Oxidation ditch sewage disposal method including rotational flow spreading treatment and device thereof

A sewage treatment method and a technology of a cyclone breaker, which are applied in the field of sewage treatment process transformation, can solve the problem of floating and swelling of sludge enriched on the surface of sludge or pores, waste of energy consumption by air aeration, and reduction of oxidation ditch. Effective volume and other issues to achieve the effect of improving sludge settling performance, increasing water flow rate, and improving sewage treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] The present invention is further described below in conjunction with specific examples. However, it should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention. The test methods for which specific conditions are not indicated in the following examples are generally in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer.

[0051] 1. Implementation process

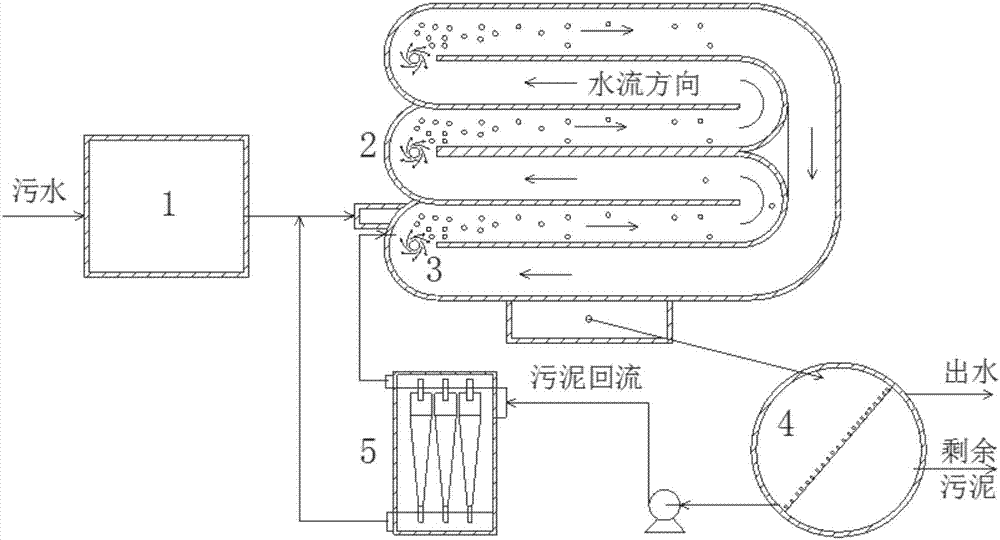

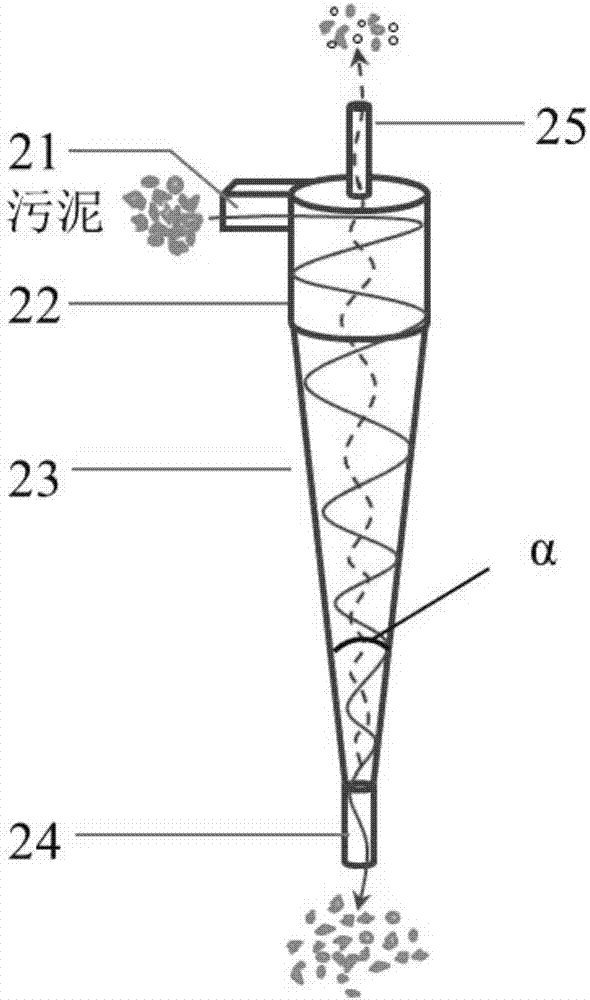

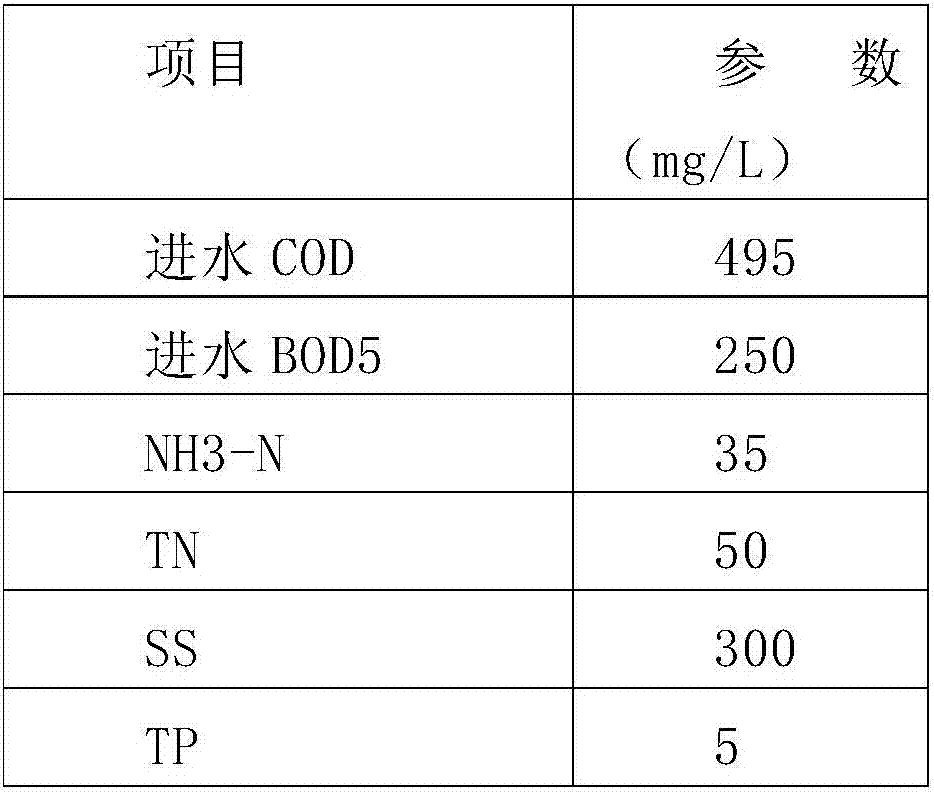

[0052] This embodiment is applied to the treatment of industrial waste water and domestic sewage in the industrial zone of the development zone, with a treatment capacity of 100,000 tons per day. The influent water quality and process parameters are shown in Table 1. Process flow diagram as figure 1 As shown, the waste water is separated by cyclone in the grit chamber 1 to remove scum to reduce the processing burden of the subsequent process, and then enters the aeration zone of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com