Patents

Literature

33results about How to "Control float" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shield synchronous grouting slurry

The invention belongs to novel materials in tunnel construction, in particular to shield synchronous grouting slurry capable of effectively controlling stratum displacement caused by shield construction and tunnel floating after escaping from the shield tail. The properties of the novel shield synchronous grouting slurry material relate to the control of stratum settlement caused by shield construction, the tunnel floating after escaping from the shield tail, and the long-term stability of the tunnel. The invention aims at overcoming the shortcoming in condensation time of conventional single-fluid activity and inertia material, mainly adopts yellow sand, lime putty and fly ash, and adds proper amount of additives to prepare the high-quality synchronous grouting material with high density, high early strength, small shrinkage deformation, good fluidity, good filling property, good stability, seismic resistance and no liquefaction. By the application of the synchronous grouting slurry in engineering test, the invention effectively controls the ground settlement and the tunnel floating after escaping from the shield tail, simultaneously excellent performance and construction effect of the synchronous grouting material obtain general consent from the building side and the construction side, and the synchronous grouting slurry has practicality and promotion value.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD

Method for controlling upward floating of pipe piece during shield machine air pushing through mining tunnel

The invention discloses a method for controlling the upward floating of a pipe piece during shield machine air pushing through a mining tunnel. The method comprises the following steps: 1) arranging one or a plurality of position-limiting matters at the upper end of the mining tunnel at intervals so as to limit the upward floating amount of the pipe piece; 2) arranging water collecting wells in the mining tunnel at intervals, and pumping water before a nose of the shield machine arrives so as to reduce the water amount in the mining tunnel; 3) arranging openings in the positions of slurry filling holes at the waist part and the bottom part of the pipe piece at intervals for water drainage so as to reduce the water level at the back of the pipe piece after the pipe piece goes out of the shield tail of the shield machine; 4) performing secondary supplementary slurry filling after the pipe piece goes out of a vehicle frame; and 5) monitoring the stability of the pipe piece during the slurry filling process. By using the method, the upward floating of the pipe piece can be well controlled before the construction of the tunnel and in the construction late stage.

Owner:SHANGHAI ROAD & BRIDGE (GRP) CO LTD

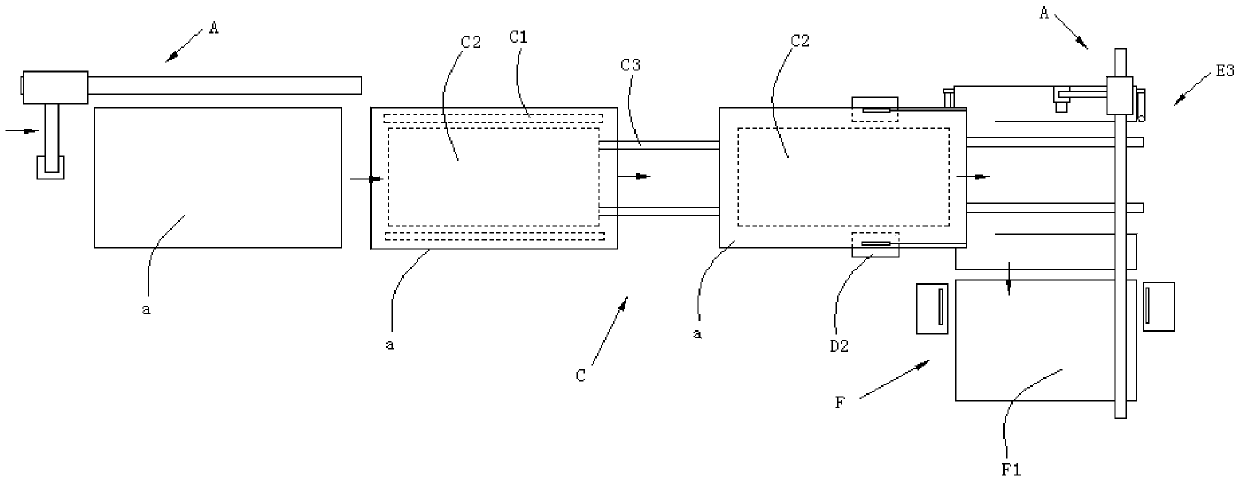

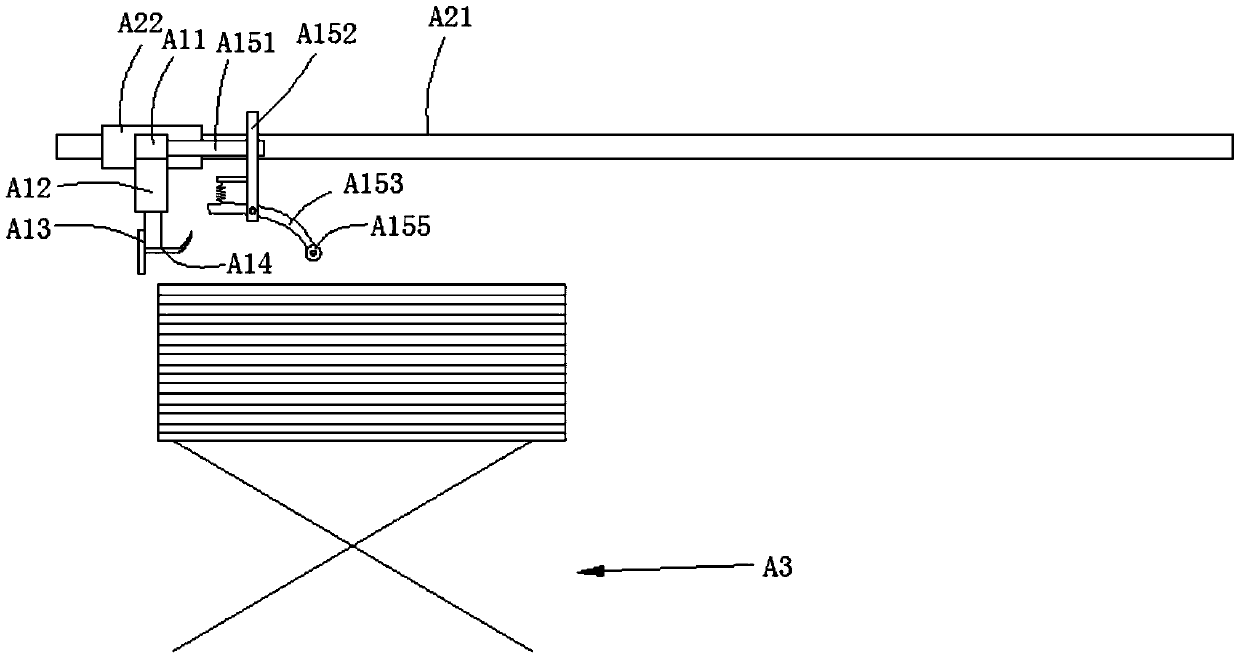

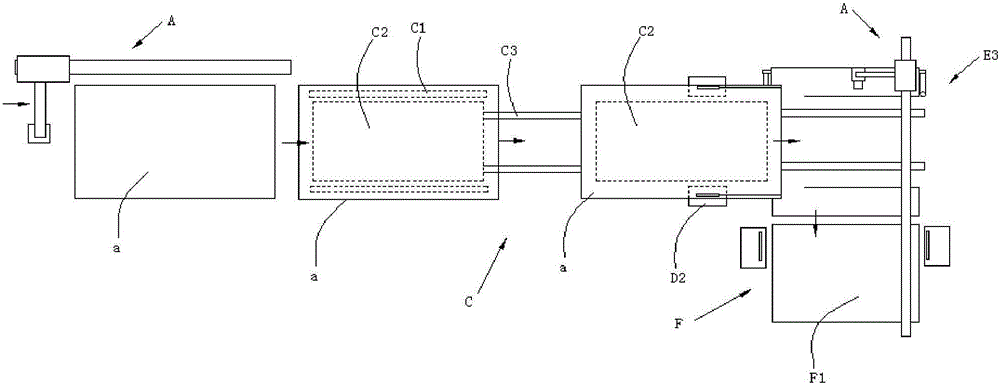

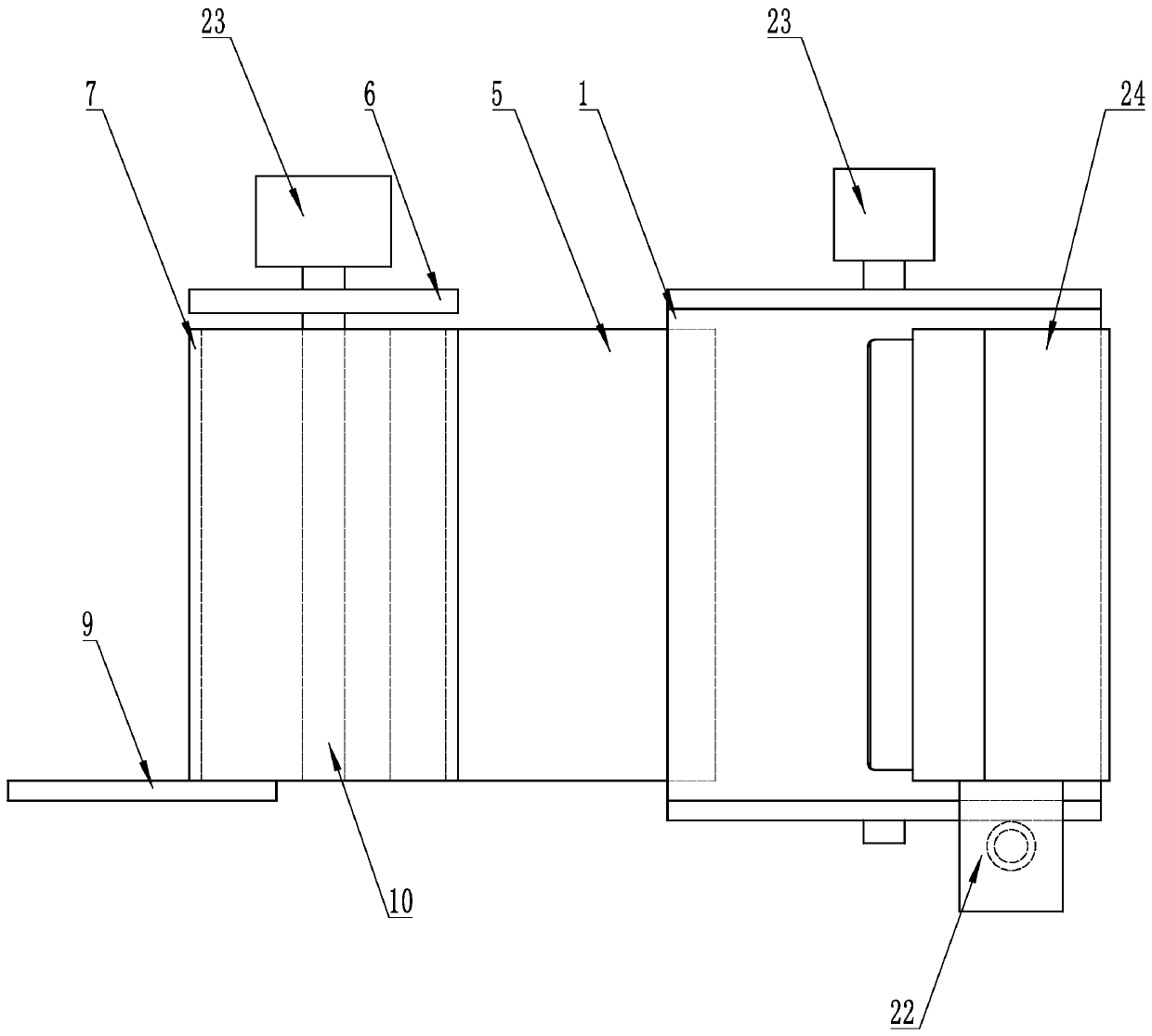

Full-automatic trimming machine

The invention provides a full-automatic trimming machine which comprises a feeding device, a long edge trimming device, a steering device and a short edge trimming device, wherein panels sequentially pass through the feeding device, the long edge trimming device, the steering device and the short edge trimming device; the long edge trimming device and the short edge trimming device are respectively positioned on the two adjacent sides of the steering device; and the horizontal-direction included angle of the long edge trimming device and the short edge trimming device is 90 degrees. Compared with the prior art, the trimming machine provided by the invention has the advantages that the structure is simple, the panel feeding is smooth, all the steps closely cooperate with each other, before the next step is carried out, the next work task is prepared in the precious step, the connection is close, and the working efficiency is high.

Owner:ANHUI ANSU WORLD HOME CO LTD

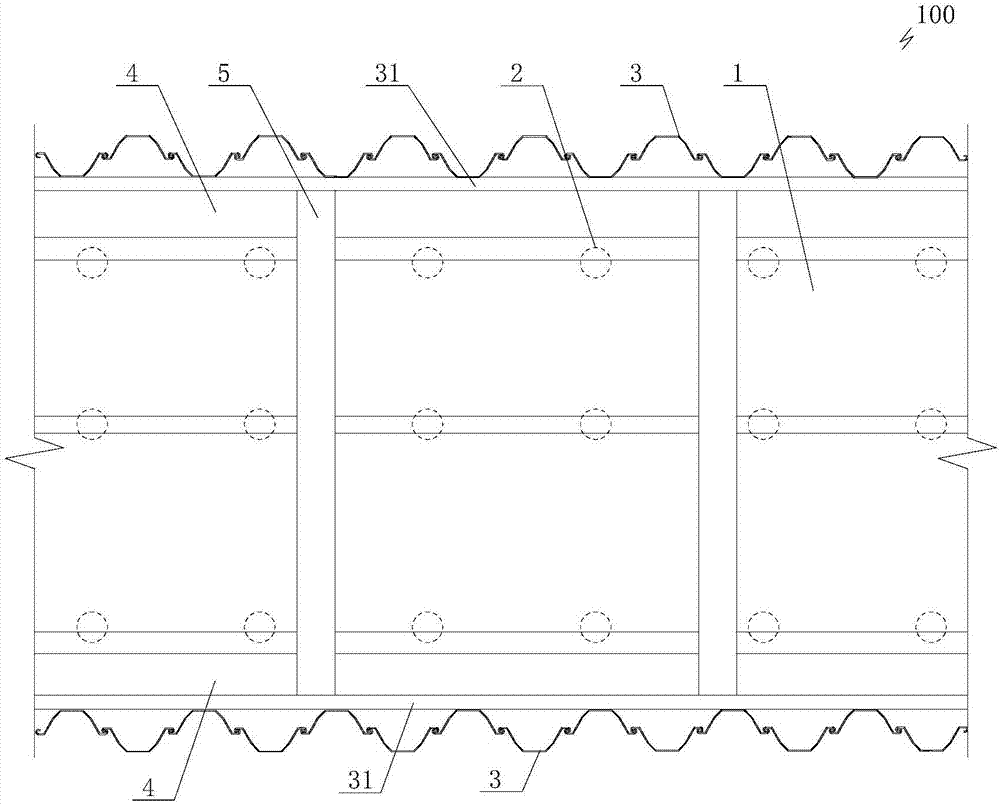

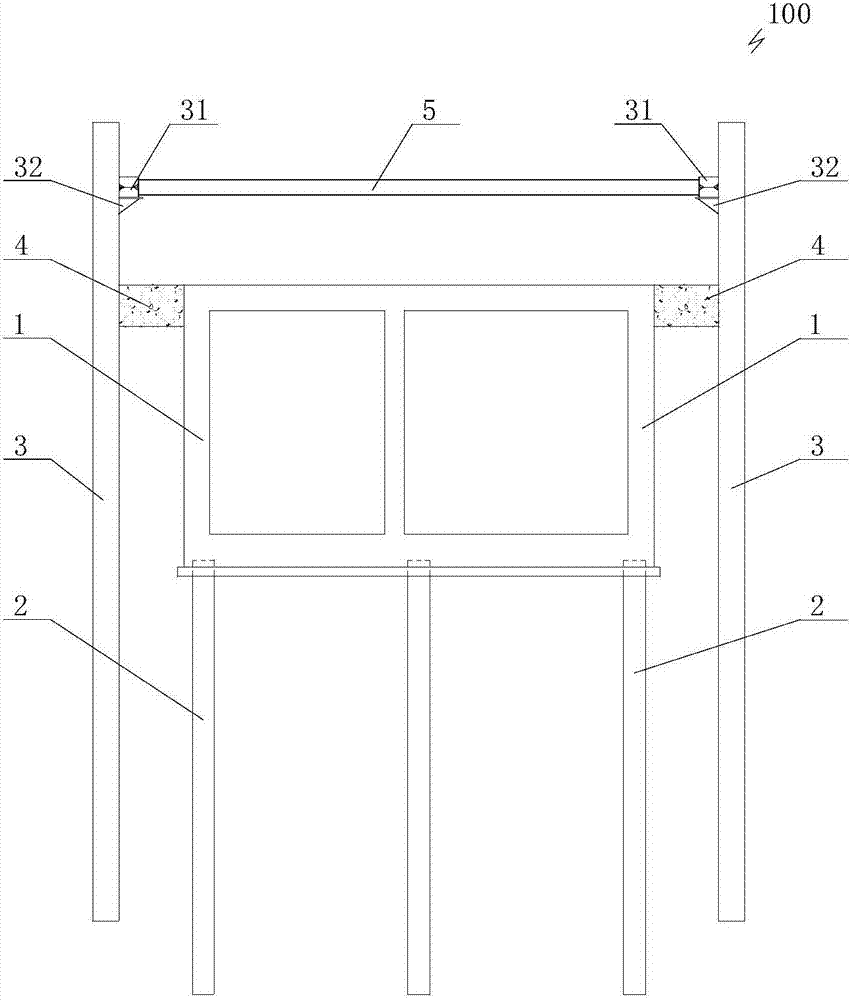

Soft soil foundation comprehensive pipe gallery and construction method thereof

The invention relates to a soft soil foundation comprehensive pipe gallery and a construction method thereof. The soft soil foundation comprehensive pipe gallery comprises a pipe gallery body. A plurality of prestressed reinforced concrete pipe piles are arranged at the bottom of the pipe gallery body. All the prestressed reinforced concrete pipe piles are arranged in a soil body at the bottom of the pipe gallery body. The top pile heads of all the prestressed reinforced concrete pipe piles are fixedly connected with a bottom plate of the pipe gallery body. Detachable Larson steel plate piles are arranged in soil bodies on the two sides of the pipe gallery body in the longitudinal direction of the pipe gallery body correspondingly. The Larson steel plate piles and the two sides of the pipe gallery body are arranged in a spaced mode. The Larson steel plate piles form a construction side supporting structure of the pipe gallery body. According to the soft soil foundation comprehensive pipe gallery and the construction method thereof, the large settlement and floating problems of soft soil foundation pipe galleries in the prior art are solved, failure of the comprehensive pipe gallery is avoided, and the stability of the comprehensive pipe gallery is effectively ensured.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

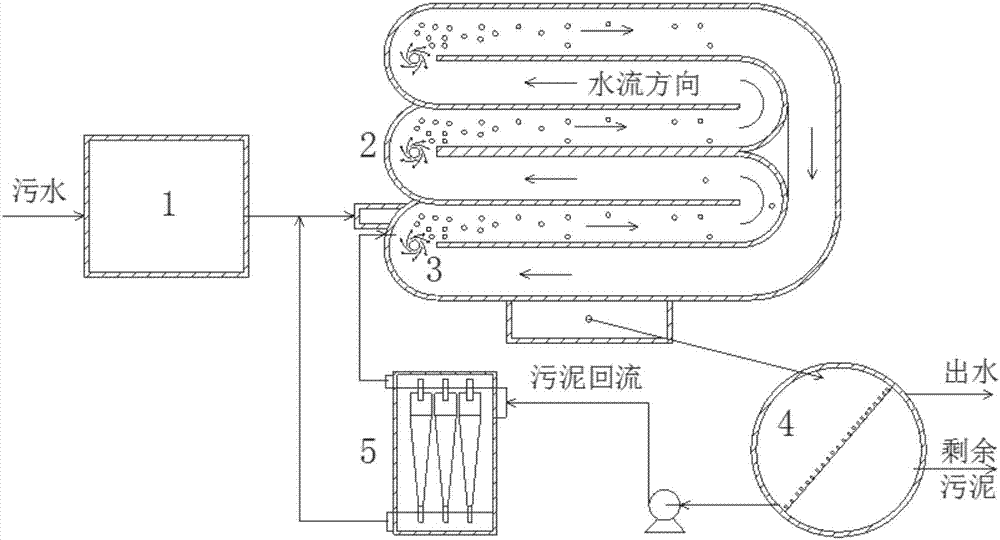

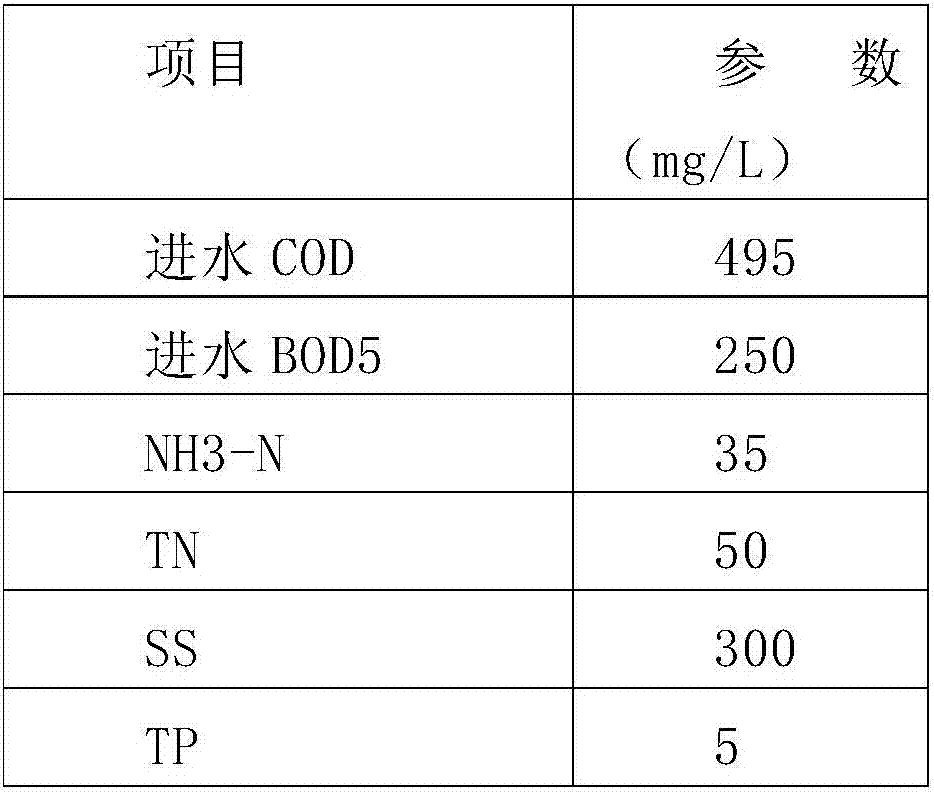

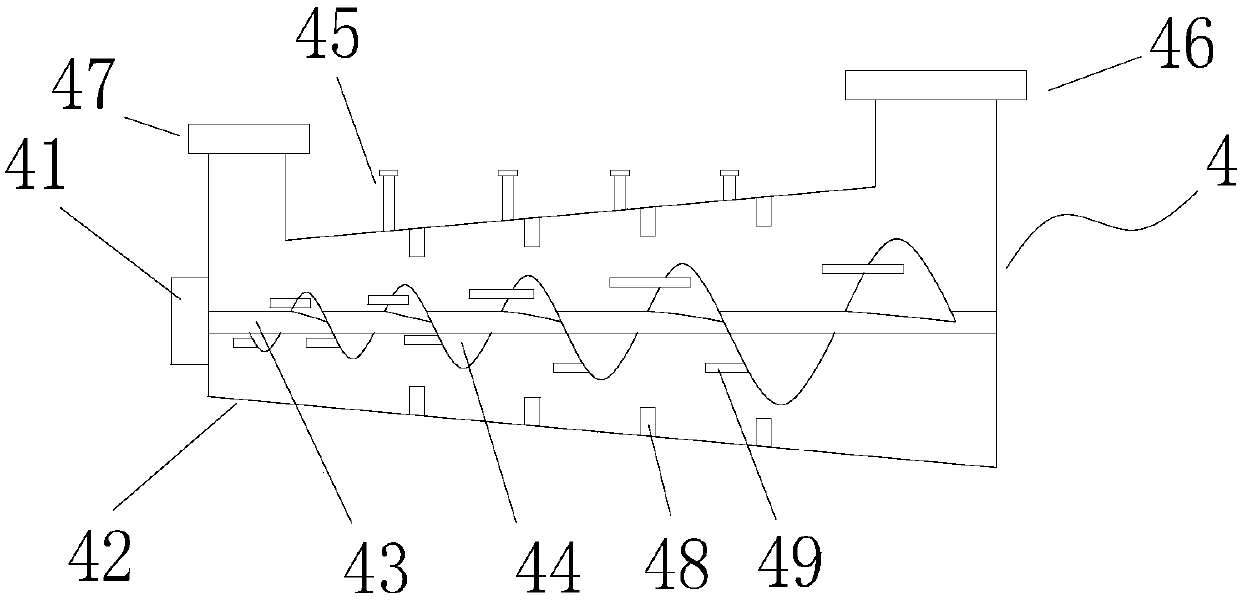

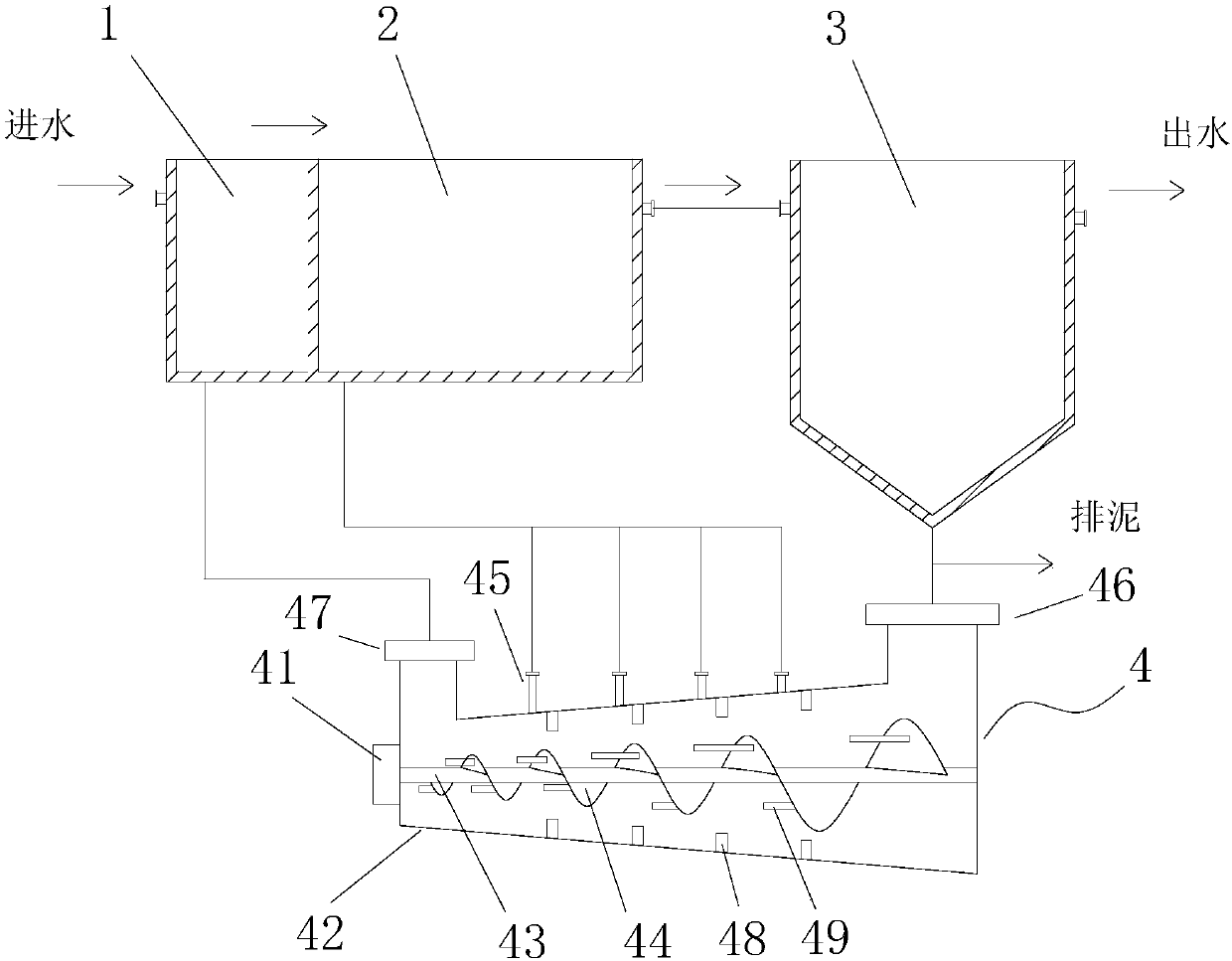

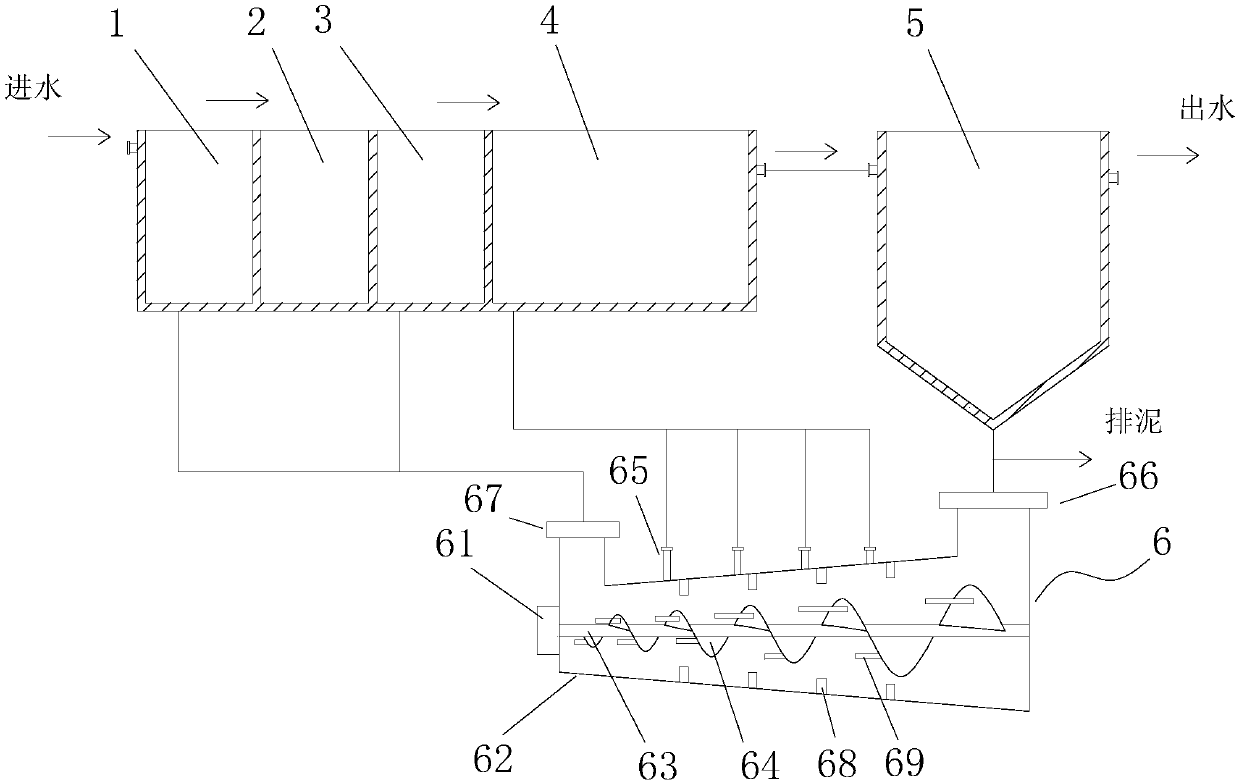

Oxidation ditch sewage disposal method including rotational flow spreading treatment and device thereof

InactiveCN106976965AHigh activityImprove processing efficiencySustainable biological treatmentBiological water/sewage treatmentWater qualityBiochemical Process

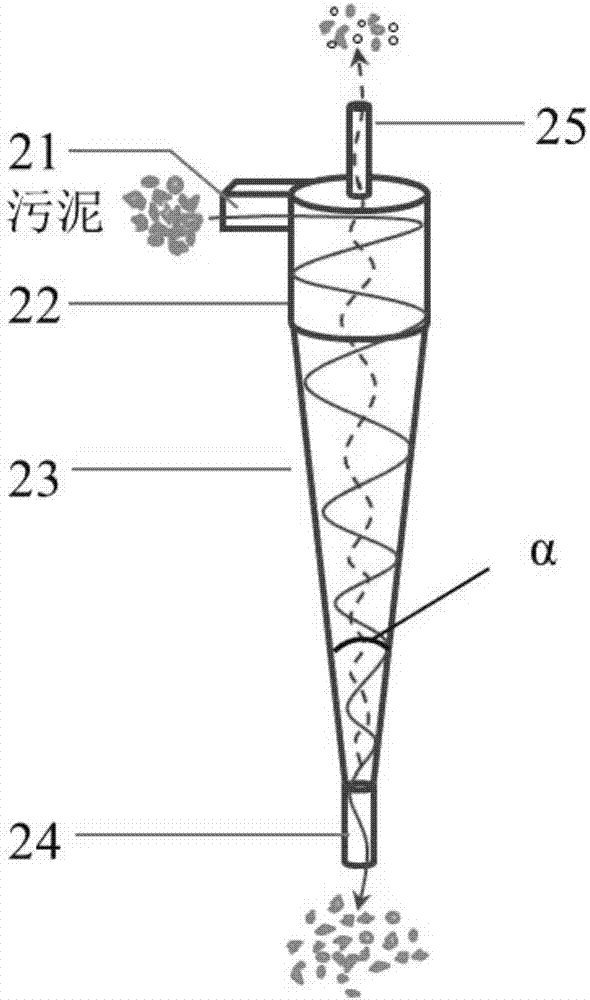

The invention relates to an oxidation ditch sewage disposal method including rotational flow spreading treatment, wherein the method includes steps of disposing sewage in a grit basin, an oxidation ditch, and a secondary sedimentation tank; backflowing at least a part of mud in the secondary sedimentation tank to a water inlet of the oxidization ditch; performing the rotational flow spreading treatment on the mud returned to the water inlet from the secondary sedimentation tank through a rotational flow spreader; intensifying the hydraulic shearing effect of the periphery of the active sludge by a speed gradient field in the rotational flow yard, and guaranteeing the high activity of zoogloea surface, removing refractory mesh impurities cpated on the surface of a flocculating body and improving the mass transfer effect from the interface of the flocculating body to the center activity zone by combining with water; meanwhile, the method pushes the sludge flow of the base layer of the oxidization ditch, thus the sludge at the aeration zone is suspended in the water body, the sludge deposition is avoided, and the sludge utilization rate is improved. Through rotational flow, the aged sludge floated for gathering the grease and air bubble is broken during the biochemical process, thereby optimizing e eluent water quality, preventing sludge expansion and improving the settling performance. The invention further relates to a device for realizing the method.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION +1

Crawler-type robot with underwater posture changing function

ActiveCN110125950ARealize multiple posture changesControlled sinkingManipulatorUnderwater equipmentPropellerEnergy consumption

The invention discloses a crawler-type robot with an underwater posture changing function, and belongs to the field of underwater robots. The crawler-type robot solves the problem that an existing underwater robot can flexibly operate in a complex underwater environment due to the fact that a propeller changes the working posture energy consumption and is unstable. The crawler-type robot comprisesa shell, a monitoring mechanism, a vertical propeller, a horizontal propeller, two sets of posture changing mechanisms and two sets of crawler walking mechanisms, wherein the monitoring mechanism isarranged at the front end of the shell and is used for underwater monitoring, the vertical propeller is arranged in through holes in the two sides of the upper part of the shell and is used for floating and transverse inclination of the underwater robot, and a horizontal propeller is arranged at the rear end of the shell and is used for advancing and retreating and turning of the underwater robot,each crawler walking mechanism is arranged on the side walls of the two sides of the shell and used for climbing the underwater robot, and the two sets of posture changing mechanisms are arranged onthe two sides inside the shell, and are used for changing the posture of the underwater robot. The crawler-type robot is used for underwater operation.

Owner:HARBIN ENG UNIV

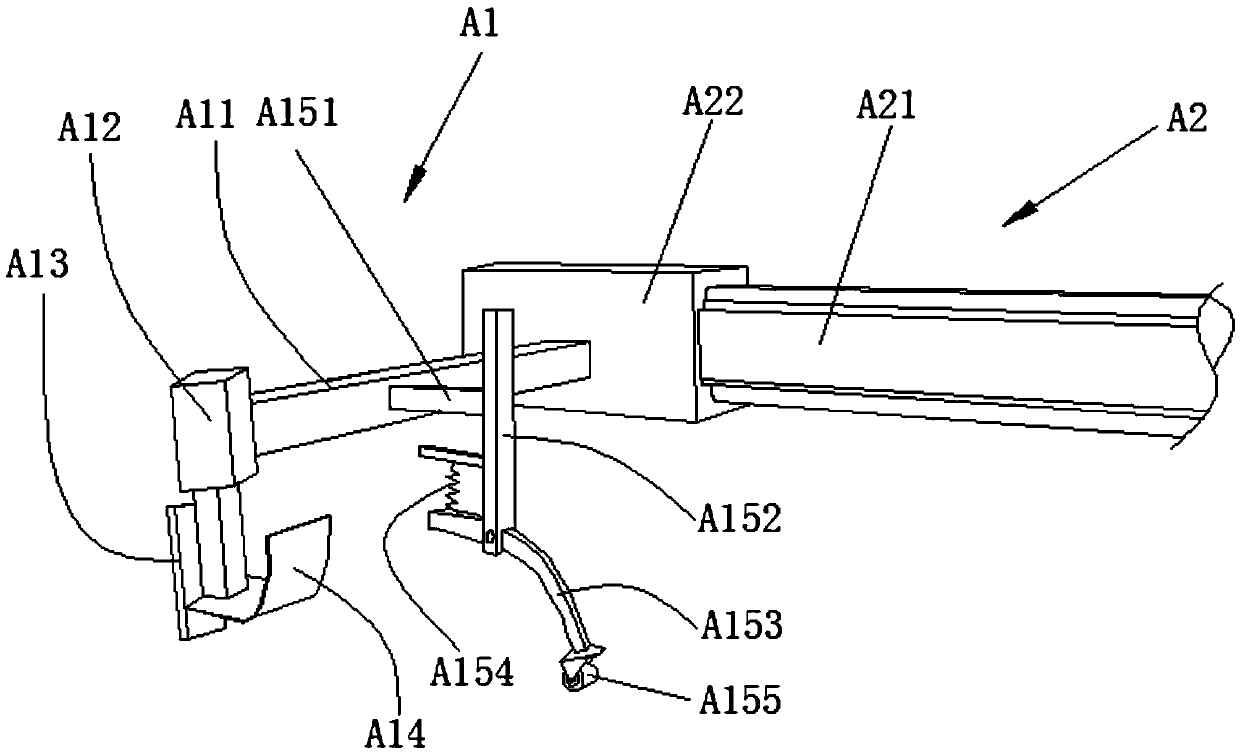

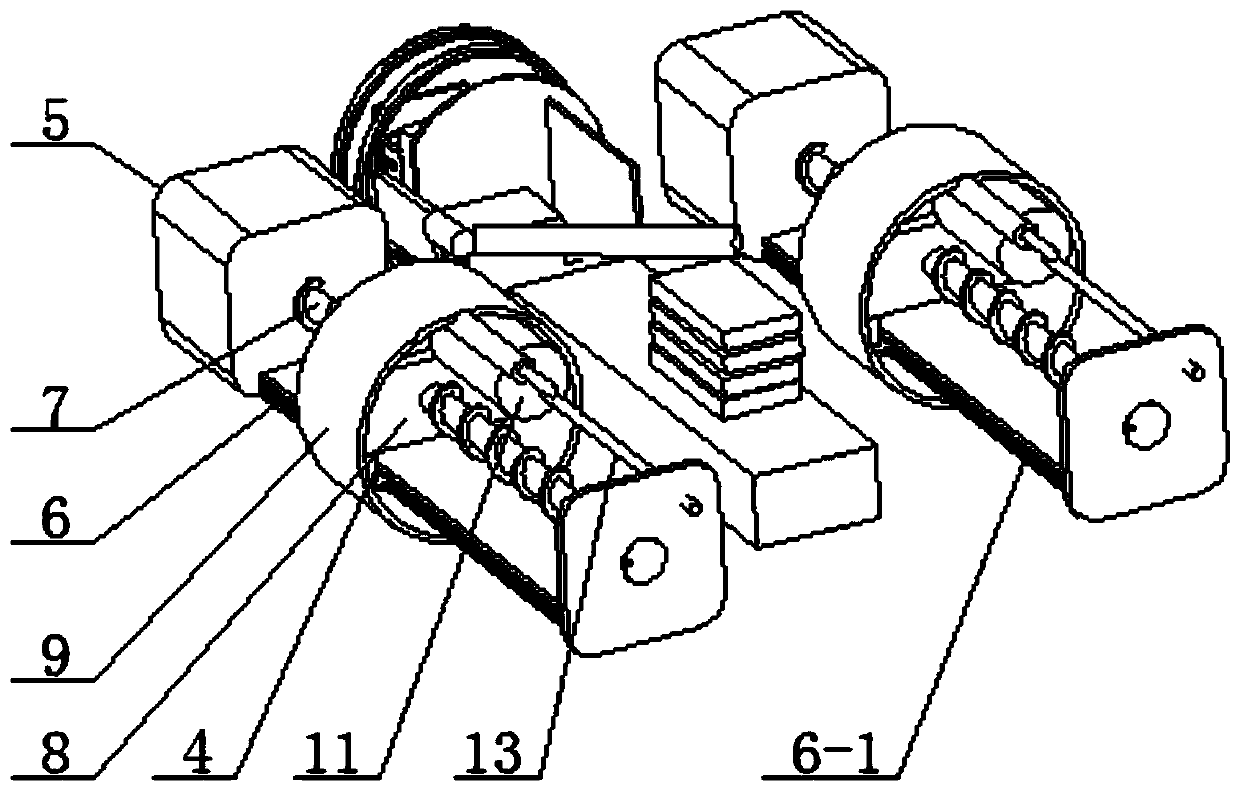

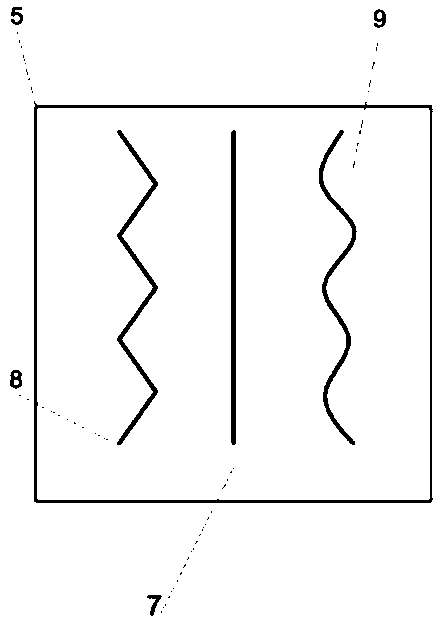

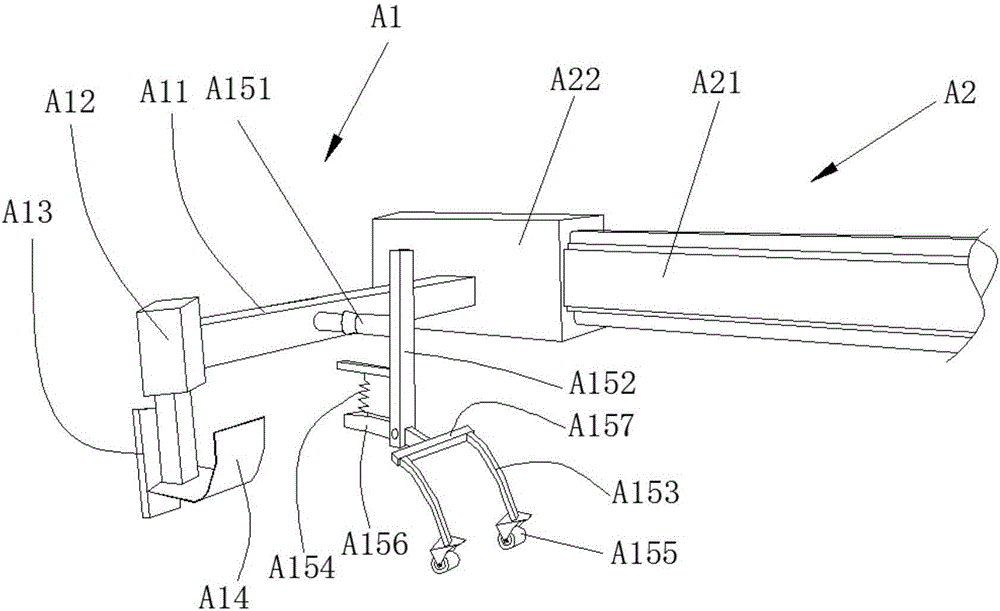

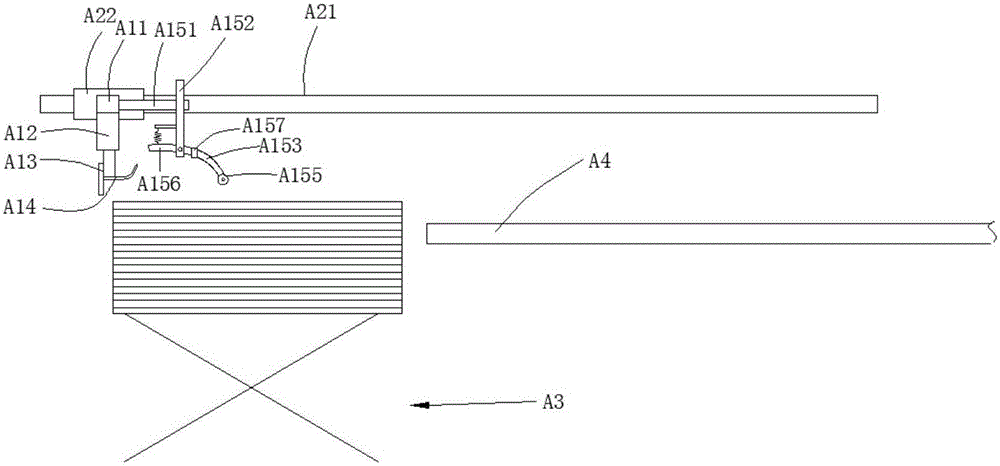

Trimming mechanism of trimming machine

InactiveCN105500461AWon't moveControl floatCircular sawsBark-zones/chip/dust/waste removalCircular sawEngineering

The invention provides a trimming mechanism of a trimming machine. The trimming mechanism is characterized in that a sawing table comprises a table and a table frame used for supporting the table, and further comprises a circular sawing machine, wherein a sawing groove is formed in the table; the circular sawing machine is positioned below the table; a part of a saw blade of the circular sawing machine penetrates through the sawing groove from down to up to be exposed above the table; dust shields are arranged above and below the sawing groove; a pressure plate device is fixed to the table; the pressure plate device comprises a bracket; the bracket comprises a vertical rod and a cross rod; the vertical rod is fixed to the table and is positioned on the outer side of the saw blade; one end of the cross rod is fixed at the end part of the vertical rod; a cylinder is vertically fixed at the other end of the cross rod; a piston rod of the cylinder moves downwards; a pressure roller is fixed at the end part of the piston rod; and the pressure roller is positioned at the material incoming end of the saw blade. Compared with the prior art, the trimming mechanism has the advantage that the pressure plate mechanism is arranged above the sawing table, and the pressure roller of the pressure plate mechanism is positioned near a trimmed edge, so that during trimming, a panel does not move due to the trimming impact and vibration.

Owner:ANHUI ANSU WORLD HOME CO LTD

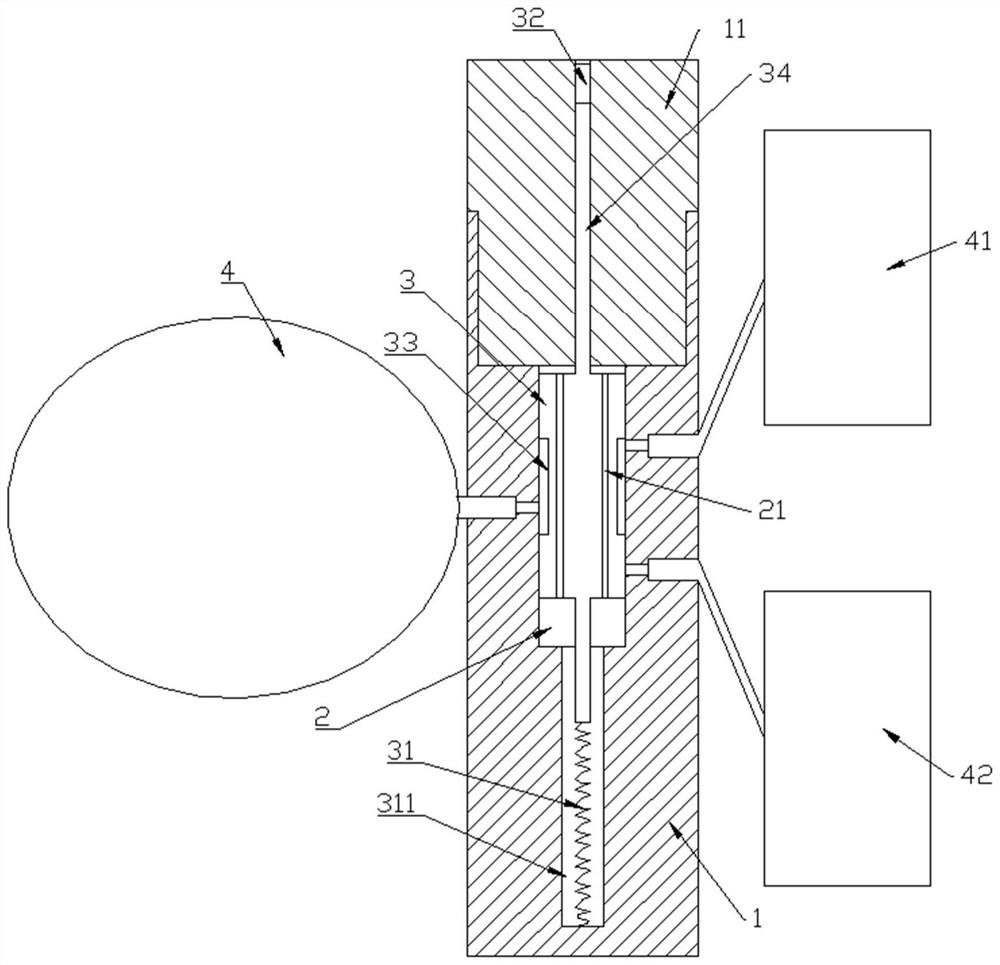

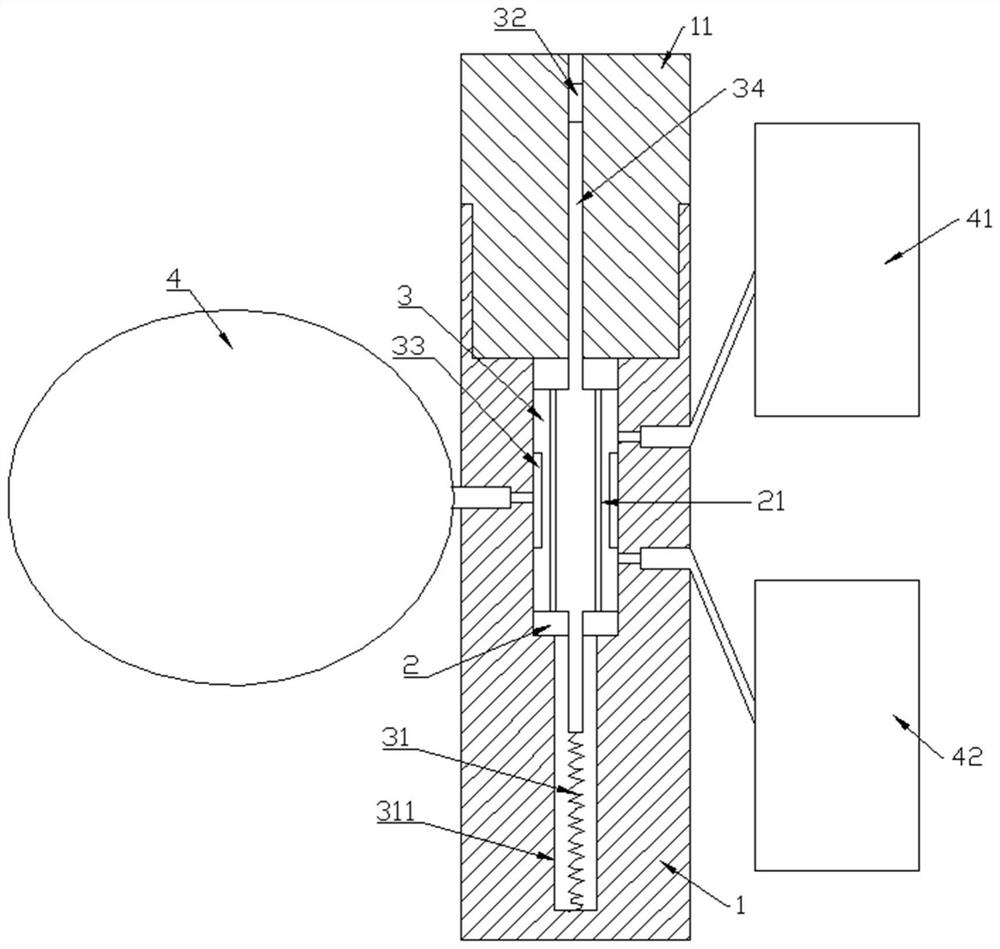

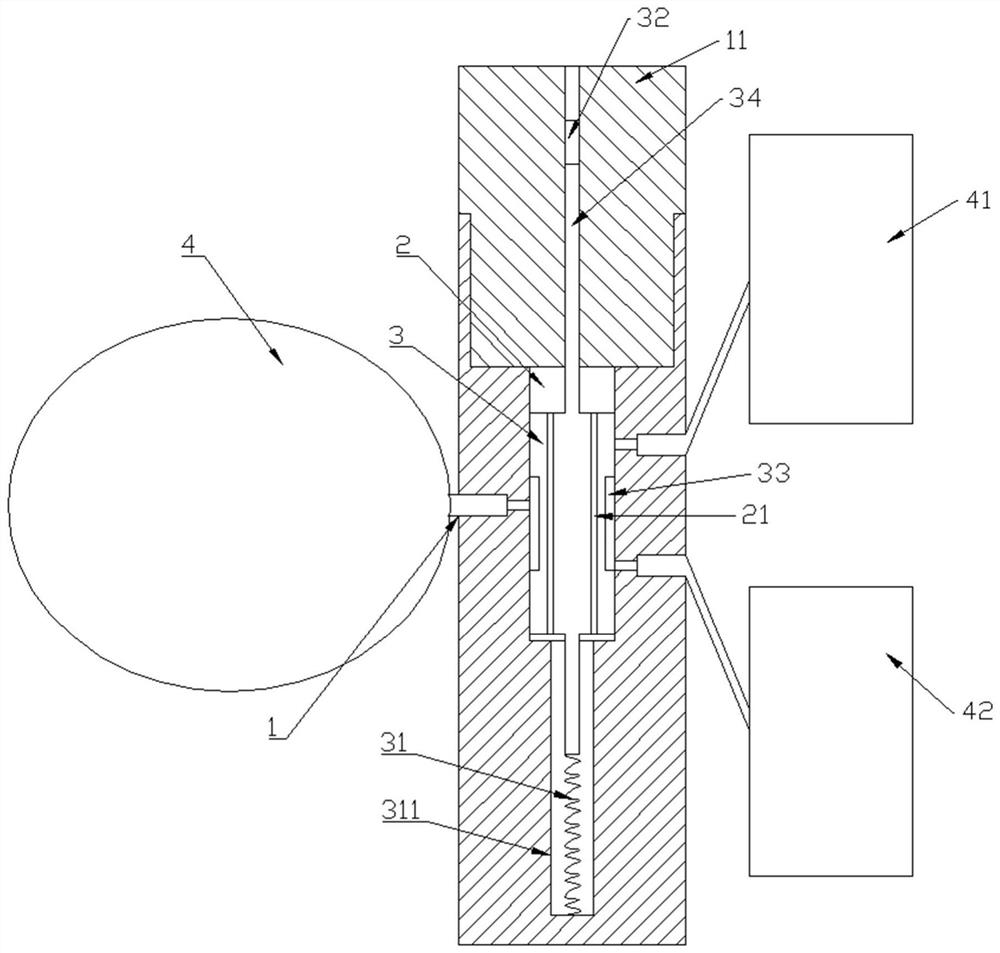

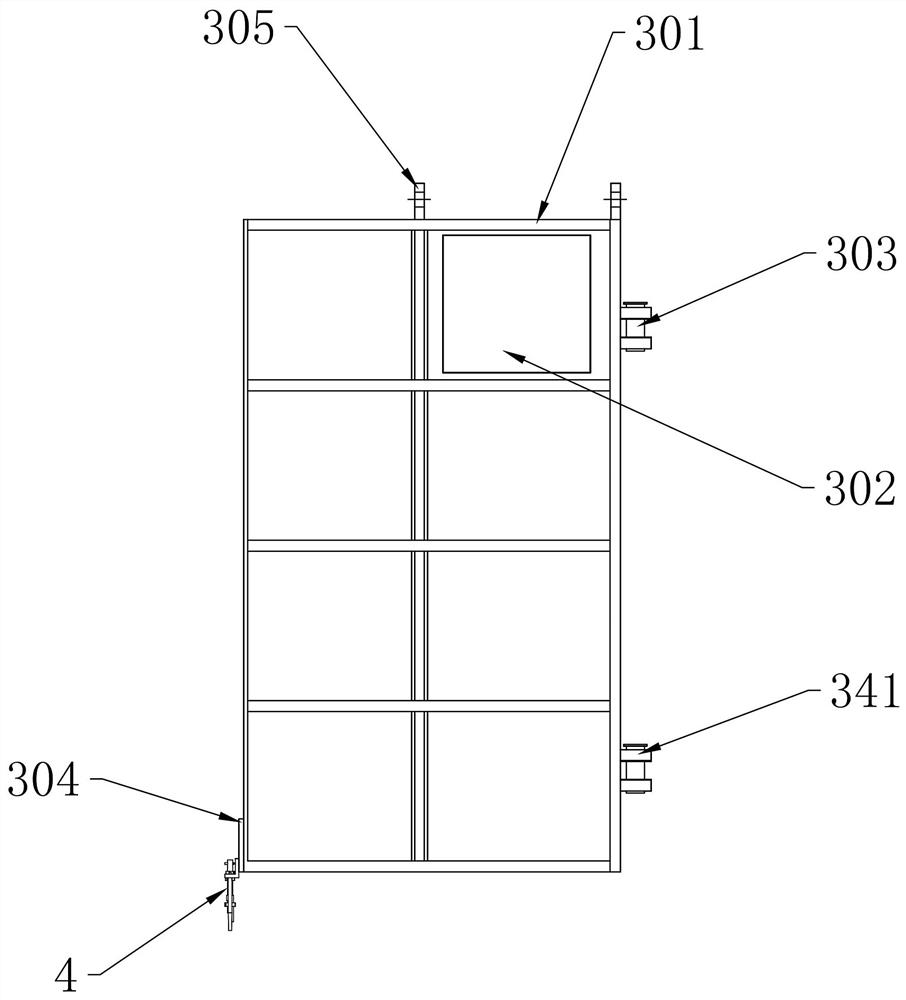

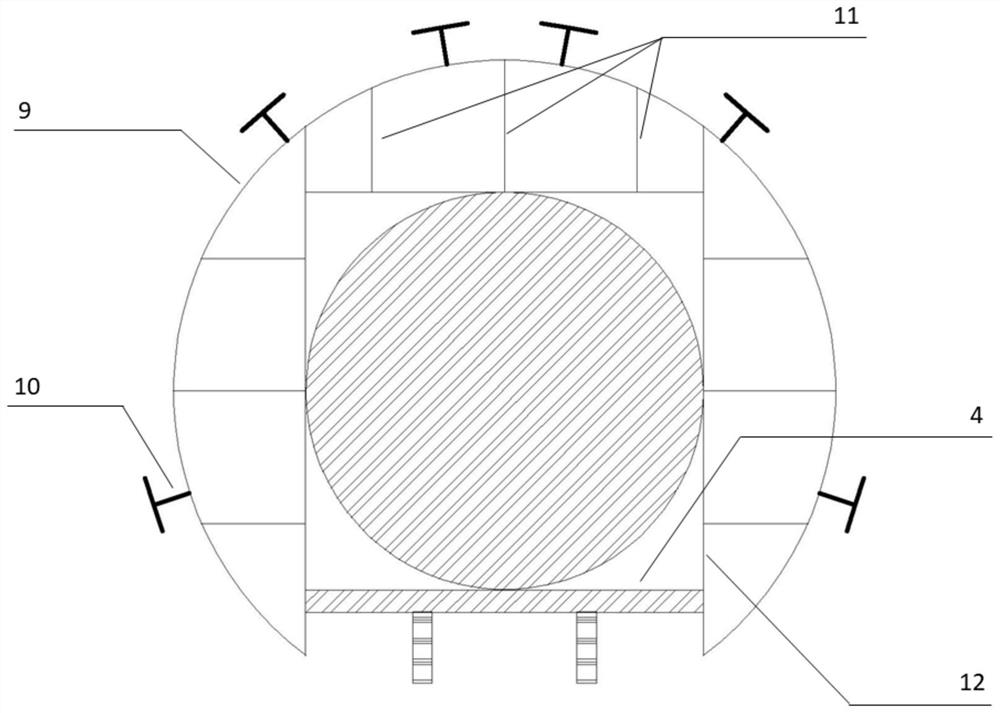

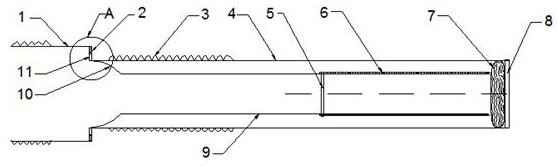

Duct piece fixing pile device for fixing shield tunnel duct piece and using method

ActiveCN111577324AControl floatFloating is effectiveUnderground chambersTunnel liningArchitectural engineeringSlurry

The invention discloses a duct piece fixing pile device for fixing a shield tunnel duct piece. The duct piece fixing pile device comprises a grouting outer sleeve and a grouting inner sleeve; a connecting part and a step part are arranged at the front end of the grouting outer sleeve, the connecting part is fixedly connected with the step part, a sealing cover is arranged at the rear end of the grouting outer sleeve; a supporting part is arranged at the front end of the grouting inner sleeve, the supporting part is located on the step part, the step part is fixedly connected with the supporting part, a grouting bag is connected to the rear end of the grouting inner sleeve; threads are arranged on the outer parts of the ends, close to the connecting part, of the connecting part and the grouting outer sleeve correspondingly; and the invention further discloses a construction method of the pipe piece fixing pile device, and the construction method comprises the steps of grouting hole opening, grouting liquid stirring, grouting and the like. According to the duct piece fixing pile device for fixing the shield tunnel duct piece, fixing the tunnel duct piece in time can be carried out during shield construction, so that the construction efficiency is effectively improved, and the construction quality is improved.

Owner:湖南中天凿岩科技有限公司

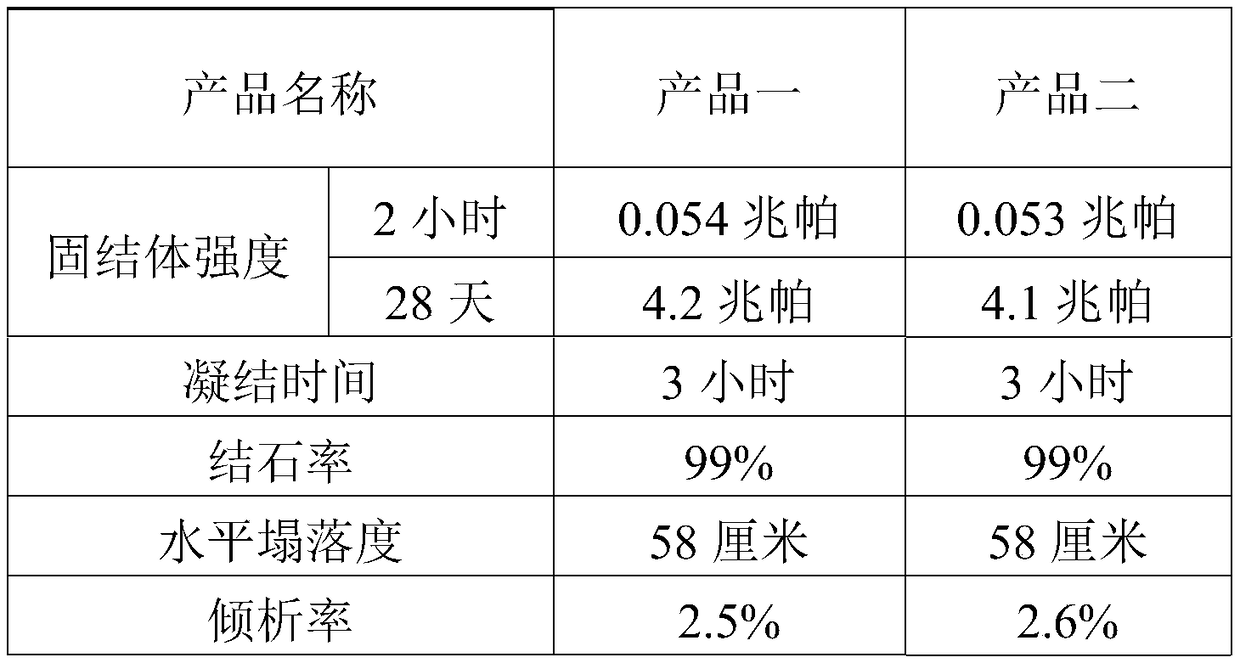

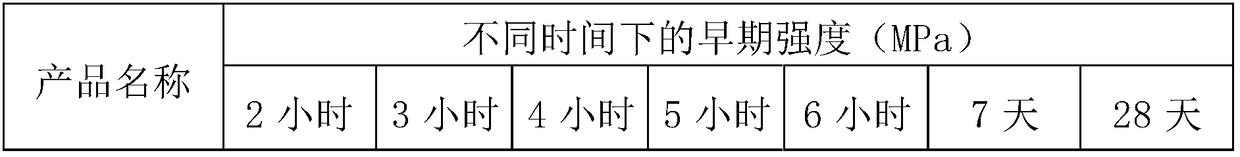

Synchronous grouting slurry applicable to abundant water stratum tunneling and preparation method

The embodiment of the invention provides synchronous grouting slurry applicable to abundant water stratum tunneling. The synchronous grouting slurry is composed of the following raw materials in partsby mass: 180-220 parts of Portland cement, 710-730 parts of machine-made sand, 710-730 parts of natural sand, 45-55 parts of bentonite, 3-6 parts of a retarder, 3-6 parts of a water reducing agent and 250-350 parts of water. The synchronous grouting slurry provided by the invention is added with an appropriate amount of machine-made sand and natural sand, so that the early strength of the productis improved, the product performance is improved, the voids inside the synchronous grouting slurry can be well filled, and the compactness is improved. The water cement ratio is reduced by adjustingthe content of the water reducing agent, and the strength of the synchronous grouting slurry is improved. Meanwhile, due to the addition of the appropriate amount of the retarder and bentonite, the concretion rate, horizontal slump and stability of the synchronous grouting slurry can be improved, the setting time is shortened, and the ground surface settlement and segment uplift can be effectivelycontrolled. Moreover, the raw materials of the synchronous grouting slurry provided by the invention are local materials and are readily available, and the material cost is reduced.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

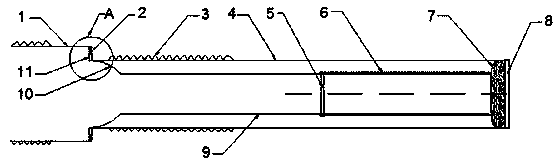

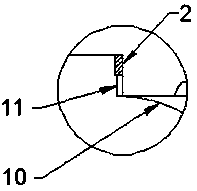

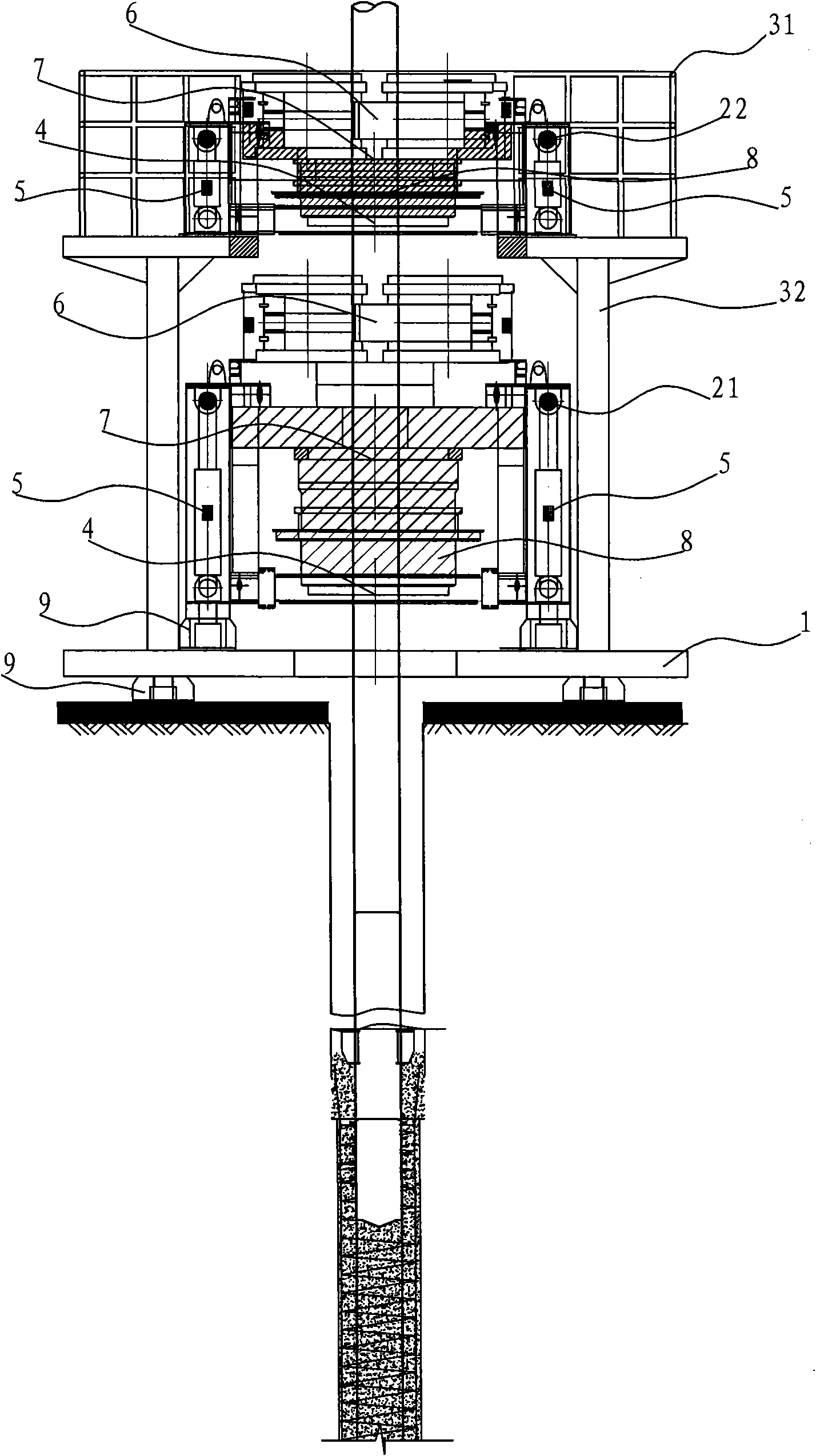

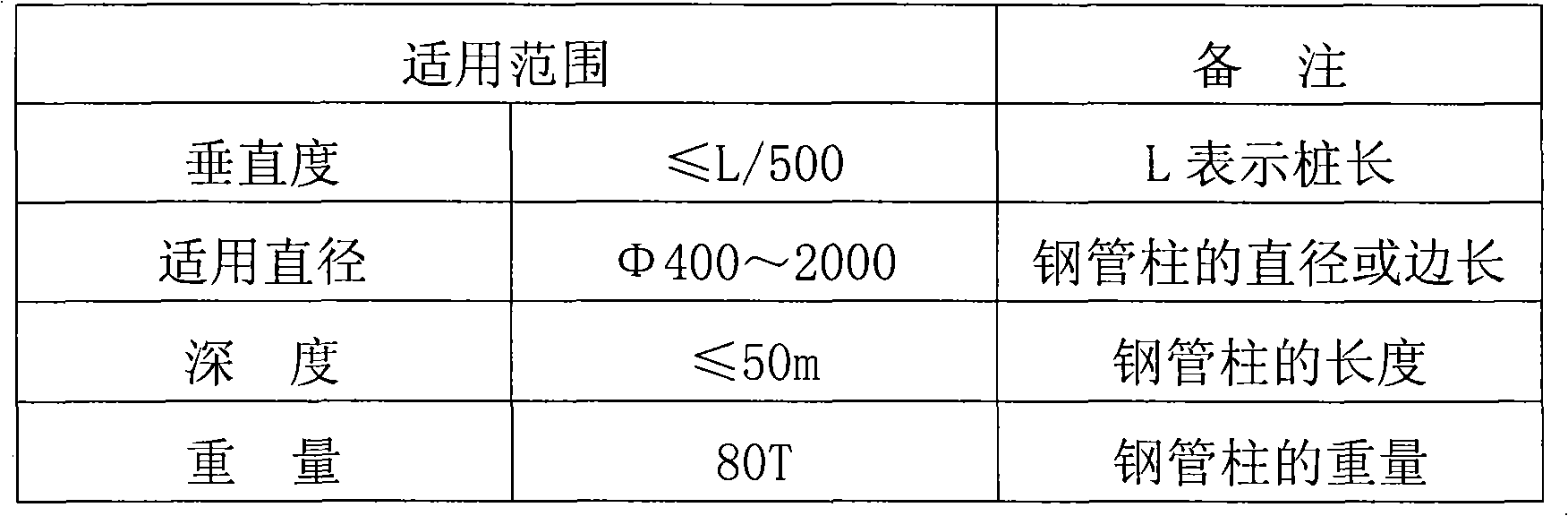

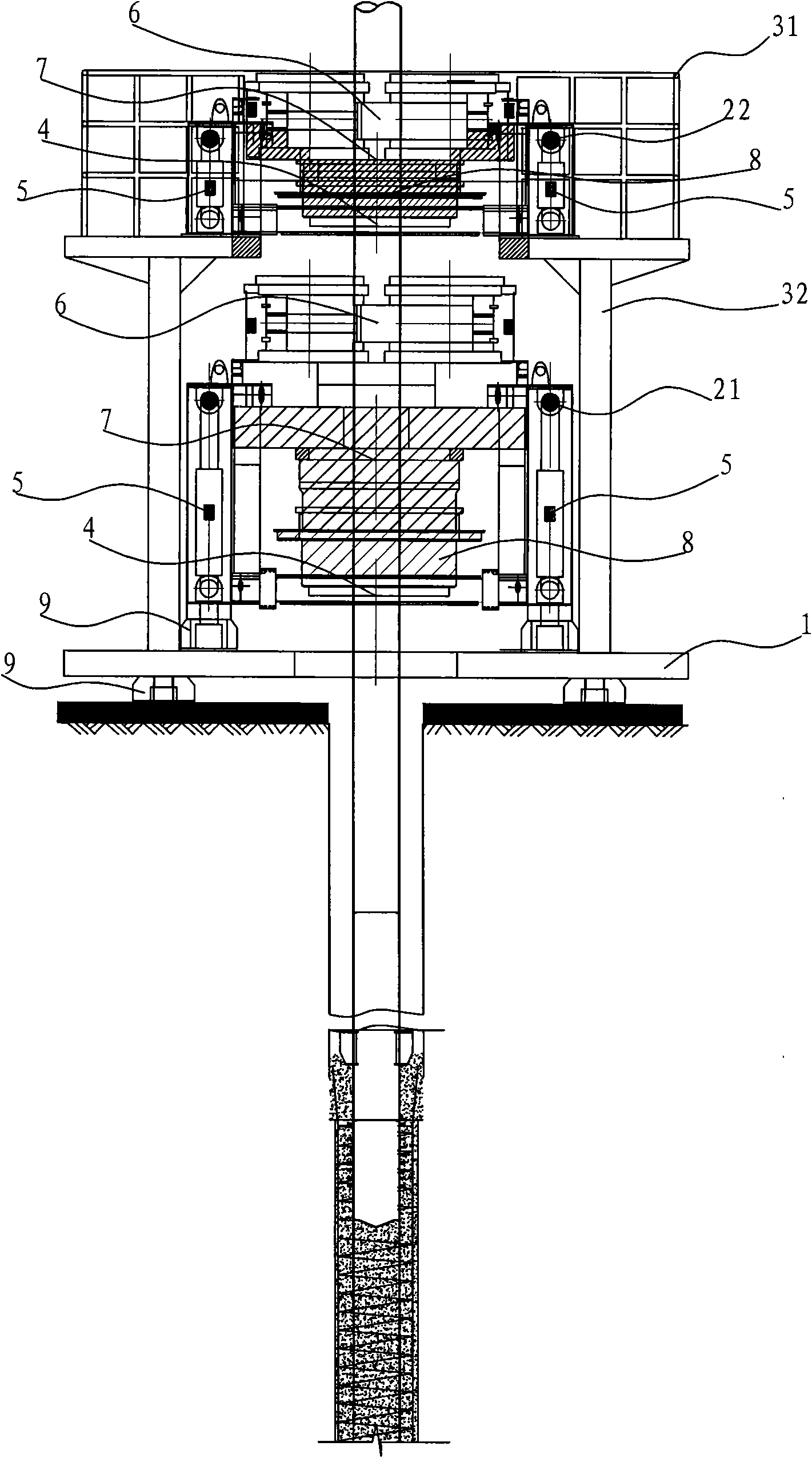

Hydraulic vertical insertion machine and method for connecting foundation pile and steel pipe column

InactiveCN101886398AControl floatGuaranteed verticalityFoundation engineeringBuilding material handlingEngineeringEnergy conservation

The invention relates to a hydraulic vertical insertion machine. The hydraulic vertical insertion machine comprises a seat body and a first hydraulic vertical insertion device arranged on the seat body, and is characterized in that the seat body is provided with a platform on which a second hydraulic vertical insertion device is arranged; the first hydraulic vertical insertion device and the second hydraulic vertical insertion device are sequentially arranged along the axial direction of the seat body; the first hydraulic vertical insertion device is arranged below the second hydraulic vertical insertion device; and the first hydraulic vertical insertion device and the second hydraulic vertical insertion device can independently or synchronously rotate 360 degrees to regulate the verticality of a steel pipe column. The hydraulic vertical insertion machine can effectively control the up-floating of the steel pipe column and ensure the vertical precision of inserting the steel pipe column. Compared with the conventional reversed construction method, the invention has the advantages of short construction period, saved energy resources and saved cost investment. The invention discloses the hydraulic vertical insertion machine and a method for connecting a foundation pile and a steel pipe column.

Owner:王薇

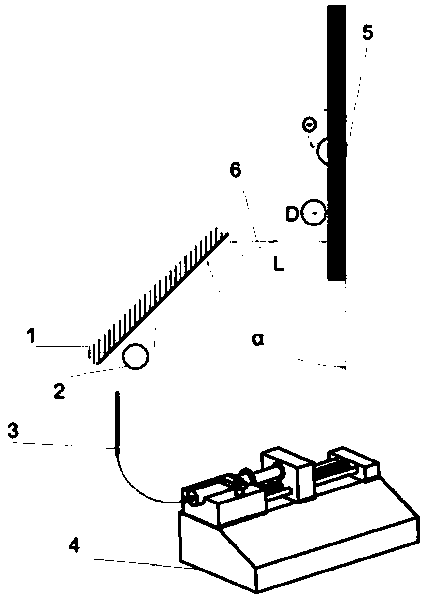

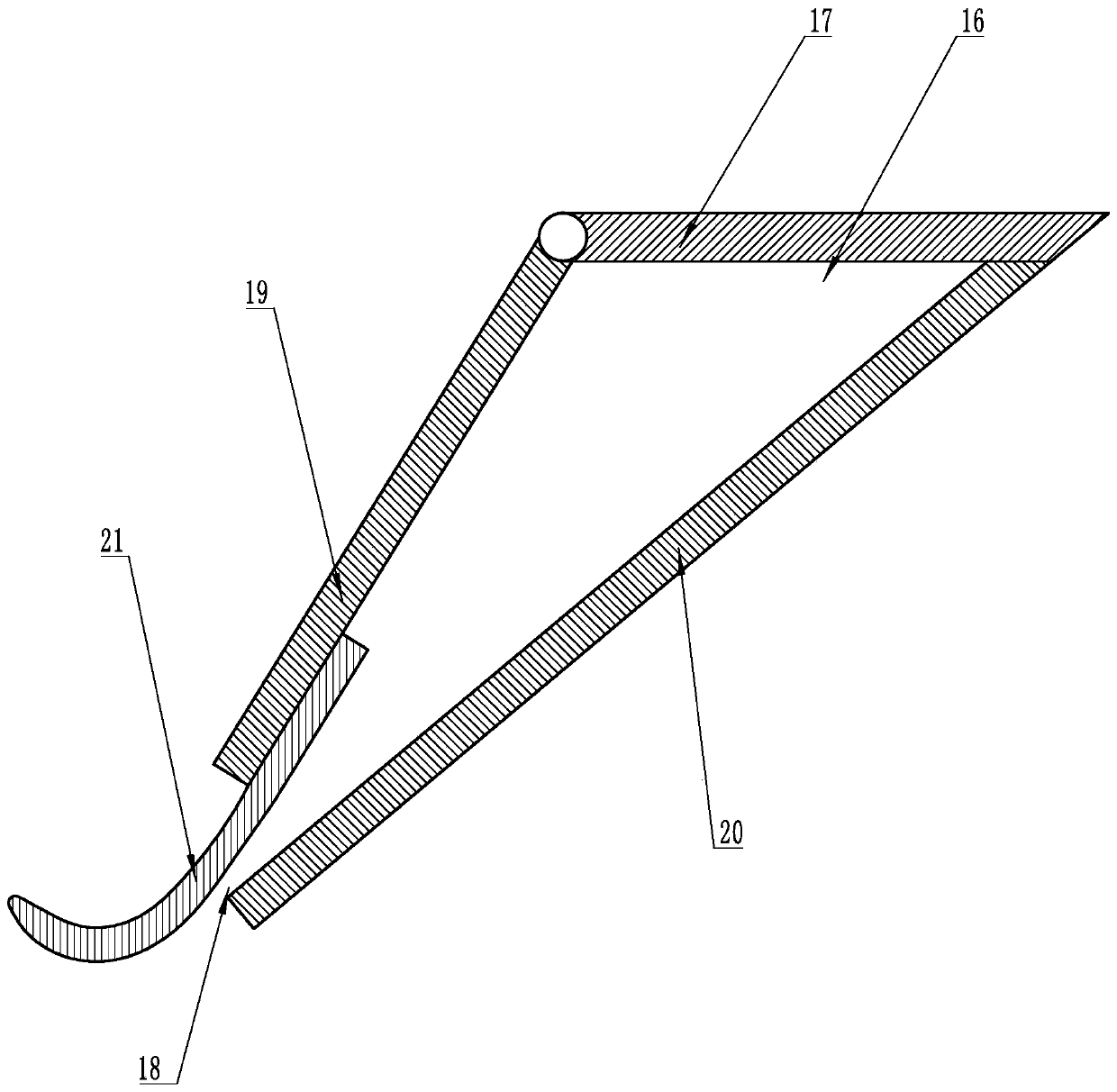

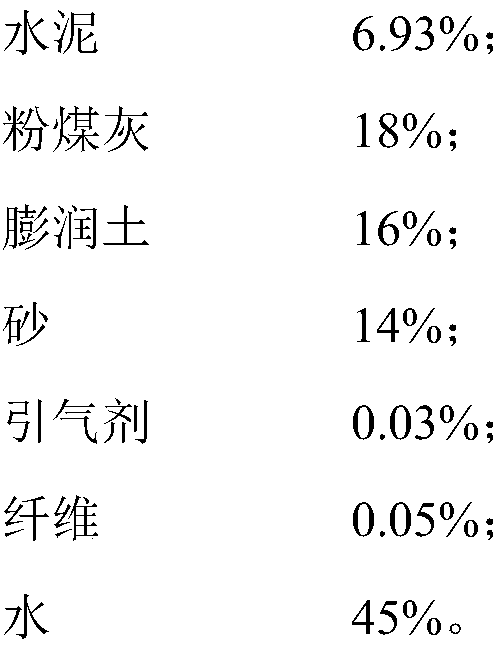

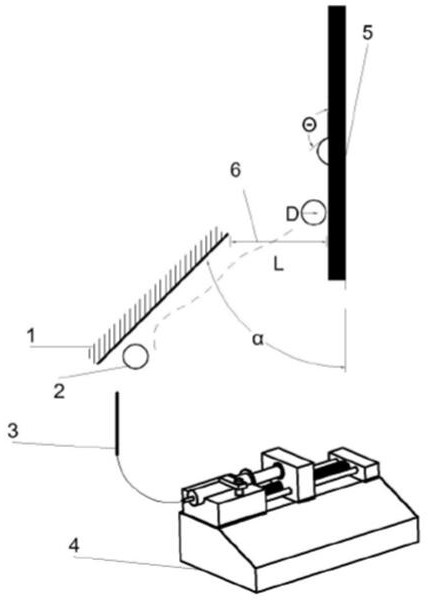

Method for controlling bubbles to adhere to super-aerophilic orbit on vertical or slant upper surface

ActiveCN110776038AImprove applicabilityControl floatLiquid degasification regulation/controlSustainable biological treatmentEngineeringMechanical engineering

The invention discloses a method for controlling bubbles to adhere to a super-aerophilic orbit on a vertical or slant upper surface. With the method, on the condition without energy input, bubbles canadhere to the super-aerophilic orbit as needed. Specifically, a super-hydrophilic flow guide plate which inclines in the direction of gravity according to a certain angle of alpha is arranged on thearea, close to a wall, of the super-aerophilic orbit; and when bubbles make contact with the super-hydrophilic flow guide plate under the action of buoyancy of themselves or upward drag force, and because of the super-aerophilic performance of the super-hydrophilic flow guide plate, bubbles move in the guiding direction of the super-hydrophilic flow guide plate till bubbles adhere to the super-aerophilic orbit smoothly and move along the super-aerophilic orbit. According to the method for controlling bubbles to adhere to the super-aerophilic orbit on a vertical or slant upper surface, bubblesare controlled to go up to float, the speed of bubbles going up is under control, no energy is input, and bubbles go up just by virtue of the buoyancy of themselves, and under the action of the factors such as the stressed drag force and wall surface adhesion force while the track of bubbles going up is under control. The method for controlling bubbles to adhere to the super-aerophilic orbit on the vertical or slant upper surface is high in applicability, the super-hydrophilic flow guide plate can be adjusted in curve radian to adapt to bubbles of different sizes, so that the purpose of controlling different bubbles to go up to float is achieved.

Owner:CHINA JILIANG UNIV

Pressure accumulation type deep sea suspension depth setting device

ActiveCN111959727AAutomatic control floatAutomatic sinkingUnderwater vesselsUnderwater equipmentPressure transmissionEngineering

A pressure accumulation type deep sea suspension depth setting device comprises a shell, and the shell is provided with a pressure transmission component and a buoyancy control structure; the pressuretransmission component comprises a sealed cavity formed in the shell, a piston is arranged in the cavity in a sliding mode, one end of the piston is fixed to the bottom of the cavity through a spring, the other end of the piston is connected with a pressure sensing unit penetrating out of the shell, the pressure sensing unit is connected with the shell in a sliding mode, and an annular groove isformed in the middle of the piston. The buoyancy control structure comprises an air bag, a high-pressure air bin and a low-pressure air bin, the high-pressure air bin is filled with high-pressure air,the air bag communicates with the middle of a cylinder sleeve, and the low-pressure air bin and the high-pressure air bin communicate with the two ends of the cylinder sleeve respectively. After thedepth position of the device is greatly changed due to the influence of marine environments such as internal waves, the device can be quickly and spontaneously adjusted to be within the preset depth range.

Owner:NAT UNIV OF DEFENSE TECH

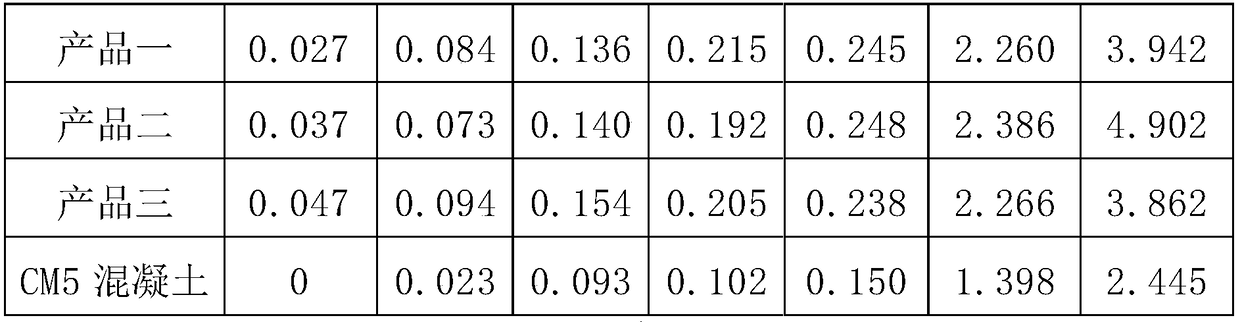

Synchronous grouting concrete and preparation method of synchronous grouting concrete

The embodiment of the invention provides synchronous grouting concrete, which is prepared from the following raw materials in parts by mass: 182 to 200 parts of Portland cement, 705 to 772.5 parts ofmachine-made sand, 705 to 772.5 parts of natural sand, 45.6 to 50 parts of bentonite, 3.65 to 4.93 parts of retarders, 0 to 4.93 parts of water reducing agents and 275 to 392.3 parts of drinking water. A proper amount of machine-made sand and natural sand are added into the synchronous grouting concrete, so that the early stage intensity of a product is favorably improved; the product performanceis improved; gaps inside the concrete can be well filled; the compactness of the synchronous grouting concrete is improved; meanwhile, a proper amount of Portland cement is added into the synchronousgrouting concrete; high pressure-resistant intensity, anti-seeping performance and anti-corrosion performance are realized; the ground surface settlement and pipe duct floatation can be effectively controlled. In addition, the synchronous grouting concrete provided by the invention has the advantages that the raw materials can be locally taken and easily obtained; the material cost is reduced; thepreparation method is simple.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

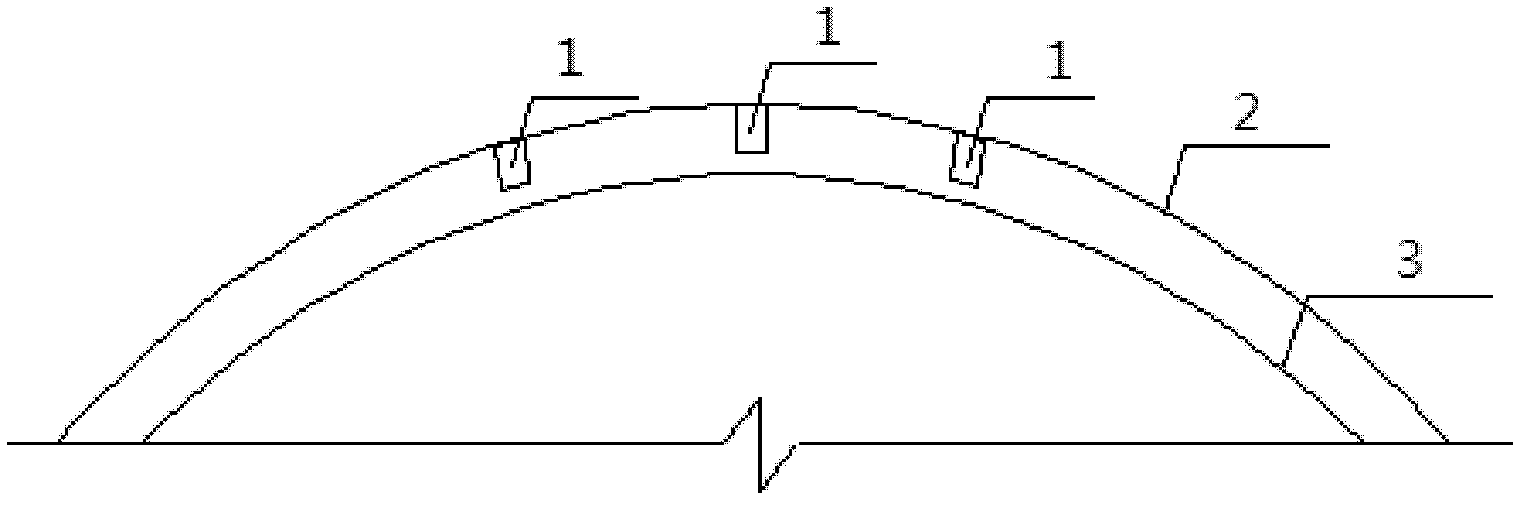

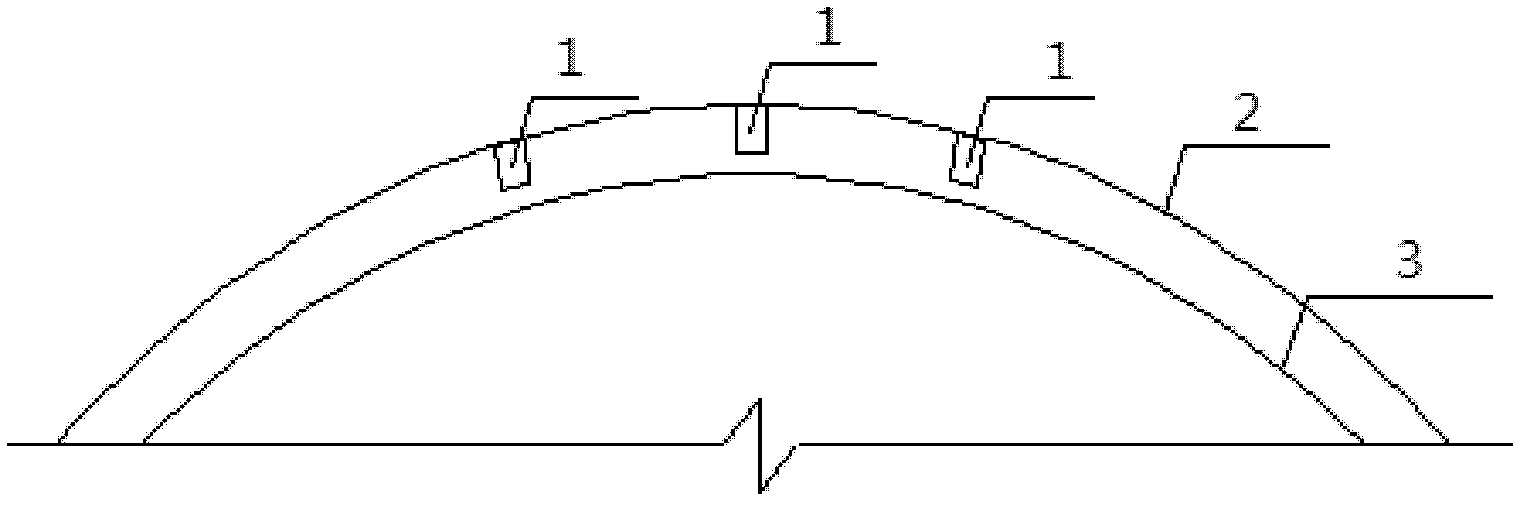

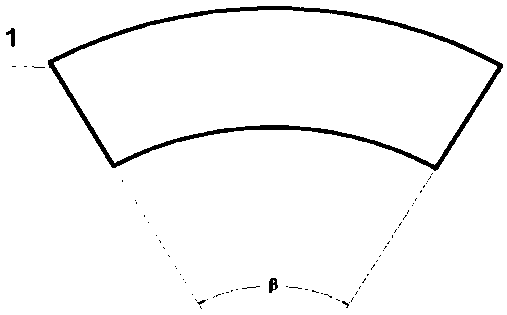

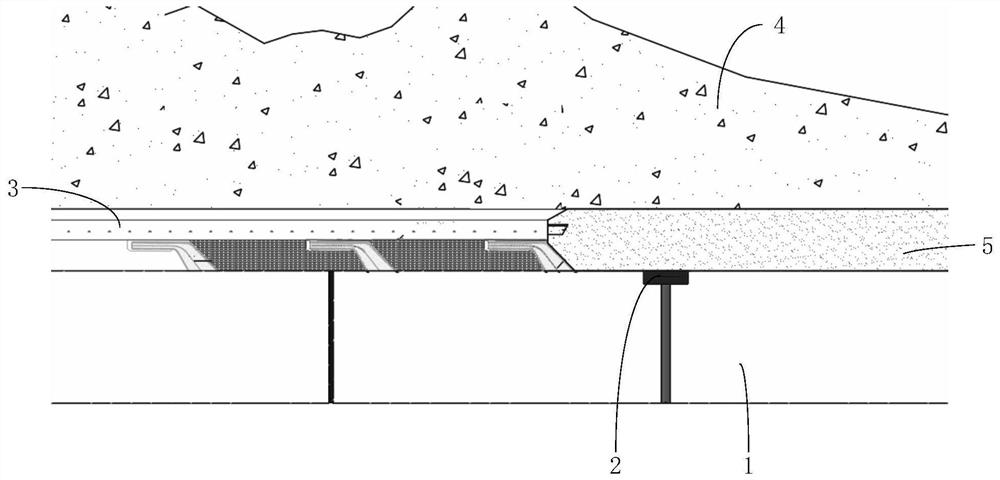

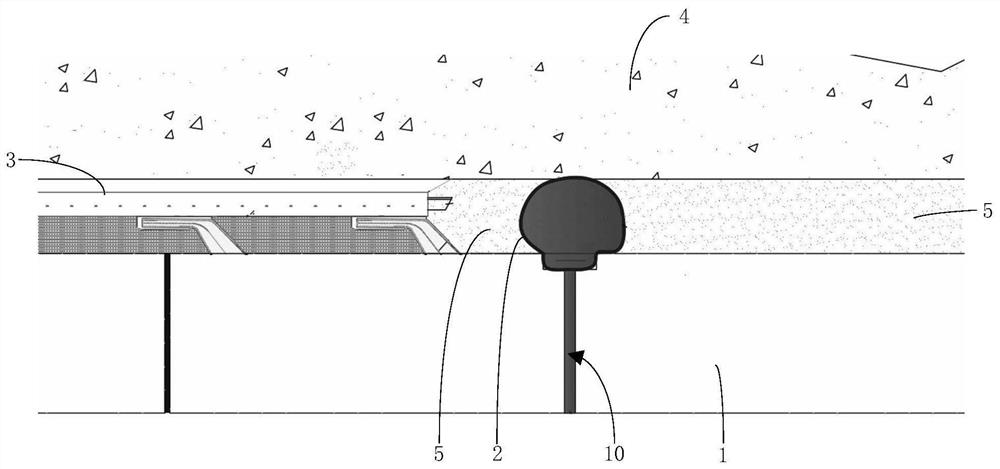

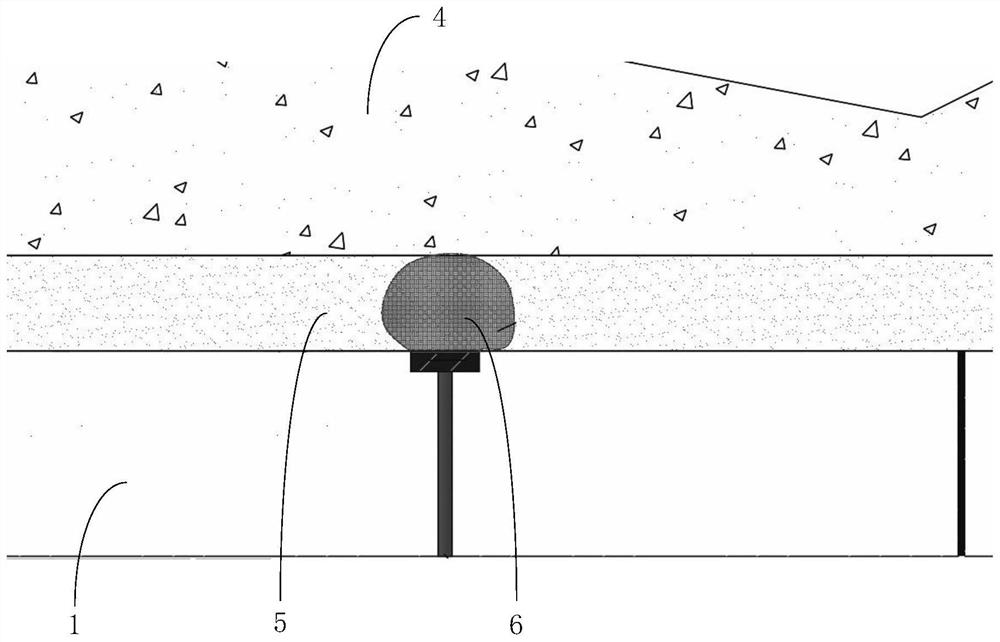

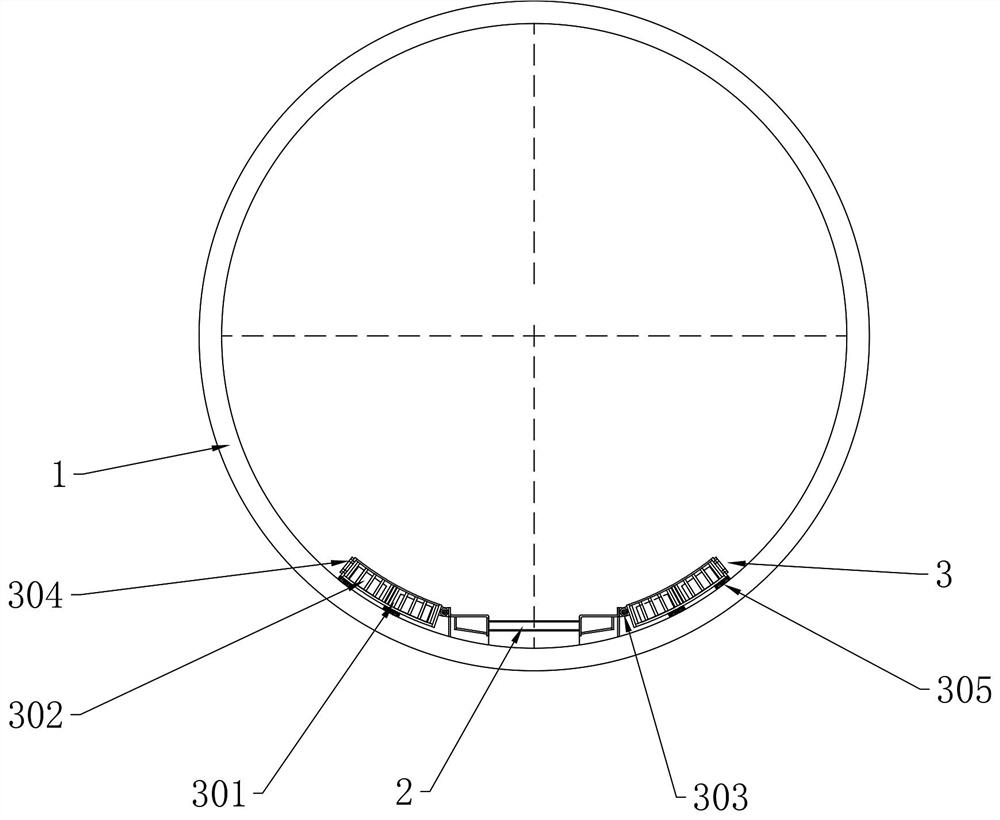

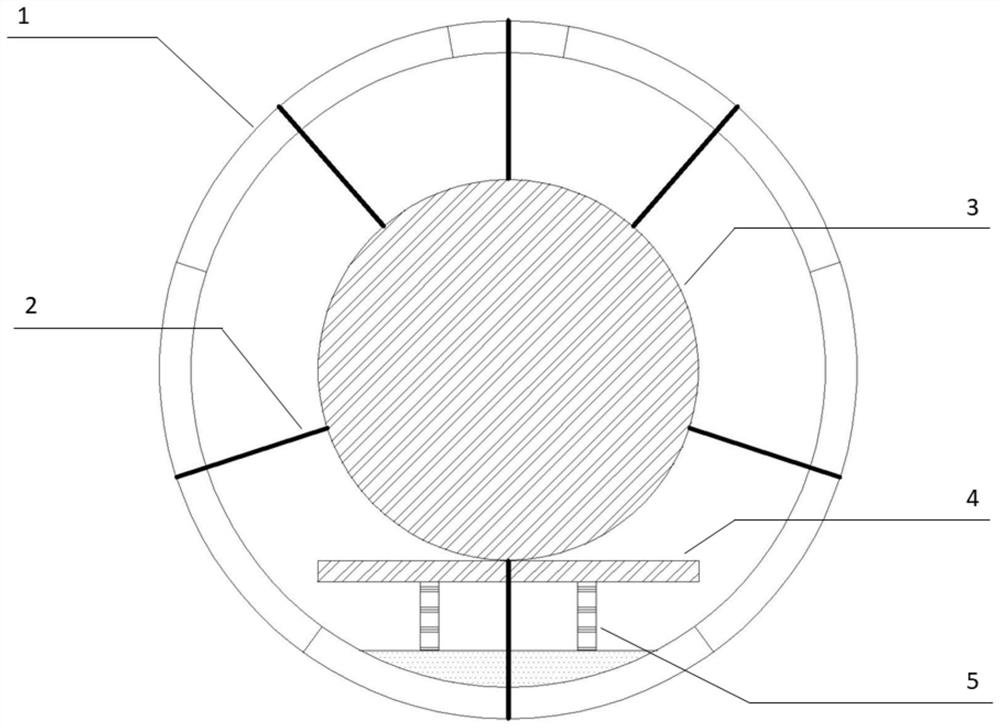

Shield segment for controlling floating, segment floating control system and control method thereof

PendingCN113073997AImprove molding qualityControl floatUnderground chambersTunnel liningControl effectControl system

The invention discloses a shield segment for controlling floating, a segment floating control system and a control method thereof. The shield segment comprises a ring of segment body and an expansion airbag, wherein a strip-shaped groove formed in the circumferential direction of the segment body is formed in the outer ring surface of the segment body, the strip-shaped groove is located at the top of the segment body, a through inflation hole is formed in the segment body, and the inflation hole communicates with the strip-shaped groove; and the expansion airbag is embedded in the strip-shaped groove, an air inlet of the expansion airbag is connected to the inflation hole, and the expansion airbag extends to the outside of the strip-shaped groove after being inflated and expanded and is supported between the outer ring surface of the segment body and the top hole wall of an excavated tunnel to adjust the distance between the outer ring surface of the segment body and the hole wall of the top of the tunnel. The shield segment solves the problem that the floating control effect of synchronous grouting after splicing and forming of a conventional shield segment is poor.

Owner:中建八局轨道交通建设有限公司

Sludge treatment device

InactiveCN107902861AImprove settlement performanceControl swellingSludge treatment by de-watering/drying/thickeningBiological sludge treatmentInternal pressureSludge

The invention discloses a sludge treatment device, which comprises a sludge treater main body, a stirring motor, a stirring shaft and a spiral blade, wherein a sludge inlet and a sludge outlet are respectively formed in the two ends of the sludge treater main body, the stirring motor is arranged on the outer side of the sludge treater main body and is connected with the stirring shaft in the sludge treater main body, the spiral blade is arranged on the stirring shaft, the sludge treater main body is of a circular-truncated-cone barrel-shaped structure, and the cross section of the sludge treater main body gradually decreases in the direction from the sludge inlet side to the sludge outlet side. In a process that sludge goes forwards in the sludge treater main body, extremely-large pressureis generated in the sludge treater main body, and the volume of the sludge gradually decreases; as the gas density is far smaller than the sludge floc density, gas is exhausted to an aerobic tank from an overflowing opening, a degassing process is achieved, an oxygen poor environment of an anoxic tank is ensured, sludge settleability is improved, sludge swelling and floating and foam generation are controlled, and effluent quality is optimized.

Owner:湖南千幻科技有限公司

Secondary grouting slurry for large-diameter shield in water-rich sand layer and seal plug thereof

PendingCN111520170AProlong clotting timeEasy to operateUnderground chambersSealing/packingAluminateSlurry

The invention provides secondary grouting slurry for a large-diameter shield in a water-rich sand layer. The secondary grouting slurry for the large-diameter shield in the water-rich sand layer comprises common silicate cement, super-early strength sulfoaluminate cement and water. In the construction process of the secondary grouting slurry for the large-diameter shield in the water-rich sand layer, the labor investment is small, the construction process is simple and easy to operate, the durability is good, the control effect on upward movement of a segment is good, the construction cost is saved, the construction efficiency is improved, and the secondary grouting slurry is worthy of application and popularization in the water-rich sand layer.

Owner:CHINA RAILWAY 14TH BUREAU GRP LARGE SHIELD ENG CO LTD

Method for replacing tail brush in extra large diameter shield driving under high water pressure condition

The invention relates to the technical field of tunnel shield construction, in particular to a method for replacing a tail brush in extra large diameter shield driving under a high water pressure condition. The method solves the problems of huge risks, high technical requirement, optimization of structural defect of the original tail brush, long construction period, high cost and the like when the tail brush is replaced in the conventional shield driving under the high water pressure condition. The method comprises the following steps of: performing preparation before the tail brush is changed; plugging high pressure underground water, synchronously injecting bentonite mud, injecting polyurethane at the shield tail, and injecting double-liquid slurry of cement and water glass to the back of a duct piece; and replacing the tail brush, detaching a capping block, detaching adjacent blocks, then cutting the damaged tail brush, optimizing the structure of the tail brush of the original design, welding a new tail brush, replacing the rest tail brush in a supporting reversal mode, replacing the tail brush at the last duct piece, and completing assembly of the duct piece of the capping block. The method has the advantages of simplicity in process, short construction period, low cost, controllable risk and the like, gains good economic benefit and social benefit, and has wide application range.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

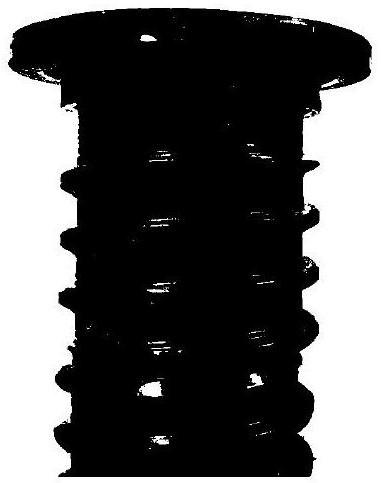

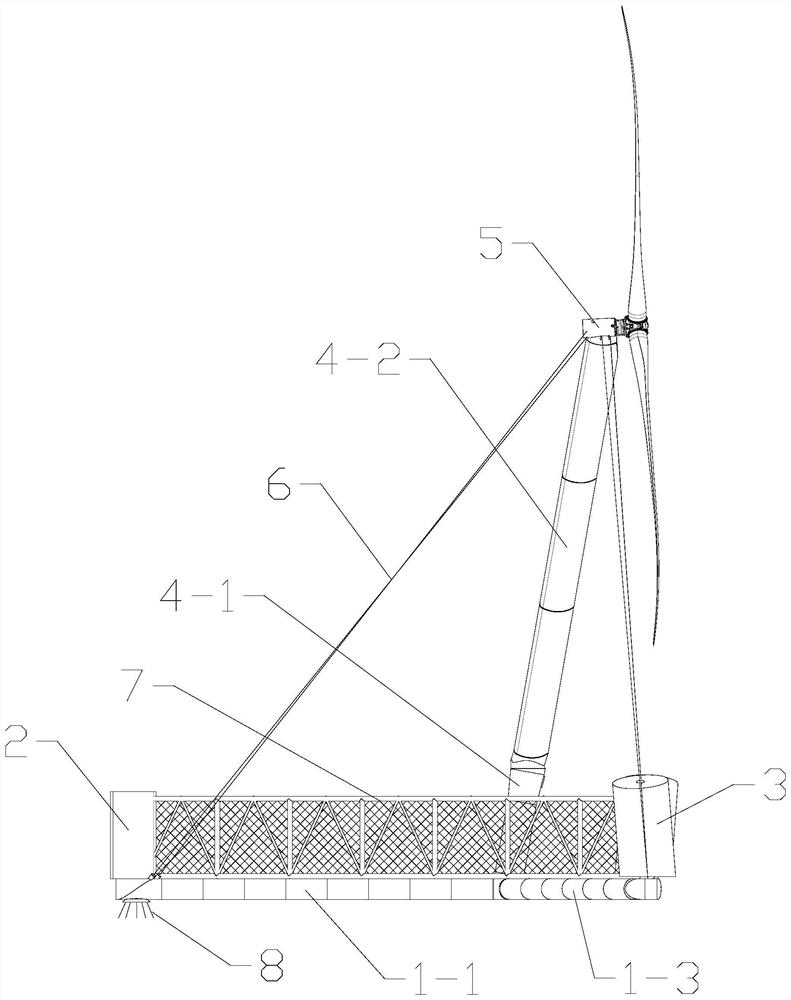

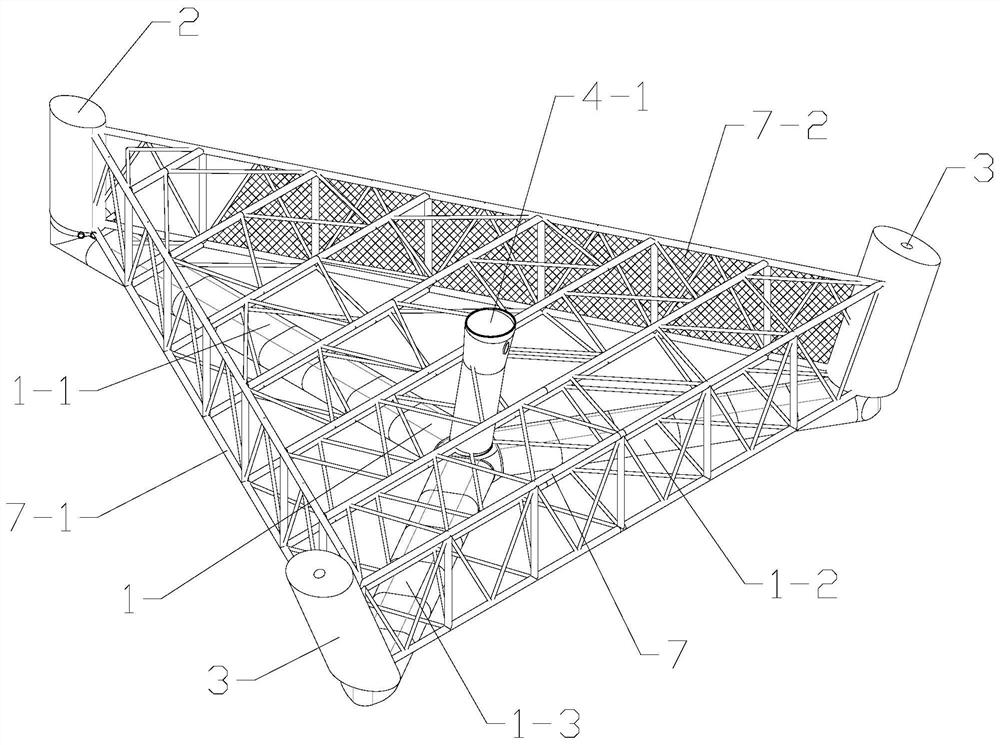

Floating platform combining wind power generation and mariculture

PendingCN112706889AEfficient use ofIncrease incomeWind motor controlWind motor supports/mountsMaricultureSea waves

The invention relates to the technical field of wind power generation, in particular to a floating platform combining wind power generation and mariculture; the platform comprises a floating foundation and a mariculture device, a tower is arranged on the floating foundation, a wind generating set is arranged on the tower, the mariculture device is arranged on the floating foundation, and the tower penetrates through the mariculture device. The wind driven generator and the mariculture device are integrated on the same floating platform; on the floating platform, wind power generation and mariculture can be synergistically carried out, marine energy can be effectively and comprehensively utilized, and comprehensive benefits are improved; according to the aquaculture net cage, an original floating foundation is fully utilized, and the aquaculture net cage and the floating foundation share one anchoring system, so that the construction cost of mariculture is greatly reduced; the aquaculture net cage is located below the sea level, the influence of sea waves can be avoided, the aquaculture net cage moves along with the Y-shaped floating foundation, seawater flowing in the aquaculture net cage is accelerated, and fish aquaculture is facilitated.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

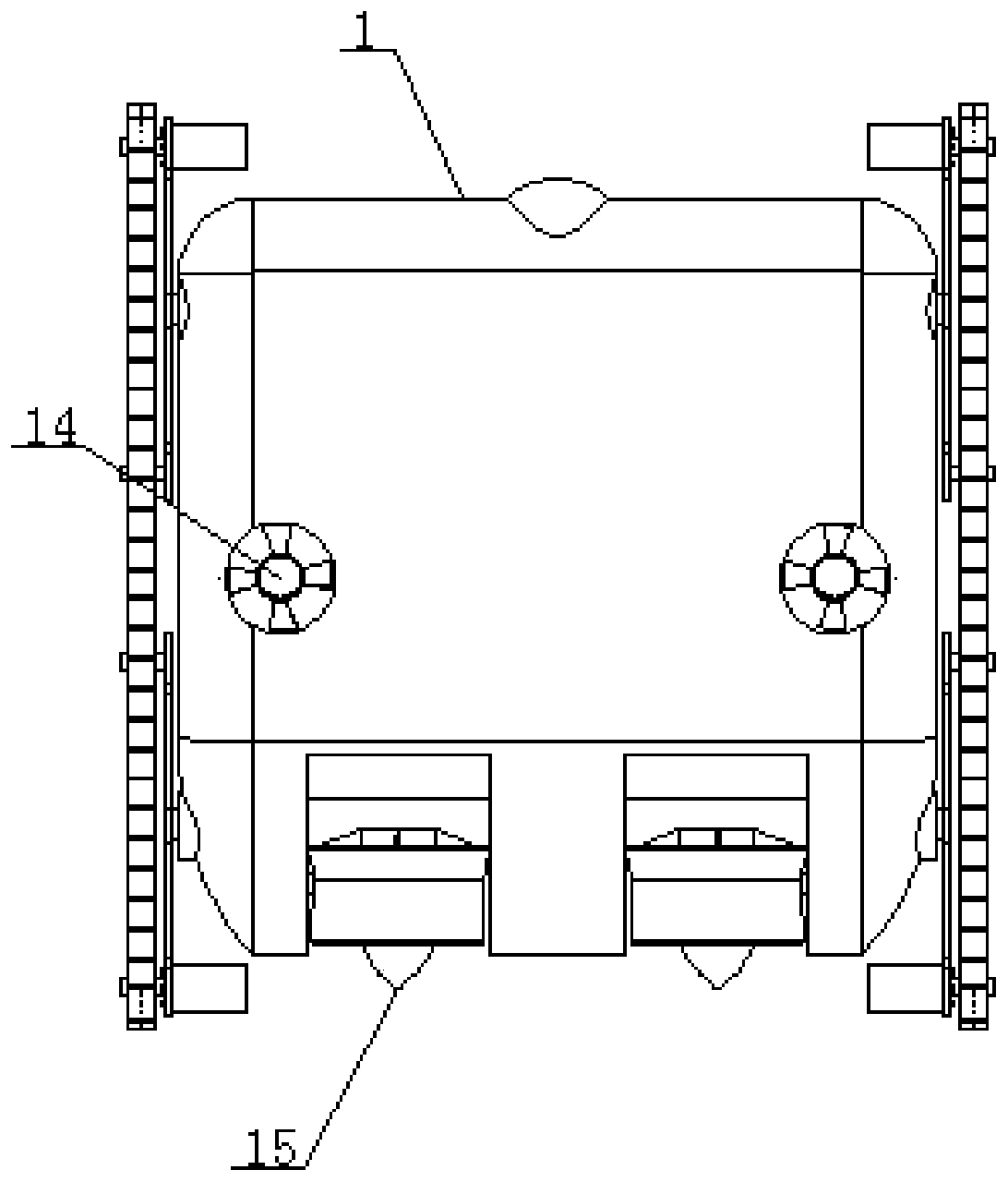

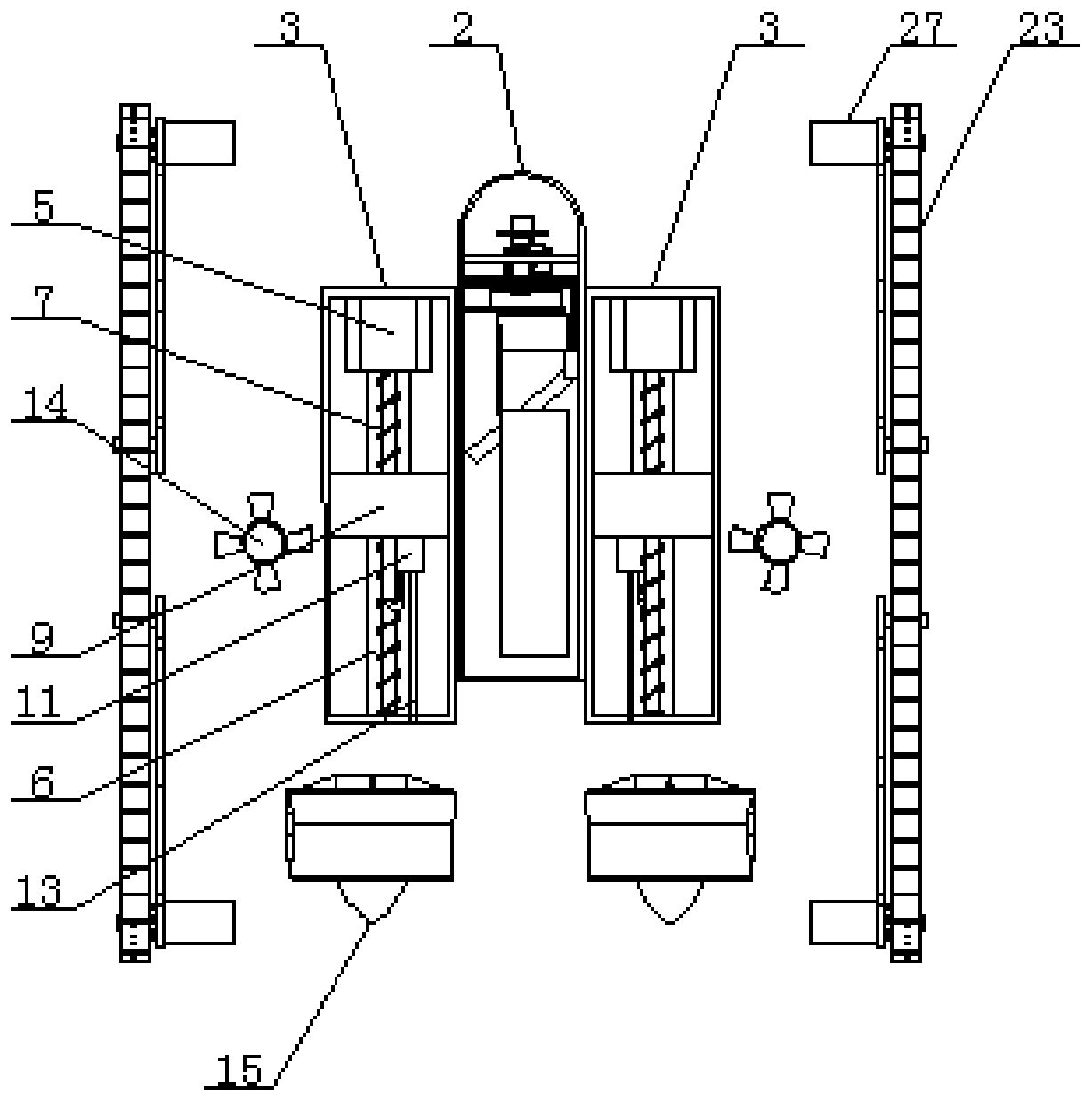

Nitrogen and carbon removal integrated equipment

InactiveCN107935181AImprove settlement performanceControl swellingSludge treatment by de-watering/drying/thickeningWater contaminantsInternal pressureSludge

The invention discloses nitrogen and carbon removal integrated equipment. The equipment comprises an anoxic tank, an aerobic tank, a settling tank and a sludge separator, wherein the sludge separatorcomprises a sludge separator body, a stirring motor, a stirring shaft and a helical blade; the helical blade is arranged on the stirring shaft; and the screw pitch of the helical blade is gradually reduced from a sludge inlet side to a sludge outlet side. During the process of advancing of sludge in the sludge separator body, with the gradual reducing of the screw pitch of the helical blade, greatinternal pressure is produced inside the sludge separator body, the volume of the sludge is continuously reduced, and as gas density is far lower than the sludge floc density, gas is discharged intothe aerobic tank from an overflow opening, a degassing process is realized, anoxic environment of the anoxic tank is guaranteed, the settling performance of the sludge is improved, expansion and floating of the sludge and the generation of bubbles are controlled, and the effluent quality is optimized.

Owner:湖南千幻科技有限公司

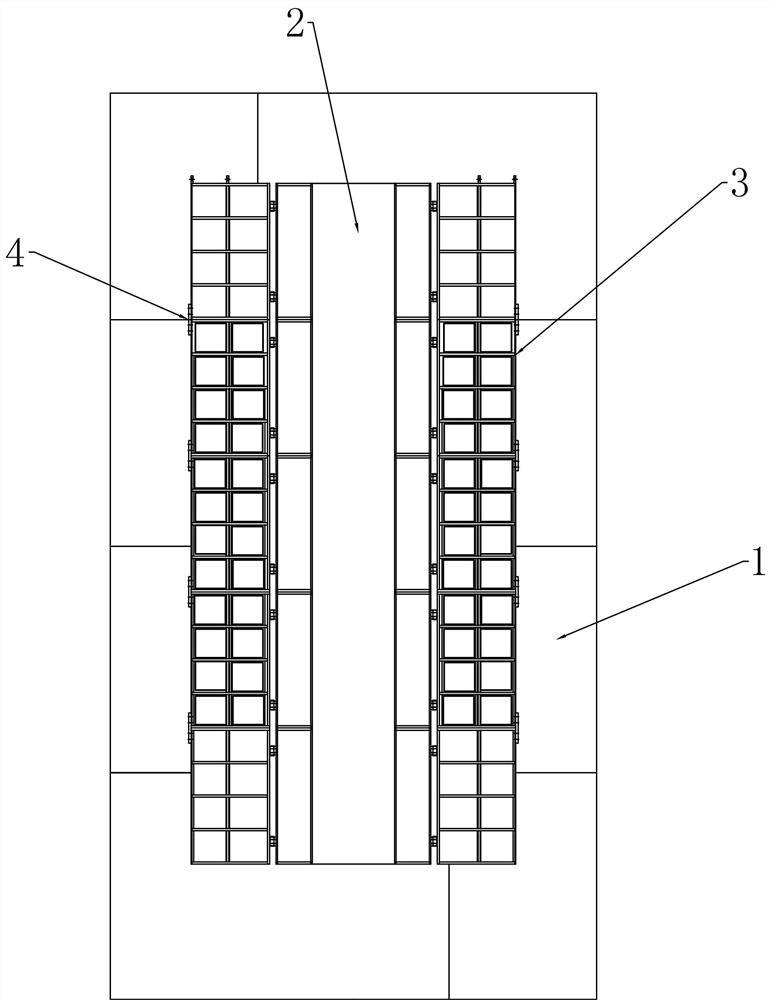

Fabricated ballasting device for preventing shield tail from floating upwards

PendingCN114526085AEasy to useImprove installation accuracyUnderground chambersTunnel liningStructural engineering

The invention provides an assembly type weight device for preventing a shield tail from floating upwards, which comprises force application units oppositely arranged on the two sides of a segment feeder, one side of each force application unit is hinged to the segment feeder, each force application unit comprises a plurality of weight devices arranged along the laying direction of segments, a bearing plate is arranged on the lower side of each weight device, a steel framework is arranged on each bearing plate, and the steel framework is arranged on the lower side of each weight device. A plurality of balance weight grooves are formed in the steel framework, balance weight bodies are detachably arranged in the balance weight grooves, a plurality of walking force transmission wheels are arranged at the bottom of the bearing plate, and the walking force transmission wheels are connected with the pipe pieces in a sliding mode. The device is compact in structure and convenient to use, can be quickly mounted and assembled in a tunnel, is convenient to adjust and control, and ensures high efficiency in the construction process, high duct piece mounting accuracy and stable state.

Owner:中交二航局(成都)建设工程有限公司

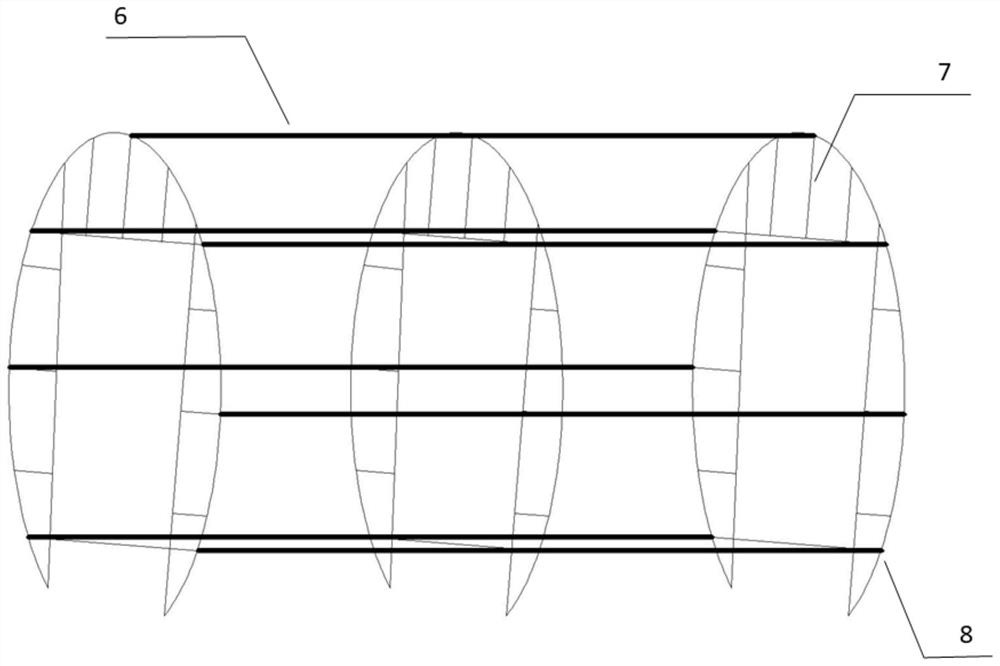

Moving device for controlling upward floating of shield tunnel and reinforcing method

PendingCN114658441AWeight increaseEnsure structural safetyMining devicesUnderground chambersWater storageWater storage tank

The invention discloses a moving device for controlling upward floating of a shield tunnel and a reinforcing method, the moving device at least comprises battery cars, water storage tanks, drainage pipes, sheet-shaped steel frames and profile steel connecting pieces, and the water storage tanks are erected on the bodies of the battery cars; each duct piece hole in the shield tunnel duct piece is connected with the water storage tank through a drainage pipe; the multiple sets of sheet-shaped steel frames are arranged in the radial direction of the shield tunnel and arranged between the periphery of the water storage tank and shield tunnel segments. The profile steel connecting pieces are connected with the sheet-shaped steel frames in the radial direction of the shield tunnel. The reinforcing method comprises the following steps: (1) draining water in the tunnel hole through the duct piece holes; (2) a plurality of battery cars are adopted in the tunnel to support the water storage tank, and all sets of sheet-shaped steel frames and profile steel connecting pieces on the periphery of the water storage tank serve as steel frame supports and are used for reinforcing and supporting shield tunnel segments; the method has the advantages of rapidness, mobility, real-time performance and the like, floating of the shield tunnel can be controlled, and the safety of the shield tunnel structure is ensured.

Owner:GUANGXI UNIV +1

Full-automatic plate trimming machine

InactiveCN105729275ATacit cooperationCompact structureGrinding machinesGrinding feedersWork taskEngineering

The invention provides a full-automatic edge sawing machine for edge trimming of plates. The edge sawing machine includes a feeding device, a long edge sawing device, and a steering device; the plate passes through the feeding device, the long edge sawing device, and the steering device; the long-side sawing device and the short-side sawing device are respectively located on the two sides adjacent to the steering device, and the horizontal direction of the long-side sawing device and the short-side sawing device The angle is 90°. Compared with the prior art, the edge sawing machine provided by the present invention has a simple structure, smooth plate feeding, and each link cooperates closely. When the next link is working, the previous link starts to prepare for the next task, the connection is tight, and the work efficient.

Owner:ANHUI ANSU WORLD HOME CO LTD

Nitrogen and phosphorus removal integrated device

InactiveCN107857448AImprove settlement performanceImprove effluent qualityWater contaminantsTreatment with anaerobic digestion processesExhaust gasInternal pressure

The invention discloses a nitrogen and phosphorus removal integrated device, which comprises a pre-anoxic pond, an anaerobic pool, an anoxic pond, an aerobiotic pond, a sediment pond, and a sludge separator; the sludge separator comprises a sludge separator main body, a stirring motor, a stirring shaft, and a spiral blade; the spiral blade is arranged on the stirring shaft, and the screw space ofthe spiral blade is gradually reduced from the mud inlet side to the mud outlet side. When sludge moves forwards in the sludge separator main body, the inner part of the sludge separator main body generates great inner pressure along with gradually reduced screw space of the spiral blade, and the sludge volume is continuously reduced; for the gas density is much less than that of the sludge floc,gas is discharged from an overflow opening to the aerobiotic pond; thus the oxygen deficiency environments of the pre-anoxic pond, the anaerobic pool, and the anoxic pond are guaranteed during the degasing process, the sludge settling performance is improved; the sludge expansion, floating and bubble generation are controlled, and effluent quality is optimized.

Owner:湖南千幻科技有限公司

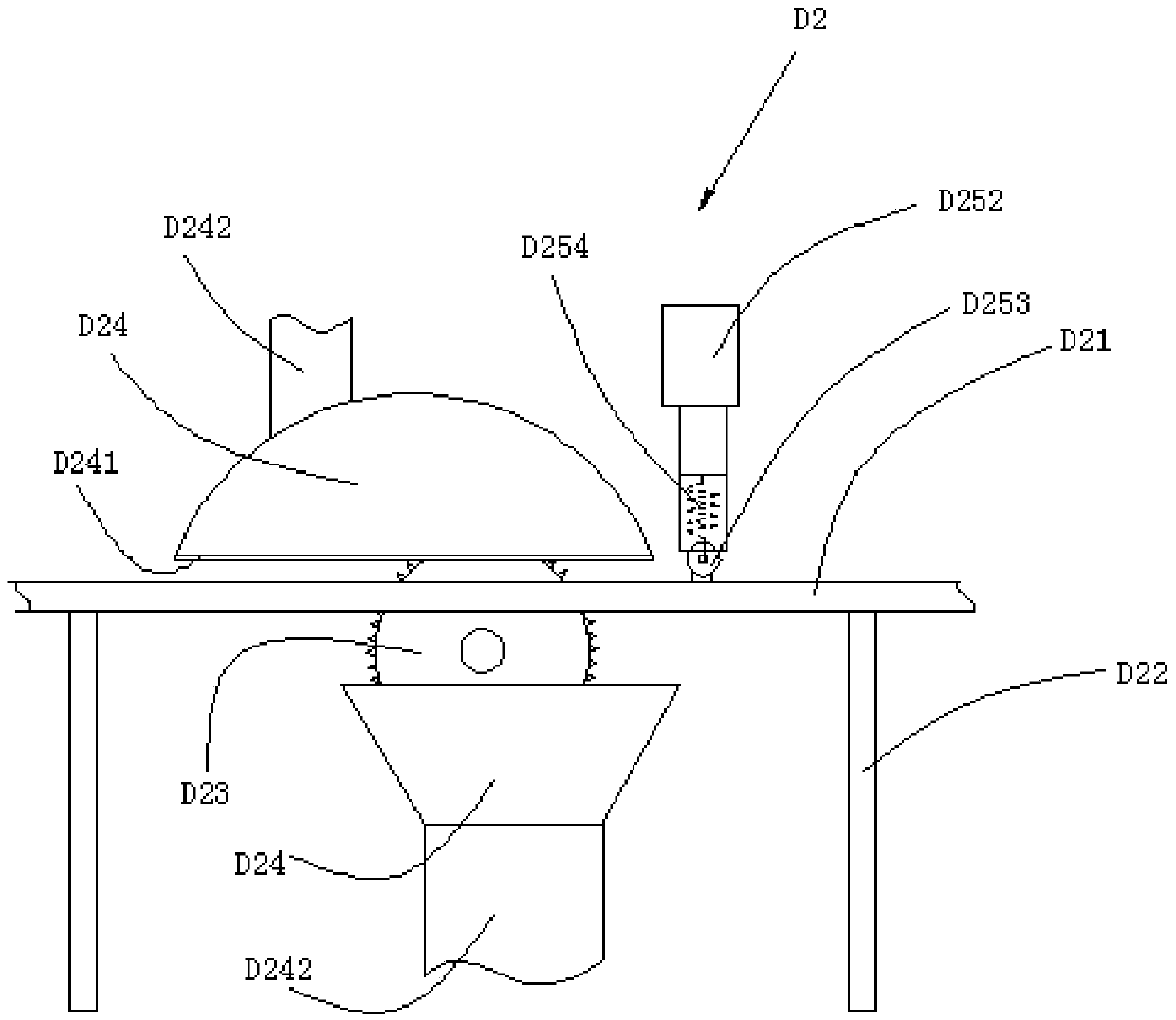

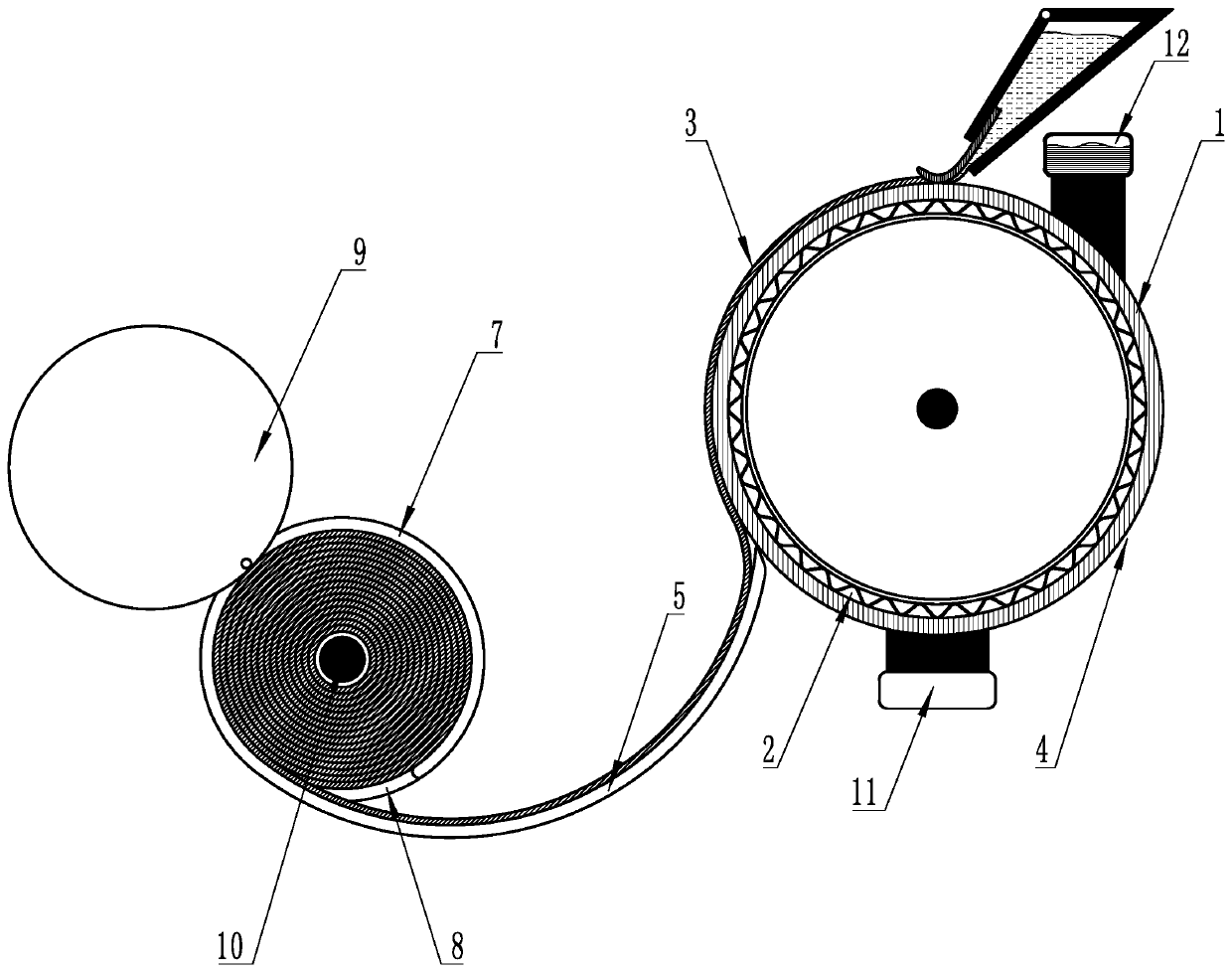

Continuous pancake machine

PendingCN111264572AImprove work efficiencyRealize continuous cake outputOil/fat bakingBaking surface cleaning/greasingEconomic benefitsEngineering

The invention relates to a continuous pancake machine. The continuous pancake machine comprises a columnar baking pan (1) and a feeding device. A central shaft of the columnar baking pan (1) is transversely arranged, and the columnar baking pan (1) rotates in the circumferential direction; the feeding device is correspondingly arranged above the columnar baking pan (1); a heating device (2) is arranged in the columnar baking pan (1) in the circumferential direction, a separating device is arranged on one side of the columnar baking pan (1), a working track (3) of the columnar baking pan (1) isformed from the feeding device to the separating device according to the rotating direction of the columnar baking pan (1), a cleaning track (4) of the columnar baking pan (1) is formed from the separating device back to the feeding device according to the rotating direction of the columnar baking pan (1), and a cleaning device is arranged on the cleaning track (4). Through the continuous pancakemachine, continuous cake discharging and automatic feeding can be achieved, operation of a user is facilitated, the working efficiency of the user is improved, and therefore economic benefits are improved.

Owner:蒋鹏

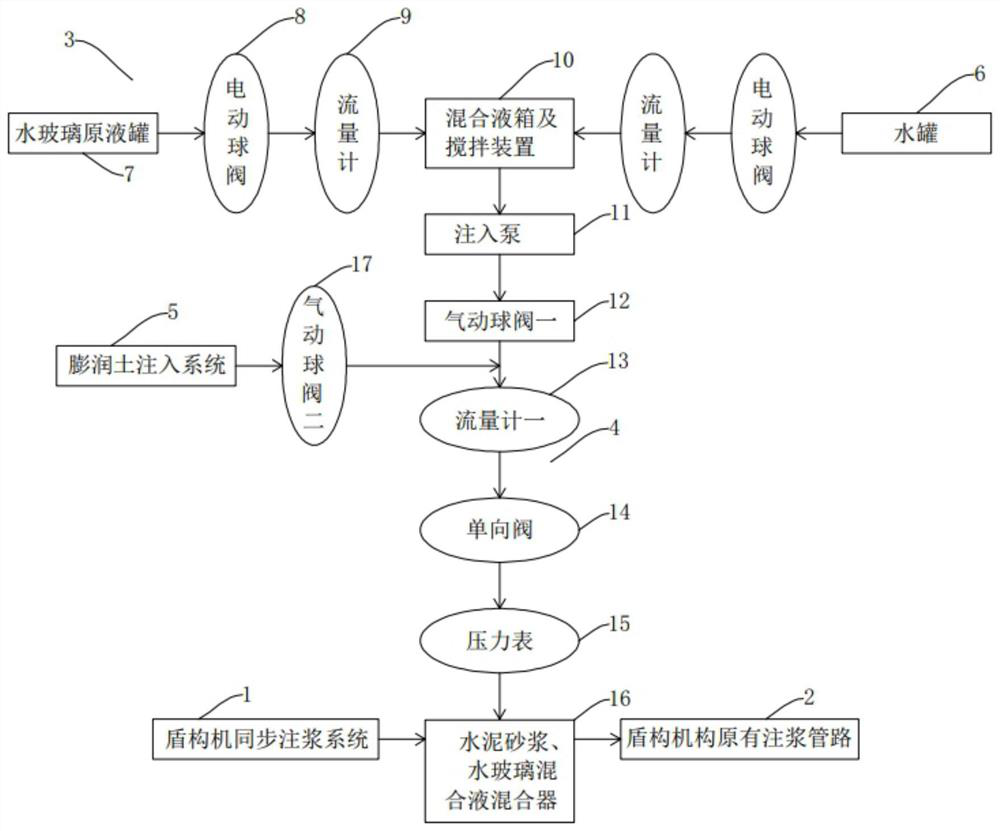

Synchronous grouting device capable of controlling pipe piece to float upwards and using method of synchronous grouting equipment

ActiveCN112761670AControl floatGuarantee molding qualityUnderground chambersTunnel liningShield tunnelingPipe

The invention discloses a synchronous grouting device capable of controlling a duct piece to float upwards. The device comprises a shield tunneling machine synchronous grouting system, a shield tunneling machine original grouting pipeline, a water glass configuration system, a water glass injection system and a bentonite injection system, and is characterized in that the water glass injection system is connected with the water glass configuration system; The bentonite injection system is connected with the water glass injection system, the shield tunneling machine synchronous grouting system is connected with the water glass injection system, and the shield tunneling machine original grouting pipeline is connected with the water glass injection system. The invention belongs to the technical field of shield construction, particularly relates to synchronous grouting equipment capable of controlling floating of duct pieces and a use method of the synchronous grouting equipment, and provides the synchronous grouting equipment capable of controlling the floating of the duct pieces to perform shield construction in a silty clay stratum, so that the floating amount of the duct pieces can be simply, quickly and effectively controlled, and the forming quality of an interval tunnel is ensured.

Owner:中铁六局集团公司交通工程分公司

A segment fixing pile device for fixing a shield tunnel segment and its use method

ActiveCN111577324BControl floatFloating is effectiveUnderground chambersTunnel liningArchitectural engineeringShield tunneling

Owner:湖南中天凿岩科技有限公司

Comprehensive treatment method for blue-green algae sludge

The invention relates to a comprehensive treatment method for blue-green algae sludge. By the method, the growth of blue-green algae can be effectively controlled. The comprehensive treatment method for the blue-green algae sludge comprises the following steps of: a, pumping water out of a lake; and b, throwing a blue-green algae sludge comprehensive treatment material into the lake, stirring to ensure that the material is combined with sludge at the lakebed, and hardening and coagulating the sludge, wherein the blue-green algae sludge comprehensive treatment material comprises aluminium sulphate salt, lime, gypsum, charcoal powder and a foaming agent; based on the total weight of the aluminium sulphate salt, the lime, the gypsum and the charcoal powder, the aluminium sulphate salt accounts for 60 to 65 percent, the lime accounts for 20 to 27 percent of lime, the gypsum accounts for 5 to 10 percent, and the charcoal powder accounts for 8 to 10 percent; and the foaming agent is added in an amount which is 10 percent based on the total weight of the aluminium sulphate salt, the lime, the gypsum and the charcoal powder. The blue-green algae can be treated together with the sludge at the lakebed by the method before the blue-green algae breeds like an explosion (namely the blue-green algae are at a spore stage), and the blue-green algae can be outrooted under the condition of isolating a new blue-green algae growth source.

Owner:NANJING HUATING ENVIRONMENTAL PROTECTION TECH DEV

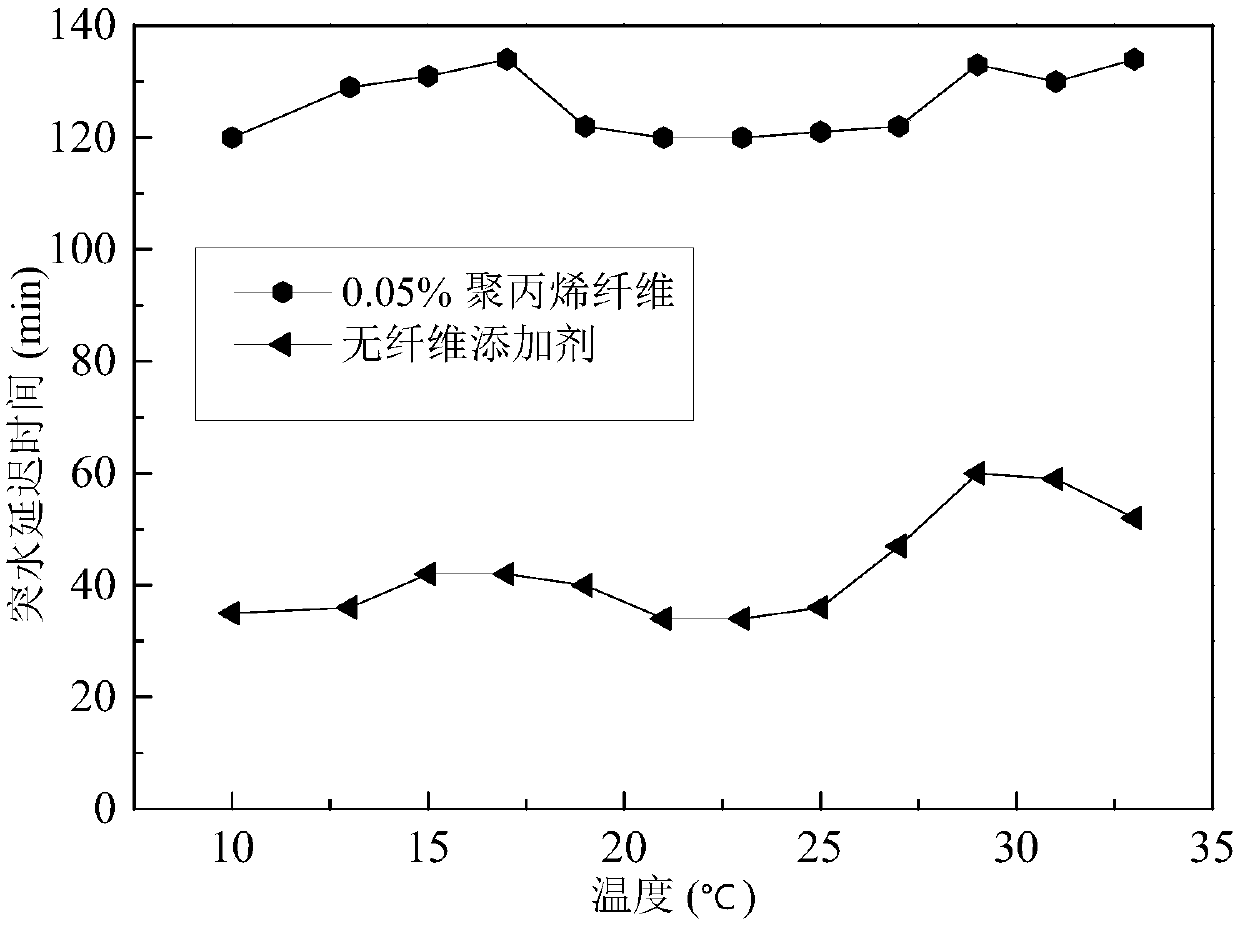

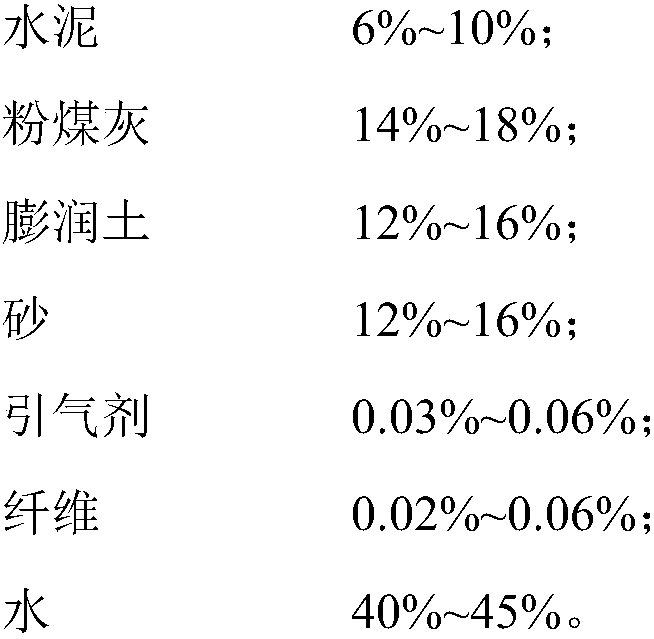

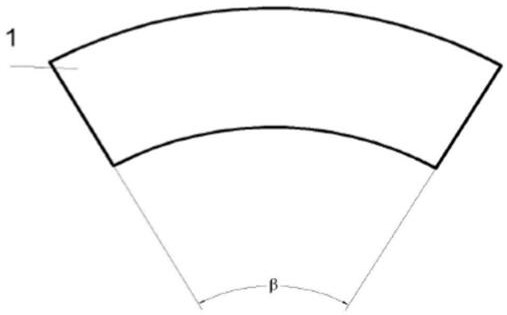

Anti-surge grouting material for shield construction in mylonite broken zone and its preparation method

The invention provides a grouting material for surge prevention in the mylonite crushing zone shield construction and a preparation method thereof. The material comprises the following components in percentage by weight: 6-10 percent of cement, 14-18 percent of fly ash, 12-16 percent of bentonite, 12-16 percent of sand, 0.03-0.06 percent of air entraining agent, 0.02-0.06 percent of fiber and 40-45 percent of water. The grouting material provided by the invention has the benefits that the proportion of various raw materials in parts by weight can be adjusted; as the polypropylene fibers are added as fiber curing agents, the consistency and the tensile property of the grouting material are enhanced by utilizing the adhesiveness of the fibers; meanwhile, as the air entraining agent is added, the workability of the grouting material is enhanced.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +2

A method to control the adhesion of bubbles to superaerophilic orbitals on vertical or inclined upper surfaces

ActiveCN110776038BEasy to controlImprove applicabilityLiquid degasification regulation/controlSustainable biological treatmentAdhesion forceMechanical engineering

The invention discloses a method for controlling the adhesion of bubbles to a super-aerophilic orbit on a vertical or inclined upper surface. Under the condition of no energy input, the bubbles can be adhered to the super-aerophilic orbit as needed, specifically, in the super-aerophilic orbit. In the area near the wall of the gas track, arrange a certain angle α A superhydrophilic deflector inclined to the direction of gravity; when the bubble contacts the superhydrophilic deflector under the action of its own buoyancy or upward drag force, due to the superhydrophobicity of the superhydrophilic deflector, the bubble will move along the The super-hydrophilic deflector guides the movement until the bubbles are smoothly adsorbed on the super-aerophilic track and move along the super-aerophilic track; in the present invention, the bubbles are controlled to float along a straight line and the floating speed has no energy input, and only relies on the buoyancy of the bubbles itself. The drag force and the wall adhesion force are used to control the floating trajectory of the bubbles. The invention has strong applicability, and adjusting the curvature of the super-hydrophilic baffle can be used for bubbles of different sizes, so as to achieve the purpose of controlling the floating of different bubbles.

Owner:CHINA JILIANG UNIV

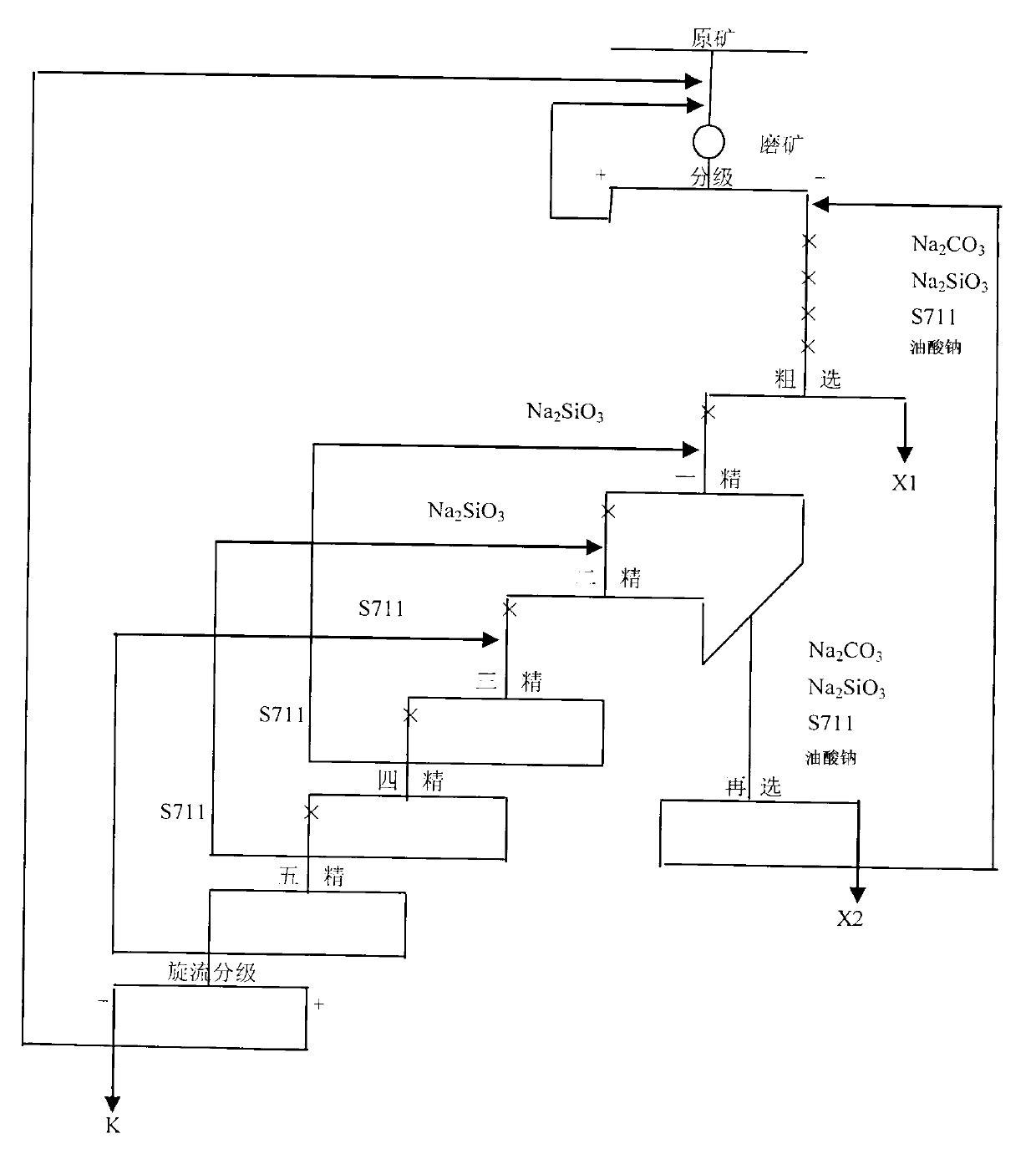

Floatation and enrichment process for silicon-calcium mass type fluorite ores

The invention relates to a floatation and enrichment process for silicon-calcium mass type fluorite ores, which is characterized by comprising the following steps: dissociating the constituent mineral monomers of the silicon-calcium mass type fluorite ores by crushing and ore grinding, flowing into a stirring tank after adding water and regulating pulp, then adding a regulating agent of sodium carbonate, water glass, S711 and a collecting agent of sodium oleate into the ore pulp for regulating the pulp, roughing the material of which the pulp is regulated, selecting roughed foam for the firsttime, selecting the foam which is selected for the first time for the second time, combining a product in a primary selecting tank, i.e. middlings which are selected for the first time and a product in a secondary selecting tank, i.e. middlings which are selected for the second time, adding the regulating agent and the collecting agent of the sodium oleate, regulating the pulp, selecting the material of which the pulp is regulated again, returning the foam which is selected again for the roughing operation, selecting the foam which is selected for the second time for the third time until selecting for the fifth time, returning the middlings which are selected for the third time, the fourth time and the fifth time by adopting the separating operation, grading the foam which is selected forthe fifth time by a cyclone, overflowing the cyclone, concentrating and filtering to obtain a fluorite concentrate product. The process disclosed by the invention has the advantages of high separation efficiency, excellent process index, high quality of obtained fluorite concentrates and the like.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com