Patents

Literature

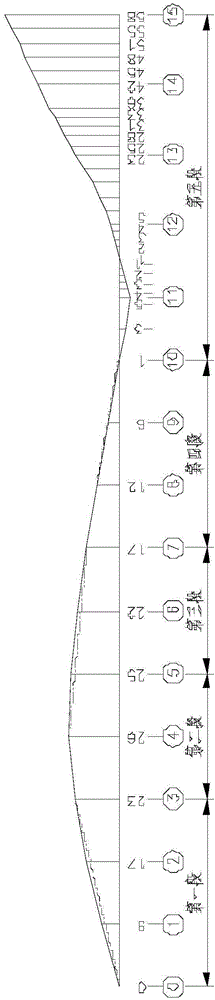

232 results about "Truss bridge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A truss bridge is a bridge whose load-bearing superstructure is composed of a truss, a structure of connected elements usually forming triangular units. The connected elements (typically straight) may be stressed from tension, compression, or sometimes both in response to dynamic loads. The basic types of truss bridges shown in this article have simple designs which could be easily analyzed by 19th and early 20th-century engineers. A truss bridge is economical to construct because it uses materials efficiently.

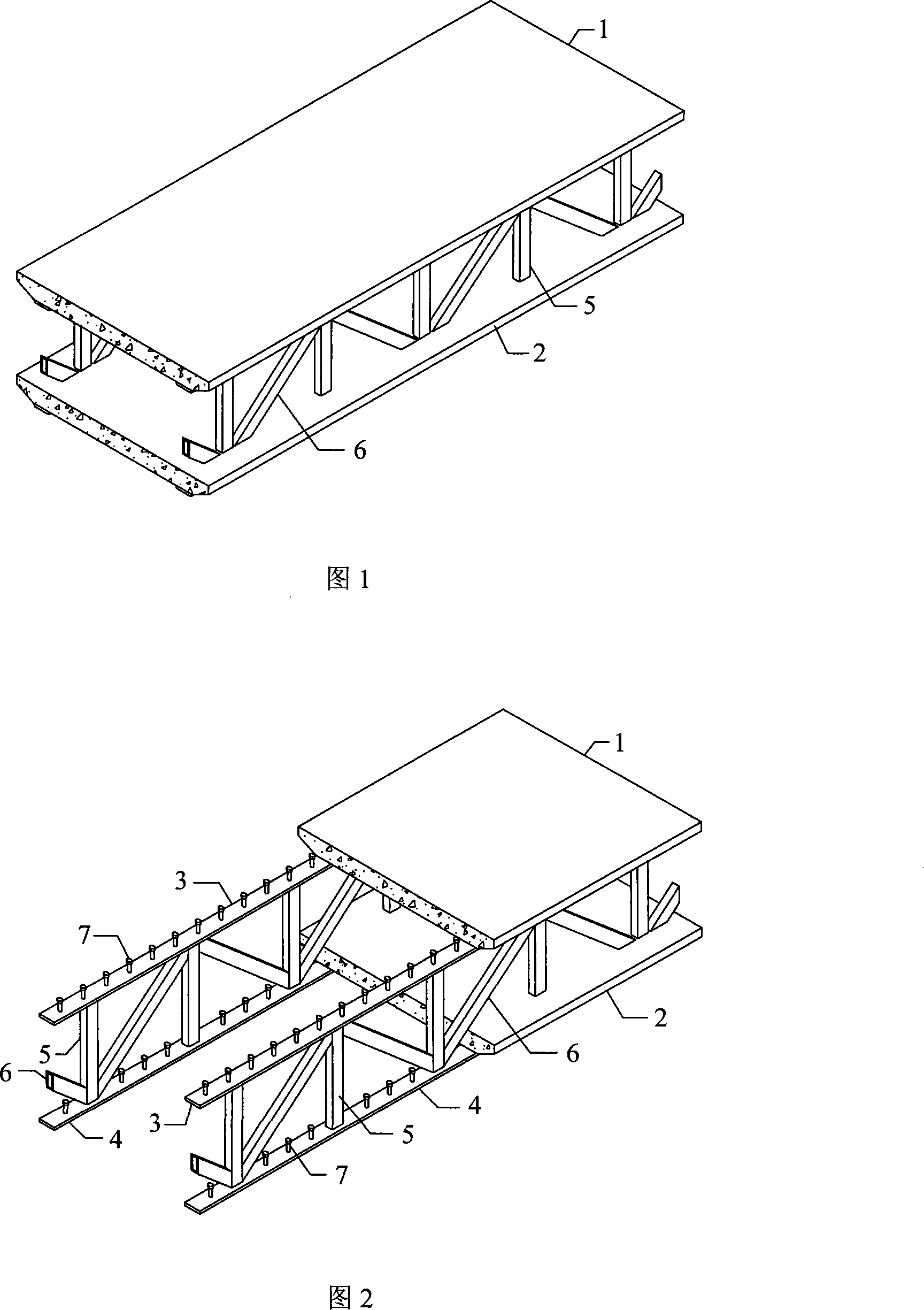

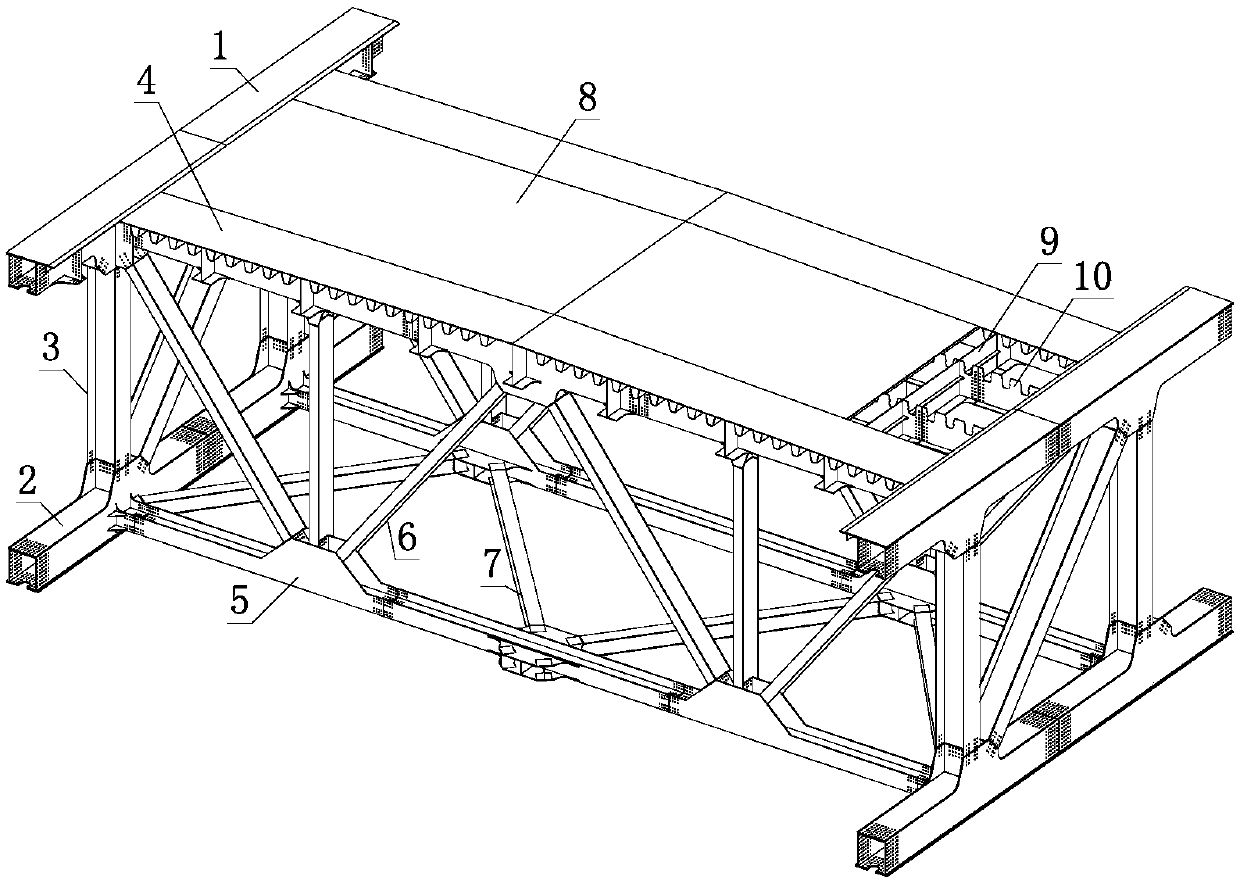

A kind of steel truss bridge and its manufacturing method

ActiveCN102277825AImprove stabilityImprove securityTruss-type bridgeBridge structural detailsBridge deckEngineering

The invention discloses a steel truss bridge and a method for fabricating the same. The steel truss bridge comprises a steel box girder bridge deck, a main truss composed of two steel trusses, and a steel portal frame. The steel truss comprises an upper chord member, a lower chord member, and a web member which is connected with the upper chord member and the lower chord member through bolts. A sidewalk bracket is arranged outside each steel truss. The lower chord member is connected to the steel box girder bridge deck and the sidewalk bracket, respectively. Besides, the two steel trusses are connected through the steel portal frame. During fabrication, all the sections of the steel trusses, the steel portal frame and the bridge deck are independently fabricated, respectively; all the sections of the upper and lower chord members of the steel truss are pre-assembled circularly with the corresponding web members, and all the sections of the steel box girder bridge deck are pre-assembled with the corresponding lower chord members by an orthotectonic method, respectively; and the steel portal frame is pre-assembled with the steel trusses. The steel truss bridge disclosed by the invention completely meets the design requirements so that the stability and safety factor of the bridge can be enhanced; and by employing the fabricating method, positioning is accurate so that the risks during the field assembling can be reduced; and the construction period can be shortened.

Owner:JIANGSU JINGHU HEAVY IND

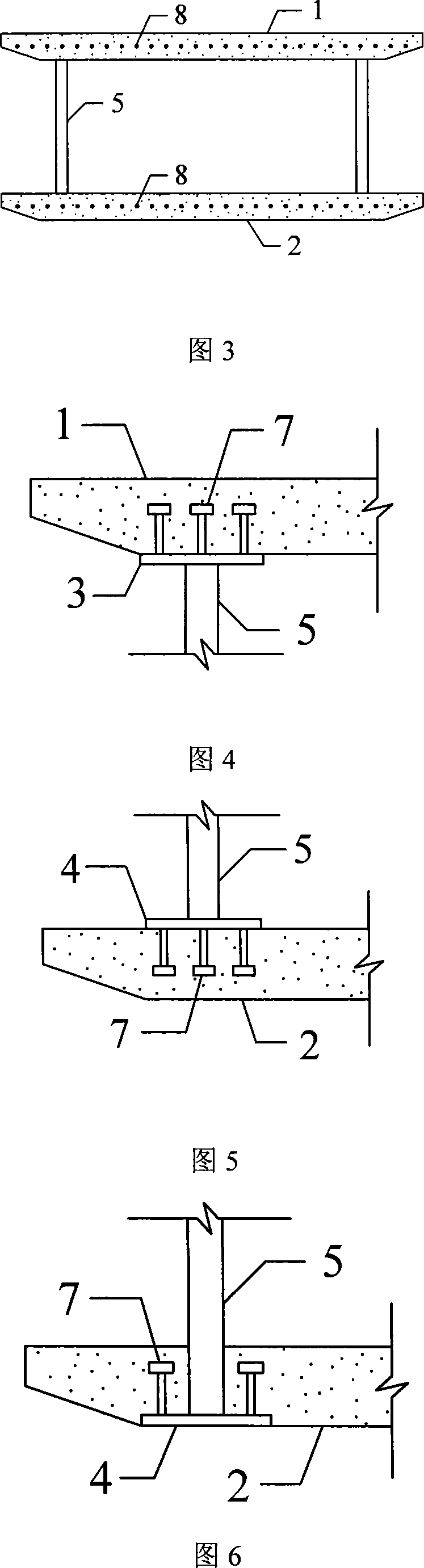

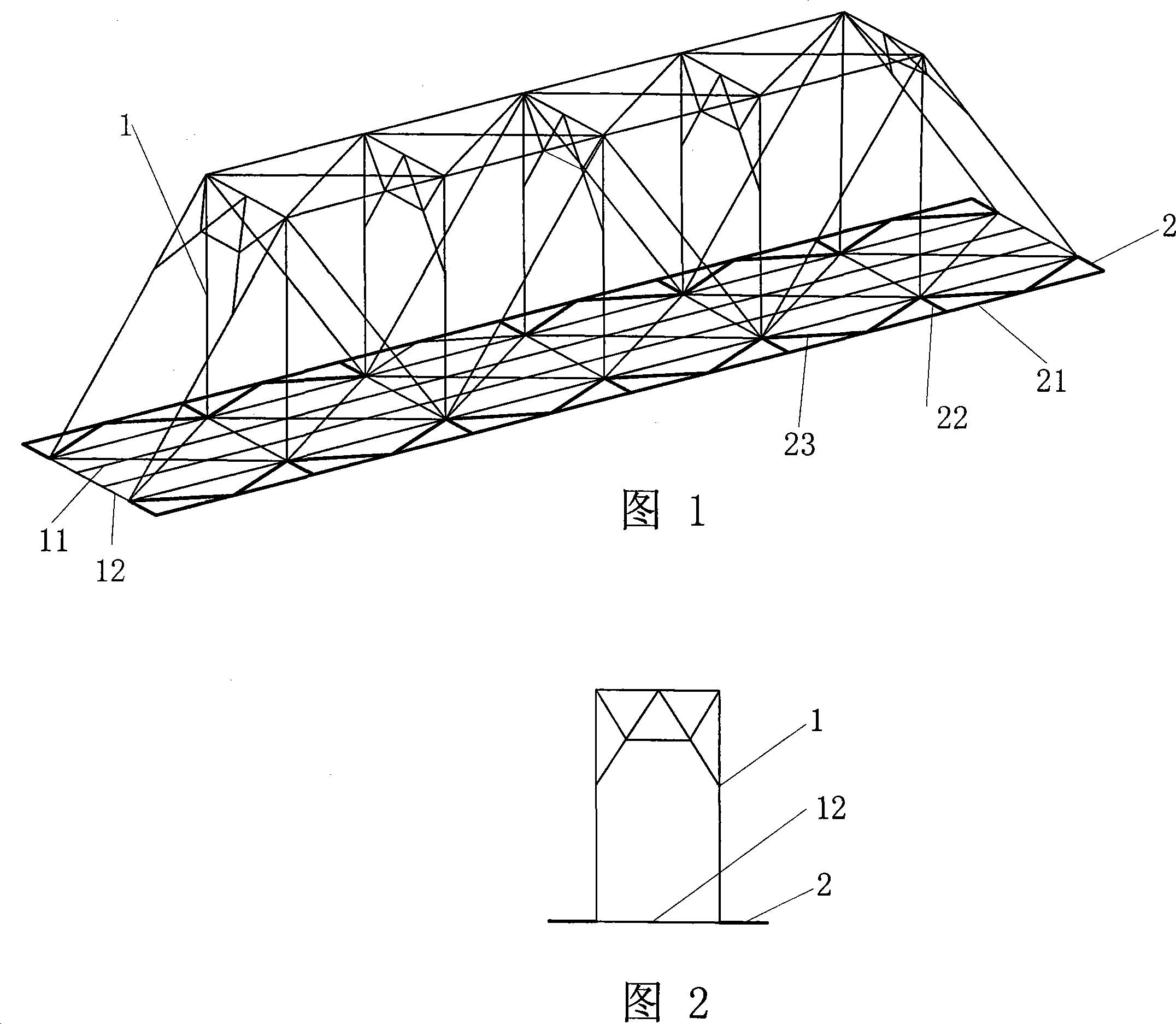

Double-deck bridge floor combined trussed girder bridge

InactiveCN101158143AIncrease capacityOpen sightTruss-type bridgeBridge structural detailsLow noiseBridge deck

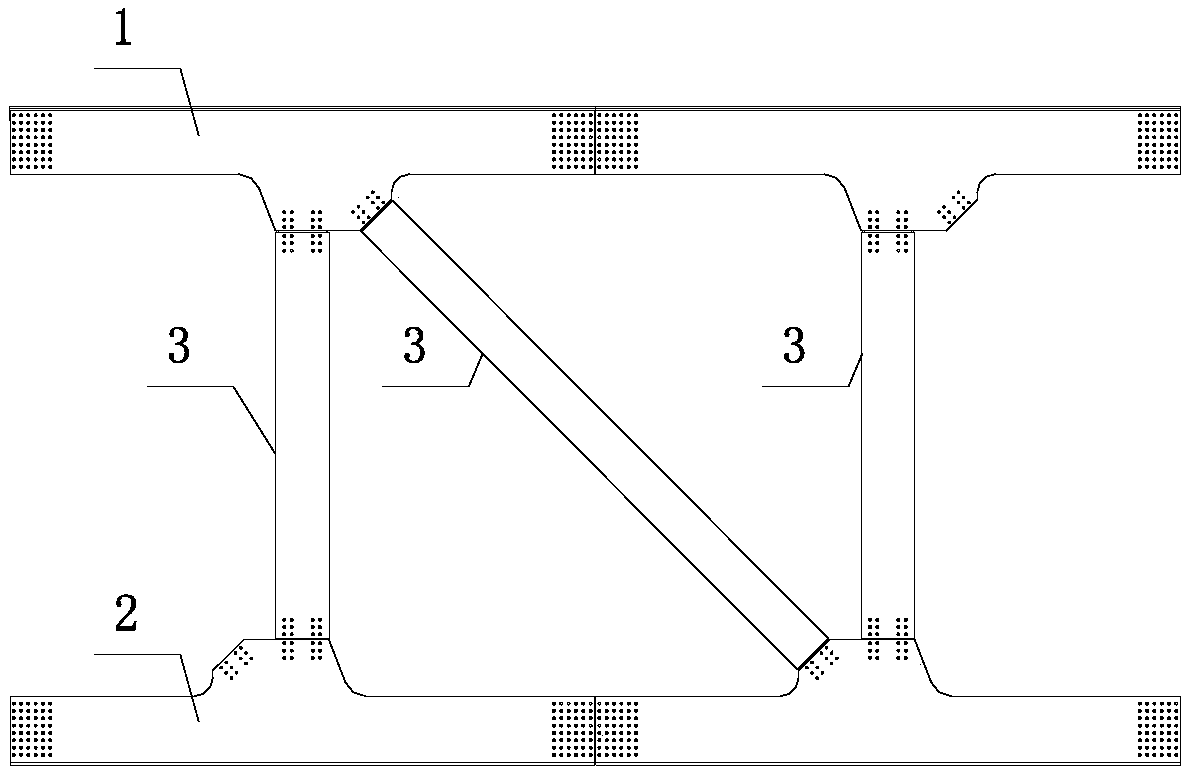

A combined truss bridge of double bridge decks relates to a novel bridge structure and the combined truss bridge of double bridge decks consists of an upper concrete bridge deck, a steel structure web member and a lower concrete bridge deck. The upper and lower bridge decks are used for bearing the load of vehicles and are used as an upper chord part and a lower chord part to share the global stress with the global structure. The steel structure web member consists of a slant web member and a vertical web member, and combines the upper and the lower concrete bridge decks as a whole to be used for resisting the shearing force of the truss bridge. The upper concrete bridge deck and the lower concrete bridge deck in tensile areas are provided with vertically stressed steel bars or section steel. The invention, compared with traditional single bridge deck combined girder bridges, enjoys greater traffic capacity and higher traffic comfort; compared with steel truss bridges, the invention remarkably reduces steel consumption by using concrete bridge decks as compression chords, and has the advantages of low noise, easy maintenance, good durability and so on.

Owner:TSINGHUA UNIV

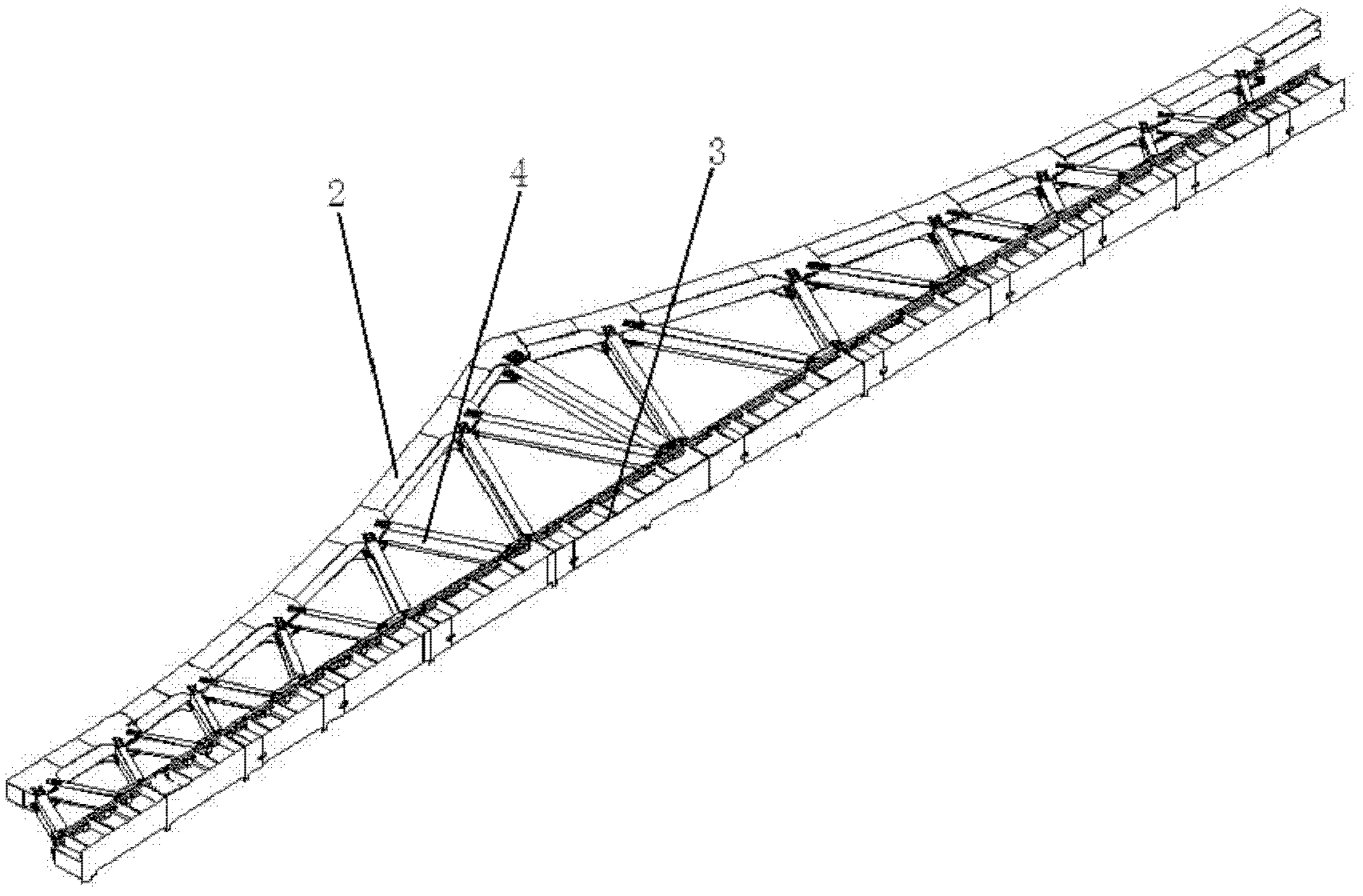

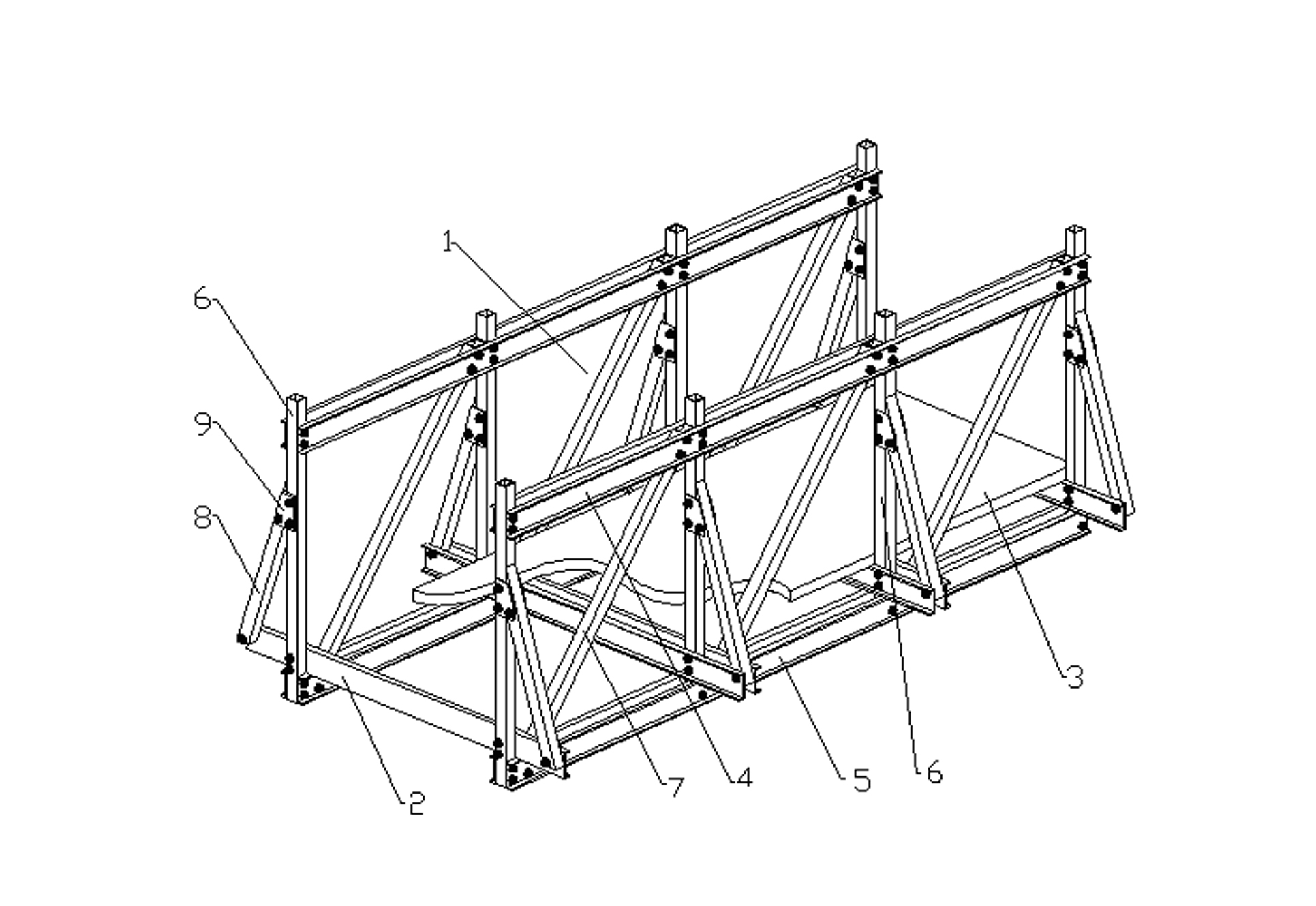

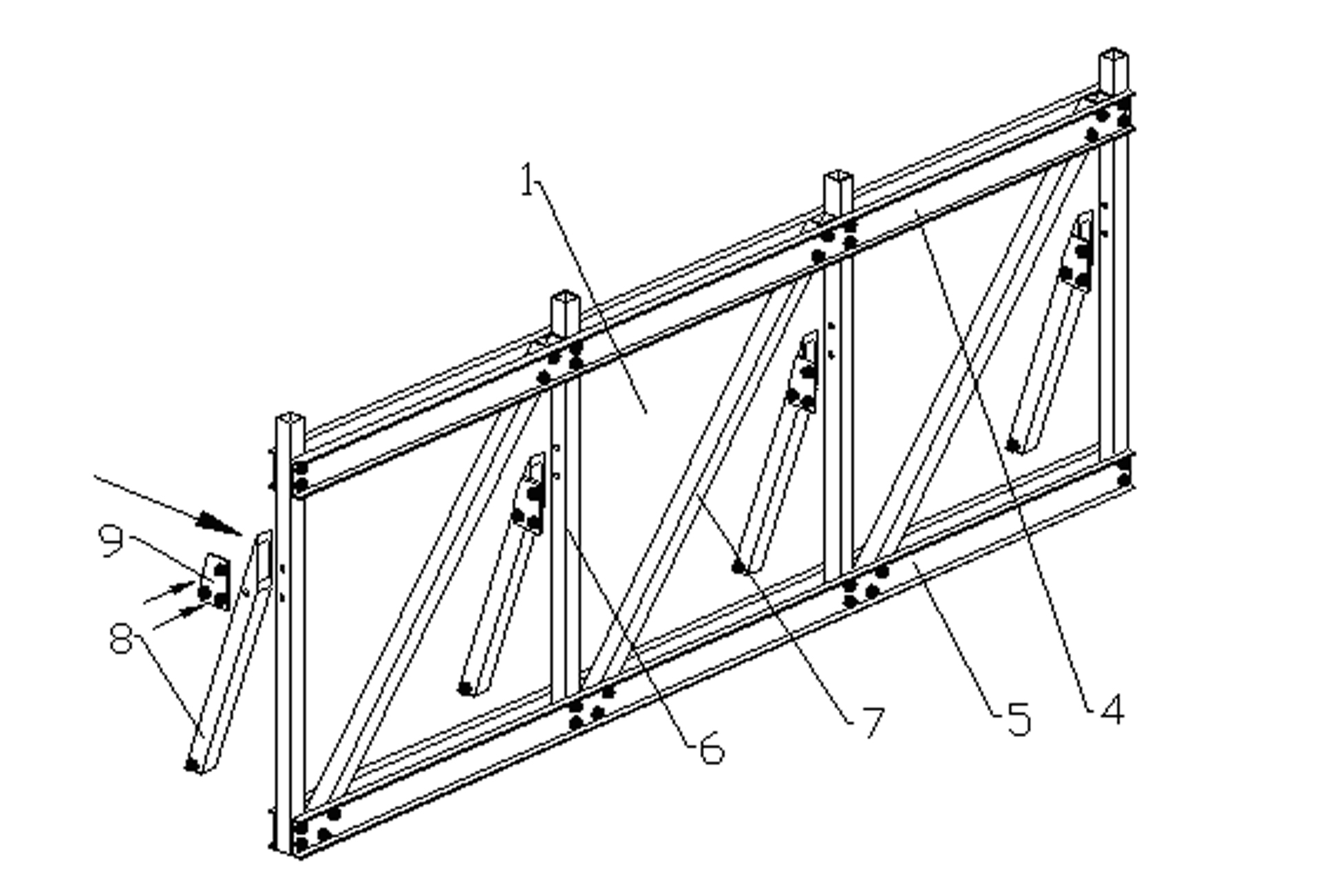

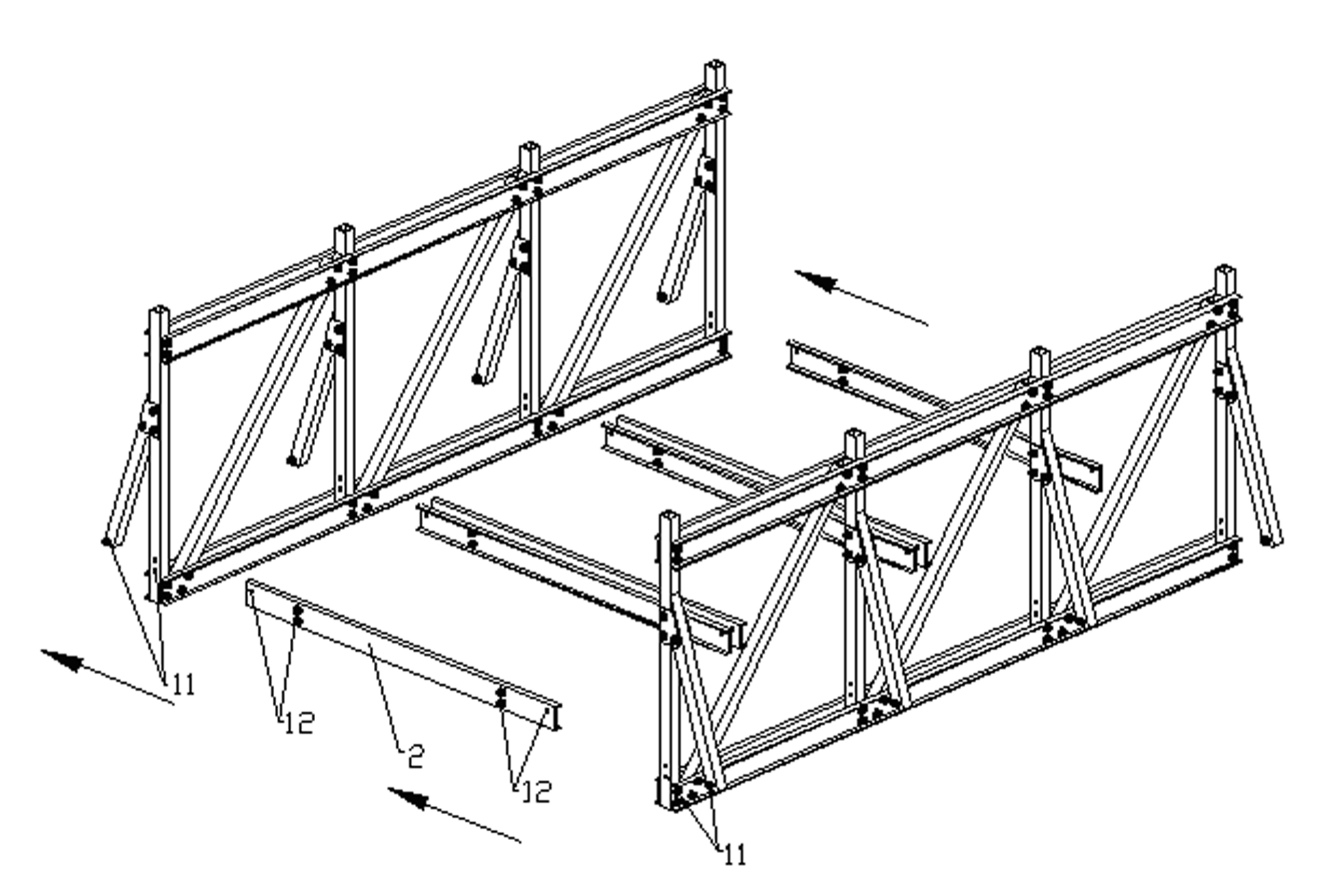

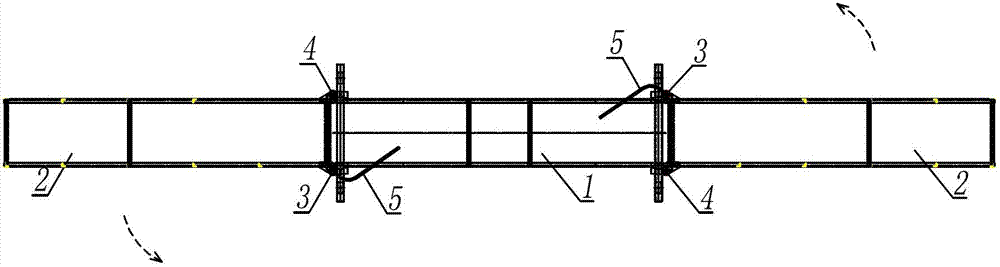

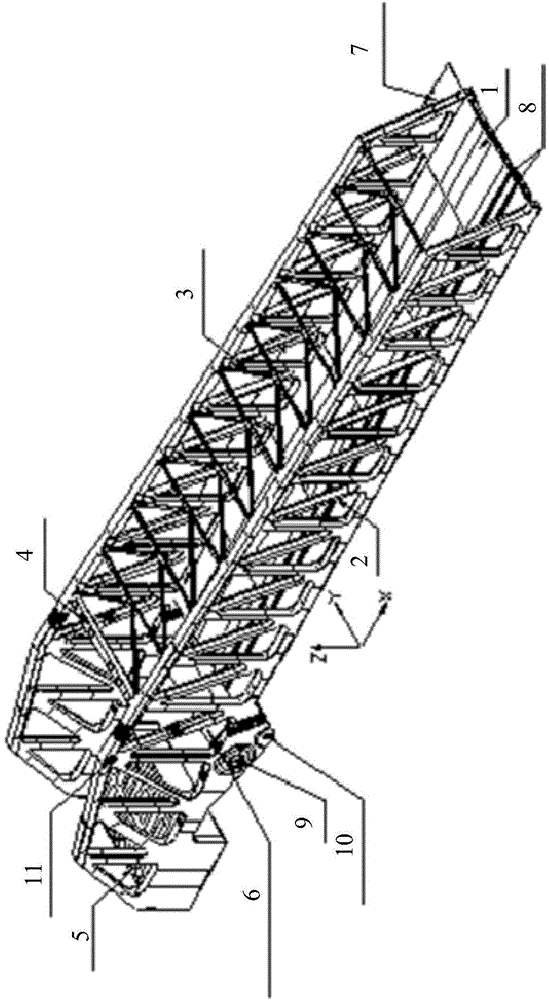

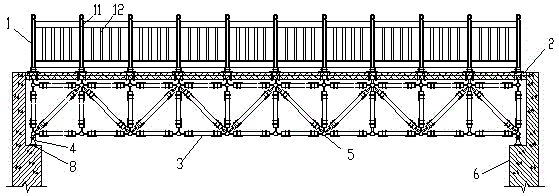

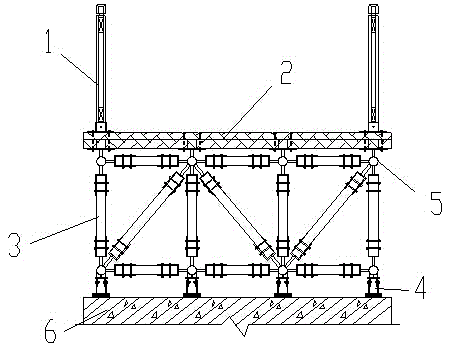

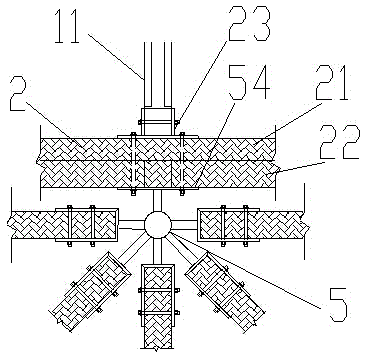

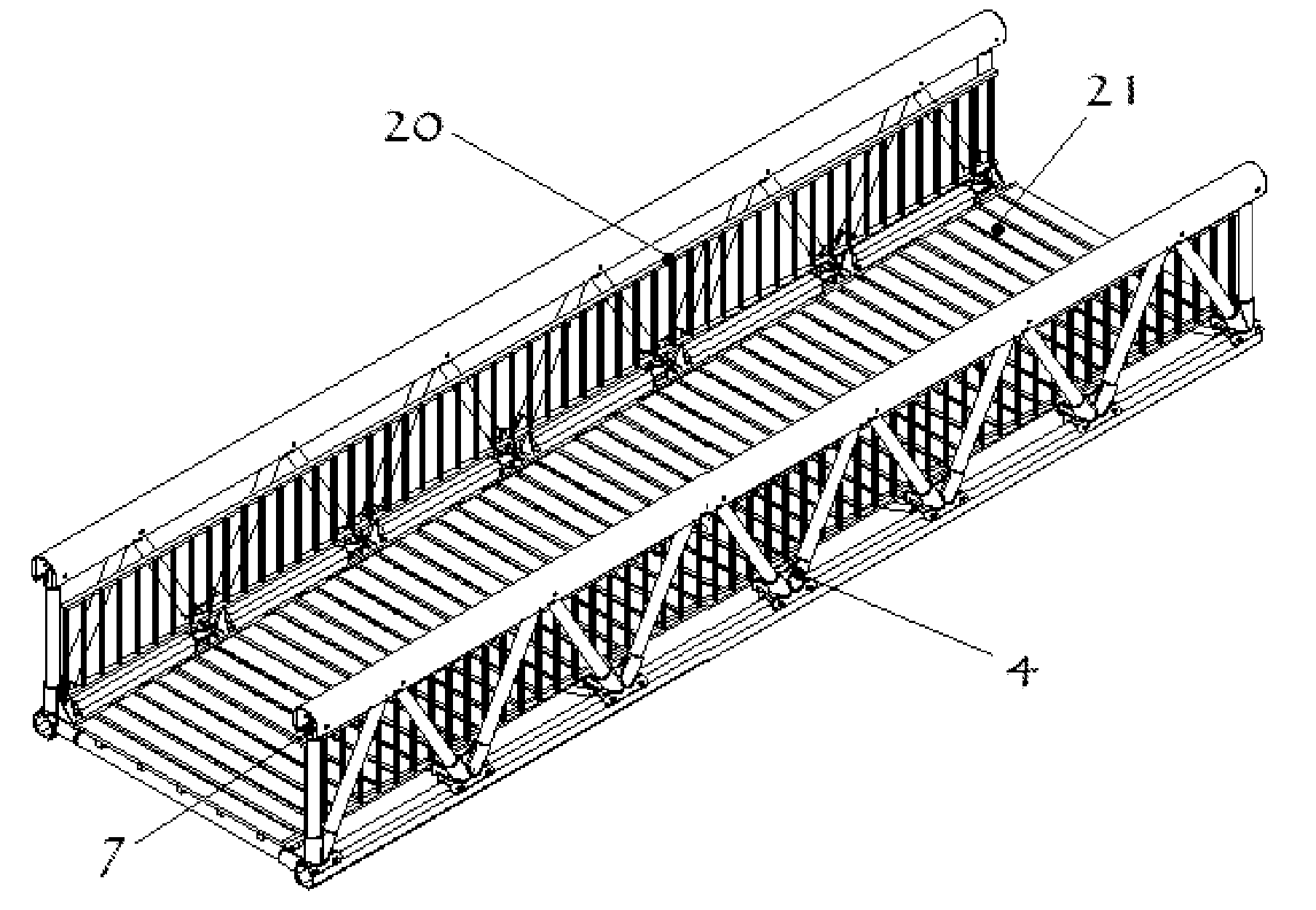

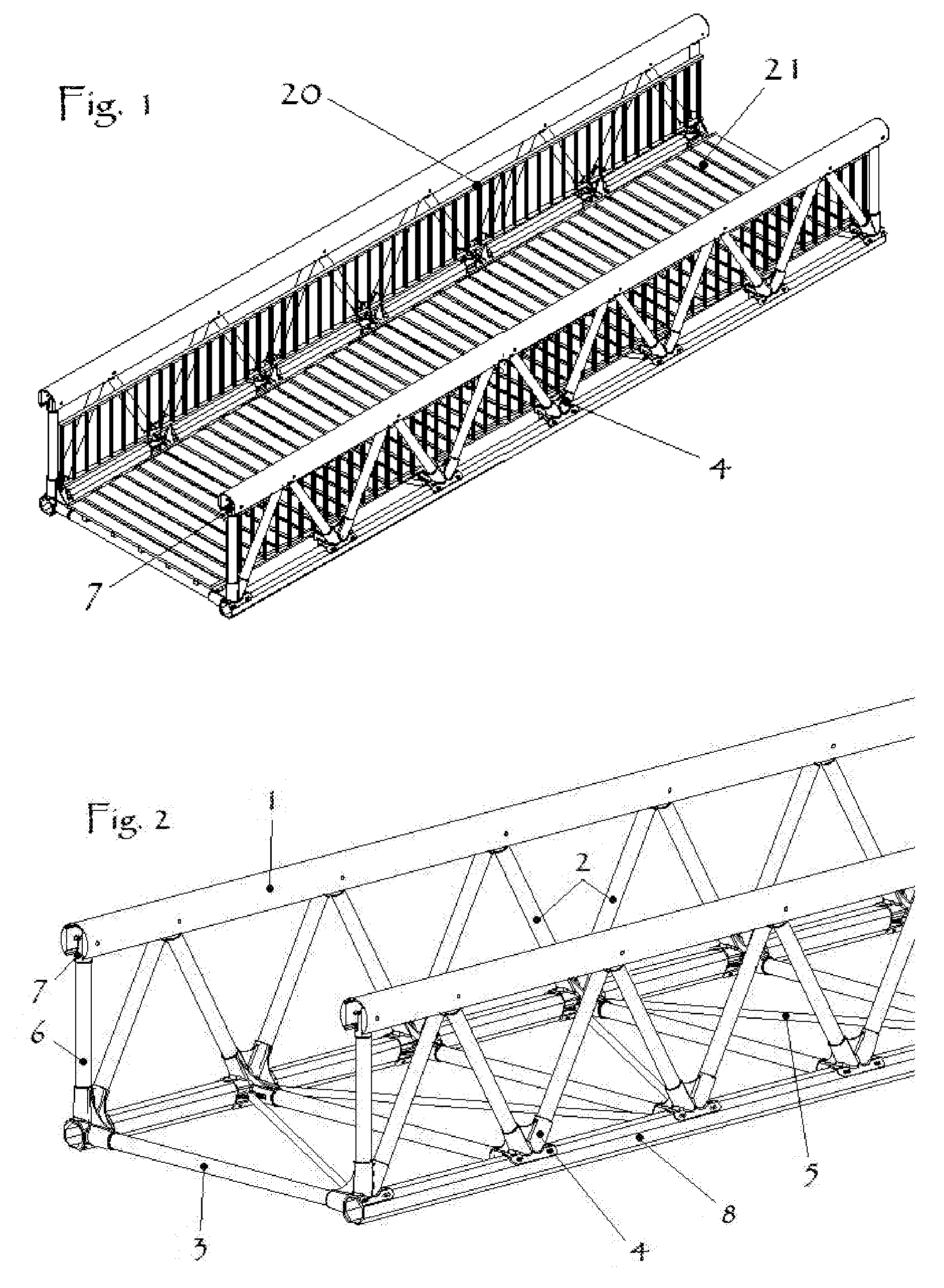

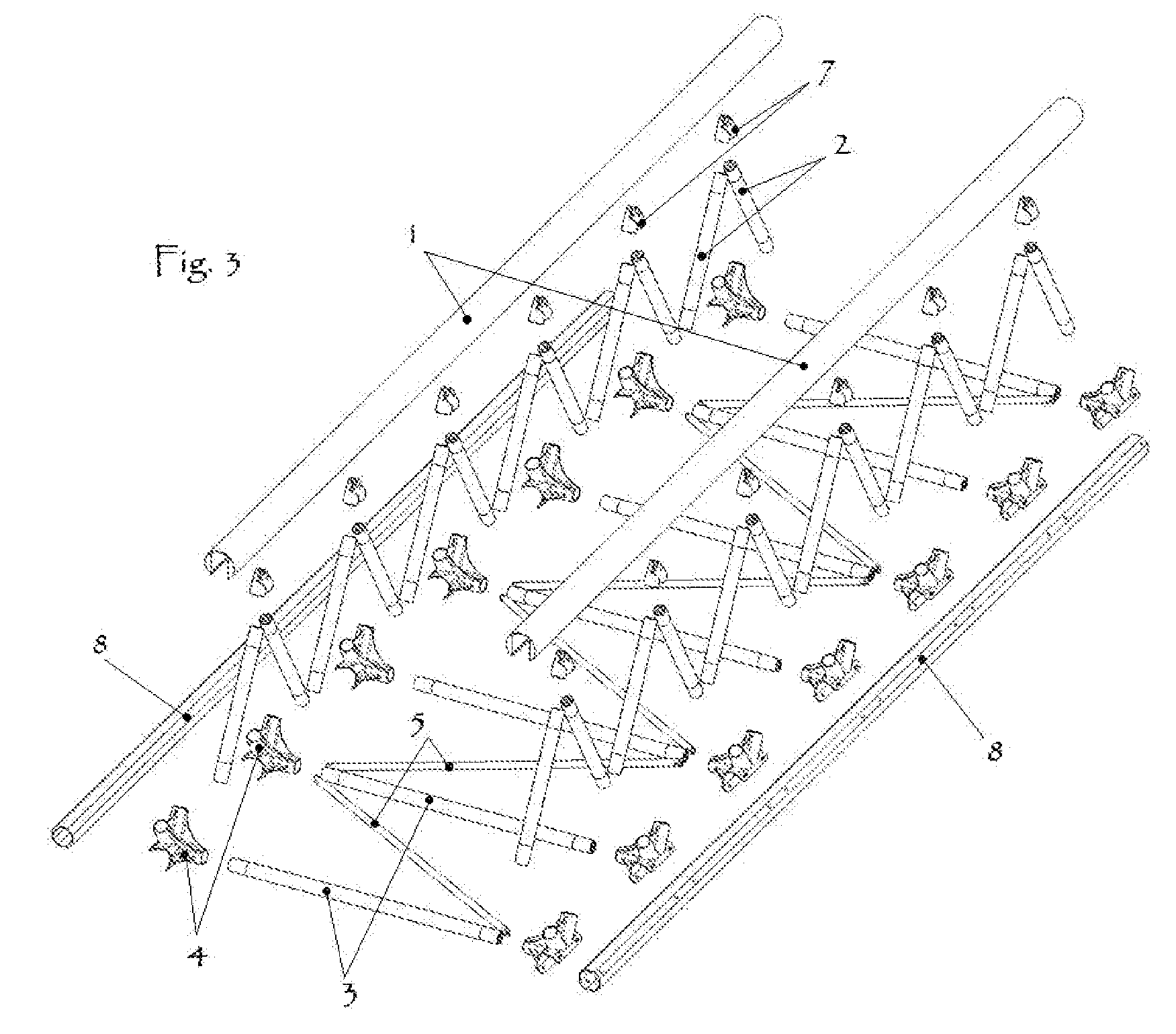

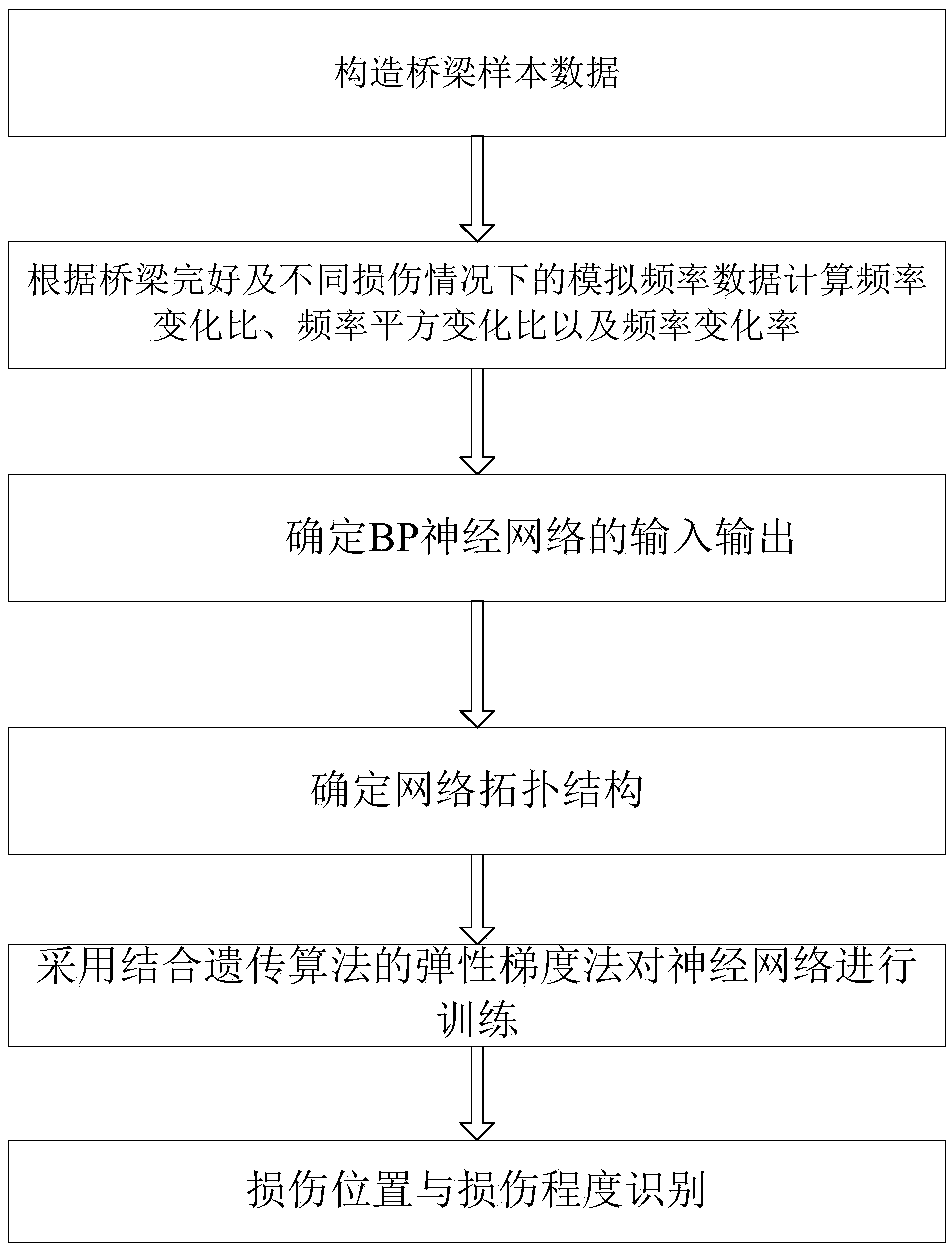

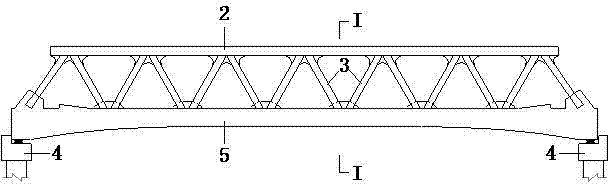

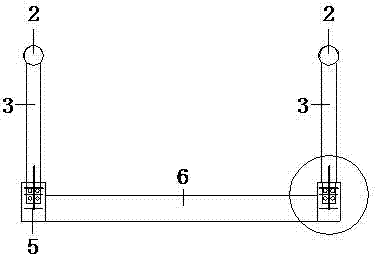

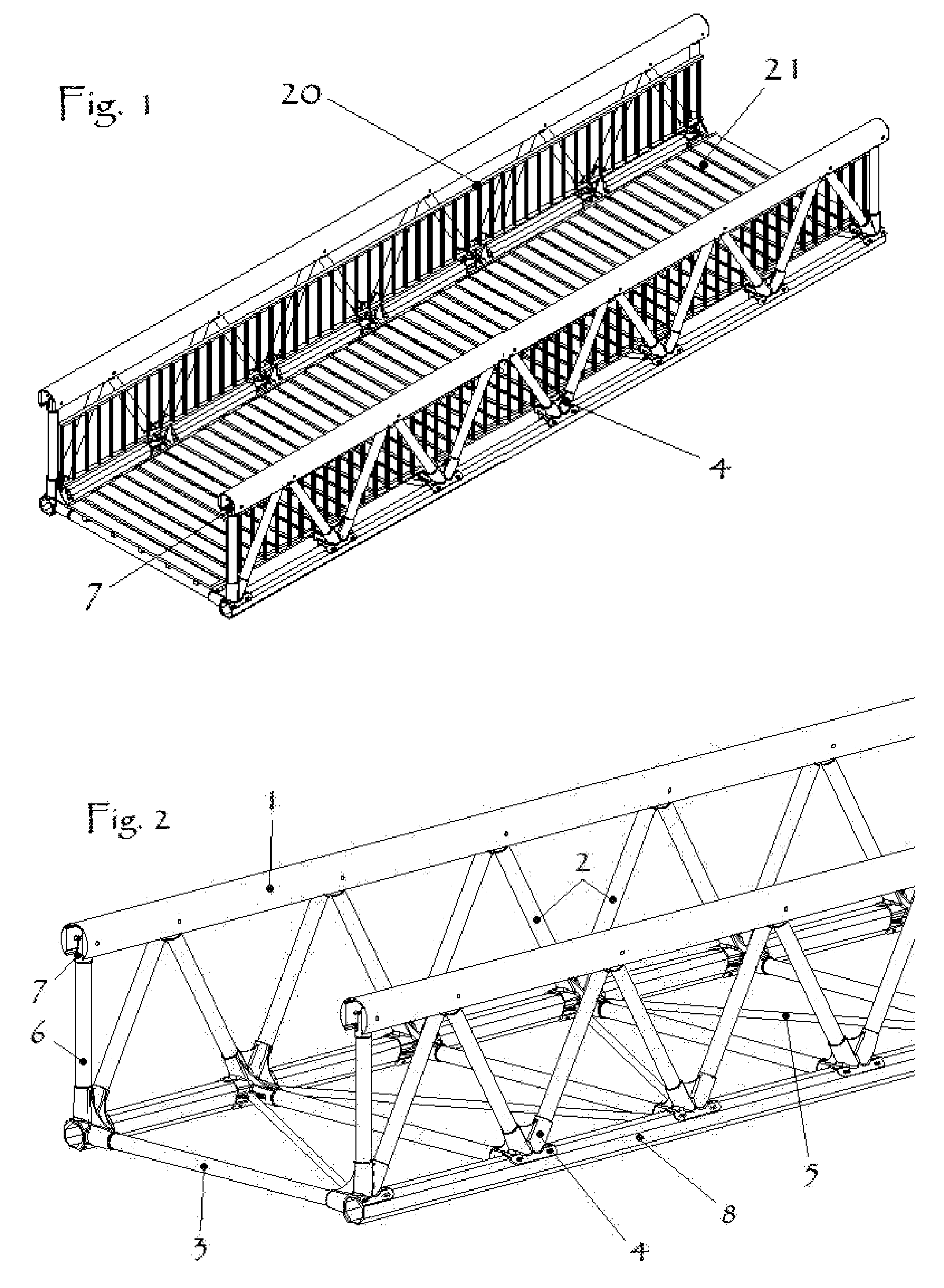

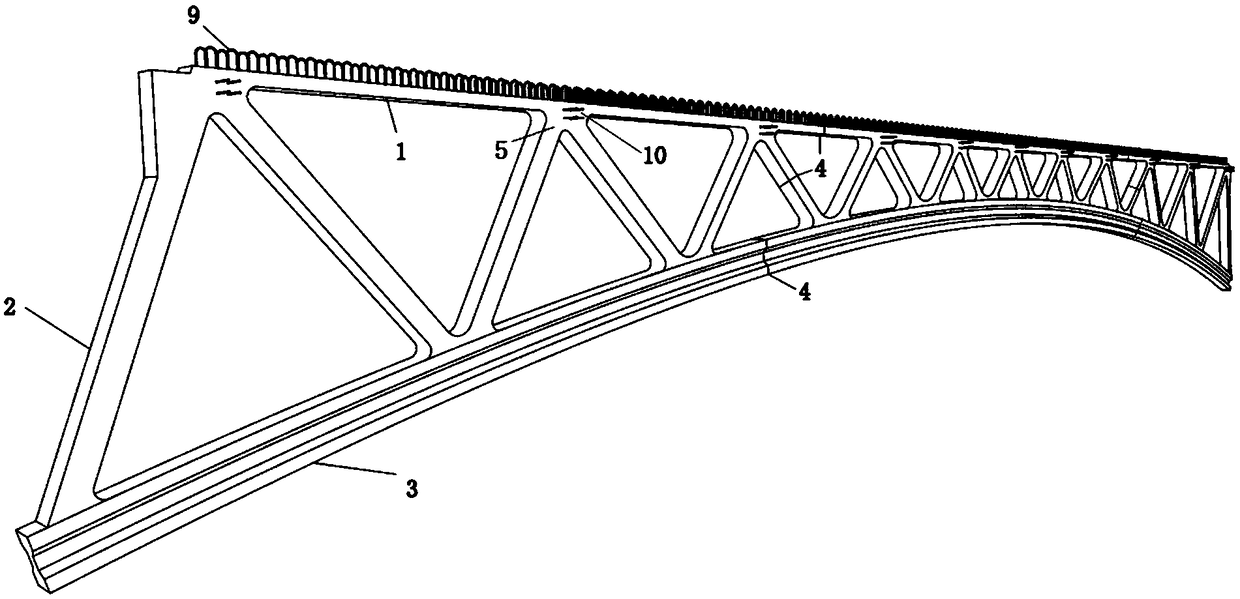

Quick-spliced sectional type composite material truss bridge

InactiveCN101967793AEliminate cracking, steel corrosion and other problemsLight in massTruss-type bridgeEmergency rescueBridge deck

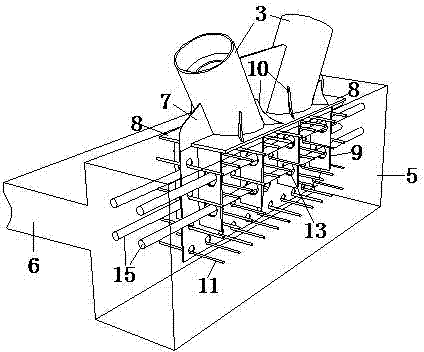

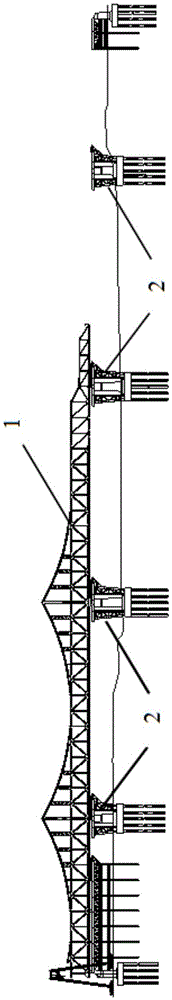

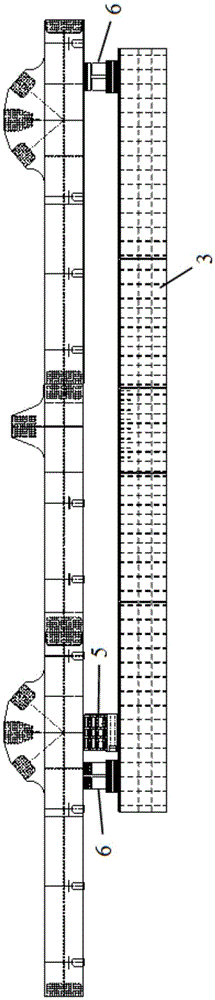

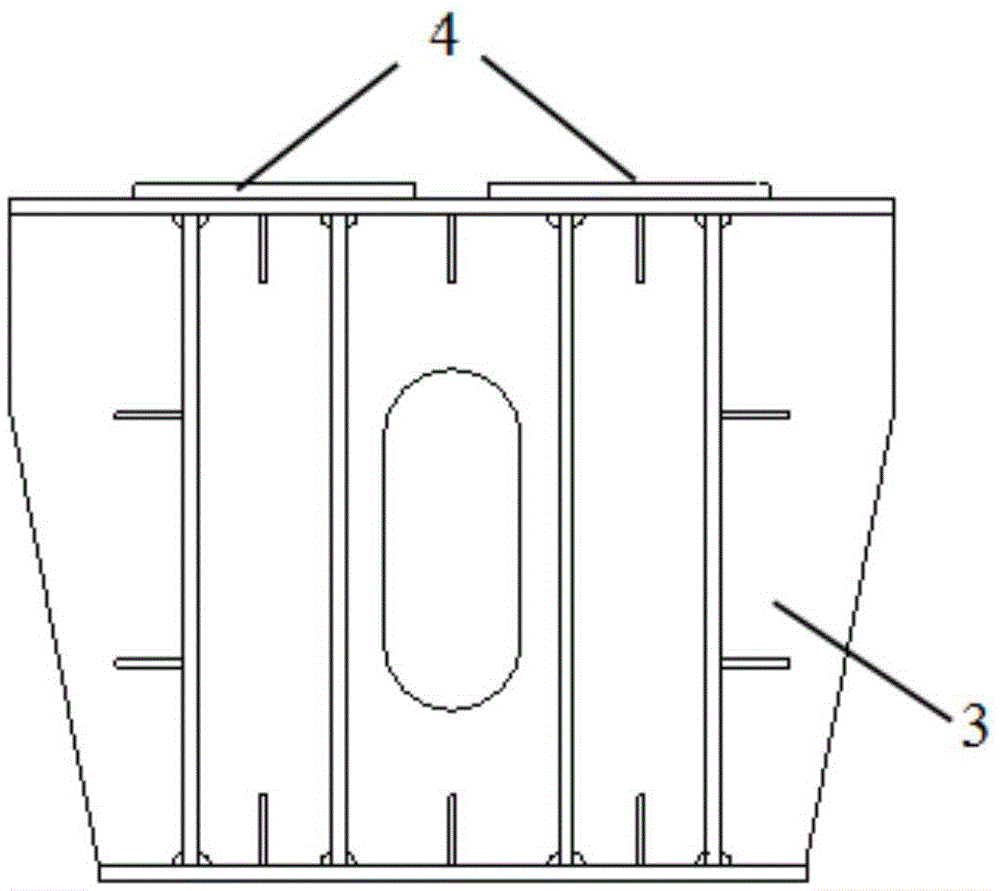

The invention relates to a quick-spliced sectional type composite material truss bridge which comprises facade trusses (1), cross beams (2) and bridge decks (3), wherein each facade truss (1) is composed of an upper chord beam (4), a lower chord beam (5), vertical web girders (6) and inclined web girders (7); the upper chord beam (4) and the lower chord beam are arranged in parallel on the facade and respectively fixed with the upper and lower ends of each vertical web girder (6); each inclined web girder (7) is slantly arranged between every two adjacent vertical web girders (6), and the upper and lower ends of each inclined web girder (7) are respectively fixed with the upper chord beam (4) and the lower chord beam (5); both ends of each cross beam (2) are respectively fixed with two vertical web girders (6) parallel to the facade trusses (1) on the corresponding sides; and each bridge deck (3) is arranged on each cross beam (2) to constitute a truss bridge unit. The invention applies fiberglass reinforced plastics to the entire truss bridge and adopts flexible sectional type design, thus, the invention has the advantages of light weight, shock resistance, corrosion resistance, and convenient and quick transportation and assembly, and has wide application prospects in emergency rescue.

Owner:NANJING UNIV OF TECH

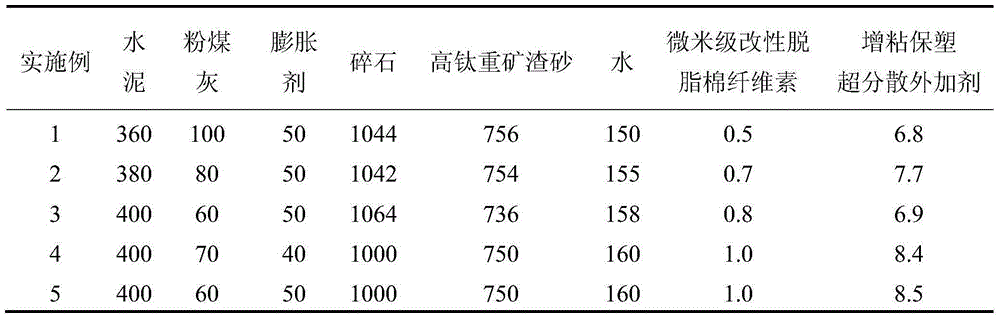

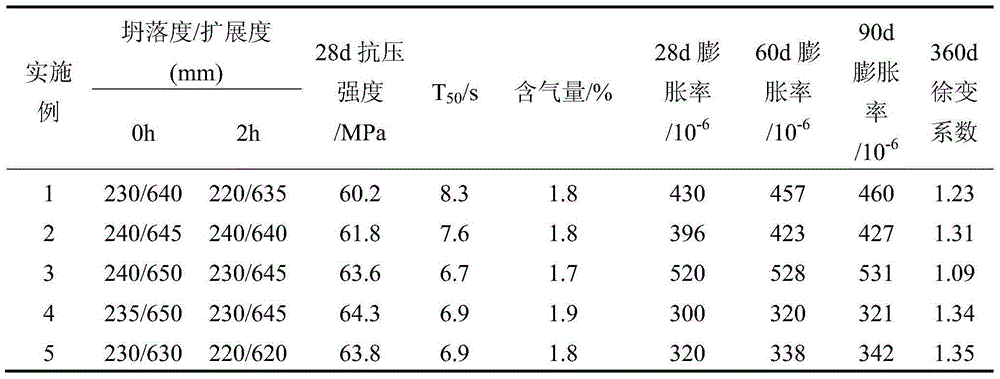

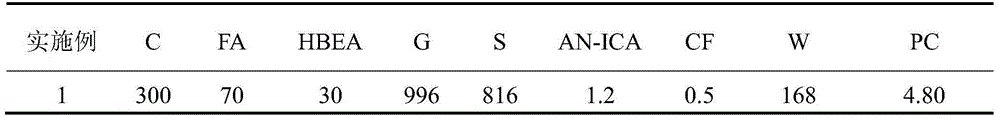

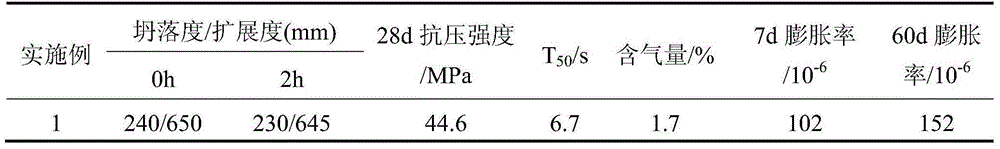

High titanium-bearing heavy slag C50 self-compacting weakly expansive concrete-filled steel tube and preparation method thereof

ActiveCN105060793AImprove cementing performanceFull hydration activitySolid waste managementCelluloseCompensation effect

The invention discloses a high titanium-bearing heavy slag C50 self-compacting weakly expansive concrete-filled steel tube, and belongs to the field of building materials. The concrete-filled steel tube is prepared from the following raw materials: cement, coal ash, composite expanding agent, macadam, high titanium-bearing heavy slag, a tackifying plasticity-maintaining super-dispersing additive, micron-sized modified absorbent cotton cellulose and water. The prepared concrete-filled steel tube has the characteristics of high flow state, low gas content, large strength extra coefficient and stable expansibility; the problem of poor working performance caused by application of high titanium-bearing heavy slag to concrete is solved; due to the water absorption and water releasing effect of the porous structure, the internal maintenance effect on the concrete-filled steel tube can be realized, the shrinkage compensation effect of the expanding agent on the concrete-filled steel tube is improved, the concrete-filled steel tube is weakly expansive to be suitable for jacking pouring of upper chord pipes and lower chord pipes of a concrete-filled steel tube arched bridge and a concrete-filled steel tube truss bridge, as well as high-casting pouring of a concrete-filled steel tube pier column. Therefore, the problem of disengaging caused by poor-density pouring of the concrete-filled steel tube is solved effectively.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

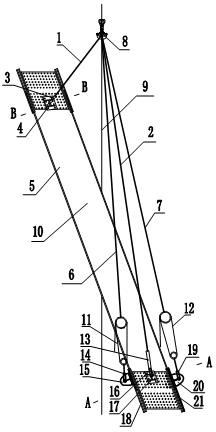

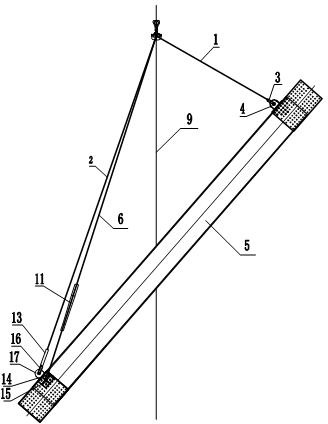

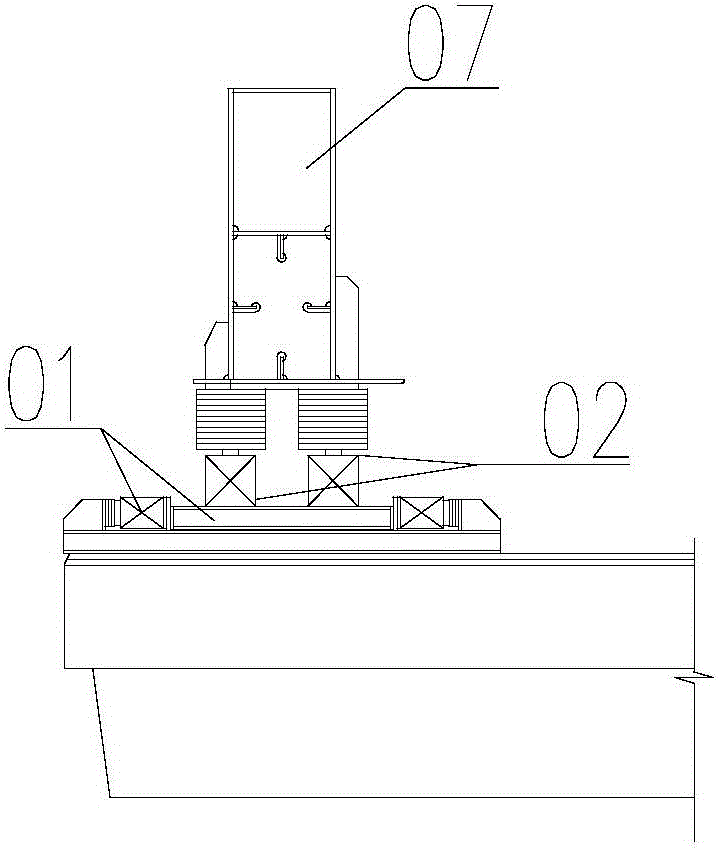

Suspender capable of adjusting spatial angle of rod member of steel truss bridge

InactiveCN102556835ASuccessful erectionHoisting safetyBridge erection/assemblyLoad-engaging elementsEngineeringVertical axis

The invention discloses a suspender capable of adjusting the spatial angle of a rod member of a steel truss bridge. The suspender comprises a main bearing and adjusting device and an auxiliary adjusting device, wherein, the main bearing and adjusting device comprises an upper main bearing lifting rope, an upper snap ring, an upper hanger, a lower bearing lifting rope, a lower heavy type turn buckle, a lower snap ring and a lower hanger, and the auxiliary adjusting device comprises a left auxiliary adjusting lifting rope, a left leading chain, a left snap ring, a left hanger, a right auxiliary adjusting lifting rope, a right leading chain, a right snap ring and a right hanger. According to the invention, the weight of a spatial angle web member is mainly borne by the two main bearing lifting ropes, an included angle between the vertical axis of the spatial angle web member and a horizontal plane is adjusted through the lower heavy type turn buckle, the transverse space horizontal angle of the spatial angle web member is adjusted through the left and right leading chains, and therefore, the purpose of adjusting the spatial angle of the spatial angle web member is realized. The suspender is especially applicable to hoisting of a spatial angle web member of an inclined main girder steel truss bridge and has the advantages of simple construction, definite bearing, convenient operation and high working performance.

Owner:THE 5TH ENG MBEC

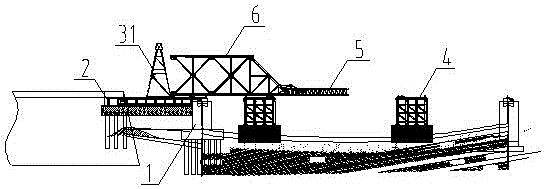

Integral welding closure method for large orthotropically combined steel truss bridge

ActiveCN102091886AGuaranteed integrityIncrease the speed of the dragonWelding/cutting auxillary devicesAuxillary welding devicesBridge deckTower

The invention relates to an integral welding closure method for a large orthotropically combined steel truss bridge, which comprises the following steps: setting a closure temperature according to closure construction hoisting time, measuring the closure gap at the temperature, jointing closed sections according to the result of the measurement, hoisting the closed sections by using four deck derrick cranes to a position, regulating the closed sections to put the closed sections in place, and after a closure temperature is reached and the closed sections are put in place, locking the closed joint by using a temporary locking device and eliminating the longitudinal locking of a girder at the position of a main tower to perform welding construction. In the invention, the closure time and closure temperature are reasonably determined, the length of the closed sections is accurately measured, the closure seam clearance is controlled to meet welding requirements, a welding process under constraints is evaluated, the reasonable welding process and sequence are determined, the reasonable temporary locking device is arranged, locking is performed after the closure gap meets requirements, welding is performed, and thus, the large-section integral welding closure is realized.

Owner:SHANGHAI FOUND ENG GRP

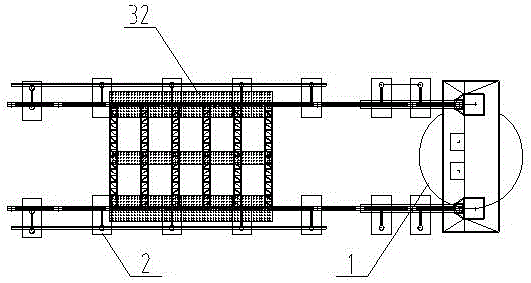

Novel bridge inspection vehicle

InactiveCN102733300ASimple structureEasy to manufactureBridge structural detailsBridge erection/assemblyCoupling systemCantilever

The invention relates to a novel bridge inspection vehicle, which is a travelling crane applied to inspection of the inner side or bottom of a truss bridge in a manner of a rotary folding vehicle body. The inspection vehicle body is composed of a middle vehicle body and additional vehicle bodies on cantilevers at two sides together, wherein the vehicle body and the additional vehicle bodies are mutually connected through a rotating hinge and a fixing pin, and a wheel mechanism is arranged above the vehicle body. The inspection vehicle walks and works under the track on which the bridge is vertically arranged in an unfolding manner in general; a hand shank is rotationally opened and closed when the inspection vehicle comes across a lateral coupling system member in a truss or a pier support; and the additional vehicle bodies on the cantilevers at two sides horizontally rotate oppositely, and are overlapped on the front and back parts of the vehicle body, and the vehicle body is folded and shortened into 1 / 3 of original length and then traverses an obstacle. According to the invention, an inspection work surface is expanded and the inspection vehicle can extend to the outer side of the truss to work. The distance between the tracks is wide, and the vehicle body and the tracks are directly connected by the wheels, so the inspection vehicle is stable in structure when walking and working. The novel bridge inspection vehicle has the advantages of being simple in structure, convenient to use, economic and practical, and has been successfully applied to engineering practice.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

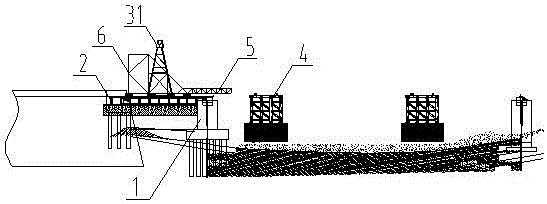

Wide span variable girder high continuous steel truss bridge cantilever erection mid-span closure construction method

InactiveCN105951609AAvoid adjustmentEnough drop beam spaceBridge erection/assemblyMiddle lineCantilever

The invention discloses a wide span variable girder high continuous steel truss bridge cantilever erection mid-span closure construction method. The method includes the steps: steel beams are lifted by a certain height in advance, an erection process is controlled, and pre-adjustment is performed after closure; a vertical deviation and the angle of a closure opening can be eliminated through the method that main piers of side pier falling beams are not erected; steel beam closure can be achieved through the method that the middle line of the bridge and a mileage deviation is adjusted by various main pier top deviation correction devices. The wide span variable girder high continuous steel truss bridge cantilever erection mid-span closure construction method can solve the problem of erection mid-span closure construction that the installation erection devices are not arranged under the closure opening in wide span steel truss mid-span closure.

Owner:STEEL STRUCTURE CONSTR CO LTD OF CHINA TIESUU CIVIL ENG GRP

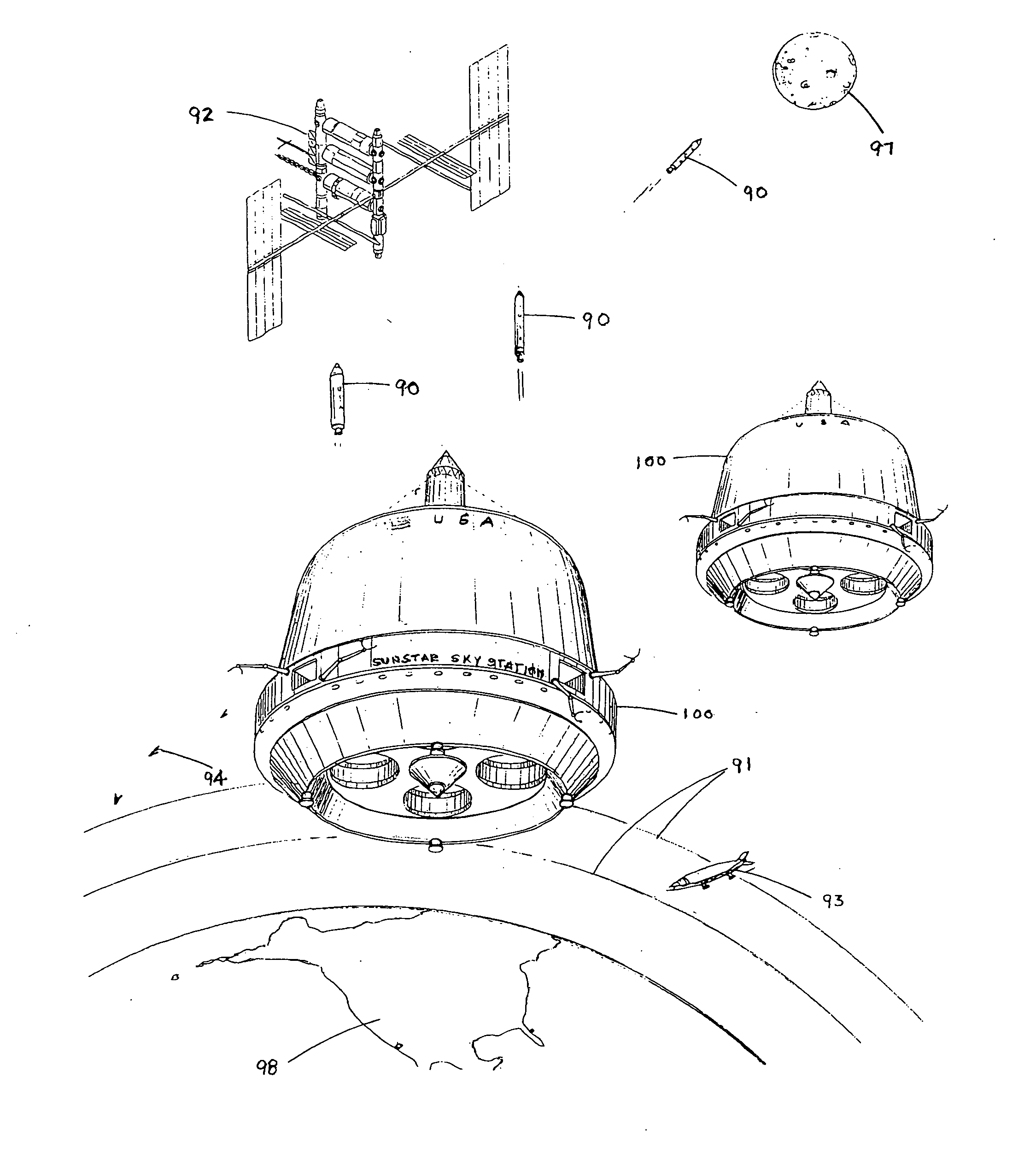

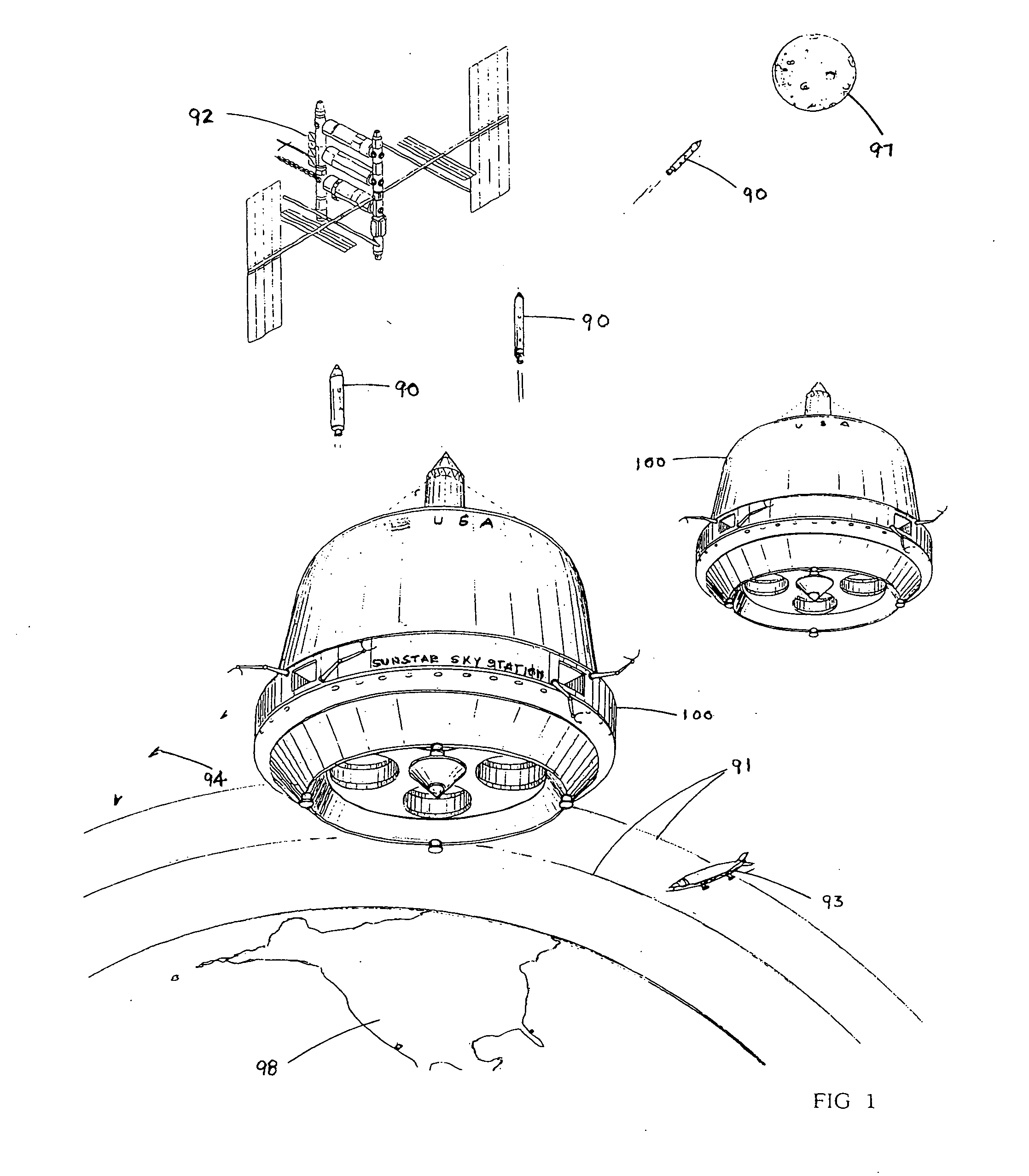

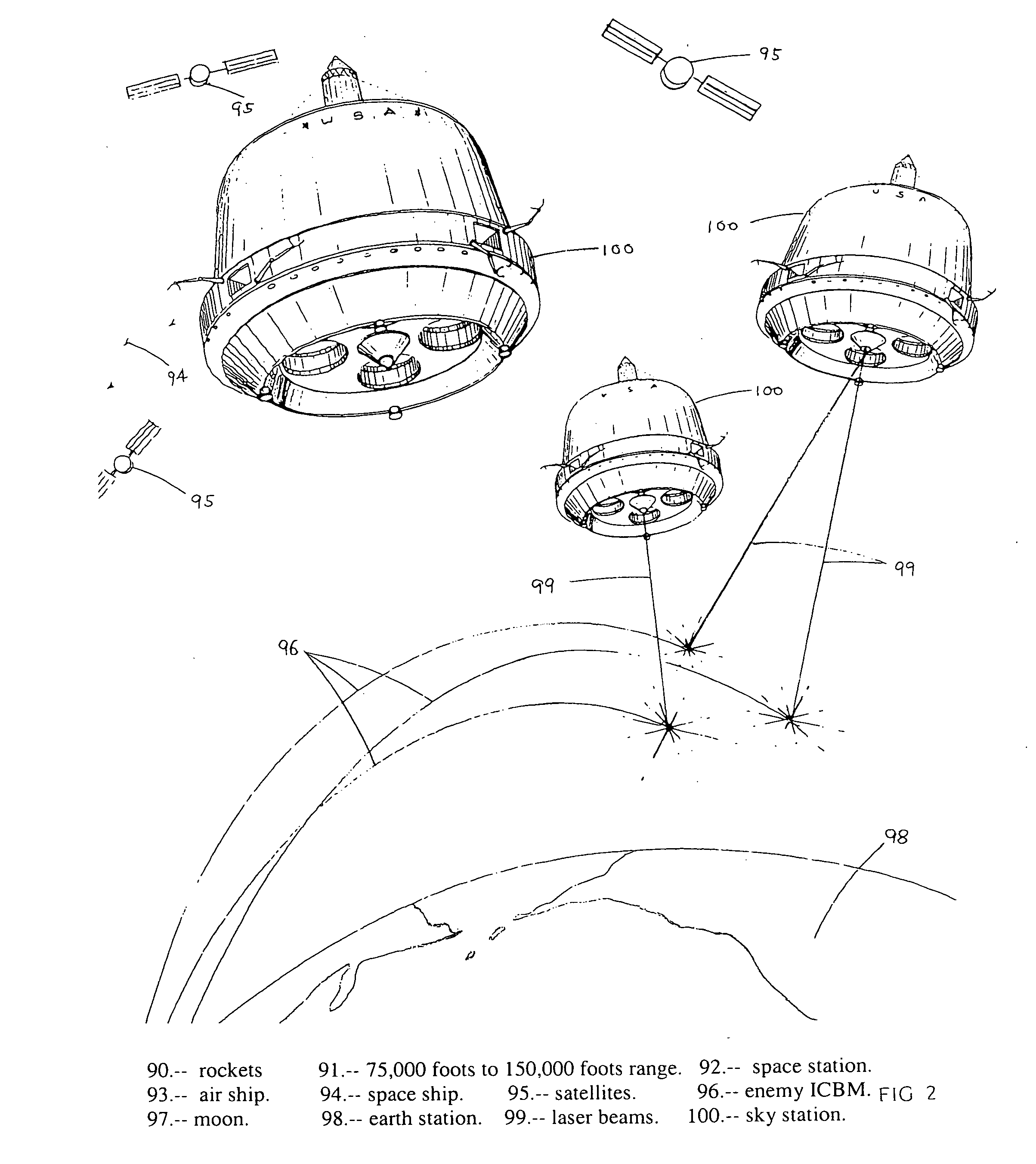

Sky station

InactiveUS20110114792A1Large capacityFully functionalCosmonautic vehiclesNon-rigid airshipsFiberCarbon fibers

Sky station structure comprises circle center core structure and circle outer Ring structure which comprises multi floor section levels.Major center core structure center elevator provide transportations from bottom Cockpit floor levels to top cockpit floor levels.First section levels of multi floors provide cockpit, control office, passenger Compartments, bed rooms, food service compartments, lavatory rooms, landing Pads, rope with winching machines and jet and rocket fuel tanks.Second section levels of multi floors provide center elevators, circle center Hangers, large circle outer ring hangers, jet and rocket power plants at outer Ring structures, inner docking and outer docking bays, multi robotic arms at Outer walls of docking bays,Third section levels of first floor levels provide center elevators, cylindrical Multi soft envelopes from floor levels to top levels of floors, cylindrical carbon Fiber honey comb composite outer envelopes from floor levels to top levels of Floors, multi envelopes of each envelope filled pressurized helium gas which Make it float at atmosphere.Third section levels of outer ring structure provide center post from floor to top Truss structure, cylindrical multi soft envelopes from floor levels to top of Truss structure, large cylindrical carbon fiber honey comb composite outer Envelopes from floor levels to top levels center truss structure, each envelope Floor zone need floor gate for repair and Inspection works.Fourth section levels comprises large circle outer truss structure, top of truss Bridge connected from center core structure to top of outer truss structure.Fifth section levels of top floor structure provide top cockpit and top control Tower.Also guy wire anchor at center of top control tower to top truss of outer Ring structures.

Owner:IM SUNSTAR

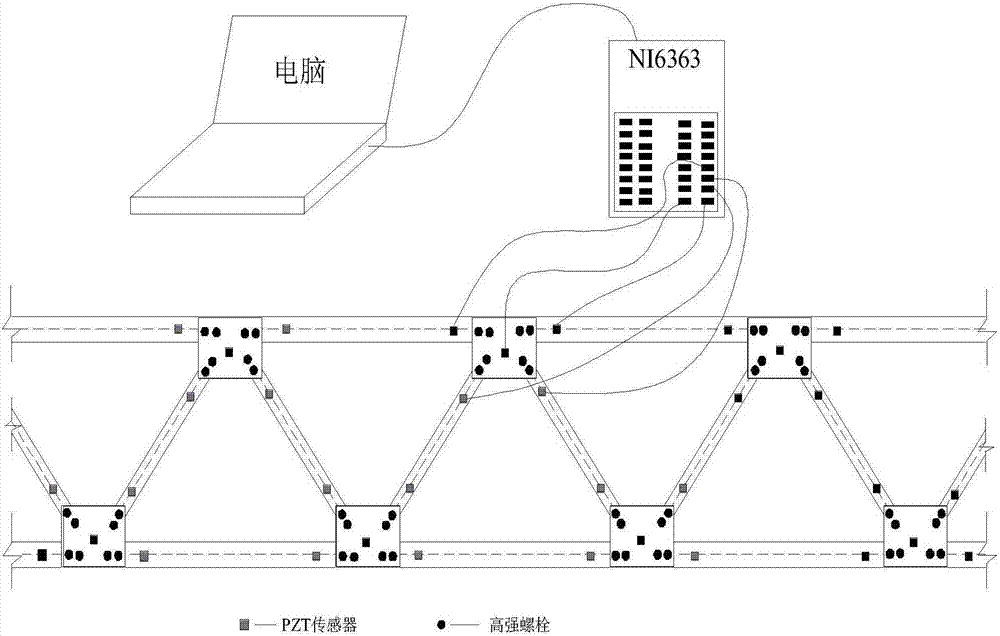

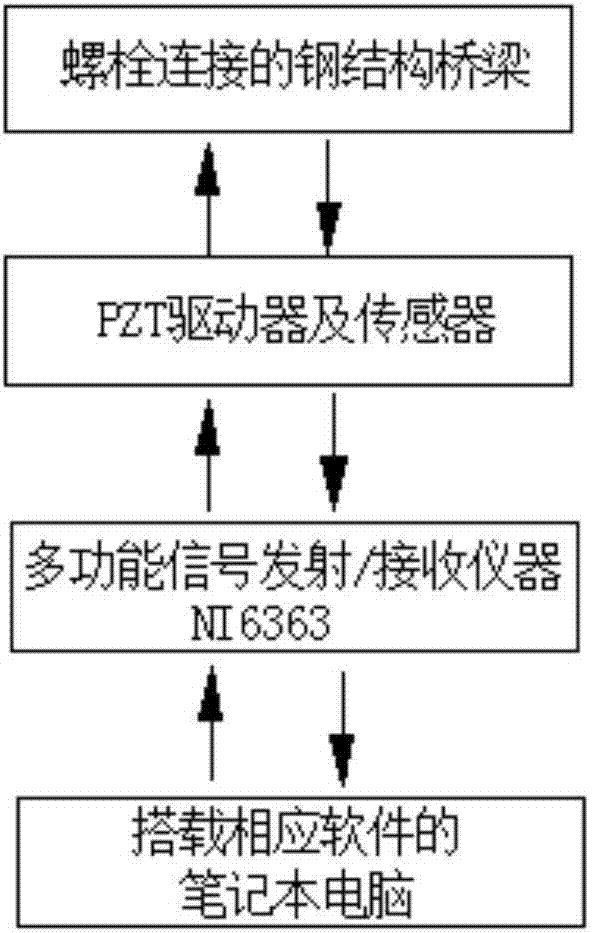

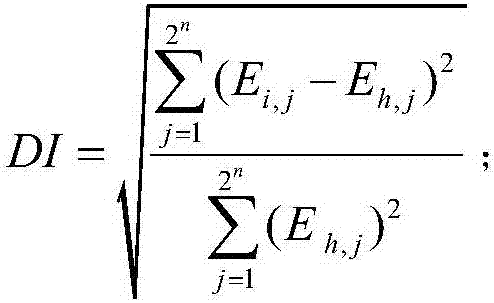

Method of monitoring high-strength bolt health of steel truss bridge key component

InactiveCN106909733ALow costEasy to operateGeometric CADDesign optimisation/simulationElectricityHigh intensity

The invention discloses a method of monitoring the high-strength bolt health of a steel truss bridge key component. In the use process of the high-strength bolts, there often exist the damage problems of bolt looseness, bolt rustiness, and bolt shearing failures. The piezoelectric bi-directional characteristics of the piezoelectric ceramic are utilized, and wide frequency bands, fast response piezoelectric ceramic actuators and piezoelectric ceramic sensors are made, through the response to the signal amplitude and energy changes, the health status of the high strength bolt is monitored and evaluated; based on the energy of the response signal, damage indicators of the same order of magnitude are defined, and further analyses and decisions are made on the damage conditions of the bolt. The health monitoring method has the characteristics of being low in cost, simple and quick in operation, and high in accuracy and the like, and is very suitable for the health performance monitoring of high strength bolts for steel truss bridges.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

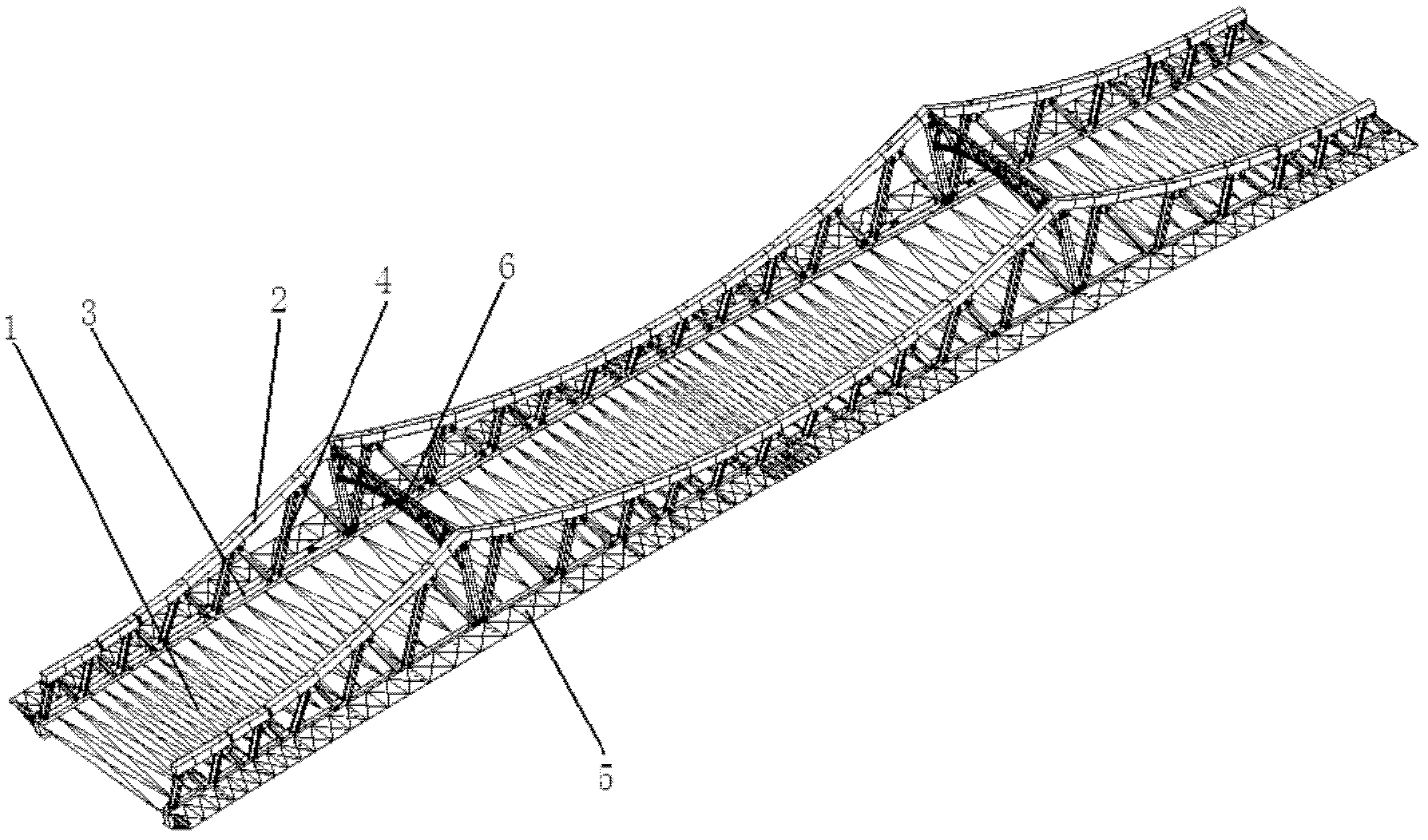

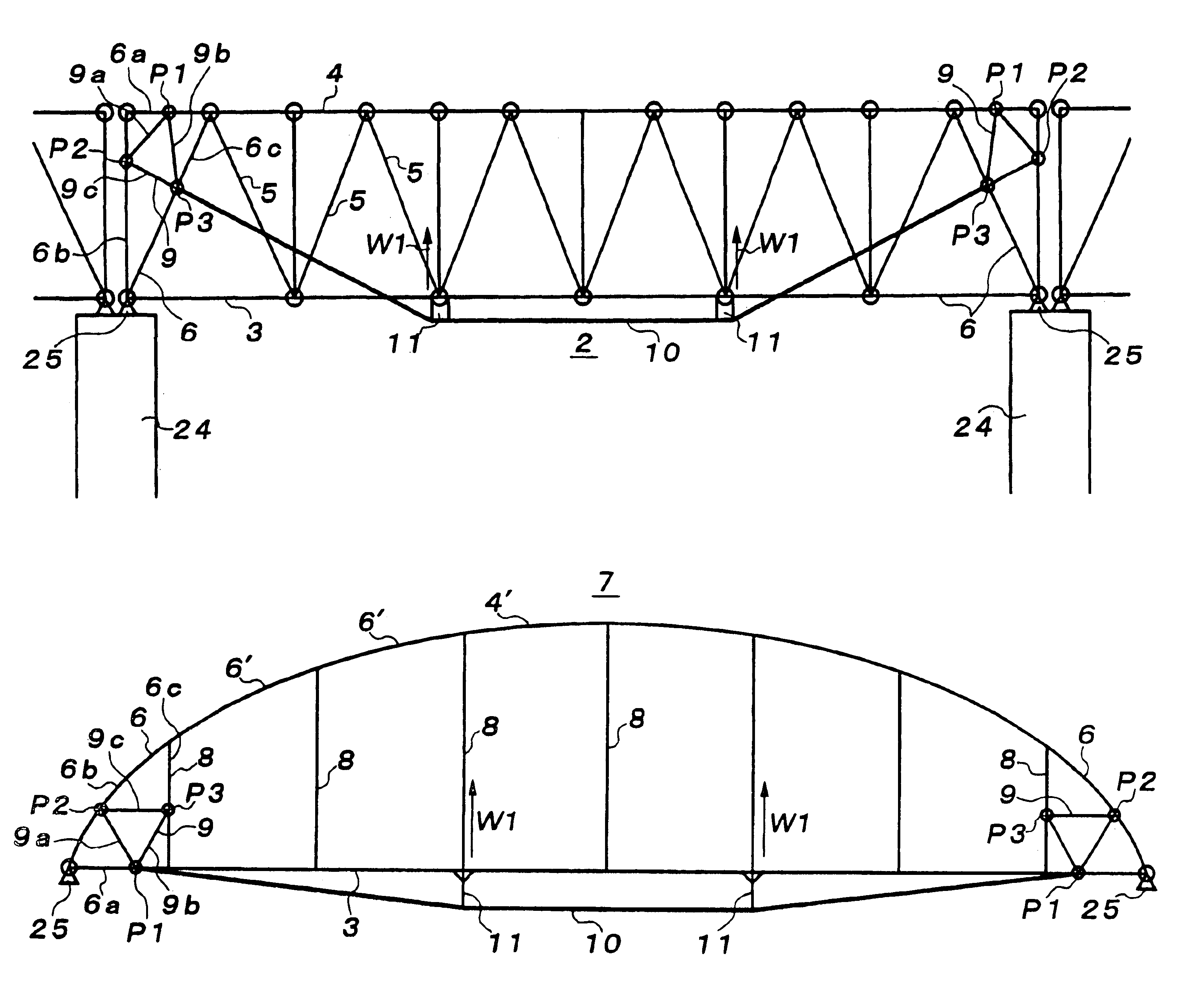

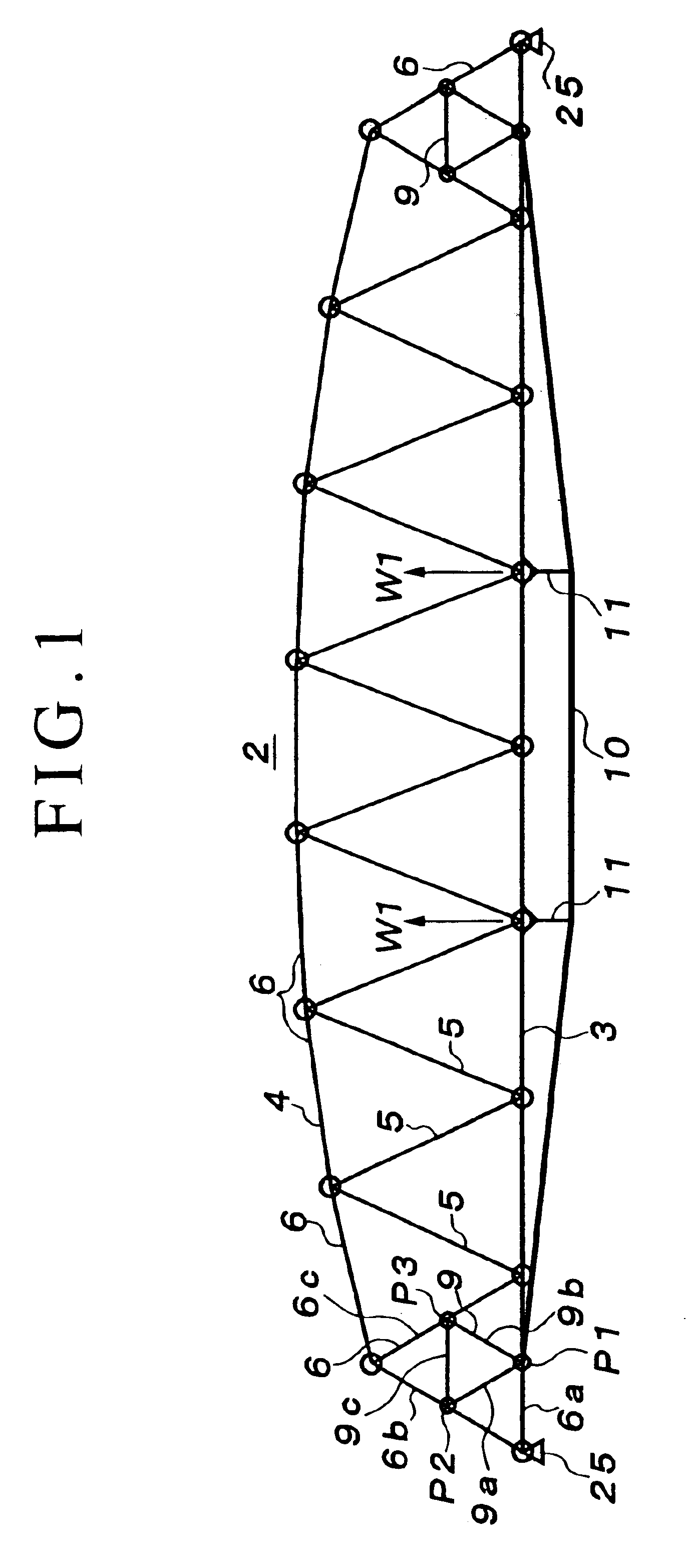

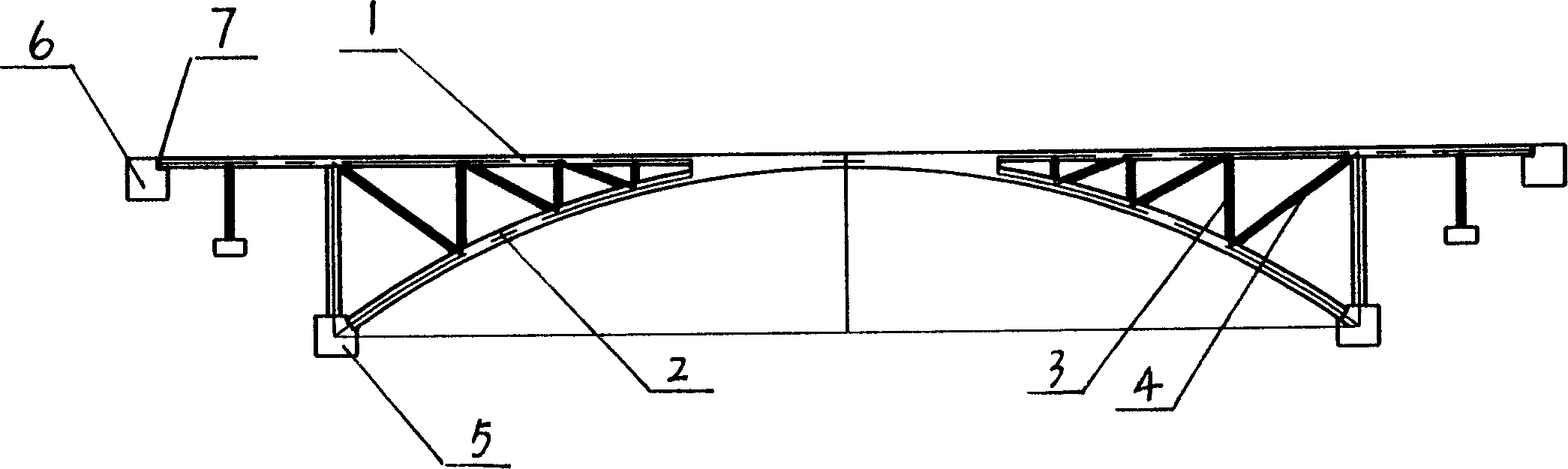

Reinforcement structure of truss bridge or arch bridge

InactiveUS6892410B2Efficient inductionTruss-type bridgeBridge structural detailsArch bridgeStructural element

Through co-action between auxiliary triangular structural frames, which are each constructed at opposite ends of a truss girder or arch girder, and a cable stretched between the auxiliary triangular structural frames, an upwardly directed force is exerted to the truss girder or arch girder, thereby effectively inducing a load resisting force. A reinforcement structure of a truss bridge or arch bridge is comprised of a truss girder or arch girder, a first and a second end of which are each provided with a main triangular structural frame. The main triangular structural frame is provided at an inner side thereof with an auxiliary triangular structural frame. The auxiliary triangular structural frame is joined at vertexes thereof with frame structural elements at respective sides of the main triangular structural frame. A cable extends in a longitudinal direction of the truss bridge, being stretched between a nearby part of a joined part at one of the vertexes of the auxiliary triangular structural frame on a side of the first end of the truss girder or arch girder and a nearby part of a joined part at a corresponding one of the vertexes of the auxiliary triangular structural frame on a side of the second end of the truss girder or arch girder. Deflecting structure, adapted to exert a downwardly directed force to the cable, is inserted between the cable and a lower chord of the truss girder or arch girder so as to tension the cable, and an upwardly directed force is exerted to the lower chord by a reaction force attributable to tension of the cable via the deflecting structure.

Owner:ASAHI ENG CO LTD +2

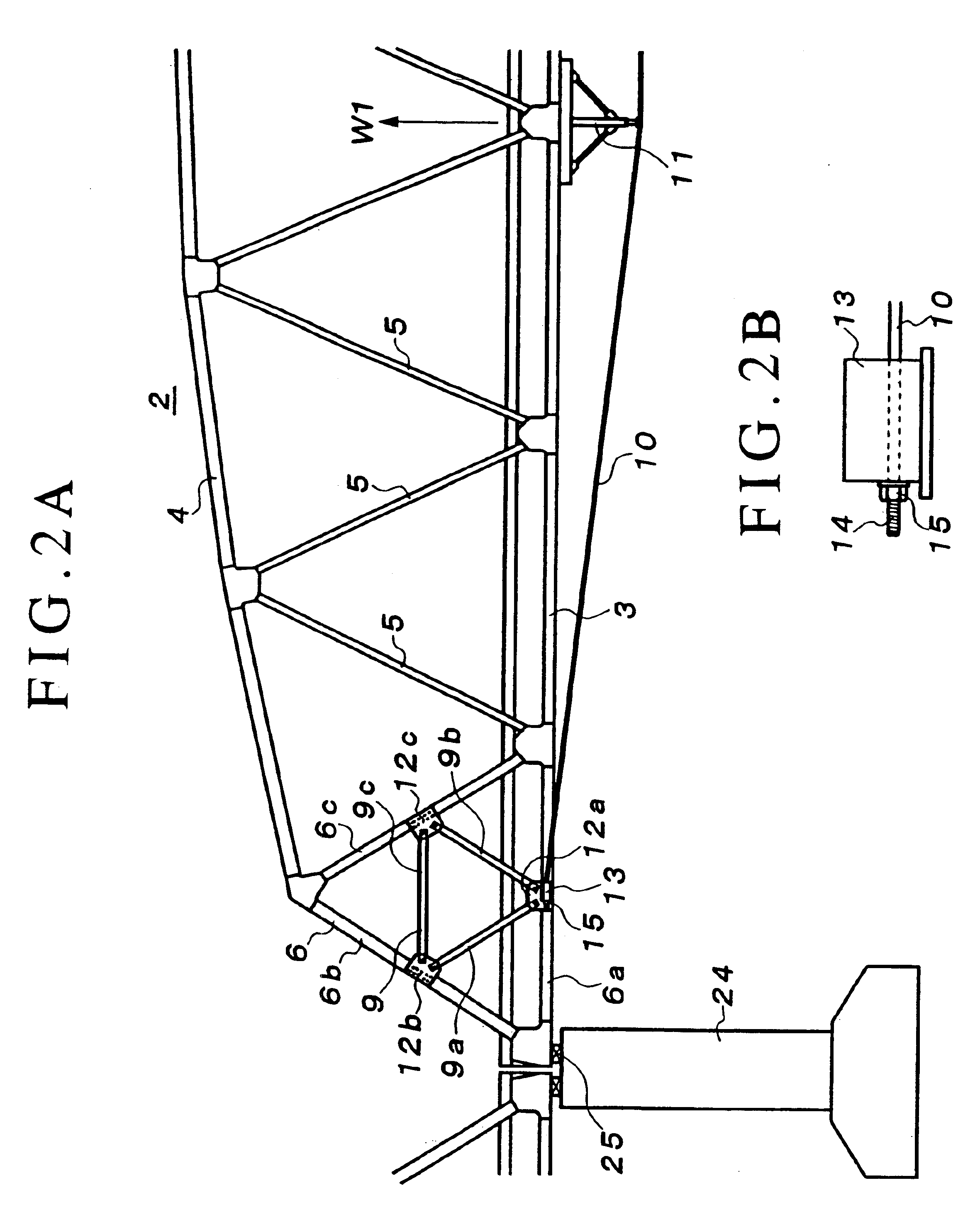

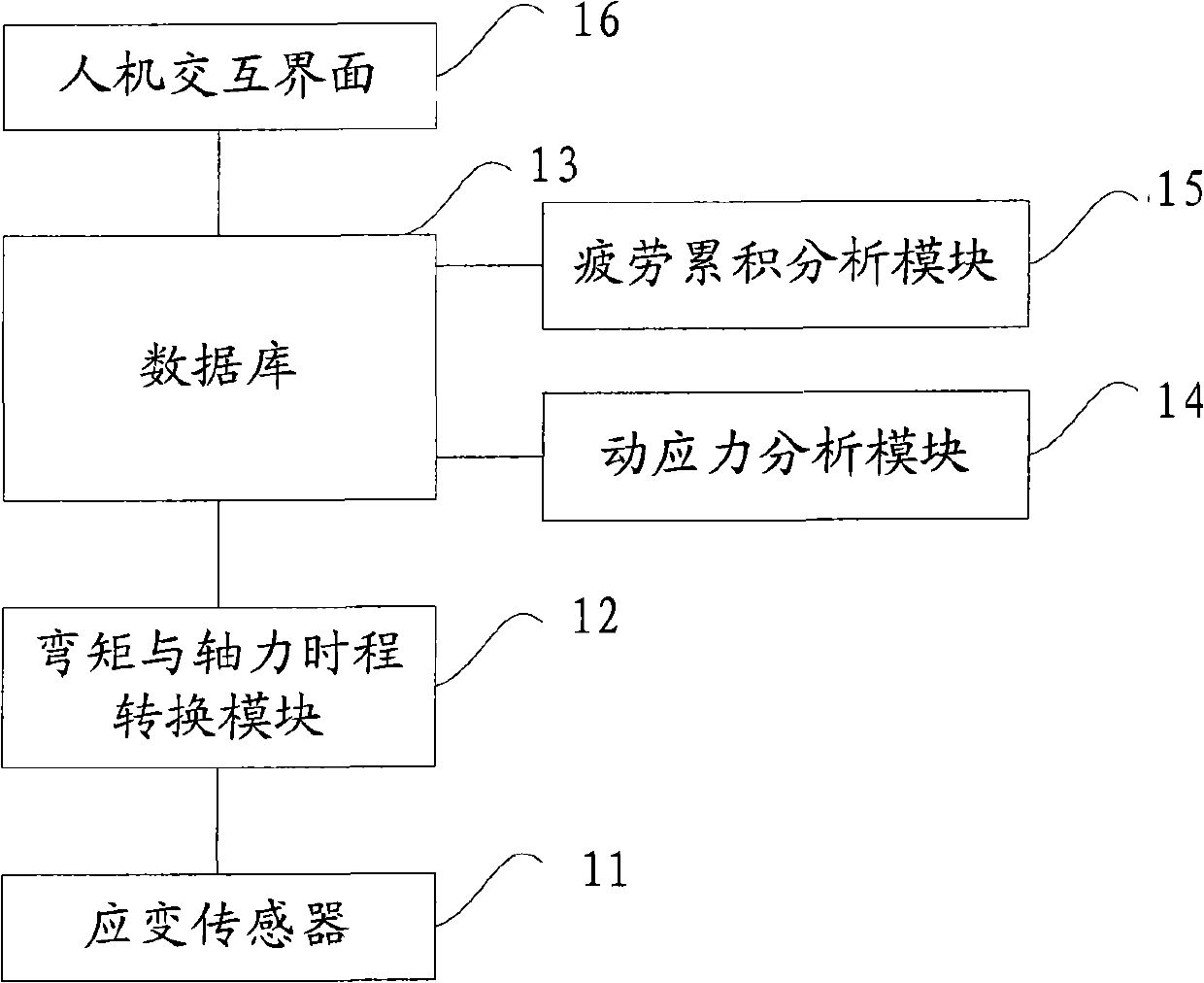

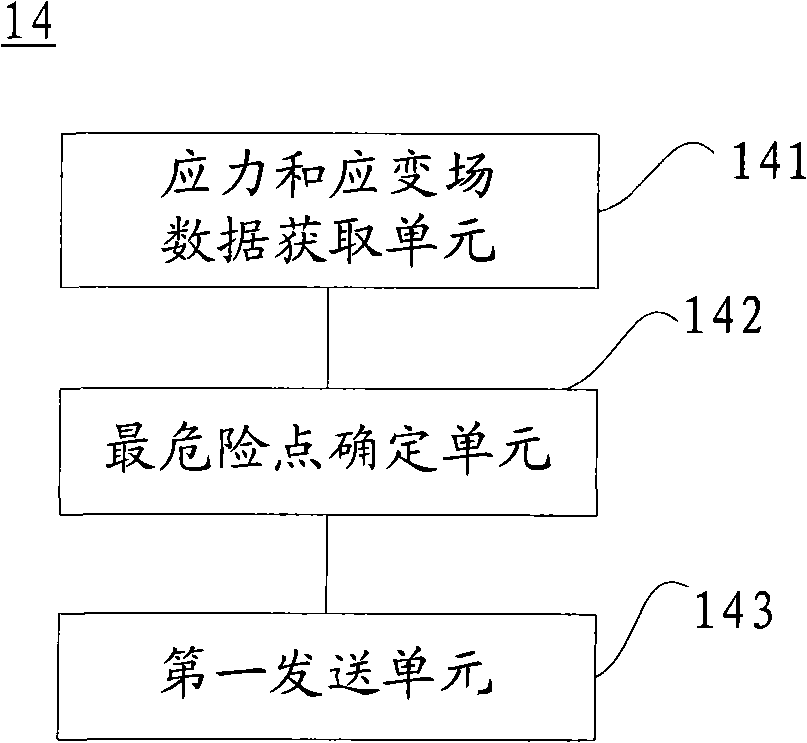

Accumulated fatigue damage self-diagnosis system for railway steel truss bridge node

InactiveCN101769913ATimely repairEnsure safetyMaterial analysisFatigue damageWelding residual stress

The invention discloses an accumulated fatigue damage self-diagnosis system for a railway steel truss bridge node. When a train boards a bridge, a stress response time-history signal of a middle cross section of a truss rod piece which is connected with the tested node when the train goes by is automatically acquired through a strain sensor; a bending moment and shaft force time-history conversion module converts the stress response time-history signal into a bending moment and shaft force time-history signal; a dynamic stress analysis module takes a node welding residual stress field which is determined according to a construction process of a node welding line as an initial stress field, and superposes a node train traveling dynamic stress field which is determined by the bending momentand shaft force time-history signal to obtain the position of a most dangerous point and the strain state of the bridge node welding line; and finally, a fatigue accumulation analysis module determines the fatigue damage accumulation degree of the most dangerous point when the train goes by according to the position of the most dangerous point and the strain state and the strain fatigue critical surface method, and then a man-machine interaction interface informs a user of the fatigue damage accumulation degree. Therefore, the system can automatically inform the user of fatigue information ofthe welding line of the railway steel truss bridge node in time so as to repair the railway steel truss bridge in time and guarantee the safety of the railway steel truss bridge.

Owner:WUHAN UNIV OF TECH

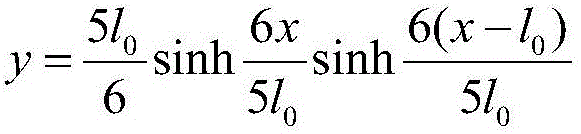

Prestressed concrete continuous truss frame arched bridge

The arch bridge is composed of upper chord, lower chord, upright posts, inclined bars, anchoring wall at bridge abutment. Supported by arch support, lower chord through upright posts, inclined bars supports upper chord. The upper chord as a continuous beam is articulated on anchoring wall at bridge abutment through hinges at two ends. There is contraction-joint between upper chord and anchoring wall at bridge abutment. The invention raises integrity of bridge, reduces deflection, vibration and jigging motion providing advantages of improving trafficked effect and durability of bridge. Comparing with box ribbed arch bridges, truss bridges etc, the invented arch bridge possesses general superiorities suitable to use in each classified highways.

Owner:郑锦文

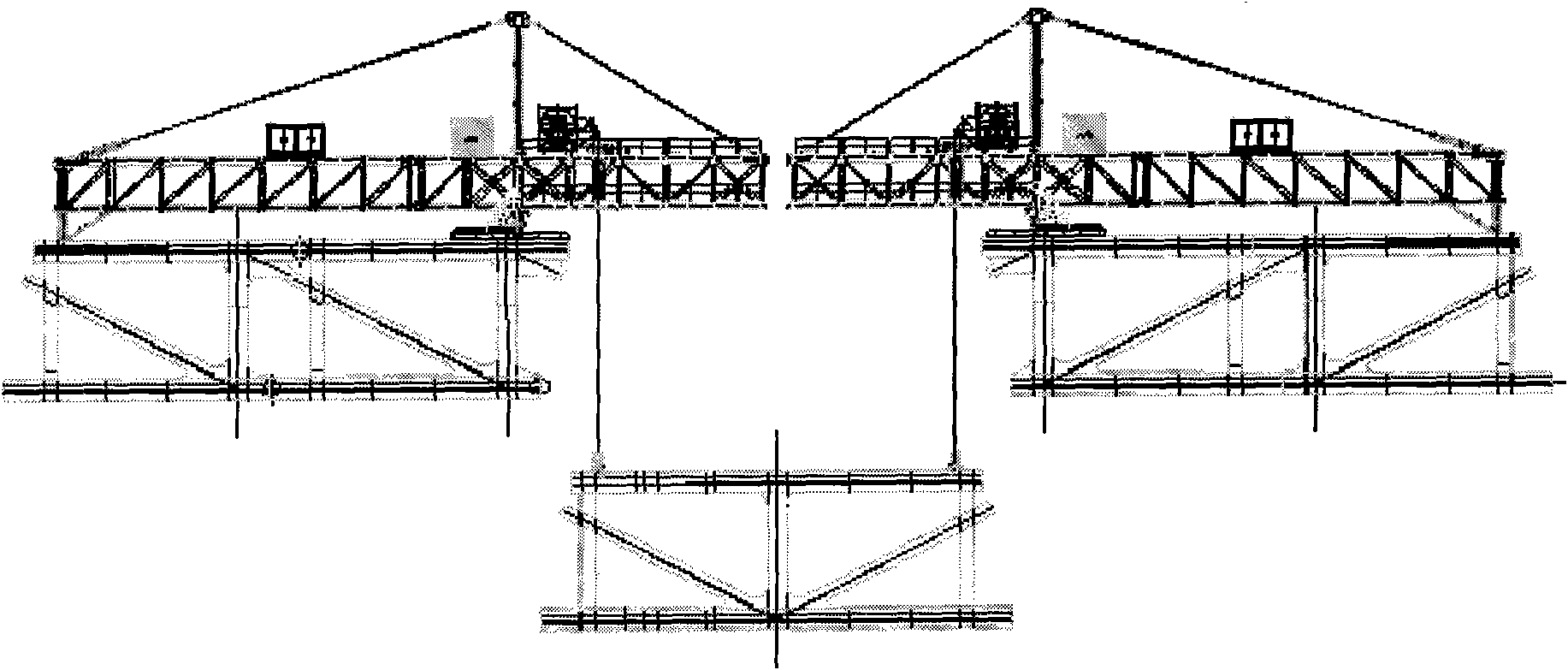

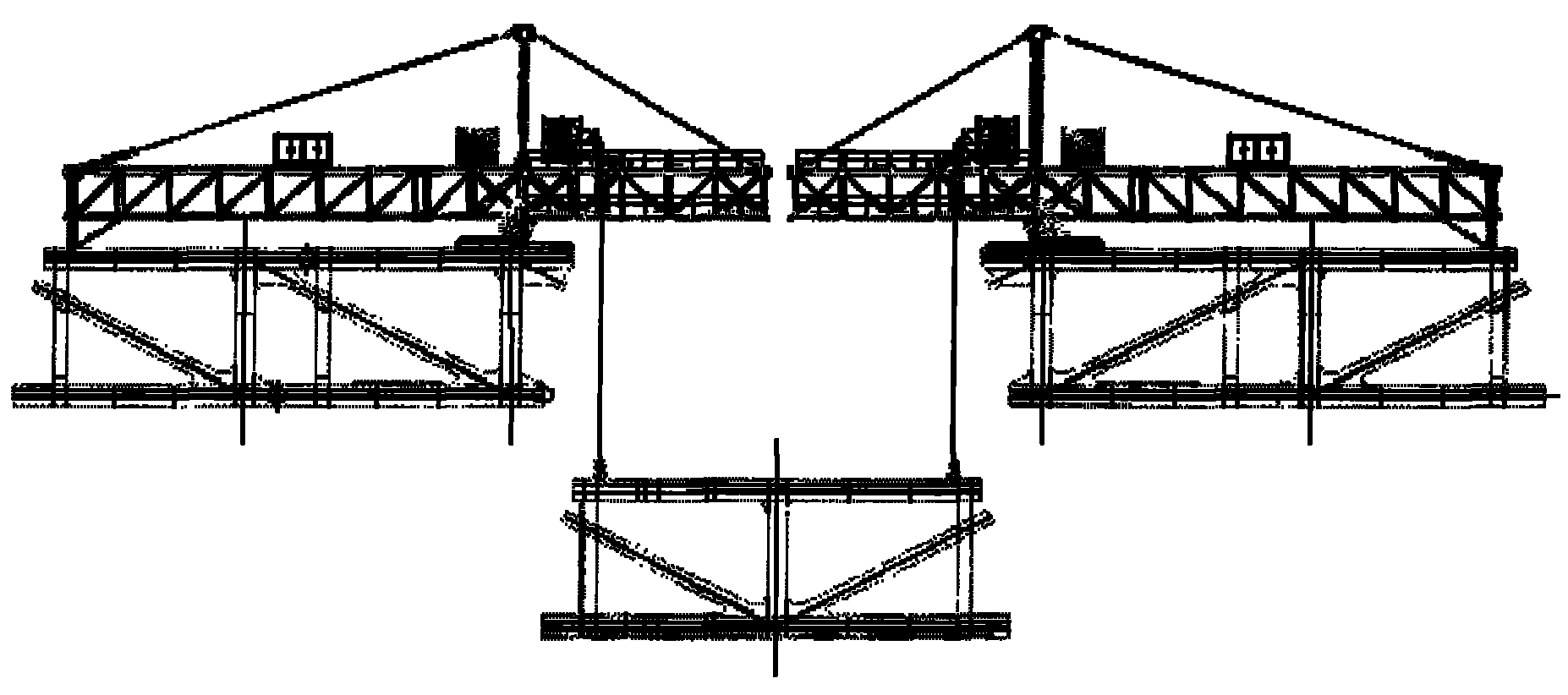

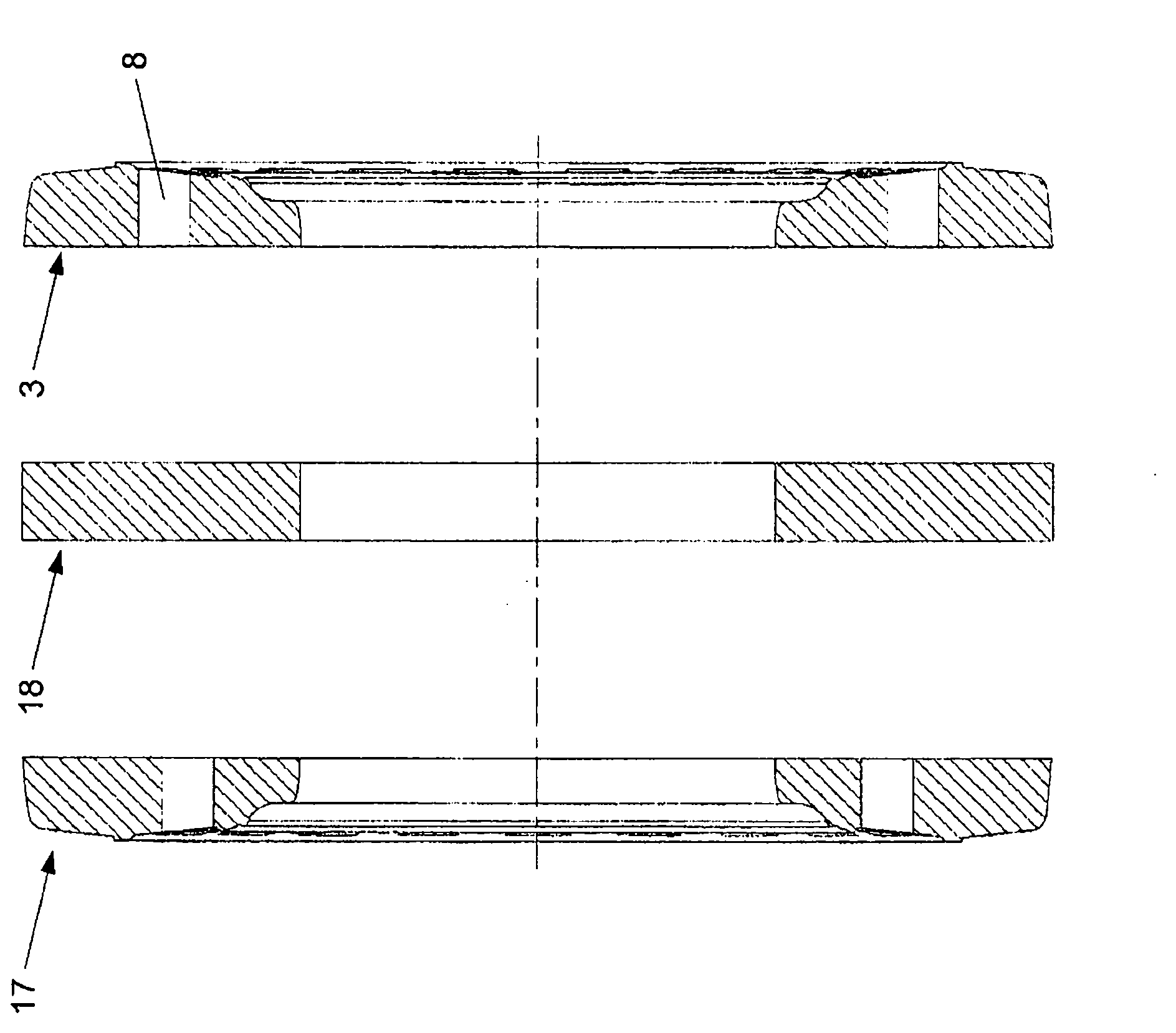

Pitching type truss bridge manufacturing method

ActiveCN104878699AReduce manufacturing difficultyBridge erection/assemblyBridge deckStructural engineering

The invention provides a pitching type truss bridge manufacturing method. A pitching type truss bridge comprises a bridge deck and truss side pieces located on two sides of the bridge deck, wherein a hinge point is arranged at one end of the pitching type truss bridge. The pitching type truss bridge manufacturing method comprises the steps of dividing the truss side pieces into multiple truss sections according to the Z-direction camber demand of the pitching type truss bridge, wherein each truss section is linear; respectively manufacturing the multiple truss sections and cutting closing-up allowances of the multiple truss sections according to the Z-direction camber demand, dividing the bridge deck into the multiple truss sections to be manufactured respectively; sequentially splicing the multiple truss sections and multiple bridge decks together. The pitching type truss bridge meeting the Z-direction camber demand can be manufactured by means of the simple method.

Owner:SHANGHAI ZHENHUA HEAVY IND

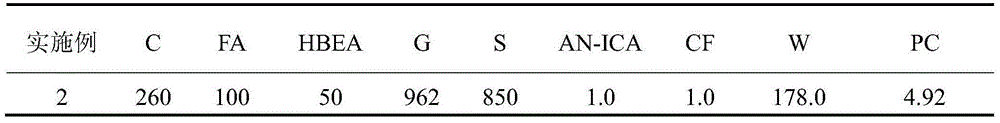

C30 self-compaction microexpanded concrete-filled steel tube and preparation method thereof

ActiveCN105084836ASolve the "out of the air" problemImprove cementing performanceSolid waste managementCelluloseCoal

The invention discloses a C30 self-compaction microexpanded concrete-filled steel tube and belongs to the field of building materials. The C30 self-compaction microexpanded concrete-filled steel tube is prepared by taking cement, coal ash, composite expansion agents, gravel, river sand, tackifying plasticity-maintaining ultra-dispersed additive, internal maintaining materials, micro-grade modified degreasing cotton cellulose and water as raw materials. The number of binding materials adopted in the C30 self-compaction microexpanded concrete-filled steel tube is small, and the C30 self-compaction microexpanded concrete-filled steel tube has the advantages of being good in self-compaction performance, low in gas content and high in durability, being slightly expanded and the like, is suitable for compact pouring of intensely reinforced large-pipe-diameter thin-wall steel tube concrete-filled steel tube underwater piles with complex shapes and a small section size, string tube pumping pouring of upper and lower concrete-filled steel tubes of concrete-filled steel tube truss bridges and high-throwing vibration-free pouring of concrete-filled steel tube pier studs. The problem of disengaging of the concrete-filled steel tube can be effectively solved, and wide application prospects are achieved.

Owner:WUHAN UNIV OF TECH

Modern bamboo sidewalk truss bridge

InactiveCN104452571ASimple structureImprove bearing capacityTruss-type bridgeBridge structural detailsBridge deckEngineering

The invention discloses a modern bamboo sidewalk truss bridge. The modern bamboo sidewalk truss bridge is characterized by comprising a pair of bridge piers made of concrete, two lines of installation supports fixed to the bridge piers and made of steel materials and primary trusses connected to the installation supports and formed by ball joint components made of steel materials and connecting rods made of recombination bamboo materials; the modern bamboo sidewalk truss bridge further comprises bridge deck slabs and handrails, and the bridge deck slabs and handrails are made of recombination bamboo materials. The modern bamboo sidewalk truss bridge has the advantages that convenience is brought to component connection, construction is simple and rapid, and convenience is brought to modulization production; in addition, the bridge is small in weight, the anti-seismic property is good, joints are stable and reliable, and therefore the obtained modern bamboo sidewalk truss bridge is green, low in carbon, environmentally friendly and economical; the requirements for normal use and durability of the bridge structure are met.

Owner:CHONGQING JIAOTONG UNIVERSITY

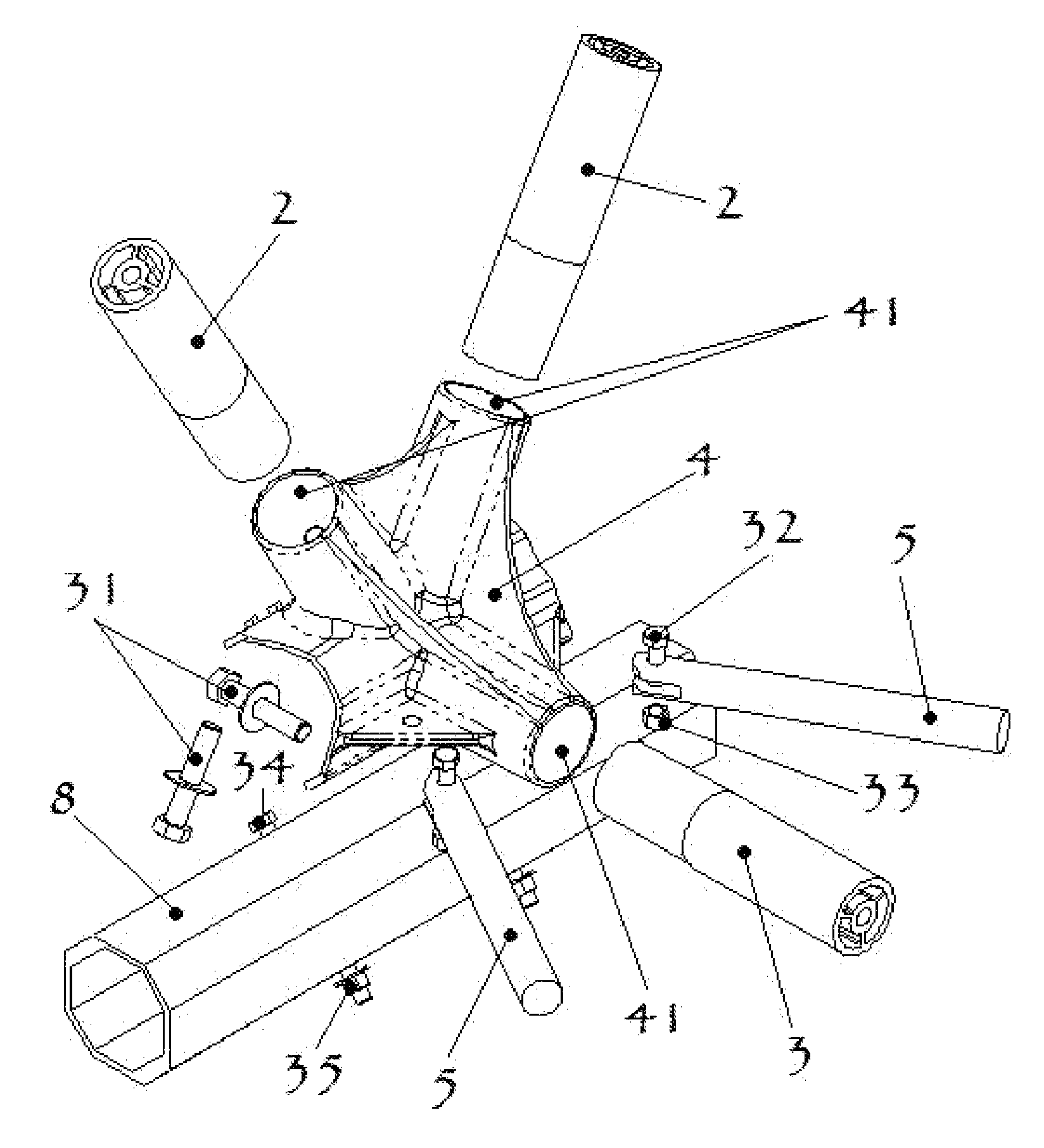

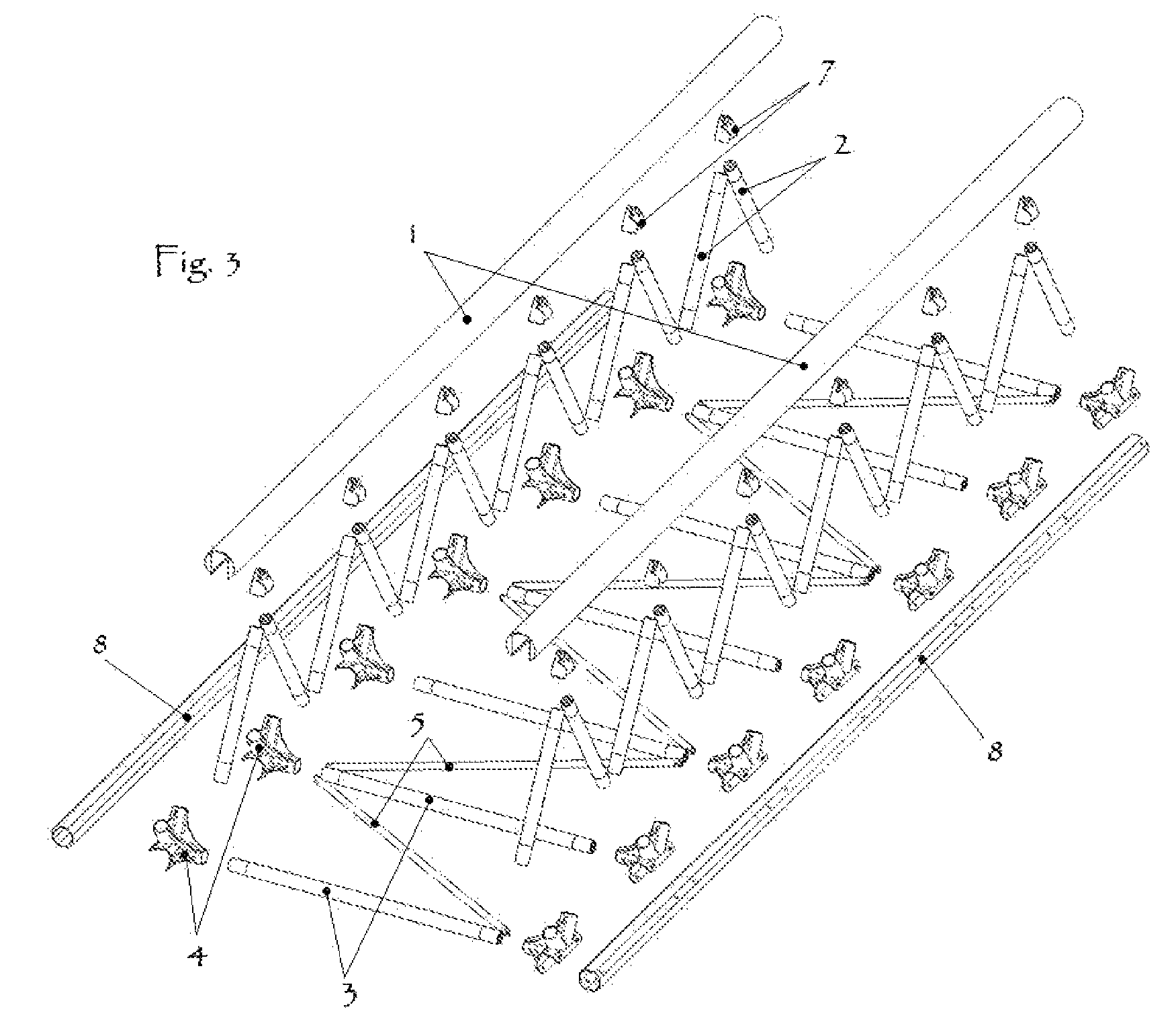

Moment-Resisting Joint and System

The present invention is directed toward a novel moment resisting connection system, for use, but not limited to, with a pony-truss bridge system. The connection system comprises multi-hollow sections that can be, but are not limited to, extruded aluminum and a joint or node connector that can be casted, milled, forged or made by any other means.

Owner:DE LA CHEVROTIERE ALEXANDRE

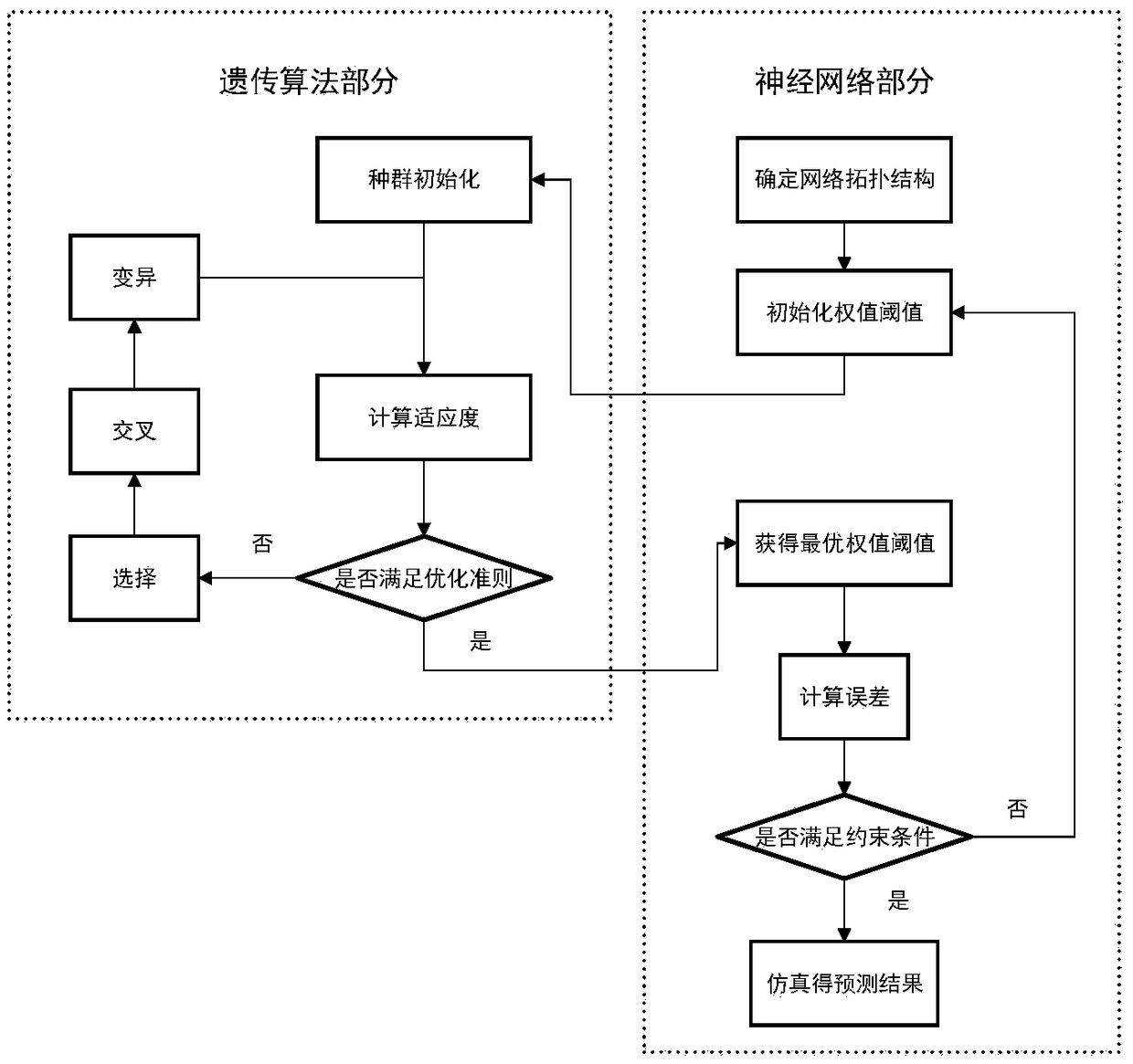

Method for identifying damage position and damage degree of truss bridge based on neural network

PendingCN109325263AFast convergenceCalculation speedGeometric CADDesign optimisation/simulationTest sampleFinite element method

The invention discloses a method for identifying damage position and damage degree of truss bridge based on neural network. The method comprises the steps of constructing the bridge sample data, usinga finite element method to establish a bridge model, and obtaining the simulated frequency data of a bridge in good condition and under different damage conditions; calculating the frequency change ratio, frequency square change ratio and frequency change rate according to the simulated frequency data of the bridge in good condition and under different damage conditions; determining the topologyof the network, using a BP neural network to determine the number of neurons in each layer and initialize the weights and thresholds of the neural network at the same time; training the neural networkby the elastic gradient method combined with a genetic algorithm and testing by test samples, and obtaining the trained neural network; inputting the real-time frequency data of the bridge into the trained neural network to realize the identification of the damage location and damage degree of the bridge. The method of the invention has the advantages of fast calculation speed and great engineering application value for the maintenance and reinforcement of the actual bridges.

Owner:WUHAN UNIV OF TECH

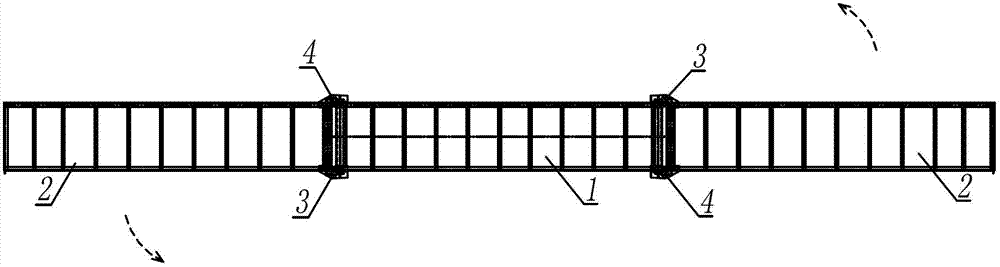

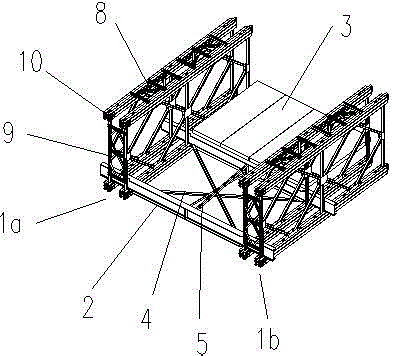

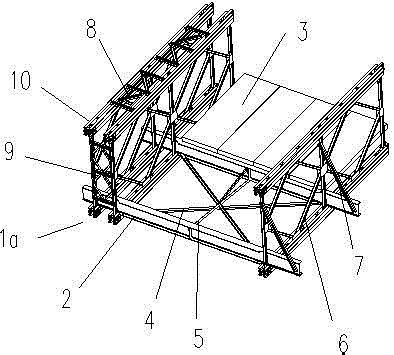

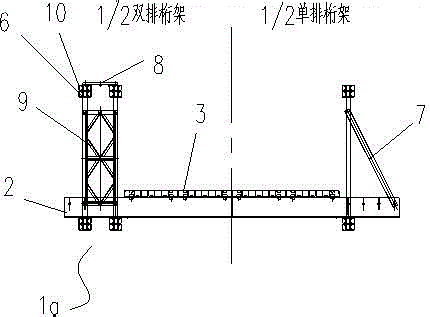

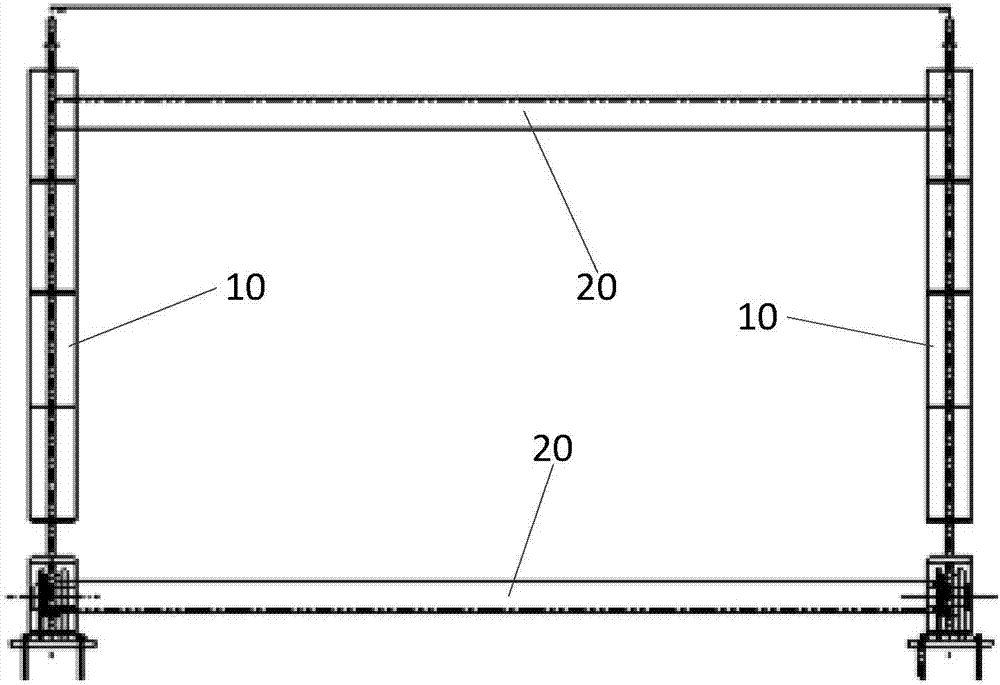

Long-span assembly type road steel truss bridge

The invention discloses a long-span assembly type road steel truss bridge which can be erected across the 90m span. The long-span assembly type road steel truss bridge comprises a left truss and a right truss. Beams are arranged between the left truss and the right truss. Wind resistance pull rods and a vertical wind structure are arranged between every two adjacent beams. A bridge face board is arranged on the beams. Reinforcing chord members are arranged on upper chords and lower chords of the trusses. The long-span assembly type road steel truss bridge is characterized in that the distance between pin holes in the height direction of each truss ranges from 2400 mm to 2800 mm, and the distance between pin holes in the length direction of each truss ranges from 5800 mm to 6000 mm; the chord member sections of upper chord members, lower chord members, vertical rods, inclined rods and the reinforcing chord members of the trusses are square pipes or rectangular pipes, and the problems that an existing assembly type steel bridge is small in span and large in deflection are solved.

Owner:CHINA HARZONE IND CORP

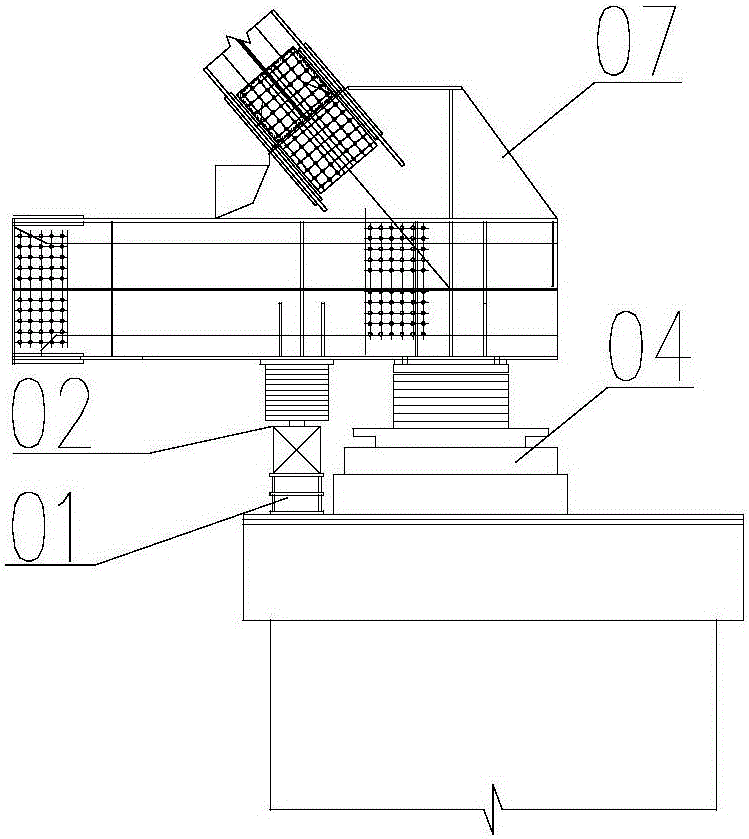

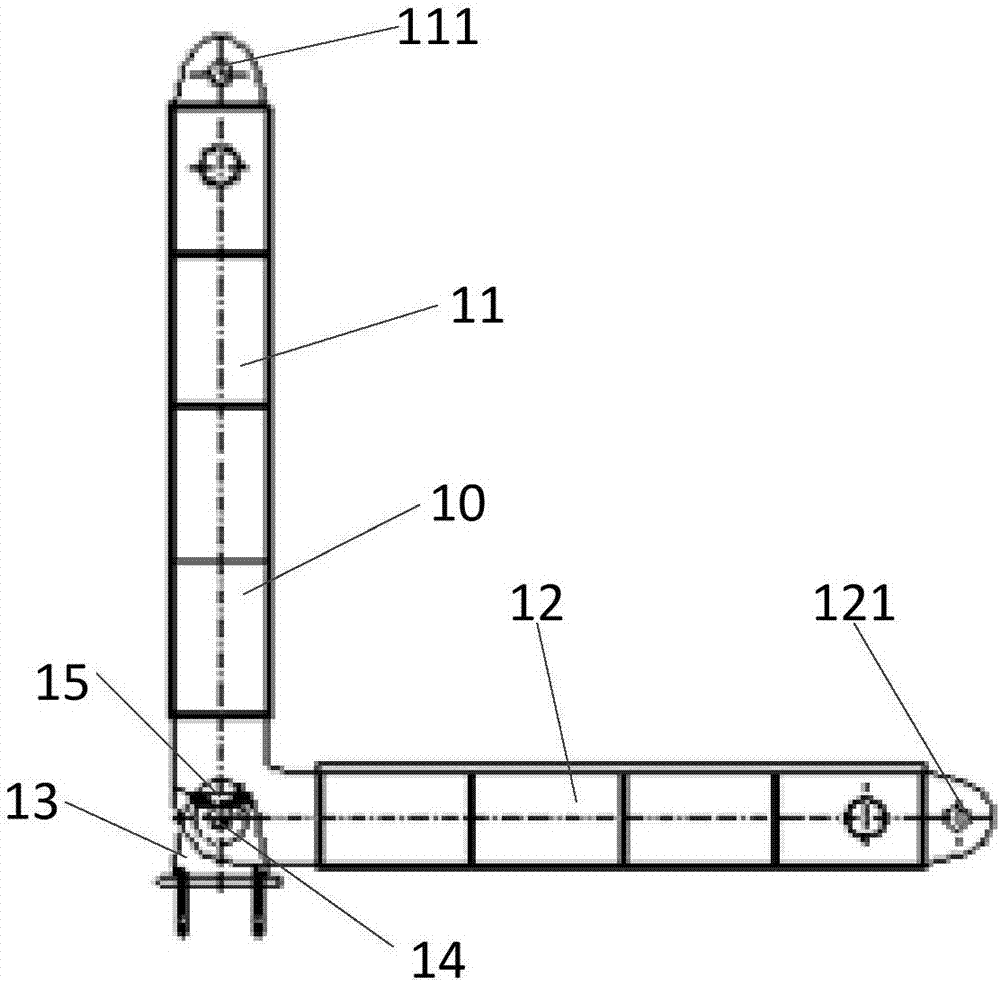

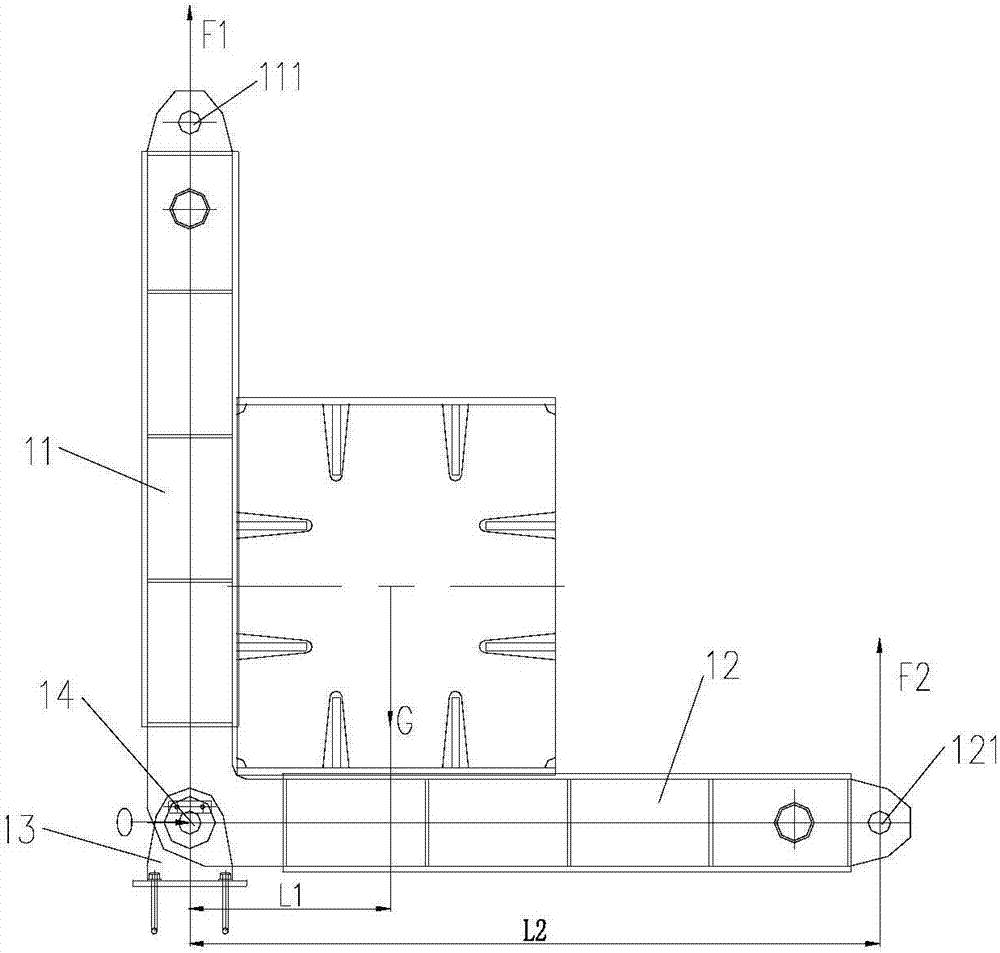

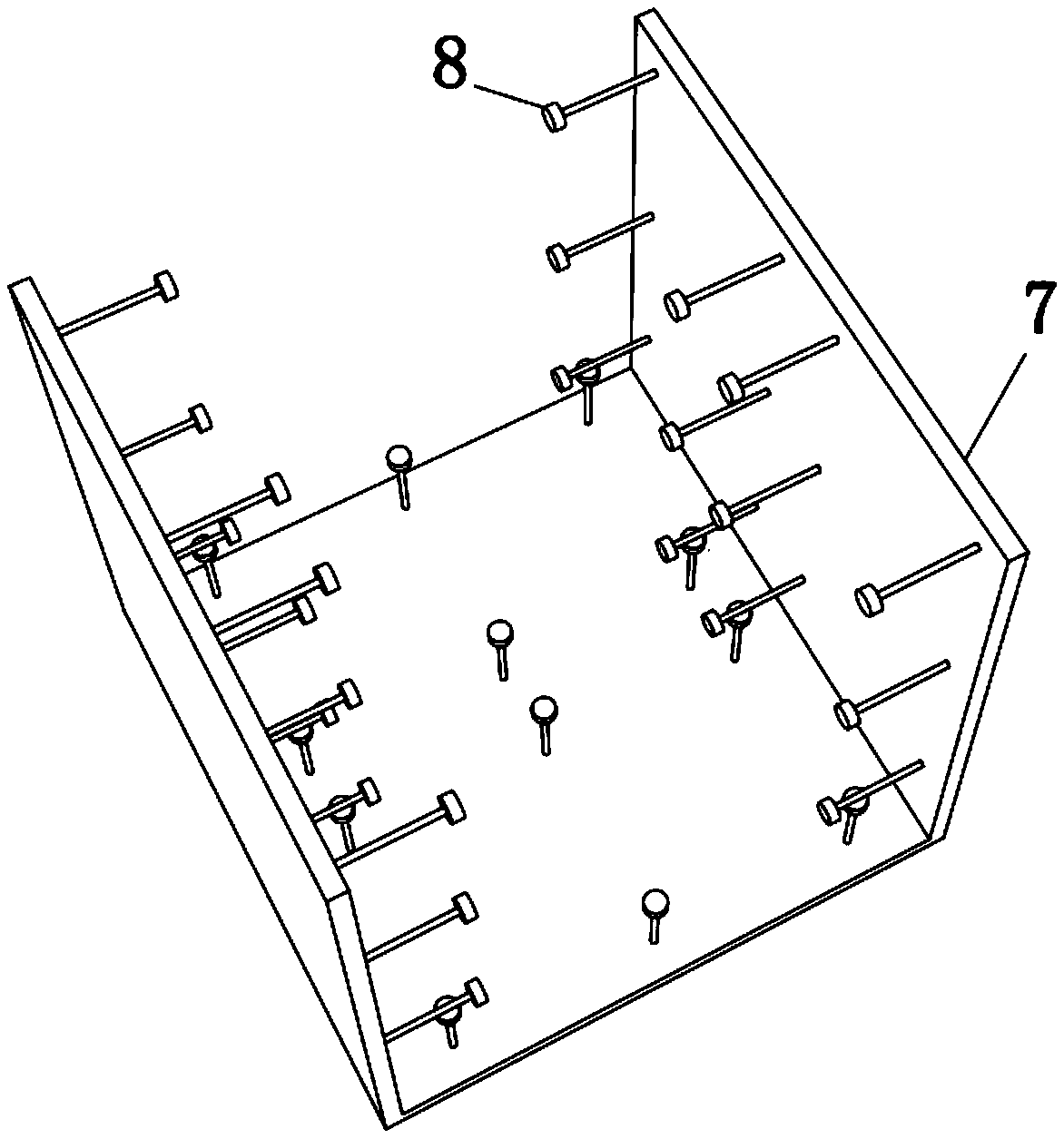

Turning rack and method of truss bridge chord piece

InactiveCN107572375AWon't hurtTroubleshoot technical issuesLifting devicesBridge erection/assemblyEngineeringMechanical engineering

The invention discloses a turning rack and method of a truss bridge chord piece. The turning rack comprises at least two L-shaped rack body assemblies and at least two connecting rods, and the two ends of the connecting rods are connected with the two L-shaped rack body assemblies correspondingly. Each L-shaped rack body assembly comprises a first turning arm and a second turning arm, wherein thefirst end of the first turning arm and the first end of the second turning arm are vertically connected, the second end of the first turning arm and the second end of the second turning arm are provided with suspension lugs, and the junction of the first turning arm and the second turning arm is rotationally fixed to a foundation. According to the turning rack and method of the truss bridge chordpiece, the vertexes of the L-shaped rack body assemblies are rotationally fixed to the foundation, the lengths of every two arms of the L-shaped turning rack are determined on the premise that the weight of rods is matched with the hoisting capacity of a lifting crane according to the lever principle, and particularly aiming at the situation that the capacity of the lifting crane is smaller than the weight of the rods, no turning suspension lug needs to be installed on the rods of the truss bridge chord piece and base materials cannot be damaged.

Owner:WUCHUAN HEAVY ENG

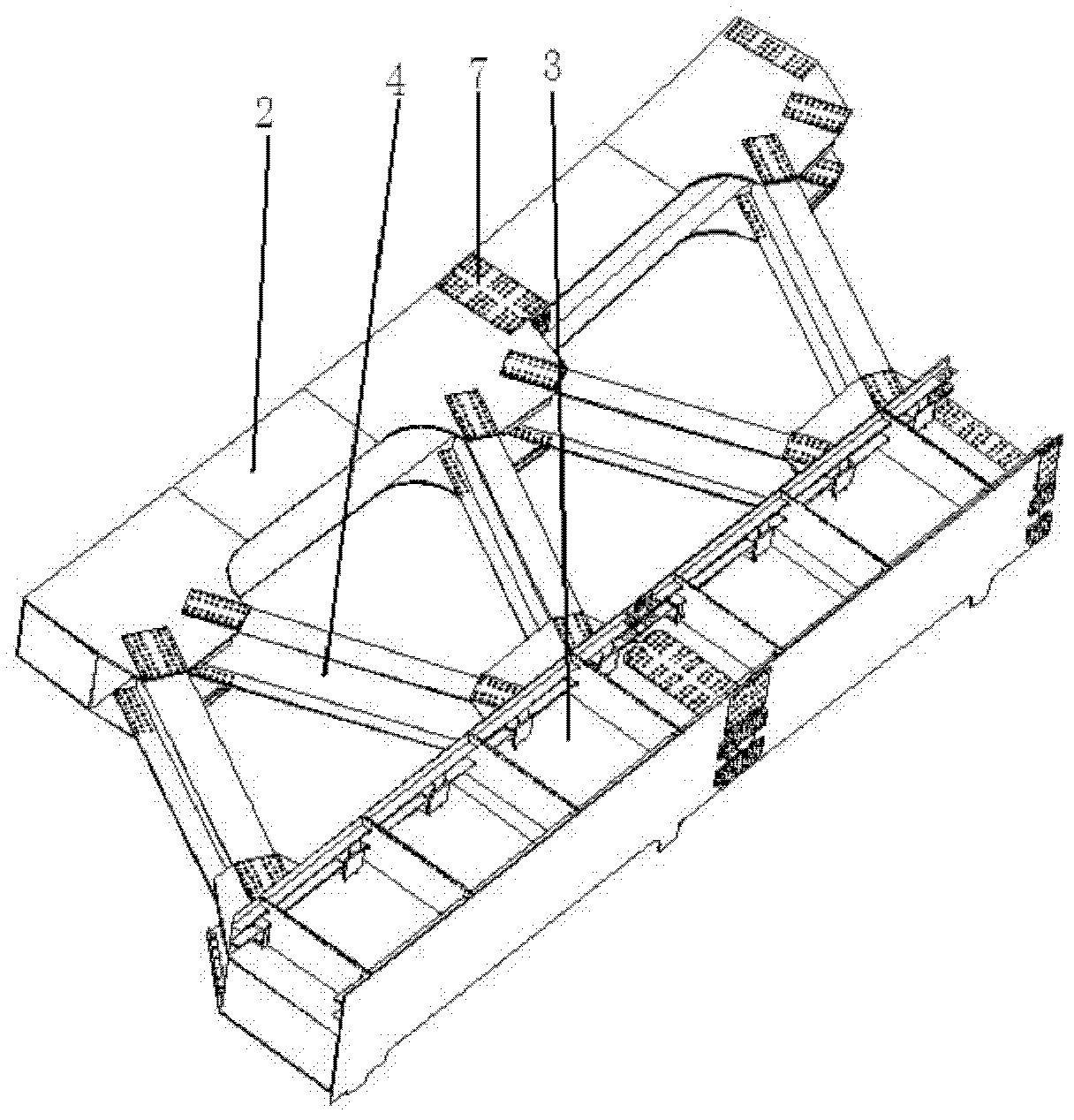

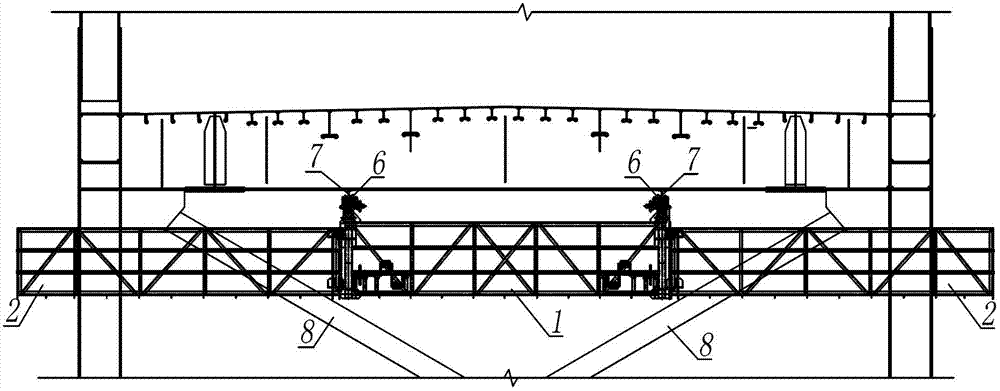

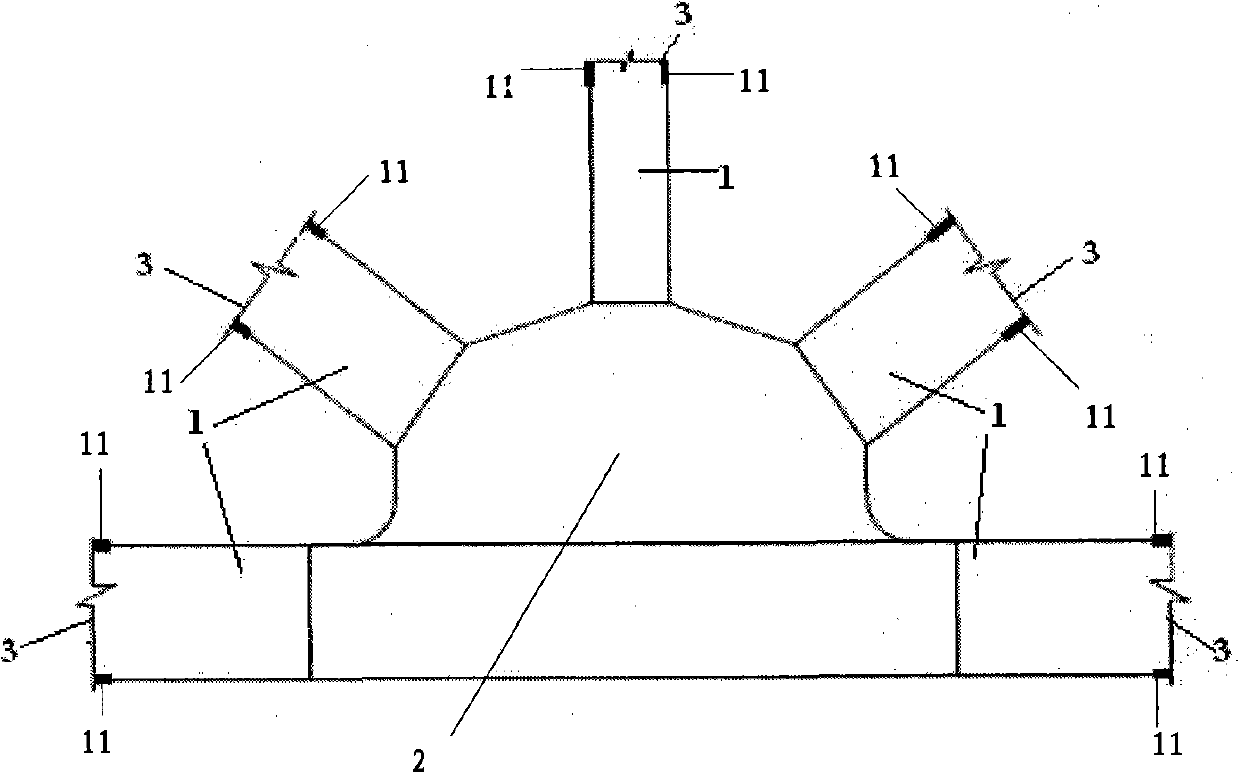

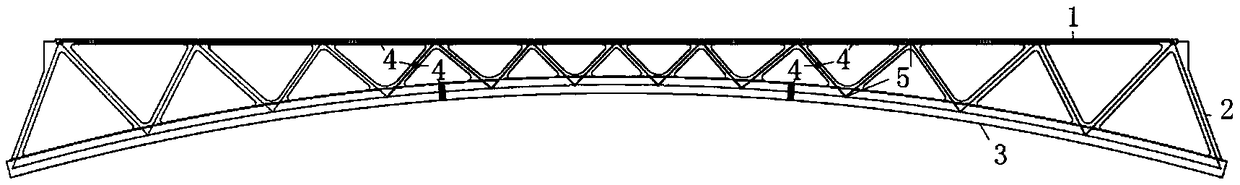

Steel pipe concrete combined truss bridge

InactiveCN102776829AStrong shear resistanceImprove shear resistanceTruss-type bridgePre stressEngineering

The invention relates to a steel pipe concrete combined truss bridge. The combined truss bridge comprises piers at two ends, a bridge panel, two upper parallel chord members and two lower parallel chord members, wherein the upper chord members and the lower chord members which vertically correspond to each other are connected through uniformly distributed web members which are sequentially connected in a W shape; parallel connecting steel plates are arranged at the peripheries of two web members at the joints of the lower chord members of the combined truss bridge; reinforcing ribs connected with the upper surfaces of the connecting steel plates are uniformly distributed at the periphery of each web member; vertical reinforcing steel plates in vertically downward state are uniformly distributed on the lower surfaces of the connecting steel plates, and positioned at the lower chord members; steel beam holes are uniformly formed in each vertical reinforcing steel plate; and longitudinal prestressing steel beams of the lower chord members pass through the steel beam holes in the vertical reinforcing steel plates. Compared with traditional connecting joint of steel rod and concrete plate, the steel pipe concrete combined truss bridge is more reliable in connecting, and the joint is simply manufactured and convenient to construct.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST

Method for controlling changes in three-truss height difference of combined highway and railway bridge for structural system

InactiveCN105986549AControl the height difference of the three trussesGuarantee smooth constructionBridge erection/assemblyControl systemHeight difference

The invention discloses a method for controlling changes in three-truss height difference of combined highway and railway bridge for a structural system. Slide beams and slides are precisely hoisted before construction of a main bridge, and a three-truss height difference of lower bearing structures of steel trusses is controlled within 10 mm. The impact of the three-truss height difference upon the main bridge is analyzed by using finite element software analysis according to a design scheme and field initial data, and a safety limit of the three-truss height difference under various construction conditions is calculated; after each pushing, slider reversing is performed and point reading is redone according to field calculated elevations, and the three-truss height difference is precisely controlled within 1 mm; the bottom of each steel beam is contacted with sliders through elastic rubber pads, limiting relative vertical displacement of three main trusses during pushing and dynamically controlling the three-truss height difference. In the method, a three-truss large-span steel truss bridge is constructed by using a three-truss height difference control system, and the method is highly operable, convenient to construct, safe and reliable, economic and reasonable and is worthy of popularization in the construction of multi-main-truss large-span steel bridges.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Moment-resisting joint and system

The present invention is directed toward a novel moment resisting connection system, for use, but not limited to, with a pony-truss bridge system. The connection system comprises multi-hollow sections that can be, but are not limited to, extruded aluminum and a joint or node connector that can be casted, milled, forged or made by any other means.

Owner:DE LA CHEVROTIERE ALEXANDRE

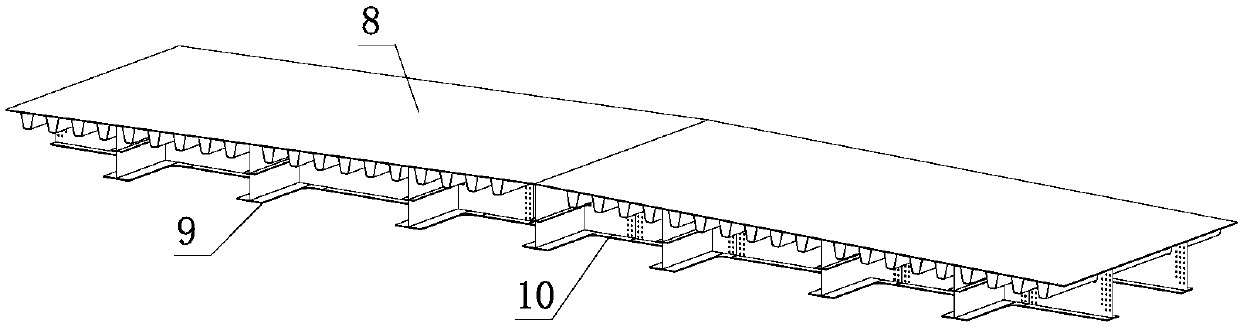

Assembling method of truss bridge segments

ActiveCN107700360AMeet the requirements of standardized mass productionReduce working at heightsBridge erection/assemblyEngineeringBatch production

The invention discloses an assembling method of truss bridge segments. The method comprises the following steps of respectively assembling two main trusses; assembling bridge surface plates; performing temporary tightening on two lower crossbeams, and respectively connecting two ends of a plurality of lower parallel connectors with the two lower crossbeams; fixing a plurality of crossbeam web members to the two lower crossbeams; performing temporary fixing on the two main trusses, two lower crossbeams and the crossbeam web members; connecting each upper crossbeam with lateral nodes of the corresponding main truss, and connecting each upper crossbeam with the corresponding crossbeam web member; and connecting the bridge surface plates with the main trusses, and connecting a stringer adapterplate of each upper crossbeam with the corresponding bridge surface plate, so as to complete the assembling of the truss bridge segments. According to the assembling method disclosed by the invention, three-dimensional assembling is firstly performed on an inner site, then integral hoisting is sequentially performed, the line shape is adjusted, and circumferential seam connection is performed; through the adoption of the assembling method disclosed by the invention, the aloft work is integrally assembled in a ground, planar and massive manner, and aloft work is reduced, so that the efficiencyis improved, the assembling quality is improved, the assembling speed is accelerated, and requirements for standardized and batch production of long-span steel truss beam are met.

Owner:WUCHUAN HEAVY ENG

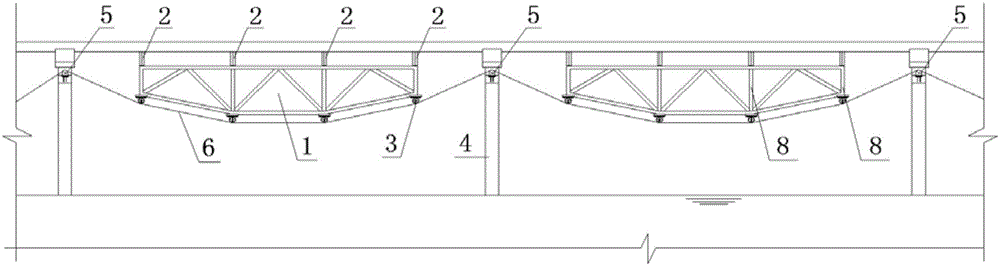

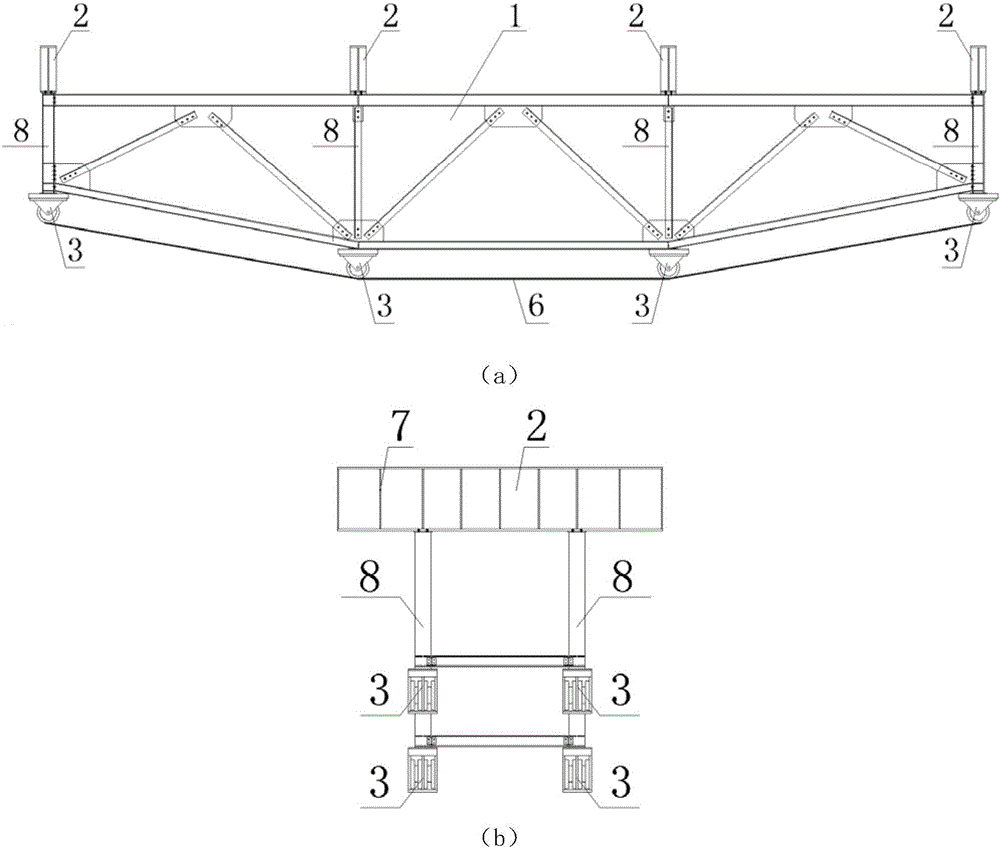

Variable-height cable-truss bridge reinforcing structure system

ActiveCN106567344ASignificant liftUniform jacking forceBridge erection/assemblyBridge strengtheningNet forcePre stress

The invention discloses a variable-height cable-truss bridge reinforcing structure system. The system comprises five parts including a prestress wire, a truss, a distributing beam, steering sliding wheels and a force transmission sliding wheel; the steering sliding wheels are fixed to the upper portion of a bridge pier, the inversed force transmission sliding wheel is fixed to the bottom of the truss, and the distributing beam is placed on the top; and the prestress wire sequentially penetrates the steering sliding wheels and the force transmission sliding wheel for connecting the fixed end and the stretching end on the two sides of an overall bridge, and therefore the distributing beam abuts against the lower surface of a top bridge plate. the prestress wire form upward resultant force at the bottom of the truss, and the resultant force is transmitted by the truss to the bridge face plate to form jacking force. The lengths of vertical web members of the truss are in bilateral symmetry, the vertical web members on the outmost sides are shortest, and the best reinforcing effect is achieved. By means of the above manner, the dead load of the bridge plate can be partially offset, the bearing capacity and the rigidity of the structure are effectively improved, and the aim of reinforcing the bridge is achieved.

Owner:ZHEJIANG UNIV

Ultra high performance concrete truss arch element, truss arch bridge and construction method thereof

ActiveCN109024225AGuarantee the pouring qualityGuarantee the quality of maintenanceTruss-type bridgeBridge structural detailsBridge engineeringIsoetes triquetra

The invention relates to the technical field of bridge engineering, and discloses an ultra high performance concrete truss arch sheet element, a truss arch sheet bridge and a construction method. Theultra-high performance concrete truss arch element consists of upper chord, web and lower chord. The web and lower chord are approximately equilateral triangle structure. Steel pas between that units.The ultra-high performance concrete (UHPC) truss arch bridge is constructed by pouring bridge deck and hanging beam between several UHPC truss arch segments. The method of erection of the bridge is as follows: sectional horizontal prefabricated truss arch element, steel is reserved at the joints. Channel structure of ultra-high performance concrete structure, erect truss arch piece on site and cast ultra-high performance concrete at the joint, install hanging beam and cast-in-place bridge deck. The bridge erected with the truss arch piece has the advantages of light dead weight, good durability, convenient and rapid construction, reducing the risk of structural cracking, economic structure, beautiful appearance and so on. It meets the requirements of the development of assembled bridge and has a good application prospect.

Owner:HUNAN UNIV

Steel truss bridge rod piece check and calculation method and system

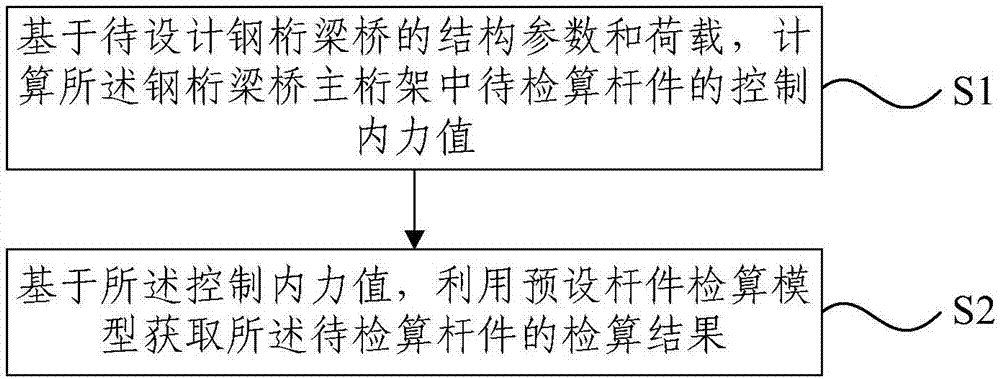

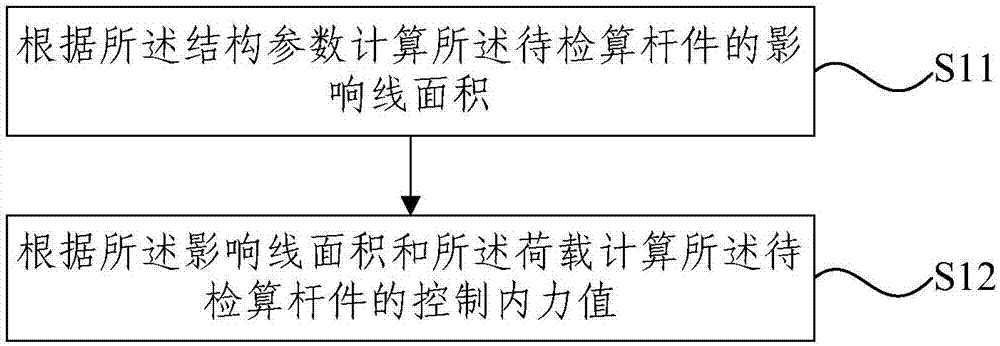

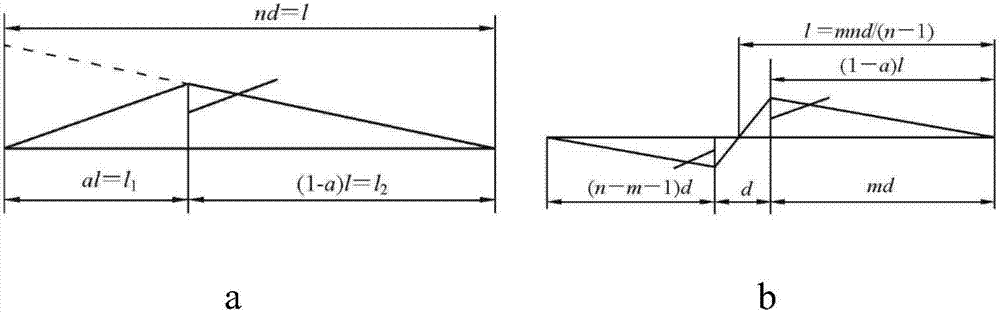

InactiveCN107391811ARealize automatic calculationAccurate and objective resultsGeometric CADTruss-type bridgeEngineeringCalculation methods

The invention discloses a steel truss bridge rod piece check and calculation method and system and relates to the field of bridge design. The method comprises the steps of 1, on the basis of structure parameters and load of a steel truss bridge to be designed, calculating out a control inner force value of a rod piece to be checked and calculated in a main truss of the steel truss bridge; 2, on the basis of the control inner force value, utilizing a preset rod piece check and calculation model to obtain a check and calculation result of the rod piece to be checked and calculated. The control inner force value of the rod piece to be checked and calculated is calculated, control inner force is used as the preset rod piece check and calculation model to input, a check and calculation result of the rod piece to be checked and calculated is output, thus whether or not the design of the rod piece to be checked and calculated meets requirements is known, automatic check and calculation can be achieved, and the check and calculation result is precise and objective.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Pushing construction method of single-line railway steel truss bridge utilizing guide beam

ActiveCN106368129ASolve the problem of limited space on the construction siteGuaranteed navigable widthBridge erection/assemblyBridge materialsEngineeringSingle line

The invention discloses a pushing construction method of a single-line railway steel truss bridge utilizing a guide beam. The pushing construction method comprises the following steps: (1) establishing a fixed supporting bent frame group; (2) setting up an assembling platform above fixed supporting bent frames; (3) establishing two temporary supporting bent frames; (4) assembling a steel truss bridge section by section and connecting the guide beam with the front end of the steel truss bridge; (5) driving the guide beam and the assembled steel truss bridge to move forward through a wheel moving box; (6) jacking the steel truss bridge through a jack mounted on a bridge pier; (7) driving the guide beam and the steel truss bridge to move forward at the same time through the wheel moving box; (8) connecting the wheel moving box on the temporary supporting bent frames with the steel truss bridge and dismounting the temporary supporting bent frames; (9) finishing pushing of the steel truss bridge; meanwhile, dismounting the two temporary supporting bent frames. According to the pushing construction method provided by the invention, used equipment is simple and convenient; in a construction process, noises are small and influences on the environment are small; normal navigation of a river channel is guaranteed.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

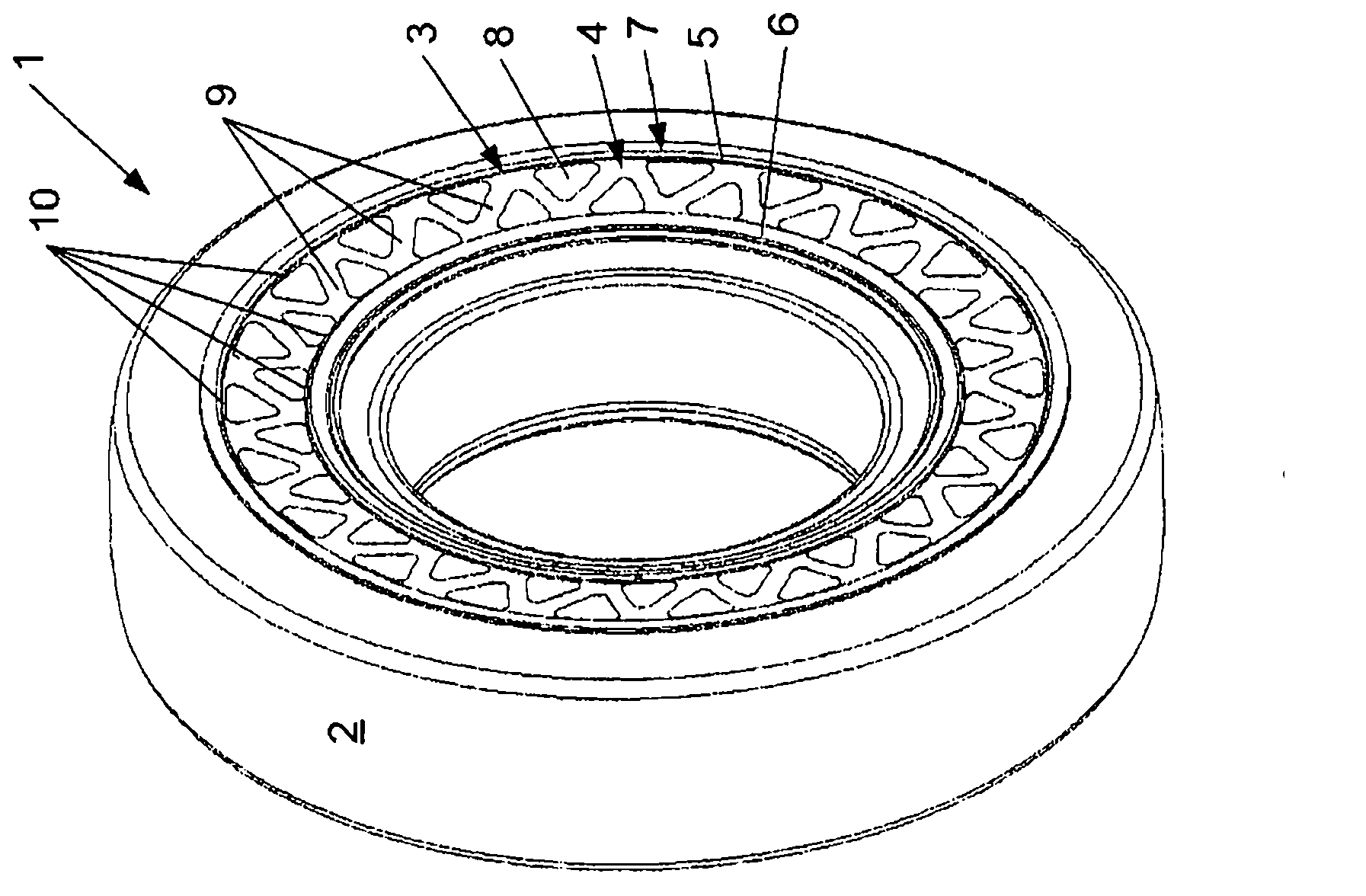

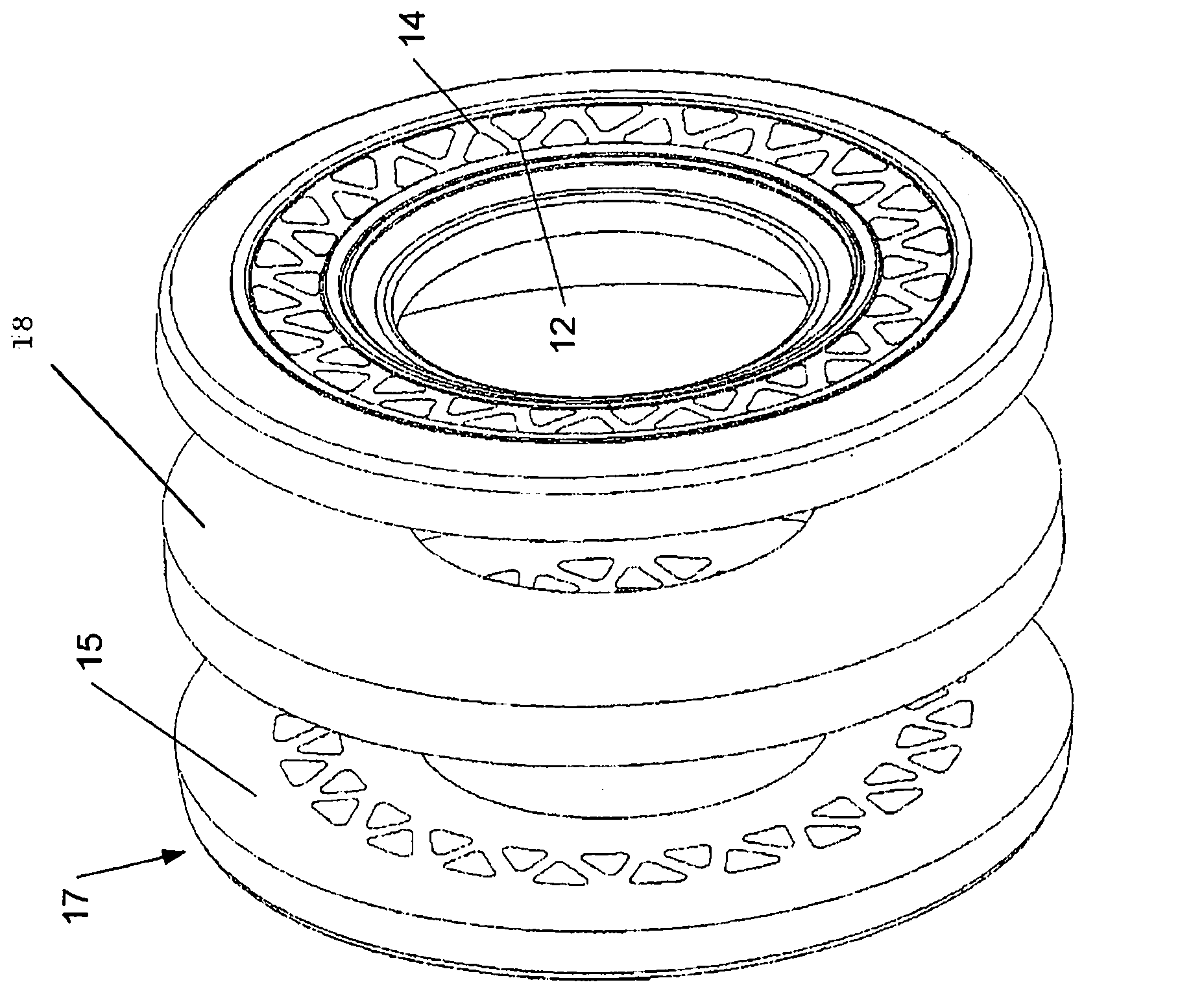

Non- pneumatic tire

ActiveCN103282214AImprove ease of manufactureGood staticNon-inflatable tyresEngineeringMechanical engineering

A tire (1) comprises a rubber tread portion (2) and a truss ring (3), wherein the rubber tread portion (2) extends in circumferential direction of the tire (1) and is provided for contacting a ground surface, and the truss ring (3) contacts and extends along the tread portion (2) for supporting the vehicle on the tread portion (2), and is composed of truss members (4) which form two circumferential chords (5, 6) concentrically positioned with respect to the tread portion (2) and a truss web (7) interconnecting the chords (5, 6). The truss members (4) are made of a truss member material comprising rubber and having an E modulus of between 4 - 18 MPa.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

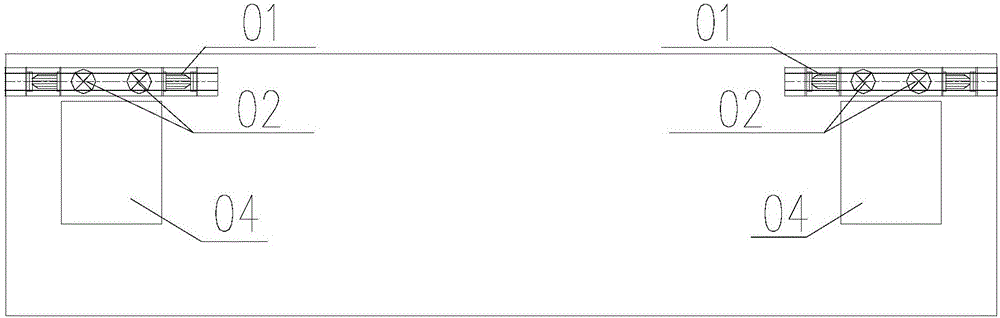

Method for reinforcing and modifying through steel truss bridge

InactiveCN101122118AIncrease horizontal widthIncrease lateral stiffnessTruss-type bridgeBridge erection/assemblyReconstruction methodLateral stiffness

A method for strengthening and reforming a down-loaded steel truss bridge, which comprises the following steps: on both sides of the bottom of a truss (1) with a rectangular cross-section, a plane bracket (2) connected to a steel structure is fixedly connected by welding or threaded ), the connected plane bracket (2) is on the same plane as the bottom of the truss (1). The method can increase the lateral rigidity of the steel truss bridge and reduce the lateral vibration amplitude; less material is used, the construction and maintenance are simple and convenient, and the required cost is low.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com