Synchronous grouting slurry applicable to abundant water stratum tunneling and preparation method

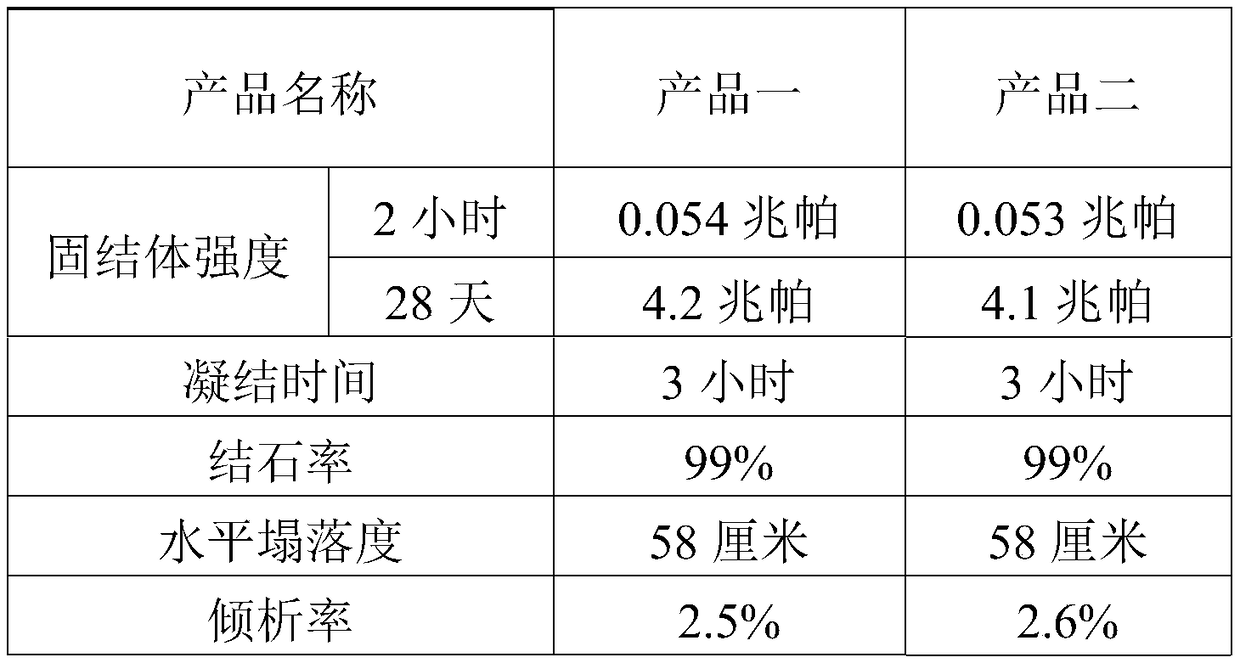

A technology of synchronous grouting and water-rich formation, applied in the field of building materials, can solve the problems of poor early strength, long setting time, and low stone formation rate, and achieve the effects of increasing strength, increasing stone formation rate, and improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the embodiments of the present invention will be described in detail below. It should be understood that the specific implementation manners described here are only used to illustrate and explain the embodiments of the present invention, and are not intended to limit the embodiments of the present invention.

[0017] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0018] The invention provides a synchronous grouting slurry suitable for shield tunneling in water-rich formations, the synchronous grouting slurry is composed of the following raw materials in parts by mass: Portland cement 180-220 parts, machine-made sand 710-730 parts, natural sand 710 parts ~730 parts, bentonite 45~55 parts, retarder 3~6 parts, water reducer 3~6 parts, water 250~350 parts.

[0019] The synchronous grouting grout suitable for shield tun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com