Sealed type negative pressure vacuum drying oven

A vacuum drying box, sealed technology, used in drying chambers/containers, local stirring dryers, dryers for static materials, etc. , The effect of enhancing the bearing capacity and reducing the damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

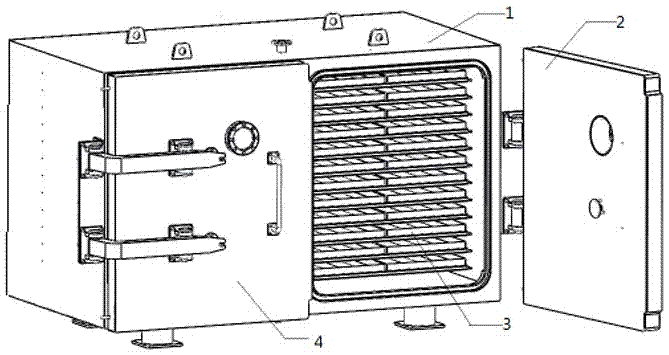

[0014] Embodiment 1: A kind of sealed negative pressure vacuum drying box, its structural schematic diagram is as follows figure 1 As shown, it includes a box body 1, a box door 2 arranged on the side of the box body 1 and a layered drying rack 3 arranged inside the box body 1. The box door 2 is connected to the box body 1 through a hinge device 4. sidewall link.

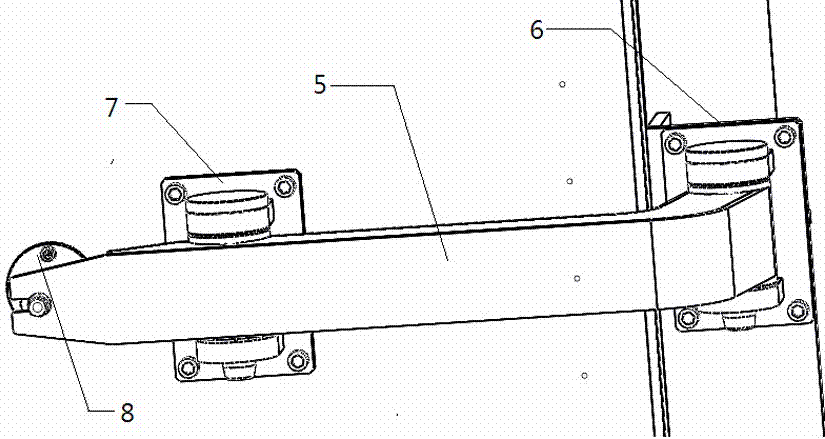

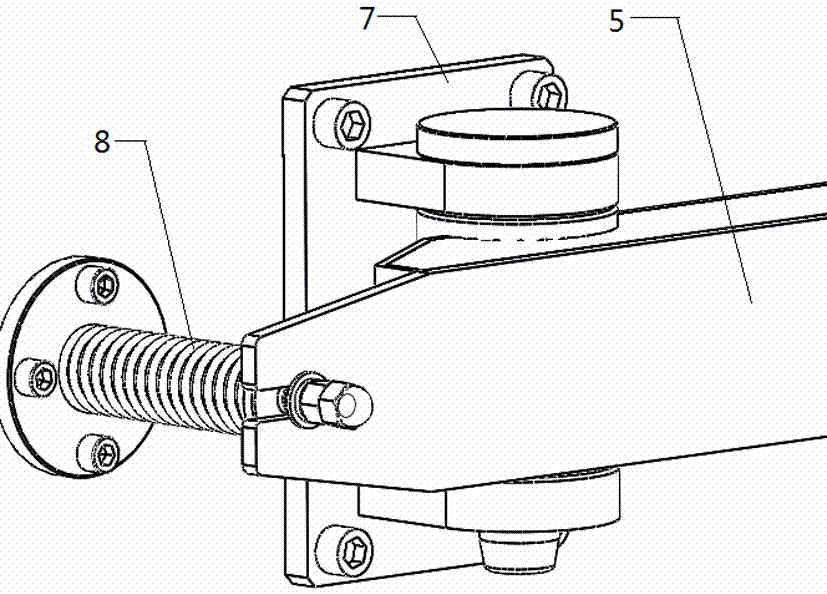

[0015] The structure schematic diagram of described hinge device is as figure 2 As shown, it includes a chain bridge 5, the tail end of the chain bridge 5 is inclined downward, and is linked with the side wall of the box body 1 through the box bearing base 6; the head end of the chain bridge 5 passes through the box door bearing The base 7 is linked with the surface of the box door 2 . The connection point between the head end of the chain bridge 5 and the surface of the box door 2 is located at 1 / 3 to 1 / 2 of the width of the box door 2 . Compared with the traditional design in which the link point is located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com