Anti-surge grouting material for shield construction in mylonite broken zone and its preparation method

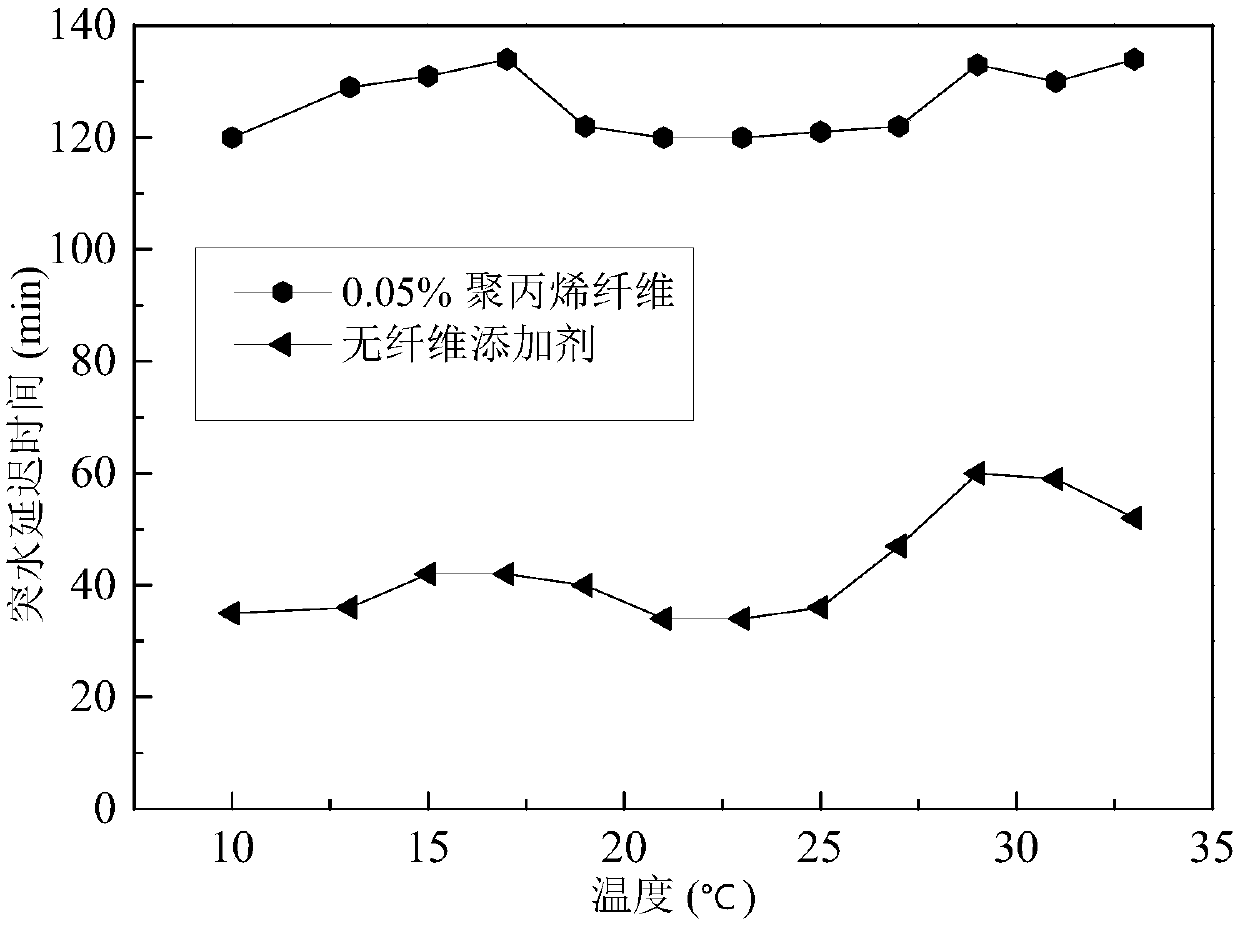

A technology of grouting material and broken zone, which is applied in the field of anti-surge grouting material and its preparation for shield tunneling construction in the broken zone of mylonite, which can solve the problem of high water content in the broken zone, inconvenience in engineering construction, and the problem of plugged grouting pipes. To achieve the effect of improving workability and durability, reducing ground subsidence, and filling the gap in the tail of the shield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

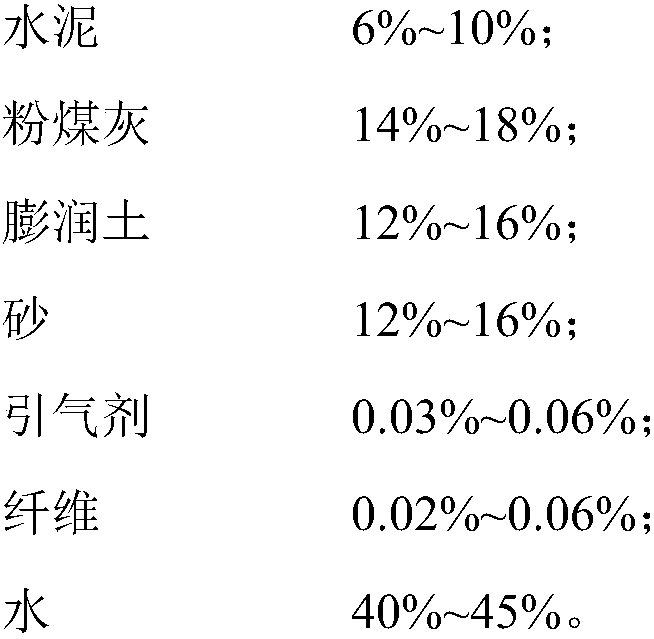

[0028] The anti-surge slurry material used in the mylonite fragmentation zone shield construction process of the present invention, prepares the described slurry material according to a specific mass ratio (kg) in the test process, and consists of the following parts by weight:

[0029]

[0030] The compound method of described slurry material comprises the following steps:

[0031] Step 1, taking the required raw materials according to the mass ratio;

[0032] Step 2, one day in advance, prepare bentonite slurry according to the mass ratio of bentonite: water = 1:1 (the water used is the water weighed in step 1), and place the prepared bentonite slurry for 24 hours to prepare the required grouting Material;

[0033] Step 3, mixing and stirring the cement, fly ash, sand, and polypropylene fibers weighed in step 1, and configuring them into a mixed powder of the raw materials;

[0034] Step 4, add the mixed powder described in step 3 and the remaining water to the mortar m...

Embodiment 2

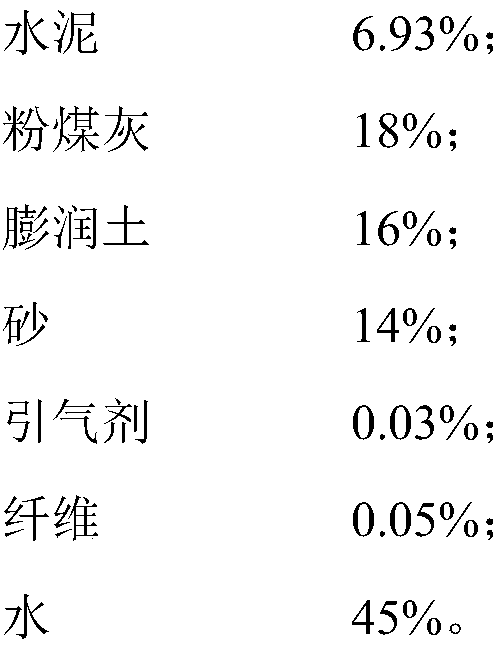

[0038] The anti-surge slurry material used in the mylonite fragmentation zone shield construction process of the present invention, prepares the described slurry material according to a specific mass ratio (kg) in the test process, and consists of the following parts by weight:

[0039]

[0040]

[0041] The compound method of described slurry material comprises the following steps:

[0042] Step 1, taking the required raw materials according to the mass ratio;

[0043] Step 2, one day in advance, prepare bentonite slurry according to the mass ratio of bentonite: water = 1:1 (the water used is the water weighed in step 1), and place the prepared bentonite slurry for 30 hours to prepare the required grouting Material;

[0044] Step 3, mixing and stirring the cement, fly ash, sand, and polypropylene fibers weighed in step 1, and configuring them into a mixed powder of the raw materials;

[0045] Step 4, add the mixed powder described in step 3 and the remaining water to ...

Embodiment 3

[0049] The anti-surge slurry material used in the mylonite broken zone shield construction process of the present invention, according to specific mass proportion (kg) preparation described slurry material in the test process, is made up of following parts by weight:

[0050]

[0051] The compound method of described slurry material comprises the following steps:

[0052] Step 1, taking the required raw materials according to the mass ratio;

[0053] Step 2, one day in advance, prepare bentonite slurry according to the mass ratio of bentonite: water = 1:1 (the water used is the water weighed in step 1), and place the prepared bentonite slurry for 48 hours to prepare the required grouting Material;

[0054] Step 3, mixing and stirring the cement, fly ash, sand, and polypropylene fibers weighed in step 1, and configuring them into a mixed powder of the raw materials;

[0055] Step 4, add the mixed powder described in step 3 and the remaining water to the mortar mixer successi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com