinese medicinal materials are discharged conveniently after being cleaned; the traditional Chinese medicinal materials fall onto a lower sponge and move forwards along with a lower conveying belt, then moisture left on the traditional Chinese medicinal materials is absorbed through the lower sponge and an upper sponge, and thus, the influence of excessive moisture on the subsequent drying process is reduced; and the upper sponge and the lower sponge are squeezed through an upper pressing roller and a lower pressing roller, so that moisture is squeezed out of the upper sponge and the lower sponge, andthe problem that the water absorption effect of the upper sponge and the lower sponge is reduced due to gradual increase of the quality of moisture on the upper sponge and the lower sponge is solved.

Owner:镇巴县鹏辉富强农牧有限公司

Crushing processing device for processing rice cakes

The invention discloses a crushing processing device for processing rice cakes. The crushing processing device comprises a rack, a first processing tank and a second processing tank, wherein a fixingrack is mounted at the upper end of the inner cavity of the rack; a first motor is mounted at the left end of the fixing rack; a transmission shaft is mounted at the left end of the first motor; a left side wall of the rack is fixed at the right end of the transmission shaft; an arc-shaped rod is mounted in the middle of the transmission shaft; the arc-shaped rod is sleeved by a sliding sleeve; the bottom end of the sliding sleeve is connected with a moveable pull rod; a connecting block is mounted at the bottom end of the moveable pull rod; a fixing plate is mounted on the bottom surface of the connecting block; a second motor is mounted on the bottom surface of the fixing plate; a processing rotating shaft is mounted at the bottom end of the second motor; the processing rotating shaft extends into the inner cavity of the first processing tank; and a plurality of crushing blades are mounted on the processing rotating shaft. By adopting the crushing processing device, processing on rawmaterials is completed through simulated manual operation, and the processed raw materials are relatively good in taste.

Owner:BEOSON JIANGSU FOOD SAFETY TECH CO LTD

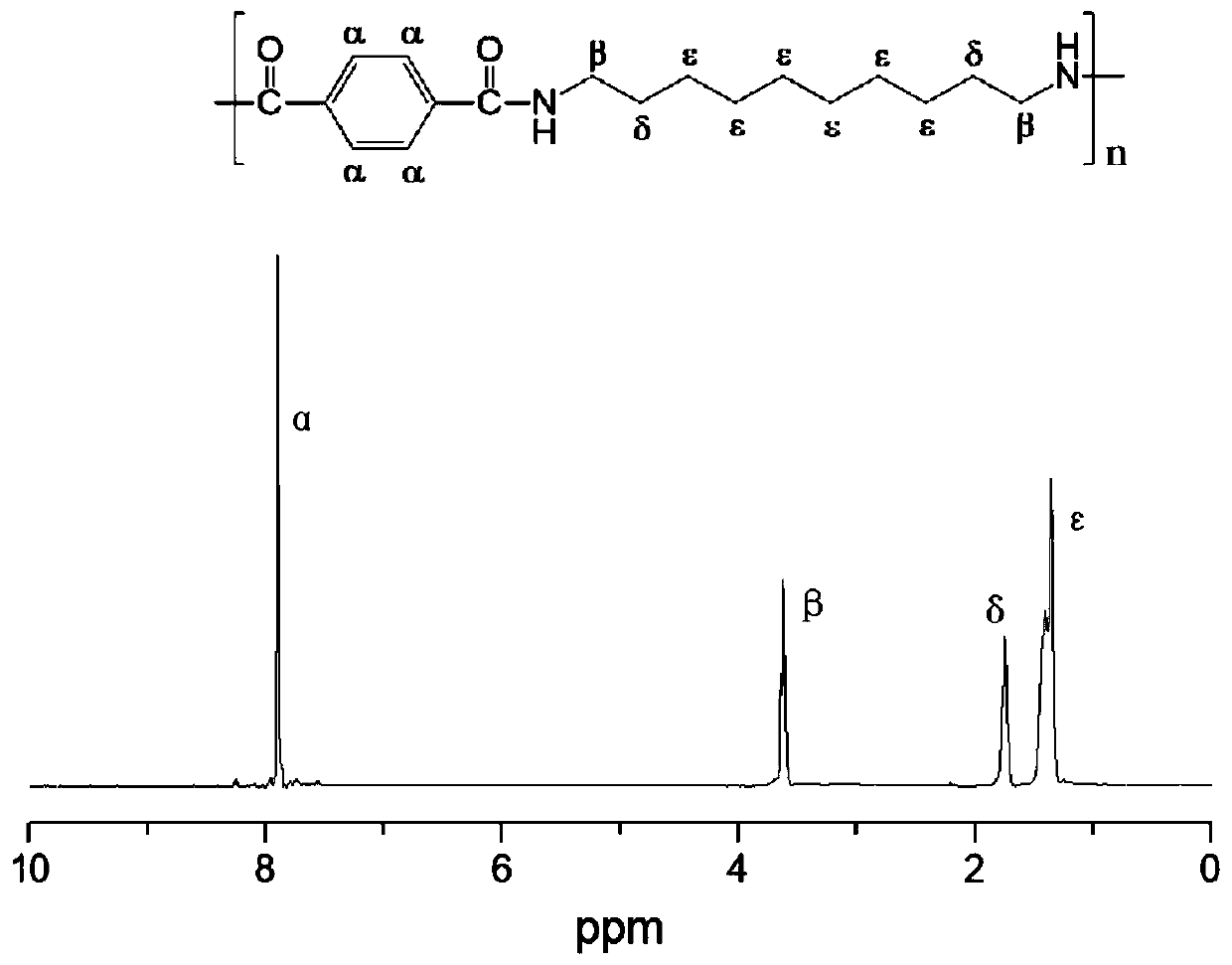

Preparation method of semi-aromatic polyamide

The invention discloses a preparation method of semi-aromatic polyamide. The preparation method comprises the following steps: 1) raw materials are placed in a reaction device and undergo a salt-forming reaction, wherein the raw materials comprise a diacid, an aliphatic diamine, a catalyst, deionized water, an antioxidant and an end capping agent; 2) a product prepared in step 1) undergoes a prepolymerization reaction to obtain a semi-aromatic polyamide prepolymer; and 3) the semi-aromatic polyamide prepolymer obtained in step 2) is subjected to a solid phase polymerization reaction to obtainthe semi-aromatic polyamide. The preparation method provided by the invention has the advantages of simple reaction steps, implementation of the prepolymerization reaction and the solid phase polymerization reaction in the same reaction device, and realization of continuous production; and the solid phase polymerization is carried out to increase the molecular weight of the polymer to obtain the semi-aromatic polyamide, so the production cost is low, and the quality of the product is easily controlled by solid phase polymerization conditions.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

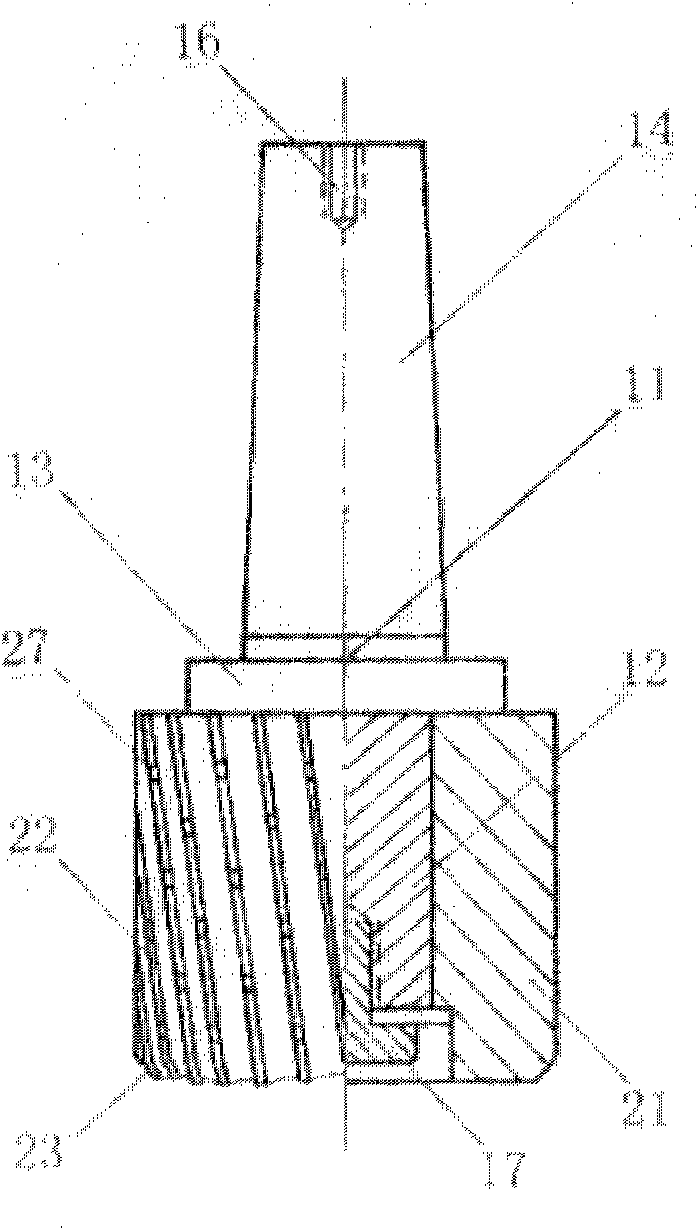

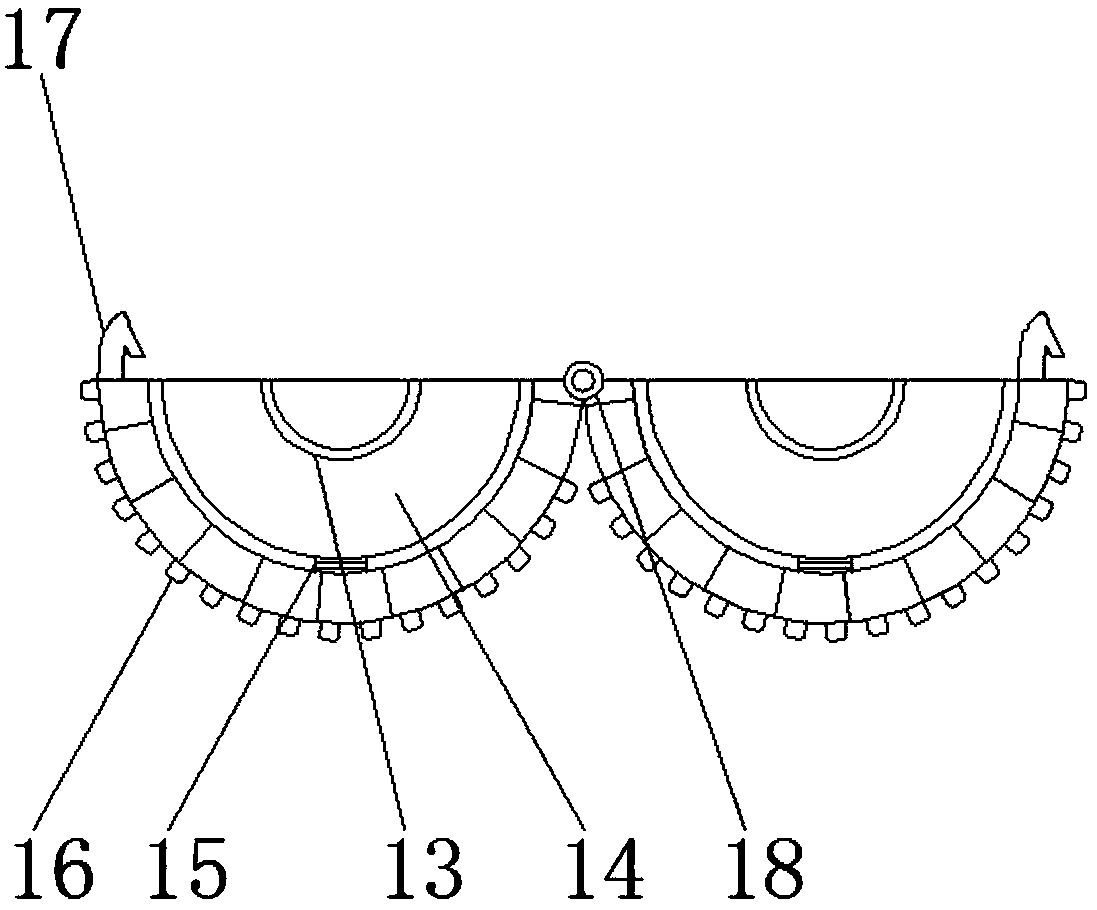

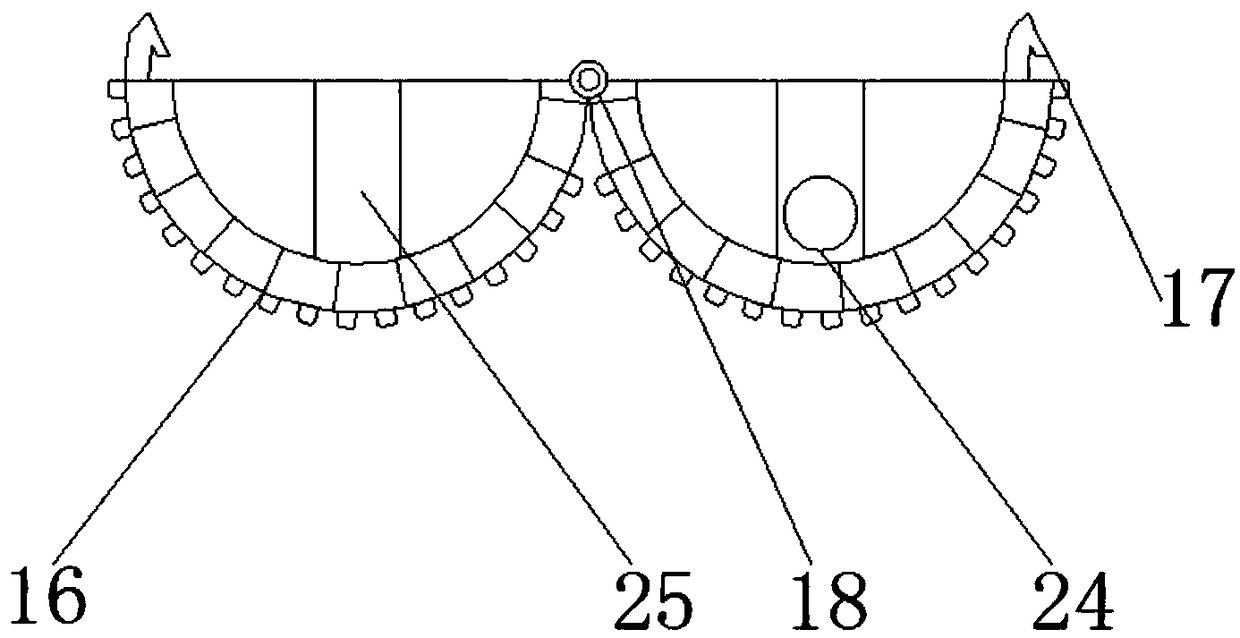

Method and milling cutter for repairing surface defect of cement concrete construction member

InactiveCN101876208AGuaranteed cutting forceGuaranteed StrengthBuilding repairsCeramic shaping apparatusMilling cutterArchitectural engineering

The invention discloses a method and a milling cutter for repairing surface defect of a cement concrete construction member, which is used for repairing the surface defects of the building construction members, such as cement concrete wall, piers, girders, plates and the like. For defects of cracks, local damage, voids and pits and the like on the surface of the building construction member, the method and the special milling cutter of the invention firstly remove defects, form a repairing groove and pour concrete again to repair. The method and the milling cutter of the invention can process the surface of the construction member into geometry, such as a plane, a cambered surface, a groove and the like, and especially processes the boundary surface of the repairing groove into regular, smooth, rough and circular-arc corner, which is favourable for construction stress and combination of new and old concrete, improves appearance quality and solves the difficulty problem that the surface of the cement concrete construction member is difficult to repair.

Owner:HEFEI UNIV OF TECH

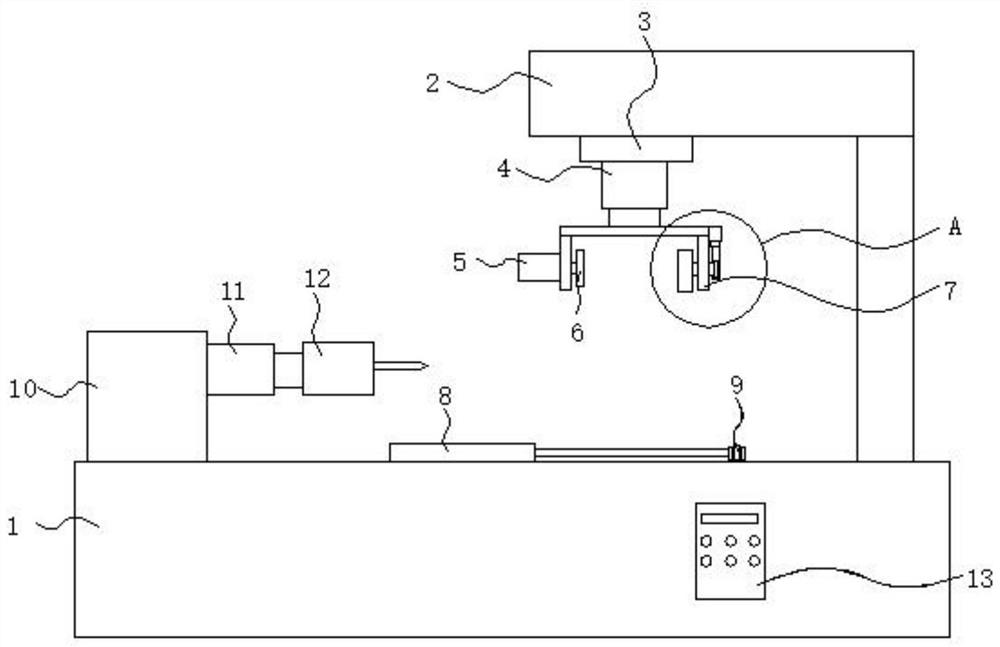

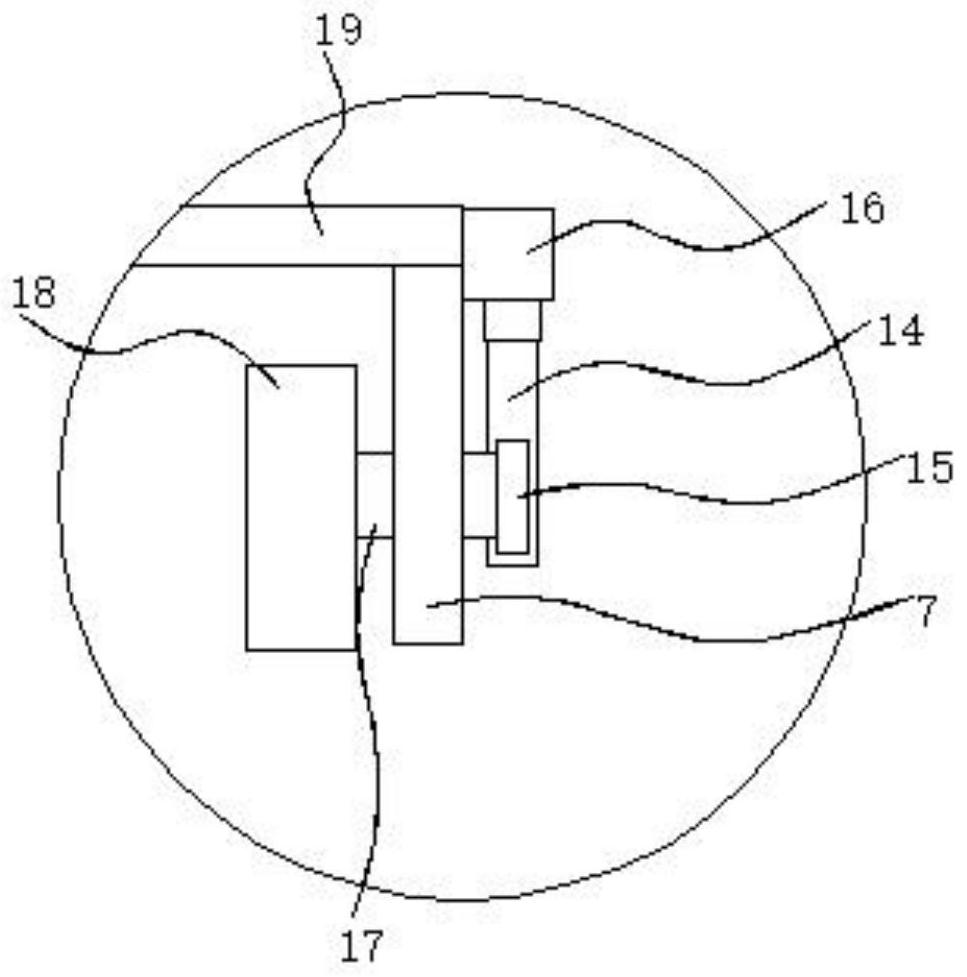

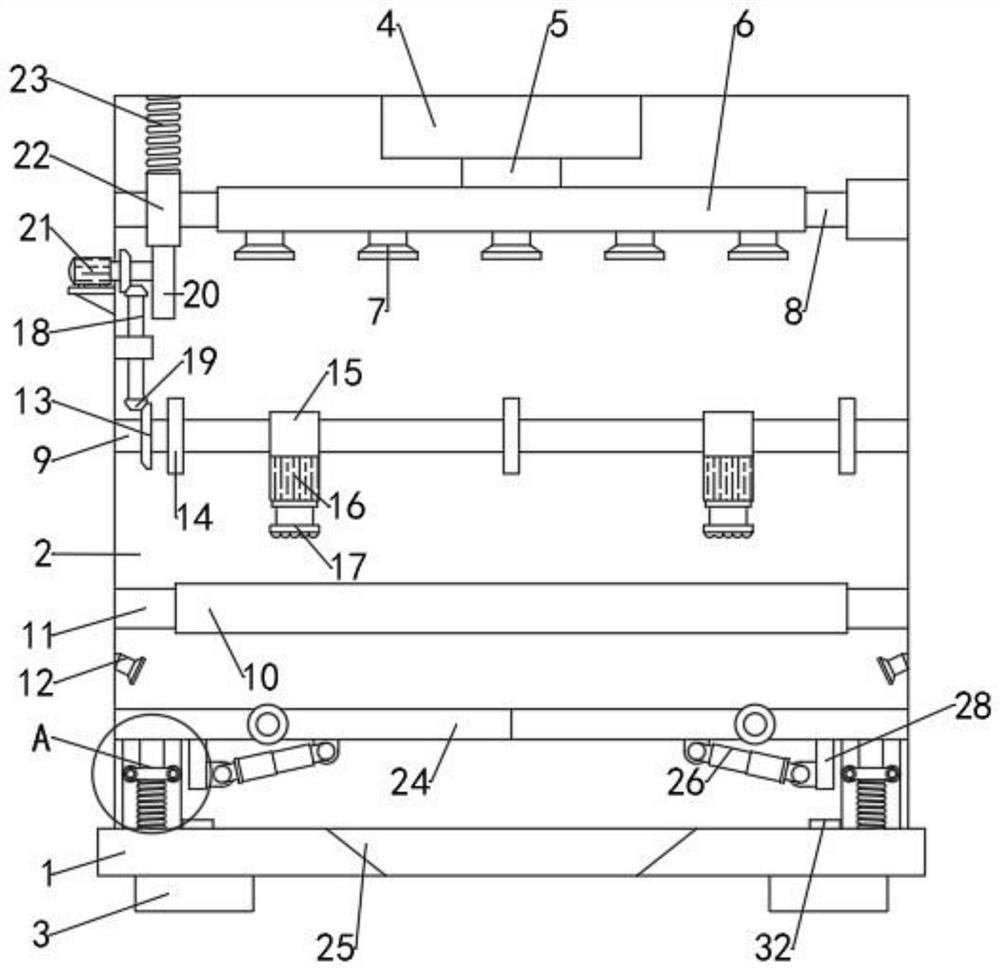

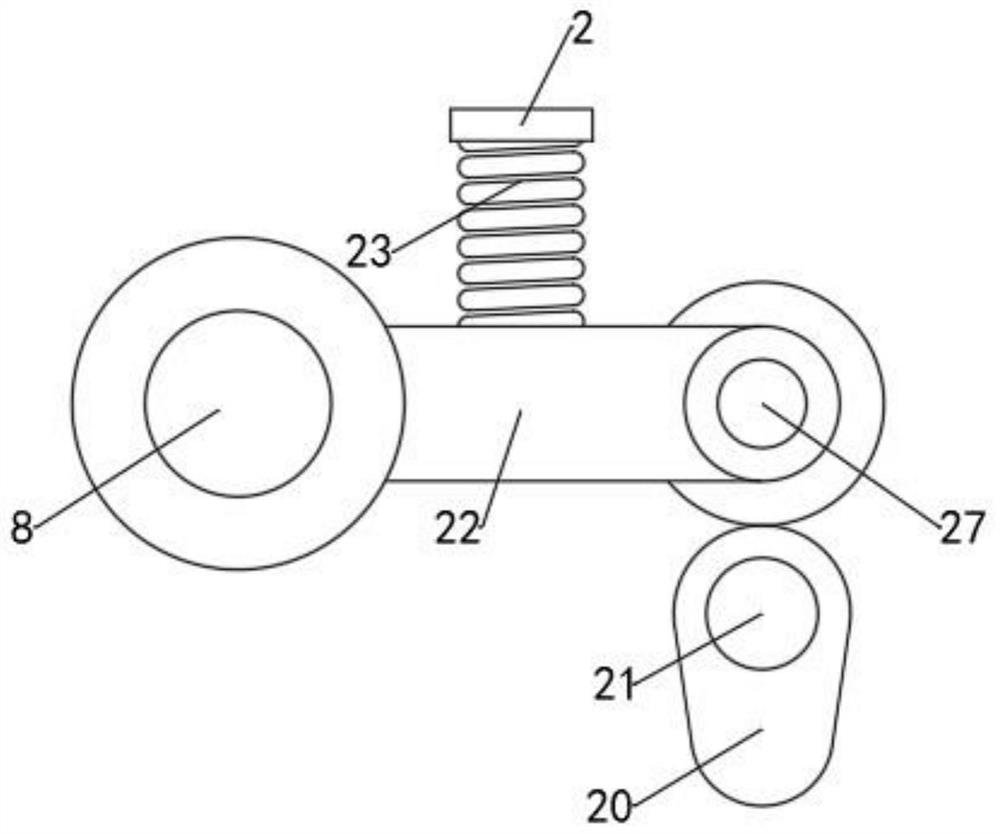

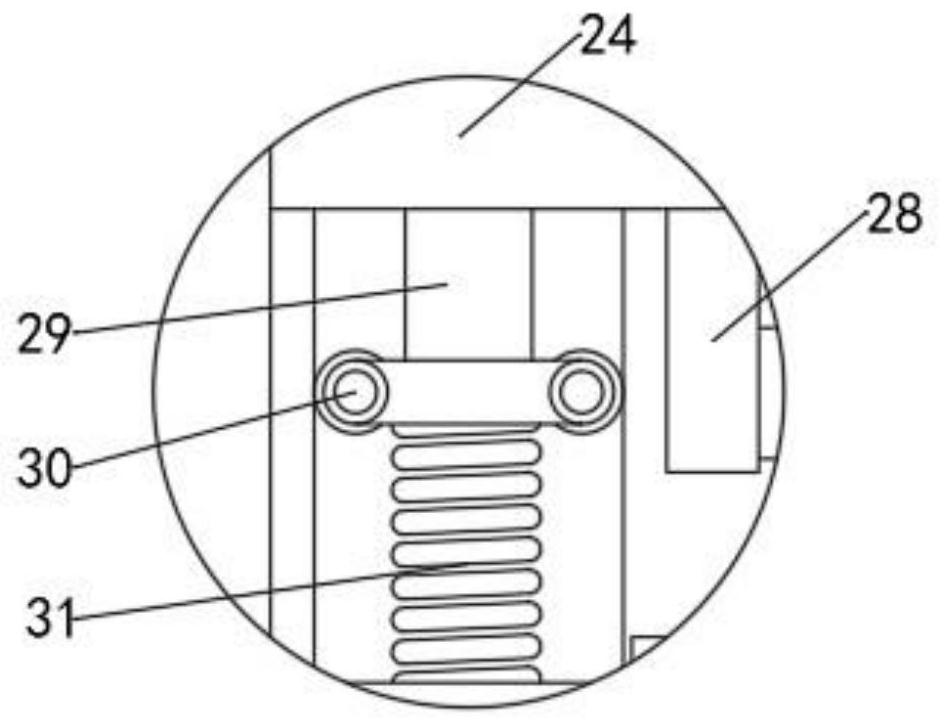

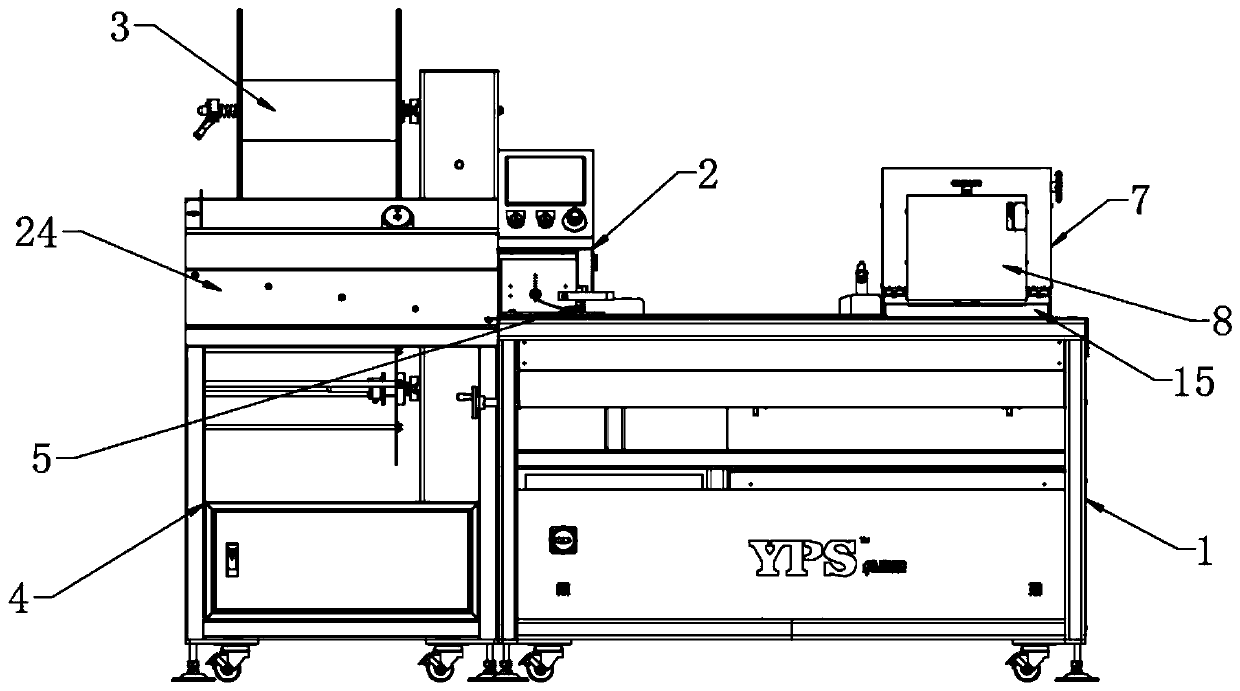

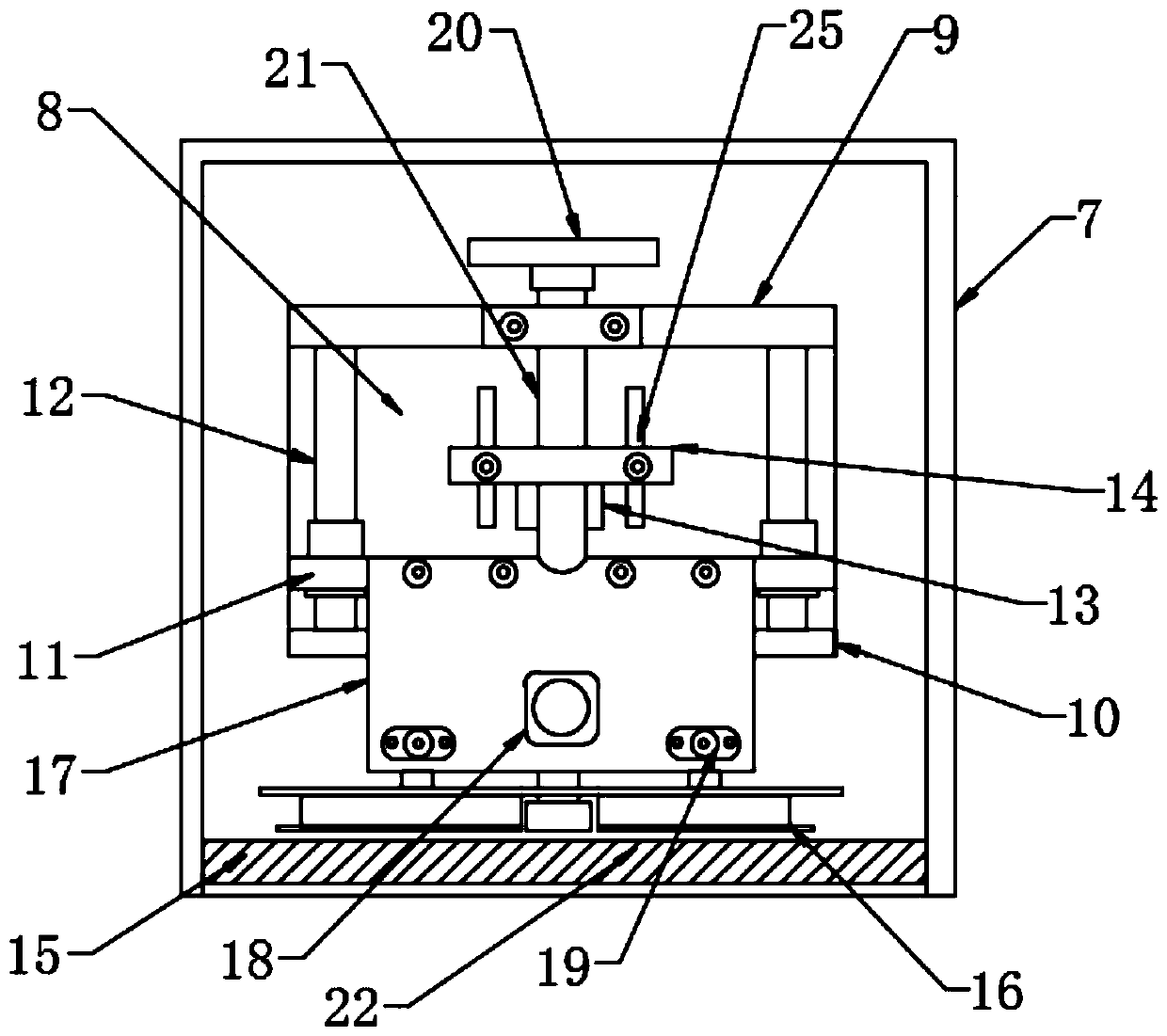

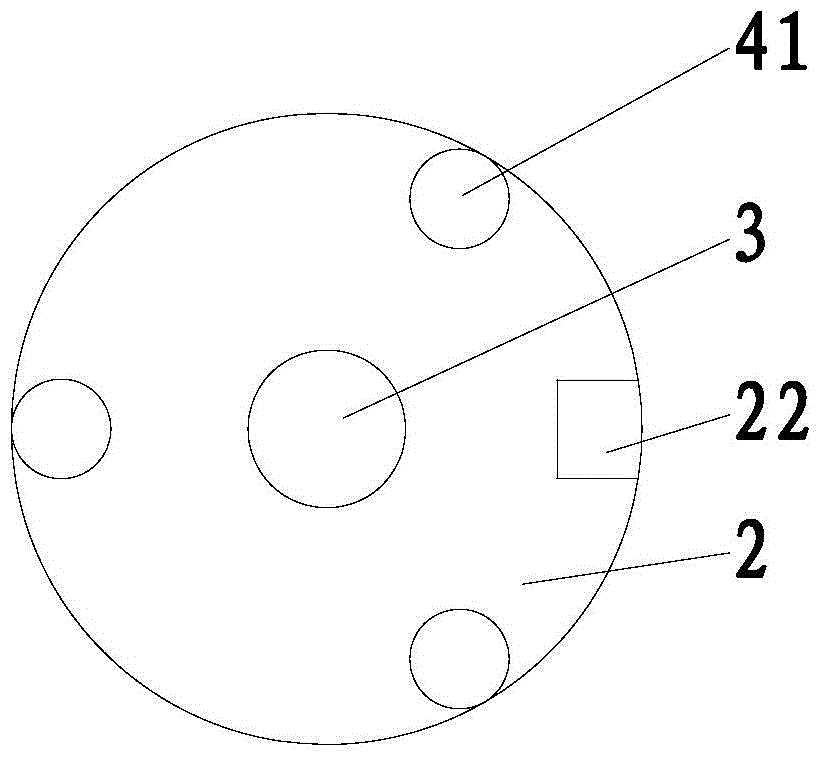

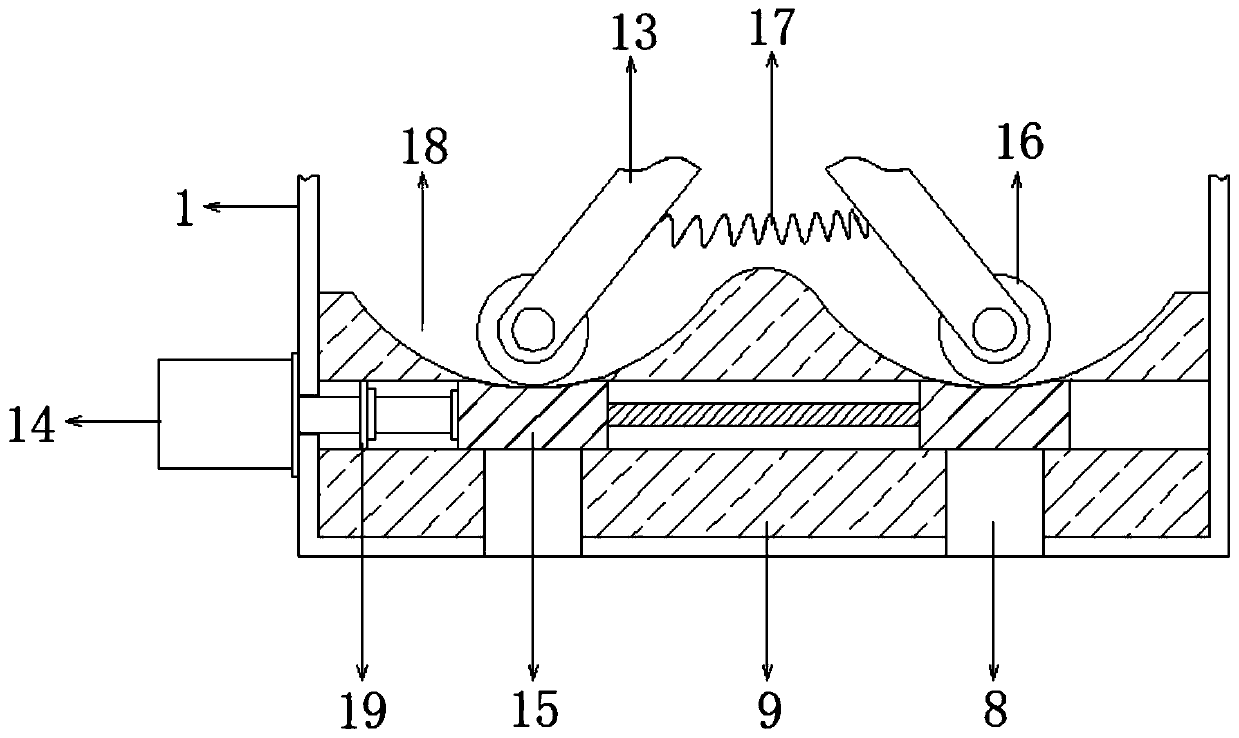

Machining equipment for flanges

ActiveCN112192271AShorten the timeEasy to dischargePositioning apparatusMetal-working holdersDrill holeStructural engineering

The invention relates to the technical field of flange machining equipment, in particular to machining equipment for flanges. The problem that drilling equipment for flange machining in the prior artis not beneficial to saving time is solved. According to the scheme, The machining equipment comprises a workbench, a mounting frame fixed to the top of the workbench, a clamping mechanism mounted onthe mounting frame and a drilling mechanism mounted at the top of the workbench; a containing groove, a discharging groove and a collection groove are formed in the top of the workbench, the containing groove and the discharging groove are oppositely formed, the side, close to the containing groove, of the collection groove communicates with the containing groove, and a limiting column is connected into the collection groove in a clamped mode; and the clamping mechanism comprises an installation block and a first telescopic device fixed to the bottom of the installation block. The machining equipment is reasonable in structure and easy to operate, the flanges can be conveniently and rapidly clamped and drilled, after drilling is finished, the discharging procedure is very simple and rapid,the flange machining time is greatly shortened, and the machining equipment is easy to apply and popularize.

Owner:盐城市新澳精密锻造有限公司

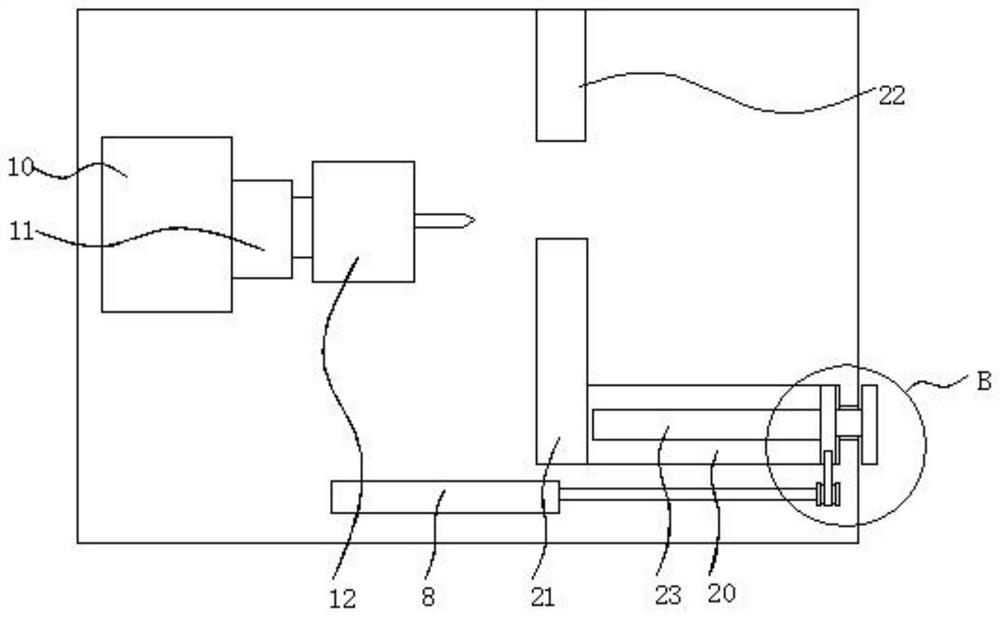

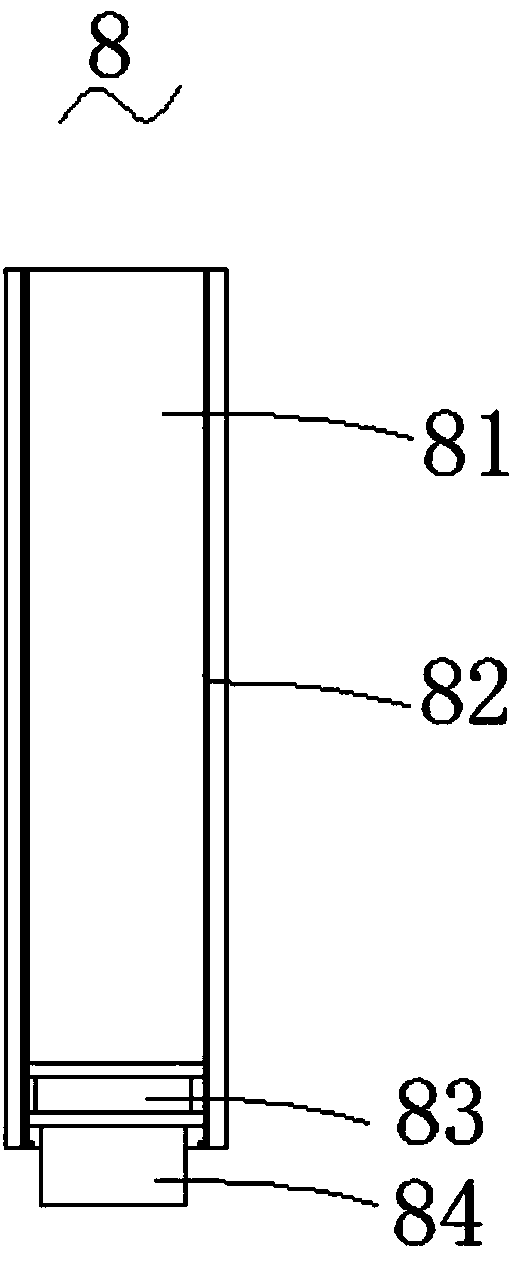

Resistance ceramic white rod forming production and processing equipment

ActiveCN108501179APrevent the entry of airEasy to dischargeDischarging arrangementFeeding arrangmentsNozzleExtrusion

The invention relates to the field of ceramic processing, in particular to resistance ceramic white rod forming production and processing equipment. The resistance ceramic white rod forming productionand processing equipment comprises an extrusion mechanism, a base, a container packing mechanism, a pushing mechanism, buttons, a moving mechanism, a falling mechanism and forming mechanisms. Throughthe extrusion mechanism, ceramic rods can be extruded and formed, the produced ceramic rods can be extruded, the ceramic rods can be container-packed through the container packing mechanism, and thepushing mechanism can push the forming mechanisms to ascend and descend. The moving mechanism can realize the movement of the forming mechanisms, and the falling mechanism facilitates the control overthe falling of raw materials. According to the resistance ceramic white rod forming production and processing equipment, the forming mechanisms are in contact with falling nozzles to feed the material in a pressurizing manner, so that air can be effectively prevented from entering, and the produced ceramic rods are ensured to be free of bubbles; and when the production is completed, pressing blocks are used for pressing to accelerate the forming under pressure, then the pressing blocks are used again for pressing, and the extruded and formed ceramic rods can be obtained, so that the discharging is convenient and quick.

Owner:安徽航睿电子科技有限公司

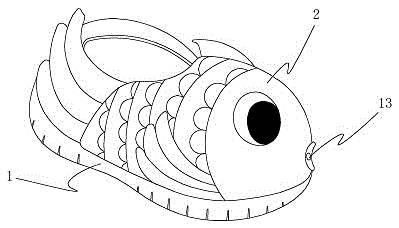

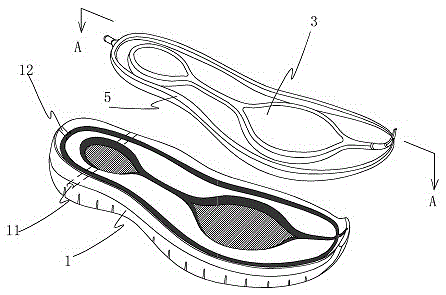

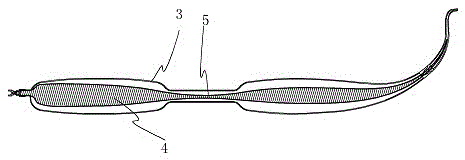

Bubble fun shoe

The invention relates to a shoe and provides a bubble fun shoe which satisfies the wearing requirement of daily life and meanwhile increases child interest for a child. The shoe comprises a shoe sole and a shoe upper arranged on the shoe sole, air bags and liquid storage bags are arranged on the shoe sole, and the liquid storage bags are filled with bubble liquid; the shoe sole is provided with an air inlet communicated with the air bags, and the air inlet is provided with a one-way air inlet valve; the shoe sole is provided with a liquid inlet communicated with the liquid storage bags, and the liquid inlet is provided with a one-way liquid inlet valve; the shoe sole is further provided with a bubble outlet, the bubble outlet is provided with two or more liquid guide pipes in a communicated mode, the liquid outlet ends of all the liquid guide pipes are arranged on the bubble outlet oppositely, and the liquid inlet ends of all the liquid guide pipes are all communicated with the liquid storage bags; the air bags are provided with an air outlet pipe in a communicated mode, an air outlet of the air outlet pipe is communicated with and faces the bubble outlet, and the air outlet pipe is provided with a one-way air outlet valve.

Owner:FUJIAN DENGTAI TECH CO LTD

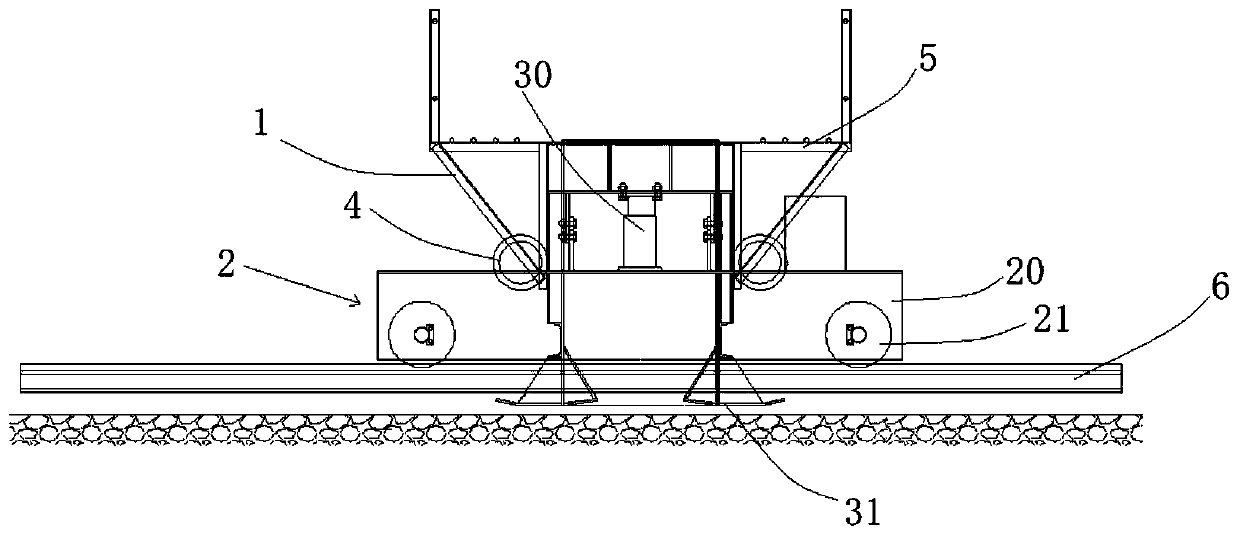

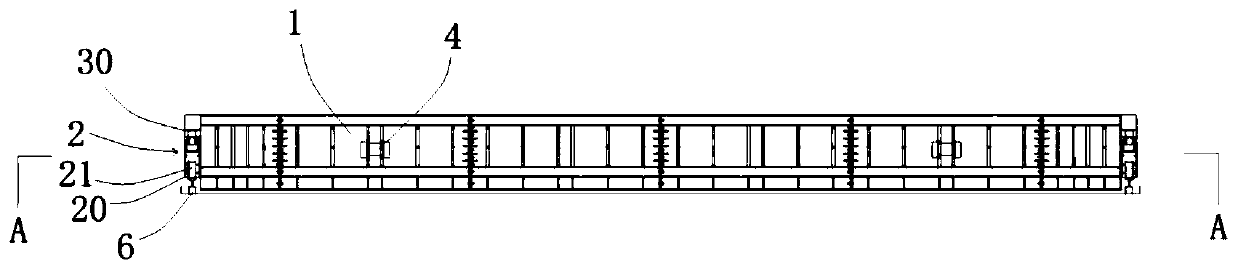

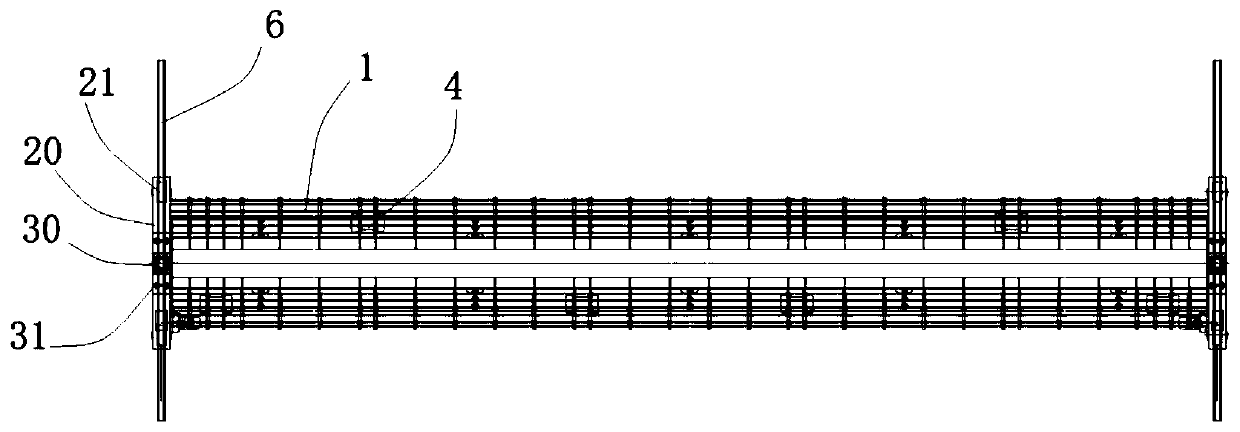

Ultra-high performance material distributing machine for concrete bridge deck construction and construction method of ultra-high performance material distributing machine for concrete bridge deck construction

PendingCN110258338AEasy to dischargeEasy to adjustBridge structural detailsBridge erection/assemblyBridge deckUltra high performance

The invention discloses an ultra-high performance material distributing machine for concrete bridge deck construction and a construction method of the ultra-high performance material distributing machine for the concrete bridge deck construction, and relates to the technical field of bridge deck construction equipment. The ultra-high performance material distributing machine comprises material box assemblies, scraping and adjusting assemblies and a travelling assembly, wherein the material box assemblies comprise at least one non-bottom material box, the scraping and adjusting assemblies comprise at least two adjusting pieces and at least one scraping and adjusting plate, the two adjusting pieces are arranged on one sides of the non-bottom material boxes correspondingly, the scraping and adjusting plates are arranged at the bottoms of the non-bottom material boxes, the travelling assemblies comprise travelling beams arranged on the two sides of the material box assemblies correspondingly, and at least two travelling wheels are both arranged on each travelling beam. According to the ultra-high performance material distributing machine for concrete bridge deck construction and the construction method of the ultra-high performance material distributing machine for the concrete bridge deck construction, the problem of uneven distribution of materials distributing in the past is solved, the structure is simple, and the practicability is high.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

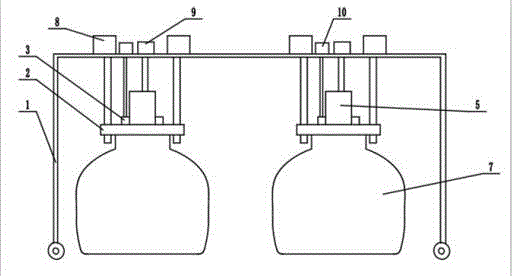

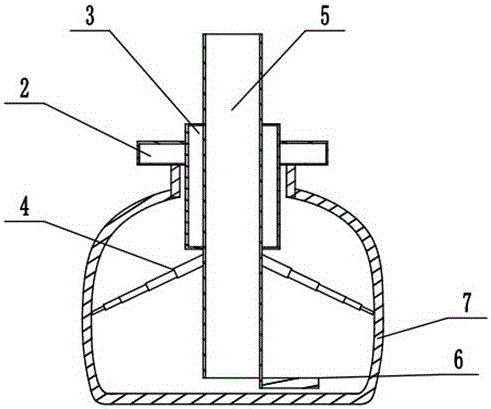

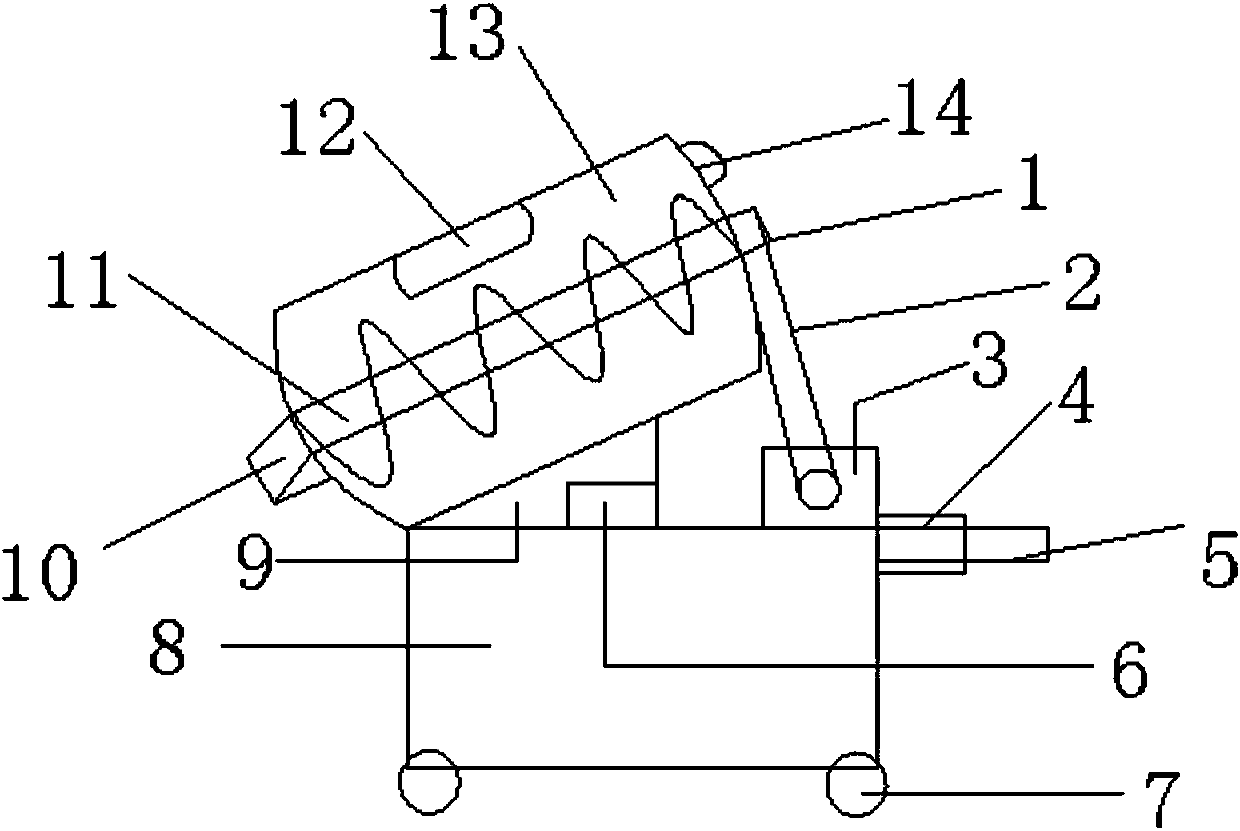

Fermented grain discharging device for brewing Baijiu

InactiveCN106350383AExtended service lifeEasy to dischargeAlcoholic beverage preparationEngineeringBrewing

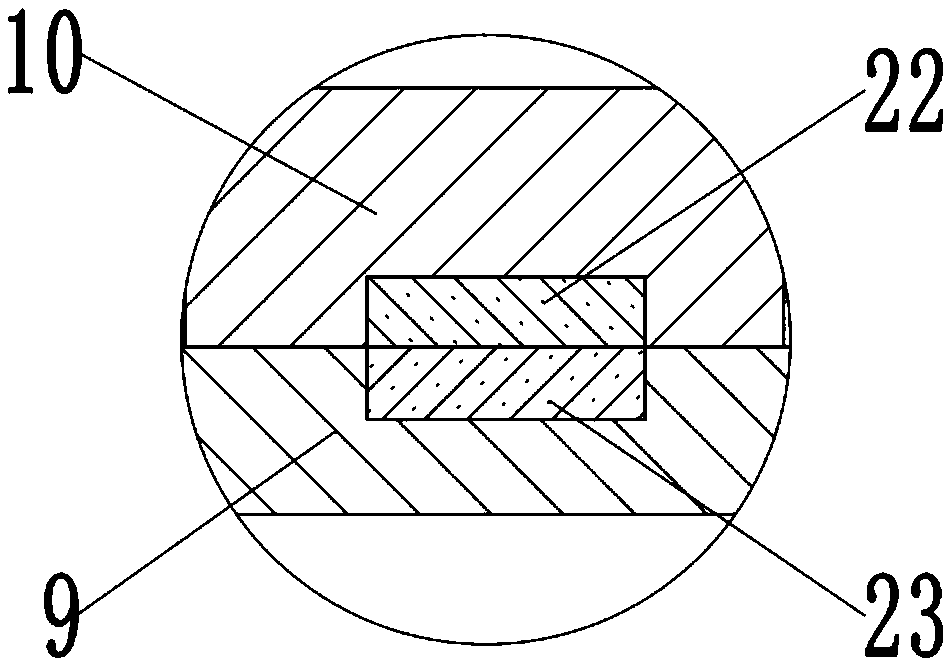

The invention belongs to the field of alcohols and in particular discloses a fermented grain discharging device for brewing Baijiu. The fermented grain discharging device comprises a movable rack, wherein a discharging mechanism is arranged on the rack and comprises a cylindrical packing auger frame driven by a power mechanism; a material receiving cylinder driven by a first driving mechanism is movably connected to the inside of the cylindrical packing auger frame; a discharge opening is formed in the top end of the material receiving cylinder; a feed opening is formed in the bottom end of the material receiving cylinder; a cylinder cover controlled by a button to be opened or closed is rotationally connected to the feed opening; a telescopic mechanism for downward pressing fermented grains is circumferentially arranged on the material receiving cylinder; a torsional spring is arranged between the telescopic mechanism and the material receiving cylinder; a lantern ring for controlling the expansion degree of the telescopic mechanism is movably connected to the top of the material receiving cylinder; the lantern ring is positioned between the material receiving cylinder and the cylindrical packing auger frame and is driven by a second driving mechanism. According to the scheme, fermented grains in a jar and fermented grains attached to the inner wall of an jar are cleaned without damaging the inner wall of the jar; in addition, the fermented grain discharging device after use is easy to clean.

Owner:贵州古酿坊酒业(集团)有限公司

Debris cleaning device for numerical control machine tool

InactiveCN112355702AEasy to dischargeSmooth runningMaintainance and safety accessoriesPhysicsWorkbench

The invention discloses a debris cleaning device for a numerical control machine tool. The debris cleaning device comprises a base, a cavity is fixed to the upper end of the base, a workbench is arranged on the inner side of the cavity, and a sweeping mechanism and an air blowing mechanism which are in linkage are arranged above the workbench at intervals. According to the debris cleaning device for the numerical control machine tool, the sweeping mechanism and the air blowing mechanism which are in linkage are arranged, so that a cleaning brush conducts reciprocating sweeping along the workbench while an air outlet pipe swings to discharge air, and the cleaning effect is ensured; in addition, a second base plate has an induction effect, when the weight of debris accumulated on the secondbase plate is too large, a fixing base is attached to an induction switch, so that an electric telescopic rod opens the second base plate, and discharging is facilitated; a second air blower is arranged above the second base plate, so that the debris is prevented from being accumulated on the second base plate; and in addition, a buffer rod and a buffer spring are arranged between the second baseplate and the cavity, so that the second base plate is stable in operation, and the debris is convenient to clean.

Owner:XINXIANG VOCATIONAL & TECHN COLLEGE

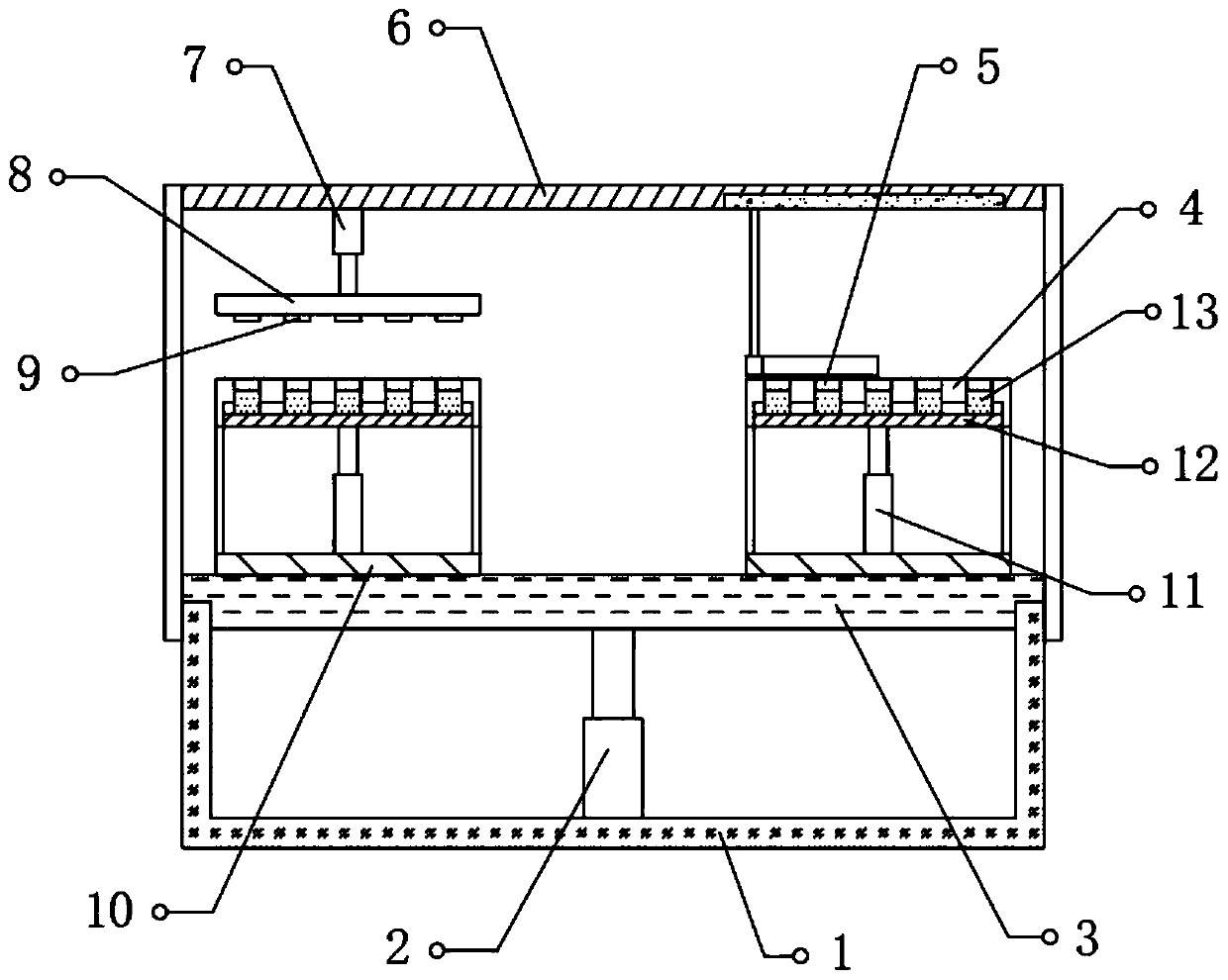

Pharmaceutical tabletting device

PendingCN110667168AImprove production rate and pharmaceutical efficiencyEasy to dischargeNon-rotating vibration suppressionPharmaceutical product form changePhysicsTableting

The invention discloses a pharmaceutical tabletting device which comprises a base box. The top end of the base box is opened, a rotating motor is fixed to the inner wall of the bottom of the base box,a base is fixed to an output shaft of the rotating motor, the bottom of the base is rotatably connected to the top of the base box, three mold plates arranged in an annular array are fixed to the topof the base, a plurality of tabletting slots are formed in the top of each mold plate, a top seat is arranged on the top of the base box, and a plurality of supporting racks are fixed between the topseat and the outer wall of the base box. According to the pharmaceutical tabletting device, the base is connected in the base box through the rotating motor and the three mold plates are fixed to thebase to correspond to a charging mechanism, a tabletting mechanism and a discharging mechanism separately, so that charging, tabletting and discharging operations are carried out on the three mold plates. The corresponding positions of the mold plates are replaced by rotating the base, so that quick tabletting circulating operations are achieved, and the integral production rate and the pharmaceutical efficiency are improved.

Owner:湖北邦瑞特药业有限公司

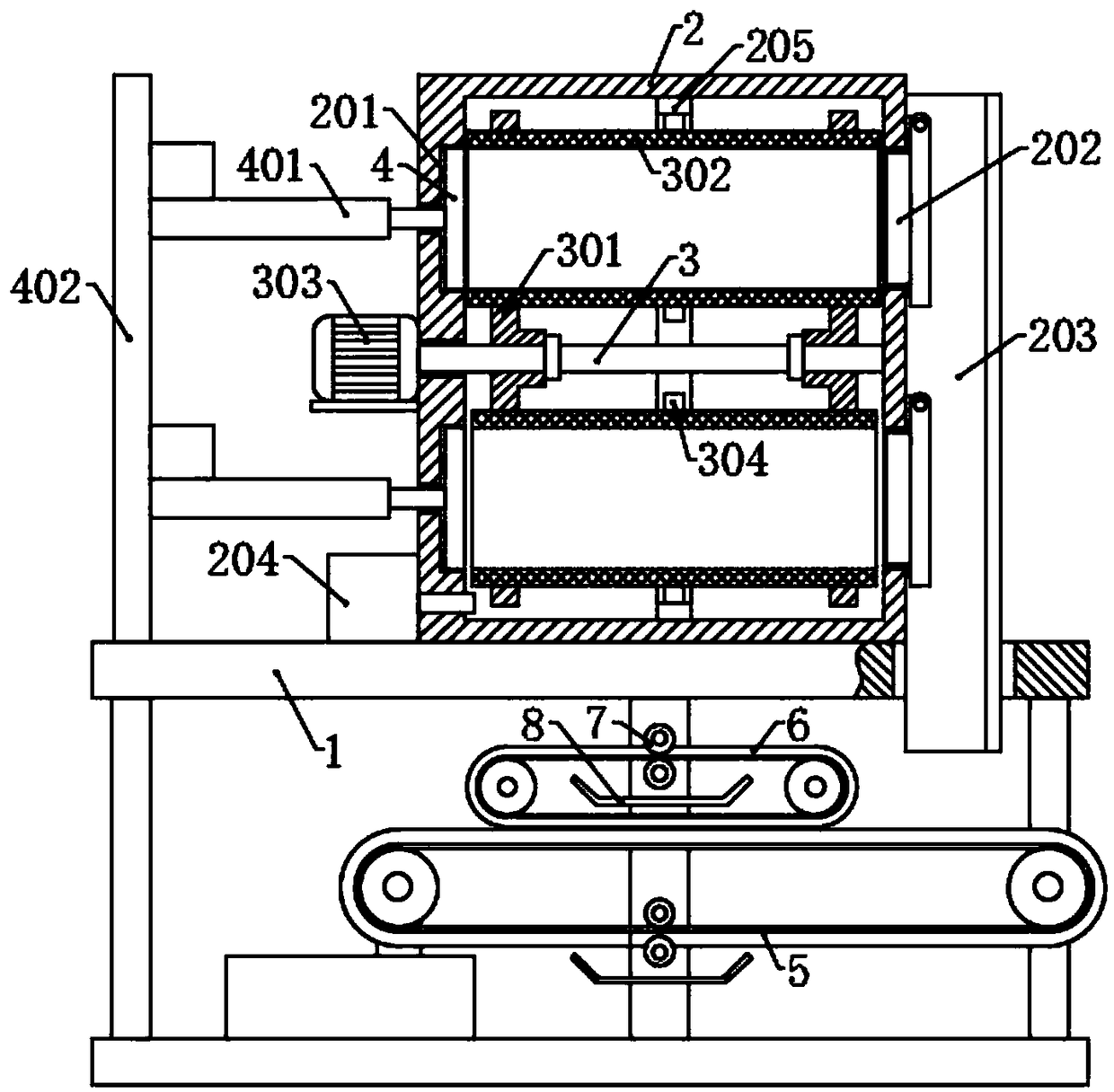

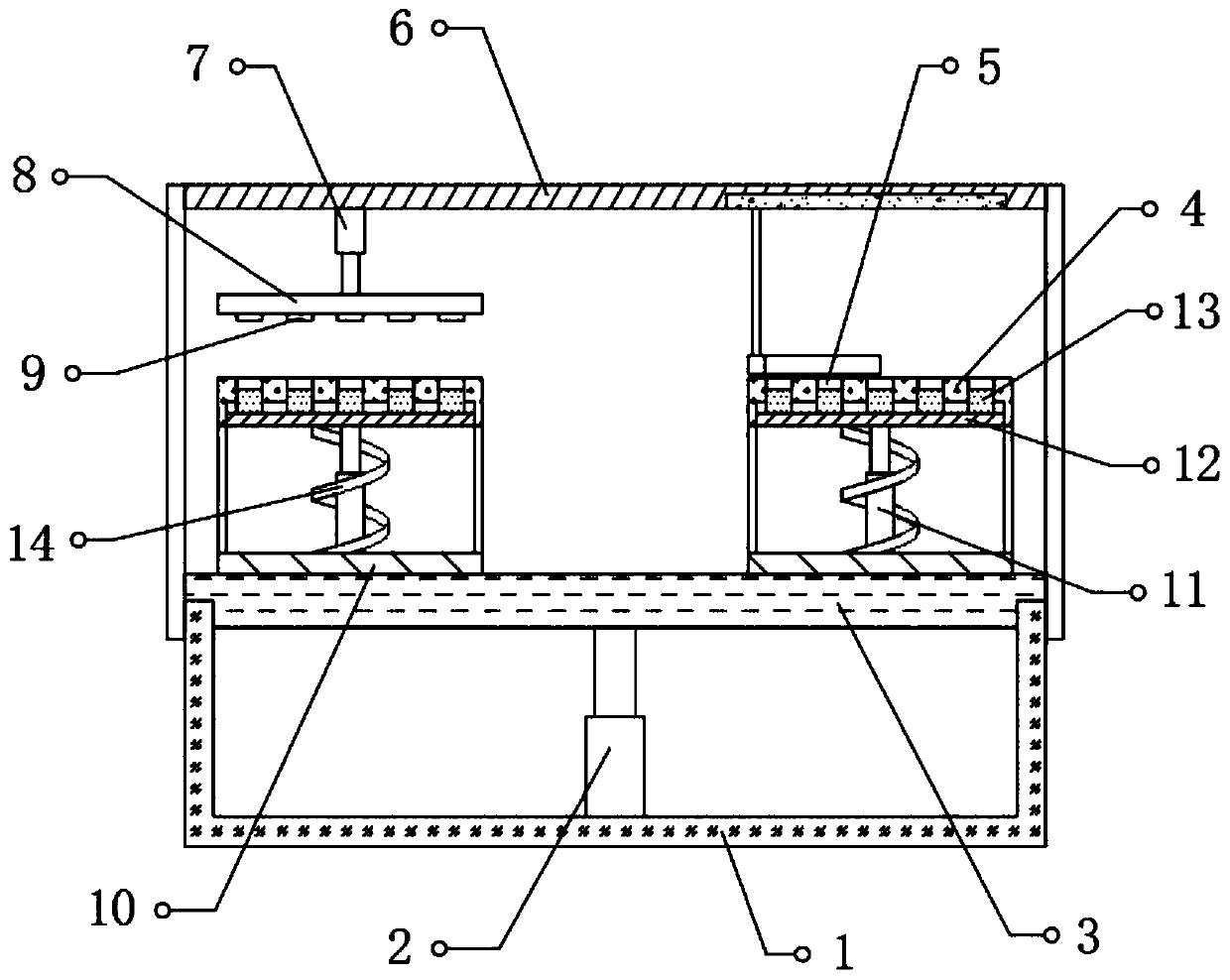

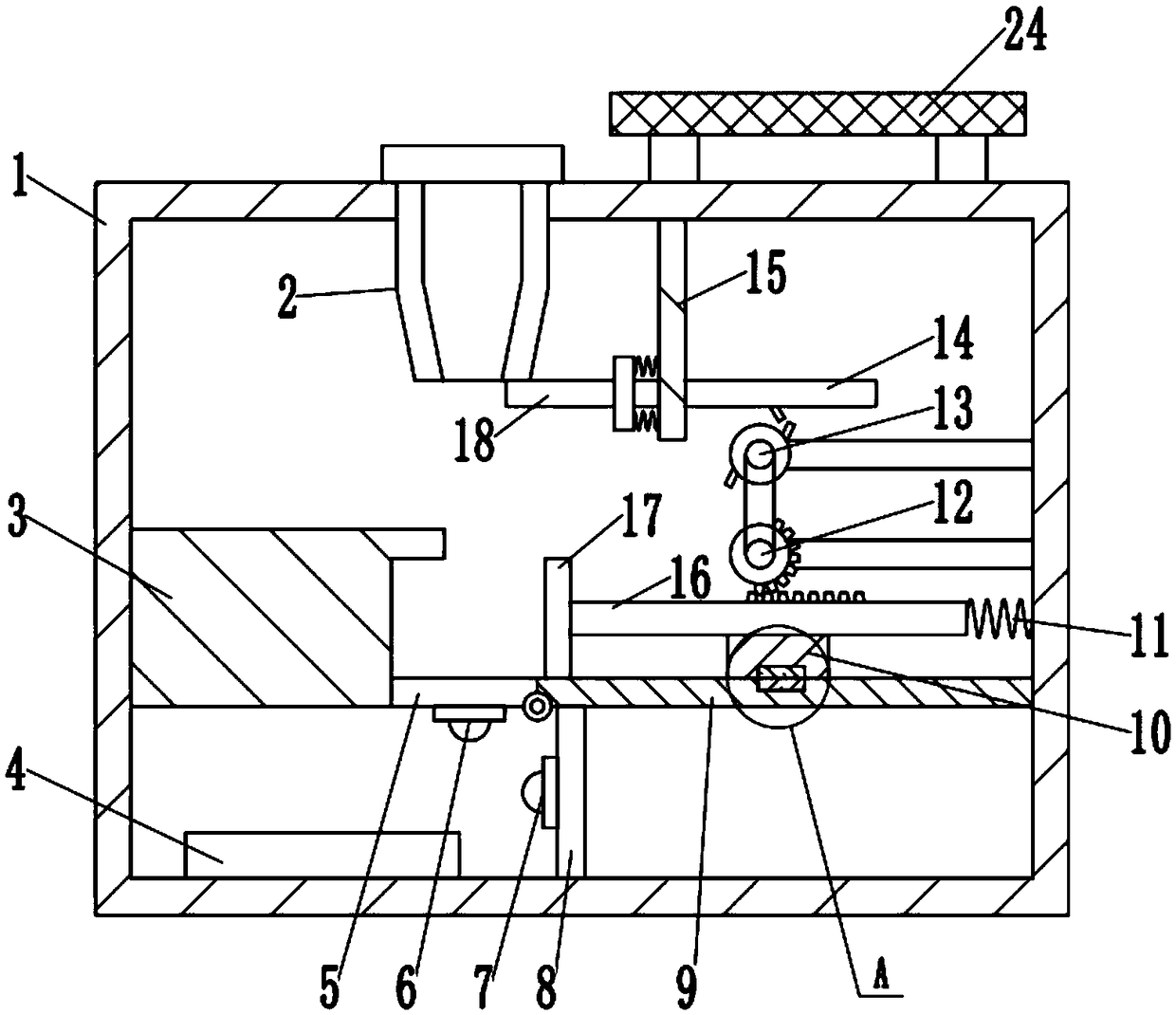

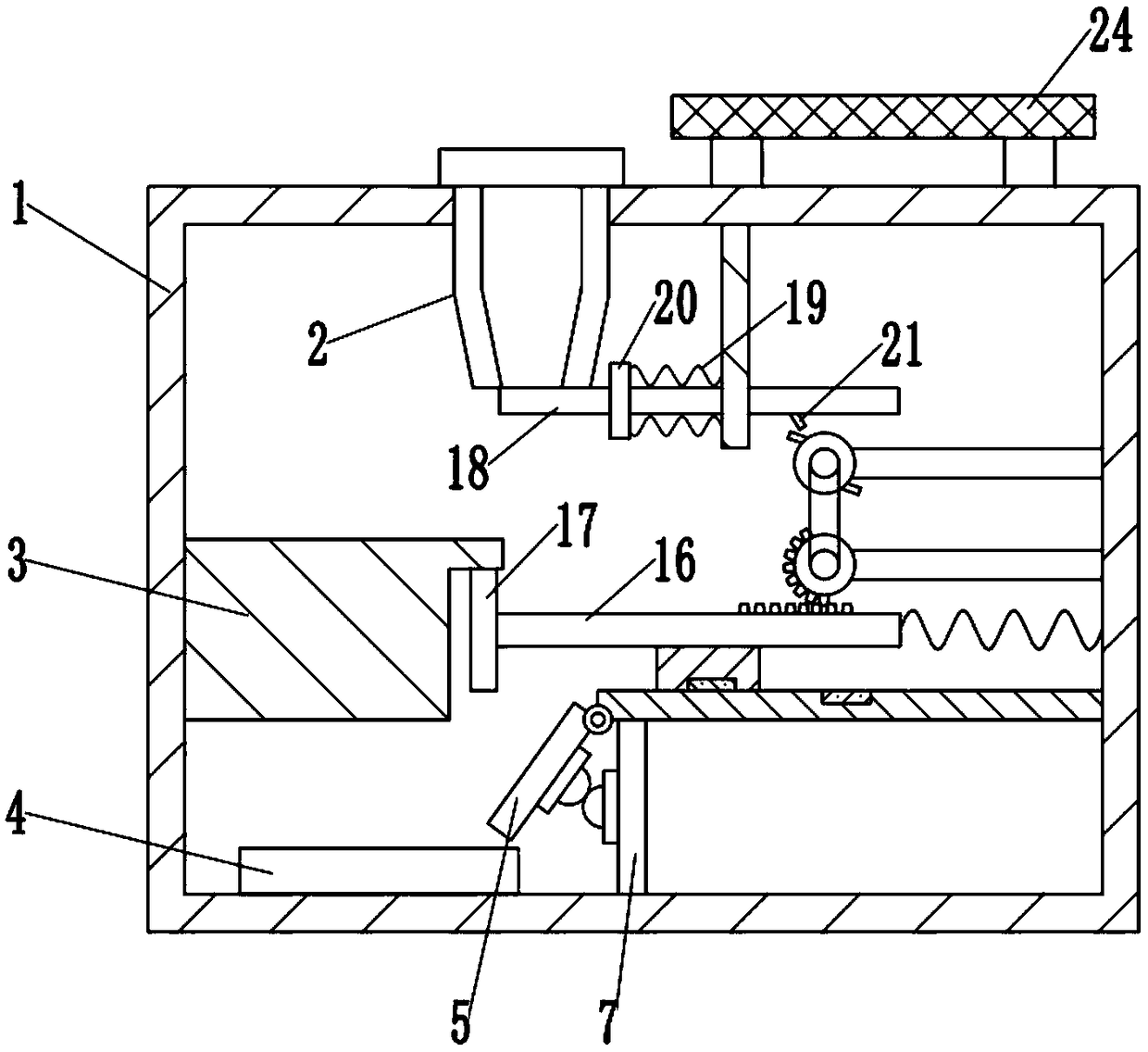

Waste metal screening equipment

InactiveCN112090492AEfficient screeningEasy to dischargeSievingGas current separationEnvironmental engineeringEnvironmental protection

The invention discloses waste metal screening equipment, and relates to the technical field of metal treatment. The waste metal screening equipment aims at solving the problems that existing screeningequipment is inconvenient to quickly screen materials and pour out screened materials, and meanwhile light impurities are inconvenient to remove. According to the scheme, the waste metal screening equipment comprises a treatment box, a crushing mechanism is arranged in the treatment box, supporting plates are fixedly connected to two sides of the treatment box, a screening mechanism is movably arranged in the supporting plates in a sleeved mode, a steering mechanism is fixedly connected to the left side of the screening mechanism, an air blowing mechanism is fixedly connected to the supporting plate located on the right side, and an extrusion mechanism fixedly connected with the supporting plates is arranged below the air blowing mechanism. According to the waste metal screening equipment, vibration screening is facilitated, the screening efficiency is improved, moreover, the screened materials can be conveniently poured down, rapid discharging is facilitated, some light impurities ona filter screen can be conveniently blown away, and the cleaning effect is improved.

Owner:安徽亿智新材料科技有限公司

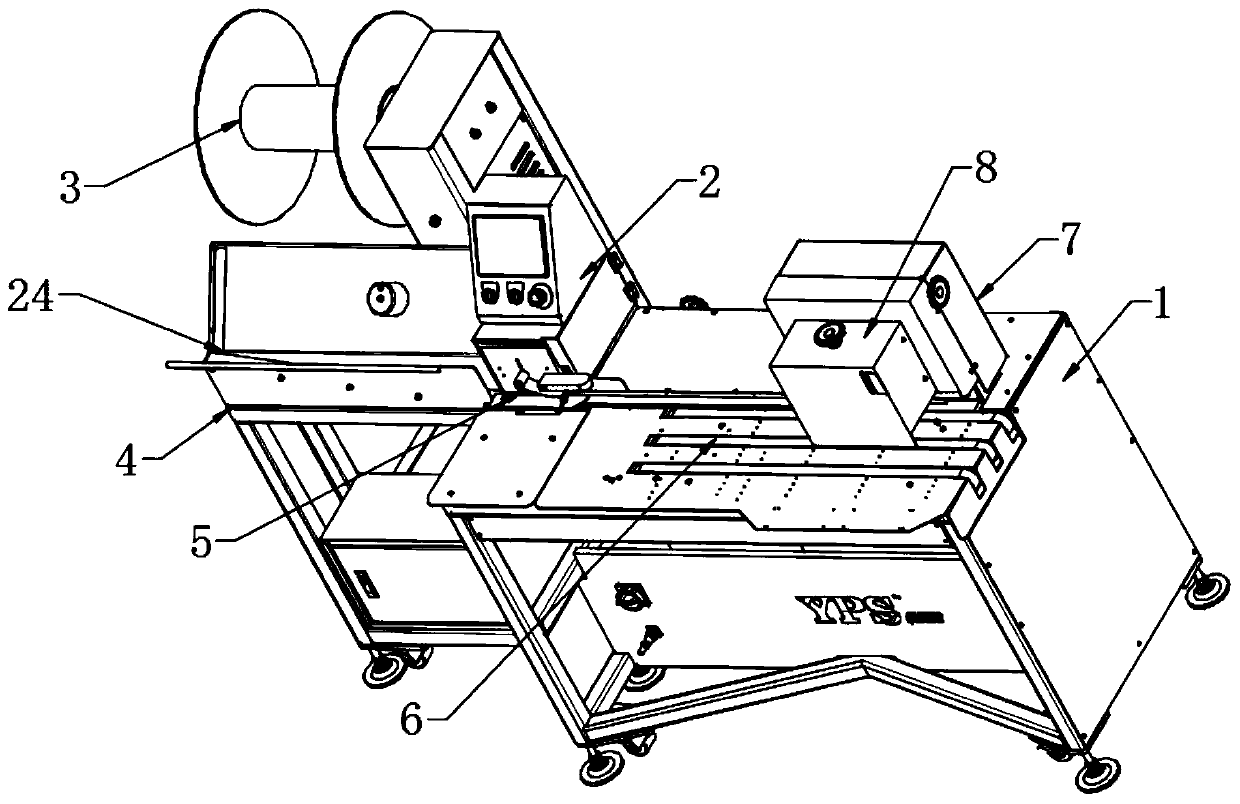

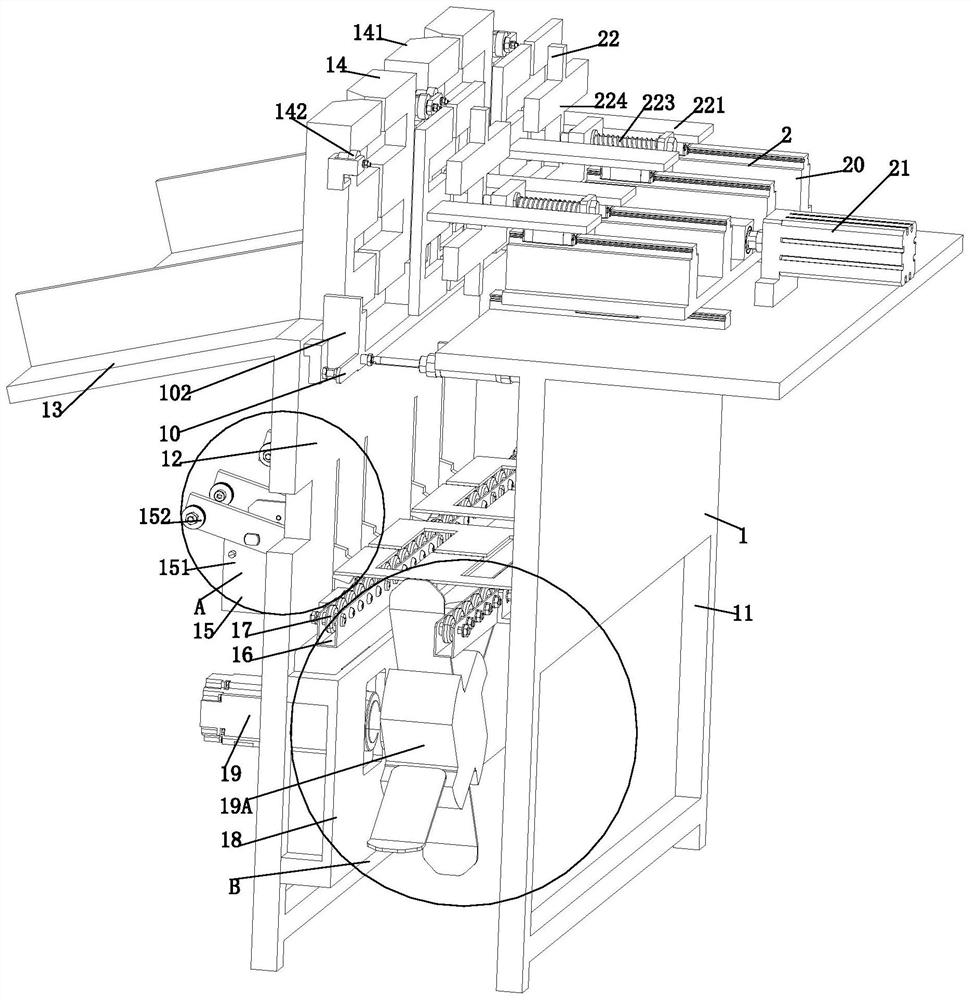

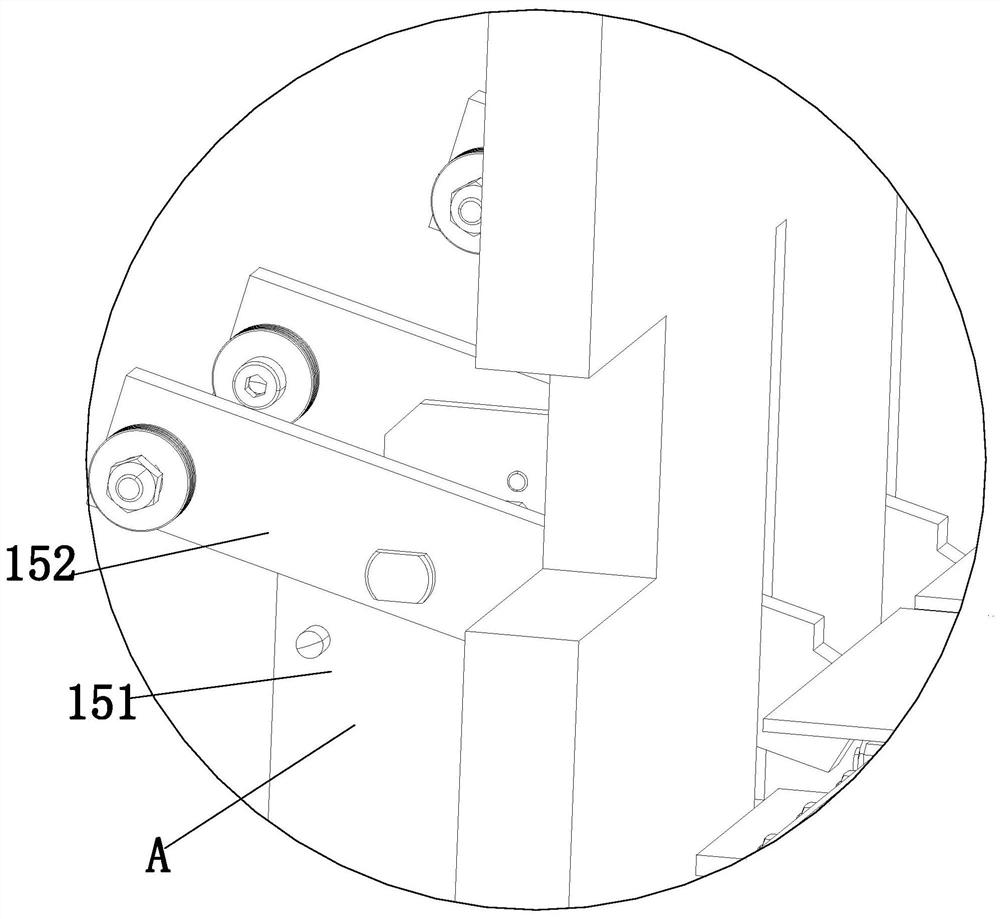

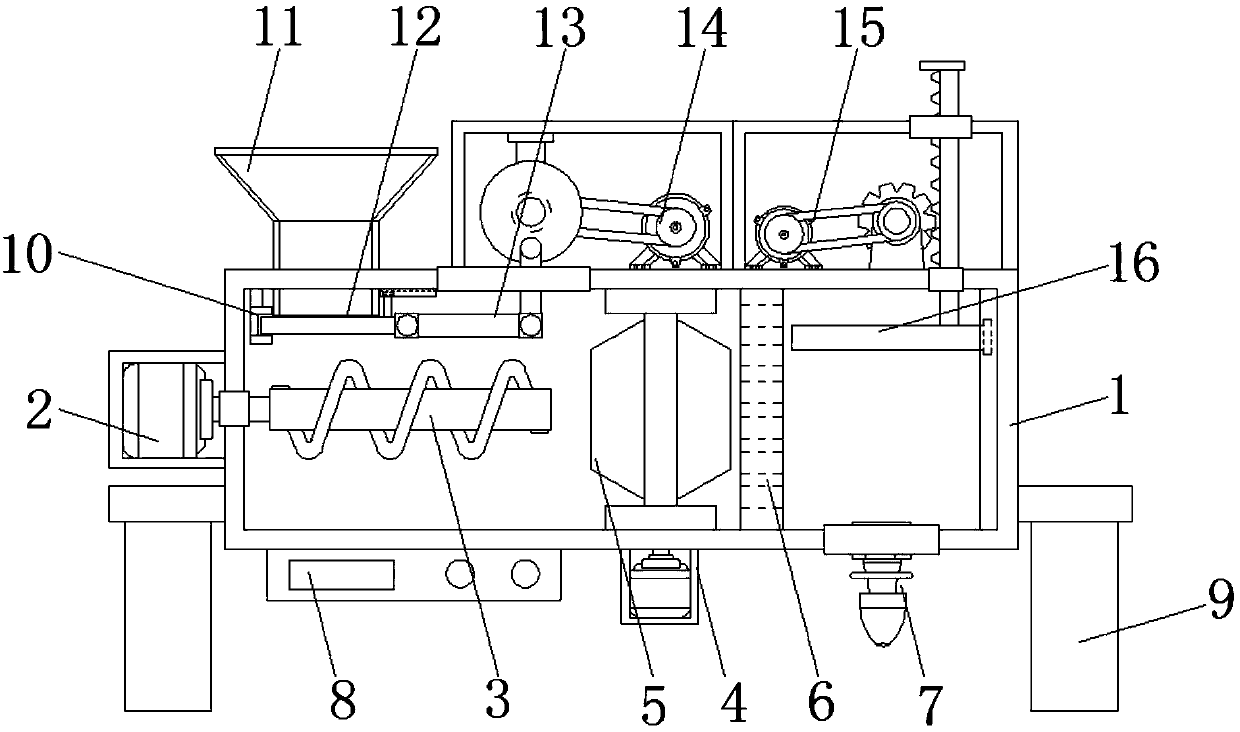

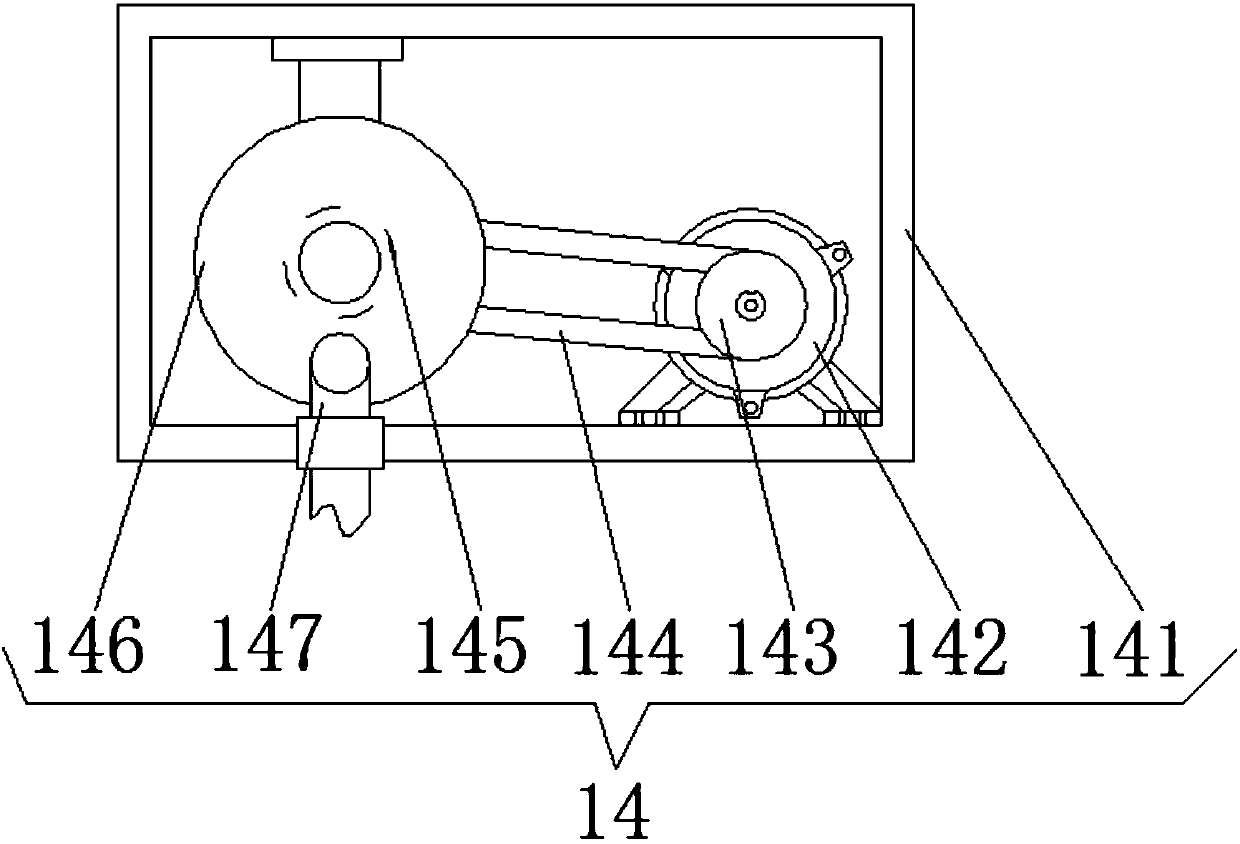

Binding machine

ActiveCN110341343AInconsistent locationEnhanced binding effectBook making processesEngineeringFixed position

The invention discloses a binding machine. The binding machine comprises a working table and a feeding frame, wherein the feeding frame is located on one side of the working table, a control assemblyis arranged on the surface of the working table, a conveying platform is arranged on the surface of the working table, a binding assembly is arranged on one side of the conveying platform, a positioning assembly is arranged on one side wall of the binding assembly, the positioning assembly is located above the conveying platform, a first fixing frame and a second fixing frame are fixedly connectedto the positioning assembly, supporting columns are connected between the first fixing frame and the second fixing frame, and movable frames are connected to the supporting columns in a lifting mode.According to the binding machine, the binding assembly is arranged, the positioning assembly is arranged on one side of the binding assembly, a to-be-bound workpiece can be conveyed to a fixed position through the conveying platform, then a positioning plate on the positioning assembly is used for preliminarily positioning a line circle, a pressing block is used for pressing a book, and the linecircle is flattened and positioned by utilizing a push plate on the binding assembly, so that the positions of the book and the line circle are prevented from being inconsistent, and the good bindingeffect can be ensured.

Owner:东莞市优品胜钉装科技有限公司

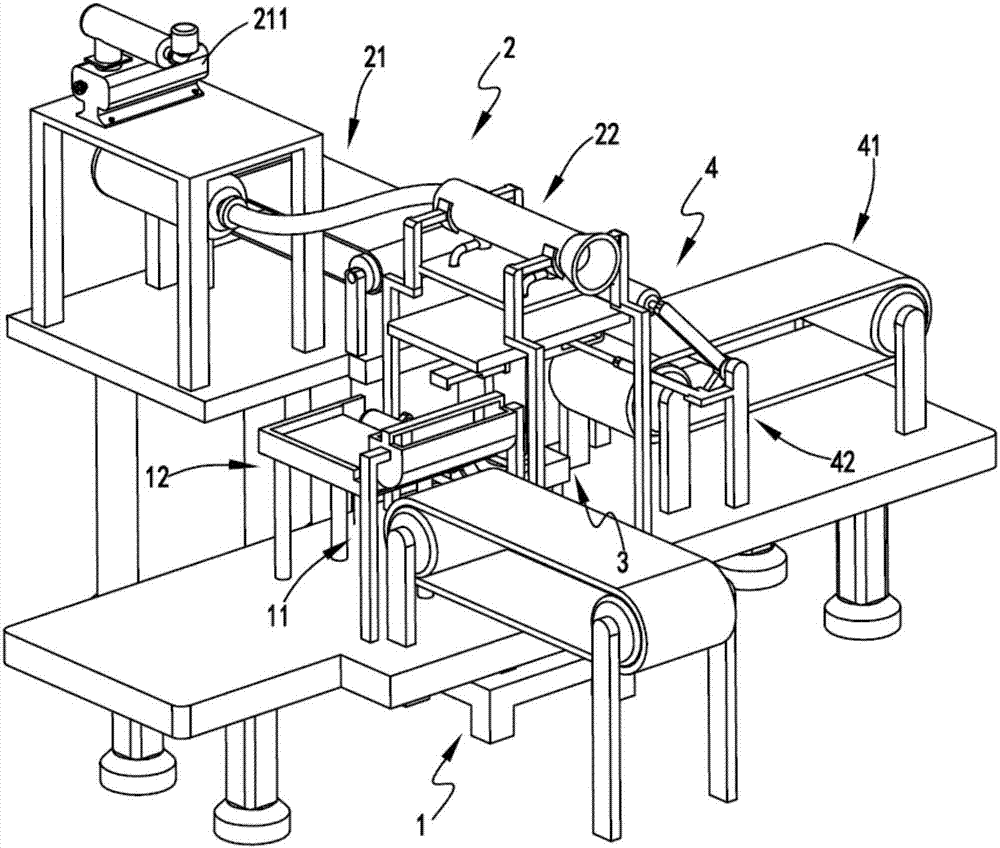

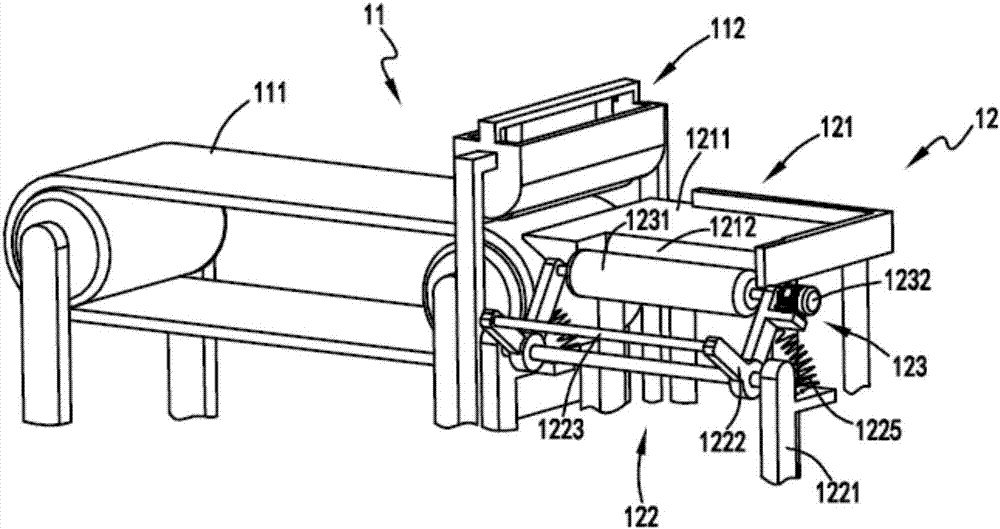

Paperboard quick coating paper production line

InactiveCN107415411ASimple structureEasy to dischargeLaminationLamination apparatusPaper sheetPaper production

The invention relates to a cardboard rapid paper-coating production line, comprising a cardboard feeding part, the cardboard feeding part includes a gluing mechanism and a feeding mechanism arranged at the rear end of the gluing mechanism; a protective paper feeding part, and a protective paper output part including a transmission mechanism And an adsorption mechanism for absorbing the protective paper transported by the transport mechanism and keeping the protective paper in a suspended state; the bonding part, the bonding part is arranged at the rear end of the feeding mechanism and the lower end of the adsorption mechanism, and the bonding part includes Accept the cardboard conveyed by the feeding mechanism, drive the cardboard to move upwards, and drive the cardboard and the protective paper attached to the cardboard to move down together after bonding with the protective paper on the adsorption mechanism; the output part, the output part includes setting The output mechanism at the rear end of the lifting mechanism and the pressure roller mechanism arranged between the lifting mechanism and the output mechanism; the invention overcomes the problems that the existing equipment does not have automatic material feeding and discharging, and the production efficiency of sheet metal stickers is low.

Owner:长兴鼎盛机械有限公司

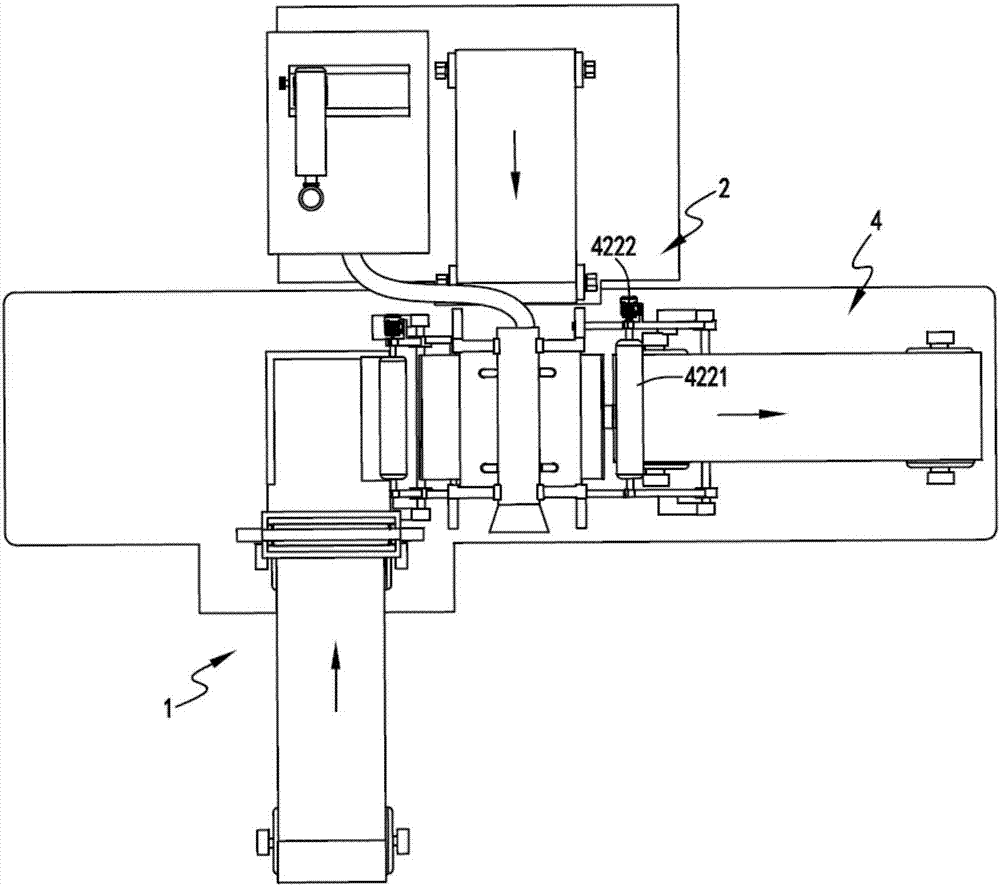

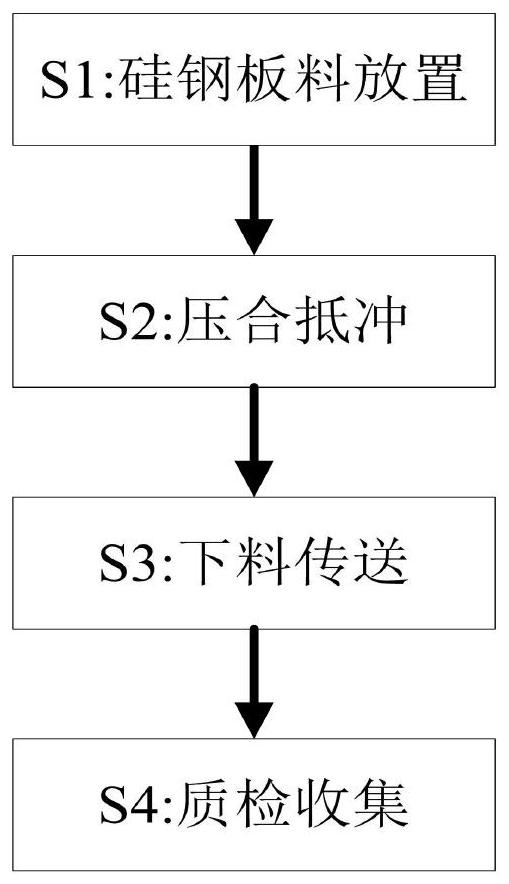

Three-phase transformer parts stamping method

ActiveCN111952066AEasy to slide and dischargeAvoid material jamsInductances/transformers/magnets manufacturePunchingTransformer

The invention provides a three-phase transformer parts stamping method which comprises a discharging mechanism and a stamping mechanism. The stamping mechanism is installed on the discharging mechanism in a sliding fit mode and is located right above the discharging mechanism. The method of the present invention solves the problems that stamping forming is adopted in the current production so as to guarantee the specification uniformity during large-batch production; many problems exist in the E-shaped iron core punching sheet production process at present, for example the fixing effect of silicon steel sheets in the machining process is worse, so that errors on the surfaces of the silicon steel sheets are increased easily in the punching process; and meanwhile, burrs on the surface of thepunching sheets are more, the quality of the surface of the punching sheets is reduced, and the quality of the iron cores directly affects the transmission power of a transformer.

Owner:青州市长城电力变压器股份有限公司

Separated type plastic extruding machine convenient to use

The invention discloses a separated type plastic extruding machine convenient to use. The separated type plastic extruding machine comprises an outer frame; a first motor is fixedly connected to the left side of the outer frame; one end of an output shaft of the first motor penetrates through the outer frame and extends into the interior of the outer frame; a stirring rod is fixedly connected to the end, located in the outer frame, of the first motor; a second motor is fixedly connected to the bottom of the outer frame; and one end of an output shaft of the second motor penetrates through theouter frame and extends into the interior of the outer frame. The invention relates to the technical field of plastic extruding machines. According to the separated type plastic extruding machine convenient to use, the purpose of increasing the heating and melting rate can be achieved, the working efficiency can be improved, the waste of time can be reduced, people can use the machine conveniently, meanwhile, energy can be saved, melted raw materials can be conveniently extruded, the extrusion quality can be improved, processing can be guaranteed, the raw materials can be convenient to enter,intermittent feeding can be realized, melting can be facilitated, plastic extruding can be facilitated, meanwhile, the stability of a device can be improved, and the service life of the device can beprolonged.

Owner:李庭裕

Automatic cosmetic lotion bottle

InactiveCN106966072AEasy to dischargeReduce adhesionDispensing apparatusBottlesScrew jointEngineering

The invention discloses an automatic cosmetic lotion bottle. The automatic cosmetic lotion bottle comprises a main bottle body, the middle of the top face of the main bottle body is provided with a lotion outlet screw joint extending upwards, a lifting motor is fixed to the middle of a bottom plate of the main bottle body, an output shaft of the lifting motor stretches out of the bottom plate of the main bottle body and is provided with a lifting screw sleeve in a screwing mode, the top end of the lifting screw sleeve is fixed to the middle of the bottom face of a lifting plate, an annular groove is formed in the outer side wall of the lifting plate, a seal ring is embedded into the annular groove, and the outer side wall of the seal ring elastically abuts against the inner side wall of the main bottle body; a bottle cover is connected to the lotion outlet screw joint in a screwed mode; an annular positioning convex ring is molded on the top face of the main bottle body, and an elastic gasket is inserted into the annular positioning convex ring in a sleeved mode. According to the automatic cosmetic lotion bottle, the lifting plate can be automatically lifted, then lotion is automatically extruded out of the main bottle body, and discharging is convenient; in addition, by lifting the seal ring, the lotion on the inner wall of the main bottle body can be scraped and lifted upwards, therefore, adhesion of the lotion on the inner wall of the main bottle body is reduced, the condition that the lotion remains in the main bottle body is reduced, and the utilization rate is increased.

Owner:徐文

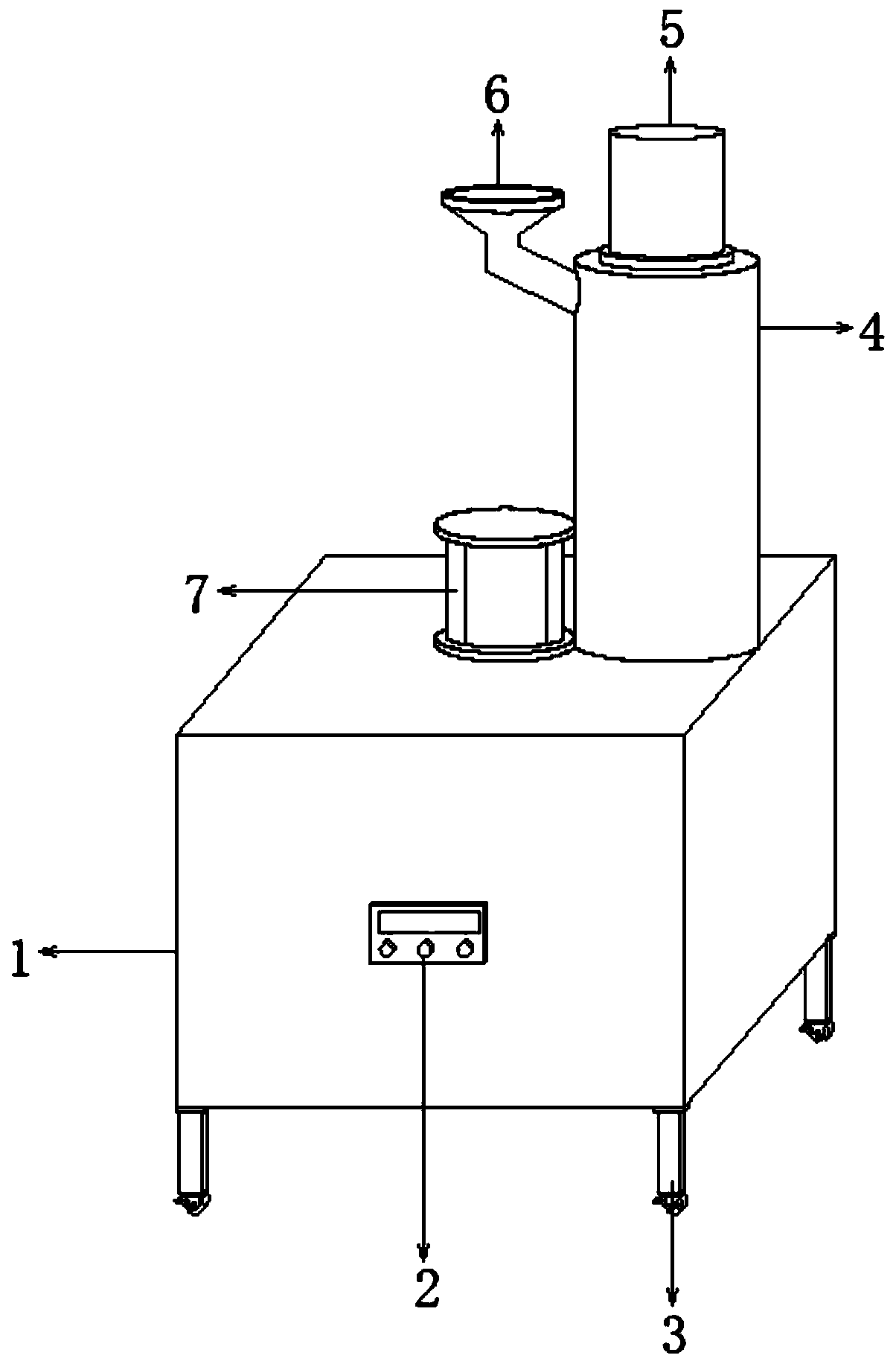

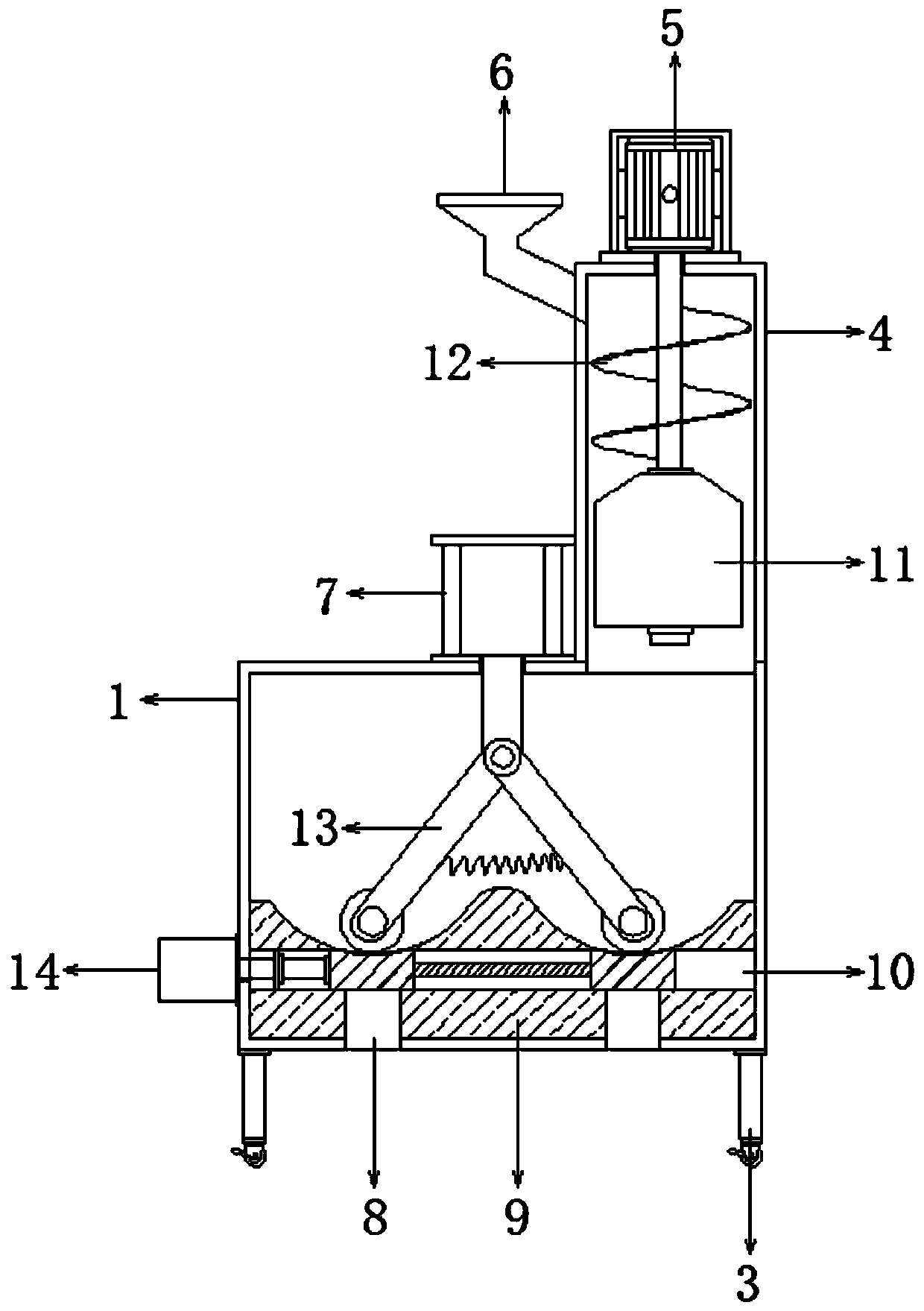

Blanking convenient molding powder stirring storage integrated machine

The invention discloses a blanking convenient molding powder stirring storage integrated machine, which comprises a base, a support plate, a cylinder, a rotary shaft, a material storage cylinder, a feeding door, a discharge door, and a scraping body. The cylinder is hollow internally, the hollow part of the cylinder is truncated cone-shaped, the top of the cylinder is provided with a cylinder cover, and several heating blocks are distributed on the cylinder inner wall. The rotary shaft stretches into the cylinder from the cylinder bottom center, and the rotary shaft's end outside the cylinder is connected to a motor. The material storage cylinder consists of an upper material storage cylinder and a lower material storage cylinder, the upper material storage cylinder is a cuboid box with an open lower end, and the lower material storage cylinder is an inverted top-removed rectangular pyramid. The inner juncture of the lower material storage cylinder and the upper material storage cylinder is arc-shaped, the top of the upper material storage cylinder is provided with the feeding door, a discharge port is connected to the feeding door, and the lower material storage cylinder is equipped with the discharge door at the bottom. The integrated machine provided by the invention enables raw materials to flip up and down during stirring, at the same time the raw materials close to the cylinder inner wall can also be flipped, so that the raw materials can be stirred evenly, and the product quality can be improved.

Owner:新昌县中邦塑粉科技有限公司

Raw material grinding device for chemical product research and development

The invention discloses a raw material grinding device for chemical product research and development. The raw material grinding device comprises a grinding box, wherein a grinding cylinder is fixedlyconnected to one side of the top of the grinding box; a feeding hopper is fixedly connected to the top of one side of the grinding cylinder; a material guide opening is formed between the bottom of the grinding cylinder and the top of the grinding box; a grinding seat is fixedly connected to the interior of the bottom of the grinding box; arc-shaped grinding grooves are formed in the two sides ofthe top of the grinding seat; discharging holes extending out of the grinding box are formed in the middle positions of the bottoms of the arc-shaped grinding grooves; a transverse groove is formed inthe middle position of the interior of the grinding seat; and an electric push rod is fixedly connected to the outer wall of the side, close to the transverse groove, of the grinding box. According to the raw material grinding device, raw materials are cut and cracked, primary grinding is carried out through a first grinding roller, and a rotating rod is adjusted to rotate in the grinding box, sothat a second grinding roller moves back and forth in the arc-shaped grinding grooves, and the raw materials are fully ground; and when the raw materials are discharged, the discharging holes are communicated, so that the device has the effect of facilitating discharging.

Owner:株洲兴润高分子新材料有限公司

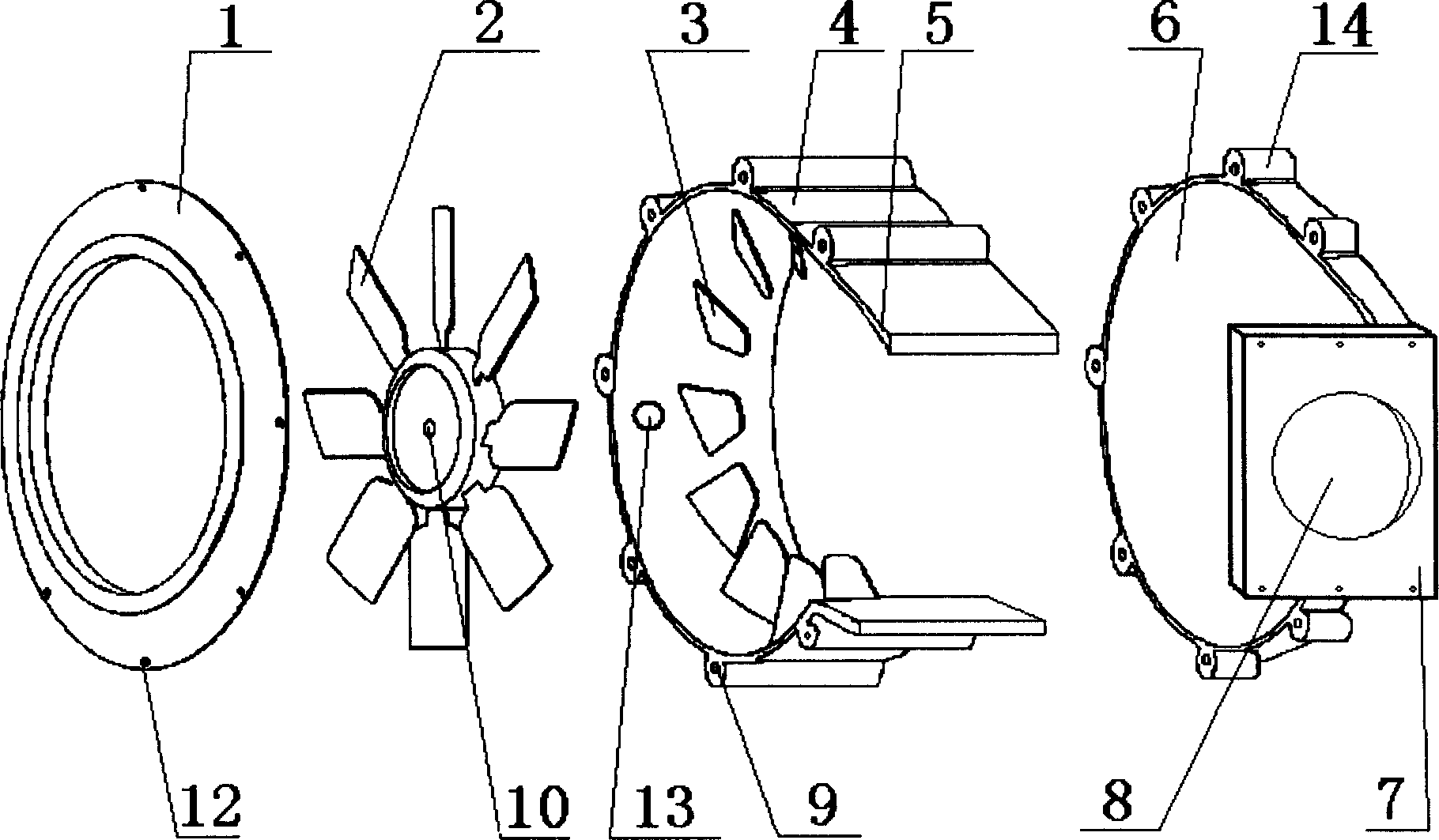

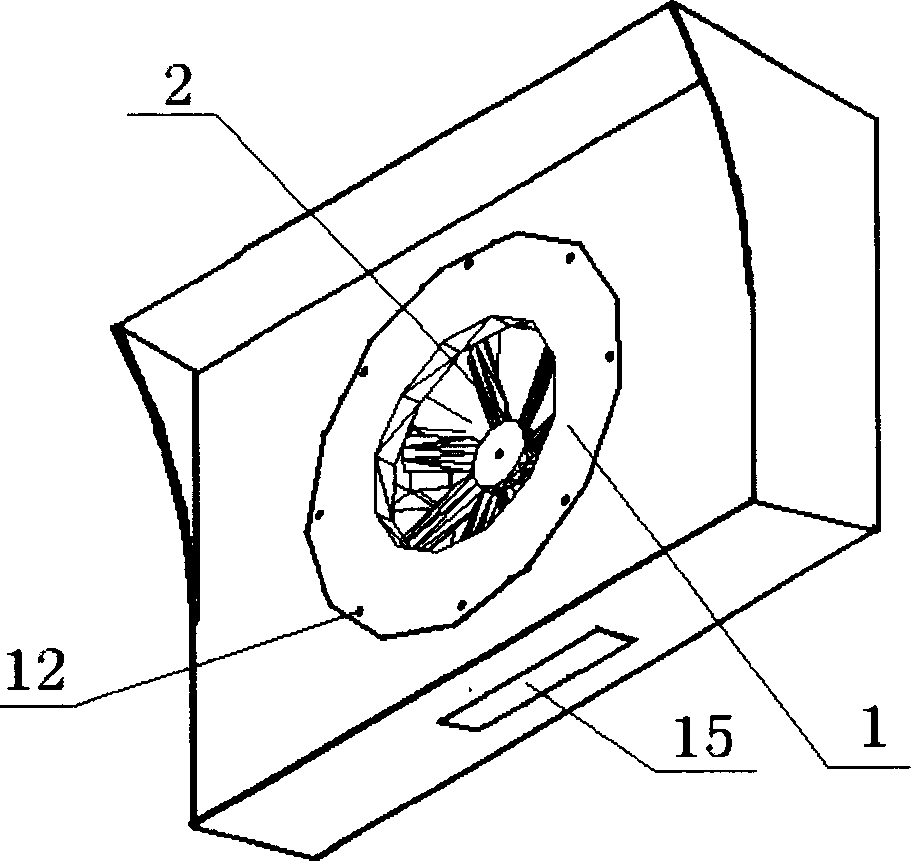

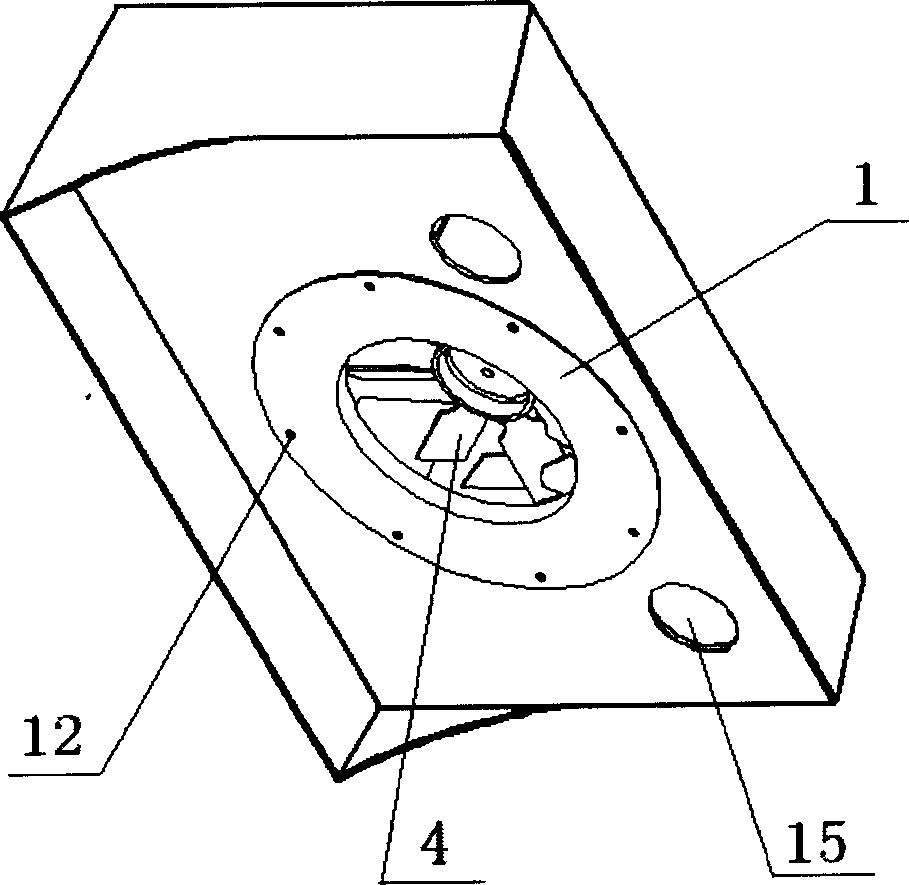

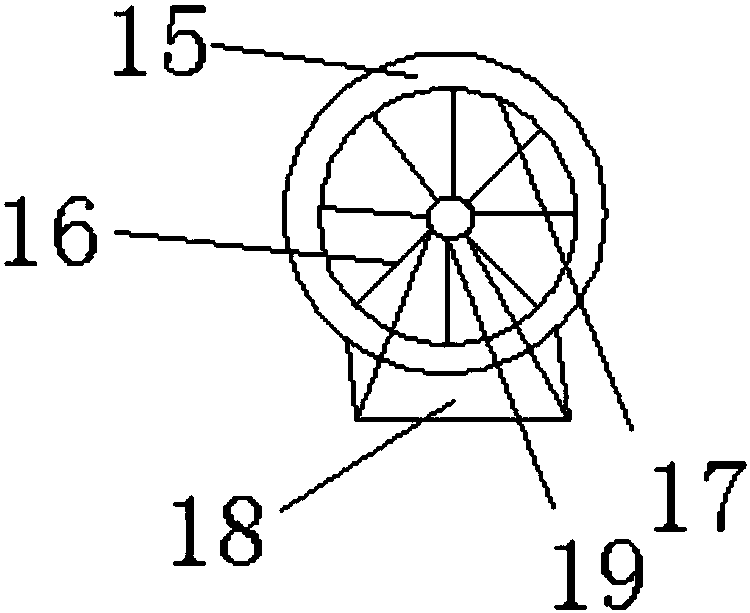

Smoke exhaust ventilator

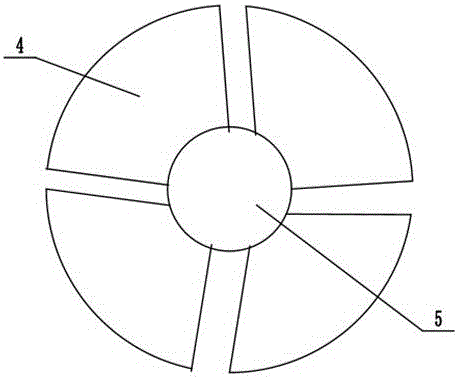

InactiveCN1789821AEasy to collectEasy to dischargeDomestic stoves or rangesLighting and heating apparatusImpellerExhaust fumes

This invention relates to one smoke exhaust ventilator with large power and green effect, which comprises the following technique points: The gas is absorbed from turbine shaft and is exhausted from the outside of the shaft; the turbine shaft is put inside wind bump with one end as panel and the other as flow guiding slice; the exhaust mouth is located around the circle; the oil exhaust mouth is located on the wind bump and panel formed space bottom. The invention mainly is used to remove the waste gas from production, experiment and cooking.

Owner:杨超敏

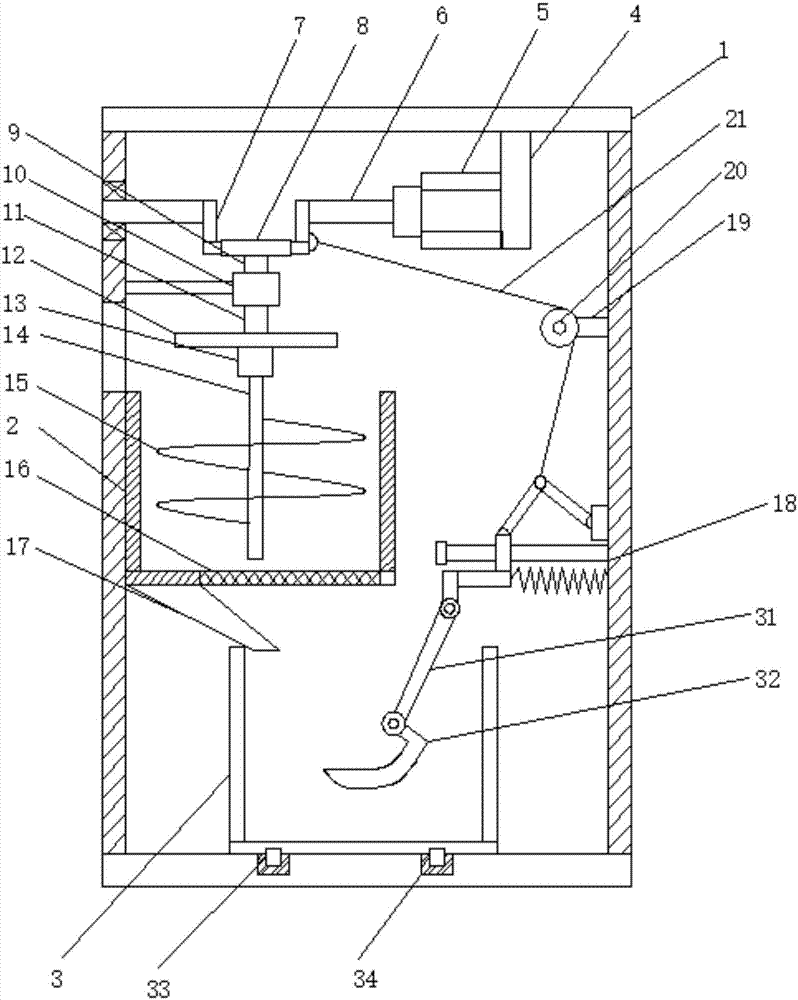

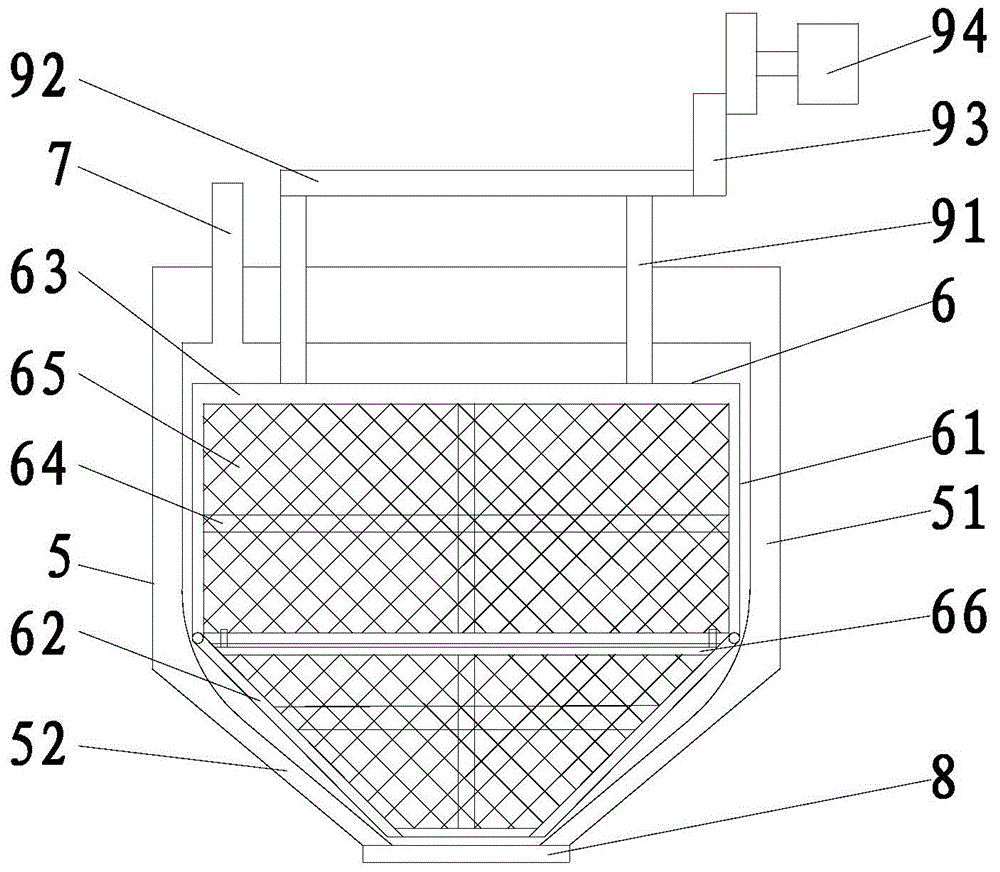

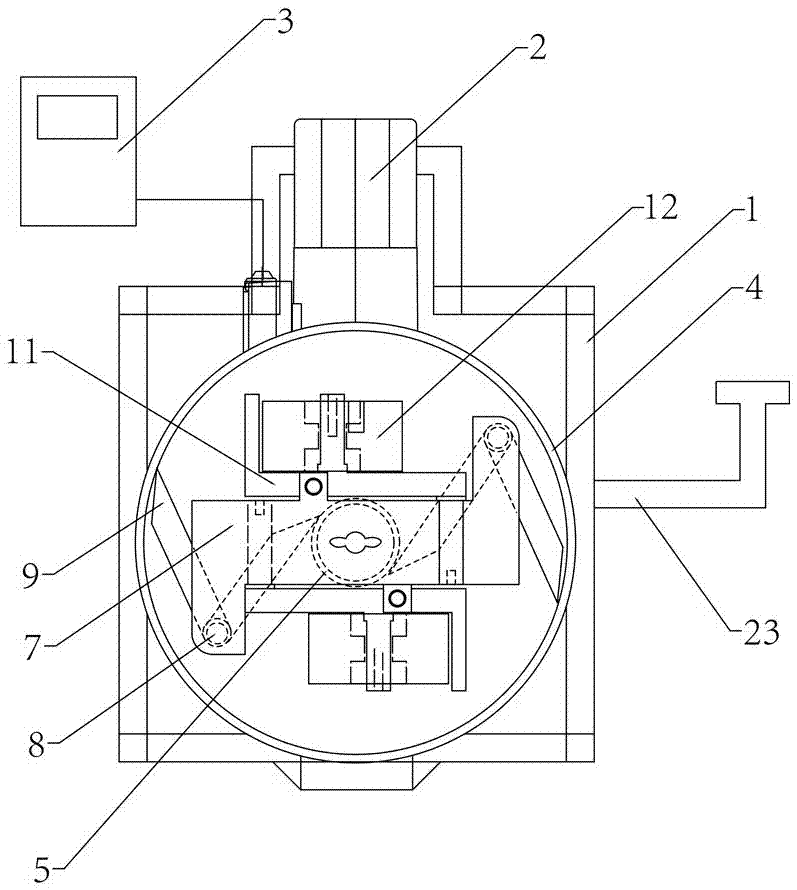

Screening machine with protective function on megestrol acetate tablets

InactiveCN108526013AEasy feedingEasy to dischargeSievingGas current separationEngineeringMegestrol acetate

The invention discloses a screening machine with a protective function on megestrol acetate tablets. The screening machine comprises a machine body, a screening roller, biting teeth and a connecting shaft; a damping pedestal is arranged at the bottom of the machine body; a vibrating motor is arranged in the machine body; a connecting spring is arranged on one side of the vibrating motor; a first screening chamber is arranged above the connecting spring; a first discharging port is formed in one side of the first screening chamber; a clamping block is arranged above the first screening chamber;a screen penetrates into the clamping block; a second screening chamber is arranged above the screen; a supporting block is arranged above one side of the second screening chamber; a second discharging port is formed in one side of the supporting block; the screening roller is arranged above the supporting block; and a handle is arranged on one side of the screening roller. The screening machinewith the protective function on the megestrol acetate tablets is provided with the screen, and the screen can screen out tiny tablets or powder, so that the tablets can be classified well and the waste tablets can be classified and recovered well.

Owner:青岛国海生物制药有限公司

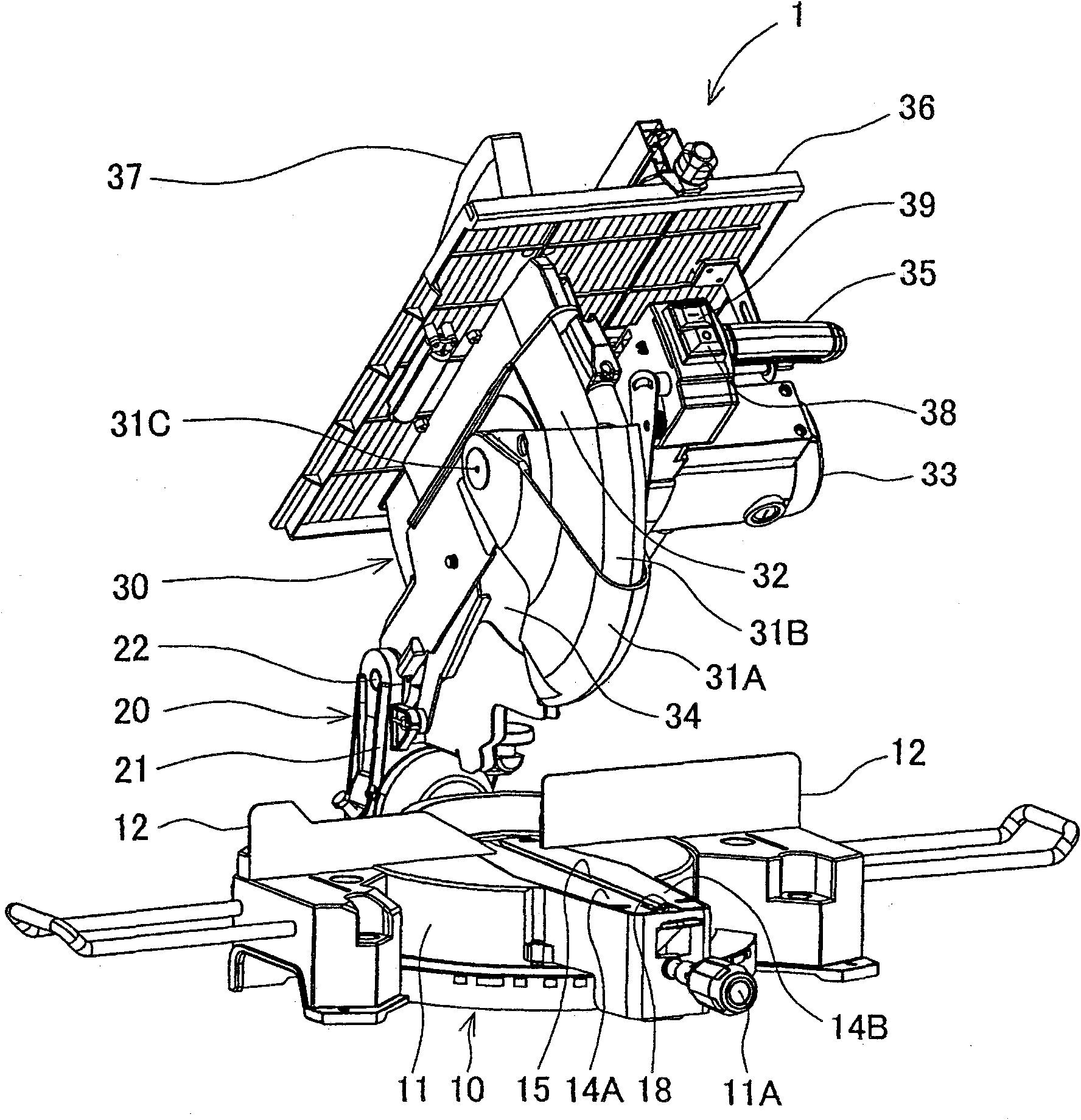

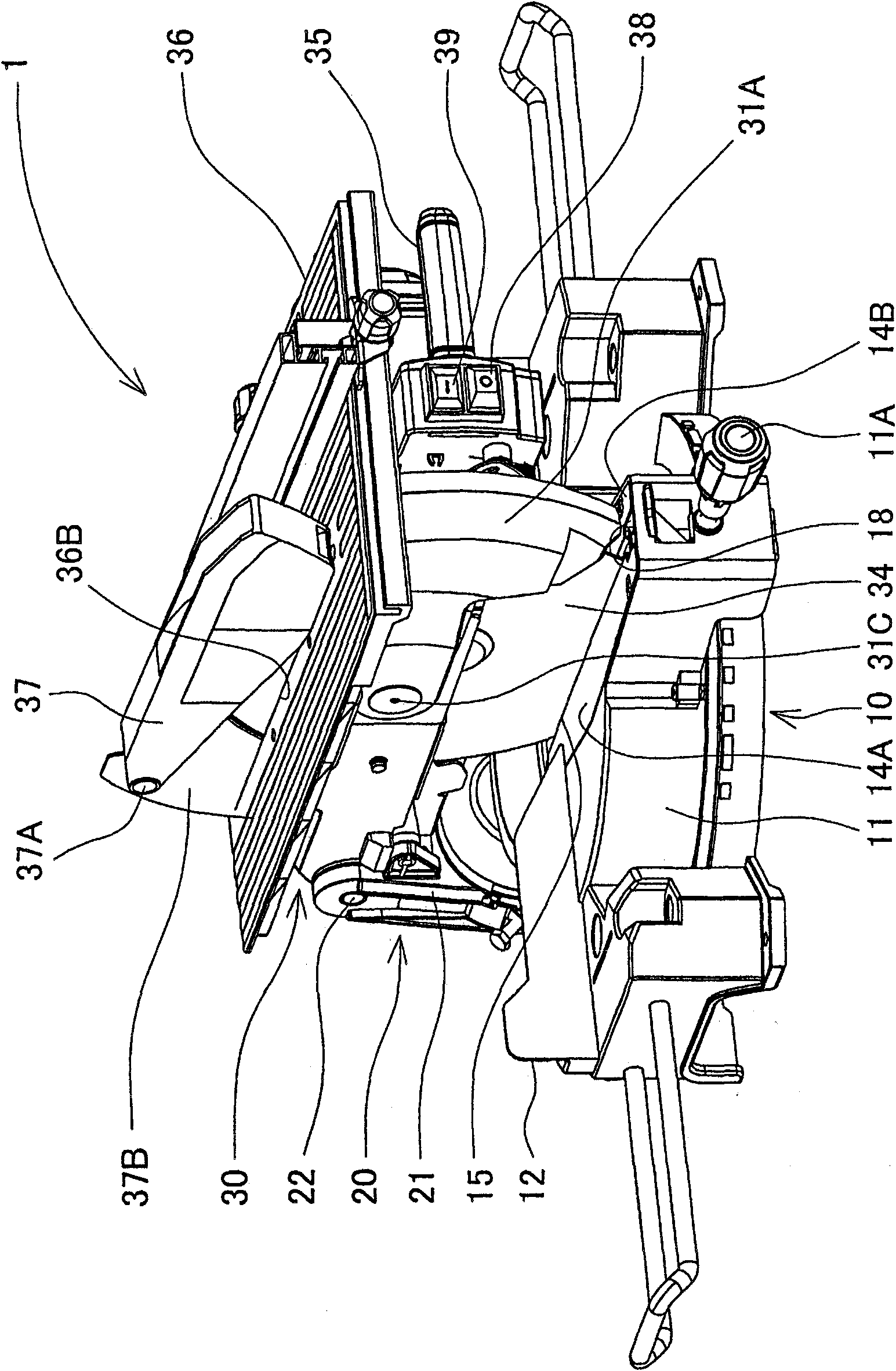

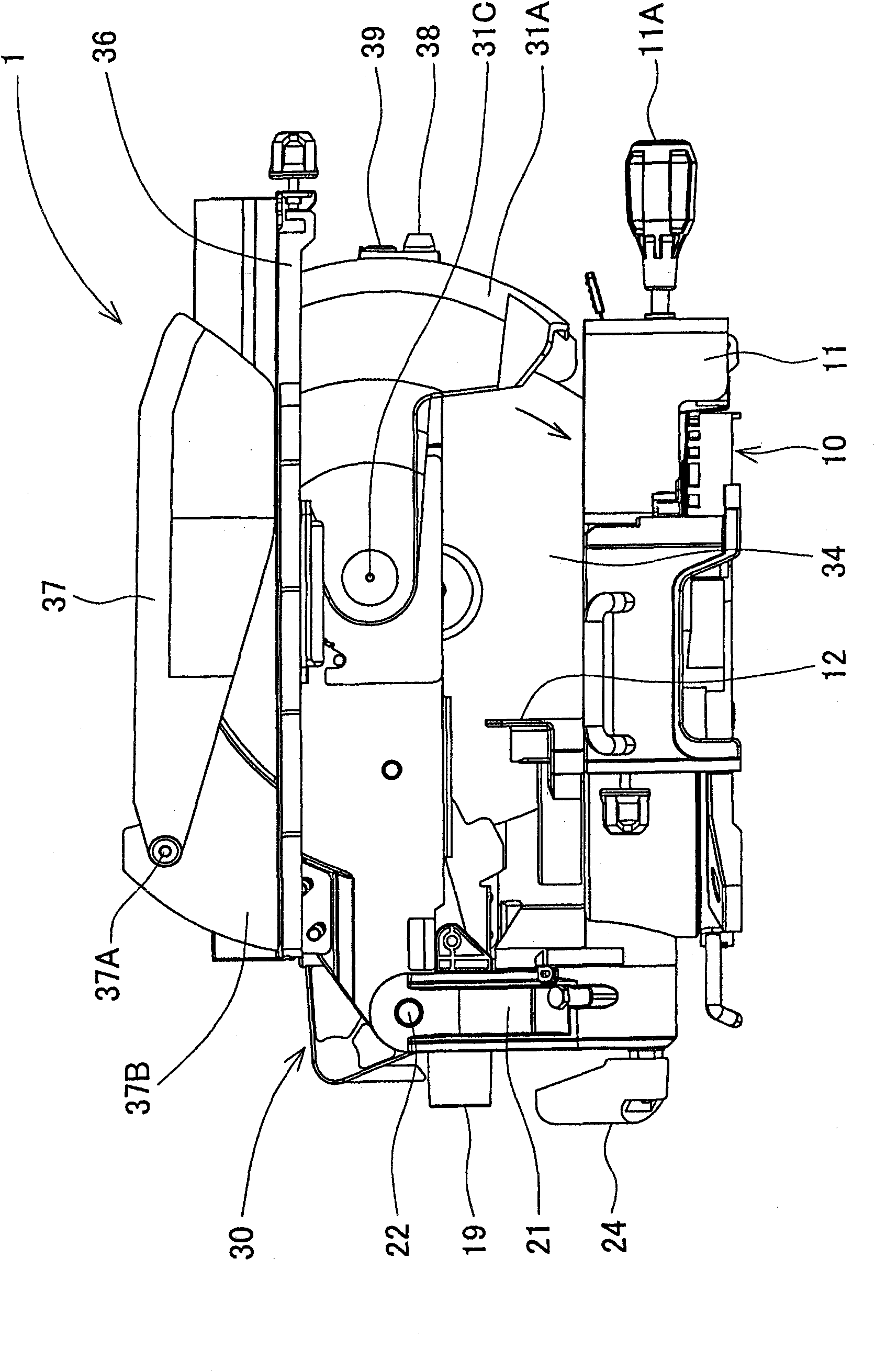

Desk type circular saw with upper table

InactiveCN101844249AEasy to operateEasy to dischargeMetal sawing devicesMetal sawing accessoriesCircular discCircular saw

The invention provides a desk type circular saw with an upper table which can please the operator in the working process and can promote the operation property. A main body is arranged on the upper surface of a base, is capable of moving vertically and is provided with a rotatable saw blade. A safety cover which is arranged on the main body is rotatable between a covering position and an opening position following the upward and downward movement of the main body; a cutter edge plate with a clearance is arranged on the upper surface of the base; the saw can enter in the clearance following the descending of the main body; an upper table is arranged on the upper part of the main body; the upper edge of the saw passes through the upper table when the main body is at a defined descending position; and the cutting material can slide back and forth on the upper surface of the upper table, wherein a chip inlet spaced from the clearance is arranged in front of the clearance on the upper surface of the base. When the main body is at a defined descending position, the chips generated by cutting the material on the table can be guided into the chip inlet through the safety cover at the opening position.

Owner:MAKITA CORP

Energy-saving wool compacting device with convenient discharge function

The invention discloses an energy-saving wool compacting device with a convenient discharge function. The energy-saving wool compacting device comprises a compacting box. A feeding opening is formed in the top of the compacting box. A feeding channel is arranged on the upper side in the compacting box. A limiting plate is fixedly mounted on the top wall of the compacting box. A sliding rod is slidably mounted on the lower portion of the limiting plate. A limiting block is fixedly mounted at the left end of the sliding rod. A material blocking plate is fixedly connected with the left side of the limiting block. A stopping block is obliquely mounted on the lower right side of the sliding rod. A round disc is rotatably mounted on the position, below the right side of the sliding rod, in the compacting box. Two lifting levels matched with the stopping block are symmetrically mounted on the round disc. Wool can uniformly fall in the compacting box. A movable rod moving leftwards and rightwards drives a pressing block to press the wool into blocks, and the block forming effect is excellent.

Owner:张连军

Multifunctional feed stirring device

InactiveCN107551862AEasy to useEasy to dischargeFeeding-stuffRotary stirring mixersEngineeringDisplay device

The invention discloses a multifunctional feed mixing equipment, which comprises a driven wheel device, a belt, a motor, a handle, an anti-slip handle, a display, a wheel device, a power distribution box, a gravity sensor inclined block, a discharge port, and a spiral stirring rod , feed inlet, mixing barrel, exhaust port, the inclined plane of the gravity sensing inclined block is connected with the mixing barrel by welding, the outlet is located at the tail of the mixing barrel and connected by welding, the upper end of the spiral stirring rod is connected with the mixing barrel from The driving wheel device is connected, the lower end is connected with the discharge port, the feed port is located on the side wall of the mixing tank, and the exhaust hole is located at the top of the mixing tank, close to the driven wheel device. The wheel of the present invention has fixed feet, which is more stable when used, and has a gravity sensing inclined block, which is convenient for weighing during stirring. It is equipped with a power distribution box, which is more convenient to use.

Owner:重庆新动生物技术有限公司

A material mixing machine suitable for viscous materials and a material mixing method for viscous materials

InactiveCN106861489AEvenly mixedEasy to dischargeTransportation and packagingRotary stirring mixersViscosityViscous material

The invention relates to a material mixing machine suitable for viscous materials and a material mixing method for viscous materials. The material mixing machine includes a rack, a material mixing device disposed on the rack and a motor disposed on the rack. The material mixing device includes a material mixing drum, a platform disposed in the material mixing drum, scraping plates disposed on the platform and runner wheels disposed on the platform. The material mixing drum is a cylindrical drum. A core tube is disposed in the material mixing drum. The tube axle of the core tube and the central axis of the material mixing drum coincide. A platform shaft penetrates through the core tube. The bottom of the platform shaft is in transmission connection with the motor after passing through the core tube. The platform is disposed at the top of the platform shaft. The lower platform surface of the platform is provided with scraping plate shafts. The scraping plates are disposed on the scraping plate shafts. The scraping plates include outer scraping plates the end edges of which are in contact with the side wall of the material mixing drum and inner scraping plates the end edges of which are in contact with the side wall of the core tube. A wheel support is disposed on the platform. The runner wheels are mounted the bottom end of the wheel support. The wheel support is provided with scraping sheets in contact with the circumference surface of the runner wheels. The material mixing machine and the method are suitable for materials with various sizes of viscosity, and can achieve uniform material mixing and no dead angle.

Owner:HEBEI LIFU CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com