Strong-permeability stratum grouting material in flowing water environment and preparation method thereof

A grouting material and water environment technology, applied in the field of material science, can solve the problems of insufficient grouting effect, rapid dilution of grout, and poor grouting effect, and achieve strong water corrosion resistance, high interface bonding strength, Effects with controllable spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

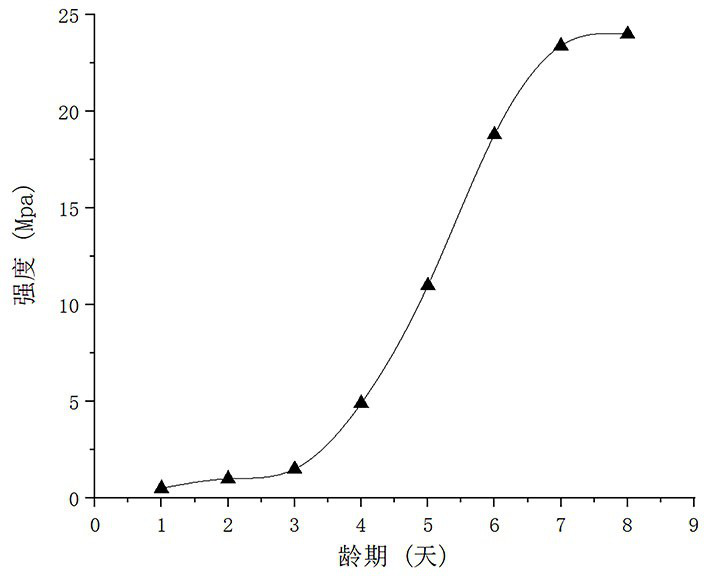

Image

Examples

Embodiment 1

[0030] A method for preparing a grouting material for a strongly permeable formation under a dynamic water environment, comprising the following steps.

[0031] 1) According to the water-cement ratio of 0.8 to 1, first add water to the mixing tank, and then add cement (strength grade P.042.5, Blaine specific surface area is 300 to 350m 2 / kg), and during the configuration process, the cement needs to be stirred continuously.

[0032] 2) According to the addition of potassium polyacrylate crystal particles per cubic meter of grouting slurry, add 1 g per cubic meter of gel material. Add 1 kg of sodium polyacrylate crystals per cubic meter of gel material.

[0033] 3) Mix the water glass with a Baume degree of 40 and the grouting slurry after adding fibers in step 2) at a volume ratio of 1:5, and inject it into the borehole with a double-liquid grouting pump.

[0034] After the current slurry in this example is injected into the borehole, compared with the simple injection of c...

Embodiment 2

[0036] A method for preparing a grouting material for a strongly permeable formation under a dynamic water environment, comprising the following steps.

[0037] 1) According to the water-cement ratio of 1 to 1, first add water to the mixing tank, and then add cement (strength grade P.042.5, Blaine's specific surface area is 300 to 350m 2 / kg), and during the configuration process, the cement needs to be stirred continuously.

[0038] 2) Add 0.8kg of potassium polyacrylate crystal particles per cubic meter of gel material per cubic meter of grouting slurry. Add 1.5 kg of sodium polyacrylate crystals per cubic meter of gel material.

[0039] 3) Mix the water glass with a Baume degree of 40 and the grouting slurry after adding fibers in step 2) according to the volume ratio of 1 to 4.5, and inject it into the borehole with a double-liquid grouting pump.

[0040] After the current slurry in this example is injected into the borehole, compared with the simple injection of cement-...

Embodiment 3

[0042] A method for preparing a grouting material for a strongly permeable formation under a dynamic water environment, comprising the following steps.

[0043] 1) According to the water-cement ratio of 1 to 1, first add water to the mixing tank, and then add cement (strength grade P.042.5, Blaine's specific surface area is 300 to 350m 2 / kg), and during the configuration process, the cement needs to be stirred continuously.

[0044] 2) According to the addition of potassium polyacrylate crystal particles per cubic meter of grouting slurry, add 0.6kg per cubic meter of gel material. Add 1.5 kg of sodium polyacrylate crystals per cubic meter of gel material.

[0045] 3) Mix the water glass with a Baume degree of 40 and the grouting slurry after adding fibers in step 2) at a volume ratio of 1:5, and inject it into the borehole with a double-liquid grouting pump.

[0046]After the current slurry in this example is injected into the borehole, compared with the simple injection o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com