Steel-self dense concrete built-up construction reinforcing means

A self-compacting concrete and composite structure technology, which is applied in building construction, building maintenance, construction, etc., can solve the problems that the quality of concrete cannot be guaranteed, and the concrete cannot be compacted by vibration, etc., and achieve good reinforcement effect, outstanding reinforcement effect, and seismic performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

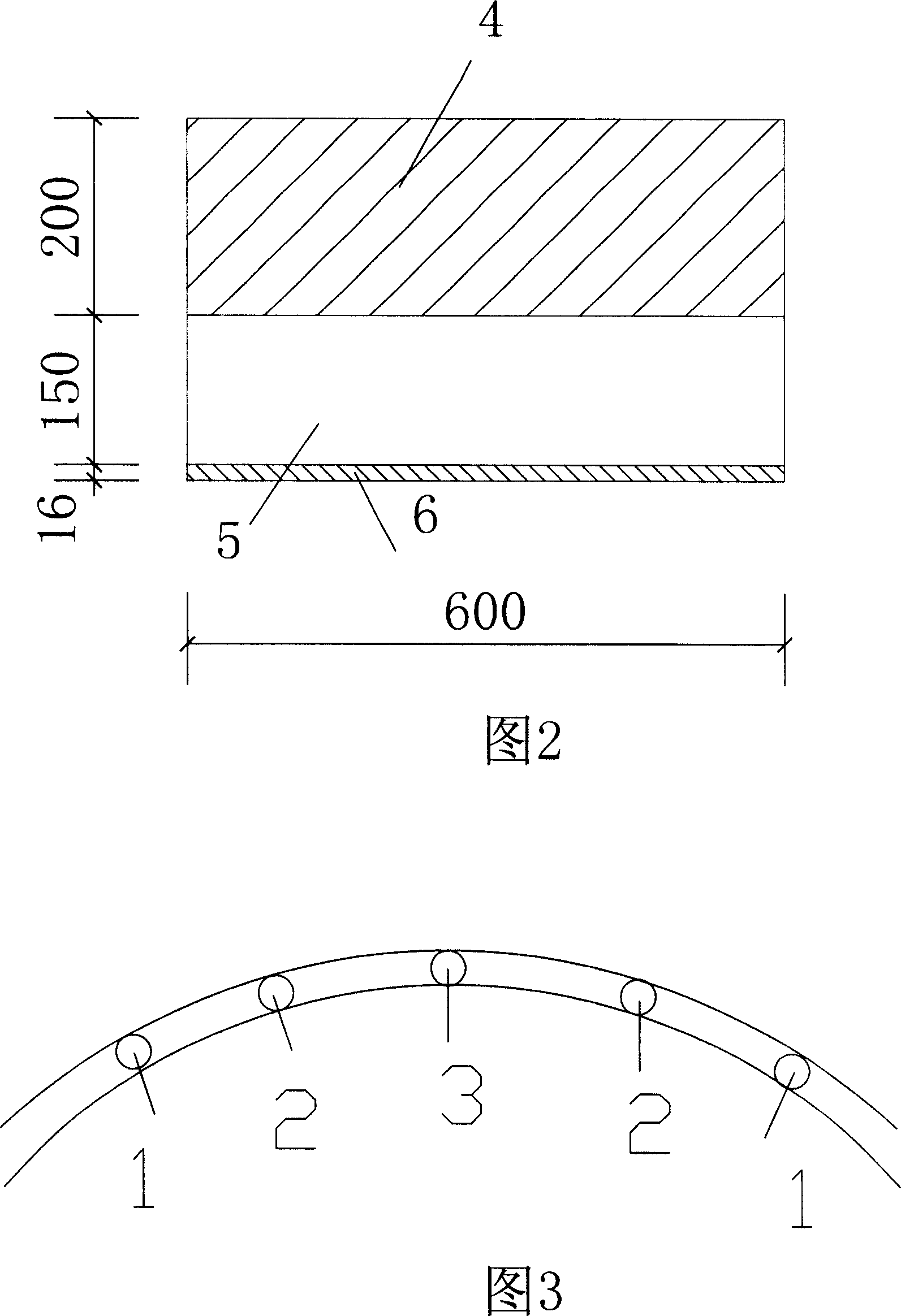

[0048] Reinforce the three-span double-curved arch bridge with equal cross-section. According to the original design data of the reinforced concrete structure, as well as the inspection and evaluation of the structure, it is decided to use steel-self-compacting concrete composite beams to strengthen the concrete arch ribs. The reinforcement design schematic diagram See Figure 2, 4 is the section of the original arch rib, 5 is the new section of the arch rib, 6 is the new steel plate, the design strength of self-compacting concrete is C35, the maximum particle size of coarse aggregate is not more than 15mm, and the slump expansion is not less than 650mm .

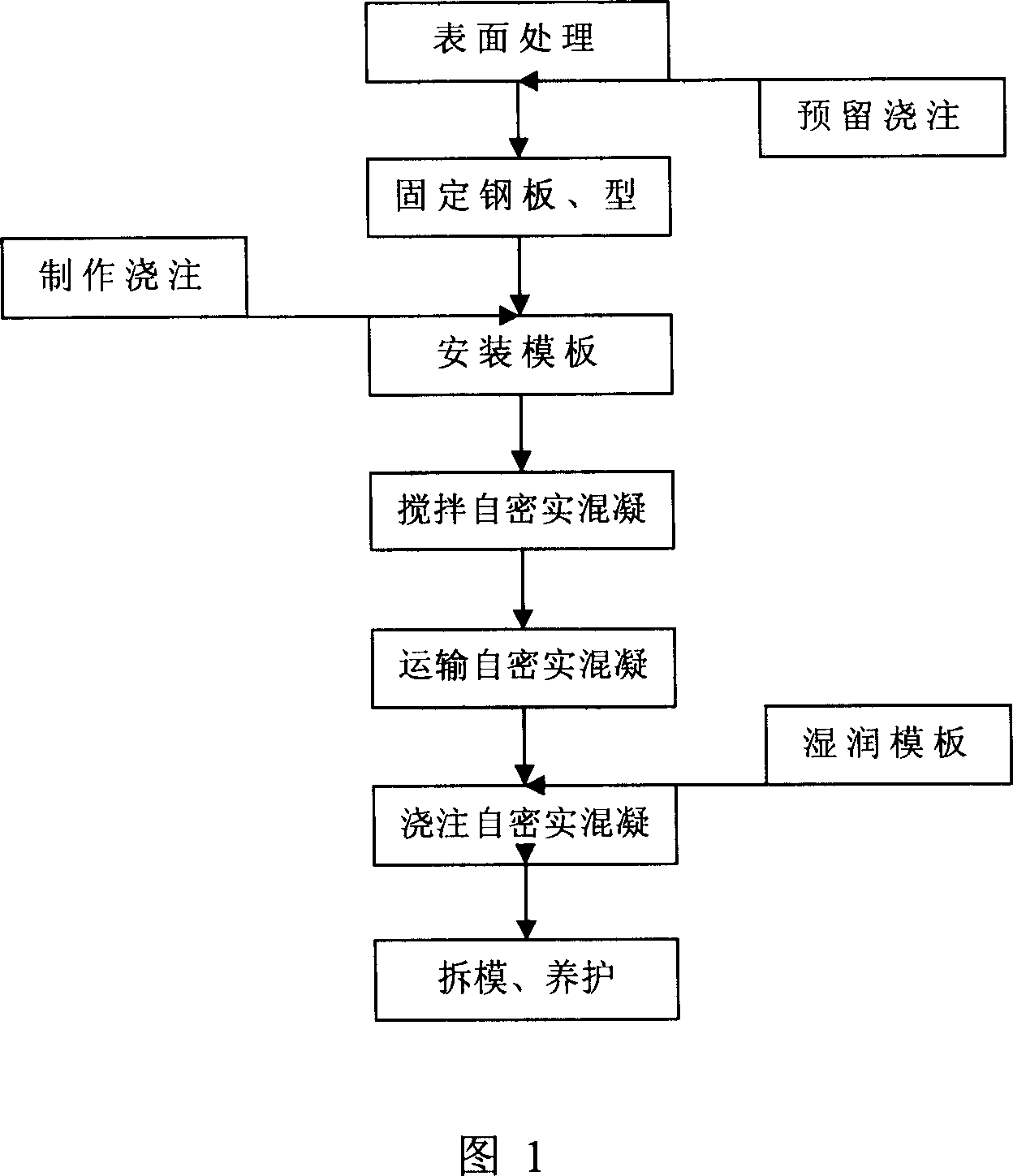

[0049] Referring to Figure 1, the technological process of steel-self-compacting concrete composite structure reinforcement technology is as follows:

[0050] 1. Treat the concrete surface of the original component with a greasy knife and a grinder, and remove the surface paint layer and decorative layer until the old concre...

Embodiment 2

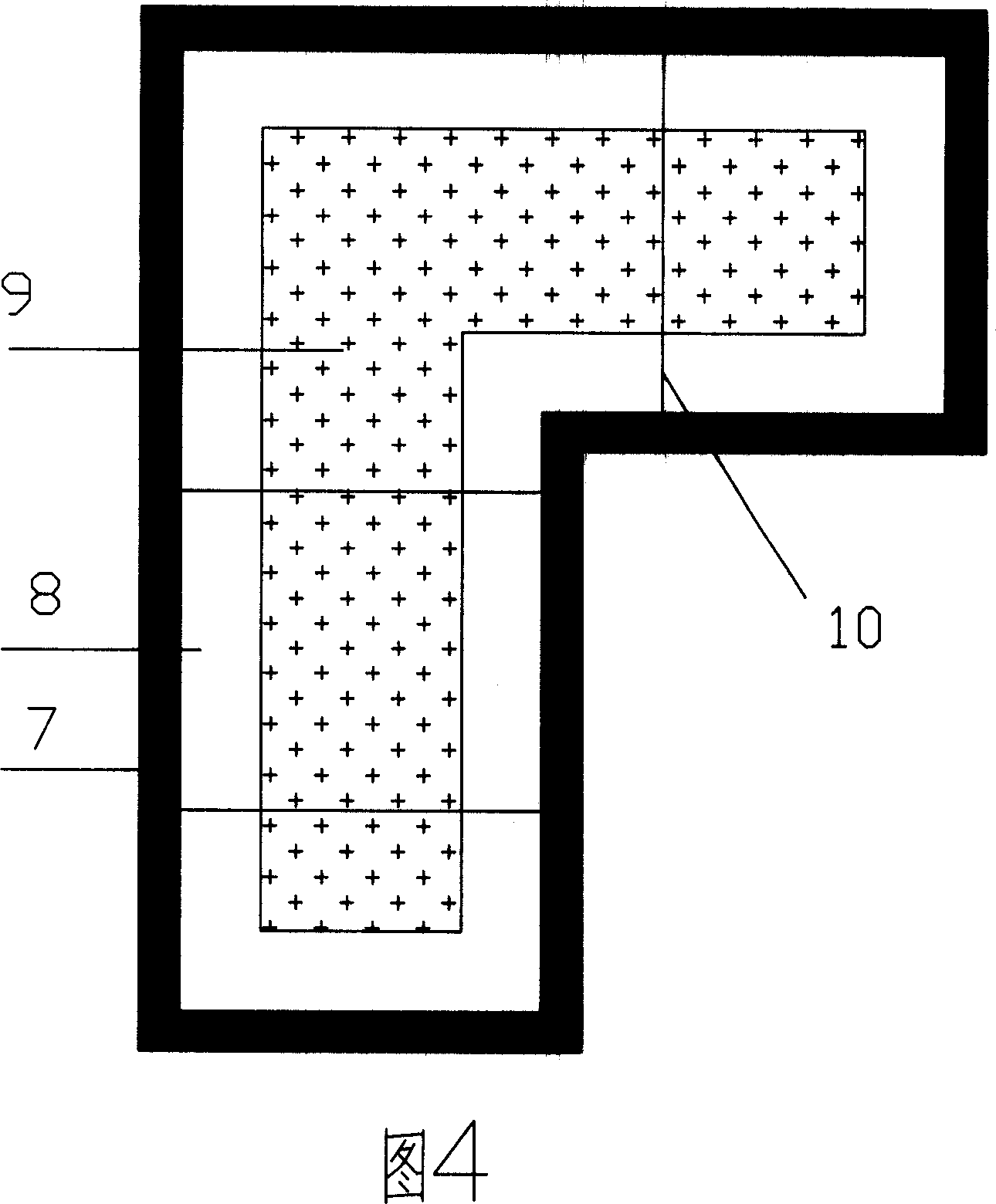

[0080] Reinforcement of a load-bearing column on the 4th floor of an 18-story residential building. Due to construction reasons, the concrete of a load-bearing column on the 4th floor of a certain 18-story residential building is loose, has no cementing ability, is of poor quality, and its strength is far lower than the design threshold. It is decided to strengthen it by steel-self-compacting concrete composite column reinforcement method. The reinforcement design is shown in Figure 4. In the figure, 7 is the newly added steel plate, 8 is the thickness of the newly added self-compacting concrete reinforced section, 9 is the original load-bearing column, and 10 is the tension steel bar. The design strength of self-compacting concrete is C50, the maximum particle size of coarse aggregate is not more than 20mm, and the slump expansion is not less than 600mm.

[0081] 1. Use the I-beam as a support to unload the four beams bearing the load of the load-bearing column, and transfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

| Slump spread | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com