Food flat screening machine

A flat screen machine, food technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of inability to control the feeding speed, waste of energy, low screening efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

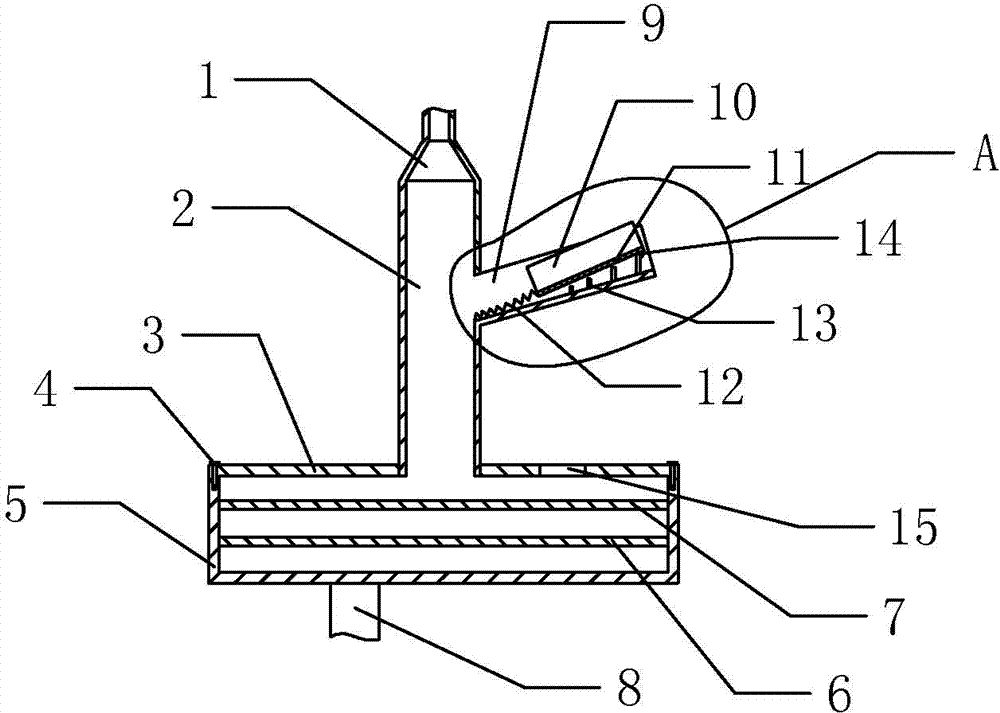

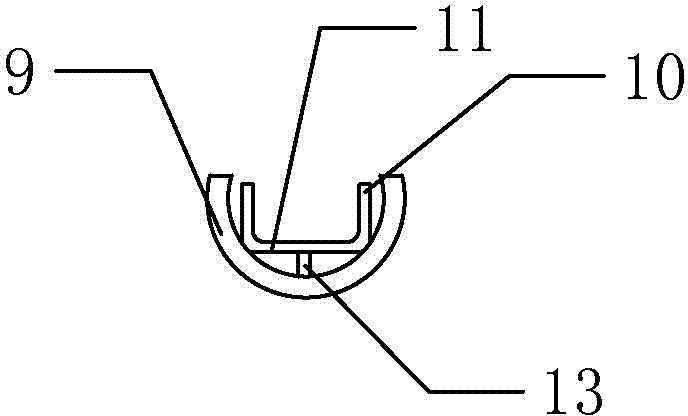

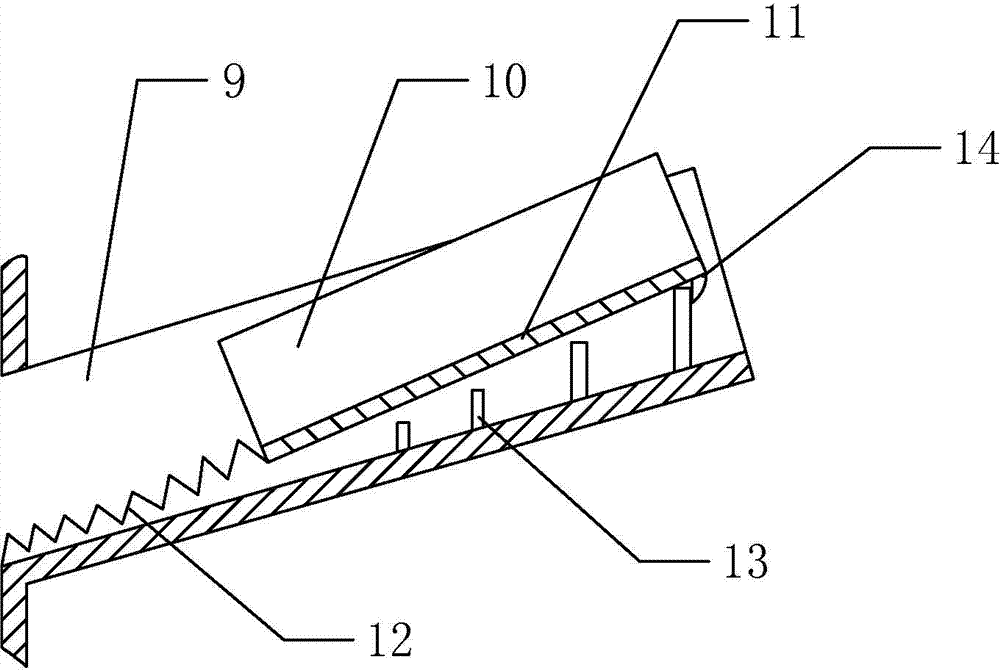

[0015] Among them: suction pipe 1, feeding pipe 2, screening cover 3, locking bolt 4, screening tank 5, small hole flat screen 6, large hole flat screen 7, rotating shaft 8, feeding tank 9, baffle 10. Feeding plate 11, tension spring 12, limit column 13, limit block 14, observation hole 15.

[0016] like figure 1 As shown, the food flat screen machine of the present invention includes a rotating shaft 8 and a circular screening tank 5, the rotating shaft 8 is vertically upward, the opening of the screening tank 5 is upward, and the top of the rotating shaft 8 is connected to the screening At the non-center of the bottom end of the groove 5, a small-hole flat screen 6 and a large-hole flat screen 7 are sequentially arranged in the screening groove 5 from bottom to top, and the outer edges of the small-hole flat screen 6 and the large-hole flat screen The side walls of the sub-groove 5 are against each other, and the top of the screening trough 5 is also provided with a screeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com