Bulk cargo wharf loading and unloading operation falling object recycling system

A recycling system and operation technology, applied in the directions of loading/unloading, transportation and packaging, can solve the problems of water quality and sediment pollution, marine water environment, adverse effects on the ecological environment, etc., achieve simple structure, protect the marine water environment, use handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

[0020] Taking the current on-site use of Zhangjiagang Port Group's coal storage yard as an example, the specific structure and working principle of the falling object recovery system for loading and unloading operations at the bulk cargo terminal are further explained.

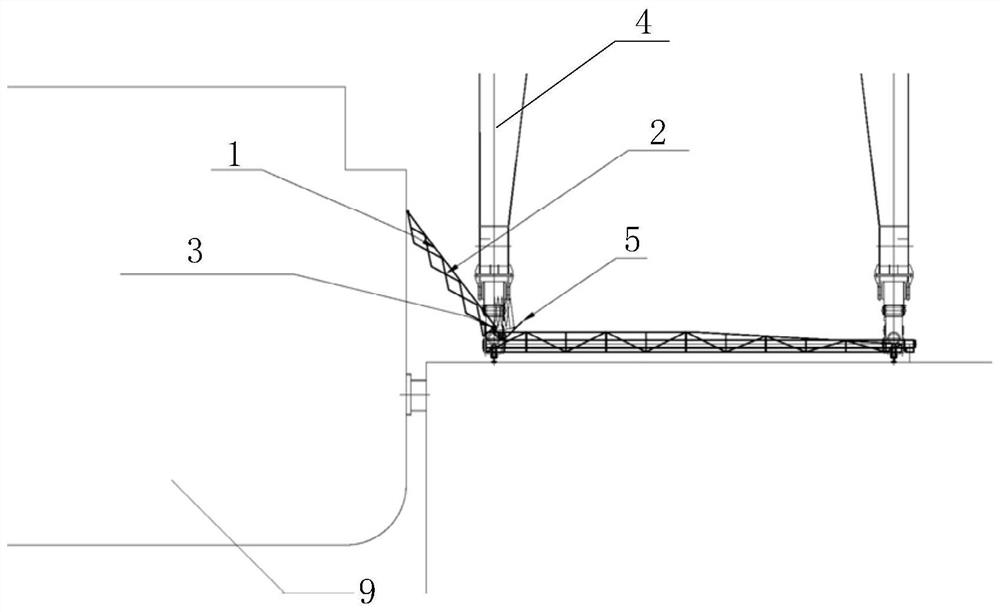

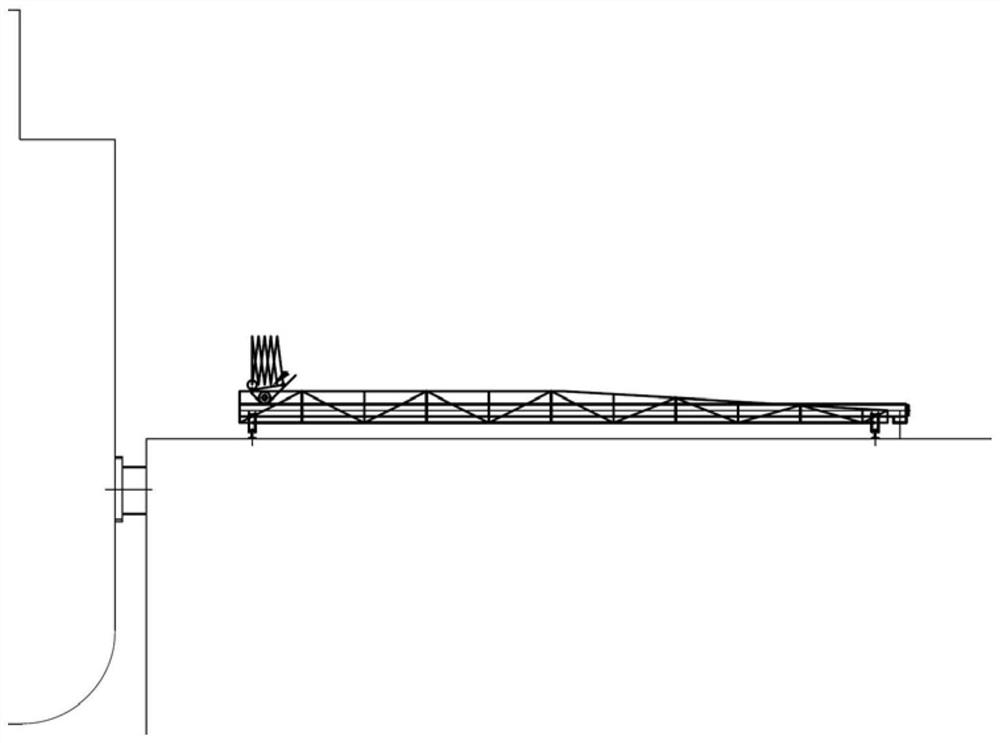

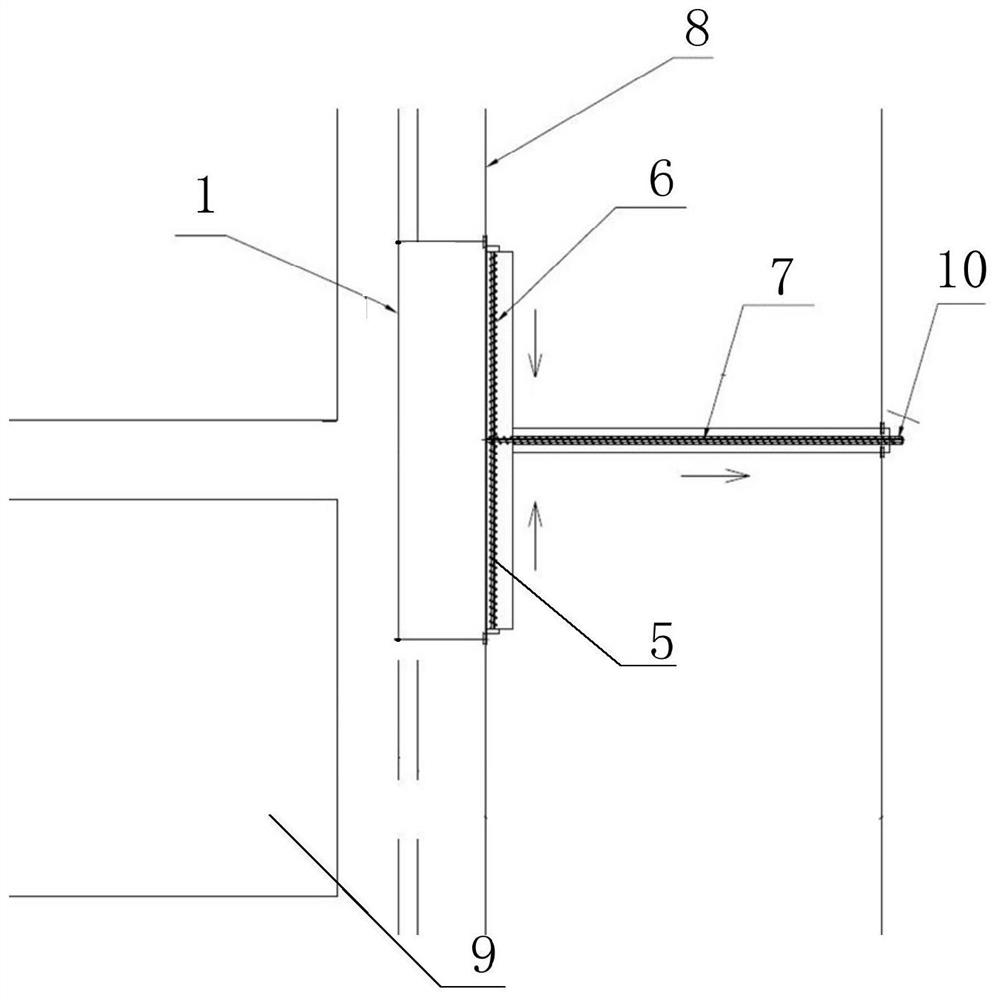

[0021] Such as figure 1 and figure 2 As shown, the falling object recovery system for loading and unloading operations at the bulk cargo terminal is used in conjunction with the ship unloader 4, which specifically includes a material receiving system and a material recovery system arranged on a base; the base is arranged below the ship unloader 4 and The four corners of the bottom surface of the base are each provided with a roller matching the ship unloader running track 8, so that it can share the same shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com