Patents

Literature

103results about How to "Easy to wash away" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorescence labeling acrylic acid-sodium acrylic sulphonate co-polymer water treatment agent and preparation method thereof

InactiveCN101381168AMild reaction conditionsEasy to operate on siteScale removal and water softeningMaterial analysis by optical meansBromineDiethylenediamine

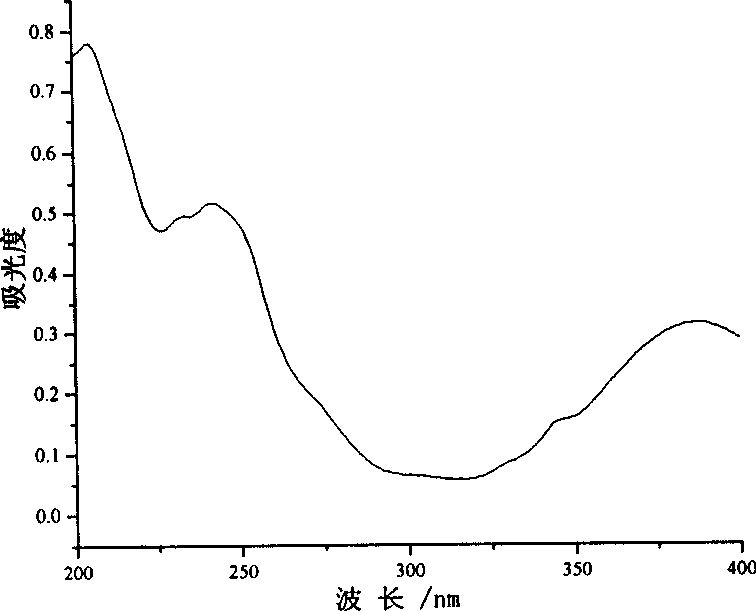

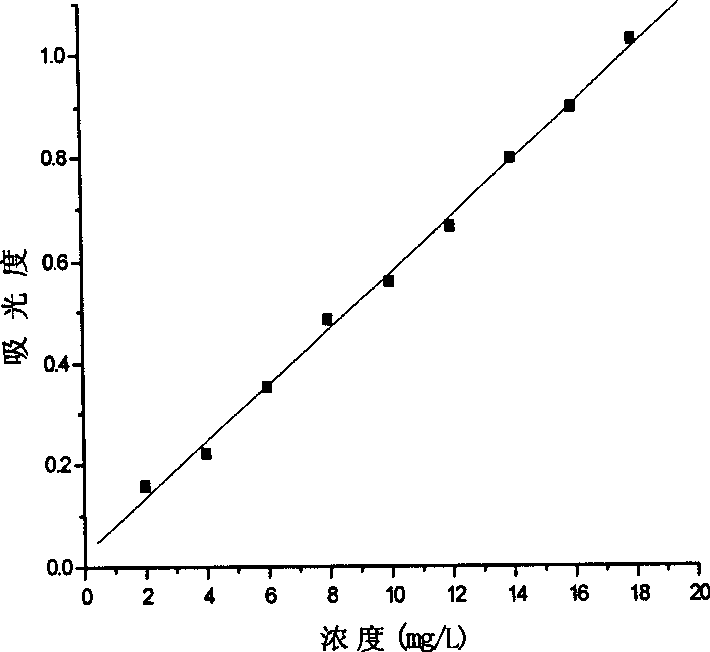

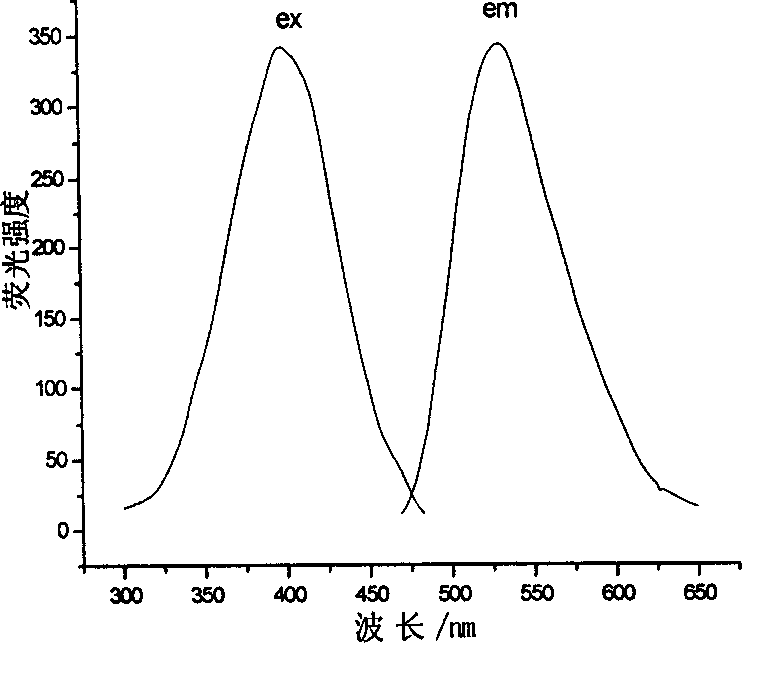

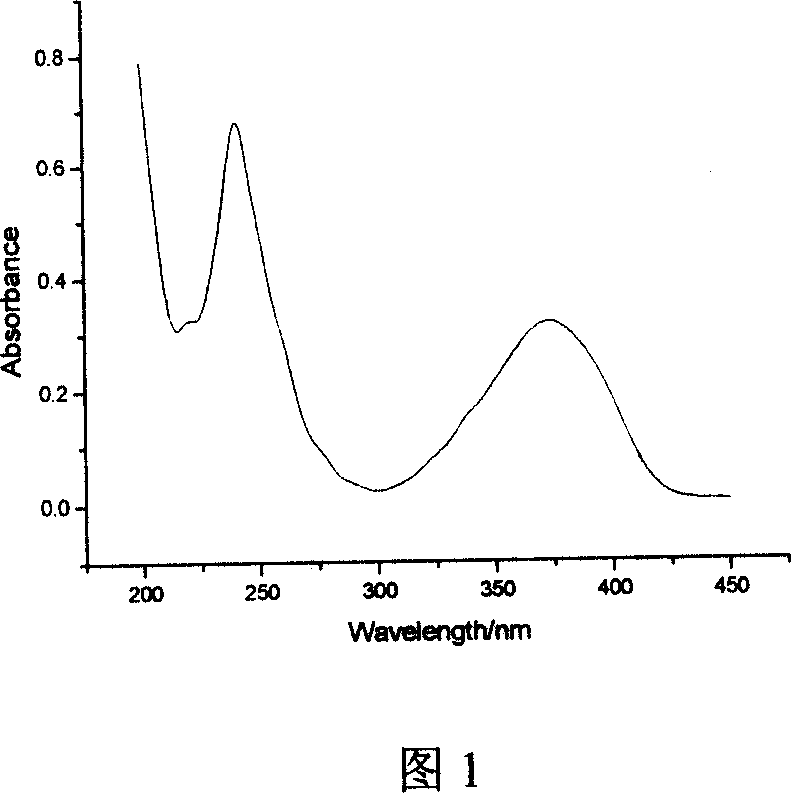

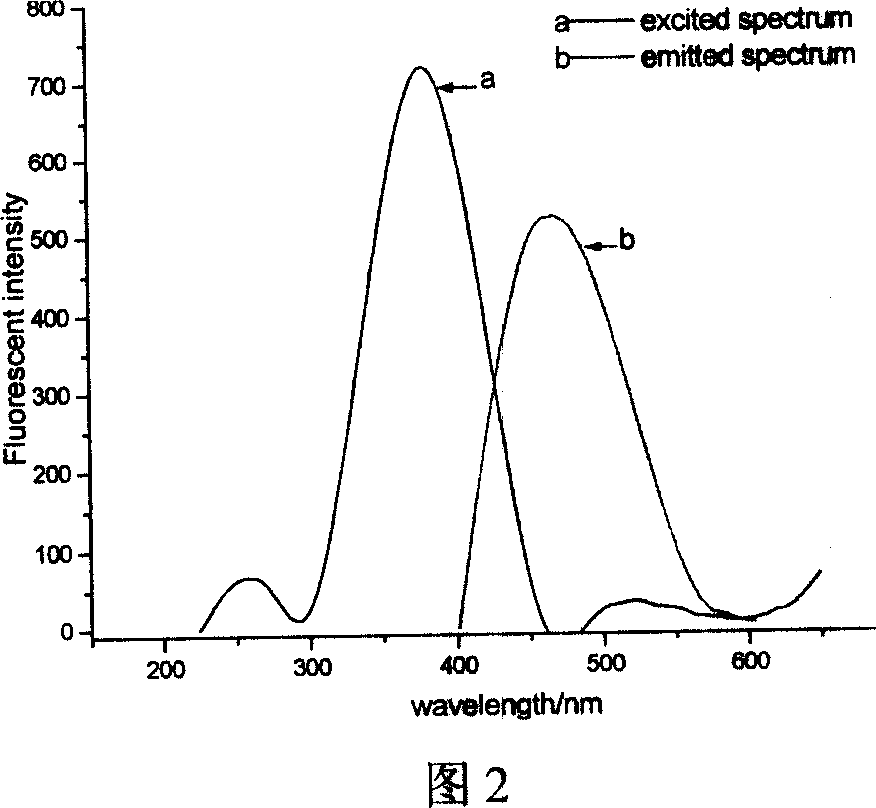

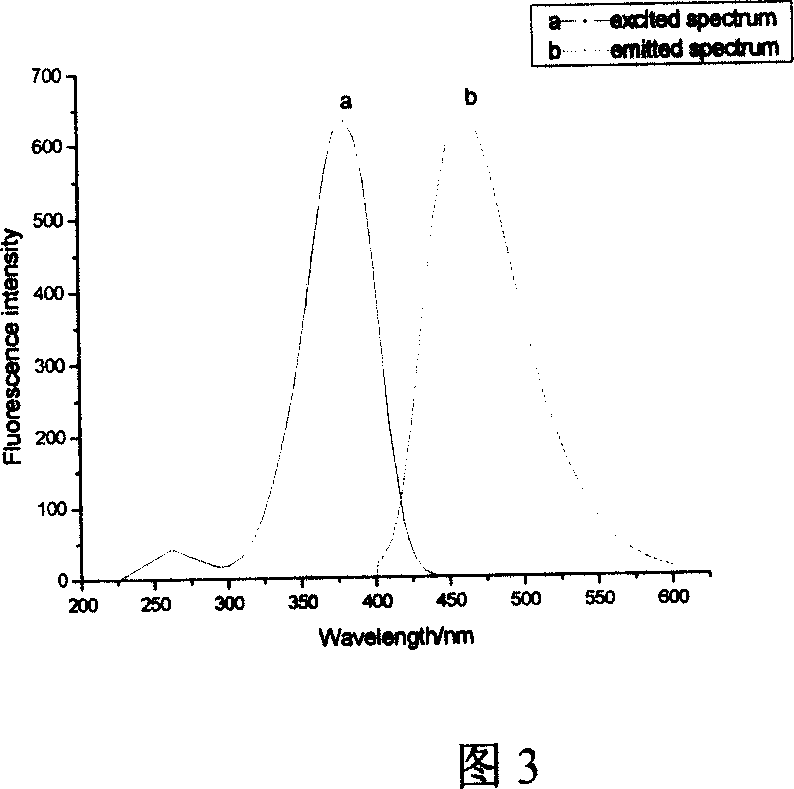

The present invention discloses a fluorescence labeled acroleic acid-sodium allylsulfonate copolymer and a method for preparing the same. The method comprises the following steps: 4-bromine-1,8-naphthalic anhydride, methylamine, N-methyl diethylenediamine, and the like are used as material and is subject to amidation reaction, amination reaction, and quaternization reaction to be synthesized, and a novel fluorescence monomer 4-(N'-methyl-1-diethylenediamine)-N-methyl-1,8-naphthalimide allyl chloride quaternary ammonium salt is obtained by synthesis; and then the fluorescence monomer is copolymerized with sodium hypophosphite, acroleic acid and sodium allylsulfonate to obtain the FC-AA-SAS product. The raw materials for synthesizing the fluorescence monomer and the polymer are easy to obtain and the reaction conditions are mild. When the product is used in circulating water, the thickness of a medicament in a circulating water system can be accurately, duly and quickly measured through the variation of the fluorescence intensity, and the on-line medicine addition and the quantitative control are realized. Therefore, the on-site operation is largely simplified, and the management level is improved. The functional groups, such as sulfonic group, phosphino group and the like, are introduced into molecules, and thus the polymer has a plurality of functions, such as fluorescent tracing, anti-precipitation, disgregation and the like.

Owner:NANTONG UNIVERSITY

Phosphine-based Marpropy multipolymer containing fluorescent base-group and its production

InactiveCN1939945ARaw materials are easy to getMild reaction conditionsSodium methoxideEthylenediamine

A phosphino-based mapropyl copolymer containing fluorescent group and its production are disclosed. The process is carried out by taking 4-bromine-1,8-naphthalic anhydride, glacial acetic acid and N, N-dimethyl-ethylenediamine as raw materials to obtain 4-bromine-N-(2-N,, N,-dimethylbenzidine-ethyl)naphthalimide, reacting it with sodium methoxide to induce methoxy-group to obtain 4-methoxy-N-(2-N,, N,- dimethylbenzidine-ethyl)naphthalimide, reacting it with allyl chloride to obtain fluorescent monomer 4-methoxy-N-(2-N,, N,- dimethylbenzidine-ethyl)naphthalimide allyl ammonia chloride with fluorescent characteristic and double-bond, polymerizing it with sub-sodium phosphate, maleic anhydride, acroleic acid and propenyl-sodium sulfate to obtain the final product. It has fluorescent tracting, corrosion-inhibting, scale-inhibiting and dispersion functions.

Owner:NANJING UNIV OF SCI & TECH

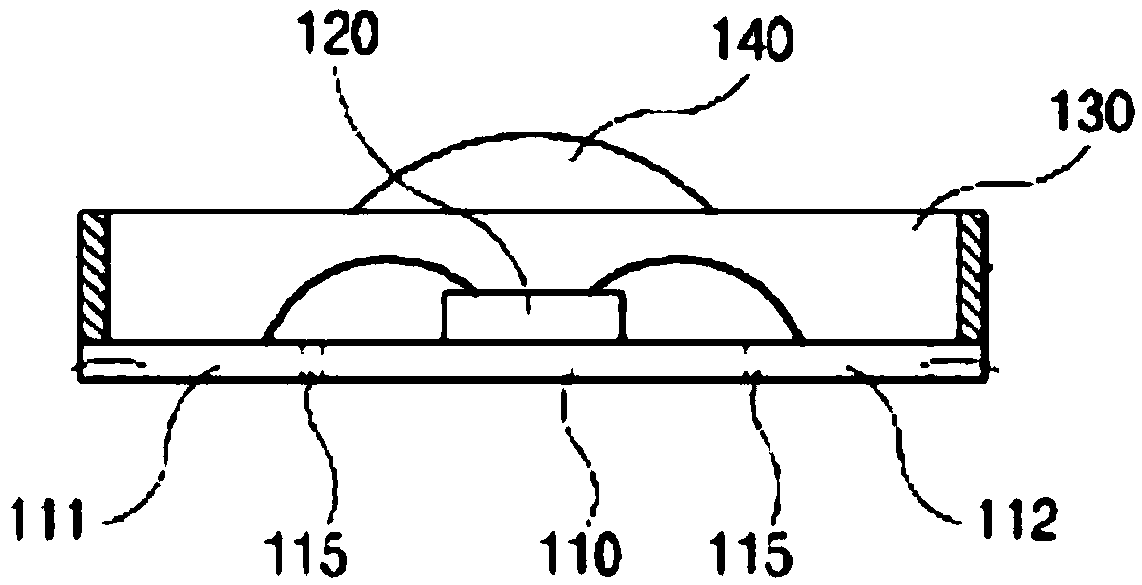

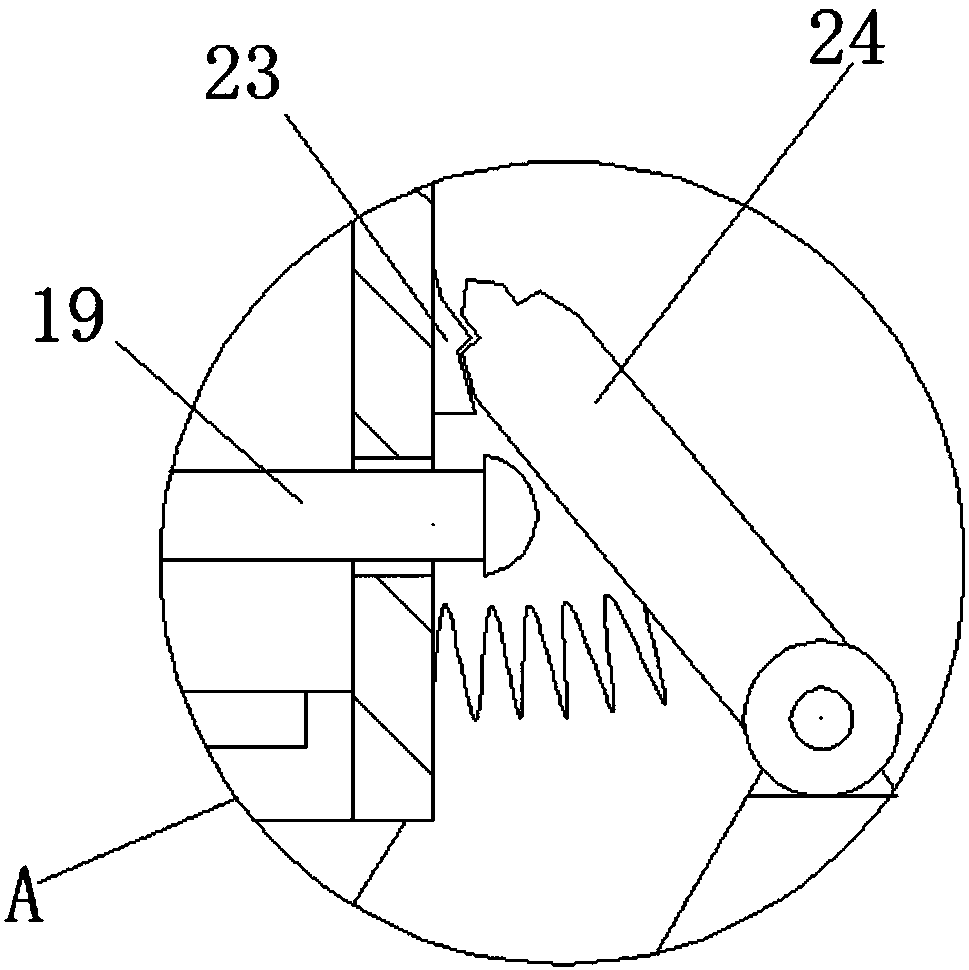

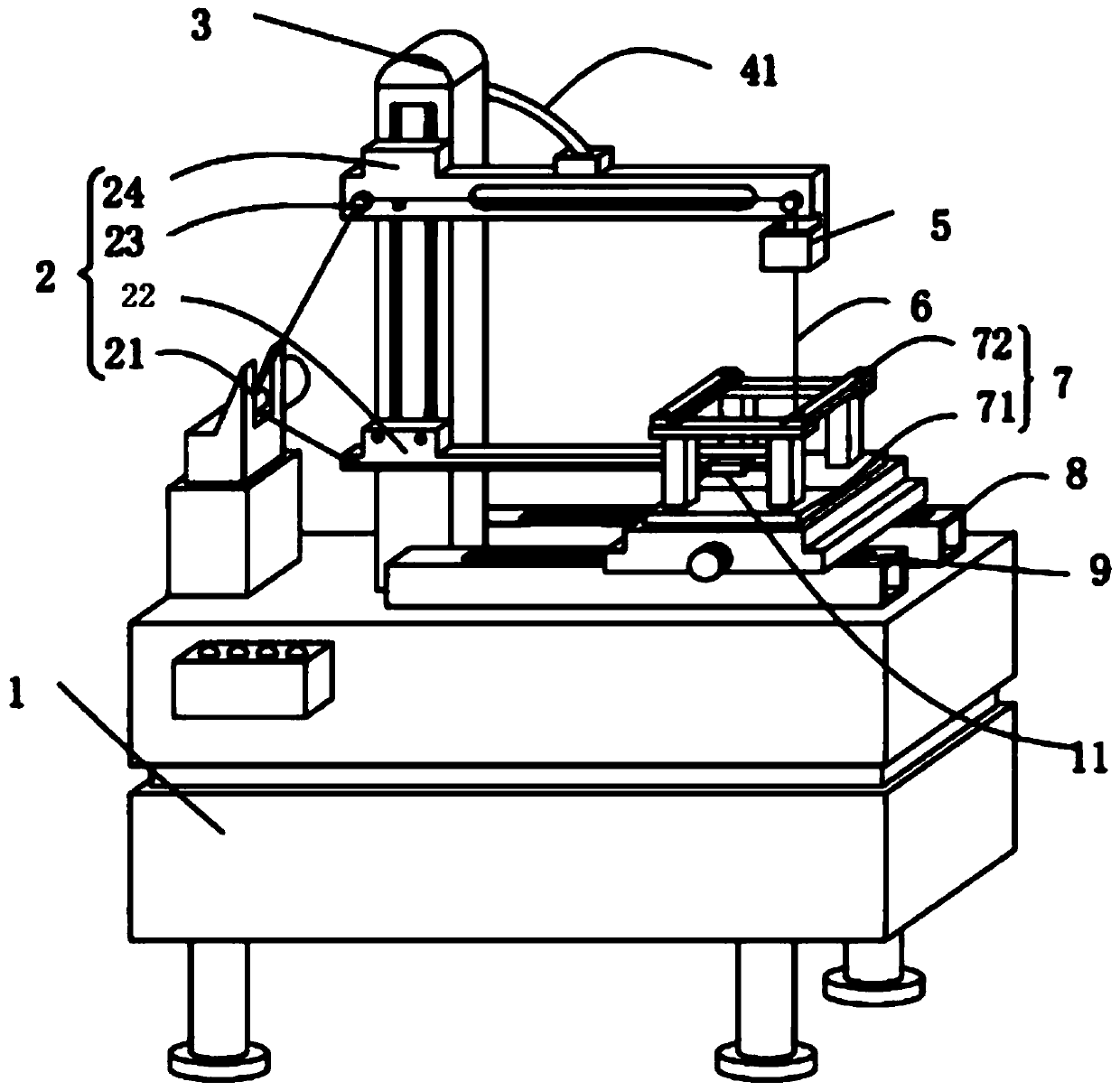

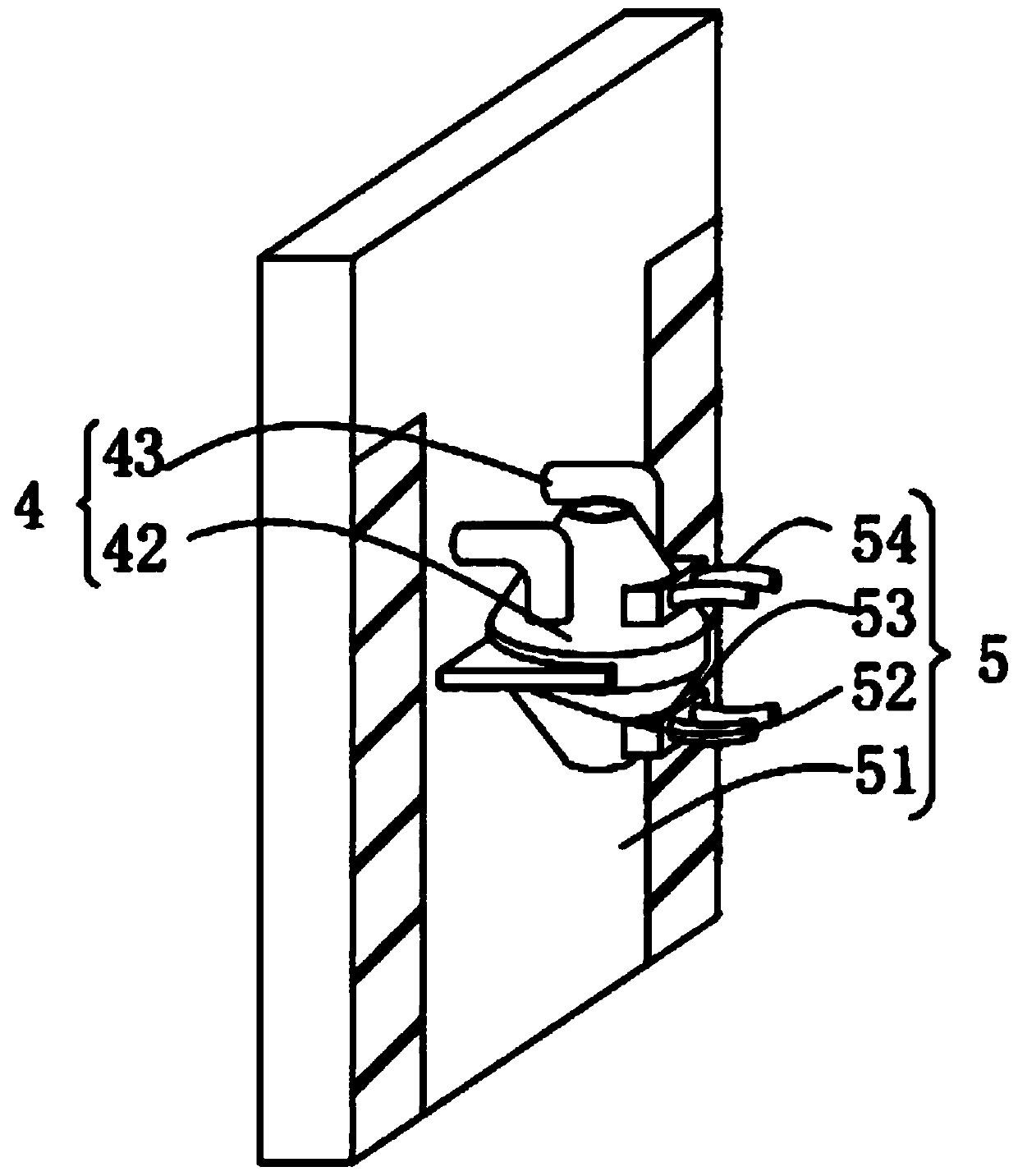

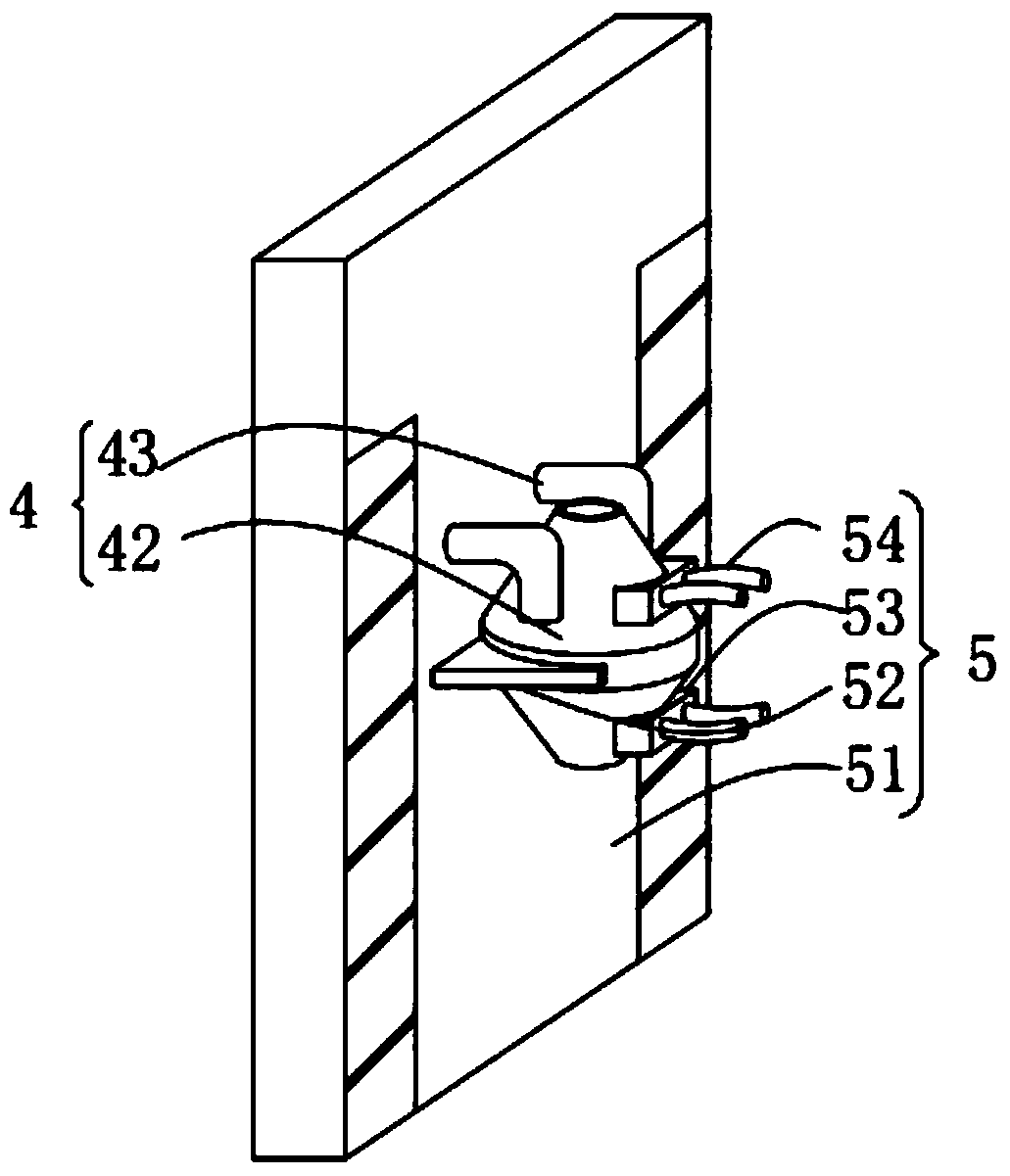

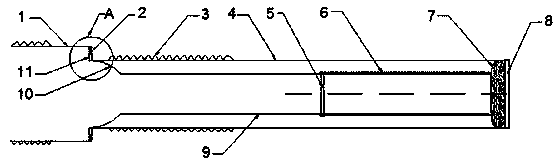

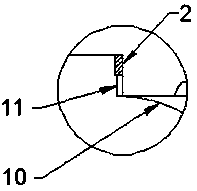

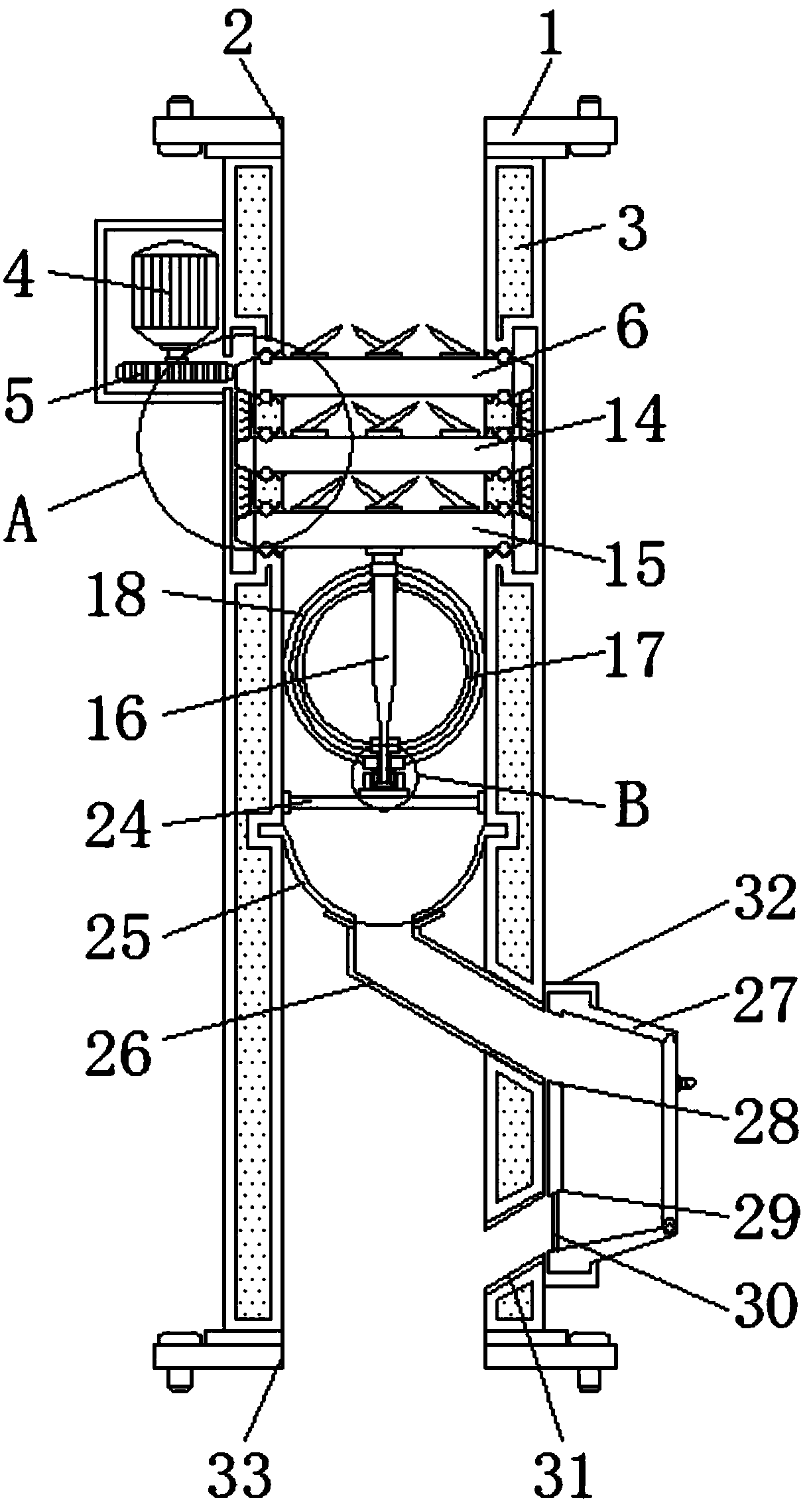

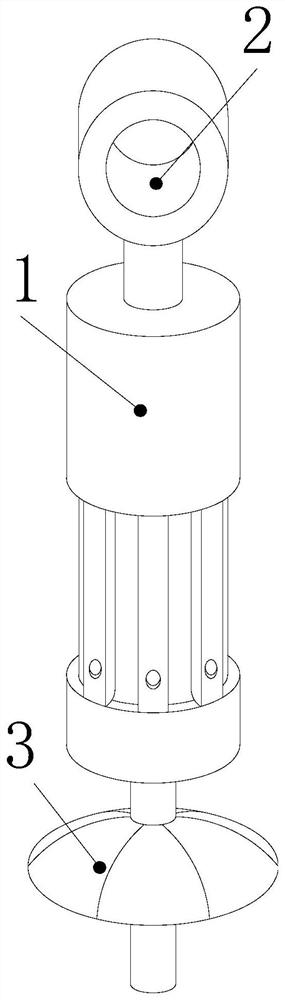

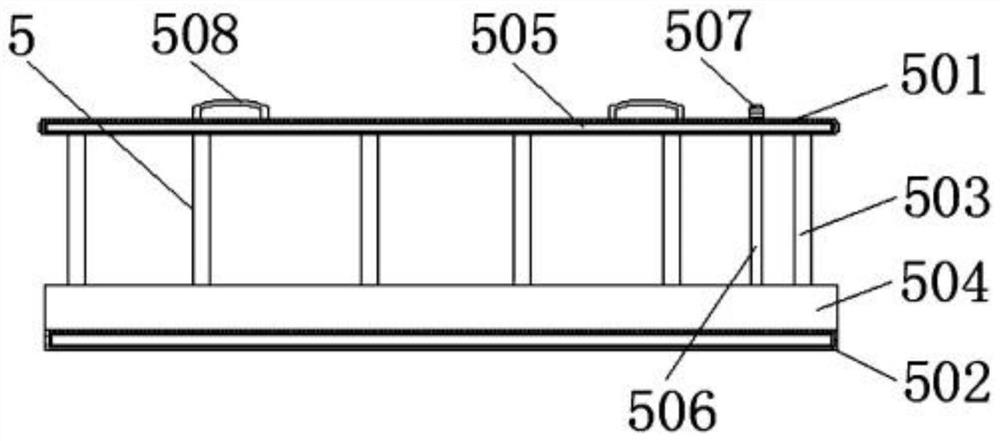

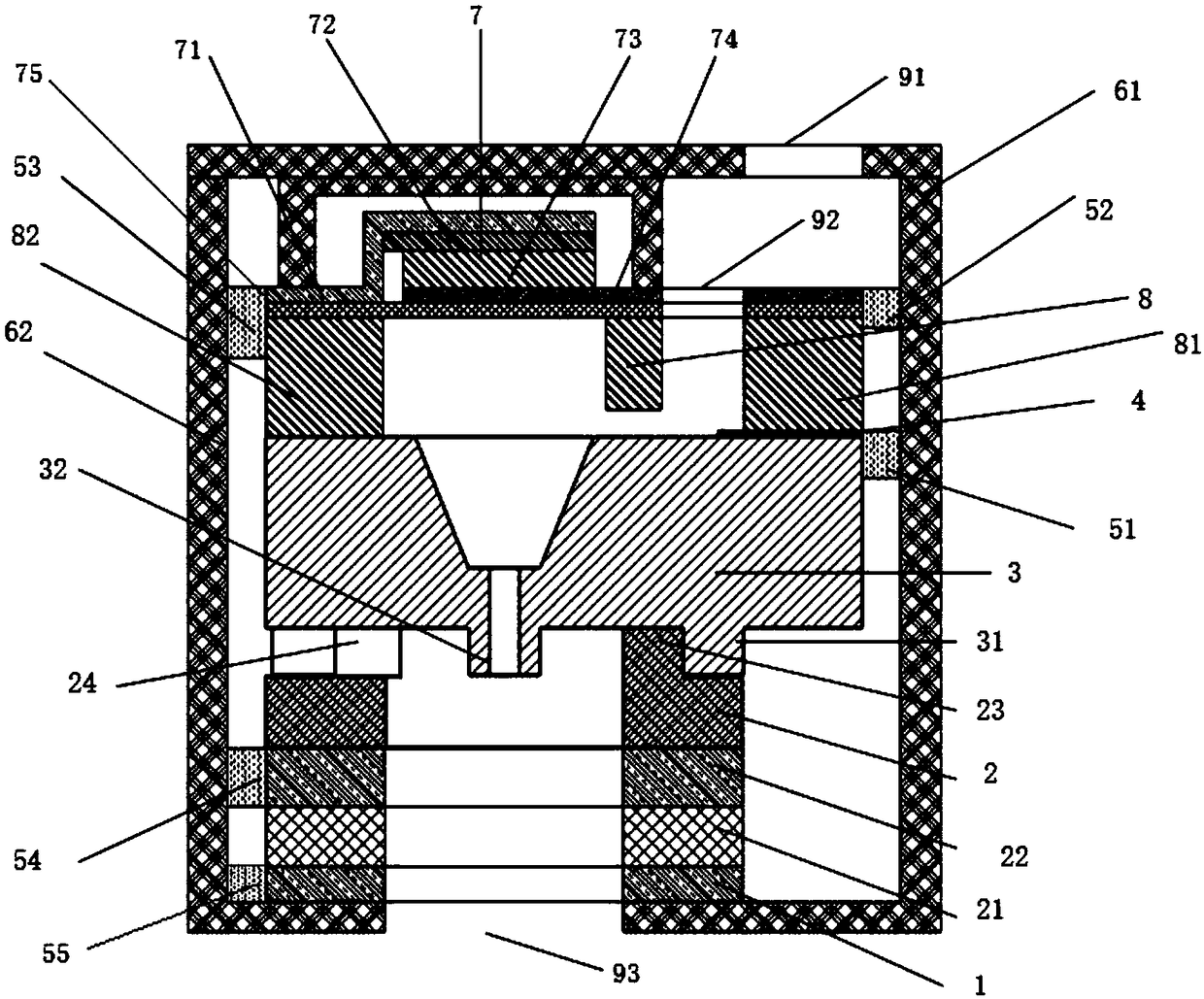

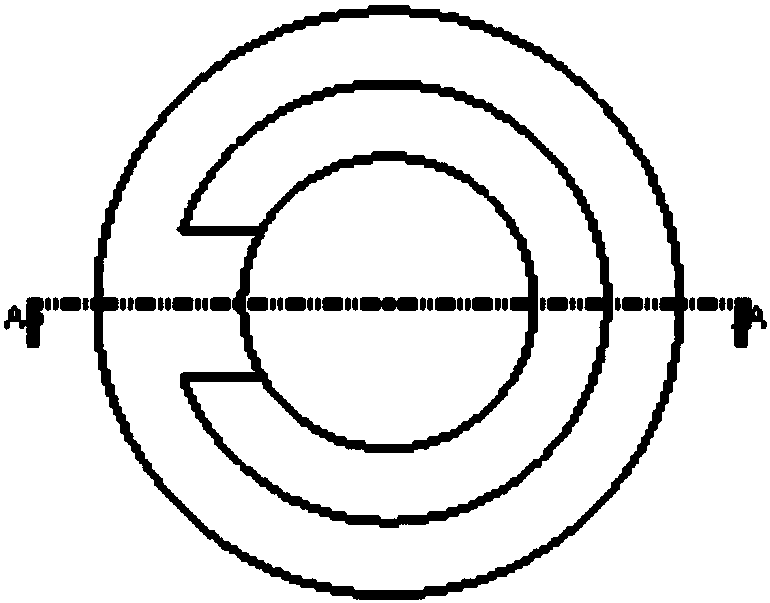

Piezoelectric type integrated spray head used for electrofluid jet printing

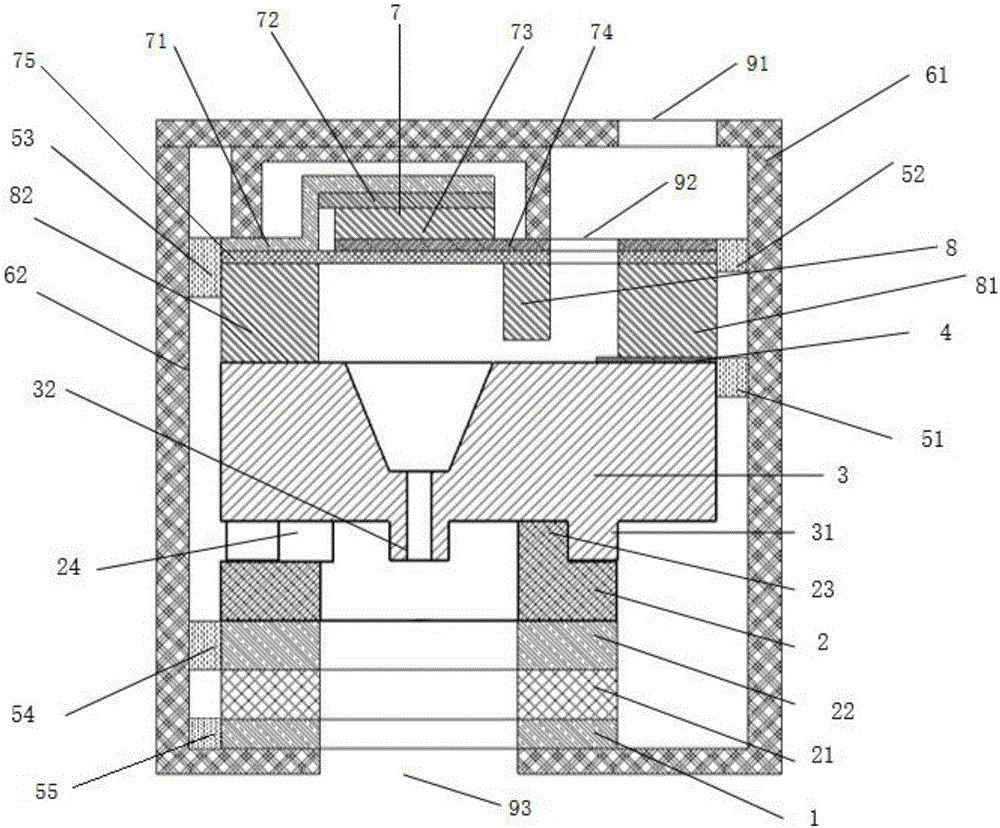

The invention relates to the field of electrofluid jet printing equipment, in particular to a piezoelectric type integrated spray head used for electrofluid jet printing. The piezoelectric type integrated spray head comprises an outer bracket, a piezoelectric structure, a spray head, a lower electrode supporting ring and a lower electrode ring, wherein the piezoelectric structure is positioned above the spray head; an upper electrode is arranged on the upper part of the spray head; the lower electrode supporting ring and the lower electrode ring are sequentially arranged below the spray head; after the piezoelectric structure, the upper electrode and a lower electrode are electrified, electric fields are formed between the spray head and the lower electrode ring, so that a solution forms Taylor cones on the spray head. The piezoelectric type integrated spray head overcomes the defect that existing electric jet printing equipment cannot meet high-frequency spraying, can realize high-frequency high-resolution printing; and the lower electrode is integrated to the spray head end, so that the whole jet printing system is more flexible, and a base plate with a complex shape can be used to print. The piezoelectric type integrated spray head further has the advantages of being simple in structure, low in manufacturing cost, suitable for large-scale production and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

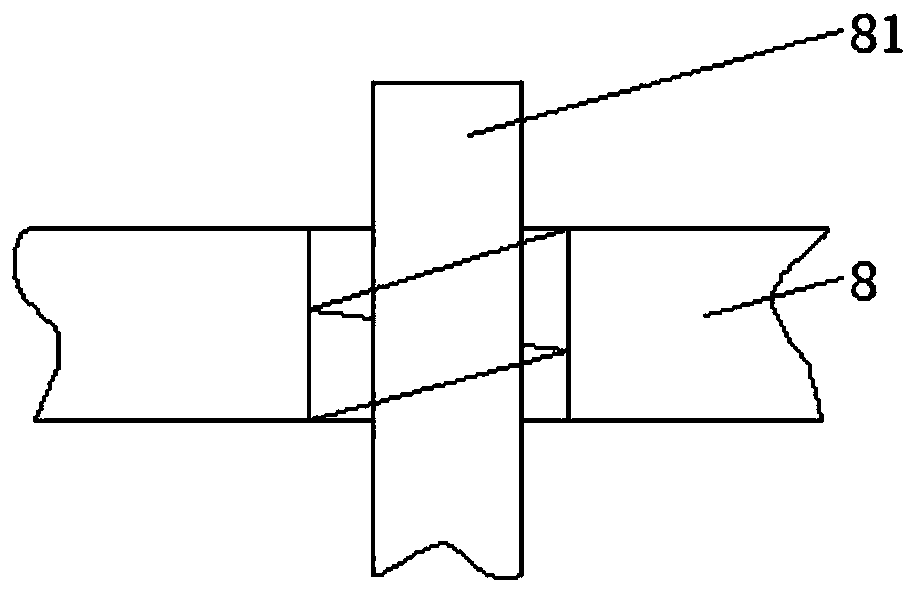

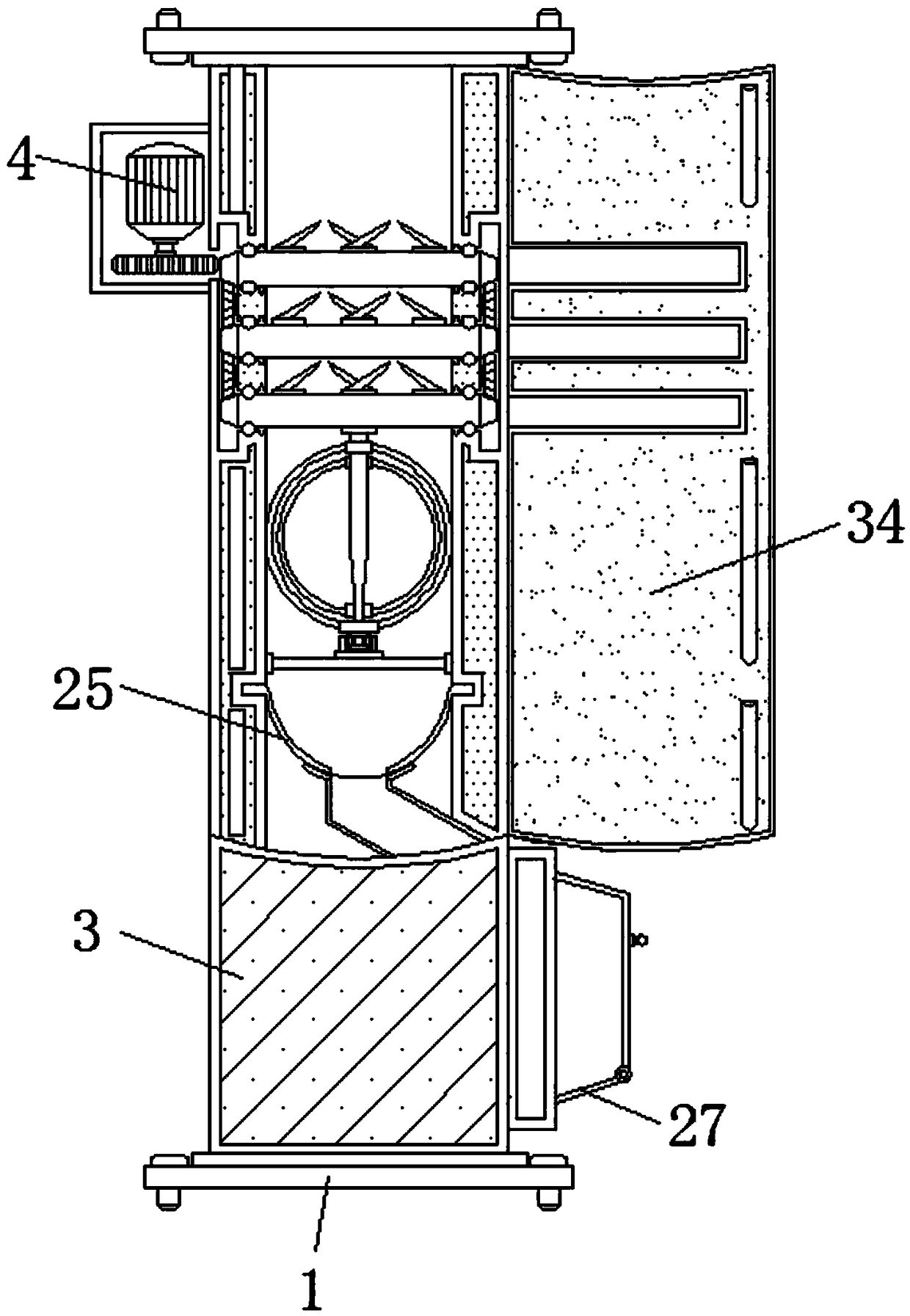

Mineral dressing technique for low ore grade iron ore and mineral dressing equipment thereof

Owner:王林

Polymaleic acid boiler scale-inhibition corrosion inhibitor

ActiveCN101580311AExcellent anti-scaling performanceImprove thermal stabilityScale removal and water softeningSeawaterChemistry

The invention relates to a polymaleic acid boiler scale-inhibition corrosion inhibitor, belonging to the technical field of chemical products, and aiming at providing a polymaleic acid boiler scale-inhibition corrosion inhibitor with high scale-inhibition rate and small corrosion rate. The average molecular weight of the polymaleic acid is larger than 5500, and the components and mass percentage thereof are as follows: 50 to 70 of aqueous solution with the content of polymaleic acid being 50 percent, 15 to 25 of aqueous solution with the content of polyepoxysuccinic acid being 50 percent, 2 to 4 of citric acid, and 10 to 14 of zinc salt. The preparation method comprises the following steps of: adding the polyepoxysuccinic acid into the aqueous solution of the polymaleic acid, and then adding the citric acid and the zinc salt, fully stirring the mixture until no precipitation exists, thus obtaining the final product. In the boiler scale-inhibition corrosion inhibitor, the scale-inhibition rate can reach more than 99 percent, and the corrosion rate is less than 0.011mm / a, thus not only being economical, practical and efficient, but also having significant economic and social benefits. The polymaleic acid boiler scale-inhibition corrosion inhibitor not only can be used for water treatment in the boiler, but also can be used for scale inhibition and corrosion inhibition in circulating cooling water in electrical power and petrochemical industries, seawater desalination, central air conditioner, water heater and the like.

Owner:安徽海瀚水处理科技有限公司

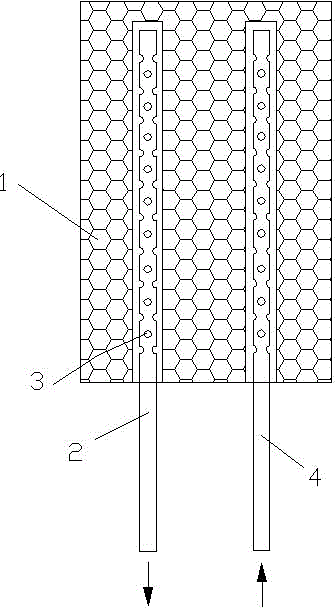

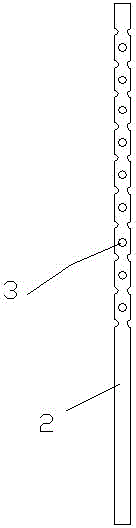

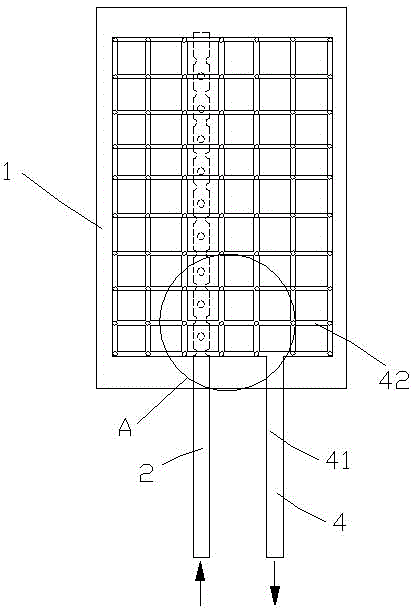

Negative pressure drainage dressing having attraction and flushing functions

InactiveCN104873332AEasy to wash awayAvoid easy cloggingCannulasEnemata/irrigatorsInhalationDrainage catheters

The present invention discloses a negative pressure drainage dressing having attraction and flushing functions. The negative pressure drainage dressing comprises a sponge body and at least one drainage conduit; one end of the drainage conduit is inserted into the sponge body; the other end of the drainage conduit is connected with a negative pressure source; and a conduit wall of the drainage conduit inserted into the sponge body is provided with a plurality of negative pressure attraction through holes. The negative pressure drainage dressing also comprises a perfusion pipeline, the perfusion pipeline is inserted into the sponge body and capable of injecting flushing liquid or soup into the sponge body to intervene in a wound, and negative pressure attraction of the wound secretion, the flushing liquid and the soup in the sponge body can be carried out by the drainage conduit. The negative pressure drainage dressing has the advantages that the liquid can be injected to the wound, the wound can be wetted and cleaned, the efficiency of attracting the secretion and edema liquid is higher, the wound can be intervened, and inhalation channels are not easy to be blocked.

Owner:傅秋良 +1

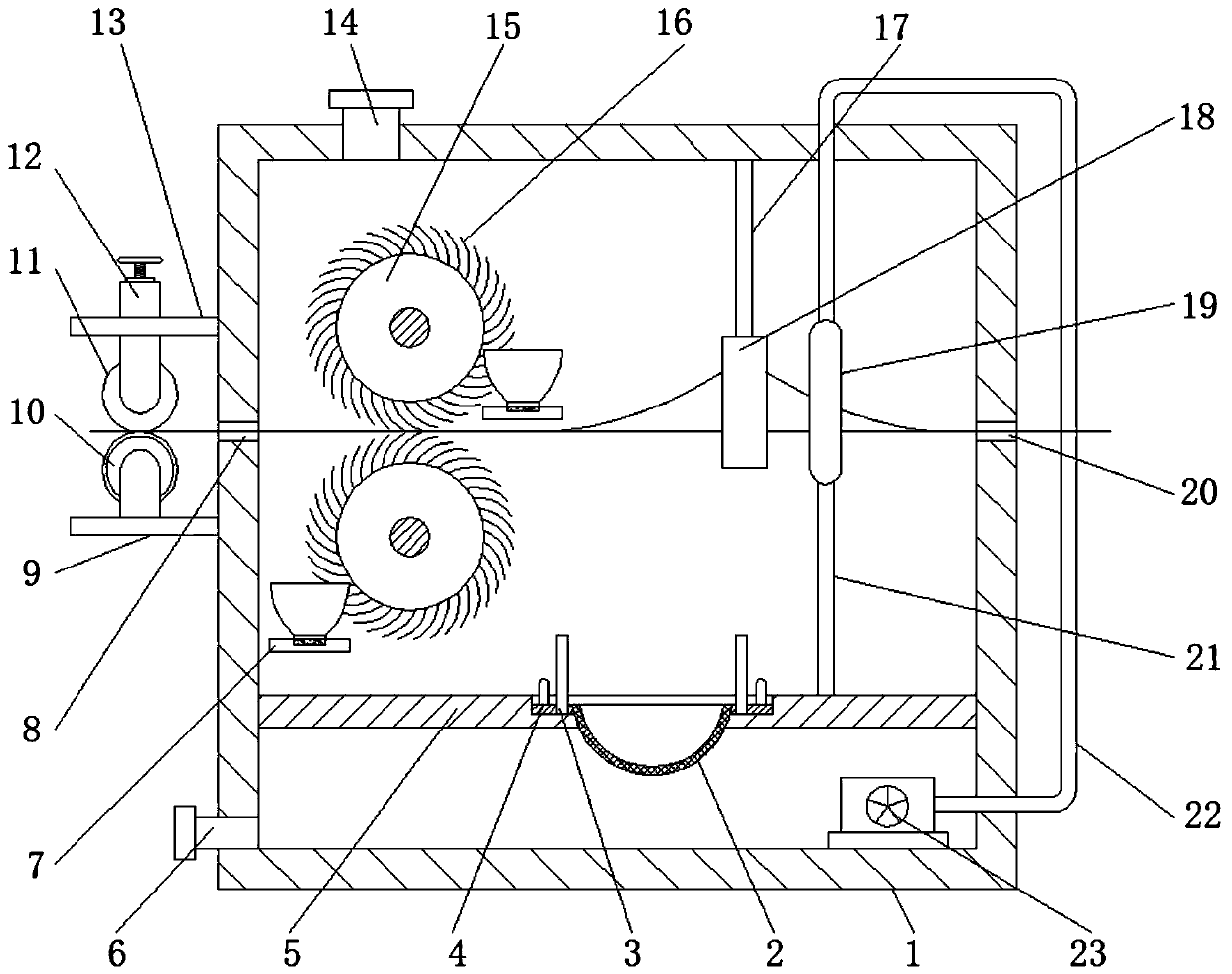

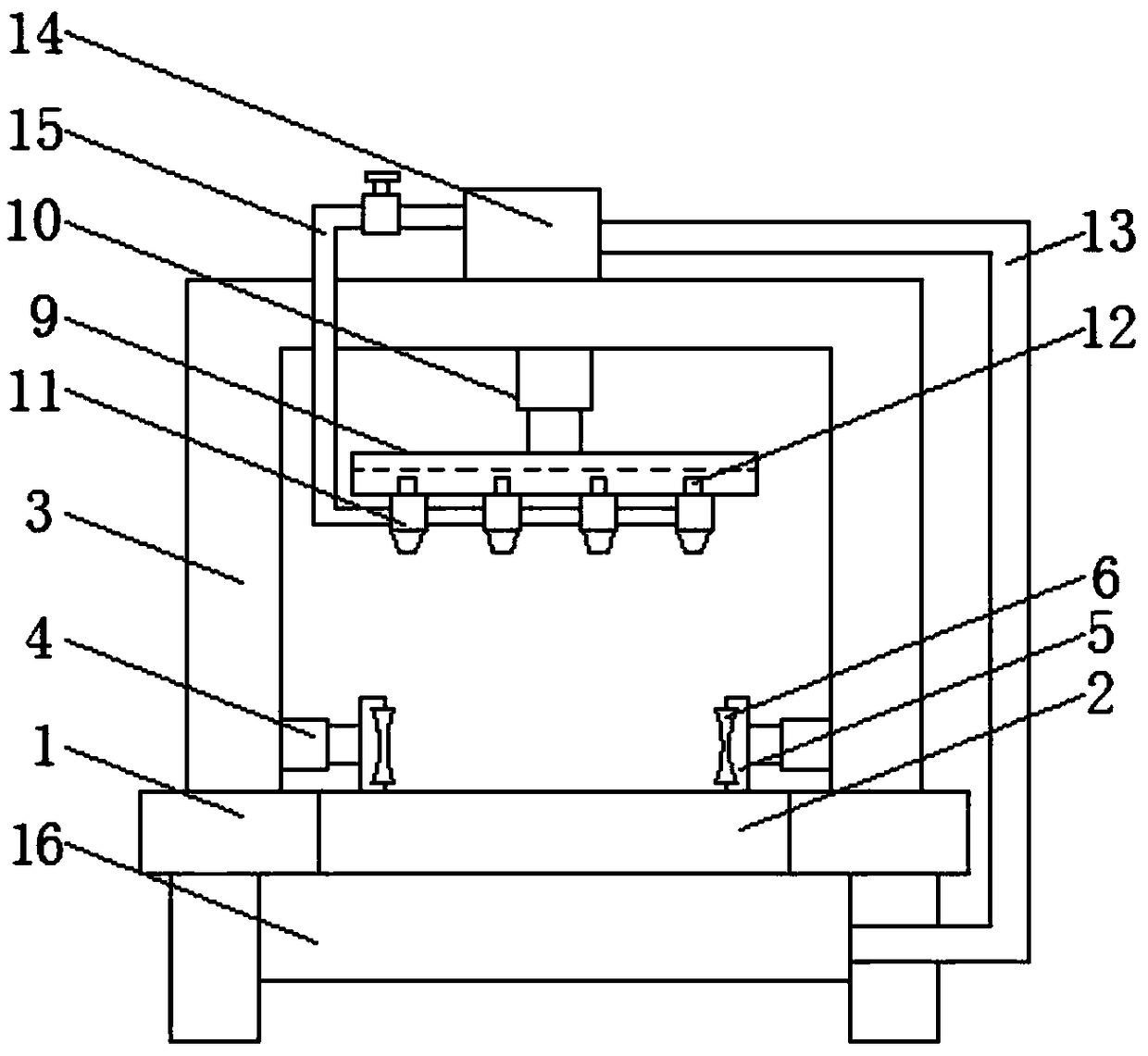

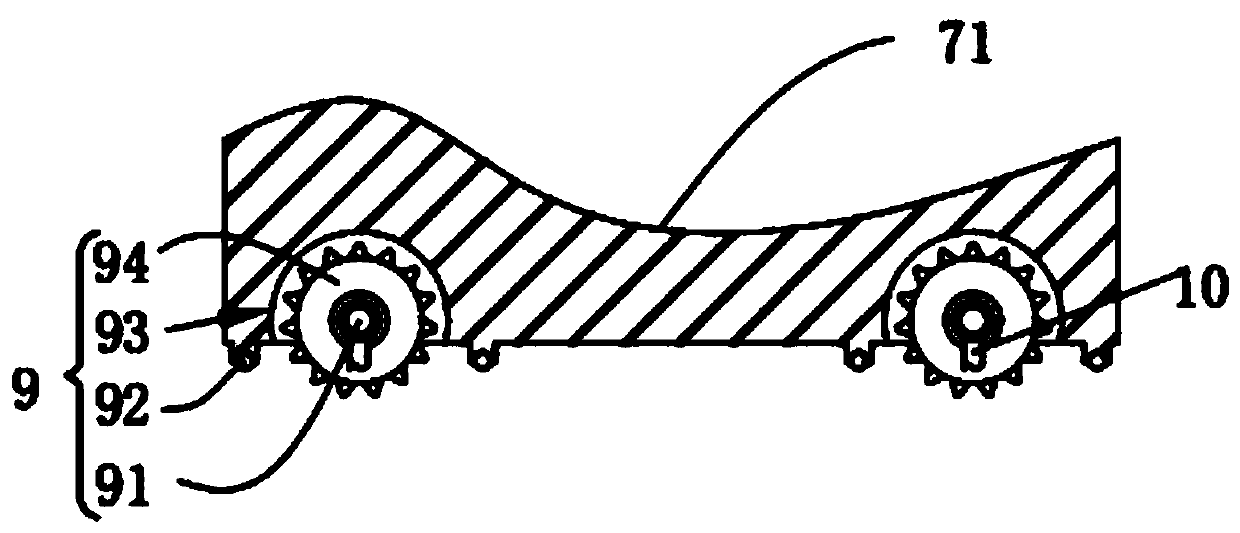

Fabric cleaning device for mechanical processing of textiles

The invention discloses a fabric cleaning device for mechanical processing of textiles. The device comprises a cleaning box, wherein the inner wall of the cleaning box is provided with a clapboard, and the outer wall of the top of the clapboard is provided with a groove; the inner wall of the bottom of the groove is provided with a limiting rod, the outer wall of the limiting rod is connected witha filter plate slidably, handles are welded to the portions, close to the two sides, of the outer wall of the top of the filter plate respectively, and the outer wall of the bottom of the filter plate is provided with a fixing opening. According to the device, a fabric can be kept in a tight state in the conveying process, and correspondingly impurities can be more conveniently cleaned away through brushing; brushes on cleaning rollers can brush away the impurities on the fabric; when the brushes rotate to a brush groove in a slag collecting box, the brush groove can maintain the impurities such as piles adhered to the brushes in the slag collecting box, so that the brushes are automatically cleaned, the cleaning effect is better, the fabric can be bent at a certain angle from the middleposition, the impurities on the bent fabric can be more easily flushed away from the two sides, and the cleaning effect of the device is further improved.

Owner:程斌

Wood board water cutting device and method having water circulation function

ActiveCN108908523AImpact cleanupReduce cleanupProfiling/shaping machinesStationary filtering element filtersPhysical healthWater storage tank

The invention discloses a wood board water cutting device and method having the water circulation function and belongs to the technical field of wood-working machinery. The wood board water cutting device comprises a working platform. An inner chamber of the working platform is provided with a conveying device. Rotating shafts are arranged in the centers of the outer walls of the left side and theright side of the top of the working platform correspondingly. The front end of each rotating shaft is connected with a guiding plate. A limiting rod is arranged on the outer wall of the top of eachguiding plate. The bottom end of each limiting rod extends to the outer wall of the bottom of the corresponding guiding plate, and the connection position of each guiding rod and the corresponding guiding plate is provided with a groove. By means of the device, chippings generated in the cutting process are flushed into a filter box for centralized treatment through water obtained after cutting, and the problem that the chippings splash everywhere to affect normal work and physical health of people is avoided; the water is separated from the chippings through the filter box, and the chippingscan be treated in a centralized manner conveniently; and meanwhile, the water collected by the filter box is conveyed into a water storage tank for reuse through a water pump, and the water resource is saved.

Owner:浙江博力莫新材料科技有限公司

Scale corrosion inhibitor for poly-maleic anhydride boiler

InactiveCN101269887AExcellent anti-scaling performanceImprove thermal stabilityScale removal and water softeningCentral air conditioningMaleic anhydride

The invention provides an antisludging inhibiter of a polymaleic anhydride boiler, which belongs to the chemical product technical field, and aims at providing an antisludging inhibiter of the polymaleic anhydride boiler, which has high ansludging ratio and small corrosion rate. The antisludging inhibiter has the material components and the mass percents thereof that: water solution with the content of polymaleic acid being 50 percent is 60-70, water solution with the content of polyepoxysuccinic acid being 50 percent is 15-25, citric acid is 2-4, and zinc salt is 10-14. The polyepoxysuccinic acid is added into the water solution of polymaleic acid, and the citric acid and the zinc salt are added, and the full mixing is performed to obtain the antisludging inhibiter. The antisludging ratio of the antisludging inhibiter of the invention can reach up to more than 99 percent, and the corrosion rate is less than 0.011 mm / a, so the antisludging inhibiter is not only economic and practical, but also has good effect, and has very marked economic and social benefits, is used for the water treatment in the boiler, and also can be applied to the scale prevention and the scale boiling of central air conditioning systems and water heaters, etc.

Owner:邢献军

External Preparation For The Skin

ActiveUS20120183492A1Moderate viscosityLess irritatingBiocideCosmetic preparationsSodium saltCopolymer

An external preparation for skin has a pH value of 2.0-5.0 and comprises: (a) 1.0-7.0 mass % of at least one of the members selected from hydroxy acids, (b) 0-0.1-3.0 mass % of a crosslinked type N,N-dimethylacrylamide-2-acrylamido-2-methylpropane sulfonic acid sodium salt copolymer, and (c) 0-0.1-3.0 mass % of an associating thickener constituted of a compound of the formula (1): R1—{(O—R2)k—OCONH—R3[—NHCOO—(R4—O)n—R5]h}m (1) wherein R1 represents a hydrocarbon group, R2 and R4 represent alkylene groups having 2-4 carbon atoms, which may be identical or different, or a phenylethylene group, R3 represents a hydrocarbon group, which may have a urethane bond, R5 represents a branched chain or secondary hydrocarbon group, m is a number of at least 2, h is a number of at least 1, k is a number within the range of 1-500, and n is a number within the range of 1-200.

Owner:SHISEIDO CO LTD

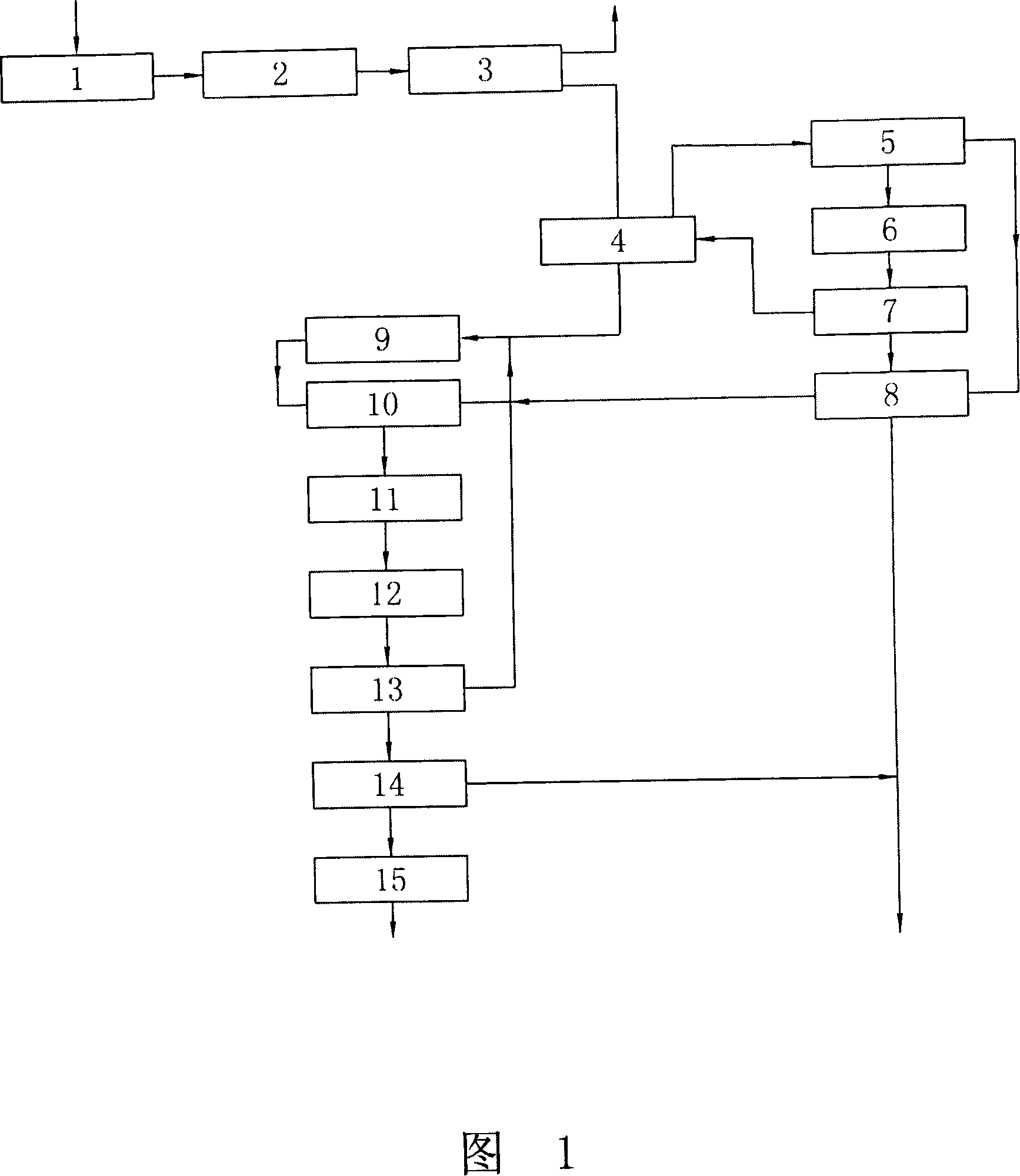

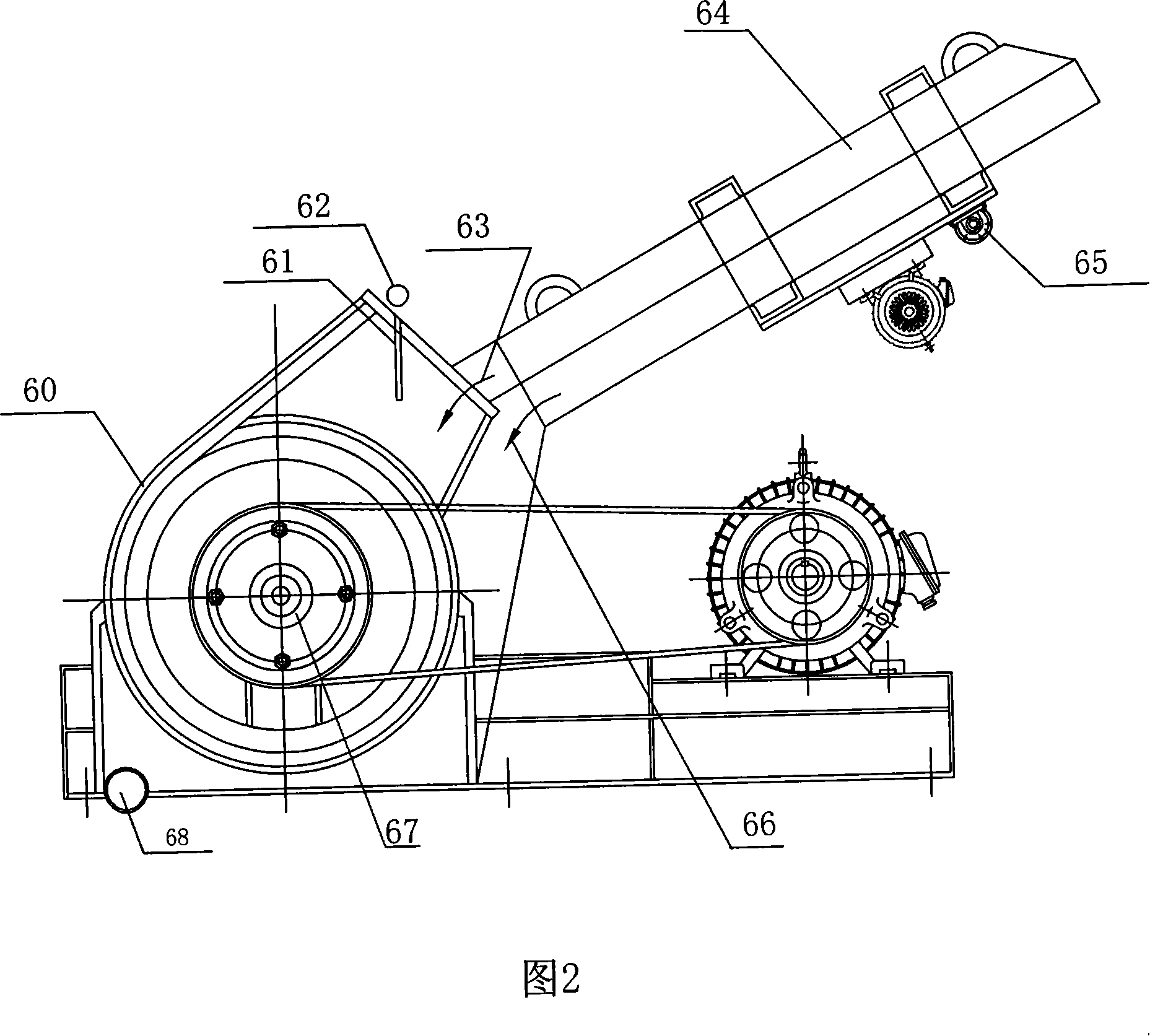

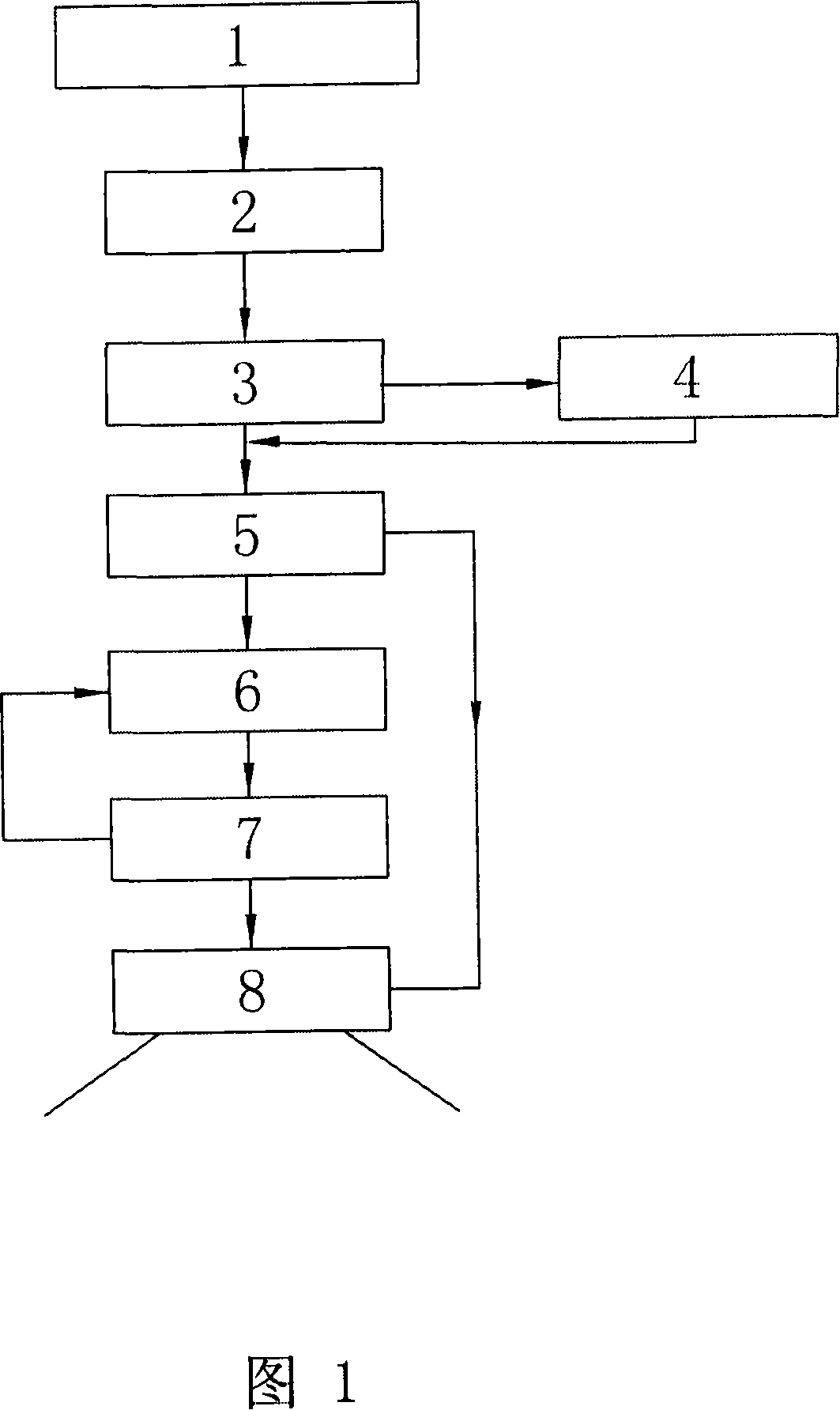

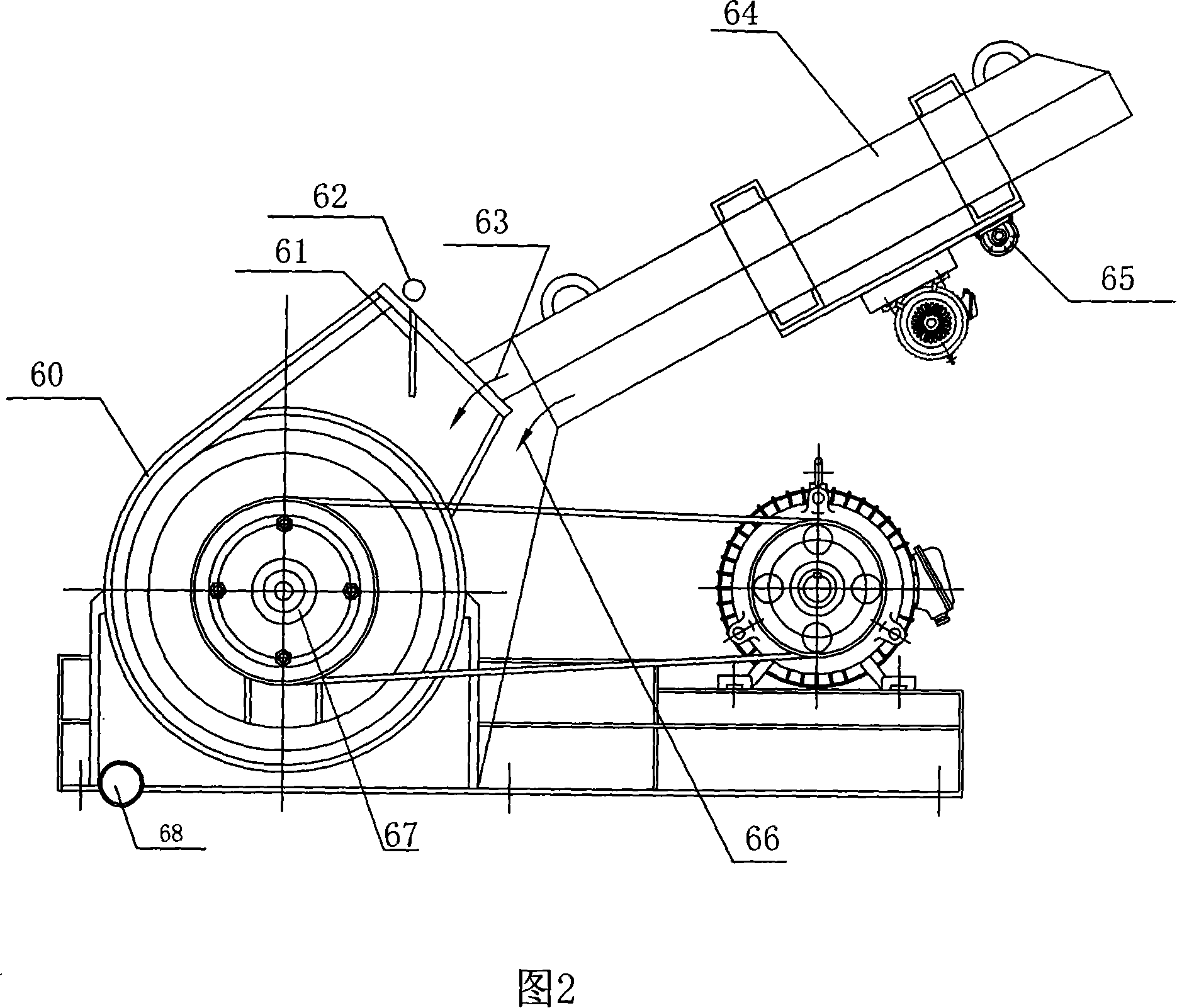

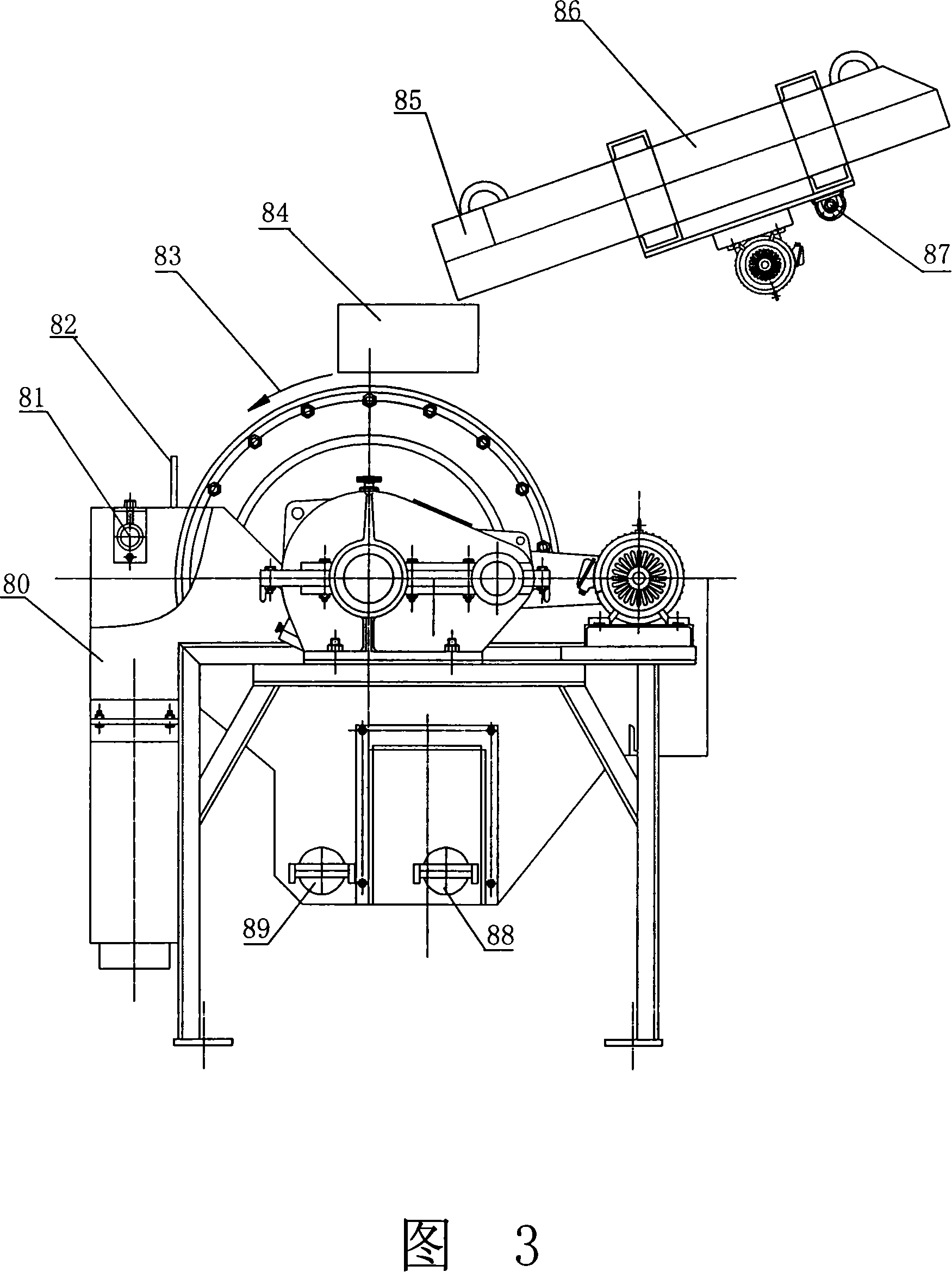

Roughing separation technique for low ore grade iron ore and mineral dressing equipment thereof

The invention discloses a low-grade iron ore dressing technique and equipment in the ore dressing technical domain, which comprises the following steps: doing rough breaking and once fine breaking; proceeding dry cleaning and sieving; milling; separating; doing magnetic cobbing and high-frequency sieving; filtering; sieving twice for ore material; obtaining the product. The ore dressing equipment comprises the following parts: rough breaking machine, fine breaking machine, dry cleaning bolter, storage bin, ball mill, separatory machine, magnetic cobber, high-frequency sieve, filter, a set of wet rougher unit between the storage bin and the separatory machine, wherein the wet rougher unit contains band conveyer, twice bolter, wet fine grinder, wet bolter and wet rougher, which has strong magnetic cobber of wet rought particle iron ore with watering device; the wet fine breaker is wet hammer breaker; the sieving feeding machine has shaker screen with eccentric oscillating device. The invention improves the production by 1-2 times under the same energy consumption condition in comparison with the present technique and equipment, which utilizes the low-grade iron ore resource sufficiently.

Owner:王林

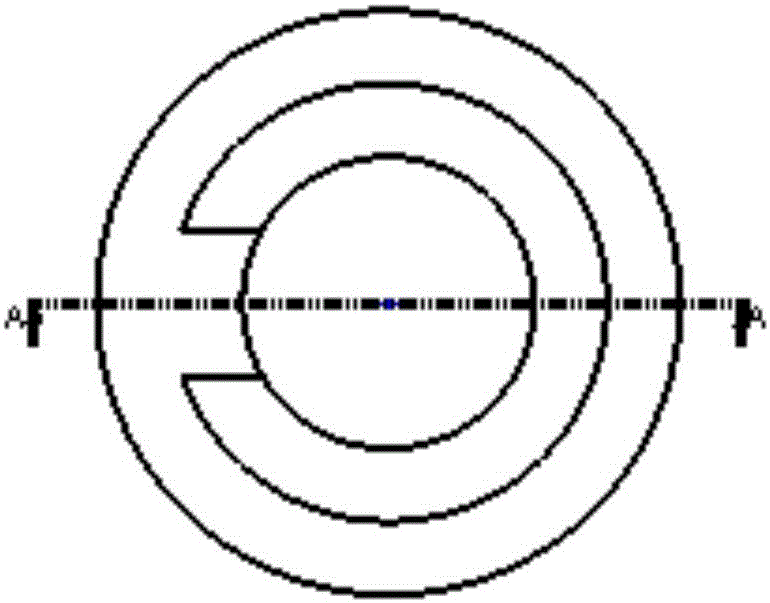

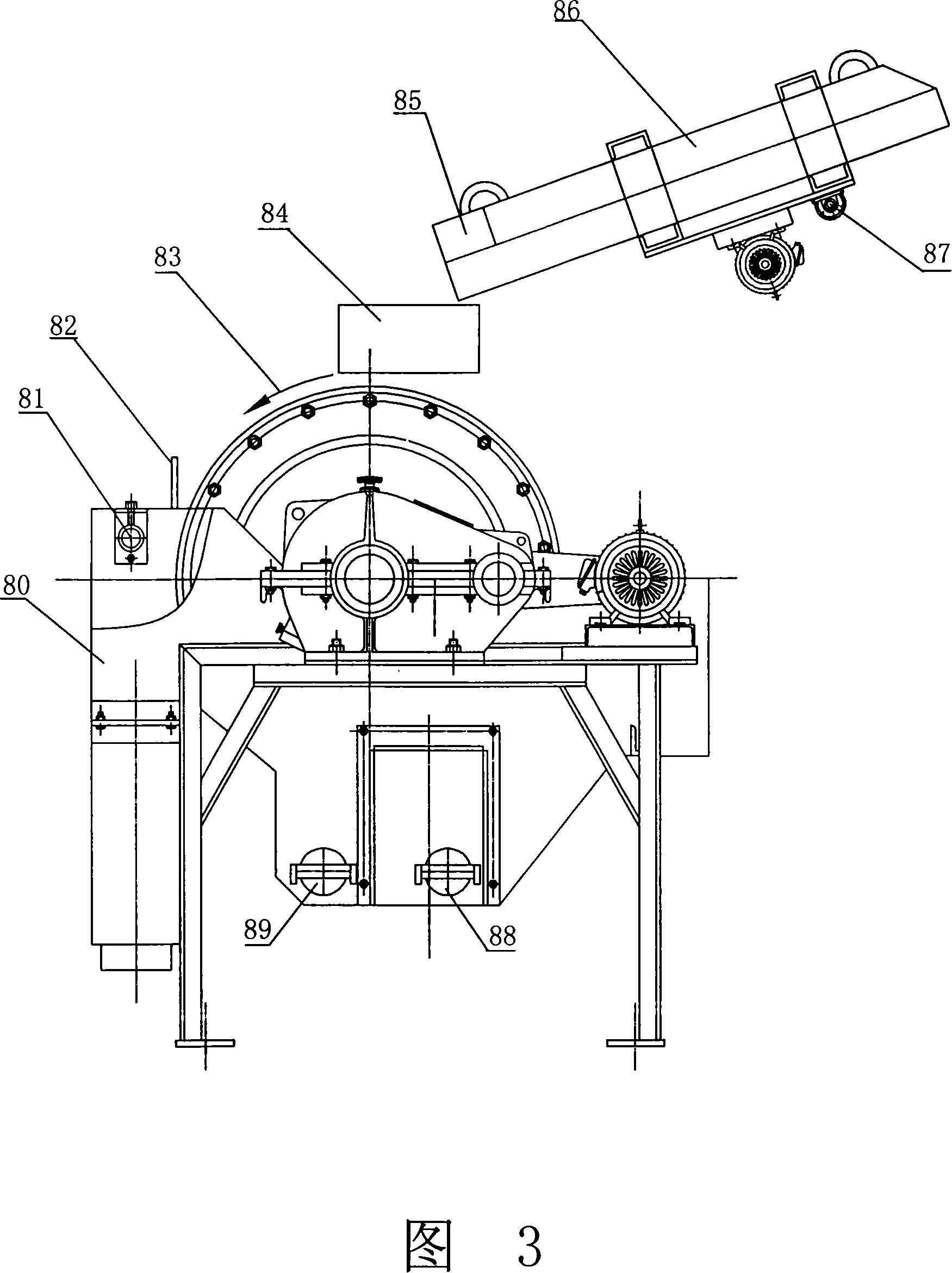

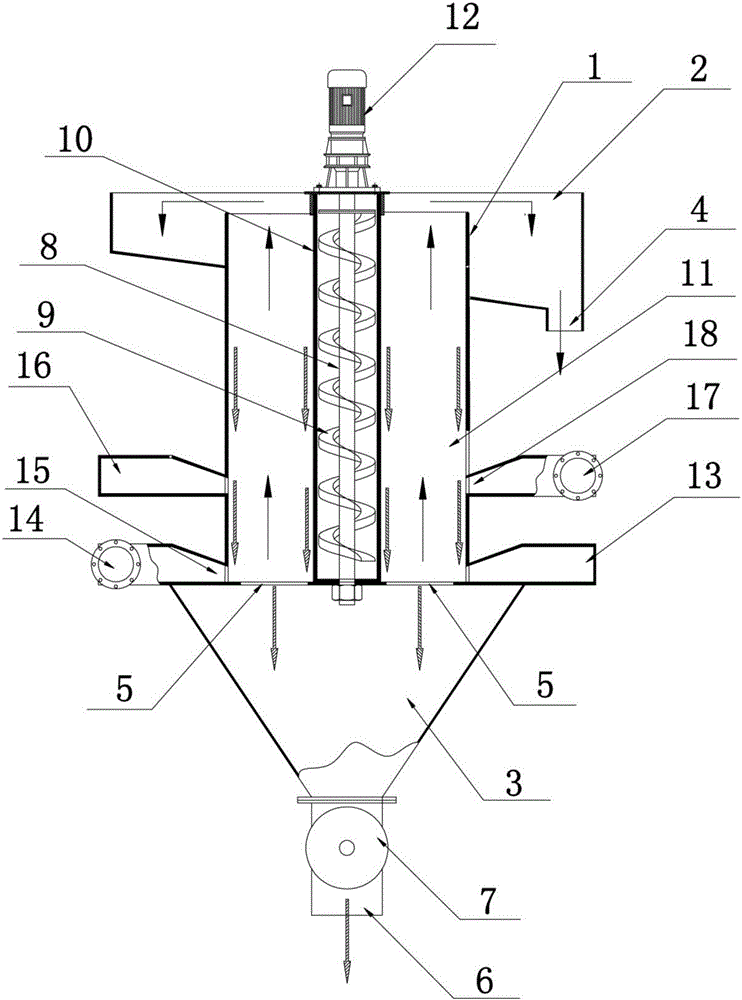

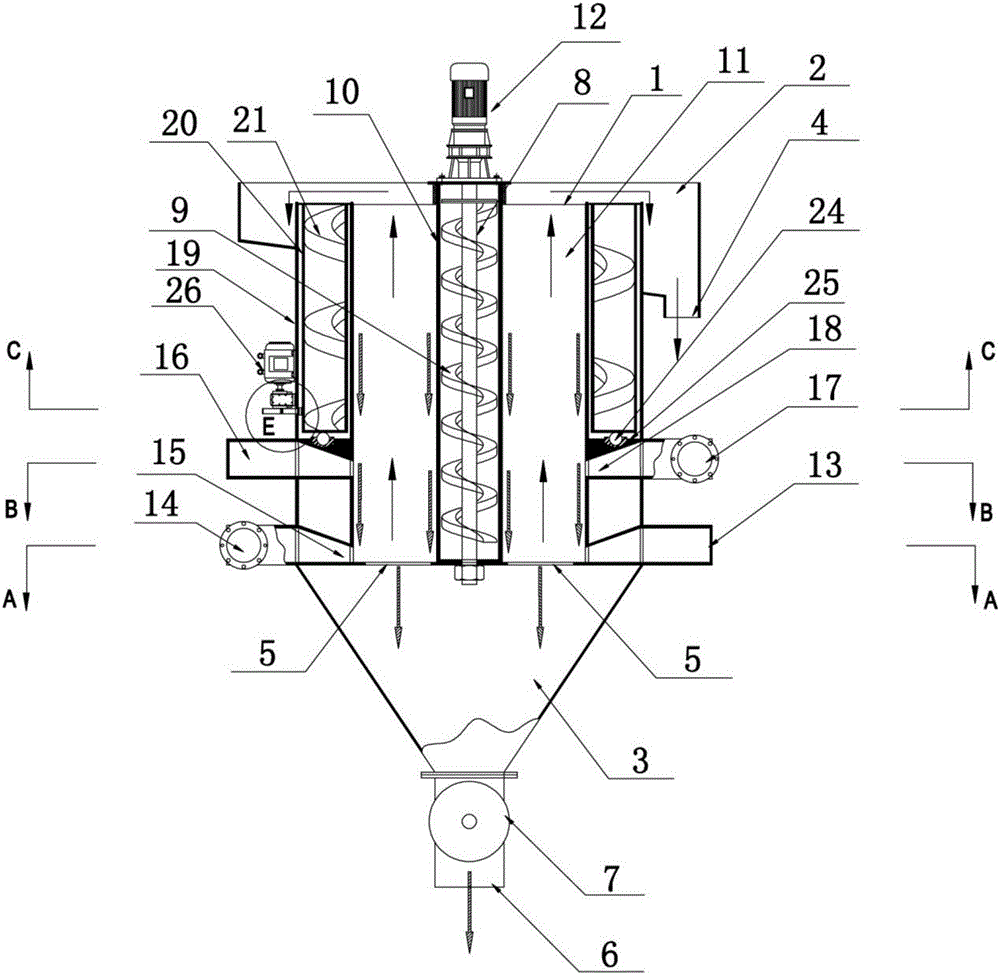

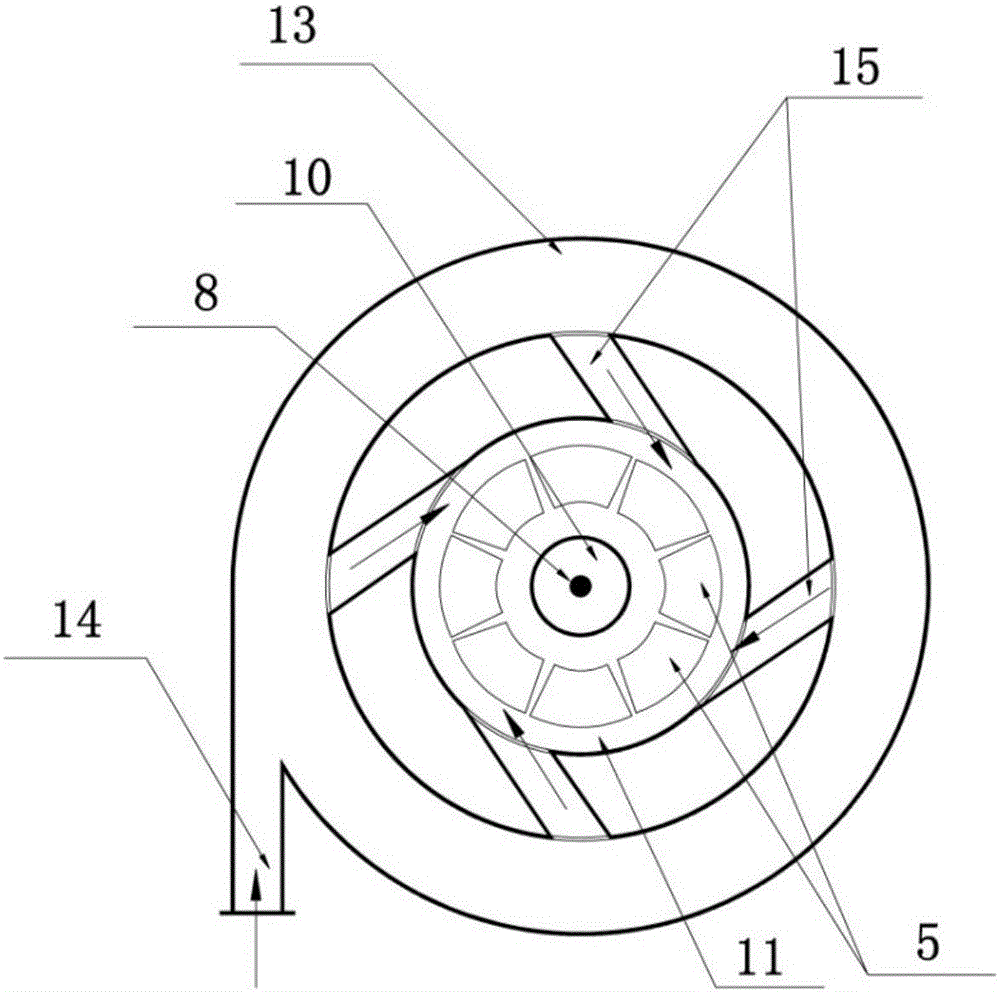

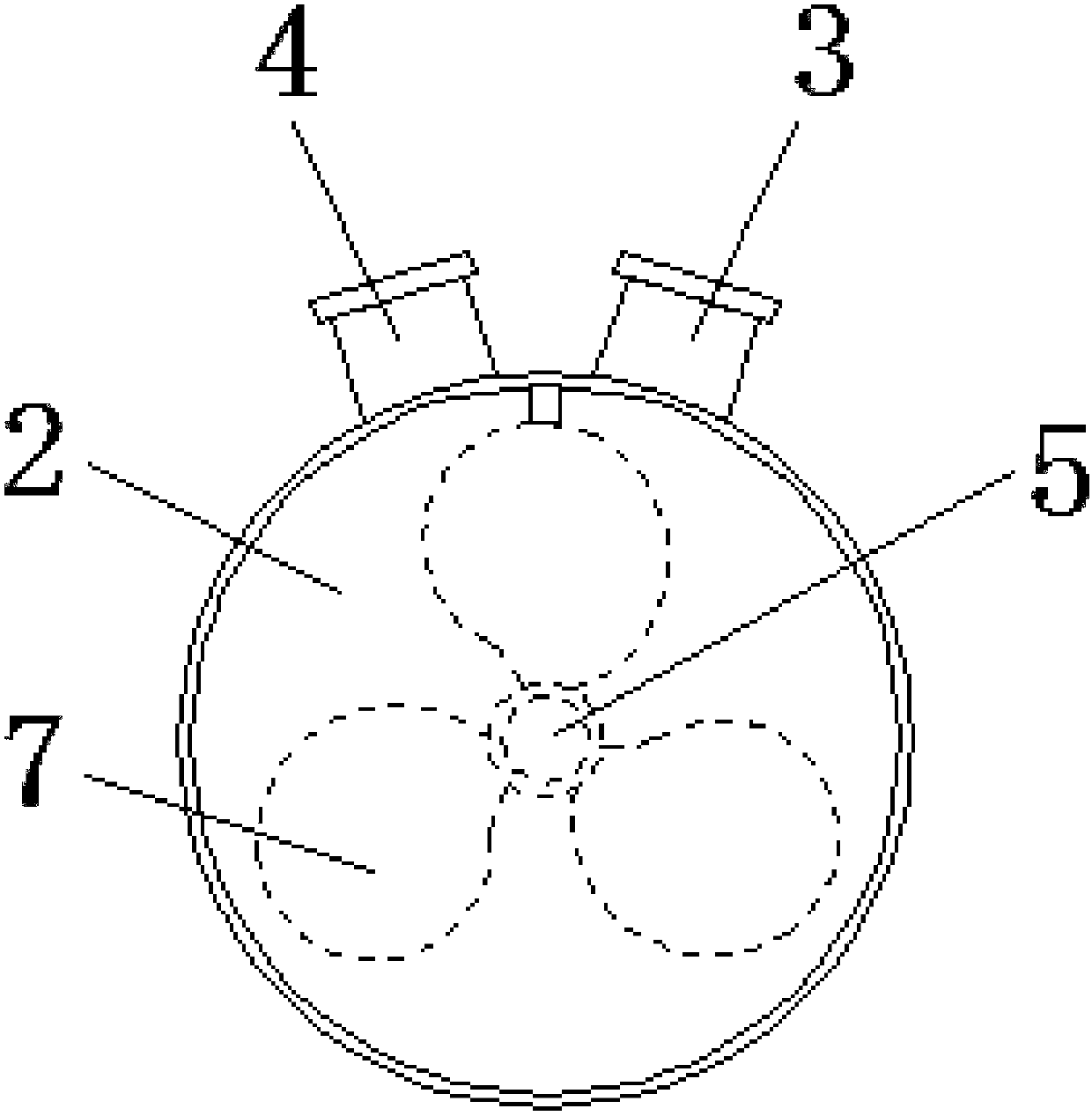

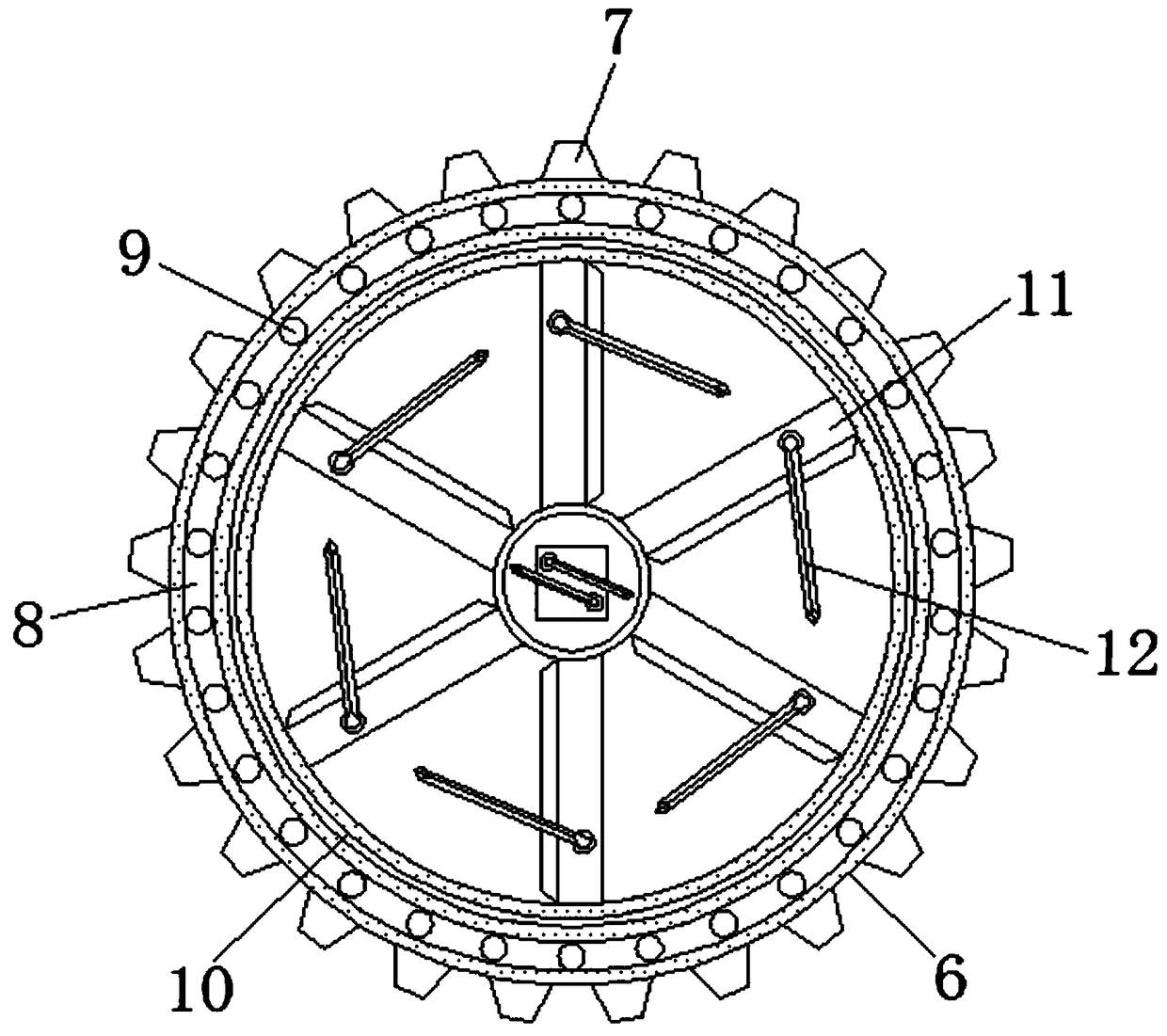

Permanent magnetic separation column suitable for strongly or weakly magnetic minerals

The invention belongs to the field of magnetic separation columns and particularly relates to a permanent magnetic separation column suitable for strongly or weakly magnetic minerals. Permanent magnetic systems are adopted, the magnetic field intensity can be adjusted within 1,600-16,000 Gs, and an inner permanent magnetic field mechanism and an outer permanent magnetic field mechanism which are in spiral distribution and movement are arranged simultaneously meet the requirement for production of big or small magnetic separation columns; fed water and minerals in a mineral separation chamber conduct inversely spiral upward movements to separate concentrate from tailing more radically, so that the concentrate grade is further improved; concentrate particles conduct obliquely downward slow movement under dual actions of the magnetic field and the dead weight, so that the tailing missing amount is reduced; and the permanent magnetic separation column is simple in structure, stable and reliable, low in water consumption, high in equipment output, and is simultaneously suitable for separation of such strongly-magnetic minerals as magnetite and such weakly-magnetic minerals as hematite, limonite and siderite.

Owner:唐竹胜

Self-cleaning LED package coating and preparation method thereof

InactiveCN109390457ASuperhydrophobic self-cleaning propertyHas superhydrophobic self-cleaning properties, has anti-humiditySemiconductor devicesUltravioletEngineering

The invention belongs to the field of coatings, and in particular relates to a self-cleaning LED package coating and a preparation method thereof. The self-cleaning LED package comprises a metal substrate cut into two sides to form an anode and a cathode. An LED chip which is located above the center of the metal substrate and a plastic package part used for packaging the metal substrate are arranged. The plastic package part and a lens part protruding above the center are integrally formed. The coating comprises a self-cleaning painting coated on the plastic package part and the surface of the lens part. The self-cleaning painting comprises, by weight, 0.1 to 0.2 part of nanoscale titanium dioxide particles, 0.5 to 2 parts of tridecafluorooctyl triethoxysilane, and 80 to 120 parts of absolute ethanol. The acquired LED package has the property of super-hydrophobic self-cleaning without ultraviolet irradiation, and has the properties of anti-wetting, anti-icing and anti-corrosion. The service life of an LED can be prolonged, and the difficulty of cleaning and maintenance is reduced.

Owner:TIANJIN UNIV

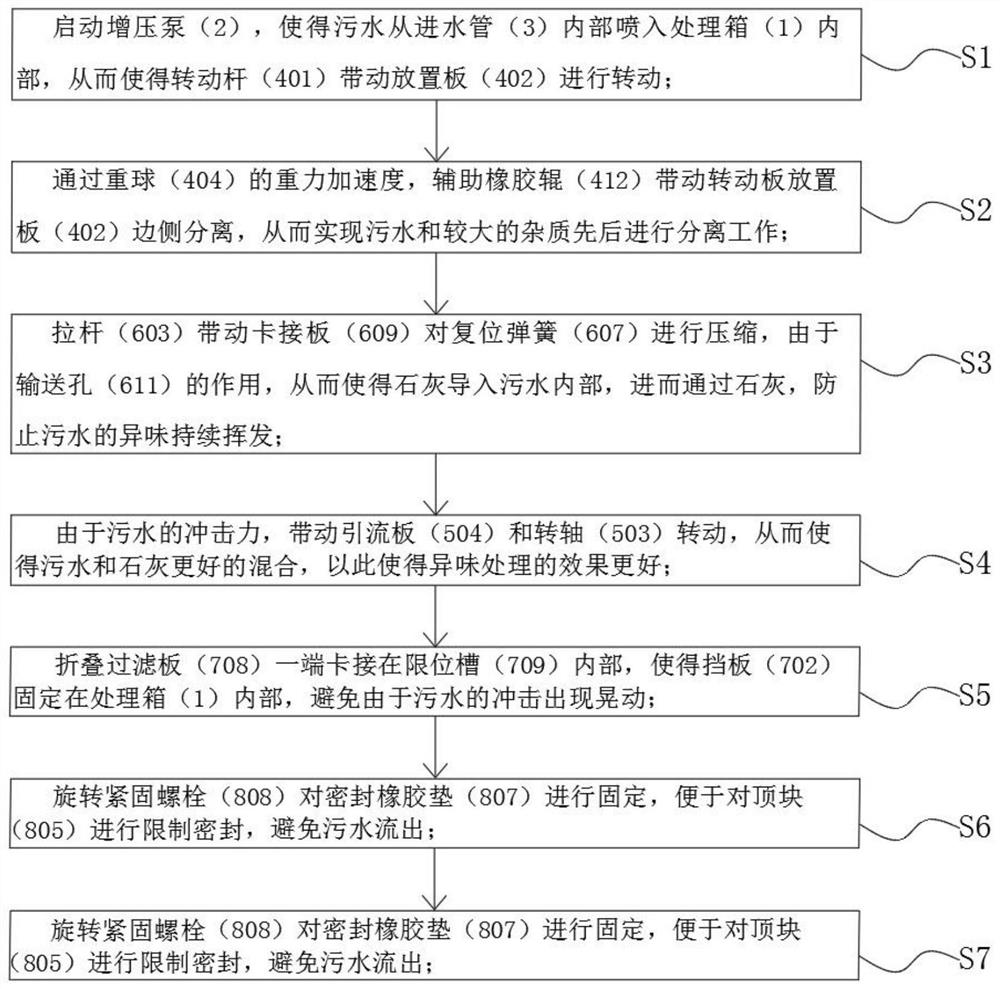

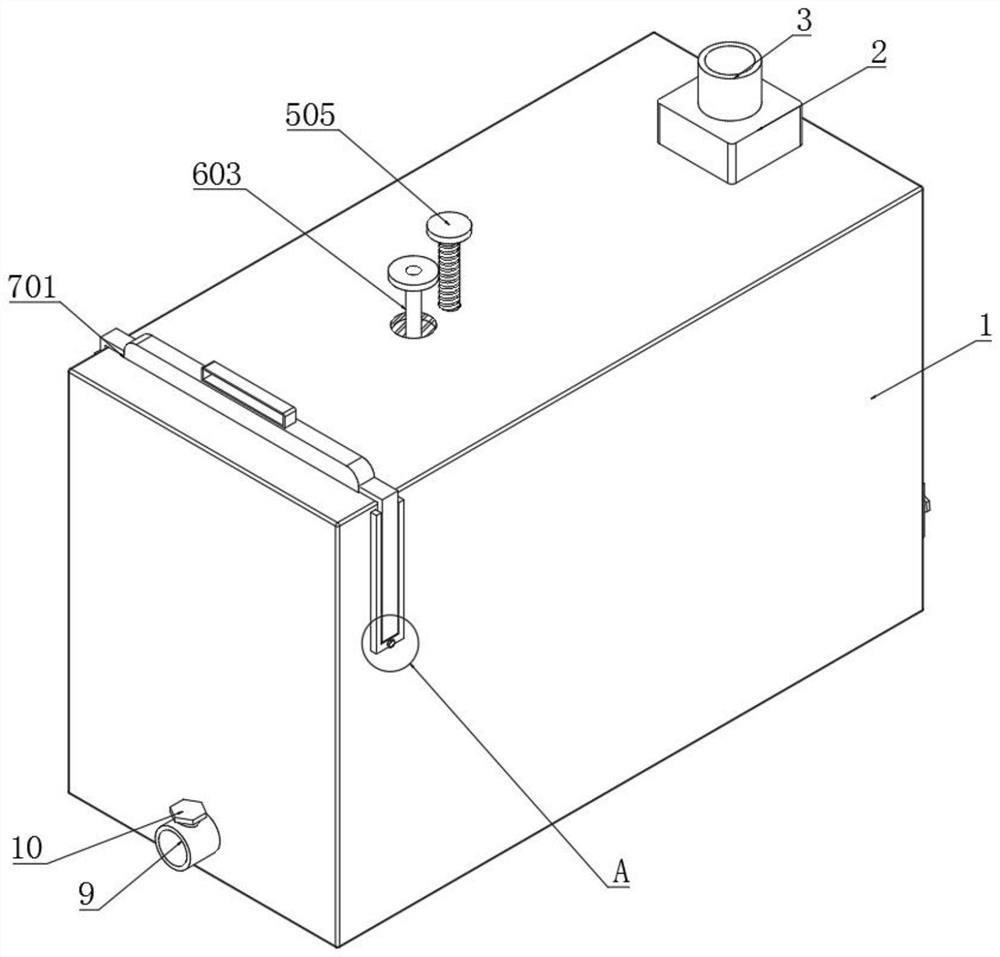

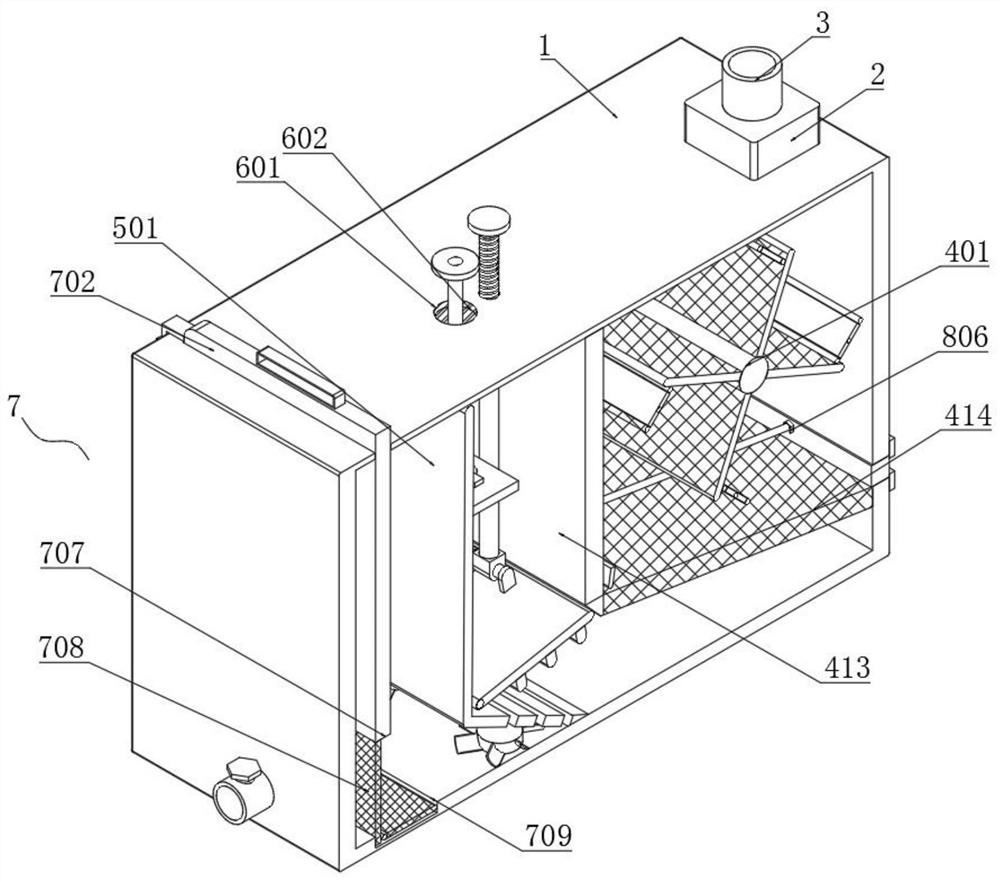

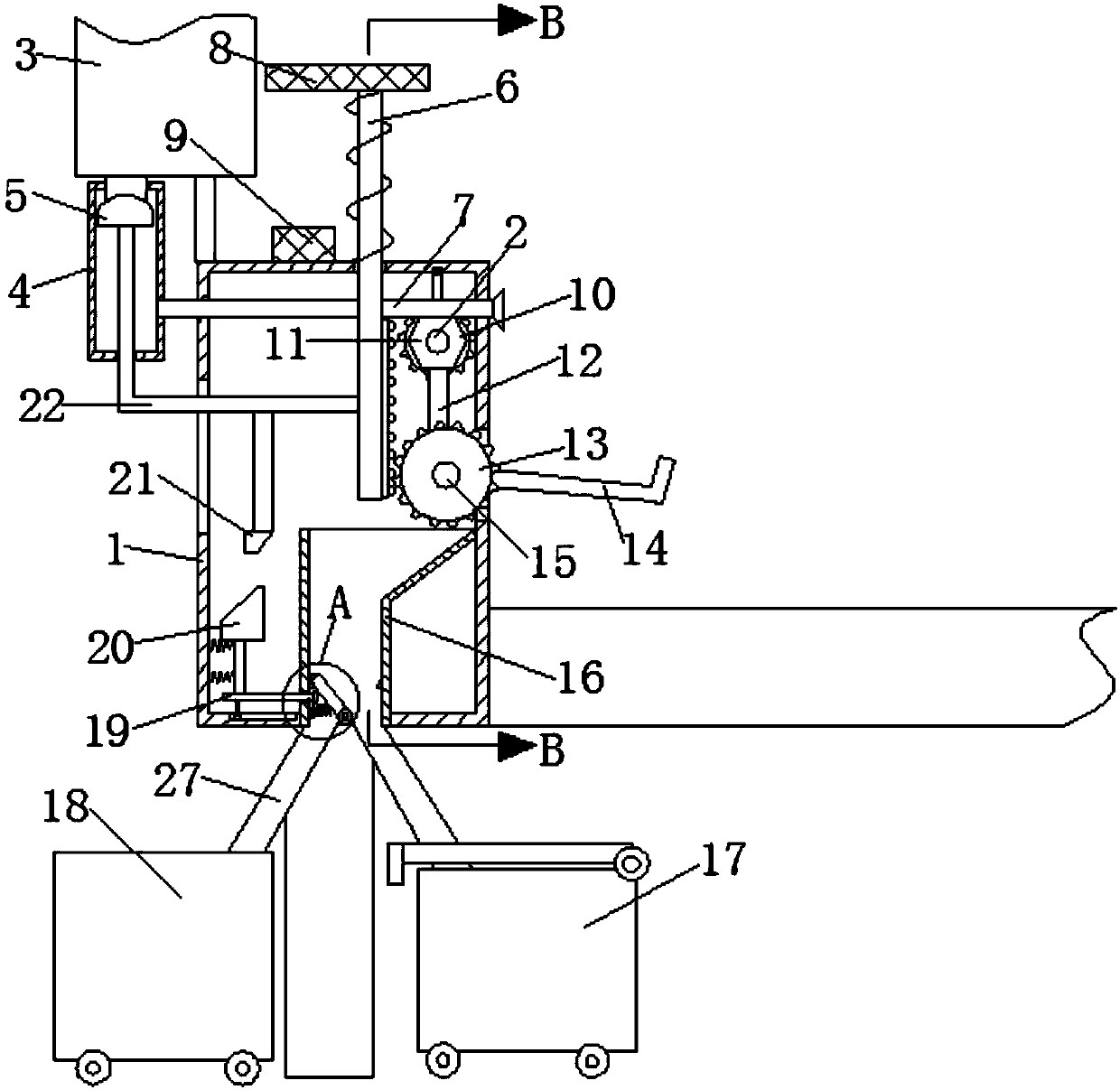

Adjustable multifunctional sewage treatment method

ActiveCN113045005AScientific and reasonable structureEasy to useSpecific water treatment objectivesTreatment involving filtrationStructural engineeringSewage

The invention discloses an adjustable multifunctional sewage treatment method, which is characterized in that a booster pump is installed at the side position of the top end of a treatment box, the input port of the booster pump is fixedly connected with a water inlet pipe, a self-separation mechanism is installed at the side position of the inner wall of the treatment box, the self-separation mechanism comprises a rotating rod, a placing plate, a supporting block, a heavy ball, a limiting plate, an ejector rod, a telescopic spring, a limiting block, a fixing block, a rotating plate, a mounting groove, an auxiliary rubber roller, a partition plate, a first grid and a second grid. According to the invention, by structurally arranging a self-separation mechanism, large impurities in sewage can be conveniently filtered under the action of a placing plate and a second grid; and when the placing plate is perpendicular to the bottom of a treatment box, an ejector rod impacts a rotating plate through the gravitational acceleration of a heavy ball, so that larger impurities can be conveniently guided into a first grid through an auxiliary rubber roller, and the sewage and the larger impurities can be separated in sequence.

Owner:JILIN JIANZHU UNIVERSITY

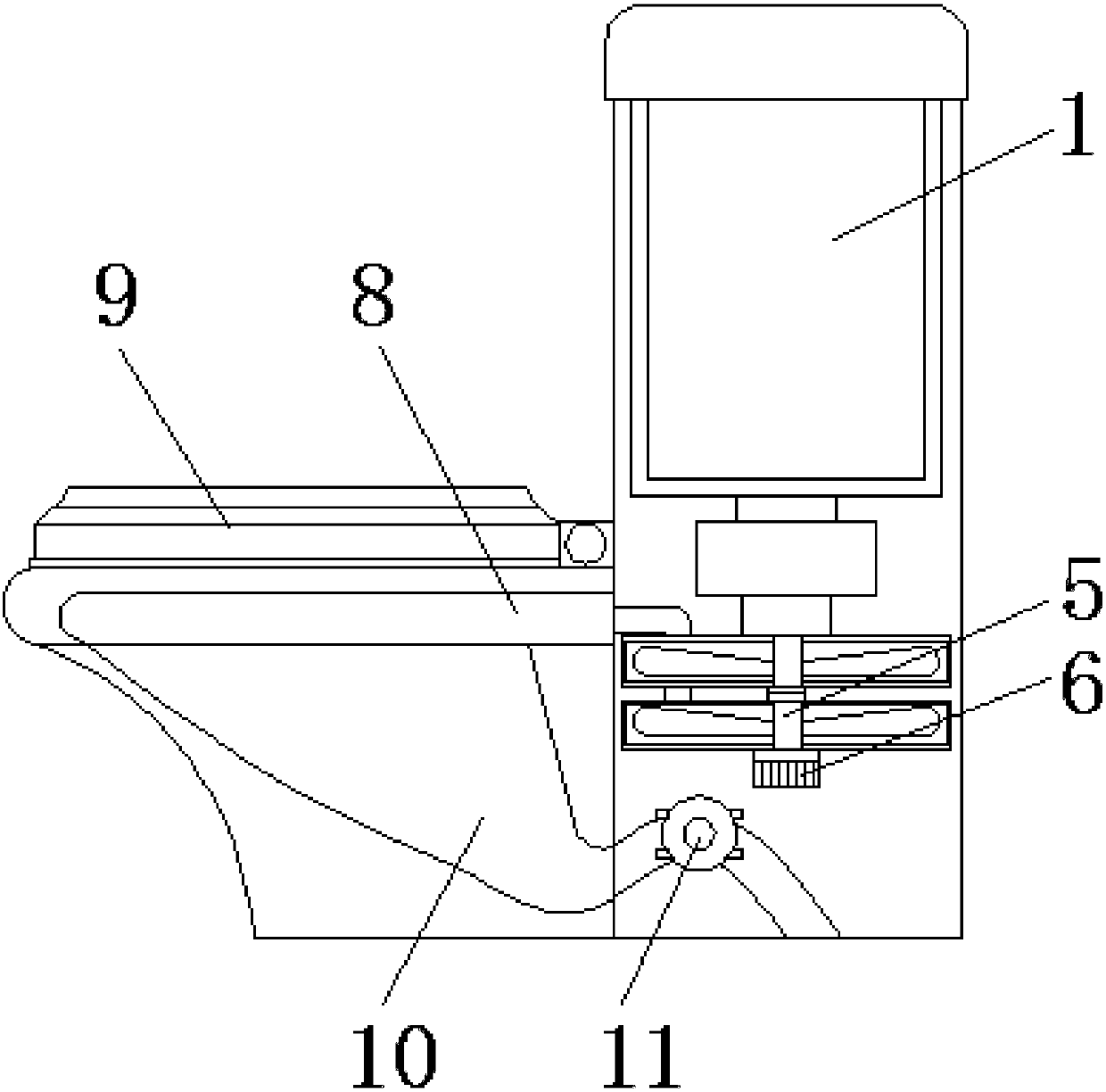

Special hospital bed for clinical digestive medicine use

InactiveCN110013401ASampling is convenientEasy to operateNursing bedsSpittle receiving devicesPistonVomiting

The invention discloses a special hospital bed for clinical digestive medicine use. According to the special hospital bed for clinical digestive medicine use, a water tank is fixedly connected with atop wall of a bed-head box; a liquid inlet is formed at the top of the water tank; a liquid outlet of the water tank is fixedly sleeved with a piston tube; a side wall of the piston tube communicateswith one end of a liquid-spraying pipe; the other end of the liquid-spraying pipe sequentially penetrates through two side walls of the bed-head box in a fixed way; and position adjustment of a bearing plate is realized by combination of a screw, the bearing plate and a liquid receiver tank, thereby facilitating sudden vomiting of a patient as well as achieving timely cleaning. Moreover, the wholehospital bed is simple to operate, so that, the hospital bed can be operated by a caregiver or by a patient himself / herself; and thus, sanitary ward environment is ensured.

Owner:许文君 +1

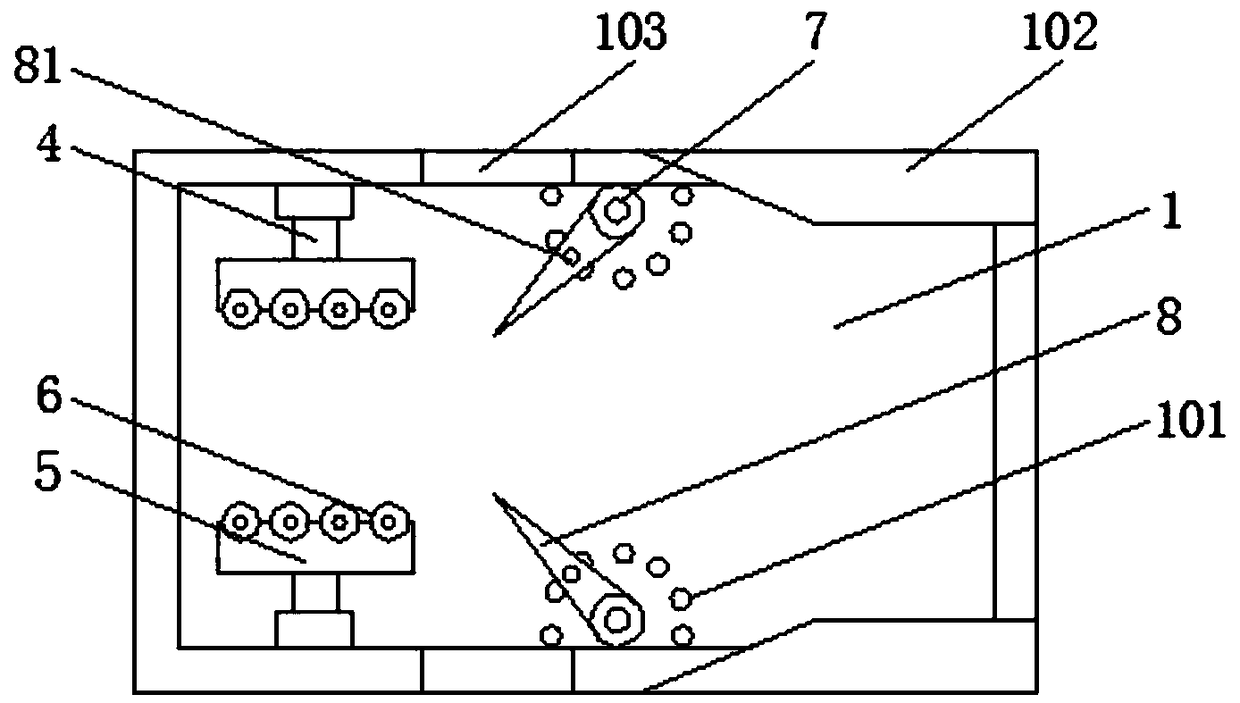

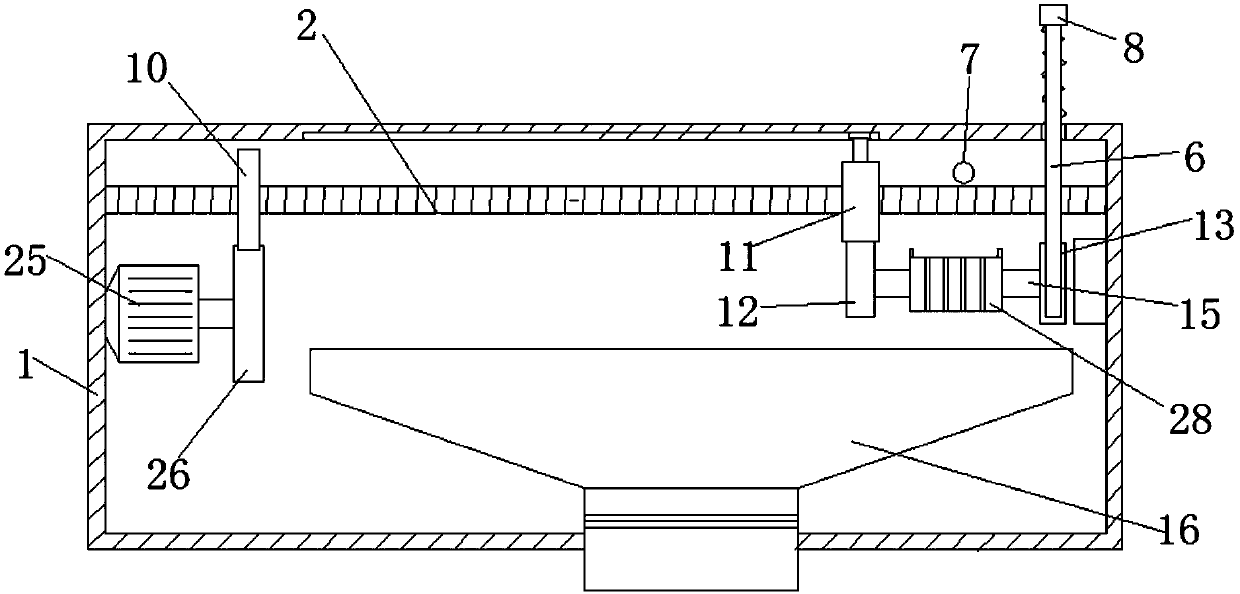

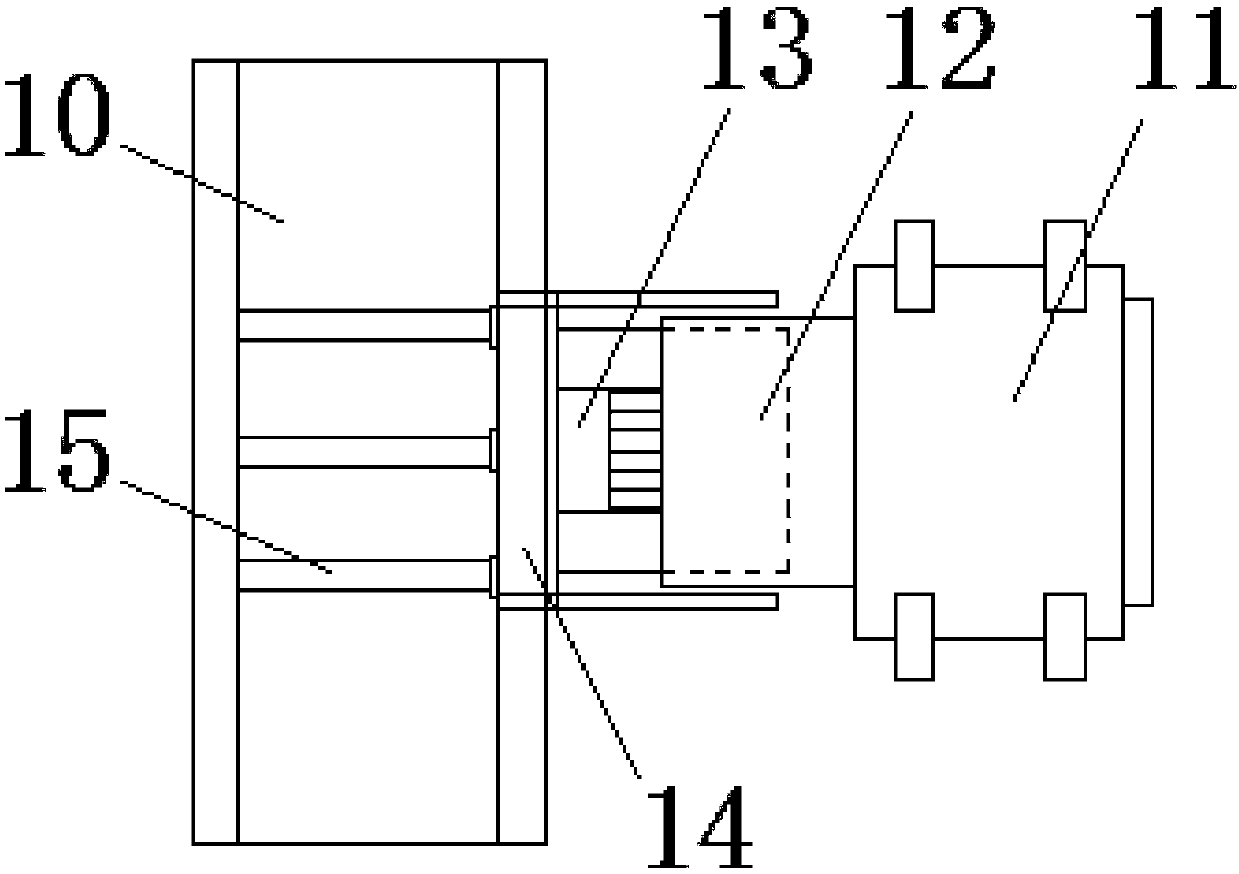

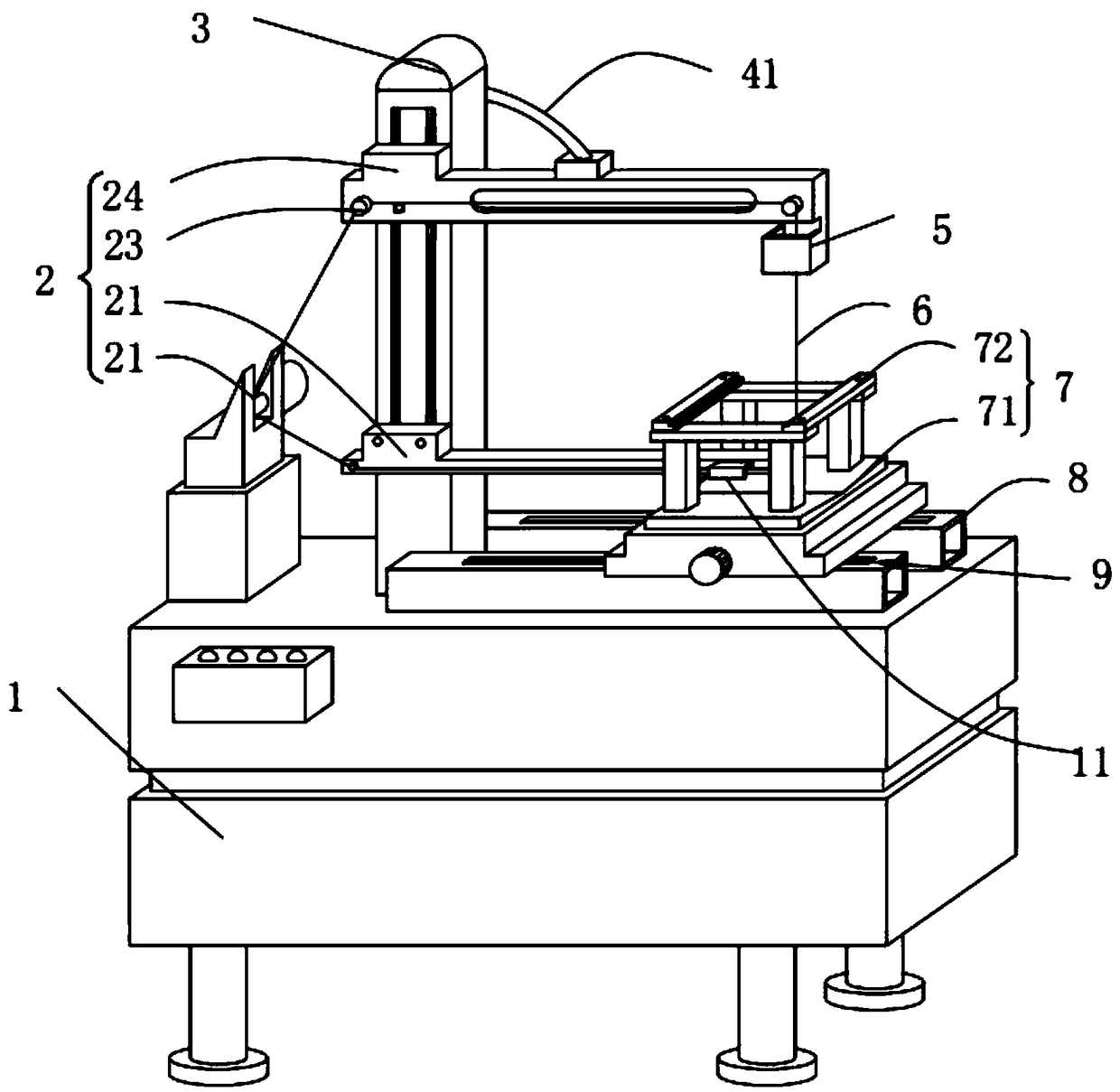

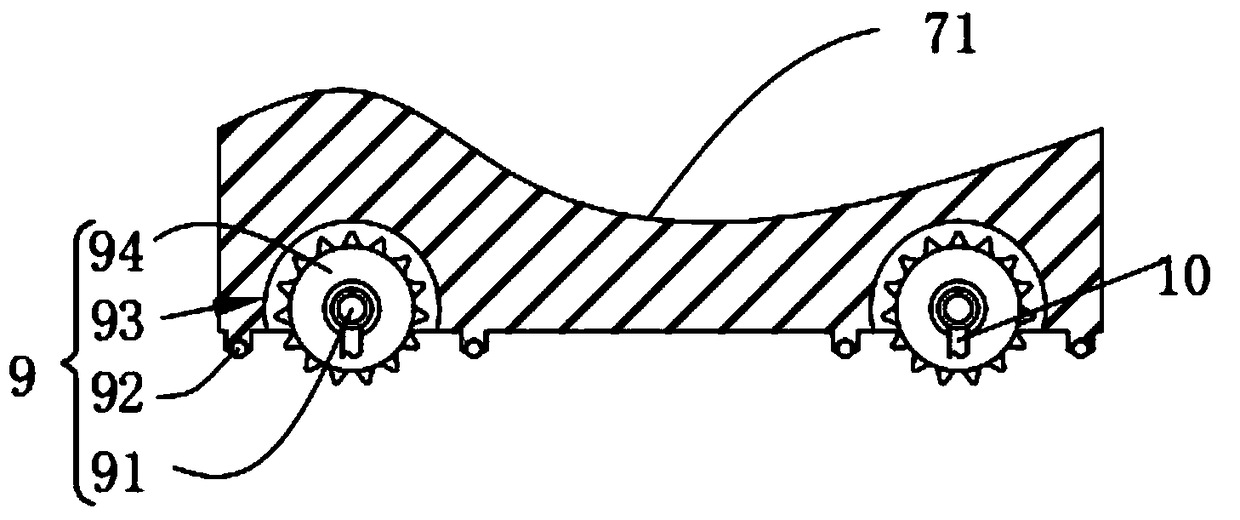

A wire electric discharge cutting device

ActiveCN108817584BReduce attachmentEasy to cleanElectrical-based auxillary apparatusWater flowEngineering

The invention relates to the technical field of machine tools, in particular to a wire-cut electrical discharge machining device. The device comprises a machine body, a wire passing mechanism, a supporting column, a water feeding mechanism, a fixing mechanism, a metal wire, a mounting mechanism, supporting plates, an adjusting mechanism, a limiting mechanism and a cleaning mechanism, the metal wire rotates on the side wall of the wire passing mechanism, and the water feeding mechanism is installed at the bottom end of the wire passing mechanism. According to the device, when the metal is cut,the liquid in the water feeding mechanism converges into huge water flow and flows to the metal surface along with the metal wire, the melted metal is quickly washed away, attachments on the metal wire are reduced, the cleaning mechanism is installed at the bottom end of the wire passing mechanism, the metal wire moves up and down in a zigzag mode inside the cleaning mechanism, so that the surfaceof the metal wire is fully contacted with the interior of the cleaning mechanism to clean up metal attachments on the surface of the metal wire; the water feeding mechanism and the cleaning mechanismare located on the top end of the mounting mechanism, the liquid and the metal fragments directly fall on the v-shaped top surface of the mounting mechanism, so that the metal fragments can be conveniently washed away by the liquid.

Owner:ANHUI MINGGUANG RUISHENG MACHINERY

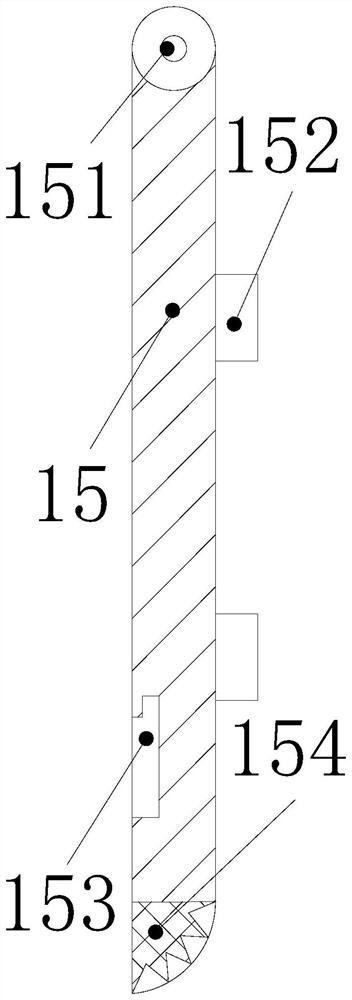

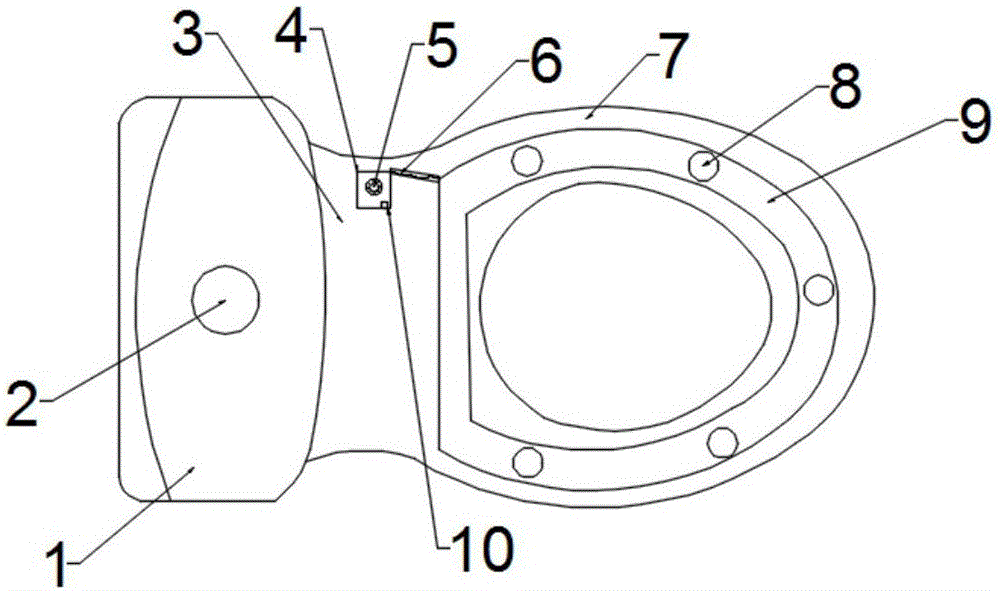

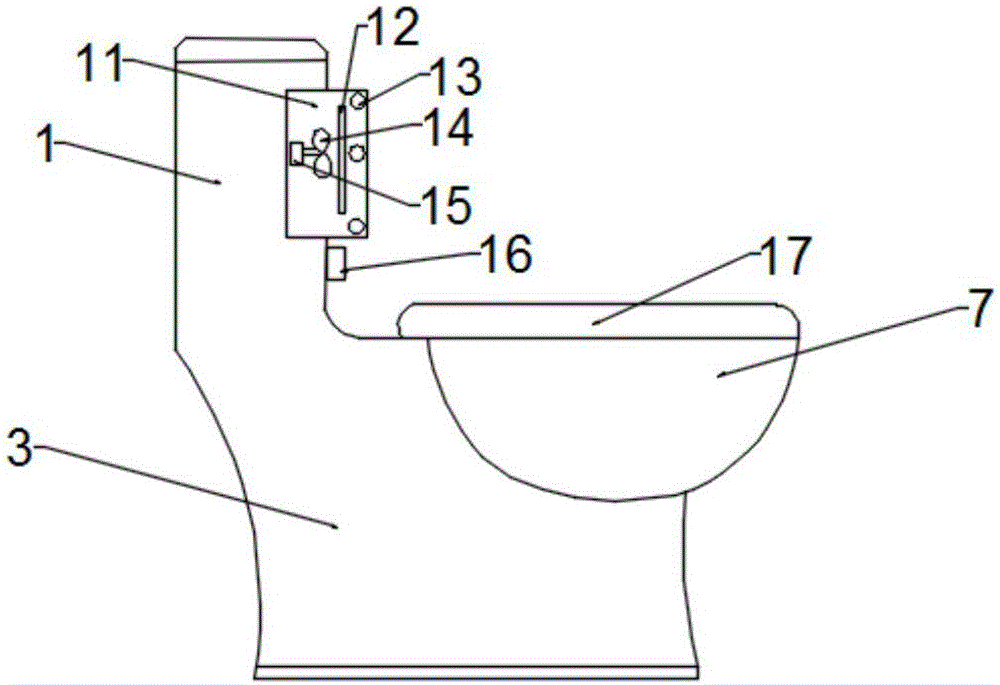

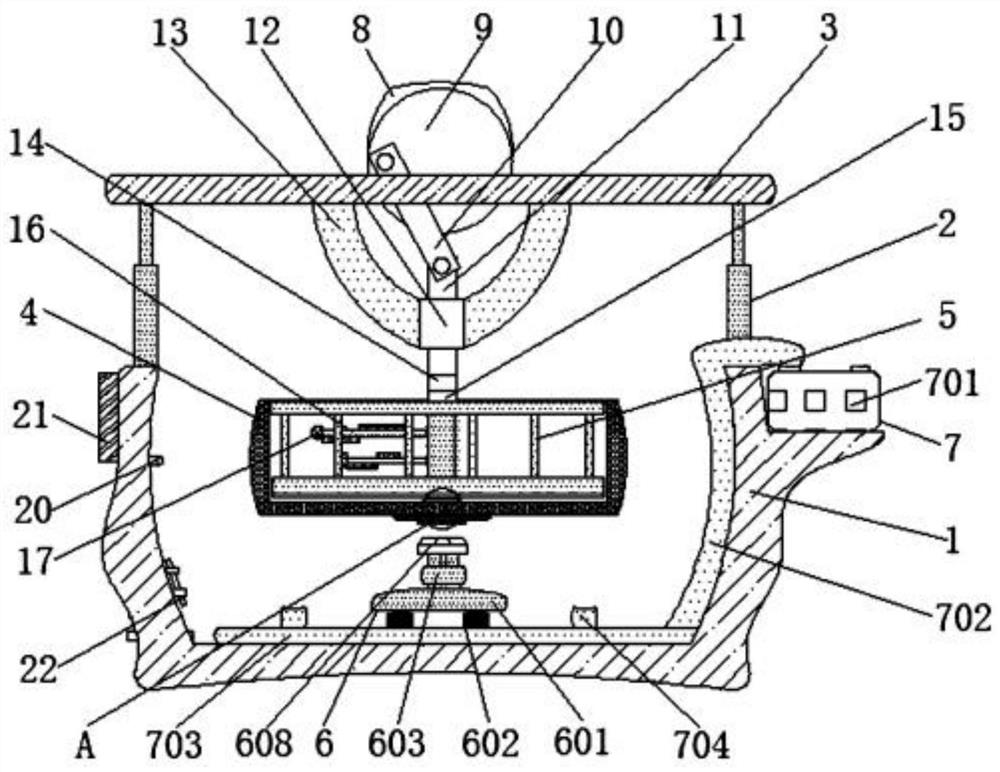

Rarely-blocked water-saving toilet bowl

InactiveCN107604993AEasy to wash awayReduce utilizationLavatory sanitoryHydraulic cylinderWater saving

A rarely-blocked water-saving toilet bowl mainly comprises a water tank, a spindle, an outflow disc, a seal cover, a second motor and stirring rods; an acceleration box is connected to the bottom of the water tank, the top of the acceleration box is provided with a water inlet and a water outlet, one side of the water inlet is provided with the water outlet, the spindle is connected with a first motor, rotating blades are fixed around the spindle, the outflow disc is connected with the acceleration box below, a pipeline is arranged below the seal cover, a hydraulic cylinder is arranged on oneside of the pipeline, a telescopic bar is connected to the left of the hydraulic cylinder, a rotating disc is arranged on the left of the telescopic bar, and the second motor is arranged in the telescopic bar. With the stirring rods and the rotating disc, the rarely-blocked water-saving toilet bowl allows blockage to be stirred apart to facilitate flushing of the blockage, and the stirring rods can be retracted when idle to avoid the fact that the stirring rods placed in the pipeline are not convenient to use in daily life.

Owner:李耀强

Wire-cut electrical discharge machining device

ActiveCN108817584AReduce attachmentEasy to cleanElectrical-based auxillary apparatusWater flowEngineering

The invention relates to the technical field of machine tools, in particular to a wire-cut electrical discharge machining device. The device comprises a machine body, a wire passing mechanism, a supporting column, a water feeding mechanism, a fixing mechanism, a metal wire, a mounting mechanism, supporting plates, an adjusting mechanism, a limiting mechanism and a cleaning mechanism, the metal wire rotates on the side wall of the wire passing mechanism, and the water feeding mechanism is installed at the bottom end of the wire passing mechanism. According to the device, when the metal is cut,the liquid in the water feeding mechanism converges into huge water flow and flows to the metal surface along with the metal wire, the melted metal is quickly washed away, attachments on the metal wire are reduced, the cleaning mechanism is installed at the bottom end of the wire passing mechanism, the metal wire moves up and down in a zigzag mode inside the cleaning mechanism, so that the surfaceof the metal wire is fully contacted with the interior of the cleaning mechanism to clean up metal attachments on the surface of the metal wire; the water feeding mechanism and the cleaning mechanismare located on the top end of the mounting mechanism, the liquid and the metal fragments directly fall on the v-shaped top surface of the mounting mechanism, so that the metal fragments can be conveniently washed away by the liquid.

Owner:ANHUI MINGGUANG RUISHENG MACHINERY

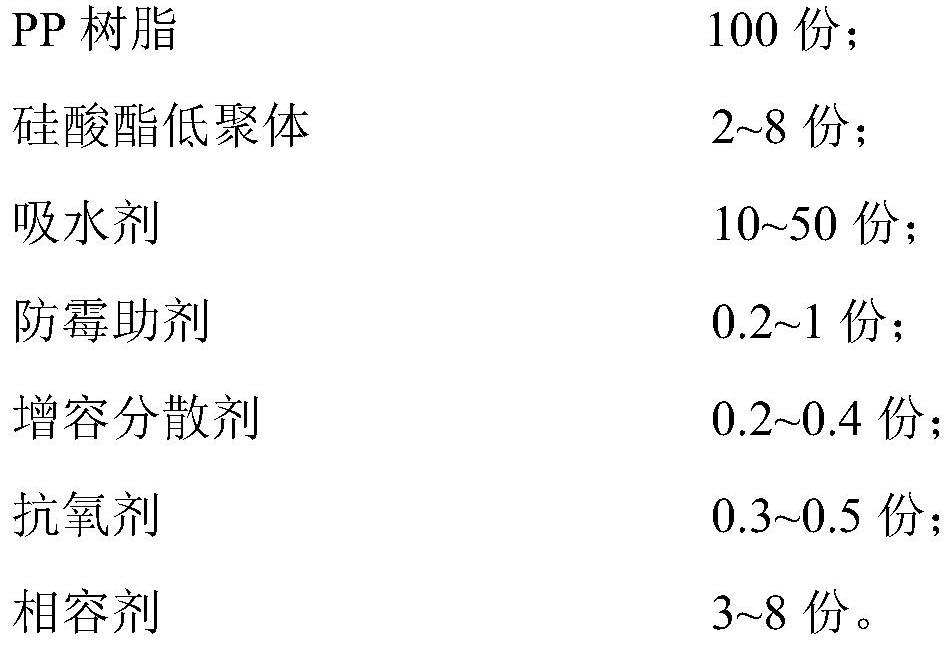

Easy-to-clean mildew-proof PP composite material and preparation method thereof

The invention relates to an easy-to-clean mildew-proof PP composite material and a preparation method thereof. The method includes: adding PP resin, silicate oligomer, a water absorbent, a compatilizer, a mildew-proof aid, a compatibilizing dispersant and an antioxidant into a high-speed mixer, mixing for 6-10min at the speed of 240-500r / min to form a premix, and putting the mixed premix into a main feed port of a double-screw extruder for granulation, and preparing the easy-to-clean mildew-proof PP composite material. The water contact angle of the prepared easy-to-clean mildew-proof PP composite material is 65-80 degrees, and the mildew-proof grade is 0 grade. According to the invention, the silicate ester oligomer is easy to decompose to generate a silanol group after encountering water, and the silanol group migrates to the surface of the polypropylene composite material to greatly improve the hydrophilicity of the surface of the material, so that dust on the surface of the material is easier to wash away under the action of water, and an easy-to-clean effect is achieved.

Owner:上海日之升科技有限公司

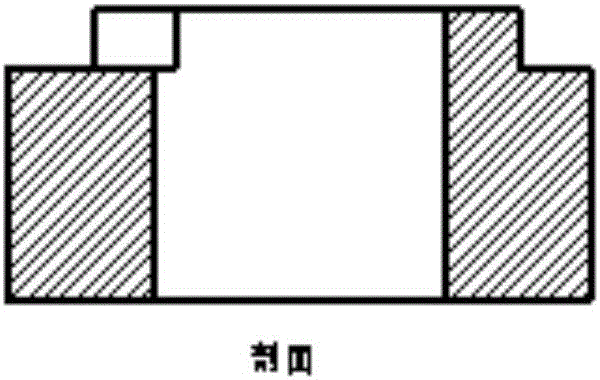

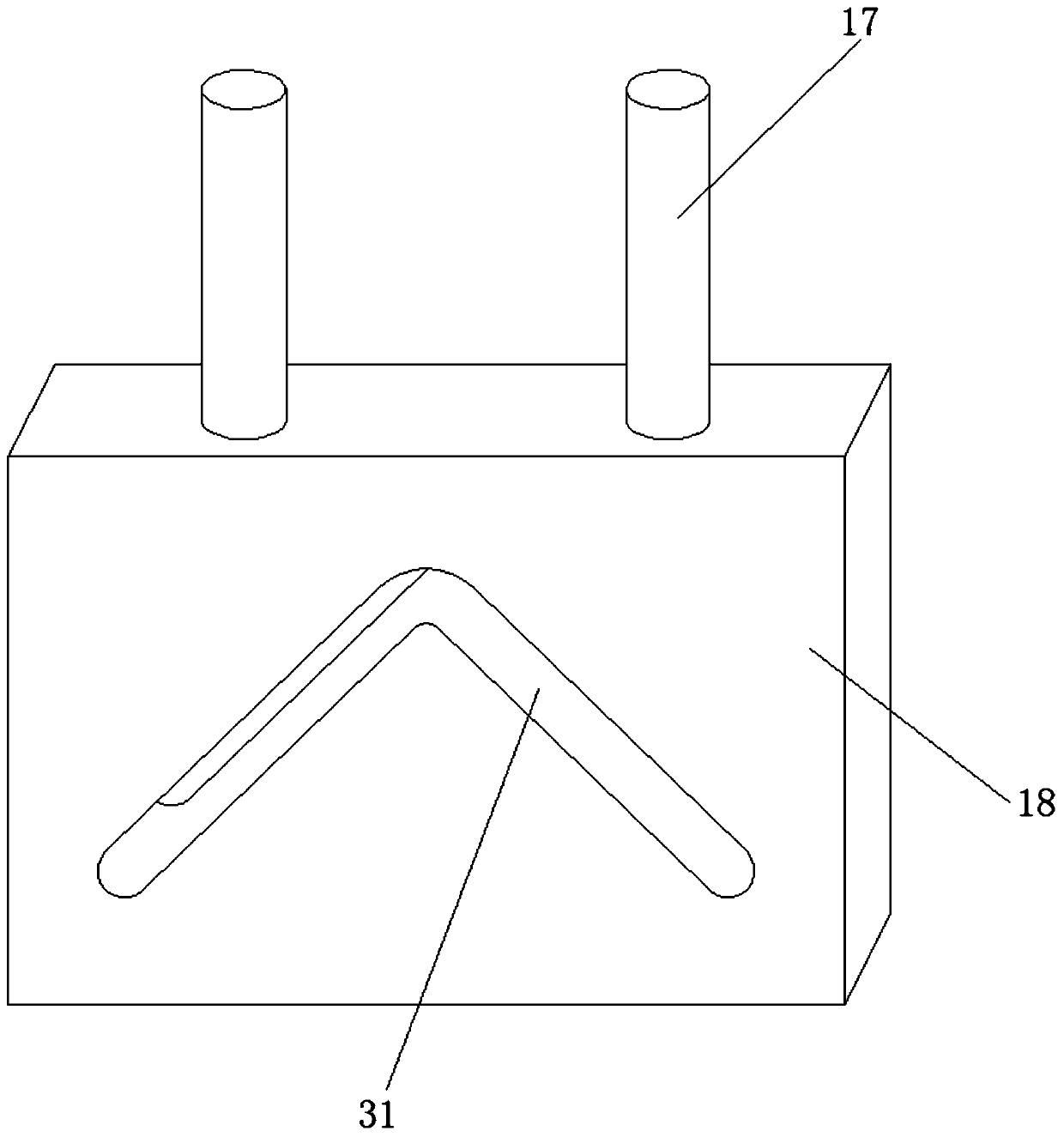

Duct piece fixing pile device for fixing shield tunnel duct piece and using method

ActiveCN111577324AControl floatFloating is effectiveUnderground chambersTunnel liningArchitectural engineeringSlurry

The invention discloses a duct piece fixing pile device for fixing a shield tunnel duct piece. The duct piece fixing pile device comprises a grouting outer sleeve and a grouting inner sleeve; a connecting part and a step part are arranged at the front end of the grouting outer sleeve, the connecting part is fixedly connected with the step part, a sealing cover is arranged at the rear end of the grouting outer sleeve; a supporting part is arranged at the front end of the grouting inner sleeve, the supporting part is located on the step part, the step part is fixedly connected with the supporting part, a grouting bag is connected to the rear end of the grouting inner sleeve; threads are arranged on the outer parts of the ends, close to the connecting part, of the connecting part and the grouting outer sleeve correspondingly; and the invention further discloses a construction method of the pipe piece fixing pile device, and the construction method comprises the steps of grouting hole opening, grouting liquid stirring, grouting and the like. According to the duct piece fixing pile device for fixing the shield tunnel duct piece, fixing the tunnel duct piece in time can be carried out during shield construction, so that the construction efficiency is effectively improved, and the construction quality is improved.

Owner:湖南中天凿岩科技有限公司

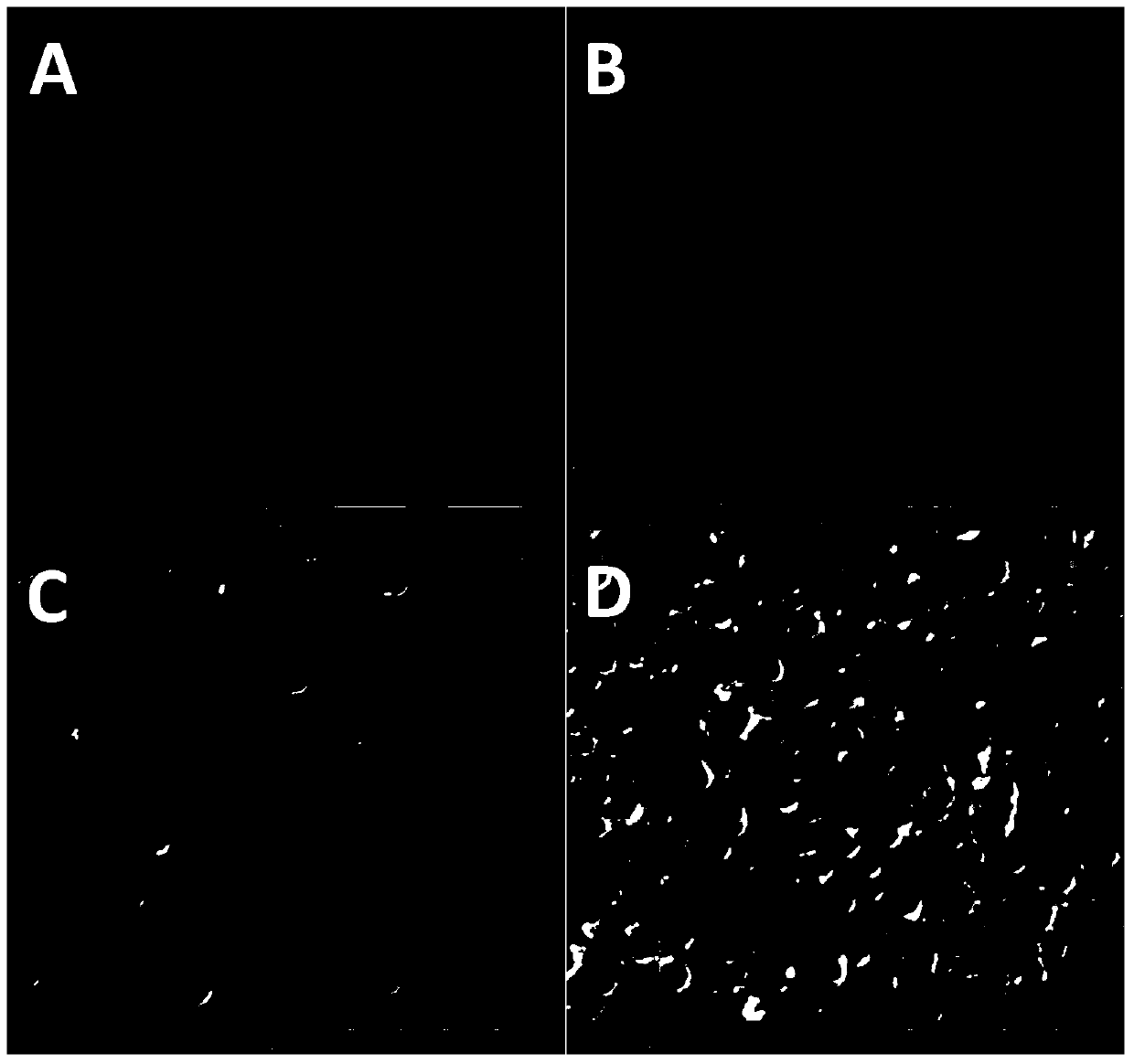

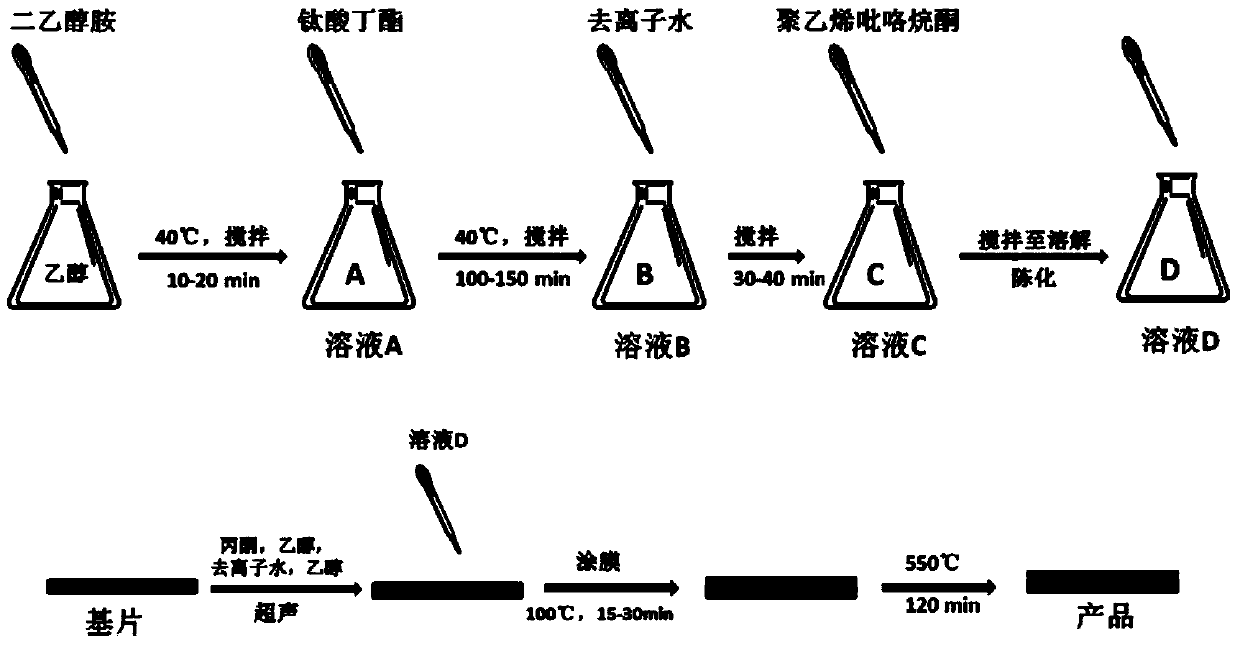

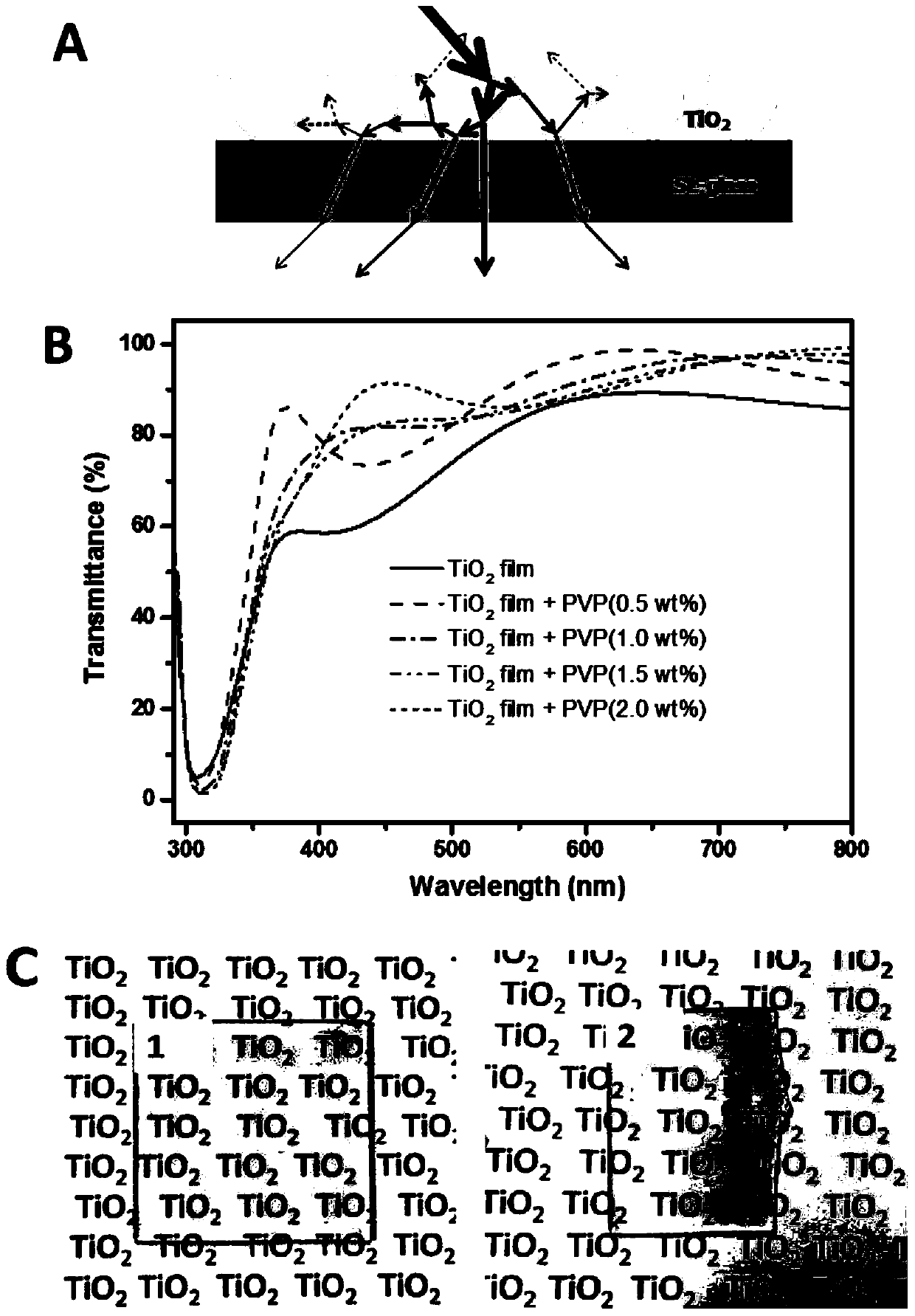

Preparation method of titanium oxide film and titanium oxide film

The invention provides a preparation method of a titanium oxide film and a titanium oxide film. The preparation method comprises the following steps: 1) preparation of titanium oxide precursor; and 2) film coating and after-treatment. The preparation method is simple in preparation technique and can implement large-scale production.

Owner:卜艳茹

Convenient-to-clean antifouling air-conditioning filter screen and preparation method thereof

InactiveCN109925793AReduce adhesionEasy to wash awayFiltration separationMonocomponent polyolefin artificial filamentAntioxidantAir conditioning

The invention provides a convenient-to-clean antifouling air-conditioning filter screen and a preparation method thereof, and relates to the technical field of air-conditioning filter screen processing. The convenient-to-clean antifouling air-conditioning filter screen is prepared from the following raw materials in parts by weight: 80-90 parts of polypropylene resin, 12-16 parts of organic silicon resin, 4-5 parts of polymethylphenyl siloxane, 2-4 parts of nano-graphene, 1 to 4 parts of divinyl benzene, 1 to 2 parts of melamine, 1 to 3 parts of palm wax, 1.2-1.6 parts of ethyl acetate, 2-4 parts of silicon dioxide, 1-3 parts of zinc oxide, 2-4 parts of lithium carbonate, 0.8-1 part of a dispersing agent, 1-1.3 parts of a plasticizer and 0.6-1.2 parts of an antioxidant. According to the invention, the defects in the prior art are overcome, various materials are added, and stubborn residue of dust and bacteria is effectively prevented, so that the prepared filter screen has a certain hydrophobic effect and is easy to clean, the cleaning cost of the air conditioner filter screen is reduced, and the filter screen is suitable for popularization and production.

Owner:安徽宏凤空调滤网有限公司

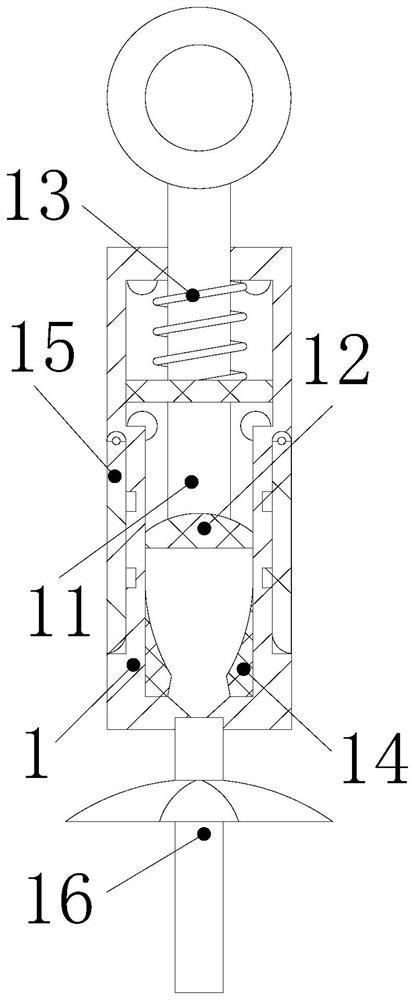

Crushing device convenient for performing integrated treatment on kitchen vegetable washing sink garbage

ActiveCN108331102AConvenient for centralized processingEasy to wash awayDomestic plumbingSewageUltimate tensile strength

The invention discloses a crushing device convenient for performing integrated treatment on kitchen vegetable washing sink garbage. The crushing device comprises a connecting flange, a first cutterhead, a second cutterhead, a second crushing cutter blade and a filtering hopper, wherein a water inlet is formed in the connecting flange; a motor is arranged on the outer side of a pipeline; a connecting gear is arranged under the motor; a filtering screen is arranged at the inner side of a discharging opening; the discharging opening and a pollution discharging opening are mutually connected; a collecting box and the pipeline are mutually connected through an installing frame; a water outlet is formed under the pipeline; in addition, a protection cover is arranged at the outer side of the pipeline. The crushing device convenient for performing integrated treatment on the kitchen vegetable washing sink garbage has the advantages that the kitchen food garbage can be conveniently crushed; various kinds of food garbage does not need to be singly collected and treated, and only needs to be poured into a vegetable washing sink to be crushed by the crushing device, so that the food garage canbe conveniently flushed away along with sewage; the requirement of the collection and transportation treatment on the garbage is avoided; the work intensity of workers is reduced.

Owner:新沂市棋盘工业集中区建设发展有限公司

Air pressure impact type closestool water seal pipeline blockage dredging equipment

The invention discloses an air pressure impact type closestool water seal pipeline blockage dredging equipment which structurally comprises a stamping rod, a pull ring and a sealing air cushion; the pull ring is connected to the top end of the stamping rod through a gap, and the sealing air cushion is mounted under the stamping rod. The air pressure impact type closestool water seal pipeline blockage dredging equipment has the beneficial effect that a positioning frame is prevented from automatically covering back under the cooperation of a limiting plate and a fixing block, the stability of the positioning frame is conveniently improved, shaking of the stamping rod is avoided, an air compressing disc is driven by the reset force of a reset spring and the attraction force of a magnetic block to downwards extrude air in the stamping rod, air can conveniently and quickly impact the interior of a closestool through an air outlet pipe to dredge blocked excrement, and the air enters the airoutlet pipe under the action of pressure; a pressurizing plate inclining inwards further increases air pressure, at the moment, air pushes a baffle downwards to open a flow limiter, the baffle extrudes a supporting strip downwards, excrement blocked in the closestool can be flushed away by the air conveniently, and when no air passes through the closestool, the baffle is supported by the supporting strip to close the flow limiter in time, so that pollutants are prevented from being sucked into a through hole.

Owner:任丘市仁正庆商贸有限公司

Novel ultraviolet disinfection closestool

The invention discloses a novel ultraviolet disinfection closestool which comprises a water tank, wherein closestool body is arranged below the water tank; a closestool seat is mounted above the closestool body; ultraviolet lamps are mounted on the upper surface of the closestool seat; a switch box is mounted between the water tank and the closestool seat; a timing rotary knob is mounted in the middle of the switch box; a disinfection box is mounted right ahead of the water tank; an electromotor is mounted in the disinfection box; fan blades are connected onto the electromotor; a heating body is mounted right ahead of the fan blades; disinfection box ultraviolet lamps are mounted right head of the interior of the disinfection box. According to the novel ultraviolet disinfection closestool, through arranging the ultraviolet lamps, bacteria in the closestool seat can be killed when the ultraviolet lamps are turned on to disinfect the closestool seat and protect health of a user; the timing rotary knob is arranged to enable the user to conveniently control the disinfection time of the closestool seat, so that man power is saved, and the user can more conveniently use the closestool.

Owner:WUHU SUNRISE NEW BUILDING MATERIALS TECH

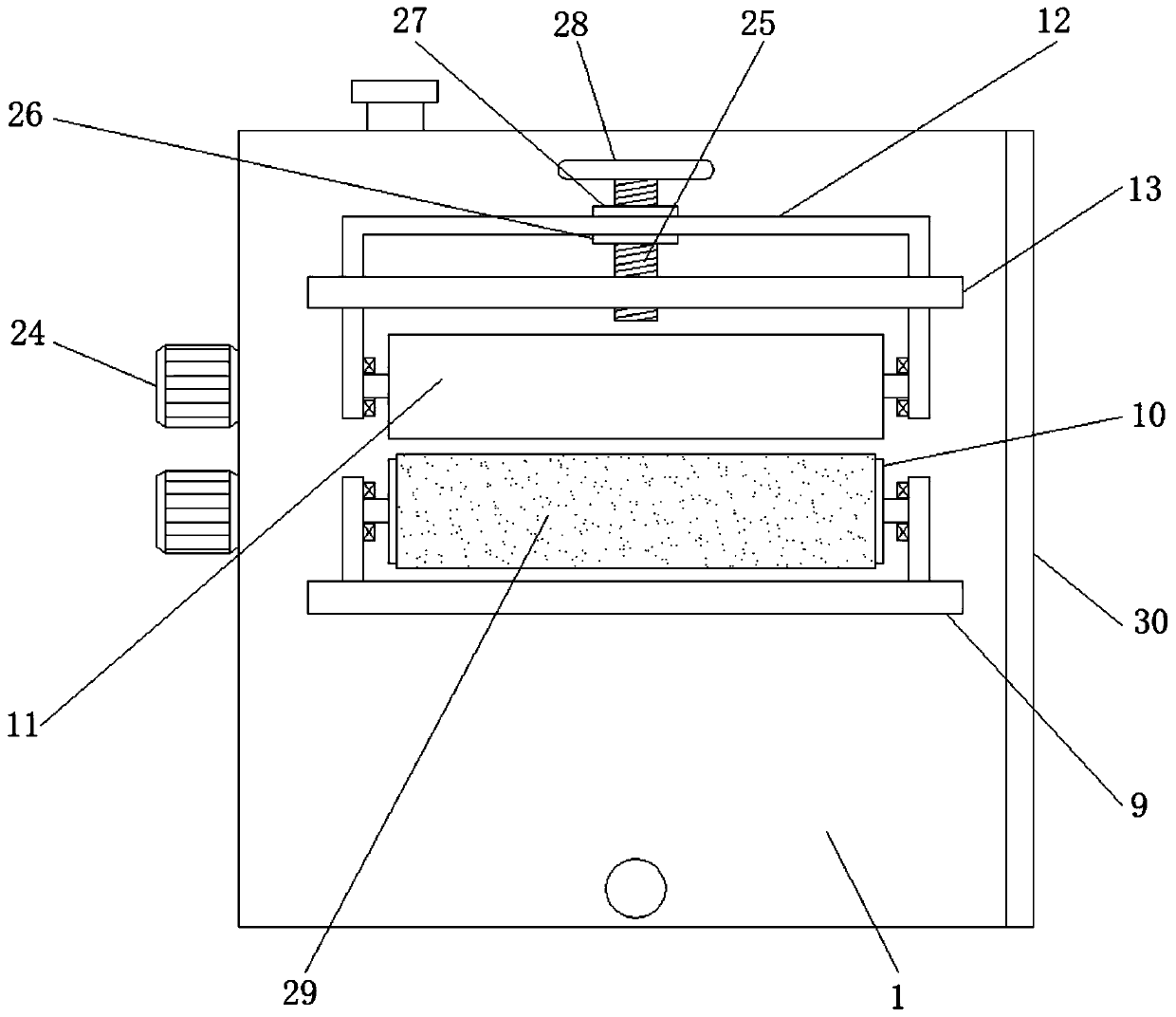

Shaking oxygenation and centrifugal sand removal ruditapes philippinarum conditioning device and using method

InactiveCN111670940AGood effect of spit sandPromote spit outBivalves processingAquatic productEnvironmental engineering

The invention provides a shaking oxygenation and centrifugal sand removal ruditapes philippinarum conditioning device and a using method, relates to the field of aquatic product cleaning machines, andsolves the problem that sand in the ruditapes philippinarum is not easy to spit out, and cleaning is inconvenient. The shaking oxygenation and centrifugal sand removal ruditapes philippinarum conditioning device comprises a conditioning and cleaning tank; the top part of the conditioning and cleaning tank is stuck to the bottom part of an erecting top plate through electric hydraulic pushing poles; a conditioning bag box is arranged in the conditioning and cleaning tank; and the bottom part of the conditioning and cleaning tank is provided with a bubble sand separating mechanism. According tothe shaking oxygenation and centrifugal sand removal ruditapes philippinarum conditioning device, a top motor controls the conditioning bag box to move vertically in the conditioning and cleaning tank to shake the ruditapes philippinarum placed in the conditioning bag box to promote the ruditapes philippinarum to spit out the inside sand thoroughly; and meanwhile, an electric heating tube heats cleaning water filled in the conditioning and cleaning tank, and shaking of the conditioning bag box promotes the temperature of the cleaning water to be uniform, and with the combination of the heating method and shaking method, the conditioning effect of the ruditapes philippinarum is better.

Owner:吕光

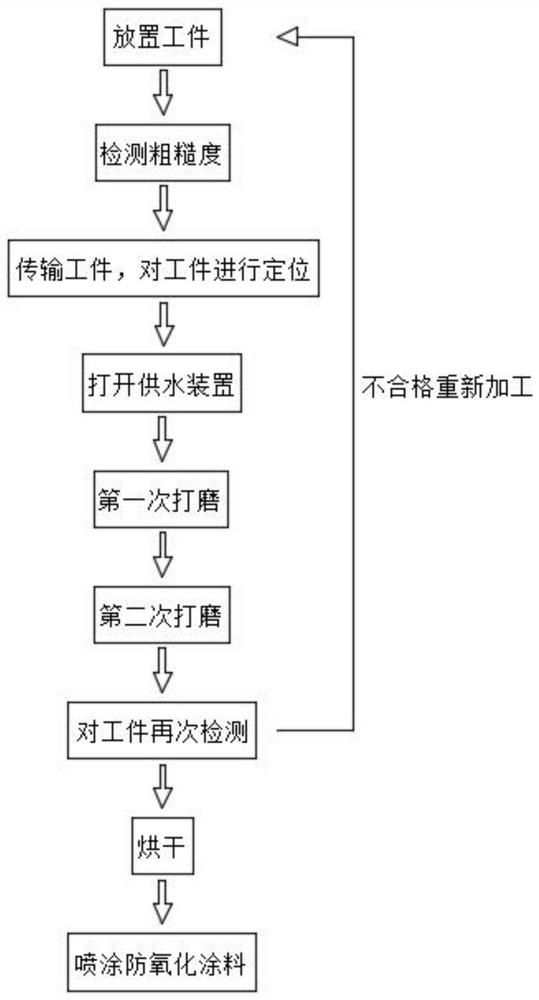

Polishing method for treating roughness and smoothness of metal structural surface

PendingCN113334179AEasy to polishHigh speedEdge grinding machinesLiquid surface applicatorsPolishingSurface roughness

The invention discloses a polishing method for treating roughness and smoothness of a metal structural surface. The polishing method comprises the following steps that firstly, a workpiece is placed, specifically, the workpiece needing to be polished is placed on a conveying device, the workpiece is carried through the conveying device, the workpiece is moved to a designated position, and the workpiece is machined; secondly, roughness is detected, and the roughness of the metal surface needing to be machined is detected through a metal roughness detector; and thirdly, the workpiece is conveyed to a grinding area through the conveying device, the two sides of the workpiece are clamped through a limiting device and a clamping structure, and the workpiece is prevented from shaking in the grinding process. According to the roughness detection device is arranged, the surface of the workpiece is checked before grinding, the position of the surface roughness is confirmed, the grinding device can conveniently grind the position which does not meet the specification, the grinding speed is increased, the grinding quality is improved, then the surface of the workpiece is checked again after machining is completed, and whether polishing meets the specified requirements is determined.

Owner:NANTONG SHUGUANG ELECTROMECHINCAL ENG

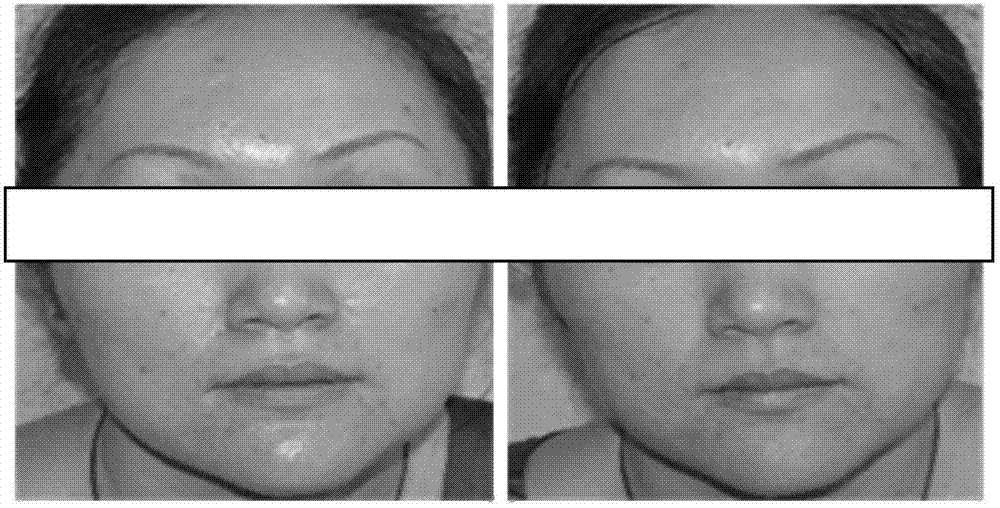

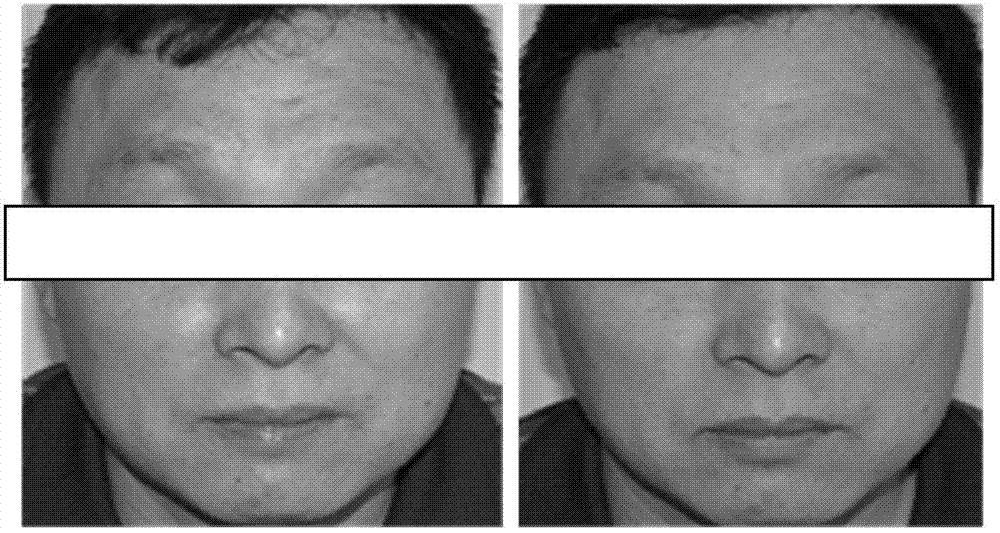

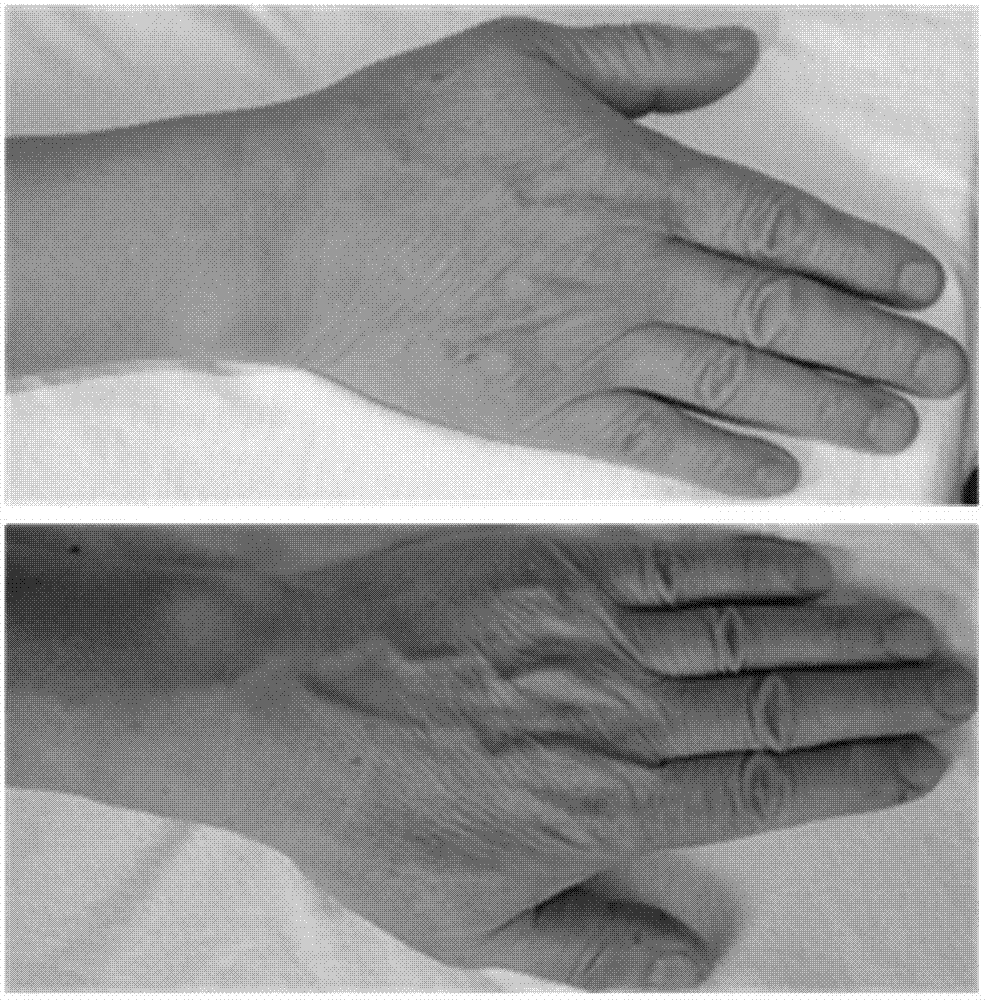

Application of salvianolic acid effective part in preparing preparation for improving skin quality

ActiveCN102949444AImprove skin qualityDelay agingOrganic active ingredientsDermatological disorderHas active ingredientSalvianolic acid B

The invention provides an application of salvianolic acid effective part in preparing a preparation for improving skin quality. The preparation is a solution agent or an ointment agent prepared from the salvianolic acid effective part as an active component and a pharmaceutic adjuvant. The content of the salvianolic acid effective part in the preparation is 10-75%. The internal and external functions of the salvianolic acid effective part with a high content of salvianolic acid B are effectively combined, so that the skin quality is improved, the skin aging is delayed and facial skin diseases such as whelk and the like are also treated. As the salvianolic acid effective part is completely water-soluble, the salvianolic acid effective part can be washed by using water and no trace is left after the use for daubing on the skin. Compared with the existing skin beauty and health products, the salvianolic acid effective part has the advantages of clear effective components, high content, high efficiency, safety, no toxicity, no sequelae, convenience for using, adaptability to all sorts of people, low price and easiness for large scale production and has a great application value.

Owner:邵明川

A Piezoelectric Integrated Nozzle for Electrofluid Printing

The invention relates to the field of electrofluid jet printing equipment, in particular to a piezoelectric type integrated spray head used for electrofluid jet printing. The piezoelectric type integrated spray head comprises an outer bracket, a piezoelectric structure, a spray head, a lower electrode supporting ring and a lower electrode ring, wherein the piezoelectric structure is positioned above the spray head; an upper electrode is arranged on the upper part of the spray head; the lower electrode supporting ring and the lower electrode ring are sequentially arranged below the spray head; after the piezoelectric structure, the upper electrode and a lower electrode are electrified, electric fields are formed between the spray head and the lower electrode ring, so that a solution forms Taylor cones on the spray head. The piezoelectric type integrated spray head overcomes the defect that existing electric jet printing equipment cannot meet high-frequency spraying, can realize high-frequency high-resolution printing; and the lower electrode is integrated to the spray head end, so that the whole jet printing system is more flexible, and a base plate with a complex shape can be used to print. The piezoelectric type integrated spray head further has the advantages of being simple in structure, low in manufacturing cost, suitable for large-scale production and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

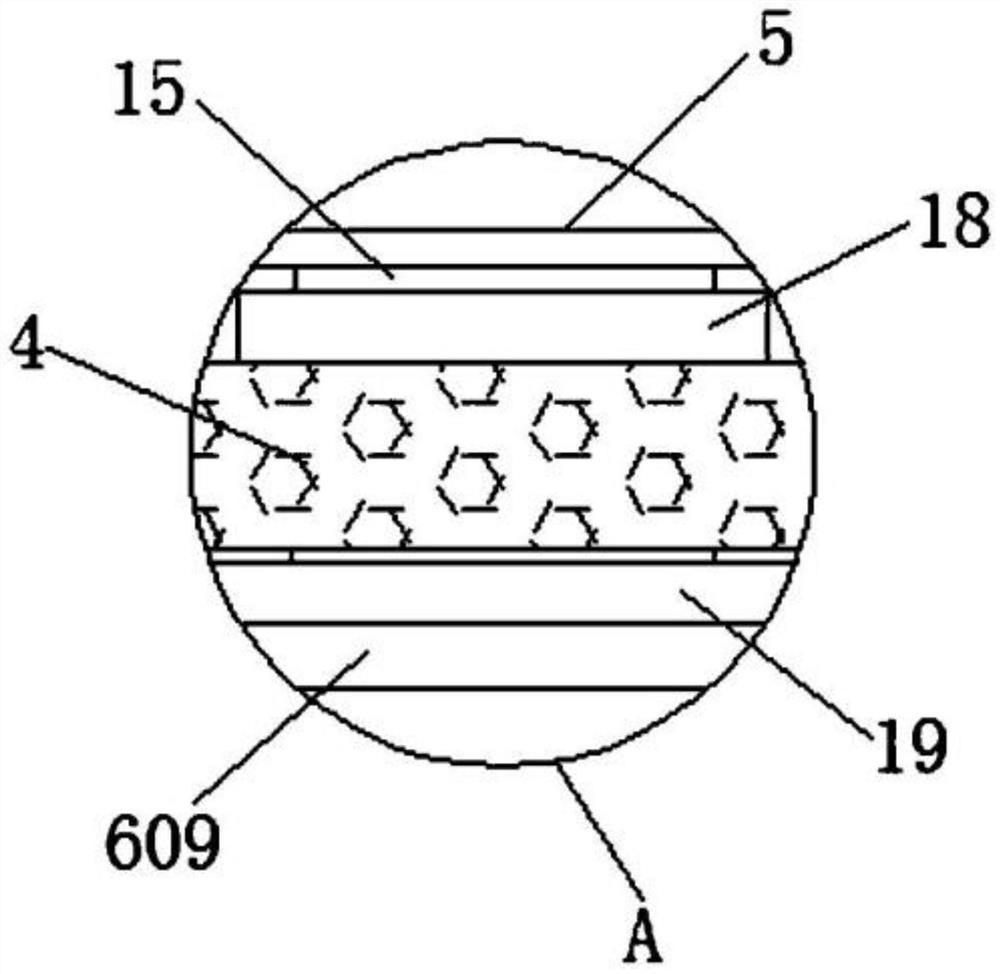

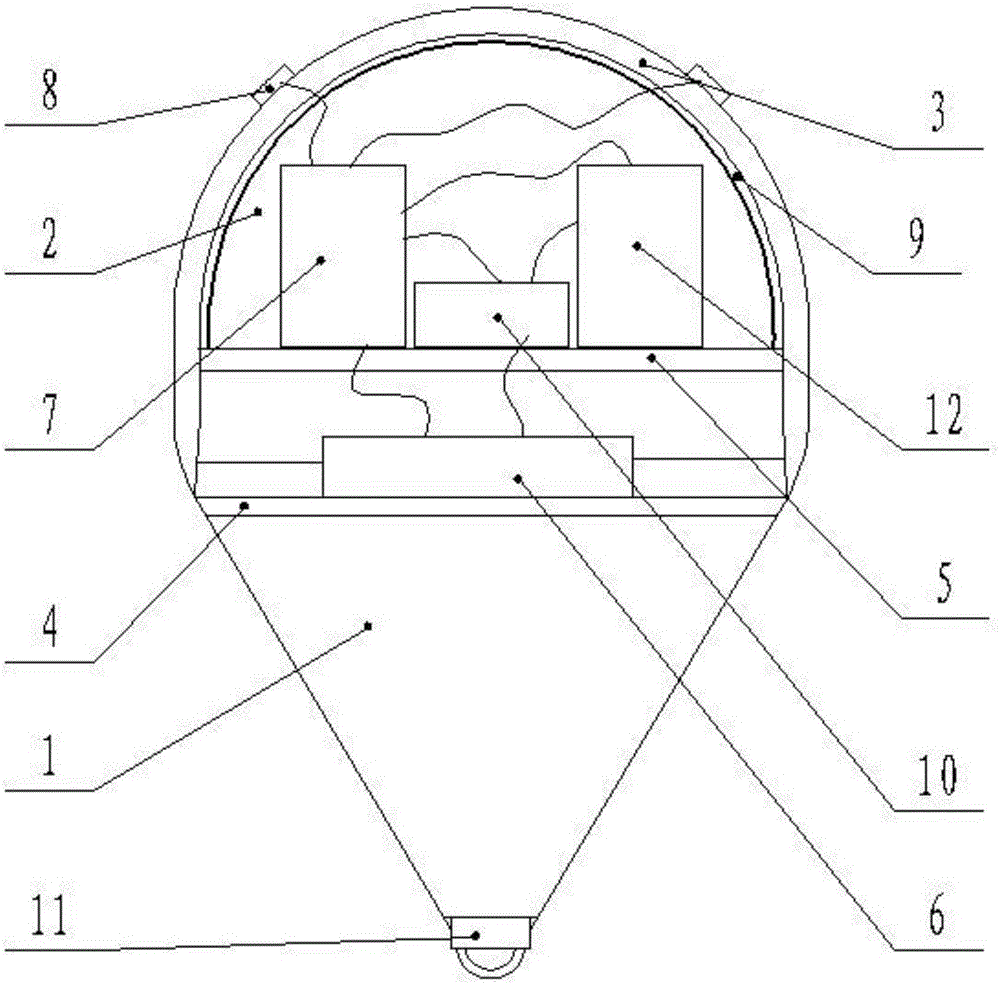

Press-resistant buoy used in ice zone

The invention provides a press-resistant buoy used in an ice zone. The press-resistant buoy comprises a lower body and an upper body, wherein a circle of water level sensor is arranged on the outer wall of the middle of the upper body, a heating layer is arranged on the inner side of the inner wall of the upper body, a heat insulating layer is arranged on the inner side of the heating layer, a heating control device is arranged between a seal partition plate and a seal heat insulating plate and is connected with the heating layer, a control center, a storage battery and a wireless transmission device are arranged on the seal heat insulating plate, the storage battery supplied power for the control center, the wireless transmission device and the heating control device, the control center is connected with the wireless transmission device, and the water level sensor is connected to the control center. The press-resistant buoy makes flowing ices pressing the top of the buoy easily washed away with water flows. The press-resistant buoy is designed with the water level sensor, the heating layer on the surface of a buoy body is started for heating when the buoy is pressed to be under the water surface by large flowing ices, the flowing ices melt through heating, and accordingly the buoy rapidly floats out of the water surface and can be used at any environment temperature.

Owner:TIANJIN TIANYUANHAI TECH DEV LTD CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com