Disconnector maintenance hoisting bracket

An isolation switch and pole technology, applied in the field of isolation switch maintenance and hoisting brackets, can solve the problems of difficult control of poles, low work efficiency, danger of assembling poles, etc. The effect of overhaul quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

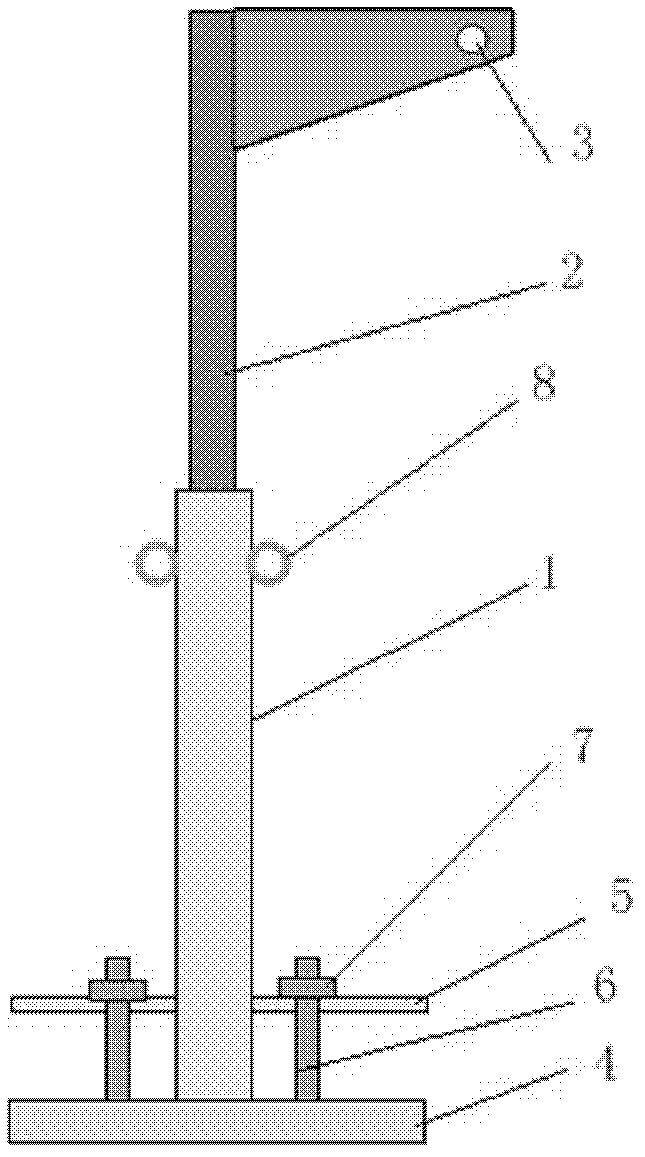

[0010] see figure 2 , The isolation switch maintenance hoisting bracket includes a vertical pole, and the vertical pole is composed of the protective tube 1 below and the rod body 2 inserted into the protective tube 1. This two-body structure is convenient for assembly. The upper end of the body of rod 2 has a hanging hole 3 for hanging double pulleys. There is a base 4 made of channel steel below the protective tube 1, and a pressing plate 5 that can move up and down is arranged on the base 4; a screw rod 6 is respectively arranged on the base 4 on both sides of the vertical rod, and there are three holes on the pressing plate 5, correspondingly passing through two A screw 6 and a protective tube 1, the screw 6 has a locking nut 7 for clamping between the pressing plate 5 and the base 4. There is the suspension ring 8 that helps tie the maintenance personnel's waist rope on the protective pipe 1 upper end.

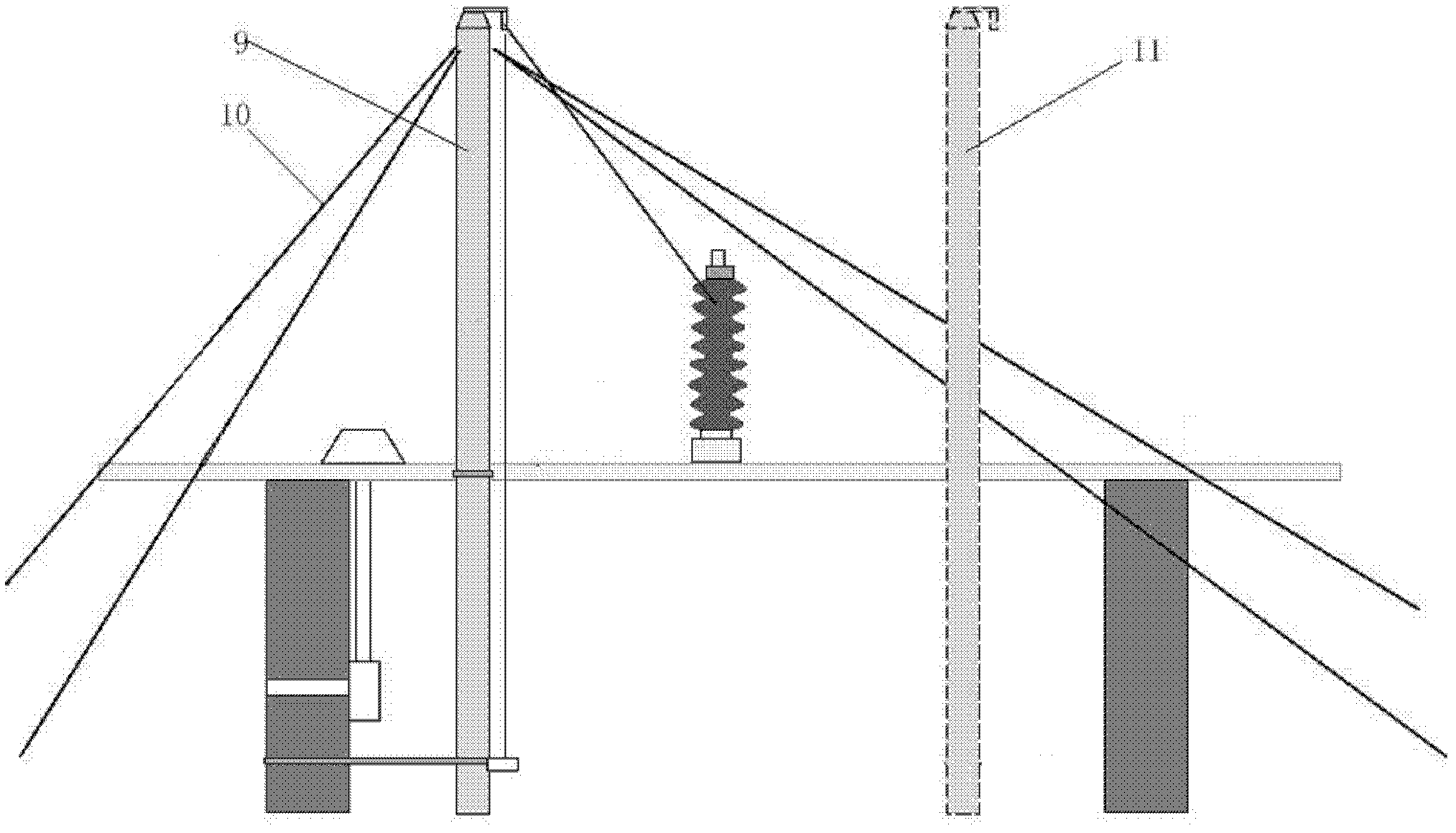

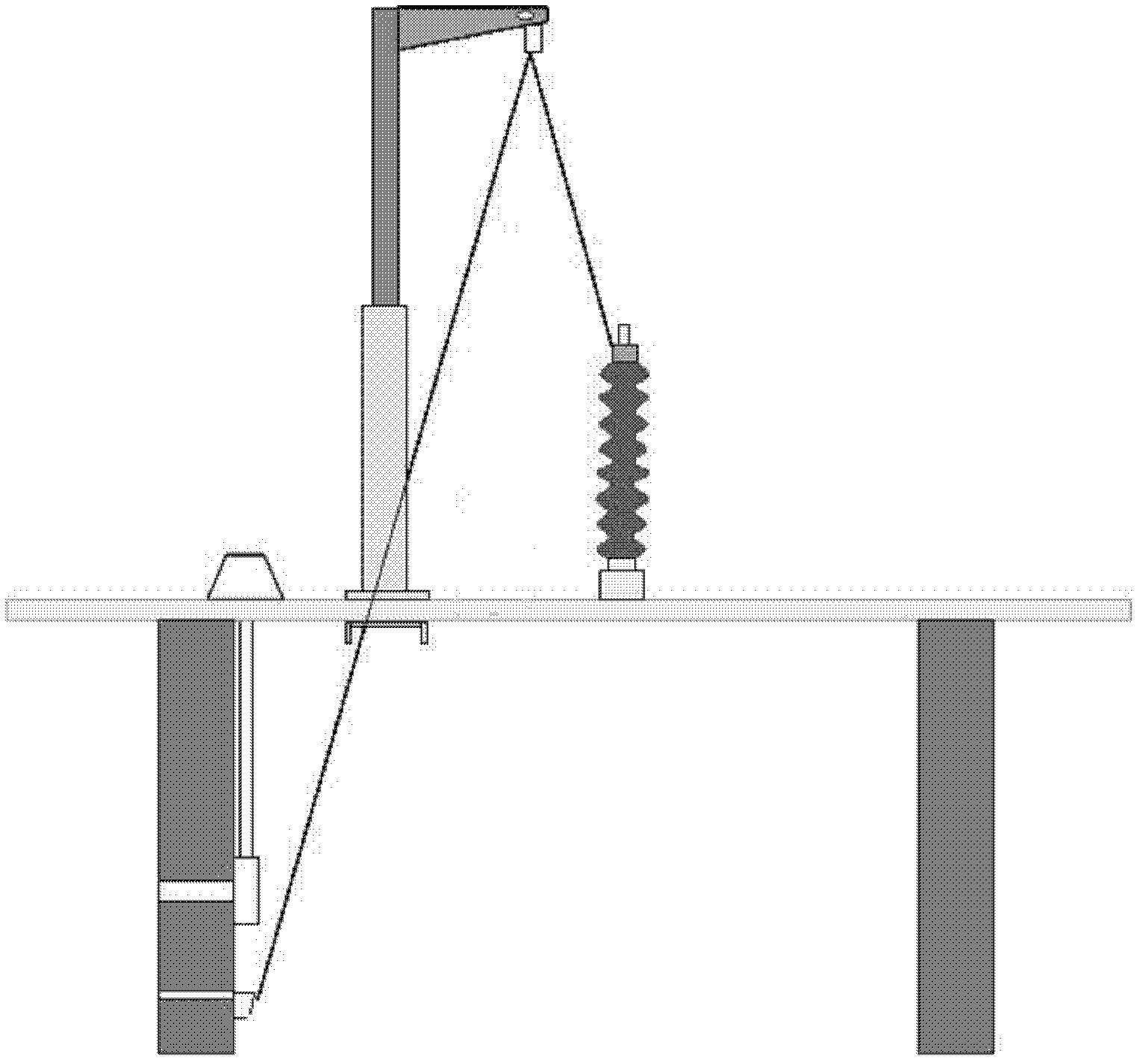

[0011] see image 3 , use the channel steel at the base of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com