Patents

Literature

39results about How to "Easy for secondary crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

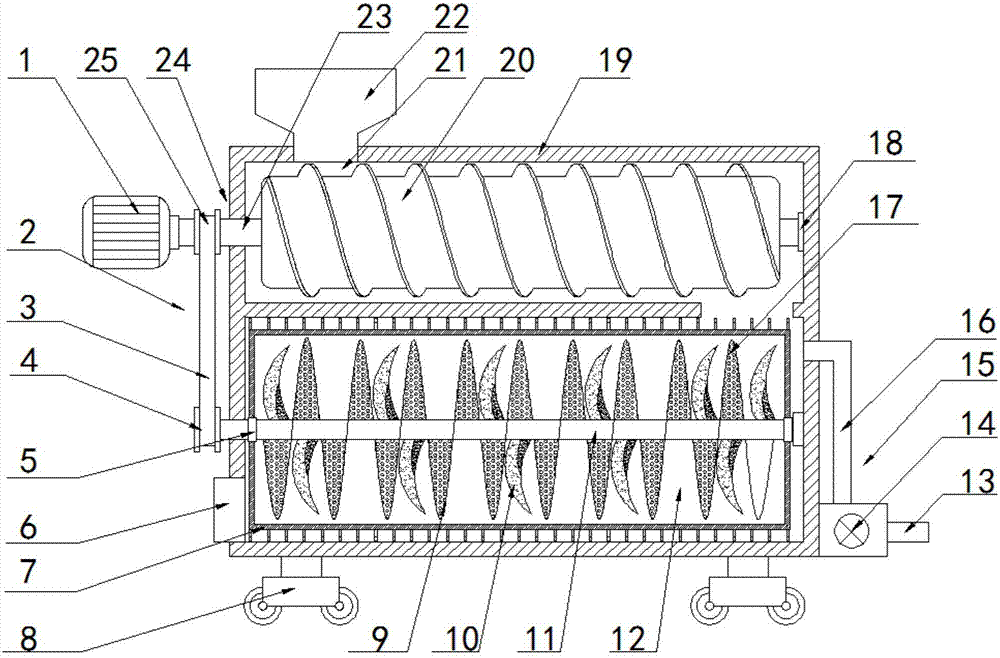

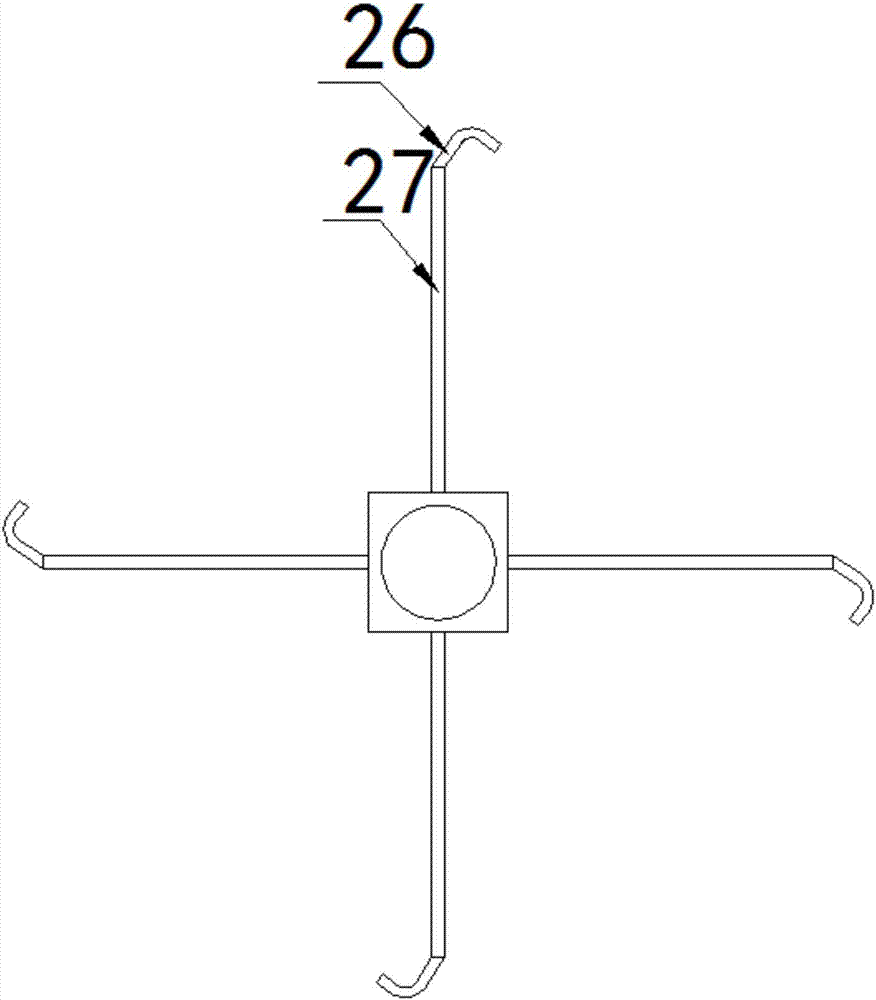

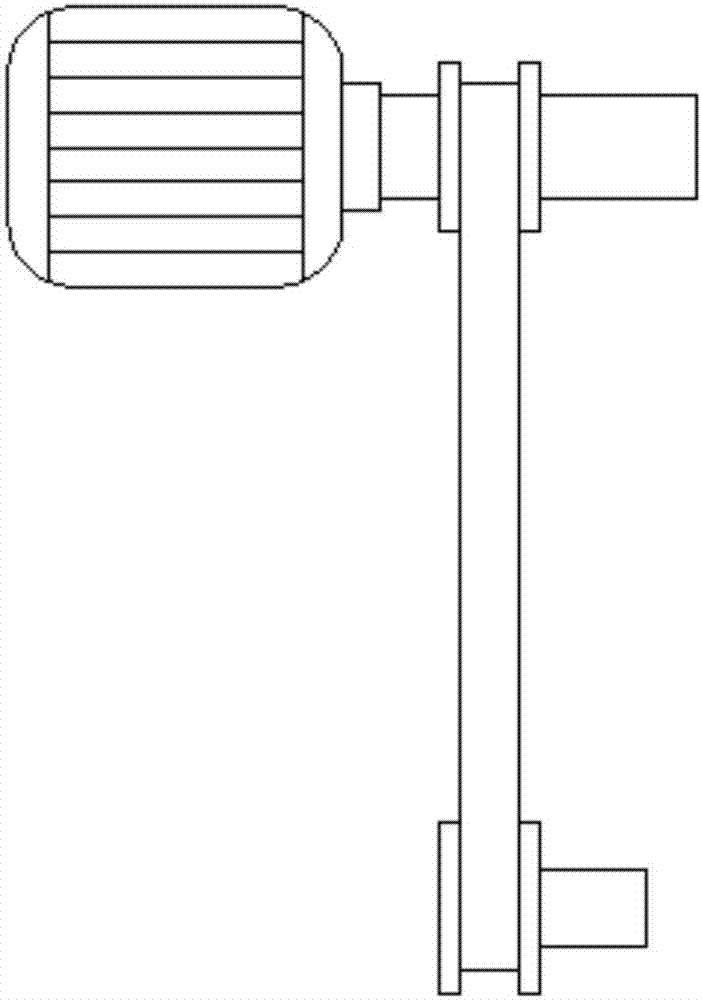

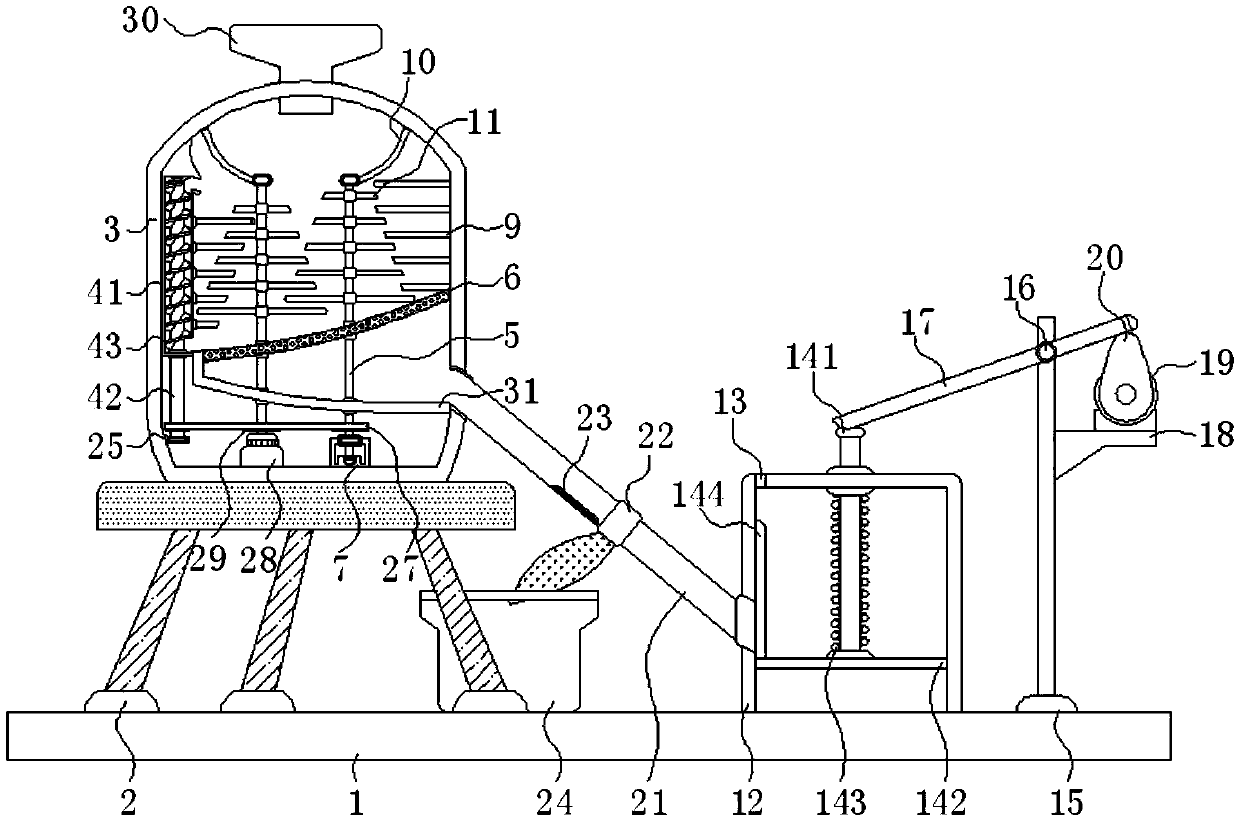

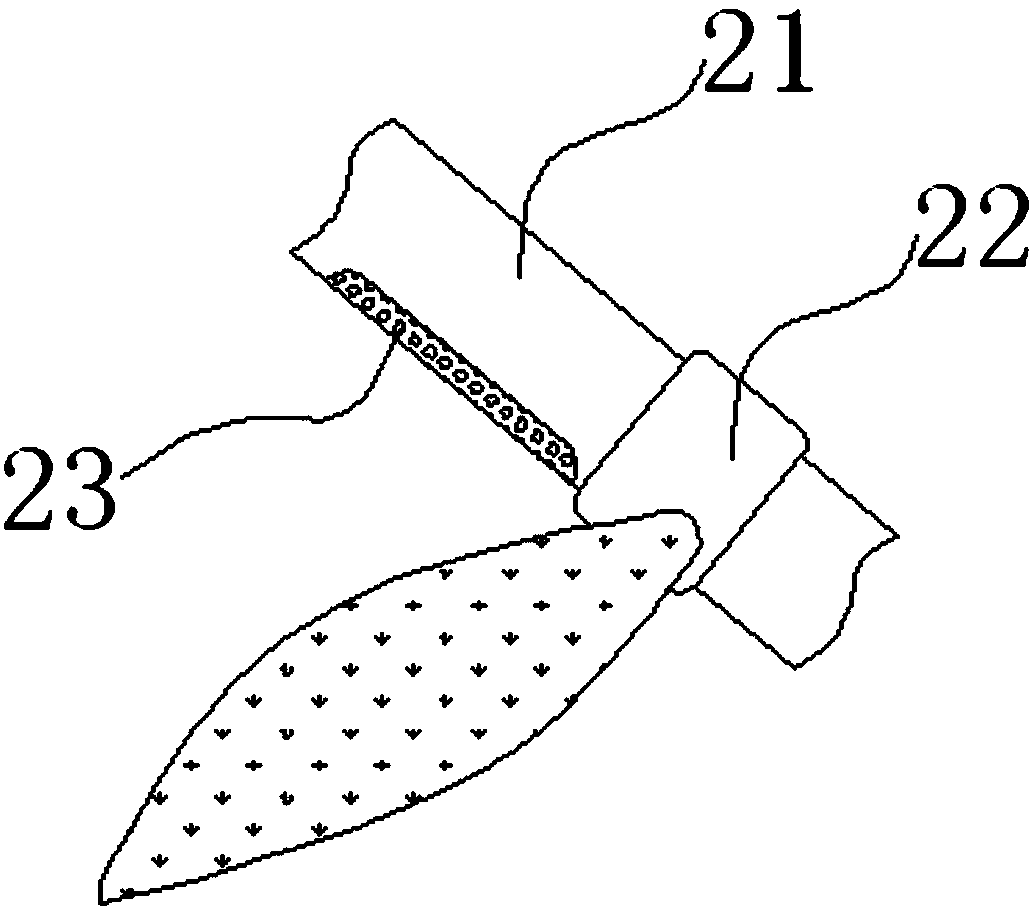

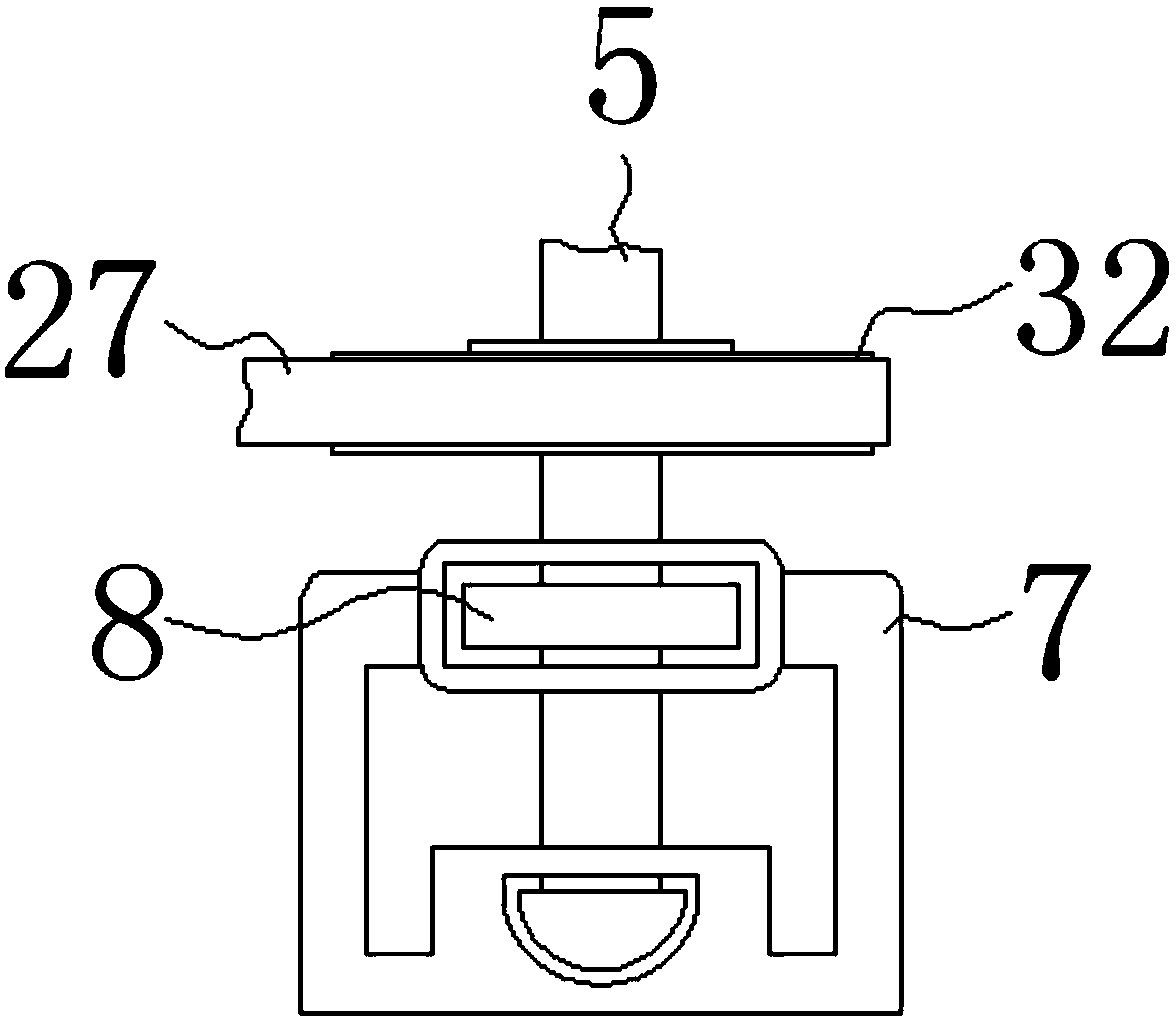

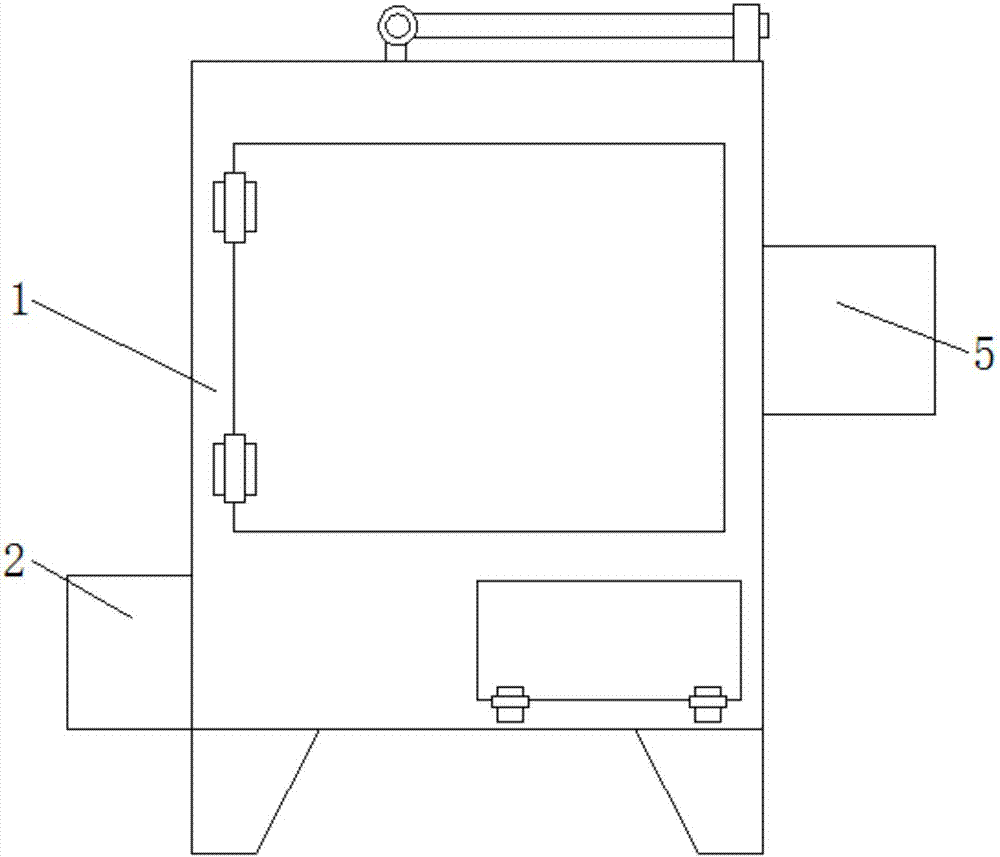

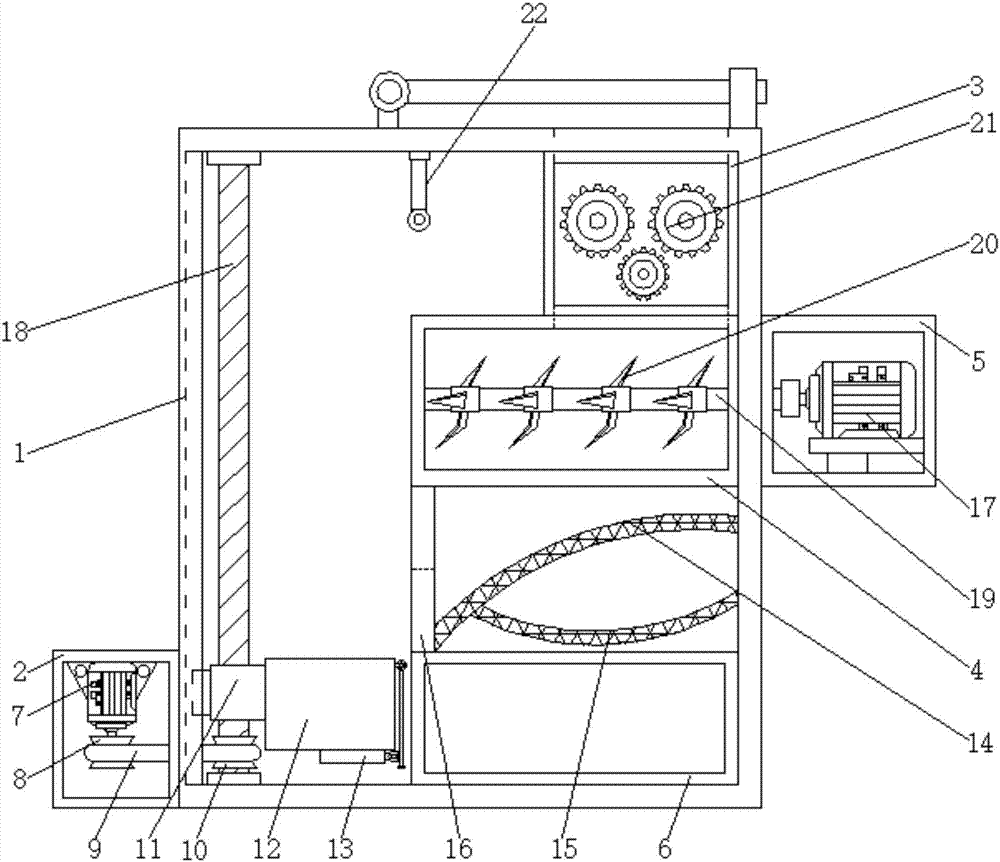

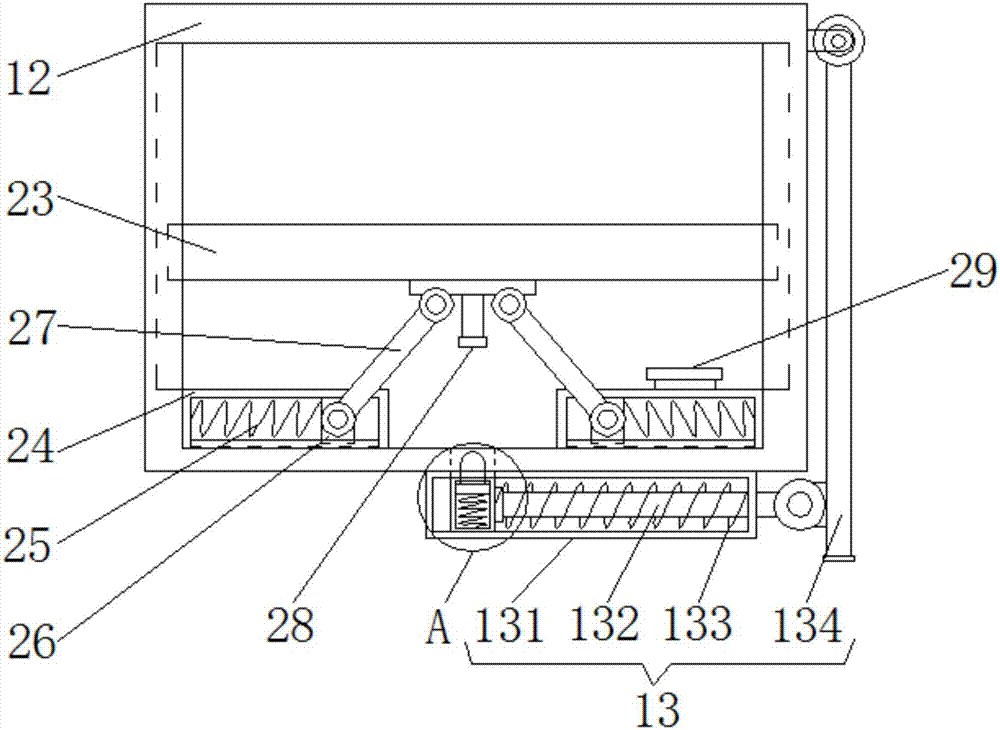

Efficient Chinese herbal medicine smashing device with stirring and drying functions

InactiveCN107350041AEasy accessEasy for secondary crushingRotary stirring mixersTransportation and packagingTraditional medicineDrug herbal

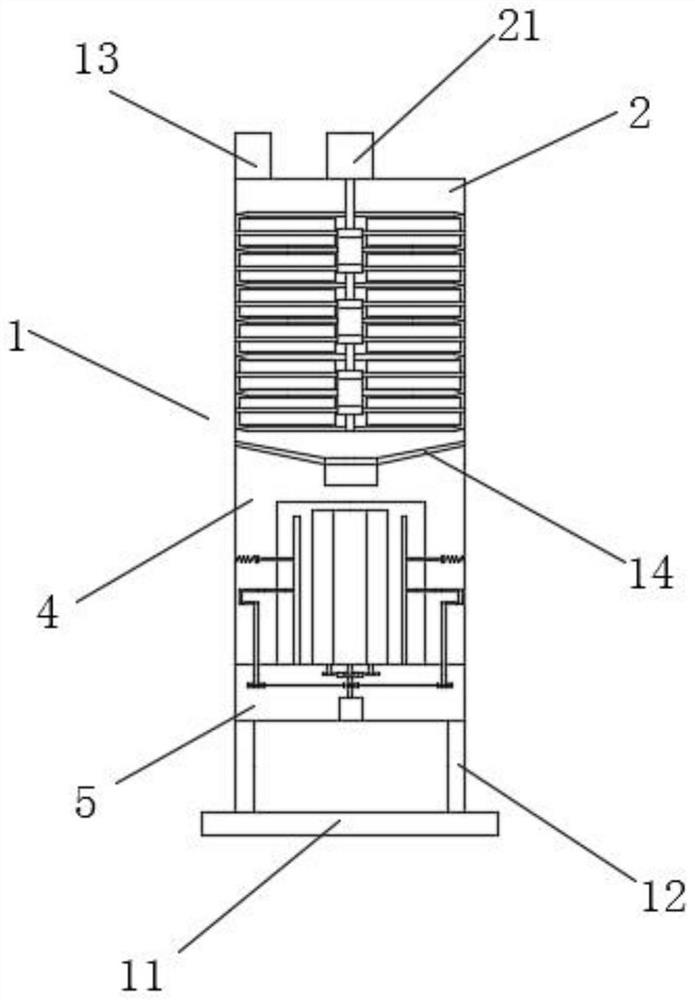

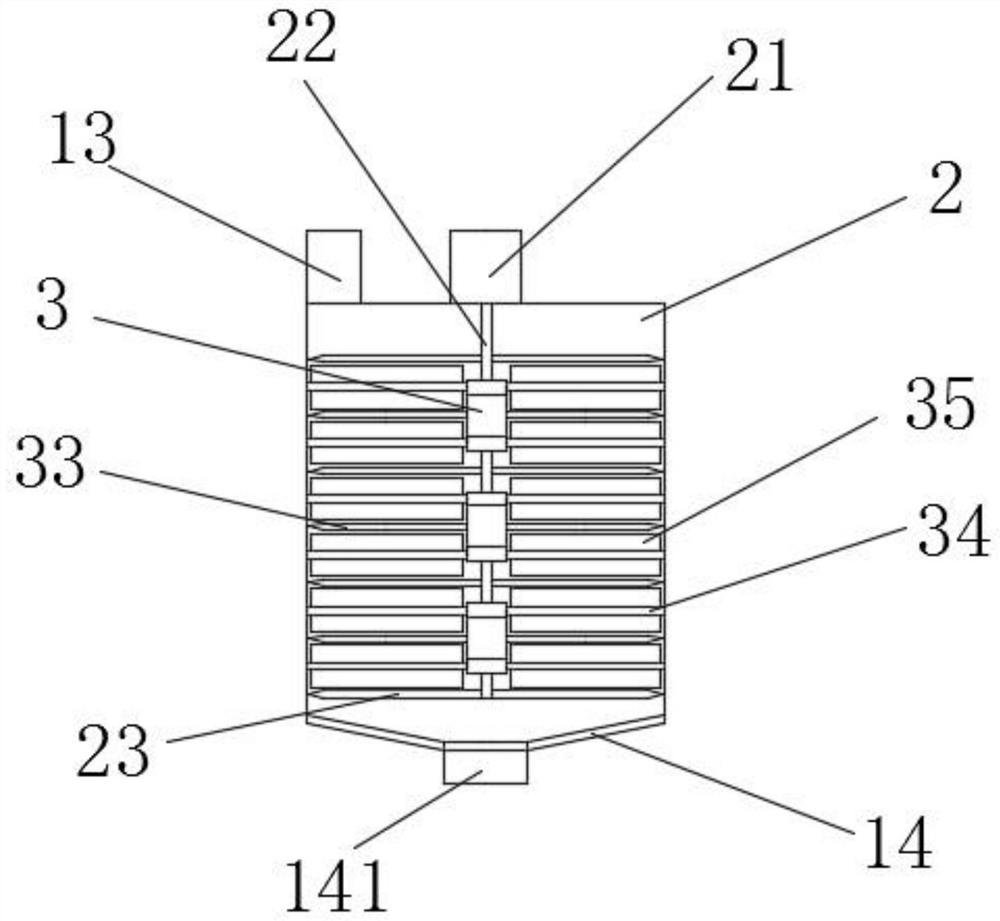

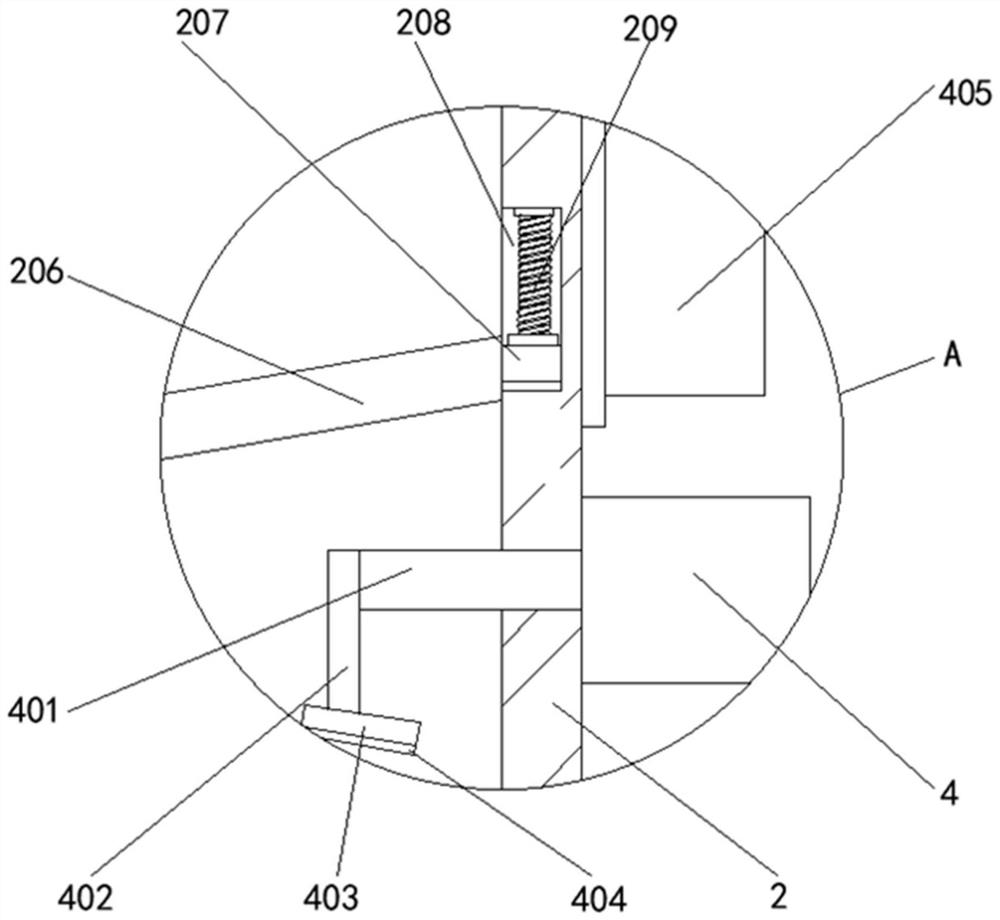

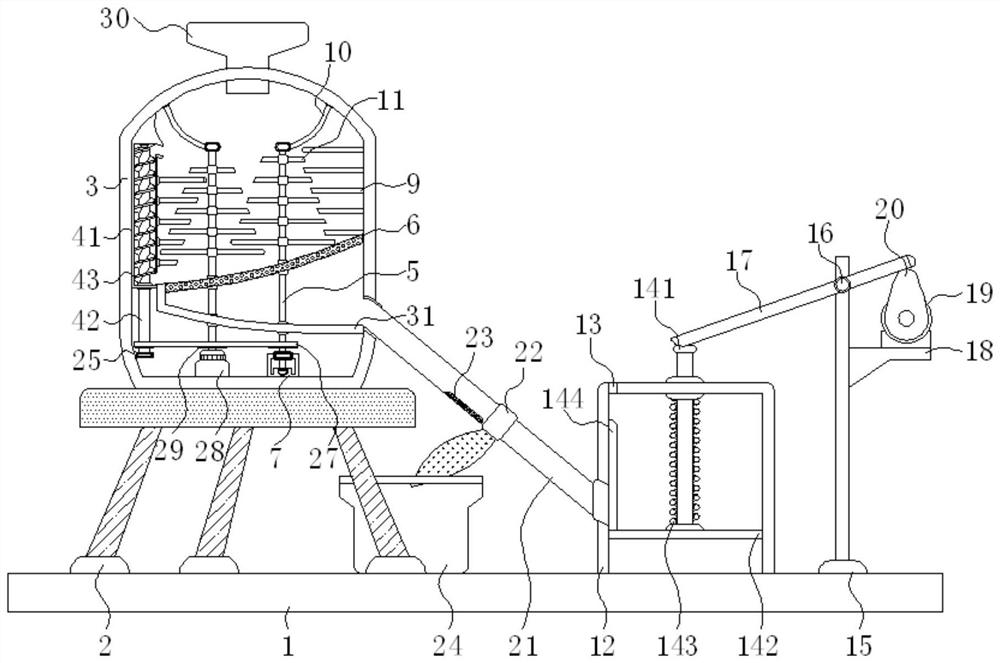

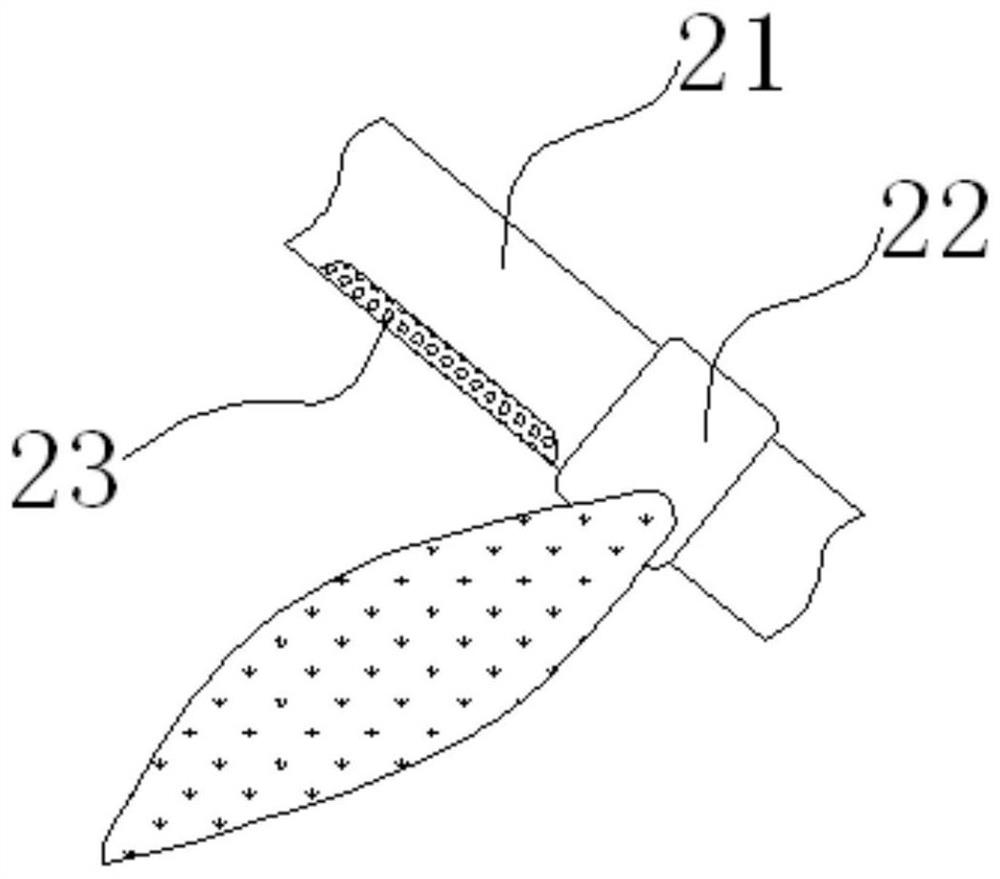

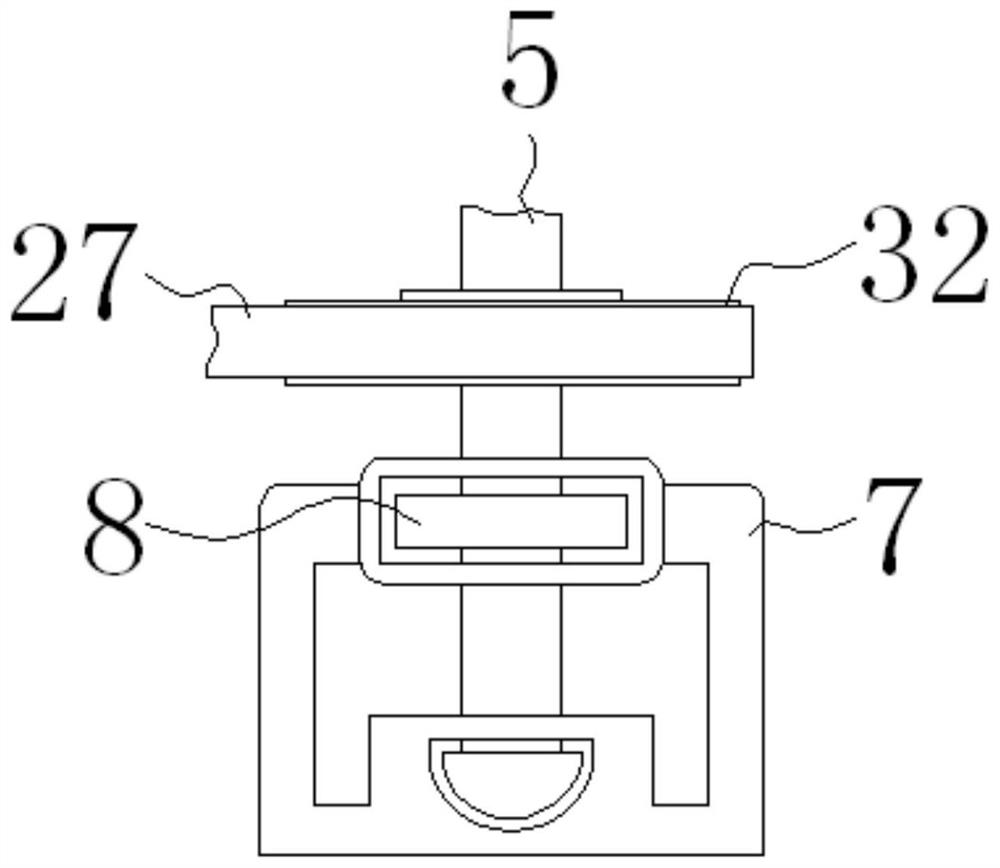

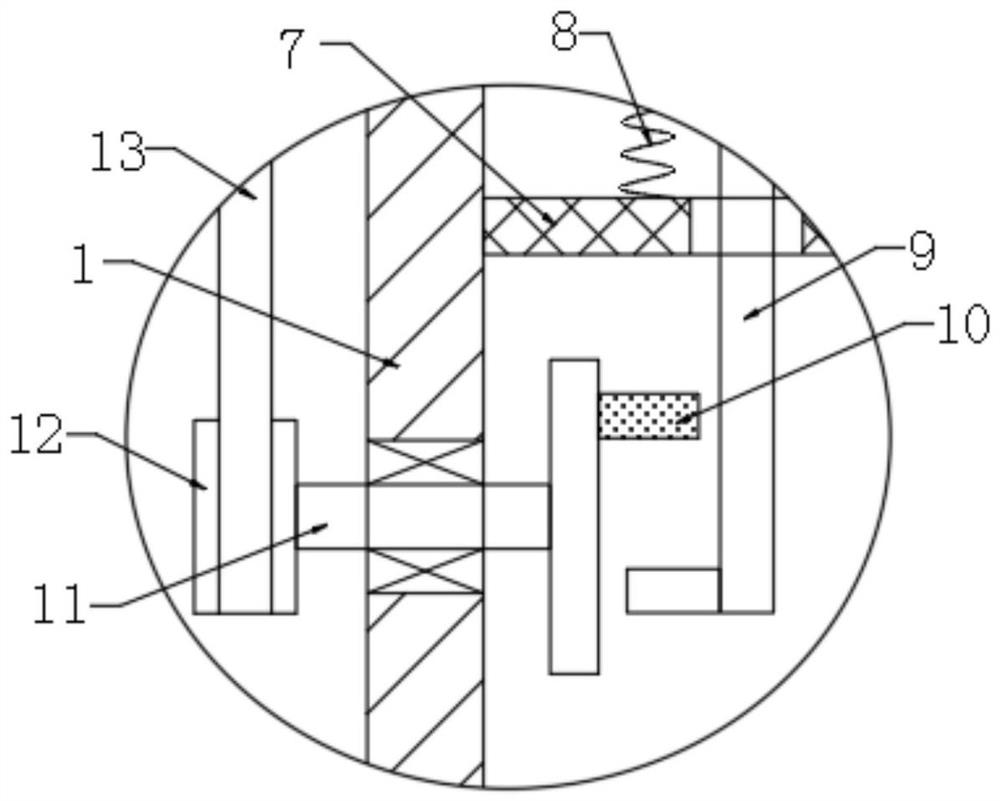

The invention discloses an efficient Chinese herbal medicine smashing device with stirring and drying functions. The efficient Chinese herbal medicine smashing device comprises a feeding device, a supporting movement device, a spiral smashing device, a spiral cutting device and a drying device; the spiral cutting device is arranged inside a cutting cavity; and a medicine smashing cavity is arranged below the cutting cavity. According to the efficient Chinese herbal medicine smashing device, Chinese herbal medicines entering the device is subject to primary smashing through the spiral cutting device, the Chinese herbal medicines conveniently enters a device at the lower portion, blockage is prevented, secondary smashing of the spiral smashing device on the Chinese herbal medicines is facilitated, and the secondary smashing time is shortened; the spiral smashing device conducts secondary smashing on the Chinese herbal medicines, and therefore the smashing effect of the Chinese herbal medicines is increased; through the arrangement of a grabbing hook in a rotary stirring device, the incomplete smashing Chinese herbal medicines are grabbed up and fall from the upper portion to enter the spiral smashing device at the lower portion again for smashing again; and through the drying device, moisture contained in the Chinese herbal medicines evaporates to dryness, and the Chinese herbal medicines are prevented from being attached to the spiral cutting device and the rotary stirring device.

Owner:惠安思奕生物科技有限公司

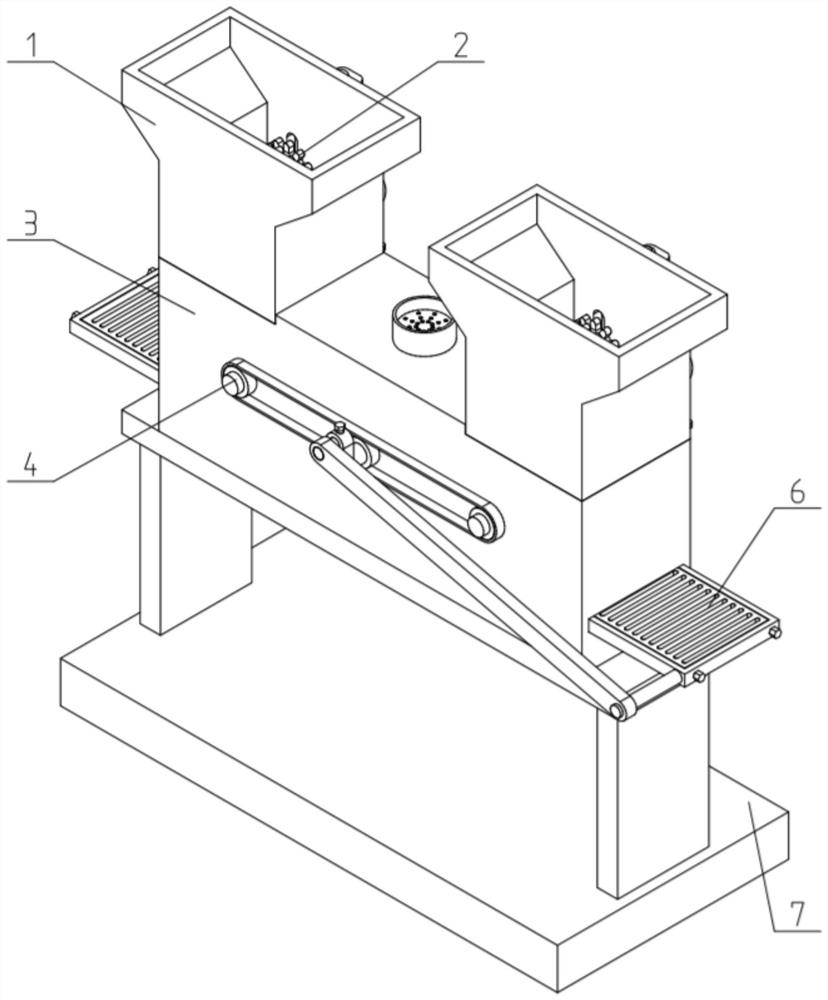

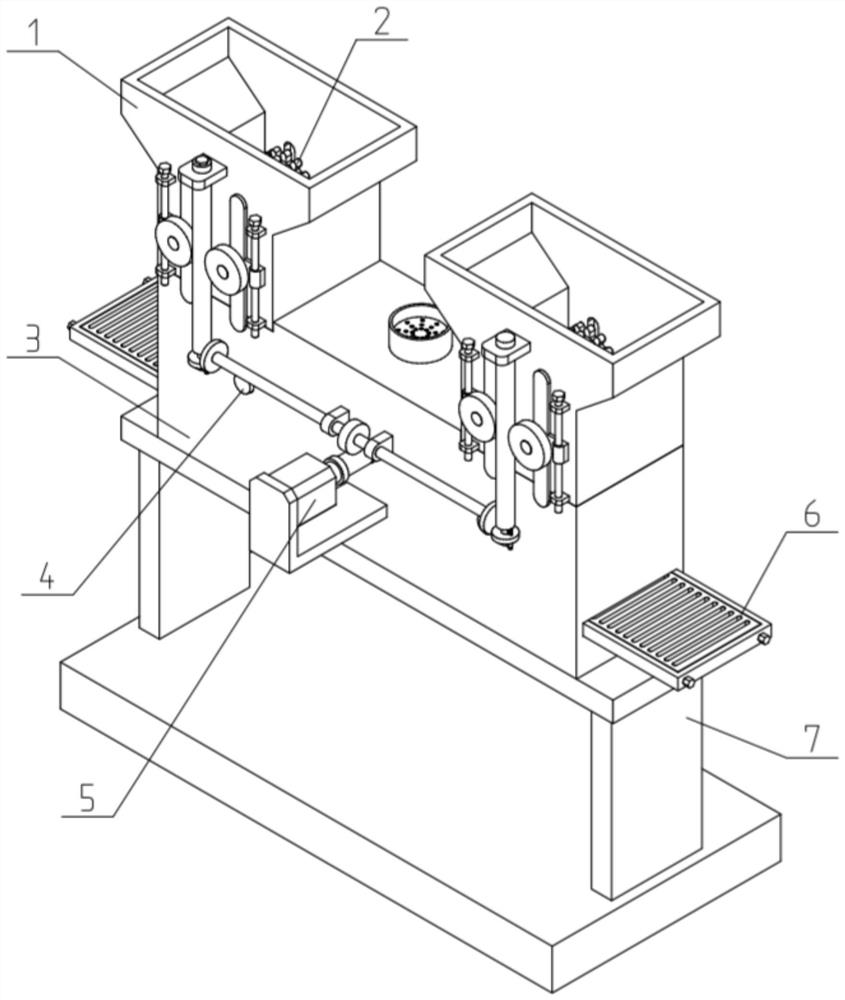

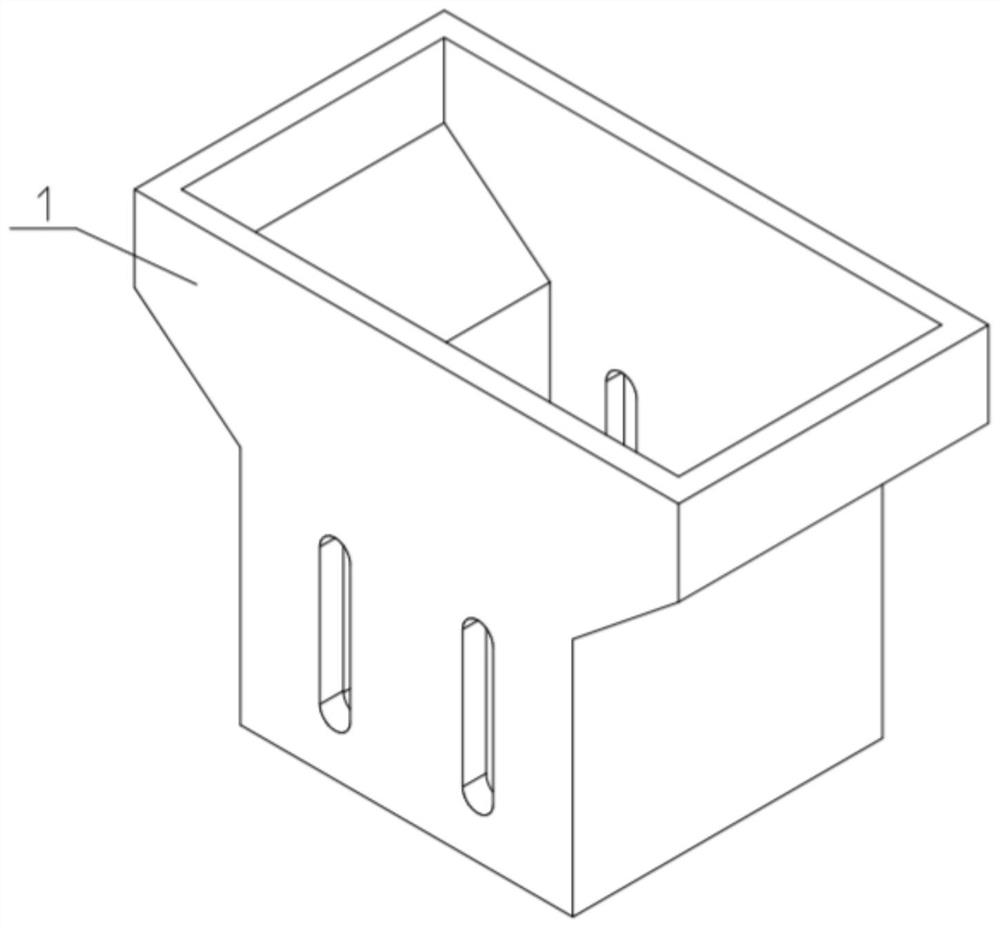

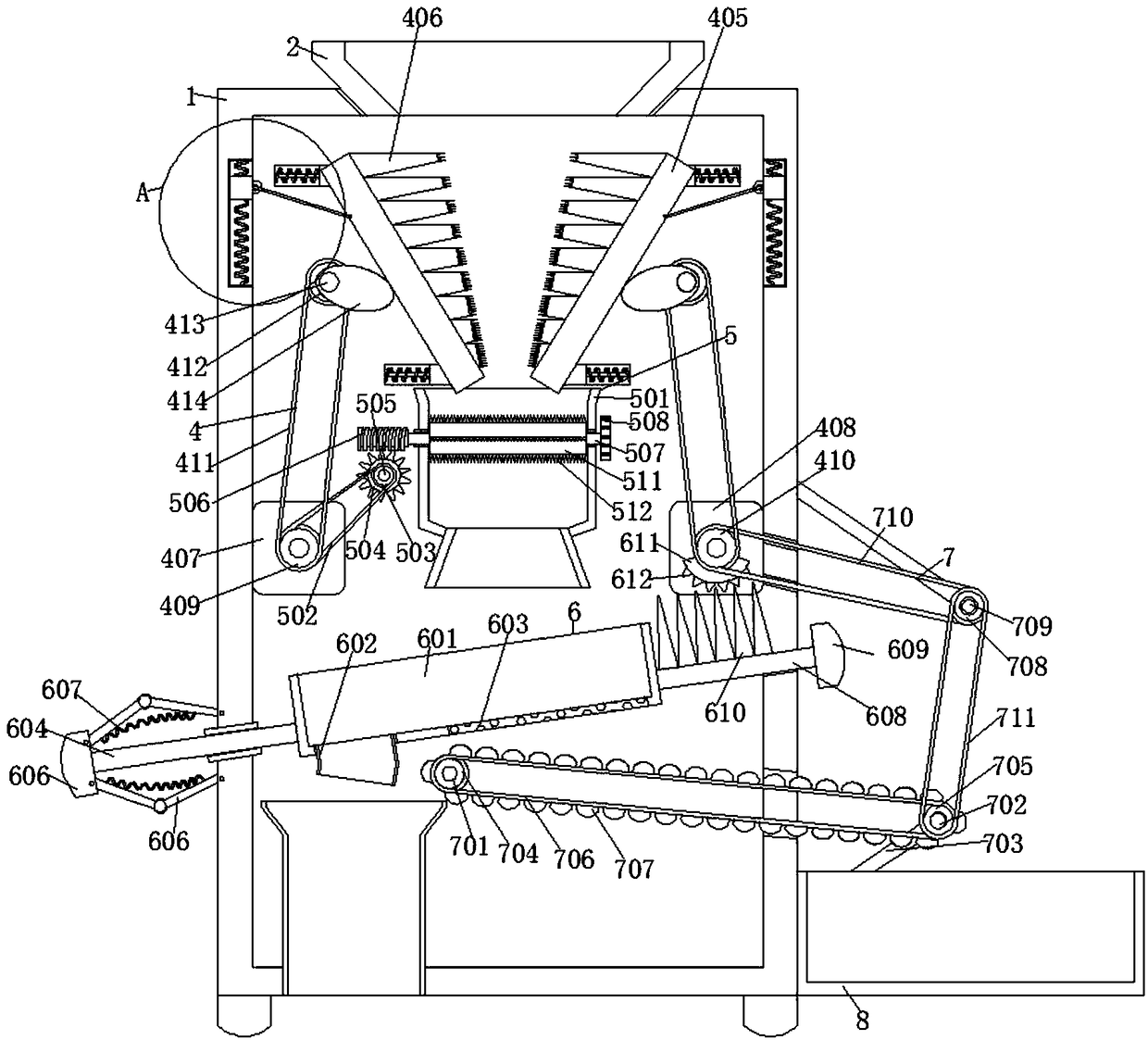

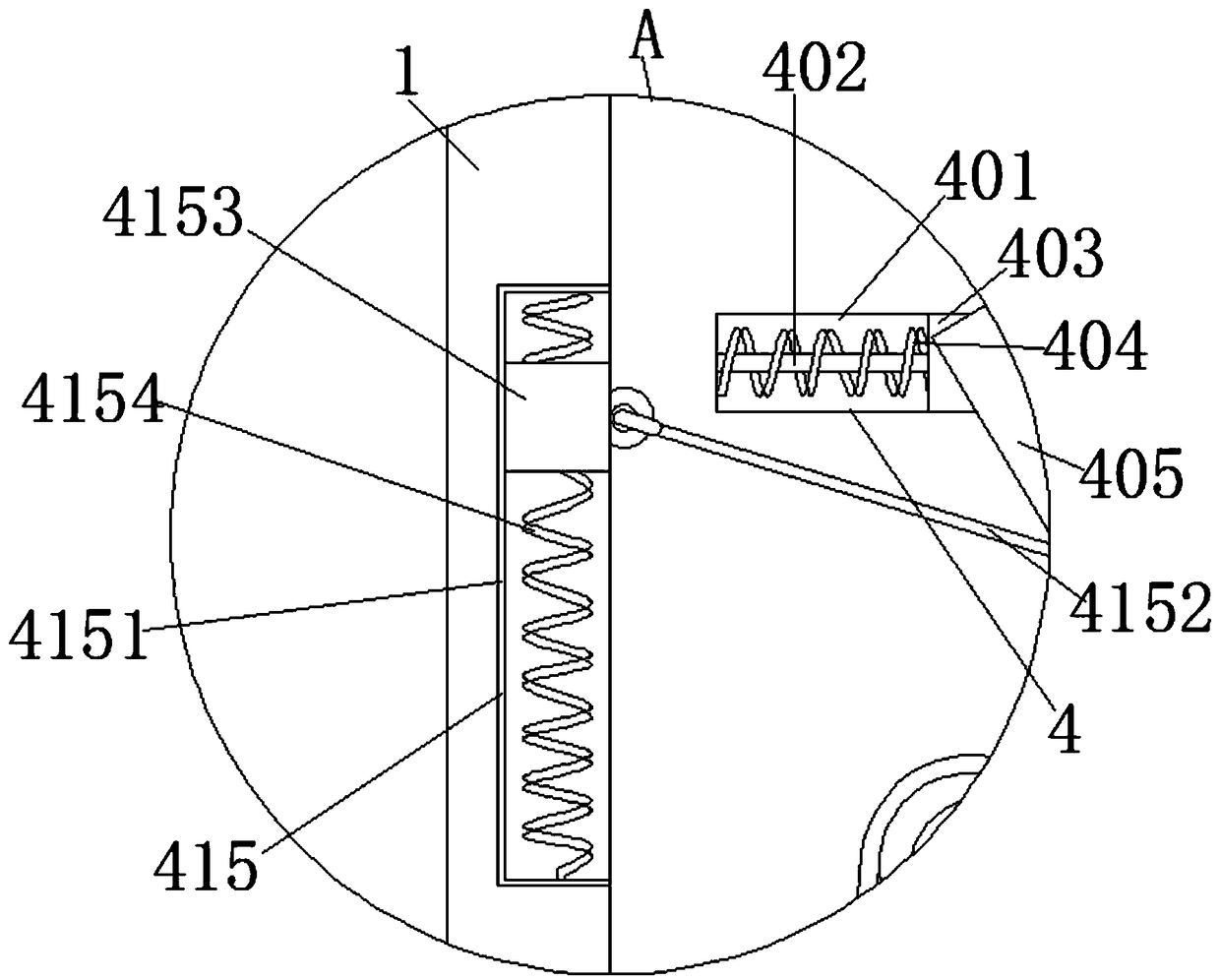

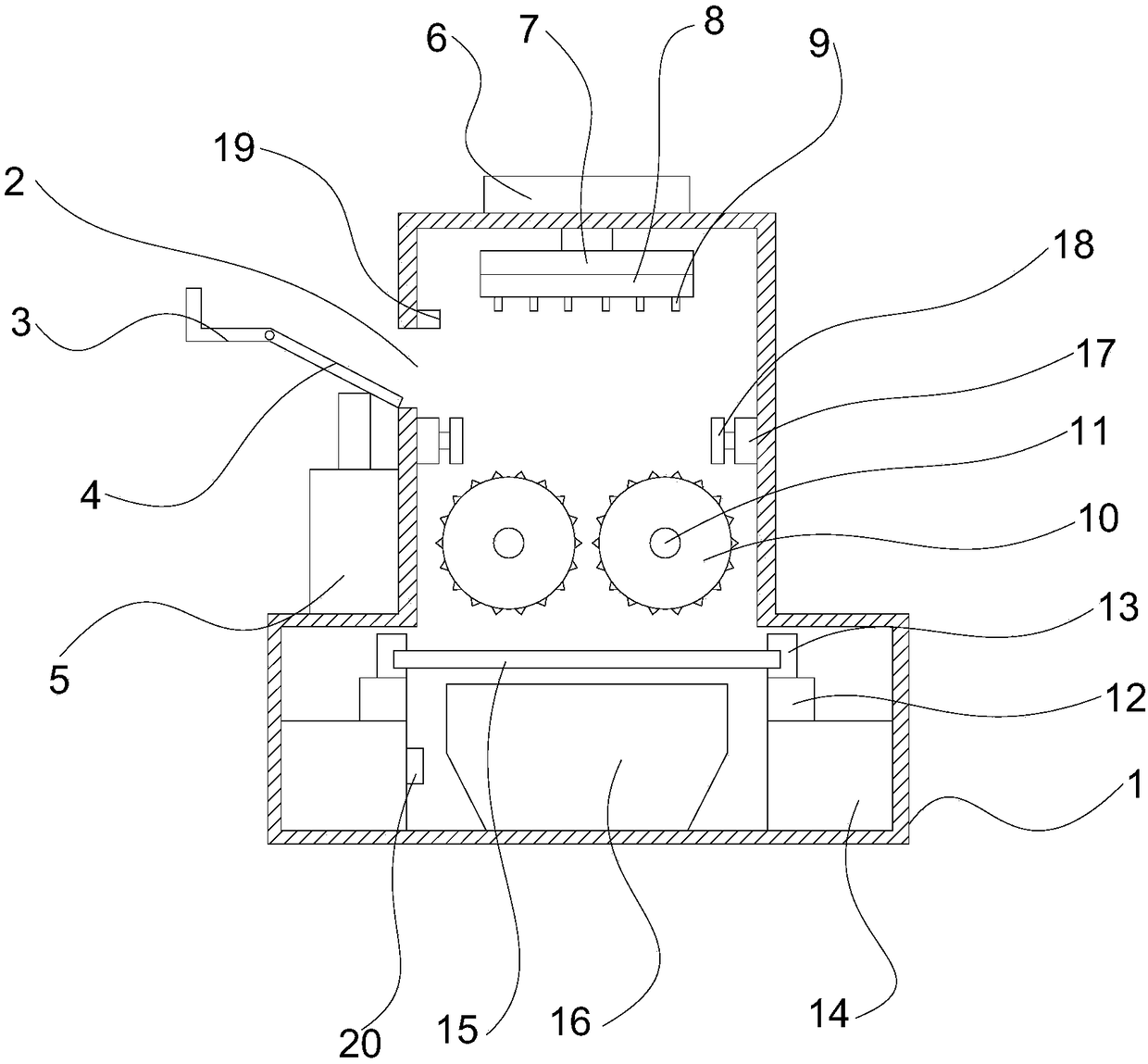

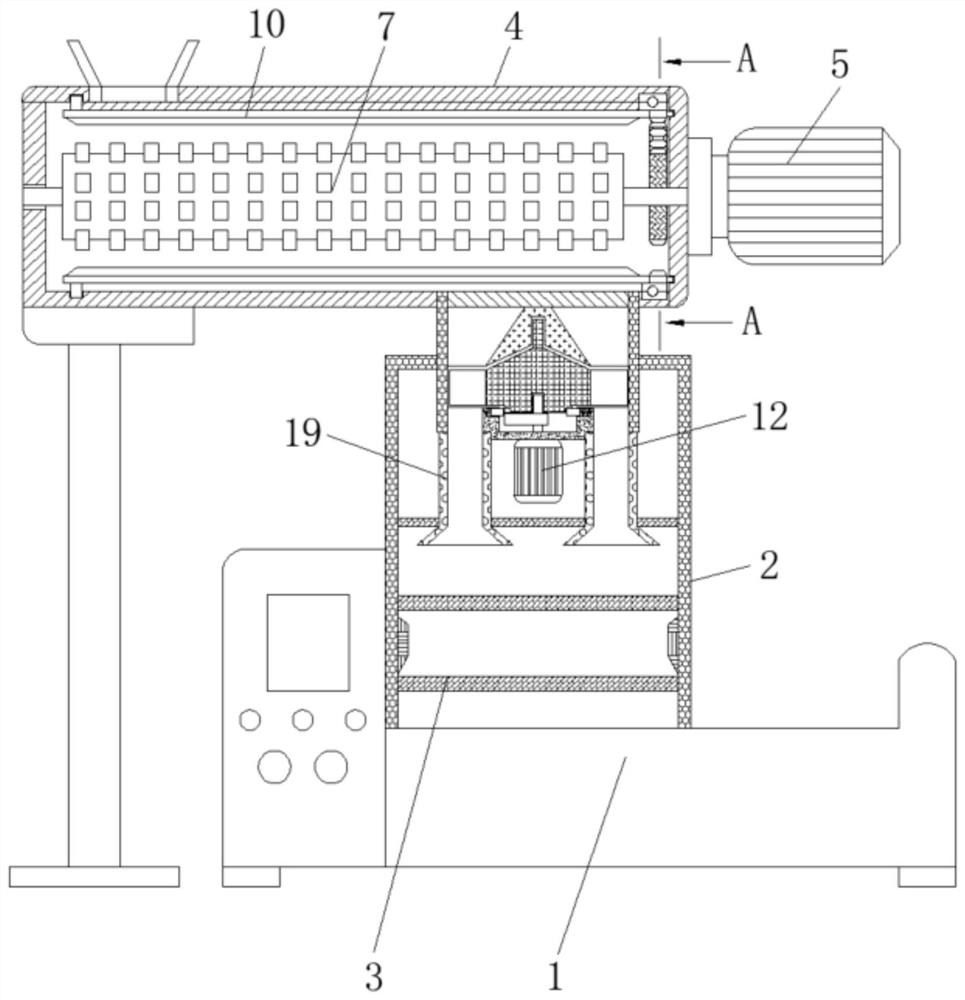

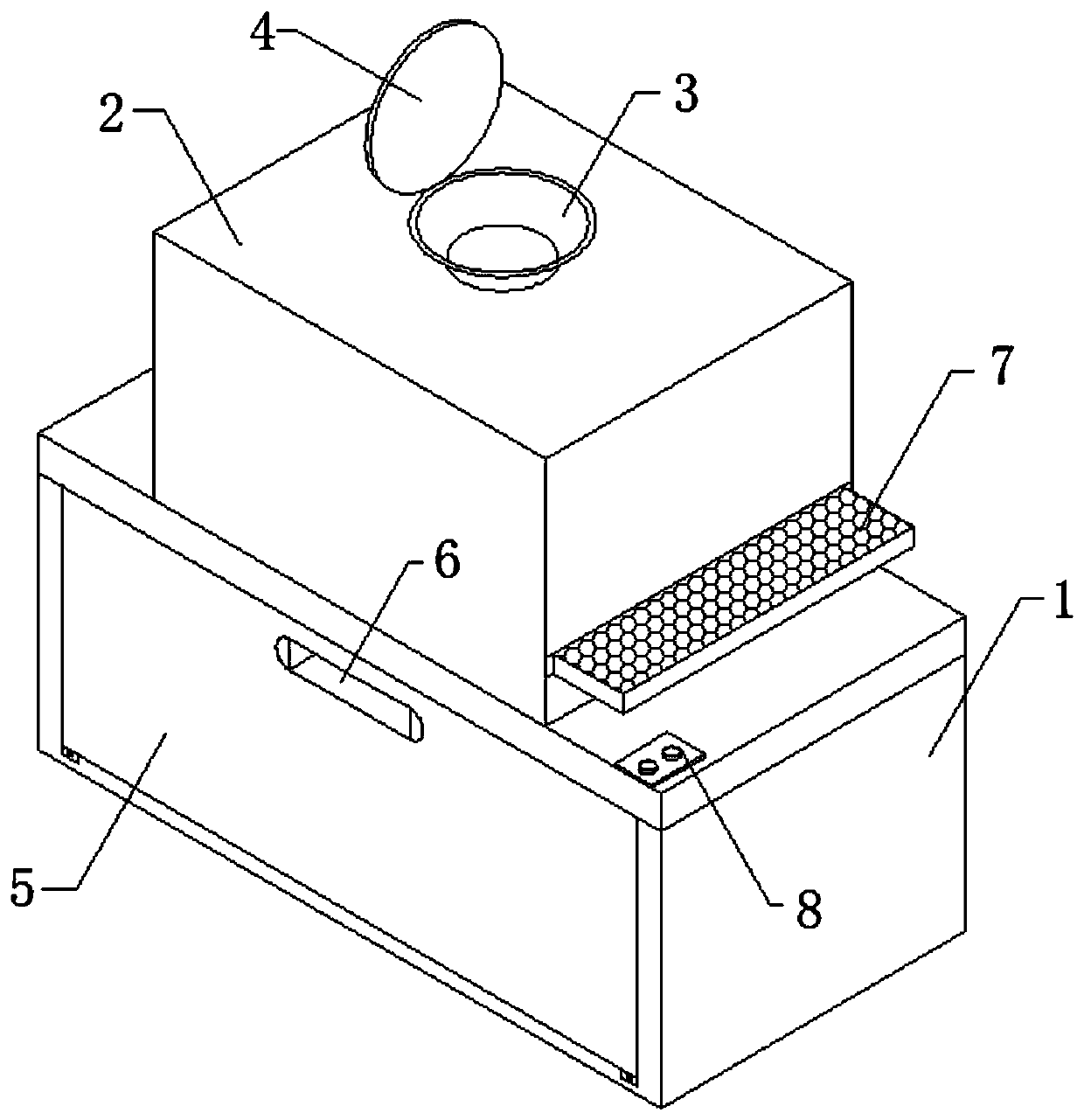

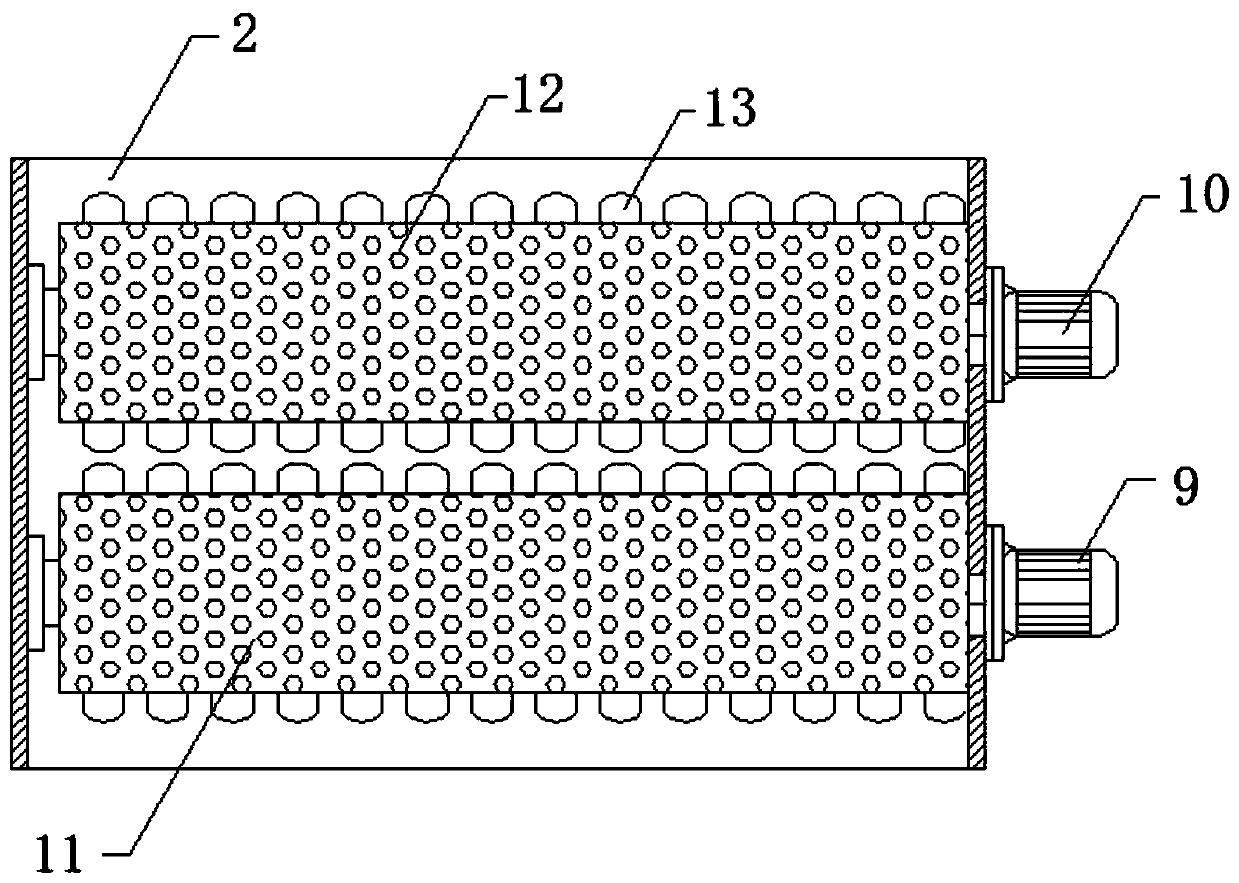

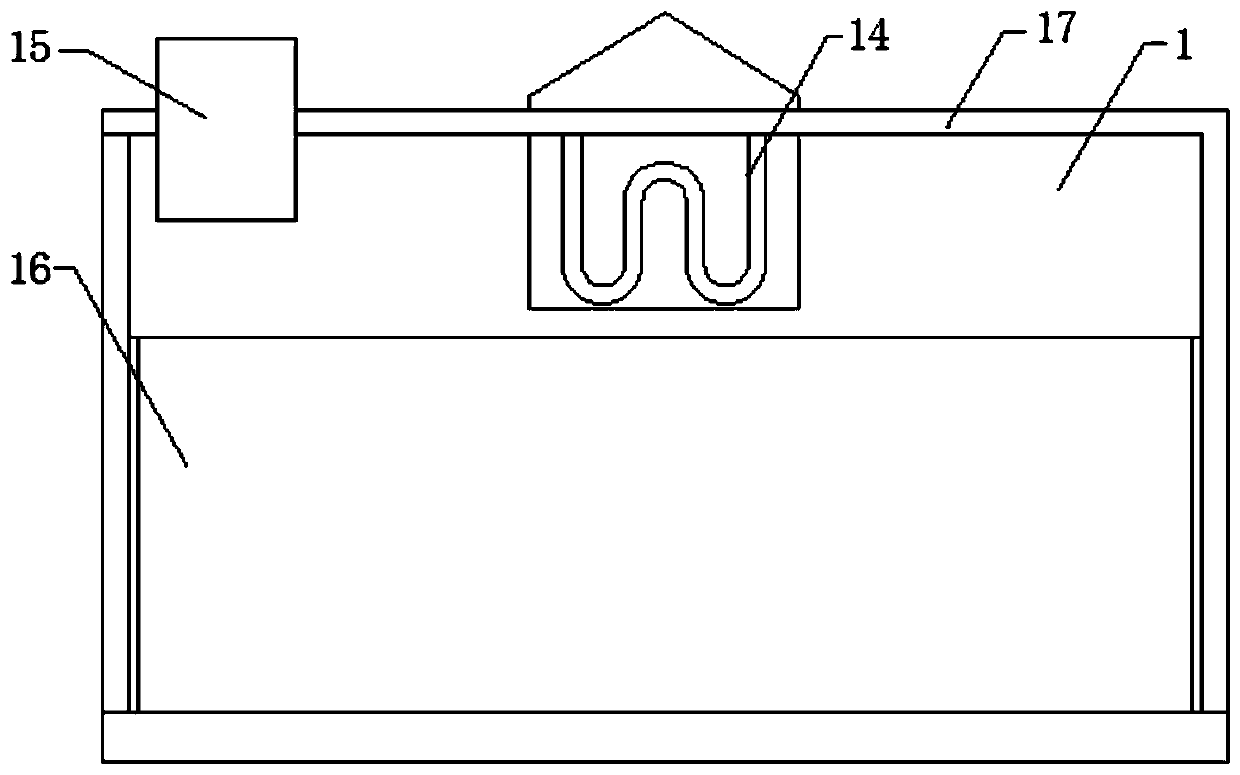

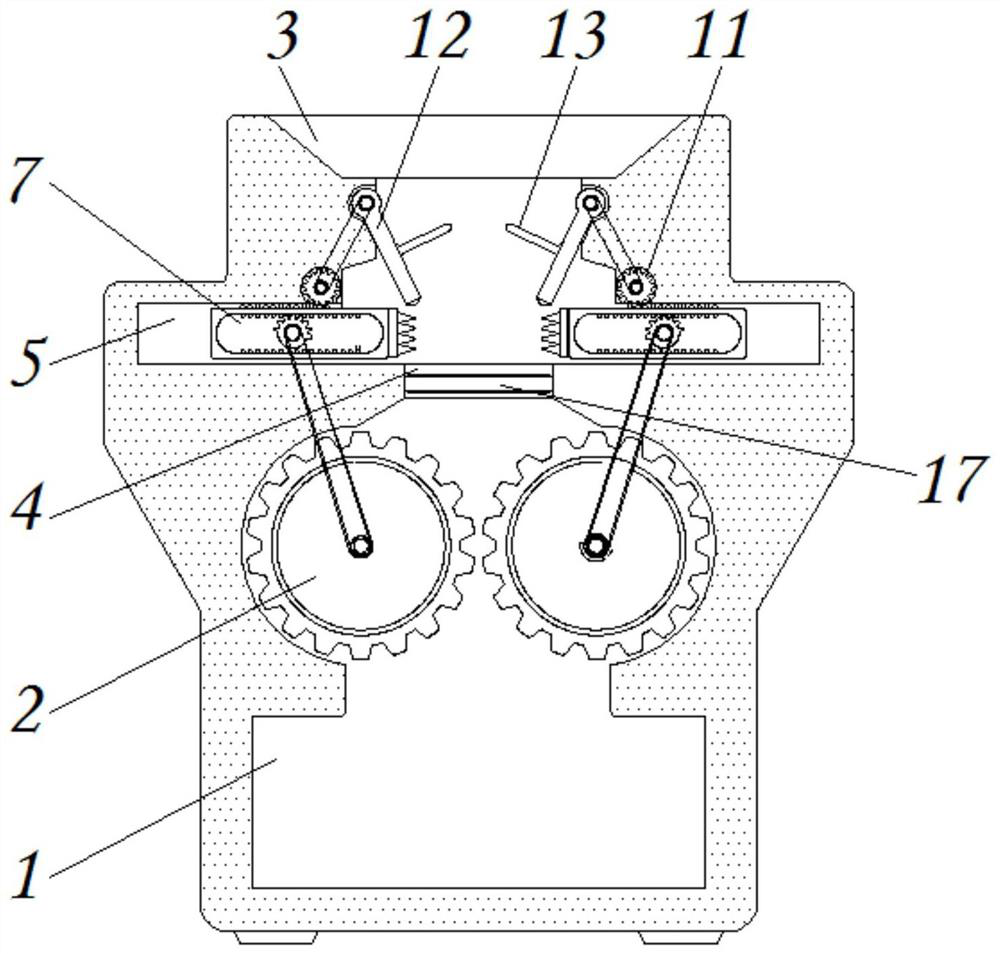

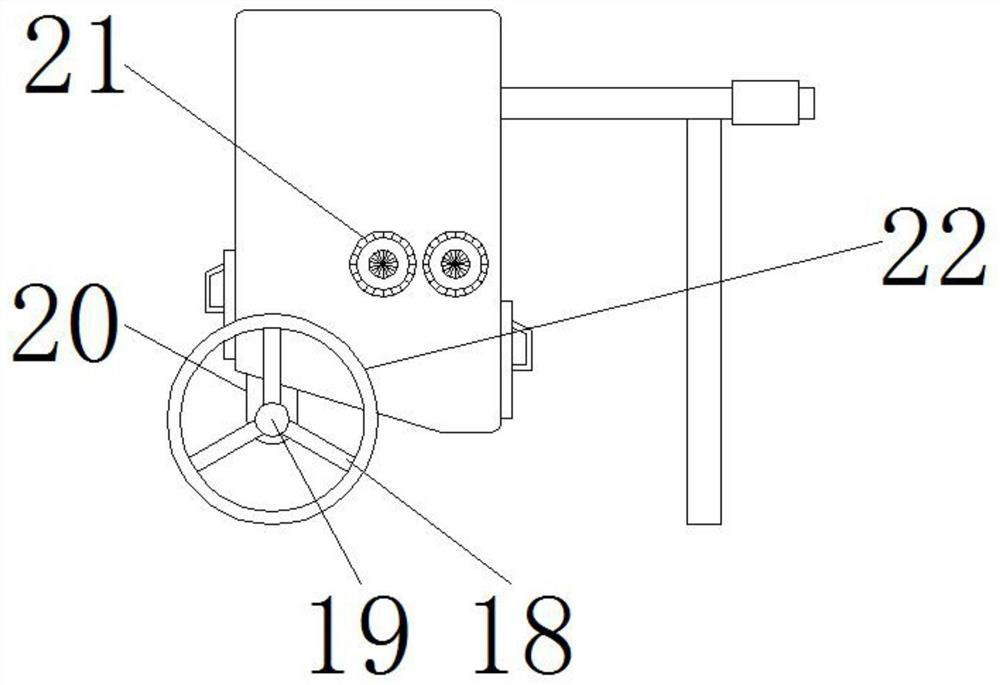

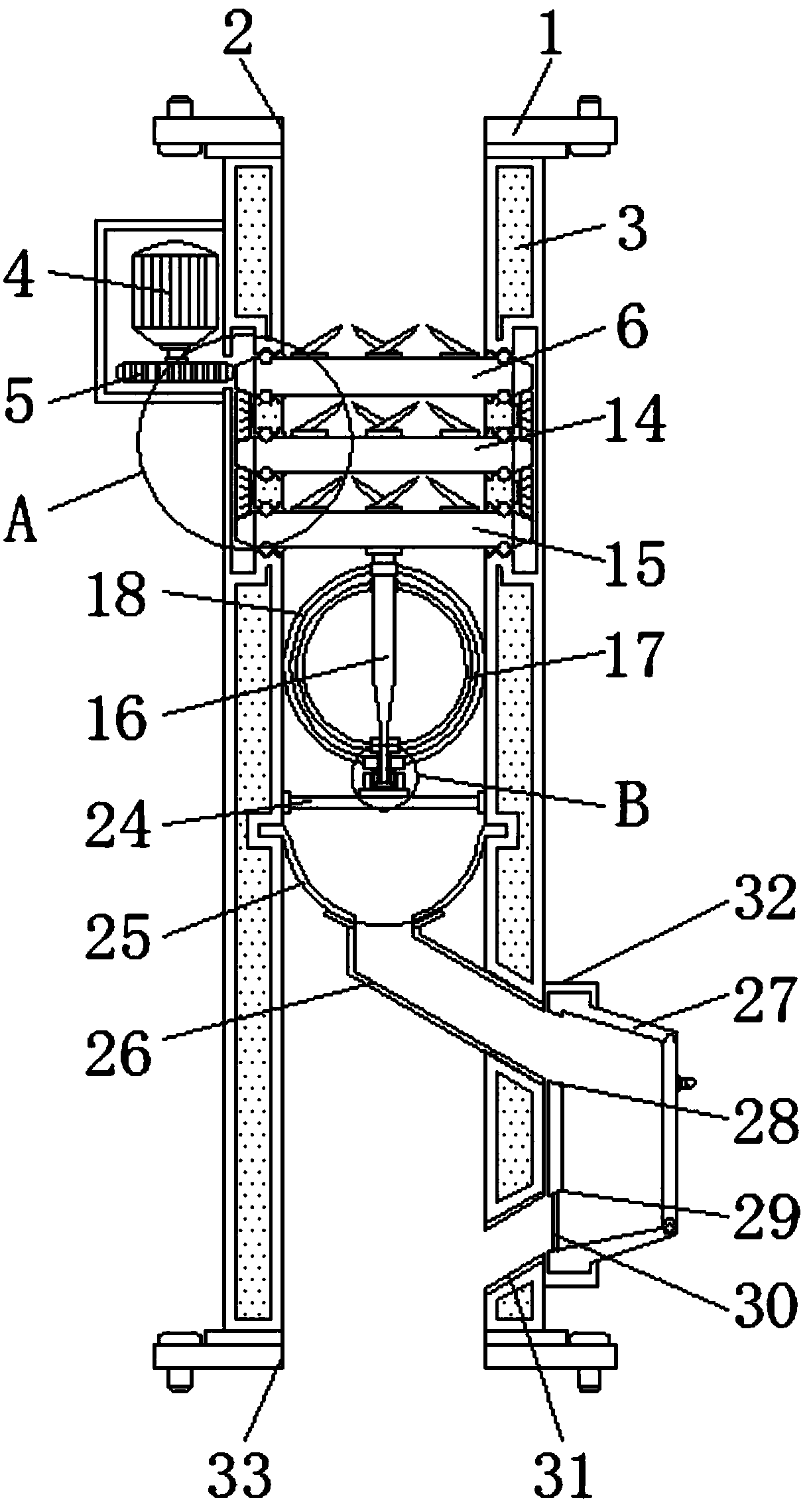

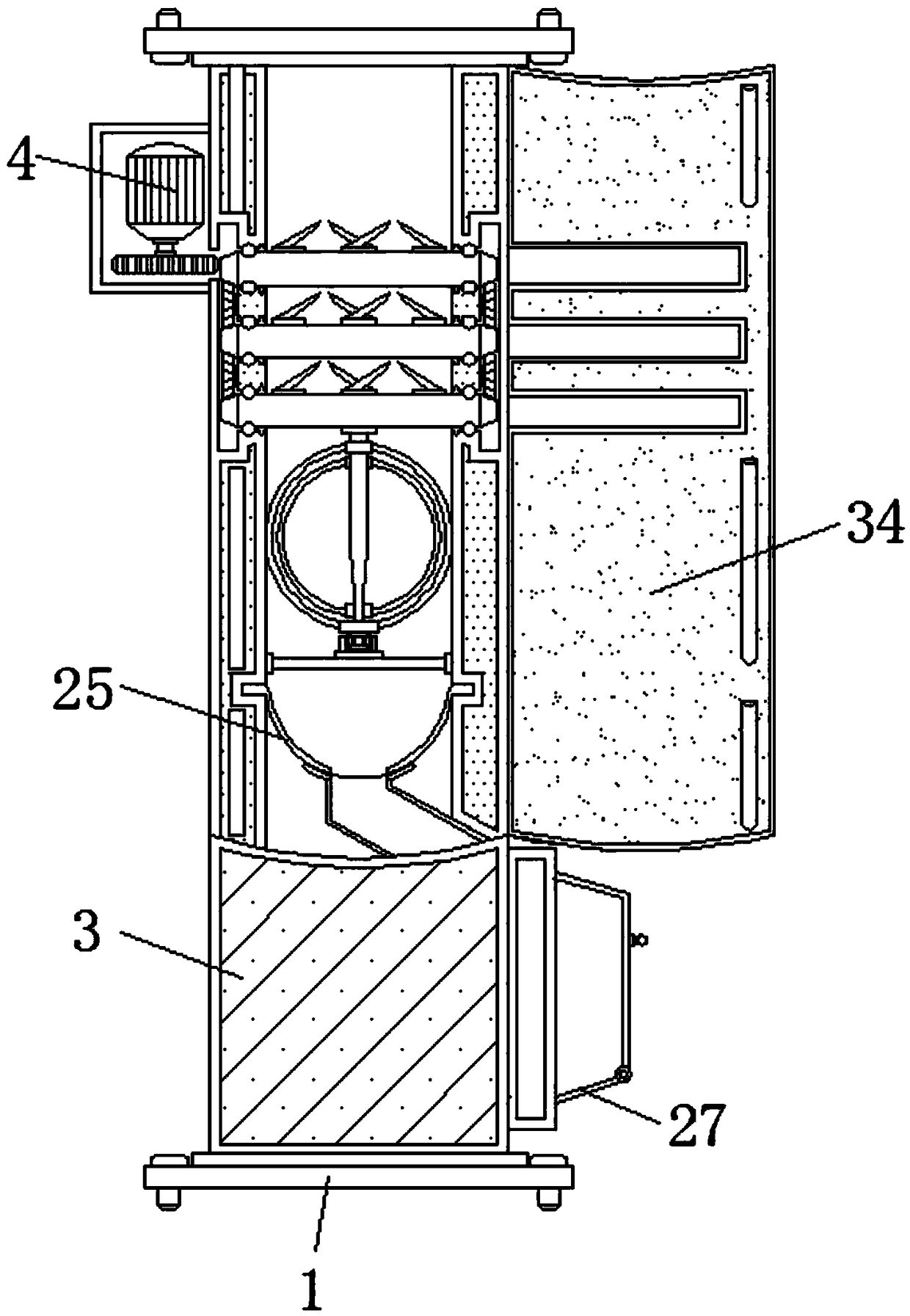

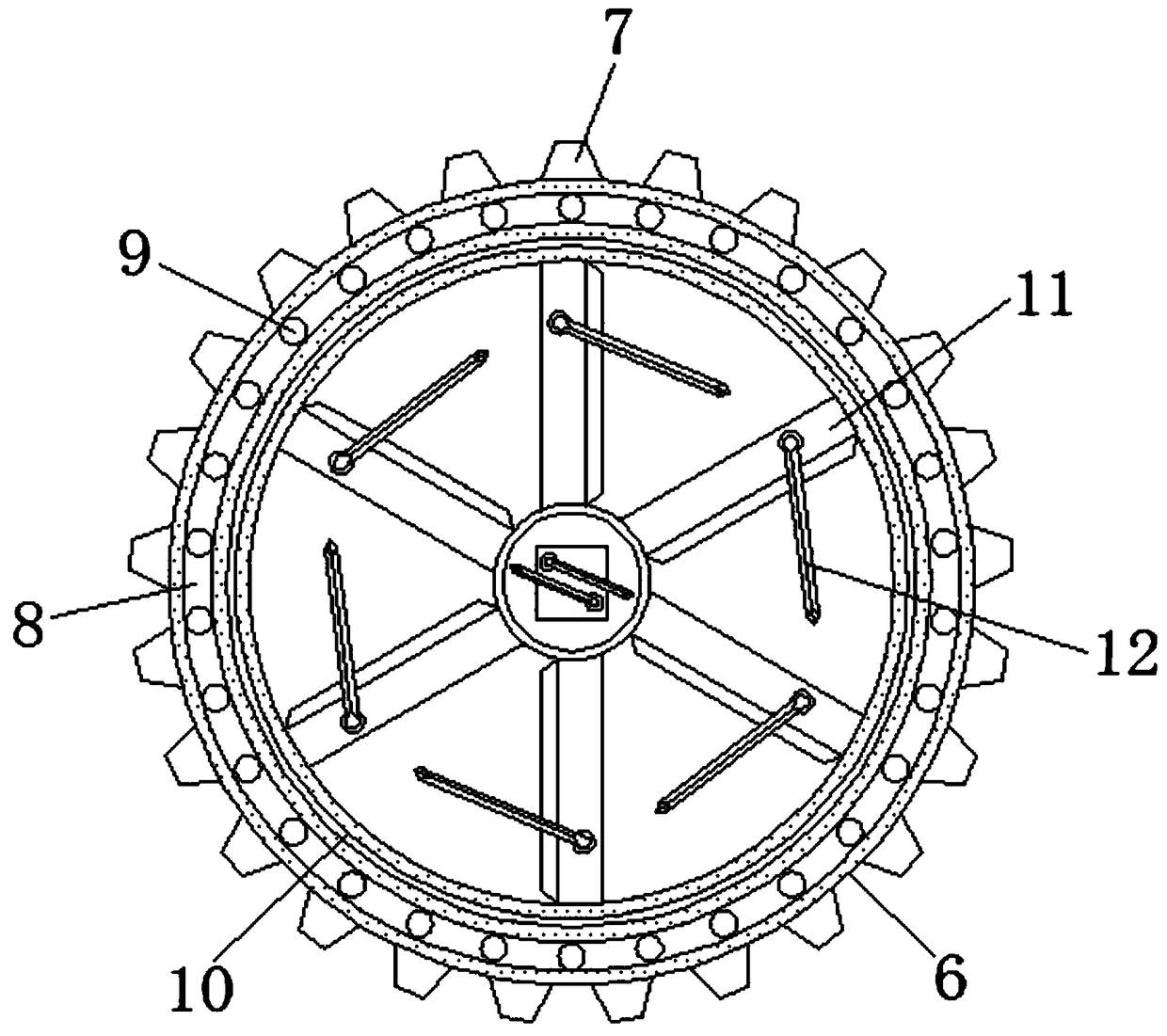

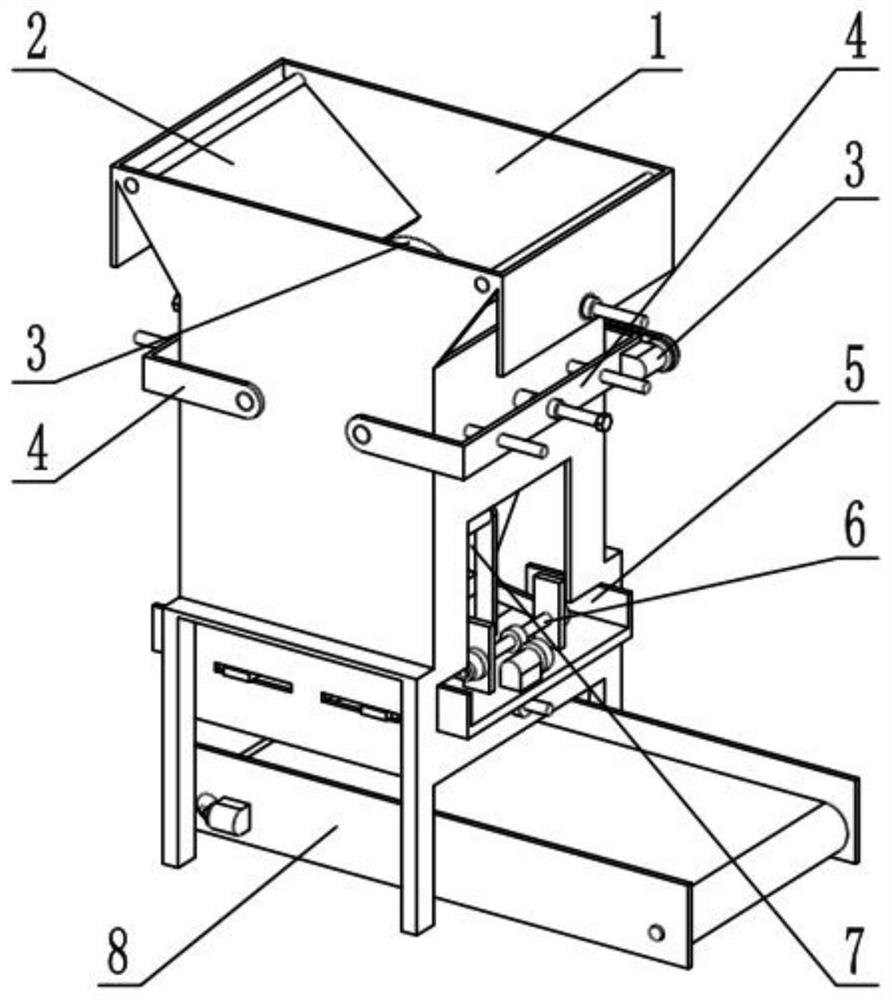

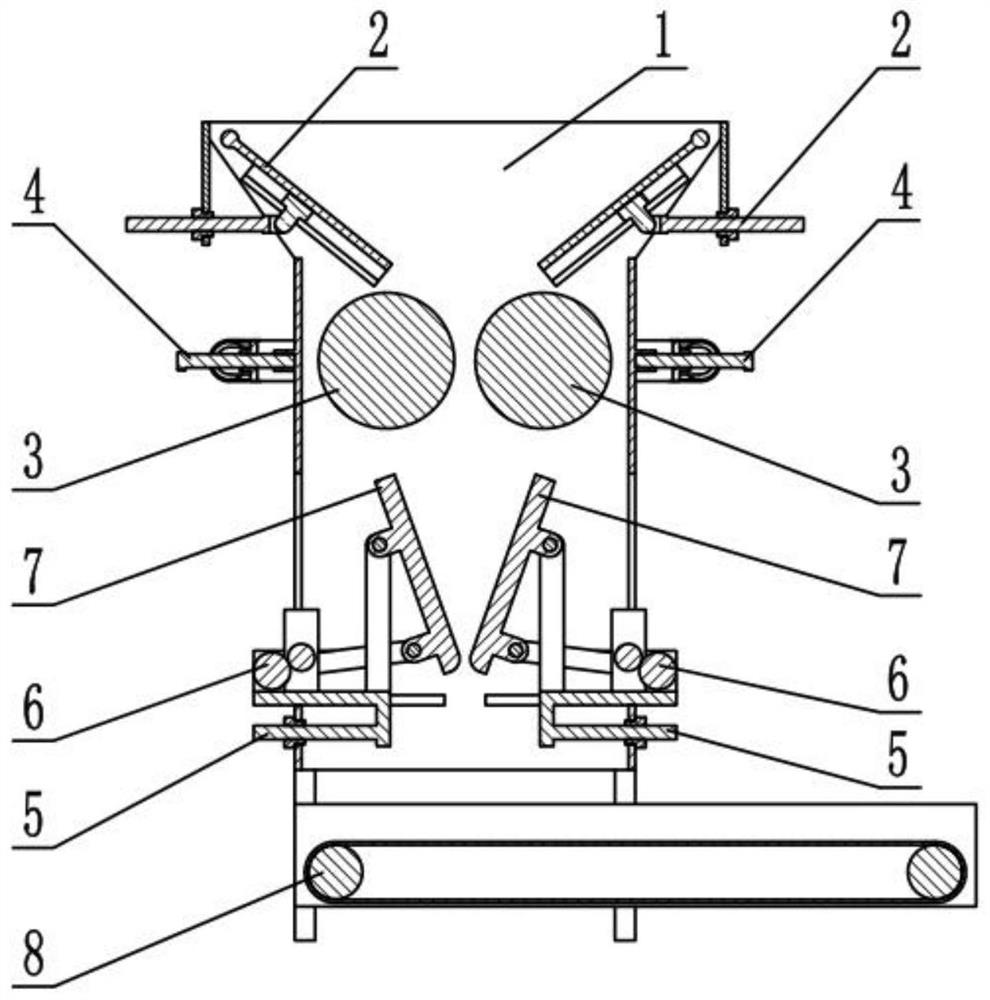

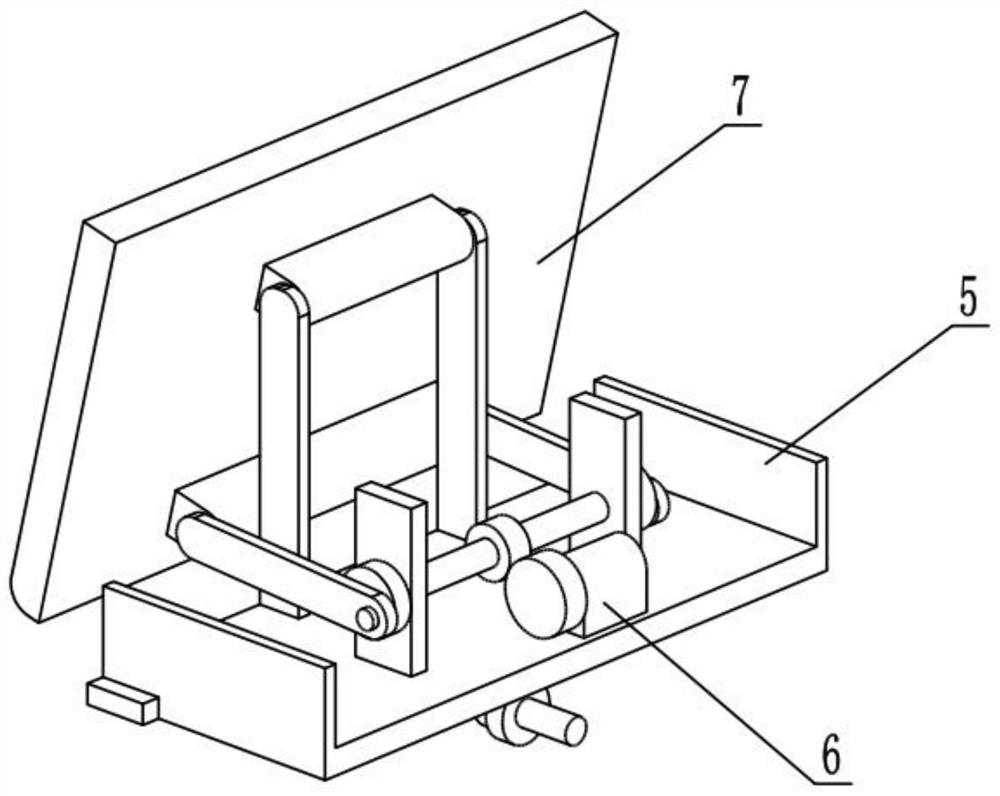

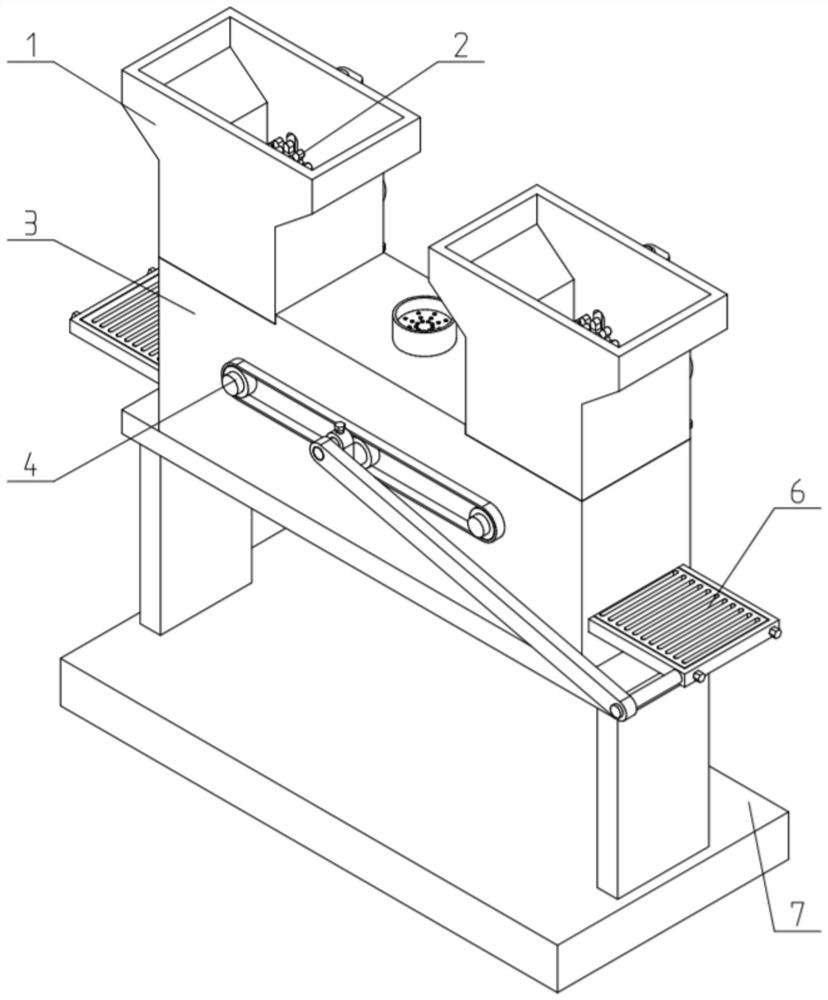

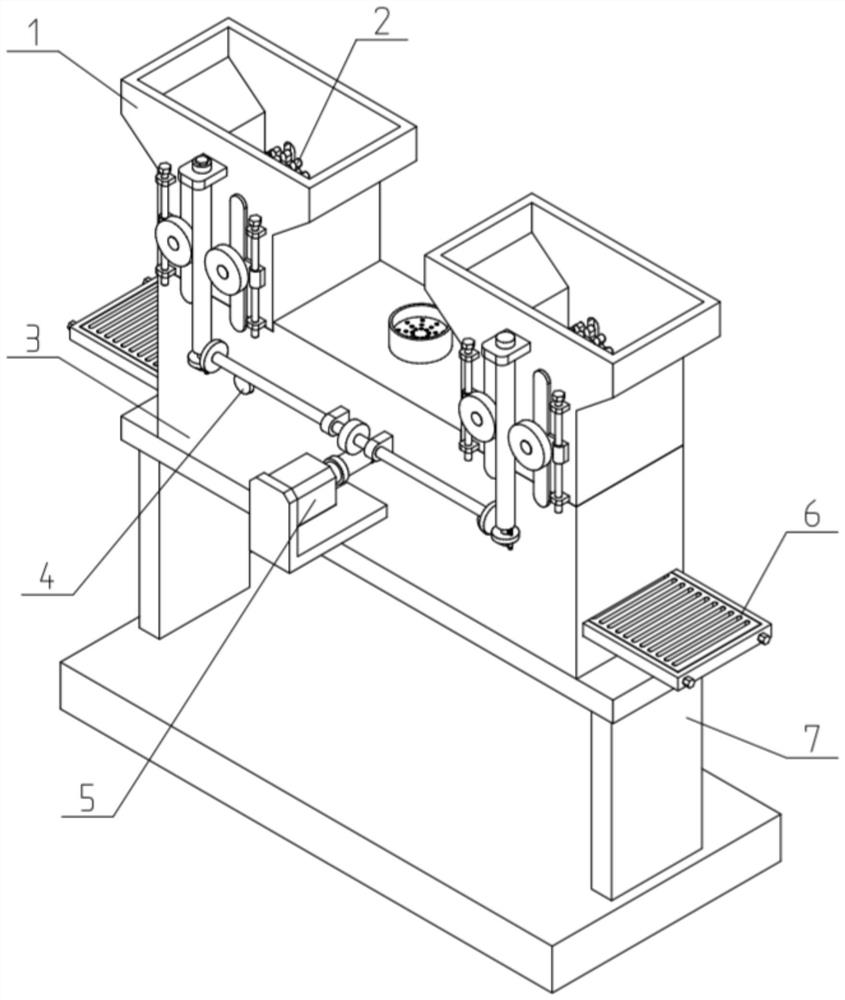

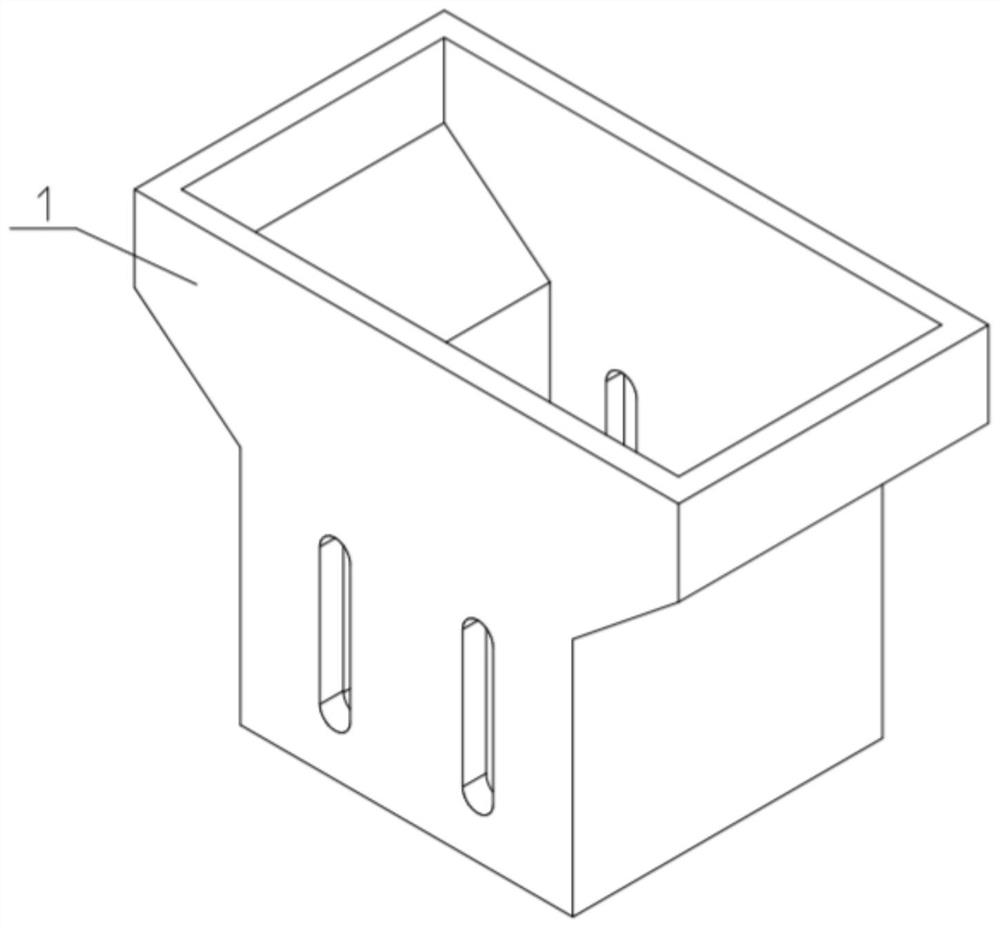

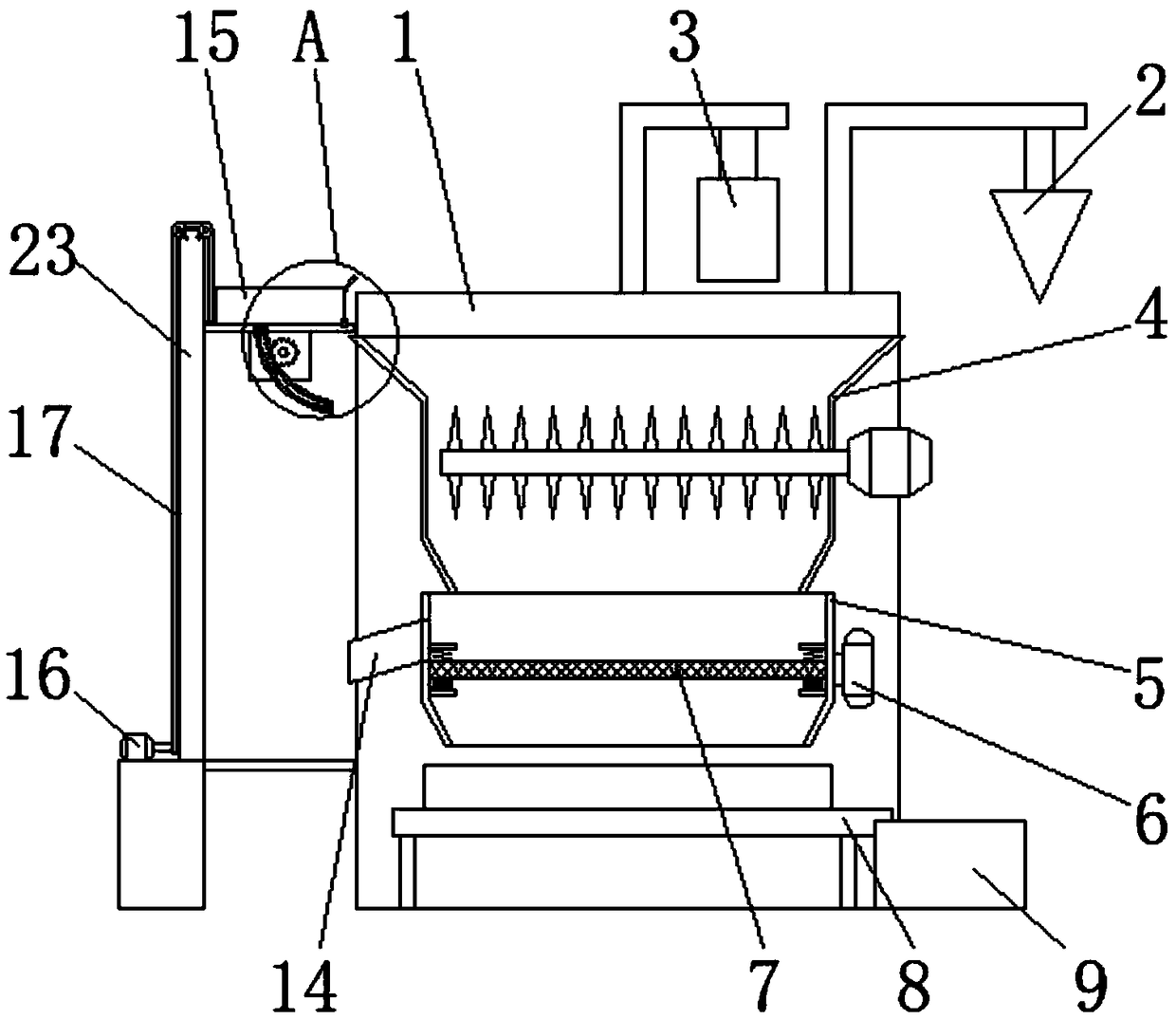

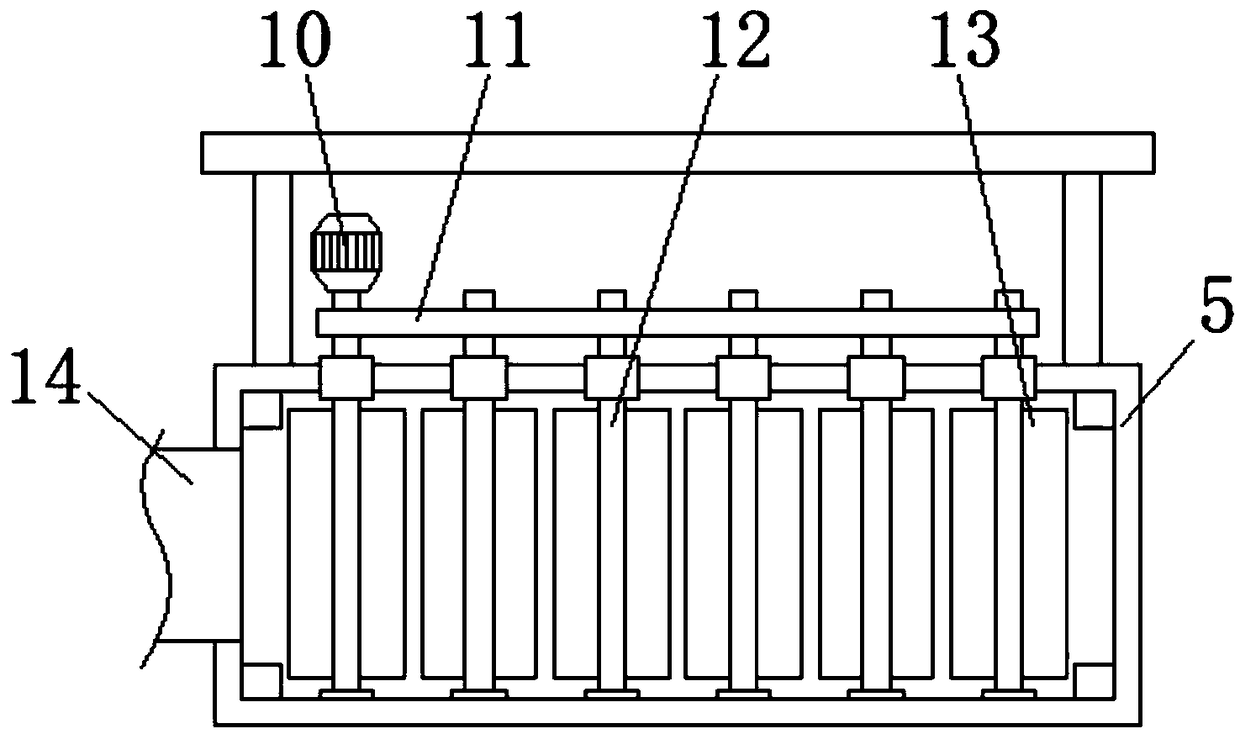

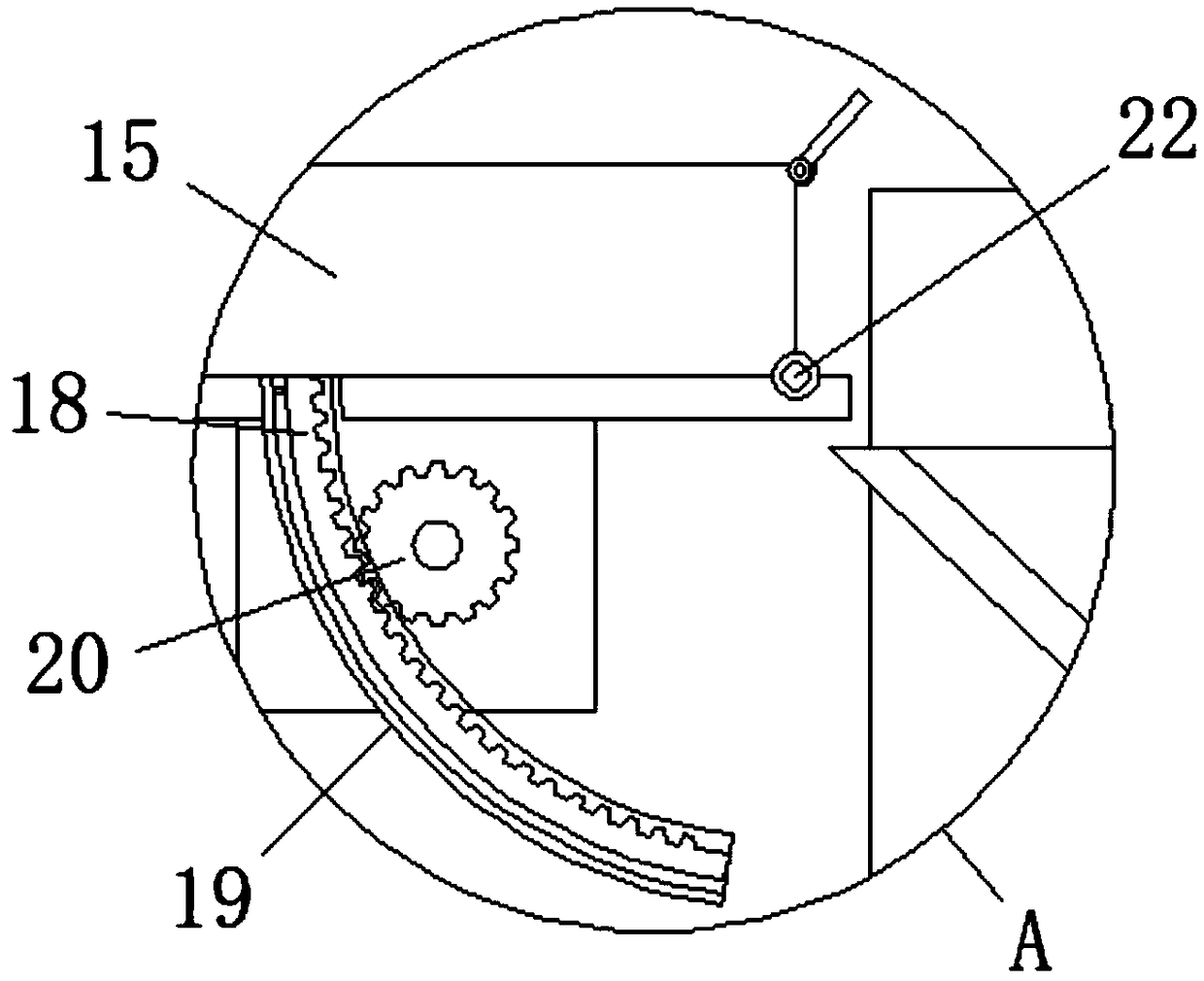

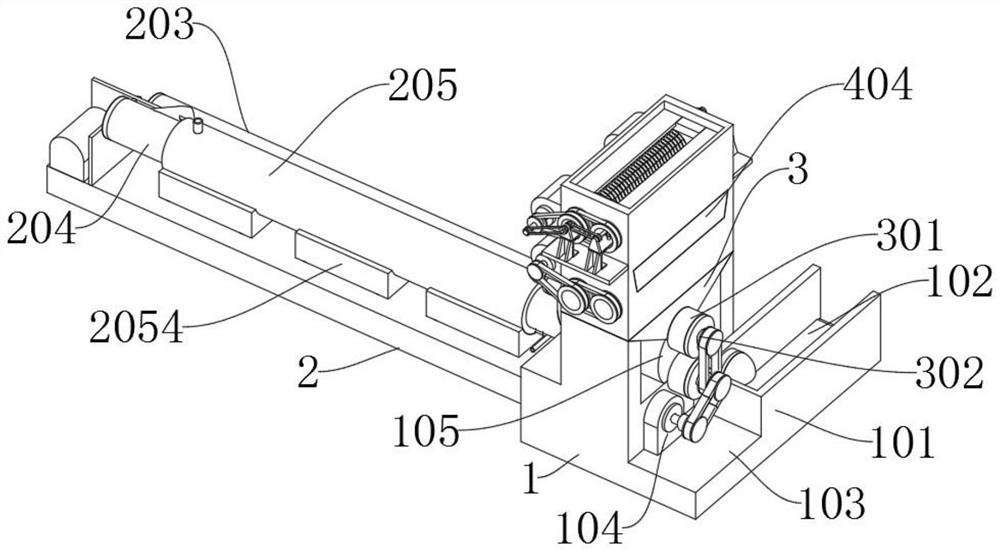

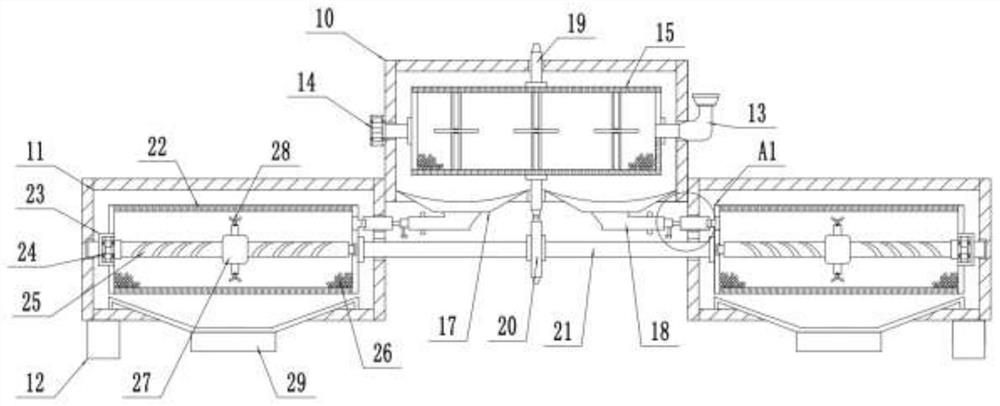

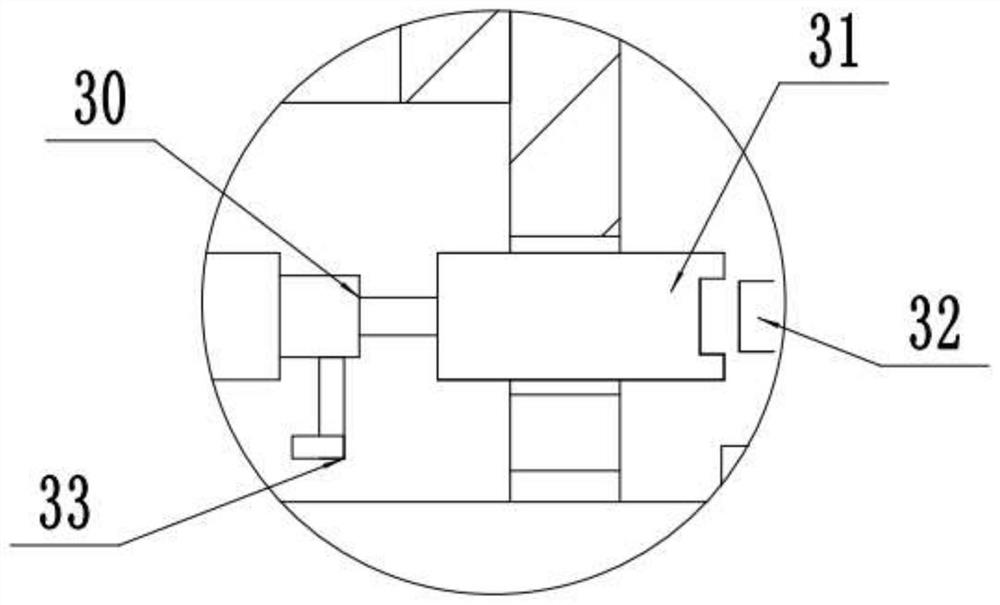

Construction waste treatment device

ActiveCN111841738AEasy for secondary crushingImprove efficiencyConstruction waste recoveryGrain treatmentsEnvironmental engineeringRefuse Disposals

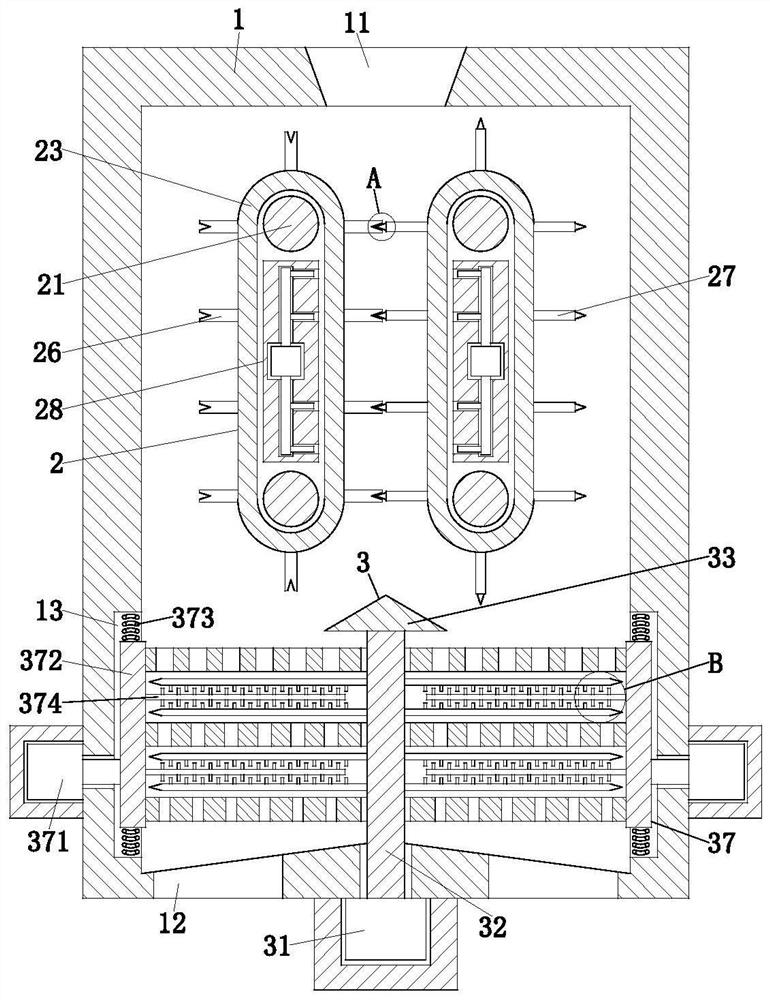

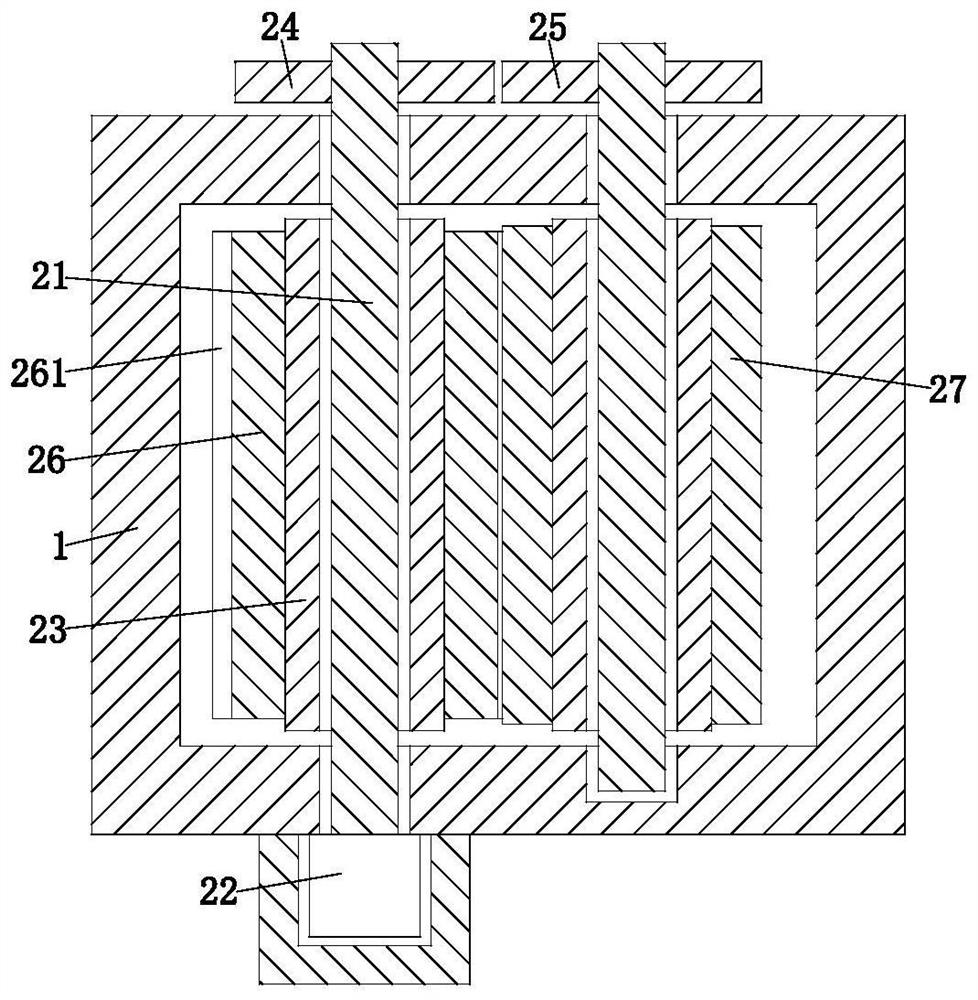

The invention relates to the technical field of construction waste treatment, and particularly relates to a construction waste treatment device. The construction waste treatment device comprises two feeding crushing boxes, crushing mechanisms, a mixing and crushing box, a stirring and crushing mechanism, a driving mechanism, a sieving device and a rack; the two feeding crushing boxes are oppositely and fixedly connected to the two ends of the top face of the mixing and crushing box; the mixing and crushing box is fixedly connected to the rack; the two crushing mechanisms are connected into thetwo feeding crushing boxes respectively; the mixing and crushing box is internally connected with the stirring and crushing mechanism; the driving mechanism is connected to the mixing and crushing box; and the driving mechanism is in transmission connection with the stirring and crushing mechanism and the two crushing mechanisms. The construction waste treatment device can crush construction waste, and subsequent transportation or recycling is facilitated.

Owner:内蒙古九鹏建设有限公司

Grinding mechanism for secondary processing of waste glass

The invention relates to the technical field of environmental protection equipment, in particular to a grinding mechanism for secondary processing of waste glass, and aims to solve the technical problems that smashing of a glass crusher is incomplete, and unqualified glass slag is inconvenient to smash. In order to solve the technical problems, the invention provides the grinding mechanism for thesecondary processing of the waste glass. The grinding mechanism comprises a case, wherein a material inlet sleeve and a material outlet sleeve are respectively inserted in openings in the top part and the bottom part of the case; clamping and crushing devices are arranged in the case and under the material inlet sleeve; the front side and the rear side of the inner wall of the case are respectively and fixedly connected with two sides of a pulverizing device. According to the grinding mechanism provided by the invention, two oblique clamping plates on the clamping and crushing devices are matched with clamping and crushing teeth arranged on the clamping and crushing devices for use, and glass can be broken when the clamping and crushing teeth collide with the glass; at the moment, secondary smashing can be conveniently carried out on the glass, and splashing glass slag can collide with the oblique clamping plates during a smashing process, so that too much glass slag can be preventedfrom splashing out.

Owner:圣云来

Solid waste processing equipment

The invention relates to the technical field of waste processing equipment and discloses solid waste processing equipment. The solid waste processing equipment comprises a bottom plate and a compression box fixedly mounted on the right side of the upper surface of the bottom plate. A supporting table is fixedly mounted on the left side of the upper surface of the bottom plate, a waste processing box is fixedly connected to the top of the supporting table, a circular feeding device is fixedly connected to the left side of the inner wall of the waste processing box, and the circular feeding device comprises a vertical pipe. The solid waste processing equipment is convenient to crush solid wastes in different positions in the waste processing box by matching the circular feeding device, a rotary rod, a filter screen, a fixed blade, a movable blade, a driving motor and a driving gear and is convenient to transfer incompletely crushed solid wastes to the upper side of the movable blade through a worm wheel in the circular feeding device, so that the solid wastes are secondarily crushed conveniently. Therefore, the solid wastes are crushed more thoroughly, so that a user can collect thesolid matters in the later period conveniently.

Owner:徐州鸿誉环境科技有限公司

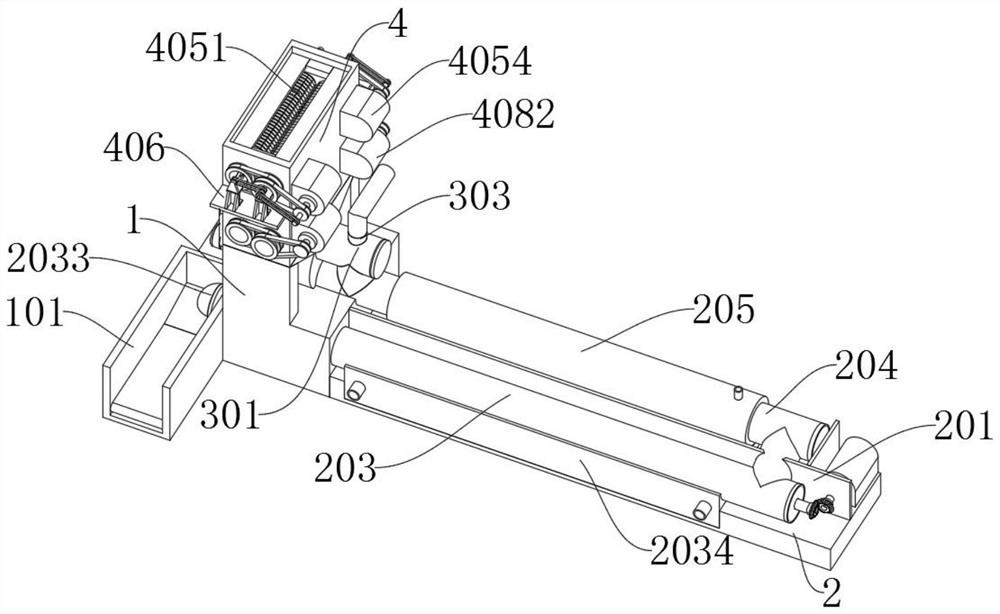

Smashing device used for traditional Chinese medicinal material processing and work method of smashing device

ActiveCN111617870AAvoid wastingTo prevent the effect of crushingGrain treatmentsProcess engineeringMaterials processing

The invention discloses a smashing device used for traditional Chinese medicinal material processing and a work method of the smashing device. The device comprises a work bin. A partition plate is arranged in the work bin. The work bin is divided into a first smashing bin and a second smashing bin from top to bottom through the partition plate. A first motor is fixed to the top end of the outer portion of the first smashing bin. A cutting shaft is fixed to the output end of the first motor and is connected with the top wall of the first smashing bin in a rotating manner. Multiple first cuttingknives which are evenly distributed are arranged on the cutting shaft. Multiple cutting blocks which are evenly arranged are further arranged on the cutting shaft. A transmission bin is arranged at the inner bottom end of the second smashing bin. A smashing chamber is arranged in the second smashing bin. The first cutting knives and second cutting knives conduct cutting in opposite directions, and therefore traditional Chinese medicinal materials can be rapidly cut into lumps of small sizes, and secondary smashing is facilitated. By arranging push plates, the traditional Chinese medicinal material lumps accumulated in the smashing chamber can be unceasingly pushed towards smashing rollers, and therefore the smashing efficiency of the traditional Chinese medicinal materials is increased, and the traditional Chinese medicinal material smashing quality is improved.

Owner:临泉县朦顺中药材有限公司

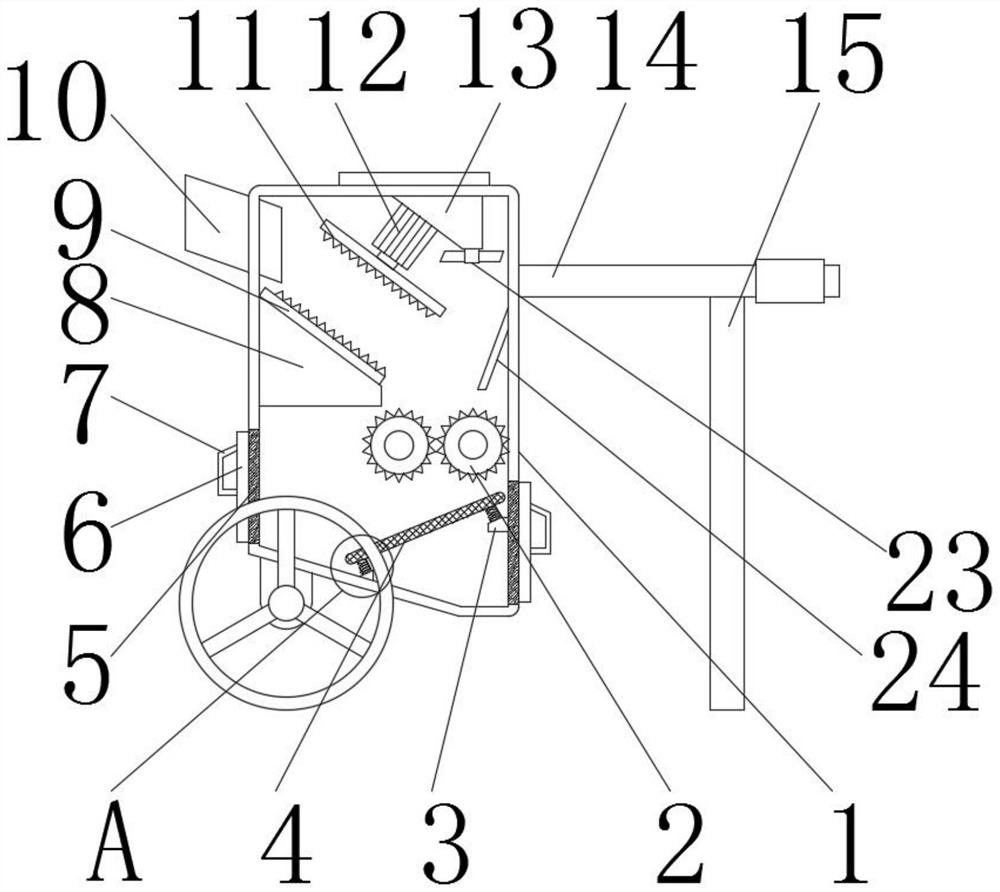

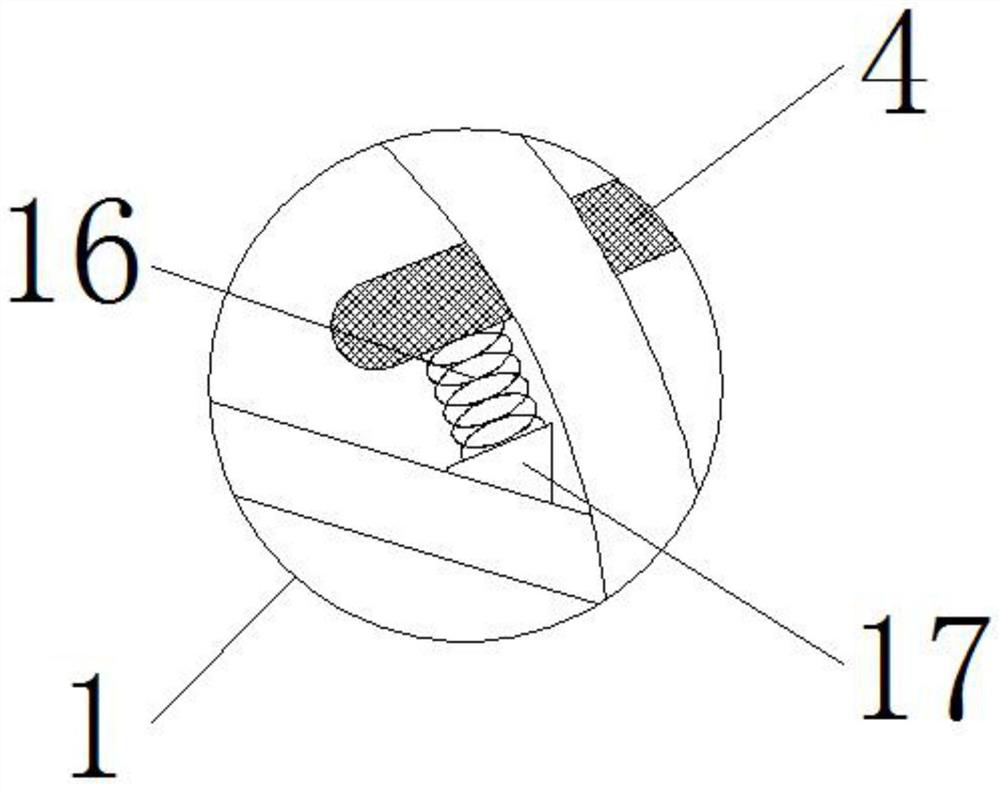

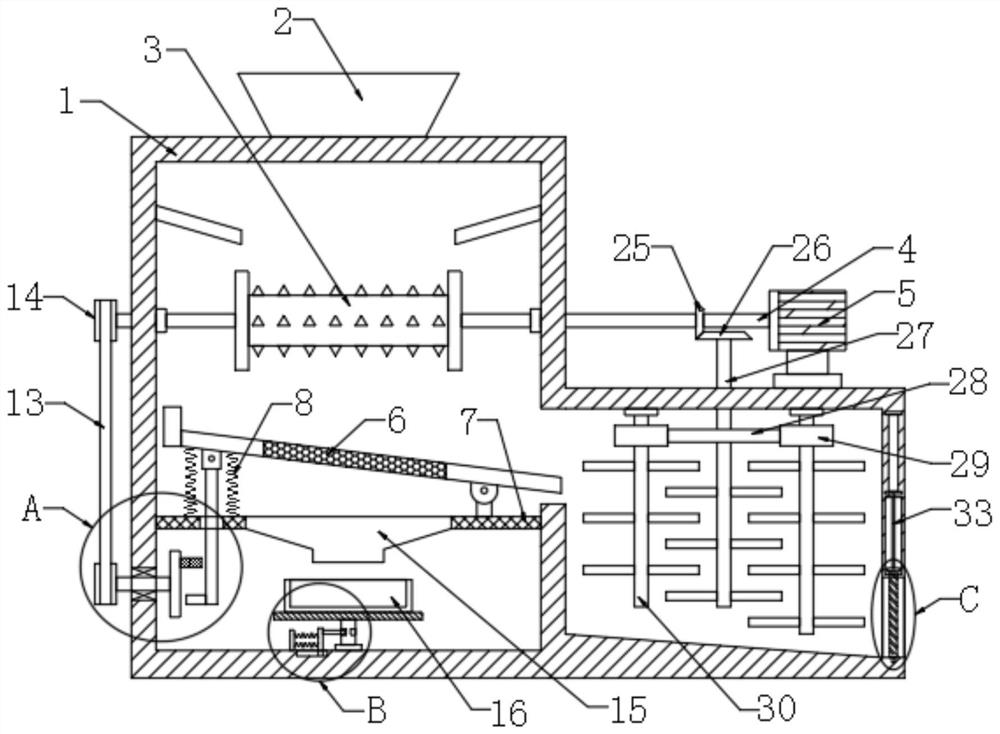

Crushing machine capable of achieving sufficient smashing

The invention provides a crushing machine capable of achieving sufficient smashing. Firstly, a material pressing assembly is arranged, therefore, in the material cutting process, a material pressing effect can be well achieved, and a preliminary cutting effect also can be well achieved; secondly, an adjusting air cylinder in a feeding assembly is arranged, therefore, the size of a feeding port canbe well adjusted, the effect of controlling the feeding speed is achieved, and the feeding port can be closed at the crucial moment; thirdly, vibration motors in a material screening assembly are arranged, therefore, vibration of a screen mesh is well achieved, and then crushed material screening is convenient; fourthly, the screen mesh is arranged in sliding rails, therefore, materials which arenot sufficiently crushed can be crushed for the second time, and then the crushing quality is guaranteed; and lastly, a first camera and a second camera are arranged, therefore, the effect of well monitoring the interior can be achieved, the problems of the screen mesh and material cutting can be found in time, and then the next-step work can be conveniently conducted.

Owner:洛阳宏润塑业有限公司

Sweet potato flour processing device convenient to use

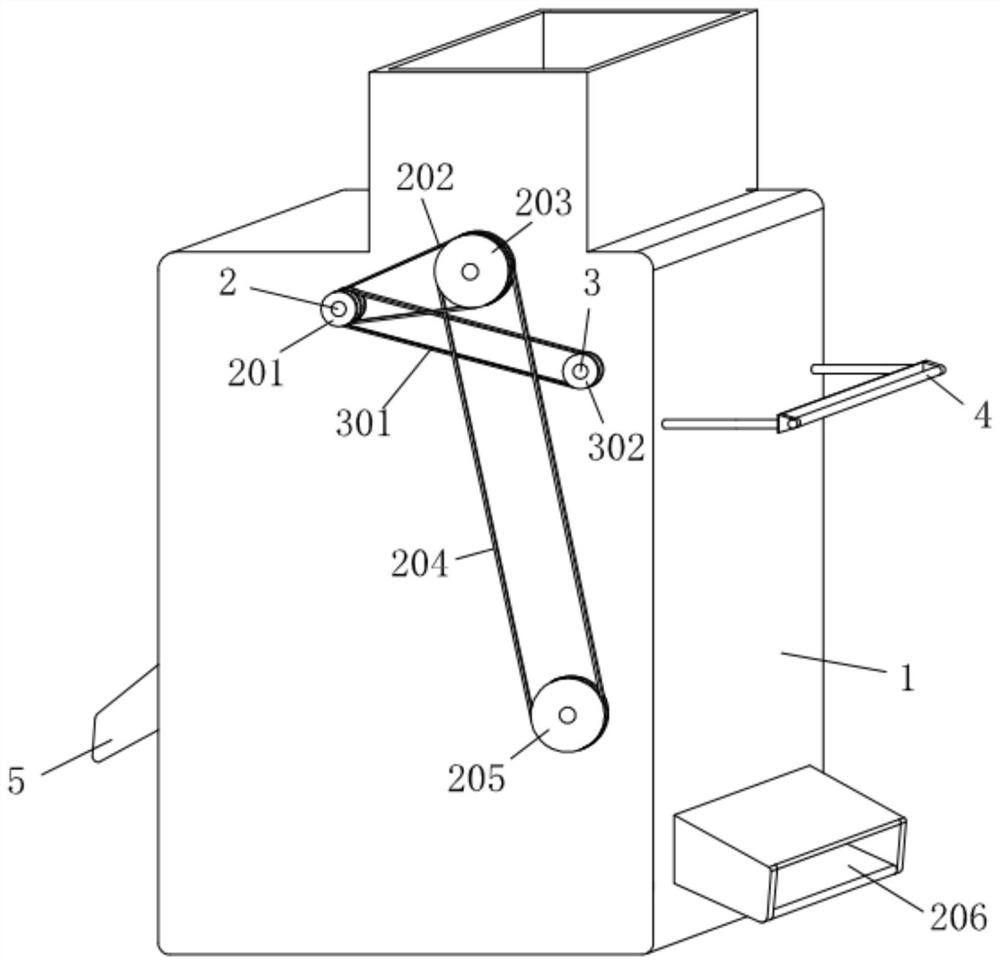

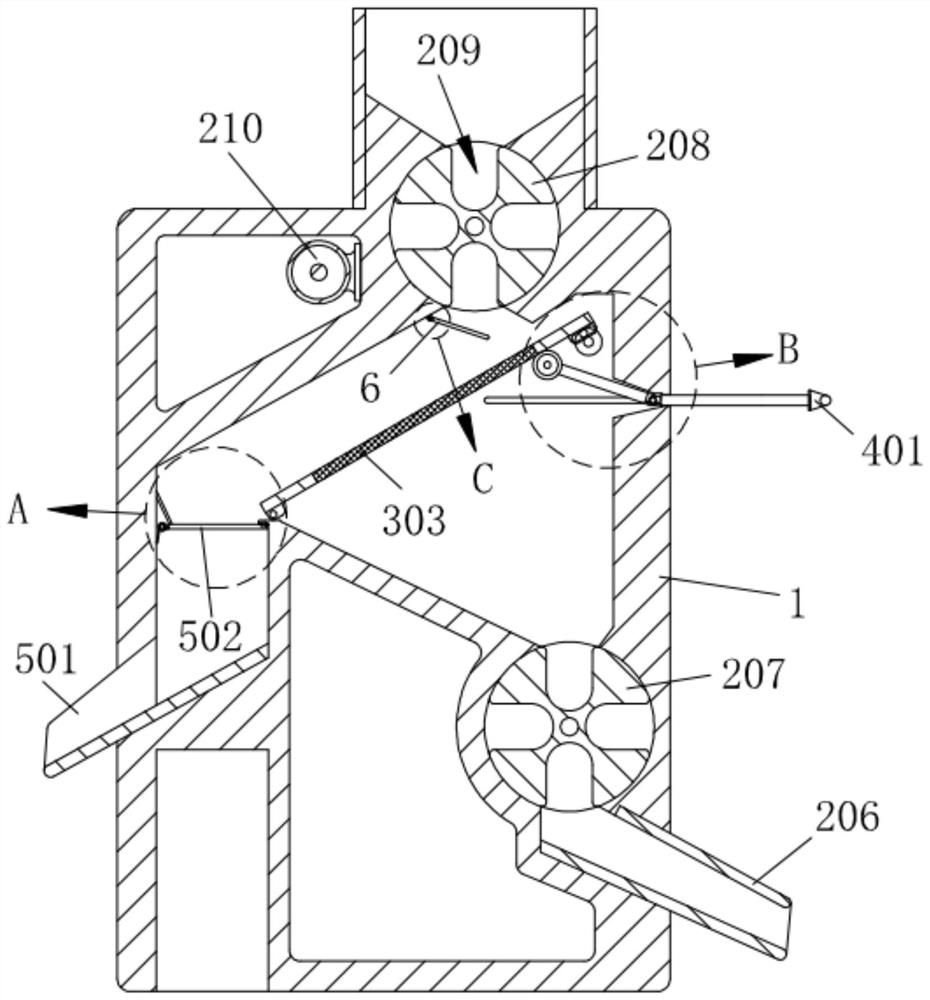

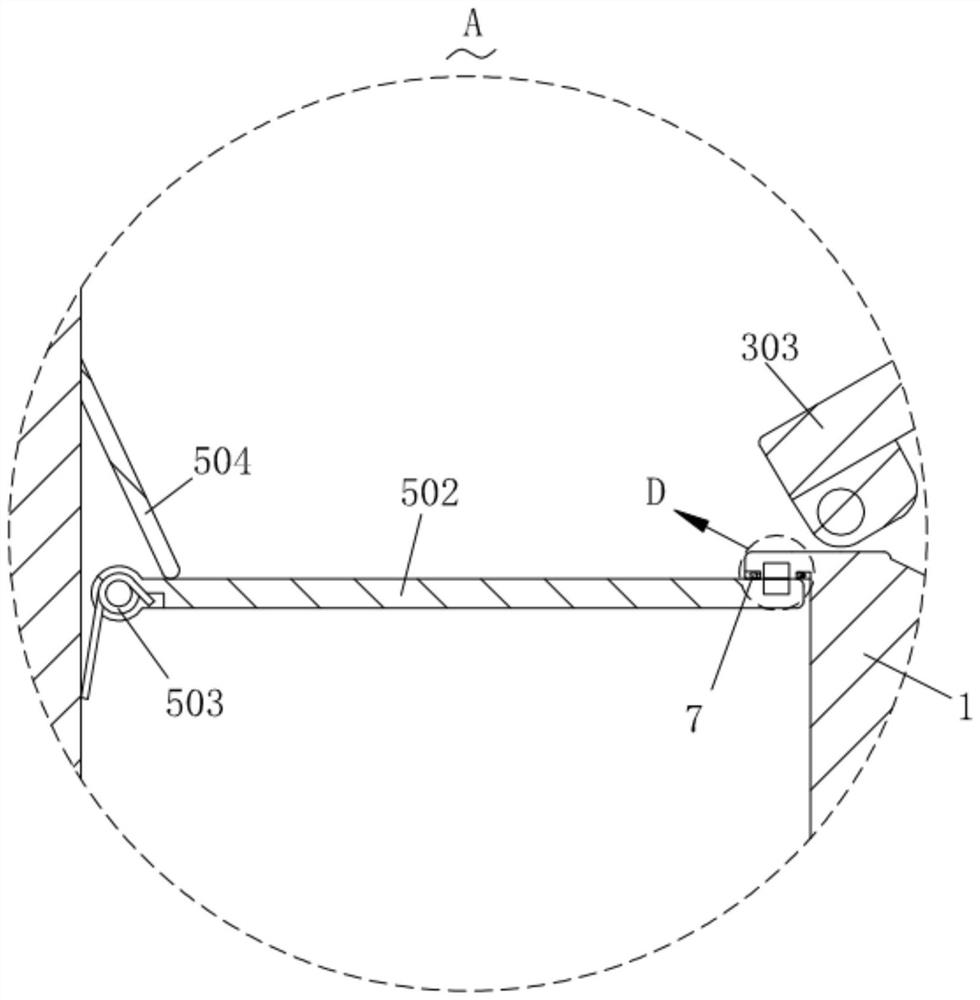

The invention discloses a sweet potato flour processing device convenient to use and relates to the technical field of food processing devices. The sweet potato flour processing device comprises a boxbody. A motor box is fixedly connected to the bottom of the left side of the box body. A first pulverization box is fixedly connected to the top of the inner wall of the box body. A second pulverization box is fixedly connected to the bottom of the first pulverization box. A top box is fixedly connected to the right side of the box body. A first motor is fixedly connected to the top of the innerwall of the motor box. A first belt pulley is fixedly connected to an output shaft of the first motor, and a belt is in transmission connection to the surface of the first belt pulley. A second belt pulley is in transmission connection to the side, far away from the first belt pulley, of the belt. By means of the sweet potato flour processing device convenient to use, residues generated in the sweet potato pulverization process can be effectively collected, and secondary pulverization can be conducted conveniently; it is guaranteed that sufficient pulp can be obtained; resource waste is reduced; work efficiency is improved; and the cost is greatly saved.

Owner:杨已颢

Wet crushing processing equipment for crude carbon black after cracking of waste rubber

The invention belongs to the technical field of wet crushing processing equipment, in particular to wet crushing processing equipment for crude carbon black after cracking of waste rubber. The wet crushing processing equipment comprises a primary crushing box, the interior of the primary crushing box is movably connected with two first crushing rollers and two second crushing rollers in sequence from top to bottom, a first screening plate is fixedly connected to the interior of the primary crushing box, the lower end face of a material discharging opening communicates with a screening box, a second screening plate is installed inside the screening box, the left side of a discharging opening communicates with a material returning spiral conveyor, therefore, the effects that the added crude carbon black is conveniently subjected to secondary crushing and respective screening, and the carbon black particles which do not achieve fine crushing are conveniently returned and conveyed into the primary crushing box to be continuously subjected to secondary crushing and re-screening are achieved, the problems that the crushing efficiency is easily reduced and the service life of fine crushing equipment is shortened in the fine crushing process due to the fact that carbon black particles obtained after primary crushing are too large are solved, and the equipment has the advantages of being compact in structure and small in occupied area.

Owner:ZHANGYE HONGJINYAN RENEWABLE ENERGY TECH DEV

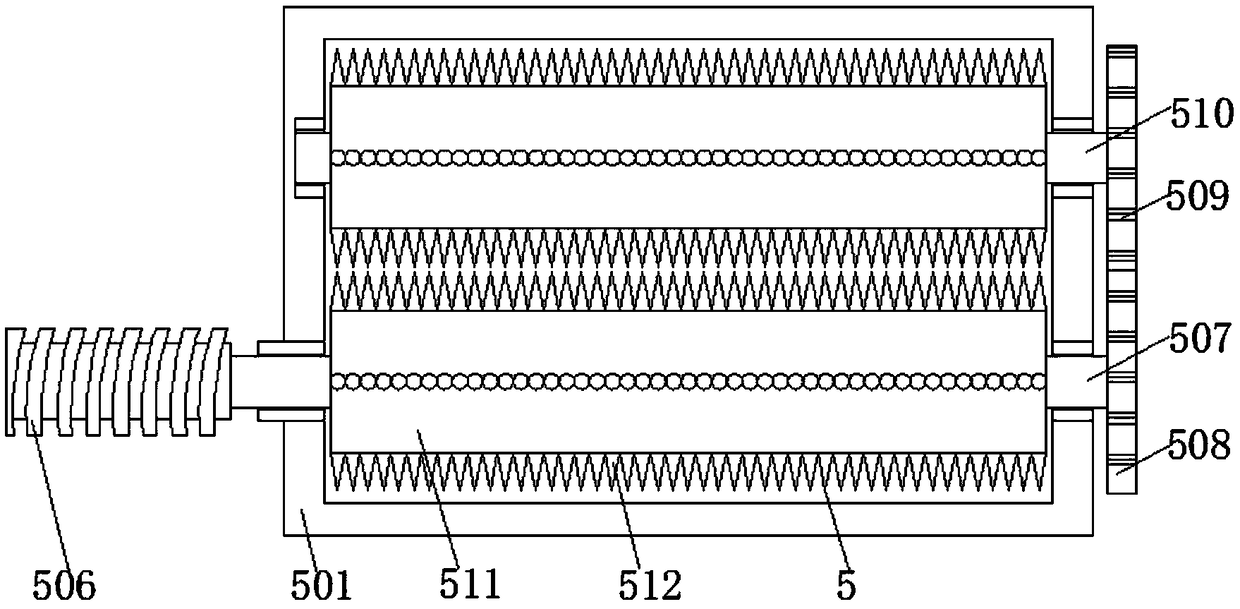

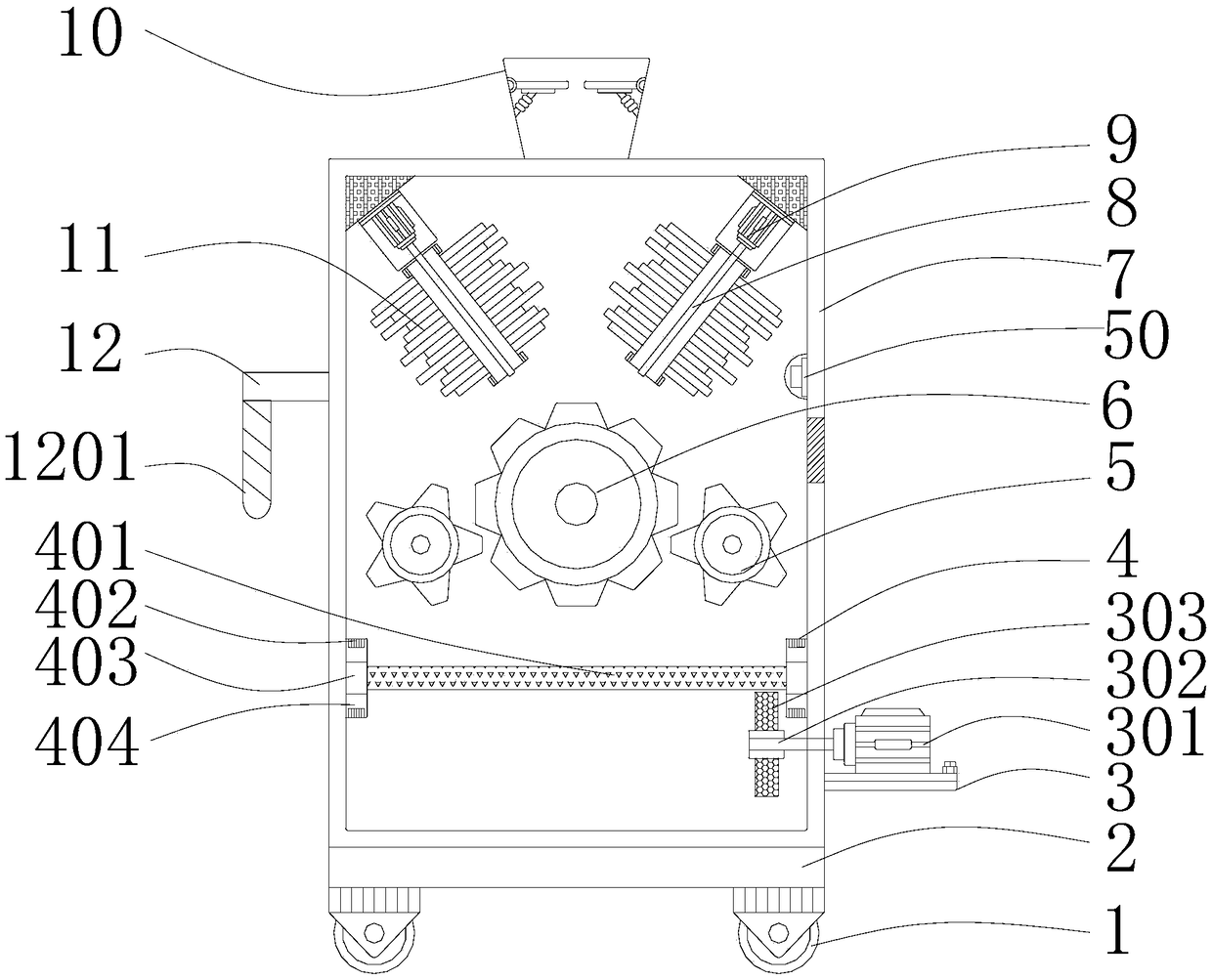

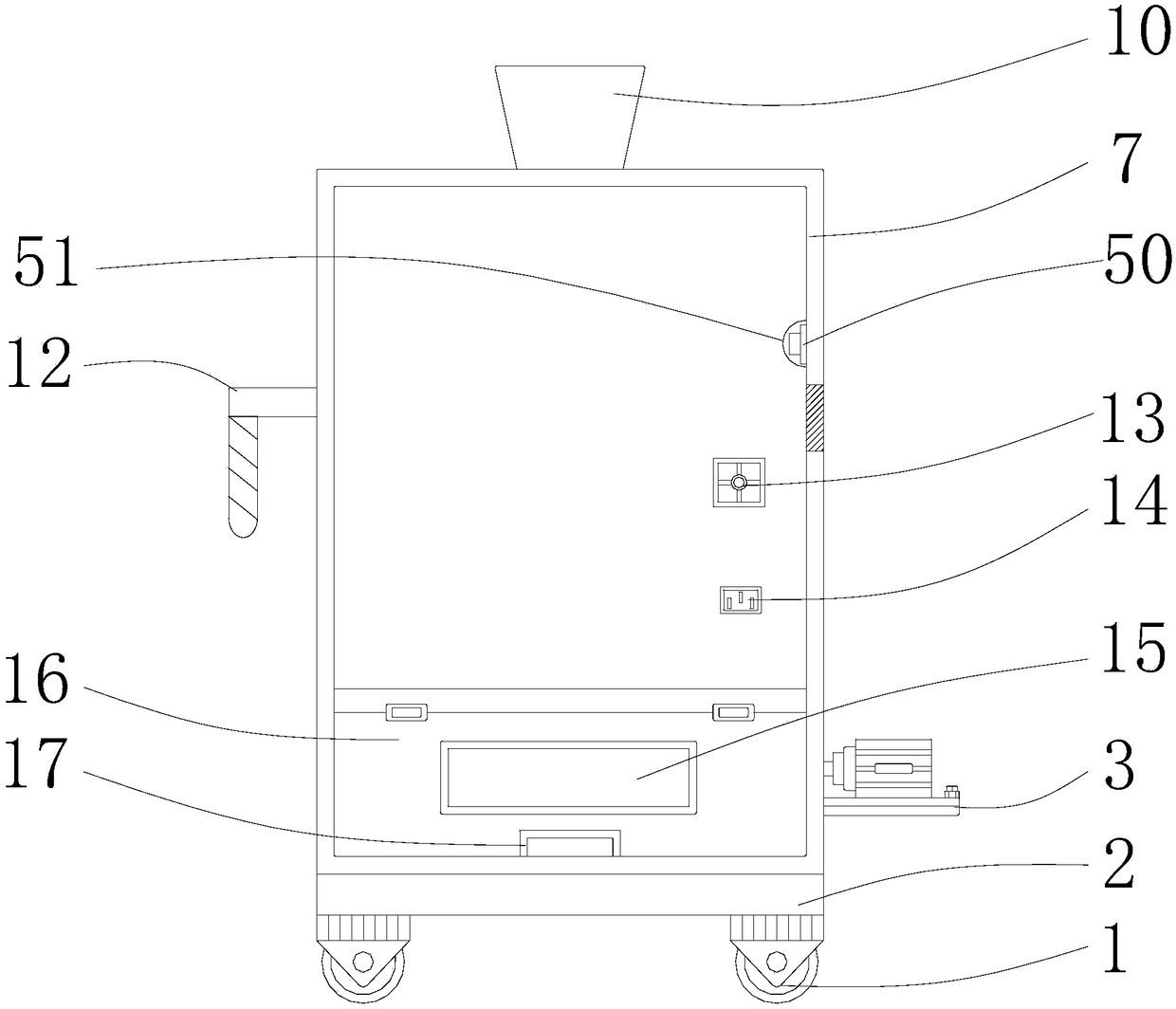

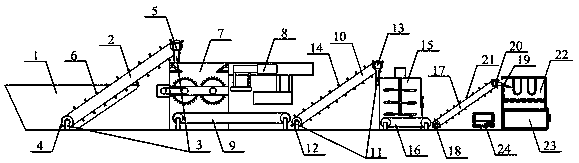

Grinding device for grain dryer

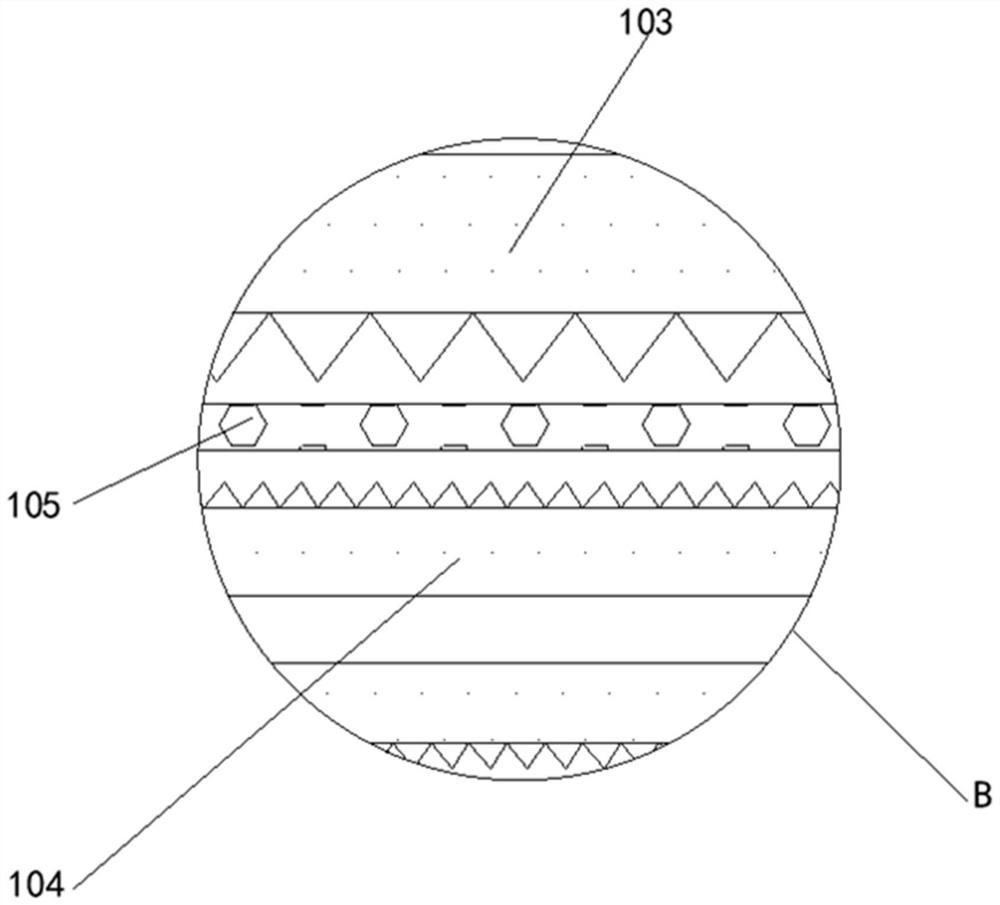

InactiveCN109092464AEasy to crush for the first timeEasy for secondary crushingGrain treatmentsEngineeringGrinding wheel

The invention discloses a grinding device for a grain dryer. The grinding device comprises bases, a box body and placing boxes. A feeding funnel is fixedly installed at the intermediate position of the top of the box body, and a screen cloth is fixedly installed in the feeding funnel. The placing boxes are fixedly mounted at the top ends, on both sides of the feeding funnel, of the box body, and first motors are fixedly mounted in the placing boxes. Primary grinding mechanisms are fixedly mounted at the output ends of the first motors, and bearing seats are correspondingly and fixedly mountedon both sides in the box body. Grinding wheels are fixedly mounted between the bearing seats, and filter mechanisms are fixedly mounted at the positions, at the bottom ends of the bearing seats, in the box body. A valve is movably mounted at the intermediate position of the bottom end of the box body, and the bases are correspondingly and fixedly mounted at the bottom ends, on both sides of the valve, of the box body. A supply hub is fixedly arranged on the surface of the box body. The grinding device has the advantages of filtering impurities and grinding thoroughly by arranging a series of structures.

Owner:ANHUI SUNMIRO AGRI TECH

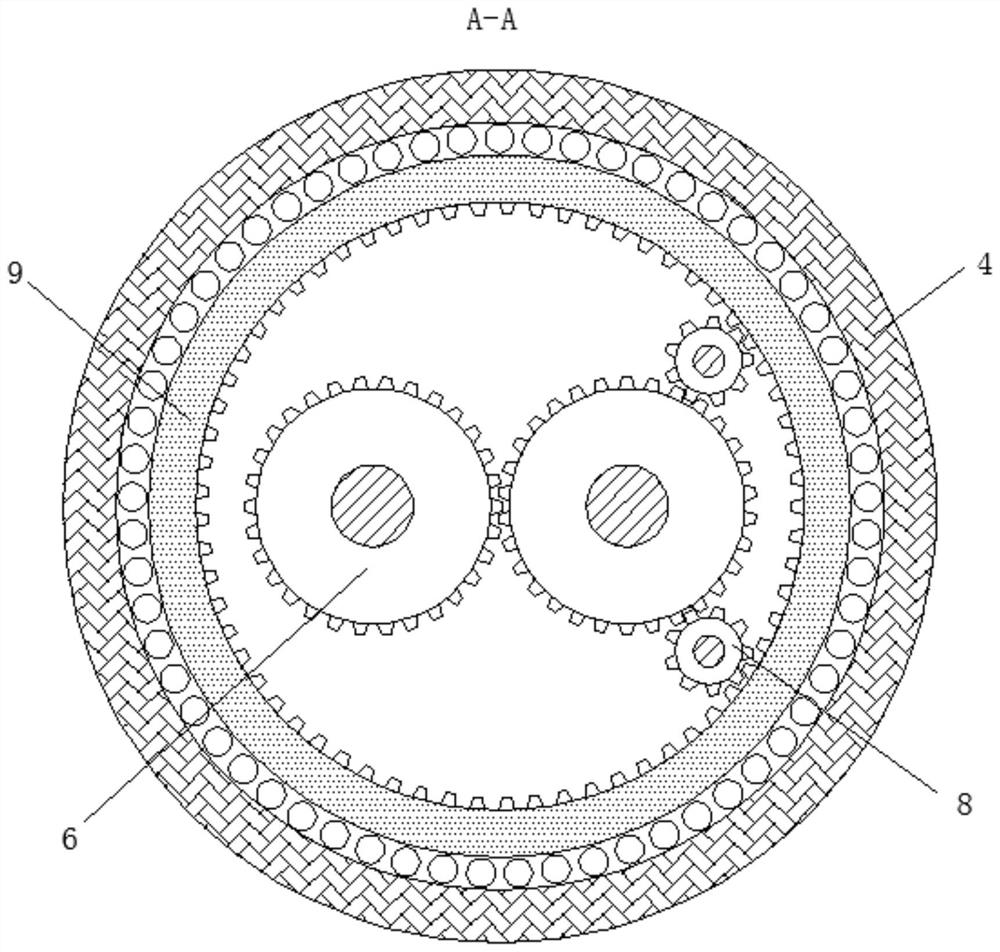

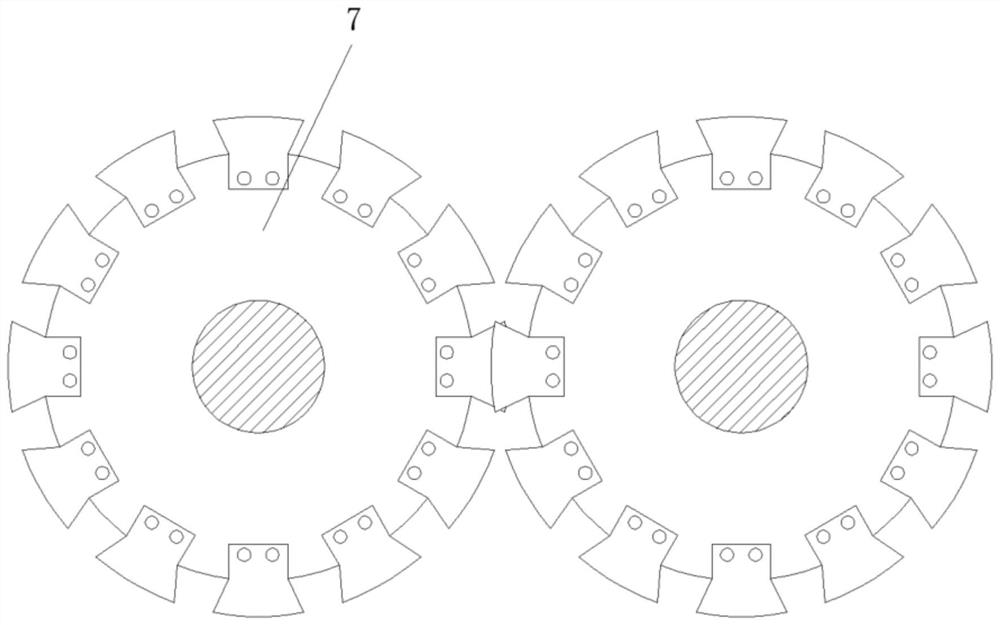

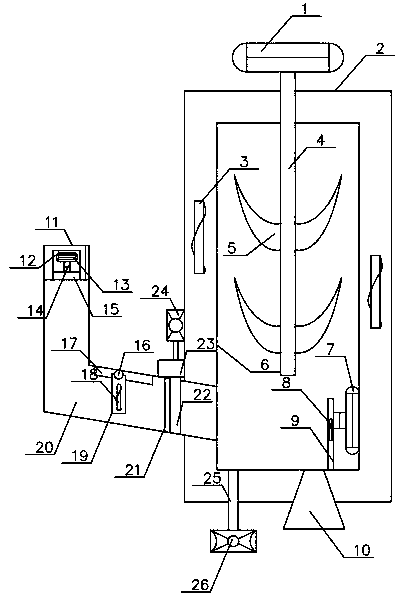

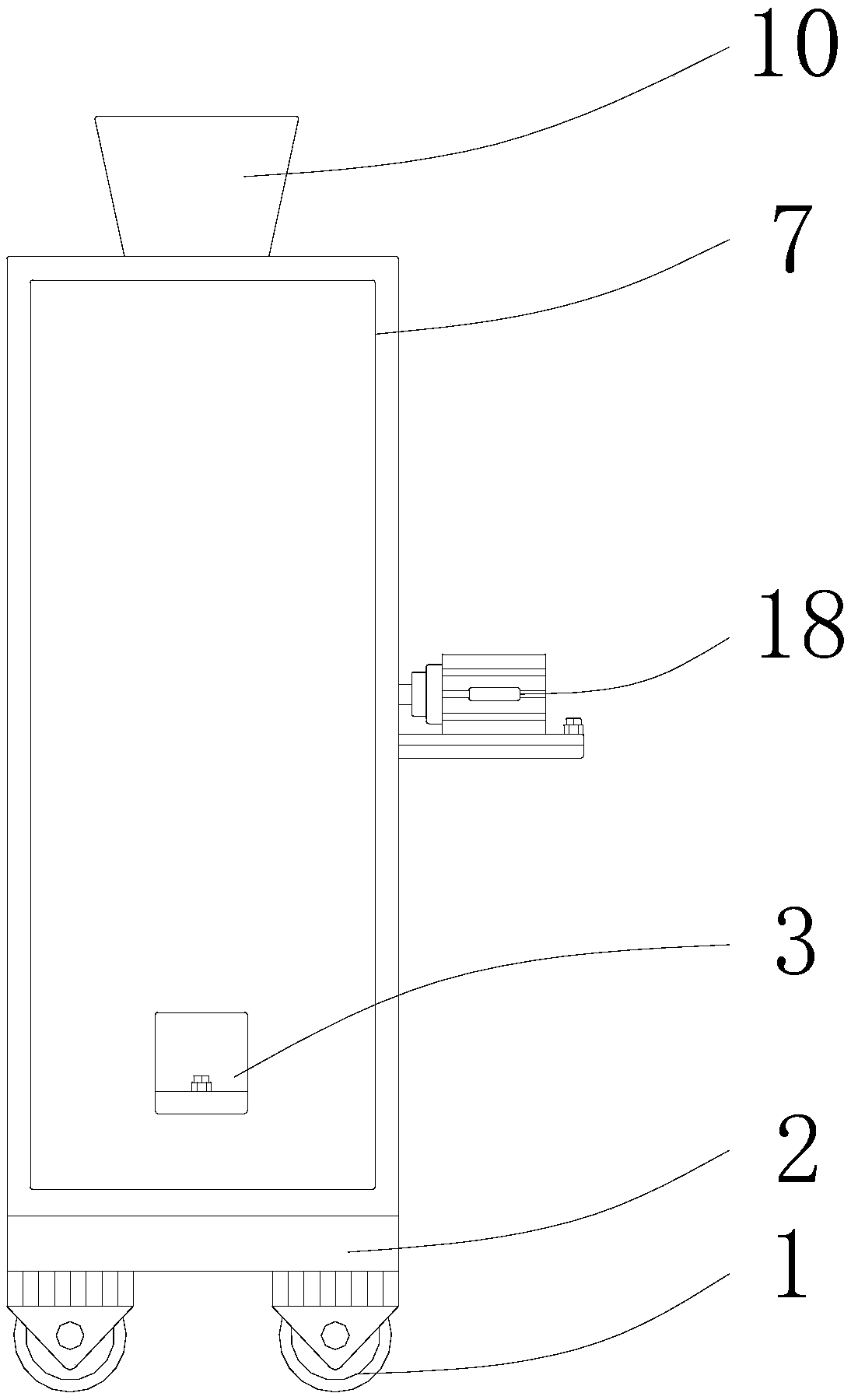

Biomass combustor capable of achieving self-smashing and intermittent equivalent feeding

InactiveCN111706852ACrushed fullyAvoid accumulationSolid fuel combustionGrain treatmentsThermodynamicsCombustion chamber

The invention relates to the technical field of combustion equipment, and discloses a biomass combustor capable of achieving self-smashing and intermittent equivalent feeding. The biomass combustor comprises a base, wherein the top of the base is fixedly connected to a combustion chamber; an inner screen board is fixedly connected inside the combustion chamber; the top of the combustion chamber isfixedly connected to a smashing chamber; the outer part of the smashing chamber is fixedly connected to a smashing motor; and the outer part of the smashing motor is fixedly connected to a main gear.According to the biomass combustor disclosed by the invention, the main gear, the smashing wheel, a connecting gear, an outer gear ring and an outer bottom frame are matched for use, so that stalks are sufficiently smashed; and meanwhile, the outer bottom frame drives the stalks inside the smashing chamber to turn over inside the smashing chamber, so that the stalks are prevented from being accumulated on the bottom of the smashing chamber, and the stalks are smashed for a second time conveniently, and therefore, the stalk smashing effect is sufficiently guaranteed, smashing speed and smashing efficiency are effectively guaranteed, the stalks are combusted sufficiently conveniently, the combustion effect is guaranteed, and sufficient combustion is effectively guaranteed.

Owner:王志强

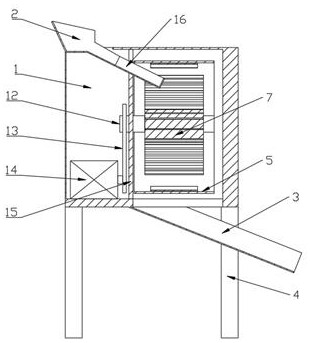

Edible fungi cultivation waste recycling device

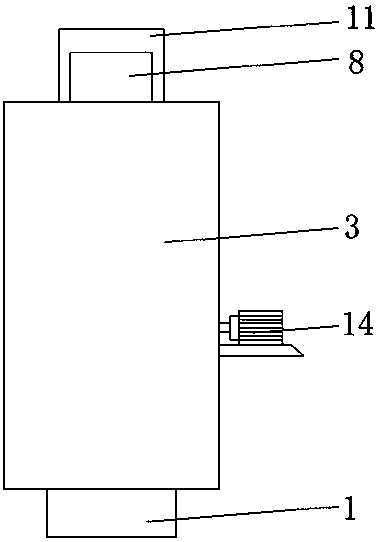

InactiveCN110756261AEasy to crushImprove filtering effectDrying chambers/containersCultivating equipmentsPulp and paper industryEdible mushroom

The invention discloses an edible fungi cultivation waste recycling device, which includes a drying chamber and a smashing chamber, wherein a top plate is fixed at the top end of the drying chamber; the top plate is fixedly connected with the bottom end of the smashing chamber; a first motor is fixedly mounted on one side on the back of the smashing chamber; the output end of the first motor penetrates through the smashing chamber, and is fixedly connected with a first smashing roller; a second motor is fixedly mounted on the other side on the back of the smashing chamber; the output end of the second motor penetrates through the smashing chamber, and is fixedly connected with a second smashing roller; a filtering sieve is movably arranged inside the smashing chamber; and one side of the filtering sieve is connected with the side wall of the smashing chamber in a crossing manner. The recycling device has the following beneficial effects: the drying chamber, a heating pipe and a blowerare arranged, so that previous crop hyphae are inactivated, and various bioactivators contained inside the hyphae are inactivated, as a result, the bad effect possibly caused by the previous crop hyphae on later crop growth is eliminated; and through arranging the first smashing roller and the second smashing roller, the fact that the sterilizing effect is affected caused by uneven moisture of mixing materials, is avoided.

Owner:YANCHENG AIFEIER MUSHROOM EQUIP TECH +3

Multistage waste crushing device for bearing brush recycling and processing

InactiveCN112691738AAvoid reducing the crushing effectImprove crushing effectGrain treatmentsGear wheelBrush

The invention discloses a multistage waste crushing device for bearing brush recycling and processing. The multistage waste crushing device for bearing brush recycling and processing comprises a device main body, a rolling roller, a push plate, a primary crushing tooth, a baffle plate and a screening board, wherein the inner side shaft of the device main body is connected to the rolling roller; the inner side shaft of an accommodating slot is connected to a half gear; the outer side of the half gear is equipped with the primary crushing tooth; a collecting box is arranged inside the device main body; the side wall shaft of a first dropping hole is connected to the baffle plate; the side surface of the baffle plate is equipped with a dredging rod; an inner shaft of the device main body is connected to a cam; the inner side of a second dropping hole is equipped with the screening board; and a through hole is formed inside the screening board. The multistage waste crushing device for bearing brush recycling and processing can perform automatic intermittent unloading for materials during crushing operation, avoids reducing crushing effect as a result of excessive unloading every time, can automatically screen the preliminarily-crushed waste, is good in crushing effect, and is high in practicability.

Owner:安徽科达汽车轴瓦有限公司

Waste electronic circuit board crushing and recycling device convenient to clean

The invention discloses a waste electronic circuit board crushing and recycling device convenient to clean. The waste electronic circuit board crushing and recycling device comprises a crushing tank body and crushing rollers. Two push rods are held by two hands to lift up the whole crushing tank body, the whole crushing tank body is supported by a support rod to work stably, a pneumatic hydraulic cylinder and two motors are started, waste electronic circuit boards are put into the crushing tank body from a feeding box and fall onto the surface of a first crushing plate on a first pressure-bearing block, the crushed electronic circuit boards and the uncrushed electronic circuit boards are taken out by opening sealing doors respectively, and the uncrushed electronic circuit boards are put into the feeding box again for crushing. By means of the waste electronic circuit board crushing and recycling device convenient to clean, the waste electronic circuit boards which are not crushed completely can be screened conveniently, secondary smashing is convenient, and therefore the smashing efficiency is improved, and moving is convenient; and a fan below a second pressure-bearing block can dissipate heat of equipment and can also blow impurities in the crushing tank body to the lower portion after operation, an inclined block is arranged on the right side of the crushing tank body, the waste electronic circuit boards can be guided to enter the crushing rollers, and the crushing efficiency is improved.

Owner:湖北至宝科技有限公司

Crushing device convenient for performing integrated treatment on kitchen vegetable washing sink garbage

ActiveCN108331102AConvenient for centralized processingEasy to wash awayDomestic plumbingSewageUltimate tensile strength

The invention discloses a crushing device convenient for performing integrated treatment on kitchen vegetable washing sink garbage. The crushing device comprises a connecting flange, a first cutterhead, a second cutterhead, a second crushing cutter blade and a filtering hopper, wherein a water inlet is formed in the connecting flange; a motor is arranged on the outer side of a pipeline; a connecting gear is arranged under the motor; a filtering screen is arranged at the inner side of a discharging opening; the discharging opening and a pollution discharging opening are mutually connected; a collecting box and the pipeline are mutually connected through an installing frame; a water outlet is formed under the pipeline; in addition, a protection cover is arranged at the outer side of the pipeline. The crushing device convenient for performing integrated treatment on the kitchen vegetable washing sink garbage has the advantages that the kitchen food garbage can be conveniently crushed; various kinds of food garbage does not need to be singly collected and treated, and only needs to be poured into a vegetable washing sink to be crushed by the crushing device, so that the food garage canbe conveniently flushed away along with sewage; the requirement of the collection and transportation treatment on the garbage is avoided; the work intensity of workers is reduced.

Owner:新沂市棋盘工业集中区建设发展有限公司

Feed screening device for powder concentrator

The invention relates to the technical field of steel slag micro-powder processing, in particular to a feeding and screening device for a powder concentrator, which comprises a shell, a control structure for controlling feeding and discharging of coarse steel slag micro-powder is connected onto the shell, a screening structure is connected onto the shell, a cleaning structure is connected onto the shell, and the cleaning structure is connected onto the shell. The shell is connected with a buffer structure, a material returning structure and a rubbing structure; the control structure facilitates uniform feeding and discharging of the steel slag micro-powder coarse materials, the screening structure can screen out the large steel slag micro-powder coarse materials, the buffering structure can effectively prevent the steel slag micro-powder coarse materials from impacting the screening structure, and the material returning structure can discharge the large steel slag micro-powder coarse materials. And meanwhile, diffusion of steel slag micro powder raised in the shell is effectively avoided, the scraping structure can scrape the material returning structure, so that normal work of the material returning structure is maintained, the screening structure can be cleaned through the cleaning structure, and the screening quality is guaranteed.

Owner:莱芜钢铁集团泰东实业有限公司

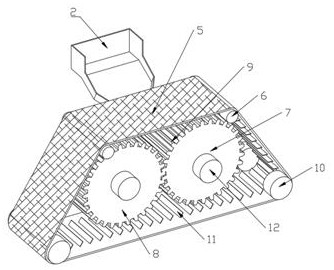

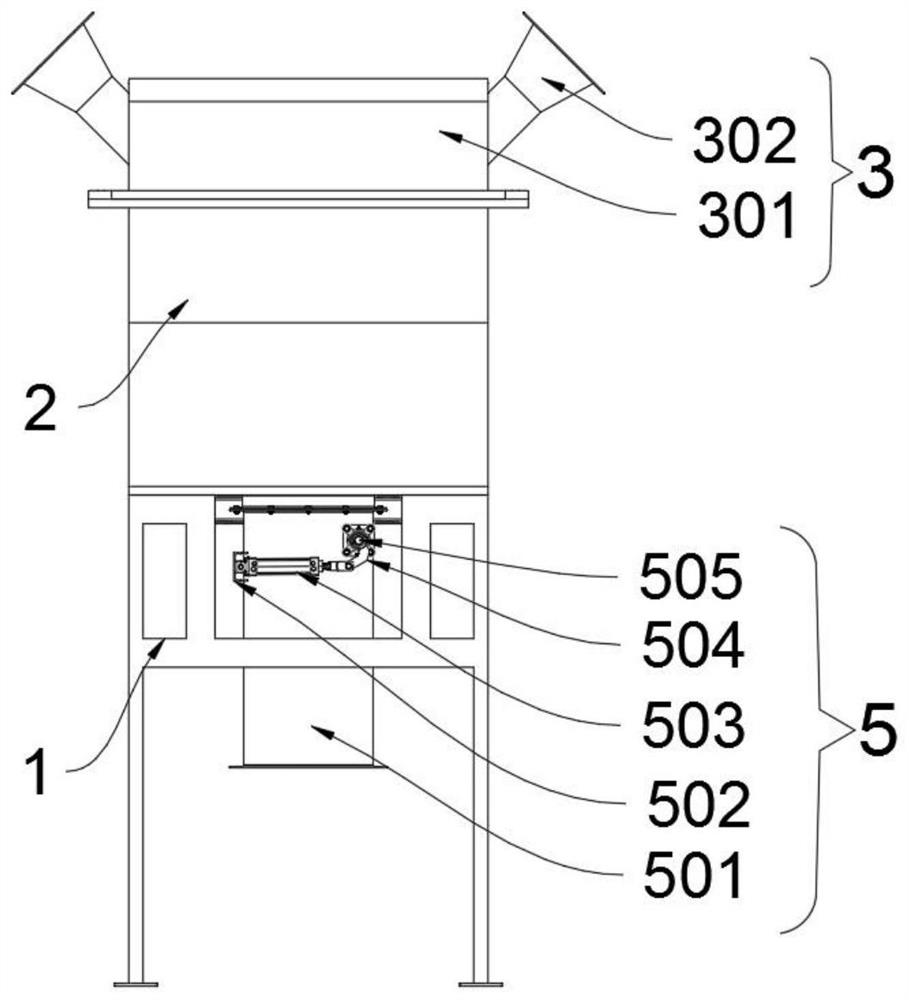

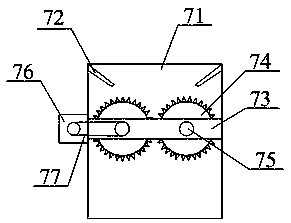

Casting molding sand recycling, crushing and screening device

InactiveCN112264130AEasy for secondary crushingImprove crushing effectGrain treatmentsElectric machineryStructural engineering

The invention discloses a casting molding sand recycling, crushing and screening device. The casting molding sand recycling, crushing and screening device comprises a crushing box body, wherein a feeding hopper is arranged at the upper end of the crushing box body, a discharging hopper is arranged in the middle of the lower end of the crushing box body, and the four corners of the lower end of thecrushing box body are fixedly connected with the same rack. According to the casting molding sand recycling, crushing and screening device, driving crushing teeth and driven crushing teeth in a crushing cavity are meshed with each other, so that molding sand is crushed in time; meanwhile, a plurality of material returning guide plates on the inner wall of a conveying screen net are used for conveniently conveying the molding sand which is not completely crushed to a crushing position for secondary crushing, so that the molding sand is prevented from being not completely crushed at a time, andthe crushing effect is improved; and meanwhile, a single driving motor runs, a driving roller and a driven roller in the crushing cavity are driven to run through belt transmission, so that the driving crushing teeth and the driven crushing teeth carry out crushing operation, meanwhile, the belt drives the conveying screen net to work, and the production cost investment is reduced.

Owner:含山县永帮再生资源利用有限公司

Crushing equipment for catalyst

InactiveCN109465078AImprove drying effectEasy accessCatalyst activation/preparationGrain treatmentsEngineeringCrusher

The invention discloses crushing equipment for a catalyst, and belongs to the technical field of chemical equipment. A cover plate is arranged at the upper end of an L-shaped feeding bin, a sliding rail is arranged at the inner upper end of the L-shaped feeding bin, a scraper is arranged at the lower end of the sliding rail and connected to the sliding rail through a sliding wheel, a primary dryeris arranged in the scraper, a concave hole is formed in the upper end of the L-shaped feeding bin, a primary pusher is arranged outside a crusher body and connected with a baffle, an inserting plateis arranged at the lower end of the baffle and is inserted between the L-shaped feeding bin and the crusher body, a lining is arranged in the crusher body, and a secondary dryer is arranged between the lining and the crusher body. The scraper moves back and forth along the slide rail, so that the drying effect and the crushing effect can be improved, secondary crushing is facilitated, and the crushing effect is improved.

Owner:宜兴市申生催化剂有限公司

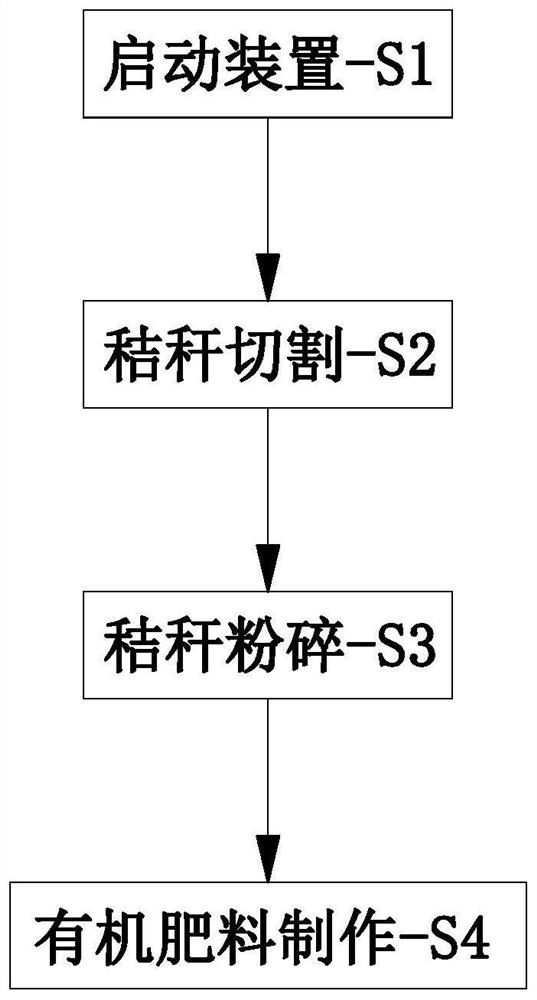

Method for preparing organic fertilizer from straws

ActiveCN112778028AEasy to processImprove cutting effectSievingBio-organic fraction processingAgricultural engineeringOrganic manure

The invention provides a method for preparing an organic fertilizer from straws. According to the method for preparing the organic fertilizer from the straw, a device for preparing the organic fertilizer from the straw is adopted. The device for preparing the organic fertilizer from the straw comprises a processing shell, a slitting unit and a smashing unit, wherein the slitting unit is arranged on the upper side of the inner wall of the processing shell, and the smashing unit is arranged on the inner wall of the lower end of the processing shell. By means of the device, the method of the invention can overcome the problems that straw is mostly processed in a manual cutting mode when being cut at present, the straw needs to be cut step by step in the manual cutting mode, residual water in the straw cannot be removed, later straw processing is affected, cutting efficiency is affected, and the labor cost is consumed; and the method of the invention can also overcome the problems that it cannot be guaranteed that the smashed straw meets processing requirements and secondary smashing processing needs to be conducted on the straw since straw is generally and directly smashed through a smashing machine and multi-stage smashing cannot be achieved through the smashing machine in the prior art.

Owner:山东宝瑞生物科技有限公司

A solid waste treatment facility

The invention relates to the technical field of waste processing equipment and discloses solid waste processing equipment. The solid waste processing equipment comprises a bottom plate and a compression box fixedly mounted on the right side of the upper surface of the bottom plate. A supporting table is fixedly mounted on the left side of the upper surface of the bottom plate, a waste processing box is fixedly connected to the top of the supporting table, a circular feeding device is fixedly connected to the left side of the inner wall of the waste processing box, and the circular feeding device comprises a vertical pipe. The solid waste processing equipment is convenient to crush solid wastes in different positions in the waste processing box by matching the circular feeding device, a rotary rod, a filter screen, a fixed blade, a movable blade, a driving motor and a driving gear and is convenient to transfer incompletely crushed solid wastes to the upper side of the movable blade through a worm wheel in the circular feeding device, so that the solid wastes are secondarily crushed conveniently. Therefore, the solid wastes are crushed more thoroughly, so that a user can collect thesolid matters in the later period conveniently.

Owner:徐州鸿誉环境科技有限公司

Chinese medicinal material grinding device

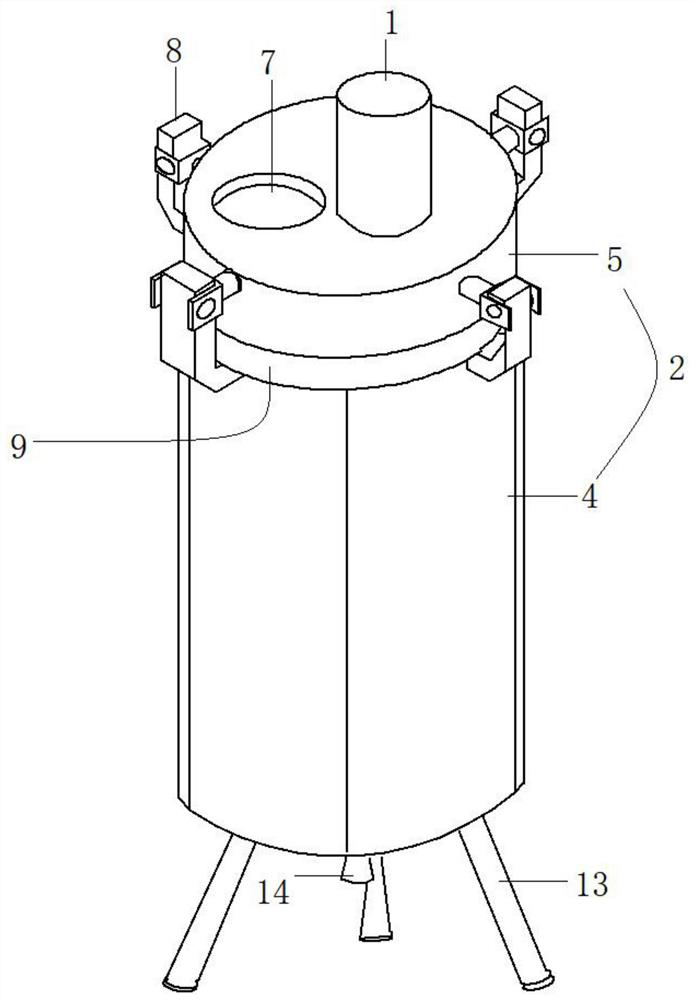

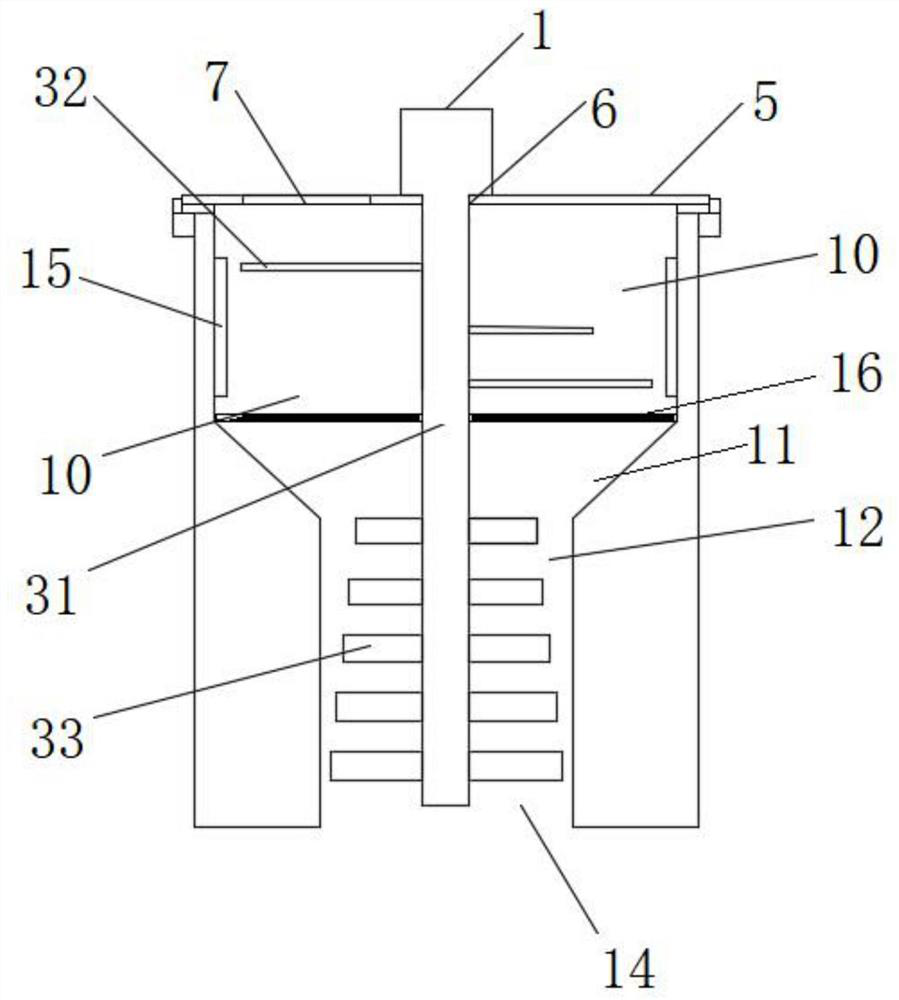

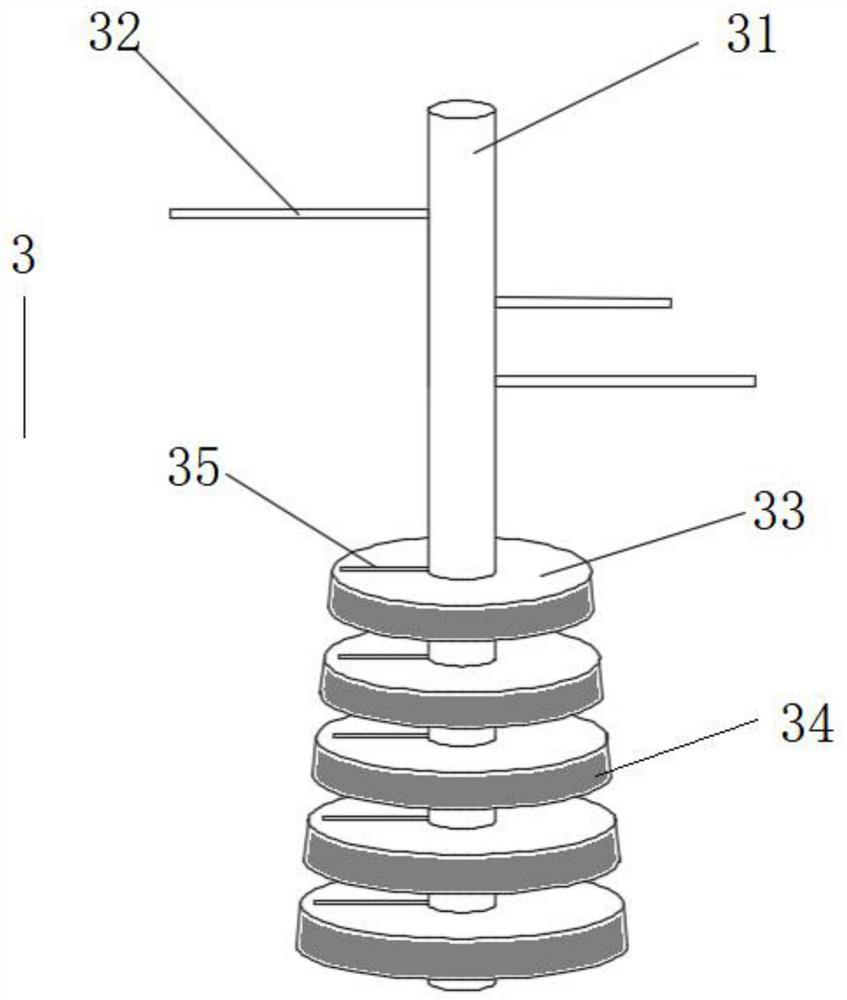

The invention relates to a Chinese medicinal material grinding device. The device includes a motor, a grinding tank, and a grinding rod. The grinding tank is composed of a circular tank body and a circular top cap fixed to the top of the tank body detachably, an opening is formed in the center position of the top cap, the motor is fixedly connected above the opening, a feeding opening is formed next to the opening, the grinding rod is connected below the motor, the grinding rod penetrates through the opening of the center of the top cap to be connected with the motor electrically and rotationally, support legs are further connected with the bottom position of the tank body, and a discharging opening is formed in the bottom face of the tank body. The device has the advantages that the structure is simple, the operation is convenient, the motor drives the grinding rod to rotate, blades located on the grinding rod can cut Chinese medicinal materials into fine particles, then the particlesare grinded to a power shape through a grinding disc in a step-by-step mode, the Chinese medicinal materials are grinded and smashed quickly, the time and labor can be saved, the grinding efficiencyis comparatively high, and the device can be used in large pharmacies, laboratories and families.

Owner:YUEYANG INTEGRATED TRADITIONAL CHINESE & WESTERN MEDICINE HOSPITAL SHANGHAI UNIV OF CHINESE TRADITIONAL MEDICINE

Industrial ore collecting and crushing device

PendingCN111632733AImprove crushing efficiencyChange spacingConveyorsGrain treatmentsClassical mechanicsStructural engineering

Owner:肖艳梅

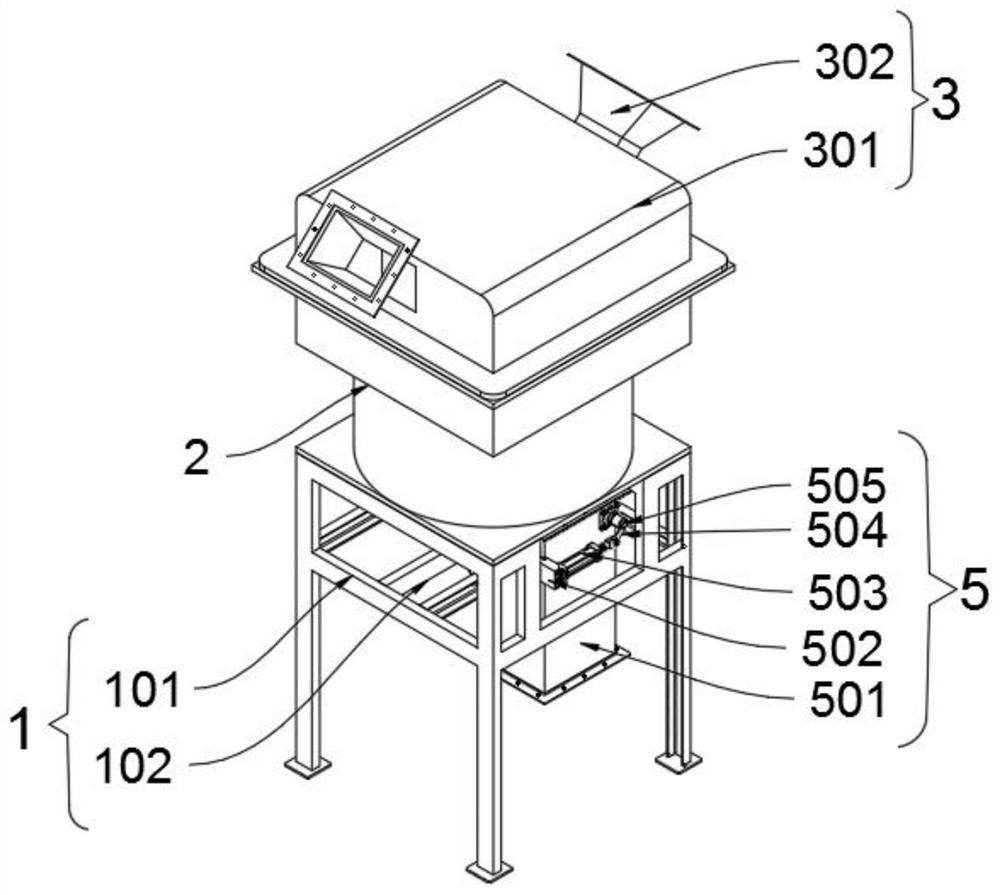

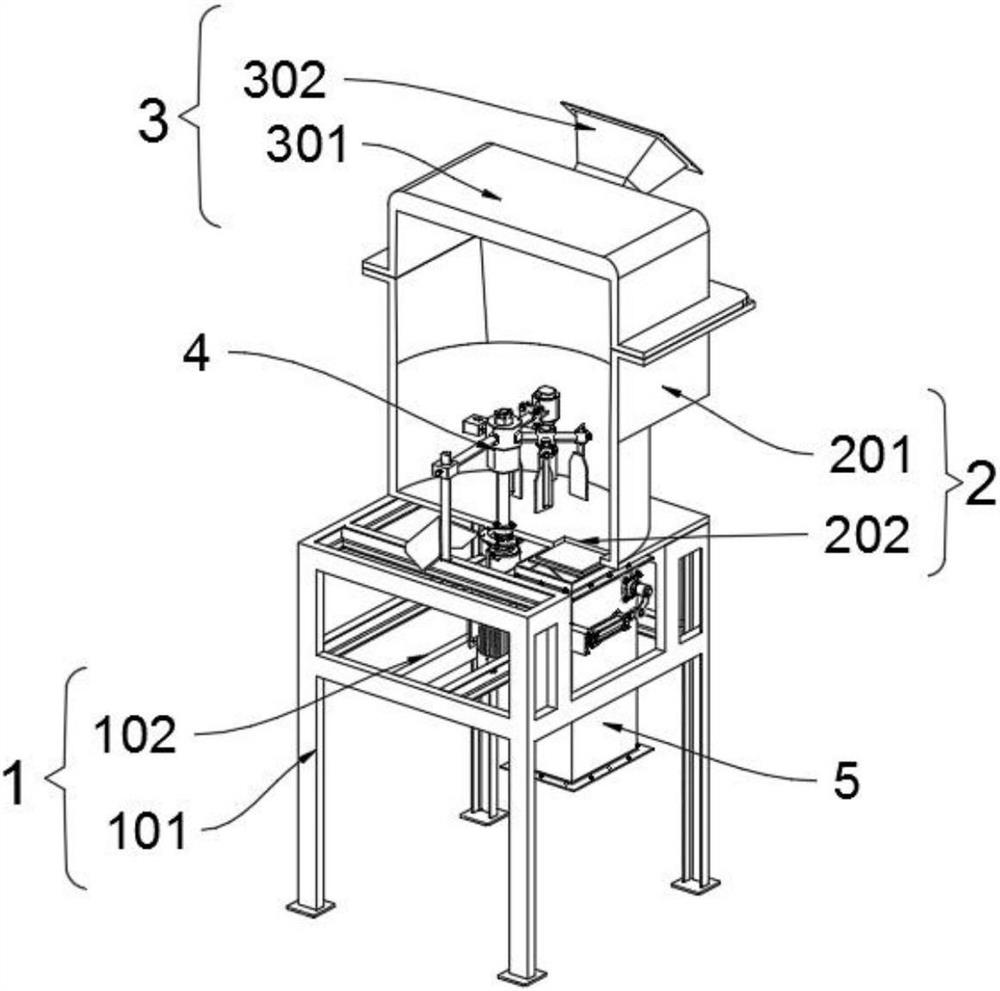

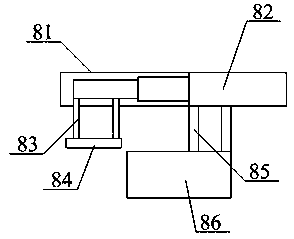

High-efficiency innocent treatment device for infectious medical waste

InactiveCN113000153AEasy for secondary crushingImprove crushing efficiencySolid waste disposalGrain treatmentsBacterial virusMedicine

The invention provides a high-efficiency innocent treatment device for infectious medical waste, and relates to the technical field of medical waste treatment. The high-efficiency innocent treatment device solves the problems that in the existing medical waste treatment process, manual carrying is needed, the body of a worker cannot be prevented from being in contact with the medical waste, so that the body of the worker is contaminated with residual medicines and bacterial viruses, furthermore, and when the medical waste is not subjected to crushing treatment, few medical waste is stacked in the same space due to the fact that the space gap is large are solved. The high-efficiency innocent treatment device for the infectious medical waste comprises a frame body mechanism, and the top of the frame body mechanism is fixedly connected with the bottom of a box body mechanism. According to the high-efficiency innocent treatment device, the worker can crush the medical waste when not making contact with the medical waste, meanwhile, the occupied space of the medical waste is reduced, the medical waste can be discharged from a discharging groove quickly while an overturning shovel rotates, and a large amount of time is saved.

Owner:金赛赛

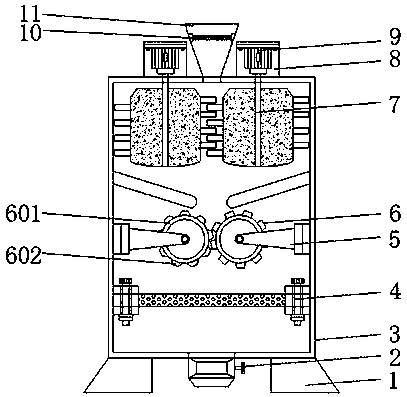

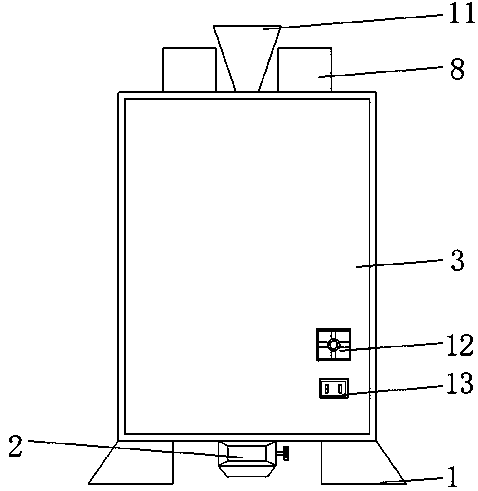

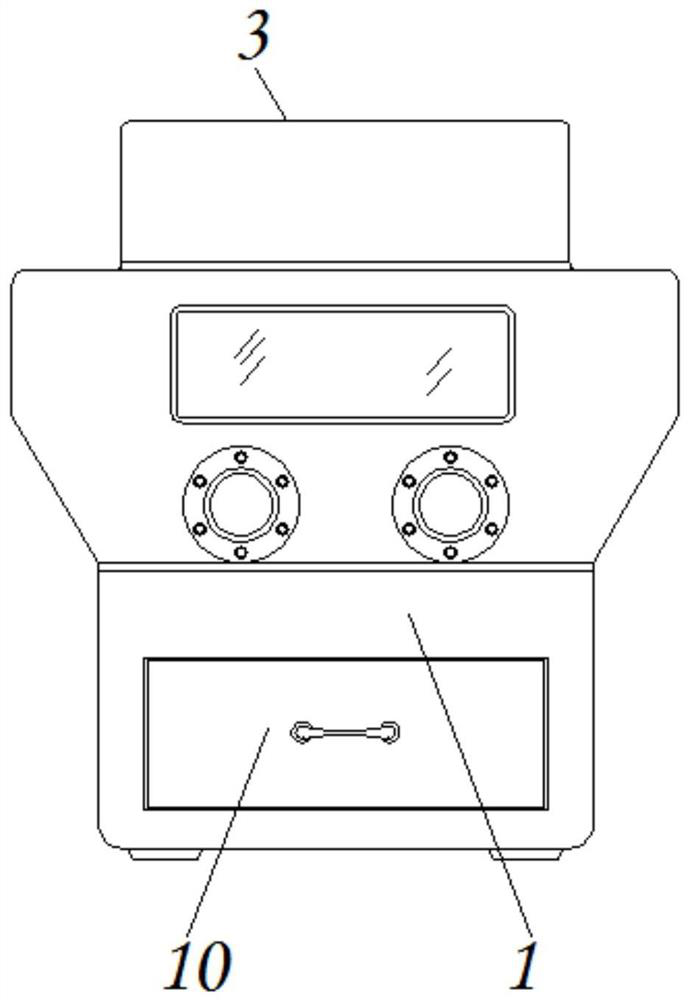

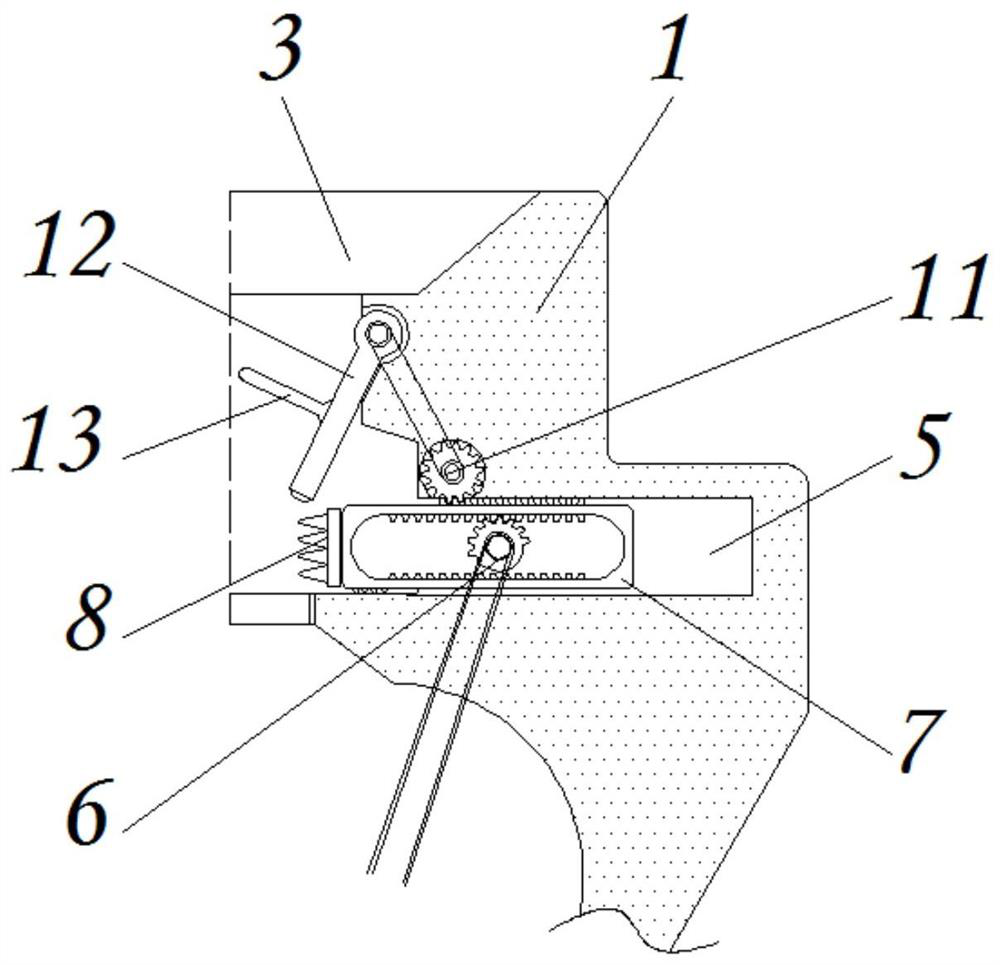

Material crushing lighting device

ActiveCN109225574AImprove filtering effectAvoid early entryNon-rotating vibration suppressionLighting elementsMechanical engineering

The invention relates to a material crushing lighting device. The material crushing lighting device comprises a base, a box body, a door body and a lighting appliance, wherein the surface of the box body is movably provided with the door body, and the door body is positioned at the bottom end of a power supply socket; the lighting appliance is mounted on a side wall of the box body, and a light emitting end of the lighting appliance faces a crushing blade; the surface of the box body is movably provided with the door body, and the door body is positioned at the bottom end of the power supply socket; and the lighting appliance is mounted on the side wall of the box body, and the light emitting end of the lighting appliance faces the crushing blade. The material crushing lighting device is convenient for carrying out primary crushing on a material; through the cooperation among an active crushing wheel, a driven crushing wheel and a third motor, the material is convenient for secondary crushing, the crushing efficiency of the device is improved, and the device is beneficial to wide popularization and use in society; and by arranging the lighting appliance, the crushing situation of the material can be conveniently and quickly observed in a crushing process of the material, so that the crushing process of the material can be better controlled, and then the crushing processing efficiency of the material is improved.

Owner:东莞市闻誉实业有限公司

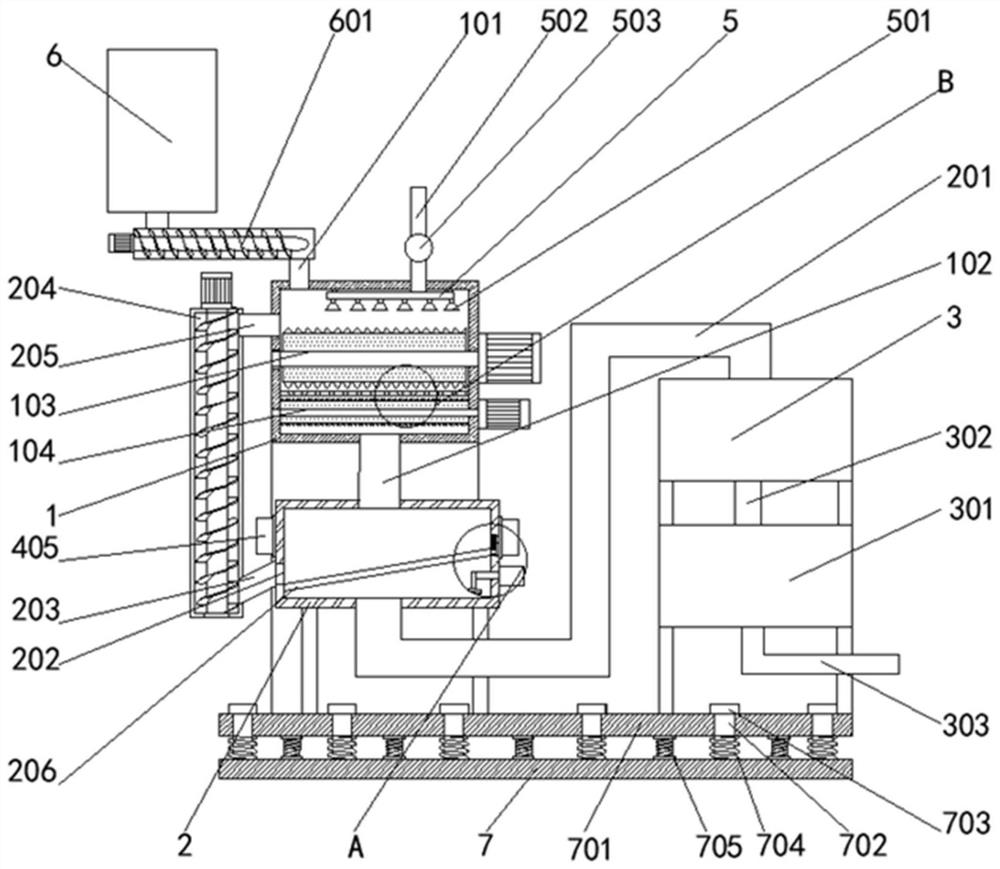

Construction waste treatment device

ActiveCN111841738BEasy for secondary crushingImprove efficiencyConstruction waste recoveryGrain treatmentsEnvironmental engineeringRefuse Disposals

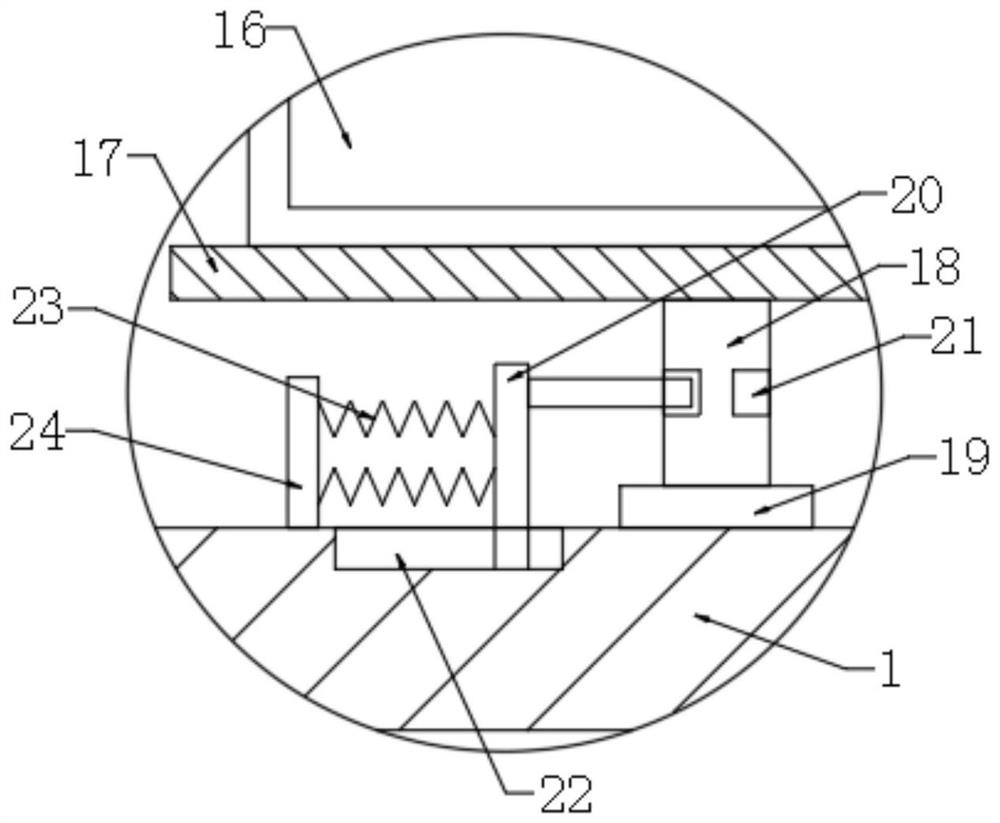

The invention relates to the technical field of construction waste treatment, more particularly, to a construction waste treatment device, comprising a feeding crushing box, a crushing and crushing mechanism, a mixing and crushing box, a stirring and crushing mechanism, a driving mechanism, a screening device and a frame , the feeding crushing box is provided with two, and the two feeding crushing boxes are relatively fixedly connected to the two ends of the top surface of the mixing and crushing box; the mixing and crushing box is fixedly connected to the frame; two Each of the feeding and crushing boxes is respectively connected with a crushing and crushing mechanism; the mixing and crushing box is connected with the stirring and crushing mechanism; the driving mechanism is connected to the mixing and crushing box; the driving mechanism drives the The stirring and crushing mechanism and the two crushing and crushing mechanisms are connected; the present invention can perform crushing treatment on construction waste, which is convenient for subsequent transportation or recycling.

Owner:内蒙古九鹏建设有限公司

Compound type coal mining machine with screening and separation function

PendingCN109365275AWith screening and separation functionEasy to filterSievingScreeningEngineeringVibration motor

The invention discloses a compound type coal mining machine with a screening and separation function. The compound type coal mining machine comprises a mining machine body, a vibration motor and a second motor. The top of the mining machine body is provided with a mining head and a collector, one side of the mining machine body is provided with a smashing machine, the bottom of the smashing machine is provided with a fixing block, one side of the fixing block is provided with a vibration motor, a filter net is installed inside the fixing block, a conveying belt is arranged at the bottom of thefilter net, a first motor is arranged on the inner side of the fixing block, one end of the first motor is connected with a connection rod, a chain is connected to the outer side of the connection rod, a stirring block is arranged on the surface of the connection rod, the other side of the fixing block is provided with a discharge outlet, and the bottom of the discharge outlet is provided with acollection box. According to the compound type coal mining machine with the screening and separation function, coal mined by the mining machine can be conveniently screened, and large coal can be automatically screened for the second time.

Owner:GUIZHOU UNIV

A multifunctional solid waste comprehensive utilization equipment

ActiveCN108262135BImprove crushing effectEasy to pick upSolid waste disposalTransportation and packagingDrive wheelDrive shaft

Owner:深鹏环保工程有限公司

Waste rubber desulfurization and plasticization processing device

ActiveCN113815153AAffect the cutting effectPrevent affecting the effect of subsequent desulfurization and plasticizationPlastic recyclingMechanical material recoveryPlasticultureWaste rubber

The invention discloses a waste rubber desulfurization and plasticization processing device, relates to the technical field of recovery processing devices, and aims to solve the problems that an existing device cannot automatically decompose waste rubber, firstly, the recovered waste rubber needs to be manually cut, and cooling operation cannot be performed after the waste rubber is heated, desulfurized and plasticized. The waste rubber desulfurization and plasticization processing device comprises a conveying carrier; a recovery cooling structure is arranged at the top of a bearing support table; a preliminary cutting structure is arranged on the inner side of a crushing carrying frame, and a reciprocating separation structure is arranged on the inner side of a cutting carrying shaft. The cutting carrying shaft is matched with a cutting knife frame to extrude, clamp and cut the collected waste rubber. According to the waste rubber desulfurization and plasticization processing device, the waste rubber with large volume is cut into small blocks instead of manual work, and secondary crushing by a subsequent device is facilitated; the waste rubber subjected to desulfurization and plasticization processing can be conveyed to the inner side of a cooling carrying pipe through a transfer sliding pipe, a conveying motor drives a recycling shaft column to rotate for pushing and recycling, and a cooling water tank attached to the cooling carrying pipe can conduct water cooling on the waste rubber subjected to desulfurization and plasticization processing.

Owner:榆树市金山环保橡胶设备制造有限公司

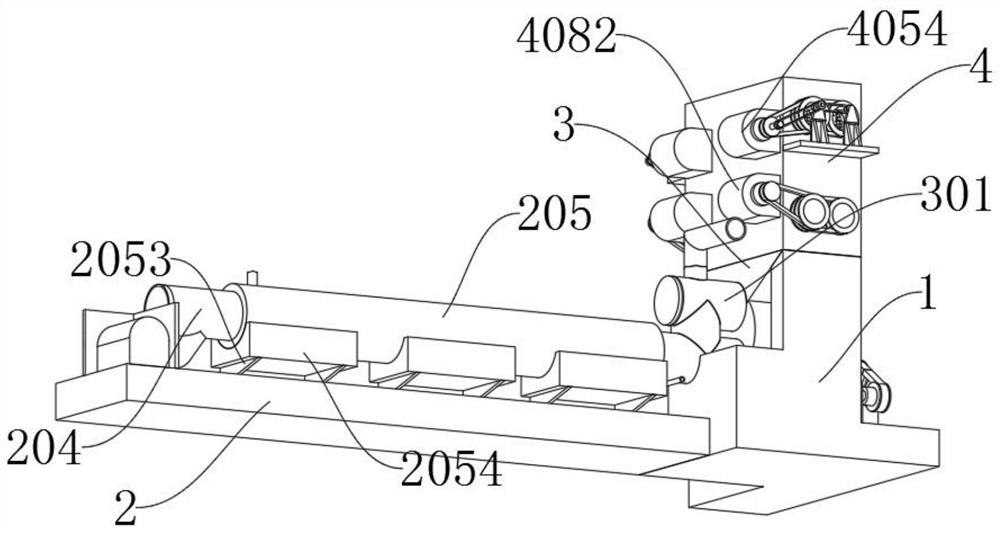

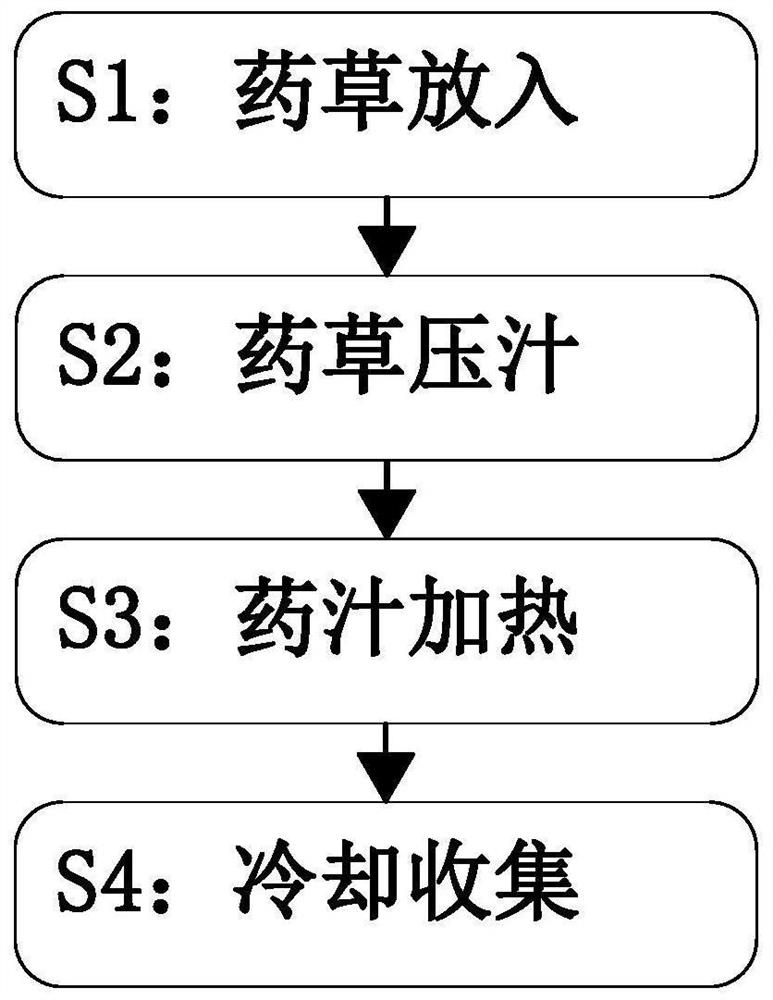

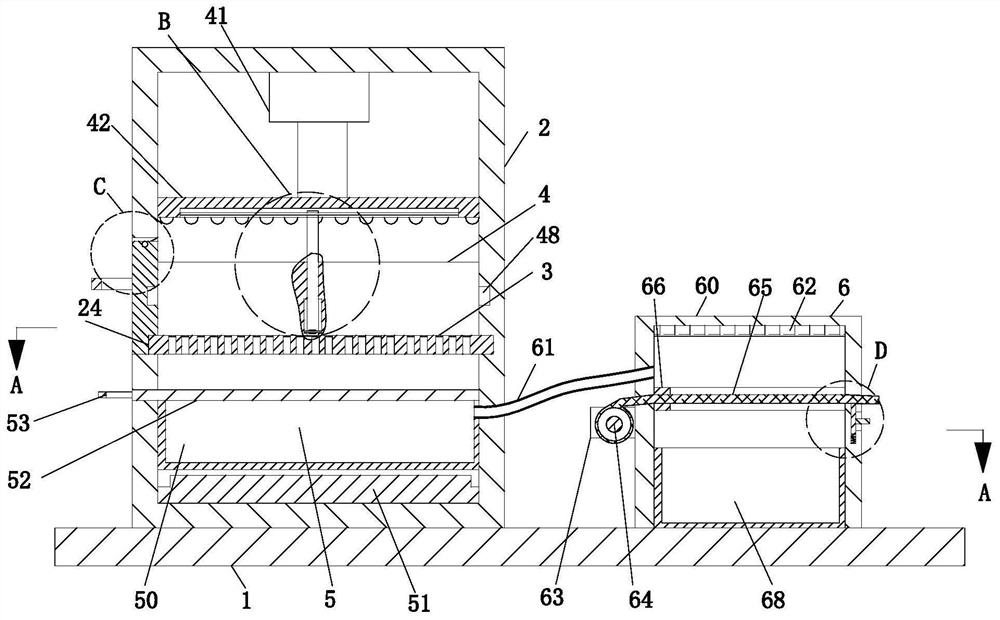

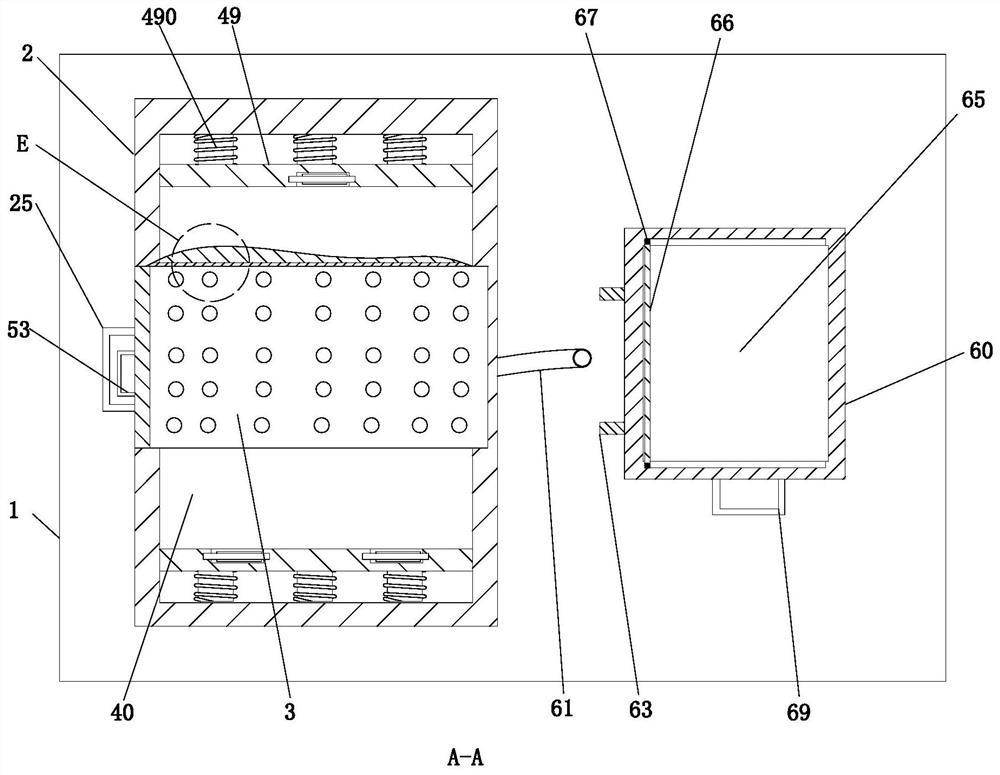

Green and environment-friendly disinfectant preparation method

InactiveCN112248510AEasy extrusionNo impuritiesVapor condensationEvaporationMedicinal herbsCool storage

The invention relates to a green and environment-friendly disinfectant preparation method. The green and environment-friendly disinfectant preparation method uses a green and environment-friendly disinfectant preparation device; the green and environment-friendly disinfectant preparation device comprises a workbench, a preparation box, a supporting net plate, a smashing and pressing mechanism, a heating mechanism and a cooling storage box; the preparation box is mounted on the left side of the upper end surface of the workbench; the preparation box is of a rectangular cavity structure; the smashing and pressing mechanism is arranged at the upper end of the inner wall of the preparation box; a supporting net plate is arranged below the smashing and pressing mechanism; the heating mechanismis arranged below the supporting net plate; and the cooling storage box is arranged on the right side of the preparation box. According to the green and environment-friendly disinfectant preparation method, the adopted smashing and pressing mechanism smashes and presses medicinal herbs and then pushes the medicinal herbs, so that the medicinal herbs pressed on the supporting net plate are stackedtogether to be convenient for secondary smashing and pressing; and the heating mechanism is adopted for heating medicine juice, and then medicine steam is conveyed into a cooling storage box to be cooled and collected.

Owner:合肥品瞻环保科技有限公司

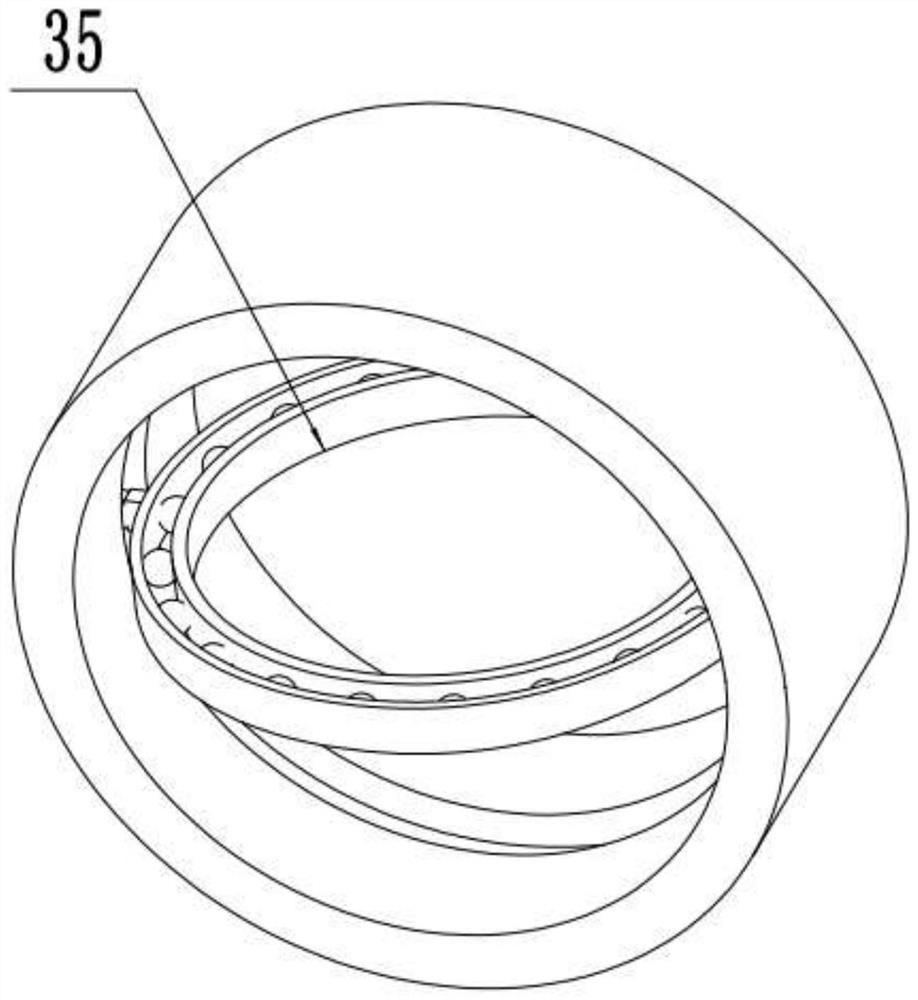

Three-cylinder bidirectional stepped ball mill

InactiveCN113413972AEasy for secondary crushingHigh precisionGrain treatmentsMechanical engineeringBall mill

The invention relates to the technical field of ball mills, and discloses a three-cylinder bidirectional stepped ball mill. The three-cylinder bidirectional stepped ball mill comprises a ball milling mechanism for performing input type grinding on a material to be ground, the ball milling mechanism comprises an upper outer cylinder, an upper inner cylinder coaxial with the upper outer cylinder is arranged inside the upper outer cylinder, two lower outer cylinders are symmetrically mounted on the lower portions of the left side wall and the right side wall of the upper outer cylinder correspondingly, supporting legs are fixedly mounted on the sides, away from the upper outer cylinder, of the bottoms of the lower outer cylinders, lower inner cylinders coaxial with the lower outer cylinders are arranged in the inner middles of the lower outer cylinders, discharging mechanisms are arranged on the two sides of the inner bottom of the upper outer cylinder, each discharging mechanism comprises a discharging groove formed in the upper outer cylinder, and a driving mechanism is arranged on the outer side wall of the middle of the upper inner cylinder.

Owner:周小飞

Forestry waste processing device

PendingCN112774832AEasy for primary crushingEasy for secondary crushingSievingScreeningWaste processingElectric machine

The invention discloses a forestry waste processing device which comprises a device body, a feeding port and crushing rollers. The feeding port is formed in the upper end of the device body, and the two crushing rollers are arranged on the lower side of the feeding port; a rotating shaft I is arranged on the crushing rollers, and a motor is arranged at the right end of the first rotating shaft; the lower end of the motor is fixedly connected with the device body, and a sieve plate is arranged on the lower sides of the crushing rollers; a supporting plate is installed at the lower end of the sieve plate, and the left end and the right end of the supporting plate are fixedly connected with the device body; and a funnel is arranged on the supporting plate. When the processing device is used, a movable door on the device body is opened, and an inserting rod is pulled leftwards to move out of an inserting groove; a fixing plate is rotated by a certain degree so that two collecting boxes are exchanged with each other, and then the inserting rod is loosened, and reinserted into the inserting groove in the other side again; the collecting boxes are easy to take out of the fixing plate, and forestry waste in the collecting boxes is cleaned; and the normal operation of the device body is not influenced.

Owner:望江县兴江新能源开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com