Patents

Literature

155results about How to "Guarantee the quality of maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full automatic vehicle-driving section safety management control system and method

ActiveCN104859687ATo achieve the overall requirements of safe productionMeet the overall requirements of safe productionRailway traffic control systemsVideo monitoringSocial benefits

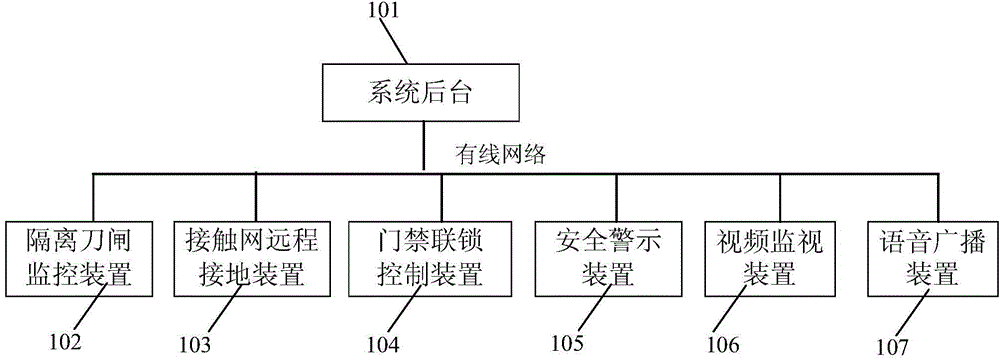

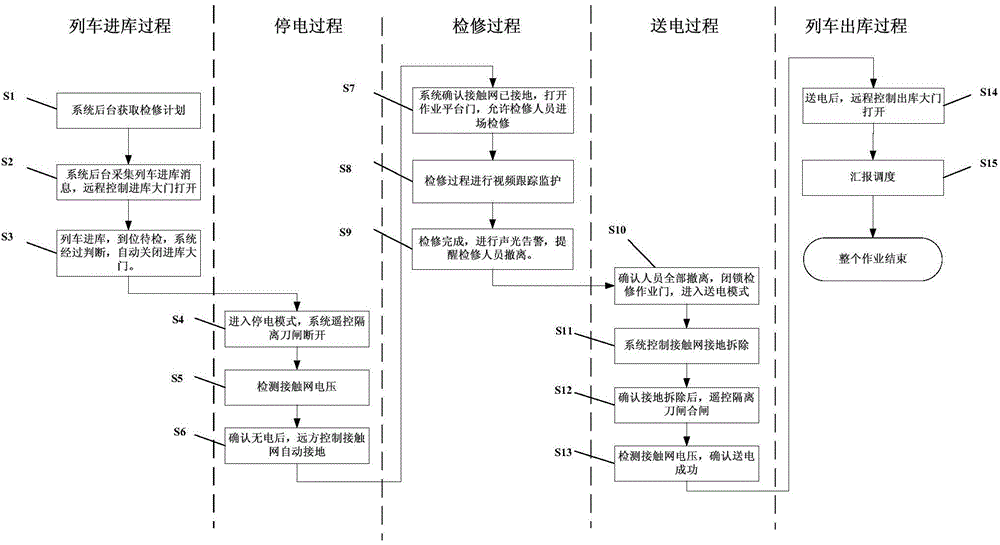

The invention discloses a full automatic vehicle-driving section safety management control system and method, wherein the safety management control system comprises a system backstage, a separation isolator monitoring device, a contact line remote grounding device, a door control interlock control device, a safety warning device, a video monitoring device and an audio broadcasting device; a system backstage host computer is connected to each device through wired network; and the safety management control method comprises the process of a vehicle entering a garage, the process of contact line black out, the process of maintaining the vehicle, the process of the contact line supplying power and the process of the vehicle getting out of the garage. The control system provided herein has the beneficial effects that the operation of maintaining the vehicle-driving section is ensured to be safe and the operation process is regulated; the work efficiency is improved; the maintaining quality is ensured; the fault rate of the device is reduced, so the track transportation is safer and more reliable; and the economy benefit and social benefit are great.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +1

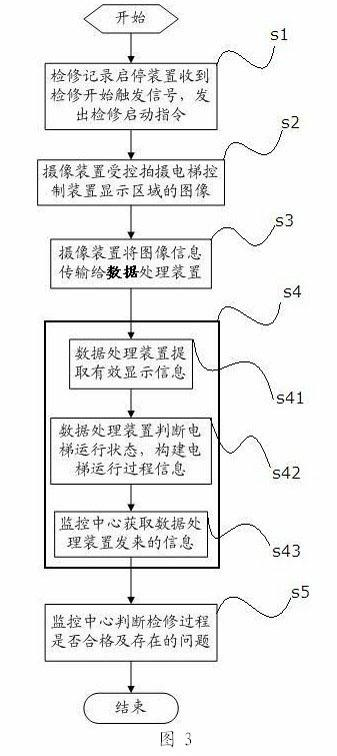

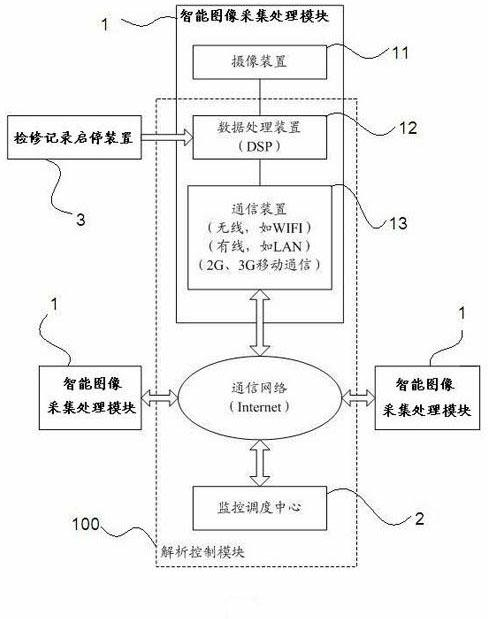

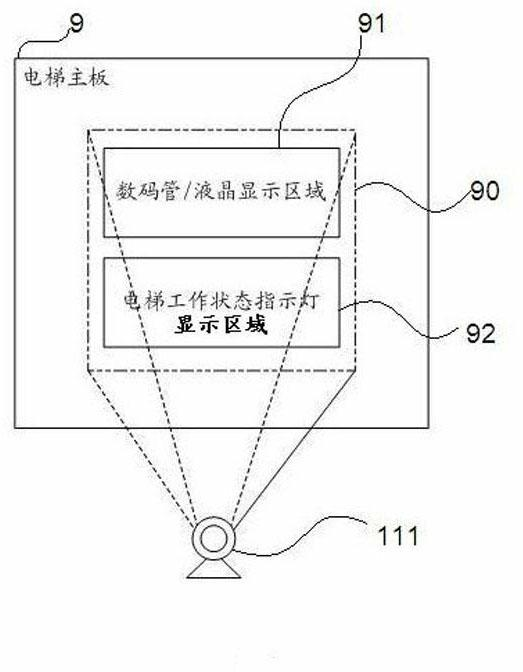

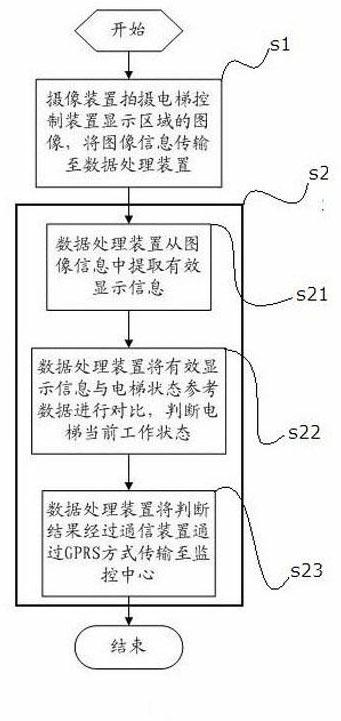

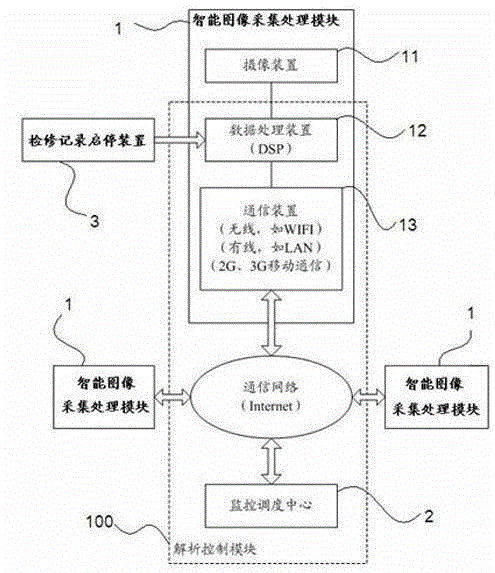

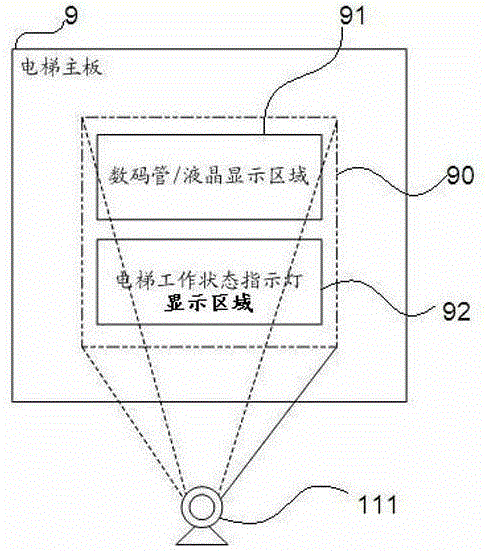

Elevator repair monitoring method

ActiveCN102602762AStandardize maintenance behaviorGuarantee the quality of maintenanceElevatorsElevator systemMonitoring system

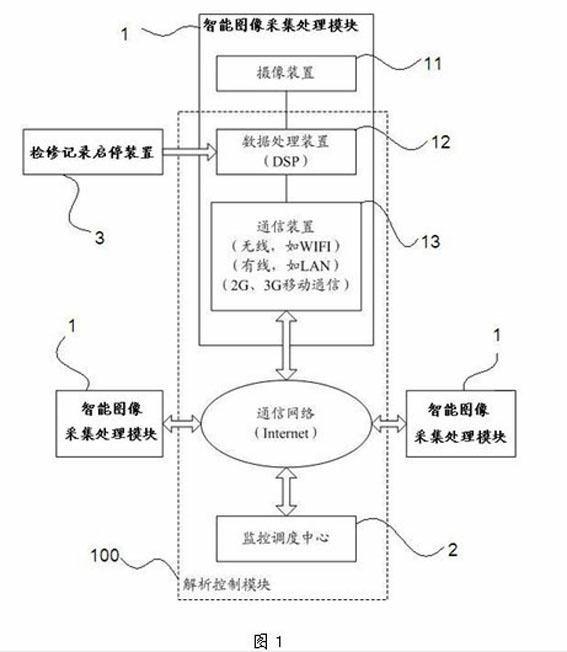

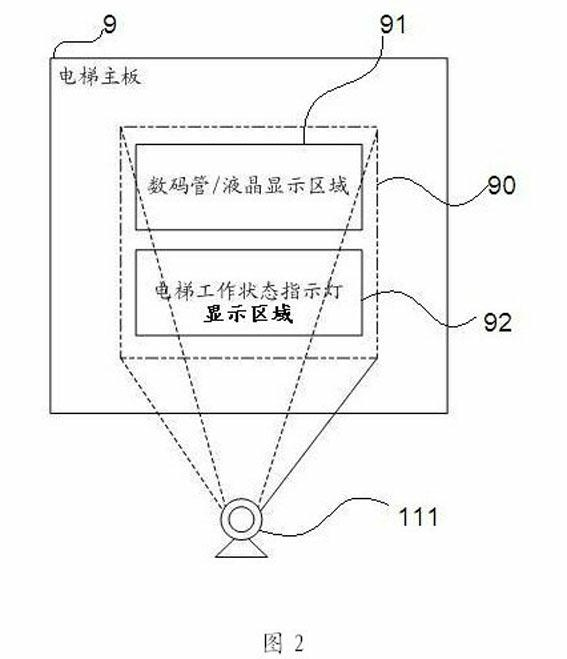

An elevator repair monitoring method includes that a step 1: a repair record starting and stopping device receives a repair starting triggering signal, and transmits a repair starting instruction to an analysis control module; a step 2: the analysis control module controls a photographic device to shoot images of a display region of an elevator control device according to the repair starting instruction; a step 3: the photographic device transmits shot image information to the analysis control module; and a step 4: the analysis control module judges a current running state of an elevator according to the image information. In the technical scheme, a whole repair process can be recorded, and repair operation of repair staffs is monitored. A non-contact type data acquisition mode is adopted, so that an elevator repair monitoring system using the repair monitoring method is independent from another system of a current elevator system, completeness of the elevator system is guaranteed, and effectiveness of the extracted information is also guaranteed.

Owner:佛山市智邦电子科技有限公司

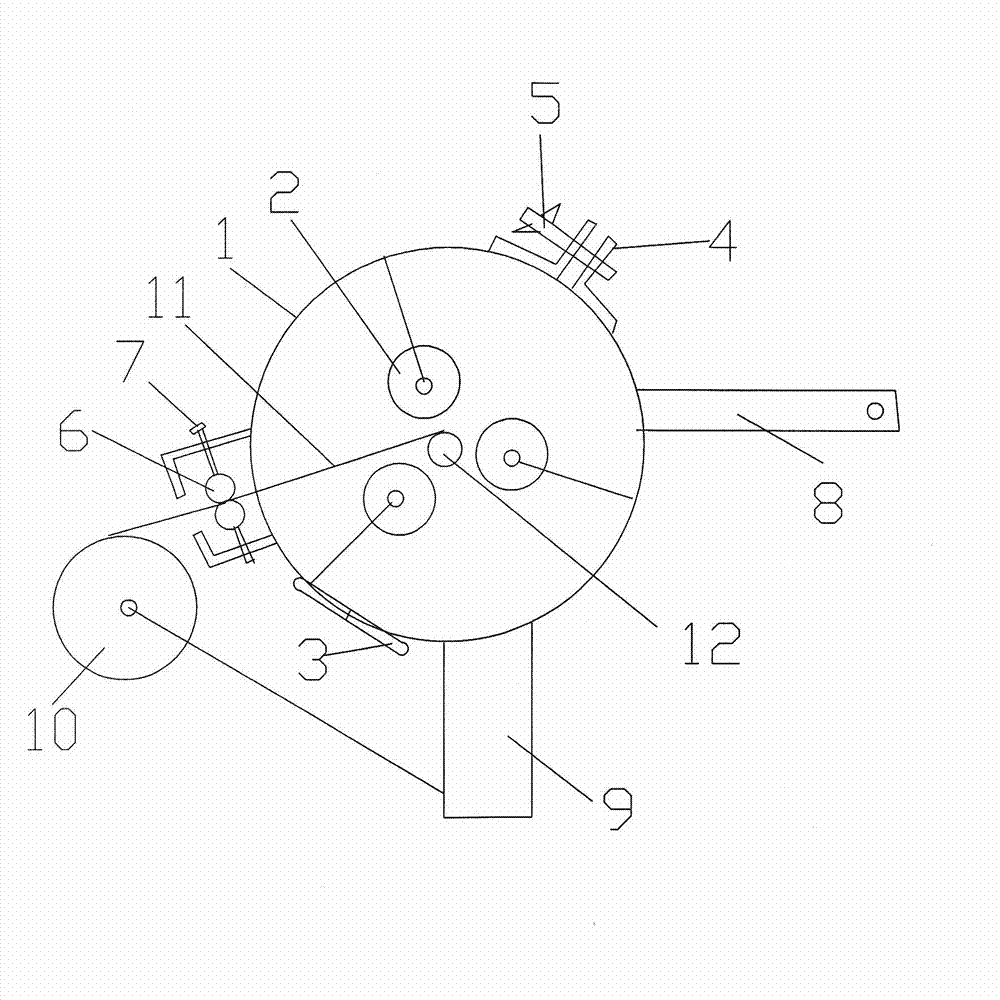

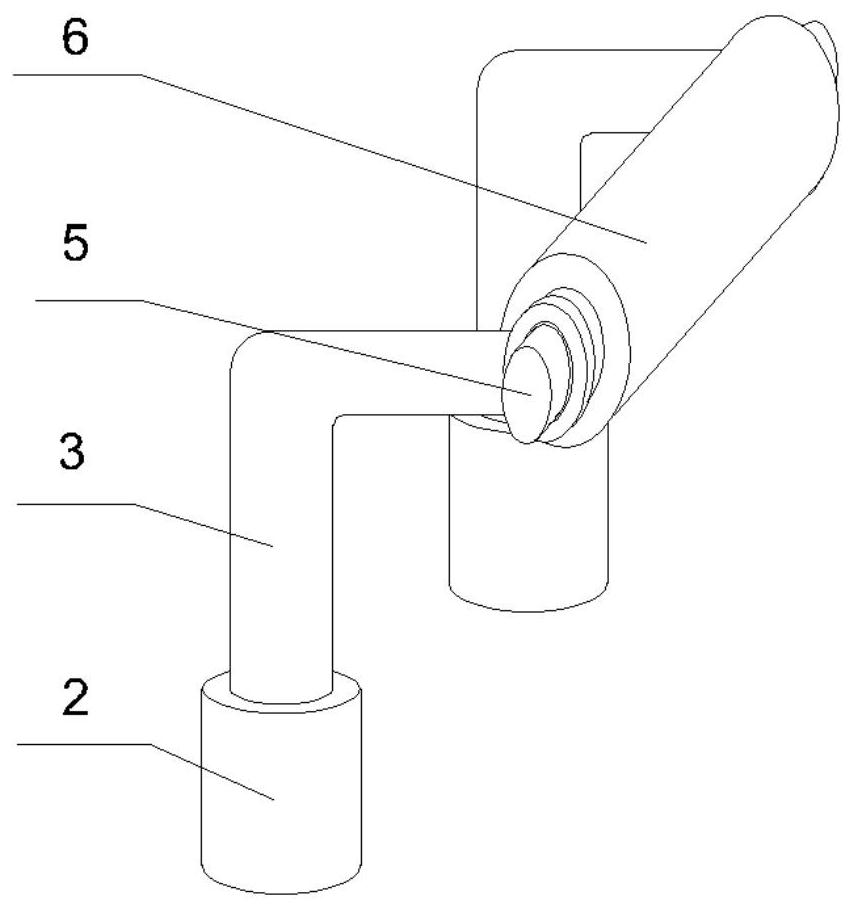

Hand-cranking overhead line repairing and winding device

ActiveCN103208758ASimple procedureShorten the timeApparatus for overhead lines/cablesOverhead lineRocker arm

The invention relates to a hand-cranking overhead line repairing and winding device. According to the device, one edges of two half-round wheels are connected through a fold to form a round wheel, fixing clips are arranged at the other edges of the two half-round wheels, an overhead line fixing device is arranged inside the round wheel, a top wheel, a rocker arm and a binding wire coil are arranged on the outer side of the round wheel, and a binding wire which is twined round the binding wire coil extends out and is twined round a repaired overhead line through the top wheel. By the aid of the device, procedures of high-place operations are simplified, the time for high-place operations is shortened, the device is applicable to overhead lines of different specifications, simple to operate, quick, convenient, standard and compact to twine, low in cost, wide in application range, safe and reliable in performance, flexible, handy and capable of guaranteeing the maintenance quality, shortening the operation time, reducing the labor intensity of operators and guaranteeing the construction safety of operators, and the device can be popularized and used in power transmission and production industries easily.

Owner:STATE GRID CORP OF CHINA +1

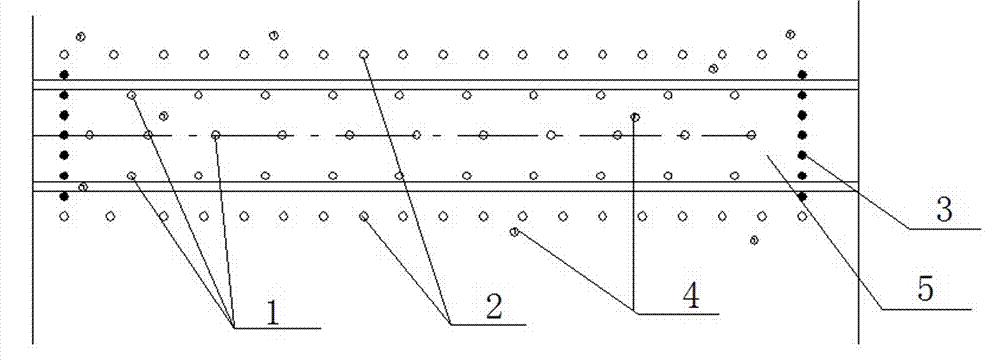

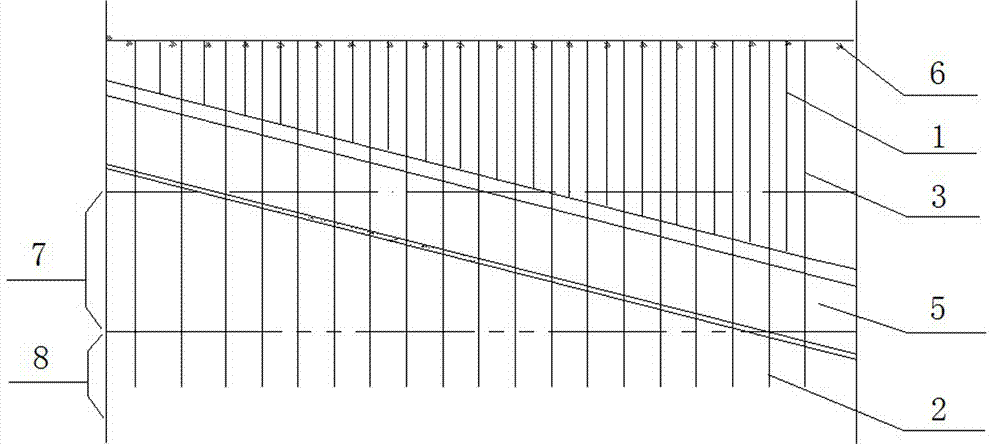

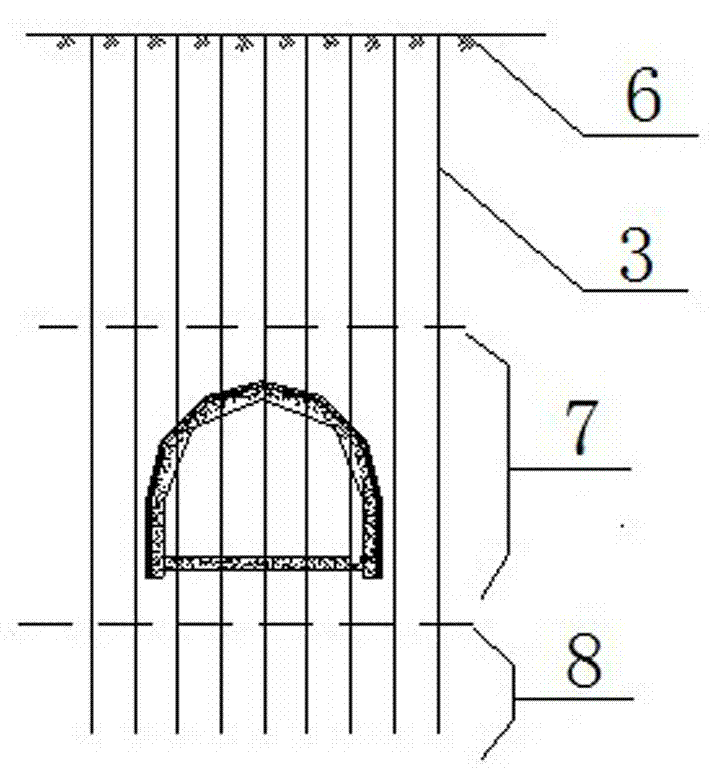

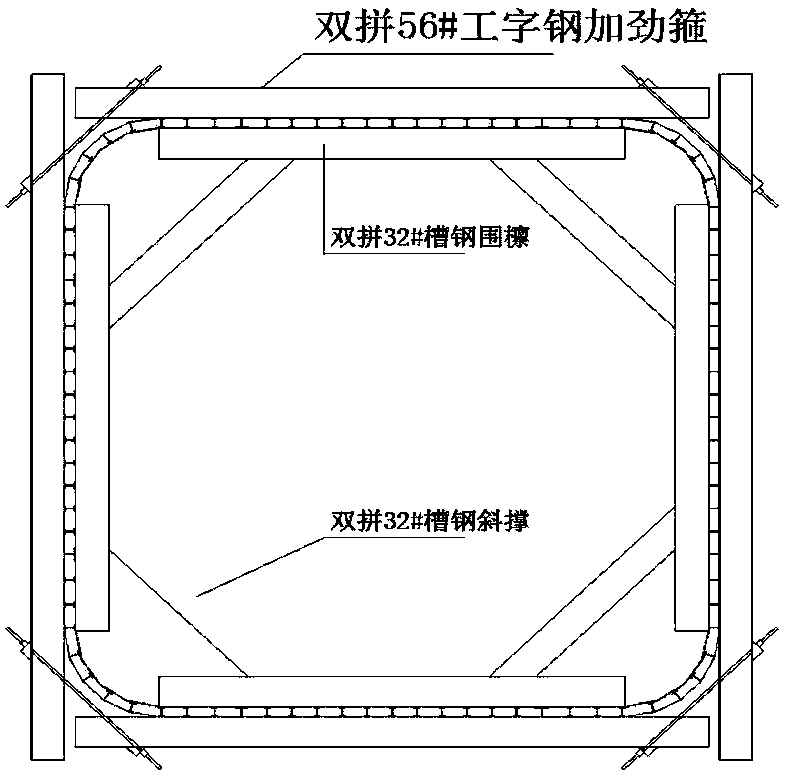

Freezing method of frozen wall of inclined shaft

The invention provides a freezing method of a frozen wall of a frozen wall of an inclined shaft, solving the problems of difficulty in digging in the construction because an aquifer of the inclined shaft is frozen and low construction speed and meeting safe and rapid construction requirements of the aquifer of the inclined shaft. The freezing method comprises the following steps of: drilling multiple rows of freezing holes which are parallel to each other and vertically distributed, on the group, along an axial freezing range of the inclined shaft, wherein the row number of the freezing holes is determined according to the cross section size of the inclined shaft and the required freezing time, the freezing holes at the lateral part and the freezing holes at the end part respectively go deep into a water-resisting layer in the depth, water in the aquifer at the lower part is isolated by the water-resisting layer, and the freezing holes at the top go deep into the top of the inclined shaft in depth; then arranging a freezing pipe and a liquid supply pipe in each drilled freezing hole, wherein the freezing pipe and the liquid supply pipe in each drilled freezing hole are communicated with an external freezing station; and finally, starting the freezing station and enabling low-temperature saline water prepared by the freezing station to flow in the each freezing pipe to absorb heat of the stratum around each freezing pipe to form a frozen cylinder, wherein all frozen cylinders are continuously enlarged and further connected to form the frozen wall which can resist earth pressure and water pressure.

Owner:YANKUANG GRP CO LTD +1

Elevator monitoring method

ActiveCN102616617ARealize real-time monitoringIntegrity guaranteedElevatorsElevator systemMonitoring system

The invention provides an elevator monitoring method. The method comprises the steps that: Step 1, a camera shooting device shoots images of an elevator control device display area, and sends corresponding image information to an analyses control module; and Step 2, the analyses control module judges current working state of the elevator according to the image information. According to the invention adopting the technical scheme, a non-contact data acquisition manner is adopted, and the camera shooting device is arranged in an appropriate position outside the elevator control device to picture the elevator control device; and due to a data acquisition data manner, an elevator monitoring system adopting the monitoring method provided by the invention is a new system independent of a current elevator system, so that not only is the integrity of the elevator system ensured, but also the validity of the extracted information is guaranteed.

Owner:佛山市智邦电子科技有限公司

Method for restoring threaded hole of locomotive axle box pull rod seat

InactiveCN105537849ALabor-saving maintenanceMaintenance time savingEngineeringUltimate tensile strength

The invention discloses a method for restoring a threaded hole of a locomotive axle box pull rod seat. The method comprises the steps that 1, locating basis fixing is carried out; 2, the threaded hole of the axle box pull rod seat is reamed, wherein a phi24.5 auger bit is used for drilling a threaded bottom hole in an axle box pull rod seat threaded hole workpiece, phi24.43o<+0.375> of the drilled threaded bottom hole and the relative position dimension are guaranteed, and the depth is 98o<+1> mm; 3, a guide thread of the threaded hole of the axle box pull rod seat is tapped; 4, hand tapping is carried out; 5, tapping residues are removed; 6, a steel wire screw sleeve is mounted; and 7, inspection is carried out through a go gauge and a non-go gauge. According to the method for restoring the threaded hole of the locomotive axle box pull rod seat, more labor and time can be saved during maintenance of the locomotive framework axle box pull rod seat, labor intensity is effectively lowered, and maintenance cost is reduced; and the maintenance process is simplified, the technical difficulty coefficient of maintenance is reduced, and the maintenance quality of the locomotive framework axle box pull rod seat can be guaranteed.

Owner:CRRC LUOYANG CO LTD

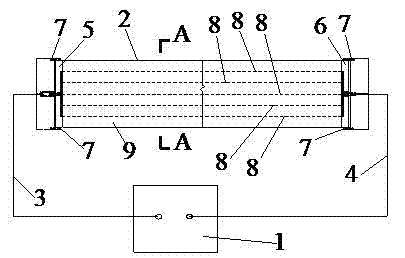

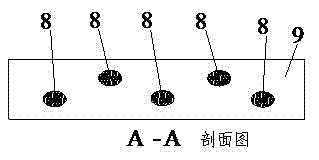

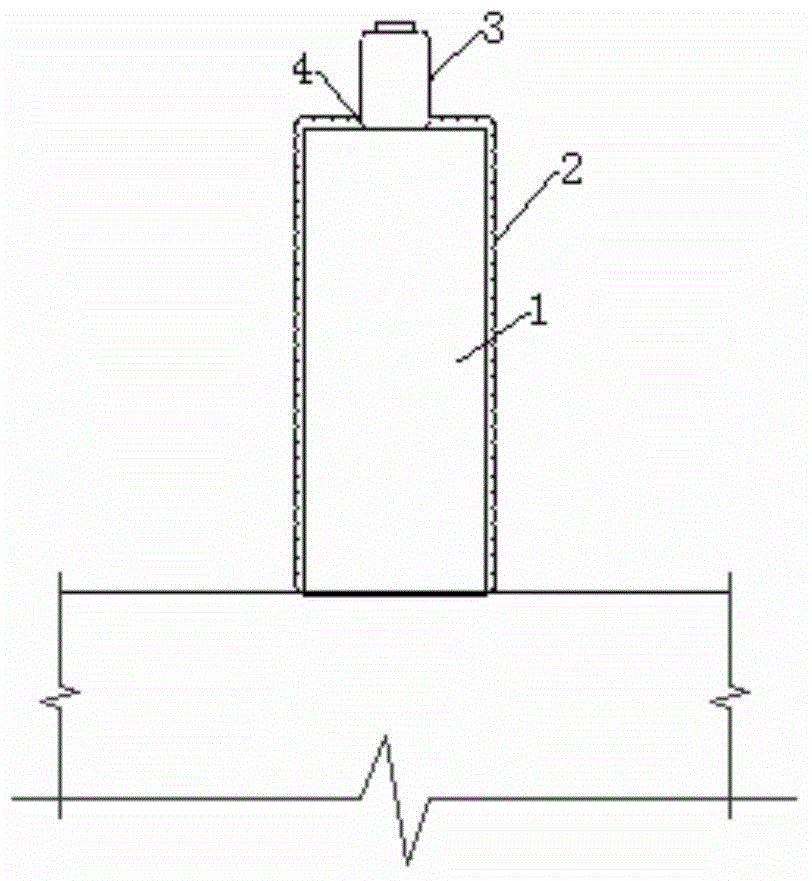

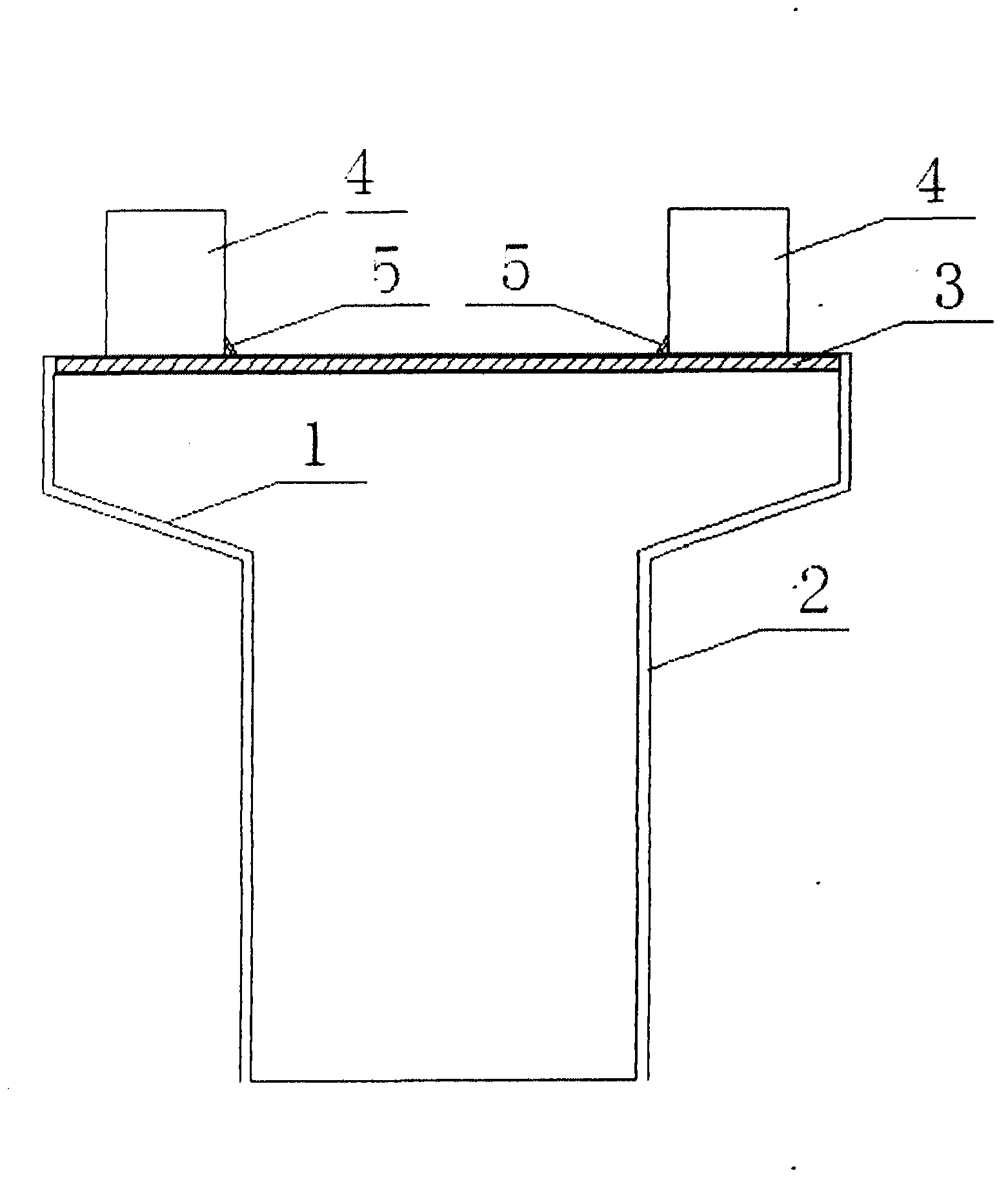

Reinforced concrete structure curing device in low-temperature environment

InactiveCN102642244AHarden fastGuarantee the quality of maintenanceCeramic shaping apparatusSocial benefitsPower flow

The invention discloses a reinforced concrete structure curing device in a low-temperature environment. The reinforced concrete structure curing device in the low-temperature environment is characterized by comprising a variable frequency power supply and a wide tape, wherein a pin-type end connector and a slot-type end connector are arranged on the wide tape; one end of the variable frequency power supply is connected with the slot-type end connector of the wide tape through a lead wire with a pin-type plug; and the other end of the variable frequency power supply is connected with the pin-type end connector of the wide tape through a slot-type plug. The device is simple in structure, easy to construct, and high in real-time controllability; the defects of conventional curing measures of a reinforced concrete structure are overcome; required heating depth can be obtained by controlling current frequency, so that the requirement on curing a specific reinforced concrete structure can be met; and therefore, the device has enormous economic, environmental and social benefits. In addition, the hardening of concrete can be accelerated by heating according to engineering requirements, so that the aim of reasonably shortening curing time is fulfilled. Therefore, the device is suitable for curing the reinforced concrete structure, and is particularly applicable for the low-temperature environment.

Owner:CENT SOUTH UNIV +2

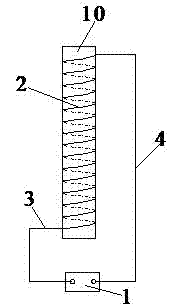

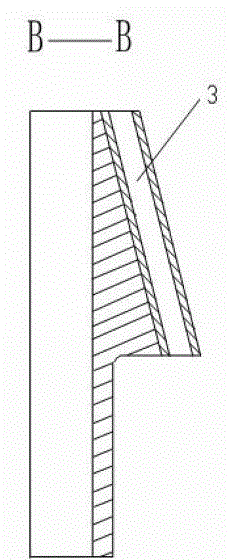

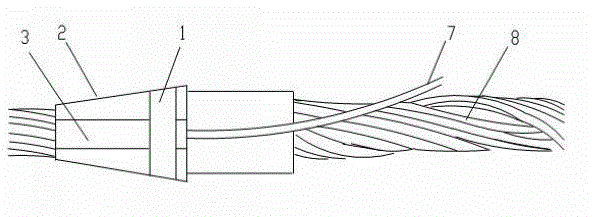

Pre-twisted wire installation clamp

ActiveCN103606856AGuarantee the quality of maintenanceEasy to moveApparatus for overhead lines/cablesLocking mechanismButt joint

The invention discloses a pre-twisted wire installation clamp and belongs to the technical field of devices of fastening wires. The pre-twisted wire installation clamp is characterized by comprising an opening and closing left pipe shell and an opening and closing right pipe shell. The left pipe shell and the right pipe shell are connected in an abutted mode through a locking mechanism to form a sleeve. The center hole of the sleeve is a round hole. A pre-twisted wire fixing mechanism is arranged on the outer surface of the sleeve. The outer face of the upper portion of the sleeve is a circular conical surface. The pre-twisted wire fixing mechanism is composed of two casing pipes which are fixed on the left pipe shell and the right pipe shell respectively. A hinge joint hinge is arranged between the left pipe shell and the right pipe shell. A snap joint which makes the left pipe shell and the right pipe shell be connected in the abutted mode is arranged on each casing pipe. The clamp can be installed on a power transmission line in a butt joint and sleeved mode, so that the head portion of a pre-twisted wire is inserted into the casing pipes and firmly fixed. The circular conical surface forms a tapered head portion. A ladder assembly sheave hung to the power transmission line can be conveniently moved from the clamp, the labor intensity can be reduced and the overhauling quality of the power transmission line can be ensured.

Owner:STATE GRID CORP OF CHINA +2

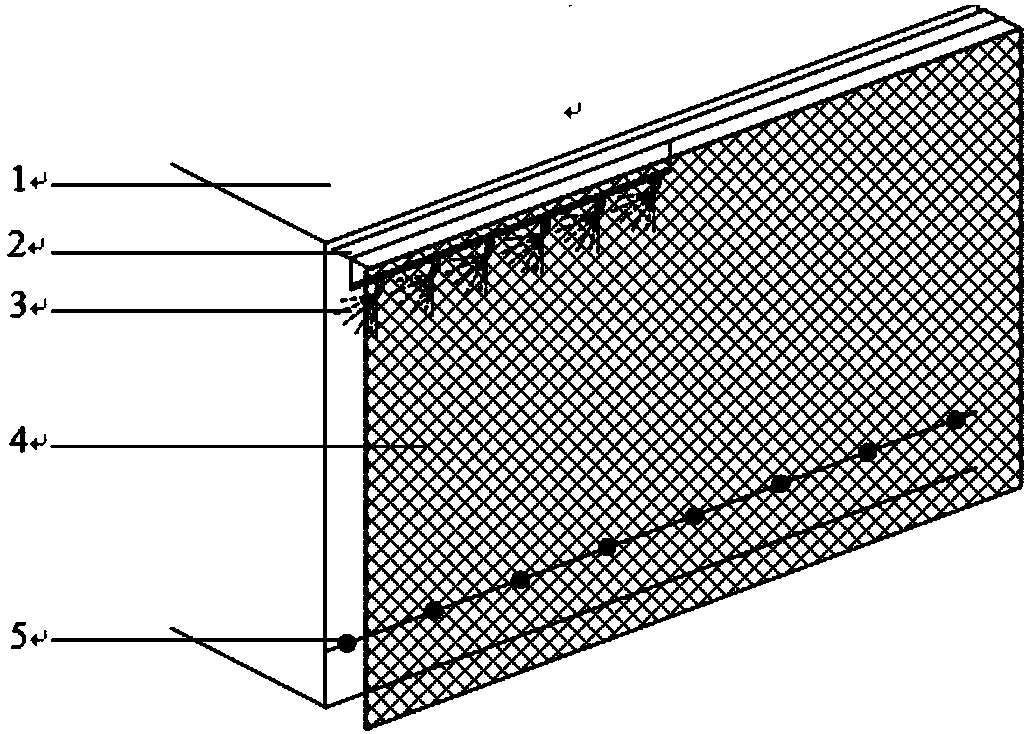

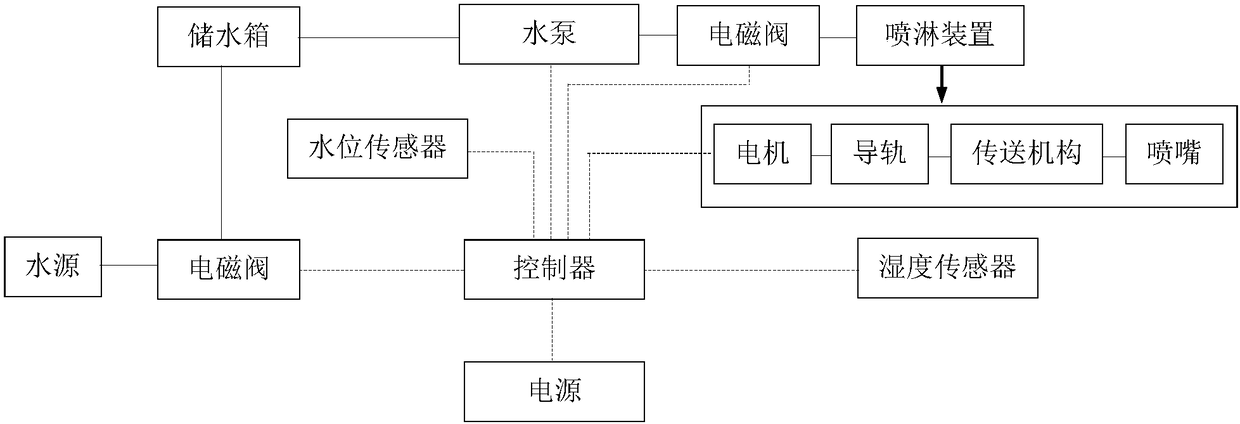

Intelligent spraying curing system and method for concrete vertical structure

ActiveCN108252525AGuarantee the quality of maintenanceSpray maintenance saves waterBuilding material handlingWater storage tankElectric machinery

The invention discloses an intelligent spraying curing system and method for a concrete vertical structure and belongs to the technical field of building engineering. According to the intelligent spraying curing system and method for the concrete vertical structure, the problem that as for existing engineering, the manual-watering curing mode is adopted for a concrete vertical structure, and consequently, the poor quality, large water consumption and high cost exist is solved. The intelligent spraying curing system comprises a water storage tank, a water pump, a controller and spraying devices. The water storage tank is used for storing spraying curing water; the controller can control the water level of the water tank; the spraying devices each comprise a motor, a guide rail, a conveyingmechanism and a plurality of nozzles; the guide rails are arranged on the upper portion of formwork equipment of the concrete vertical structure, and the conveying mechanisms are slidably connected with the guide rails and provided with the multiple nozzles; and the nozzles can move with the conveying mechanism along the guide rails under driving of the motors. Starting and stopping of spraying curing are controlled by monitoring the humidity of the concrete vertical structure, the spraying curing frequency is automatically adjusted according to the humidity changing situation, the concrete curing quality is ensured, and the curing water is saved.

Owner:SHANGHAI CONSTRUCTION GROUP

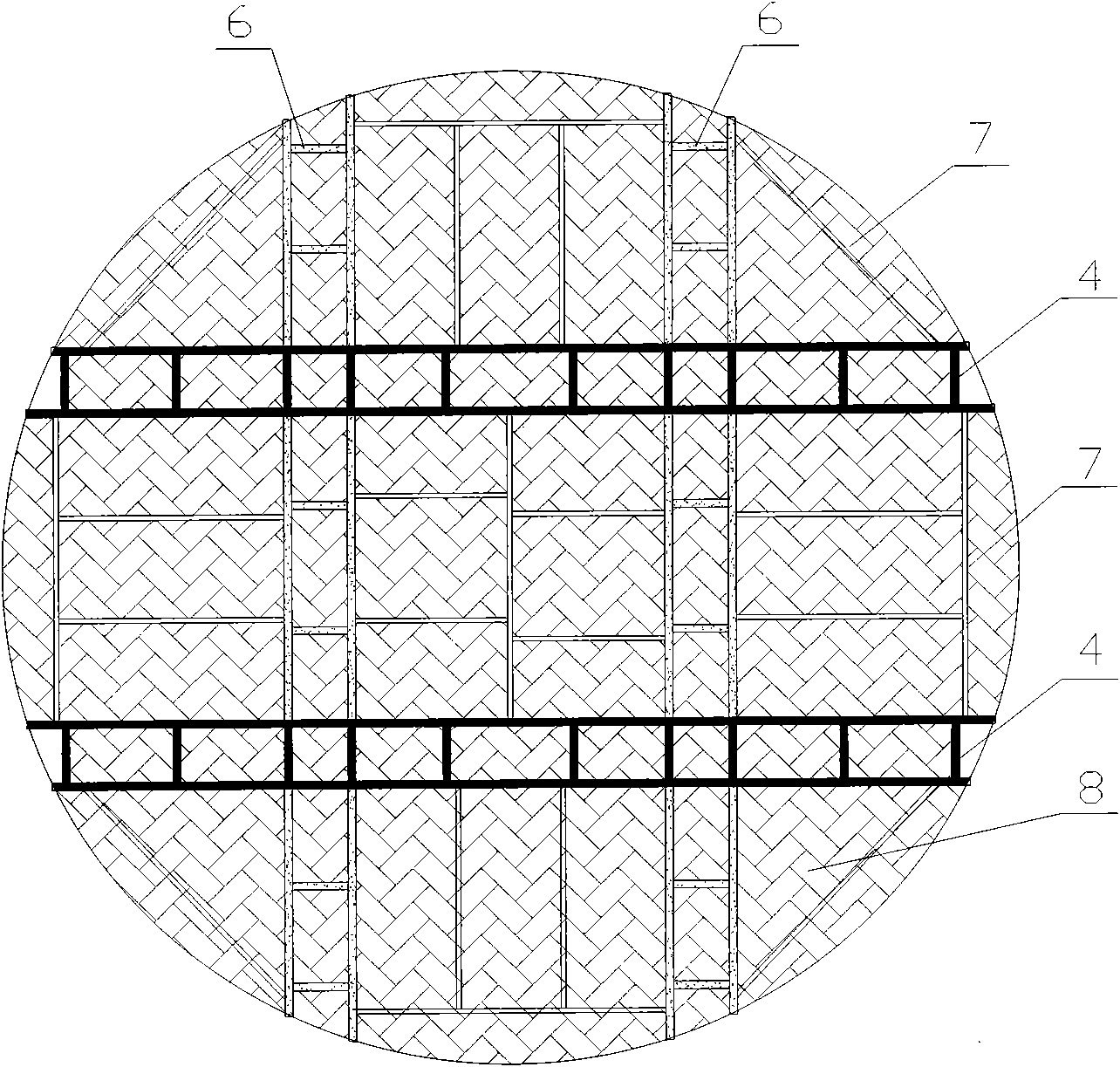

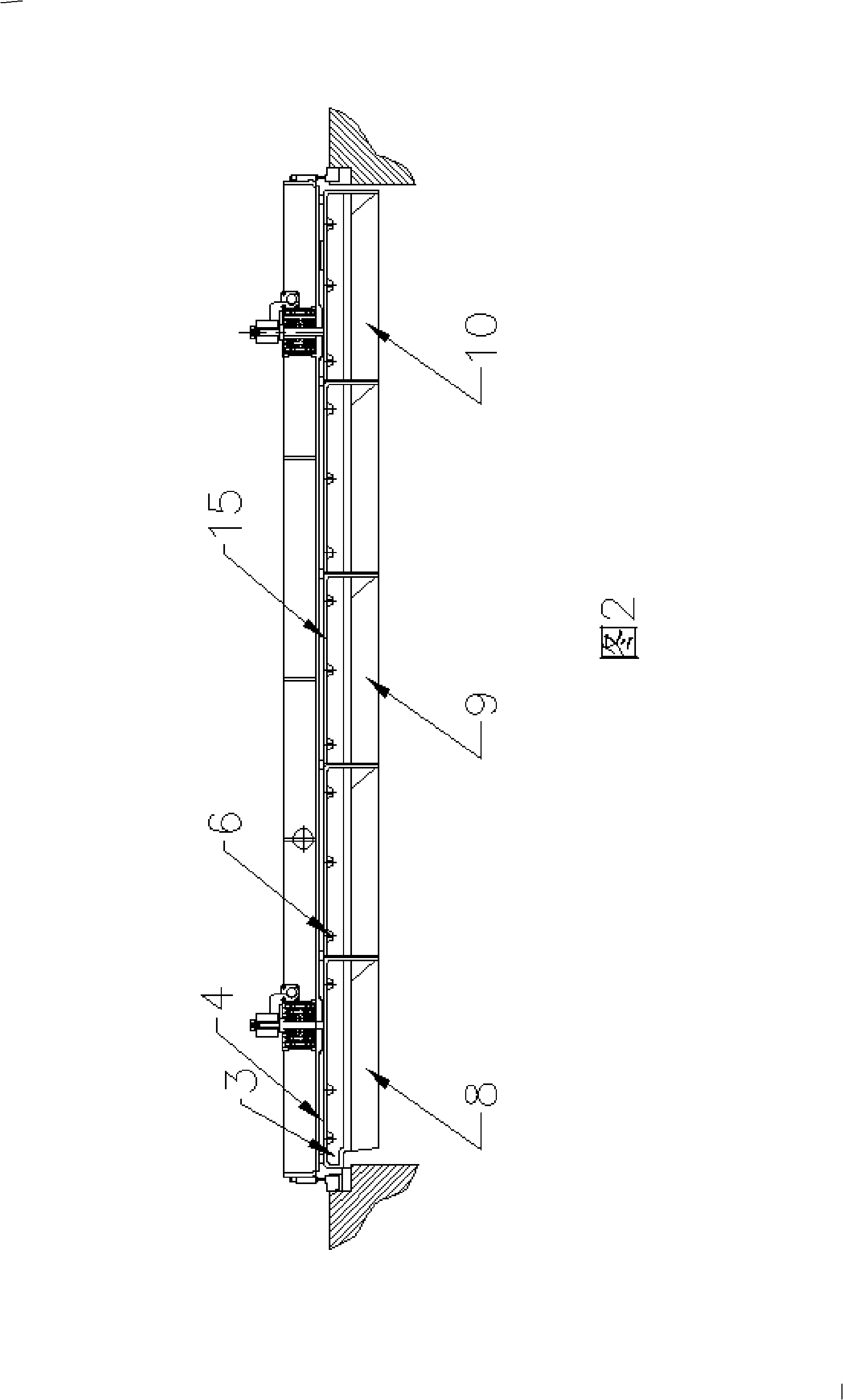

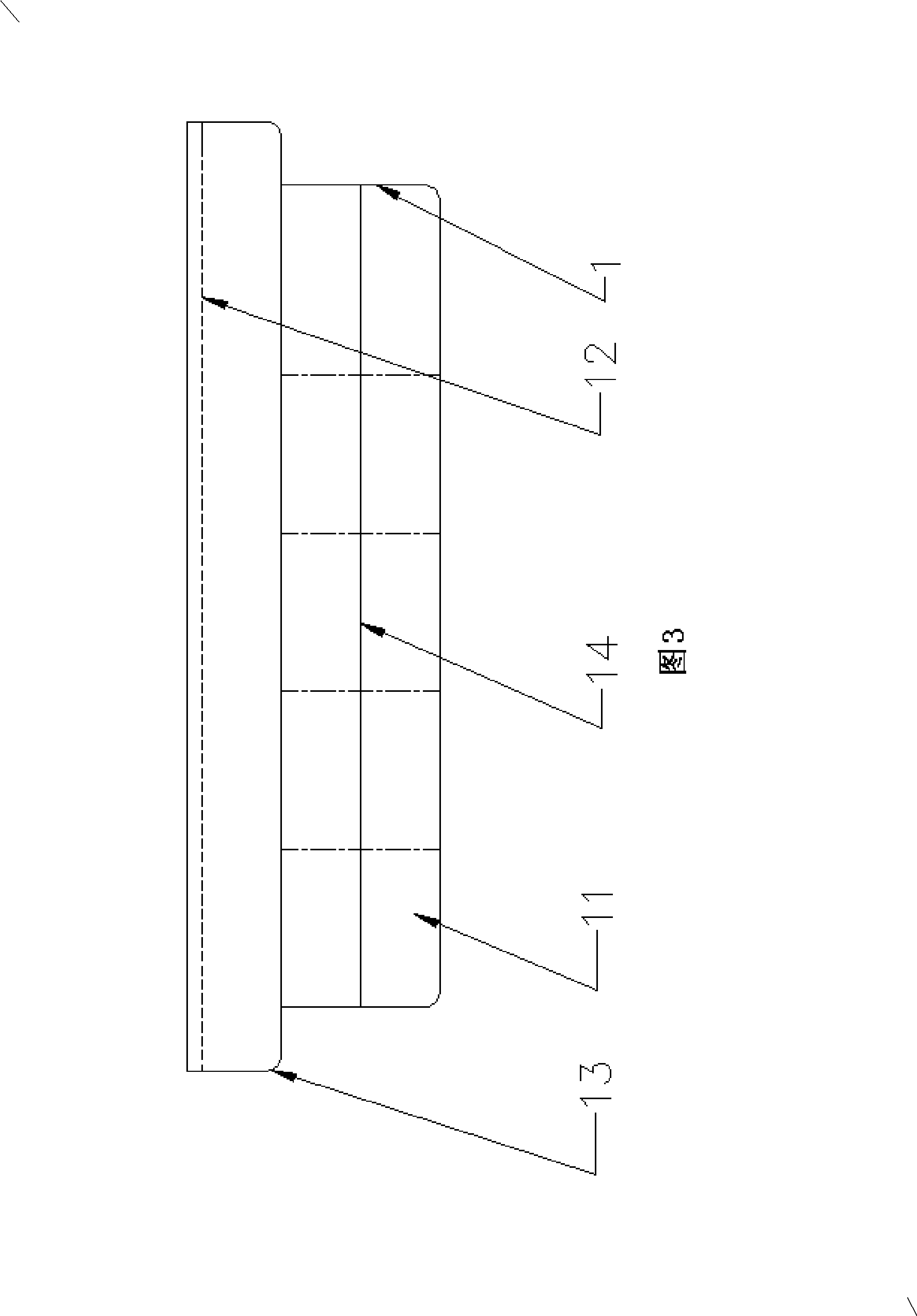

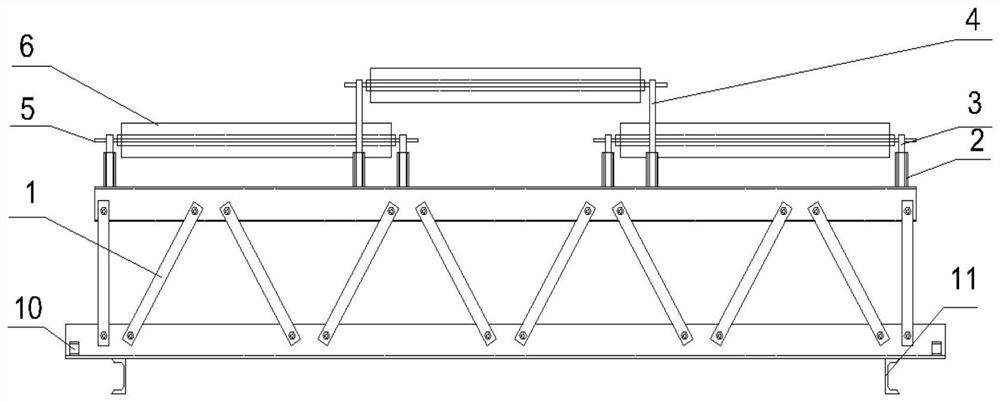

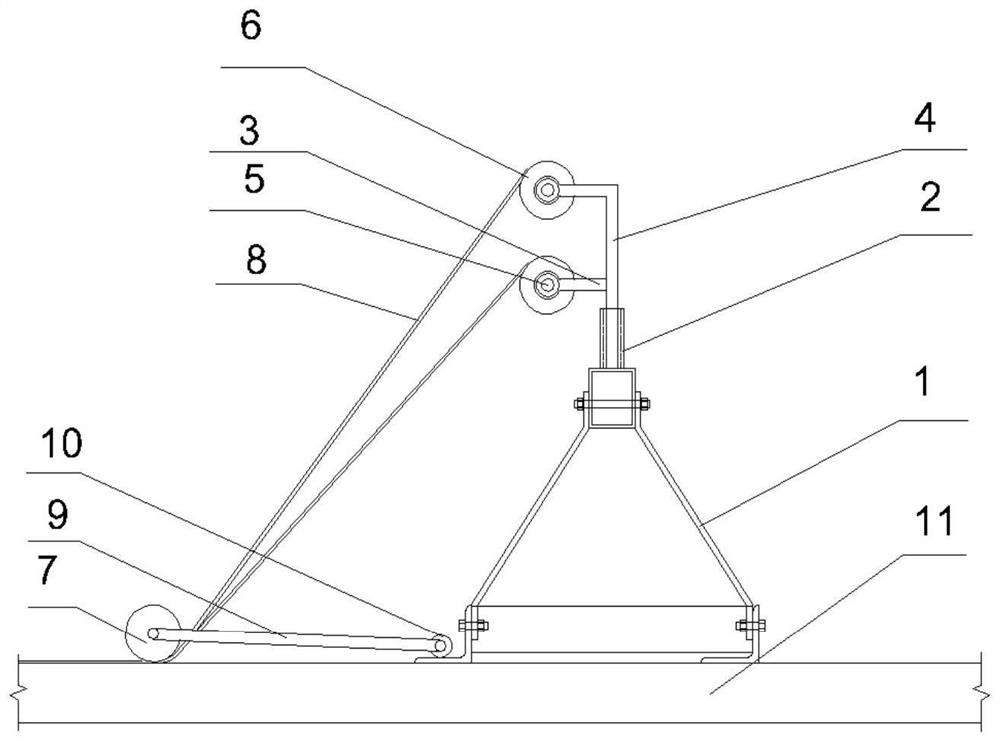

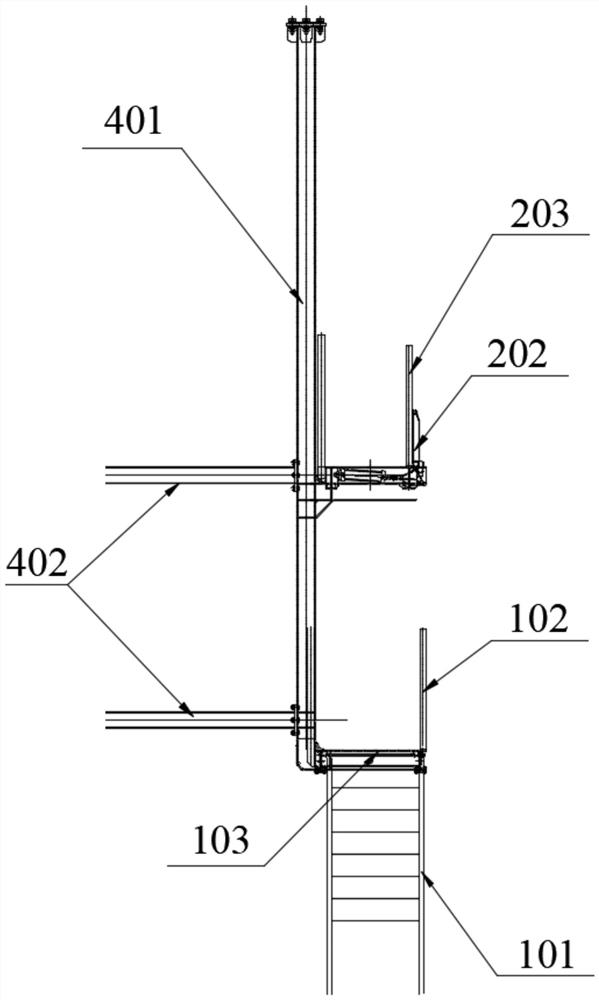

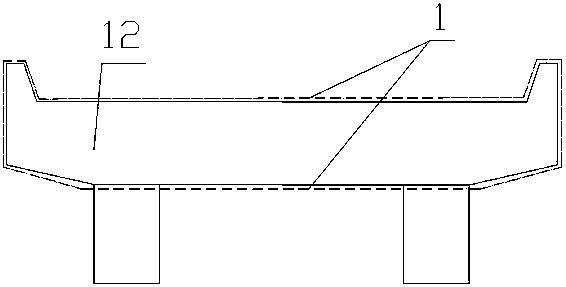

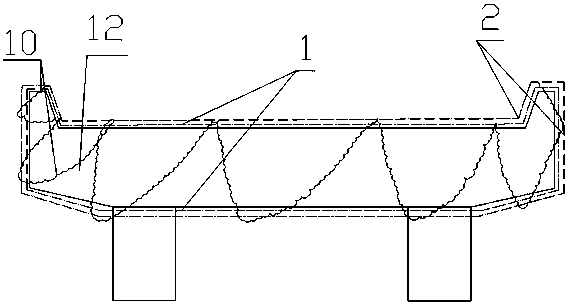

Elevation type tail water overhauling platform and manufacturing method and application thereof

InactiveCN101560826AImprove securityEasy to checkFinal product manufactureWater-power plantsMarine engineeringWater pipe

The invention provides an elevation type tail water overhauling platform, which comprises an elevating gear, a platform main girder, a platform auxiliary girder, a support girder and a platform plate. The elevating gear is connected and fixedly arranged on the platform main girder, the platform auxiliary girder is crossly fixed on the platform main girder, the support girder is fixedly arranged on the platform main girder and / or the platform auxiliary girder, both ends of the support girder are respectively connected and fixed on the platform main girder and / or the platform auxiliary girder, and the platform plate is fixedly arranged on the platform main girder, the platform auxiliary girder and the support girder. The platform causes a two-dimensional plane working position to expand to a three-dimensional solid working position by the elevation and descent of the platform, thus facilitating the inspection, maintenance and overhauling of any part such as tail water pipe inner wall and hydroturbine vanes.

Owner:SAIKAER BEIJING INDAL TECH

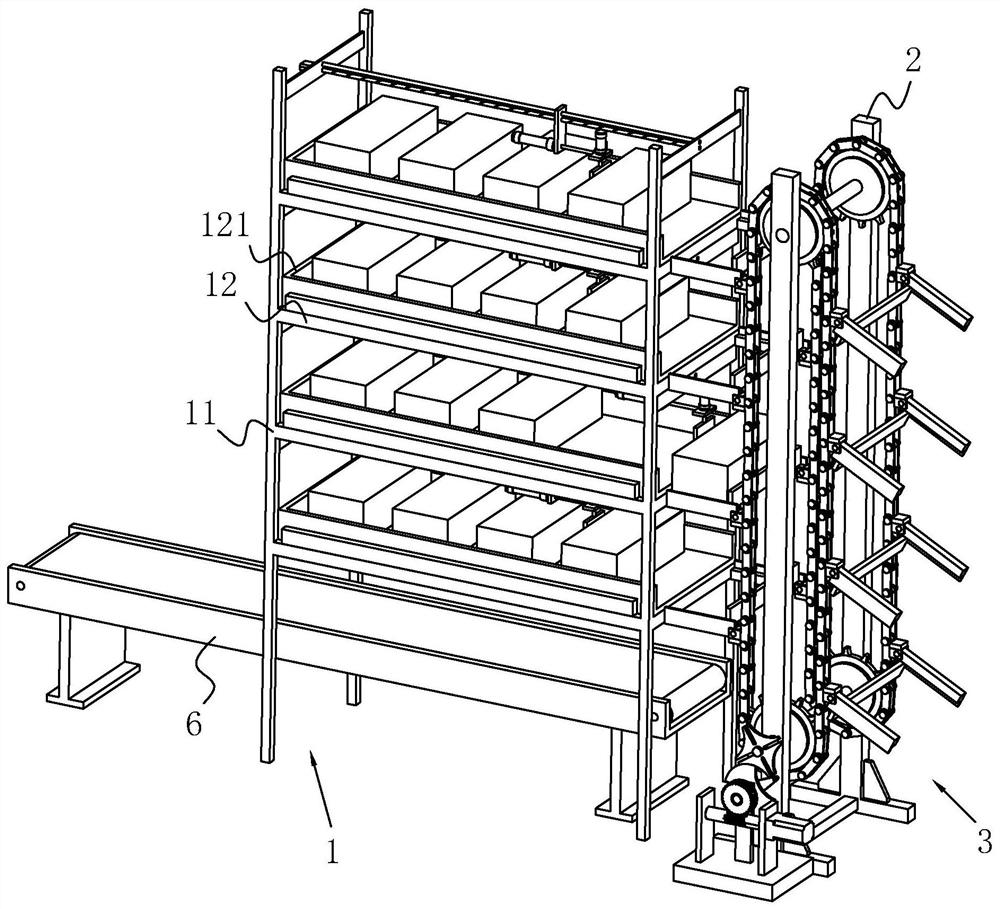

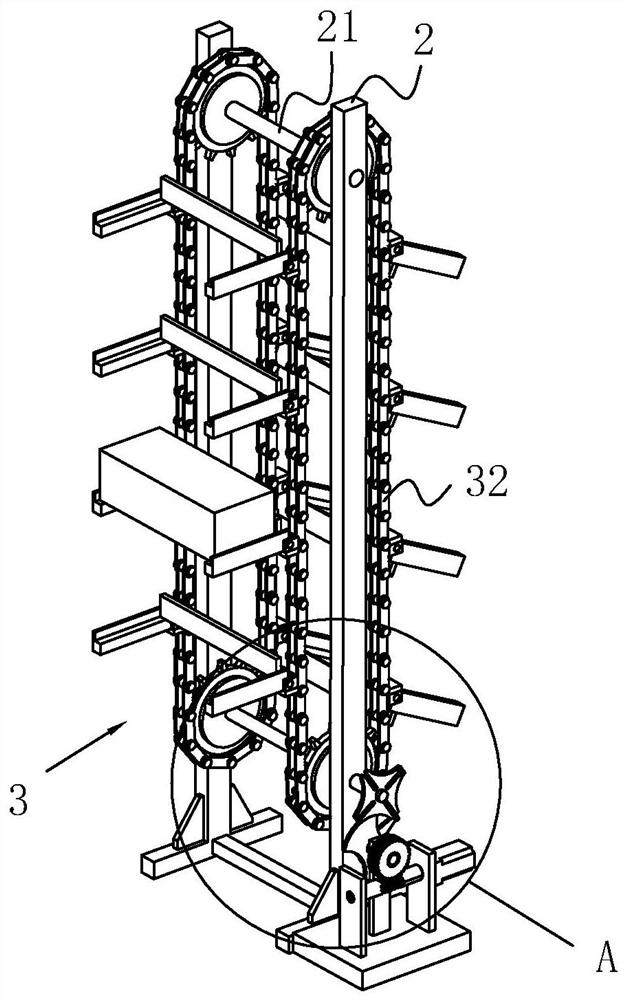

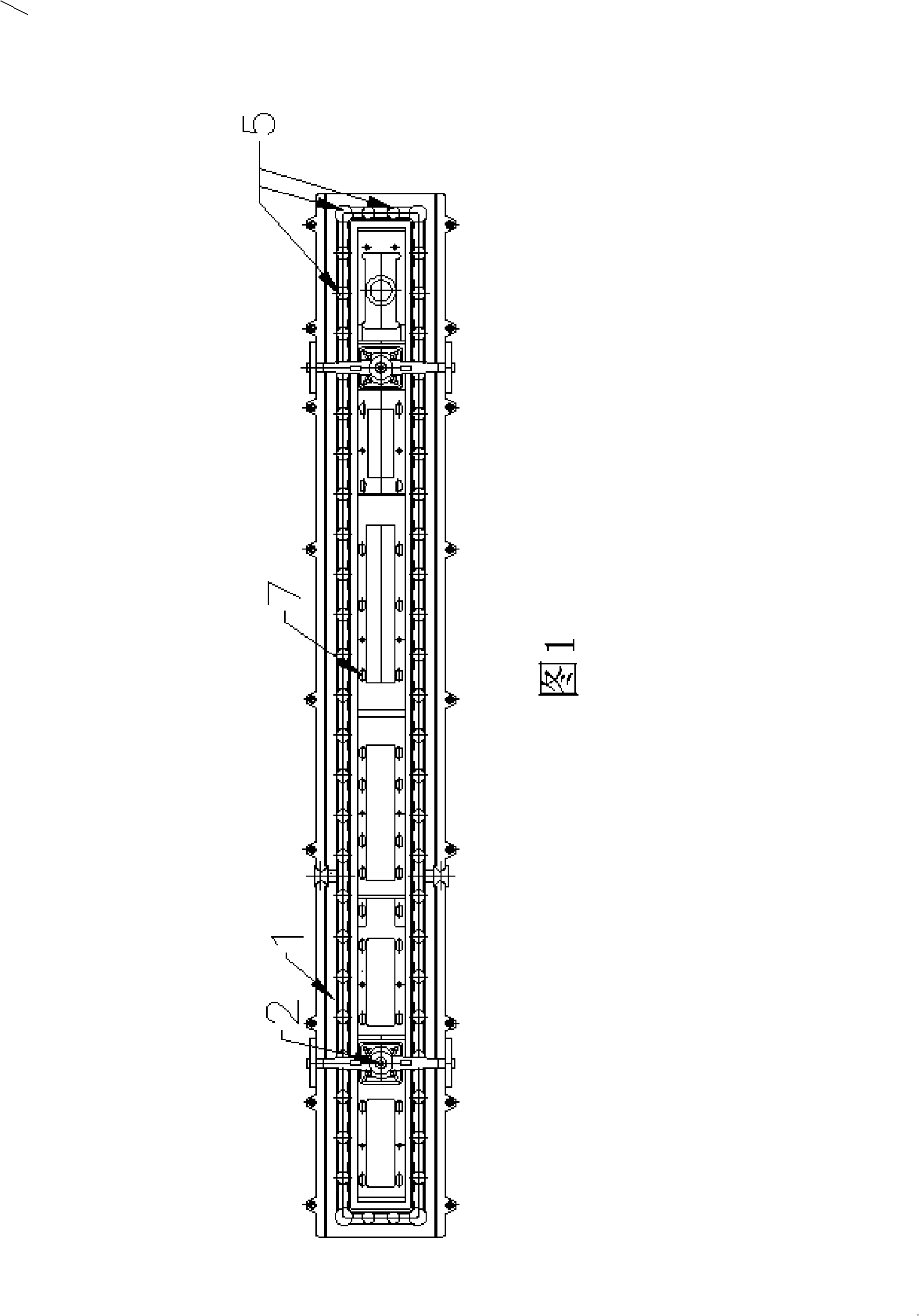

Automatic recording system for concrete sample information

ActiveCN112140309AGuarantee the quality of maintenanceSmall footprintAuxillary shaping apparatusEngineeringStructural engineering

The invention relates to an automatic recording system for concrete sample information, and relates to the technical field of concrete test block curing. The automatic recording system comprises a goods shelf and curing boxes for containing samples. The goods shelf comprises stand columns and cross beams fixedly arranged on the stand columns, and the curing boxes are arranged on the cross beams; and sensing devices for sensing sample curing information are arranged on the side walls of the curing boxes, the automatic recording system further comprises a rack, a vertical conveying device used for conveying the samples is arranged on the rack, the ends, close to the rack, of the curing boxes are open, and a driving assembly for driving the samples to move to the vertical conveying device isarranged on the the goods shelf. During use, the samples are placed in the curing boxes, the curing information of the samples in the curing boxes is monitored in real time through the sensing devices, and the curing quality is guaranteed; and after the curing time is up, the driving assembly drives the samples to move to the vertical conveying device, the samples are taken out through the vertical conveying device, and the curing quality is guaranteed.

Owner:四川精益达工程检测有限责任公司

Curing method for concrete column body structure

InactiveCN104675128AMaintenance Quality AssuranceLow costBuilding material handlingWater pipeEngineering

The invention relates to the field of civil engineering, in particular to a curing method for a concrete column body structure. A sprinkling bucket provided with dripping holes is arranged at the top of a concrete column, so unmanned uninterrupted maintenance for the concrete column can be realized; in addition, a plastic film wraps the side face of the concrete column, so that all faces of the concrete column are enabled to be in a wet state, and a better guarantee is provided for the curing quality of the concrete. According to the curing method, the labor cost and the cost of laying a curing water pipe are reduced, and better economy is obtained.

Owner:NO 1 ENG COMPANY CO LTD OF CCCC FIRST HARBOR ENG COMPANY +1

Maintenance method for coke oven door

InactiveCN101302429AEasy alignmentEasy recovery installationCoke oven doors/closuresRelative displacementBrick

The invention discloses a method for maintaining a coke oven door with higher efficiency. The points of the method different from those of the common method are as follows: firstly, after the oven door is introduced on a maintenance scaffolding, a temporary fixing piece is used to fixedly connect an oven door body and brick grooves, and then an oven door body connecting bolt and brick groove connecting bolts are released; secondly, knife edges and knife-edge web plates are disassembled, maintained and reassembled; thirdly, after the oven door body connecting bolt and the brick groove connecting bolts are refastened, the temporary fixing piece is disassembled. The oven door body and the brick grooves are not disassembled and the parts of the knife edges and the knife-edge web plates which are usually damaged are pertinently overhauled during the maintenance process, thereby the maintenance quality can be guaranteed; simultaneously, lining tiles are not required to be cleaned and rebuilt and no relative displacement is generated between the brick grooves of the oven door body during the maintenance process, thereby the method is convenient for contraposition and recovery assembly of various detachable parts, can shorten the maintenance time and reduce the maintenance cost, and is particularly suitable for being applied to the overhaul of the coke oven door.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

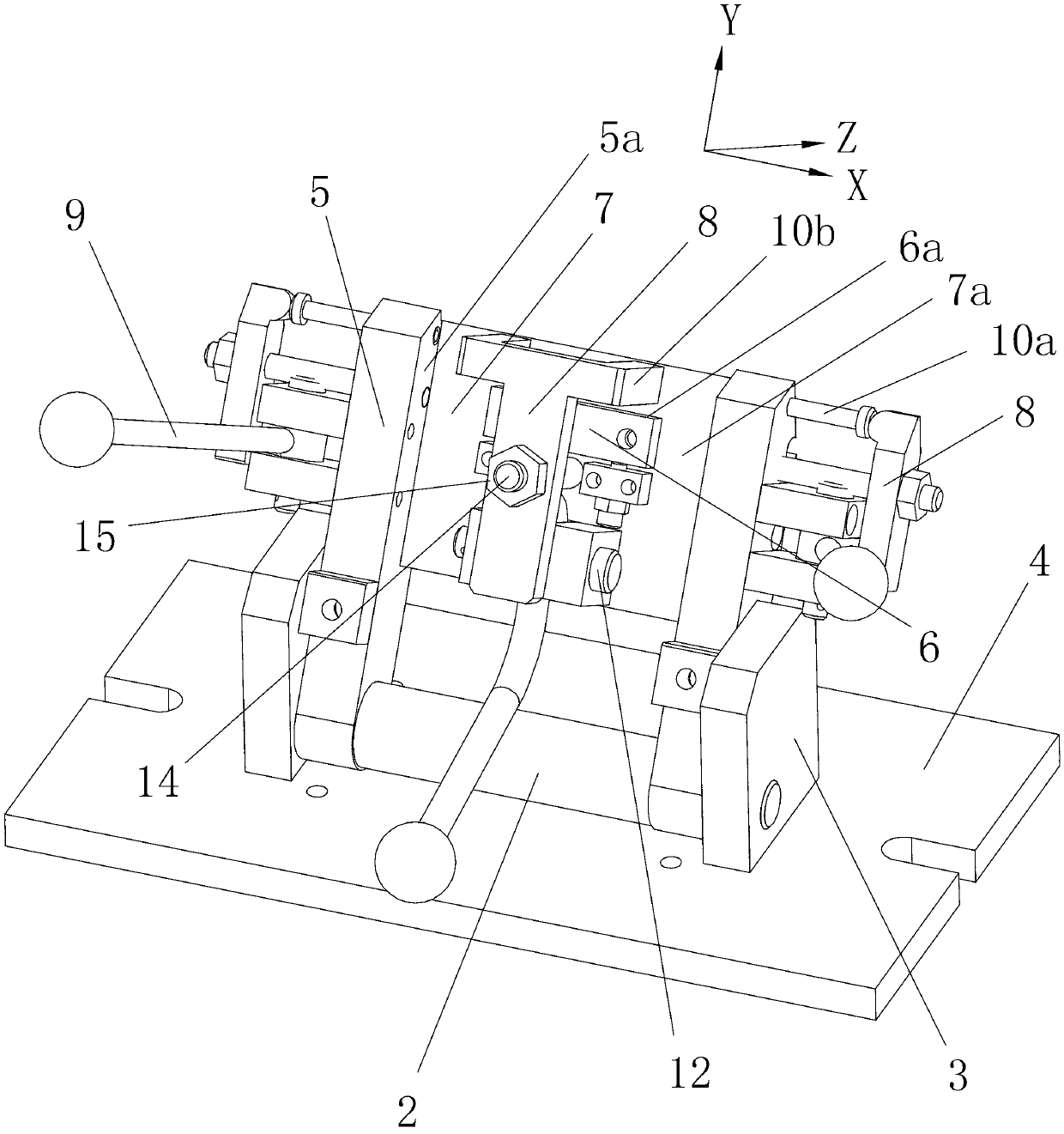

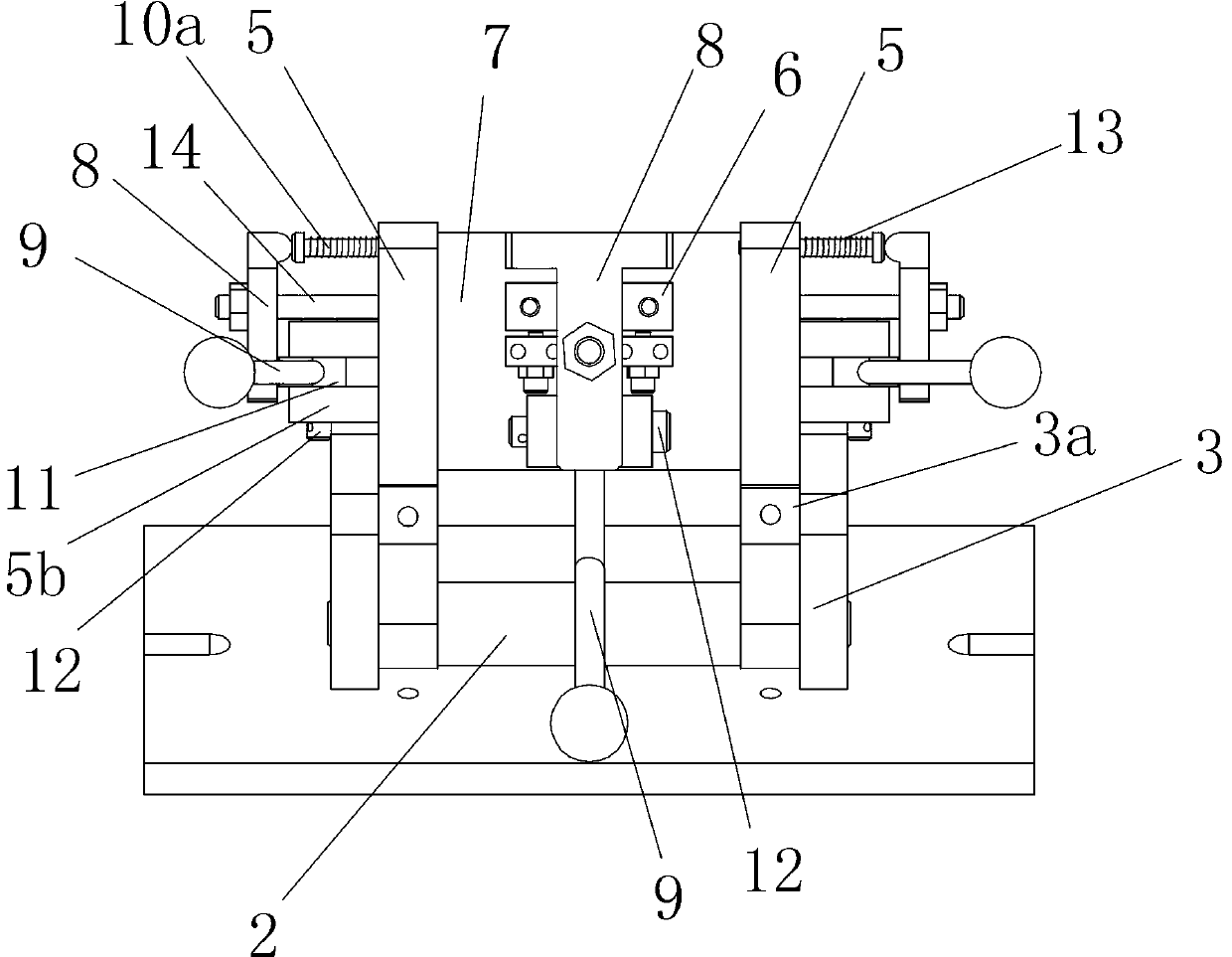

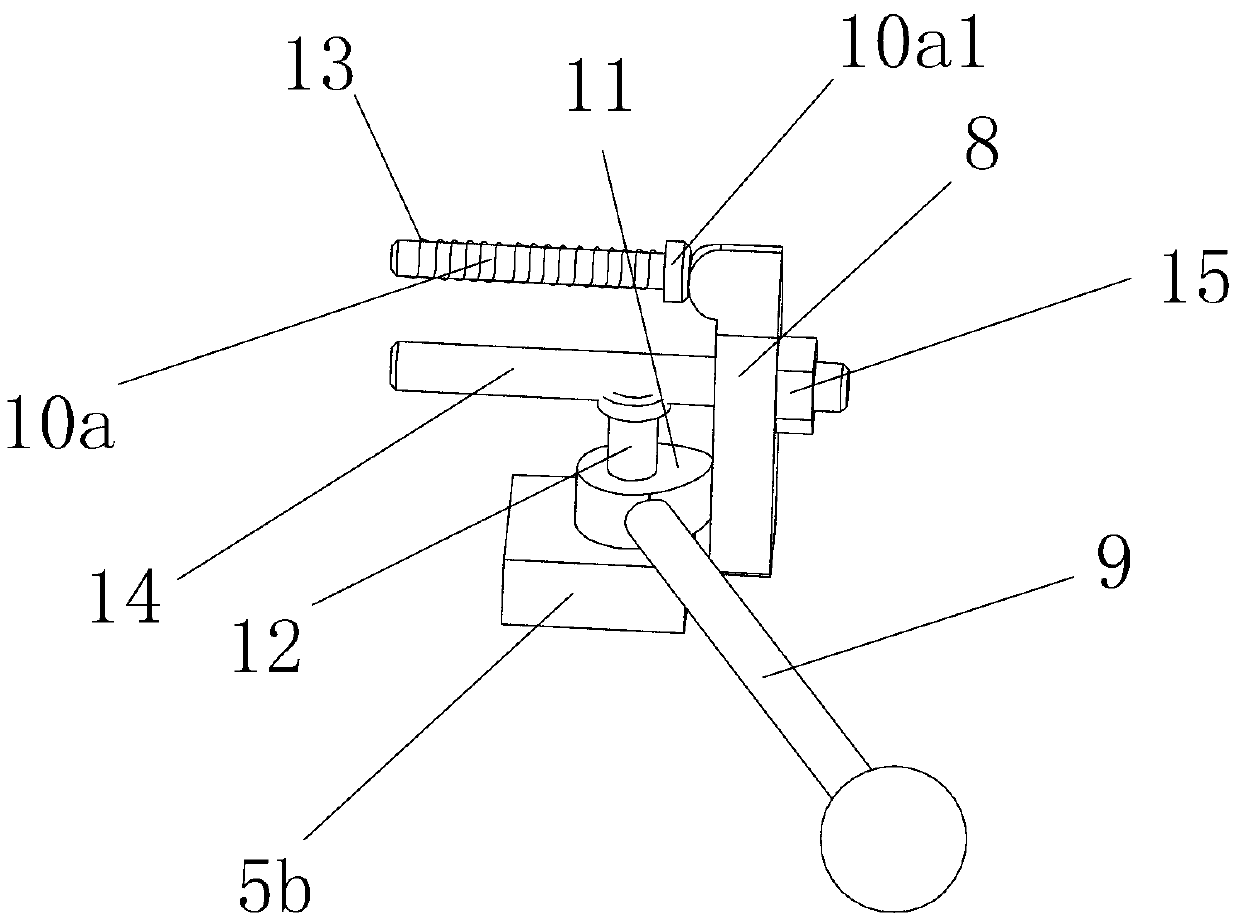

Special fixture for knife edge angle square repair

InactiveCN103128659AGuaranteed stabilityEliminate positioning errorsGrinding work supportsEngineeringMechanical engineering

The invention provides a special fixture for knife edge angle square repair, and belongs to the technical field of measuring instrument maintenance. The special fixture for knife edge angle square repair solves the problems of repair difficultness and ineffectiveness due to the fact that no effective professional fixture for positioning is provided in the repair process of grinding equipment of existing knife edge angle squares. The special fixture for knife edge angle square repair comprises a base plate, a workpiece clamping device and a datum plane positioning device for eliminate positioning errors, wherein the datum plane positioning device includes an X-axis positioning portion, a Y-axis positioning portion and a Z-axis positioning portion, the workpiece clamping device includes an X-axis clamping portion and a Z-axis clamping portion, the X-axis clamping portion and the X-axis positioning portion are respectively arranged beside both sides of a workpiece and matches with each other to clamp the workpiece, and the Z-axis clamping portion and the Z-axis positioning portion are respectively arranged beside both sides of the workpiece and matches with each other to clamp the workpiece. According to the special fixture for knife edge angle square repair, a plurality of positioning portions and clamping portions are used for positioning the workpiece in three dimensions, so that the positioning errors are eliminated, and the stability of the workpiece in the repair process is ensured.

Owner:JINHUA TECHNICIAN COLLEGE

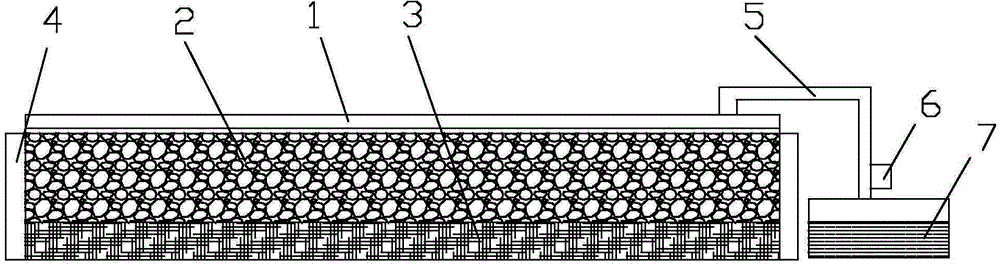

Concrete maintenance device

InactiveCN104802294AGuarantee the quality of maintenanceSufficient water absorptionCeramic shaping apparatusWater savingWater source

The invention relates to the technical field of concrete manufacturing, and specifically relates to a concrete maintenance device comprising a water catchment layer, a foam plastic layer and a linen layer. The water catchment layer is a plastic film bag with water-permeable holes opened in its bottom. The plastic film bag is arranged above the foam plastic layer. The foam plastic layer is arranged above the linen layer. The peripheries of the water catchment layer, the foam plastic layer and the linen layer are connected head-to-tail and sealed by limiting plates. The plastic film bag is connected with a water pipe; and the water pipe is communicated with a water tank through a water pump. The concrete maintenance device is simple in structure; the arrangement of the water catchment layer can ensure the foam plastic layer to be always in a wet state; the foam plastic layer provides a water source having enough water to the linen layer, thereby allowing the linen layer to completely absorb water for conveniently implementing heat preservation and wet preservation operations to the concrete. The concrete maintenance device is convenient to use, is water-saving and labor-saving, and is able to keep the humidity and the substantially constant temperature of the concrete maintenance surface, accordingly ensuring the concrete maintenance quality as much as possible.

Owner:TIANJIN HOUDE CEREMENT PROD CO LTD

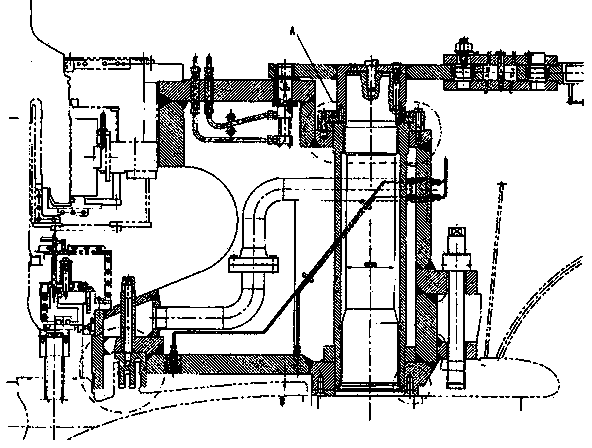

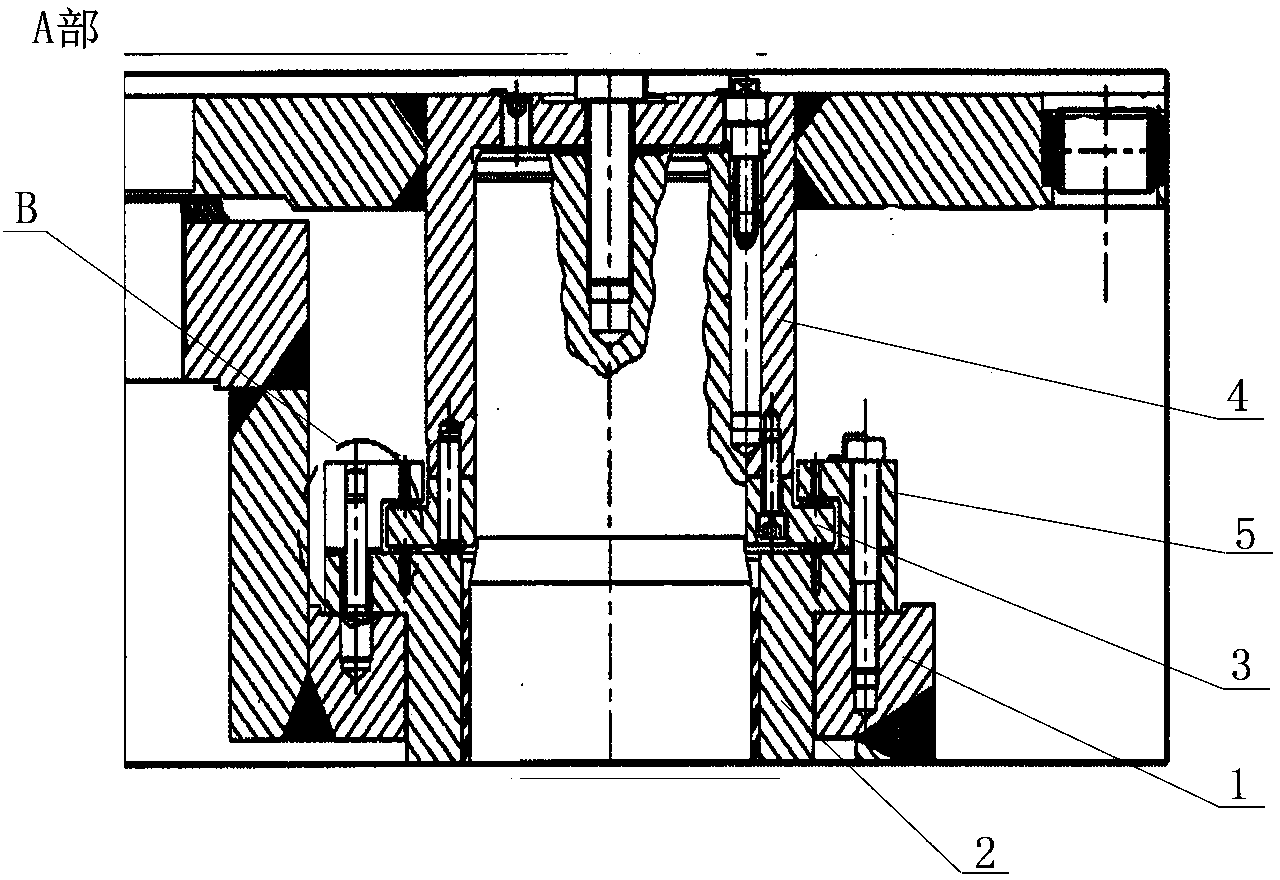

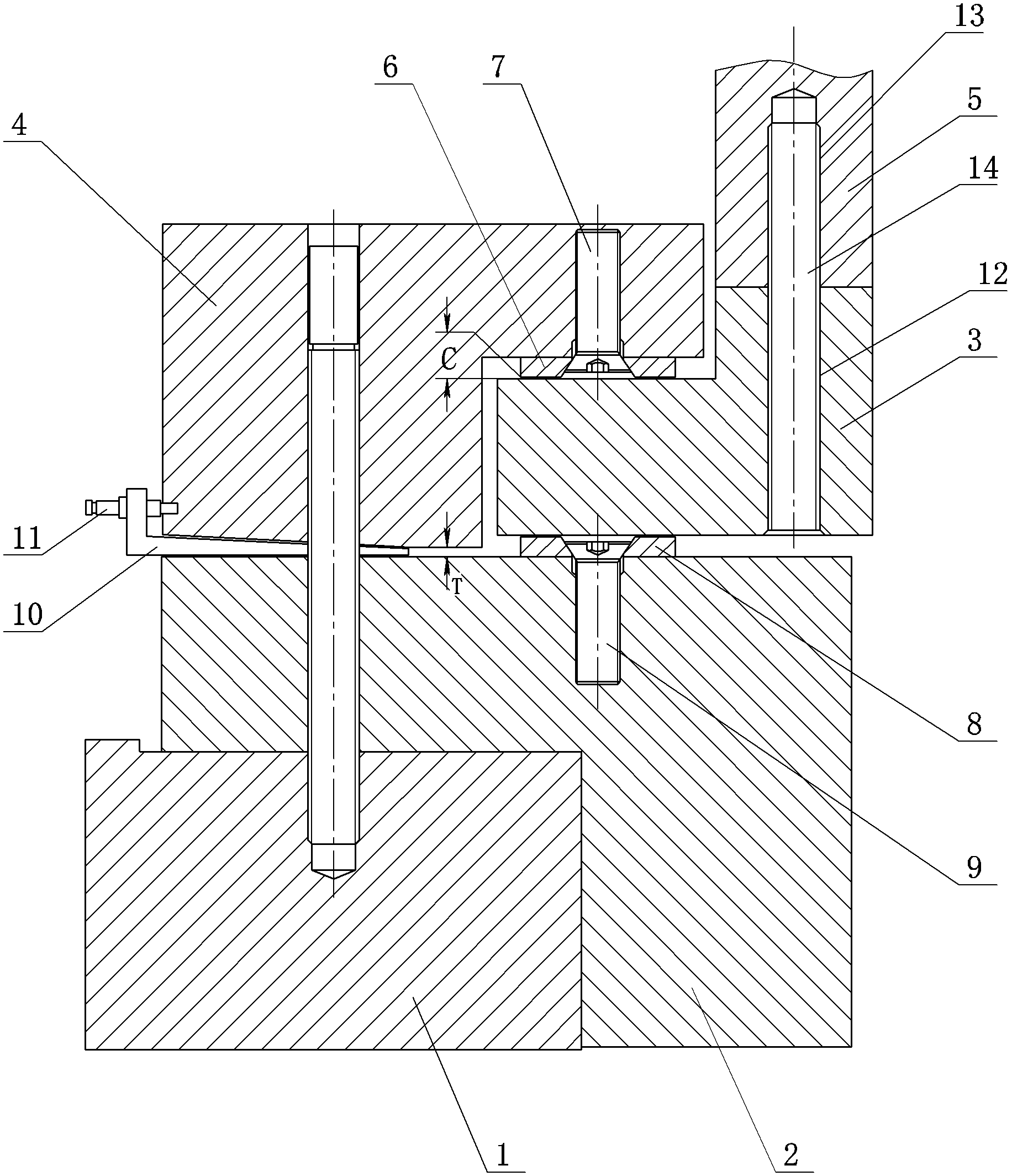

Water turbine guide vane thrust gap adjusting structure

ActiveCN104005899AShorten the timeSave human effortHydro energy generationReaction enginesWater turbineThrust bearing

The invention discloses a water turbine guide vane thrust gap adjusting device. L-shaped wedge plates are symmetrically arranged in an adjusting gap between an L-shaped guide vane thrust ring and a guide vane sleeve in a padding mode, an adjusting screw rod is transversely installed at the corner positions of the L-shaped wedge plates, and the inner end face of the adjusting screw rod makes contact with the outer end face of the L-shaped guide vane thrust ring. Two 1:20 slopes are processed between each fixing bolt hole and each pin hole in the two sides of the guide vane thrust ring, the L-shaped wedge plates with the installation gradient being 1:20 are installed at the bottom of the thrust ring, the in-out depth of the wedge plates is increased and decreased by adjusting the screw rod, and therefore the guide vane thrust gap is adjusted. The water turbine guide vane thrust gap adjusting device can save time and labor, is convenient to operate, can play a great role in the unit overhaul period, and can shorten the overhaul project duration on the premise that the overhaul quality is ensured.

Owner:STATE GRID CORP OF CHINA +2

Stainless steel furnace cover crack repairing method

The invention relates to the field of a metallurgical equipment maintaining method, in particular to a stainless steel furnace cover crack repairing method capable of rapidly realizing stainless steelfurnace cover crack repairing. The stainless steel furnace cover crack repairing method comprises the following steps: A, performing preparation before welding: (a) drilling the tail end of the crackby a drill bit to form a crack stopping hole, (b) selecting a grinding machine to eliminate crack defects, and (c) drying welding rods; B, welding; C, performing checkout and surface treatment: (a) examining air hole, slag inclusion and undercutting defects on the surface of a weld joint after cooling a welding joint to room temperature, and (b) polishing the surface residual height of the weld joint by an angular grinding machine to be in level with the surface of the original weld joint and perform transition smoothness with the edge fusing position; and D, after the above checkout and surface treatment are qualified, completing crack repairing. By the stainless steel furnace cover crack repairing method, the repairing quality is guaranteed, the furnace cover repairing and maintaining time can be shortened to 2 to 3 hours, the furnace stopping time can be effectively shortened, powerful guarantee is provided for recovering normal operation as soon as possible, and the stainless steel furnace cover crack repairing method is particularly suitable for a stainless steel furnace cover crack repairing process.

Owner:PANGANG GROUP TITANIUM INDAL

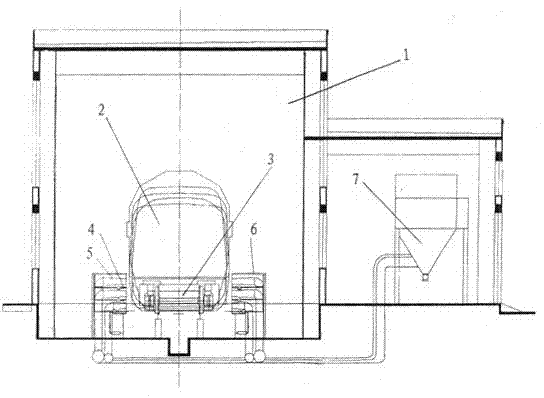

Method for cleaning bottom equipment of bullet trains

ActiveCN102343890ADoes not affect other jobsGuarantee checkCleaning apparatus for vehicle exteriorsHigh pressureWaste management

Owner:CHINA RAILWAY DESIGN GRP CO LTD

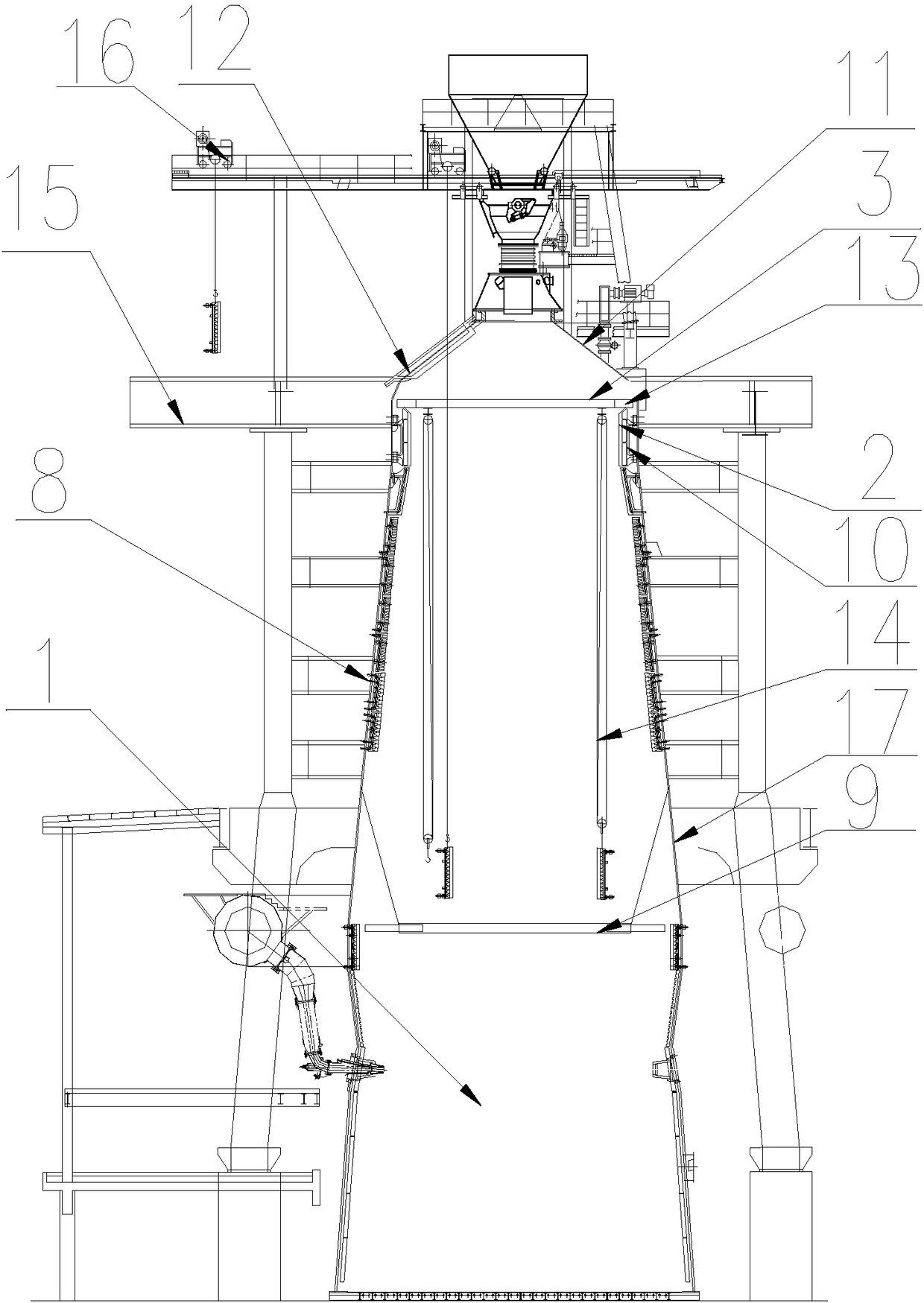

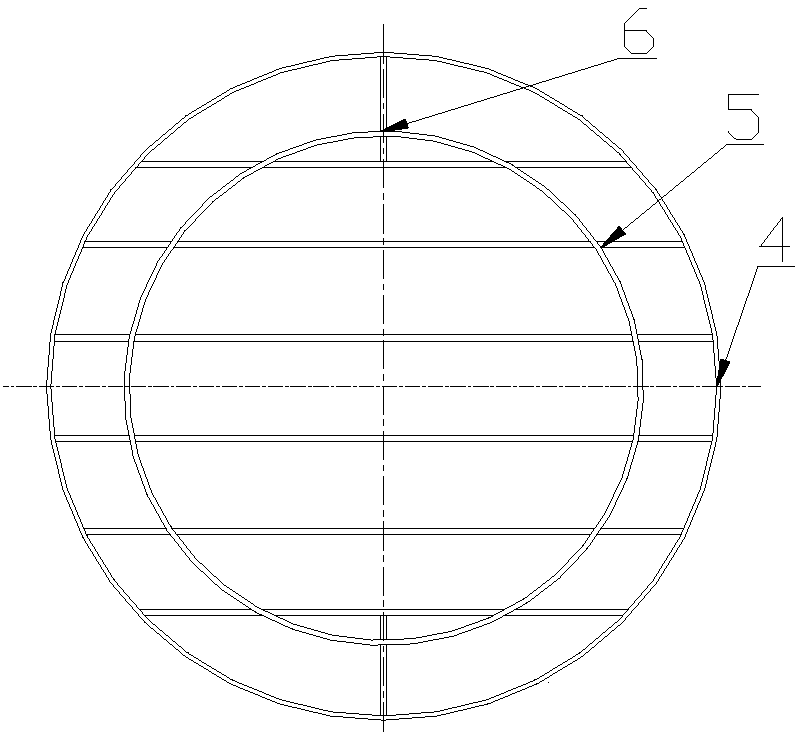

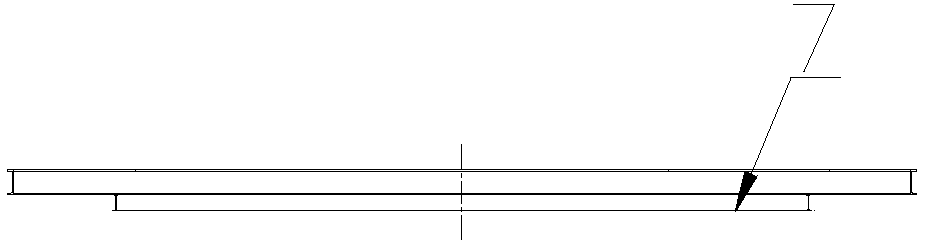

Device for replacing blast furnace cooling walls without damaging furnace shells and replacing method thereof

The invention discloses a device for replacing blast furnace cooling walls without damaging furnace shells and a replacing method thereof, and belongs to the technical field of blast furnace construction. The device comprises a hoisting ring beam, and the outer ring of the hoisting ring beam is provided with a temporary supporting part; the outer side of the temporary supporting part is provided with a blast furnace body, a furnace throat is arranged at the upper part of the blast furnace body, and a furnace throat steel brick is laid on the inner wall of the furnace throat; and a movable hanging plate is arranged in the interior of the blast furnace body, a furnace body platform is arranged outside the blast furnace body, and a slow-acting winch is fixedly installed on the table surface of the furnace body platform. According to the device and the method, the movable hanging plate is assembled in the blast furnace body, the hoisting ring beam is assembled on the movable hanging plate,the hoisting ring beam is erected on the steel brick, so that construction can be carried out; and when overhaul is carried out, the furnace shells and the cooling walls of corresponding position ofthe blast furnace are not required to be damaged, and the extra furnace shells and the cooling walls are prevented from being replaced; the overhaul efficiency is effectively improved, the overhaul cost is saved, the construction intensity is reduced, the overhaul period is shortened, and the overhauling quality is guaranteed.

Owner:ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

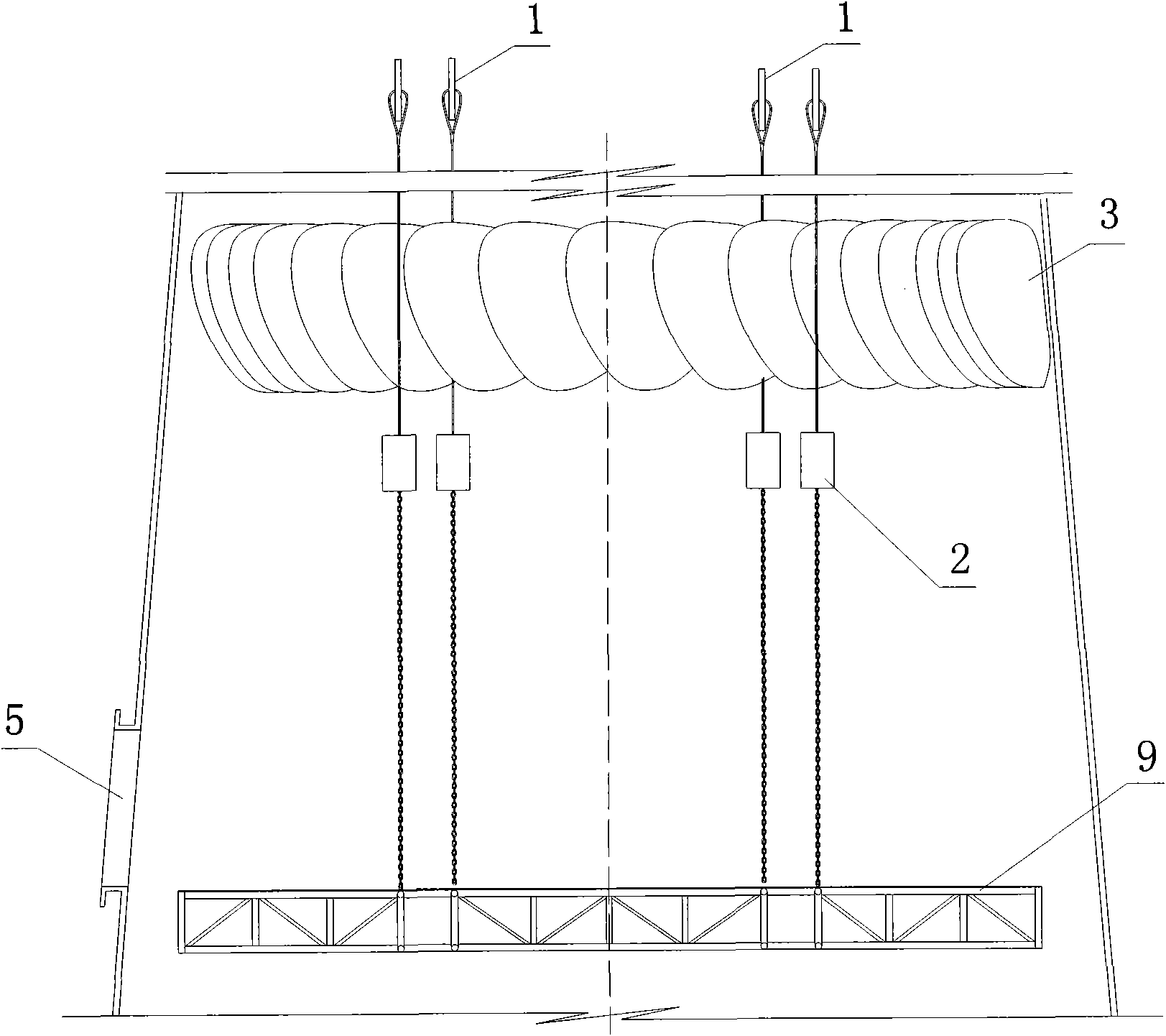

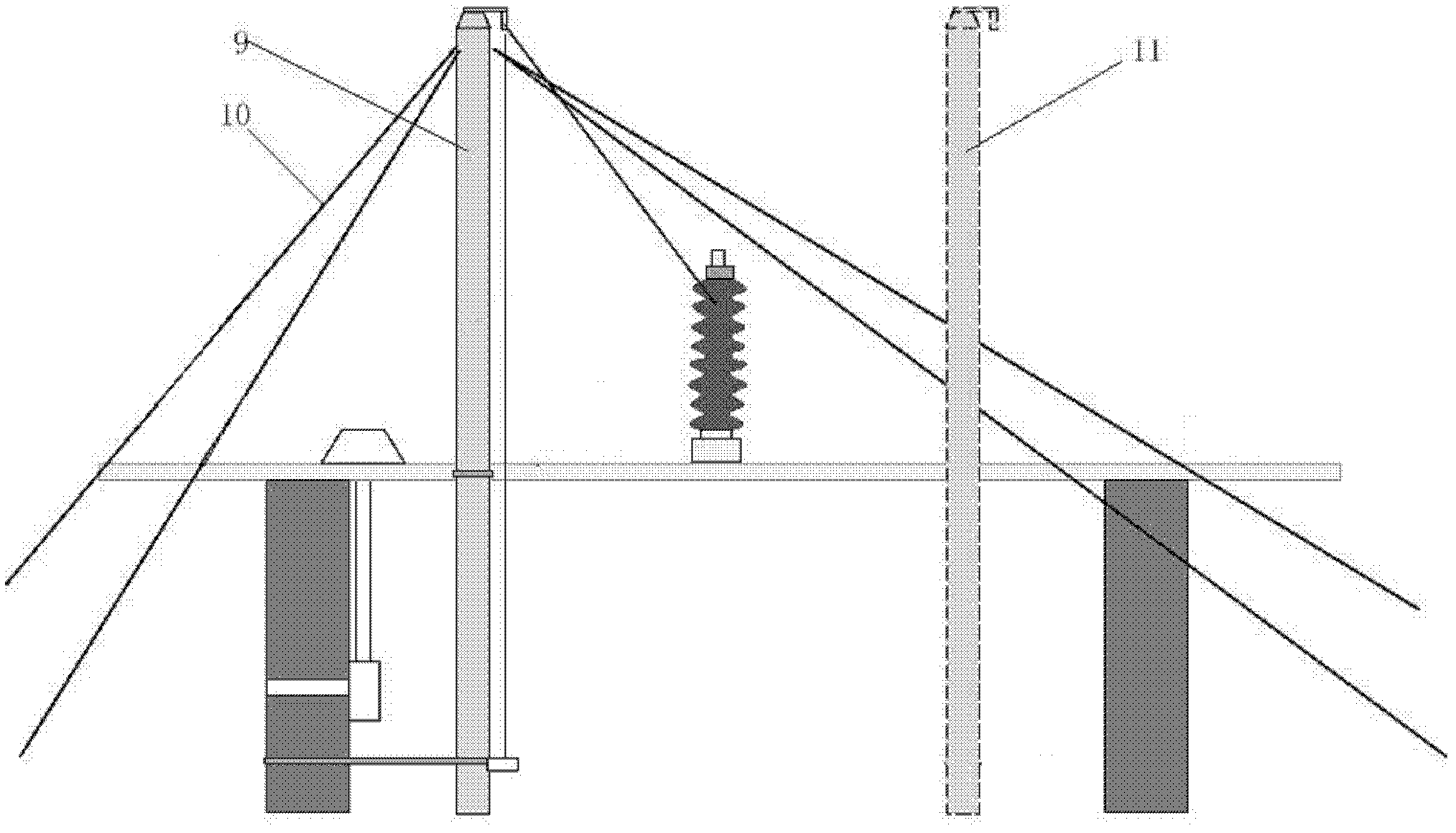

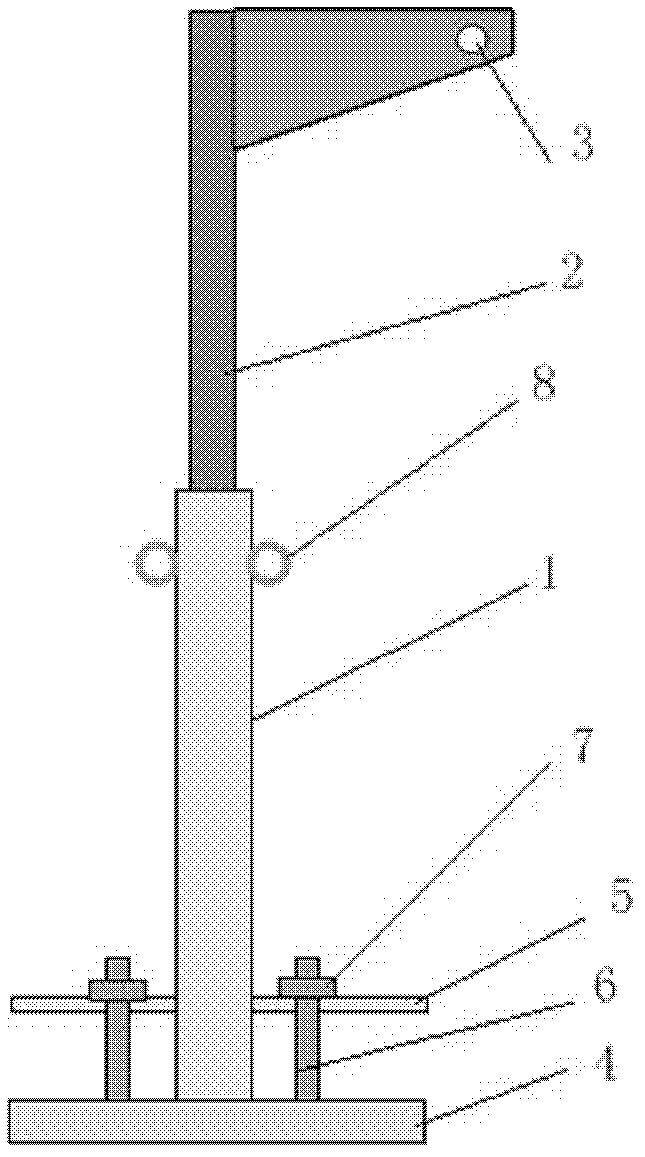

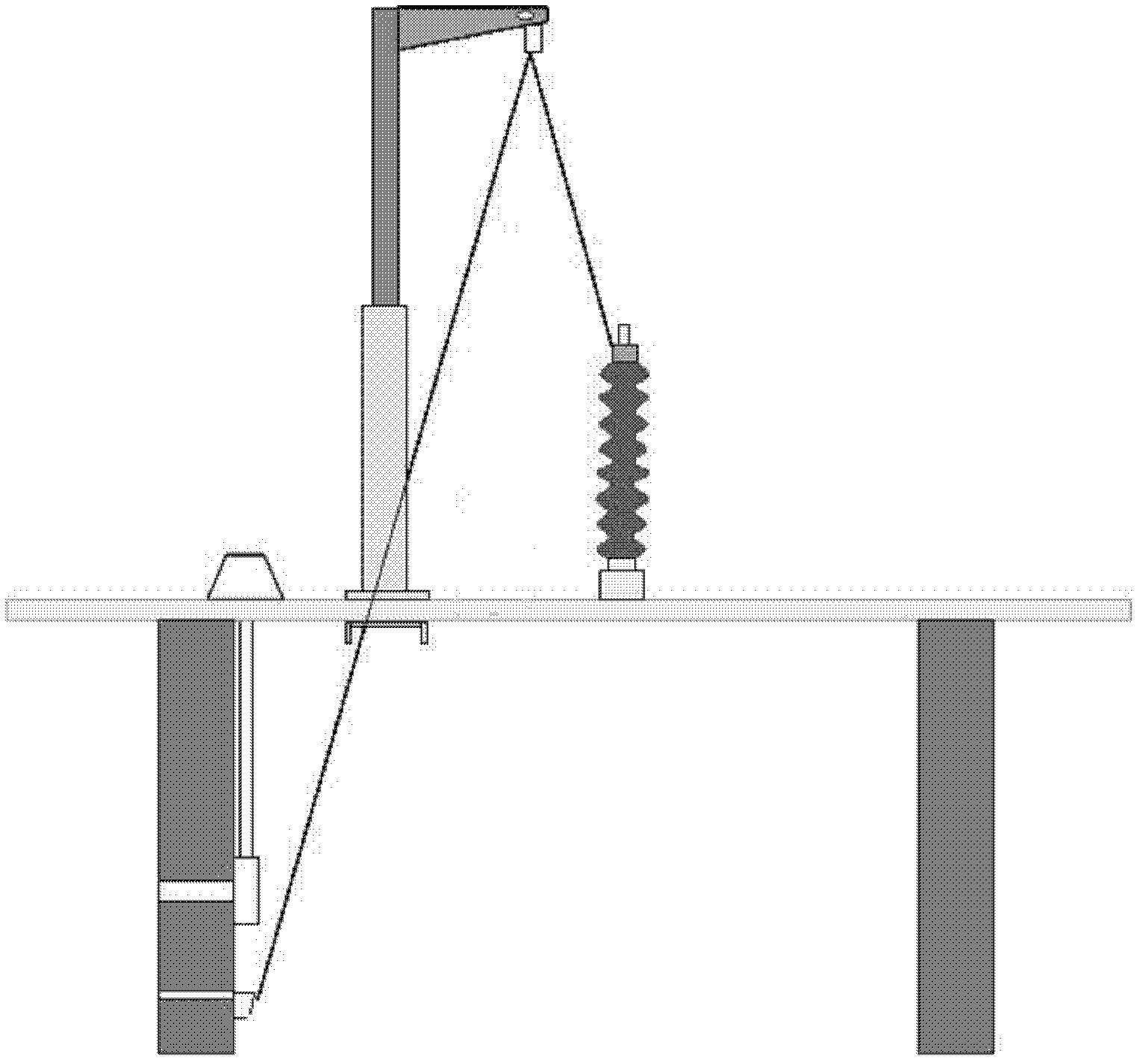

Disconnector maintenance hoisting bracket

InactiveCN102447224AShorten the lengthChange the fixation methodBase supporting structuresBraking devices for hoisting equipmentsEngineeringUltimate tensile strength

The invention relates to a maintenance tool, namely a disconnector maintenance hoisting bracket. The disconnector maintenance hoisting bracket comprises an upright rod; and the upper end of the upright rod is provided with a hanging hole for hanging a pulley. A base is arranged below the upright rod; two screw rods are respectively arranged on the base at the two sides of the upright rod; a pressing plate capable of moving and adjusting up and down is arranged on the base and is provided with three holes, and the two screw rods and the upright rod correspondingly pass through the three holes; and each screw rod is provided with a locking nut. The invention has the advantages that through shortening the length of embracing rods and changing the fixed mode of the embracing rods, the weight is reduced, so that the disconnector maintenance hoisting bracket is convenient to fixedly connect on the site, is light and flexible, is quick and convenient to disassemble and is safe and reliable; the work intensity is reduced, the condition that a plurality of persons maintain a group of switches is eliminated, and the labor efficiency is improved; the labor output is reduced, the work efficiency is high, and the maintenance quality is ensured.

Owner:STATE GRID CORP OF CHINA +1

Simple automatic laminating device on vibrating beam

PendingCN112392278AAvoid confictFree rotationBuilding material handlingLap jointMechanical engineering

The invention discloses a simple automatic laminating device on a vibrating beam. The simple automatic laminating device comprises the vibrating beam, a support base is arranged at the upper end of the vibrating beam, a low support is arranged at the upper end of the support base, a high support is arranged on one side of the low support, a rotating shaft is arranged in the low support and the high support in a penetrating mode, a film roll is arranged on the outer side of the rotating shaft in a penetrating mode, a laminating rolling bar is arranged on the side, close to the film roll, of thevibrating beam, a film is arranged between the film roll and the laminating rolling bar, and a rolling bar traction rod is arranged on the side, close to the vibrating beam, of the laminating rollingbar. According to the device, by arranging the low support and the high support, film lap joint can be facilitated, and the maintenance quality of film covering is ensured. By arranging the laminating rolling bar, the film can be evenly, flatly and tightly attached to the surface of concrete, and the frequency of manual rework is reduced. By arranging the support base, the low support and the high support can be mounted and dismounted more conveniently.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Energy-saving concrete curing device

InactiveCN103507150AGuaranteed aestheticsSave waterCeramic shaping apparatusWater resourcesWater diversion

An energy-saving concrete curing device comprises plastic film used for wrapping bridge piers. Cotton felt for being soaked through water diversion is paved on the top faces of the bridge piers. Two plastic barrels are arranged on the top surface of the cotton felt and provided with water outlets which are connected with water outlet pipes. The energy-saving concrete curing device effectively saves water resources, can carry out uniform curing, ensures curing quality, has been widely applied to the curing process of bridge concrete construction of high-speed railways in a wind region, and has important significance in ensuring attractive appearance of priority projects and commemorative architecture.

Owner:CHINA RAILWAY 19TH BUREAU GRP 1ST ENG

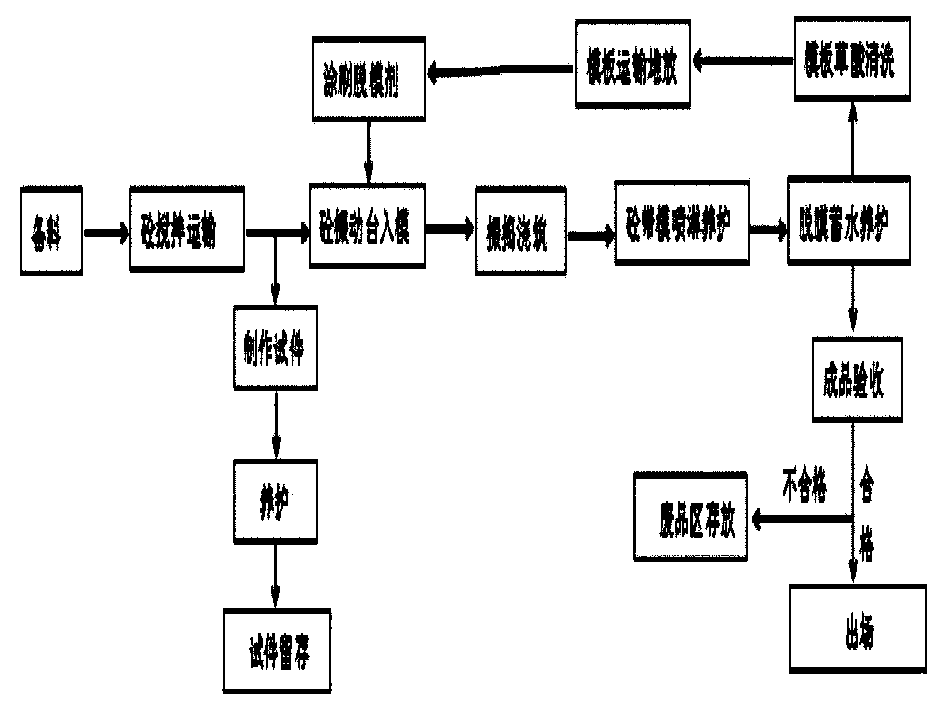

Small prefabricated part water storage and maintenance process

InactiveCN109866303AHeat of hydration dissipates evenlyReduce labor costsCeramic shaping apparatusWater storageEngineering

The invention relates to the technical field of concrete prefabricated components, in particular to a small prefabricated part water storage and maintenance process. The small prefabricated part waterstorage and maintenance process comprises the following steps: preparing, concrete mixing, test piece preparation, concrete vibrating, plastering, spraying and maintaining, water storing and maintaining, component storing and unqualified prefabricated part processing. De-moulded concrete is integrally soaked into a water storage pool, the maintained component is completely isolated from air, andthe component is soaked into water to hydrate and dissipate uniformly, so that the probability that the small component has dry shrinkage cracks and warm-shrinkage cracks is very low, and maintainingquality of the concrete component is ensured; in the water storage pool, a constructor does not need to watch maintenance, so that labor cost is reduced. The prefabricated part obtained by the maintenance process is high in qualification rate, is good in quality and is low in labor cost.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

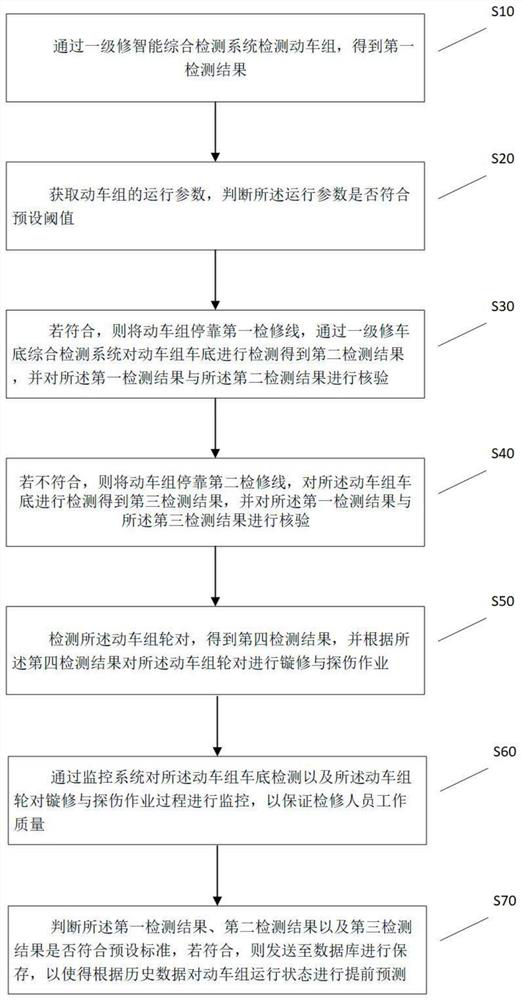

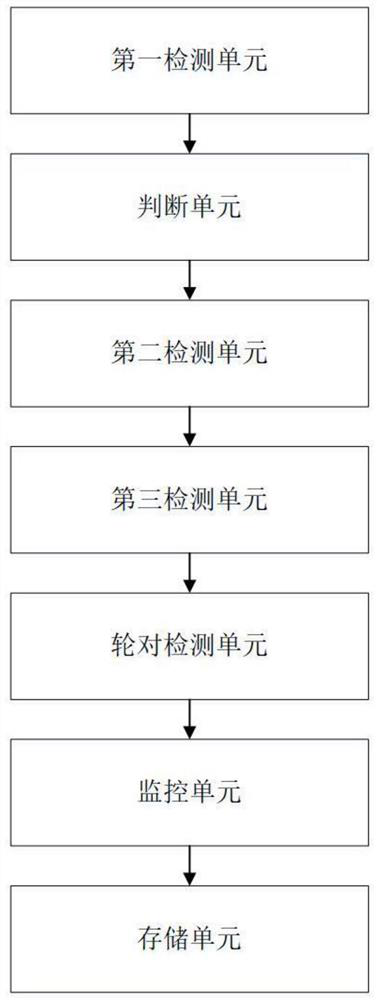

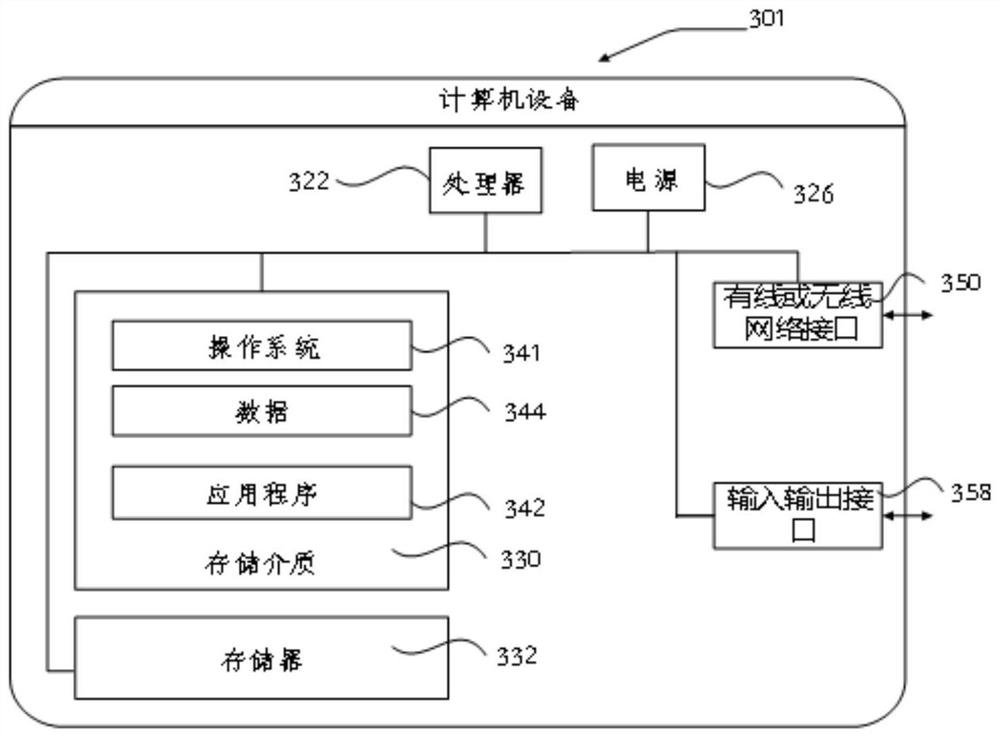

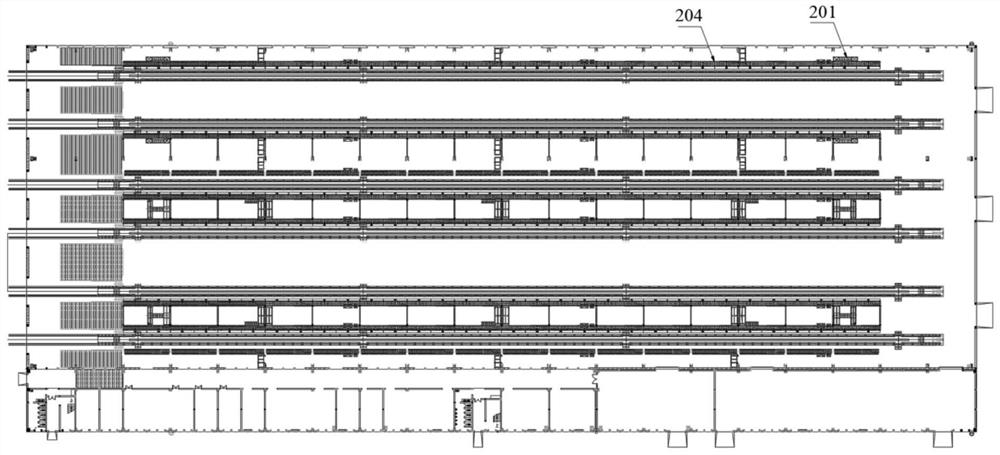

Intelligent hybrid maintenance method, device and equipment for motor train unit, and storage medium

PendingCN111798040AReduce process linksGuarantee the quality of maintenanceForecastingResourcesMonitoring systemData bank

The invention provides an intelligent hybrid maintenance method for a motor train unit. The method comprises steps of detecting the motor train unit through a primary maintenance intelligent comprehensive detection system, and obtaining a first detection result; acquiring operation parameters of the motor train unit, and judging whether the operation parameters conform to a preset threshold valueor not; if yes, the motor train unit being parked on a first maintenance line, and the bottom of the motor train unit being detected through a primary vehicle bottom maintenance comprehensive detection system; if not, the motor train unit being stopped on a second maintenance line, and the bottom of the motor train unit being detected; detecting the wheel set of the motor train unit; monitoring the detection process through a monitoring system; and judging whether the detection result meets a preset standard or not, and if yes, sending the detection result to a database for storage. The methodis advantaged in that manual participation links in the maintenance process of the motor train unit can be reduced, and the maintenance quality of the motor train unit is guaranteed, in addition, theembodiment of the invention provides an intelligent hybrid maintenance device and equipment for the motor train unit and a storage medium.

Owner:天津远程华瑞工业技术有限公司 +1

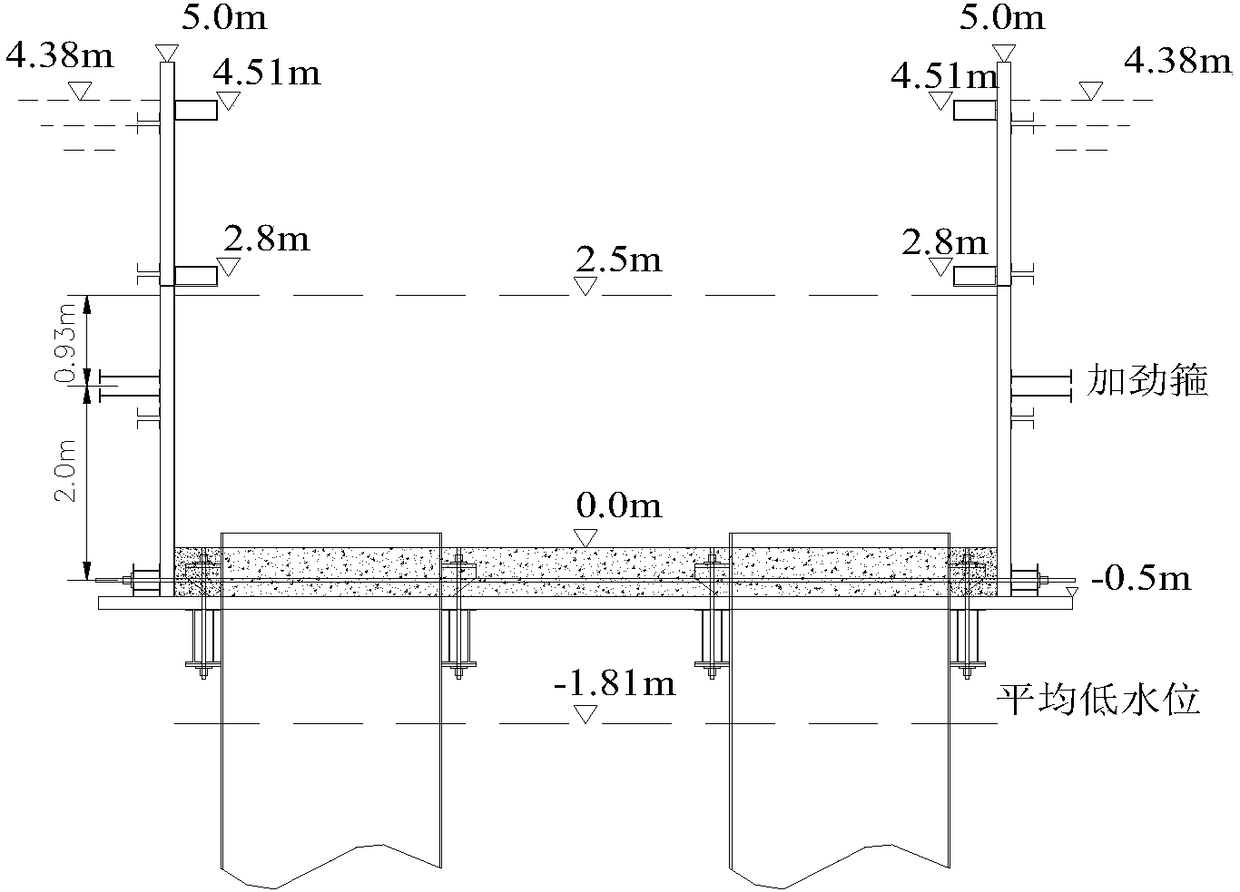

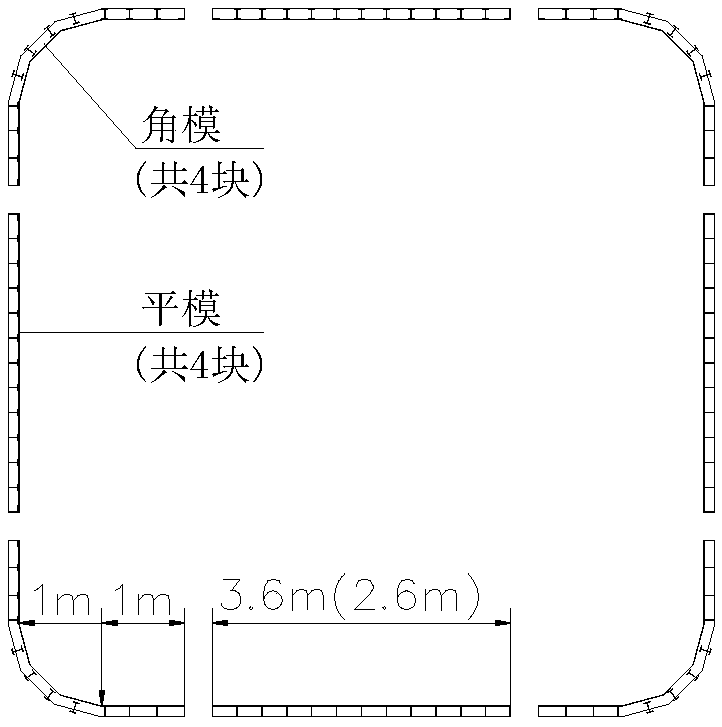

Water bearing platform suspension supporting platform and construction method thereof

ActiveCN108342993ARealize fully automatic controlNo human intervention requiredFoundation engineeringBridge erection/assemblyAutomatic controlArchitectural engineering

The invention provides a water bearing platform suspension supporting platform and a construction method thereof. The water bearing platform suspension supporting platform comprises a side mold, a stiffening hoop and an internal support thereof, a bottom sealing concrete and a bearing platform and further comprises a falling object preventing hanging basket member and a running construction hopper; and the running construction hopper comprises a base, a frame and a hopper. The corresponding construction method for the water bearing platform suspension supporting platform comprises 13 steps ofsteel suspension box template designing and making, supporting platform erection and so on; the construction method further comprises a construction method using a falling object preventing hanging basket and a maintenance method; and the maintenance method adopts a maintenance device, which comprises three circulating sub systems of a non-tower water supply system, an automatic spraying maintenance system and a water circulation use system, and adopts sequential control automatic circulation control technology. According to the water bearing platform suspension supporting platform, omnibearing, all-weather and all-wet uninterrupted maintenance is realized and full automatic control is also realized; different construction environments can be matched; and the use stability and high efficiency of the system are greatly enhanced.

Owner:LIYUE GROUP

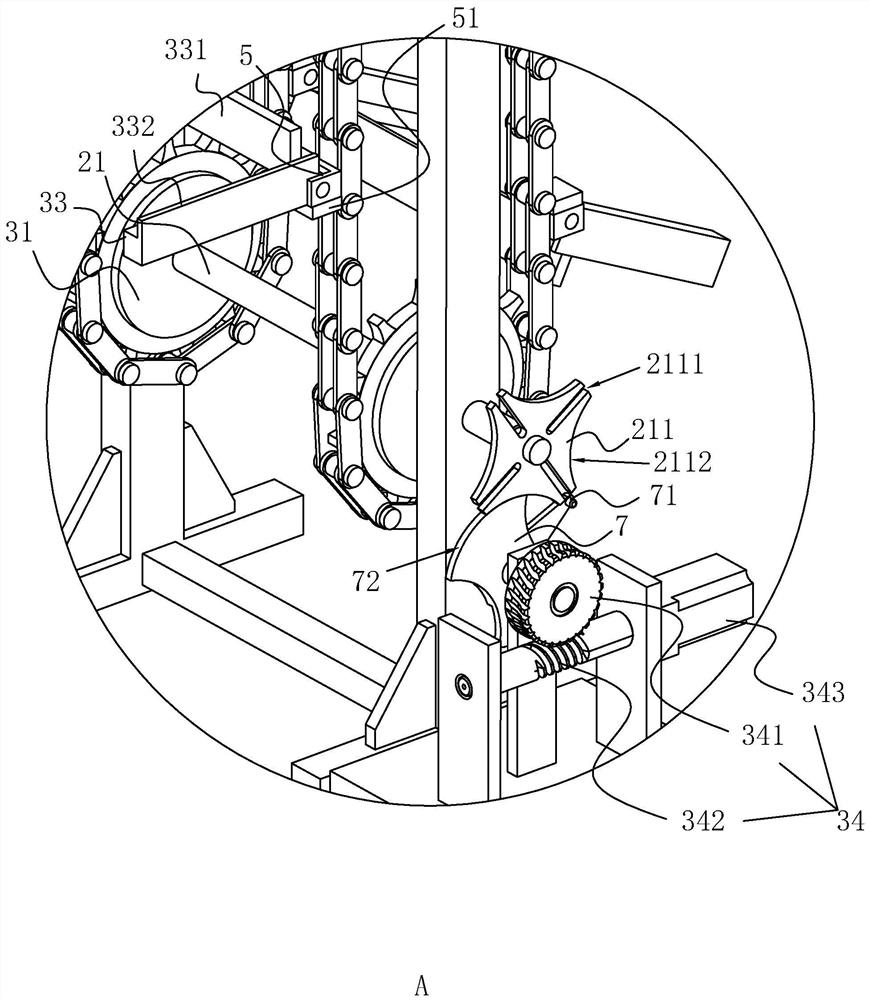

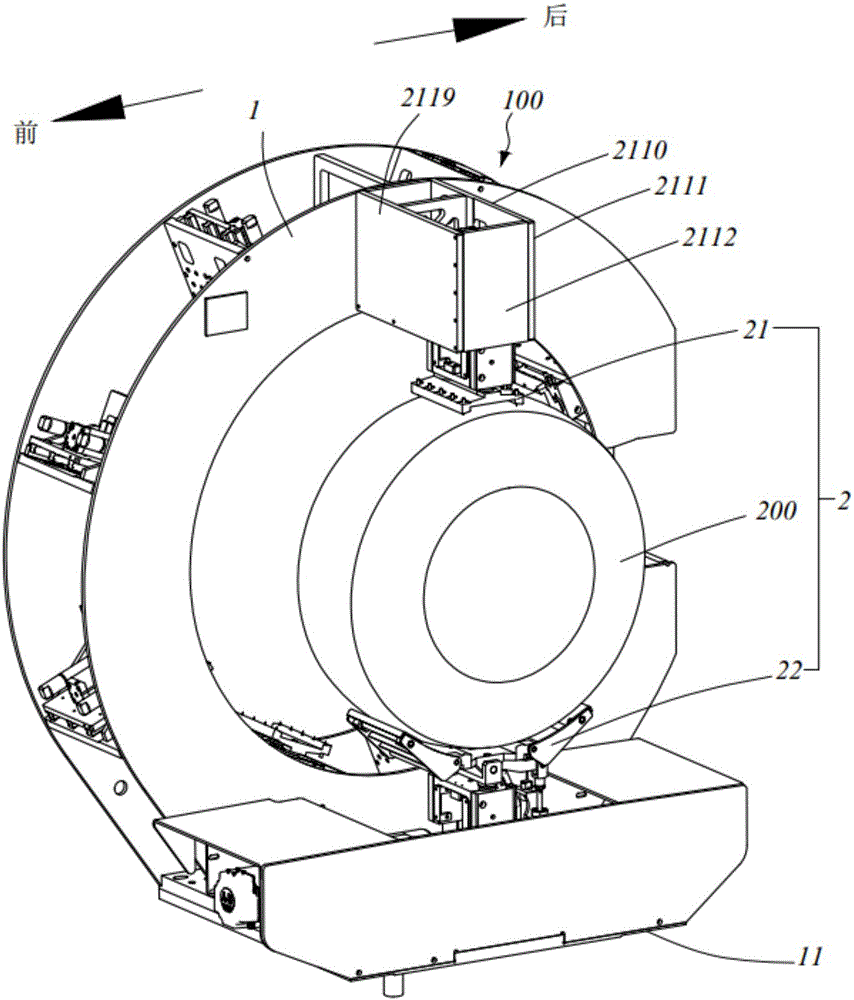

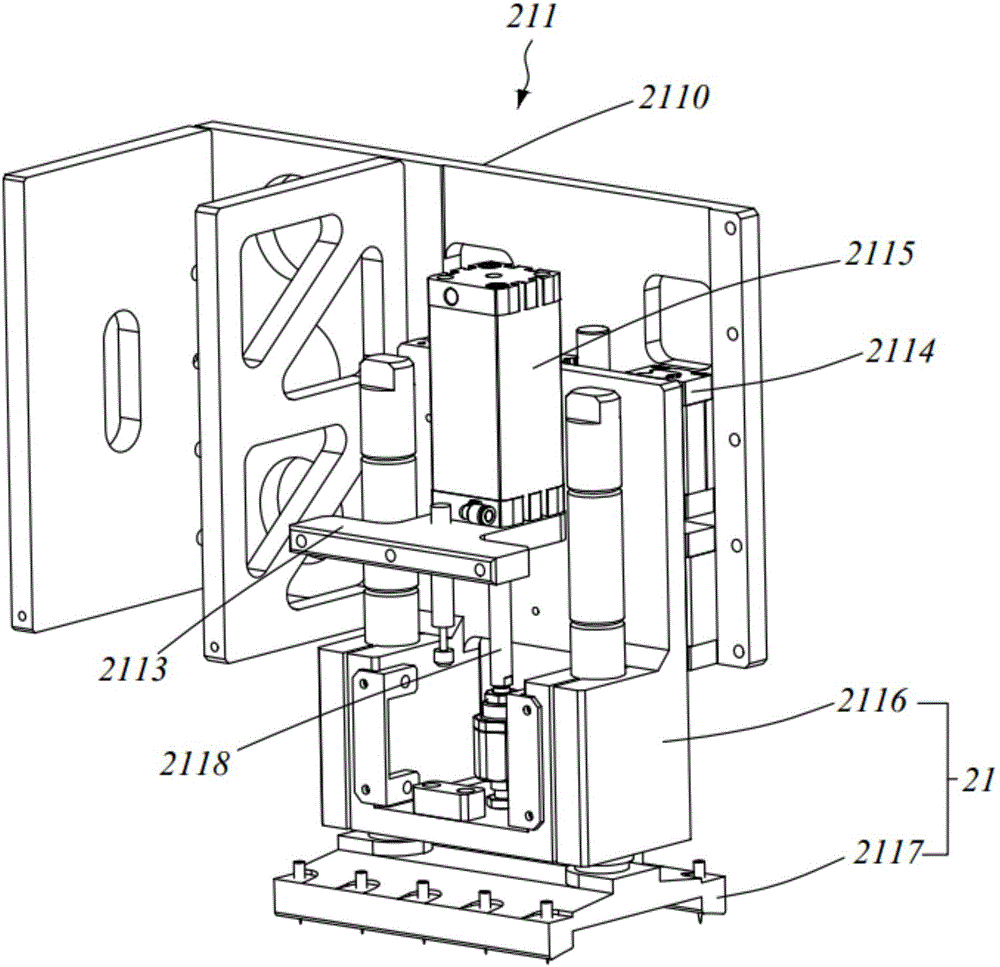

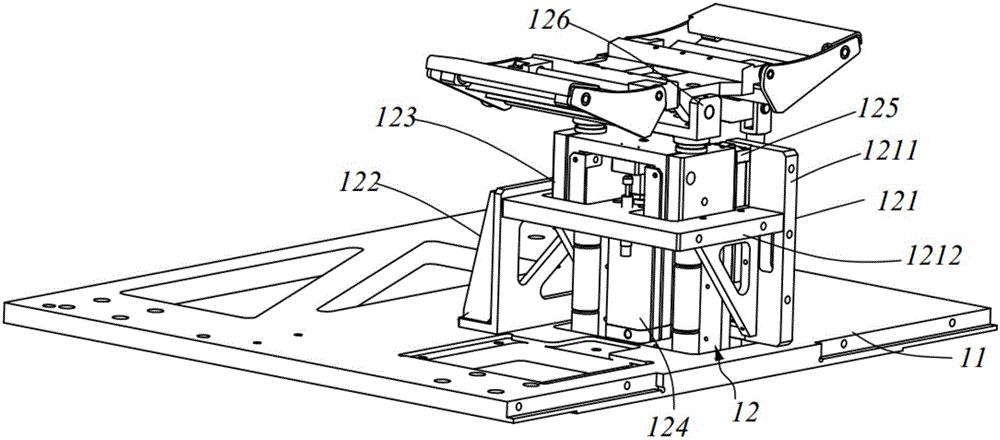

Tire unloading device for tire building machine

ActiveCN106346806AGuarantee the quality of maintenanceFull overhaulTyresEngineeringFront and back ends

The invention provides a tire unloading device for a tire building machine, which is used for forwards or backwards unloading green tires to be built. The tire unloading device comprises a horizontal shifting support frame, an automatic tire unloading mechanism arranged on one side of the support frame and a control assembly, wherein the automatic tire unloading mechanism comprises a depressing part arranged at the upper part of the support frame and a holding part arranged at the lower part of the support frame, and at least one of the depressing part and the holding part can shift up and down to grip or loosen a green tire to be built; the holding part comprises a bearing plate with up and down rotatable front and back ends, at least two holding paws pivoted with the front and back ends of the bearing plate, and a tire unloading driving assembly for driving the bearing plate to rotate; and when the automatic tire unloading mechanism is in a tire unloading state, the tire unloading driving assembly drives the bearing plate to rotate and causes the bearing plate to tilt forwards or backwards, thereby guiding the green tire to be built to be unloaded forwards or backwards.

Owner:SAFE RUN & HISCENT MACHINERY SUZHOU

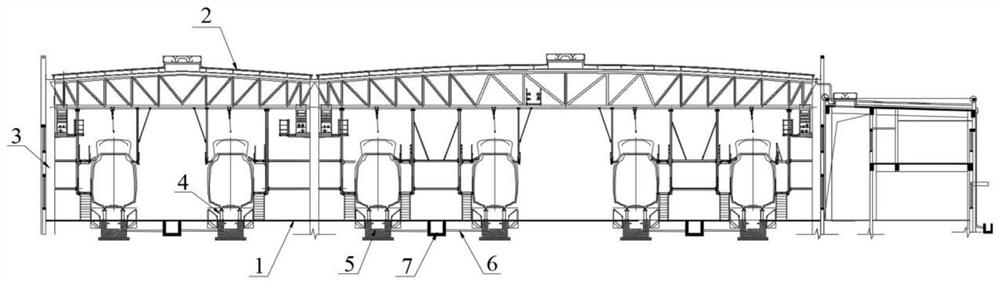

Safety interlocking system suitable for urban railway vehicle maintenance warehouse

PendingCN112184955AEnsure safetyGuarantee the safety of lifeTelevision system detailsColor television detailsSignal lightSafety Interlock

The invention discloses a safety interlocking system suitable for an urban railway vehicle maintenance warehouse, which belongs to the technical field of urban railway traffic maintenance, and is characterized in that an on-off assembly, an access control assembly and a signal lamp guide assembly are arranged corresponding to each maintenance line; by utilizing the combined arrangement of corresponding parts in each assembly, the on-off control of the overhead line system and the switching and display of various maintenance states can be accurately completed, and the reliable isolation of a top climbing platform and a boarding platform when the overhead line system is powered on can be realized. The safety interlocking system suitable for the urban railway vehicle maintenance warehouse issimple in structural composition and arrangement form, can accurately achieve on-off control over the overhead line system, can synchronously achieve switching and display of various maintenance states, achieves isolation of the top climbing platform and the boarding platform when the overhead line system is powered on, avoids the occurence of safety accidents, guarantees the safety and reliability of climbing operation of maintainers, improves the efficiency and quality of vehicle top maintenance, and has good application prospects and popularization value.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Cast-in-place concrete bent cap maintenance method

InactiveCN108203929AGuarantee the quality of maintenanceImprove work efficiencyBridge erection/assemblyBuilding material handlingWater storageSocial benefits

The invention relates to a cast-in-place concrete bent cap maintenance method. The method includes the steps that a poured cast-in-place concrete bent cap with a formwork removed is coated and coveredwith a wet water retention non-woven fabric; the water retention non-woven fabric is coated with a layer of plastic cloth, and the plastic cloth and the cast-in-place concrete bent cap are bound tightly through a binding rope outside the plastic cloth; a water storage barrel full of water is placed on each of the left side and the right side of the cast-in-place concrete bent cap, a water outletof each water storage barrel is connected with one end of a water dropping hose, and the other end of each water dropping hose is placed in the proper position on the upper portion of the cast-in-place concrete bent cap; and water outflow control valves on the water storage barrels are opened and adjusted to control the water yield, and the bent cap coating water dropping maintenance method is achieved. The maintenance method is convenient and quick to implement, work efficiency is improved, the work intensity of constructors is effectively reduced, a construction period is shortened, engineering cost is saved, meanwhile, the concrete maintenance quality of the cast-in-place concrete bent cap can be improved, and economic benefits and social benefits are good.

Owner:CHINA 22MCC GROUP CORP

Elevator monitoring system

Owner:佛山市智邦电子科技有限公司

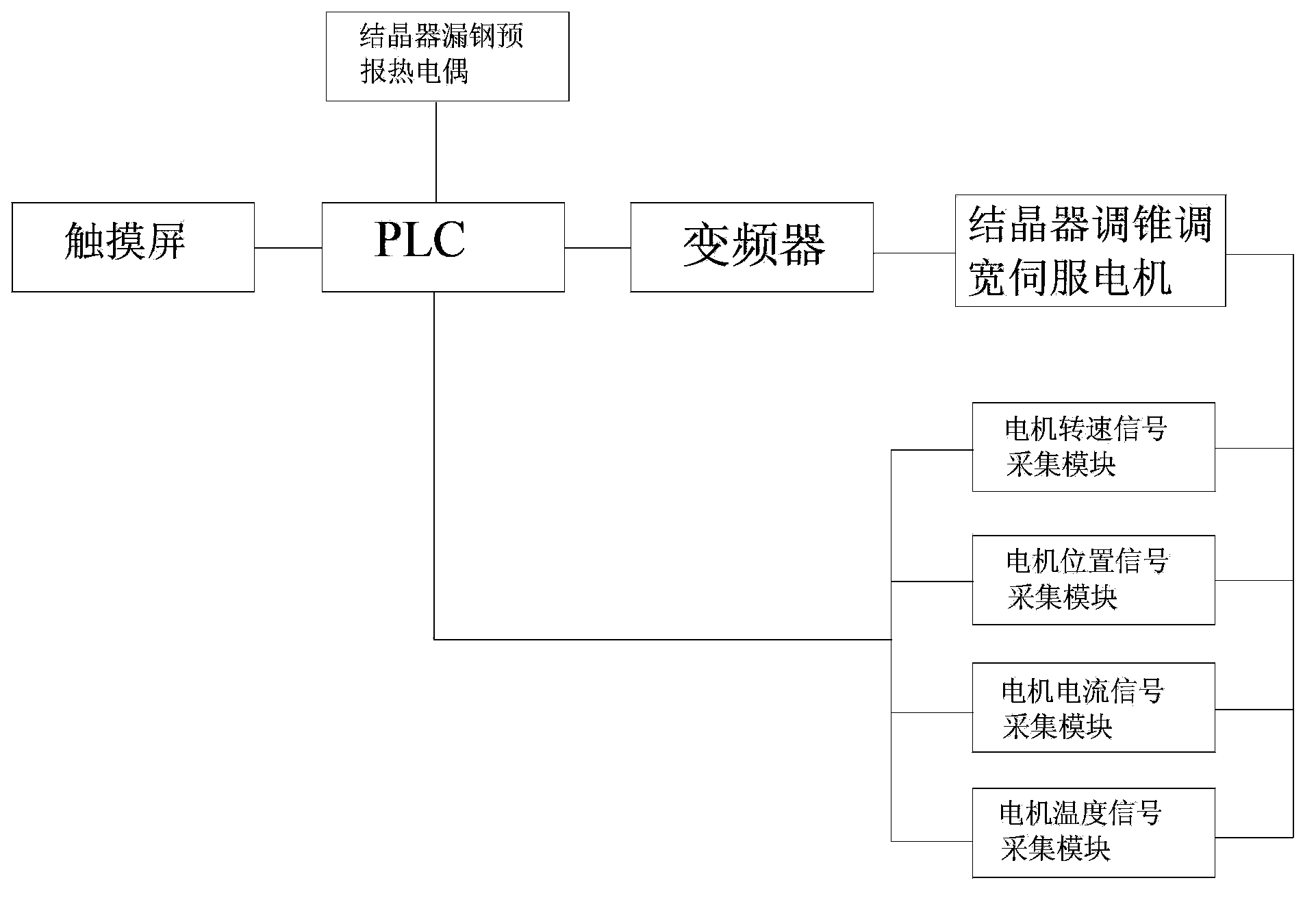

Off-line test equipment for continuous casting crystallizer

InactiveCN103838174AEasy to detectGuarantee the quality of maintenanceMeasurement devicesProgramme control in sequence/logic controllersFrequency changerMotor speed

The invention discloses off-line test equipment for a continuous casting crystallizer. The off-line test equipment for the continuous casting crystallizer comprises a crystallizer taper adjusting and width adjusting servo motor, a PLC, a frequency changer, a motor speed signal collecting module, a motor position signal collecting module, a motor current signal collecting module and a motor temperature signal collecting module, wherein the control signal output end of the PLC is connected with the control end of the crystallizer taper adjusting and width adjusting servo motor through the frequency changer, and the coder signal output end of the crystallizer taper adjusting and width adjusting servo motor is connected with the feedback signal input end of the PLC through the motor speed signal collecting module, the motor position signal collecting module, the motor current signal collecting module and the motor temperature signal collecting module. The off-line test equipment for the continuous casting crystallizer completes the collection of data such as the speed, the position, the current, the torque, the temperature and the bleed-out forecast thermal couple temperature of the crystallizer taper adjusting and width adjusting servo motor, the data are displayed on a touch screen, a detection result is clear at a glance, the detection capability on off-line area crystallizers is improved, and the overhaul quality of the crystallizers used on lines is ensured.

Owner:武钢集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com