Method for replacing electrode of aluminum electrolysis cell

An aluminum electrolytic cell and aluminum electrolysis technology, which is applied in the field of improving the electrode replacement method of the aluminum electrolytic cell, can solve the problems of increasing the production cost of electrolytic aluminum, increasing the consumption of fluoride salts in the electrolytic cell, and increasing environmental pollution in the workshop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

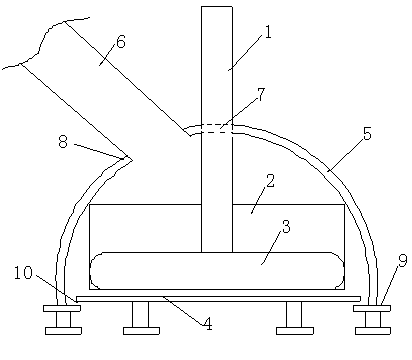

[0020] 1. In the electrolysis workshop, it is convenient to change poles, does not affect other operations, and can be connected with the original flue gas pipeline at equal intervals. figure 1 The device for purifying and reducing the consumption of fluoride salts shown is mainly composed of an anode tray 4, a sealing cover plate 5, a cover plate base 9, a gas collecting flue 6, a joint part 8 of the flue cover plate, and a joint part 10 of the tray cover plate 1. The sealing part 7 between the guide rods is used to store the new pole 2 and the residual pole 3.

[0021] 2. The cover plate on the side connected to the flue can be pre-fixed together with the flue 6 and the cover base 9; the cover plate 5 on the non-flue side can be opened in pieces to facilitate the entry and exit of a single anode, and the cover base 9 It can be fixed or not; the seal 7 between the guide rods is a seal for the space reserved on the tray cover in order to satisfy the anode guide rod 1 going i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com