Floatation and enrichment process for silicon-calcium mass type fluorite ores

A technology of fluorite ore and silicon-calcium, which is applied in the field of flotation of fluorite ore, can solve problems such as difficult to obtain and unsatisfactory suppression effect, and achieve improved separation and separation efficiency, high quality, and high separation efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

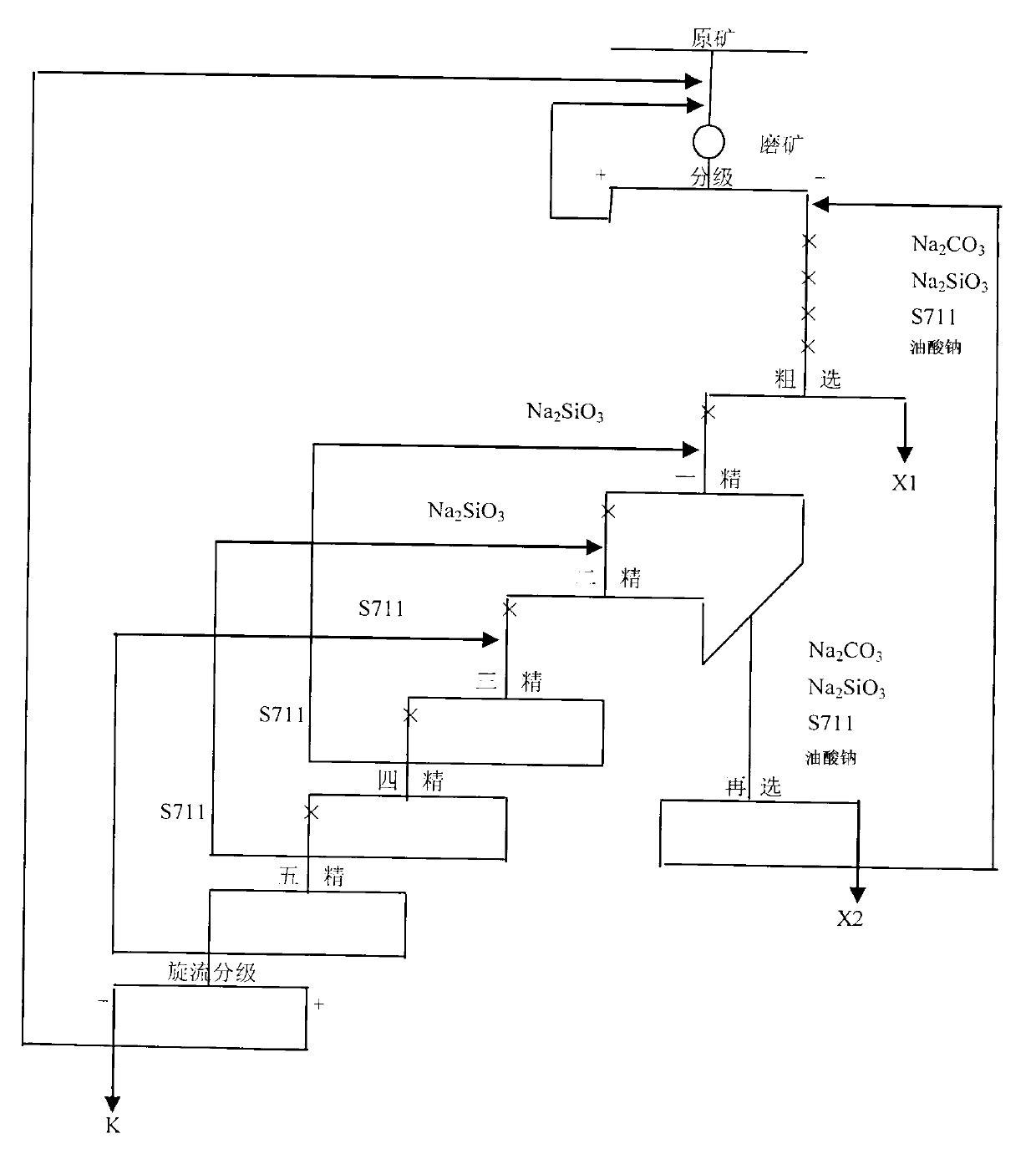

[0018] Embodiment 1, with reference to figure 1 , a flotation enrichment process of siliceous-calcium fluorite ore, the siliceous-calcium fluorite ore is crushed and ground to dissociate the constituent mineral monomers, and water is added to adjust the slurry to a concentration of 20% ore, and then Flow into the stirring tank, and then add regulator sodium carbonate, water glass, S711 and collector sodium oleate to the slurry to adjust the slurry. The material after slurry adjustment enters the flotation system for rough separation, and the product in the tank is tailings X1 , discharged and piled up, the rough selection foam product is added to the water glass for slurry mixing, and the first selection is carried out after the first selection foam is added to the water glass slurry, and then the second selection is carried out. The product in the selection tank, that is, the secondary refined medium ore, is mixed and added with regulator sodium carbonate, water glass, S711 a...

Embodiment 2

[0019] Embodiment 2, with reference to figure 1 , a flotation enrichment process of siliceous-calcium fluorite ore, the siliceous-calcium fluorite ore is crushed and ground to dissociate the constituent mineral monomers, and water is added to adjust the slurry to a concentration of 50%, and then Flow into the stirring tank, and then add regulator sodium carbonate, water glass, S711 and collector sodium oleate to the slurry to adjust the slurry. The material after slurry adjustment enters the flotation system for rough separation, and the product in the tank is tailings X1 , discharged and piled up, the rough selection foam product is added to the water glass for slurry mixing, and the first selection is carried out after the first selection foam is added to the water glass slurry, and then the second selection is carried out. The product in the selection tank, that is, the secondary refined medium ore, is mixed and added with regulator sodium carbonate, water glass, S711 and c...

Embodiment 3

[0020] Embodiment 3, with reference to figure 1 , a flotation enrichment process of siliceous-calcium fluorite ore, the siliceous-calcium fluorite ore is crushed and ground to dissociate the constituent mineral monomers, and water is added to adjust the slurry to a concentration of 40%, and then Flow into the stirring tank, and then add regulator sodium carbonate, water glass, S711 and collector sodium oleate to the slurry to adjust the slurry. The material after slurry adjustment enters the flotation system for rough separation, and the product in the tank is tailings X1 , discharged and piled up, the rough selection foam product is added to the water glass for slurry mixing, and the first selection is carried out after the first selection foam is added to the water glass slurry, and then the second selection is carried out. The product in the selection tank, that is, the secondary refined medium ore, is mixed and added with regulator sodium carbonate, water glass, S711 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com