Multifunctional feed stirring device

A feed mixing and multi-functional technology, which is applied to feed, mixer accessories, mixers with rotary mixing device, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

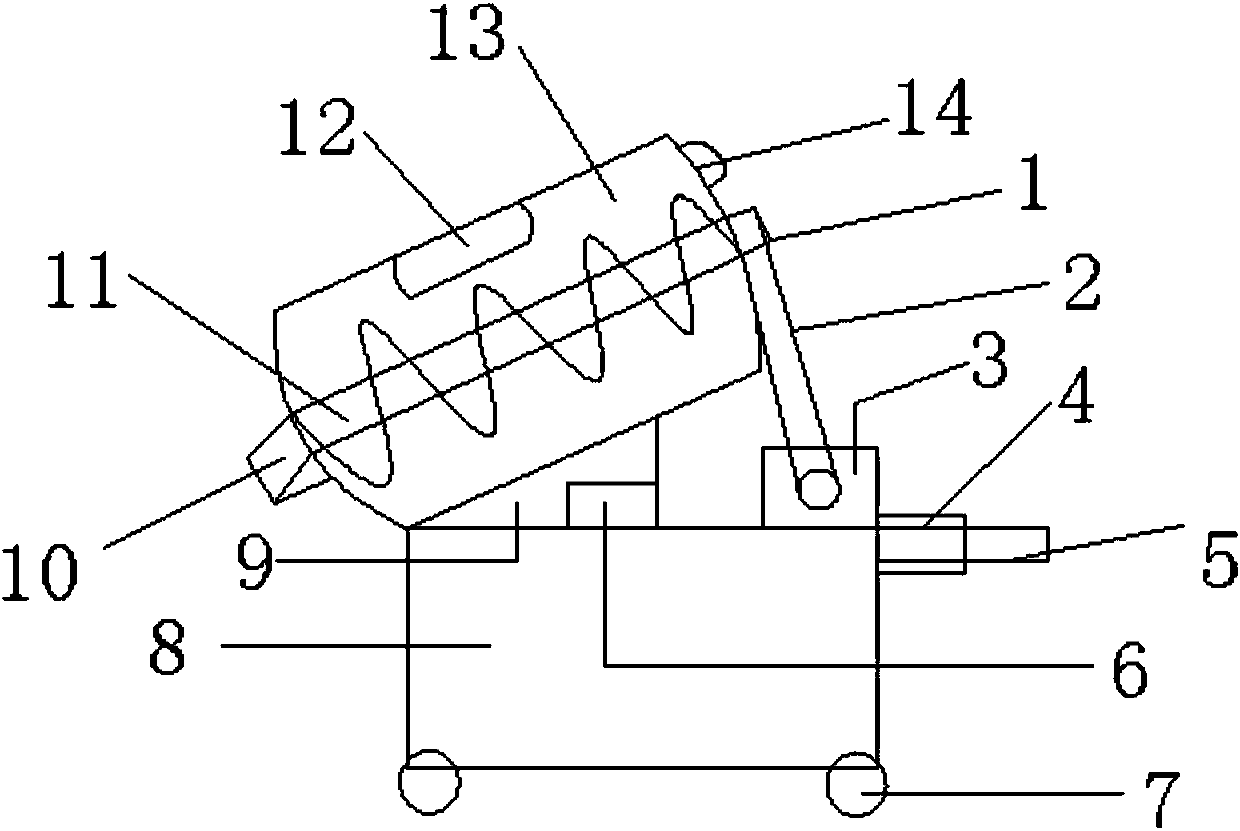

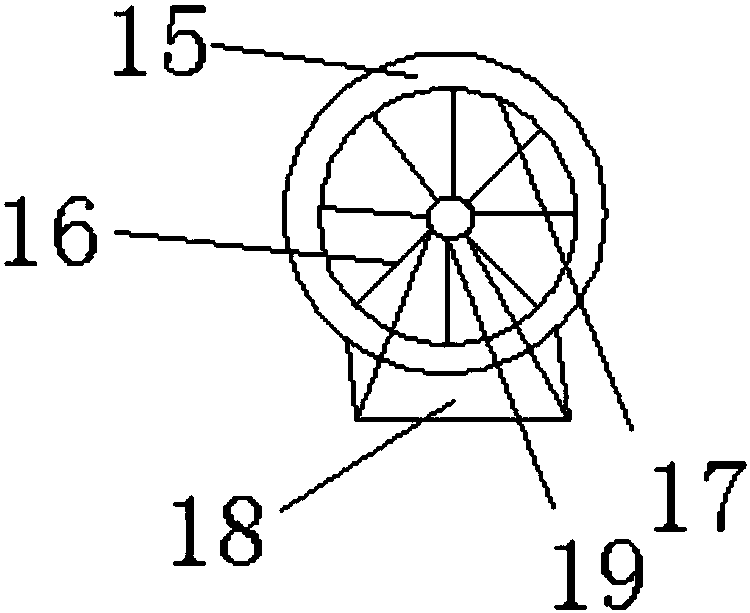

[0013] refer to figure 1 , figure 2 , a multifunctional feed mixing equipment, its structure includes a driven wheel device 1, a belt 2, a motor 3, a handle 4, a non-slip handle 5, a display 6, a wheel device 7, a power distribution box 8, a gravity sensing inclined block 9, an outlet Material port 10, spiral stirring rod 11, feed port 12, mixing barrel 13, exhaust port 14, the driven wheel device 1 is connected with the motor 3 through the belt 2, and the display 6 is located on the side of the gravity sensing inclined block 9 , the display 6 is connected to the gravity sensing slanting block 9 through a circuit, the gravity sensing slanting block 9 is fixedly connected to the distribution box 8 through a nut, and the inclined surface of the gravity sensing slanting block 9 is connected to the mixing tank 13 Connected by welding, the discharge port 10 is located at the tail of the mixing tank 13 and connected by welding, the upper end of the spiral stirring rod 11 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com