Filter and washing machine

A filter and washing machine technology, applied to washing machines with containers, other washing machines, washing devices, etc., can solve problems such as troublesome maintenance, clogging, and poor user experience, and achieve easy and convenient discharge, water saving, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

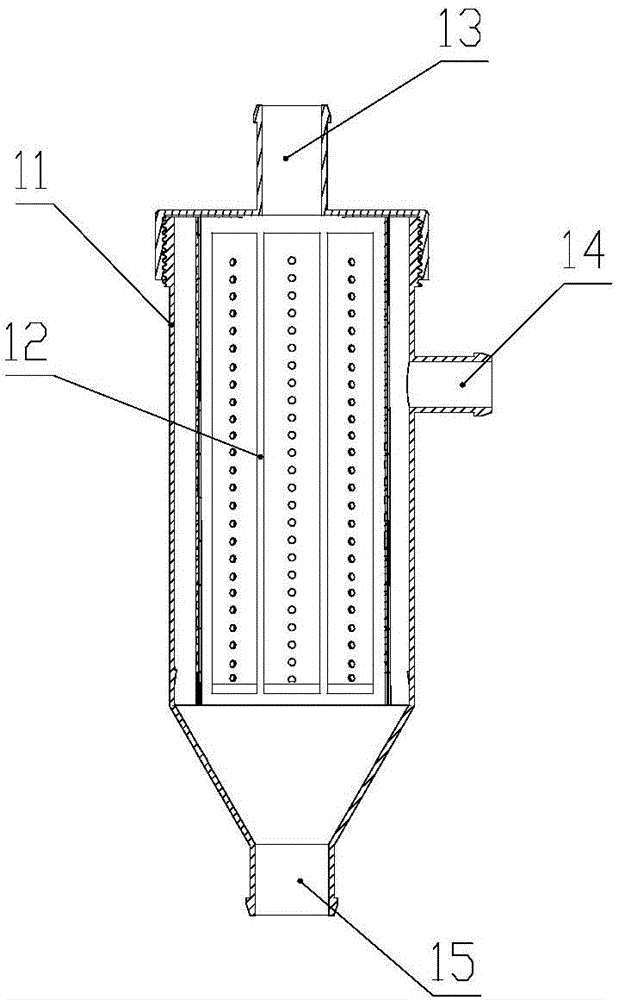

[0036] This embodiment is a filter, such as figure 1 As shown, the filter includes a filter cylinder 11 and a filter screen 12 installed in the cylinder 11 . The cylinder 11 is provided with a water inlet 13, a water outlet 14 and a sewage outlet 15, the water inlet is arranged on the top of the cylinder, and the water outlet 14 is arranged in the middle of the cylinder wall around the cylinder 11, The sewage outlet 15 is arranged at the bottom of the cylinder body 11, and the lower end of the cylinder body (11) is also provided with an inverted tapered transition section to connect the inner cavity and the sewage outlet 15. The inverted tapered transition section The setting can facilitate the discharge of impurities. The cylinder body 11 is a detachable structure, and its upper cover can be opened to facilitate the removal and loading of the filter screen. The filter screen 12 is installed vertically in the cylinder body 11 in a cylindrical shape, and divides the inner cav...

Embodiment 2

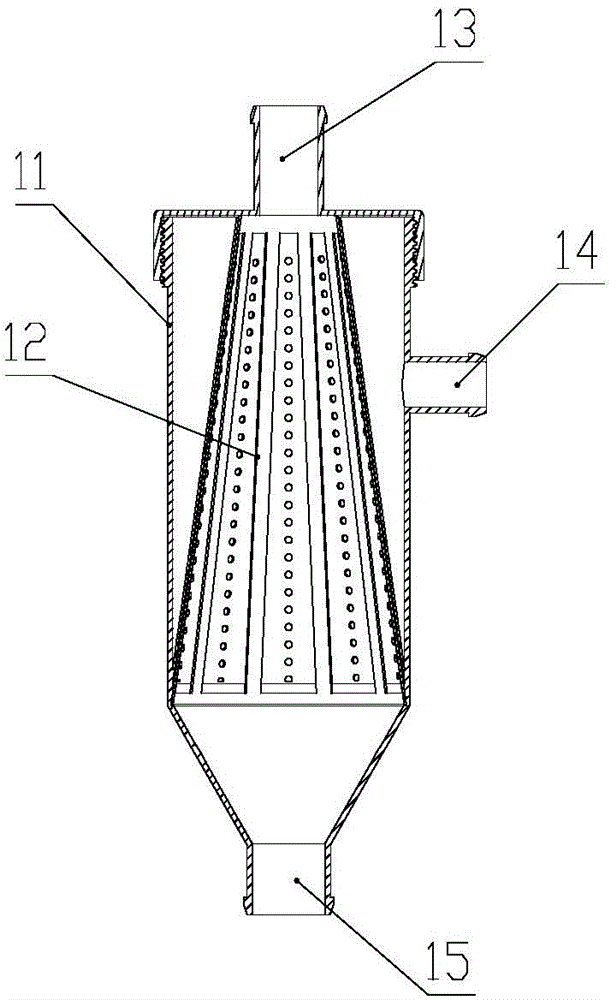

[0039] This embodiment is a filter, such as figure 2 As shown, the basic structure of the filter of this embodiment is the same as that of Embodiment 1, including a filter cylinder 11 and a filter screen 12 , and the cylinder 11 is provided with a water inlet 13 , a water outlet 14 and a sewage outlet 15 . The difference from Embodiment 1 is that the filter screen 12 is installed vertically in the cylinder body 11 in a conical shape, the small end of the filter screen 12 is connected to the water inlet 13, and the large end is connected to the sewage discharge port. Port 15, sewage flows into the inner cavity from the water inlet 13 through the small end of the filter screen 12, enters the external cavity after being filtered by the filter screen 12, and flows out through the water outlet 14, and the filtered impurities are discharged through the sewage outlet 15 .

[0040] The filter screen 12 is tapered and vertically installed in the cylinder body 11, so that the filtered...

Embodiment 3

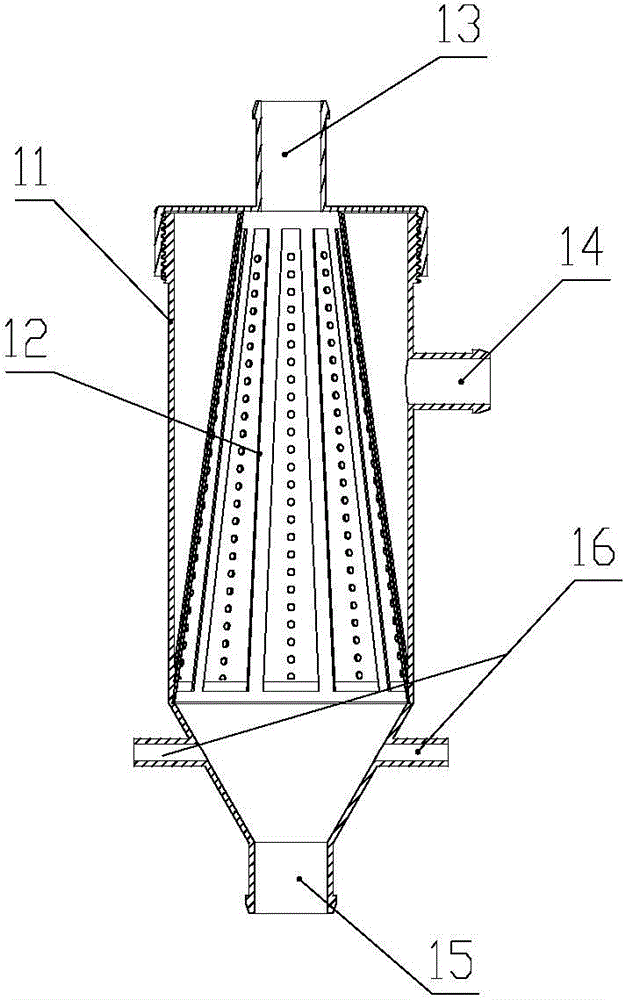

[0042] This embodiment is a filter, such as image 3 As shown, the basic structure of the filter of this embodiment is the same as that of Embodiment 2, including a filter cylinder 11 and a filter screen 12, and the cylinder 11 is provided with a water inlet 13, a water outlet 14 and a sewage outlet 15. The filter screen 12 is installed vertically in the cylinder body 11 in a conical shape. The difference from the second embodiment is that two air pumping ports 16 for connecting the air pumping device are arranged symmetrically on the wall of the cylinder body 11. The pumping port 16 is located between the large end of the filter screen 12 and the sewage outlet 15, blows gas into the filter through the pumping device, stirs the water in the filter screen 12, and makes the impurities on the filter screen 12 come off more thoroughly through the action of water flow.

[0043] Such as Figure 4 with 5 Shown is another structural form of the filter in this embodiment, four pumpin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com