Waste PET (Polyester) heat-proof tackifying and reinforcing composite material and preparation process thereof

A technology for reinforcing composite material and preparation process, which is applied in the field of waste PET heat-resistant and tackifying reinforced composite material and its preparation process, can solve the problems of inability to mix waste PET and auxiliary agents uniformly, poor product quality, etc., and achieves delaying oxidation or automatic Effects of oxidation process, viscosity enhancement, shortening cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation process of waste PET heat-resistant and tackified reinforced composite material, which includes the following steps:

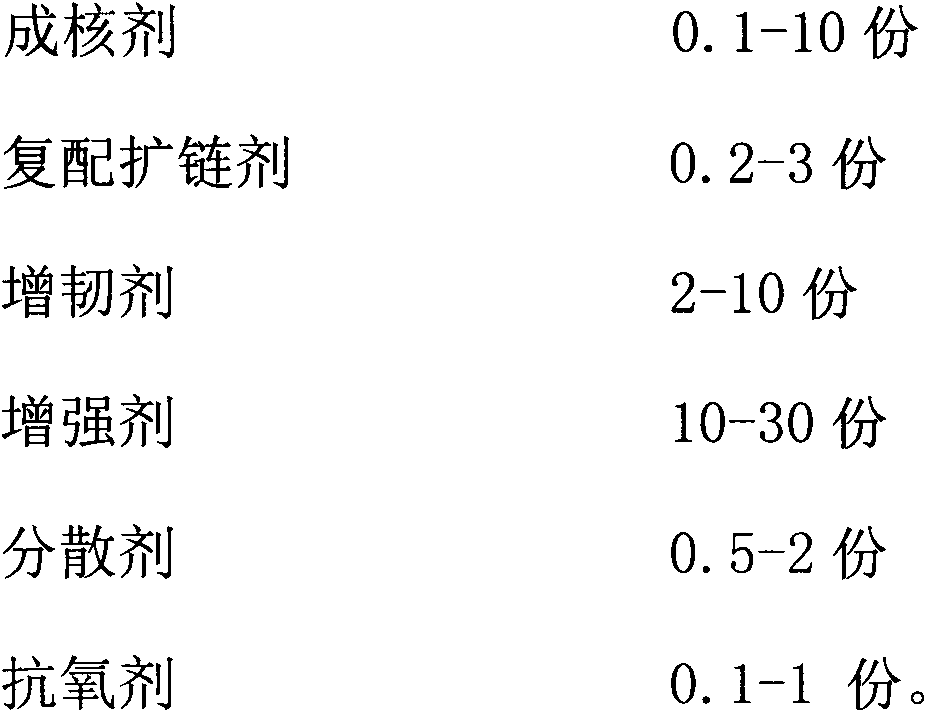

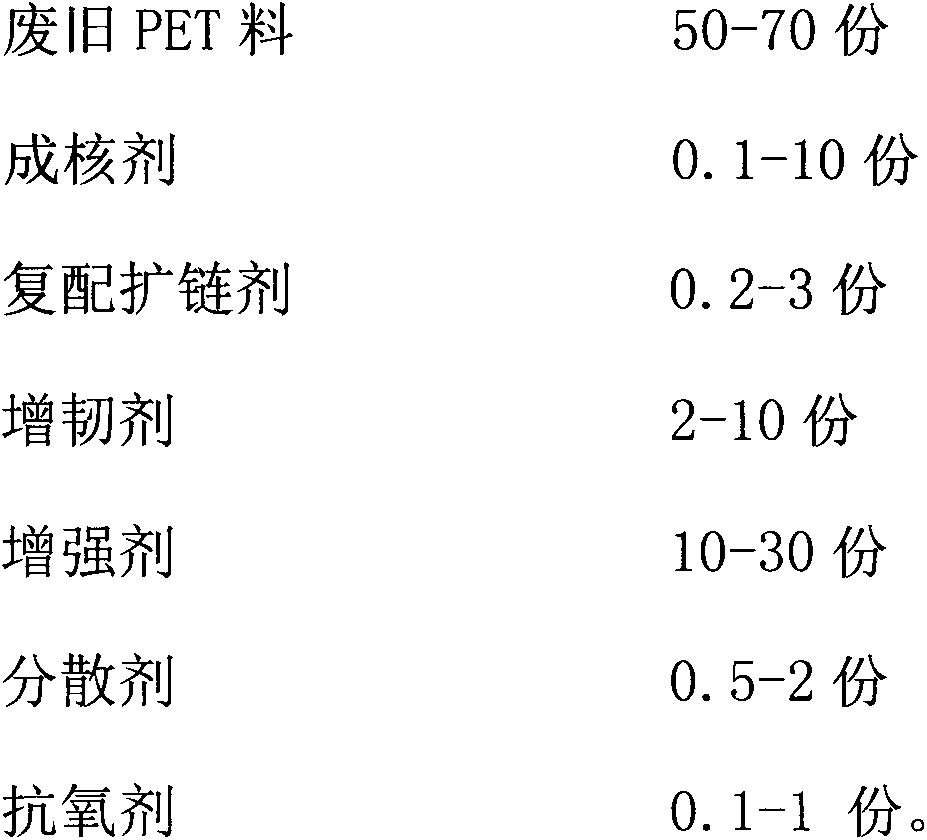

[0026] Step 1. Prepare the following raw materials:

[0027]

[0028] Step 2. Dry the crushed and cleaned waste PET main material at 120°C for 5 hours;

[0029] Step 3. Put the waste PET dried in step 2 and the toughening agent into a mixer and stir evenly at high speed to obtain a first blend;

[0030] Step 4. Put the dispersant, chain extender, nucleating agent and antioxidant into a high-speed mixer and blend for 3-6 minutes to prepare a second blend;

[0031] Step 5. Add the first blend to the main feed port, and add the second blend to the powder side feed port installed on the main feed port, and then move the enhancer to the side feed of the twin screw extruder In the feed port, set the temperature of each zone of the extruder at 220-280°C for extrusion molding.

[0032] In step 5 of the above scheme, the temperature in the first zone of the ...

Embodiment 2

[0038] A waste PET heat-resistant and tackifying reinforced composite material prepared by using the preparation process of Example 1, and its components and weight percentages are as follows:

[0039] 60-70 parts of waste PET materials;

[0040] Nucleating agent 0.6-1.5 parts of talc, 0.6-1.5 parts of hydrophobic silica with a particle size of 15-40 nm nanometers, 0.3-1 parts of TMC-328 polyamide compound;

[0041] Compound chain extender 0.2-0.5 parts of pyromellitic dianhydride, 0.1-0.5 parts of phthalic anhydride, 0.2 parts of ADR-4370S;

[0042] Toughener 5-10 parts of maleic anhydride graft;

[0043] Reinforcing agent 20-30 parts of glass fiber surface treated with silane coupling agent;

[0044] Dispersant: 0.8-1. 5 parts of ethylene bis-stearic acid amide;

[0045] Antioxidant Temperature resistant antioxidant P262 0.3-0.8 parts.

Embodiment 3

[0047] A waste PET heat-resistant and tackifying reinforced composite material prepared by using the preparation process of Example 1, and its components and weight percentages are as follows:

[0048] 60 parts of waste PET materials;

[0049] Nucleating agent: 1 part of talc powder, 1 part of hydrophobic silica with a particle size of 30nm nanometers, 0.5 part of TMC-328;

[0050] Compound chain extender 0.3 parts of pyromellitic dianhydride, 0.2 parts of phthalic anhydride, 0.2 parts of ADR-4370S;

[0051] Toughening agent 8 parts of maleic anhydride graft;

[0052] Reinforcing agent 30 parts of glass fiber surface-treated with silane coupling agent;

[0053] Dispersant: 1 part of ethylene bisstearic acid amide;

[0054] Antioxidant 0.5 part of temperature resistant antioxidant P262.

[0055] The following list is the performance comparison between the detection data of this embodiment and the waste PET modified material prepared in the prior art. The detection data can intuitively refle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com