Patents

Literature

559results about How to "Effective reinforcement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

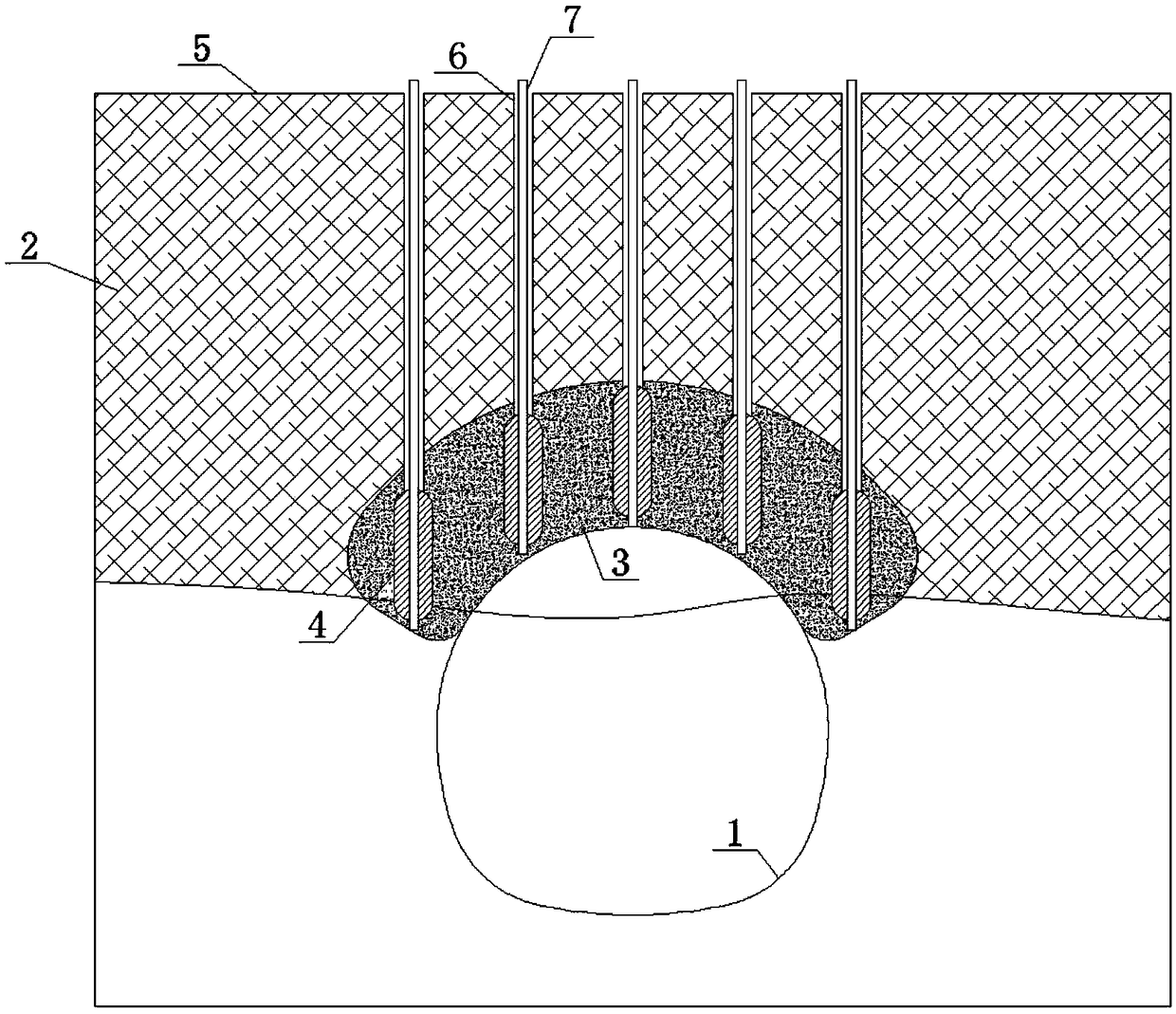

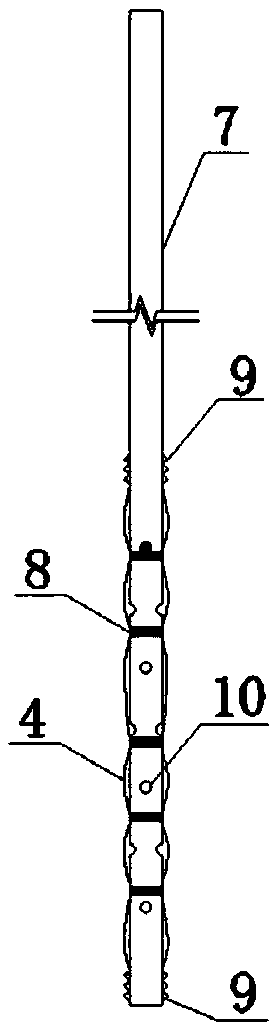

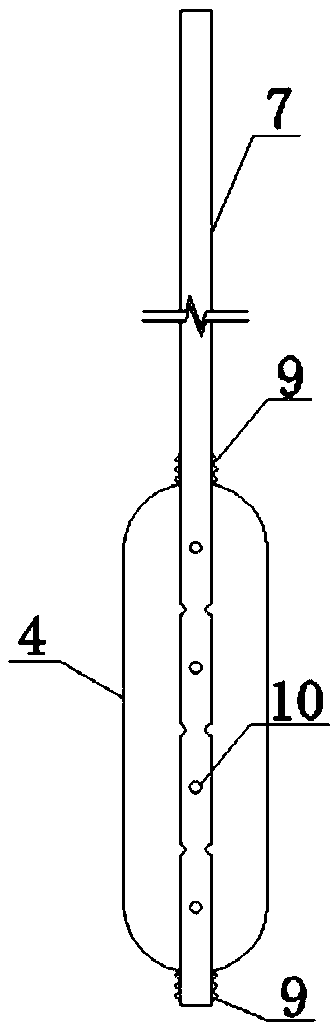

Method for exchanging tool of shield machine for tunnel construction

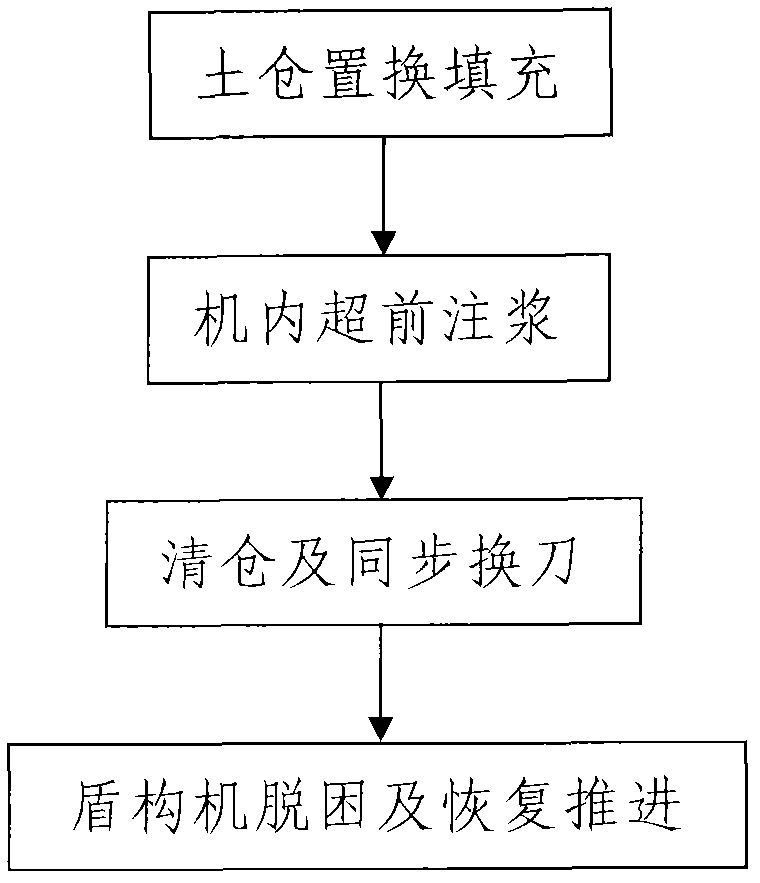

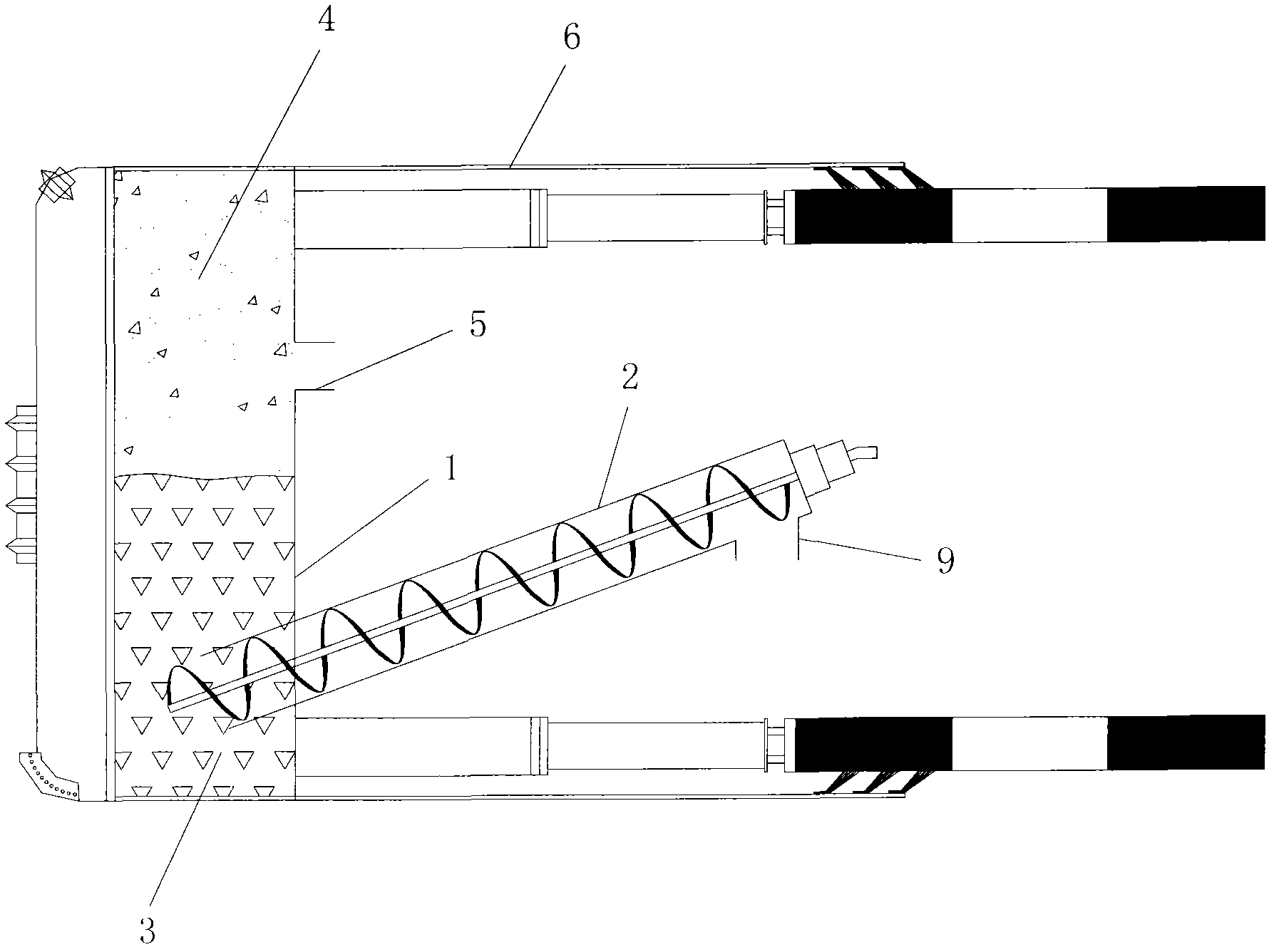

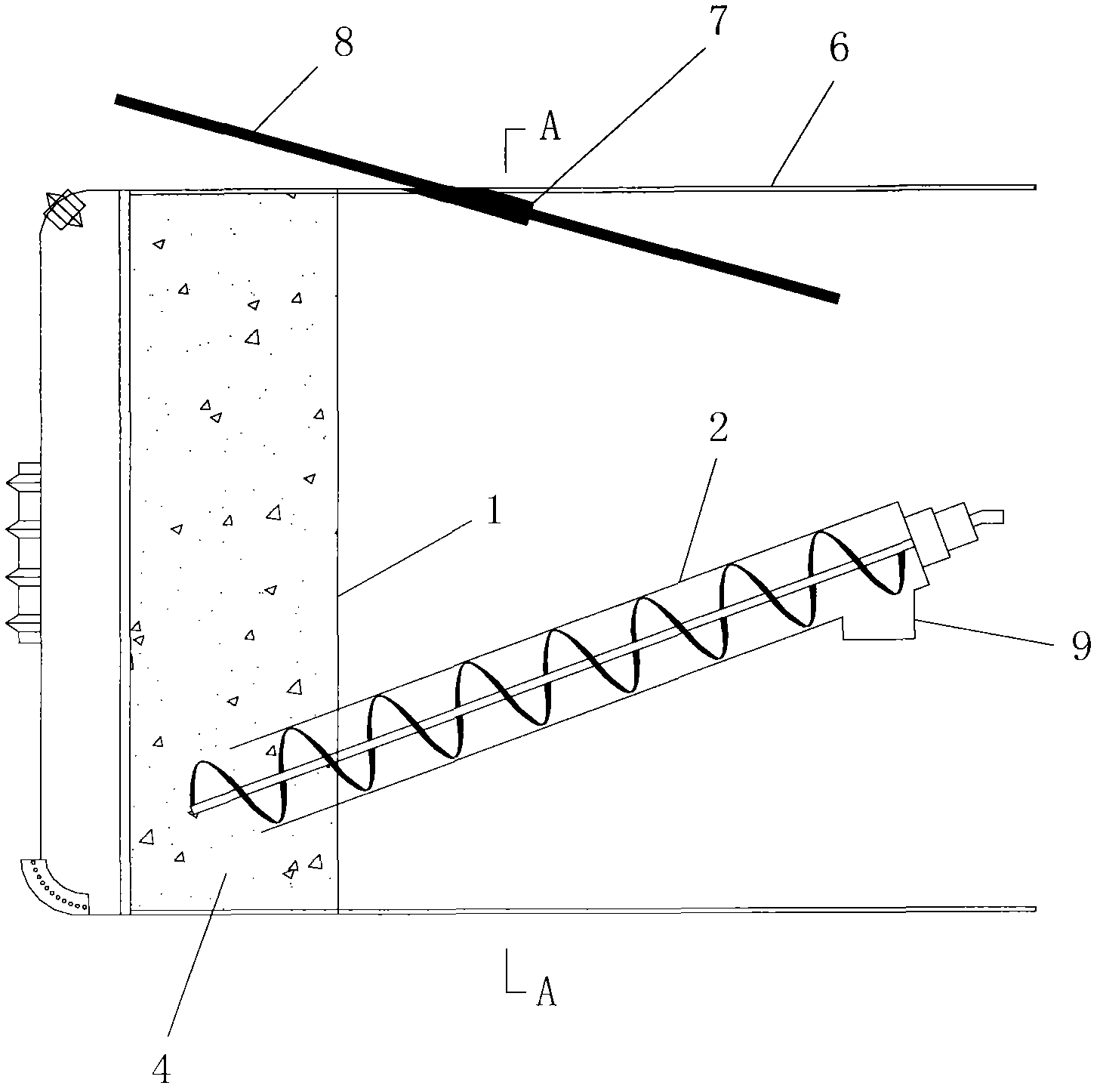

The invention discloses a method for exchanging a tool of a shield machine for tunnel construction, which comprises the steps of: (1) soil cabin replacement filling: performing the process of soil cabin replacement filling by using a spiral excavating machine and a slip casting system synchronously working with the spiral excavating machine; (2) advanced slip casting inside the machine: beating a plurality of slip casting pipes into the soil on the upper part of the shield machine from inner to outer inside the shield machine by respectively passing through a plurality of advanced geologic holes and then synchronously injecting cement paste into the soil on the upper part of the shield machine through the slip casting pipes by using a slip casting device till the cement paste cannot be injected any more; (3) cleaning cabin and exchanging tool synchronously: manually cleaning the cement plaster solidified inside the soil cabin and synchronously exchanging the tool mounted on the shield machine; and (4) getting rid of the difficult position of the shield machine and recovering the process. The method provided by the invention has the advantages of reasonable design, convenience for operation, low cost, high safety factor, good use effect and capable of solving the problem that the tool cannot be exchanged in the traditional tool exchanging mode under severe tool exchanging conditions.

Owner:URBAN RAIL TRANSIT ENG CO LTD OF CHINA RAILWAY FIRST GRP CO LTD +1

Foundation treatment method for controlling post-construction settlement and deformation of soft soil

InactiveCN102226335AIncrease effective preloadEffective reinforcementSoil preservationEngineeringCut and fill

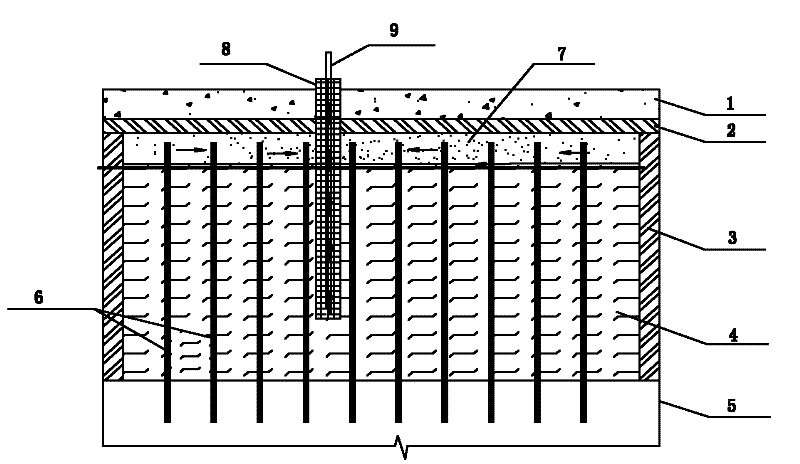

The invention discloses a foundation treatment method for controlling the post-construction settlement and deformation of soft soil. the method sequentially comprises the following steps: setting a vertical envelope wall around an area to be reinforced; inserting vertical drainage systems and laying horizontal drainage systems in the area to be reinforced; paving sealing materials on the surface of a foundation; backfilling settlement refills or exerting pre-loads on the foundation; carrying out vacuumizing, well-point dewatering or vacuum well-point dewatering on the drainage systems so as to reinforce the foundation; and after the consolidation degree of the foundation reaches 60-90%, carrying out sealing on all the vertical and horizontal drainage systems. The method disclosed by the invention is used for simultaneously carrying out reinforcement and plugging on an untreated soft soil foundation, so that the post-construction settlement can be controlled while the foundation is treated. Duo to the one-time treatment, the treatment time can be saved, and the treatment cost can be reduced, thereby achieving the purpose of effectively reinforcing the foundation and controlling the post-construction settlement.

Owner:CCCC FOURTH HARBOR ENG INST +4

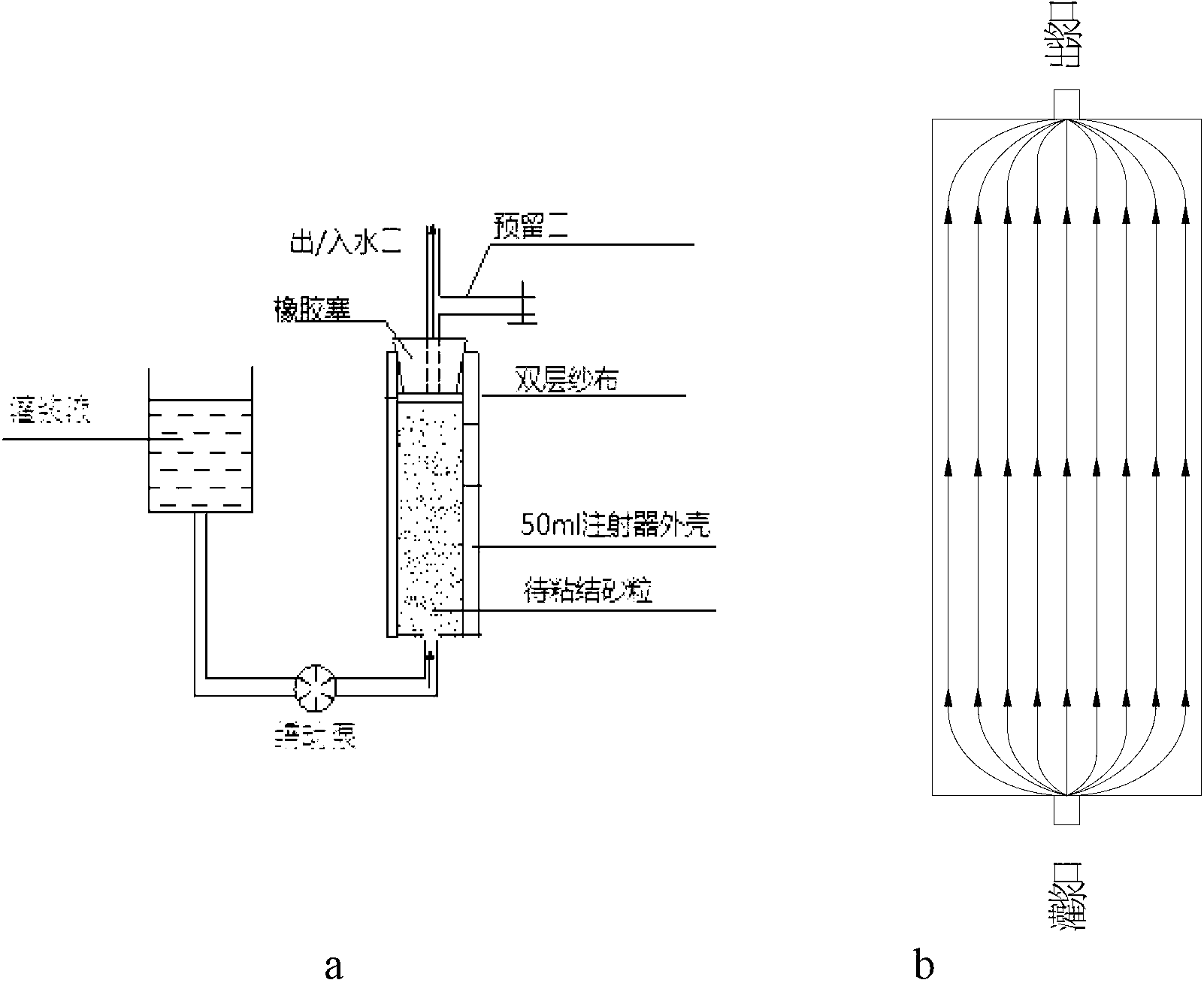

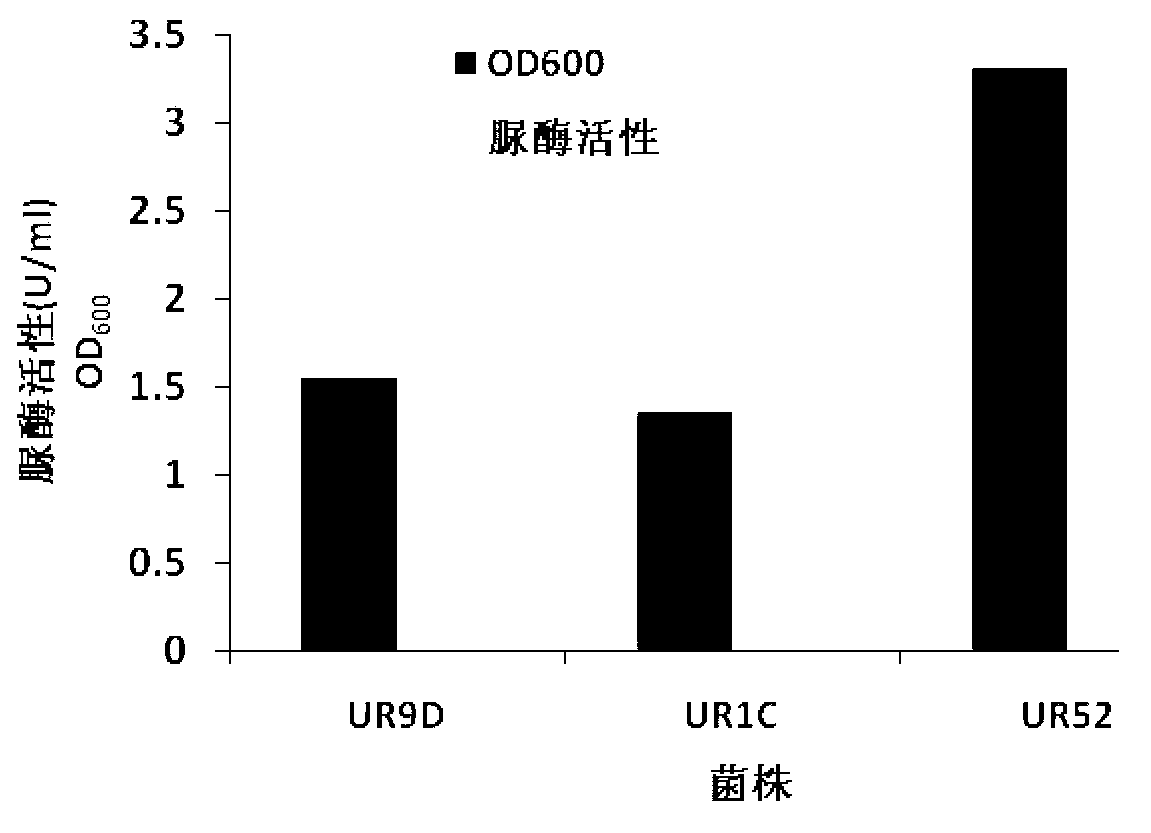

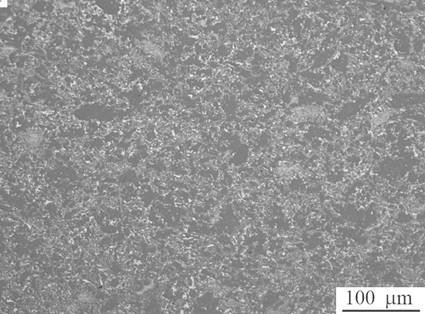

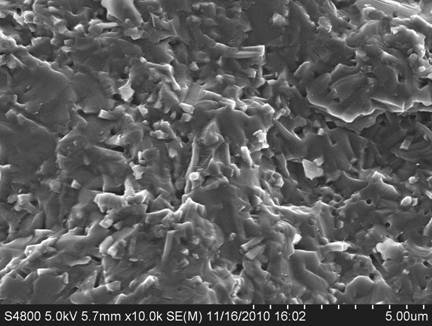

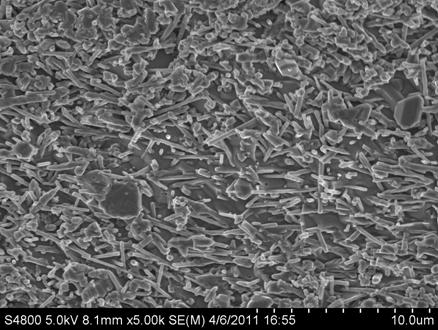

Bacillus lentus and method for generating by inducing bacillus lentus for reinforcing foundation

InactiveCN103266070AShort duration of intensityGood effectBacteriaMicroorganism based processesBacillus lentusTwo step

The invention provides bacillus lentus and a method for generating by inducing bacillus lentus for reinforcing foundation, the bacillus lentus URIC, the bacillus lentus UR9D, and the bacillus lentus UR52 are preserved in China General Microbiological Culture Collection Center (CGMCC) on August 29, 2012; the method comprises: firstly, respectively fermenting and culturing a single bacterium colony of bacillus lentus in a fermentation medium, then grouting in two steps, filling bacteria liquid into a sand column pumped with deionized water, and filling a mixed solution of reaction solution calcium chloride and urea, to form a microbe-calcium carbonate-sand grains consolidating body in a sand grain-solution system, and furthermore to enhance bonding degree and intensity of the sand grains. The bacillus lentus and the method of the invention has advantages of short solidification time, good effect and low cost, and will not cause pollution on environment.

Owner:TSINGHUA UNIV

Anchoring-grouting integrated reinforcing method for roadway floors

InactiveCN102322273AImprove integritySolve the problem that the construction cannot be carried out, and the surrounding rock in the deep part of the floor cannot be reinforcedUnderground chambersTunnel liningWall rockGrout

The invention relates to an anchoring-grouting integrated reinforcing method for roadway floors. Aimed at the problems that the deep of the soft, fractured roadway floor in a geologically abnormal zone is hard to reinforce and floor heave is difficult to control, the anchoring-grouting integrated reinforcing method is adopted and comprises the following steps: severe grout runout or grout leakage is first prevented during grouting when the roadway floor is constructed, shallow hole grouting is then carried out to block shallow fractures and form a shallow grout-stopping layer, moreover, after grouting, the integrity of wall rocks within the grouting range is enhanced, and thereby the problem of subsequent grouting borehole collapse is solved; deep grouting holes are then constructed, grouting pipes and anchor ropes are mounted, full-length anchoring is carried out on the anchor ropes while grout is injected to solidify deep rocks, finally, channel steel, I-shaped steel and the like are adopted to combine single anchor ropes into anchor rope beams, and thereby the deformation of the roadway floor can be effectively controlled.

Owner:CHINA UNIV OF MINING & TECH

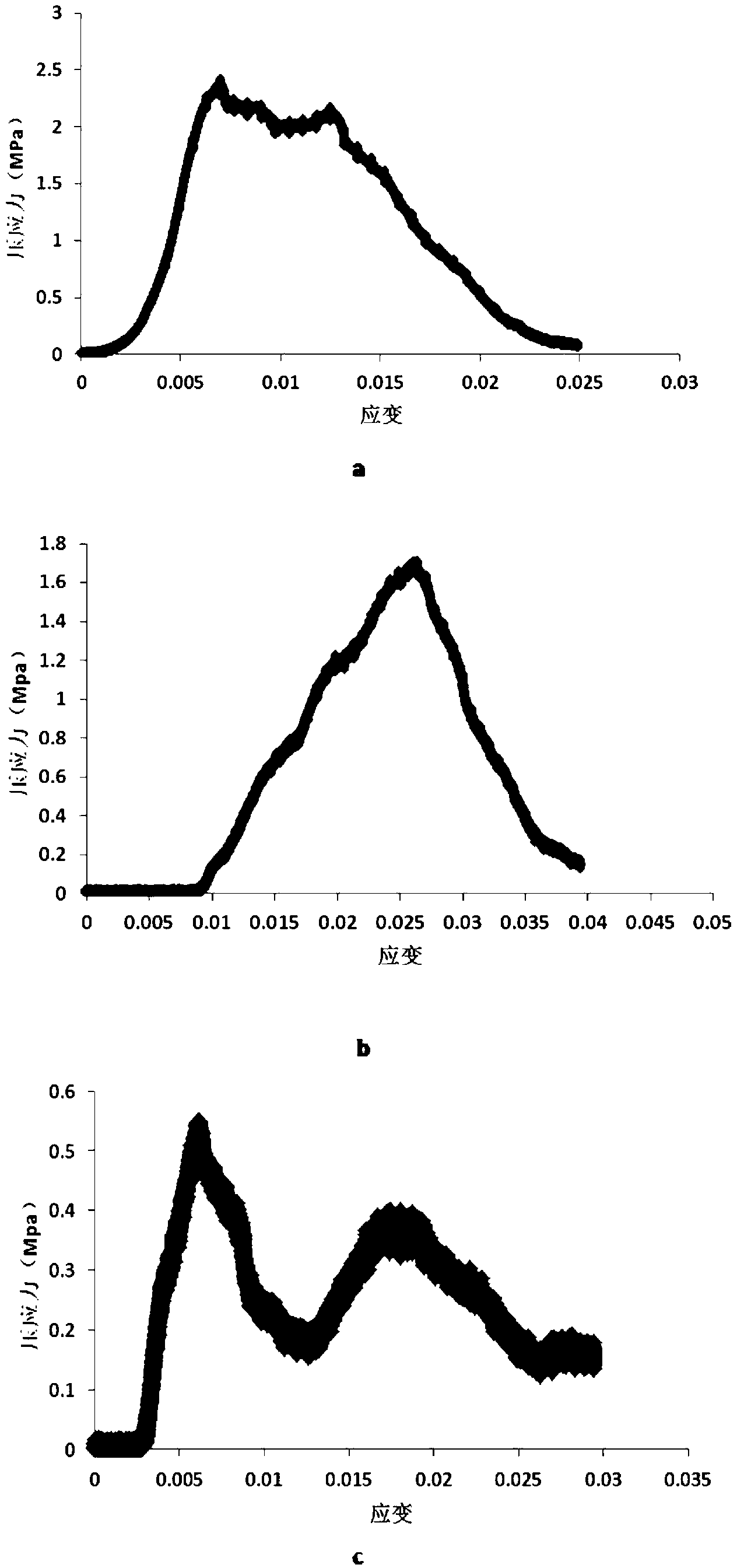

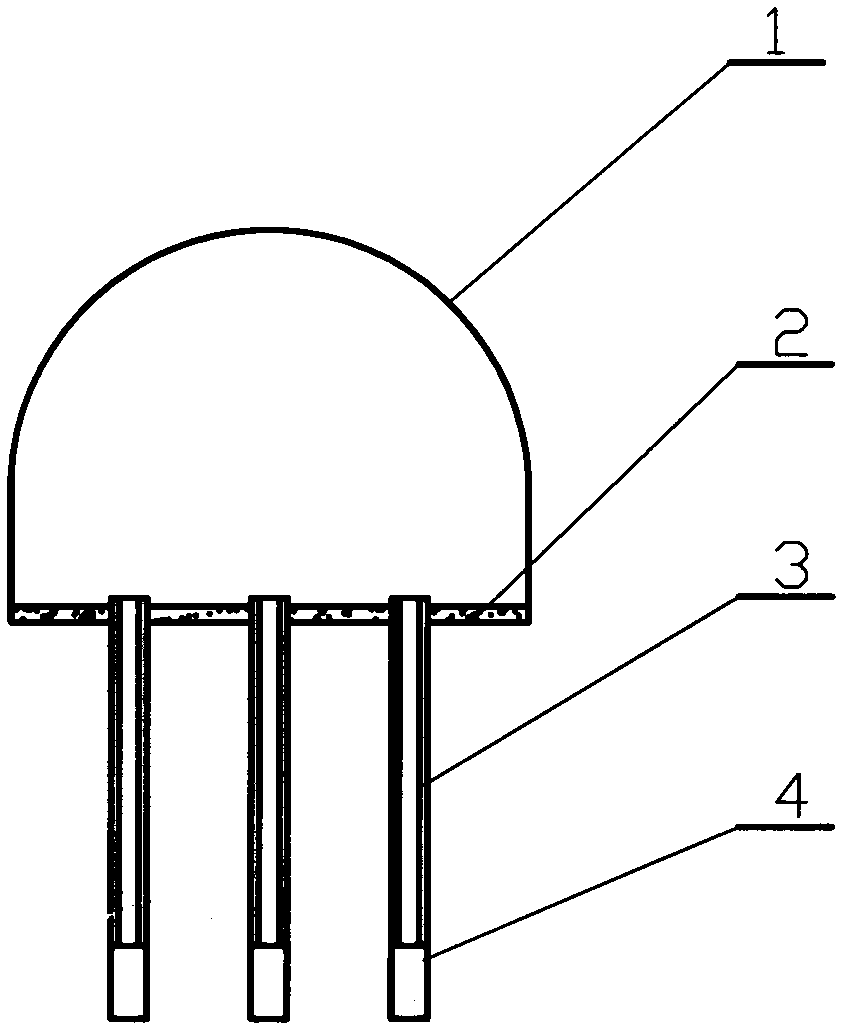

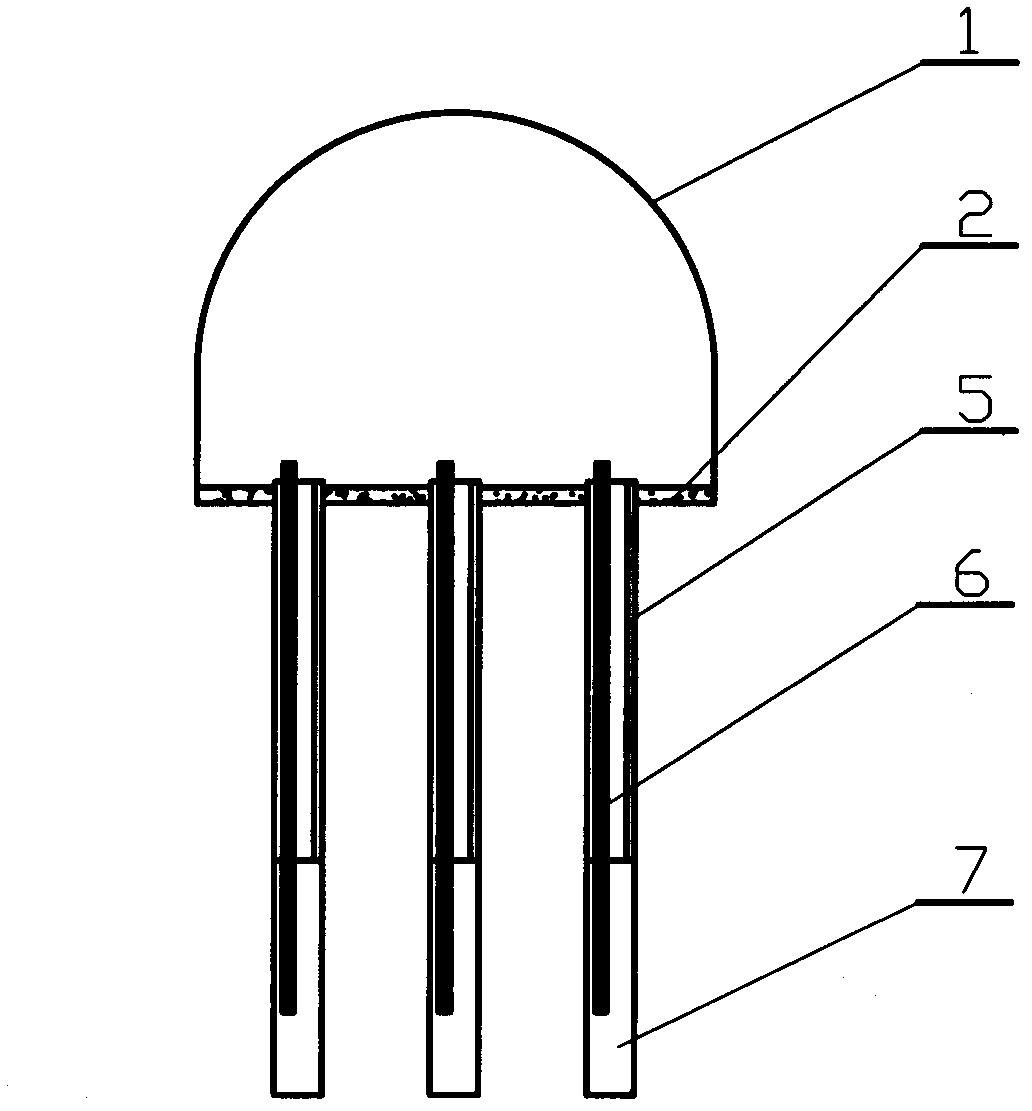

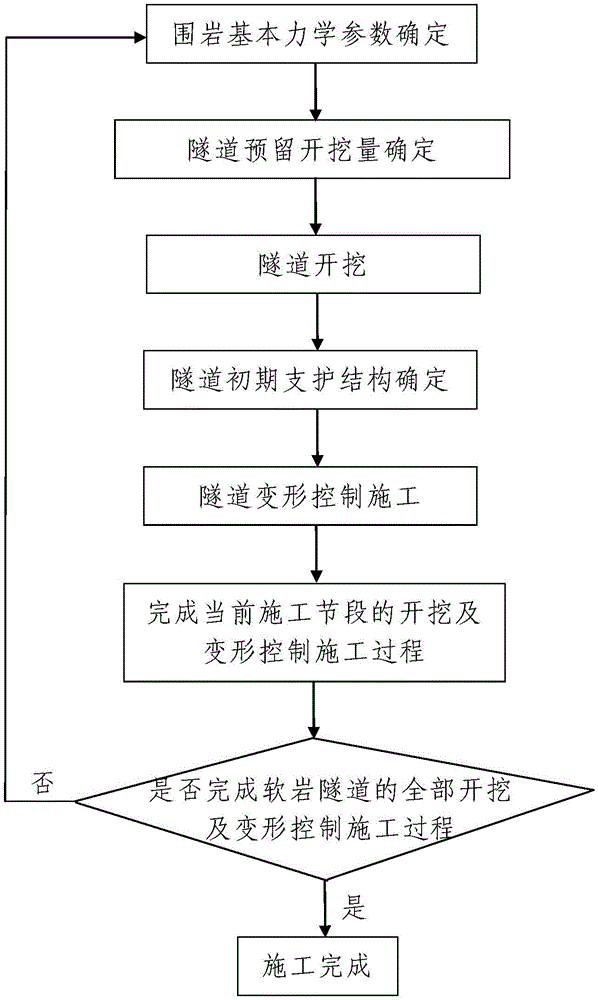

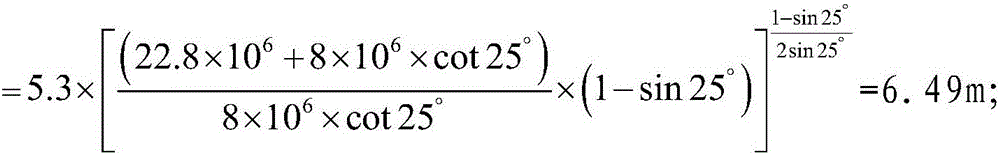

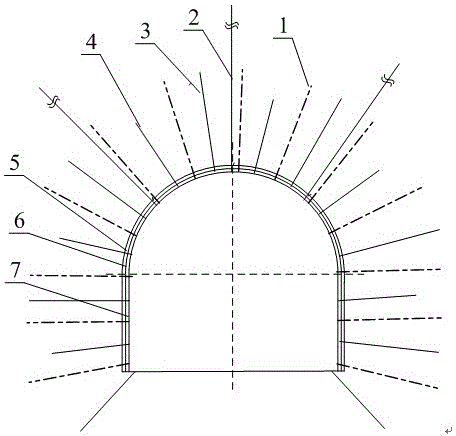

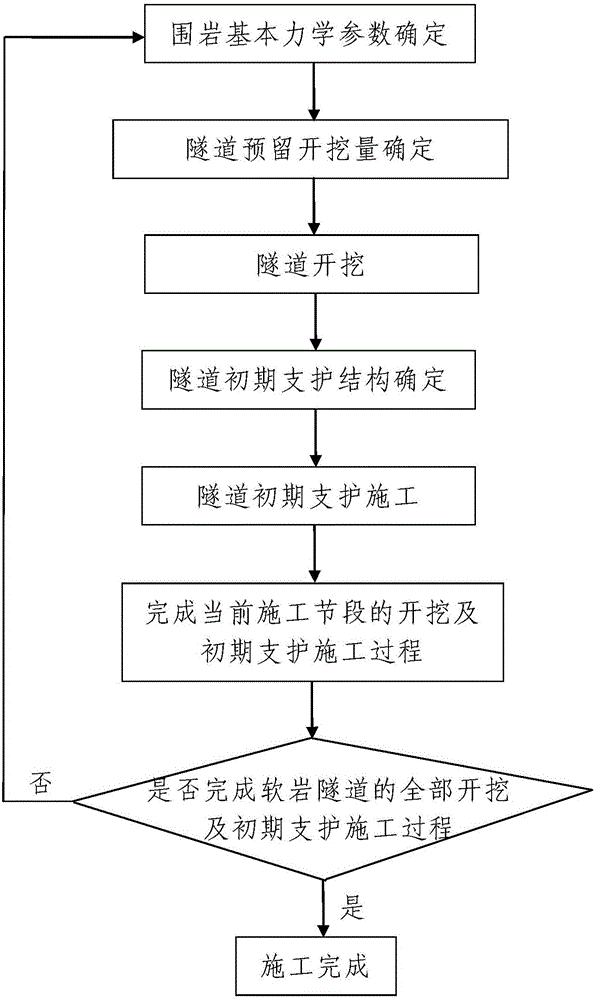

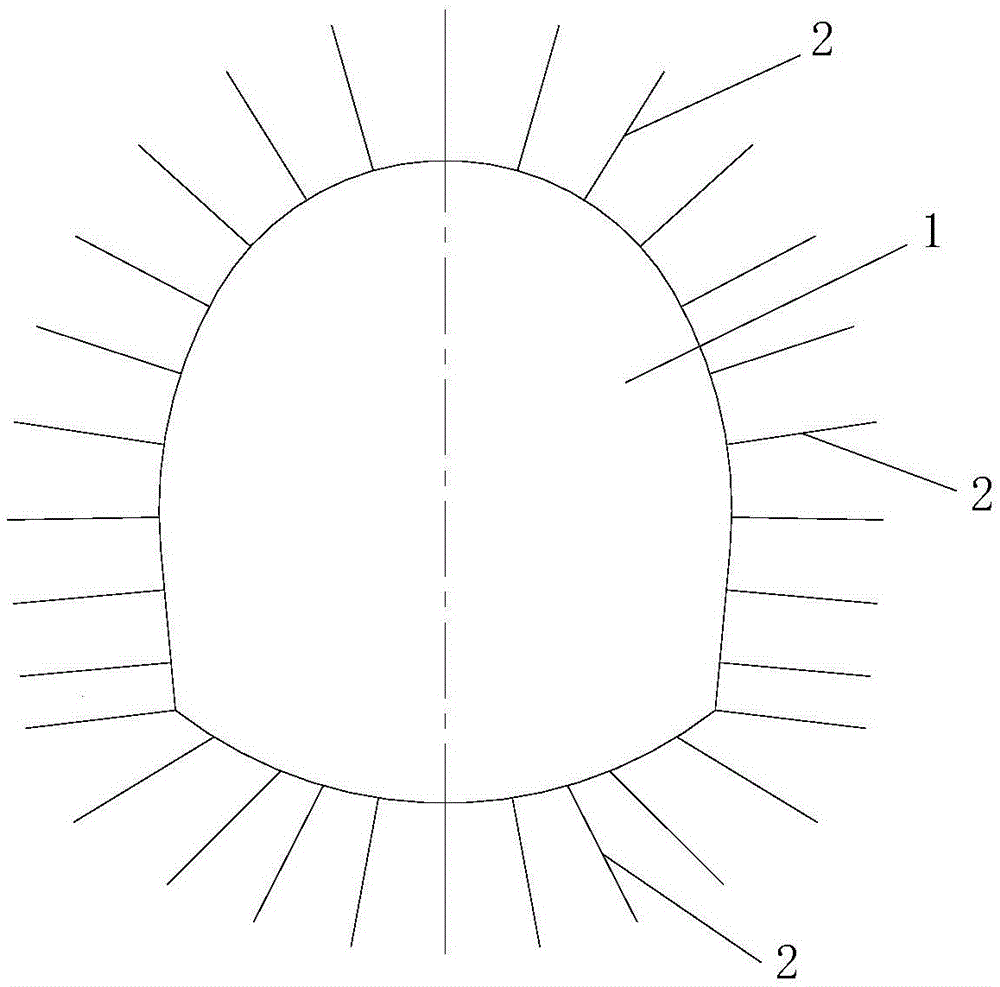

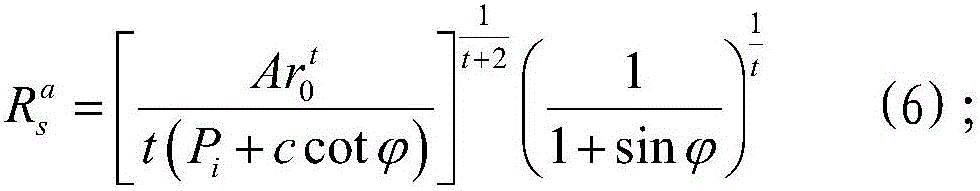

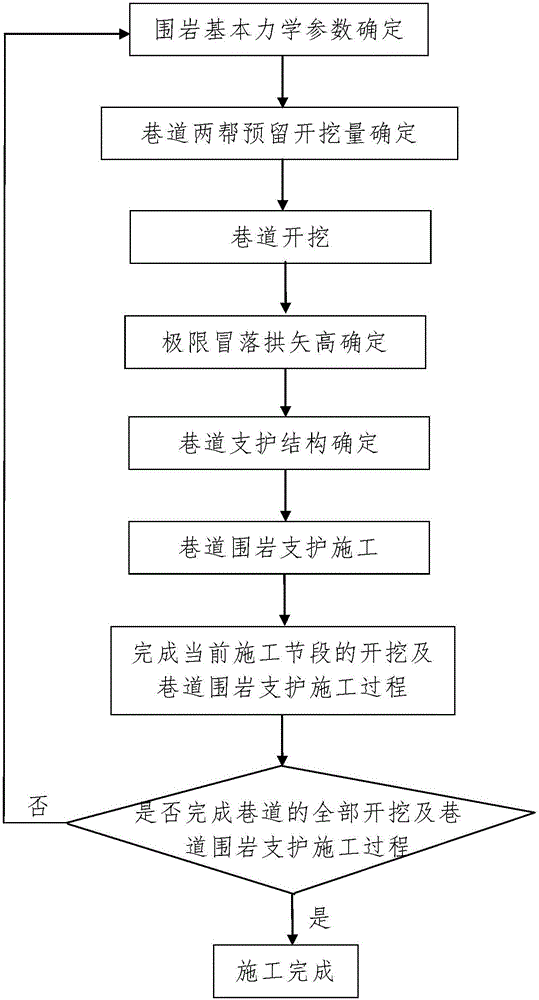

Soft rock tunnel deformation control method based on anchor rod force analysis

InactiveCN106499397AThe method steps are simpleEasy to implementUnderground chambersTunnel liningStructure of the EarthForce analysis

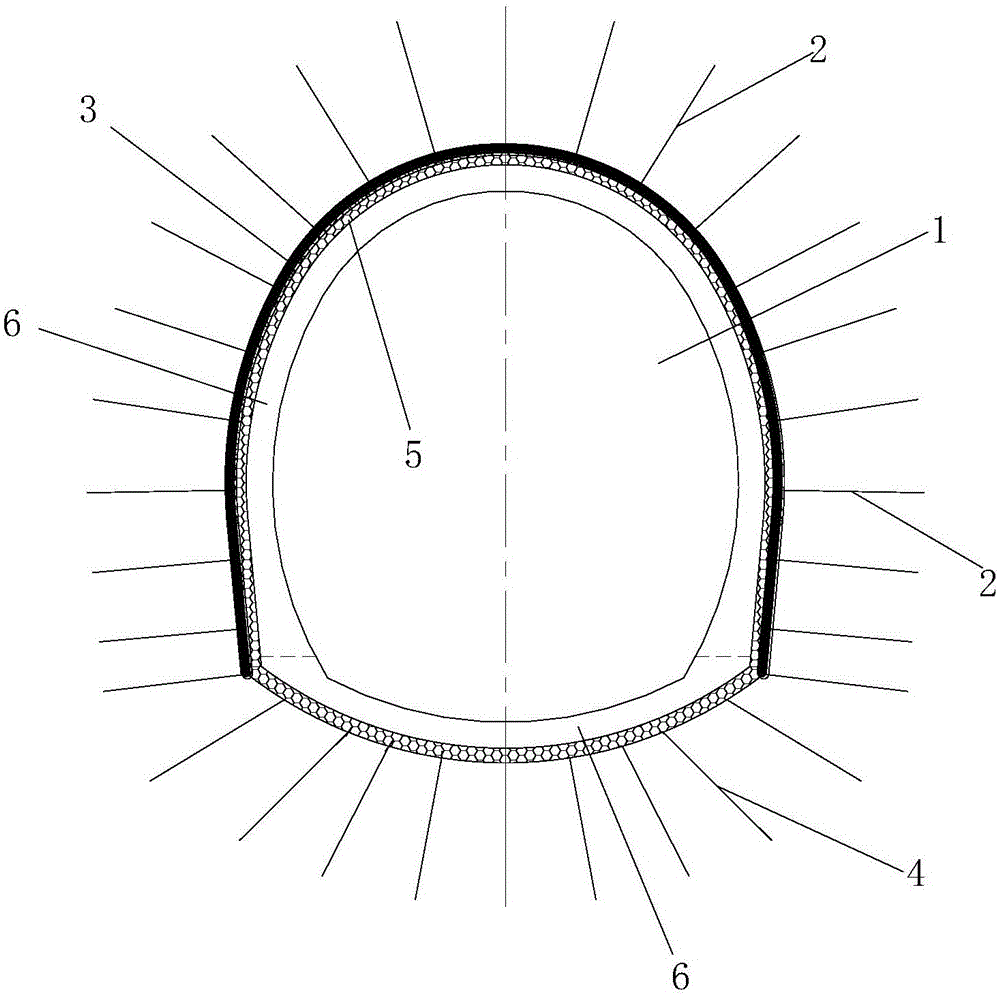

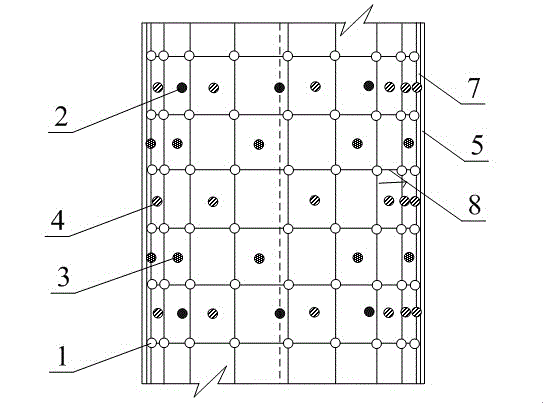

The invention discloses a soft rock tunnel deformation control method based on anchor rod force analysis. A soft rock tunnel is excavated and subjected to deformation control construction from back to front according to multiple segments, and when any segment is excavated and subjected to deformation control construction, the method includes the steps that 1, surrounding rock basic mechanical parameters are determined; 2, the tunnel reserved excavated volume is determined; 3, the tunnel is excavated; 4, a tunnel preliminary bracing structure is determined; 5, tunnel deformation control construction is carried out, wherein in the tunnel preliminary bracing construction process, a flexible mold bracing structure is constructed from back to front; 6, a next segment is excavated and subjected to deformation control construction; 7, the step 6 is repeated multiple times till the full excavation and deformation control construction process of the soft rock tunnel is completed. The soft rock tunnel deformation control method is reasonable in design, convenient to achieve and good in use effect, the reserved excavated volume is determined according to the surrounding rock deformation condition of the soft rock tunnel, the flexible mold bracing structure is adopted for carrying out full-section bracing on the tunnel, the flexible mold bracing structure and the tunnel preliminary bracing structure are in coordination deformation, and deformation of the soft rock tunnel can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

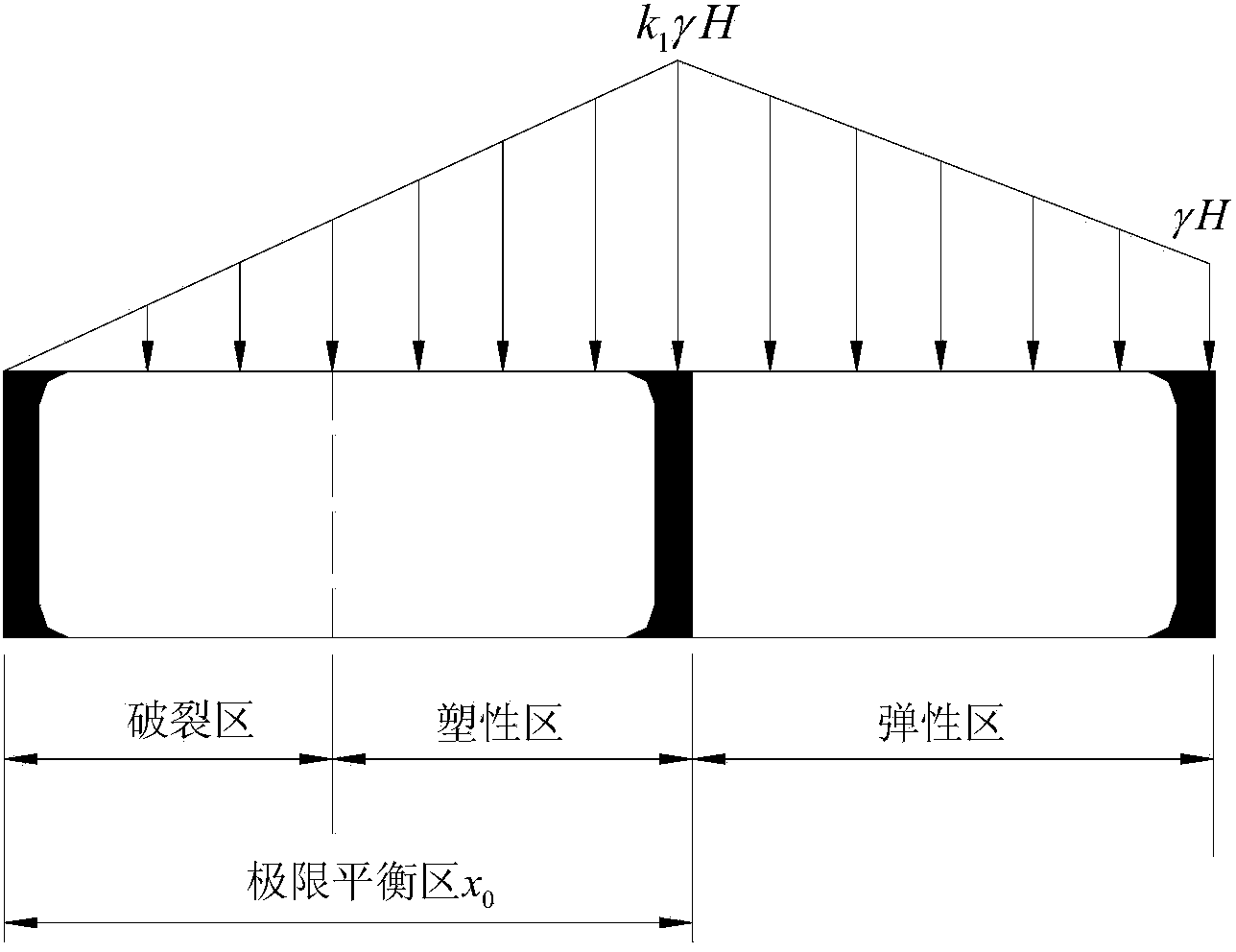

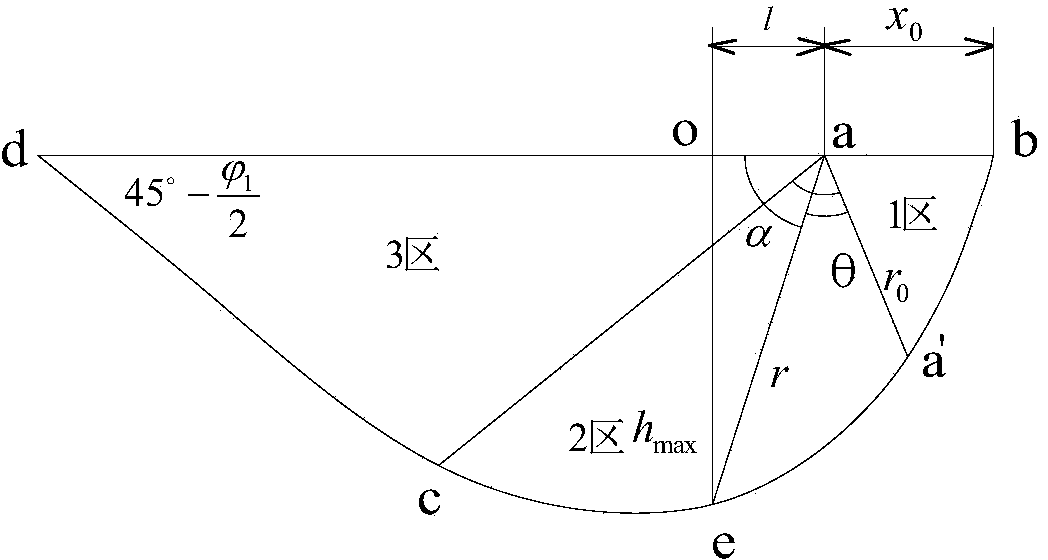

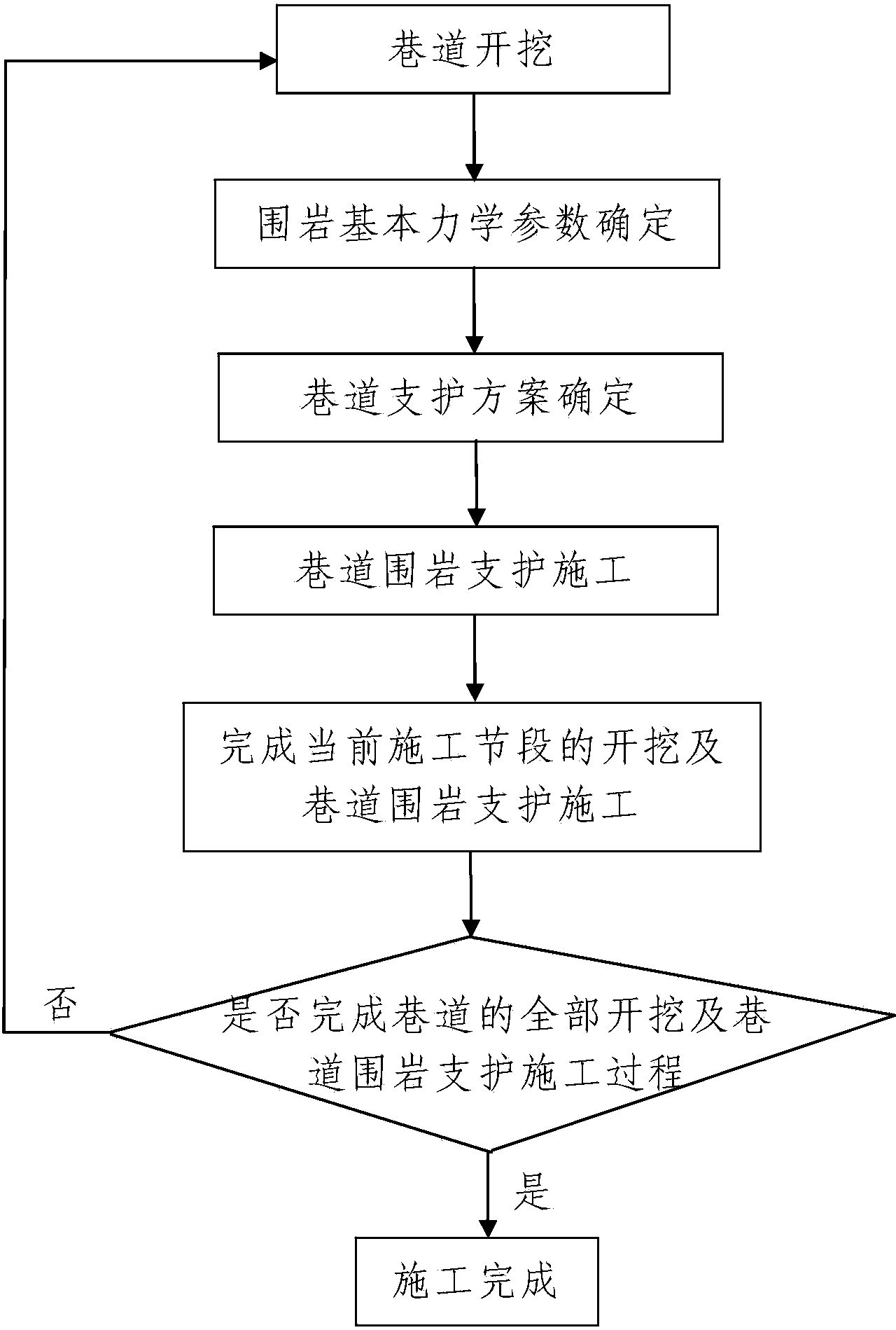

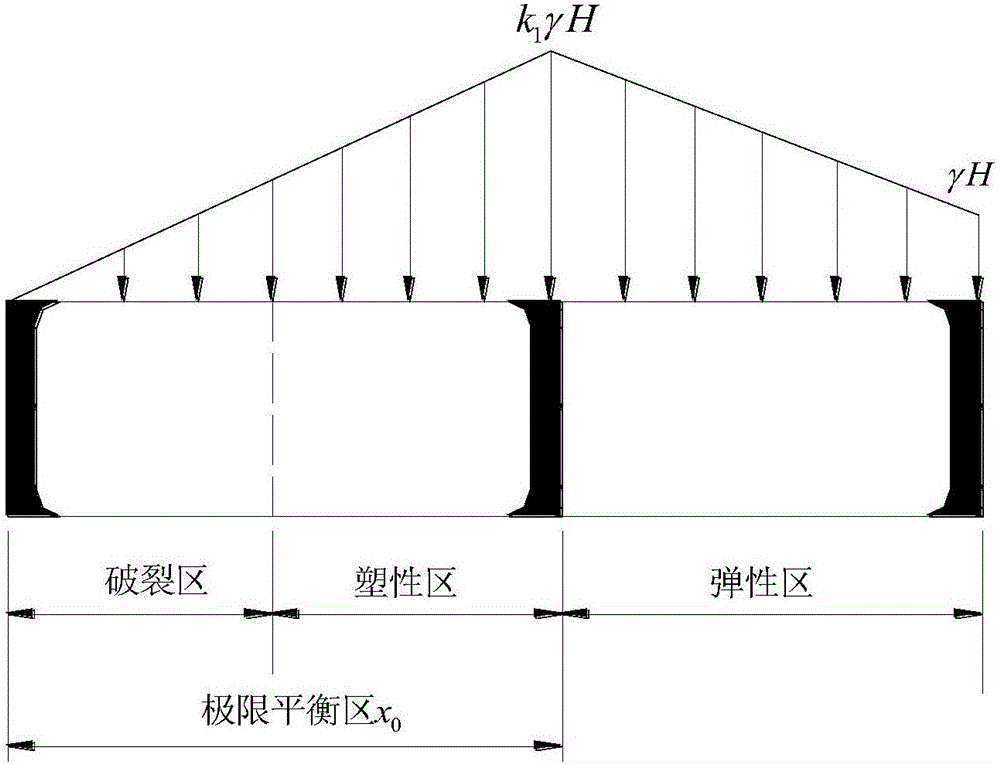

Rectangular roadway surrounding rock deformation and failure control method

The invention discloses a rectangular roadway surrounding rock deformation and failure control method which comprises steps as follows: 1), a roadway is excavated; 2), basic mechanical parameters of a surrounding rock are determined; 3), a roadway support scheme is determined as follows: roadway side unstability is judged, the caving arch rise is determined when the roadway side is in a stable state, the width of roadway side olistolith, the caving arch rise, the roadway side limit equilibrium area width, the maximum failure depth of a roadway bottom board and a horizontal distance between the maximum failure depth position and an adjacent roadway side wall are determined when the roadway side is in an unstable state, and a roadway support unit structure is determined; 4), a roadway surrounding rock support is constructed; 5), the next section is excavated, and the roadway surrounding rock support is constructed; and 6), the step 5) is repeated until all excavation and roadway surrounding rock support construction processes of the rectangular roadway are completed. The method is simple in step, convenient to implement and good in use effect, the roof caving and bottom swelling problems of the rectangular roadway can be effectively solved, and deformation and failure of the roadway surrounding rock can be effectively controlled.

Owner:XIAN UNIV OF SCI & TECH

Supporting method of permeable soft broken rock stratum roadway

InactiveCN103603675AEffective deformationEffectively closedUnderground chambersTunnel liningSteel barCement slurry

The invention relates to a supporting method of a roadway in a coal mime, particularly to a supporting method of a permeable soft broken rock stratum roadway. The supporting method aims at solving the problems that soft broken rock stratum roadways especially permeable soft broken rock stratum roadways are poor in supporting effect, high in cost and the like. The supporting method comprises the steps of first concrete spraying; combined support through high strength deformed steel bar anchor rods and diamond metal nets; anchor cable installation; secondary concrete spraying; installation of chemical pulp grouting anchor rods; installation of cement slurry grouting anchor rods.

Owner:张瀚

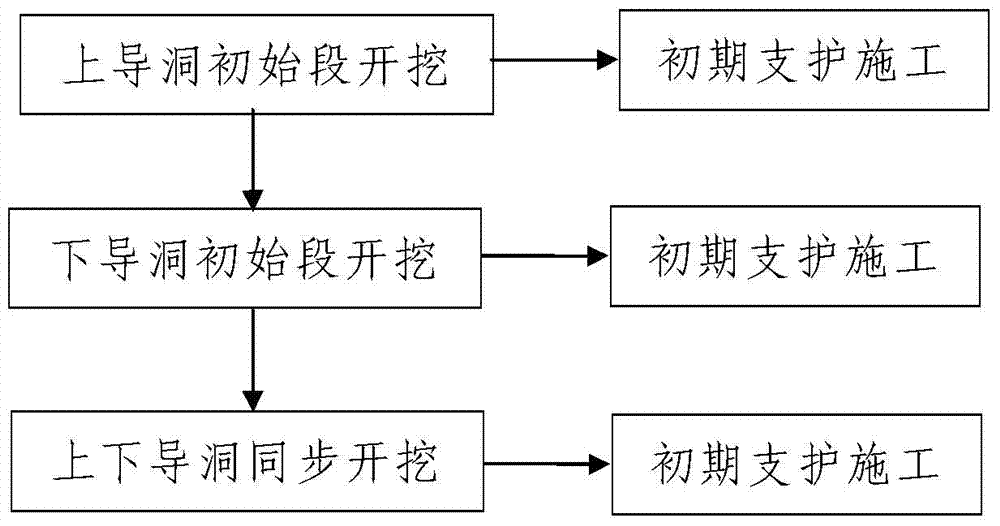

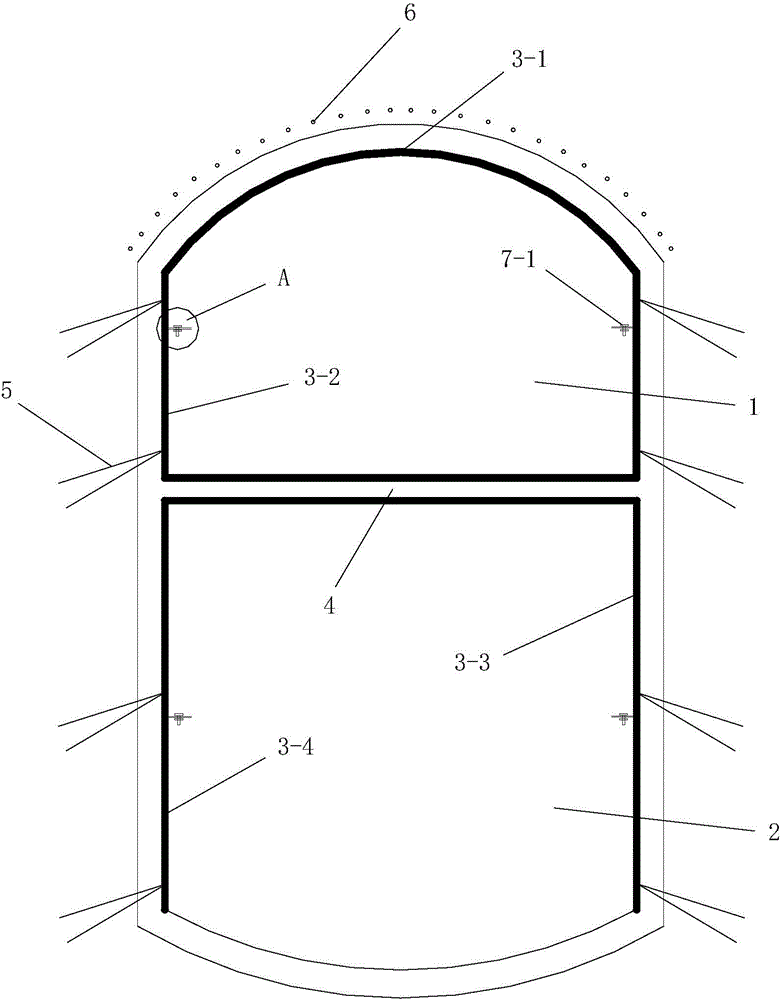

Construction method for enabling shallowly buried and darkly excavated tunnel to pass through cottage area

ActiveCN104500077AThe method steps are simpleReasonable designUnderground chambersTunnel liningRebarInitial segment

The invention discloses a construction method for enabling a shallowly buried and darkly excavated tunnel to pass through a cottage area. The construction method comprises the following steps: excavating a tunnel hole of the constructed shallowly buried and darkly excavated tunnel from back to front through a step excavation process, and performing preliminary bracing on the tunnel hole formed by excavating from back to front in an excavating process, wherein the tunnel hole consists of an upper guide hole and a lower guide hole positioned right below the upper guide hole, the rear part of the tunnel hole is connected with a vertical well, the preliminary bracing structure of the tunnel hole comprises a plurality of grating steel frameworks for supporting the tunnel hole from back to front, a layer of bar-mat reinforcement suspended on the inner wall of the tunnel hole and a concrete layer jetted on the inner wall of the tunnel hole. The process for excavating the tunnel hole of the shallowly buried and darkly excavated tunnel comprises the following steps: I, excavating the initial segment of the upper guide hole; II, excavating the initial segment of the lower guide hole; III, synchronously excavating the upper and the lower guide holes. The construction method disclosed by the invention is simple in step, reasonable in design, convenient in construction, good in construction effect, capable of simply completing the construction process of the shallowly buried and darkly excavated tunnel that passes through the cottage area, and safe and reliable in a construction process.

Owner:CHINA RAILWAY 20 BUREAU GRP

SiC whisker reinforced SiC ceramic matrix composite and preparation method thereof

The invention belongs to the field of the preparation of ceramic matrix composites, and particularly relates to a SiC whisker reinforced SiC ceramic matrix composite and a preparation method thereof. The SiC whisker reinforced SiC ceramic matrix composite is prepared from a preform through a Si or Si alloy infiltration reaction, and the preform is prepared by compressing and molding a raw material comprising a rice hull SiC whiskerized product. By the method, the preparation process is simple, the temperature of the infiltration reaction is low, external pressure is not required, and the preform can be prepared into complicate shapes and can be used for preparing members with complicated shapes. A main composition phase SiC of the composite comes from rice hull, the raw material is rich, the cost is low, the manufacturing cost of the ceramic matrix composite can be remarkably reduced, the resource is saved and the environment is protected. The SiC ceramic matrix composite has good performance, SiC whiskers have the effect of strengthening materials, and the SiC whisker reinforced SiC ceramic matrix composite can be used for applicable occasions of SiC reaction sintering ceramic material products such as sliding bearings, corrosion-resistant and wear-resistant pipelines, valves and fan blades, military and civil body armors and the like.

Owner:ZHEJIANG UNIV

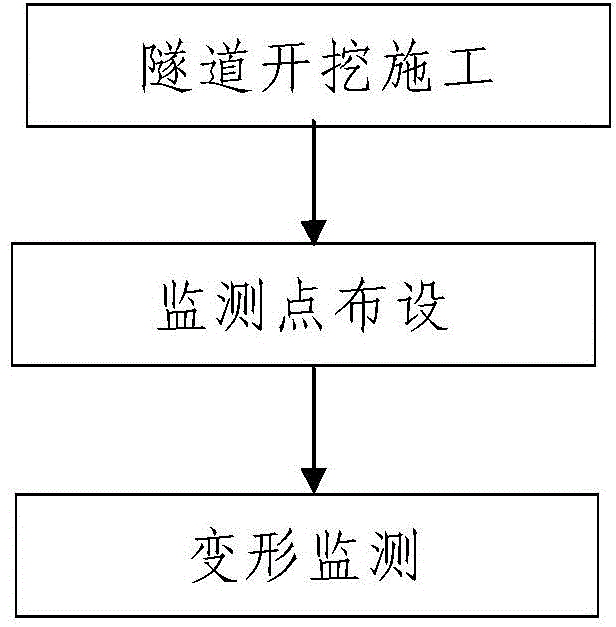

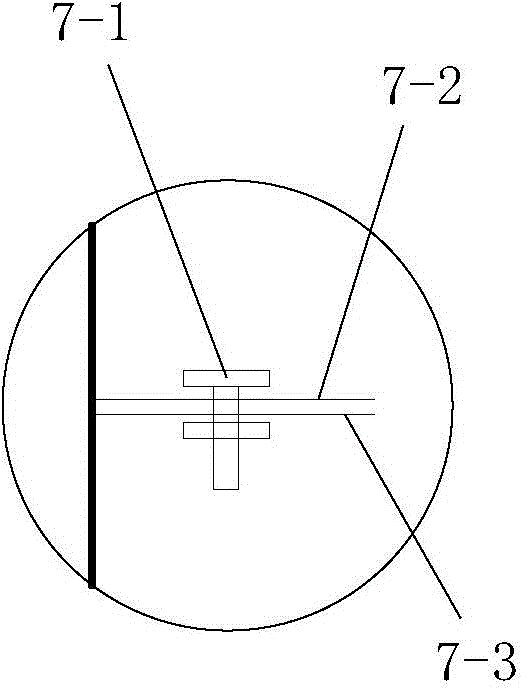

Deformation monitoring method for shallow-buried excavation tunnel construction

ActiveCN104564128AThe method steps are simpleReasonable designMining devicesUnderground chambersTunnel constructionCondition monitoring

The invention discloses a deformation monitoring method for shallow-buried excavation tunnel construction. The deformation monitoring method comprises the following steps: 1) digging a tunnel: digging a tunnel cavity for a constructed shallow-buried excavation tunnel from back to front, primarily supporting the dug tunnel cavity from back to front during the digging process, and forming a primary supporting structure, wherein the primary supporting structure comprises a plurality of grating steel frames for supporting the tunnel cavity from back to front, and each grating steel frame is composed of an arch supporting steel frame and left and right vertical supporting steel frames; 2) arranging monitoring points: arranging multiple sets of supporting state monitoring points on the primary supporting structure of the constructed tunnel cavity from back to front during the digging process, and meanwhile, arranging a plurality of ground surface settlement monitoring points in a construction area of the constructed shallow-buried excavation tunnel from back to front; 3) monitoring the deformation. The method provided by the invention has the advantages of simple steps, reasonable design, convenience in construction, good use effect and capability of effectively monitoring the stability of the constructed shallow-buried excavation tunnel and the ground surface settlement.

Owner:CHINA RAILWAY 20 BUREAU GRP

Excavation and preliminary bracing method for soft rock tunnel

InactiveCN106481343AThe method steps are simpleEasy to implementUnderground chambersTunnel liningRock tunnelWall rock

The invention discloses an excavation and preliminary bracing method for a soft rock tunnel. The excavation and preliminary bracing construction for the soft rock tunnel are performed in sections from back to front. When any section is subjected to excavation and preliminary bracing construction, the method comprises the following steps: 1) confirming basic mechanical parameters of the surrounding rock; 2) confirming the reserved excavated volume of the tunnel: confirming the reserved excavated volume of the currently constructed section according to a theoretical value of inward displacement of the surrounding rock of the soft rock tunnel after being braced; 3) excavating the tunnel; 4) confirming a preliminary bracing structure of the tunnel; 5) constructing the preliminary bracing of the tunnel; 6) performing the excavation and preliminary bracing construction of the next section; and 7) repeating the step 6) till all the processes of the excavation and preliminary bracing construction of the soft rock tunnel are completed. The method disclosed by the invention has the advantages of simple steps, reasonable design, convenience in realization and good use effect; the reserved excavated volume is confirmed according to the surrounding rock deformation condition of the soft rock tunnel; and the steel bracket and the anchoring net sprayed preliminary bracing structure are coordinated for performing all-section preliminary bracing on the tunnel.

Owner:XIAN UNIV OF SCI & TECH

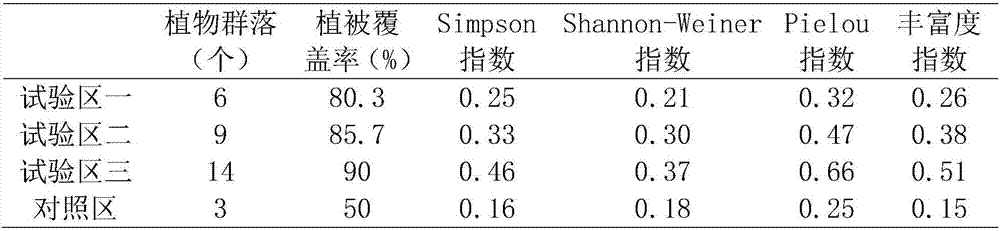

Ecological restoration method for damaged seacoast wetland

ActiveCN107459138AImprove the quality of the ecological environmentGuarantee healthy developmentSeawater treatmentSustainable biological treatmentSalt marsh cordgrassTrophosome

The invention relates to an ecological restoration method for a damaged seacoast wetland, and belongs to the field of wetland vegetation recovery. The ecological restoration method comprises the following steps: (1) selecting a restoration area to carry out living condition research; (2) restoration of a sinking type erosive seacoast wetland: establishing a flood bank and a broken water peninsula, carrying out dredging mud covering, and establishing a tidal channel and a gentle slope; (3) building a wetland plant community, wherein wet plants comprise aquatic plant and halophilous plant, and sowing and trophosome transplanting combined planting; (4) establishing an ecological isolation belt: planting trees and shrubs and emergent aquatic plant in the peripheral range of 2 to 4 m in the wetland as the ecological isolation belt; (5) scientifically controlling the growth of Spartina alterniflora Loisel: controlling the growth of Spartina alterniflora Loisel via water quantity control, and manpower and machine harvesting and burying. Dredging mud is used for ecological restoration of the damaged seacoast wetland, the erosive seacoast wetland can be reinforced, the sediment is effectively stabilized via the construction of the wetland plant community, a diversified environment is created, and the ecological environment quality of the seacoast wetland is improved.

Owner:广东筑奥生态环境股份有限公司

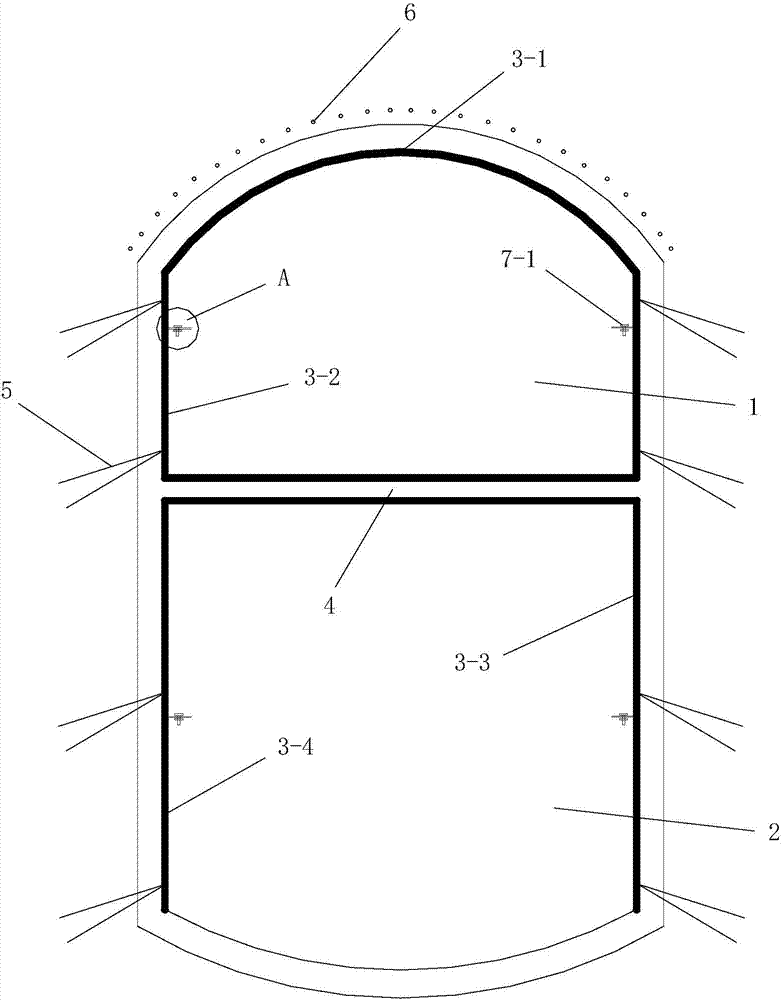

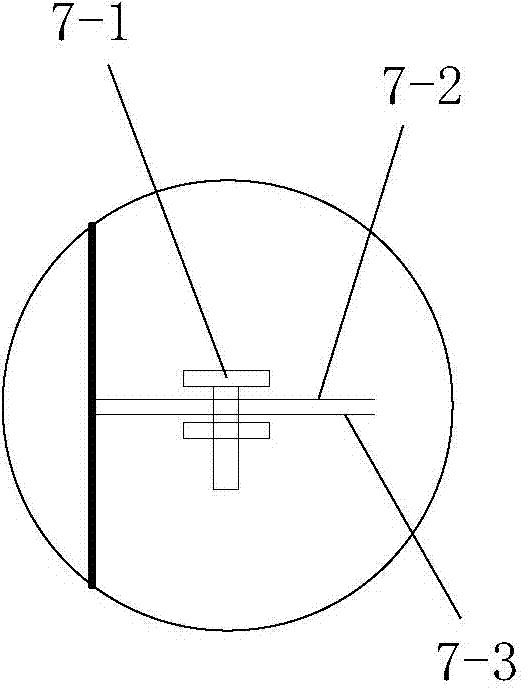

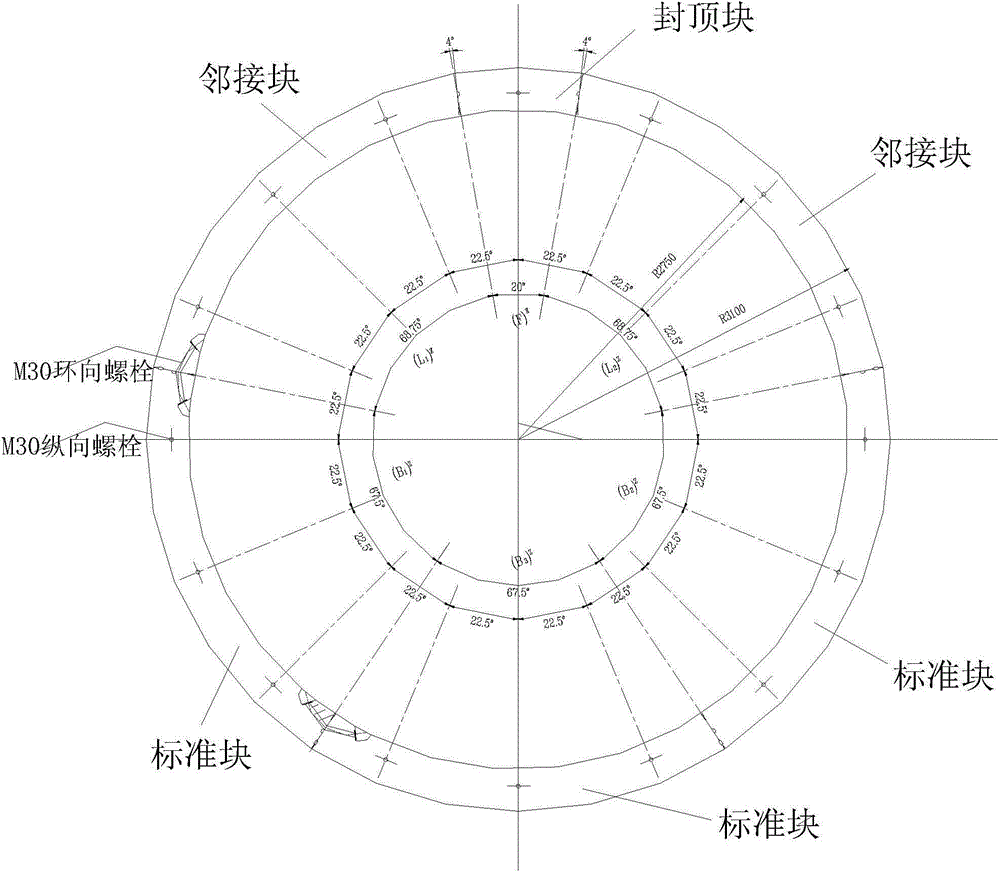

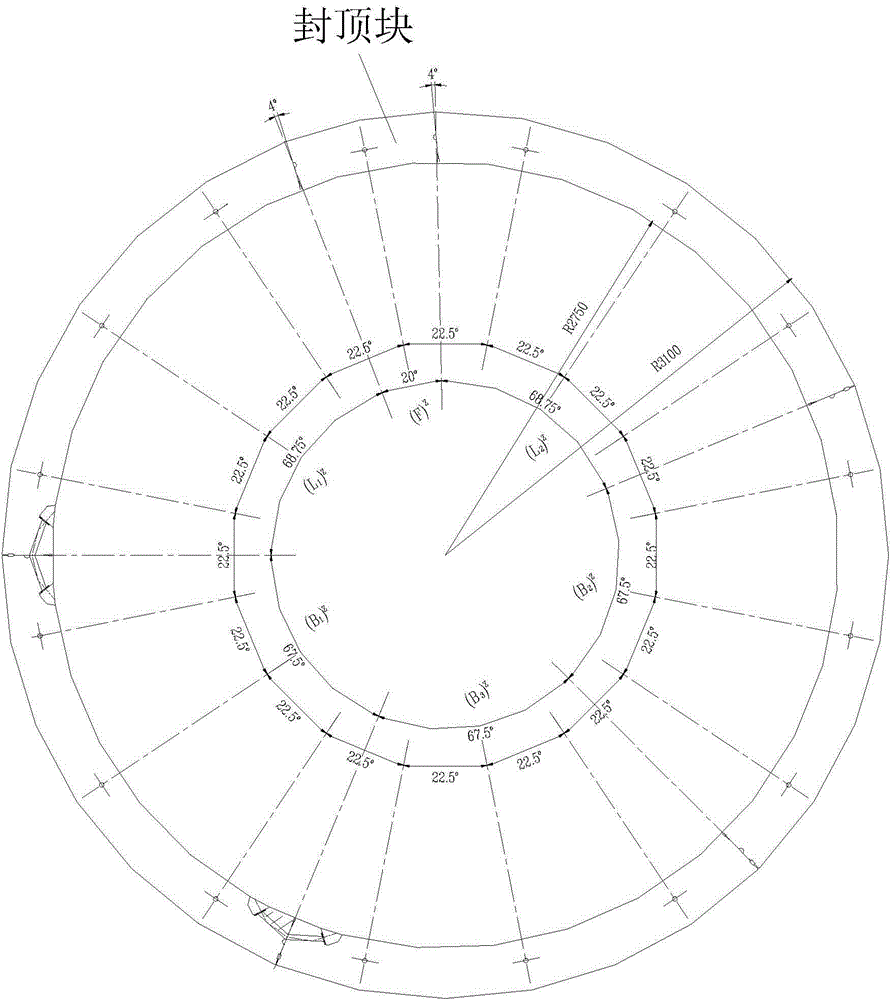

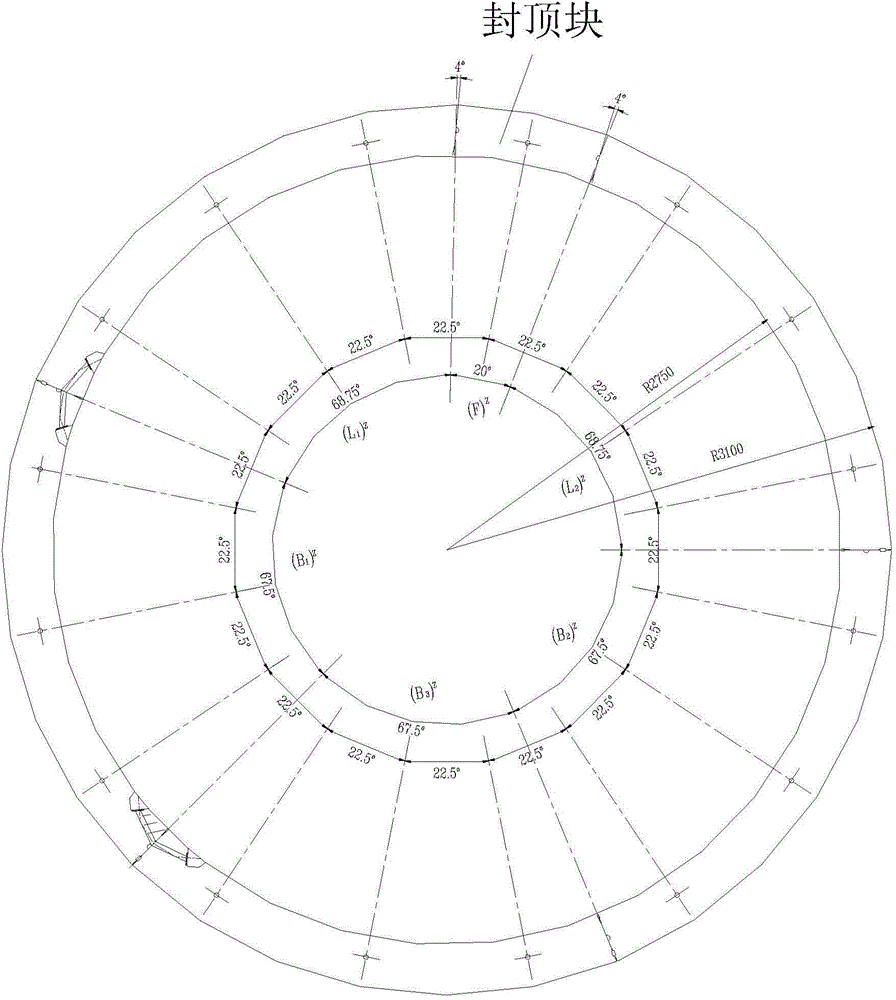

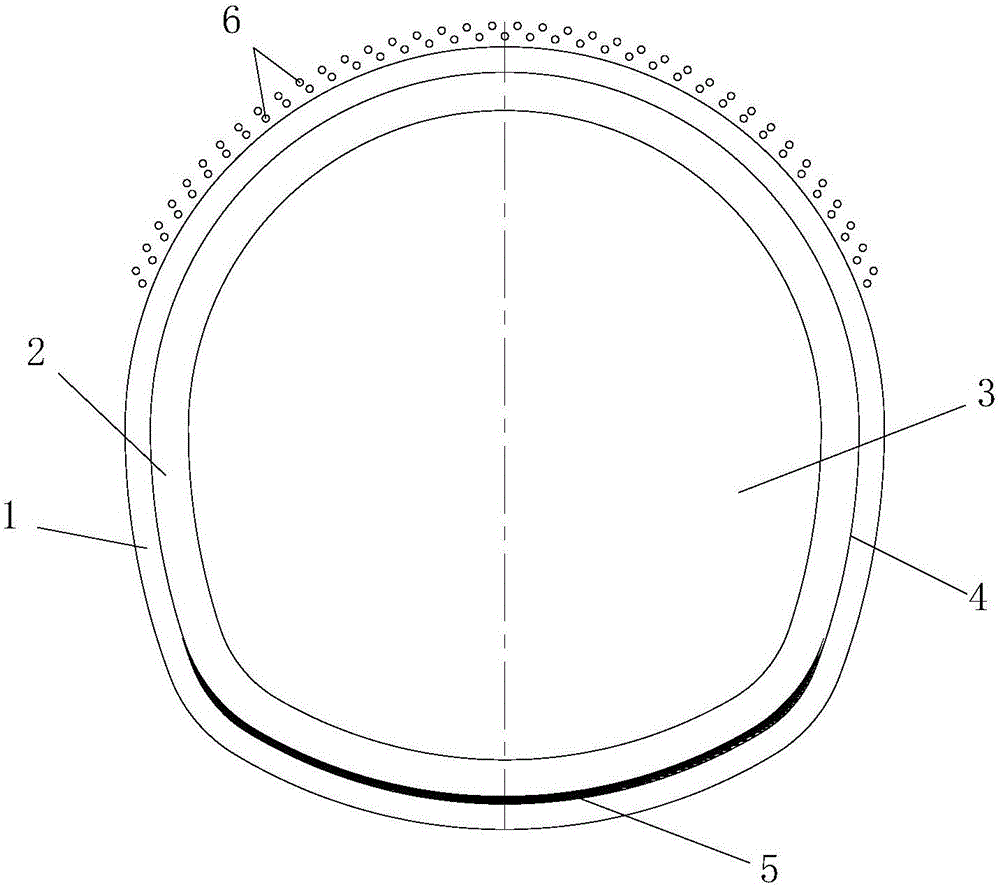

Lining segment structure of city subway up-down section overlapping shield tunnels

ActiveCN104612711AEffective reinforcementMeet the performance of grouting constructionUnderground chambersTunnel liningStress reliefShield tunneling

The invention discloses a lining segment structure of city subway up-down section overlapping shield tunnels. The structure can satisfy construction loads such as the weight of a shield tunneling machine, the pressure supplied by the shield tunneling machine and stratum excavation stress relief under construction and structure safety and deformation under the effect of water and soil pressure and subway train loads during operation, satisfy construction performance of secondary slip casting on the back of a lining segment structure wall and synchronous and uniform slip casting of interlayers between the up-down overlapping tunnels, and at last satisfy the waterproofness and durability of tunnel use. The lining segment structure can be applied to V-level and VI-level strata in a city subway, the separation distance of the up-down overlapping section tunnels is 2 m-3 m, the shield excavation order of down first and then up is used for supplying technical assurance to the segment structure of the city subway up-down section overlapping shield tunnels under the conditions of up-down overlapping complex lines, and the section overlapping tunnels can better solve the problems of limit of surrounding environment, narrow boundary lines of roads and requirements for a net operation transfer function and is applied widely.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD +1

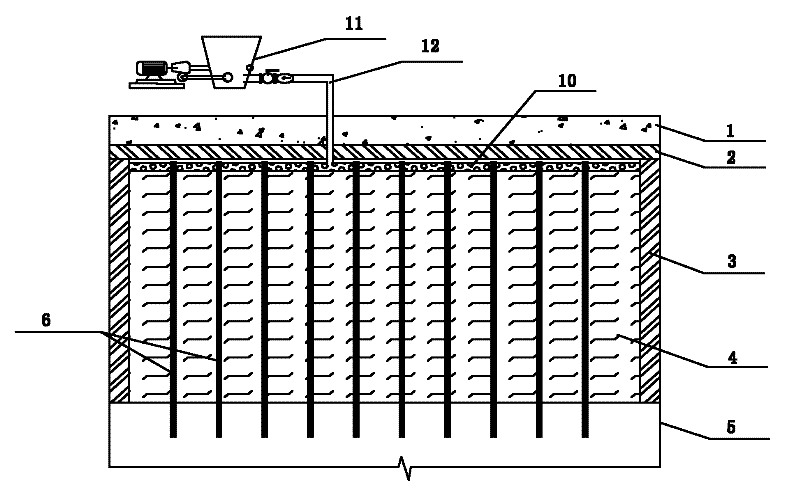

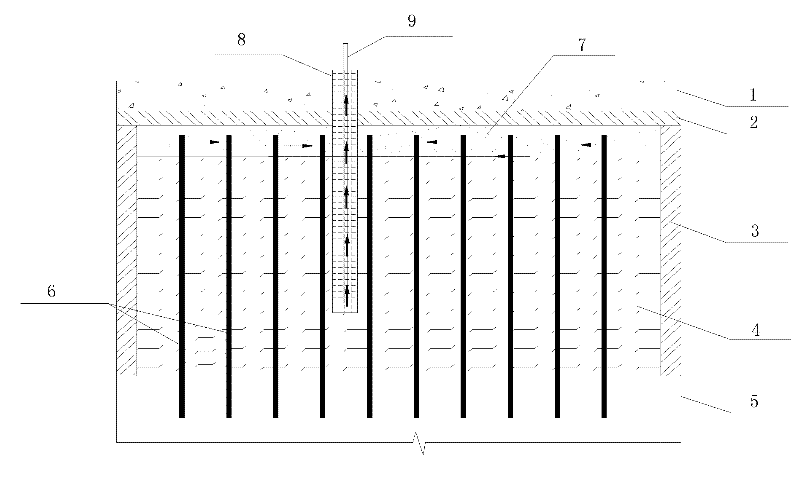

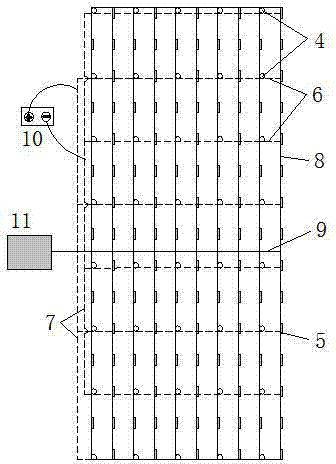

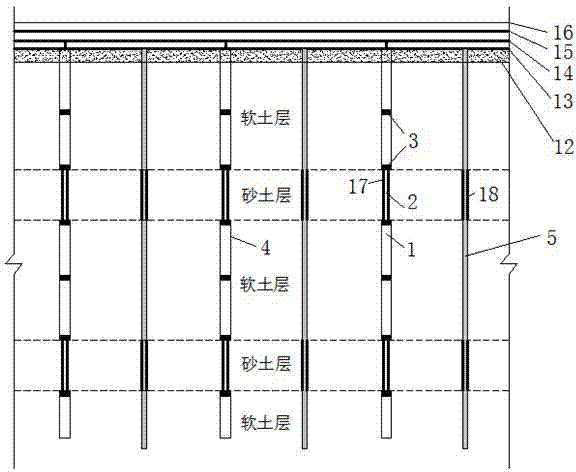

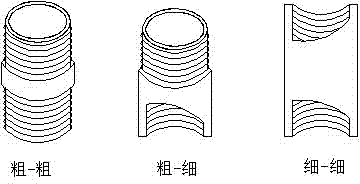

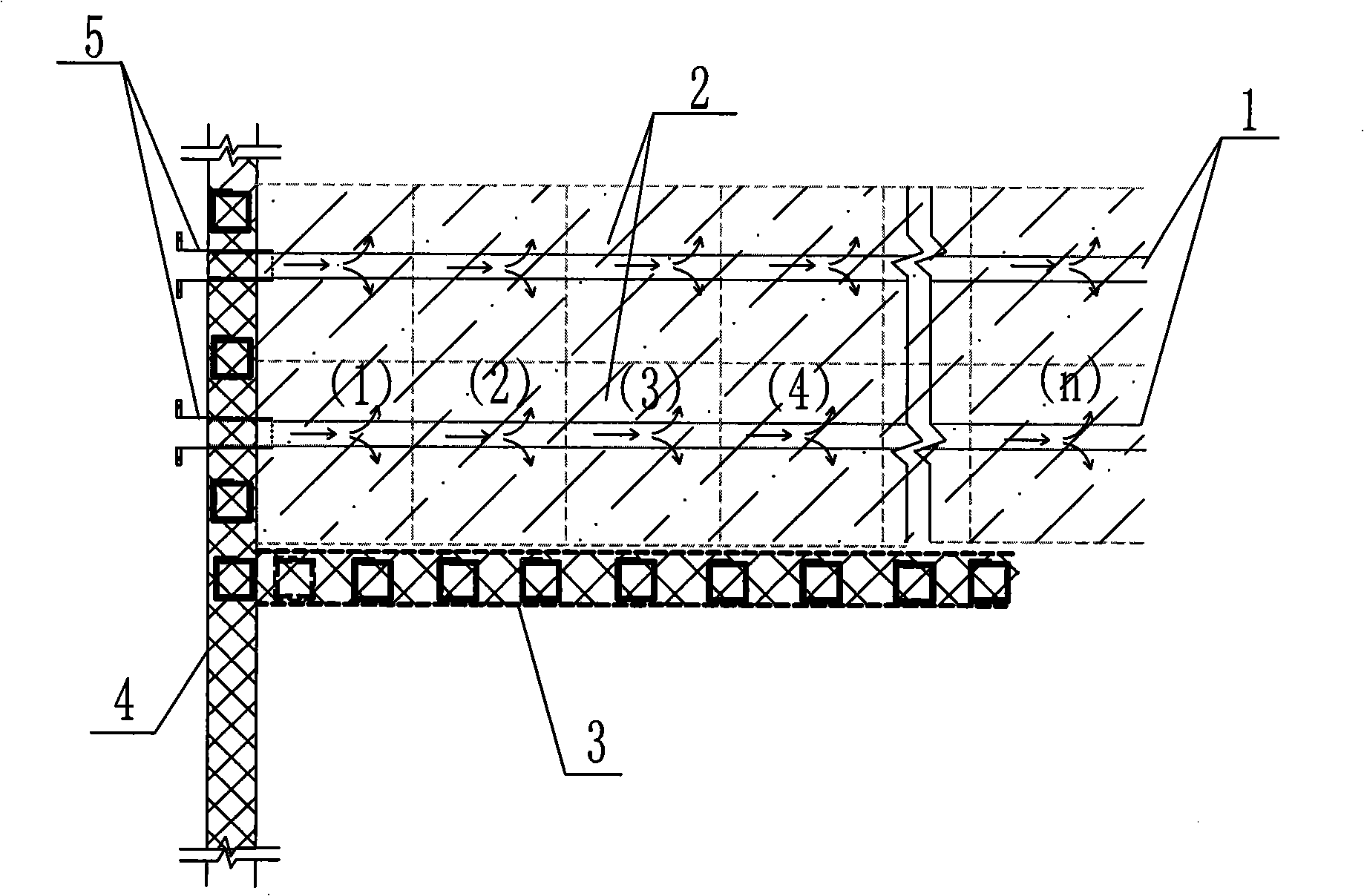

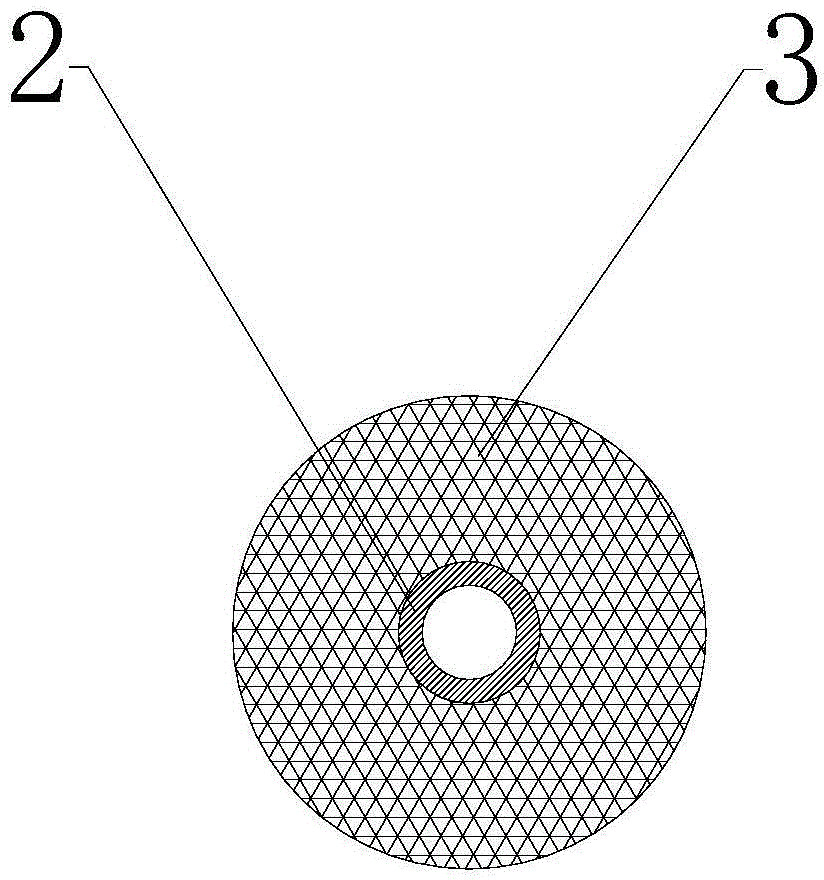

System and method for reinforcing sand-contained soil interlayer soft foundation in vacuum-electro-osmosis combination mode

The invention discloses a system for reinforcing a sand-contained soil interlayer soft foundation in a vacuum-electro-osmosis combination mode. The system is composed of subsection EKG drainage electrodes, flexible conductive joints, conductive circuits, a direct-current power supply, a power supply control system, plastic drainage boards, horizontal drainage pipelines, a vacuum pump and the like. The subsection EKG drainage electrodes are connected with one another through the flexible conductive joints, the rough drainage electrodes are used in a soft soil layer, the fine drainage electrodes are used in a sand soil layer, each fine drainage electrode is sleeved with a corrosion-resistant insulating rubber tube, and part, located on a sand soil interlayer, of the drainage boards are wound with a ring of water-proof material through strong water-proof adhesives. The invention further discloses a use method of the system, static sounding is conducted on the positions of the drainage electrodes and the positions of the drainage boards, processing and assembling are conducted on the drainage boards and the drainage electrodes according to results, and finally the soft foundation is reinforced in the vacuum pre-compaction and electro-osmosis drainage combination mode. The system can reinforce the sand-contained soil interlayer soft foundation by combining a vacuum pre-compaction ground treatment method and an electro-osmosis drainage ground treatment method.

Owner:HOHAI UNIV

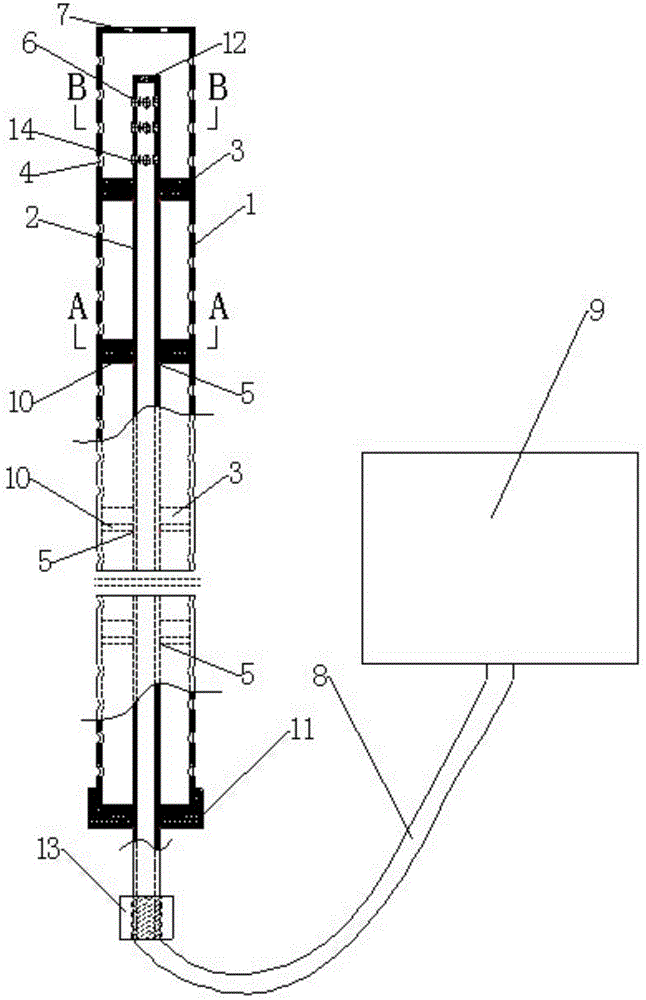

TGRM subsection moving-on type advanced deep hole grouting construction process

The invention relates to a TGRM segmental advancing-type leading deep-hole grouting construction process. The construction process comprises the following steps that: a slurry stop wall is made first; a hole is drilled on the set hole position; an orifice pipe is arranged in the drilled hole; a drill bit is replaced; first-segment drilling is carried out through the orifice pipe; after a depth is reached, the drilling is stopped and a drilling tool is withdrawn; grouting corollary equipment is arranged on the orifice pipe, so as to inject TGRM cement-based special grouting material into stratum; after a grout soil body reaches certain strength, the grouting equipment is removed, and second-segment drilling is carried out through the orifice pipe; the two segments of drilling are repeated till the set hole depth is reached; and then the steps are carried out to another hole position till all grouting holes are completed. The construction process has the advantages that: aiming at subsurface tunnels, in particular to tunnels of which an arch part is positioned in an unbonded and in low self-stability sand layer and other stratum and passes through the bottom of a building, segmental advancing-type leading deep-hole grouting is carried out to the stratum, which can comprehensively reinforce the stratum, so as to further slow down or avoid the settlement after the stratum is destroyed and the damage to buildings (constructed objects).

Owner:BEIJING MUNICIPAL CONSTR +1

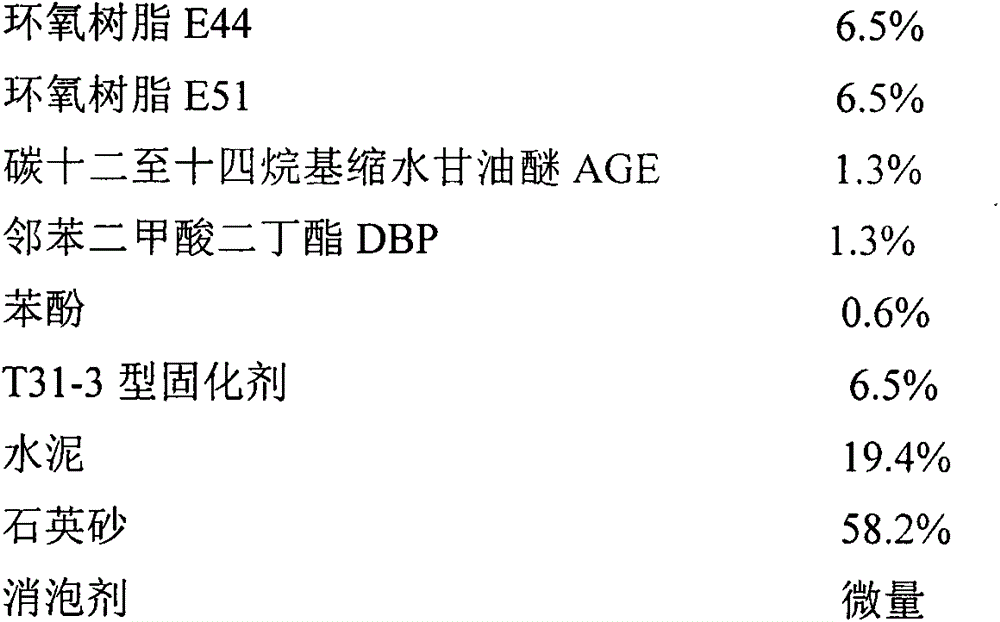

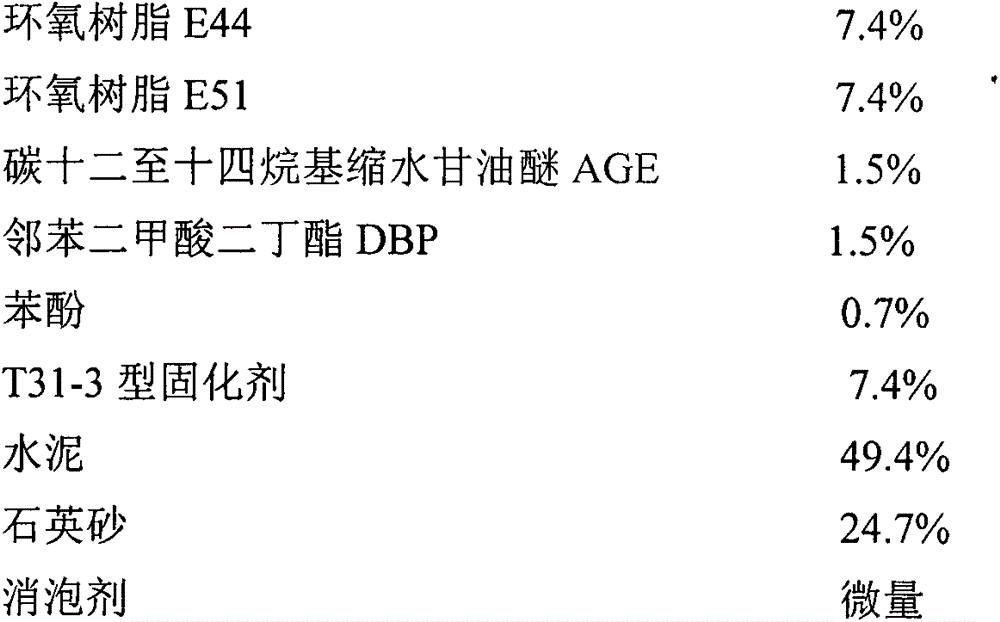

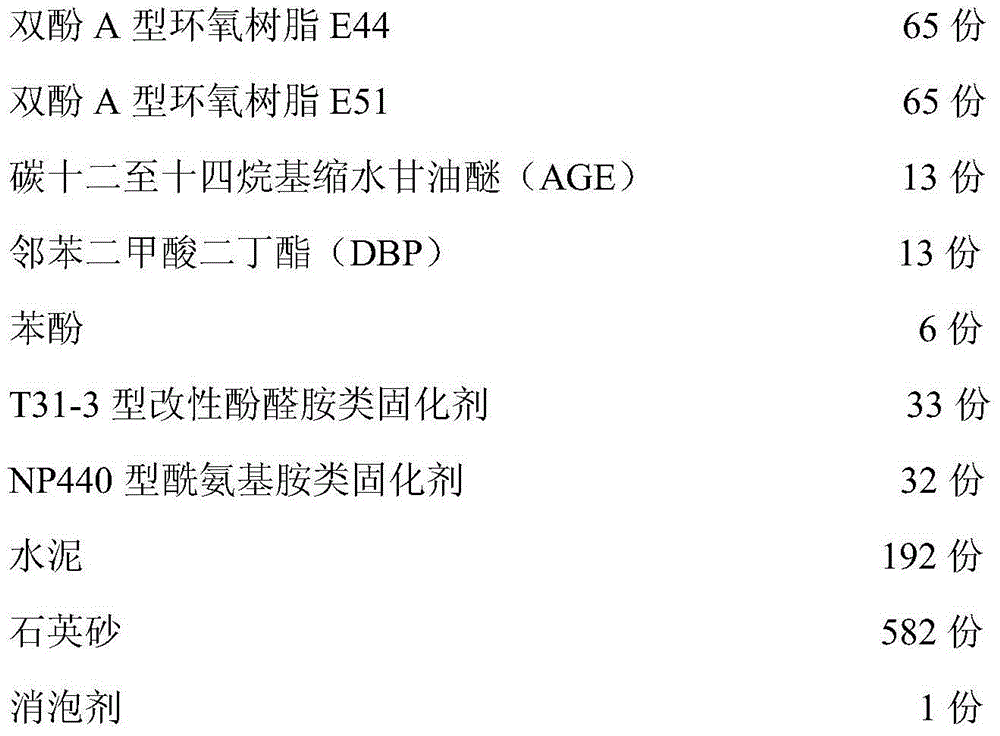

Preparation method of epoxy mortar for filling ocean oil and gas pipeline

InactiveCN103819144ASimple preparation processMeet the replacement requirementsShock resistanceSeawater

The invention belongs to the technical field of application of polymer mortar and particularly relates to a preparation method of epoxy mortar for filling an ocean oil and gas pipeline. The epoxymortar consists of a component A, a component B and a component C, wherein the component A is prepared by defoaming after blending epoxy resin, a reactive diluent, a plasticizer, an accelerator and pigments according to the proper proportion and; the component B is a special underwater T31-3 type curing agent; the component C is aggregate formed by mixing cement with quartz sand according to a certain proportion. When the epoxymortar is used for construction, the component A is heated to 30-50DEG C and stirred to homogeneousphase, and then the component A and the component B are mixed according to certain proportion and uniformly stirred; the component C is subsequently added into the mixture for uniformly blending to obtain an epoxymortar mixture for filling the ocean oil and gas pipeline. The mortar mixture is simple in preparation process; the prepared mixture has the advantages of high curing speed and strong cohesiveness as well as excellent compress and shock resistance and seawater corrosion resistance. The mortar mixture can be used for filling and strengthening an anode protection anticorrosive structure of the ocean oil and gas pipelines.

Owner:TIANJIN UNIV OF SCI & TECH +1

Method for rapid treatment of damage of cavity beneath cement concrete pavement slab

InactiveCN102900016AEfficient fillingImprove waterproof performanceRoads maintainenceRoad surfaceSlurry

The invention provides a method for rapid treatment of damage of a cavity beneath a cement concrete pavement slab and has the advantages of low cost, a fast repairing speed and a good effect. According to the invention, a falling weight deflectometer and a ground penetrating radar are used for determination of a cavity position at corners and a center position of a cement concrete pavement slab; then grouting holes are arranged in the cement concrete pavement slab, wherein an emulsified asphalt cement-based composite material is used as a grouting slurry; a grouting pump is employed to pump the grouting slurry from a mixer, and the grouting slurry is injected into the cavity position of the cement concrete pavement after pumping pressing by a high-pressure rubber hose; after grouting is finished, the cement concrete pavement is maintained for 4 to 6 h; and mortar is used to plug the grouting holes, after the grouting holes are stood for 8 to 12 h, and then parts of the pavement higher than the pavement is polished until the parts of the pavement are as high as the original pavement.

Owner:SHANXI LUZHONG ROAD & BRIDGE CO LTD

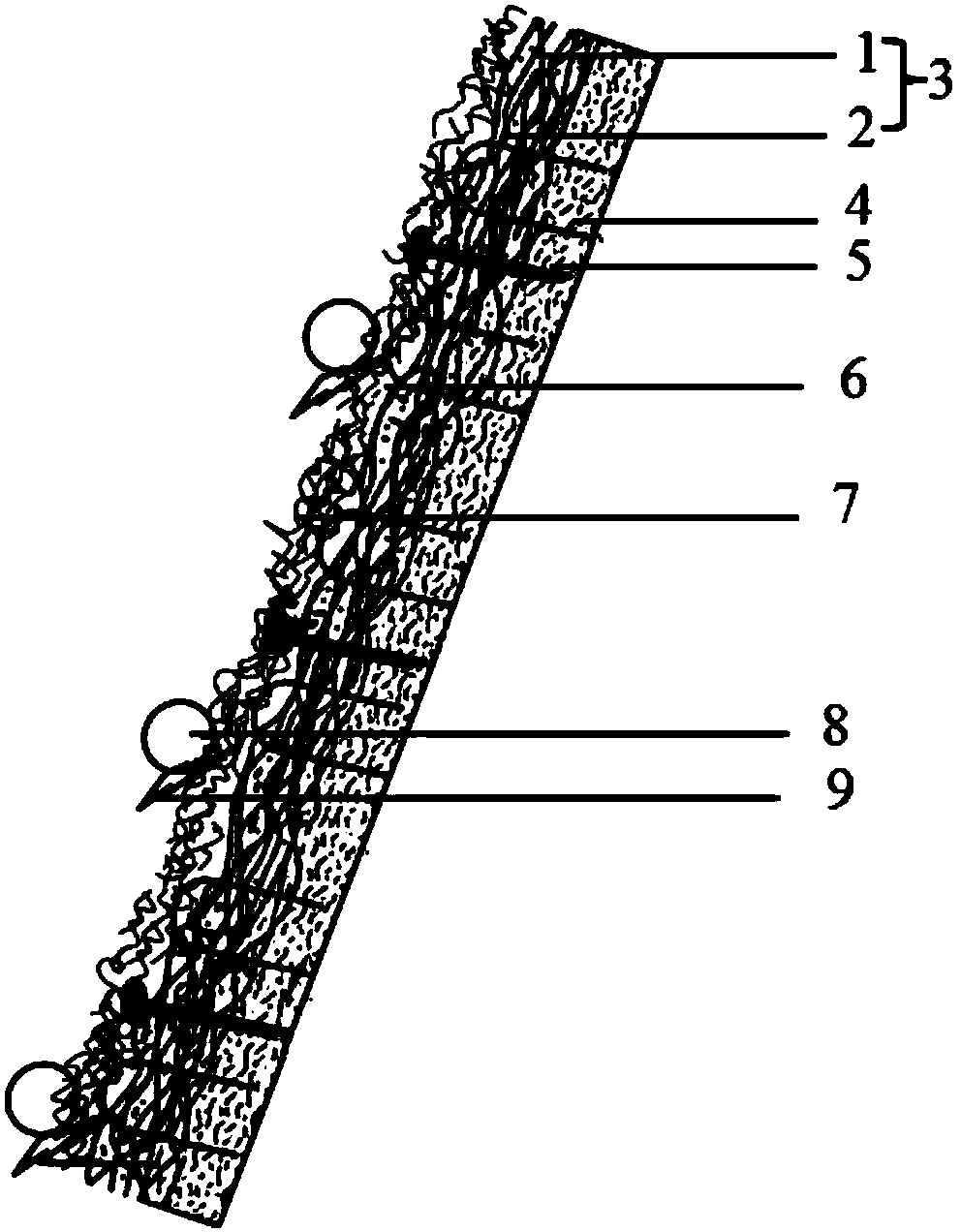

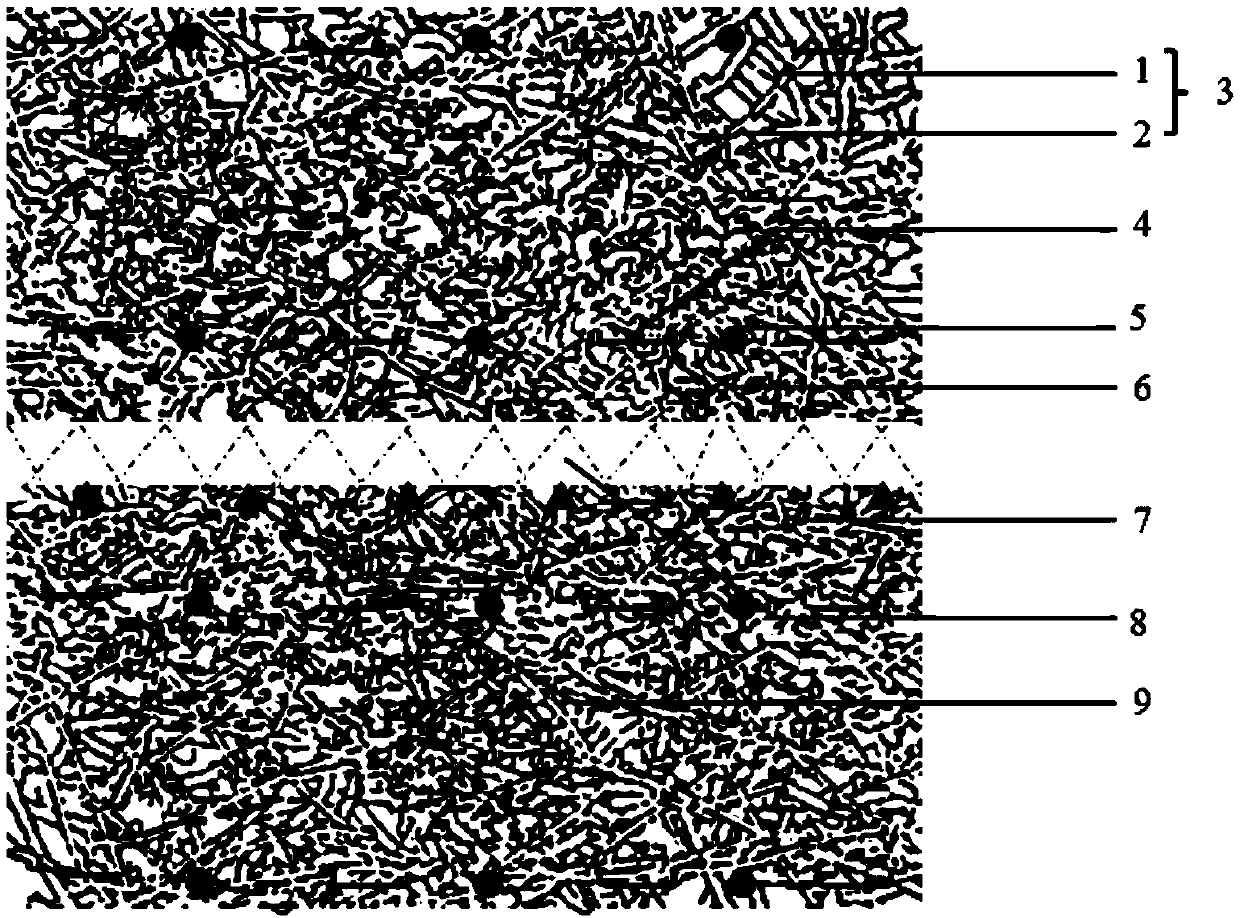

High and steep slope reinforcing and greening device and method

ActiveCN107711170AImprove water retentionWith filter functionFlowers cultivationHops/wine cultivationFiberLandslide

The invention relates to the field of environment protection, and discloses a high and steep slope reinforcing and greening device and method. The high and steep slope reinforcing and greening devicecomprises reinforced three-dimensional polypropylene gauze pads, U-shaped nails, anchor rods, vegetation seeds, soil improvement fiber mixtures, erosion-resistant fiber mixtures, fiber filtering tubesand wedges. The high and steep slope reinforcing and greening device is simple in construction process and convenient to operate; after the reinforced three-dimensional polypropylene gauze pads are fixedly arranged on a slope surface of a high and steep slope by the anchor rods and the U-shaped nails, the fiber filter tubes are laid, and then a mixture of the vegetation seed and the soil improvedfiber mixture and a mixture of the vegetation seeds and the erosion-resistant fiber mixture are successively sprayed and sowed. A soil living condition for growth of plants can be improved effectively, nutrient elements required for growth and metabolism are provided for the plants, and the technical problems that by an existing high and steep slope reinforcing method, the slope is easily washedby rainstorm, secondary landslide is caused, the collapse water-retaining property is poor, and meanwhile, secondary pollution to the environment will be caused are solved.

Owner:JOFO GREEN CO LTD

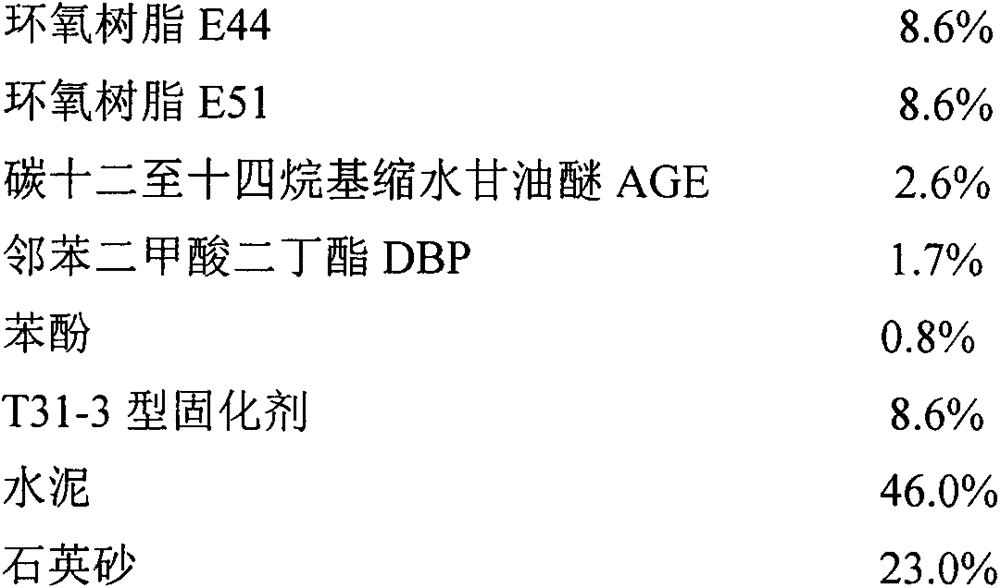

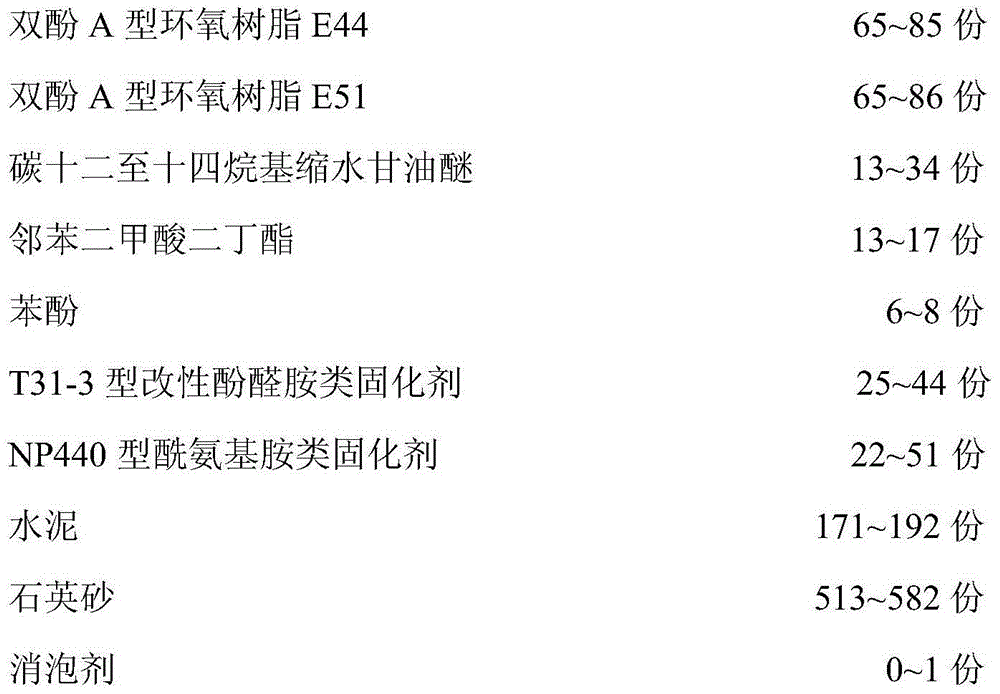

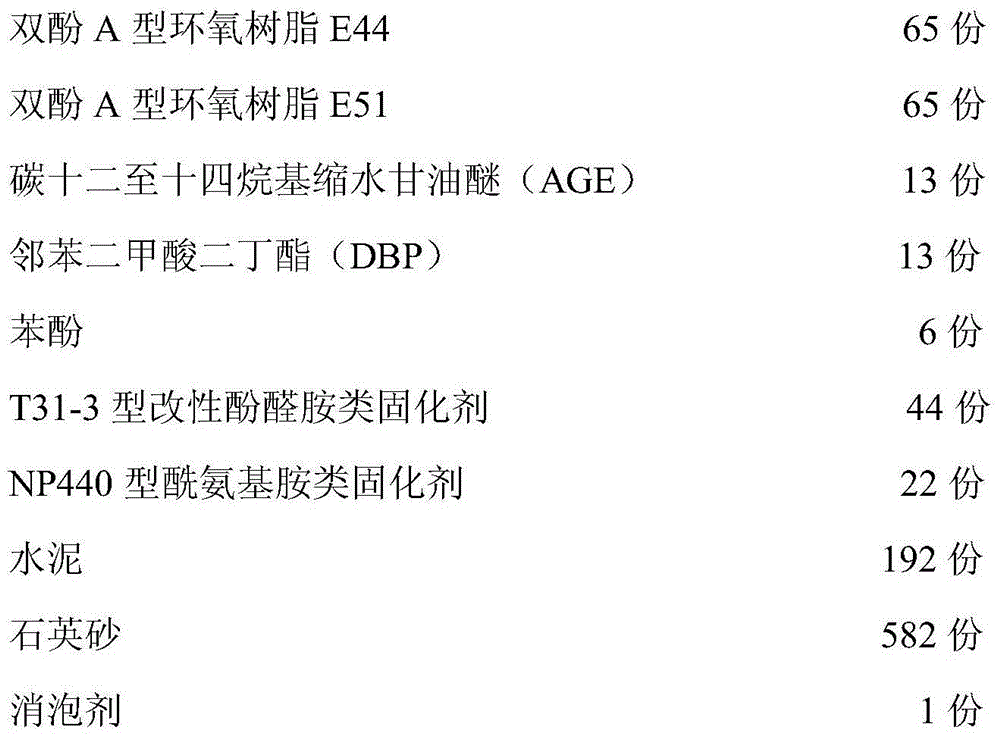

Epoxy mortar used for repairing sea oil gas pipeline and preparation method thereof

The invention discloses an epoxy mortar used for repairing sea oil gas pipeline and a preparation method thereof, which belongs to the technical field of polymer mortar application. The epoxy mortar is composed of a component A, a component B and a component C, the component A is prepared by bisphenol A epoxy resin E44, E51 and a certain amount of auxiliary agent, the component B is prepared by mixing a T31-3 type modified phenolic amine curing agent and a NP440 amidoamines curing agent according to a certain proportion, and the component C is an aggregate by mixing cement and quartz sand according to a certain proportion. The preparation method comprises the following steps: heating the component A to the temperature of 30-50 DEG C, stirring to homogeneous phase, then mixing the component A and the component B according to a certain proportion, uniformly mixing, adding the component C according to a certain proportion, and uniformly blending to obtain the epoxy mortar. The preparation method has simple technology, the epoxy mortar has strong cohesiveness, the epoxy mortar through solidification has excellent anti-compression, anti-punching and anti-seawater corrosion performances, and the epoxy mortar can be used for repairing and reinforcing a concrete coating on the sea oil gas pipeline and a thin layer of an underwater concrete structure.

Owner:TIANJIN UNIV OF SCI & TECH +1

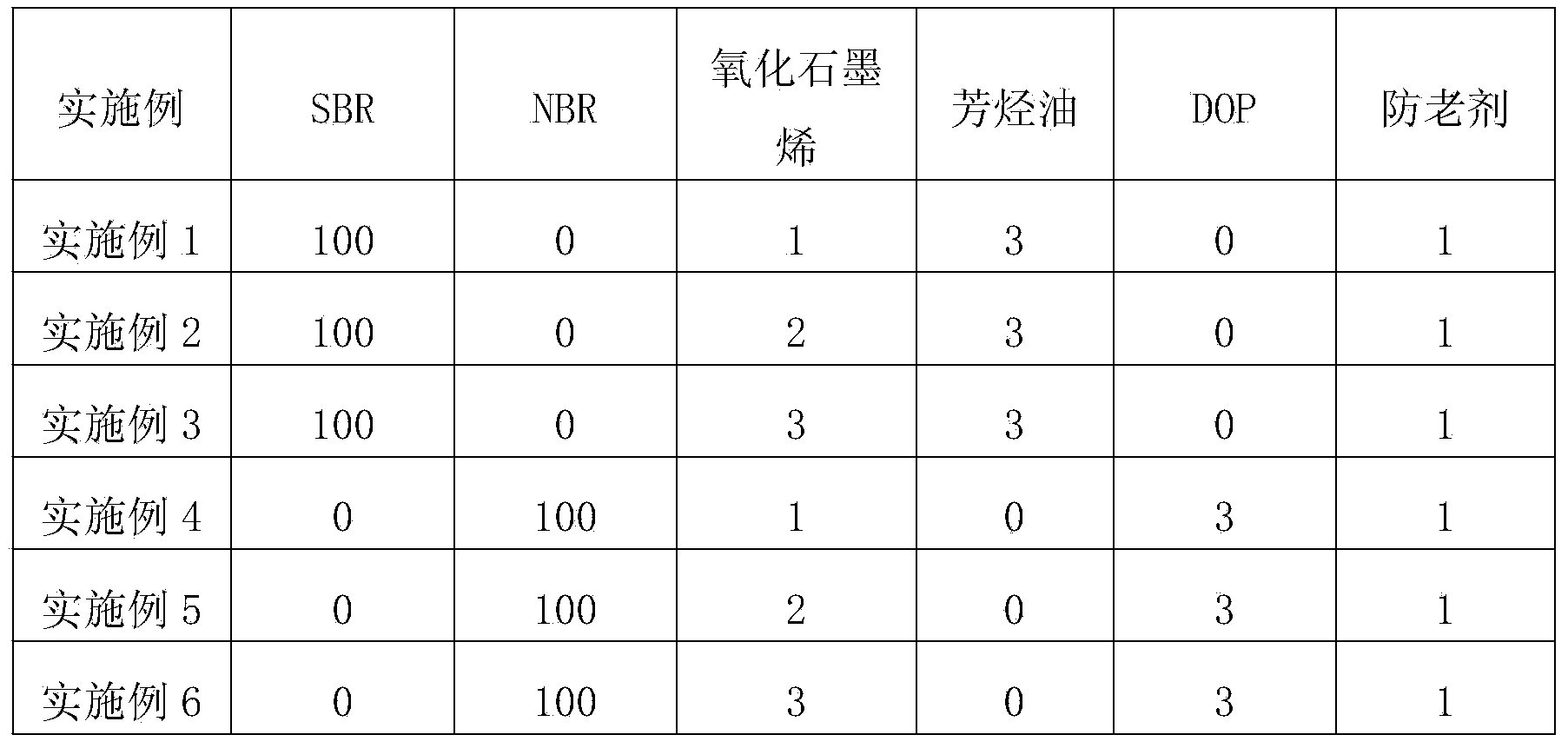

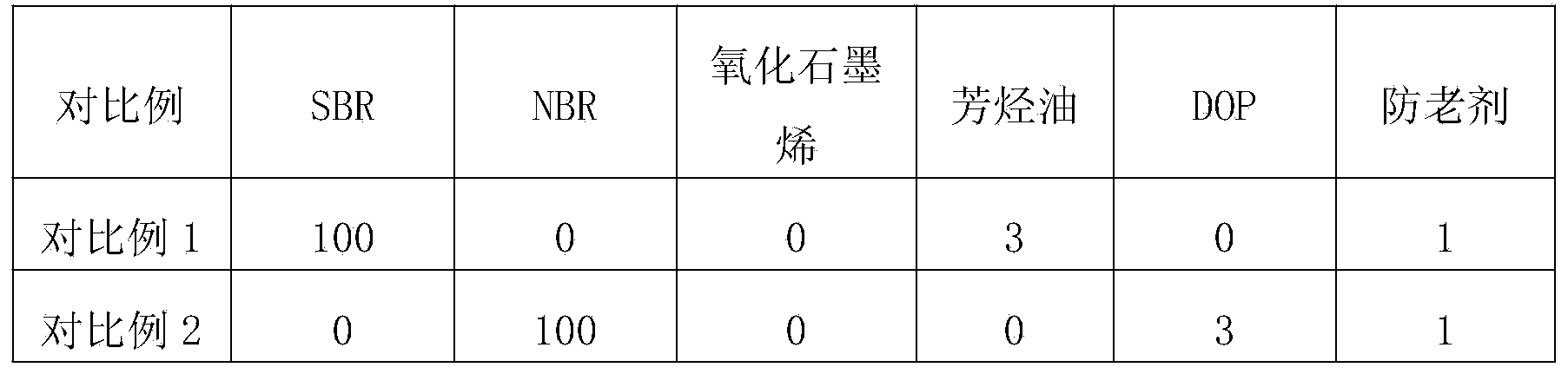

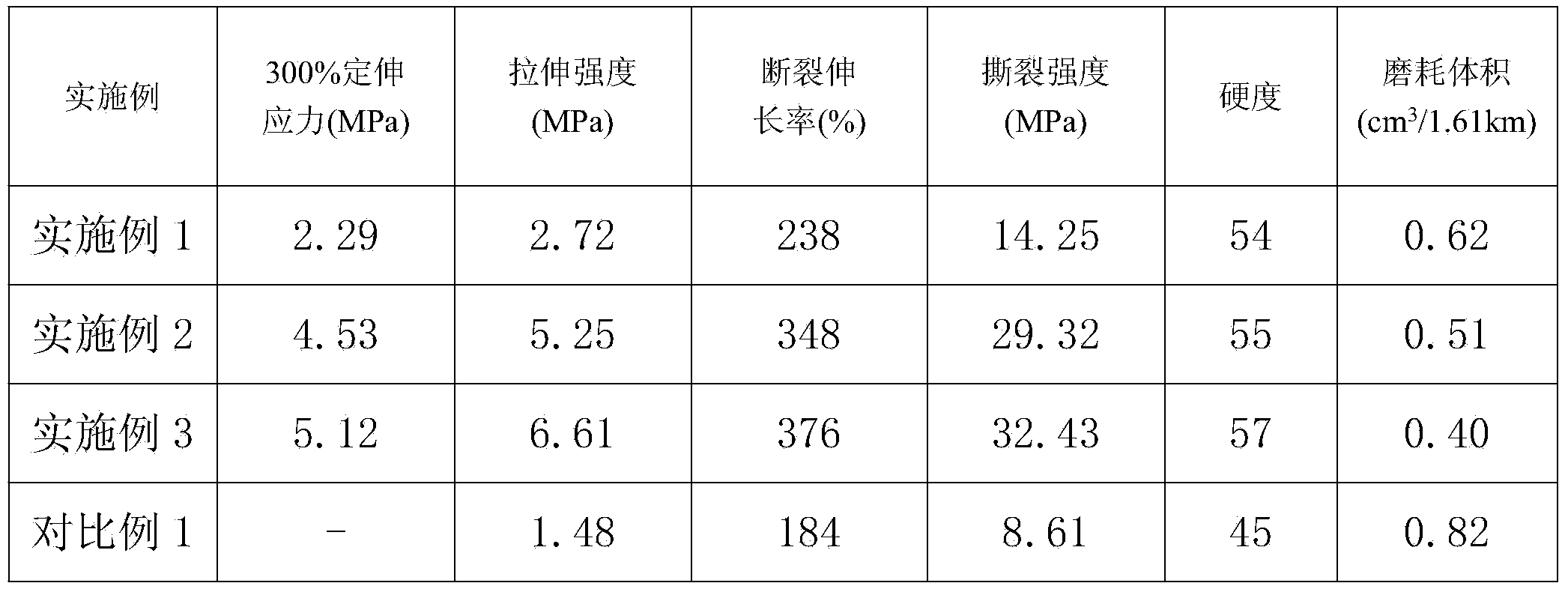

Oil-filled and graphene oxide emulsion-filled co-coagulated rubber and preparation method thereof

The invention discloses oil-filled and graphene oxide emulsion-filled co-coagulated rubber and a preparation method thereof. The co-coagulated rubber comprises the following main components by weight parts: 100 parts of rubber, 1-40 parts of oil, 1-20 parts of graphene oxide and 0.1-5 parts of an anti-ageing agent. The preparation method comprises the following steps: adding graphene oxide suspension liquid and the anti-ageing agent into rubber latex, and stirring at 30-60 DEG C for 0-30 minutes to obtain a mixture; adding emulsified oil into the mixture and stirring for 1-10 minutes; and adding a flocculant for flocculating, dewatering and drying to prepare the oil-filled and graphene oxide emulsion-filled co-coagulated rubber. The method is simple and feasible, low in cost and easy for industrialized production, and has good economic and social benefits. The oil-filled and graphene oxide emulsion-filled co-coagulated rubber prepared by adopting the method is relatively high in tensile strength, stress at definite elongation and tear strength and low in wear volume, and the characteristics of high reinforcement and high wear resistance of graphene oxide are fully reflected.

Owner:QINGDAO UNIV

Material for reinforcement of coal and rock and preparation process and application thereof

InactiveCN101747524ADoes not affect admissibilityImprove adhesionMine roof capsCeramicwareOrganic acidPlasticizer

The invention relates to a material for reinforcement of coal and rock and a preparation process and application thereof. In the technical scheme, resol, a plasticizer, fire-resistance polyether and methanol are used as raw materials and are heated under alkaline conditions to form modified phenolic resin with an inter-penetrating structure through copolymerization and condensation, the modified phenolic resin is then mixed with an organic acid catalyst system by a pump, and the mixture is then poured into a broken coal and rock to be cured and to be closely combined with the coal and rock. The preparation process comprises preparation of the modified phenolic and preparation of the coal and rock curing material. The modified phenolic resin has low viscosity and can infiltrate into tiny cracks. The cured phenolic material has excellent bounding capacity and can achieve strong viscosity with the formation. Due to the excellent flexibility properties, the material can withstand the subsequent formation movement without retardant fire, thereby improving the safety of underground operation. Moreover, the material can not affect the mineability of coal, and can be easily planed and cut, thereby realizing the easy breakage of large coal lumps bonded together.

Owner:滕州市华海新型保温材料有限公司

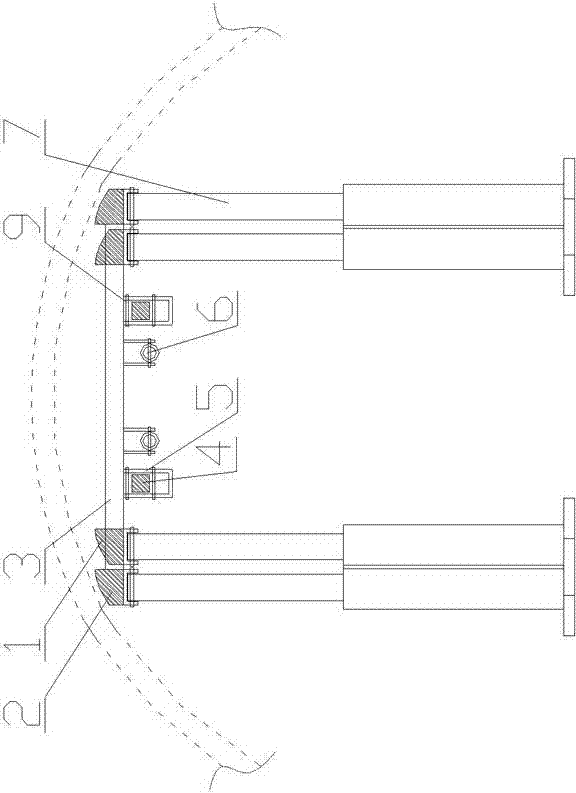

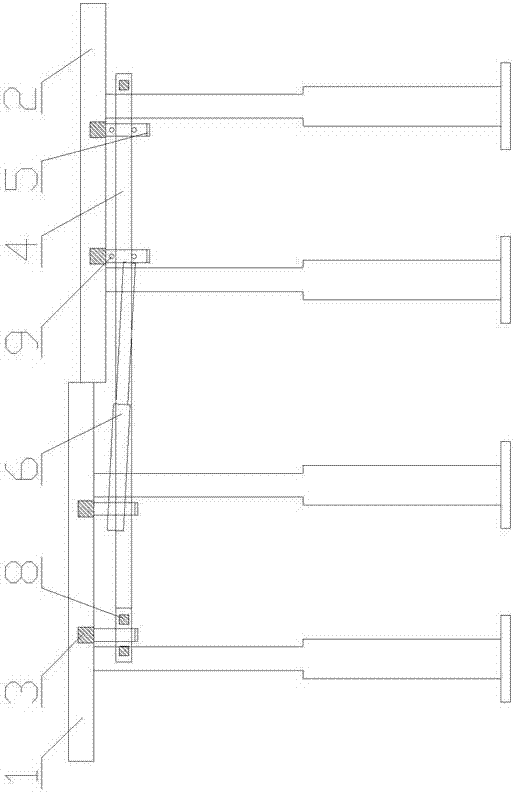

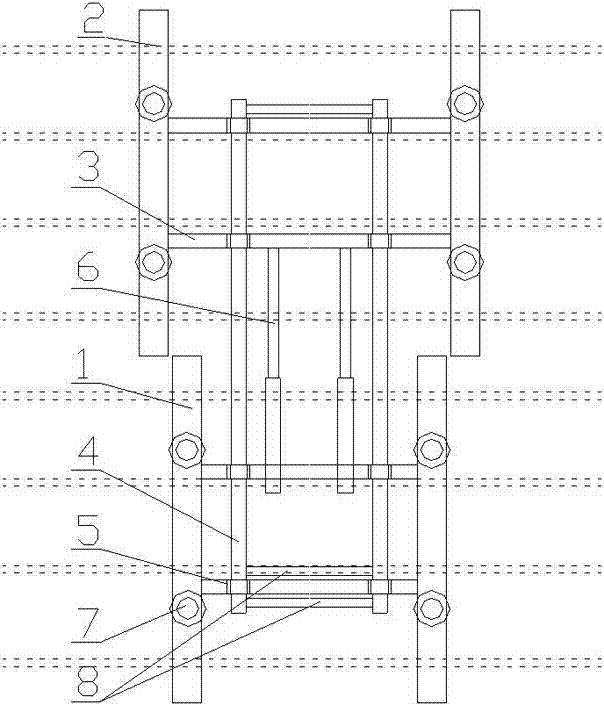

Hydraulic supporting device of suspended top beams for roadways in shed

InactiveCN103867223ASimple structureImprove carrying capacityMine roof supportsStructural engineeringPedestrian

The invention discloses a hydraulic supporting device of suspended top beams for roadways in a shed. The hydraulic supporting device comprises two parts, i.e., a front-section bracket and a rear-section bracket, wherein the front-section bracket comprises two parallel front-section longitudinal beams (2); the rear-section bracket comprises two parallel rear-section longitudinal beams (1); four cross beams (3) are arranged between the parallel front-section longitudinal beams (2) and the parallel rear-section longitudinal beams (1); two supporting-beam sliding grooves (5) are respectively arranged under each cross beam (3); the front-section bracket and the rear-section bracket are connected by supporting beams (4) in the supporting-beam sliding grooves (5). The hydraulic supporting device disclosed by the invention has the advantages that the structure is simple, the bearing capability is high, the mechanical degree is high, the full-hydraulic control is realized, the stability of the bracket is good, the installation and removal are convenient, no base is arranged and pedestrians of the roadway are not influenced. By adoption of the brackets, the roadways in the advanced stress range of two roadways on a stoping working face can be effectively reinforced, the heights and the sections of the roadways can be maintained, the self movement along with the propulsion of the working face can be realized and the promotional and practical values are higher.

Owner:欧亚伟 +1

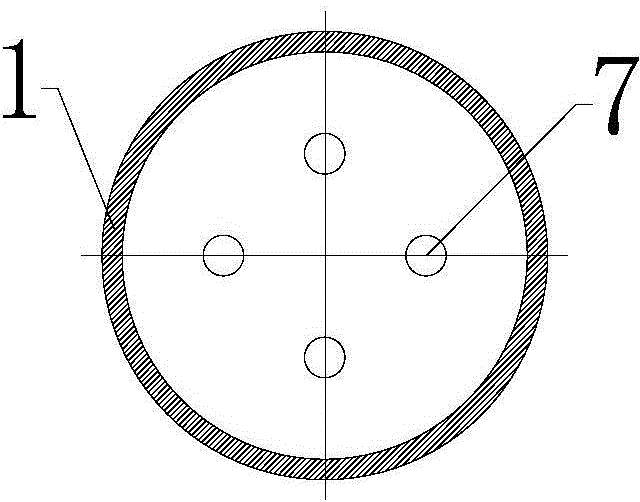

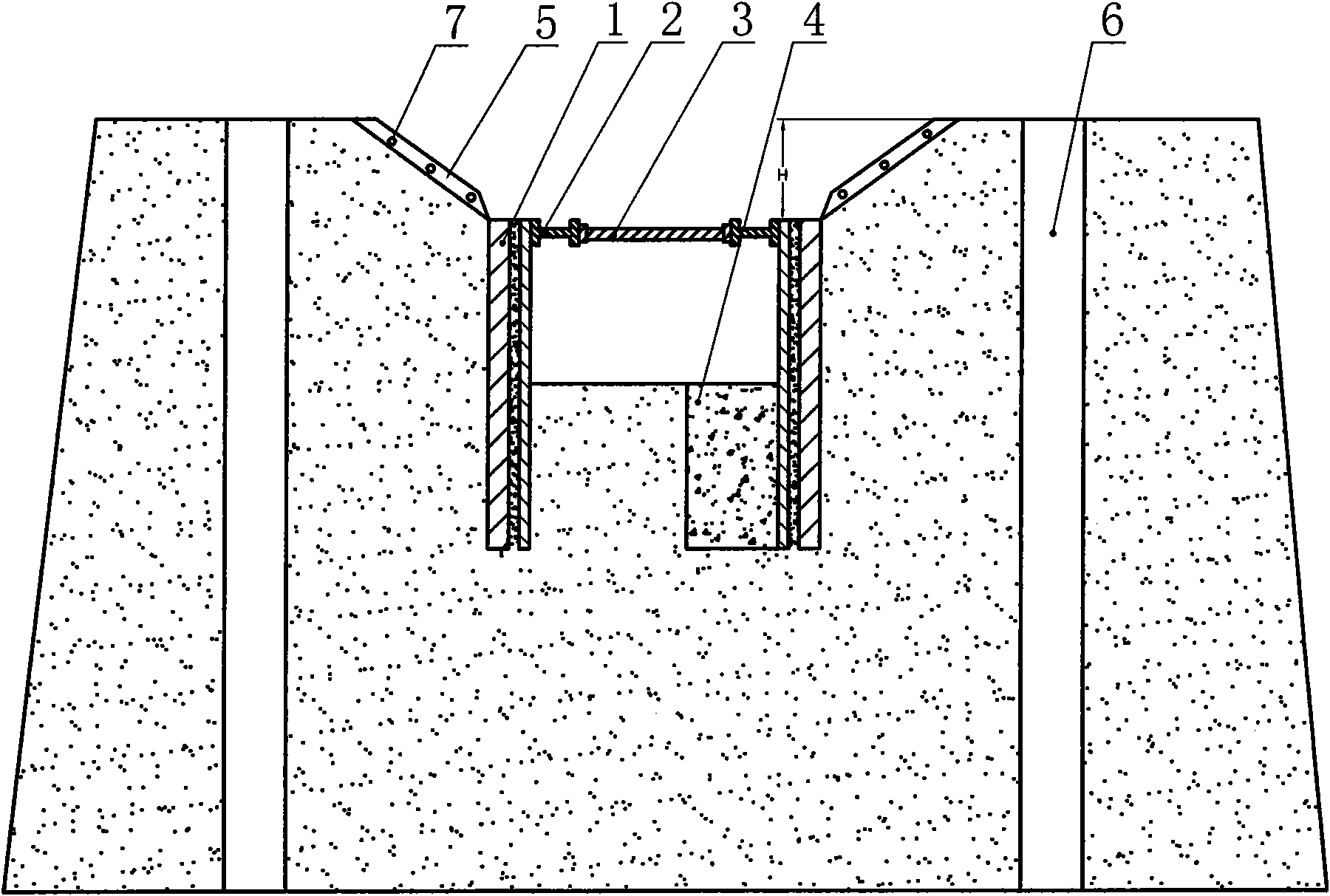

Grouting pipe for miscellaneous fill stratum and construction method

InactiveCN104975594AEffective reinforcementEasy to processSoil preservationArchitectural engineeringSlurry

Disclosed are a grouting pipe for a miscellaneous fill stratum and a construction method. The grouting pipe is mainly composed of an external grouting pipe body, an internal grouting pipe body, a slurry stop plug, a segment spacer ring and a sealing plug, wherein one end of the external grouting pipe body and the surface of the pipe body are provided with grouting holes; the internal grouting pipe body is fixed to the segment spacer ring through the slurry stop plug; a grouting hole is formed in the top end of the internal grouting pipe body, and grouting holes are evenly distributed around one end of the pipe body; the bottom end of the internal grouting pipe body is connected with a grouting machine through a mortar conveying pipe; the segment spacer ring is fixed to the inner wall of the external grouting pipe body. The grouting pipe has the characteristics of low pressure, high frequency, segmentation and quick grouting, thereby accurately controlling the grouting pressure and grouting parameters for the complex situations of miscellaneous fill stratums containing large gravel or building rubbish; a grouting curtain within a certain range is formed in the stratum, greening vegetation over the stratum is not affected, and the purpose of effectively reinforcing the miscellaneous fill stratum is achieved. The grouting pipe is convenient to use, conducts grouting quickly and can be widely applied to miscellaneous fill stratums needing reinforcing.

Owner:CHINA UNIV OF MINING & TECH

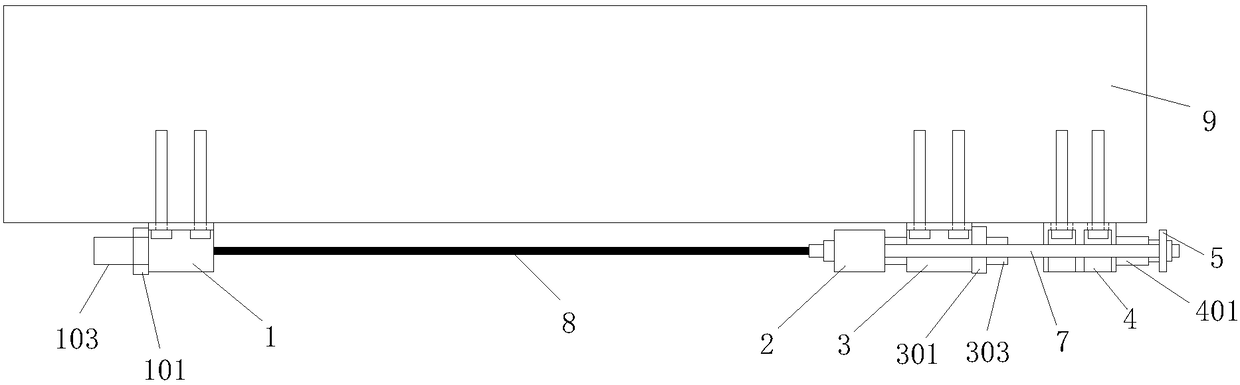

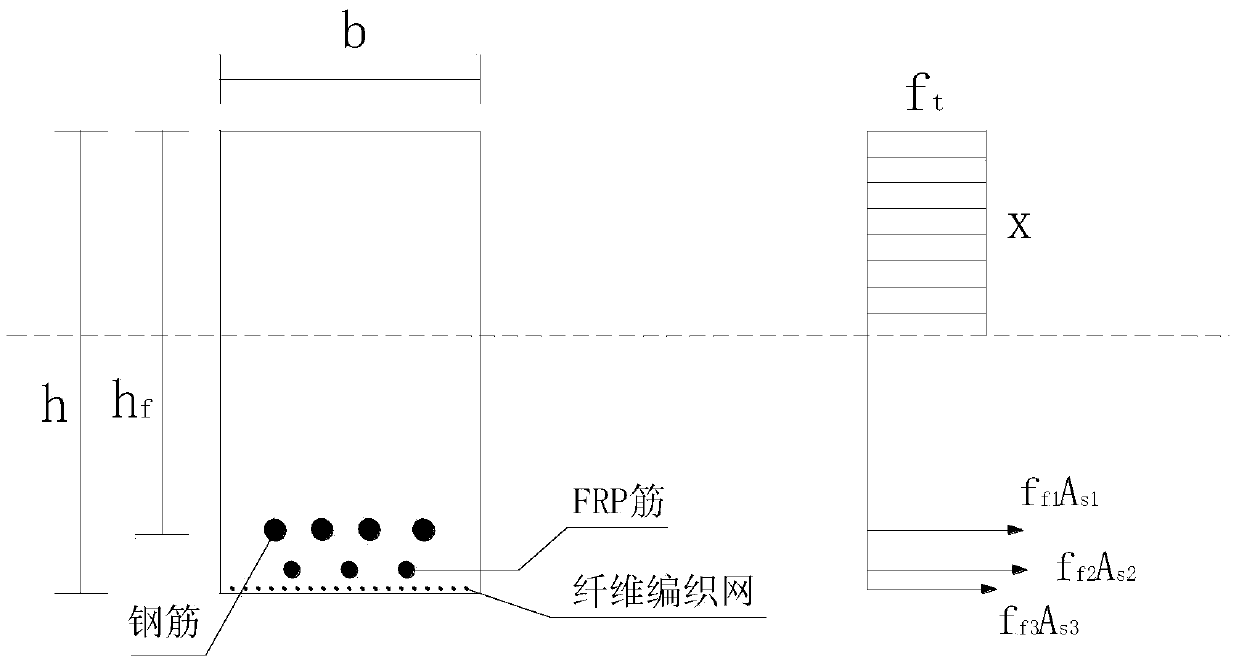

Carbon fiber bar reinforcement device and method for reinforced concrete beam and slab

The invention discloses a carbon fiber bar reinforcement device and method for a reinforced concrete beam and a reinforced concrete slab. The carbon fiber bar reinforcement method comprises the following steps: first, assembling a carbon fiber bar and anchorage devices, opening holes in a beam, fixing the anchorage devices to the beam by using chemical anchors, mounting a tensioning device and thecarbon fiber bar onto brackets, tensioning the carbon fiber bar by using a jack, and detaching the mounting brackets after tensioning is completed. The carbon fiber bar is used for reinforcing the reinforced concrete beam, so that the reinforced concrete beam has a smaller area than a carbon fiber plate, the carbon fiber bar reinforcement device and the carbon fiber bar reinforcement method are suitable for beam and slab reinforcement in civil buildings, and during anchorage, less holes need to be opened in an original structure, so that less damage is caused to the structure; the circular carbon fiber bar is directly fixed to supports through nuts, and no connection screw rod is required, so that the length of the anchoring end is short, the prestress loss is less, and the reinforced concrete beam and the reinforced concrete slab can be effectively reinforced; when walls exist at the two ends of the bottom of the beam required to be reinforced, the beam can be reinforced from two sides of the beam; the carbon fiber bar reinforcement device is simple in structure; the reinforcement method is easy to implement; the carbon fiber bar reinforcement device and the carbon fiber bar reinforcement method can be popularized and applied to a variety of occasions where reinforced concrete reinforcement is required.

Owner:NANNING UNIV

Method for repairing and reinforcing concrete structure under severe environment

The invention provides a method for repairing and reinforcing a concrete structure under a severe environment, and belongs to a method for repairing and reinforcing a concrete structure. The method specifically includes the step of FRP rib reinforcement and the step of fiber woven mesh reinforcement. In the step of FRP rib reinforcement, grooving and dust removing are conducted in a concrete protection layer of a beam to be reinforced through a cutting machine, wherein the surface of concrete is kept dry and is not wet; a half of the portion inside each groove is filled with epoxy resin and epoxy resin curing agents or high-performance fine concrete bonding materials; FRP ribs are placed in the grooves, and the grooves are filled with the bonding materials by slightly conducting extrusion; the surfaces are smeared flat, and operators need to wait till the bonding agents are solidified. In the step of fiber woven mesh reinforcement, firstly, the surface of a building to be reinforced is machined to be uneven; the surface of the building to be reinforced is wetted by water, and stirred fine concrete is sprayed to the structure and the surfaces of fiber woven meshes; a layer of fine concrete is sprayed on each layer of fiber woven mesh each time a layer of fiber woven mesh is laid, and water curing is conduced on the fine concrete through water till the age. By means of the good corrosion resistance of the FRP ribs and the fiber woven meshes, the method is more effective under the severe environment such as ocean.

Owner:CHINA UNIV OF MINING & TECH

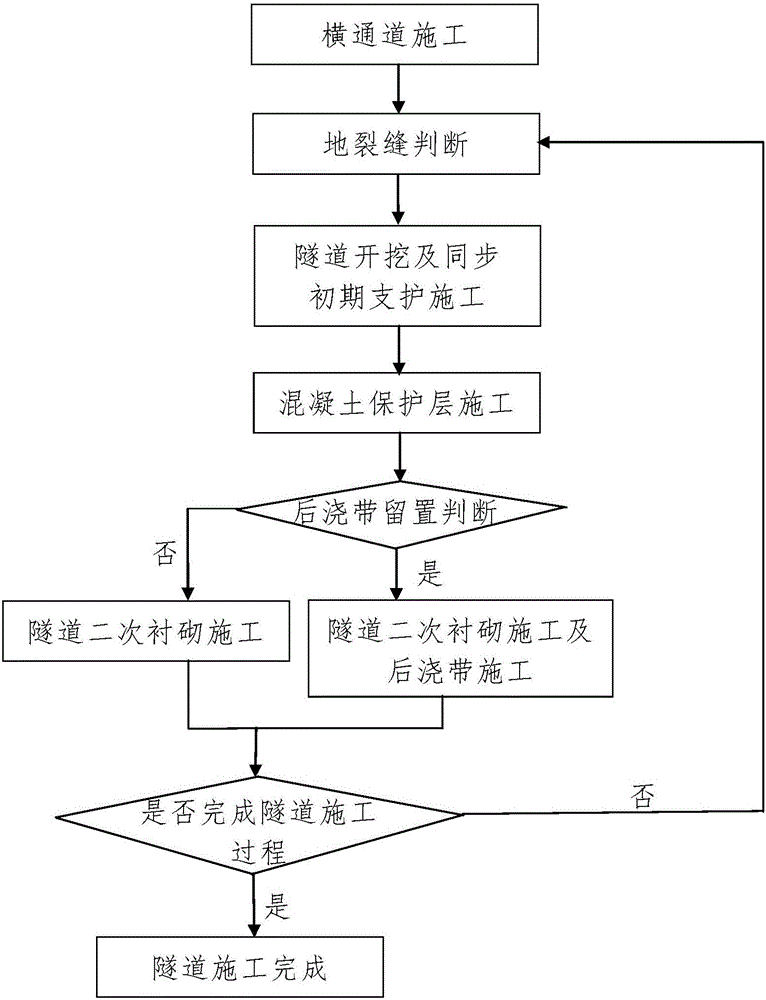

Ground fracture crushed zone passing construction method for shallow-buried tunnel excavation

ActiveCN106437726AThe method steps are simpleReasonable designUnderground chambersTunnel liningProtection layerTunnel construction

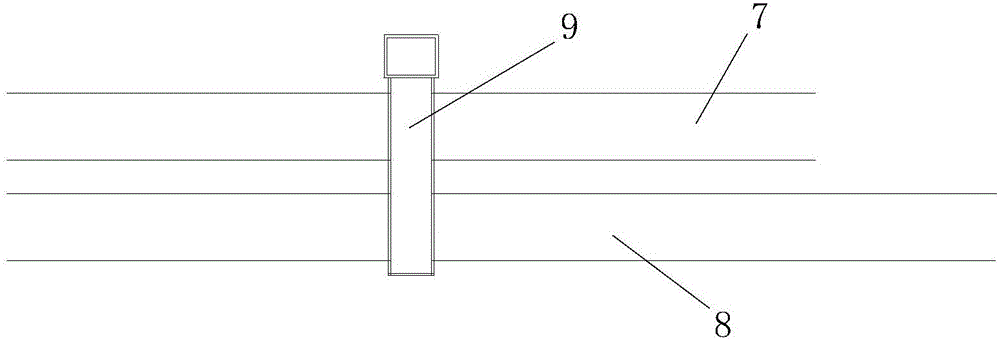

The invention discloses a ground fracture crushed zone passing construction method for shallow-buried tunnel excavation. A constructed shallow-buried excavation tunnel comprises a left line tunnel and a right line tunnel which are communicated through a transverse channel. During construction of the constructed shallow-buried excavation tunnel, the method comprises the steps that 1, transverse channel construction is performed; 2, tunnel construction is performed, wherein the two tunnel sections of the left line tunnel and the right line tunnel are constructed through the transverse channel, the construction is performed in the mode of multiple tunnel sections in the longitudinal extending direction of the tunnel from back to from during construction of any one tunnel section, and the construction of any one tunnel section includes the processes of ground fracture judgement, tunnel excavation and synchronous preliminary bracing construction, concrete protection layer construction, post-cast strip retention judgement, secondary tunnel lining construction and post-cast strip construction. The method includes simple steps and is reasonable in design, convenient to construct, good in construction effect, capable of simply and conveniently completing the shallow-buried tunnel excavation construction process of a ground fracture crushed zone and safe and reliable in construction process.

Owner:中铁二十局集团第五工程有限公司

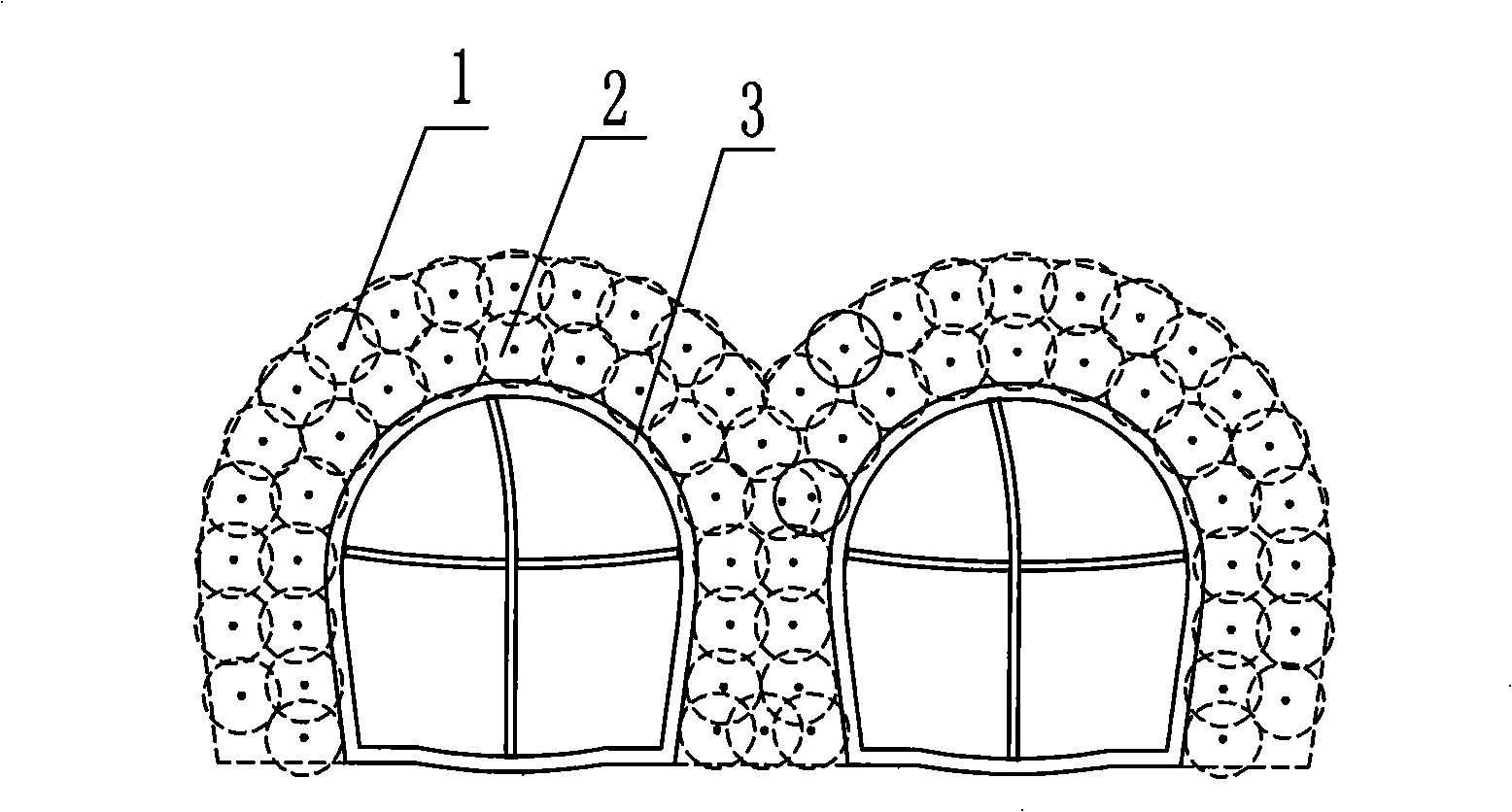

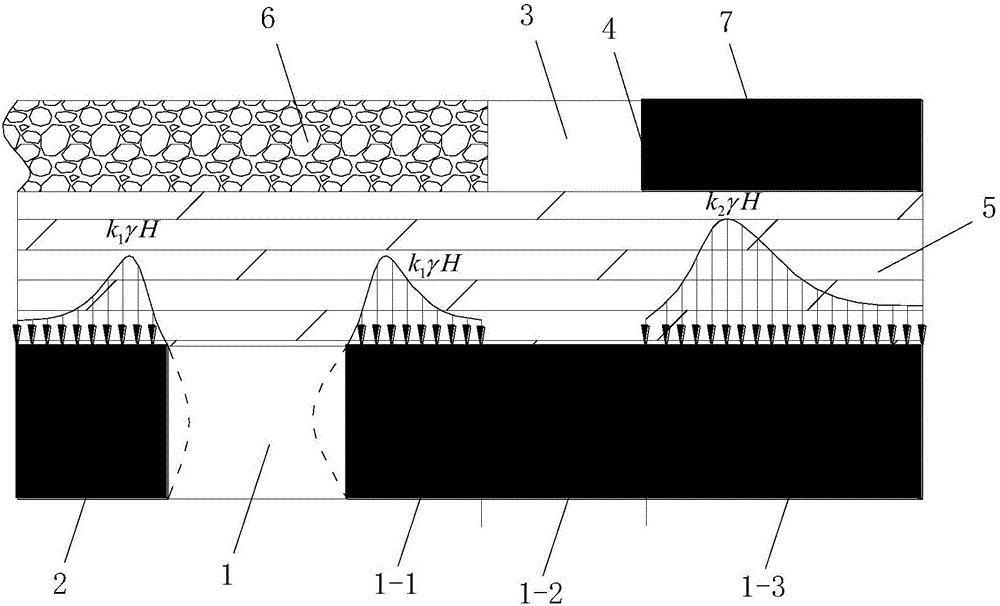

Method for advanced compaction grouting reinforcement of spongy stratum suitable for shallow-buried excavation tunnel

ActiveCN109162722AEffective reinforcementStrong mechanical propertiesUnderground chambersTunnel liningEarth surfaceGeotextile

The invention discloses a method for advanced compaction grouting reinforcement of a spongy stratum suitable for a shallow-buried excavation tunnel. The method comprises the following steps that: a stratum compaction performance of penetration of a tunnel into a spongy stratum is tested by the experiment and thus compaction degrees of the stratum under different grouting pressures as well as mechanical and anti-penetrability performances corresponding to different compaction degrees are determined; influences on tunnel excavation stability by the different stratum compaction degrees and grouting reinforcement ring thicknesses are analyzed, so that a target grouting pressure and a grouting reinforcement ring thickness are determined; a maximum expansion radius of an expansive soil geotextile bag and an earth surface grouting hole arrangement interval are determined; a grouting pipe with the expansive soil geotextile bag is made; grouting hole drilling work is carried out on the earth surface and the grouting pipe with the expansive soil geotextile bag is inserted after the grouting holes reache a predetermined depth; grouting is carried out by using a quick-setting grouting materialand grouting is stopped when the grouting pressure reaches the target grouting pressure; the gaps between the grouting pipe and the grouting holes are filled and sealed; and grouting work of all grouting holes is completed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Short-distance coal seam roadway excavating and supporting method

ActiveCN106014423AThe method steps are simpleEasy to implementUnderground chambersTunnel liningSupporting systemShortest distance

The invention discloses a short-distance coal seam roadway excavating and supporting method. The method comprises steps as follows: 1, basic mechanical parameters of surrounding rock are determined; 2, reserved excavated volumes of two sides of a roadway are determined; 3, the roadway is excavated; 4, a roadway side supporting structure is determined and comprises roadway supporting units and grouted rock bolts which are arranged in a staggered manner, and the roadway supporting units comprise top plate supporting systems, bottom plate supporting systems and roadway side supporting systems; and the limit caving arch rise is determined; 5, the roadway supporting structure is determined; 6, roadway surrounding rock supporting construction is performed; 7, excavation of the next section and roadway surrounding rock supporting construction are performed; 8, the step 7 is repeated multiple times, and the short-distance coal seam roadway construction process is completed. The method is simple, reasonable in design, convenient to realize and good in use effect, the reserved excavated volumes of the two sides of the roadway are determined respectively according to surrounding rock deformation conditions of the short-distance lower coal seam roadway, and whole section supporting is performed on the roadway through combination of the grouted rock bolts with the roadway supporting units.

Owner:鄂尔多斯市国源矿业开发有限责任公司

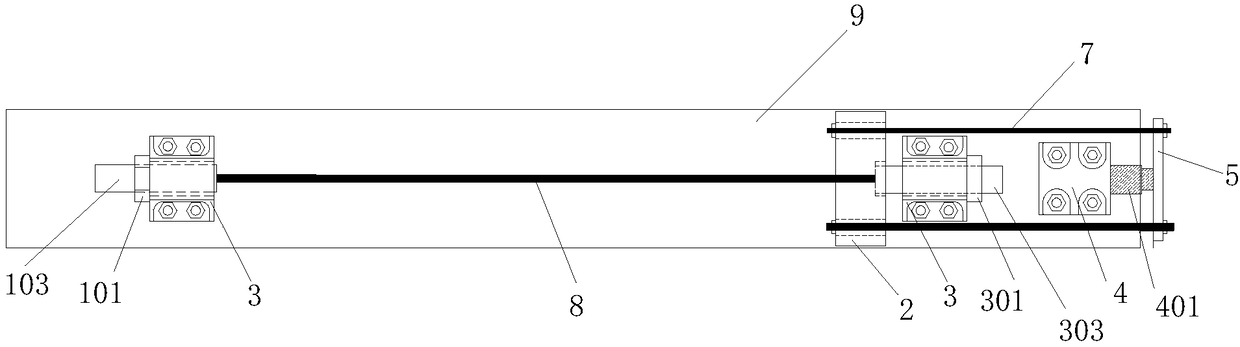

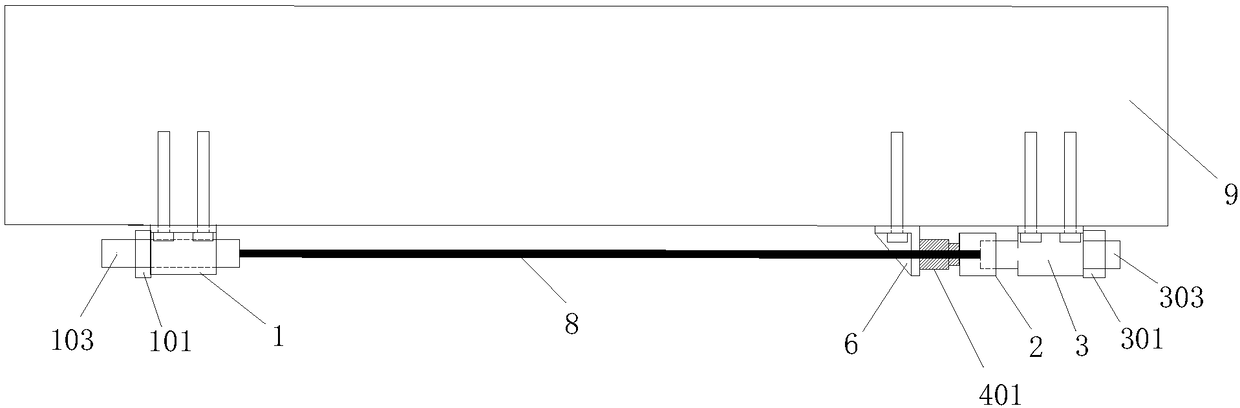

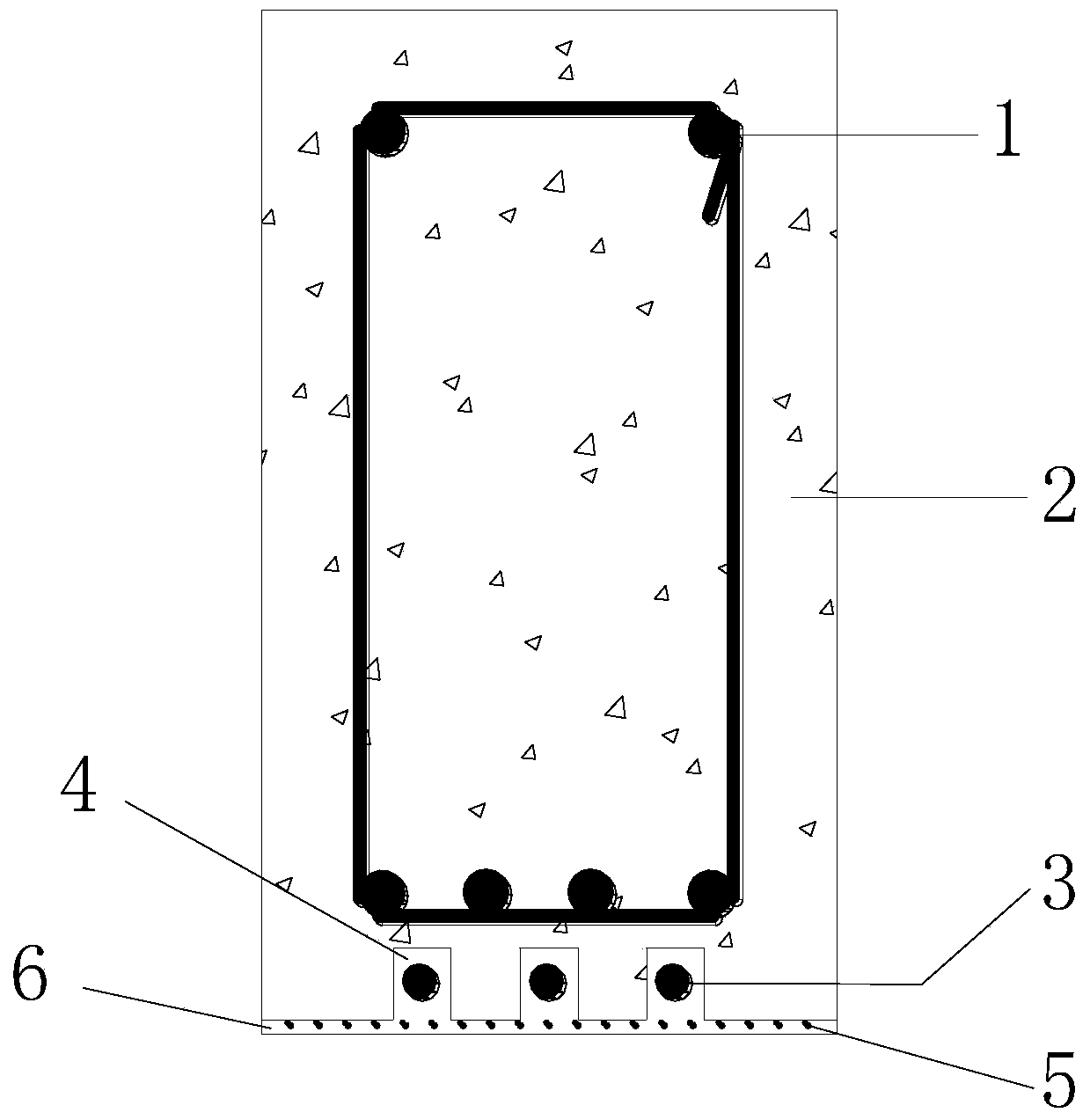

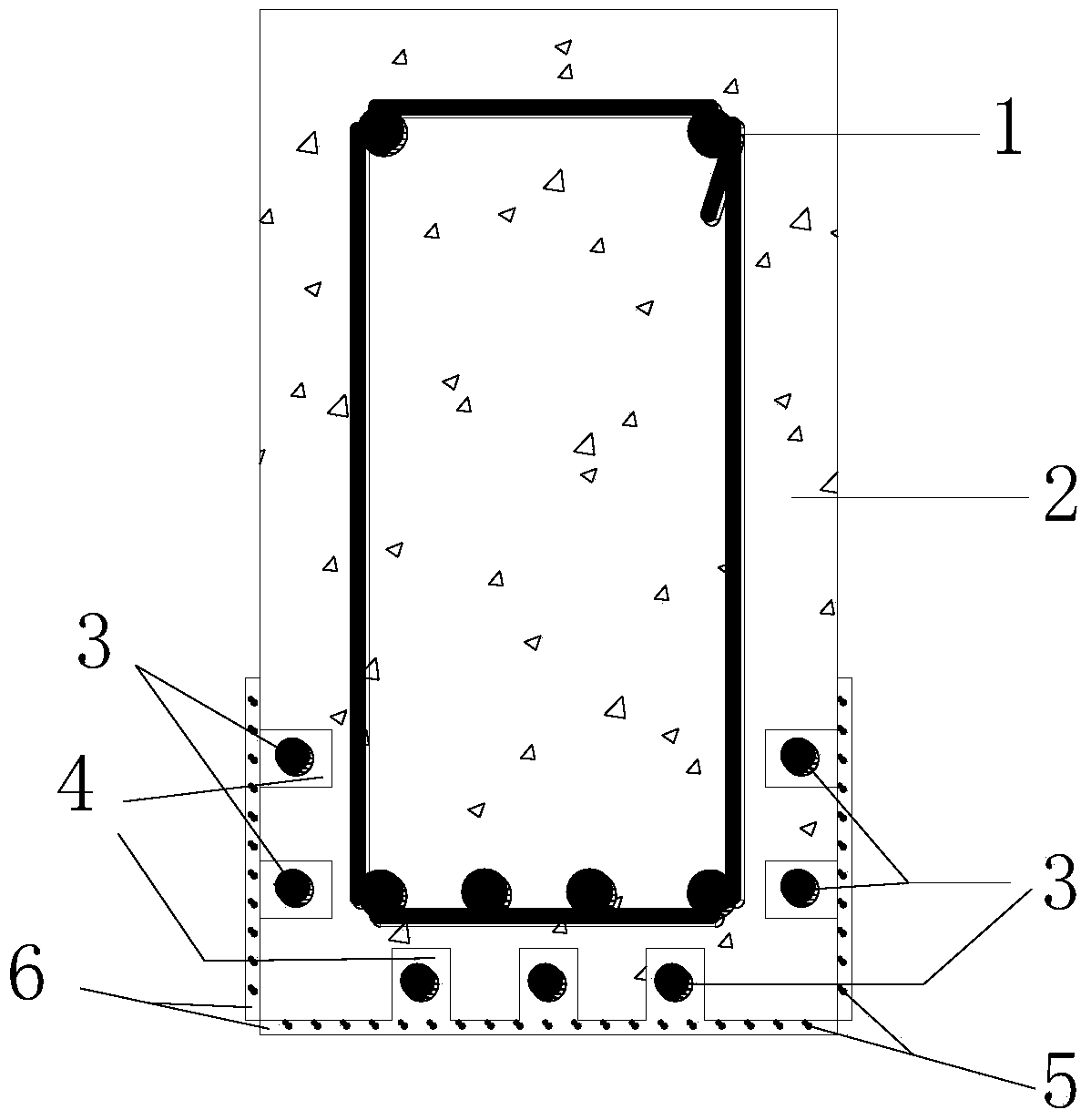

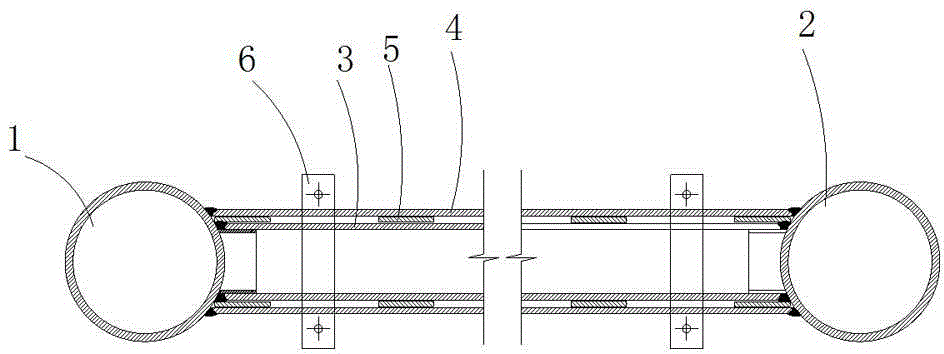

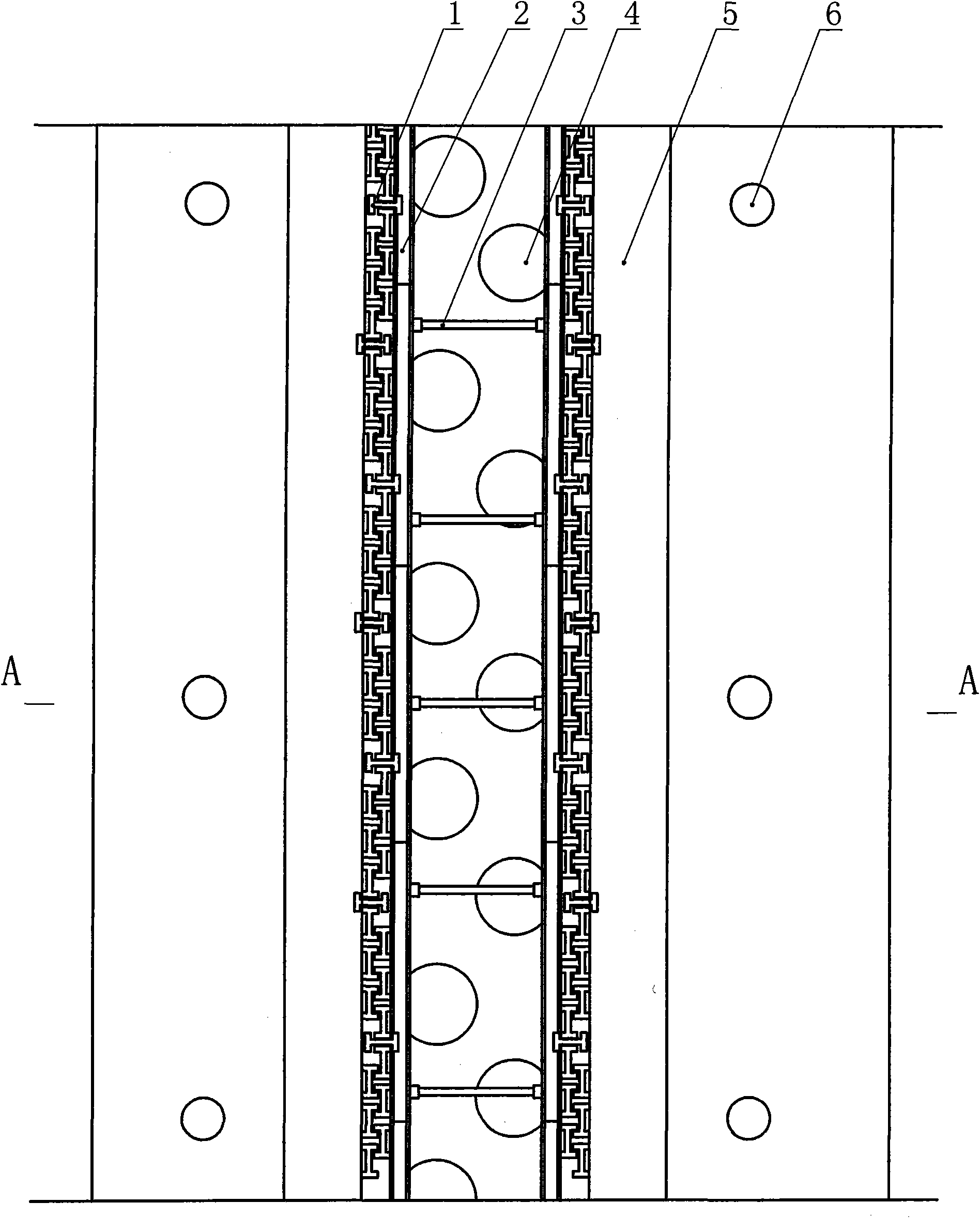

Construction joint for reinforcing welded ball space-frame pole and construction method of construction joint

ActiveCN104895343ACompact structureEffective reinforcementBuilding repairsWelding apparatusArchitectural engineeringSpace frame

The invention relates to a construction joint, in particular to a construction joint for reinforcing a welded ball space-frame pole and a construction method of the construction joint, and belongs to the field of steel structures. The construction joint comprises a left welded ball, a right welded ball and the space-frame pole, the left welded ball is fixedly arranged at the left side end of the space-frame pole, the right welded ball is fixedly arranged at the right side end of the space-frame pole, an outer wrapping steel pipe sleeves the space-frame pole, the left side end of the outer wrapping steel pipe is fixed to the left welded ball, the right side end of the outer wrapping steel pipe is fixed to the right welded ball, and outer wrapping liner pipes are uniformly distributed between the space-frame pole and the outer wrapping steel pipe. The construction joint for reinforcing the welded ball space-frame pole is compact in structure, the welded ball space-frame pole is effectively reinforced, use functions are improved, cost is saved, and investment is decreased.

Owner:浙江东南网架股份有限公司

Forming method of large shallow foundation pit with soft soil foundation

InactiveCN101565949AReduce slippageImprove securityExcavationsBulkheads/pilesEngineeringEarth surface

The invention relates to a forming method of a large shallow foundation pit with a soft soil foundation, which comprises the following steps: firstly, slope making: the slope making is performed for a soil body within 1.5-2.0 m under the earth surface of the foundation pit, the slope gradient is 1:1-1:0.5, and the side slope of the soil body is protected by adopting cement mortar with the proportion being 1:3; secondly, shoring: a shoring structural pile and a top beam are fixedly arranged near the wall of the foundation pit after the slope making, and the top level of the shoring structural pile and the top beam is 1.5-2.0 m less than that of the earth surface; thirdly, raining; fourthly, earthwork excavating; fifthly, pit bottom reinforcing: the pit bottom surface is reinforced by adopting a cement mixing method in a flower arrangement way, the reinforcement depth is 0.4-0.6 times of that of the foundation pit, and the foundation pit is formed after the bottom surface of the foundation pit is reinforced. The invention has simple construction method, good stability after forming and high safety factor and can effectively reinforce the shallow foundation pit, especially the large shallow foundation pit with a 3.5-6 m soft soil foundation in depth.

Owner:MCC TIANGONG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com