A construction technology of on-site pre-assembly and overall hoisting of large cylinder auxiliary grids of lattice-type steel sheet piles

A grid-type steel sheet pile and large cylinder sub-grid technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of long piles, poor geological conditions, etc., achieve fast vibration settling speed, and simple operation on piling site. , the effect of fewer process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

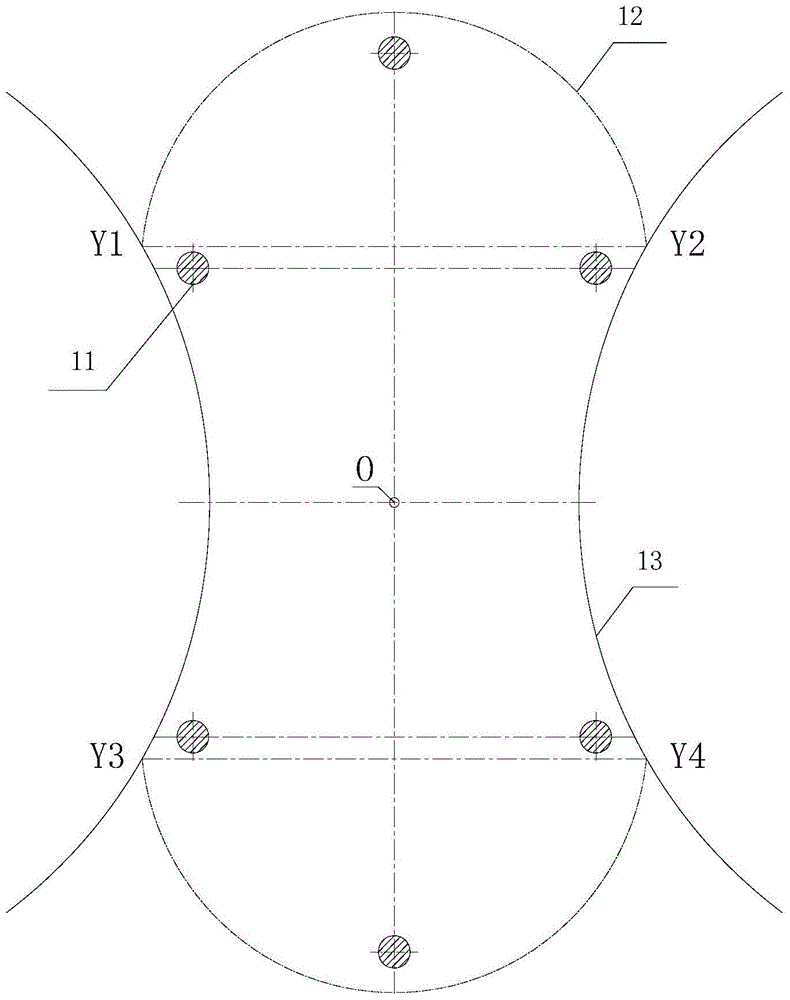

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

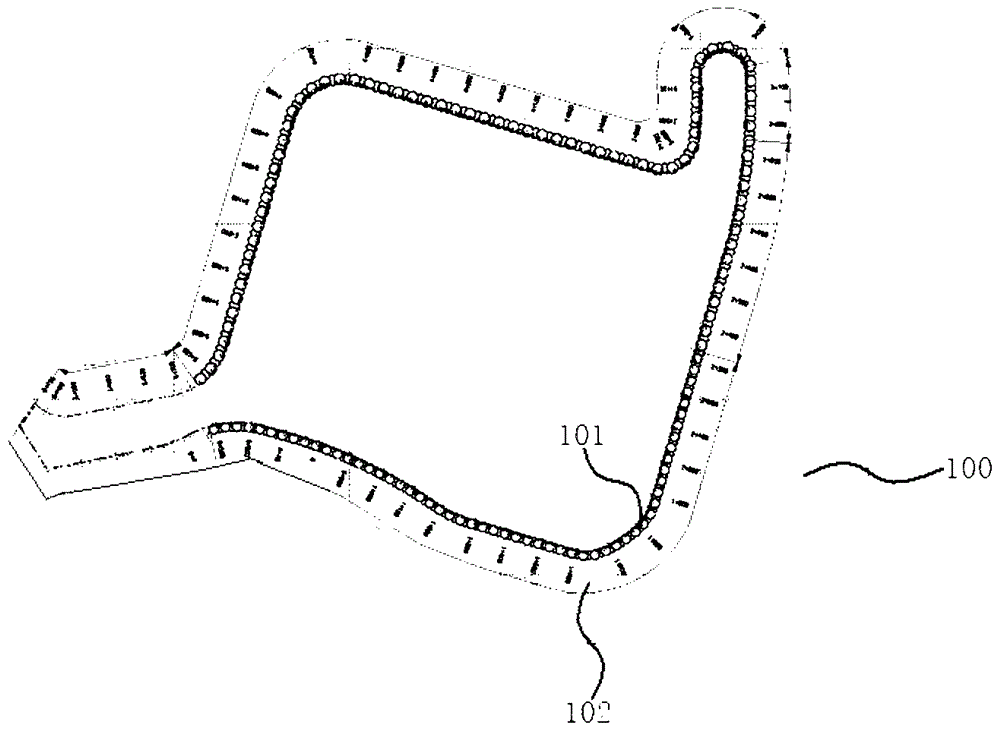

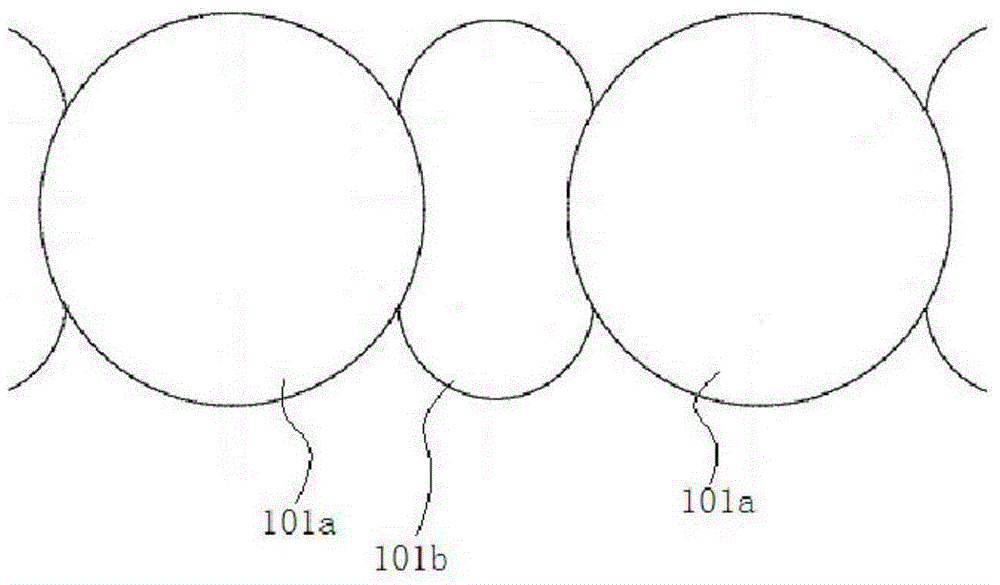

[0031] This example takes the steel sheet pile grid island wall of the artificial island described in the background technology section as the corresponding construction project, in order to specifically illustrate the entire implementation of the combined construction process of the grid-type steel sheet pile large cylinder auxiliary grid pre-assembled and integrated, and pile-connected and scattered process.

[0032] In this example, the implementation of the project has the following conditions:

[0033] 1) On-site height limit conditions

[0034] This project is close to Hong Kong Chek Lap Kok International Airport, and the entire construction area is located in the aviation height limit area of Hong Kong Chek Lap Kok Airport. The constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com