Intelligent spraying curing system and method for concrete vertical structure

A technology of vertical structure and maintenance system, which is applied in the construction of buildings, construction, and the processing of building materials, etc., can solve the problems of difficult to guarantee maintenance quality, water consumption, high labor cost, and achieve scientific and standardization, reduce Labor cost, the effect of ensuring the quality of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

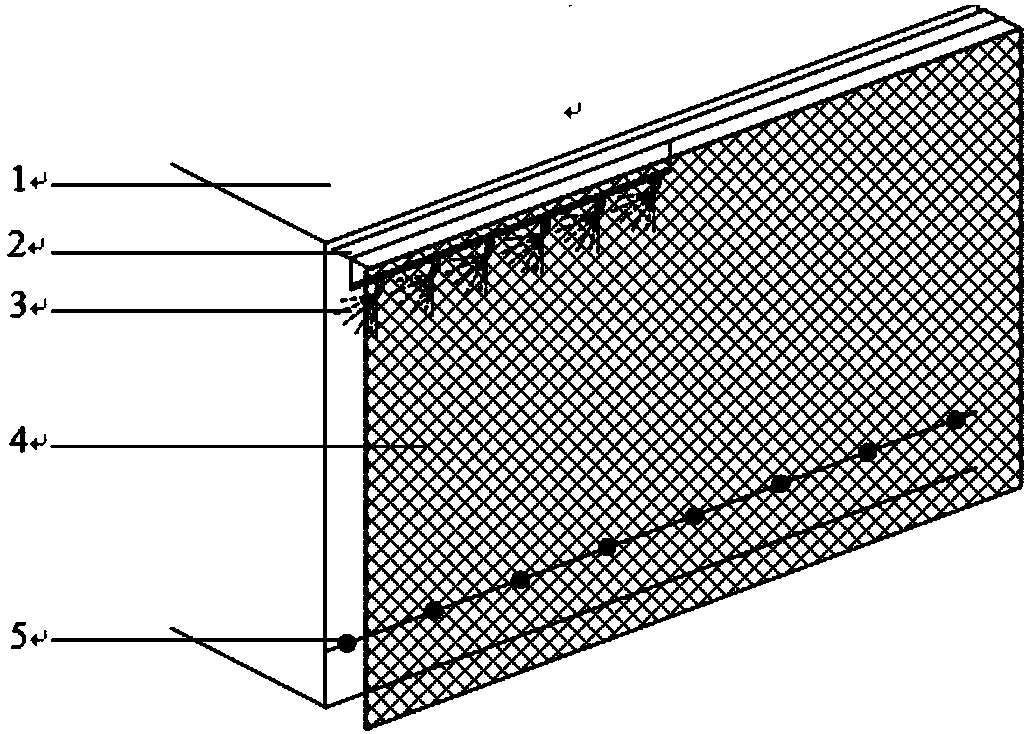

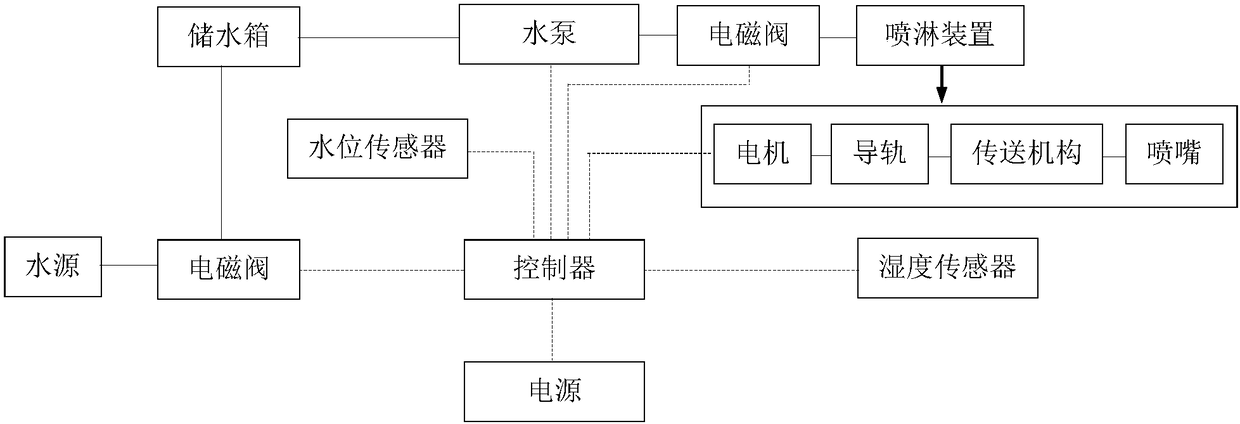

[0033] Such as figure 1 and figure 2 As shown, an intelligent sprinkler maintenance system for concrete vertical structure, including a water storage tank (not shown), a water pump (not shown), a controller (not shown) and a sprinkler device (not shown), the water storage tank It is used to store water for spraying maintenance. The controller can control the water level of the water tank. One end of the water storage tank is connected to the engineering water source through a solenoid valve, the other end of the water storage tank is connected to the water inlet of the water pump, and the water outlet of the water pump is connected to the water supply through another solenoid valve. The sprinkler device is connected; the sprinkler device includes a motor (not shown), a guide rail 2, a transmission mechanism (not shown) and a nozzle 3, the guide rail 2 is arranged on the upper part of the formwork equipment 4 of the concrete vertical structure 1, and the transfer mechanism and...

Embodiment 2

[0038] Please continue to refer figure 1 and figure 2 , the present embodiment provides the concrete vertical structure intelligent spray maintenance method of the present invention, the method includes the following steps:

[0039] Step 1. Provide the aforementioned concrete vertical structure intelligent spray maintenance system for standby;

[0040]Step 2. Analyze the water level signal sent by the water level sensor in the water storage tank. When the water level is lower than the set minimum water level, the controller sends a signal to the solenoid valve 1, opens the valve, and water flows into the water storage tank. When the water level reaches the set maximum water level, the control The device sends a signal to close the solenoid valve 1;

[0041] Step 3: After demolishing the concrete vertical structure 1, install the guide rail 2 on the upper part of the formwork on the same layer (or at the upper part and the middle part at the same time), install the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com