Oil-filled and graphene oxide emulsion-filled co-coagulated rubber and preparation method thereof

An oil-filled, oxygen-filled, and gelatinized rubber technology, applied in the field of polymer-based nanocomposite materials, can solve the problems of poor composite material performance, uneven dispersion, flying dust, etc., and achieve excellent reinforcement effect, strong operability, easy to use effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

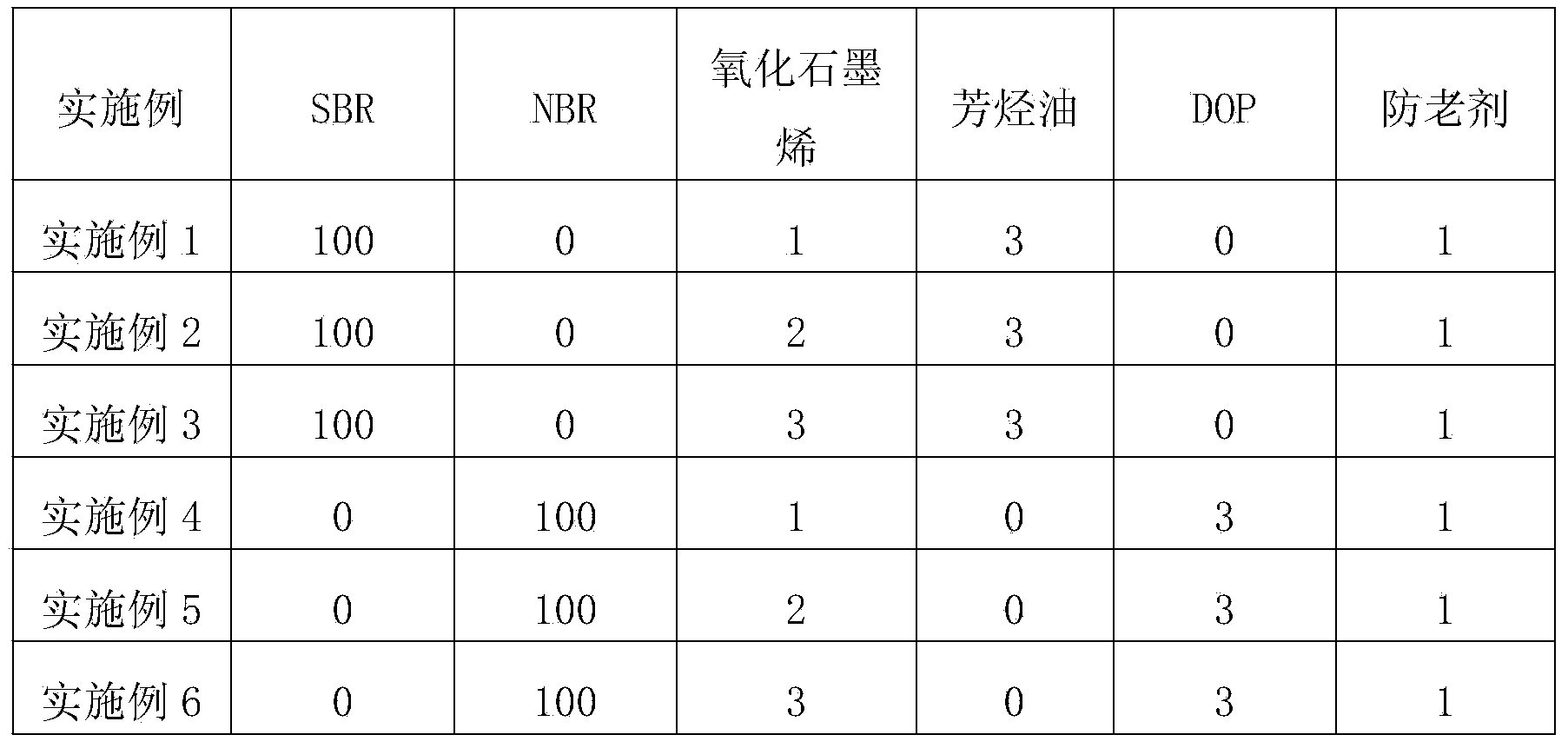

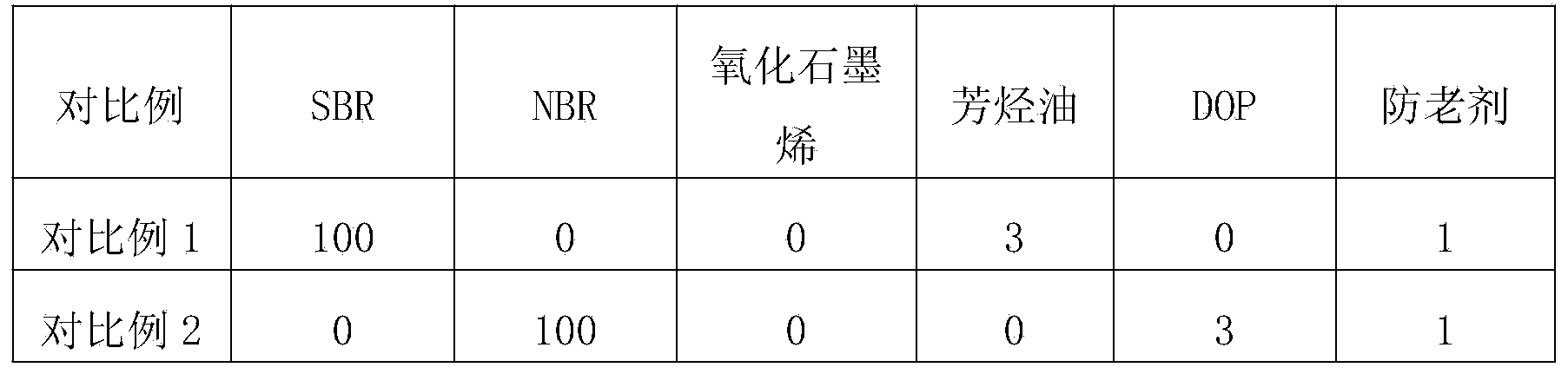

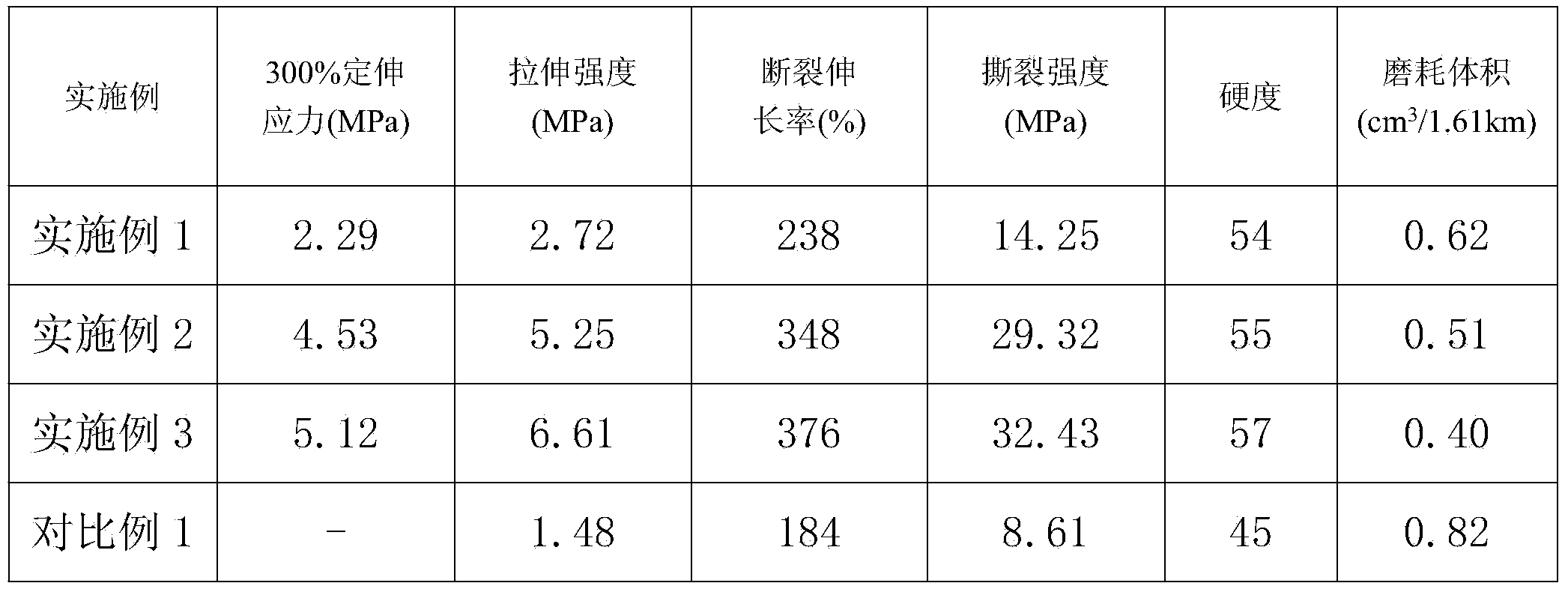

[0020] Embodiment 1-6: take the co-coagulation styrene-butadiene rubber of filling aromatic hydrocarbon oil filling graphene oxide emulsion, filling DOP filling graphene oxide emulsion co-coagulation nitrile rubber as example, illustrate the present invention's oil-filled filling graphene oxide emulsion co-coagulation rubber Preparation method and properties.

[0021] (1) Preparation of graphene oxide suspension: adding graphite into sulfuric acid with a concentration of 98%, stirring for 20 minutes, adding potassium permanganate thereto, controlling the reaction temperature to less than 10° C. and stirring in a water bath for 3 hours. Add a certain amount of deionized water to the reaction system for dilution, and continue stirring in a water bath. 20% hydrogen peroxide was added to the system, after 15 minutes of ultrasonic stripping, centrifugation and washing, the graphene oxide suspension was prepared.

[0022] (2) Preparation of emulsified oil: uniformly mix aromatic oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com