Safety interlocking system suitable for urban railway vehicle maintenance warehouse

A technology for safety interlocking and railway vehicles, applied in the field of safety interlocking systems, can solve problems such as reduced maintenance efficiency, casualties, vehicle roof falling, etc., to ensure safety and reliability, ensure life safety, and synchronize safety interlocking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

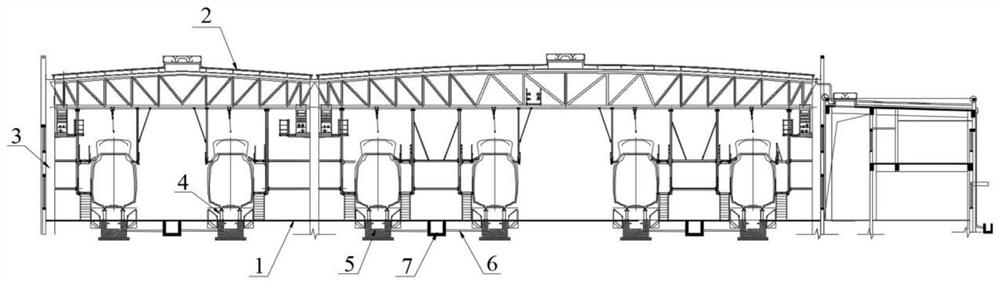

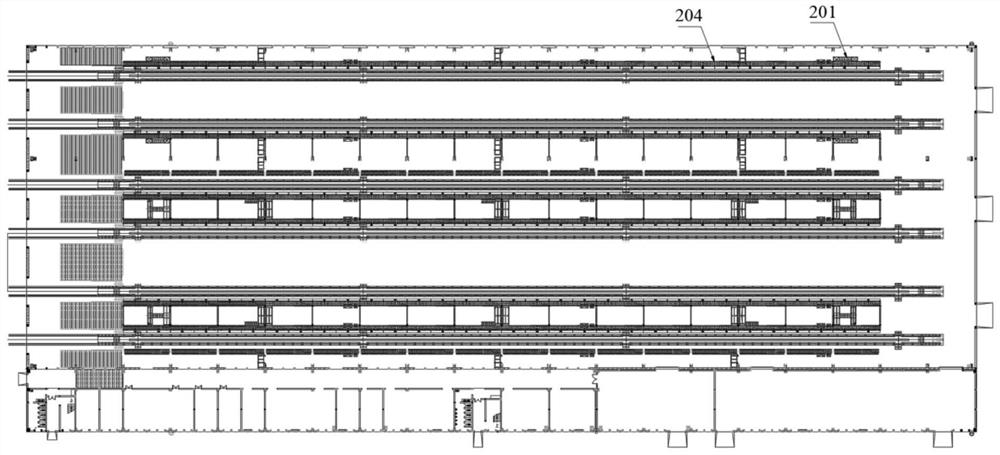

[0056] In the preferred embodiment of the present invention, it is suitable for the boarding operation maintenance warehouse of urban railway vehicles such as figure 1 , 2 As shown in , the maintenance depot is provided with a plurality of maintenance lines 4, which can simultaneously realize the simultaneous maintenance of multiple groups of urban railway vehicles. Specifically, a plurality of maintenance lines 4 are arranged in parallel and at intervals, and the extension direction of the maintenance lines 4 is the longitudinal direction of the maintenance warehouse, and the horizontal direction perpendicular to the longitudinal direction is the horizontal direction, that is, urban railway vehicles are parked in the maintenance warehouse along the longitudinal direction.

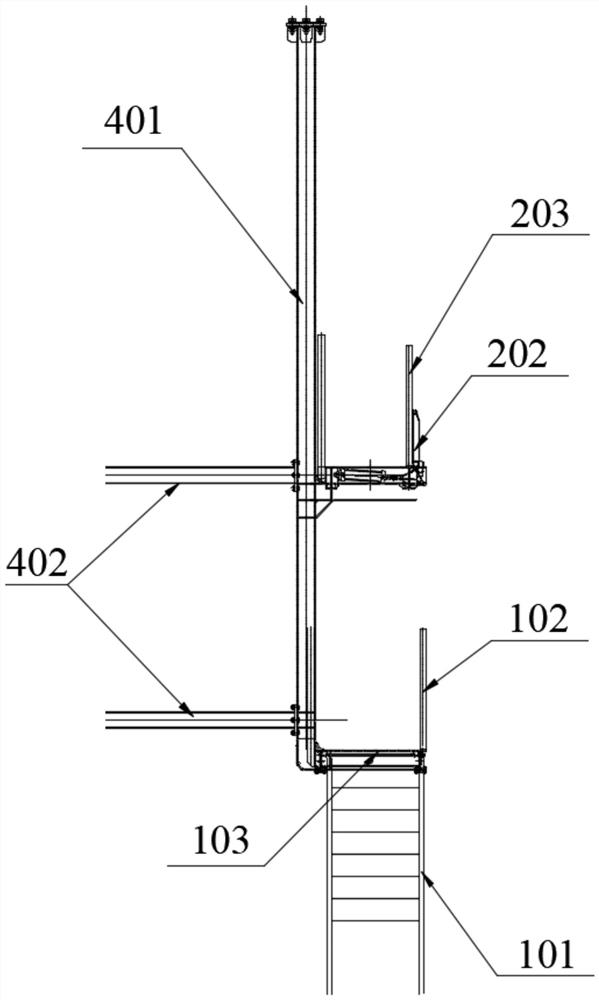

[0057] Further, a ceiling 2 is provided on the top of the maintenance garage, and a plurality of transversely extending beams 302 are arranged at the bottom of the ceiling 2, and a plurality of supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com