Crushing machine capable of achieving sufficient smashing

A crusher and casing technology, applied in the direction of solid separation, mechanical material recovery, filtering and screening, etc., can solve the problems of difficult screening, unclear internal conditions of the machine, insufficient crushing, etc., to achieve easy screening and good internal monitoring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

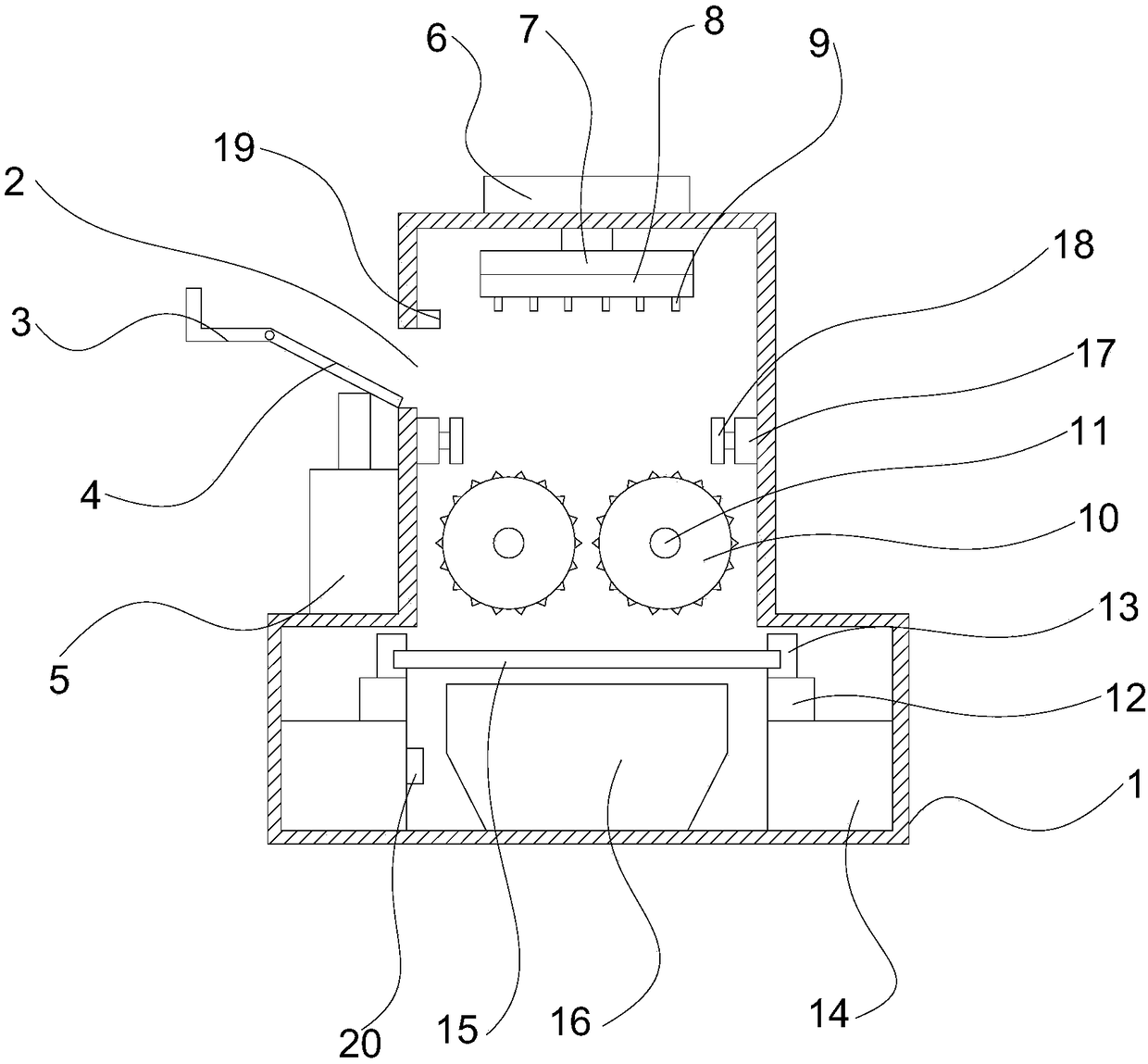

[0022] like figure 1 As shown, the present invention provides a fully crushed crusher, comprising: a casing 1, a feed port 2 is arranged on the left side of the casing 1; a feed assembly, the feed assembly includes a discharge platform 3, a feed slope 4 and the adjusting cylinder 5, one end of the feeding slope 4 is hinged with the discharge platform 3, and the other end communicates with the feeding port 2, the adjusting cylinder 5 is fixed on the casing 1 and the piston rod of the adjusting cylinder 5 can push the feeding slope 4 Lifting; pressing assembly, the pressing assembly includes a push cylinder 6, a rotary cylinder 7, a rotating disk 8 and several annular cutters 9, the push cylinder 6 is fixed on the top of the casing 1 and the piston rod of the push cylinder 6 passes through The top of the casing 1 is fixedly connected with the rotating cylinder 7, the rotating disk 8 is arranged on the bottom of the rotating cylinder 7 and the rotating cylinder 7 can drive the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com