Off-line test equipment for continuous casting crystallizer

A technology of continuous casting crystallizers and testing equipment, which is applied in the direction of program control in instruments, measuring devices, and sequence/logic controllers, and can solve problems such as impact, no detection circuit, and undetectable crystallizer width and taper , to achieve the effect of ensuring the quality of maintenance and improving the detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

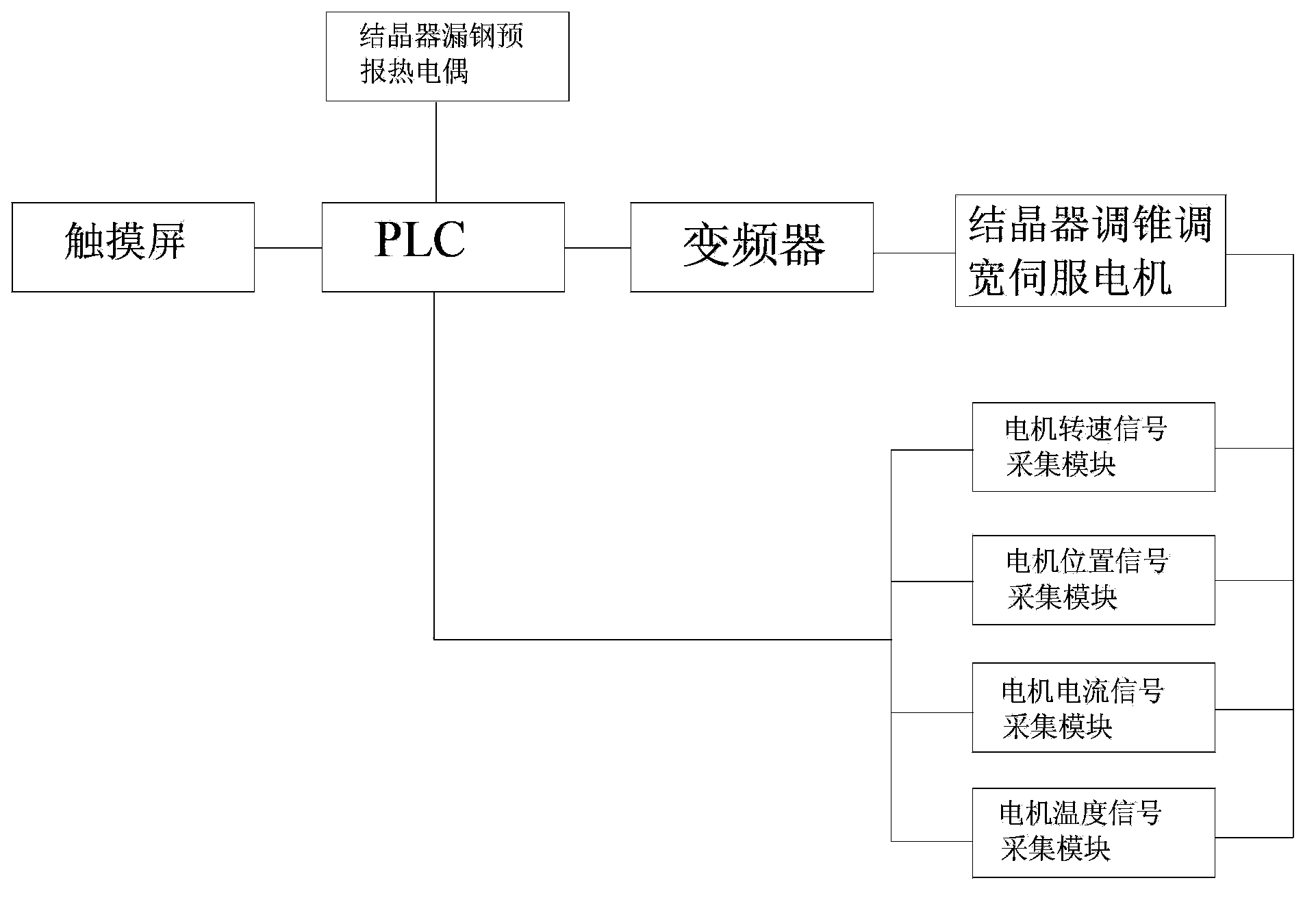

[0010] The continuous casting mold offline test equipment shown in Figure 1 includes the servo motor for adjusting the taper and width of the mold, and also includes PLC, frequency converter, motor speed signal acquisition module, motor position signal acquisition module, motor current signal acquisition module and motor Temperature signal acquisition module. Wherein, the control signal output end of the PLC is connected to the control end of the crystallizer cone-adjusting and width-adjusting servo motor through a frequency converter, and the encoder signal output end of the crystallizer cone-adjusting and width-adjusting servo motor is respectively passed through the motor speed signal acquisition module, The motor position signal acquisition module, the motor current signal acquisition module and the motor temperature signal acquisition modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com