Crushing equipment for catalyst

A technology of crushing equipment and catalysts, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve problems such as poor crushing effect, achieve improved drying effect, simple structure, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

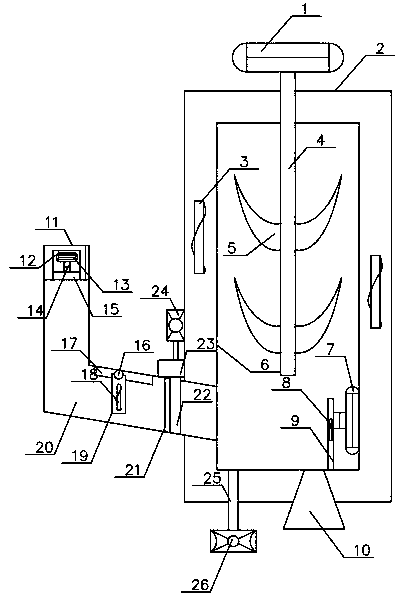

[0020] Such as figure 1 As shown, a crushing equipment for catalyst according to the present invention includes a motor 1, a crusher body 2, a secondary dryer 3, a rotating shaft 4, a crushing blade 5, a lining 6, a secondary pusher 7, Three-stage dryer 8, push plate 9, discharge port 10, cover plate 11, cavity 12, hydraulic pump 13, hydraulic rod 14, hammer head 15, pulley 16, slide rail 17, primary dryer 18, Scraper 19, feeding bin 20, socket 21, inserting plate 22, baffle 23, primary pusher 24, ventilation pipe 25, air pump 26, motor 1 is set on the upper end of crusher body 2, and motor 1 is connected by rotating shaft 4 The pulverizing blade 5 is provided with an L-shaped feeding bin 20 on one side of the crusher body 2, a cover plate 11 is arranged at the upper end of the L-shaped feeding bin 20, a slide rail 17 is arranged at the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com