Patents

Literature

32results about How to "Avoid affecting screening efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

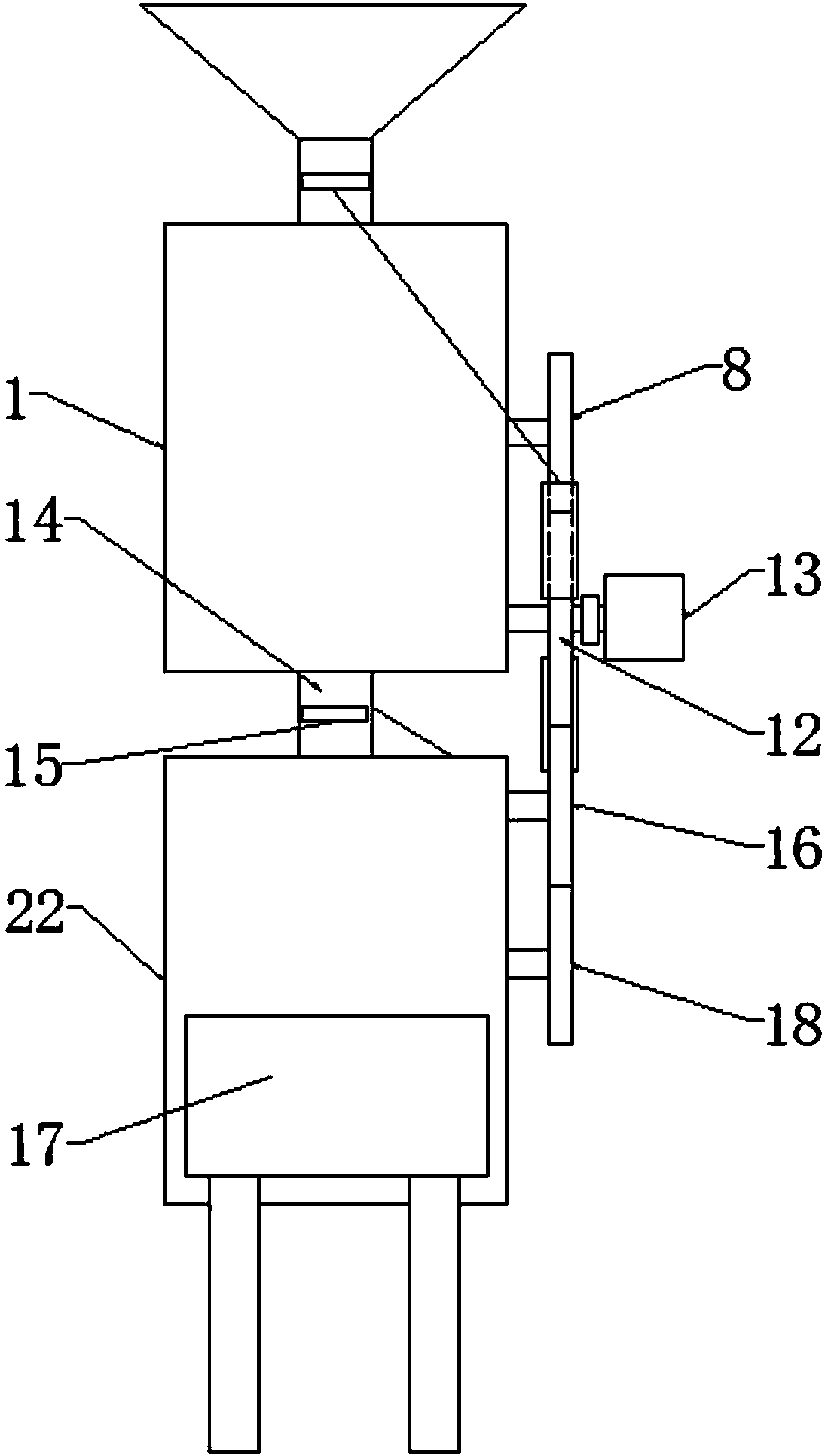

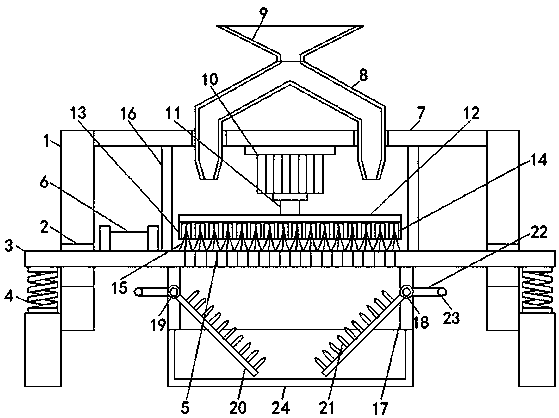

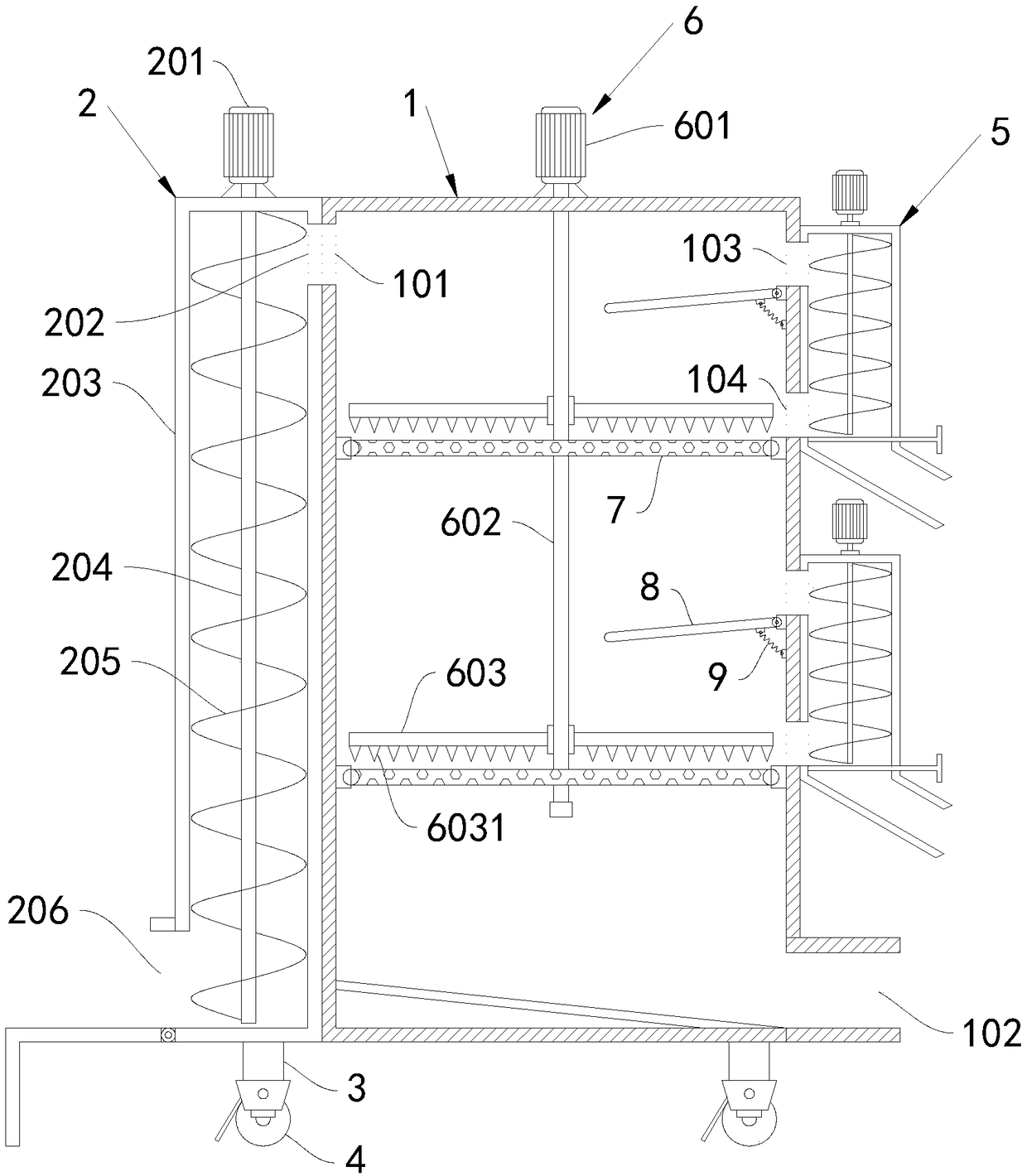

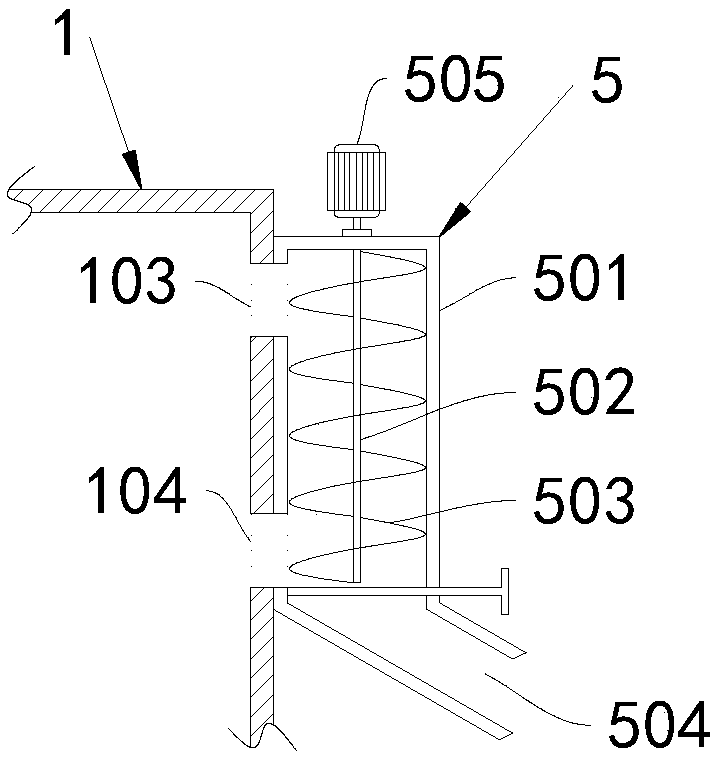

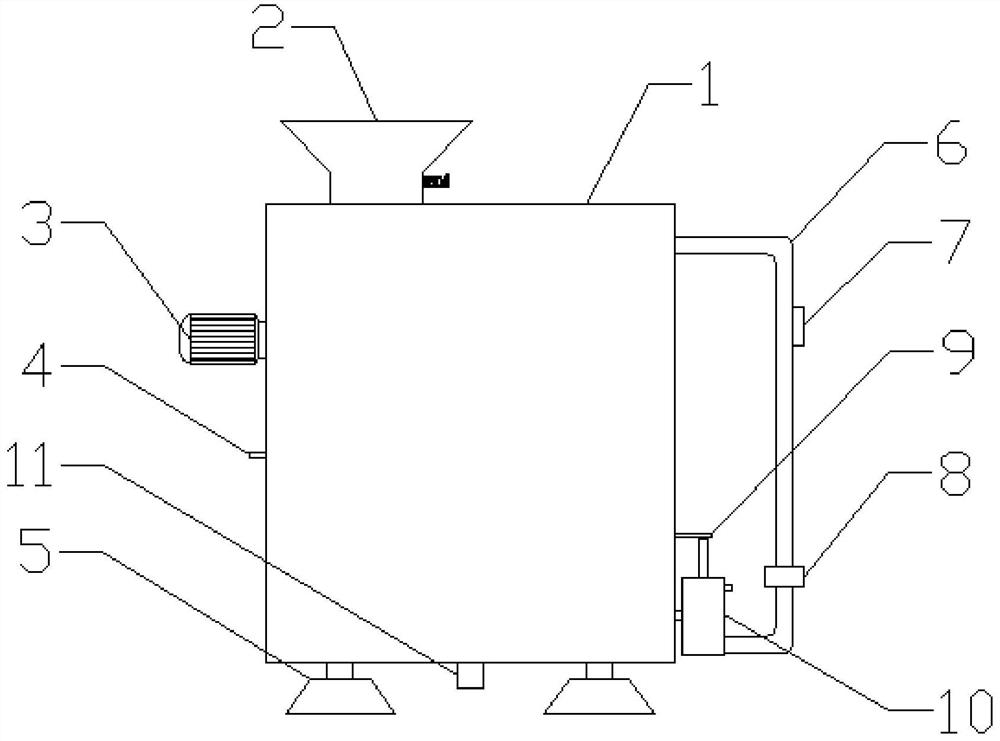

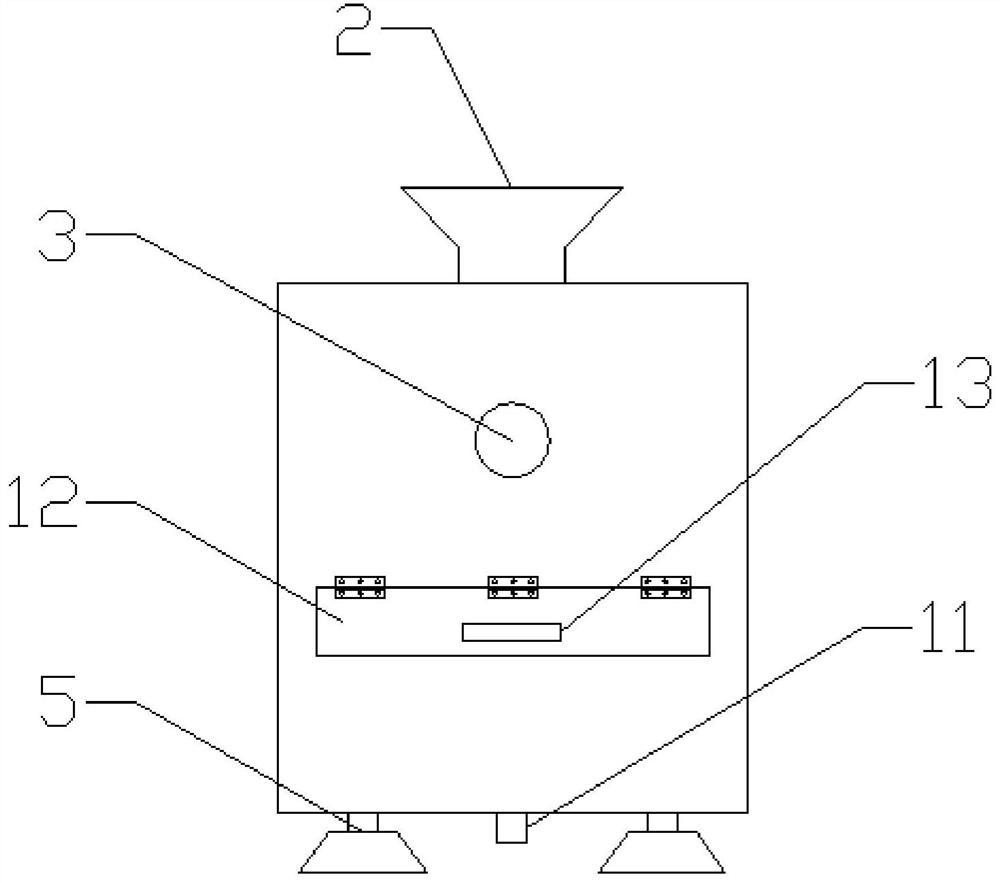

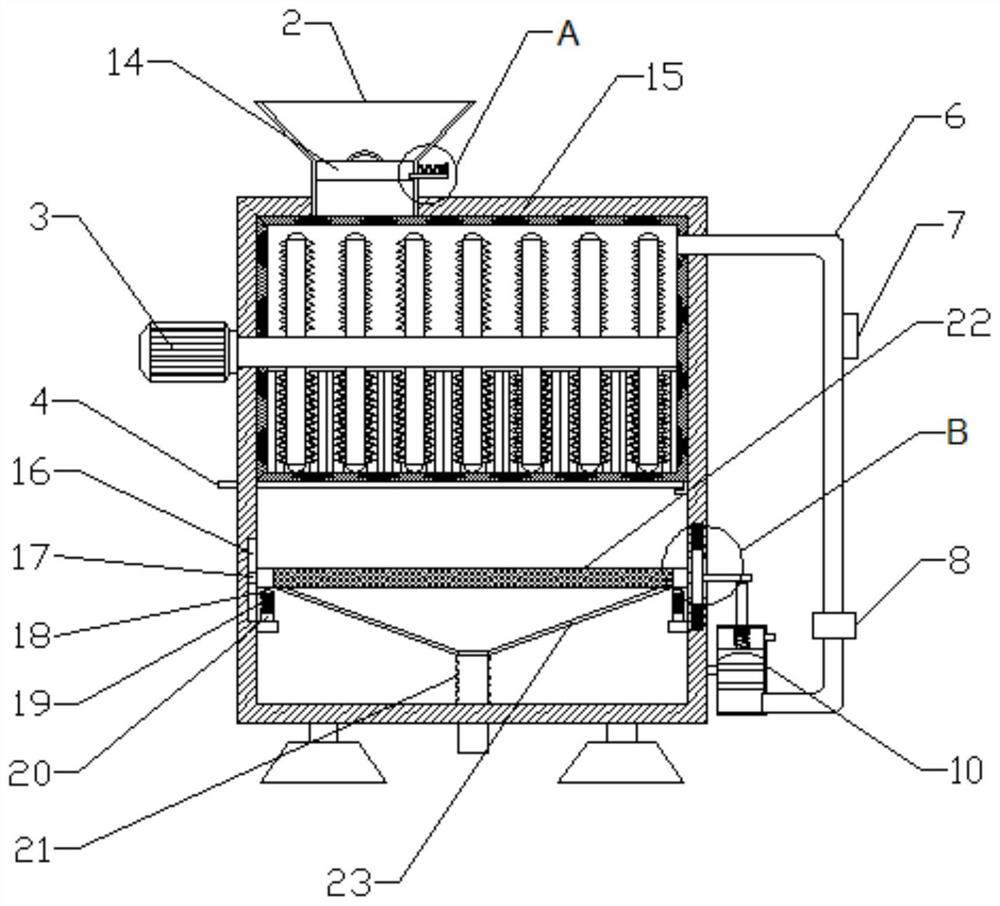

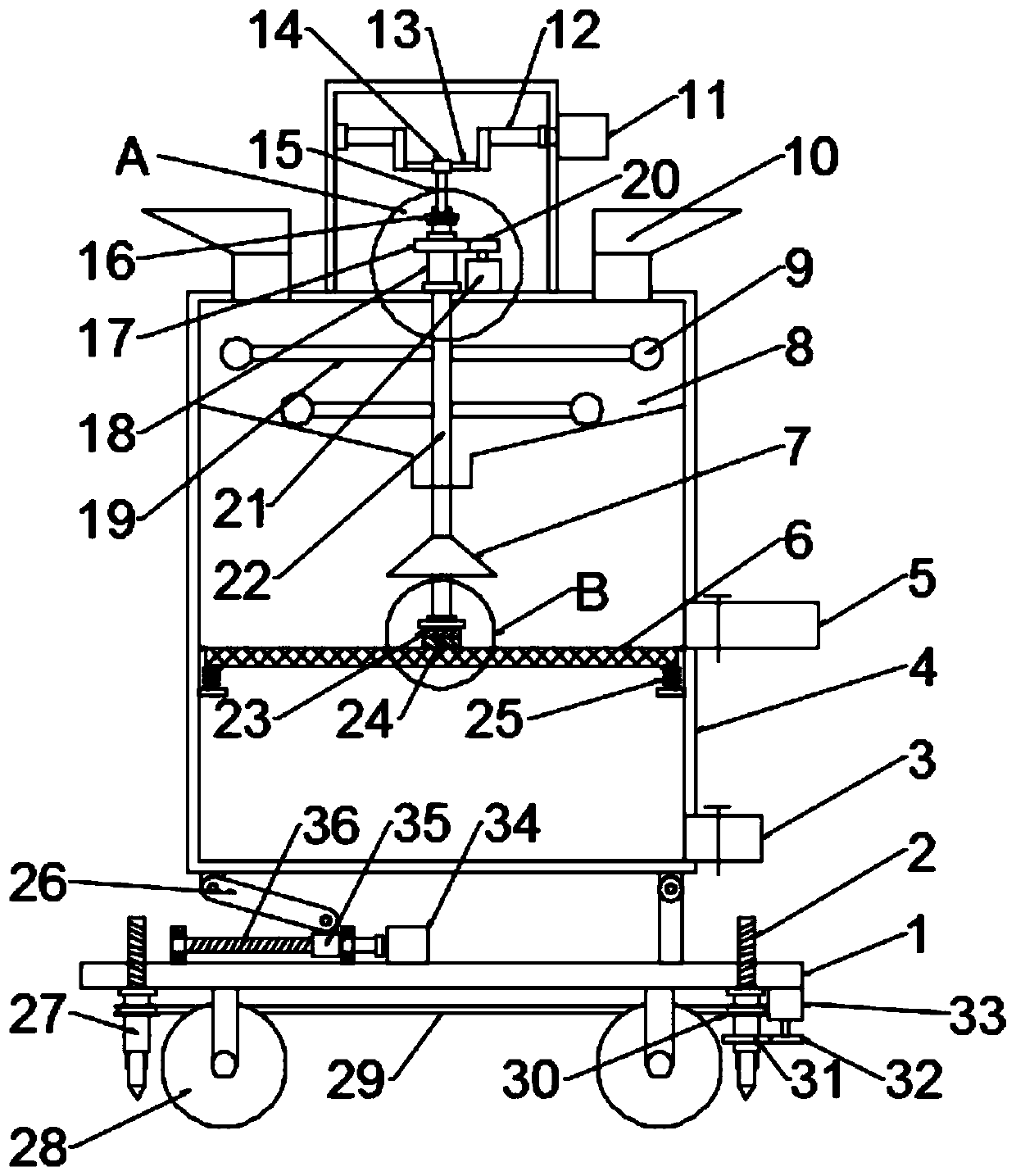

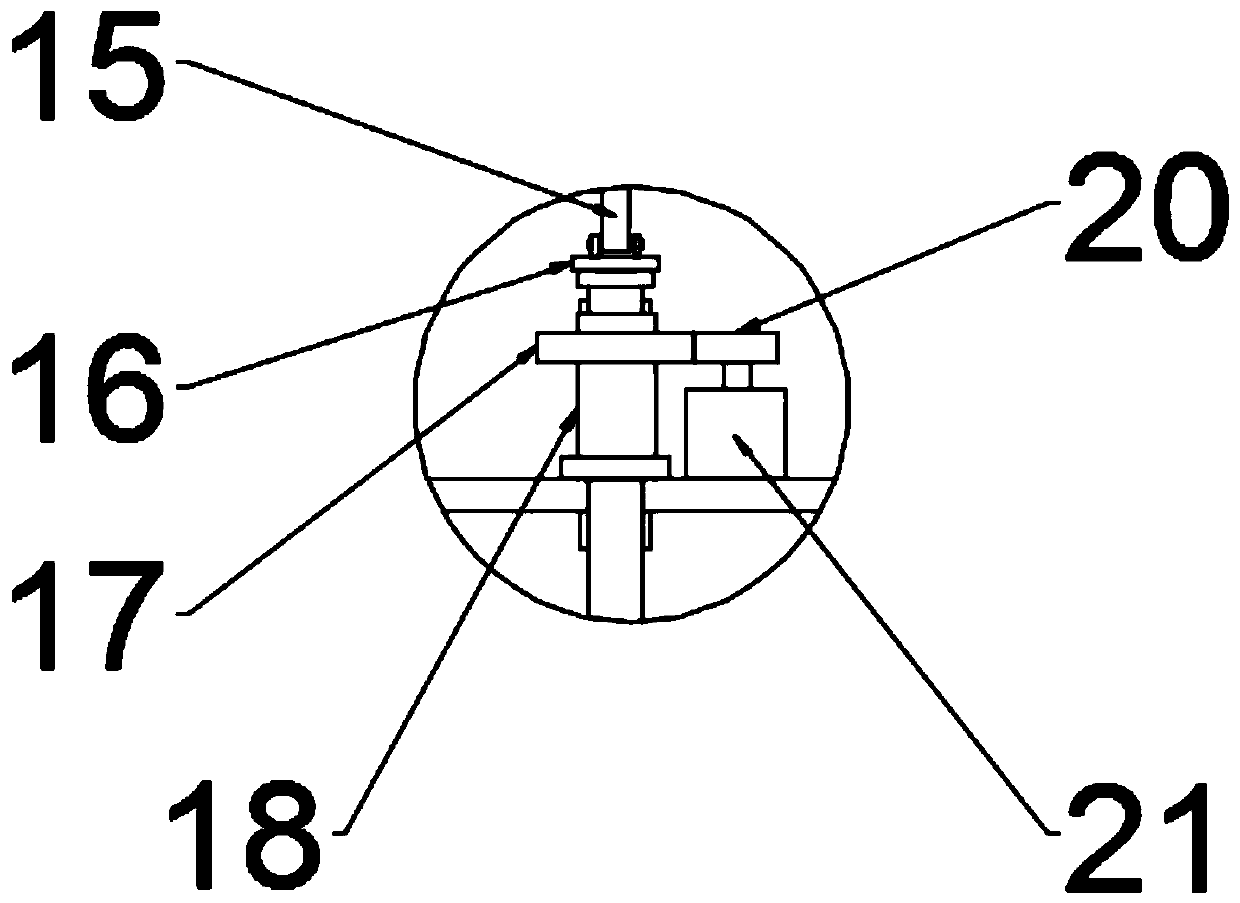

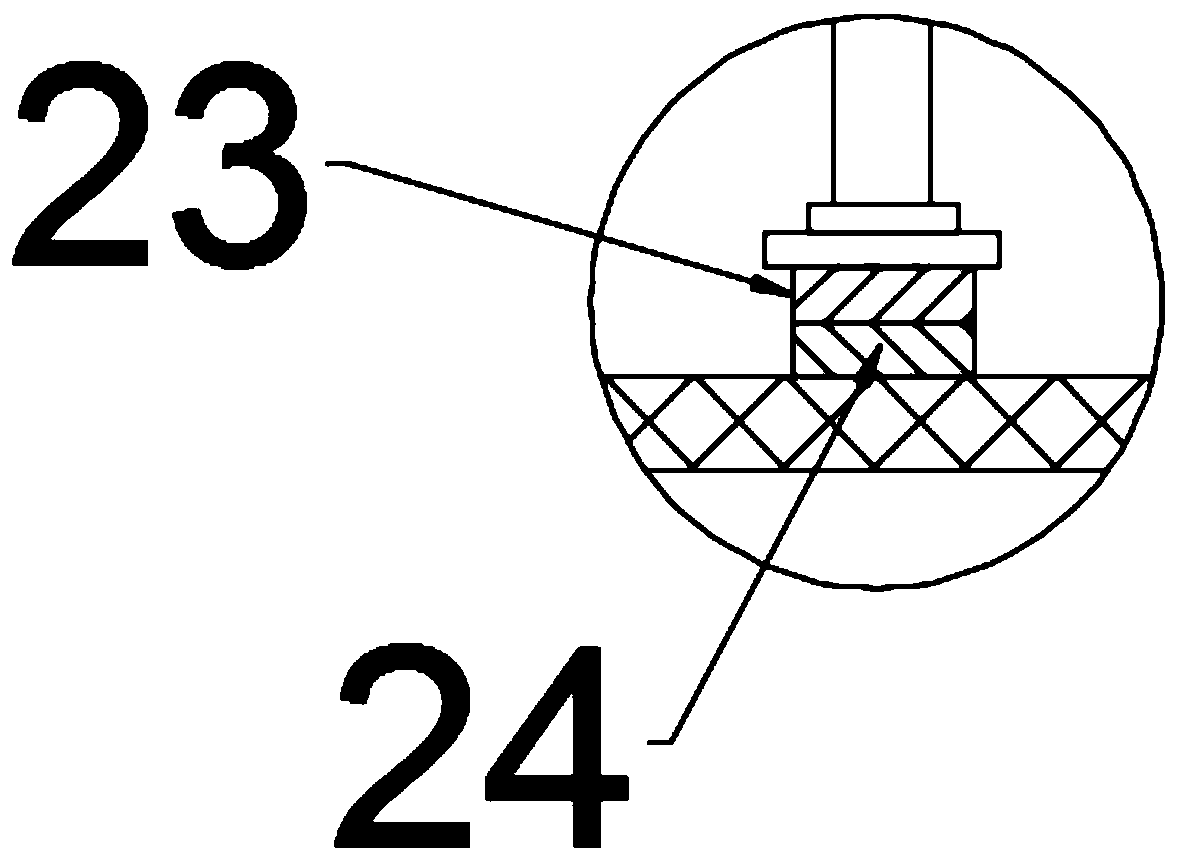

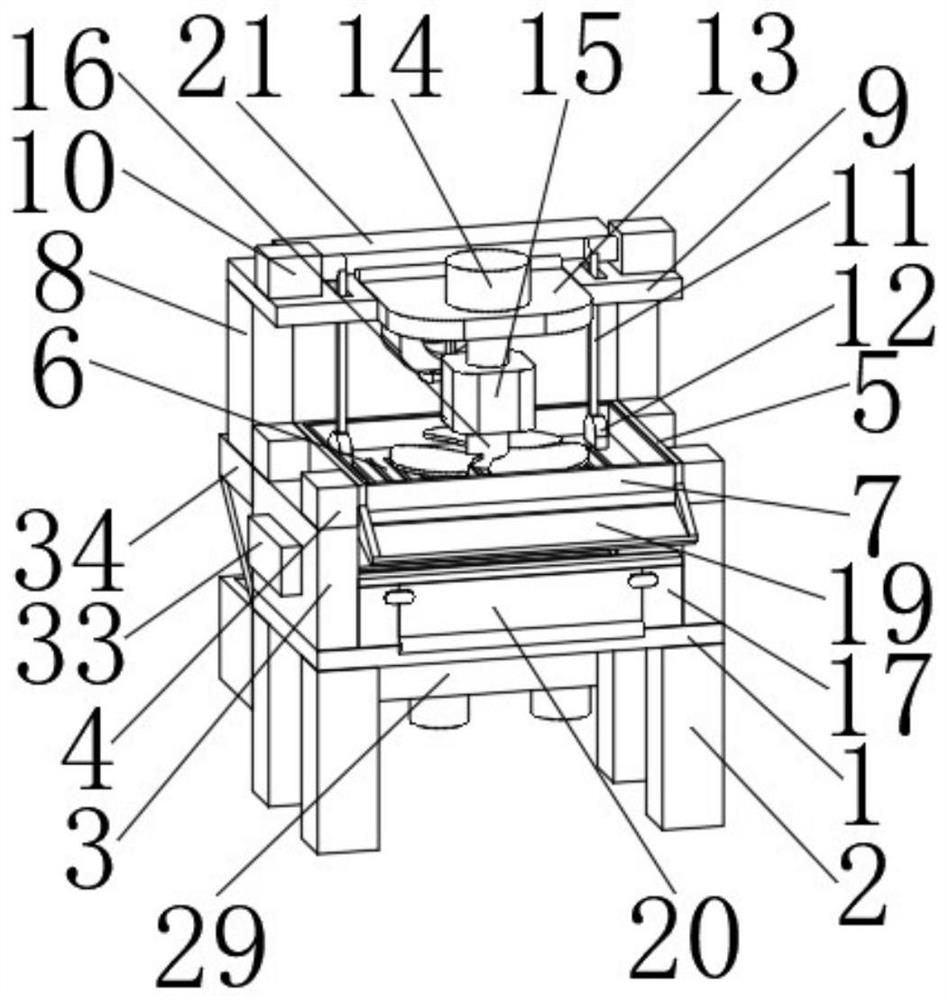

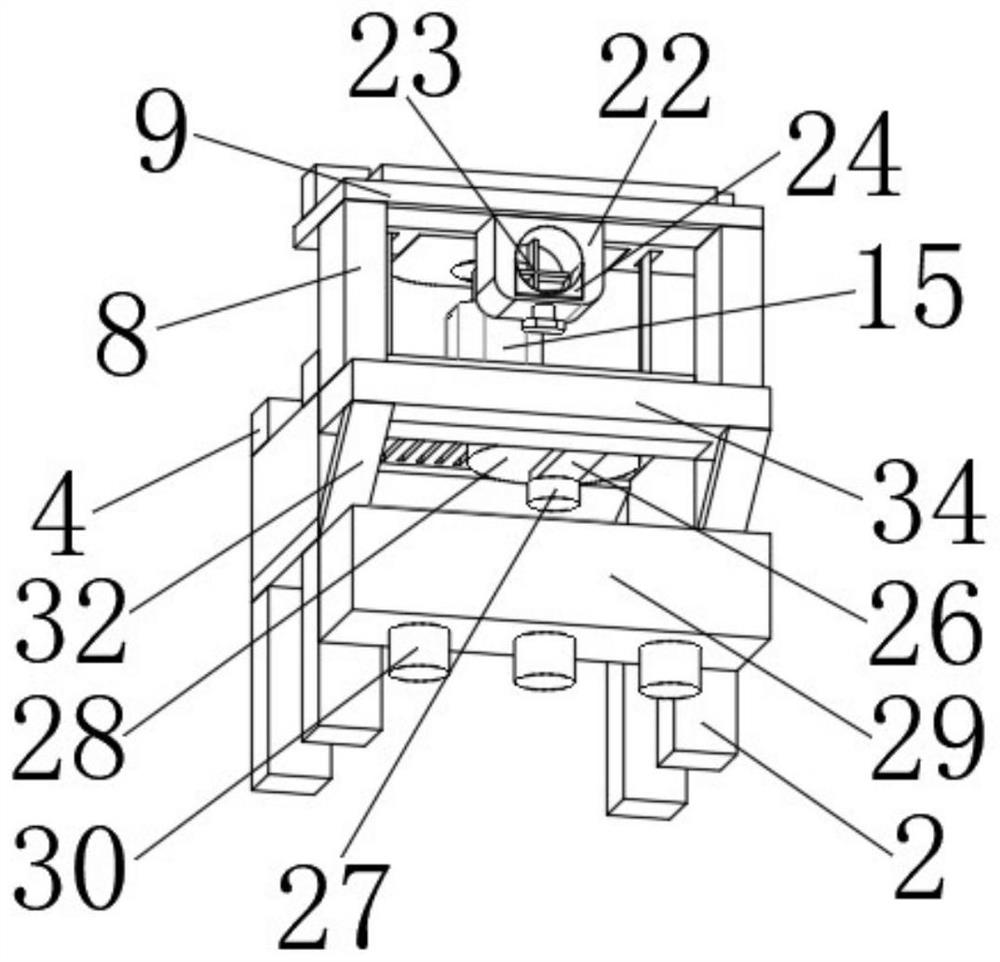

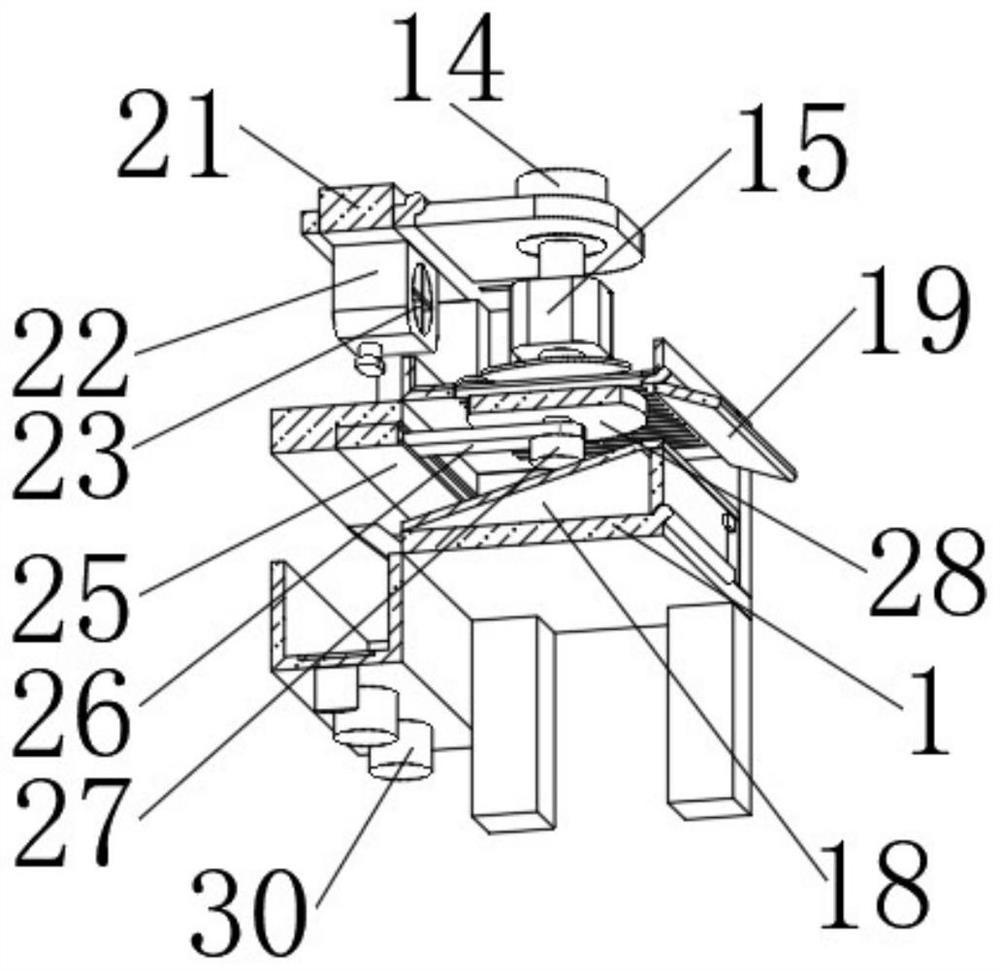

Efficient Chinese medicinal material grinding and screening integrated machine

InactiveCN107486315AAvoid affecting screening efficiencyGrind fullySievingScreeningBevel gearScreening effect

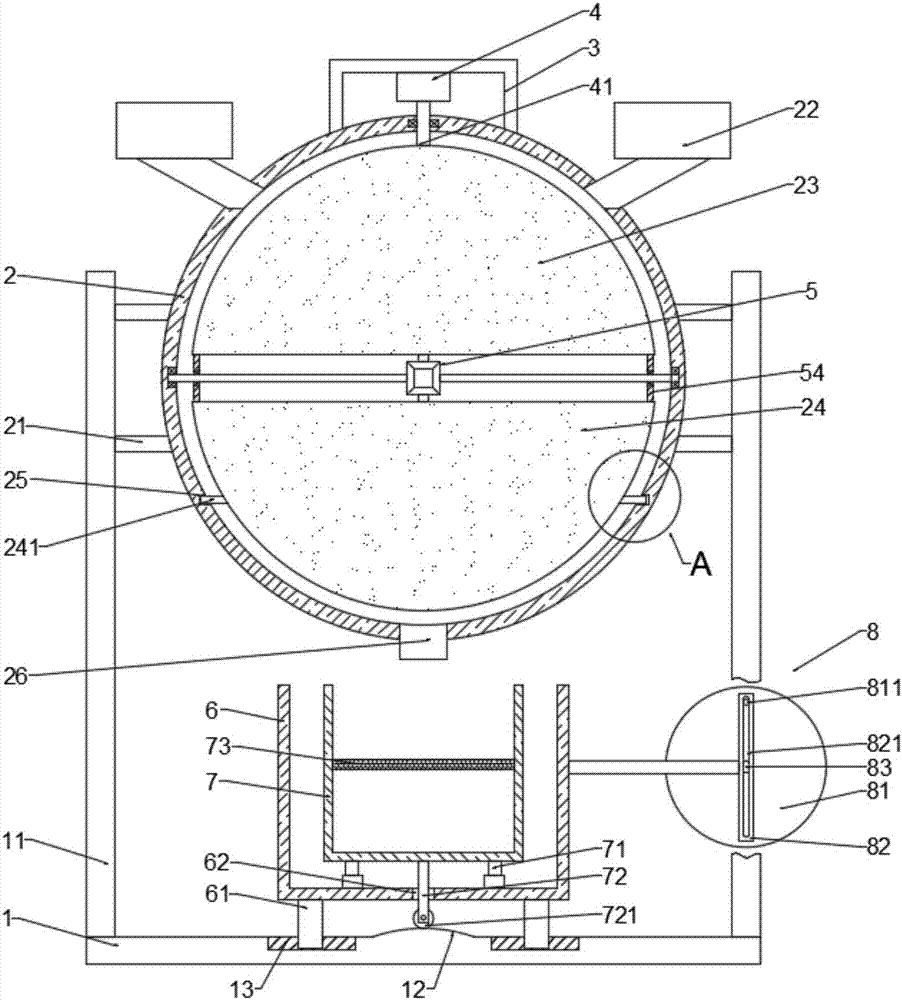

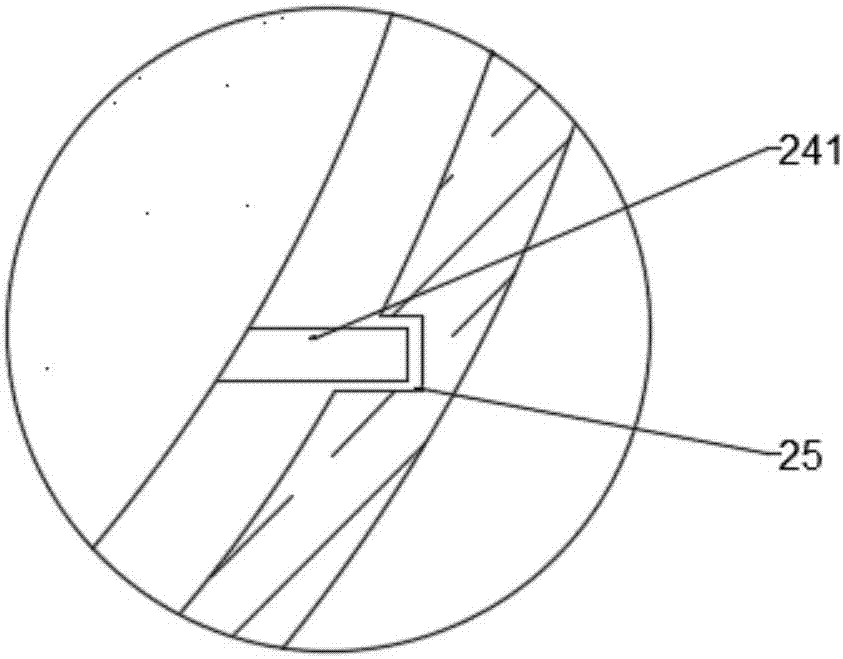

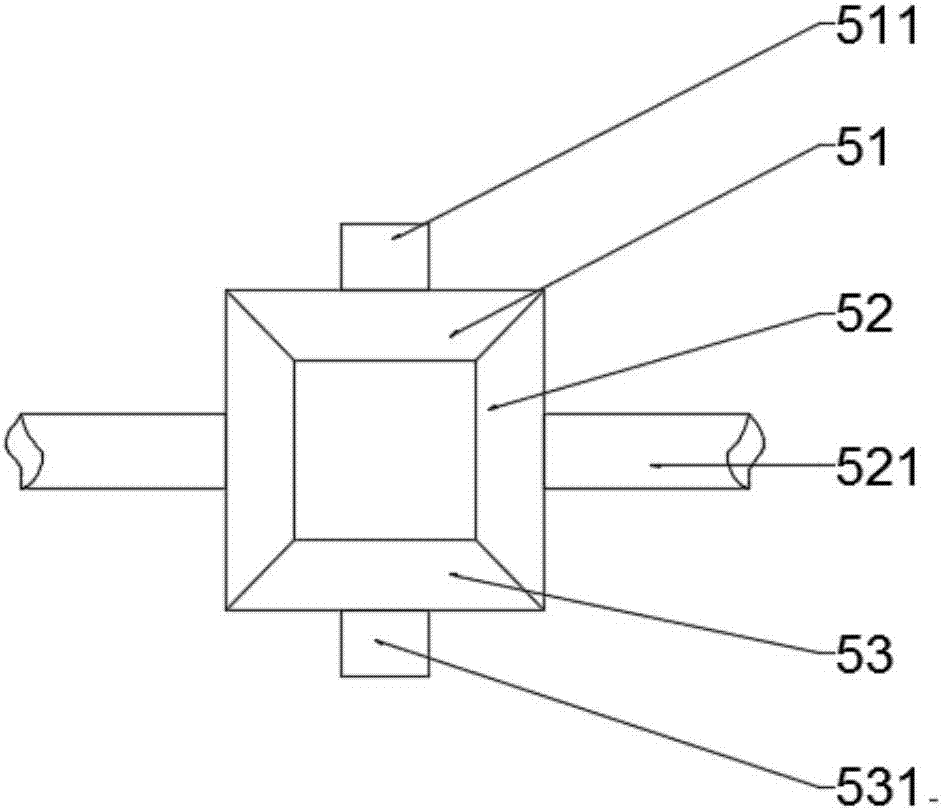

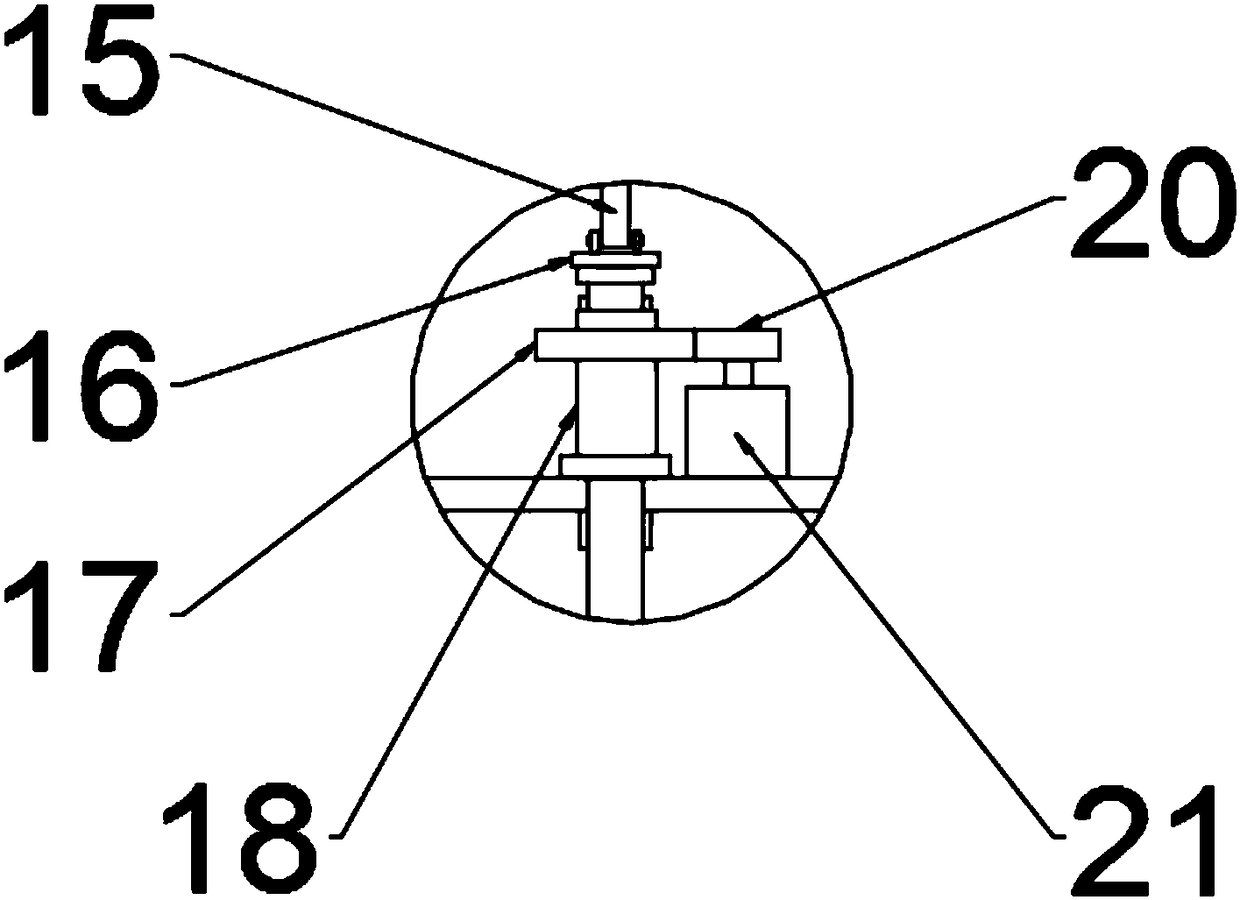

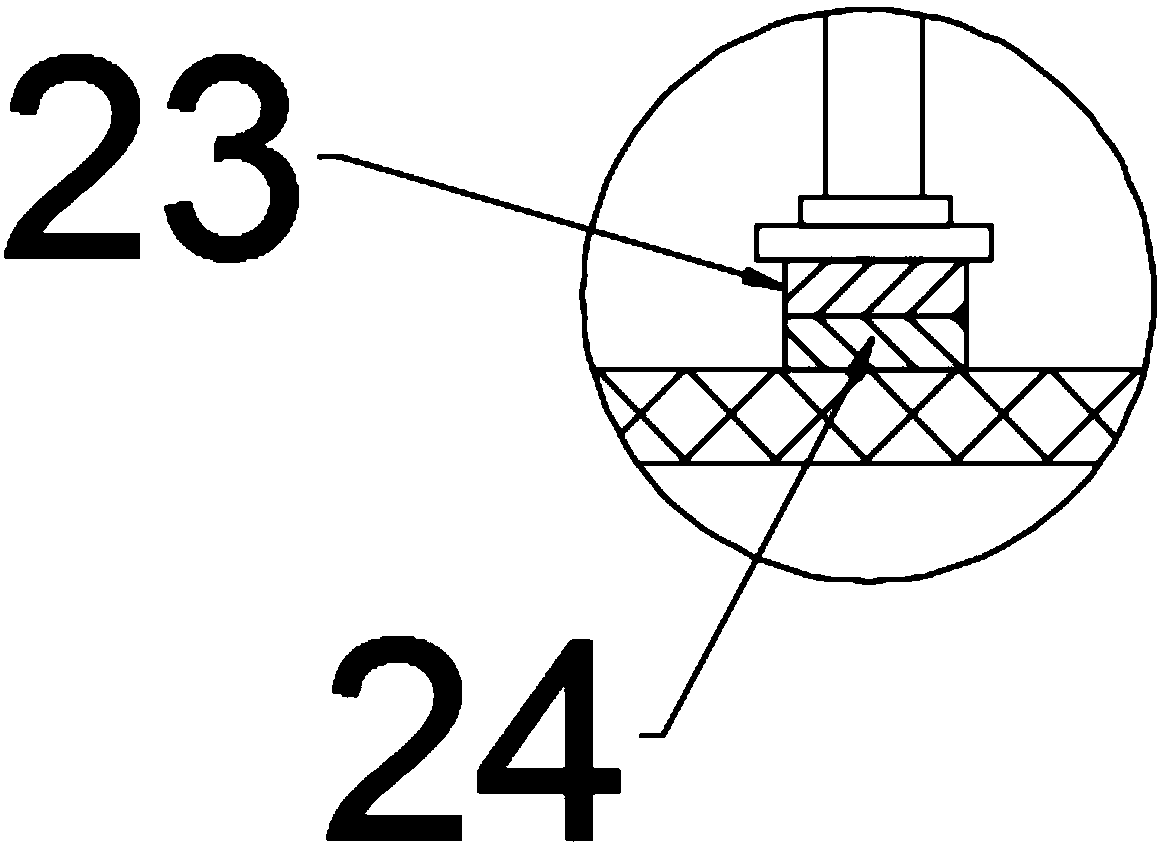

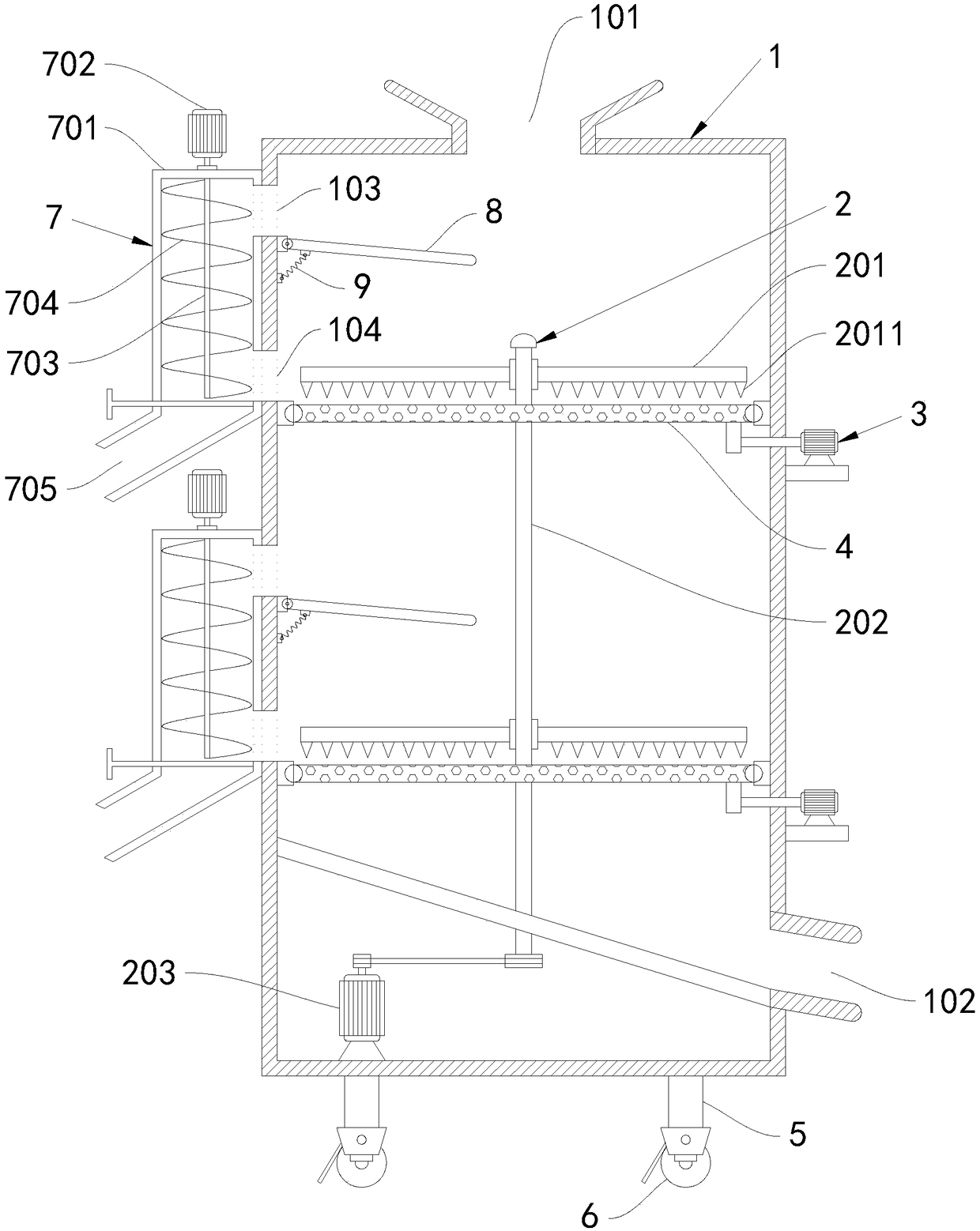

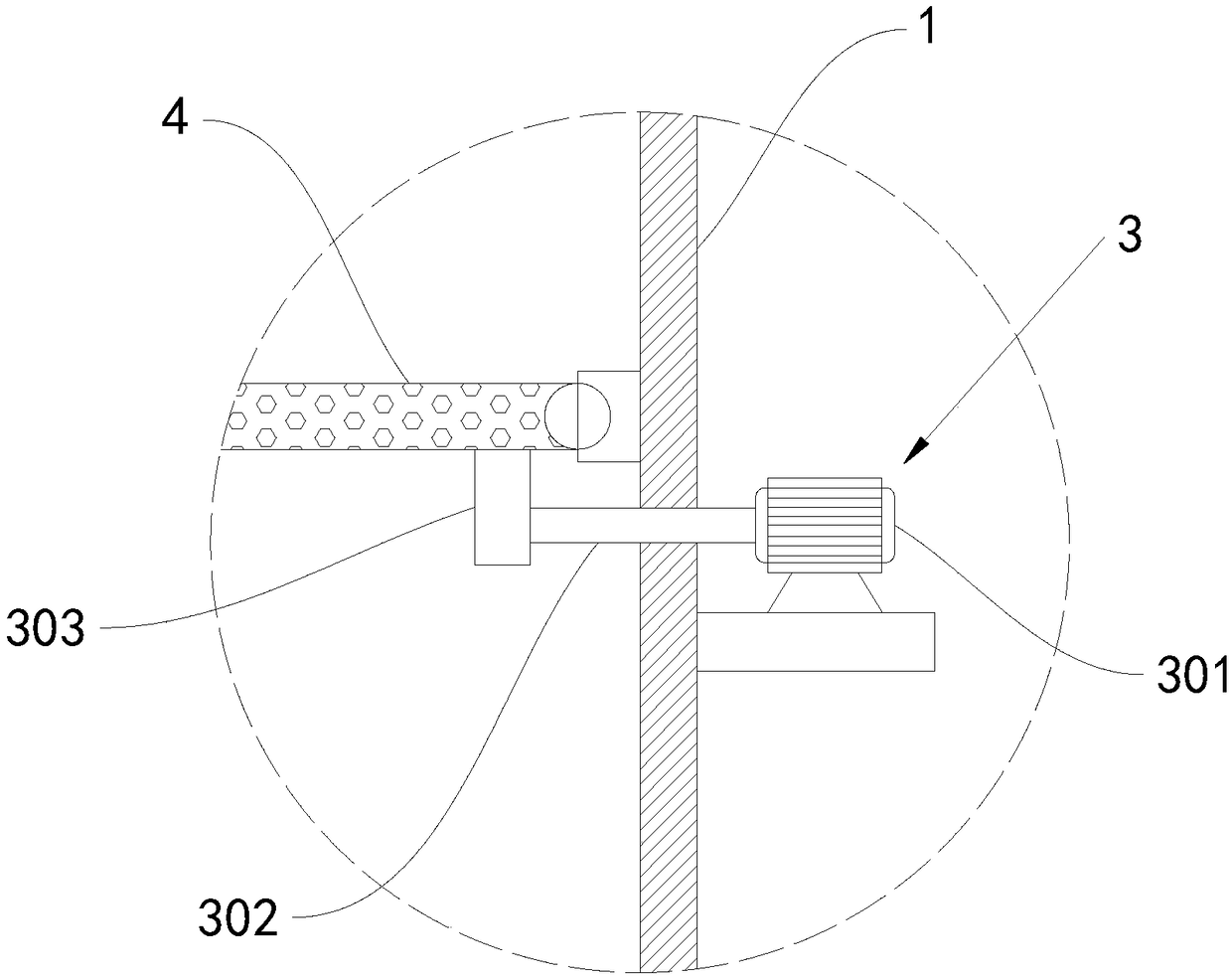

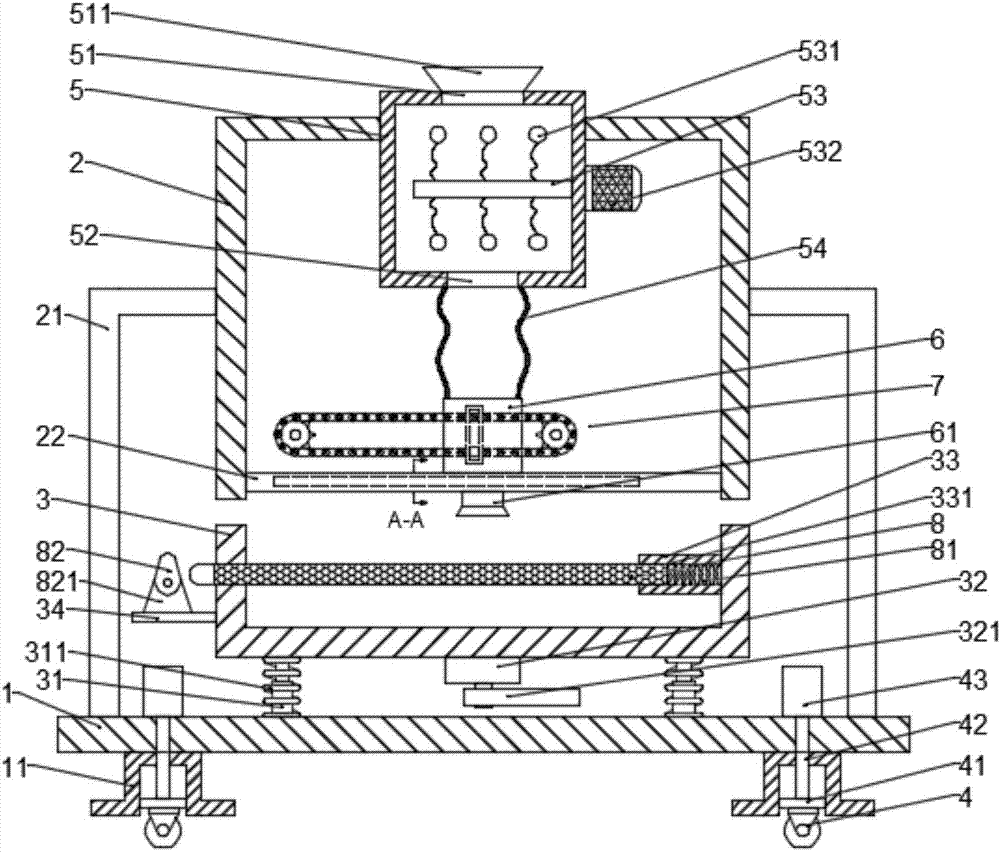

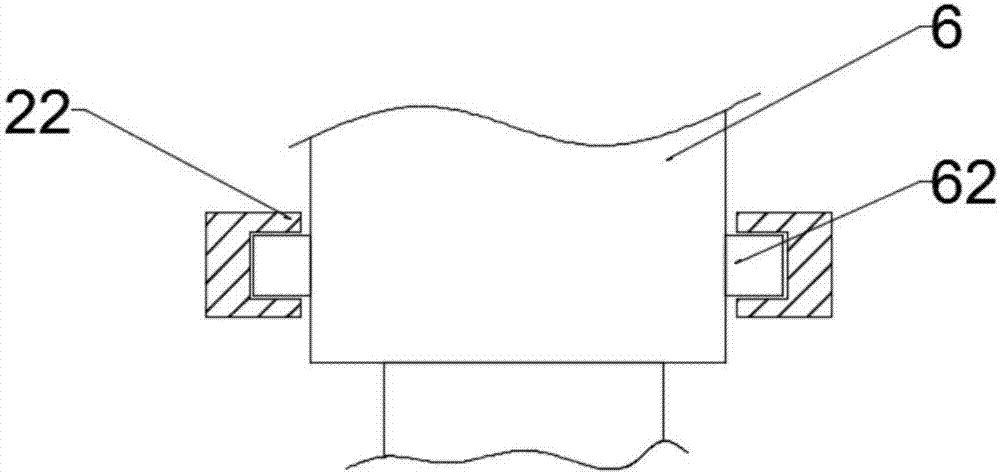

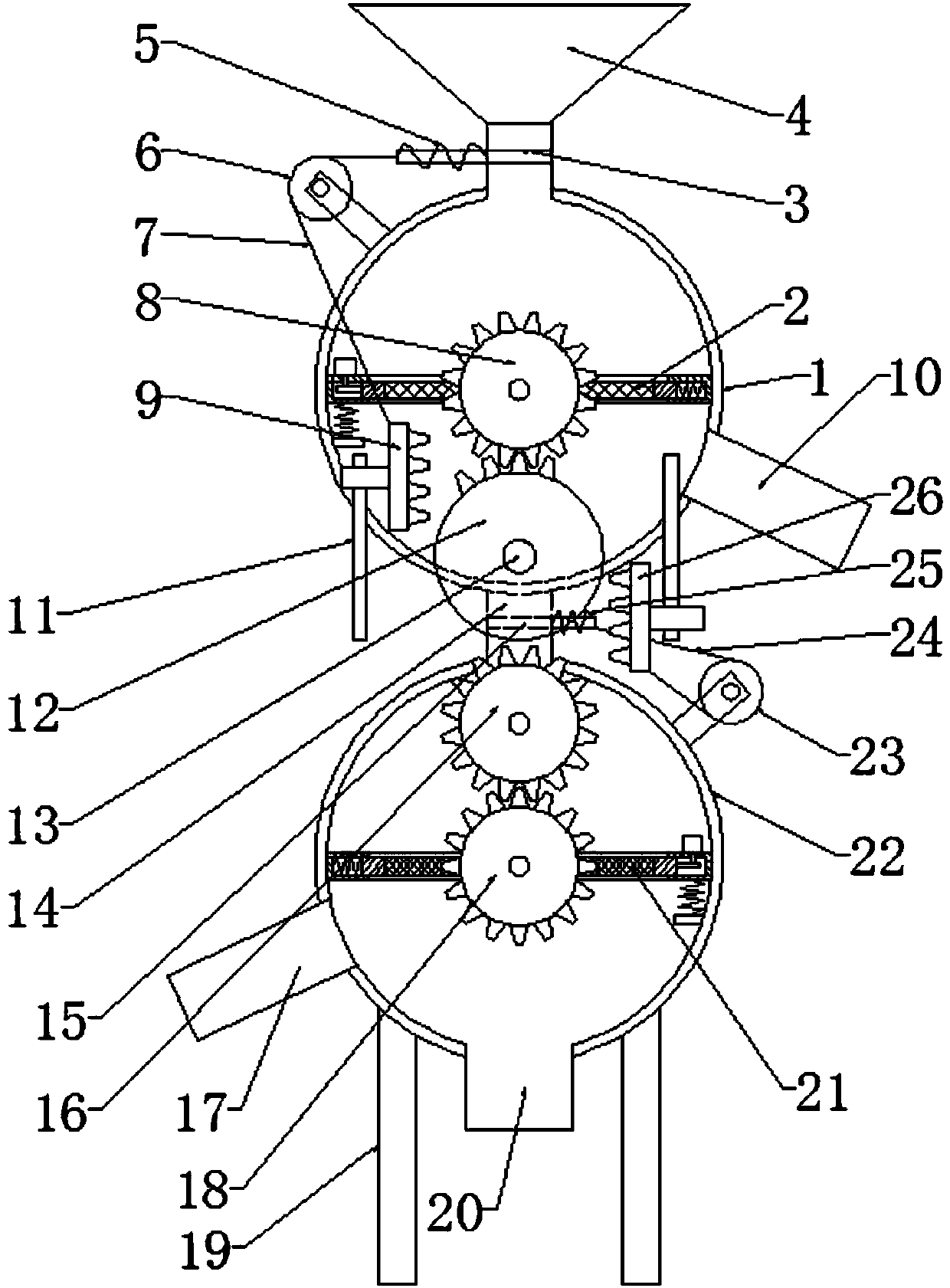

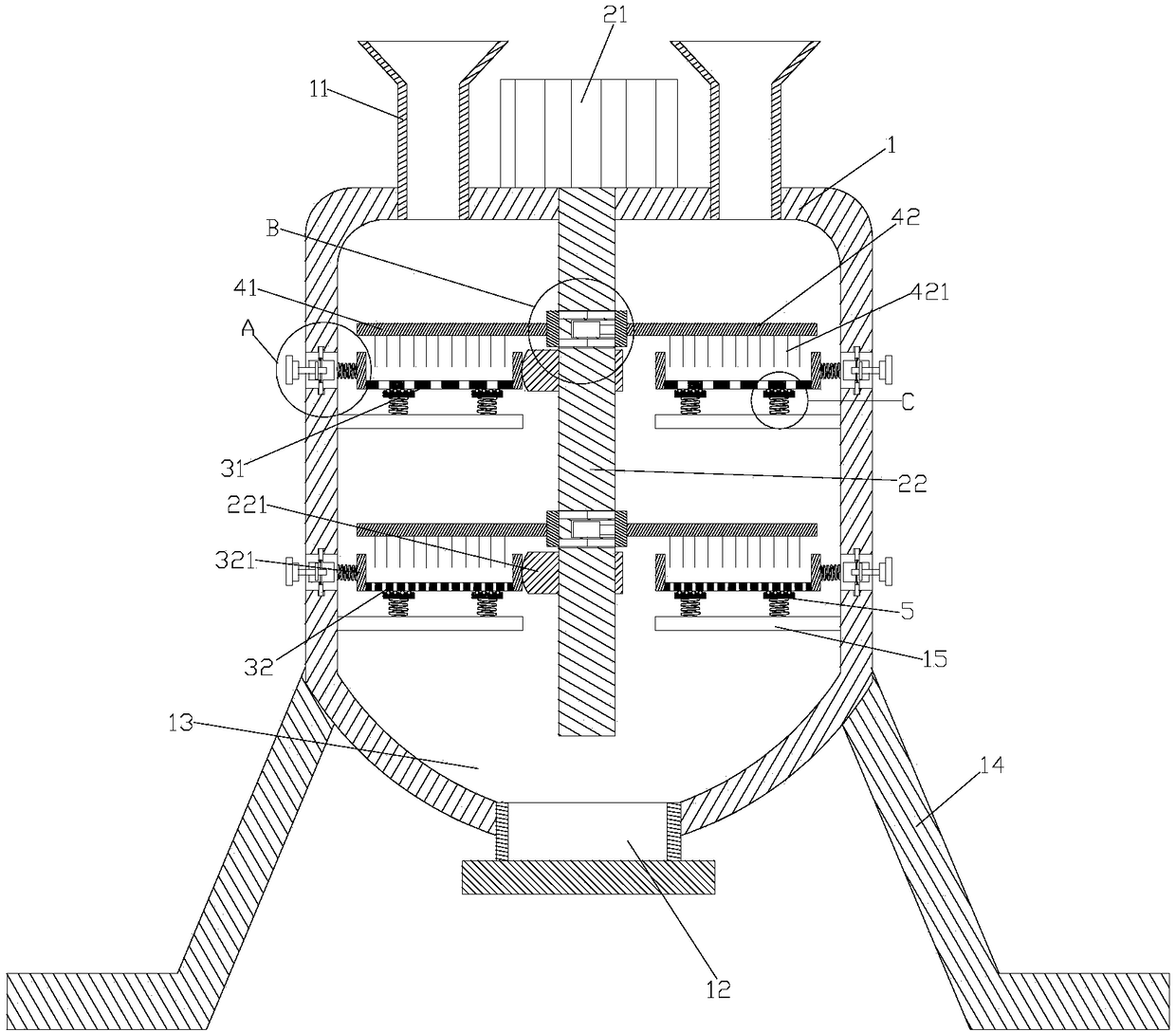

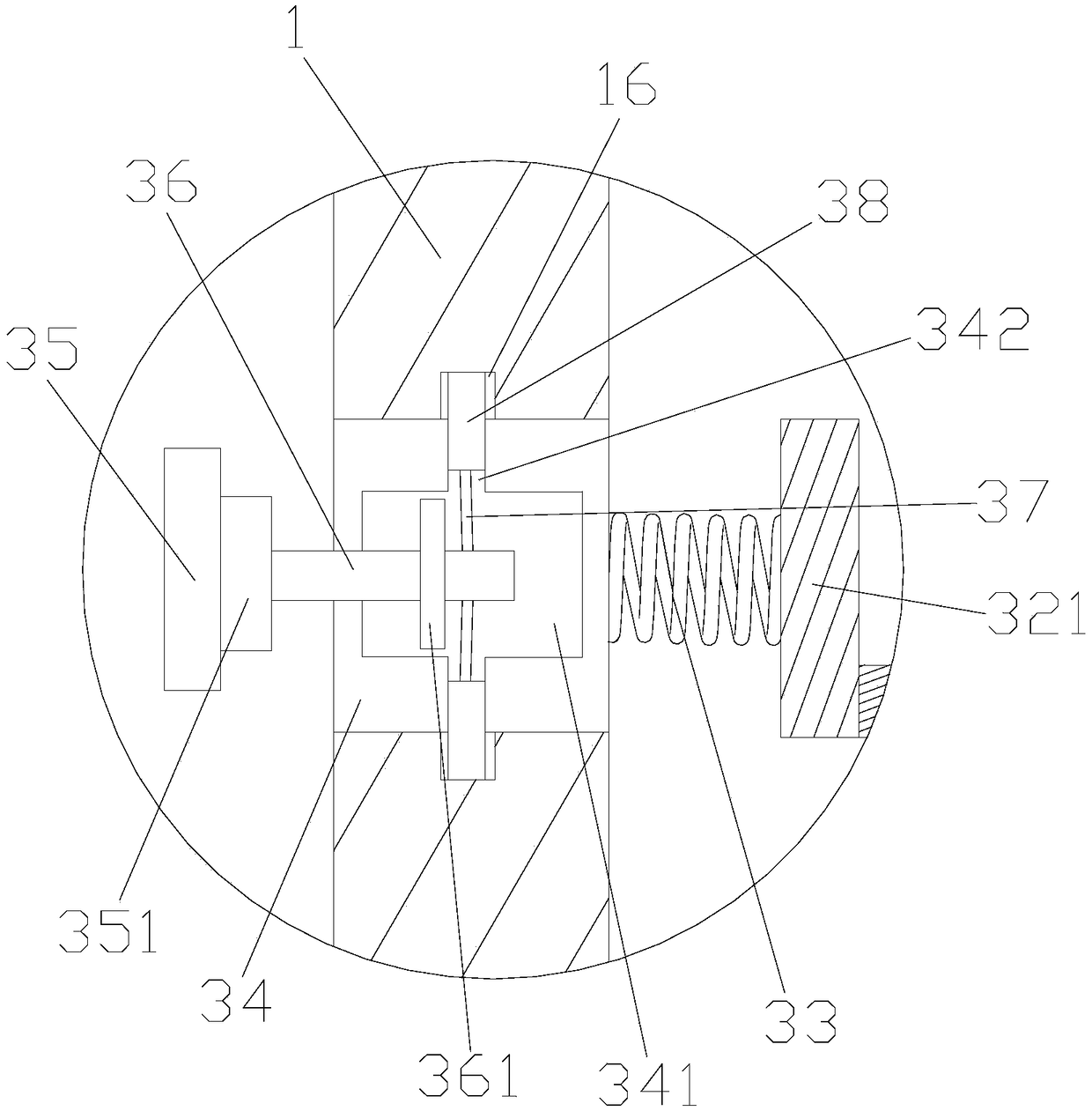

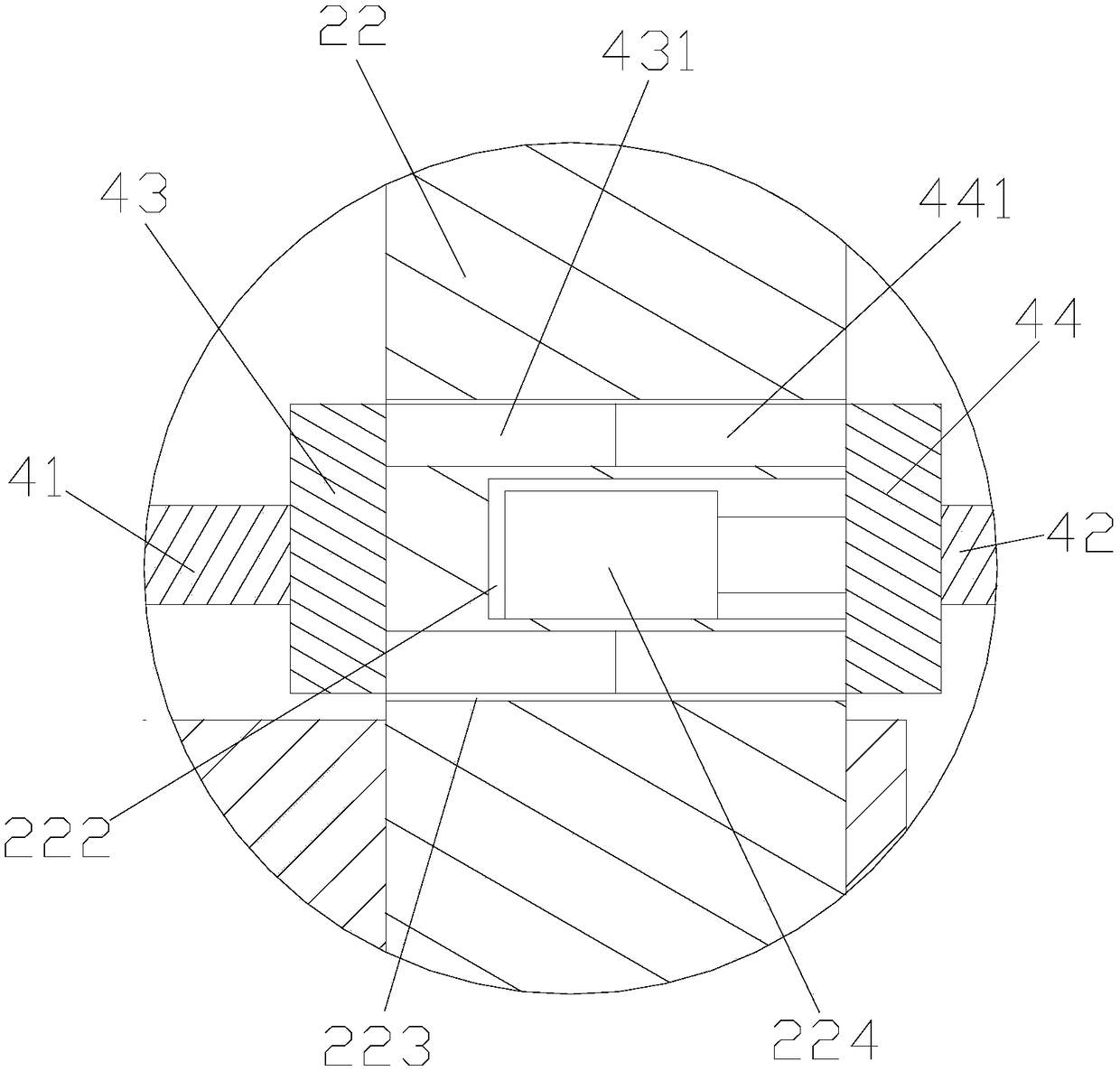

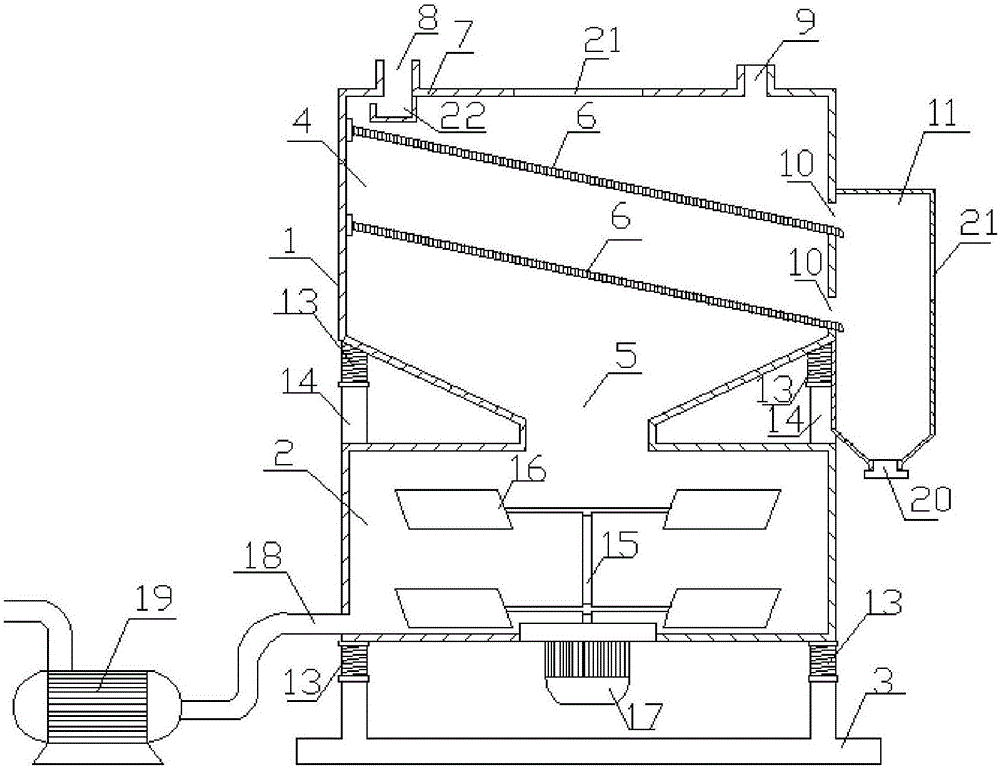

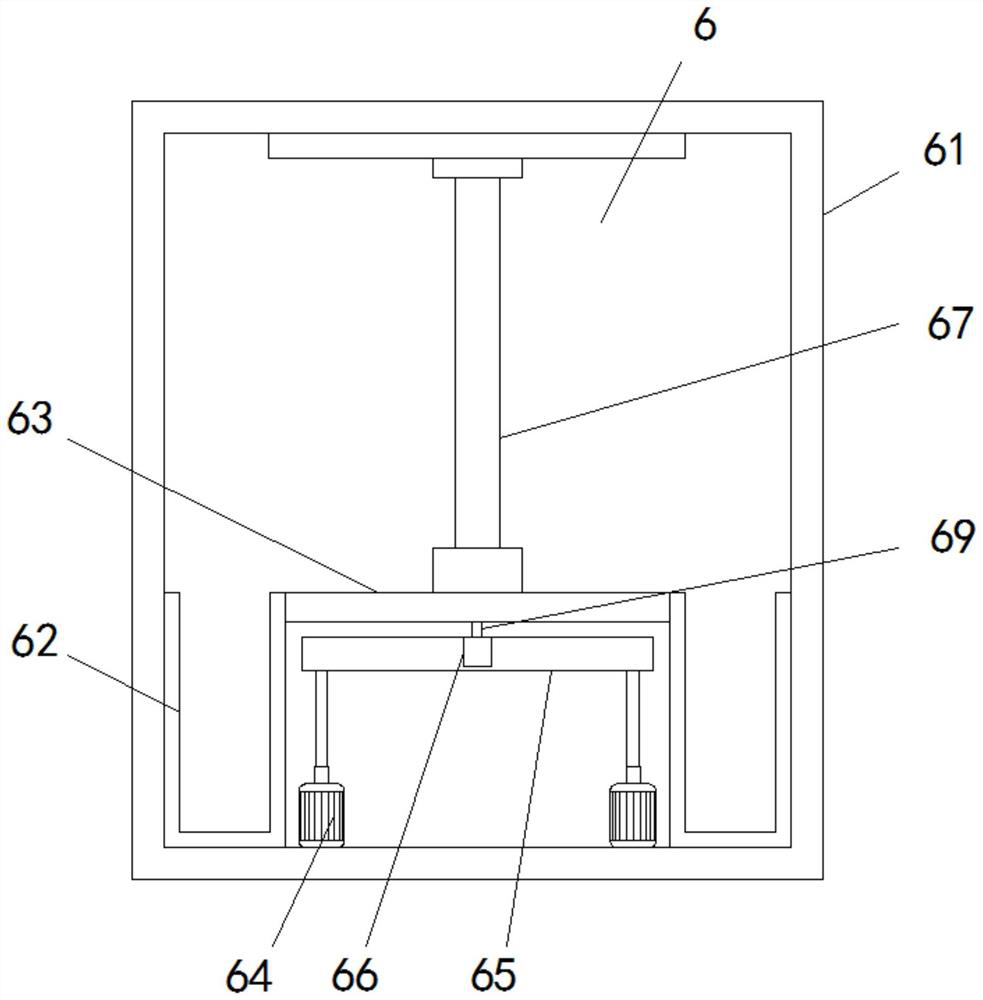

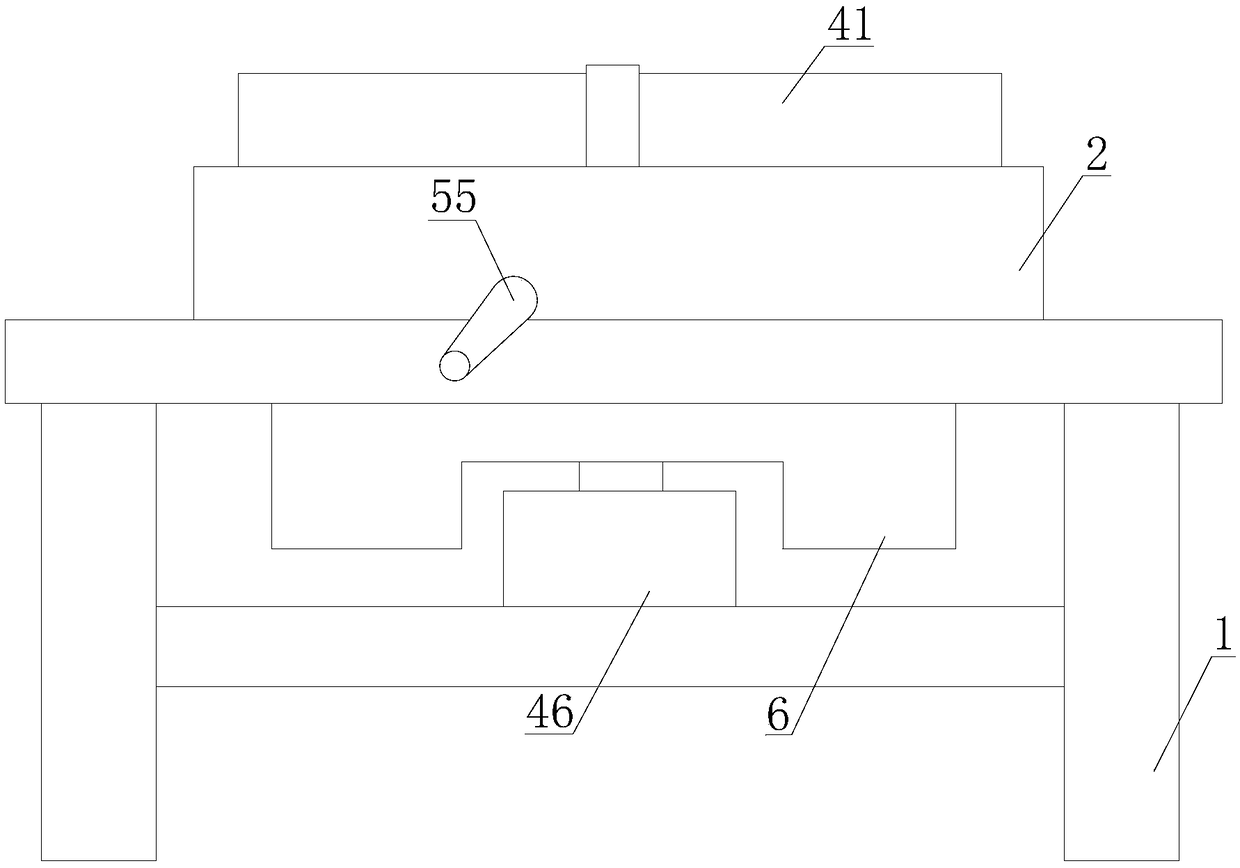

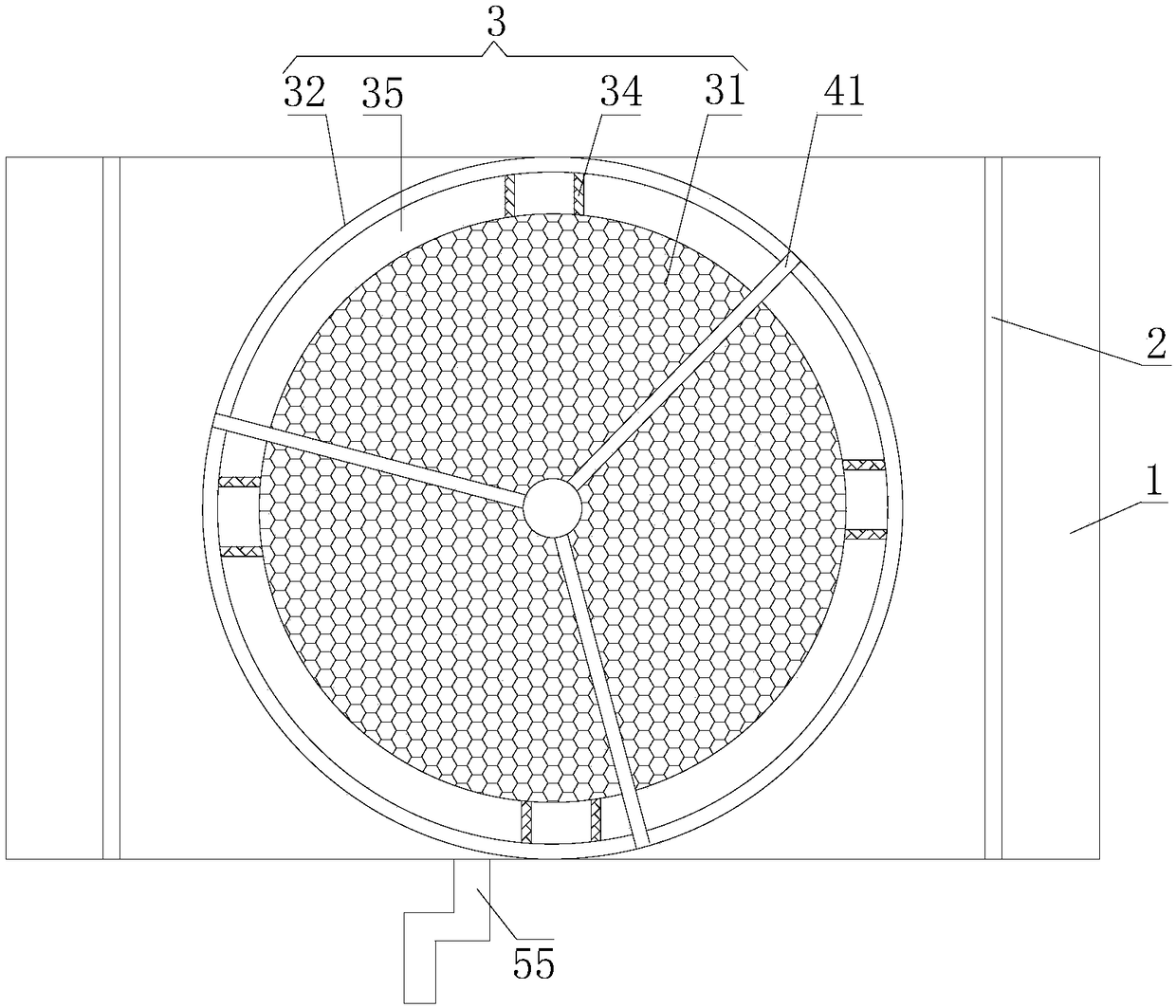

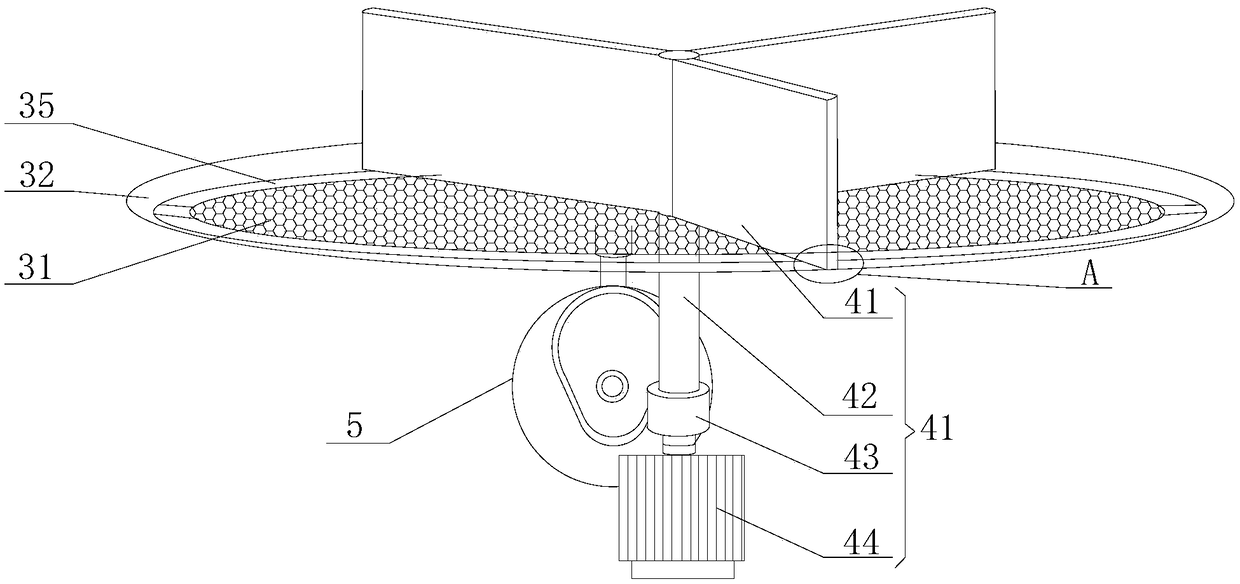

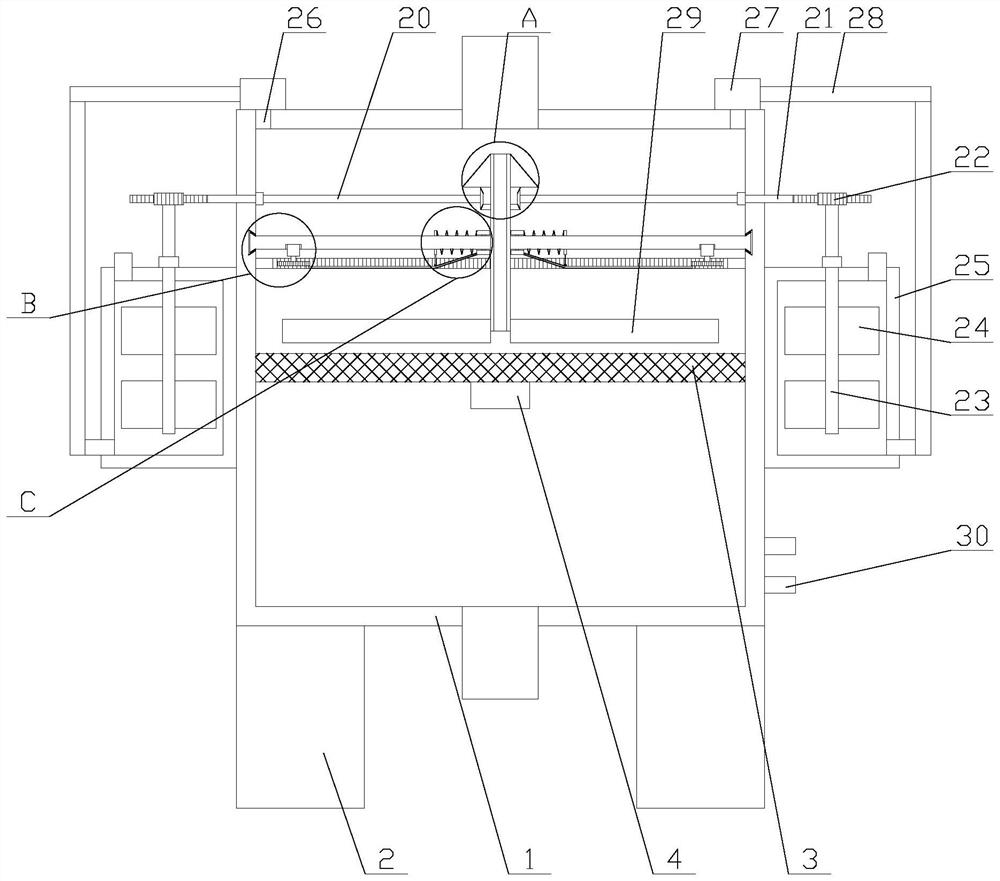

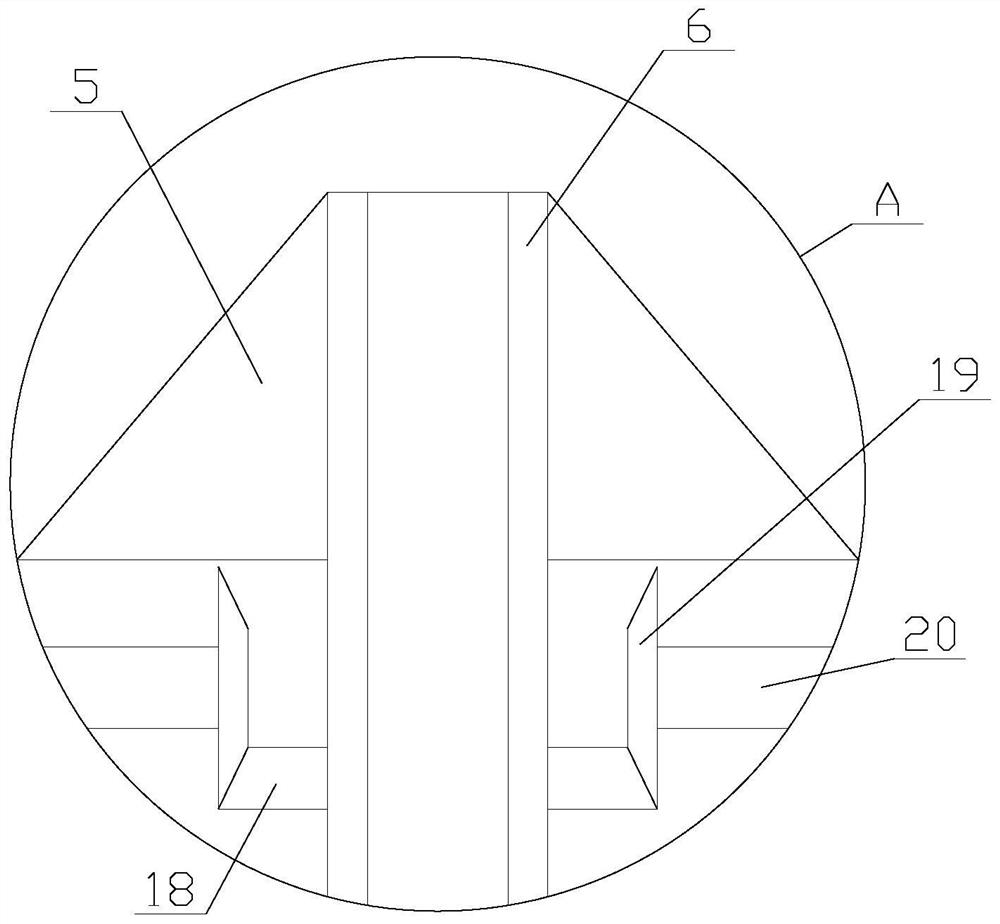

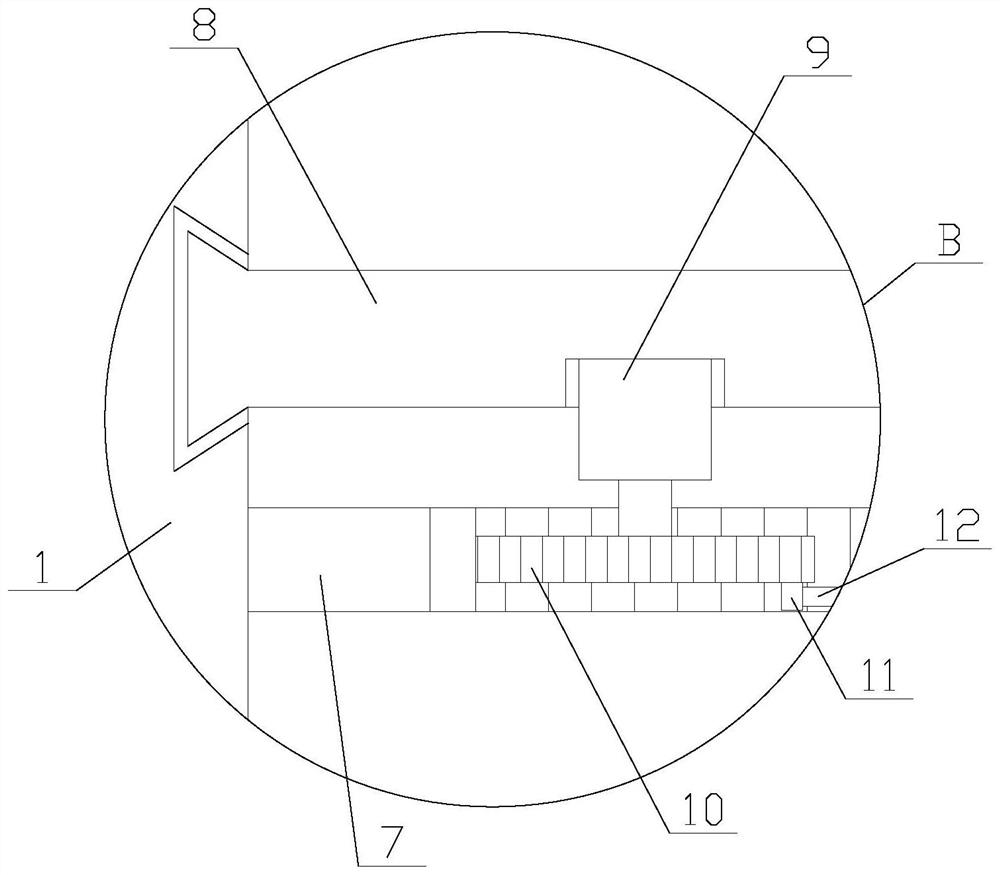

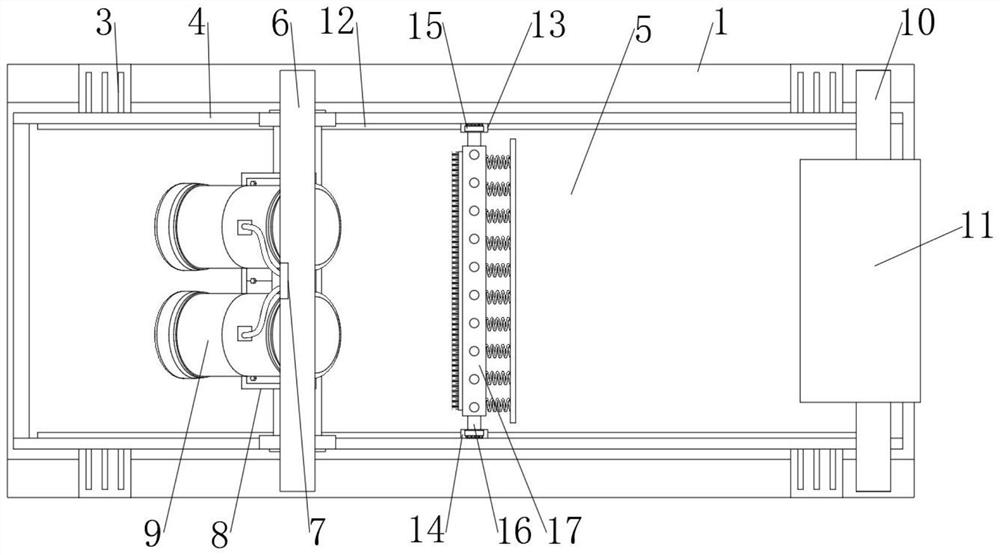

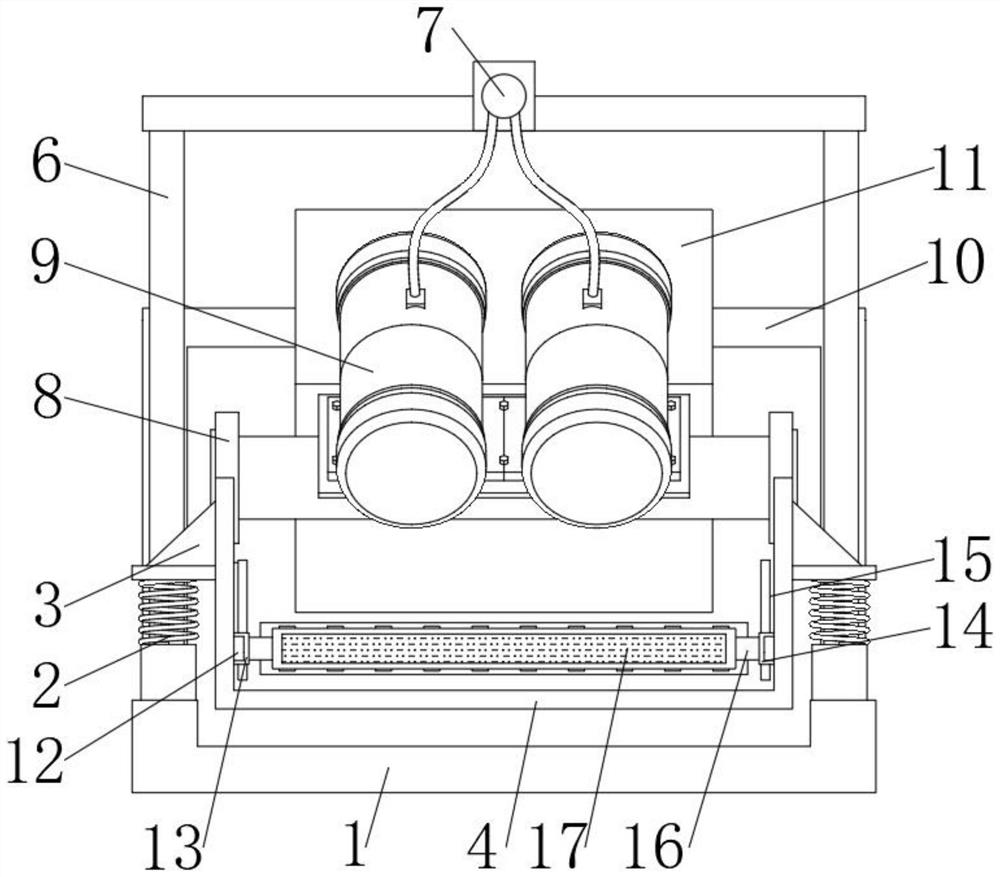

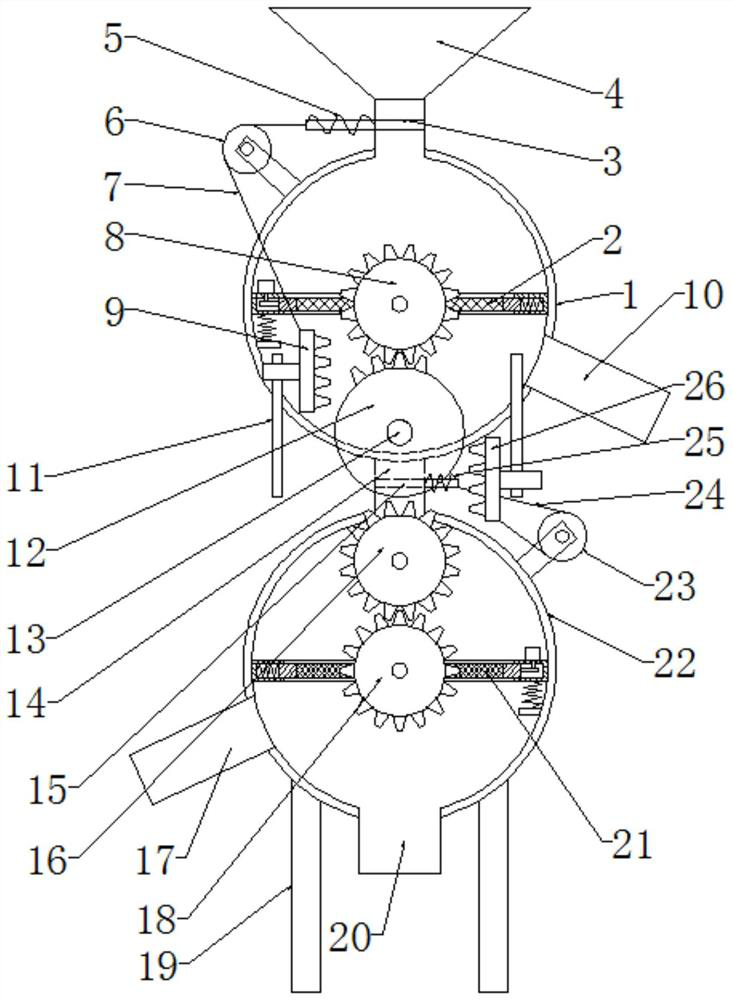

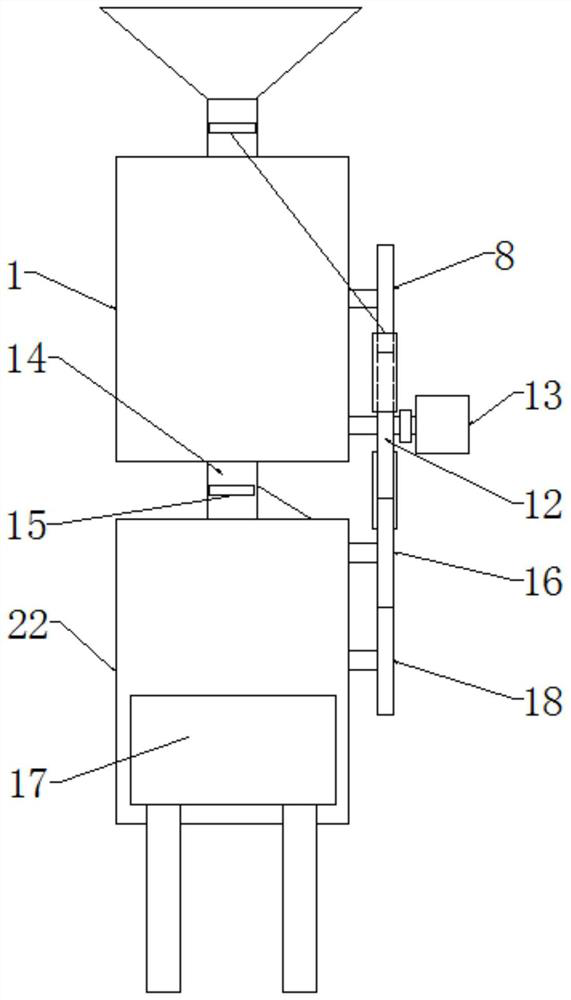

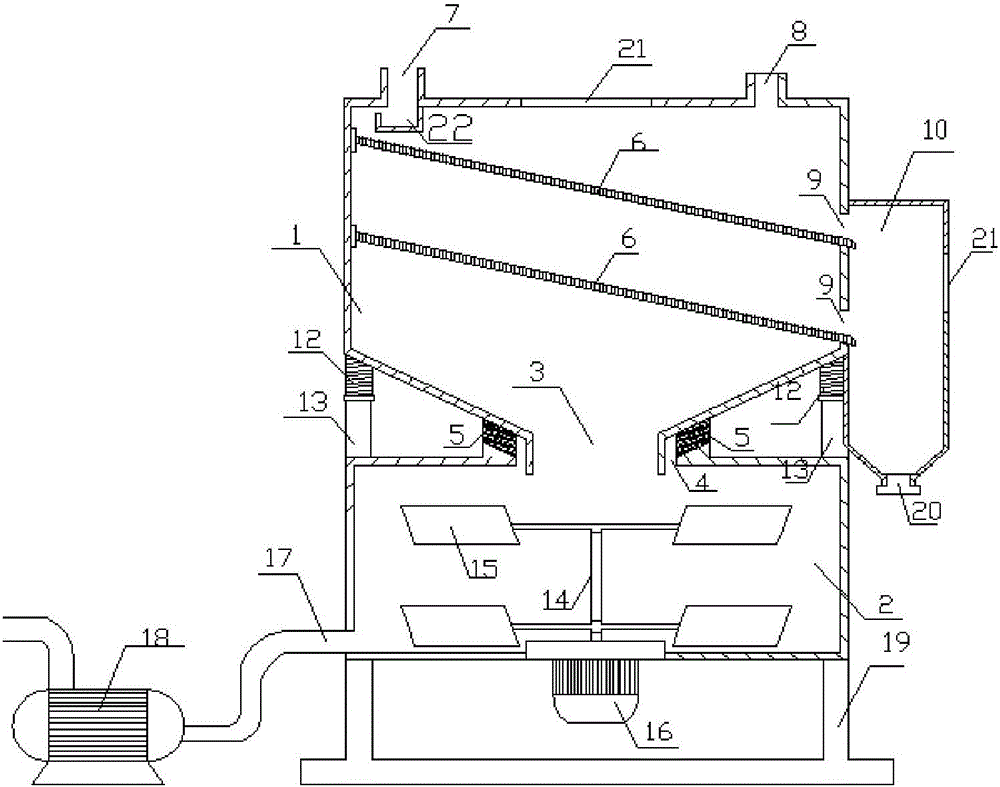

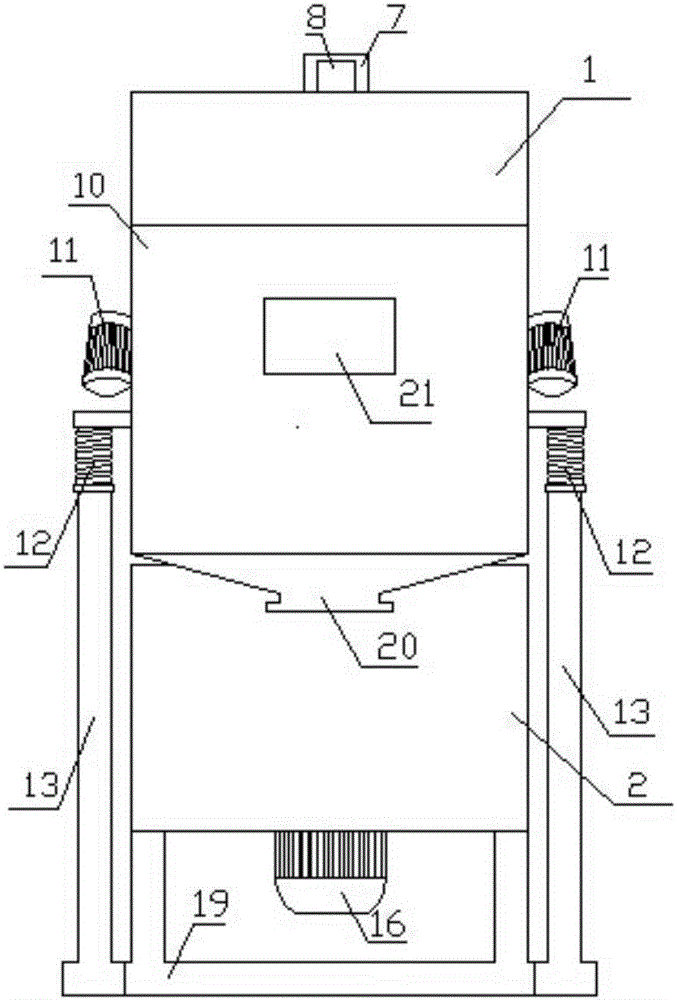

The invention discloses an efficient all-in-one machine for grinding and screening traditional Chinese medicinal materials, which comprises a base, a spherical shell, an outer frame and an inner frame. In the present invention, the reverse rotation of the upper grinding block and the lower grinding block is realized through the bevel gear set, so that the Chinese herbal medicines are successively ground in two directions during the falling process, so that the grinding is more sufficient and the grinding effect is guaranteed; The driving mechanism drives the outer frame to move left and right, so that the medicinal materials falling from the feeding pipe evenly fall onto the sieve plate, so as to avoid the accumulation of medicinal materials on the sieve plate, which will affect the screening efficiency. At the same time, the inner frame follows the outer frame to reciprocate left and right The movement makes the pulley move left and right on the raised surface, thereby driving the connecting frame to move up and down, and then making the inner frame drive the sieve plate to vibrate up and down, resulting in a vibrating sieve effect and improving the screening efficiency.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

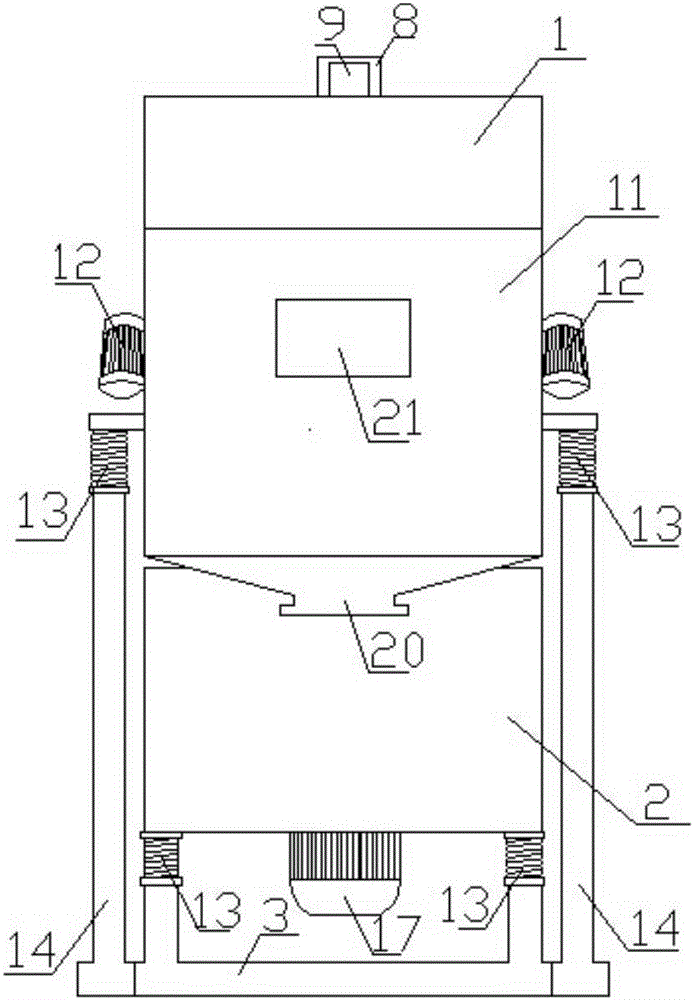

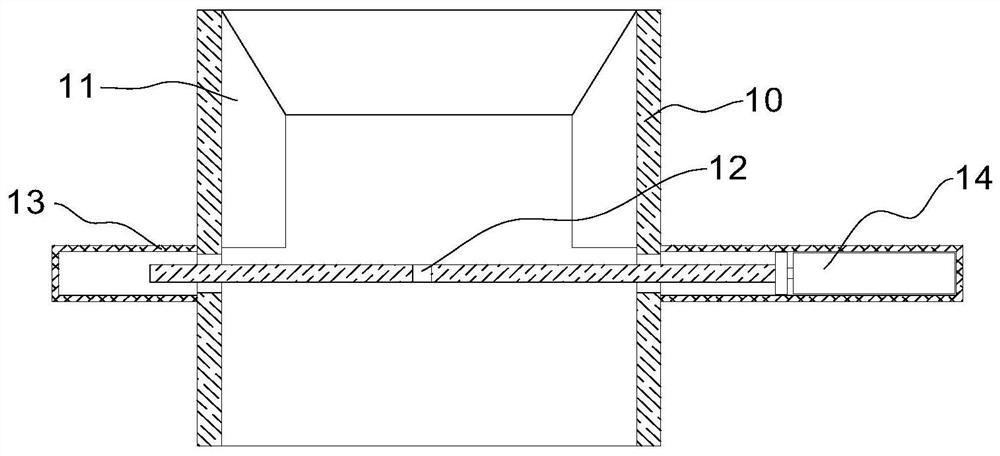

Sand screening device for constructional engineering

The invention discloses a sand screening device for constructional engineering. The sand screening device for the constructional engineering comprises a bottom plate, a screen net, a sand screening box, a second motor, a second threaded rod, a second sleeve, a connection rod, a third motor, a crankshaft, a linking rod, a rotating shaft, a fourth motor, a third gear, a fourth gear, a spring, a stirring rod, a shredding ball, a conical material dividing plate, a magnet and an iron sheet. The sand screening device for constructional engineering is provided with a first motor, a first gear, firstsleeves and first threaded rods, the whole device is fixed, and equipment damage and a safety accident caused by toppling and falling of the device are avoided; the second motor, a second sleeve, a second threaded rod and the connection rod are arranged, the sand screening box is made to incline, discharging is facilitated, sand which cakes because of moisture is smashed, and it is avoided that the screening efficiency is affected; meanwhile, falling sand is uniformly thrown to the periphery through the conical material dividing plate, sufficient and uniform screening is performed, and it is avoided that the sand is accumulated at one position of the screen net and the screening speed is decreased; and the magnet, the iron sheet and a spring are arranged, the screen net is made to shake violently, and the screening efficiency is improved.

Owner:河北地质大学

Building gravel screening machine having anti-blocking function

InactiveCN108855899AAvoid cloggingImprove efficiencySievingGas current separationEngineeringDrive motor

The invention discloses a building gravel screening machine having an anti-blocking function, relates to the technical field of screening devices and aims to solve the technical problems that screening plates of existing screening equipment are prone to being blocked, repeated screening is needed, gravel different in particle size cannot be screened in one time, and screening efficiency is low. The building gravel screening machine comprises a box, a feeding port and a discharging port are arranged on the box, a scraping plate component and at least two screening plates are arranged in the box, the scraping plate component comprises a first rotating shaft which is vertical, a first driving motor and multiple scraping rods sleeving the first rotating shaft and positioned above the corresponding screening plates, a circulating outlet and a circulating inlet which are matched with the corresponding screening plate are arranged on the box, a material lifting device positioned on the outerside of the box is connected on the circulating outlet and the circulating inlet, and a gravel outlet is arranged at the bottom of the material lifting device. The building gravel screening machine has the advantages that blocking of the screening plates is prevented effectively, clean gravel can be screened in one time while gravel different in particle size can be screened in the other time, andscreening efficiency is high.

Owner:ZHENGZHOU JIZHI TECH CO LTD

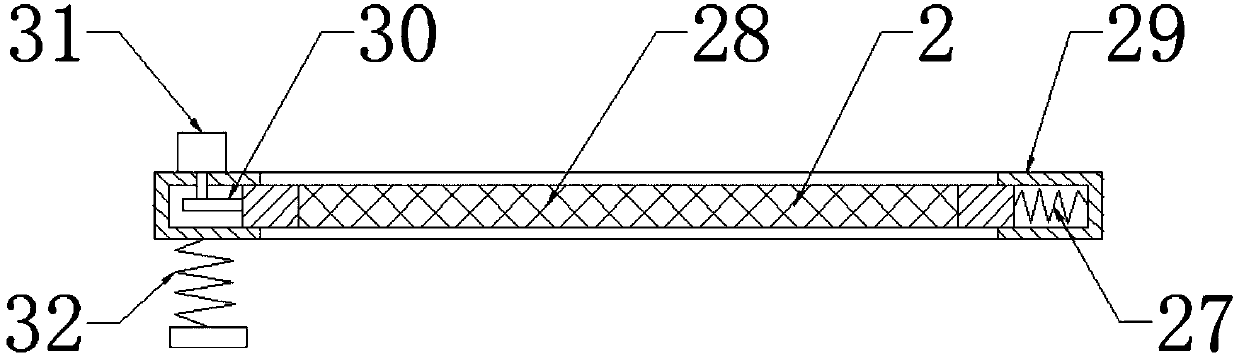

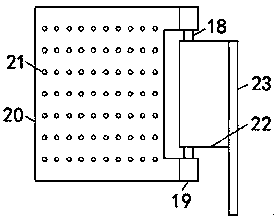

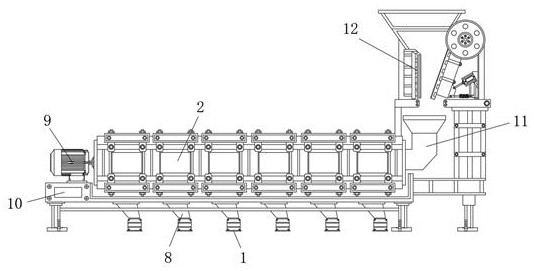

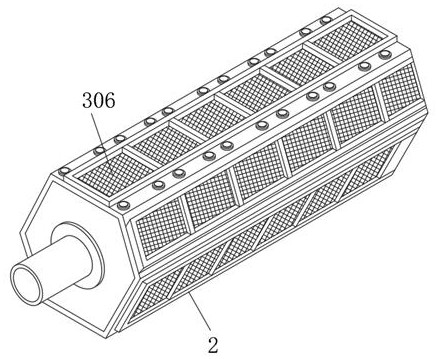

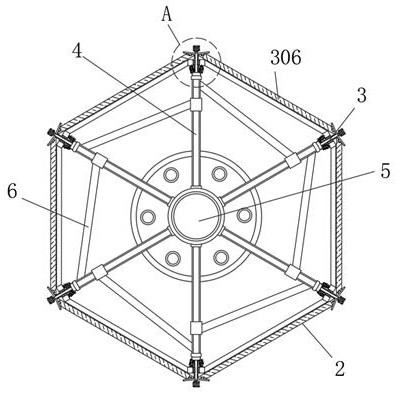

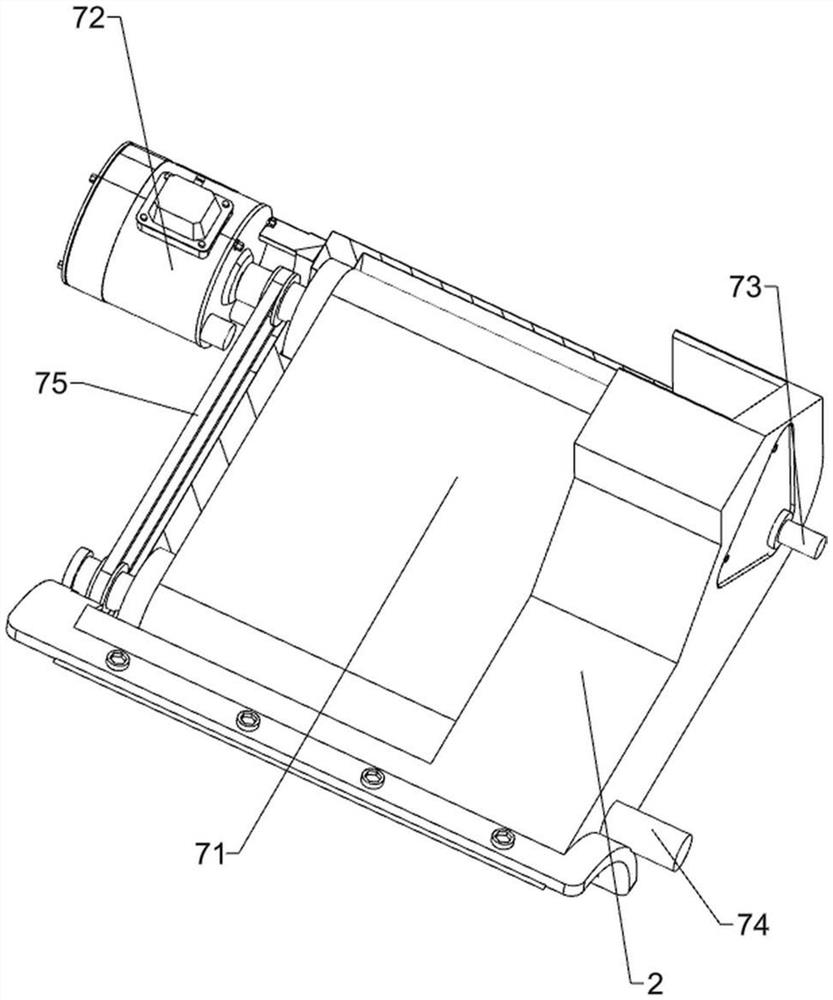

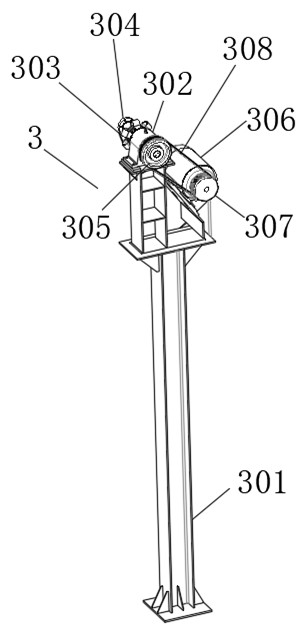

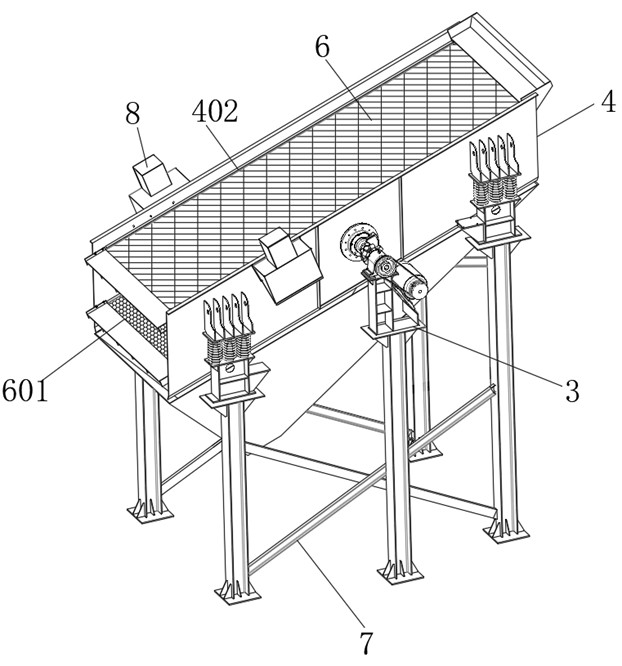

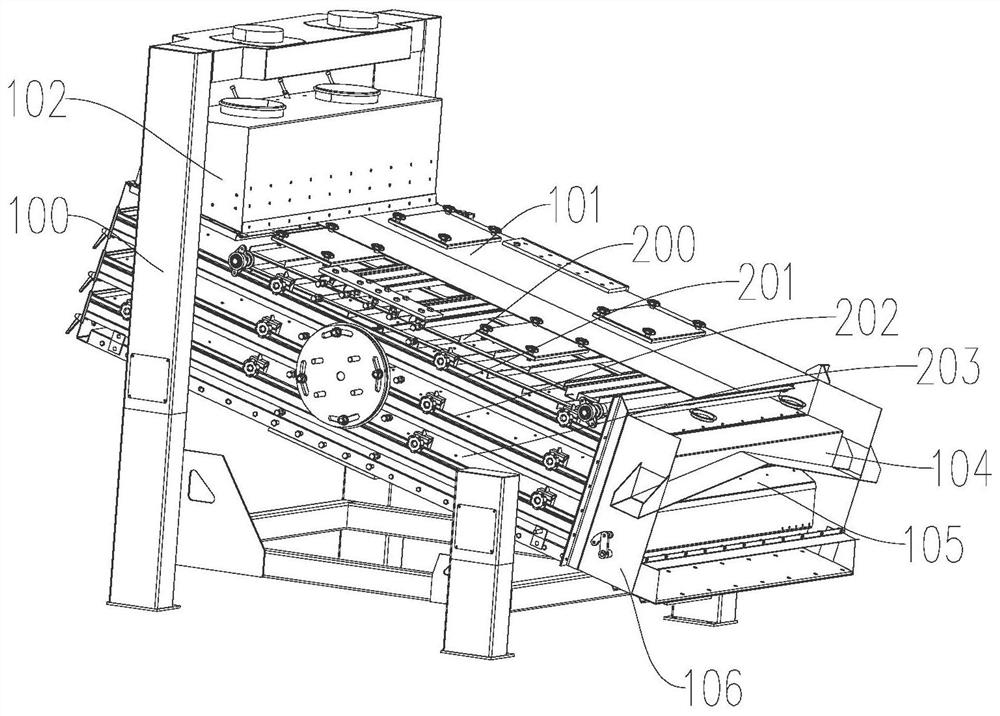

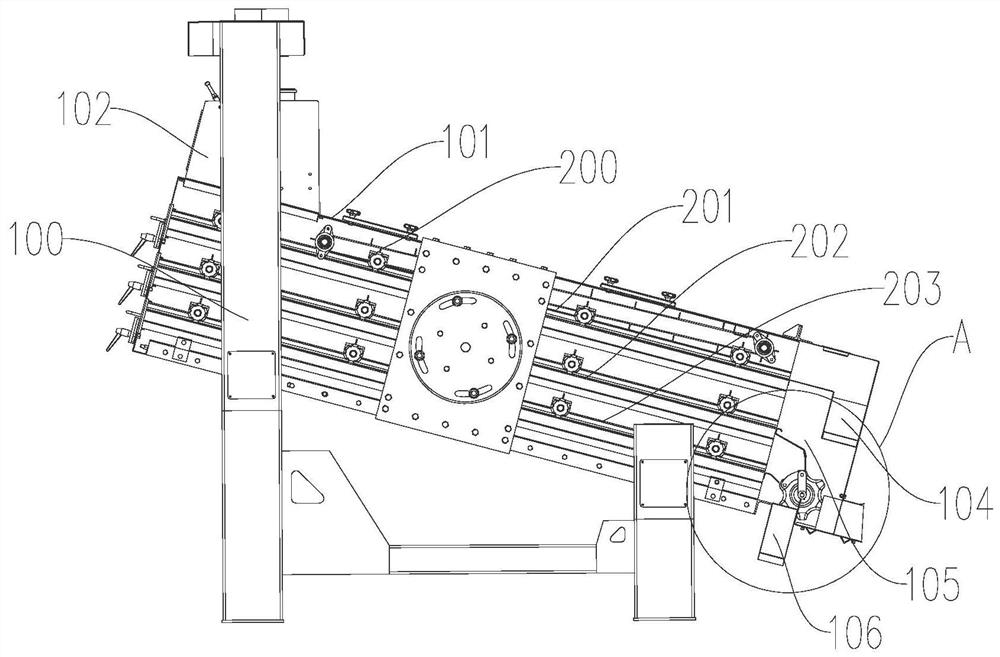

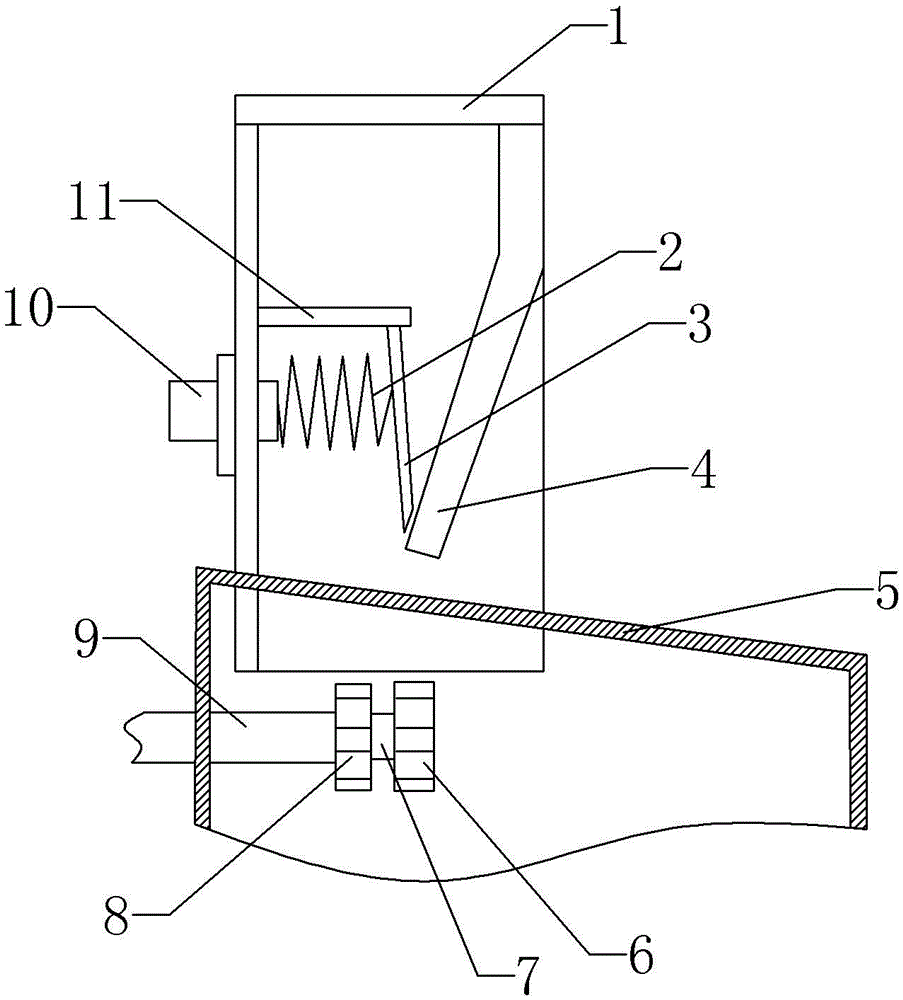

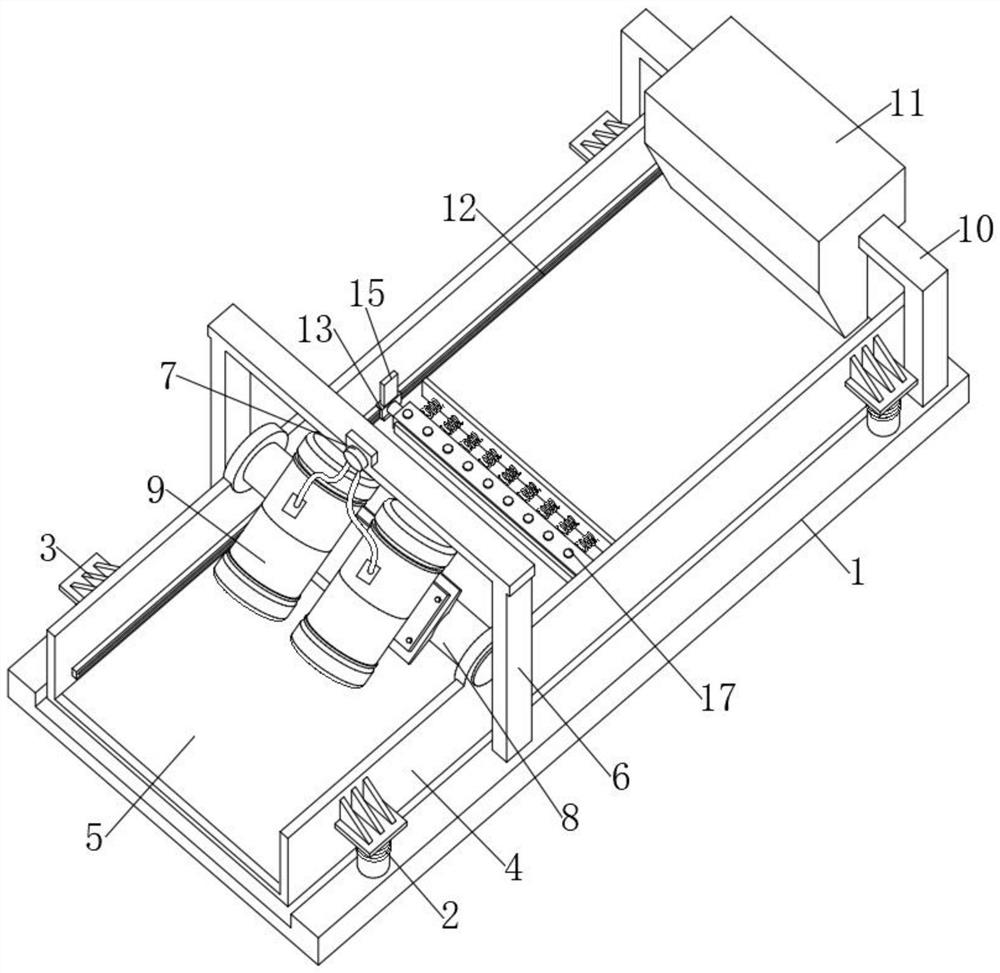

Efficient sand screening device with conveying frame

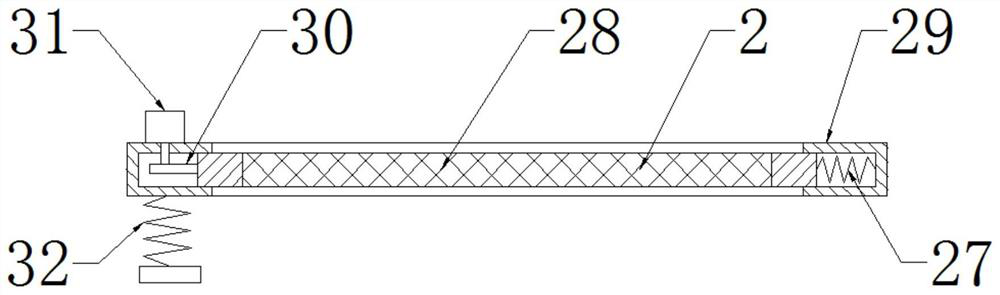

InactiveCN107457044AAchieve vibrationAvoid affecting screening efficiencySievingScreeningScreening effectMechanical engineering

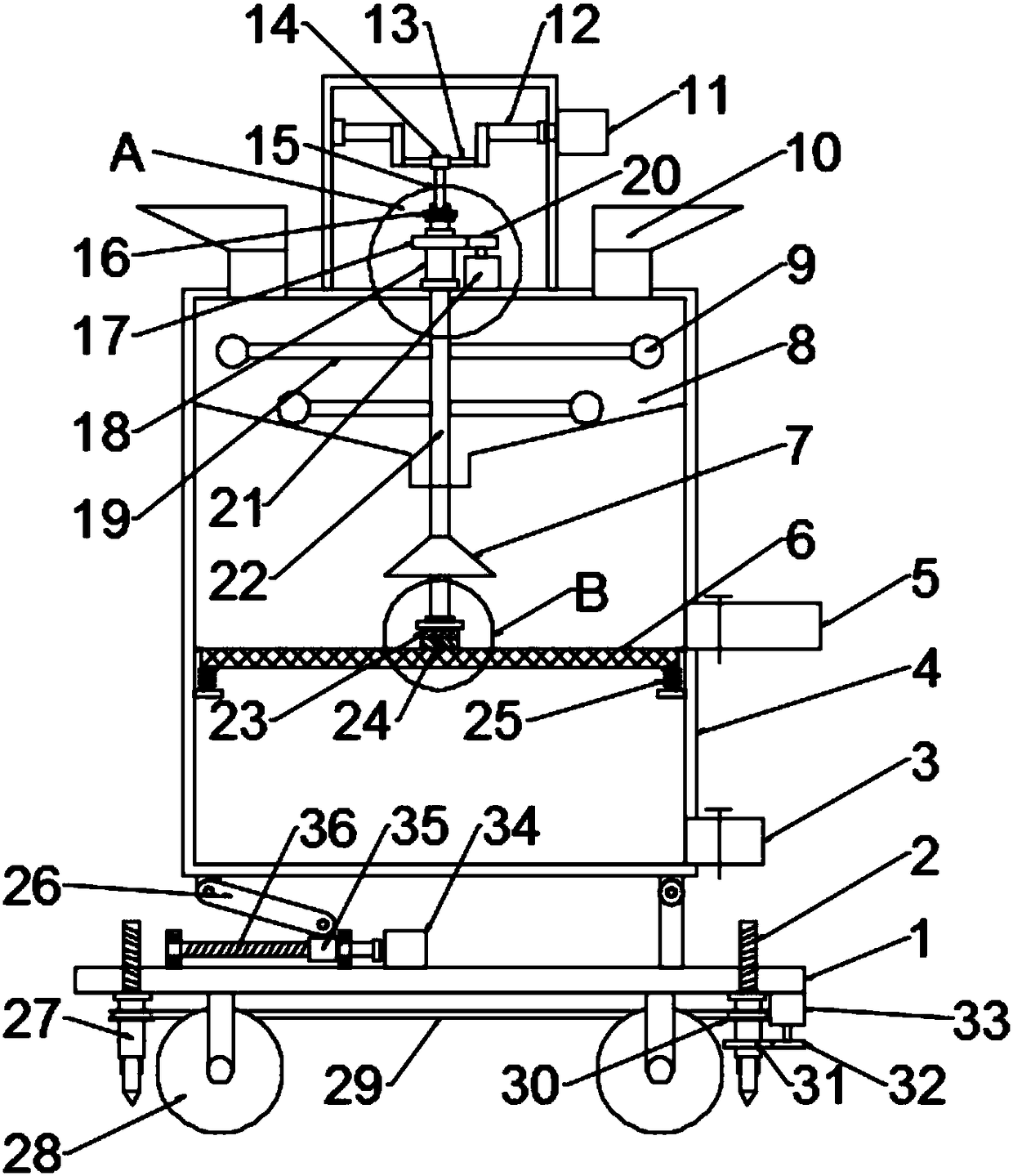

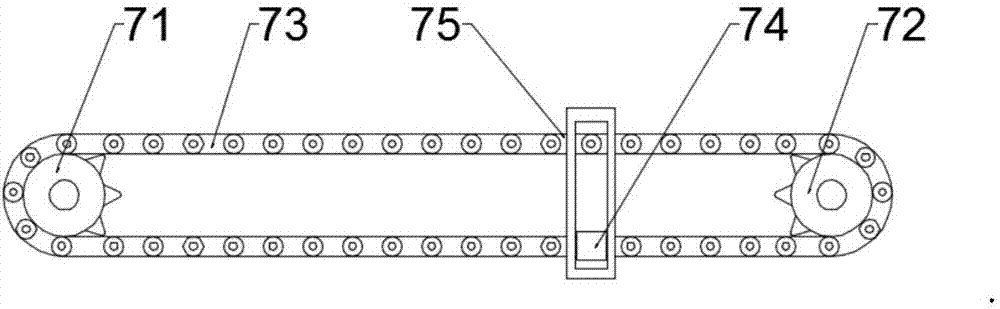

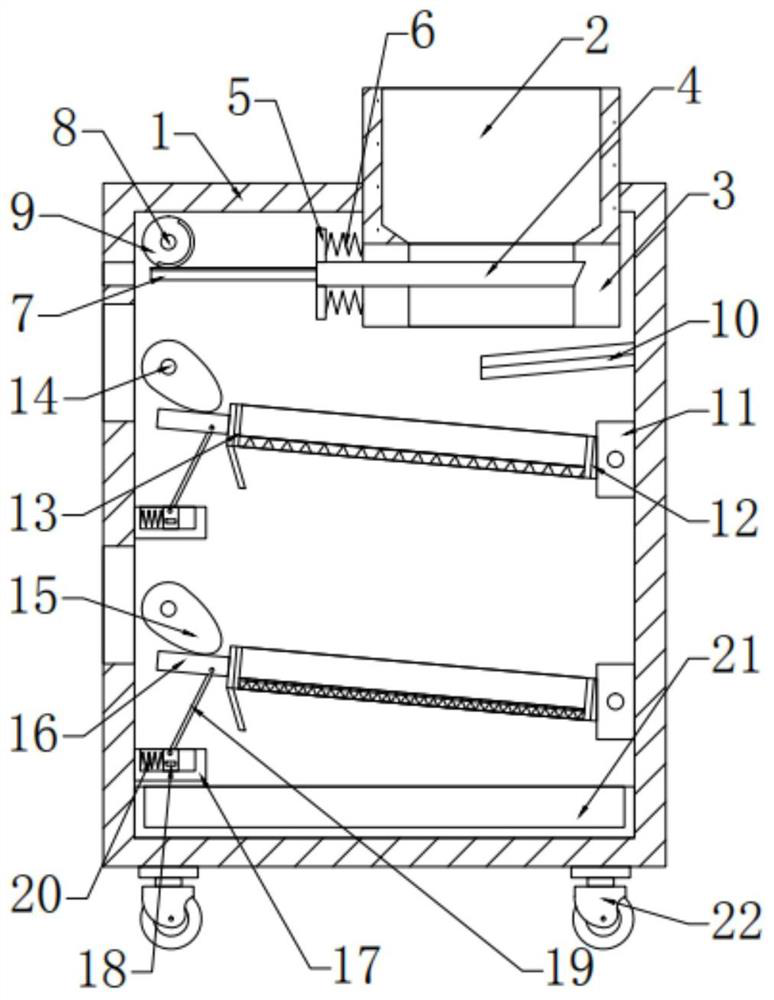

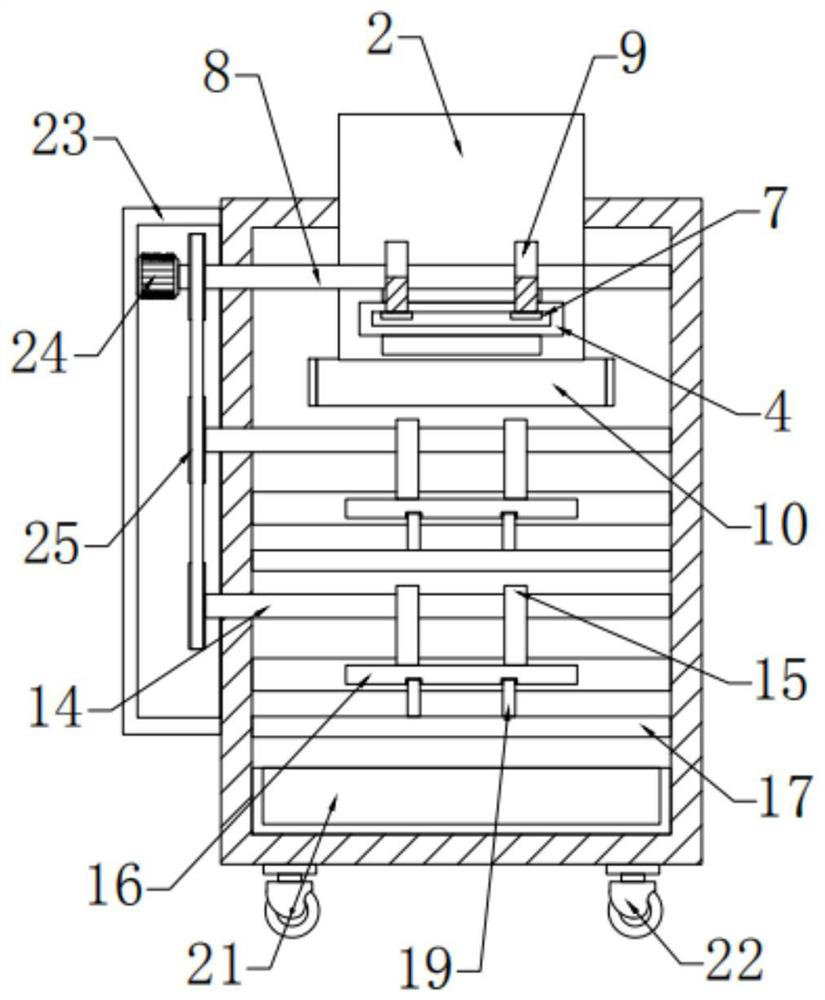

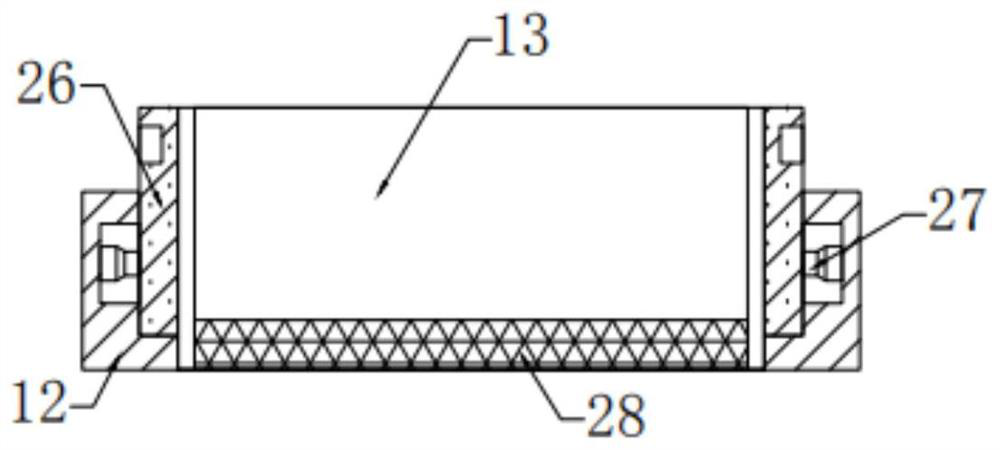

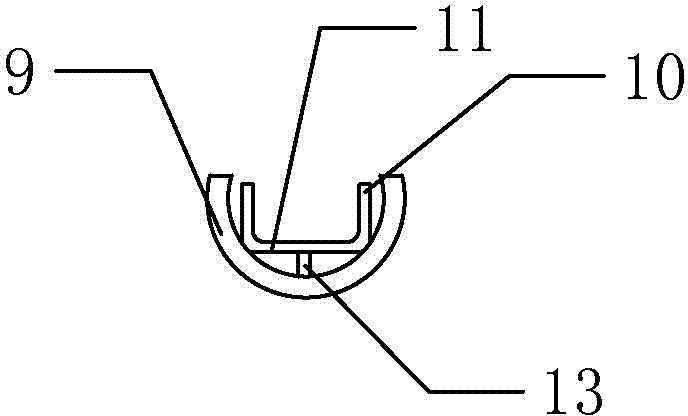

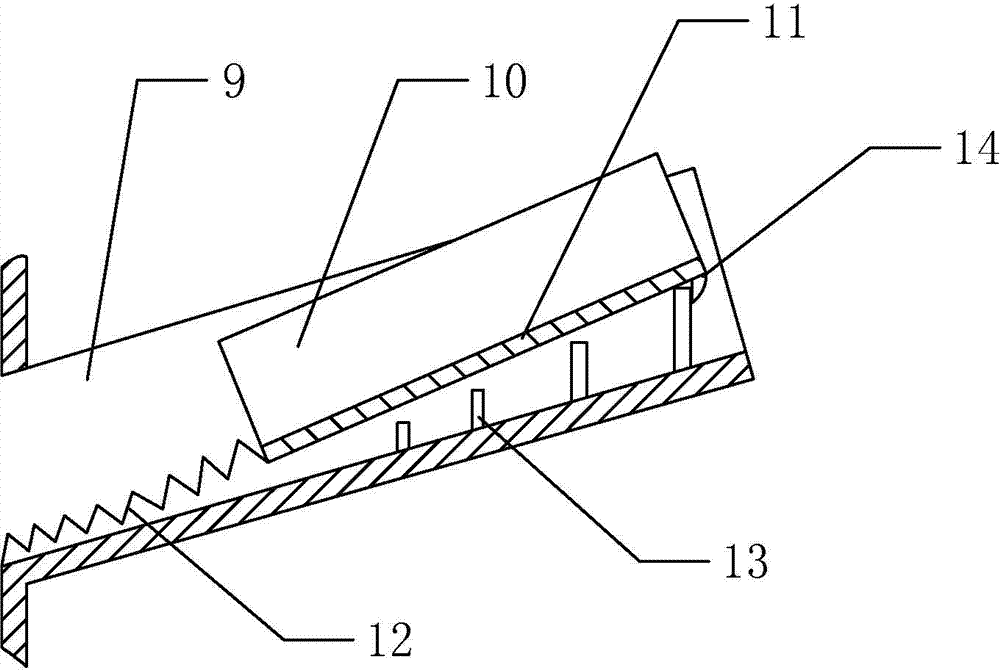

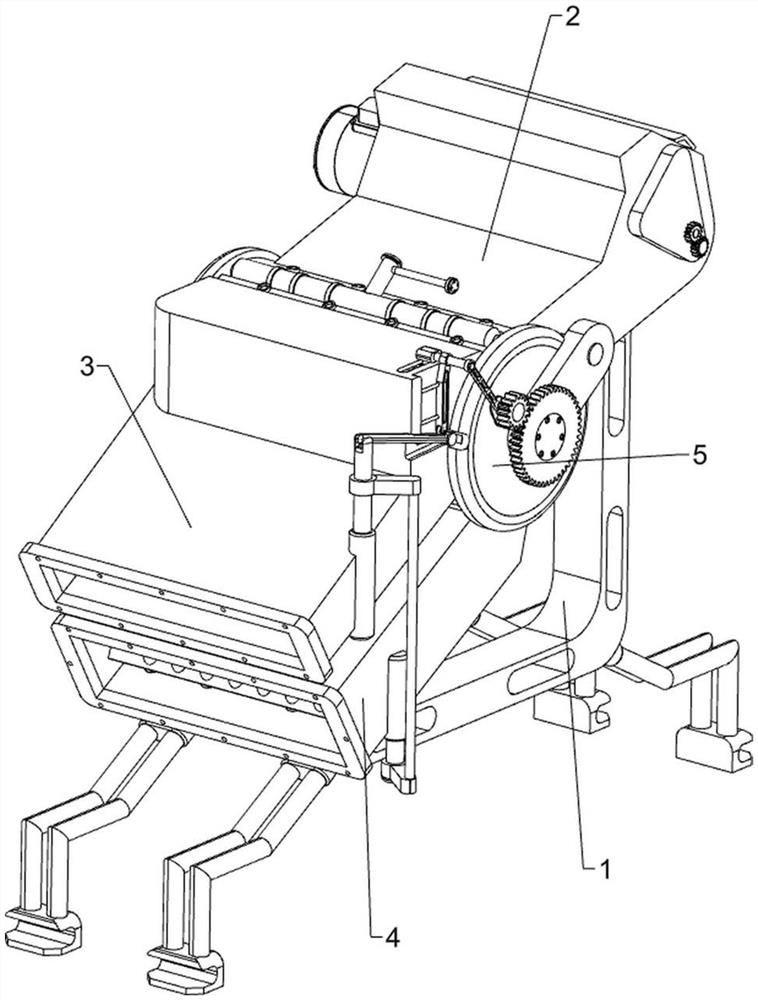

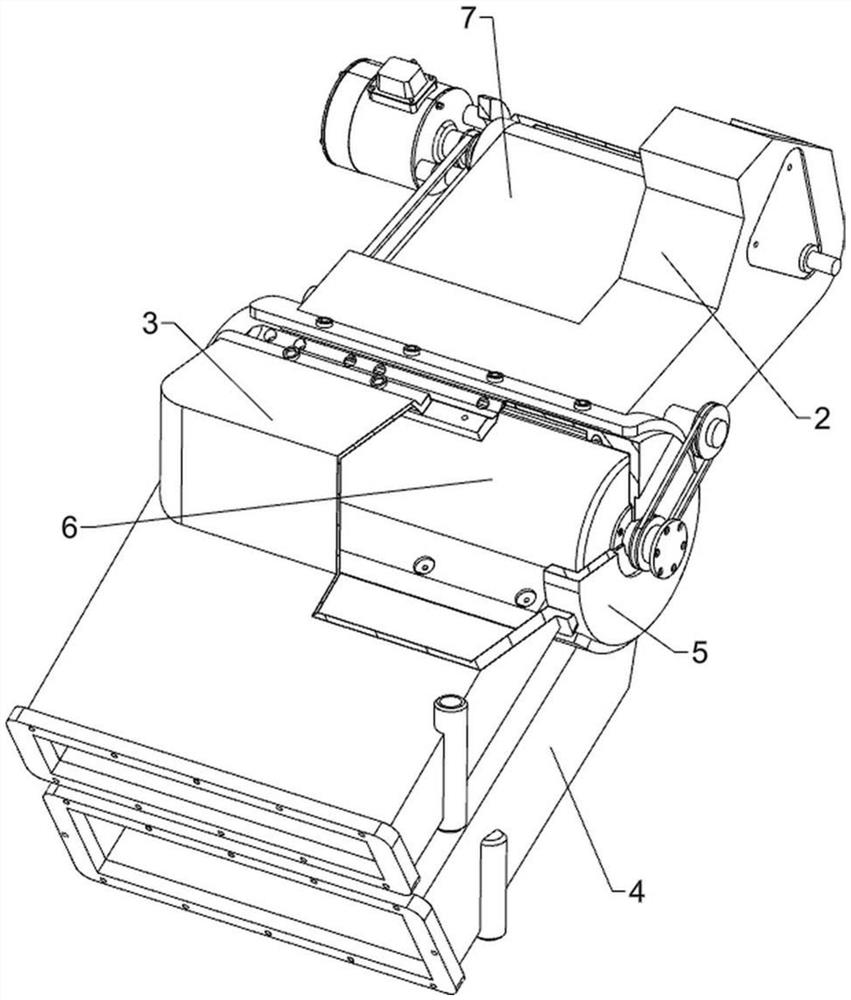

The invention discloses a high-efficiency sand screening device with a conveying frame, which comprises a conveying frame, a sand screening frame and a base arranged from top to bottom; Lifting rollers are provided; the conveying frame is connected to the base through a bracket, a feeding frame is embedded on the top plate of the conveying frame, and a breaking hammer is arranged in the feeding frame; U-shaped Guide rails, a hollow movable block is arranged between the U-shaped guide rails on both sides, and a left and right reciprocating mechanism is arranged on the inner side of the movable block to drive it to move; High drive mechanism. The sand screening device of the present invention can effectively solve the problems of sand agglomeration and concentrated accumulation, and improve the sand screening efficiency; meanwhile, the setting of multi-directional vibration can effectively improve the sand screening effect.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

Intermittent discharge type multi-stage screening device for building

ActiveCN107694914AAvoid cloggingAvoid the impact of sand screening efficiencySievingScreeningElectric machineEngineering

The invention discloses an intermittent discharge type multi-stage screening device for building. The device comprises a first screening box, a second screening box, a first sand screening device, a second sand screening device, a second motor, an incomplete gear, a first gear, a second gear, a third gear, a first rack, a first baffle and a second baffle. The first sand screening device comprisesa square frame, a screening net, a first spring, a first motor, a cam and a second spring. Since the first sand screening device and the second sand screening device are arranged, multi-stage sand screening can be carried out to meet different working requirements; since the second motor, the incomplete gear, the first gear, the second gear, the third gear, the first rack, the second gear, the first baffle and the second baffle are arranged, intermittent discharge is achieved by matching the components, the problem that net holes of a screening net are blocked since the one-time discharge amount is too high so as to affect the screening efficiency is avoided, sand on the screening net can be immediately discharged after each screening, and the screening efficiency is prevented from being affected.

Owner:湖北铭元建设工程有限公司

Tablet particles screening machine for preventing blockage of powder

InactiveCN108160468AImprove work efficiencySolve the easy to cause blockageSievingScreeningEngineeringVibration motor

The invention relates to the technical field of pharmaceutical production equipment, and discloses a tablet particles screening machine for preventing blockage of powder. The tablet particles screening machine comprises two supporting plates, the opposite sides of the two supporting plate are both provided with movable holes, the inner portion of the two movable holes are movably connected with asieve plate, the left and right sides of the bottom of the sieve plate are both fixedly connected with springs arranged equidistantly, the top of the sieve plate is provided with sieve holes distributed uniformly, the left side of the top of the sieve plate is provided with a vibration motor, a top plate is fixed connected between the two supporting plates, a cross-shaped conduit is fixedly connected on the top of the top plate, and the top of the cross-shaped conduit is fixedly connected with a receiving hopper. The tablet particles screening machine for preventing blockage of powder has theadvantages that it is avoided that the blocked sieve holes cause the filtering rate to slow down, thereby the work efficiency of the screening machine is reduced, a lot of time and labor to clean up the blocked sieve holes are saved, unnecessary troubles are avoided, and the work efficiency of the tablet particles screening machine is improved.

Owner:盐城市瑞普医药化工有限公司

Quick-feeding screening machine for building gravel

InactiveCN108855852AHigh speedImprove efficiencySievingGas current separationSpiral bladeEngineering

The invention discloses a quick-feeding screening machine for building gravel and relates to the technical field of screening devices. The quick-feeding screening machine comprises a box, a feeding port and a discharging port are arranged on the box, a feeding mechanism is arranged on the outer side of the box and comprises a first shell, a first rotating shaft which is vertical is arranged in thefirst shell, a first driving motor is arranged at the top of the first rotating shaft, a first spiral blade sleeves the first rotating shaft, a gravel inlet is arranged at the lower end of the firstshell, and a gravel outlet is arranged at the upper end of the first shell and communicated with the feeding port; at least two screening plates are arranged in the box, a circulating outlet and a circulating inlet are arranged on the box, the bottom end of the circulating outlet is flush with the upper surface of each screening plate, a material lifting device positioned on the outer side of thebox is connected on the circulating outlet and the circulating inlet, and a discharging opening is arranged at the bottom of the material lifting device. The quick-feeding screening machine has the advantages of being quick in feeding, capable of screening gravel in one time, capable of screening gravel different in particle size in one time and high in screening efficiency.

Owner:ZHENGZHOU JIZHI TECH CO LTD

Plastic particle screening device

The invention discloses a plastic particle screening device comprising a box body, a first filter layer disposed in the box body, a second filter layer disposed under the first filter layer and a support for supporting the box body. The pore diameter of the first filter layer is smaller than that of the second filter layer. The top of the box body is provided with a feed port disposed above the first filter layer. The bottom of the box body is provided with a storage chamber, and the bottom of the storage chamber is provided with a discharge port. The first filter layer and the second filter layer are detachably connected with the box body. The plastic particle screening device further includes a shaking device for causing the first filter layer and the second filter layer to shake. When the plastic particle screening device is used for screening plastics, the filter layers can shake to improve the screening effect. By means of the detachable connection of the filter layers, materialson the filter layers can be cleaned conveniently, the filter layers can be replaced and dredged conveniently, and the service life of the filter layers is prolonged.

Owner:杭州大橙知一科技有限公司

Intermittent discharging type multi-stage screening device for building

InactiveCN111957553AImprove sand screening efficiencyAvoid affecting screening efficiencySievingScreeningElectric machineryMotor drive

The invention relates to the technical field of building equipment, in particular to an intermittent discharging type multi-stage screening device for a building. The device comprises a housing, wherein a feeding box is fixedly connected to the top of the housing, a discharging mechanism is arranged at the bottom of the feeding box, a plurality of screening mechanisms are arranged on the lower side of the discharging mechanism, the screening mechanism is connected to the discharging mechanism through a transmission mechanism, and a collecting box is arranged at the bottom of the inner side ofthe housing. According to the device, as the discharging mechanism is arranged, intermittent discharge of the device is achieved as a baffle plate moves repeatedly left and right by means of an incomplete gear and a first spring, so that a condition that the screening efficiency is affected as meshes of a filter screen are blocked due to excessive discharge at one time is avoided. By arranging thetransmission mechanism, a motor drives a transmission bar to rotate, the transmission bar drives a cam to rotate, and under interaction of the cam and a second spring, a placing frame vibrates, so that the sand screening efficiency is improved. By arranging the multiple screening mechanisms, the device can screen various sand of different grain sizes, thereby meeting the demand of different workof people.

Owner:苏州格瑞格登新材料科技有限公司

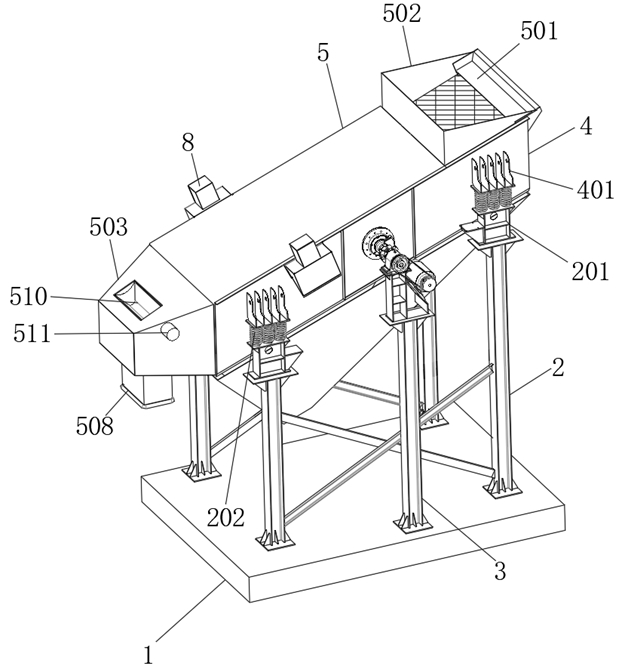

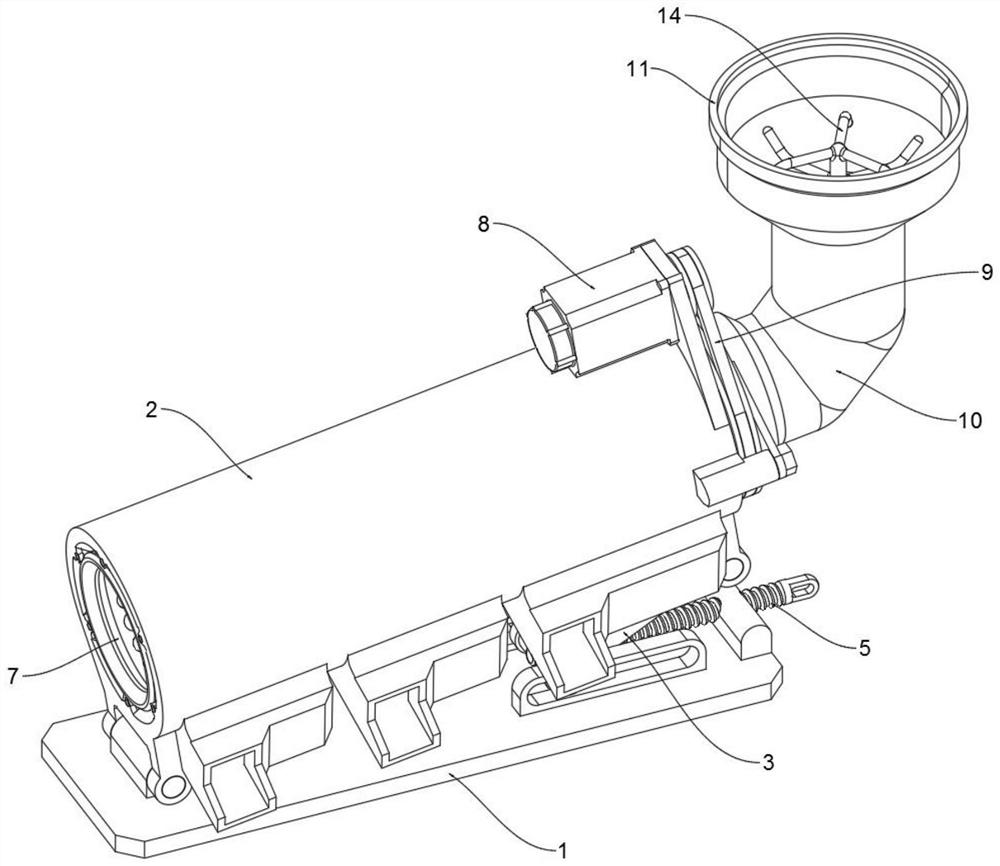

Petroleum drilling fluid shaker

The invention provides a vibrating screen for petroleum drilling fluid, which includes a screening box, a liquid collection box arranged at the bottom of the screening box and connected with the screening box, and a bracket provided at the bottom of the liquid collection box; the upper part of the screening box is a Screening area, the lower part is the liquid passing area connected with the screening area, the screening area is a cuboid structure, and the liquid passing area is a downward convex conical structure; the liquid passing area is connected with the liquid collection tank; the screening area is equipped with an inclined The installed vibrating screen, the side wall of the screening box corresponding to the lower end of the vibrating screen is provided with a debris outlet, and the position corresponding to the side wall of the screening box and the debris outlet is provided with a debris collection box. A stirring device is fixed inside the tank, and a liquid outlet pipe connected to the liquid discharge mud pump is provided on the side wall of the liquid collection tank. The invention has the advantages of small volume, simple structure, high screening efficiency and good effect, and effectively prevents drilling fluid from splashing.

Owner:天津帅通科技发展有限公司

Agricultural product quality detecting and screening device

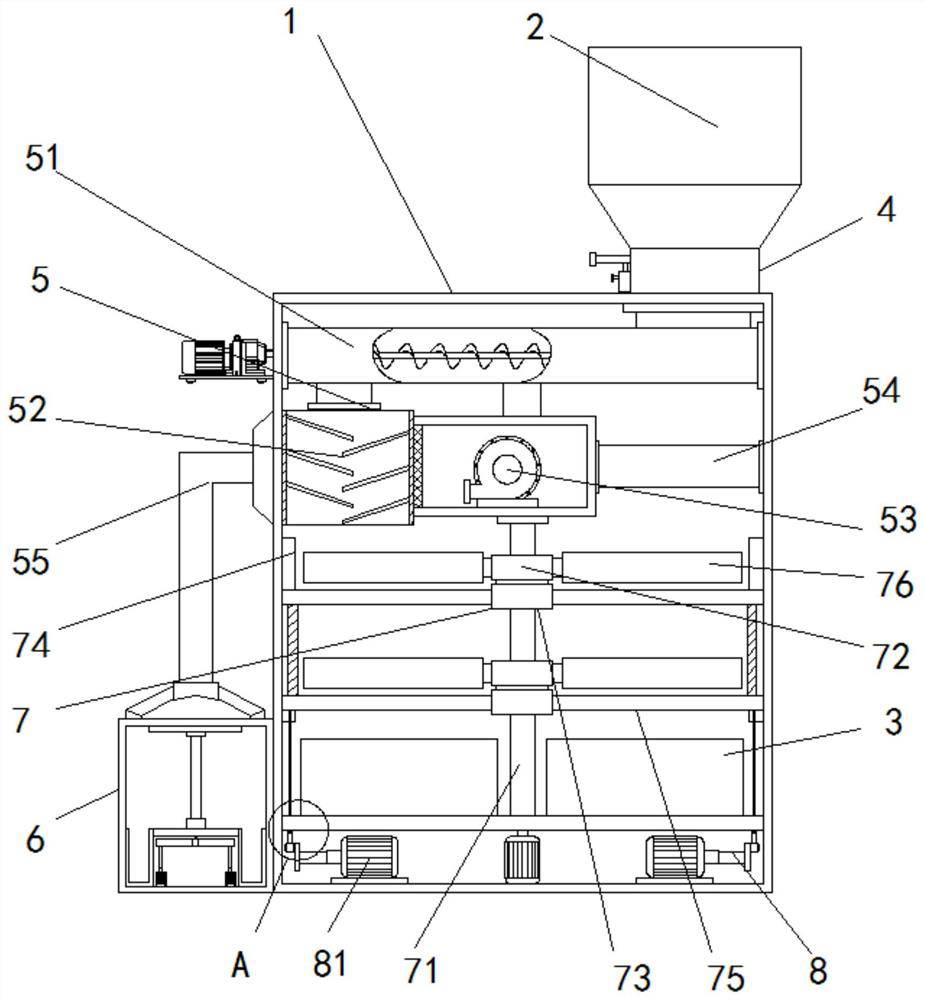

InactiveCN113414108AAdjust the feeding amountChange timeSievingScreeningAgricultural scienceAgricultural engineering

The invention relates to an agricultural product quality detecting and screening device. The device comprises a screening box, a feeding hopper and a collecting box, a regulating and controlling mechanism and a screening mechanism are arranged on the screening box, the regulating and controlling mechanism comprises a limiting device and a discharging device, and a cleaning device communicating with the discharging device is arranged outside the screening box. The screening mechanism is further composed of a double-selection device and a shaking device in a matched manner, the feeding hopper is arranged at the top of the limiting device, and the collecting box is fixedly installed in the screening box and located below the double-selection device. According to the agricultural product quality detecting and screening device, screening is conducted through a double-layer screening net, impurities of different sizes can be separated conveniently, meanwhile, stacked agricultural products can be pushed and scattered through relative rotation of stirring blades and a screening net, and the situation that the screening efficiency is affected due to stacking is avoided; and meanwhile, a vibration sensing rod in a vibration device regularly pushes the double-layer screening net to shake, the screening efficiency is further improved, and the screening effect of the device is good.

Owner:深圳成武金石农业开发有限公司

Material sieving device and operation method thereof

InactiveCN109078840ASimple transmissionAchieve vibration effectSievingScreeningCircular discCoupling

The invention discloses a material sieving device and an operation method thereof. The material sieving device comprises a rack. A protecting cover is mounted on the rack, and a material sieving mechanism and a material separating mechanism are mounted in the protecting cover. The material sieving mechanism comprises a material sieving net and a material sieving steel ring, and the material sieving net is connected to the material sieving steel ring through a stretching spring. A vibration mechanism is arranged below the material sieving net and comprises a transmission rod, a cam and a disc.The material separating mechanism comprises a three-blade material separating plate, a rotating shaft, a coupling and a motor. The motor is arranged on the lower portion of a material collecting box,and the interior of the material collecting box is divided into a finished material bin and a waste material bin which correspond to the material sieving net and a material filtering trough. Accordingto the material sieving device and the operation method thereof, building materials on the material sieving net are sieved and filtered through the material sieving mechanism and the vibration mechanism, the material sieving device is good in vibration effect, and the mechanism transmission mode is simple; and secondly, the situation that the large-particle materials remain on the material sieving net, and consequently, the sieving efficiency of the subsequent process is affected can be avoided through the material separating mechanism, the whole device treats the materials in a graded mode,the collecting effect is better, reutilization in the subsequent process is facilitated, and energy conservation and environmental protection are achieved.

Owner:ANHUI NVISION TECH DEV

Concrete crushing and screening device

InactiveCN114453052ASolve the blockageAvoid affecting operationSievingScreeningEngineeringStructural engineering

The invention discloses a concrete crushing and screening device which comprises a screen piece disc, a screen hole groove, a threaded seat and a bolt rod, so that after aggregate is soaked, a plurality of adjustable upper-layer screen pieces parallel to the axis of a roller are arranged in a roller screen in the circumferential direction at equal intervals, and the hole diameter of the upper-layer screen pieces can be several times larger than the control granularity of an outer-layer main screen; the main effect is to prevent a large number of materials from being accumulated on the screen surface of the outer layer main screen mesh at the same time, the ball shifting balls are arranged on the upper layer screen piece, and when aggregates with different sizes are fed and discharged on the shifting balls, the aggregates can roll into the screening groove, so that the aggregates are effectively prevented from being clamped in the discharging groove, blockage and material clamping between the aggregates and the screen pieces are effectively reduced, and the screening efficiency is improved. And the situation that the sliding discharging operation of the aggregate is affected by crushed aggregate dust on the wave beads is prevented, the discharging speed during rotary screening can be controlled when the aggregate is stacked, and therefore the problem that screen holes are blocked when the screened material is screened is solved.

Owner:济南潇屹新型建材有限公司

Food flat screening machine

InactiveCN104492682AControl the feeding speedAvoid affecting screening efficiencySievingScreeningEngineeringEnergy conservation

The invention discloses a food flat screening machine comprising a rotating shaft and a screening slot which are connected with each other. A large-hole flat screen and a small-hole flat screen are arranged in the screening slot. A screening cover is arranged at the top of the screening slot. A locking bolt group is arranged between the screening cover and the screening slot. A feed inlet is formed in the screening cover. A feeding pipe is further provided and connected to the upper end of the screening cover. A feeding slot obliquely upward is formed in the side wall of the feeding pipe. A tension spring is arranged on a joint of the feeding slot and the feeding pipe. A limiting column set is arranged at the bottom of the feeding slot. Heights of the limiting columns gradually increase from inside to outside. A feeding plate is arranged in the feeding slot. One end of the feeding plate is connected with the tension spring, and the other end of the feeding plate is provided with a limiting block which is abutted against the limiting columns. By the use of the food flat screening machine, the technical defect of the conventional food flat screening machine that feeding speed is out of control, causing low screening efficiency and energy waste is overcome; feeding speed is under control, screening efficiency is increased, and energy is saved.

Owner:CHONGQING JIDING FOOD

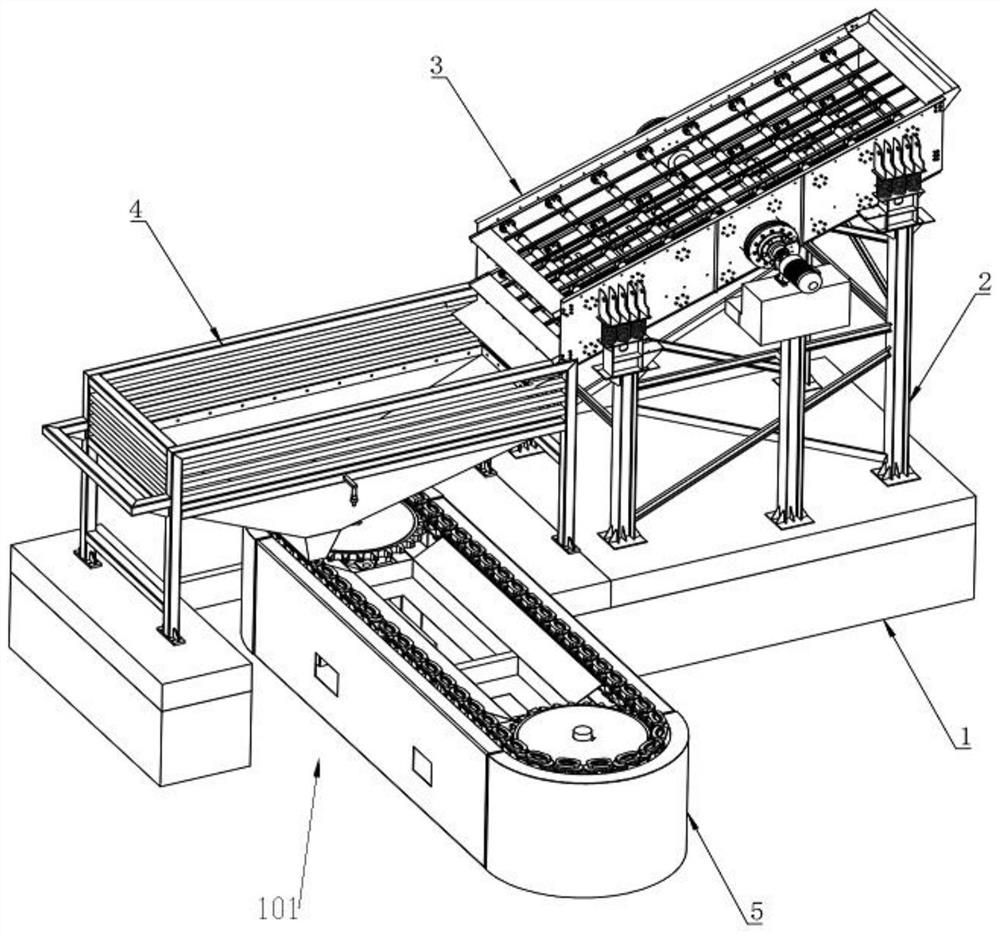

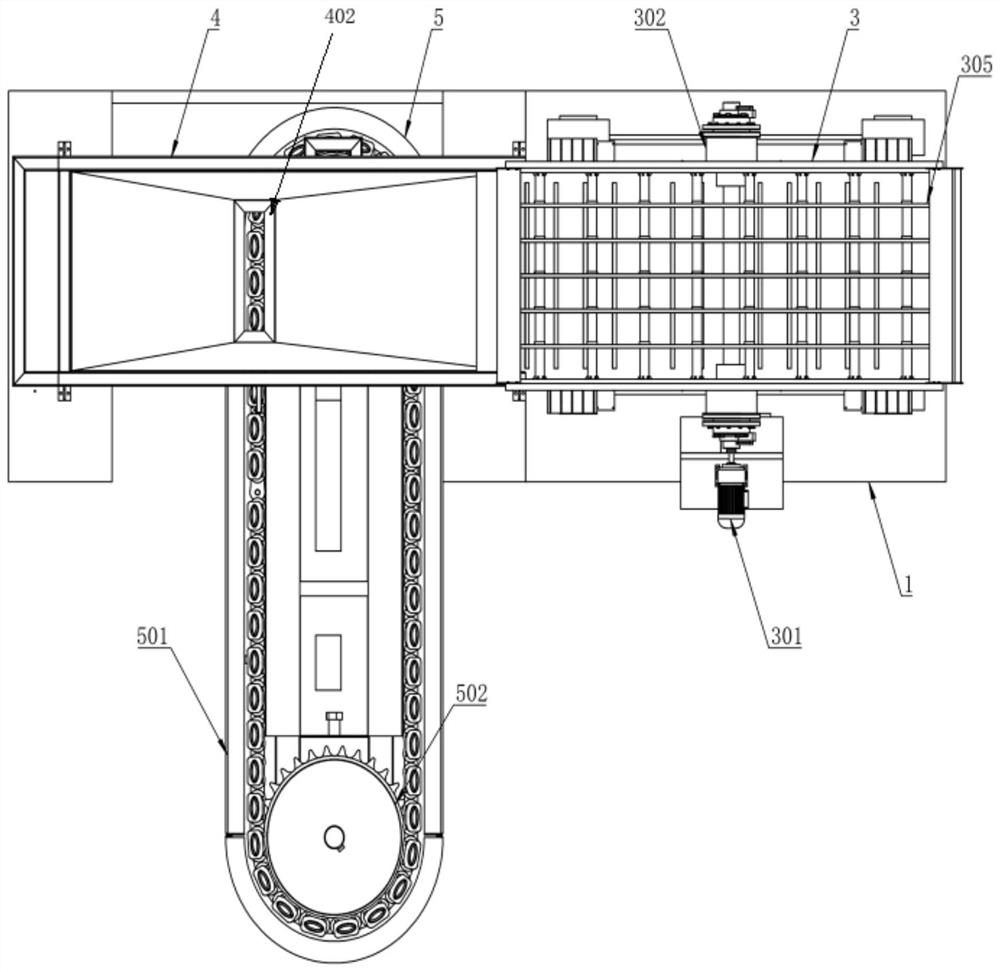

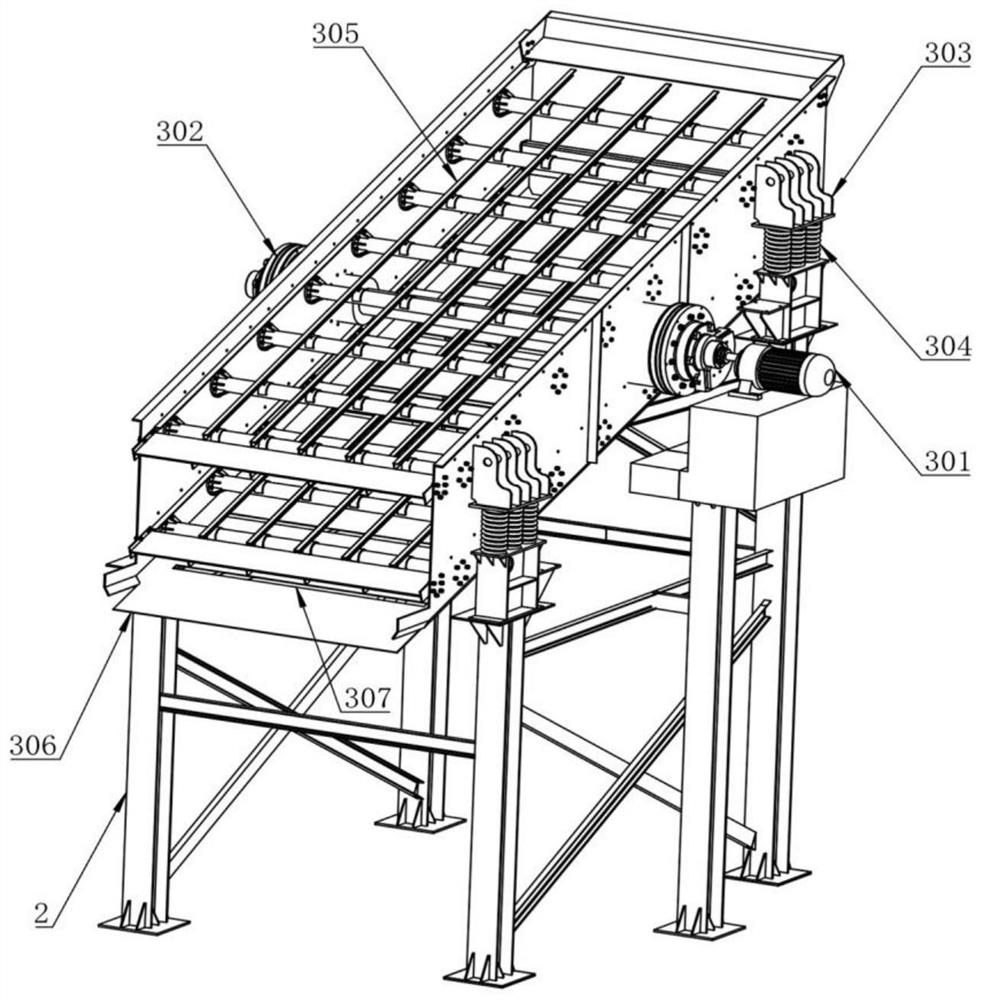

Mine ore material magnetic separation and distribution equipment

PendingCN114798173AQuality is not affectedAvoid dischargeMagnetic separationMaterial SeparationMineralogy

The invention relates to material separation equipment, in particular to magnetic separation material separation equipment for mine ore materials. According to the magnetic separation and distribution equipment for the mine ore materials, iron powder in the ore materials can be screened and removed, and the production quality of the ore materials is not affected. Magnetic separation equipment for mine ore materials comprises a supporting bottom frame, a feeding square pipe and a first discharging pipe, the feeding square pipe is connected to the upper side of the right portion of the supporting bottom frame, a screening cylinder is connected to the left portion of the feeding square pipe in a bolt connection mode, and the first discharging pipe is connected to the upper side of the left portion of the screening cylinder. A proper amount of ore materials are poured in, the servo motor is started, then iron powder is adsorbed to the screening cylinder through the magnetic separation frame, the ore materials which are not adsorbed fall into the second discharging pipe through the screening cylinder to be discharged, meanwhile, when the iron powder rotates reversely to the left side, the iron powder also falls into the first discharging pipe to be discharged, and therefore the iron powder is discharged through the first discharging pipe. And iron powder in ore materials can be screened and removed, and the production quality of the ore materials is not affected.

Owner:CHINA NAT INST OF STANDARDIZATION

Screening mechanism for flour processing and working method thereof

ActiveCN114160411AStable jobPromote environmental protectionSievingScreeningProcess engineeringMicroparticle

The invention relates to the technical field of flour processing, in particular to a screening mechanism for flour processing and a working method thereof.The screening mechanism comprises a bottom plate, a vibration assembly, a screening box, a box cover and a dust collection assembly.The first filter screen plate and the second filter screen plate are used for vibration screening, large impurities and small particle impurities in wheat can be removed, the impurity removal range is widened, and the screening efficiency is improved. The first filter screen plate and the second filter screen plate are installed by arranging the sliding ways, so that installation of the first filter screen plate and the second filter screen plate is simpler and quicker, convenience is provided for assembly and use of the screening mechanism, meanwhile, the first filter screen plate and the second filter screen plate are also convenient to disassemble, and the screening mechanism is convenient to use. And convenience is provided for cleaning the first filter screen plate and the second filter screen plate, the convenience of maintenance and cleaning of the screening mechanism is improved, and therefore the service life of the screening mechanism is prolonged.

Owner:ANHUI WANXUE FOOD

Screening equipment for new material production

InactiveCN112264291AAvoid pollutionRealize the function of purification and dust removalSievingRotary stirring mixersGear wheelDust control

The invention relates to screening equipment for new material production, which comprises a main body, a feeding pipe, a discharging pipe, a screen, a vibrator and two support legs, and further comprises a flat spreading mechanism and two dustproof mechanisms. The spreading mechanism comprises a flow dividing block, a connecting pipe, a fixing ring, a transmission assembly, two rotating assembliesand a plurality of flat spreading plates; the rotating assemblies comprise rotating rods, motors, gears and vibration units; and the dustproof mechanisms comprise air exhaust assemblies, purificationboxes, stirring assemblies and exhaust pipes. According to the screening equipment for new material production, through the flat spreading mechanism, raw materials are flatly spread above the screen,and the situation that the raw materials are accumulated on the screen and moved out so as to affect the screening efficiency is avoided, so that the working efficiency of the equipment is improved;and through the dustproof mechanisms, the air purification and dust removal functions are achieved, and the situation that much dust is mixed in air exhausted into the atmosphere is avoided, so that the surrounding environment is prevented from being polluted, and the environmental protection property of the equipment is improved.

Owner:北京嘉顺鸿科科技有限公司

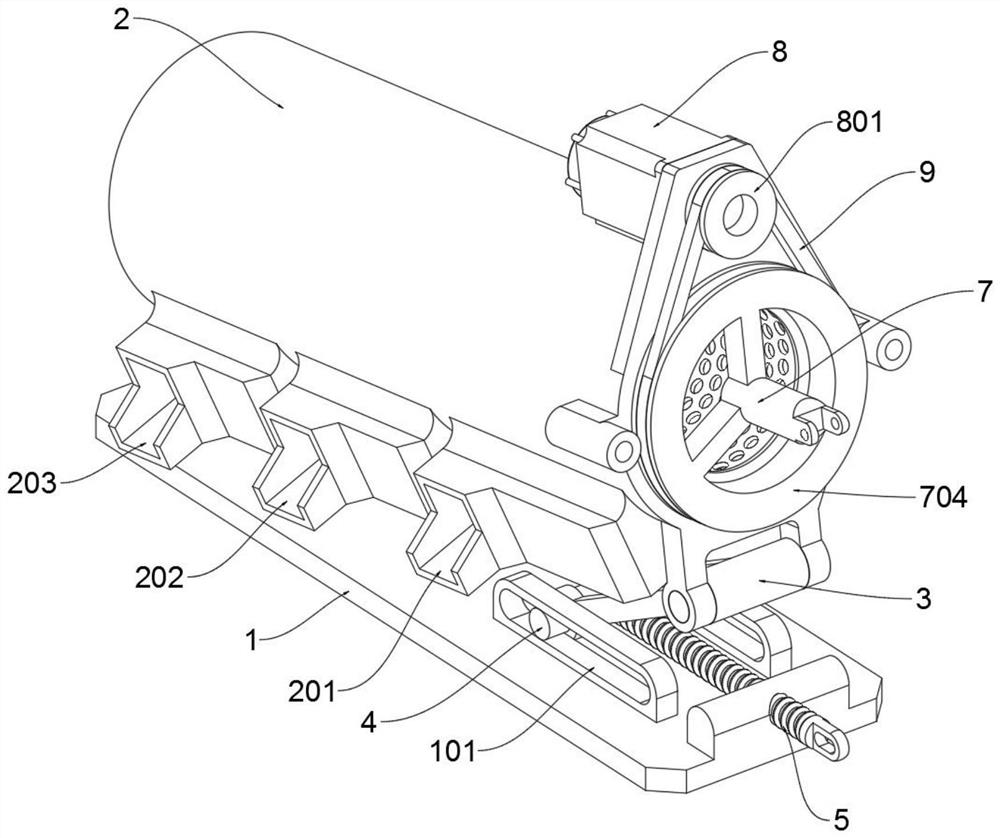

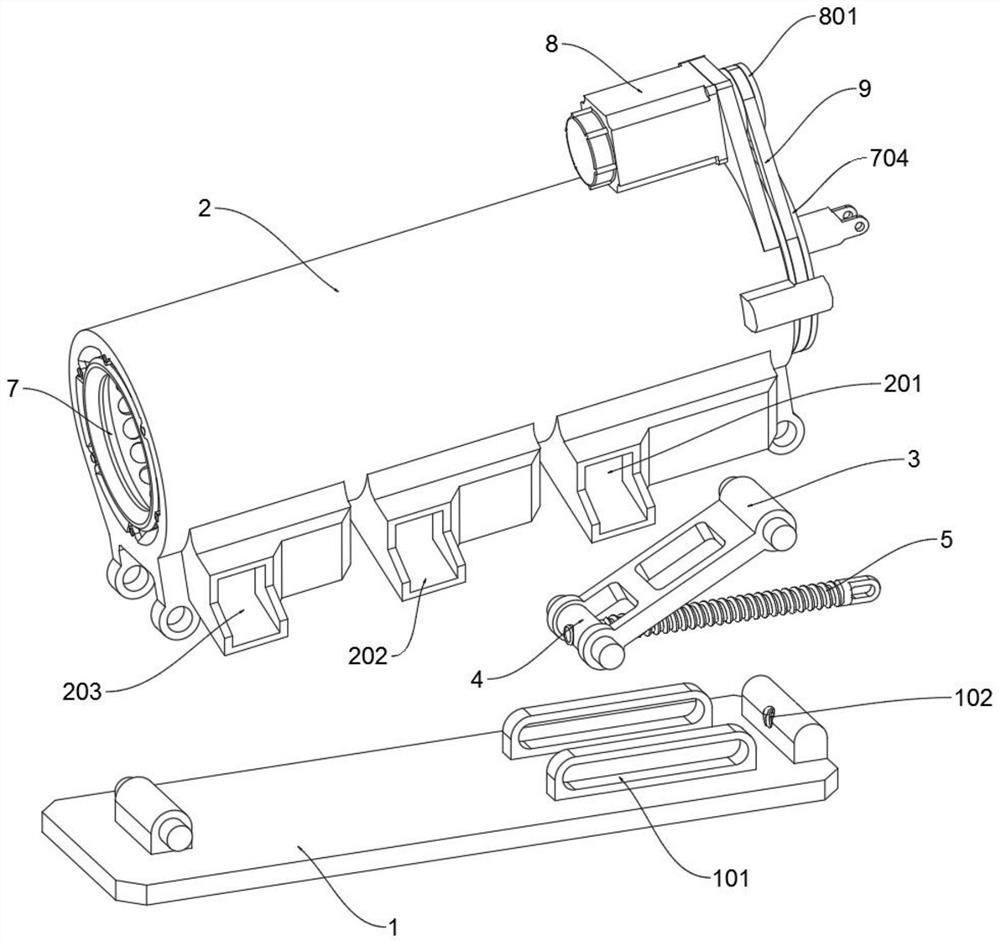

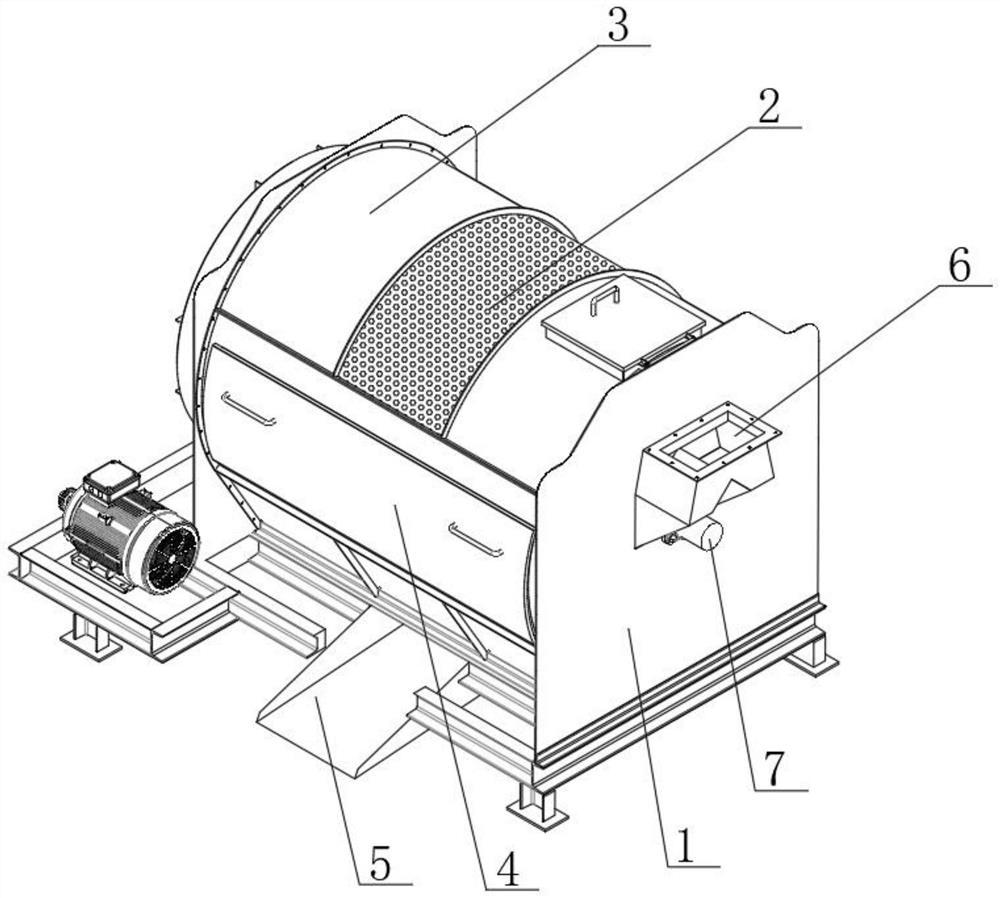

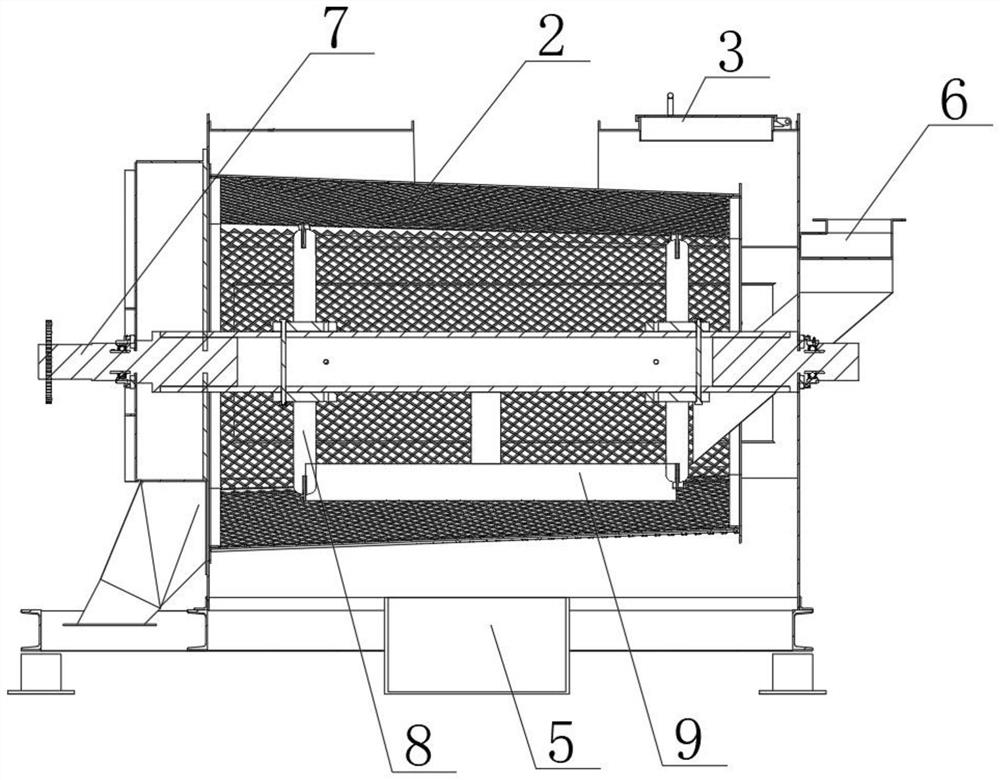

Screening equipment based on comprehensive utilization of energy waste

The invention provides screening equipment based on comprehensive utilization of energy waste, and relates to the technical field of comprehensive utilization of energy. An outer cylinder is installed on the top of the base, the rear end of the outer cylinder is connected with a supporting frame, and the bottom end of the supporting frame is connected with the base through a movable shaft. A screening cylinder is installed in the outer cylinder, and a driven belt wheel is arranged at the rear end of the screening cylinder and located outside the rear end of the outer cylinder. A motor is installed at the top of the outer cylinder, and a driving belt wheel is installed on a driving shaft of the motor. According to the waste screening device, when waste enters the screening barrel through the rear end of the screening barrel, the waste is sequentially and rotationally screened through the fine screening barrel, the middle screening barrel and the coarse screening barrel, so that the waste of different specifications can be discharged through different discharging openings, and the waste of different specifications can be comprehensively and reasonably utilized. The problems that when traditional screening equipment is used, the screening efficiency is low, and applicability adjustment is difficult to conduct according to different types of energy waste are solved.

Owner:韦佳培

Food fermentation screening device utilizing microorganisms

PendingCN112662546ASave resourcesQuality assuranceBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringBiotechnology

The invention relates to the technical field of food fermentation screening devices, in particular to a food fermentation screening device utilizing microorganisms. The food fermentation screening device comprises a shell, a fixed box, a fermentation box and a screen, wherein a feeding hopper is fixedly mounted on the left side of the top end of the shell through bolts; a base is fixedly mounted at the bottom end of the shell; the fermentation box is fixedly mounted at the inner top of the shell; a bottom plate is arranged at the bottom end of the fermentation box; the screen is transversely and fixedly installed in the shell and located below the fermentation box; the fixed box is fixedly installed on the outer wall of the right side of the shell through a connecting rod; and a discharging opening is fixedly formed in the bottom end of the shell through bolts. According to the food fermentation screening device utilizing microorganisms, the problems that an existing food fermentation device is low in fermentation speed and long in fermentation time are solved, sufficient fermentation can be conducted, a large number of resources are saved, the quality of fermented products is well guaranteed, and economic losses caused to people are avoided.

Owner:龙进强

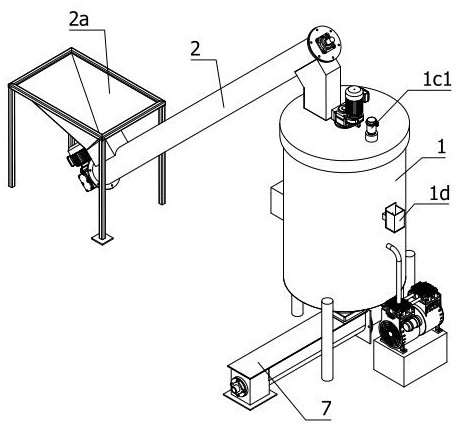

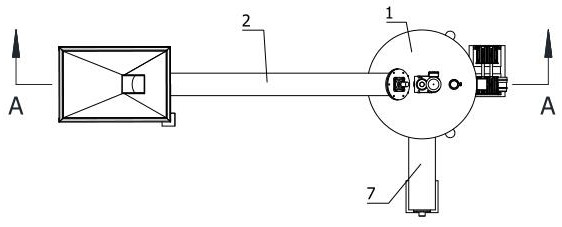

A negative pressure sieve equipment for the preparation of concrete composite admixture

InactiveCN112517362BAvoid accumulationImprove cleanlinessSievingGas current separationArchitectural engineeringStructural engineering

The invention relates to the field of building material processing equipment, in particular to a negative pressure screening equipment used for the preparation of concrete composite admixtures, comprising: a screening tank, the top and bottom of which are respectively provided with a first feed inlet and a first outlet The feed port, the top of the screening tank is also provided with an air inlet pipe, and the peripheral surface of the screening tank is also provided with a miscellaneous outlet for discharging large-volume admixtures; the inclined screw feeder is arranged on one side of the screening tank and the top is connected to the The first feed port is connected; the bulk feeder, the working end is set on the top inside the screening tank; the sieve plate is coaxially set in the screening tank and is located on the top of the working end of the bulk feeder; the multi-task rotary negative pressure device, the negative pressure part is inclined The downward coaxial setting is inside the screening tank and is located at the bottom of the sieve plate; the coaxial pusher is coaxially fixed on the top of the output shaft of the multi-function rotary negative pressure device, and the bottom end of the coaxial pusher slides with the top of the sieve plate Coordination; horizontal screw feeder, the feed end is connected with the discharge end, the device can screen admixtures in large quantities.

Owner:安徽水地建设工程有限公司

Sand screening device for construction engineering

Owner:HEBEI GEO UNIVERSITY

Vibrating screening device

PendingCN112827802AEasy to cleanImprove screening effectSievingGas current separationMetallurgyPhysical chemistry

The invention discloses a vibrating screening device. The vibrating screening device is characterized in that raw grains are vibrated and screened through a screening plate obliquely arranged in a screening bin, so that the purpose of removing impurities in the raw grains is achieved; particularly, in order to avoid the phenomena that the raw grains are caked and accumulated in the screening process and the impurity cleaning effect is poor, a spreading and cleaning mechanism is arranged in cooperation with the screening plate; after the raw grains are spread and pushed on the screening plate through the spreading and cleaning mechanism, the screening plate can quickly screen and remove the impurities through vibration; and the spreading and cleaning mechanism is used for cleaning the impurities (rice, wheat or oat and other raw grains are easily clamped in sieve holes to block the sieve holes) clamped on the sieve holes, and therefore, the purposes of improving the cleaning effect and the screening efficiency are achieved.

Owner:HUNAN YINGCHUN STEEL SILO MFG CO LTD

Impurity screening device applied to rice flour processing and using method of impurity screening device

The invention discloses an impurity screening device applied to rice flour processing and a using method thereof.The impurity screening device comprises a dispersing mechanism, the dispersing mechanism comprises a dispersing box, the inner wall of the dispersing box is provided with a drying unit and a stirring unit which are arranged up and down, and the bottom of the dispersing box is fixedly connected with a conveying groove; one end of the conveying groove is fixedly connected with a spreading mechanism, and a screening mechanism is arranged at the bottom of the spreading mechanism; the drying unit is arranged, hot air is fed into the dispersing box, rice is heated and dried through the hot air, the humidity of the rice is reduced, rice caking is avoided, the stirring unit is matched for drying, dehumidifying and dispersing the fed rice, the falling rice is stirred, dispersed and separated, and rice screening work is facilitated; and by arranging the spreading mechanism, the rice can be uniformly spread on the vibrating screen, and the screening efficiency is improved.

Owner:凤台县晶谷粮油股份有限公司

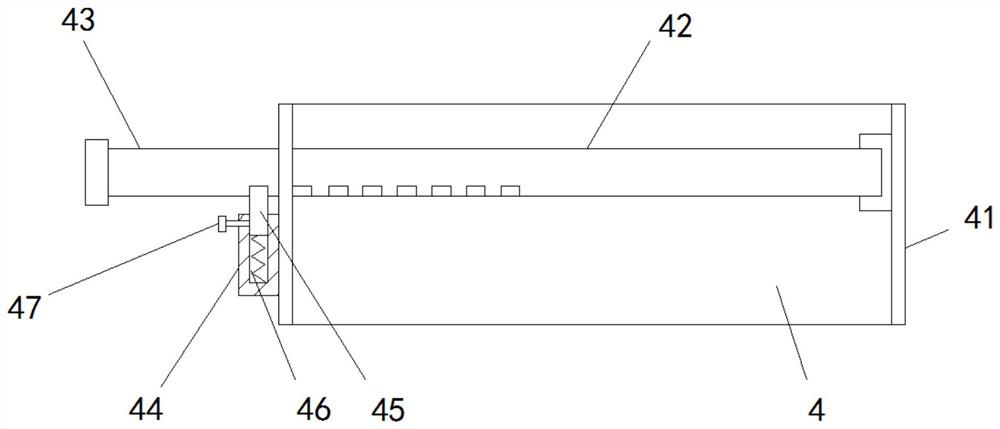

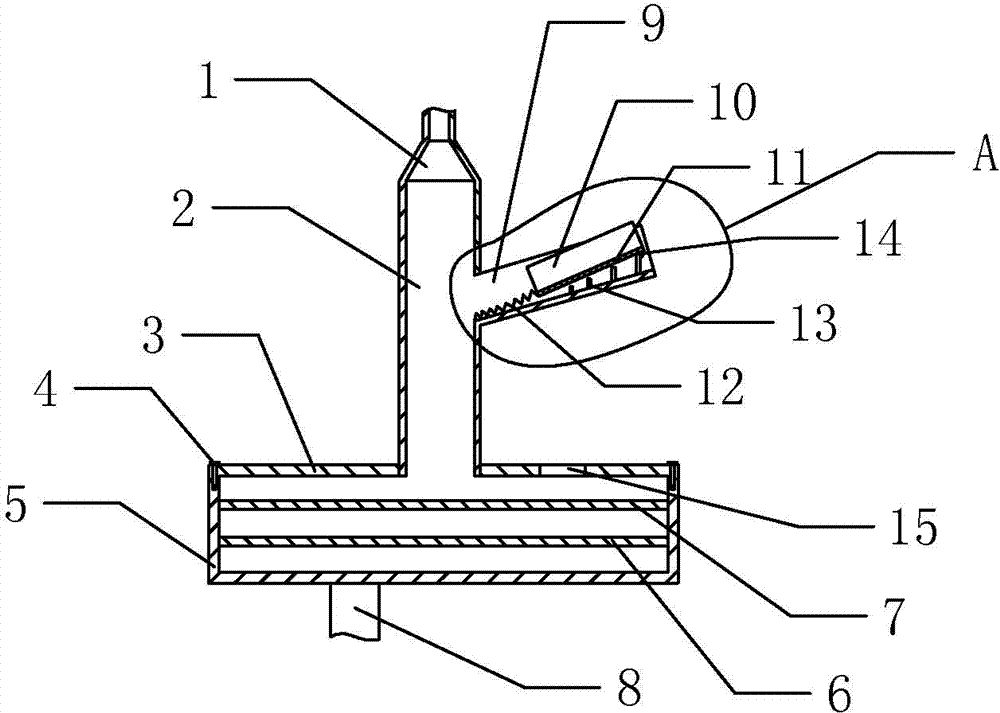

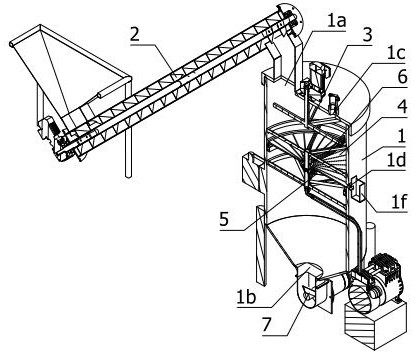

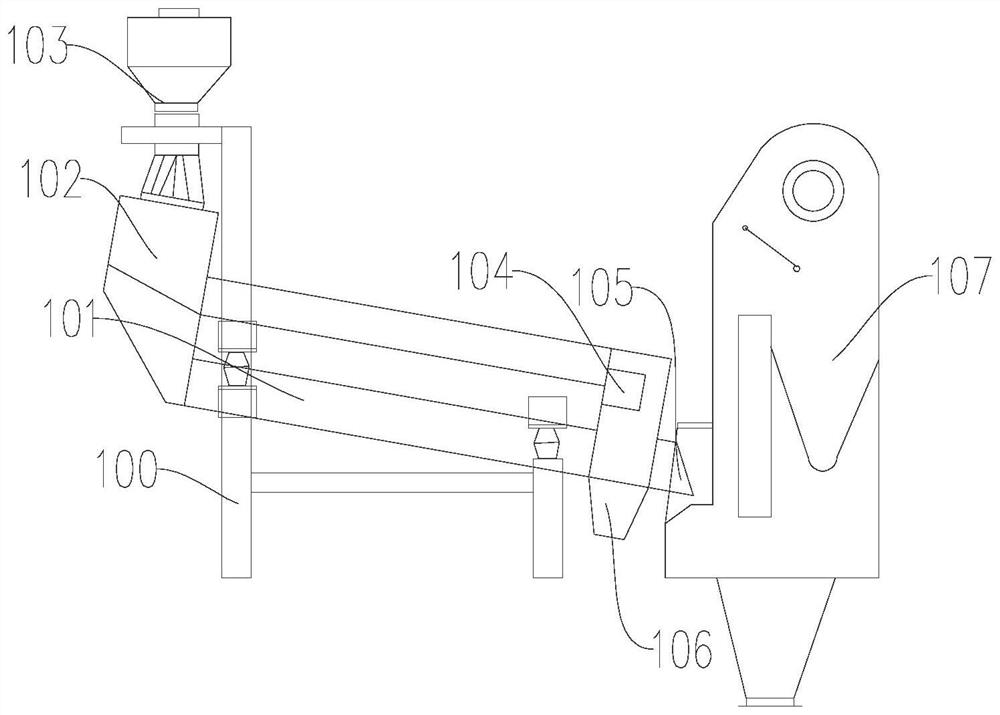

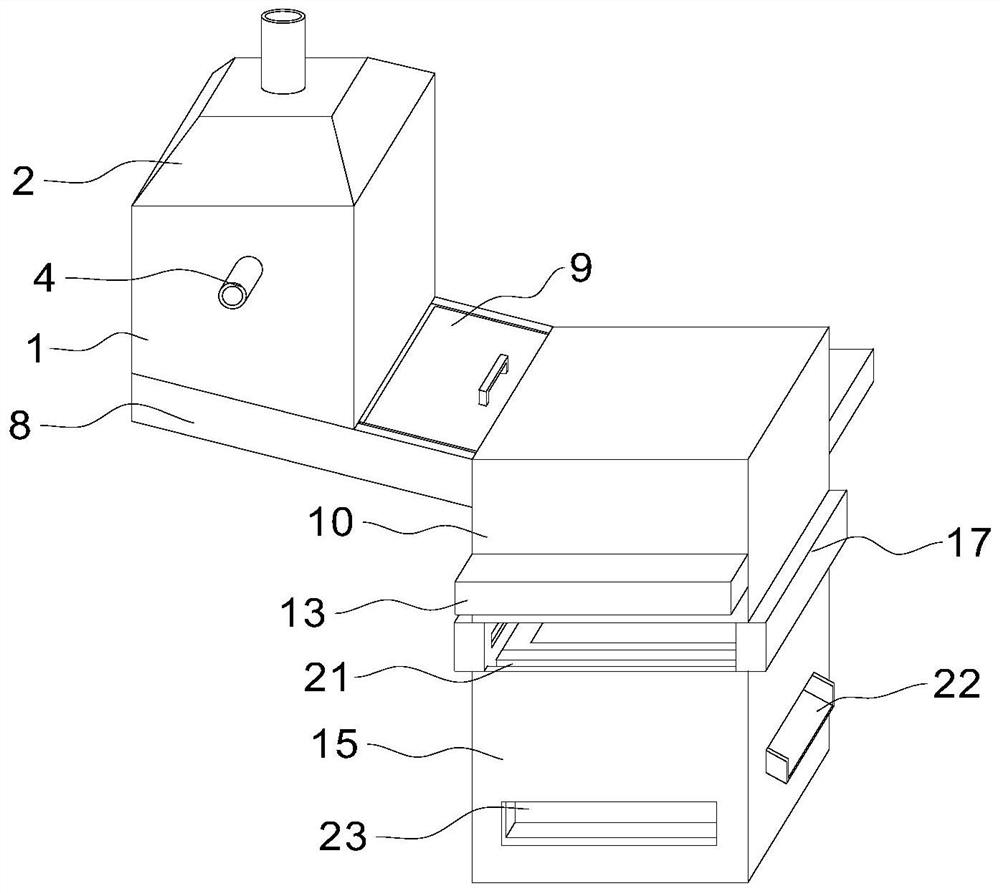

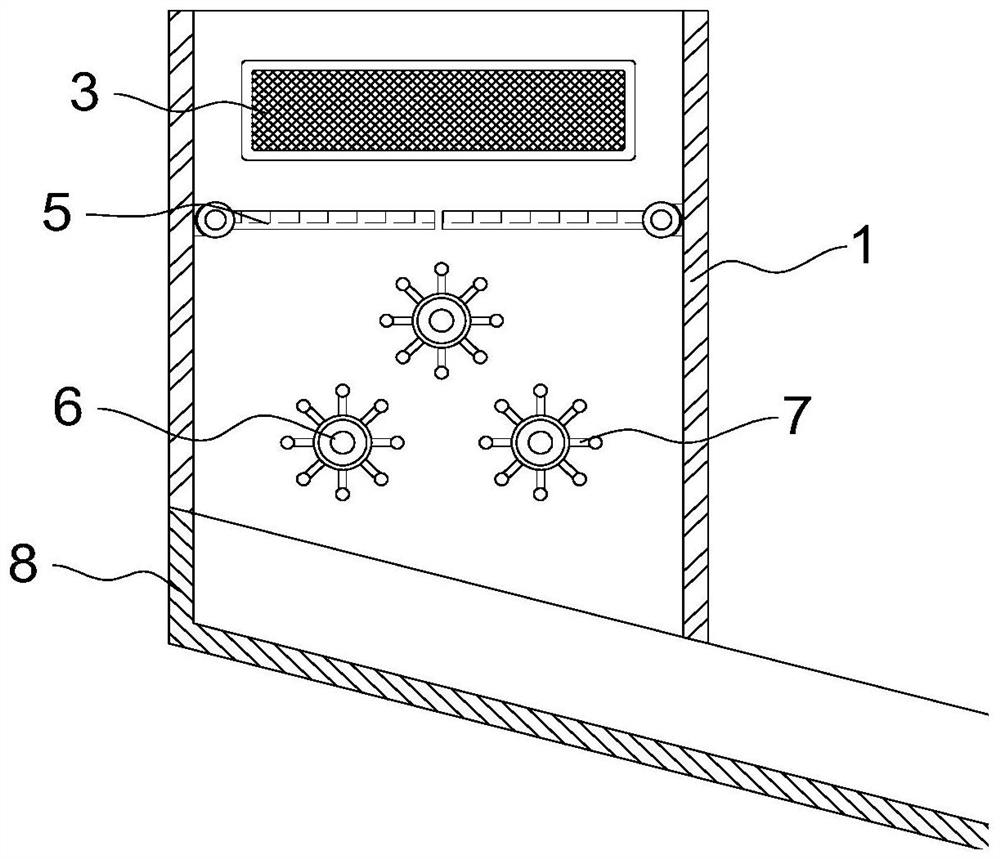

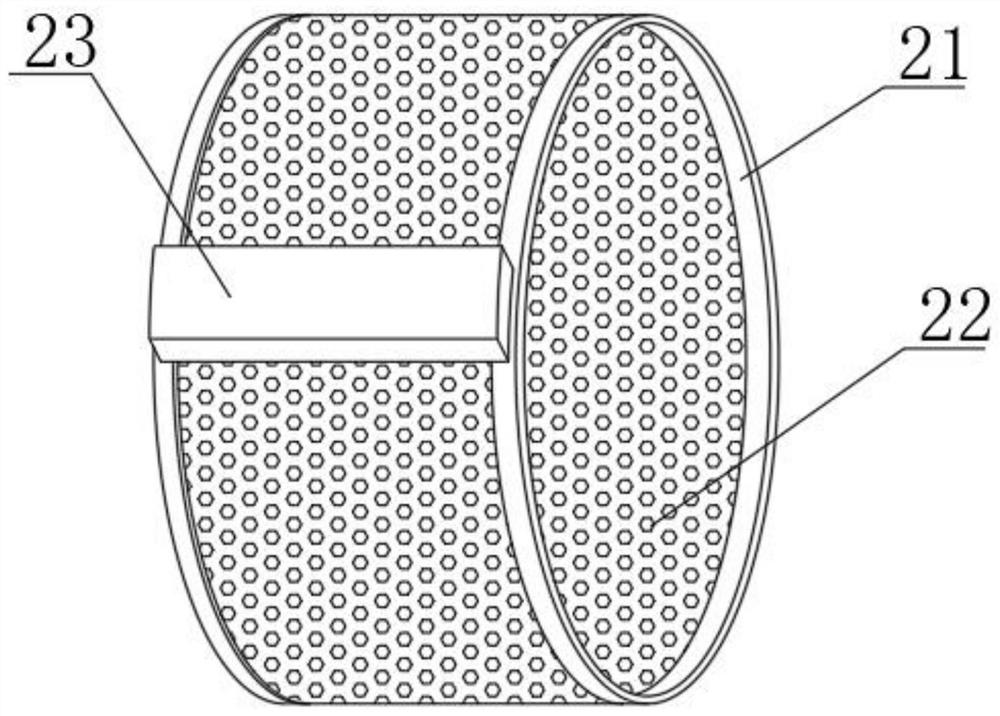

Feeding mechanism for germ extraction machine

InactiveCN105414012AEvenly dispersedAvoid affecting screening efficiencySievingScreeningEngineeringMechanical engineering

The invention discloses a feeding mechanism for a germ extraction machine. According to the feeding mechanism, materials falling from a feeding opening are prevented from accumulating on a vibrating screen. The feeding mechanism for the germ extraction machine comprises a vertically-arranged feeding barrel, the lower portion of the feeding barrel stretches into a cover arranged on the periphery of the vibrating screen, a discharging opening is formed in the lower portion of the feeding barrel, and two relatable material dividing wheels are arranged at the positions, above the vibrating screen, in the cover side by side; the rotating directions of the two material dividing wheels are opposite, and the two material dividing wheels are located under the discharging opening; and the outer circles of the two material dividing wheels are each provided with a plurality of material dividing pawls, and the distance between the two material dividing wheels is adjustable.

Owner:CHONGQING LONGYUE FOOD

Screening device for research and development of electronic materials

InactiveCN113953172AImprove applicabilityImprove stabilitySievingScreeningStructural engineeringMechanical engineering

The invention discloses a screening device for research and development of electronic materials. The screening device comprises side walls and a collecting seat, and a rotating roller and a screening assembly are connected between the two side walls. The screening assembly comprises connecting rings and a screening net, the side edge of the screening net is embedded in the connecting rings, and a connecting seat is arranged between the two adjacent connecting rings. Winding rollers are connected to the interior of the connecting seat through bearings, and the two ends of the screening net are wound around the exteriors of the two sets of winding rollers correspondingly. According to the screening device for research and development of the electronic materials, firstly, the screening net is arranged between the two sets of winding rollers, and the inner diameter of filtering holes in the outer portion of the screening net is gradually increased from one end to the other end, so that different screening standards can be freely adjusted according to needs, and the applicability of raw material screening is improved; and secondly, a cylindrical covering cylinder is arranged outside the screening assembly in a sleeving mode, the screening net at the position can be selected according to needs, meanwhile, the influence of other screening nets on the raw materials can be prevented, and therefore the screening stability is improved.

Owner:苏州华佑信息科技有限公司

Almond moth-eaten seed sorting machine

ActiveCN111701847BAvoid enteringPlay a shock absorbing roleSievingScreeningHuskAgricultural engineering

The invention relates to the technical field of nut quality sorting, in particular to a sorting machine for almond moth-eaten seeds. Using the combination of vibrating screen and screening and receiving device, the untreated raw materials are firstly passed through the vibrating screen, then screened by the vibrating net, and some impurities are discharged through the strip-shaped slots on the bottom plate, so as to avoid other impurities from entering the screening line; One nut is transported on each loading board, which is convenient for the removal of bad nuts; the probe installed on the top of the screening and receiving device detects the bad nuts on the loading board in time, so that the ejector pin acts on the loading board in time to remove the bad nuts ;The unloading auxiliary plate on the right side of the body shell lifts the moving loading plate upwards at a certain angle, so that the material is dumped for collection; the torsion spring on the rotating shaft at the bottom of the loading plate retracts the loading plate in time To the initial state, it avoids the impact on the screening efficiency due to the failure of the loading plate to recover in time; it solves the problems of high bad fruit rate and low sorting efficiency of traditional sorting machines.

Owner:加州原野(霸州市)食品有限责任公司

Metal Particle Screening Machine for Additive Manufacturing

ActiveCN112547498BImprove screening efficiencyScreening Efficiency ImpactSievingScreeningElectric machineryStructural engineering

The invention discloses a metal powder screening machine for additive manufacturing, which includes a bottom plate, a support rod and a movable plate; the bottom plate: supporting legs are arranged at four corners of the lower surface, and two fixed plates are respectively installed at the left and right ends of the upper surface of the bottom plate, And the front and rear ends of the upper surface of the fixed plate are respectively provided with vibrating motors, a fixed frame is arranged between the opposite surfaces of the vibrating motors on both sides, and the upper end of the fixed frame is provided with a sieve plate, and the upper surface of the fixed frame is provided with a sieve plate. The sieve hole corresponds to the diversion hole, and the front end of the sieve plate is handed over with a side baffle and a vibrating sieve plate, which can automatically sieve the material and reduce the manual operation steps, so that the screening efficiency is higher, and it can Clean the screen to avoid screen clogging and affect the screening efficiency of the material. At the same time, the equipment can stir the material when screening the material to ensure that the material can fall evenly during screening and avoid material accumulation that affects the screening efficiency.

Owner:株洲精特硬质合金有限公司

Oil extraction mud purification device and purification method thereof

ActiveCN112023492BReduce use costAvoid destructionFatty substance recoveryMoving filtering element filtersPurification methodsProcess engineering

Owner:鄂尔多斯市华北瑞达油气工程技术服务有限责任公司

An intermittent feeding type multi-stage screening device for construction

ActiveCN107694914BAvoid cloggingAvoid the impact of sand screening efficiencySievingScreeningElectric machineGear wheel

The invention discloses an intermittent discharge type multi-stage screening device for building. The device comprises a first screening box, a second screening box, a first sand screening device, a second sand screening device, a second motor, an incomplete gear, a first gear, a second gear, a third gear, a first rack, a first baffle and a second baffle. The first sand screening device comprisesa square frame, a screening net, a first spring, a first motor, a cam and a second spring. Since the first sand screening device and the second sand screening device are arranged, multi-stage sand screening can be carried out to meet different working requirements; since the second motor, the incomplete gear, the first gear, the second gear, the third gear, the first rack, the second gear, the first baffle and the second baffle are arranged, intermittent discharge is achieved by matching the components, the problem that net holes of a screening net are blocked since the one-time discharge amount is too high so as to affect the screening efficiency is avoided, sand on the screening net can be immediately discharged after each screening, and the screening efficiency is prevented from being affected.

Owner:湖北铭元建设工程有限公司

Drilling fluid vibrating stirring equipment

The invention provides drilling fluid vibrating stirring equipment. The drilling fluid vibrating stirring equipment comprises a screening box and a liquid collecting box arranged under the bottom of the screening box. The upper portion of an inner cavity of the screening box is of a cuboid structure, the lower portion of the inner cavity of the screening box is of a downward-protruding conical structure, and a material passing port is formed in the middle of the bottom of the screening box. A feeding port is formed in the position, corresponding to the material passing port, of a top plate of the liquid collecting box, the material passing port stretches into the feeding port, an elastic pad is arranged at the position, in contact with the outer surface of the bottom of the screening box, of the feeding port, inclined vibrating screens are arranged in a screening area, chip outlets are formed in the positions, corresponding to the lower ends of the vibrating screens, of the side wall of the screening box, a chip collecting box is arranged at the position, corresponding to the chip outlets, of the outer side wall of the screening box, a stirring device is fixedly arranged in the liquid collecting box, and a liquid outlet pipe connected with a liquid discharging slurry pump is formed in the side wall of the liquid collecting box. The drilling fluid vibrating stirring equipment has the advantages of being small in size, simple in structure, high in screening efficiency, good in screening effect, capable of effectively preventing drilling fluid from splashing and long in service life.

Owner:天津帅通科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com