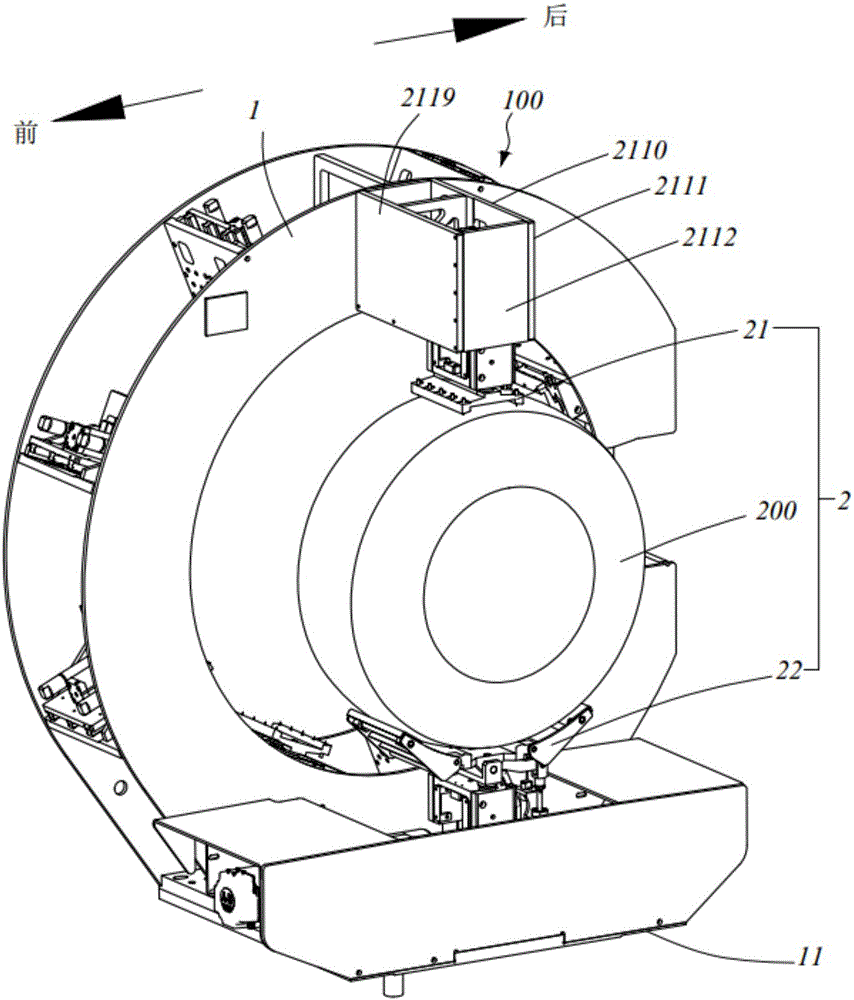

Tire unloading device for tire building machine

A tire building machine and technology to be formed, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of collision of raw tires, high workload of workers, and low degree of tire automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

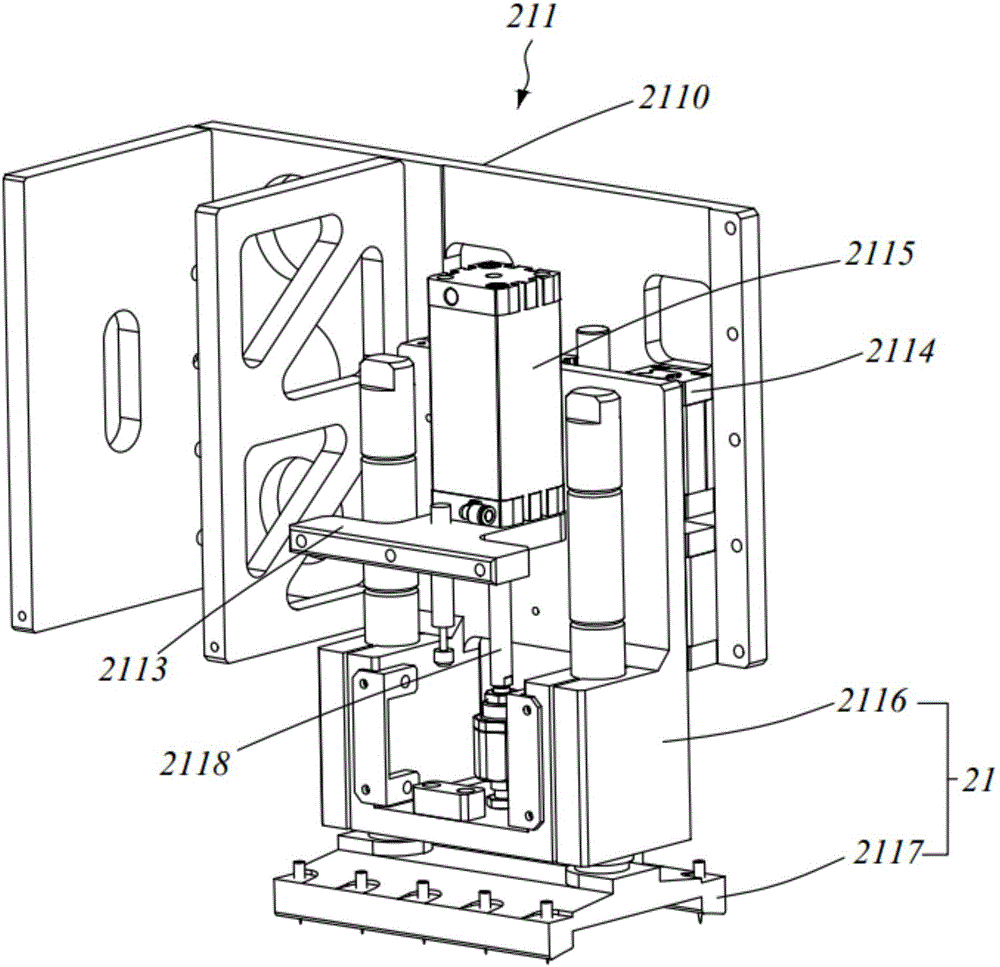

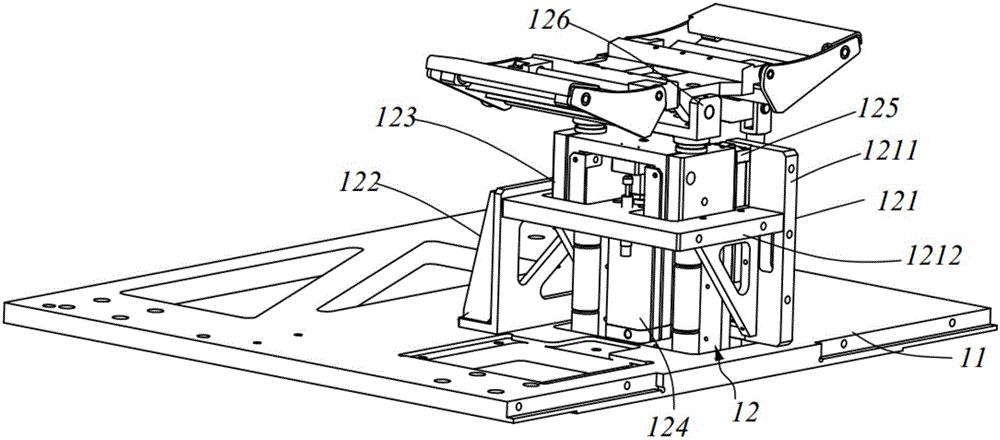

[0033] See Figure 4 ~ Figure 11 As shown, as the first embodiment of the present invention: the arm holding portion 22 includes a support plate 221 that can rotate up and down on both sides of the front and rear sides, at least two claws 222 that pivot at the front and rear ends of the support plate 221, and a drive The gripper 222 pivots to carry out the gripping driving assembly 223 of holding or loosening, the tire unloading driving assembly 224 that drives the support plate 221 to rotate, and the position detection assembly (not labeled) electrically connected with the control assembly ).

[0034] Both sides of the bottom of the supporting plate 221 rotate and cooperate with the corresponding two sides of the fitting 126 through a first rotating shaft 226, so that the supporting plate 221 drives the supporting claws 222 to tilt and rotate forward or backward to guide The green tire is unloaded forward or backward. The front and rear ends of the support plate 221 are piv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com