Patents

Literature

65results about How to "High rate of stones" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

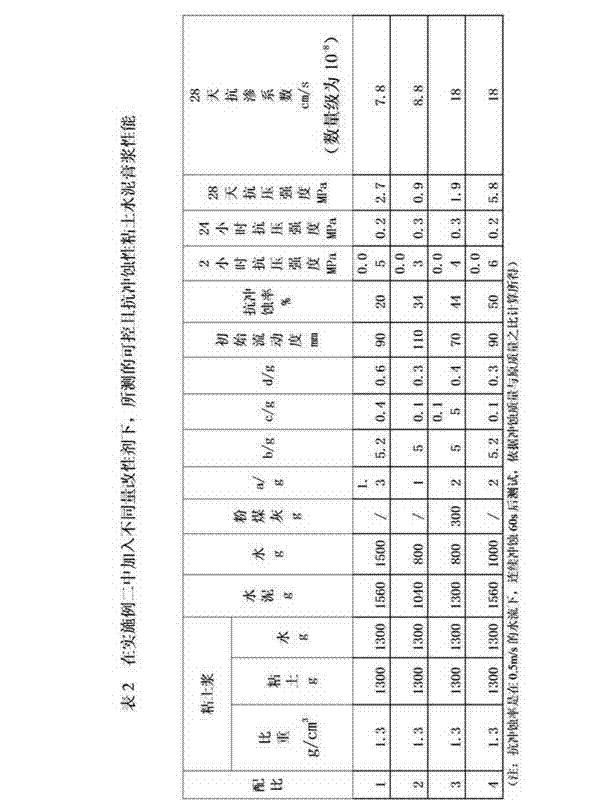

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Micro-expansion grouting material and preparation method thereof

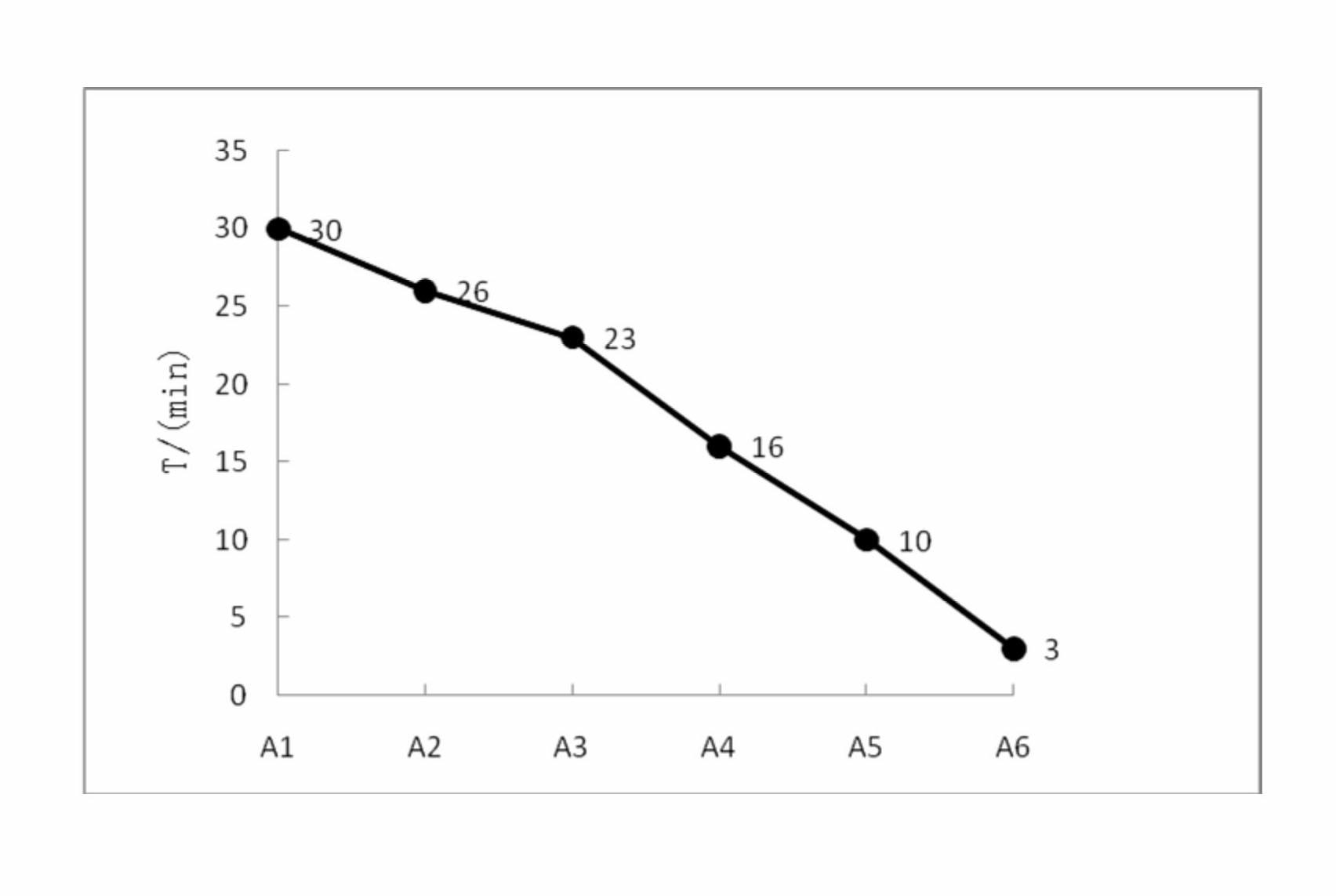

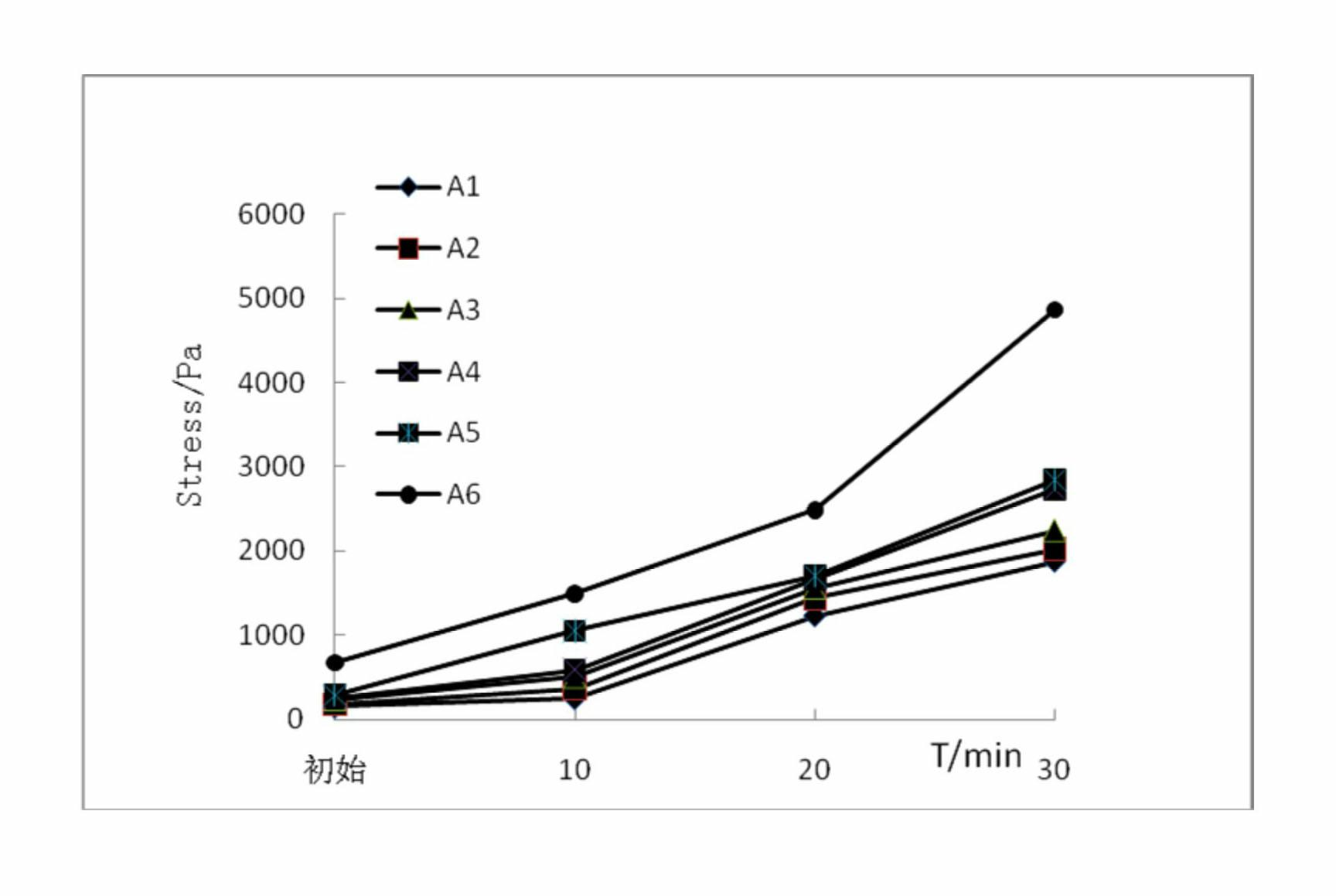

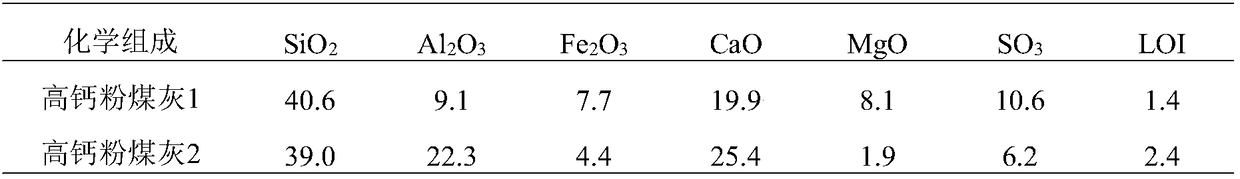

The invention discloses a micro-expansion grouting material. The micro-expansion grouting material is characterized by being prepared from the following materials in parts by mass: 30-50 parts of high-calcium flyash, 15-30 parts of calcined shale, 5-20 parts of phosphorus gypsum, 10-20 parts of ordinary silicate cement and 5-15 parts of rapidly-hardened sulphate aluminum cement. Further, additivematerials and water are added according to the times of the total parts by mass of the above materials on the basis that the total parts by mass of the materials are prepared to 100 parts. The additive materials comprise 0.5-1 part of a polycarboxylic acid water reducer, 0.1-1 part of redispersible latex powder, 0.05-0.15 part of hydroxypropyl methyl cellulose ether, 0.2-0.4 part of calcium lignosulphonate and 0.1-0.5 part of a cationic organic polymer; the water accounts for 8-10 parts. The micro-expansion grouting material has the characteristics of excellent mechanical property, micro expansion, low preparation cost, high solid waste utilization rate, green and environmental protection and high compatibility with soil.

Owner:重庆建工第七建筑工程有限责任公司 +1

Early-strength erosion-resistant clay cement paste

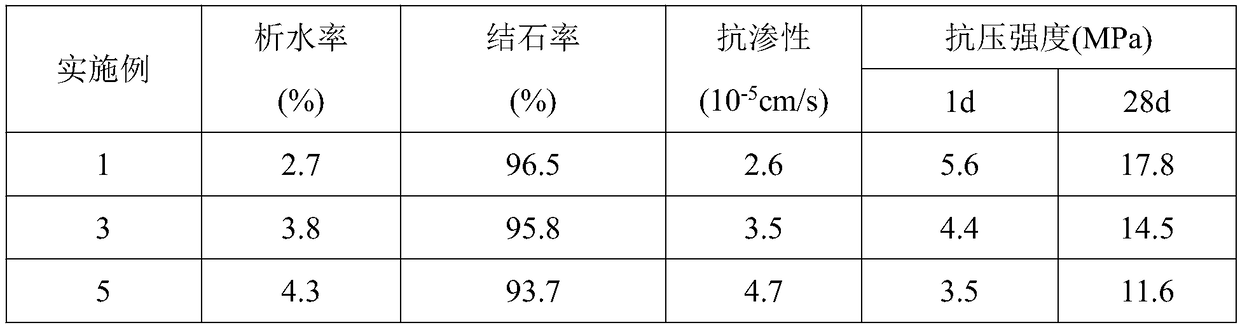

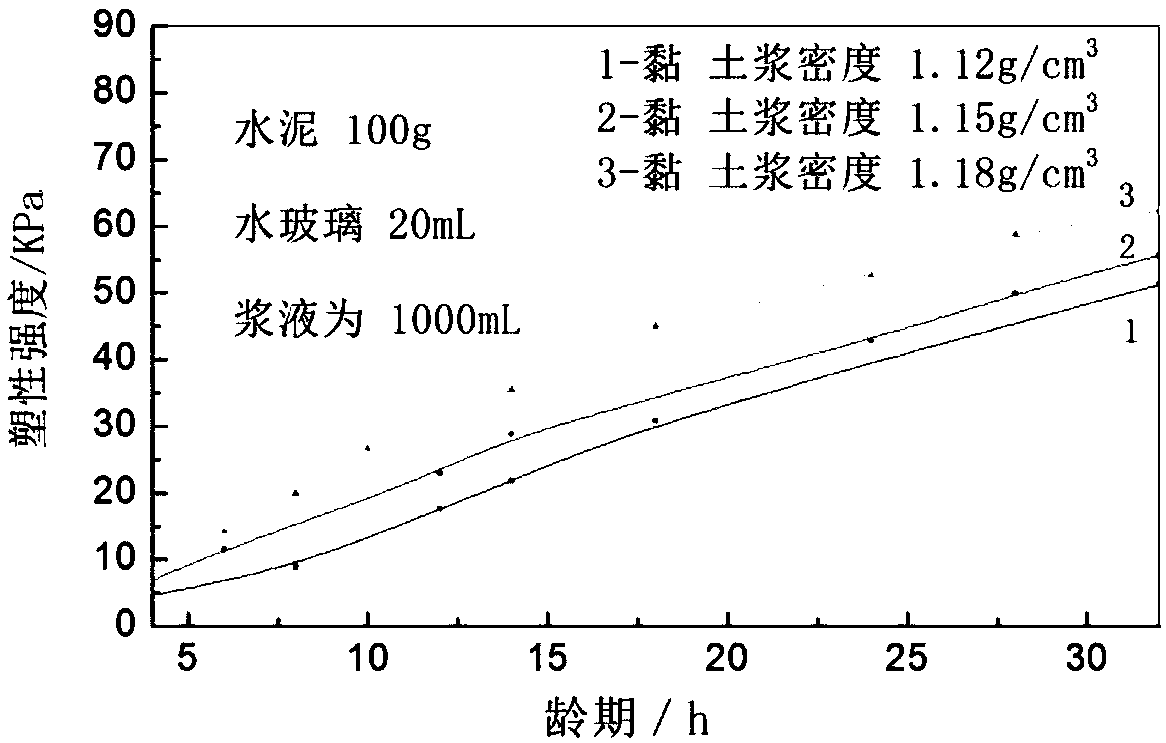

ActiveCN103755275AImproved controllabilityImprove stone rate and impermeabilitySpecific gravityAluminium salts

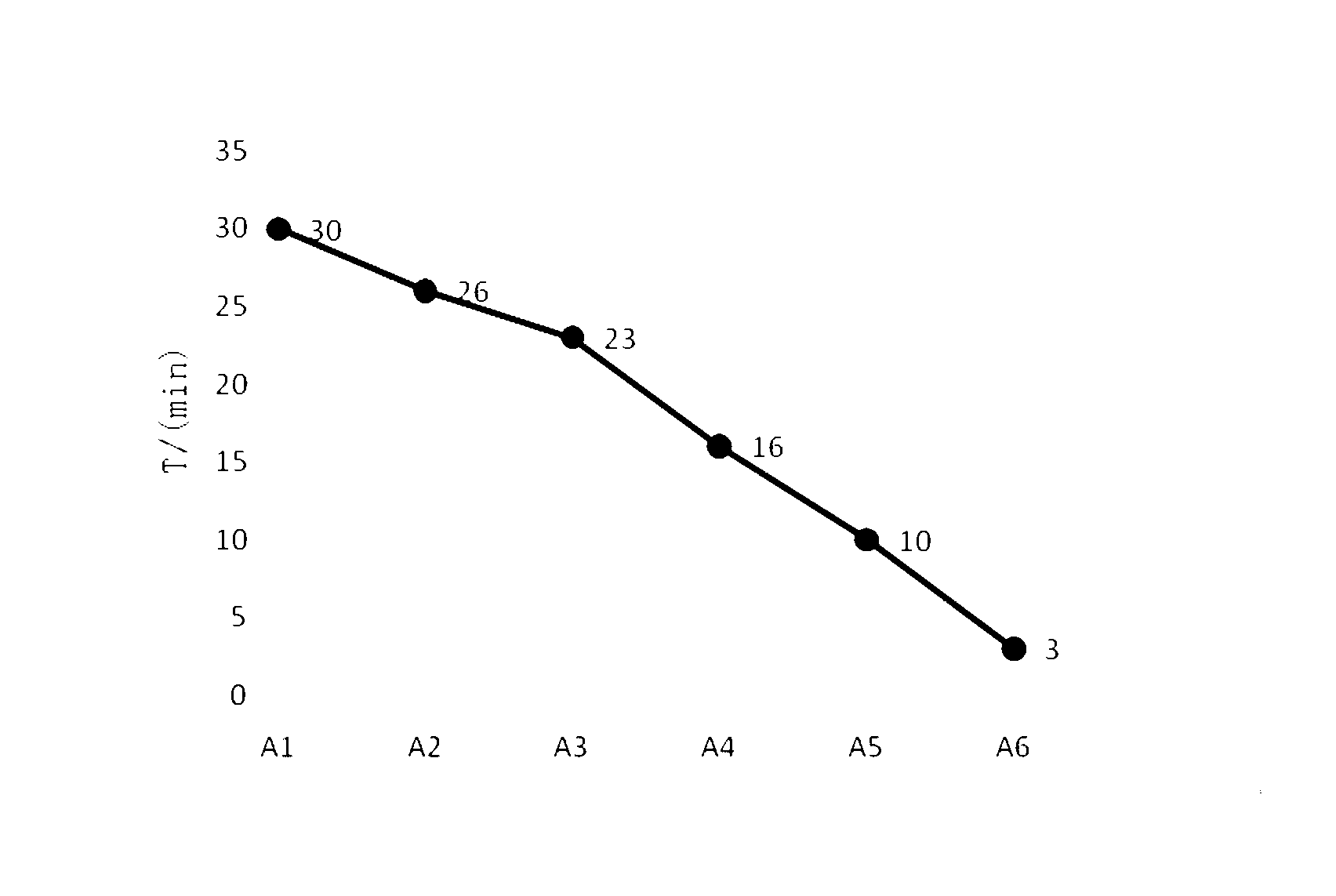

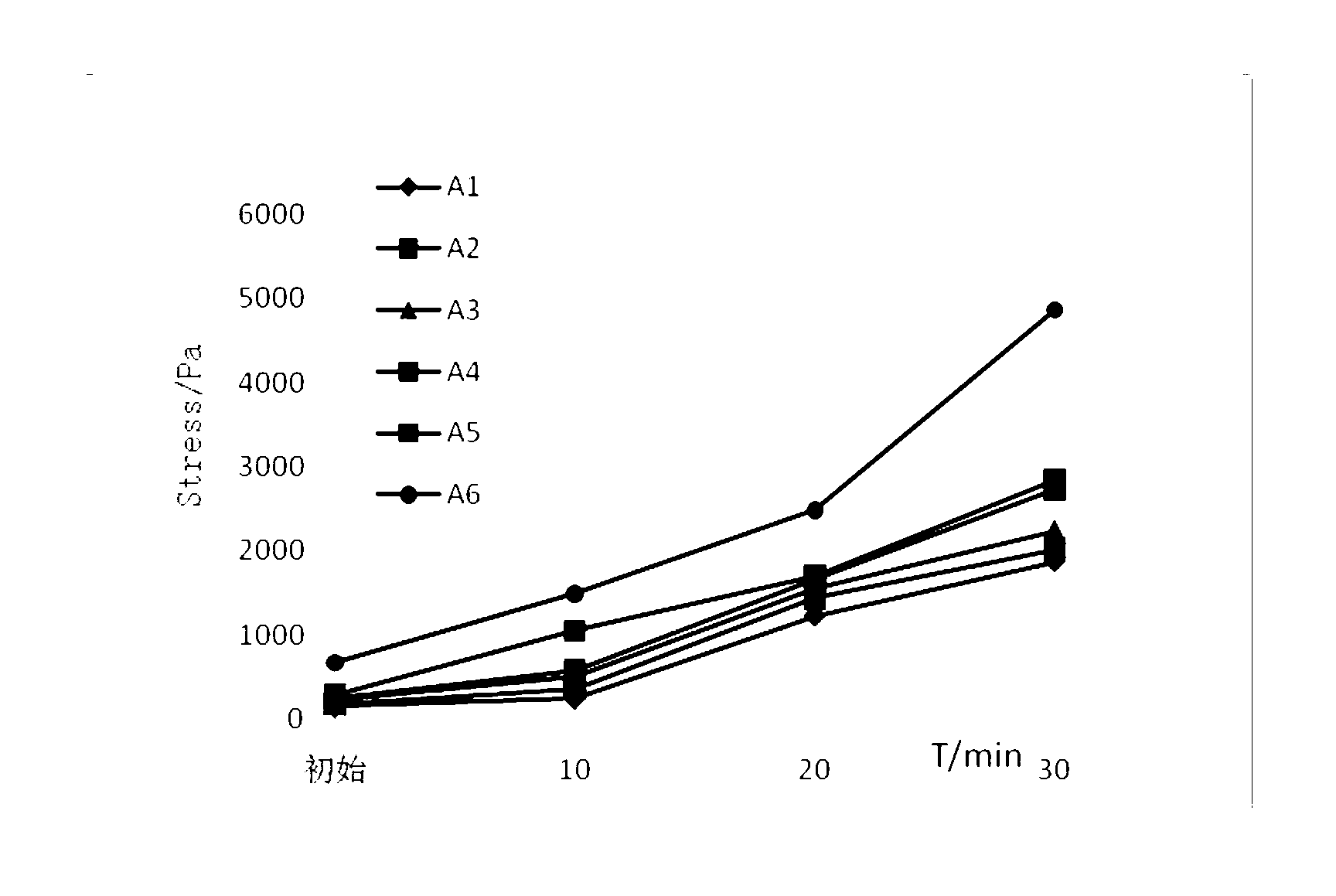

The invention provides an early-strength erosion-resistant clay cement paste which comprises a clary cement paste and a matched modifier, wherein the clary cement paste is prepared from clay raw stock, cement and the balance of water; the clay raw stock is obtained by stirring clay with water, and the specific gravity of the obtained clary raw stock ranges from 1.15g / cm<3> to 1.40g / cm<3>; the ratio of the total mass of the clay in the clary raw stock and the cement to the mass of water ranges from 10: 7 to 10: 14; the modifier is composed of sodium metaaluminate, soluble sodium metasilicate powder, aluminum sulfate and polyacrylamide, and the content of the polyacrylamide accounts for 1-10% of the sum of the weights of the aluminum sulfate, the sodium metaaluminate and the soluble sodium metasilicate powder. The early-strength erosion-resistant clay cement paste has the advantages of good controllability, good water erosion resistance, short solidification time, high early strength, excellent anti-seepage performance, low cost, environmental protection and the like.

Owner:湖南宏禹工程集团有限公司

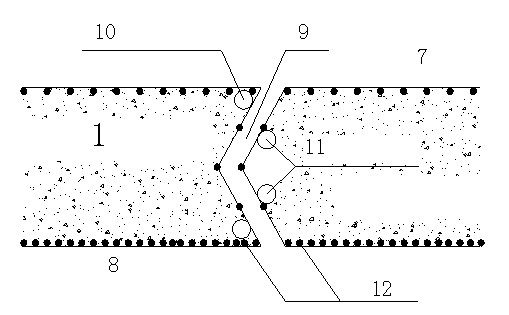

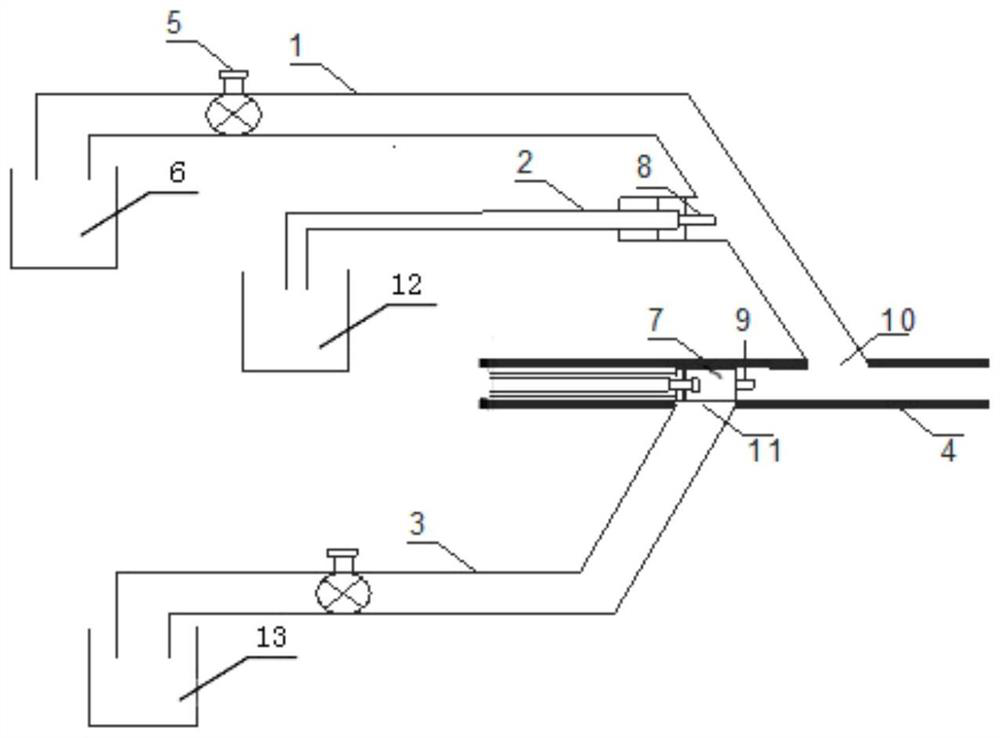

Liquid division slip casting reinforcing method for subsurface structure construction joints

InactiveCN102002950APrevent leakageImprove compactnessArtificial islandsUnderwater structuresWater leakageStructural engineering

The invention discloses a liquid division slip casting reinforcing method for subsurface structure construction joints, mainly aiming at the problems that as the subsurface structure construction is severely influenced by ground water, the peripheral structure leaks water, the material strength is reduced, the structure integrity is poor and the like. A purpose-made grouting pipe is arranged at the construction joint of a structure connector with weak stress in the process of subsurface structure peripheral construction, and the liquid division slip casting reinforcing operation is performed based on a designated method, thus making up for the defects of poor rigidity and poor waterproof effect at the construction joint of the subsurface structure preferably. The method in the invention has good grouting effect and high grouting success rate, can effectively improve the strength and the integrality of the subsurface structure, and reduce the leakage of the construction joint of the subsurface structure.

Owner:SOUTHEAST UNIV +1

Tunnel water inrush prevention and treatment method

InactiveCN111810199AGuarantee the safety of useHigh rate of stonesMining devicesUnderground chambersWall rockWater resource management

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD

High performance no-contraction cement base grouting material and its preparing method

The high-performance no-contraction cement-base grouting material consists of portland cement, sulphoaluminate clinker, bentonite, sodium methyl naphthalenesulfonate condensate, defoaming agent, quartzite, etc. in certain proportion. The grouting material has controllable solidification time, excellent flowability, excellent grouting performance, relatively high volume stability and no contraction. The present invention may be used widely in the repair and construction of various concrete engineering.

Owner:TONGJI UNIV

Slow-setting cement grout

Disclosed is slow-setting cement grout. The ratio of basic cement grout includes that the water-cement ratio is 1-1.25:1, 1.5-2wt% of a suspending agent and a retarder are adulterated in the basic cement grout, the retarder is a mixture mixed by one, two or more of six retarders including sodium pyrophosphate, sodium tripolyphosphate, tartaric acid, potassium sodium tartrate, citric acid or zinc chloride according to arbitrary mixing ratio, wherein the mixing amount of the sodium pyrophosphate is 0.1%-0.5%, the mixing amount of the sodium tripolyphosphate is 0.1%-0.6%, the mixing amount of the tartaric acid is 0.2-0.4%, the mixing amount of the potassium sodium tartrate is 0.4%-0.5%, the mixing amount of the citric acid is 0.05%-0.35%, and the mixing amount of the zinc chloride is 0.2%-0.3%, and the suspending agent is sodium bentonite. The slow-setting cement grout has the advantages that stability of the cement grout is enhanced, settling time of cement particles is prolonged, and the concretion ratio of the grout is increased.

Owner:CHINA COAL NO 5 CONSTR

Slurry suitable for back filled grouting of low-strength stratum shield segments

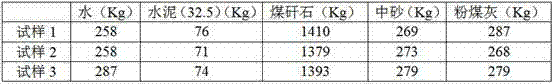

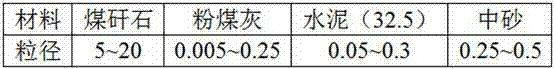

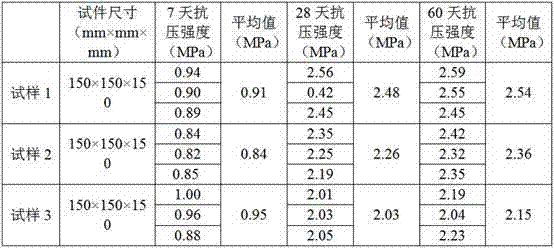

InactiveCN107129221AHigh rate of stonesHigh stone strengthTunnelsCement slurryUltimate tensile strength

The invention discloses slurry suitable for back filled grouting of low-strength stratum shield segments, and belongs to the field of grouting materials. The slurry is prepared from synchronous grouting slurry and secondary grouting slurry, wherein a mix proportion (mass ratio) of the synchronous grouting slurry is cement to sand to water to coal ash to bentonite equal to 160 to 830 to 450 to 400 to 50, and a mix proportion (mass ratio) of the secondary grouting slurry is cement to water to sodium silicate equal to 445 to 356 to 685. The synchronous grouting slurry disclosed by the invention has the characteristics of high stone rate, high stone body strength, good durability and the like, and invalid grouting caused by flushing and leaching of underground water in the synchronous grouting is avoided. The secondary grouting slurry disclosed by the invention overcomes the defects of long coagulation time of single-liquid cement slurry, difficulty in controlling, low stone rate under a flowing water condition and the like, a cement grouting effect is improved, a range of cement grouting is expanded, and the waste situation caused by a poor grouting effect of ordinary cement slurry and multiple grouting is avoided.

Owner:THE FIRST ENG CO LTD OF CTCE GRP

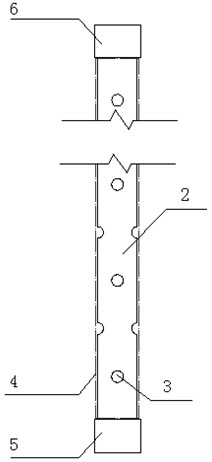

High-water-pressure super-large-diameter underwater shield tunnel double-liquid grouting slurry, process and application

ActiveCN114180930AImprove performanceImprove pore structureSolid waste managementUnderground chambersCelluloseFiber

The invention discloses a high-water-pressure super-large-diameter underwater shield tunnel double-liquid grouting slurry, and a process and application thereof. The slurry I is prepared from the following raw materials: 35-45 parts of cement clinker; 15 to 25 parts of slag; 24 to 35 parts of fly ash; 15-25 parts of steel slag; 5 to 15 parts of bentonite; 4-10 parts of limestone tailings; 0.3-2 parts of a water reducing agent; 0.5 to 2.5 parts of cellulose; the slurry II is prepared from the following raw materials in parts by weight: 0.2-3.8 parts of chopped fibers; 96-99 parts of a sodium silicate solution; and 0.8-4.8 parts of a viscous high polymer. A double-slurry preparation process of crushing, screening, grinding, grouped mixing and grouped stirring at different speeds is formed, the volume ratio of the slurry I to the slurry II is (1: 1)-(10: 1) during grouting, the slurry is injected into a shield gap through the grouting process of shield tail six-point location and segment 3 + 2 + 1 splicing synchronization, and the grouting method can be applied to a high-water-pressure super-large-diameter underwater shield tunnel with the water pressure larger than or equal to 0.5 MPa and the diameter larger than or equal to 14 m.

Owner:OCEAN UNIV OF CHINA

Modified clay reinforcing paste slurry

The invention relates to modified clay reinforcing paste slurry. Existing clay reinforcing paste slurry has no good erosion-wear resistance in flowing water, and since more modifier need to be added in order to reduce to the fluidity of a material, the using cost is relatively high. The modified clay reinforcing paste slurry is characterized by being prepared from the following components in ratio by mass: 20 to 40 of bentonite, 15 to 30 of cement, 10 to 20 of silicate minerals, 3 to 10 of additive, 10 to 15 of calcium oxide and the balance of water, wherein the additive is prepared from a silane coupling anggent, sodium fluosilicate, sodium metaaluminate and calcium chloride. According to the modified clay reinforcing paste slurry disclosed by the invention, not only are controllability and water erosion-wear resistance of paste slurry improved, but also the stone rate and the impervious performance of a stone body are increased, the cost is lower, and the problems of instability in operation of the bentonite and the like of common cement bentonite paste slurry are solved.

Owner:ANJI YUHONG CLAY CHEM

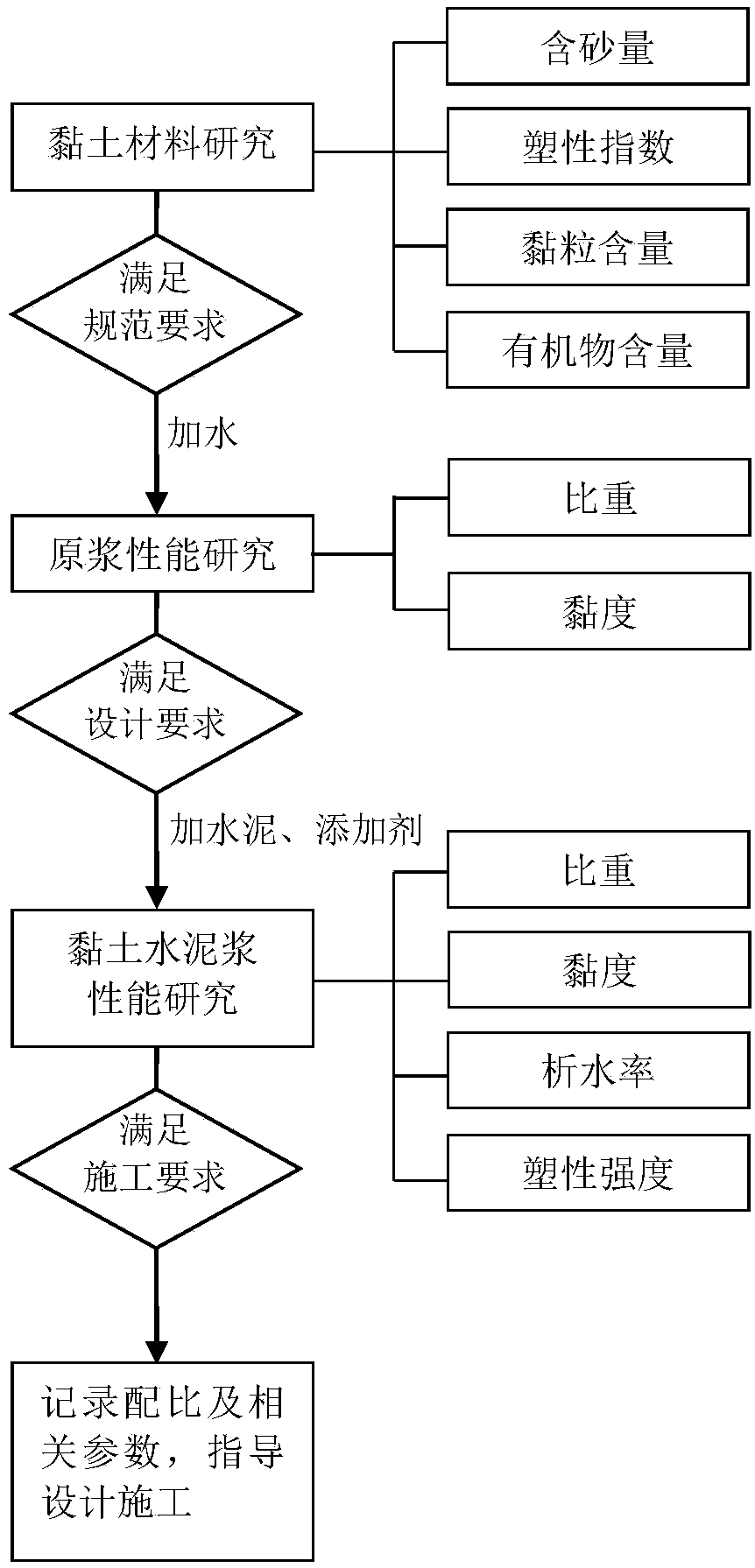

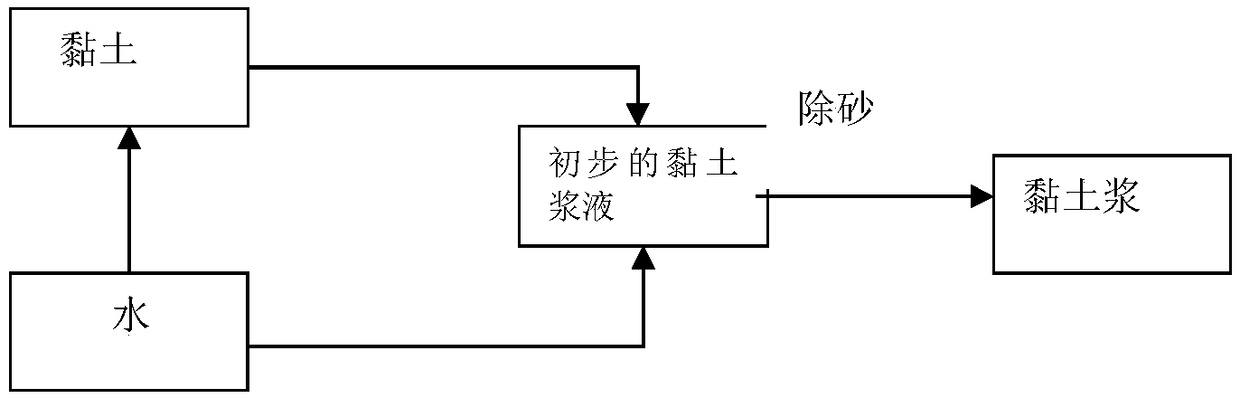

Environment-friendly grouting material based on red soil in Wumeng Mountain area

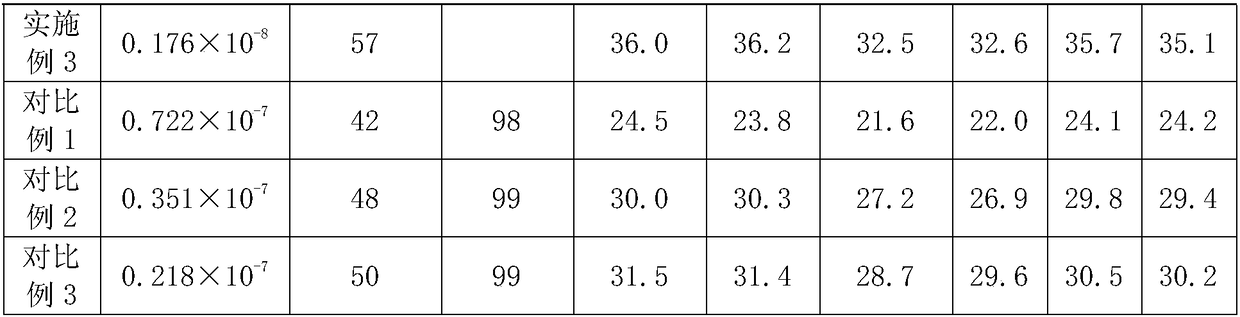

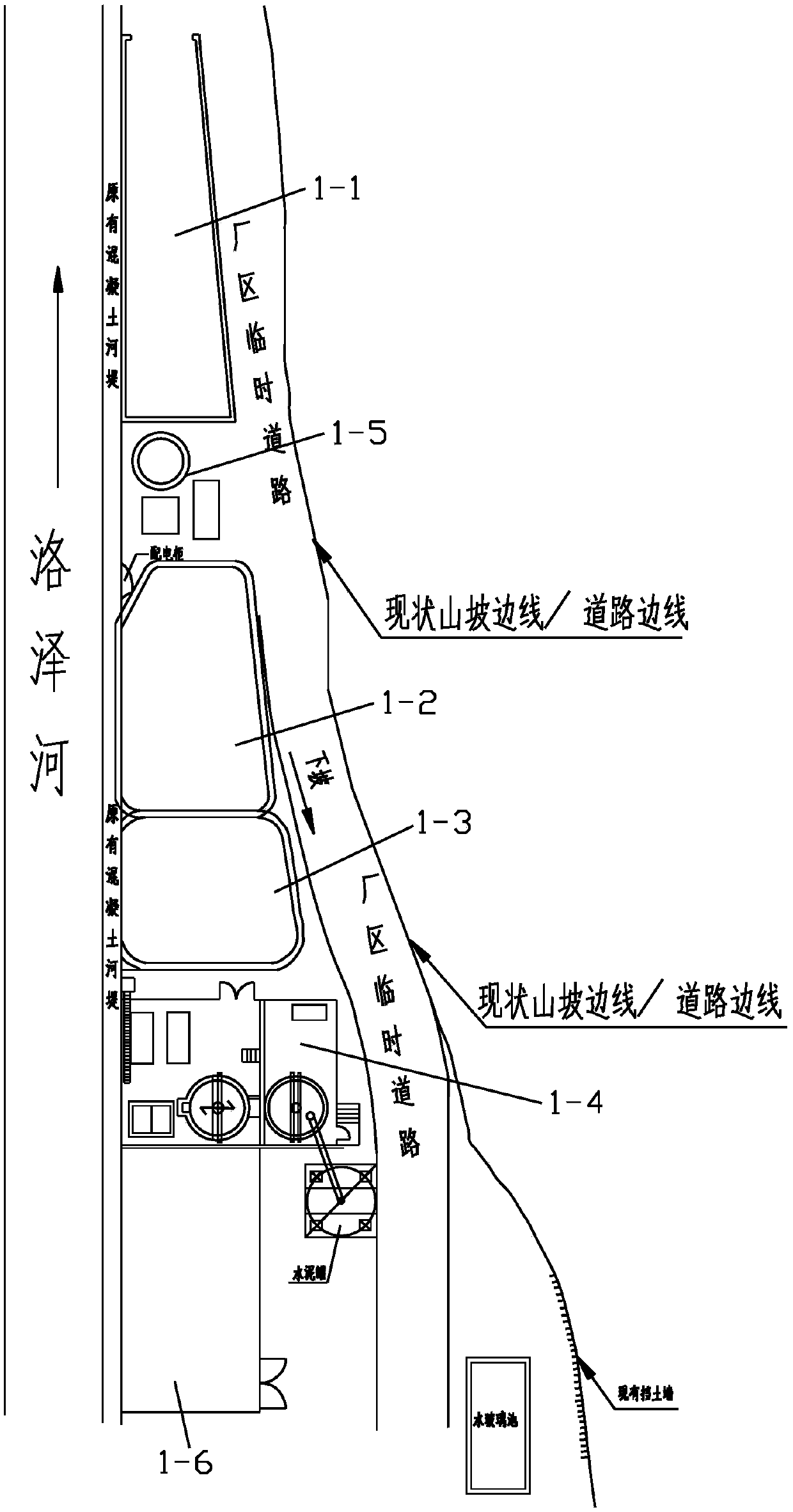

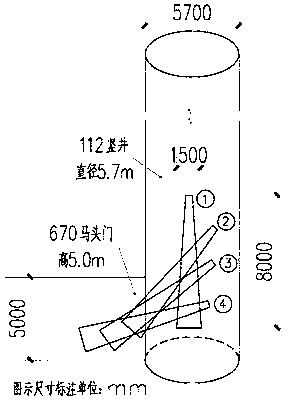

The invention discloses an environment-friendly grouting material based on red soil in a Wumeng Mountain area. The environment-friendly grouting material based on the red soil in the Wumeng Mountain area is CL-C type clay cement paste, and the CL-C type clay cement paste is composed of clay paste, cement and additives. The environment-friendly grouting material based on the red soil in the WumengMountain area is good in past stability, the paste is not separated or precipitated in pumping and diffusion processes, and in a solidification process, the water bleeding is little, the concretion rate is high, and the anti-permeability performance is good. Clay particles in the clay paste are fine, are low in sand content, and have a high dispersion degree, so that the environment-friendly grouting material based on the red soil in the Wumeng Mountain area is good in fluidity and easily permeates into fine cracks of rock stratums. In a Maoping lead-zinc ore 112-line vertical shaft pre-grouting water-plugging engineering of the Yiliang Chihong mining limited company, 15189.132 m<3> of clay cement paste prepared from the environment-friendly grouting material provided by the invention is injected, and the residual water burst amount of the well shaft after grouting is about 4.83 m<3> / h and meets the qualified standard of a construction contract.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

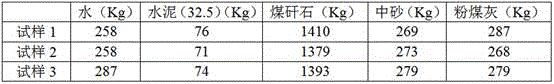

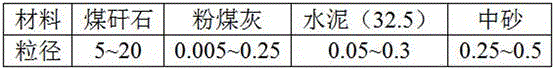

Like concrete filling material suitable for road large cavity goaf treatment

The invention discloses a like concrete filling material suitable for road large cavity goaf treatment. The material comprises 32.5 grade slag Portland cement, fly ash, medium sand, gangue and a high efficiency water reducer, and a ratio of water to cement to fly ash to medium sand to gangue is 12.4:3.2:12.05:12.05:60.3. The density of like concrete is greater than the density of water, so underground water residual in large cavities is discharged; and the like concrete has a high concretion rate, so large goaf is filled and densified to realize no future troubles. Ingredients of the like concrete are changed to valuables, so the like concrete filling material saves resources, protects environment, can meet pumping transmission demands, and has very good economic benefits and social values.

Owner:山西交科岩土工程有限公司 +1

High-strength non-shrinkage concrete master batch

The invention relates to a construction material, in particular to a high-strength non-shrinkage concrete master batch, and aims to solve the problems that: the conventional concrete production process is relatively complex and has high technical threshold; the conventional material is not suitable to be purchased and stored on a large scale because the strength of the conventional material is influenced by storage time and storage environment; and the produced product has poor high fluidity under the condition of high viscosity, and can generate segregation phenomenon when the proportion of the water is larger. The technical scheme adopted by the invention to solve the technical problems is that: mixing 9.5 percent of high-efficiency water reducing agent melamine, 76.1 percent of UEA swelling agent, 0.6 percent of antifoaming agent, 0.6 percent of methyl cellulose ether, 12.2 percent of calcium formate and 1.0 percent of subdivisible emulsion powder; sufficiently and uniformly stirring the mixed materials; grinding the obtained product in a ball grinding mill; and selecting the ground particles of which the particle diameter is controlled to between 5 and 10mu m as the master batch. The master batch is used together with portland cement, fast setting and hardening cement, sulphoaluminate early strength cement and quartz sand to produce various concretes with different application.

Owner:CHINA MCC 2 GRP CO LTD

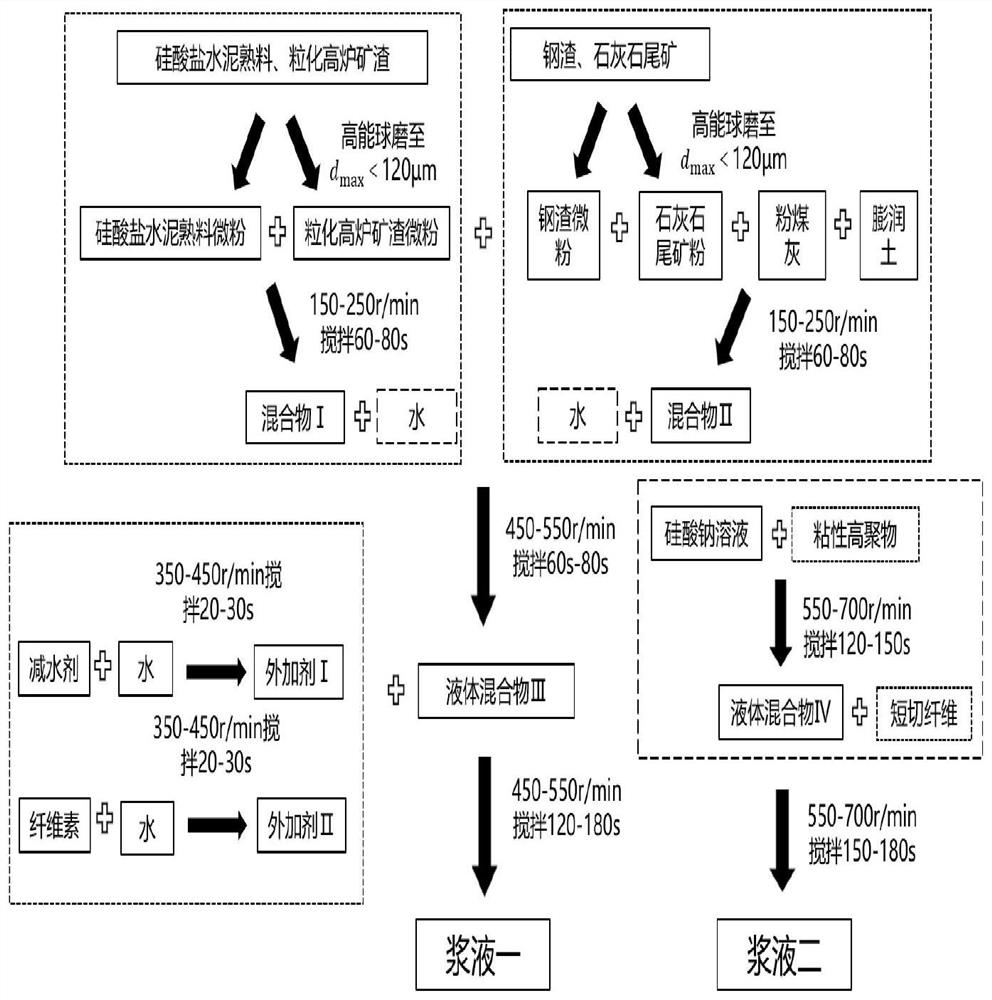

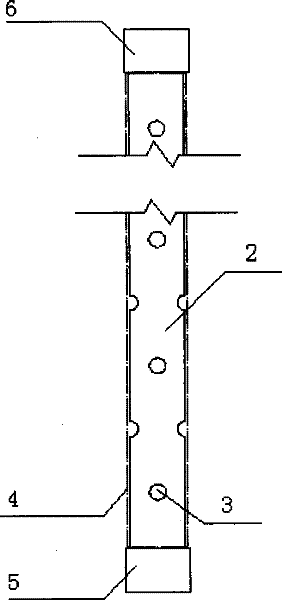

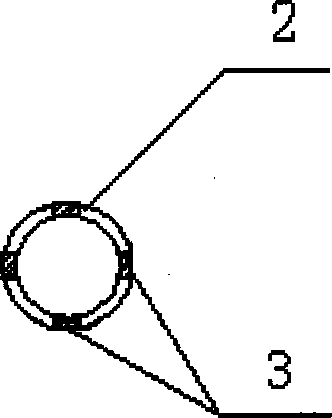

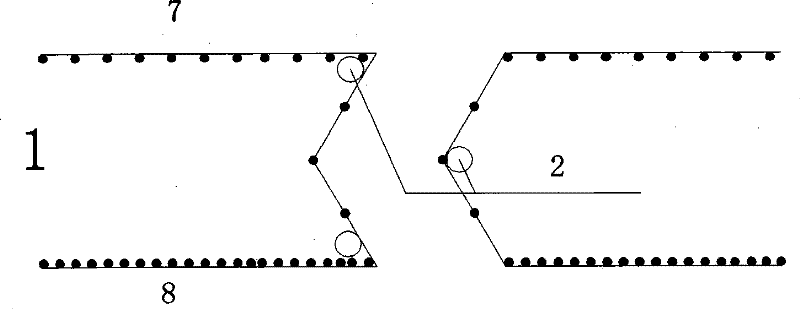

Post-grouting reinforcement construction method for flexible joints of ground-connected walls

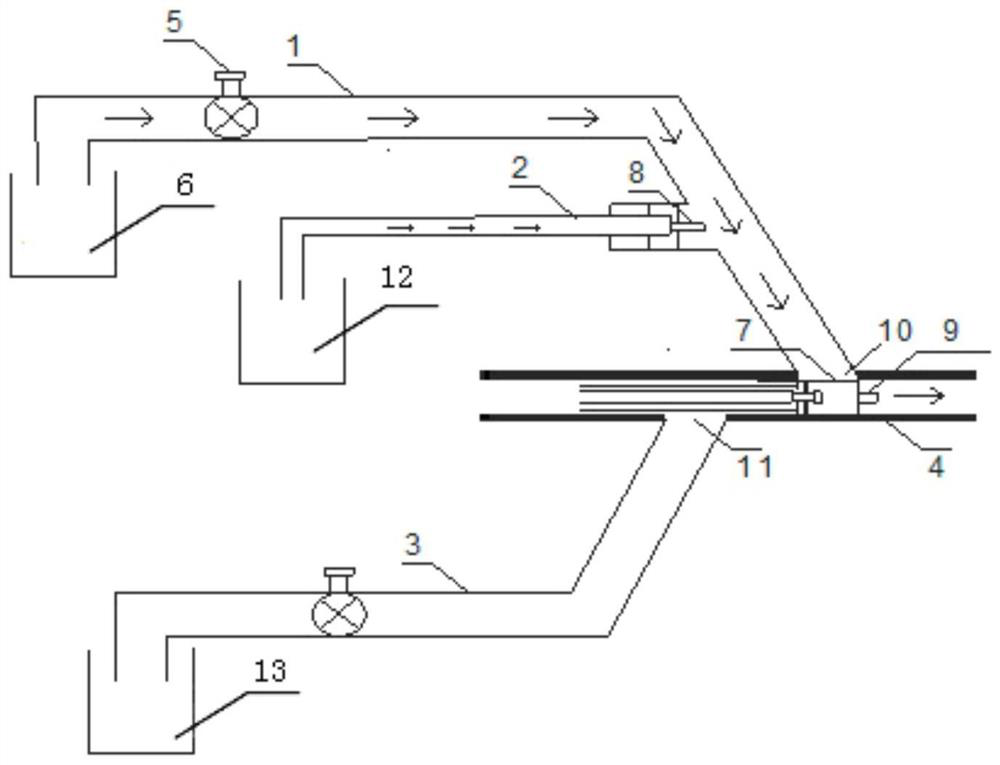

InactiveCN102296617ARich sourcesNo pollution in the processExcavationsBulkheads/pilesSlurry wallPorous sheet

The post-grouting reinforcement construction method of the flexible joint of the ground connection wall is the construction technology of the ground connection wall of the subway foundation pit engineering. Grouting pipe (2): Place the porous grouting pipe at the end of the reinforcement cage, and tie it together with the reinforcement cage with iron wire, or weld it on the reinforcement cage with electric welding, and lower it together with the reinforcement cage; there are three porous grouting pipes, They are respectively installed at the ends of steel cages of two underground diaphragm walls, one grouting pipe is installed on both sides of the end of one underground diaphragm wall, and one grouting pipe is arranged in the middle of the end of the other underground diaphragm wall; when the underground diaphragm wall The concrete of the wall reaches more than 70% of the design strength. Before final setting, a high-pressure pump is used to inject reinforcing cement slurry into the wall through a porous grouting pipe. The invention has good grouting effect and high grouting success rate, can effectively improve the integrity of the ground connection wall and reduce the leakage problem of the flexible joint of the ground connection wall.

Owner:SOUTHEAST UNIV

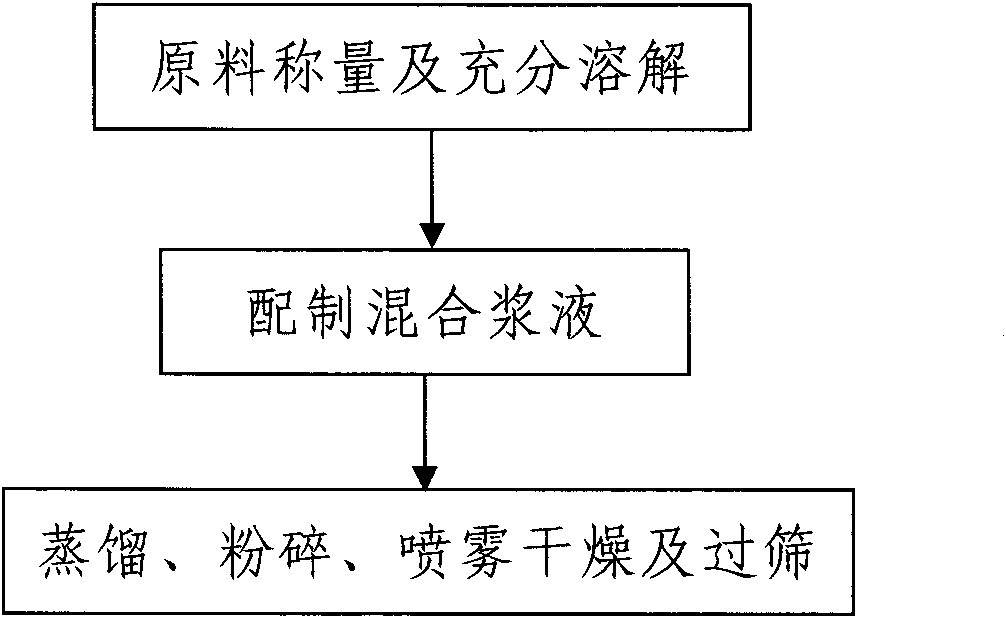

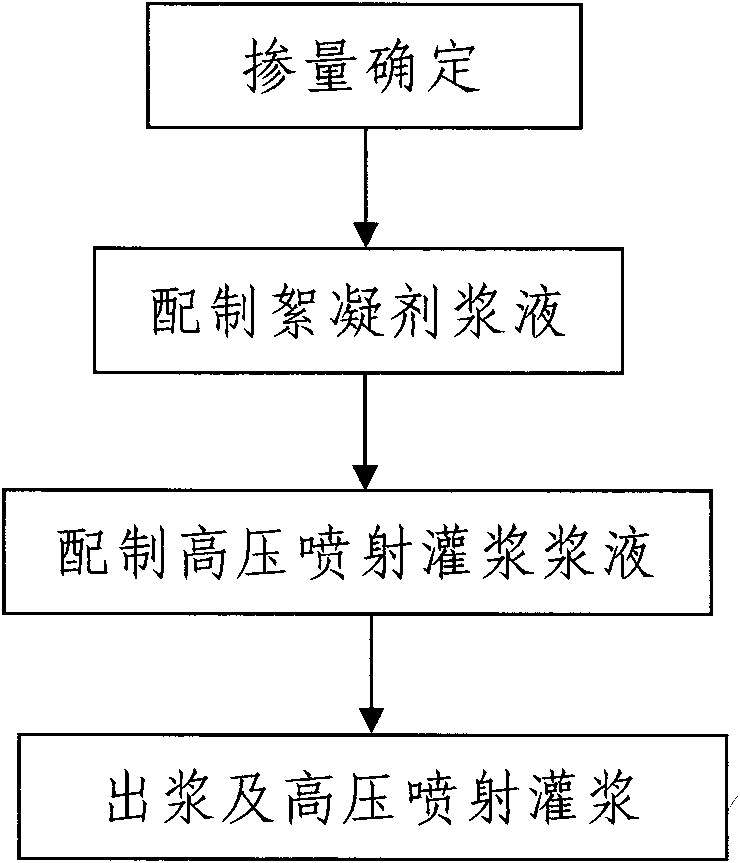

Flocculating agent for cement high pressure jet grouting and preparation method and application thereof

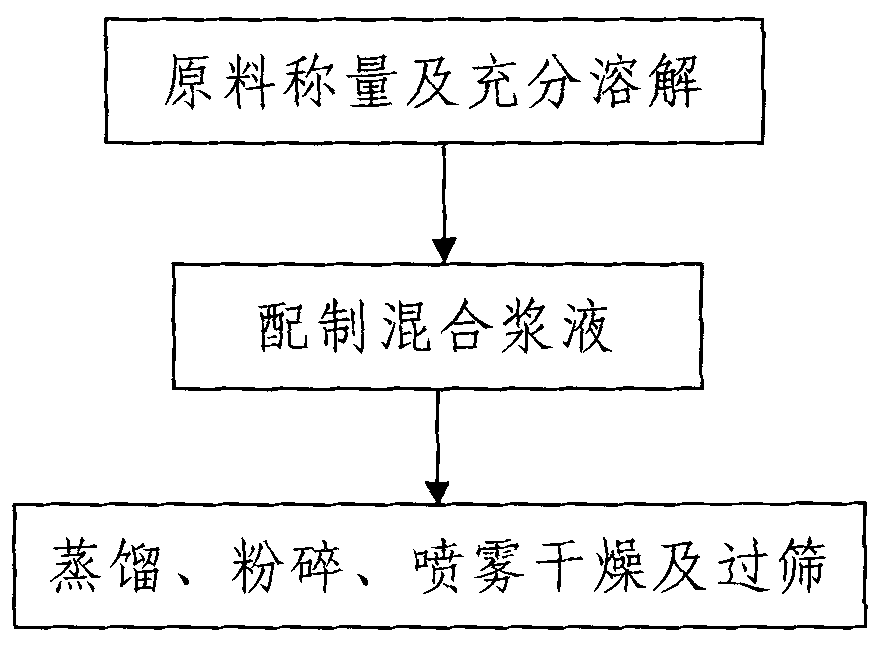

The invention discloses a flocculating agent for cement high pressure jet grouting and preparation method and application thereof. The flocculating agent is composed of konjac glucomannan, carbonate, rheological agent, dispersing agent, early strength agent and water by uniform stirring, distillation and smashing, and the weight ratio of the konjac glucomannan, carbonate, rheological agent, dispersing agent and early strength agent is 35-45: 22-28: 8-12: 13-17: 8-12; the preparation thereof includes the steps: raw material weighing and fully dissolution, mixed slurry confecting and distillation, spray drying, smashing and sieving; and the application thereof includes the steps: admixture determination, flocculating agent cement slurry confecting and slurry grouting completing by utilizing high pressure jet grouting process. The invention has simple preparation step, low cost and simple and convenient use and has no harm on human body, application in high pressure jet grouting construction is simple and convenient and processing effect is good, and the problems that pure cement slurry has poor adhesion, high cement slurry drain, high construction cost and influence on construction progress existed in high pressure jet impermeable grouting can be solved.

Owner:SINOHYRDO ENG BUREAU 3 CO LTD

Rock crack grouting material prepared from cement stone phase and preparation method of grouting material

The invention discloses a method for preparing a mining crack grouting material by utilizing a cement stone phase in waste concrete. The mining crack grouting material includes the following raw materials in percentages by weight: 40-60% of the cement stone phase, 20-30% of coal gangue, 10%-30% of furnace slag, and a water reducing agent which is 0.5-1% by mass of powder. The mining crack groutingmaterial disclosed by the invention adopts an ultra-fine cement stone regenerated cementing material as a substrate material, is supplemented by other materials, and has the advantages of ultrafine particles, a high hardening rate, micro expansion performance, a low water separating rate and good stability; and when a water-cement ratio is 1:1, 28-day compressive strength can reach 15 MPa or more. The mining crack grouting material disclosed by the invention overcomes the defects that ordinary Portland cement grouting slurry has a large water separating rate, poor stability and longer coagulation time, and is not easily poured into micro cracks, and production pollutes the environment, consumes a large amount of energy resources and resources, and has high costs; and the method disclosedby the invention is green and environmentally friendly, and has low costs.

Owner:CHINA UNIV OF MINING & TECH

Synchronous grouting slurry for shield construction of water-rich stratum and preparation method thereof

The invention relates to synchronous grouting slurry for shield construction of a water-rich stratum and a preparation method thereof. The synchronous grouting slurry comprises a component A, a component B and a component C, wherein the raw materials of the component A comprise silicate 42.5-grade cement, II-grade fly ash, river sand and sodium bentonite, the raw materials of the component B comprise hydroxyethyl methyl cellulose and tap water, the raw material of the component C comprises nano silicon dioxide, the tap water, the ratio of the blending amount of the component B to the blending amount of the component A is 3: 5, and the ratio of the blending amount of the component C to the blending amount of the component A is 1: 2; the synchronous grouting slurry is high in early-stage shear strength, good in groutability, stable, high in stone rate, low in bleeding rate and good in dilution resistance, certain shear resistance is provided after the synchronous grouting slurry is injected, then duct pieces are inhibited from floating upwards, the effect of stabilizing the duct pieces can be achieved, and the problems of cracking and water seepage of the duct pieces are solved.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

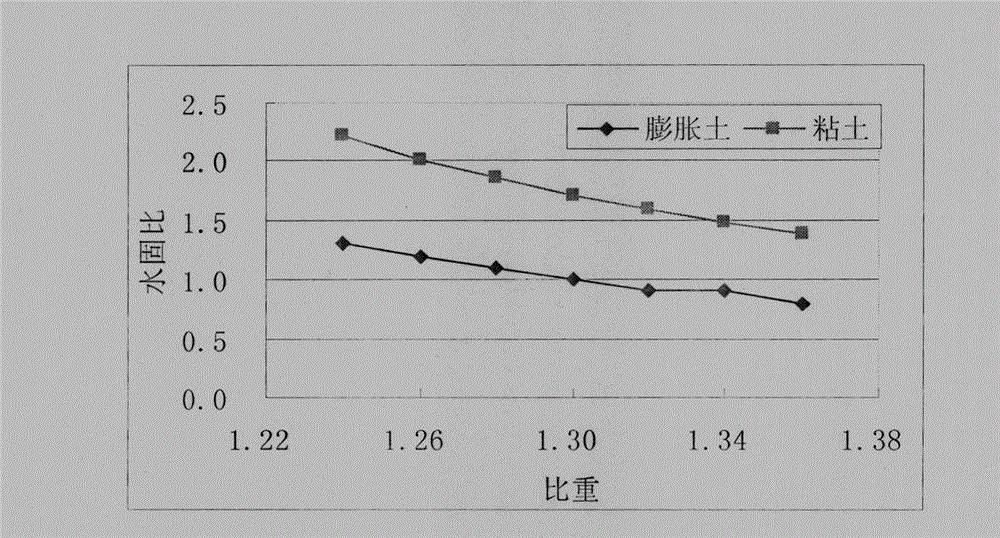

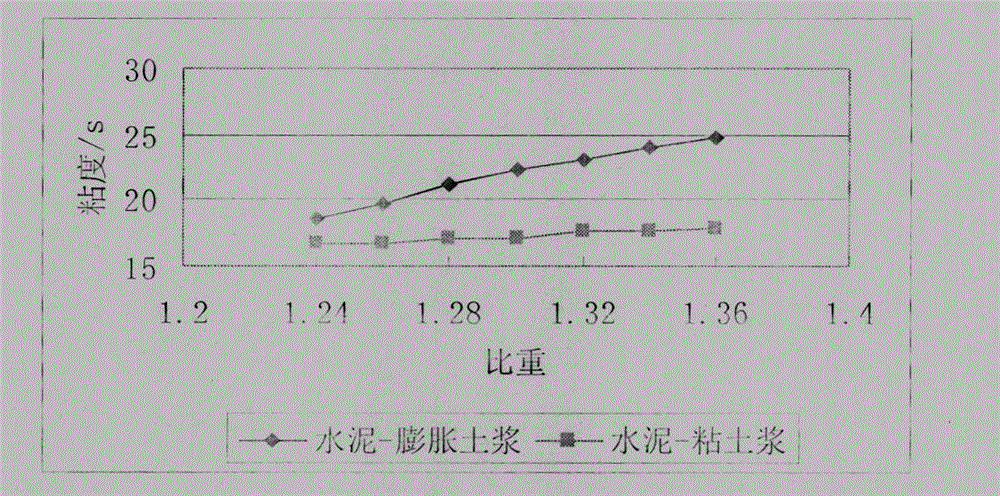

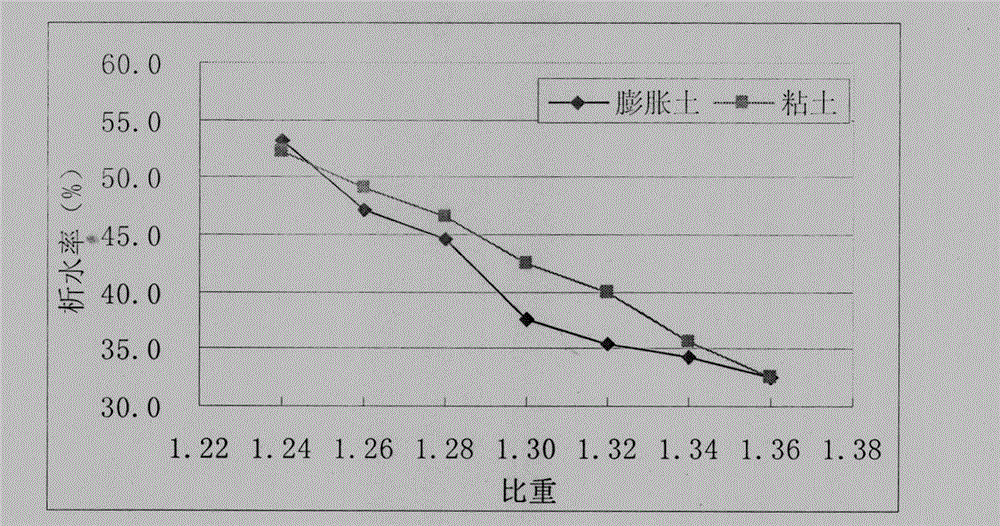

Paste injecting material of expansive soil cement paste

The invention discloses a paste injecting material of expansive soil cement paste. The expansive soil cement paste comprises expansive soil, cement and water, wherein the weight ratio of the expansive soil and the cement is 3:7, the pastes ratio is 1.24-1.36. Through replacing common clay by expansive soil, the expansive soil-cement paste is better than clay-cement paste in every respect, in two pastes with the same ratio, the expansive soil-cement paste can achieve a better paste injecting effect. During the paste injecting under the same base plate condition, with the pastes having the same proportion, the stone forming ratio of the expansive soil-cement paste is higher, and a better water plugging effect is achieved.

Owner:安徽恒源煤电股份有限公司

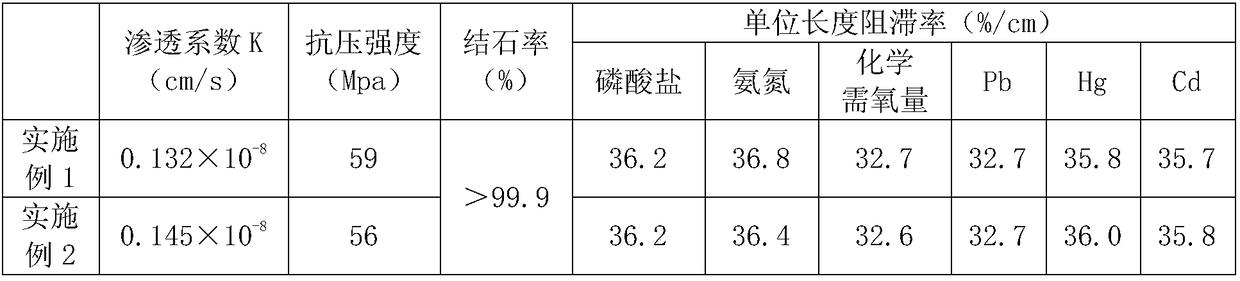

Method for preparing impermeable cement slurry for garbage landfill bases

The invention provides a method for preparing impermeable cement slurry for garbage landfill bases. The method includes carrying out modification treatment on blast furnace slag and bentonite to obtain modified blast furnace slag and modified bentonite; mixing and stirring the modified bentonite, defoaming agents and water reducing agents with one another to obtain first premixes; mechanically stirring oleic monoethanolamide, the modified blast furnace slag, ordinary silicate cement, gypsum and water, then adding the first premixes into the oleic monoethanolamide, the modified blast furnace slag, the ordinary silicate cement, the gypsum and the water and continuing to sufficiently stir the first premixes, the oleic monoethanolamide, the modified blast furnace slag, the ordinary silicate cement, the gypsum and the water to obtain the impermeable cement slurry. The method has the advantages that the impermeable cement slurry prepared by the aid of the method is high in concretion rate, and permeation of garbage leachate can be effectively stopped by the impermeable cement slurry.

Owner:黑龙江省宾州水泥有限公司

Technical method for controlling water in kilometer-level internal shaft in metal mine

The invention discloses a technical method for controlling water in a kilometer-level internal shaft in a metal mine. The technical method comprises the steps of (A) grouting hole drilling and (B) grouting hole grouting. A feasibility test is carried out on a 112-line internal-shaft shaft pre-grouting project in MaoPing lead zinc mine of the YiLiang ChiHong Mining Limited Company on December 30, 2016, and the feasibility test is completed on September 14, 2017 and lasted 258 days. During the grouting hole drilling grouting construction process, the preparation work of a metal rock internal-inclined-shaft shaft is not delayed by adopting the technical method for controlling the water in the kilometer-level internal shaft in the metal mine, and since a drilling chamber is arranged at the position 14m away from an internal inclined shaft, the preparation work of the metal rock internal-inclined-shaft shaft is not affected, so that the grouting hole drilling grouting construction and the preparation work of the metal rock internal-inclined-shaft shaft are carried out at the same time.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Clay cement-aggregate mixed grouting material and preparation method thereof

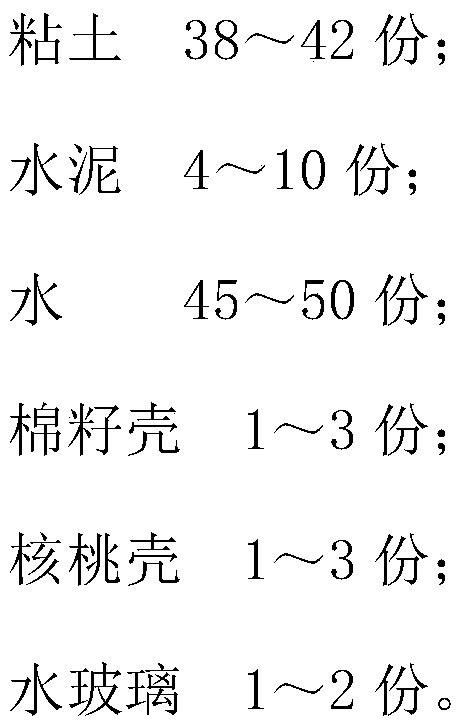

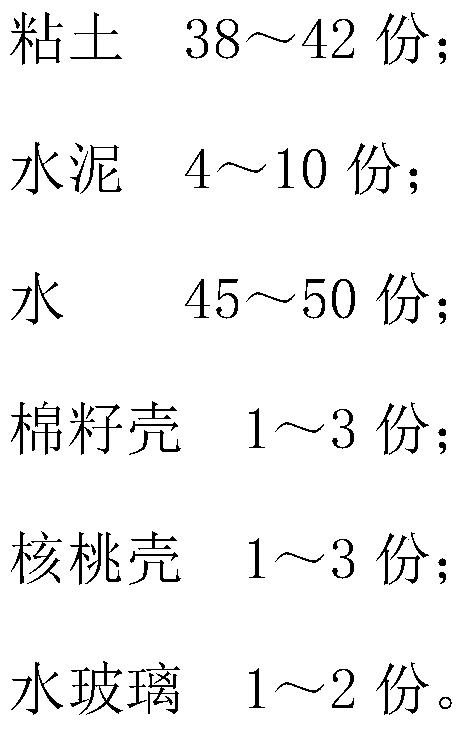

The invention discloses a clay cement and aggregate mixed grouting material.The material is prepared from 38-42 parts of clay, 4-10 parts of cement, 45-50 parts of water, 1-3 parts of cottonseed hulls, 1-3 parts of walnut hulls and 1-2 parts of water glass. The invention further discloses a preparation method of theclay cement-aggregate mixed grouting material.The preparation method comprises thesteps that 1, 38-42 parts of clay is uniformly added in 45-50 parts of water, and stirring is conducted at room temperature to form mixed slurry; 2, 4-10 parts of cement is added in the mixed slurry,and stirring is conducted to form mixed slurry; 3, 1-3 parts of cottonseed hulls and 1-3 parts of walnut hulls are added in the mixed slurry, and stirring is conducted to form mixed slurry; 4, 1-2 parts of water glass is uniformly added in the mixed slurry, stirring is conducted to be uniform, and the clay cement-aggregate mixed grouting material is obtained. According to the clay cement-aggregatemixed grouting material and the preparation method thereof, the cost of coal seam floor reinforcement is lowered, and pollution is not likely to be produced.

Owner:北京大地高科地质勘查有限公司

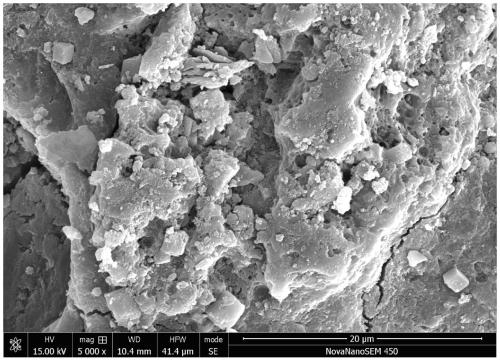

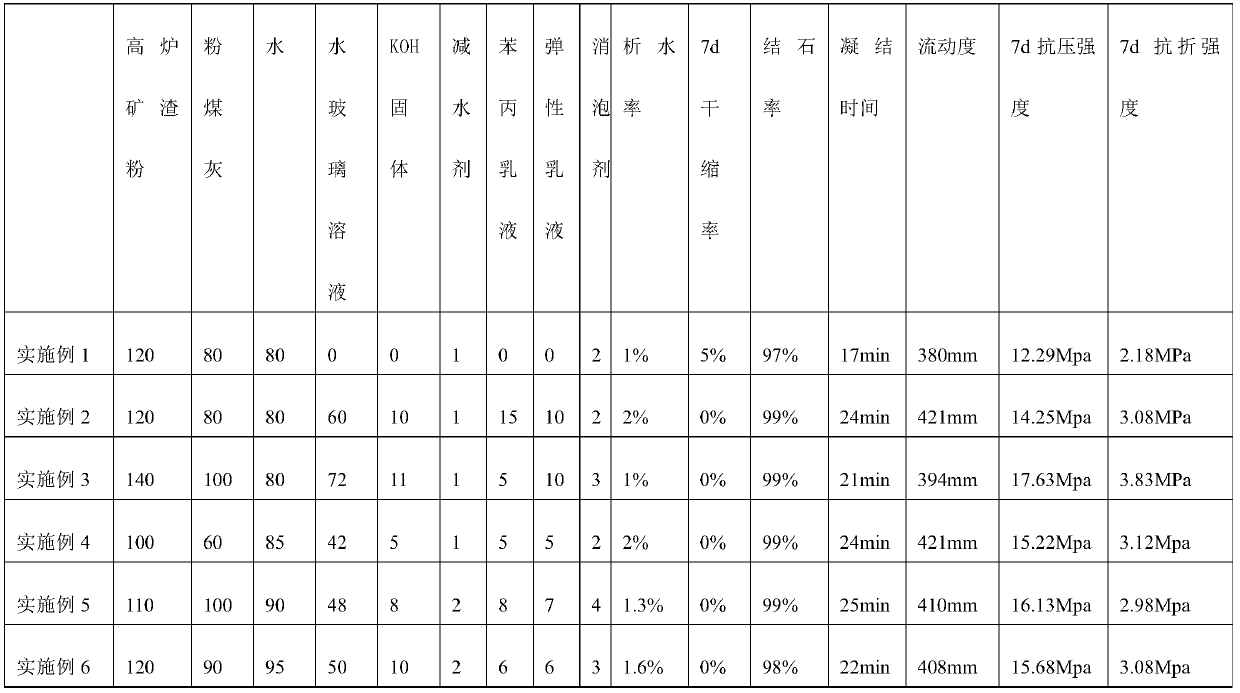

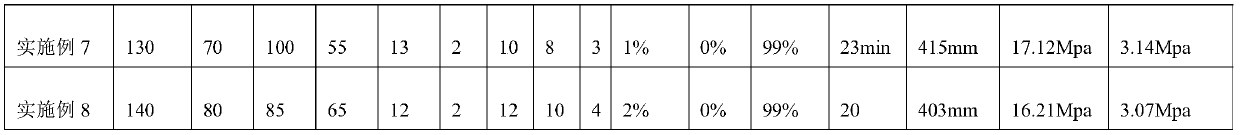

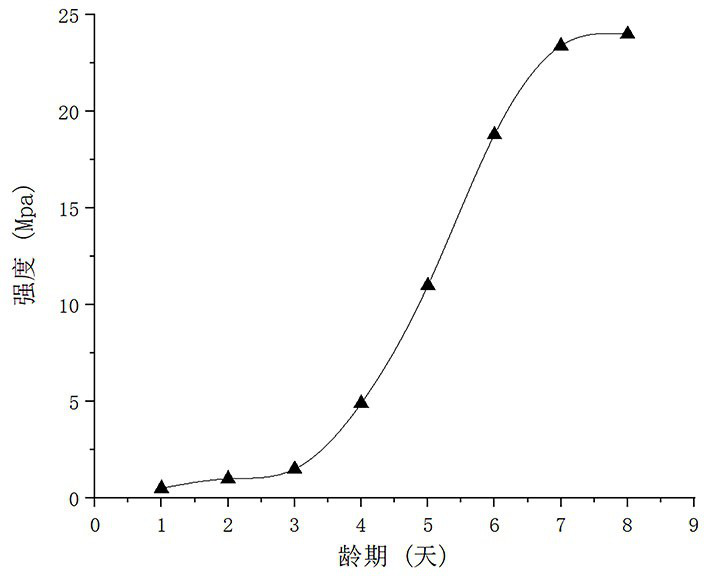

Slag powder and coal ash grouting-filling material and preparation method thereof

The invention discloses a slag powder and coal ash grouting-filling material and a preparation method thereof. The preparation method comprises the following steps: enabling water glass solution and KOH solid to be mixed to form alkaline solution, after adequately mixing blast furnace slag powder, coal ash and water, adding styrene-acrylic emulsion, elastic emulsion, a deformer and a water reducer, enabling the blast furnace slag powder and the coal ash to be adequately mixed, increasing a contact area between the blast furnace slag powder and the coal ash, reducing bubbles generated while stirring the organic emulsion by using the defoamer, reducing the residual bubbles in slurry, and using the obtained alkaline solution to be mixed with the blast furnace slag powder and the coal ash, enabling an aluminum oxide in the blast furnace slag powder and the coal ash to react firstly, and reacting to generate a calcium oxide and providing long-term strength increase, and mixing the slag powder and the coal ash in the above proportion, preventing a single type of the slag powder or the coal ash from being excessively rapidly coagulated, and adding the styrene-acrylic emulsion and the elastic emulsion, preventing from generating a dry-shrinkage phenomenon after reunion in coal ash and slag powder reaction processes.

Owner:CHANGAN UNIV

Strong-permeability stratum grouting material in flowing water environment and preparation method thereof

The invention relates to a strong-permeability stratum grouting material in a flowing water environment and a preparation method thereof, and belongs to the field of preparation of flowing water plugging materials. The grouting material comprises a cementing material, an expansion material and a quick-setting material, and the expansion material comprises potassium polyacrylate crystal particles and sodium polyacrylate crystals. The method comprises the following steps of: (1) preparing a cementing material into a groutable fluid; and (2) adding an expansion material into the slurry in the step (1), uniformly stirring, adding a setting accelerator within 30 minutes, and carrying out grouting. The grouting material provided by the invention has the characteristics of adjustable setting time, water swelling of slurry particles, strong groutability, good water gushing leaking stoppage effects, controllable slurry diffusion range, low cost, no toxicity and the like, and is an excellent-performance strong-permeability stratum grouting reinforcement and seepage prevention material in a flowing water environment.

Owner:SHANDONG UNIV OF SCI & TECH

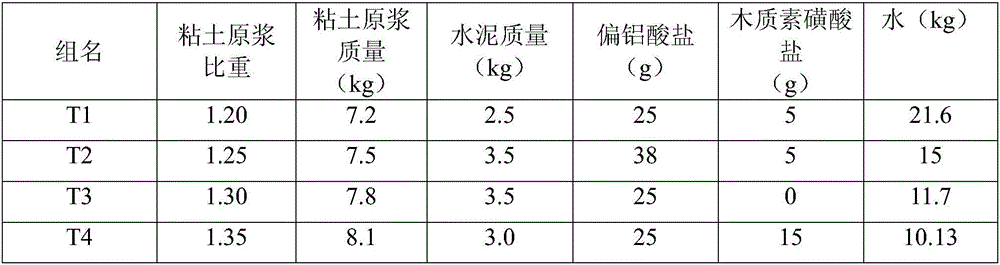

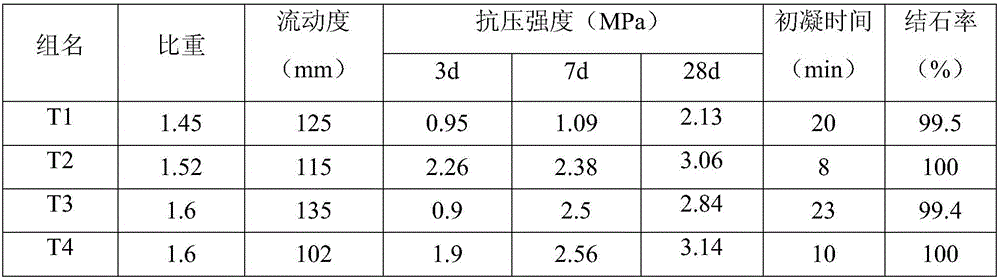

Filling paste slurry suitable for tunnel construction goaf

The invention discloses a filling paste slurry suitable for a tunnel construction goaf. The filling paste slurry is mainly prepared from a clay mud, a cement and water; the clay mud is prepared by stirring clay and water, a modifier is added in the filling paste slurry, the modifier comprises meta-aluminate and lignosulfonate, the mixing amount of the meta-aluminate is 0.5-1.5% of the mass of the cement, and the mixing amount of the lignosulfonate is 0.2-0.4% of the mass of the cement. The filling paste slurry is high in stone rate, has a good filling effect, and is environmentally friendly, convenient to prepare, and suitable for filling the tunnel construction goaf, the raw materials are cheap and easy to get, the setting time is controllable, the on-site construction operation is simple, and then a tunnel safely goes through the goaf.

Owner:CENT SOUTH UNIV +1

Concrete-like filling materials suitable for the treatment of goafs with large hollows in highways

The invention discloses a like concrete filling material suitable for road large cavity goaf treatment. The material comprises 32.5 grade slag Portland cement, fly ash, medium sand, gangue and a high efficiency water reducer, and a ratio of water to cement to fly ash to medium sand to gangue is 12.4:3.2:12.05:12.05:60.3. The density of like concrete is greater than the density of water, so underground water residual in large cavities is discharged; and the like concrete has a high concretion rate, so large goaf is filled and densified to realize no future troubles. Ingredients of the like concrete are changed to valuables, so the like concrete filling material saves resources, protects environment, can meet pumping transmission demands, and has very good economic benefits and social values.

Owner:山西交科岩土工程有限公司 +1

Economical high-strength and early strength grouting material and soft rock tunnel grouting reinforcement method

ActiveCN109578021ASimple componentsGood effectUnderground chambersTunnel liningSulfatePortland cement

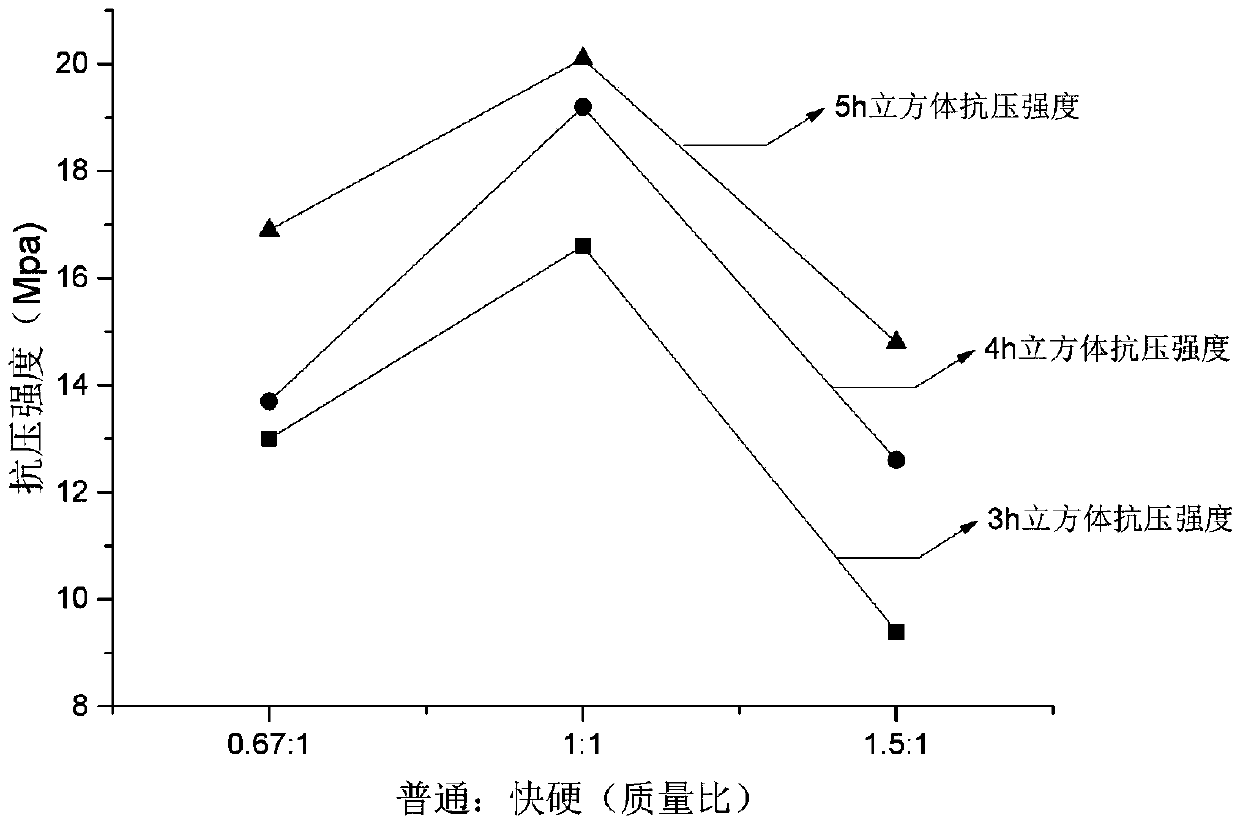

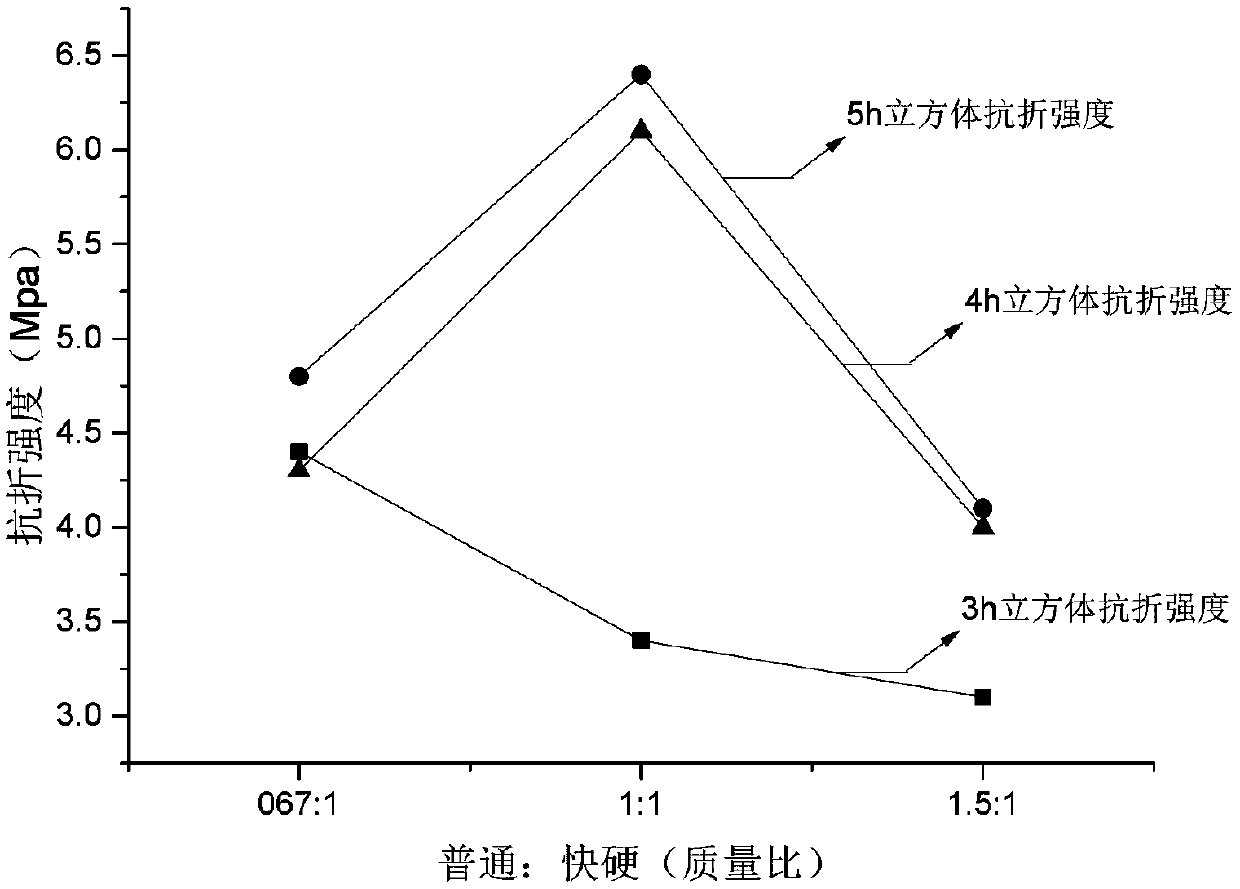

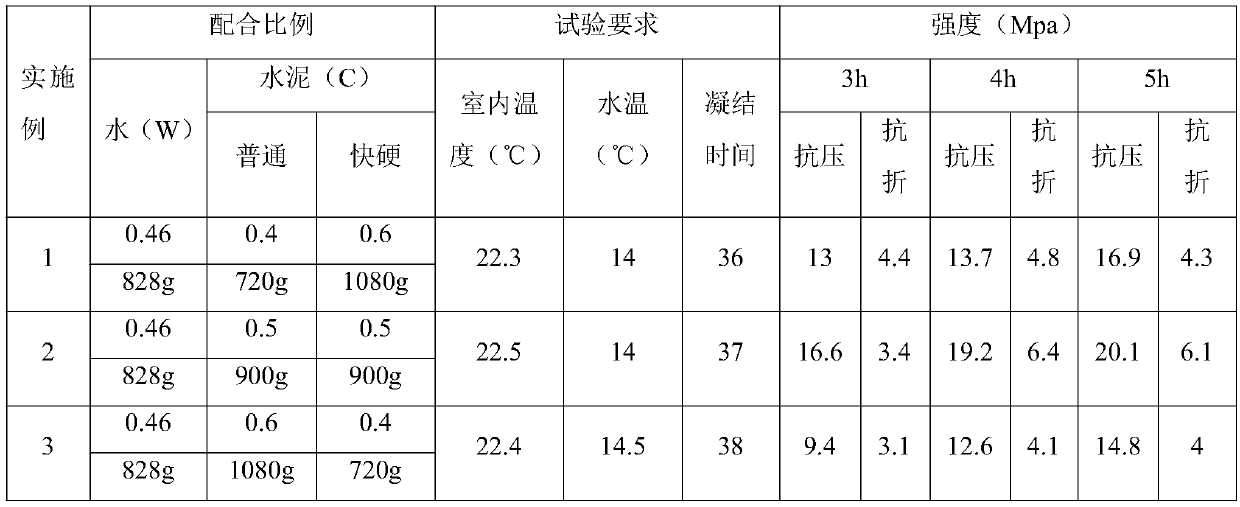

The invention discloses an economical high-strength and early strength grouting material and a soft rock tunnel grouting reinforcement method. The economical high-strength and early strength groutingmaterial is composed of common Portland cement, early strength sulfate aluminum cement and water; the ratio of the weight of the water to the sum weight of the common Portland cement and the early strength sulfate aluminum cement is 0.46:1, and the weight ratio of the early strength sulfate aluminum cement and the common Portland cement is (0.67-11.5):1; the initial setting time of the economicalhigh-strength and early strength grouting material is 35-45 min, and the cube crushing strength of the economical high-strength and early strength grouting material cured for 4 h is not lower than 10MPa. The economical high-strength and early strength grouting material has the advantages of being high in mortar setting speed, simple in preparation and high in strength and is applicable to meetingthe rapid construction demands of soft rock tunnels.

Owner:CHANGAN UNIV

Alkali-activated slag-based cement mixture grouting material and preparation method thereof

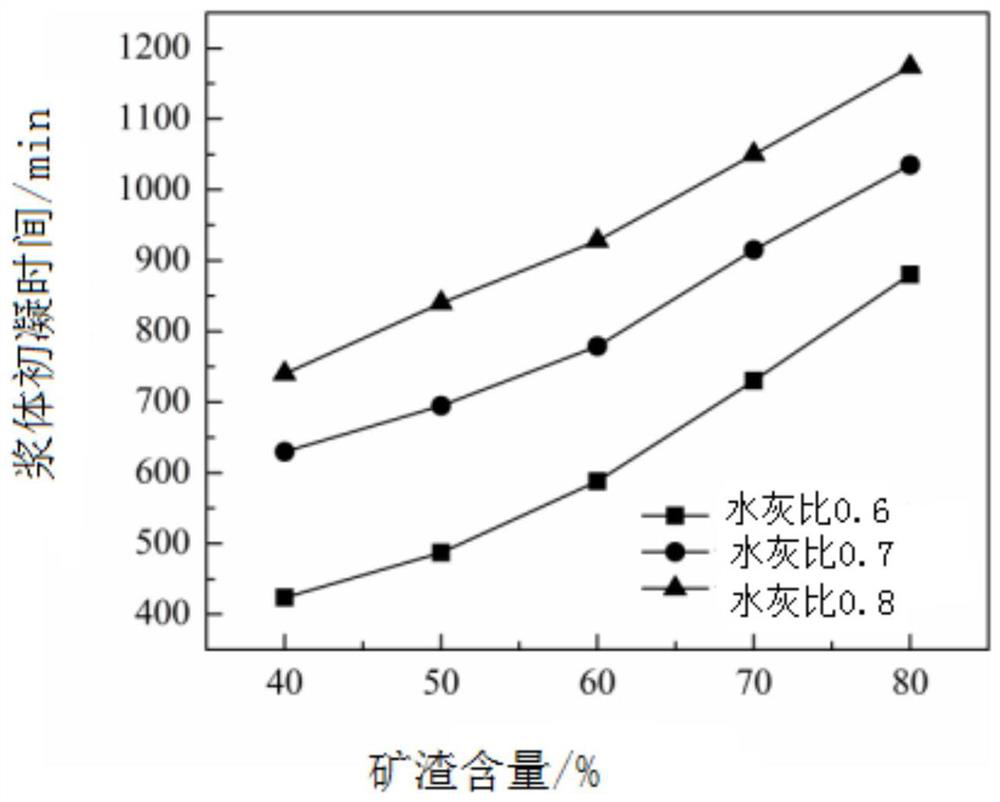

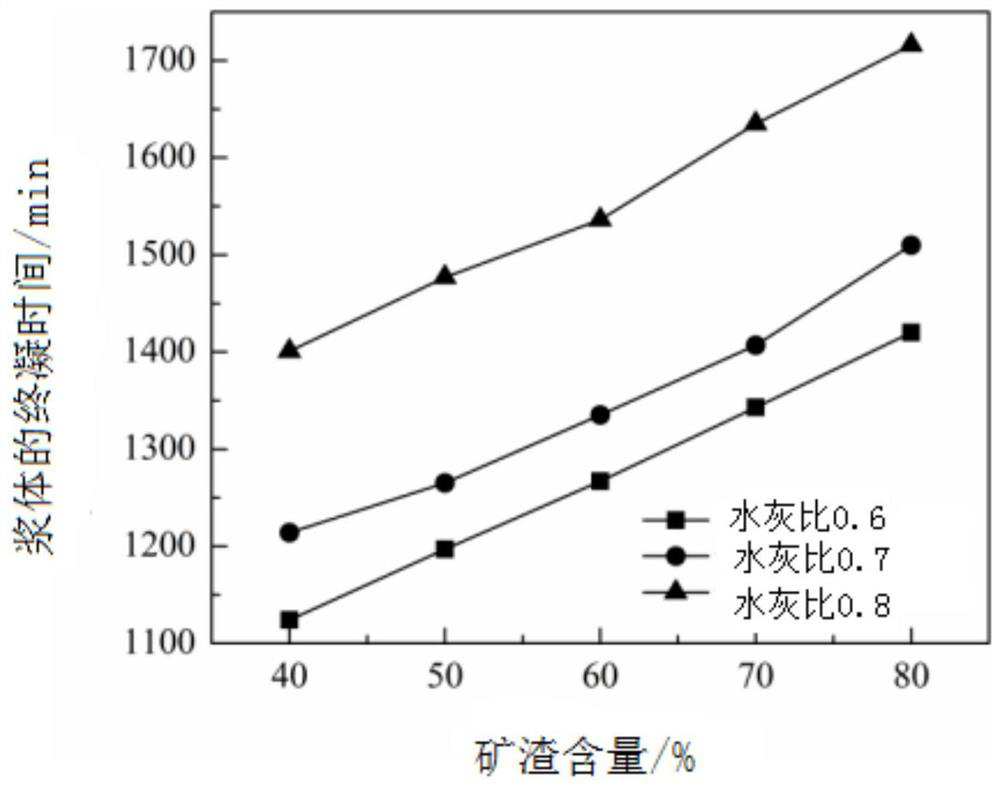

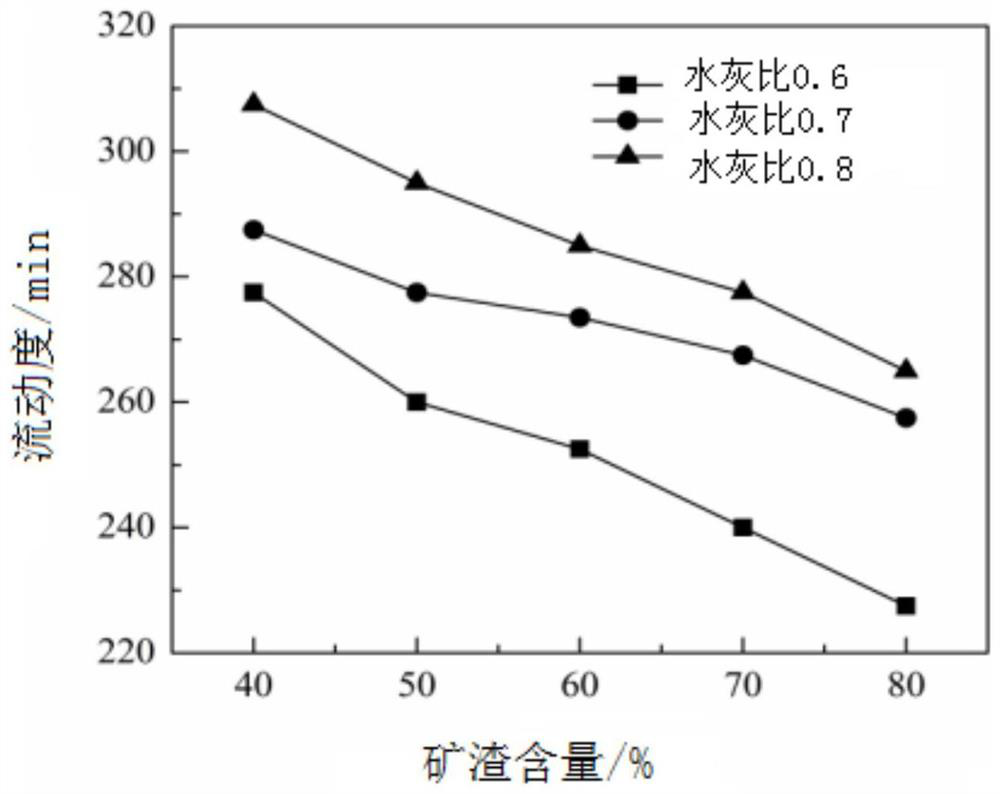

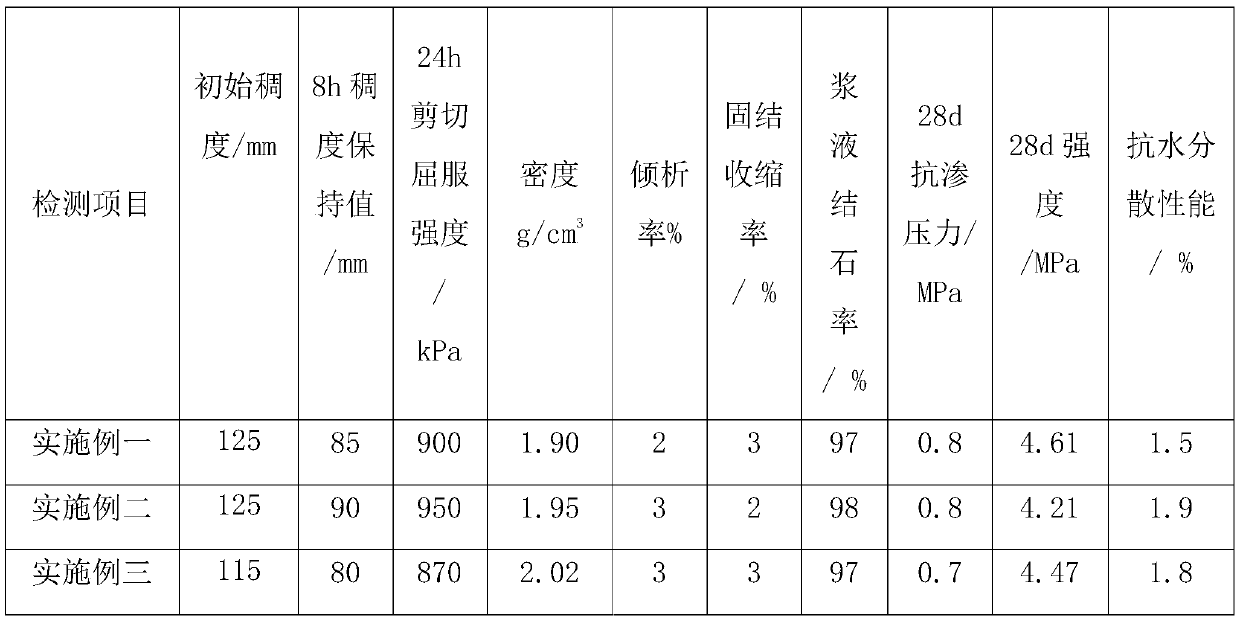

The invention relates to an alkali-activated slag-based cement mixture grouting material and a preparation method thereof. The alkali-activated slag-based cement mixture grouting material is preparedfrom the following raw materials: Portland cement, water glass, slag and water. The grouting material is prepared from Portland cement, water glass and slag as mixed main materials according to a specific ratio, and has the advantages of good fluidity, controllable setting time, high stone rate, economy, environmental protection and the like, and the proportion of the slag in slurry has obvious influence on the performance of the grouting material; specifically, the higher the slag content is, the smaller the unconfined compressive strength of the slurry is, the smaller the fluidity is, the longer the initial setting time and the final setting time are, and the higher the stone forming rate is; in addition, the industrial waste residues are adopted, good recycling is achieved, and great significance is achieved for environmental protection.

Owner:QINGHAI UNIVERSITY

High waterproof synchronous grouting grout for subsea shield tunnel

The invention provides a high-waterproofness synchronous grouting slurry for submarine shield tunnels. The high-waterproofness synchronous grouting slurry comprises the following components as raw materials in percent by weight: 7.0-9.5% of a cementing material, 14.5-17.5% of ground limestone powder, 2.6-4.2% of sodium-based bentonite, 55-60% of river sand, a waterproofing agent of which the usingamount is 3.0% of that of the cementing material, a water reducing agent of which the using amount is 1.0% of that of the cementing material, hydroxypropyl methyl cellulose of which the using amountis 0.5% of that of the cementing material, polyacrylamide of which the using amount is 0.1% of that of the cementing material, an air entraining agent of which the using amount is 0.03% of that of thecementing material, and the balance of water, wherein the cementing material comprises cement and slaked lime according to a mass ratio of (4.0-5.5):(3.0-4.0). The high-waterproofness synchronous grouting slurry provided by the invention has relatively high waterproofness, relatively high early shear strength and strong seawater seepage resistance, and can provide certain shear resistance, so that the problems of floating of duct pieces and cracking-caused water seepage can be effectively solved and a role in stabilizing the duct piece is played.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

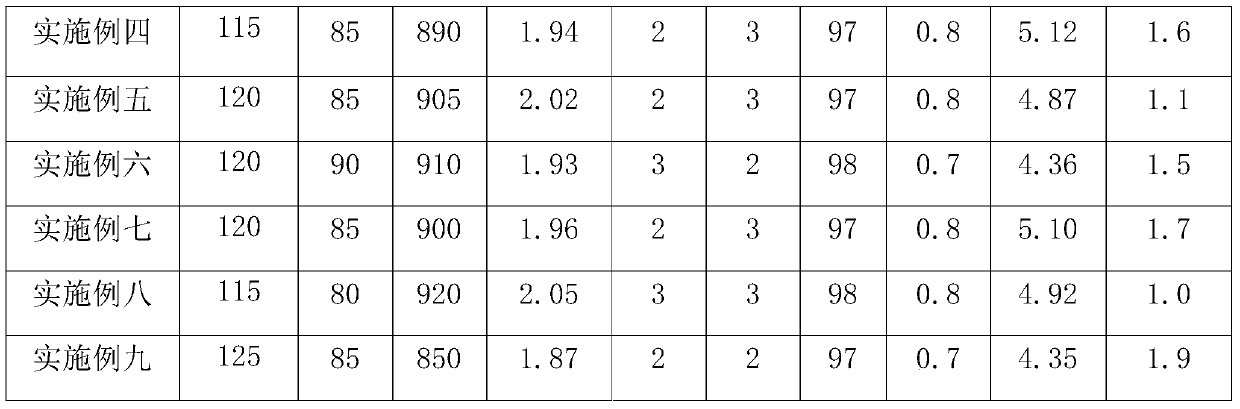

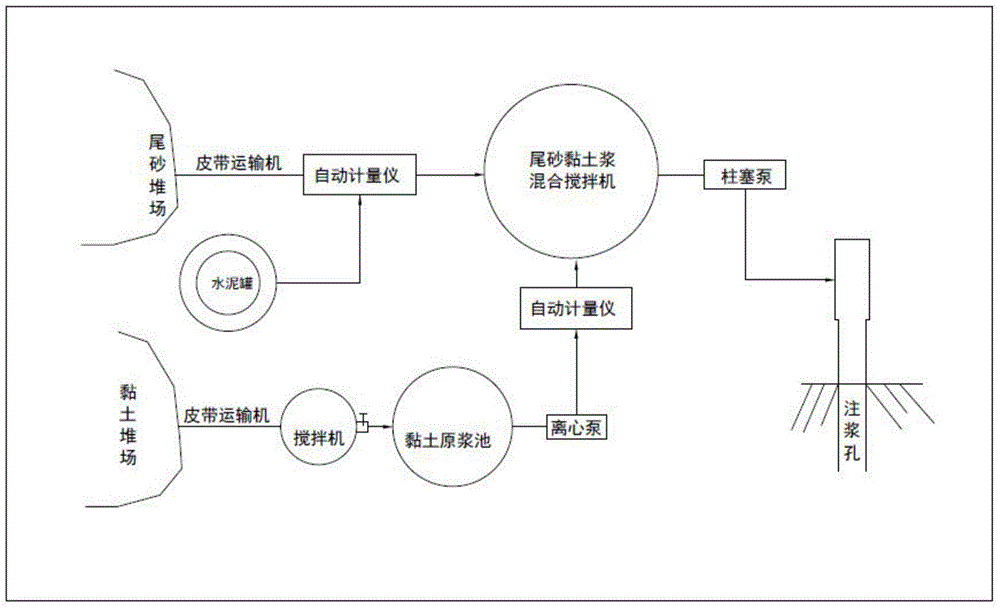

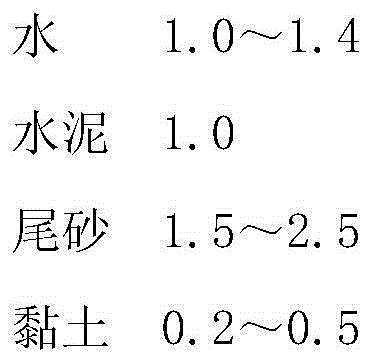

Modified tailing slurry and pulping and grouting process thereof

The invention discloses modified tailing slurry. The modified tailing slurry comprises the following components in parts by weight: 1.0-1.4 parts of water, 1.0 part of cement, 1.5-2.5 parts of tailing and 0.2-0.5 part of clay, wherein the tailing is graded tailing with the particle size in the range of 10-100 mu m; the particle size of the clay is in the range of 0.002-0.5mm, and the clay comprises the following components in percentage by mass: 20%-40% of clay particles, 50%-70% of powder particles and 0.5%-10% of sand particles; the cement is ordinary silicate bulk P.032.5 cement. The invention further discloses a pulping and grouting process of the modified tailing slurry. The pulping and grouting process is performed according to the following process steps: 1) preparing the modified tailing slurry disclosed by the invention; and 2) conveying and injecting the prepared modified tailing slurry into a grouting hole through a plunger pump.

Owner:深圳市中金岭南有色金属股份有限公司凡口铅锌矿 +1

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com