A material mixing machine suitable for viscous materials and a material mixing method for viscous materials

A technology of mixing machine and material, which is applied to mixing methods, mixers with rotary stirring devices, mixers, etc., can solve the problems of poor mixing effect and unsuitable viscous materials, etc., and achieve convenient material discharge and material mixing Uniform, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: A mixer suitable for viscous materials.

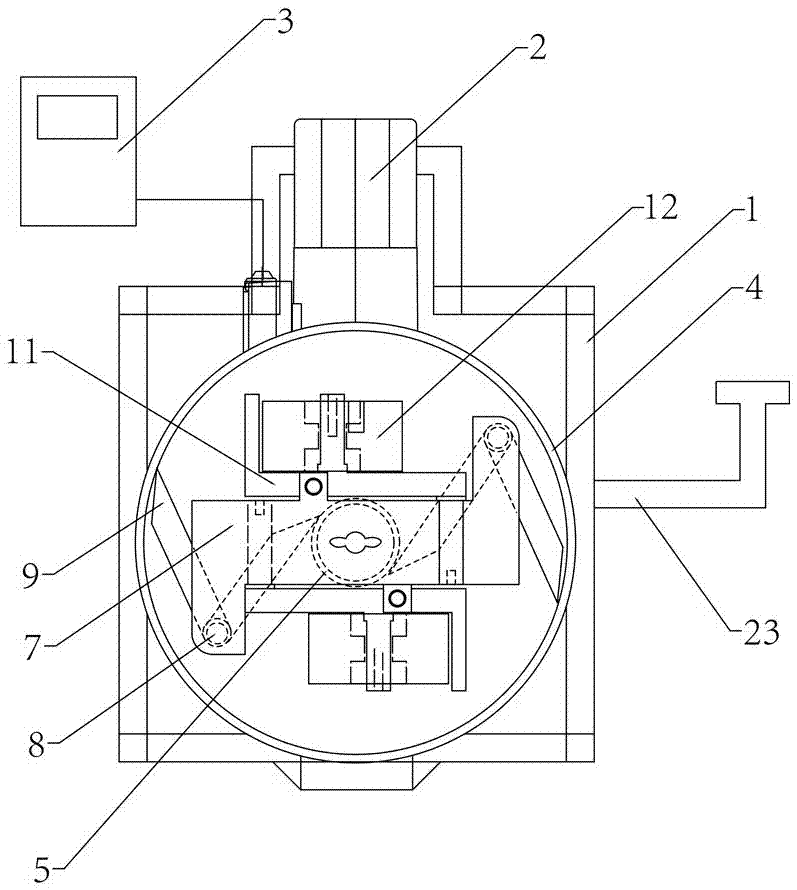

[0037] like figure 1 As shown, the present invention mainly includes parts such as frame 1, mixing device, motor 2 and control device 3.

[0038] Frame 1 comprises motor support and mixing tank support, and mixing tank support is arranged on the motor support, is provided with turning handle 23 on the motor support, after mixing finishes, pull turning handle 23, motor support, motor 2 , Mixing barrel 4 are turned over together to facilitate unloading.

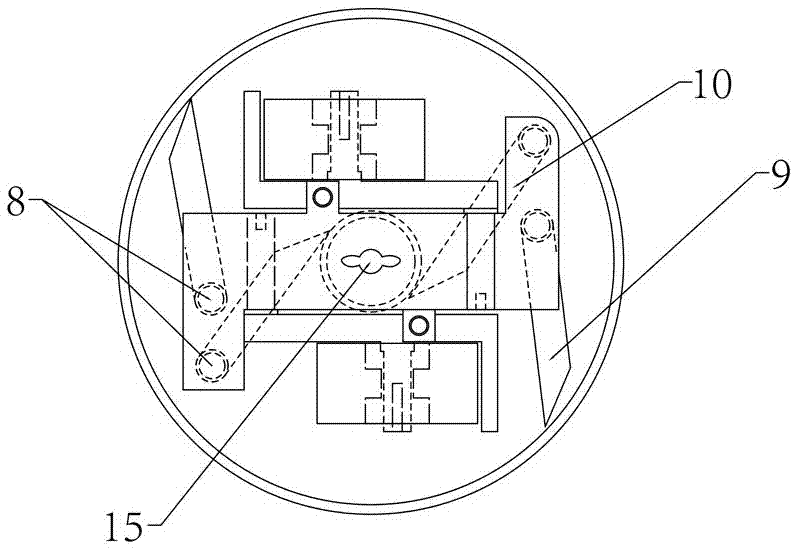

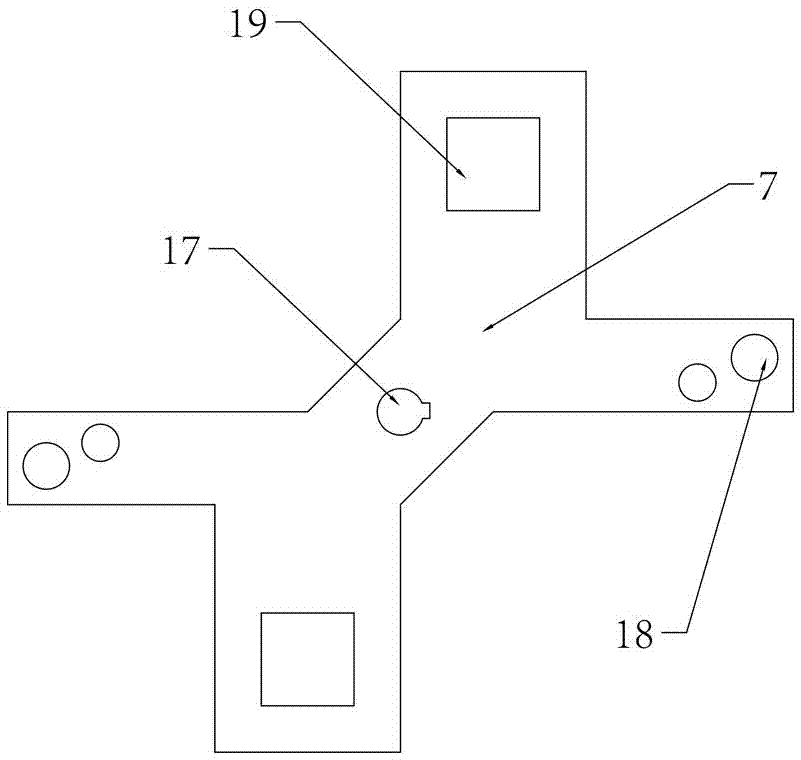

[0039] The mixing device includes a mixing tank 4 , a platform 7 arranged in the mixing tank 4 , and a scraper and a grinding wheel 12 arranged on the platform 7 .

[0040] The mixing tank 4 is a cylindrical barrel with an open top as the inlet of the material. For preventing the material in the tank from being polluted, a bung is provided on the top of the mixing tank 4 . A through hole is provided at the center of the barrel bottom plate of the mixing tank 4, and ...

Embodiment 2

[0053] Embodiment 2: the mixing method of viscous material.

[0054] The mixing method of viscous material comprises the following steps:

[0055] 1. The mixing machine mentioned in the embodiment 1 is set, the bung of the mixing tank 4 is opened, and the material to be mixed is added in the mixing tank 4.

[0056] 2. Set the rotation speed and time according to the material characteristics, the control device 3 controls the motor 2 to start, the motor 2 rotates, and the platform shaft 6 drives the platform 7 to rotate, and the scraper and the roller 12 set on the platform 7 also rotate accordingly , during the rotation process, the grinding wheel 12 rolls the material in the barrel, so that the material adheres to the inner side wall of the mixing barrel 4 and the outer side wall of the core tube 5, and the outer scraper 9 will adhere to the inner side wall during the rotation process. The material on the inner wall of the mixing tank 4 is scraped off, and the inner scraper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com