Method for cleaning bottom equipment of bullet trains

A vehicle and vehicle bottom technology, which is applied in the direction of vehicle external cleaning devices, etc., can solve the problems of inability to clean the bottom plate of the motor vehicle, secondary pollution, and vehicle cleaning methods that cannot adapt to the substantial increase in the maintenance of motor vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

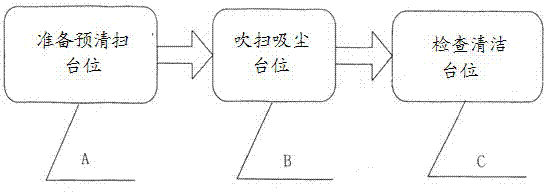

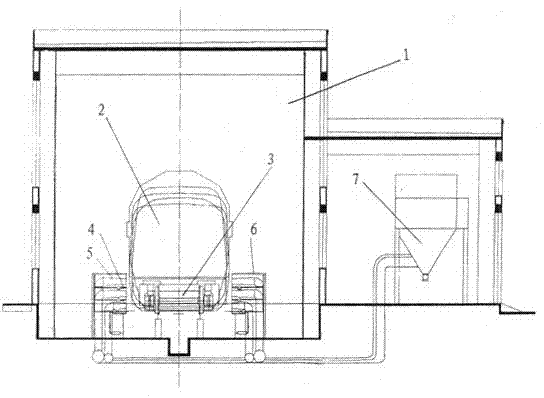

[0026] Now in conjunction with accompanying drawing, the method for cleaning the equipment at the bottom of motor vehicles involved in the present invention will be further described, figure 1 Display the cleaning flow of equipment under the motor vehicle vehicle, figure 2 show figure 1 The CMU vehicles enter the cleaning working state of the second station.

[0027] As shown in the figure, the method for cleaning the undercarriage equipment of the motor vehicle involved in the present invention utilizes three stations with different cleaning facilities provided in the EMU cleaning depot 1 to simultaneously clean the undercarriage equipment of the three motor vehicle vehicles at different stages. Water cleaning operations. The three stations are: the first station, the pre-cleaning station A; the second station, the blowing and vacuuming station B; the third station, the inspection and cleaning station C.

[0028] The vehicle that has completed the cleaning of the first pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com