Patents

Literature

274results about How to "Construction stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

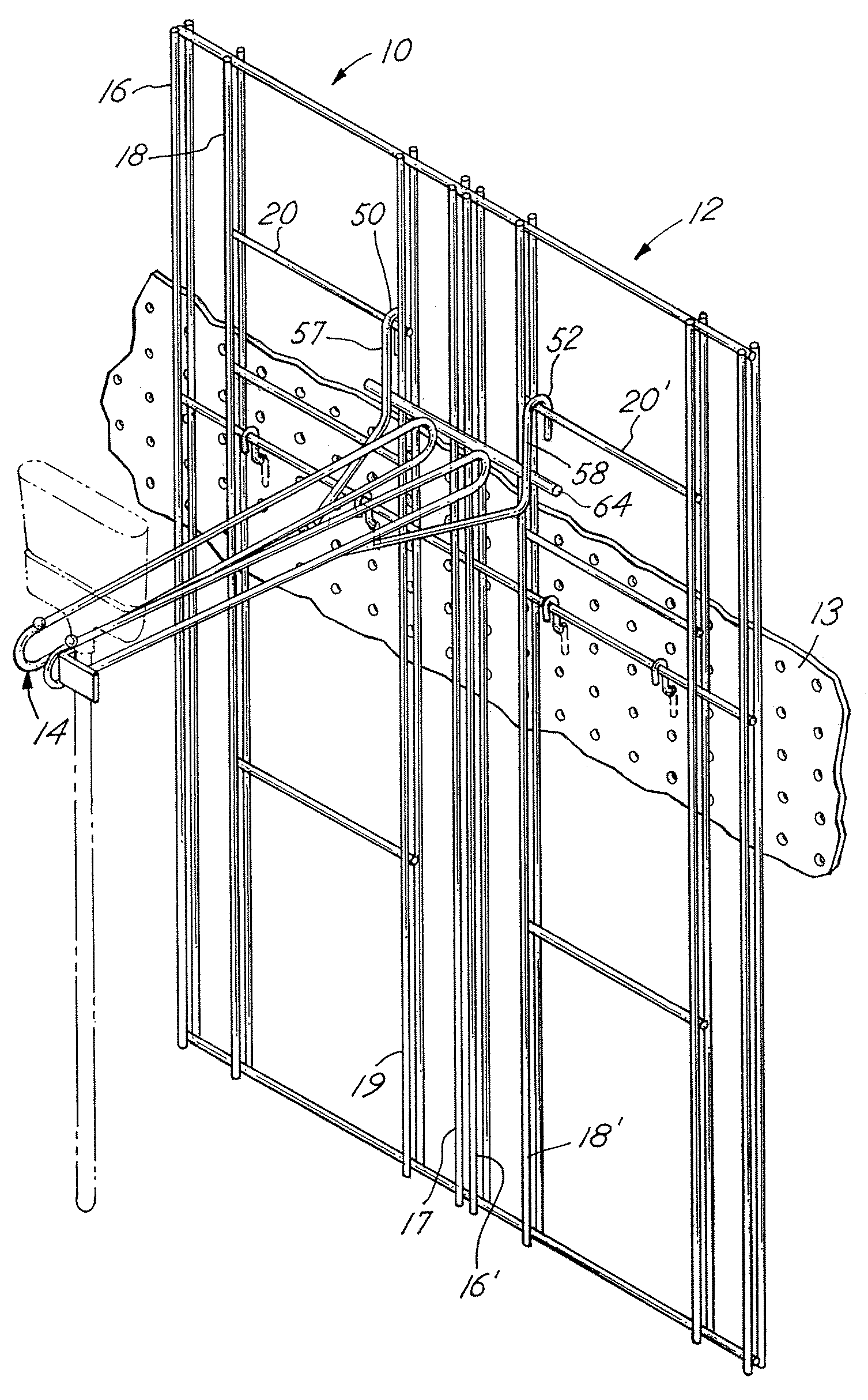

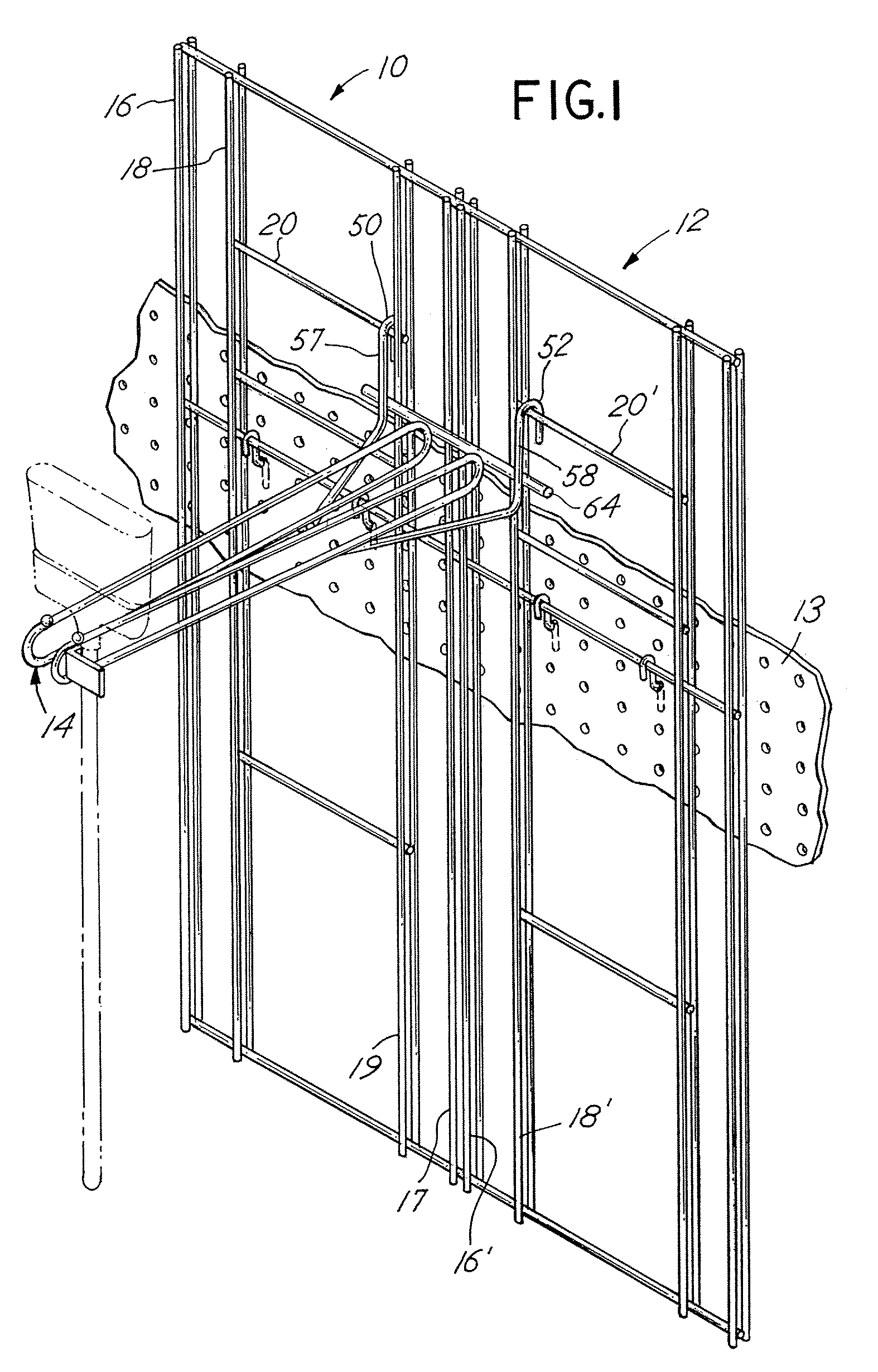

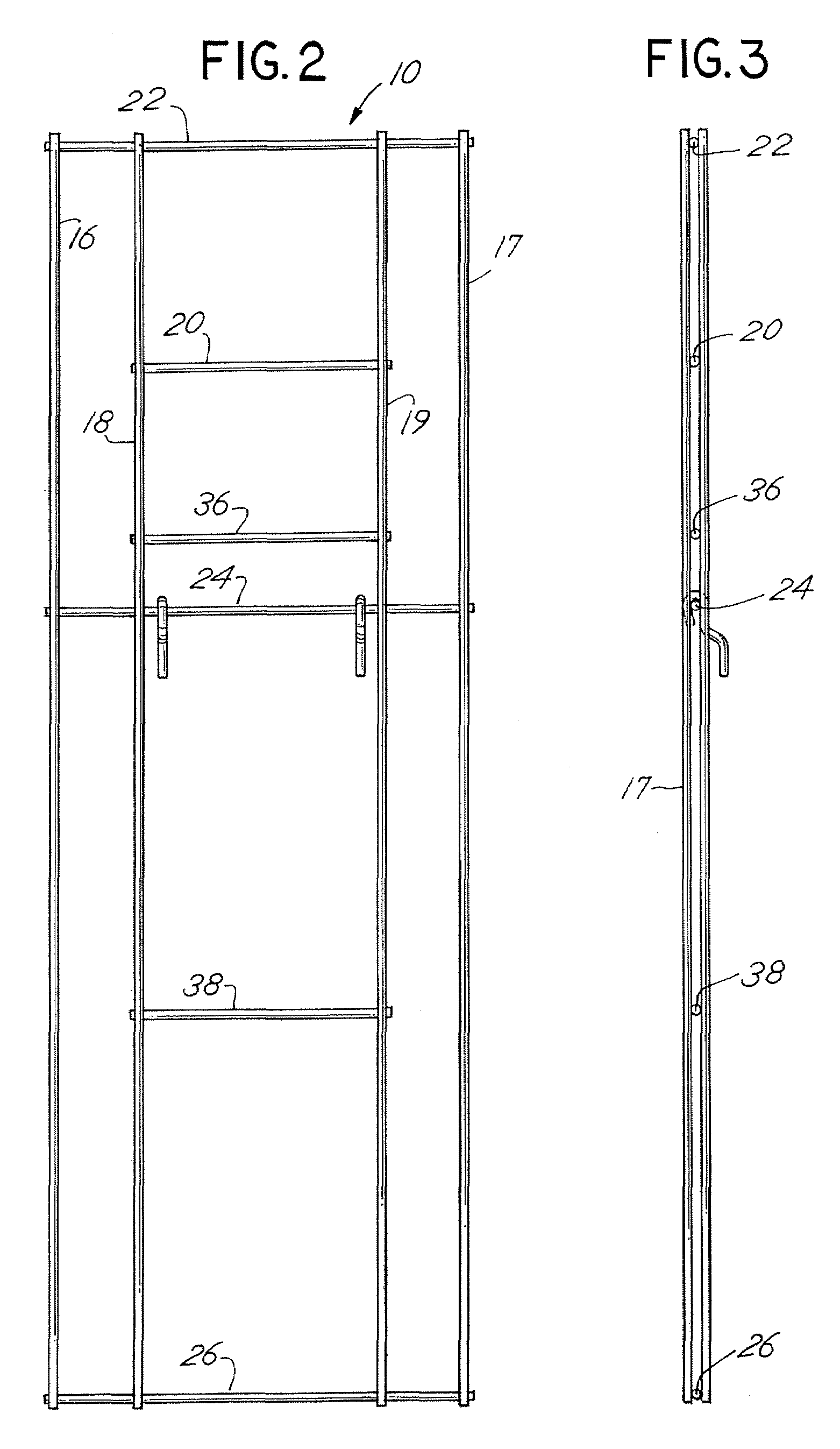

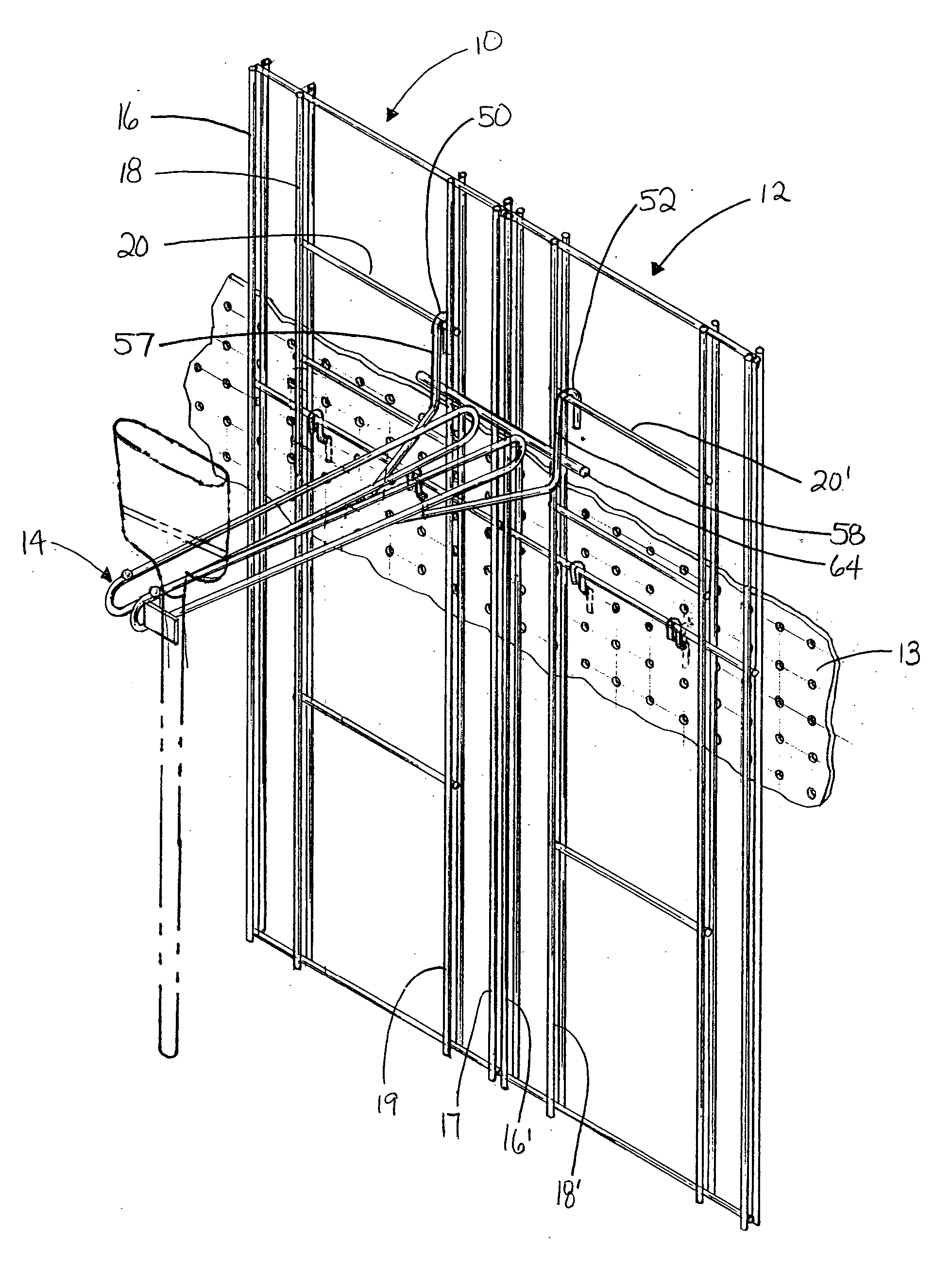

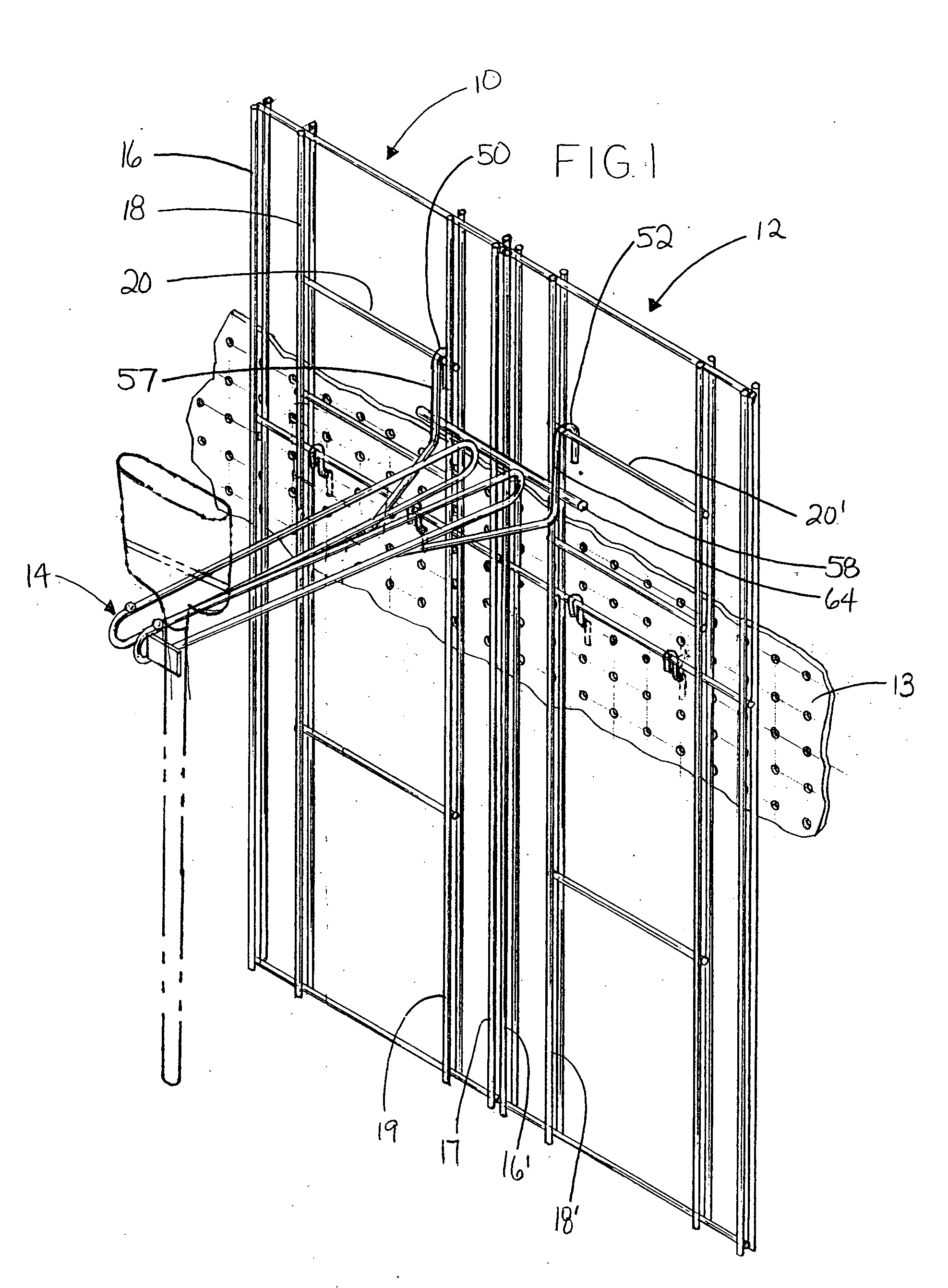

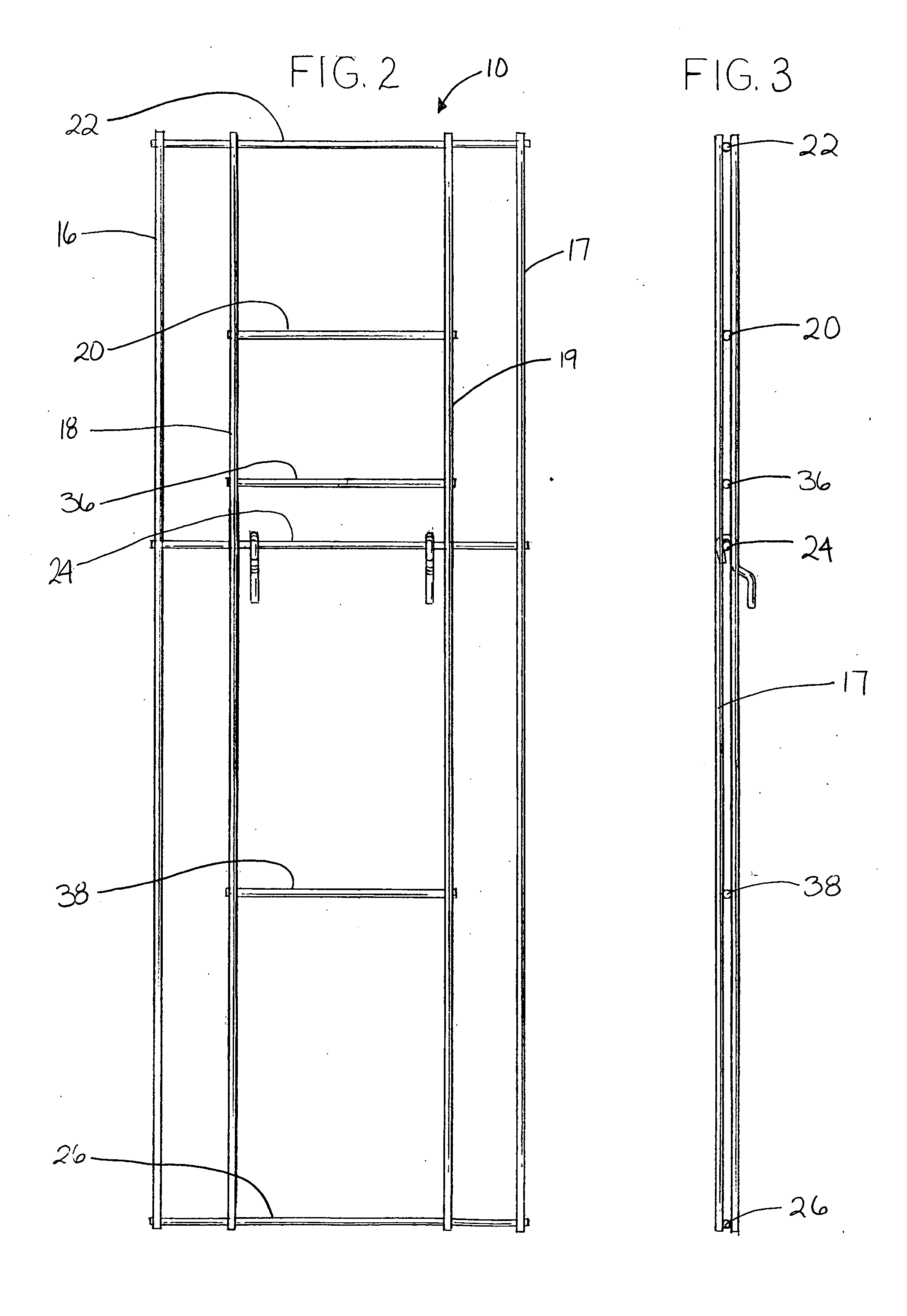

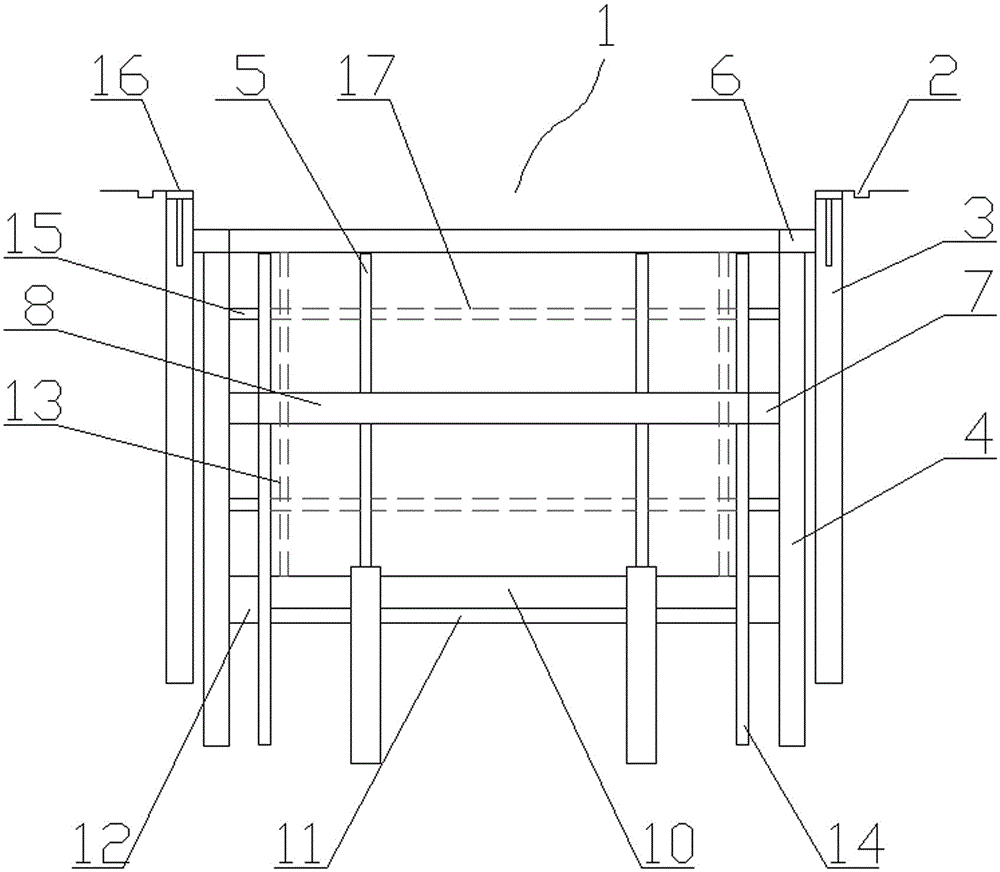

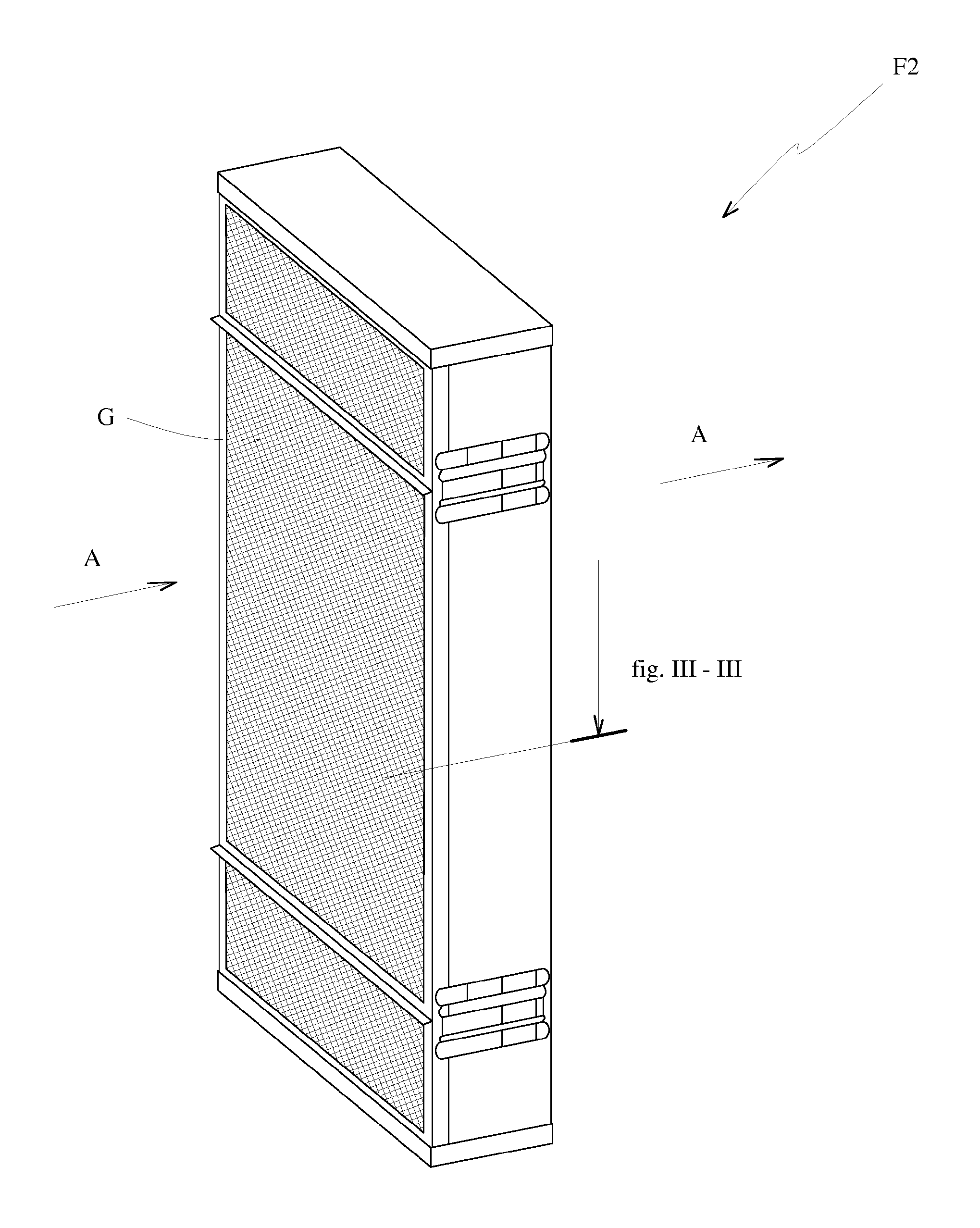

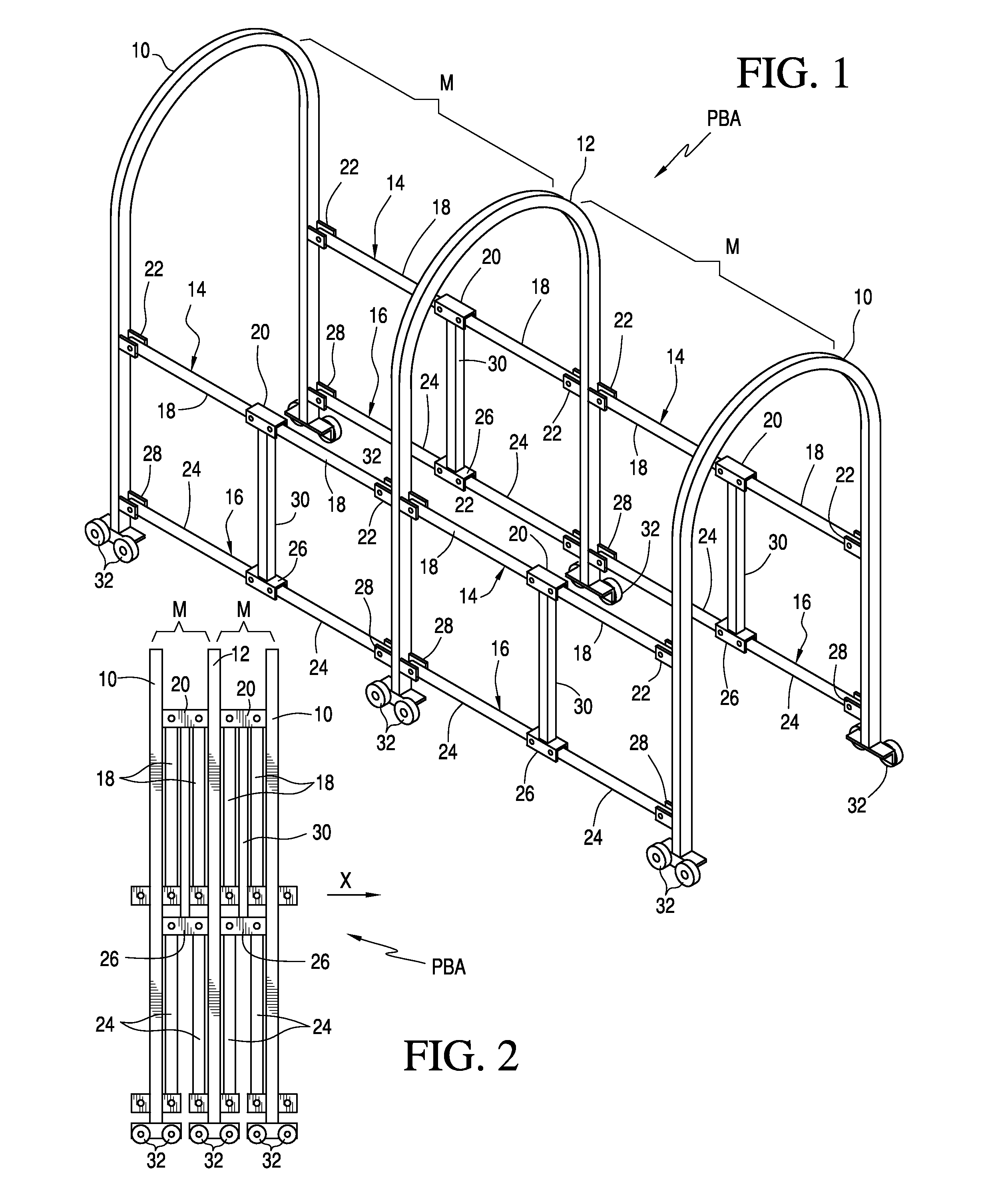

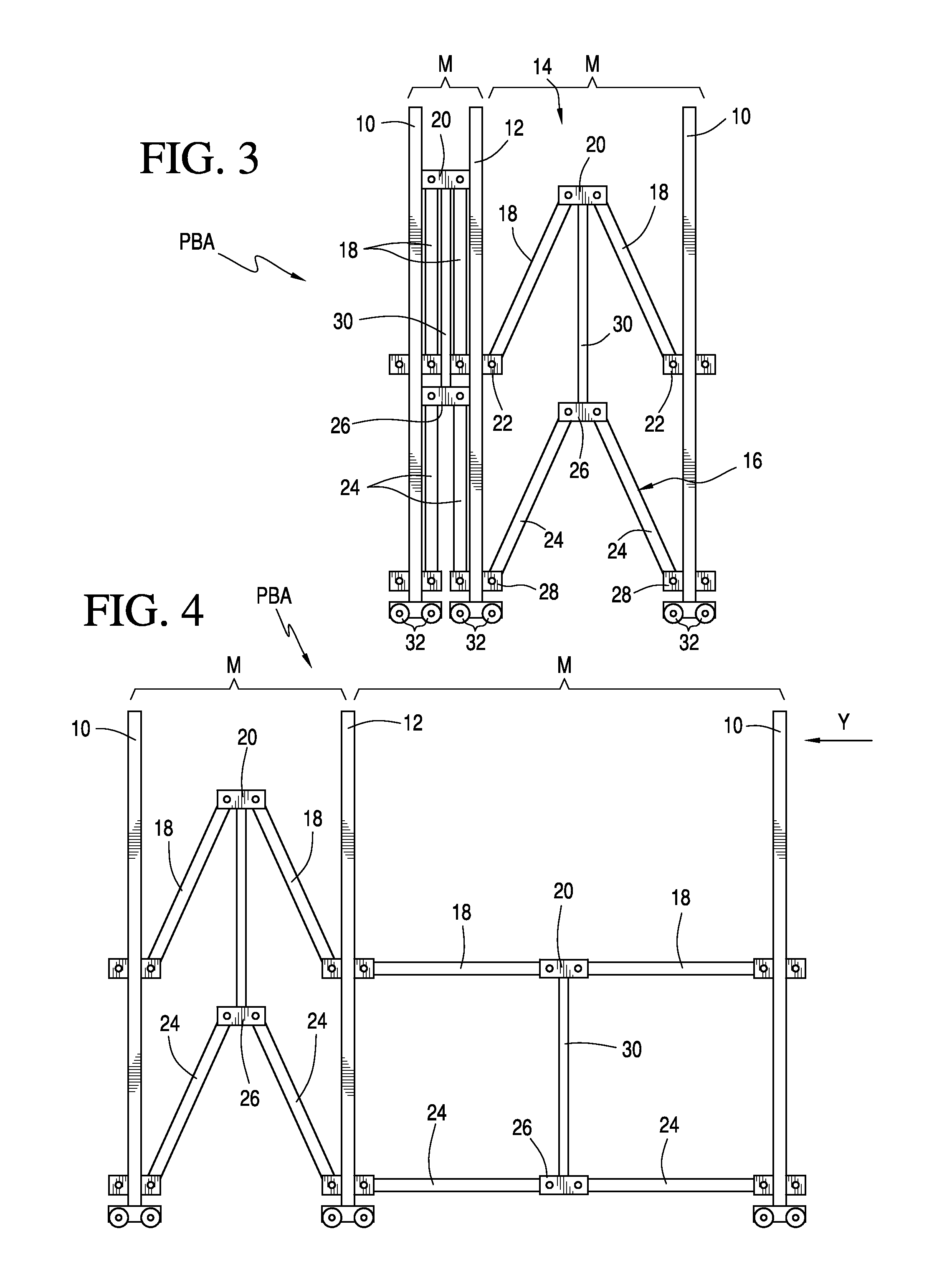

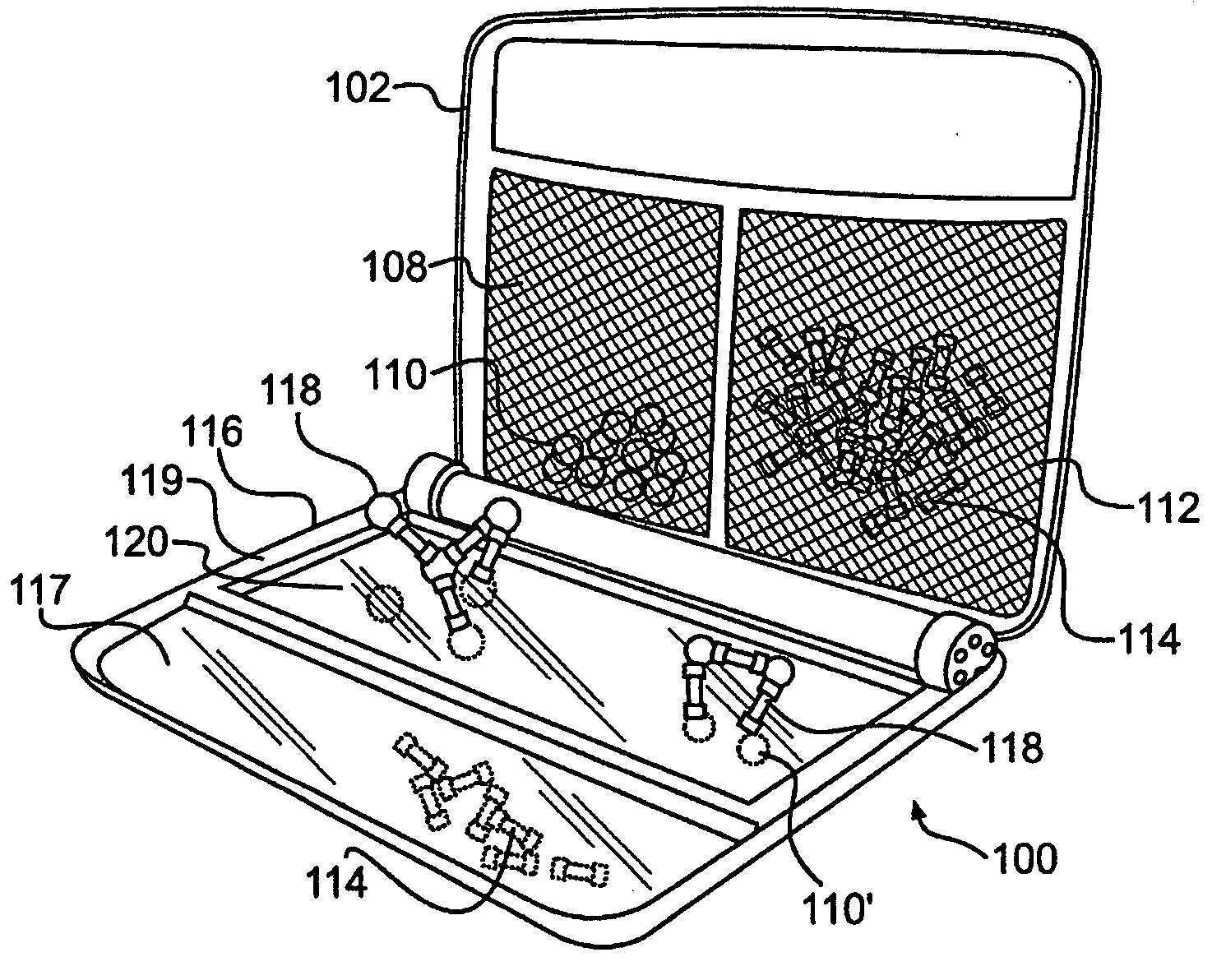

Display rack construction

InactiveUS7178681B2Easy to installConstruction stabilityFolding cabinetsDismountable cabinetsEngineeringSelf positioning

A display rack construction includes at least first and second grid assemblies in combination with a removable bracket assembly. The bracket assembly is designed to functionally join the grid assemblies and simultaneously act to support items for purposes of display. The combination of grid assemblies and bracket assembly provides a self-positioning display rack construction that is generally stable with respect to lateral movement of the individual grid assemblies.

Owner:LIBMAN

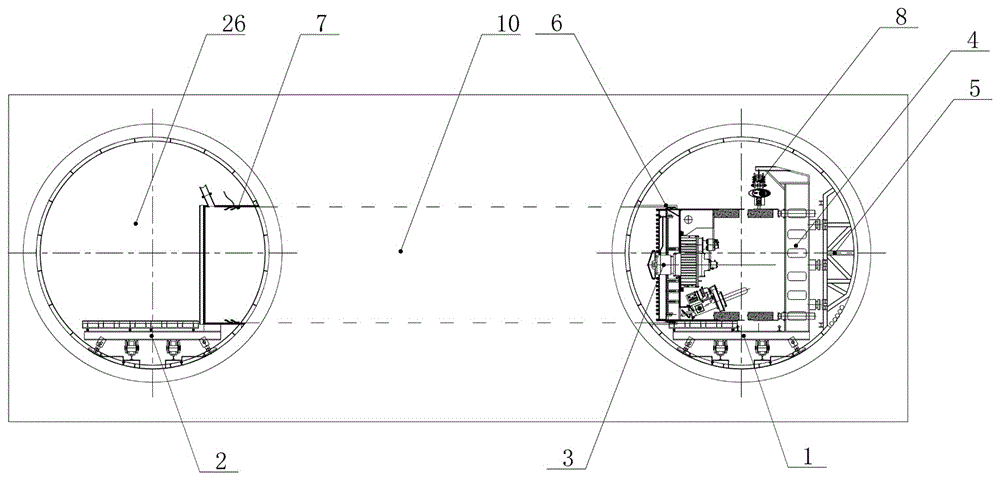

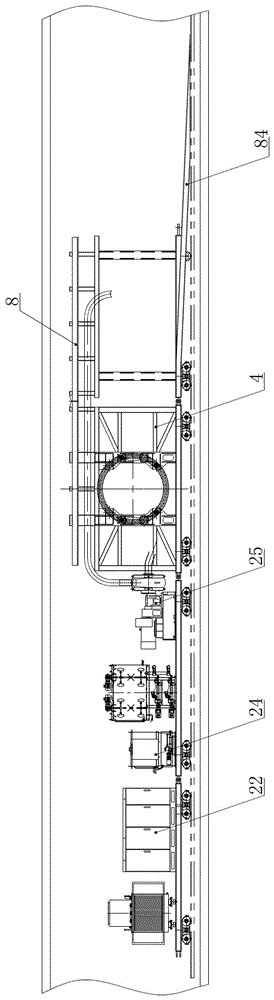

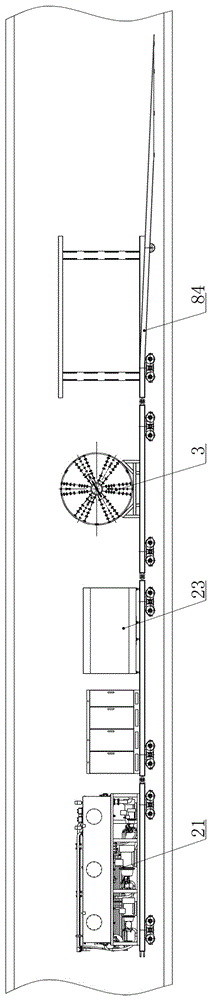

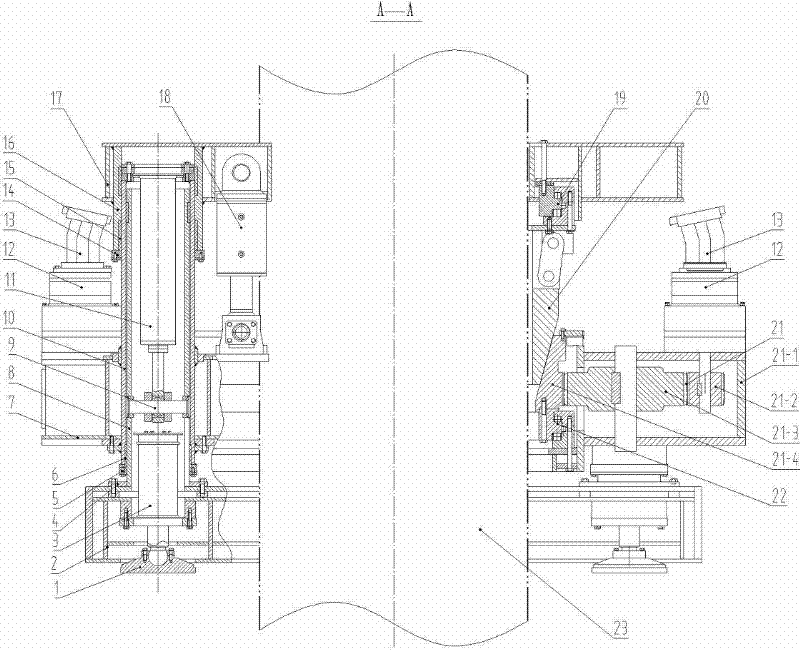

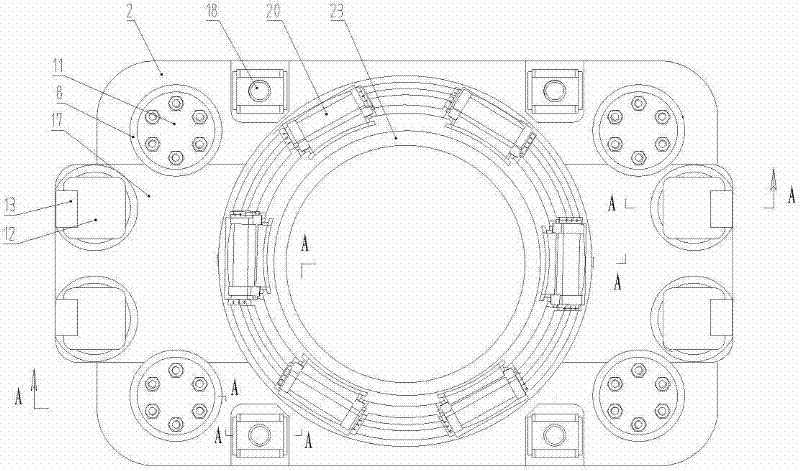

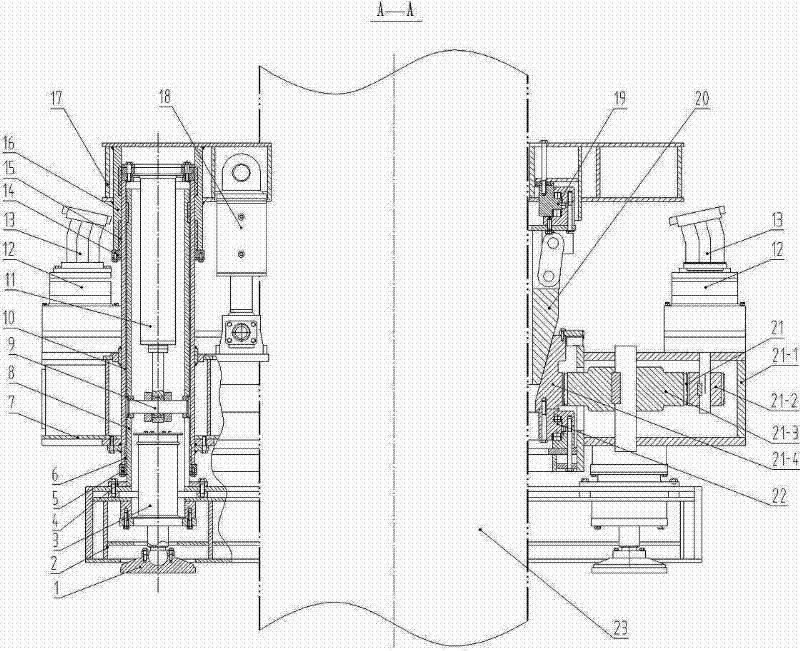

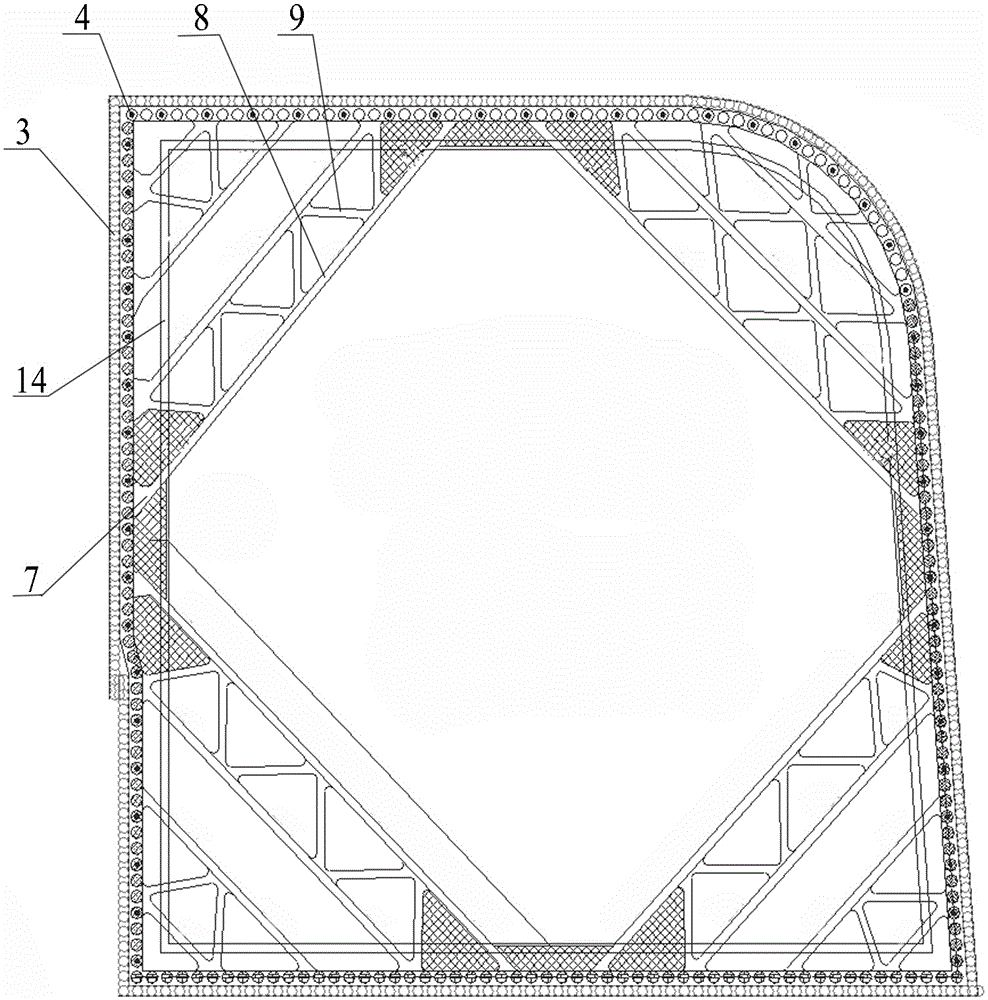

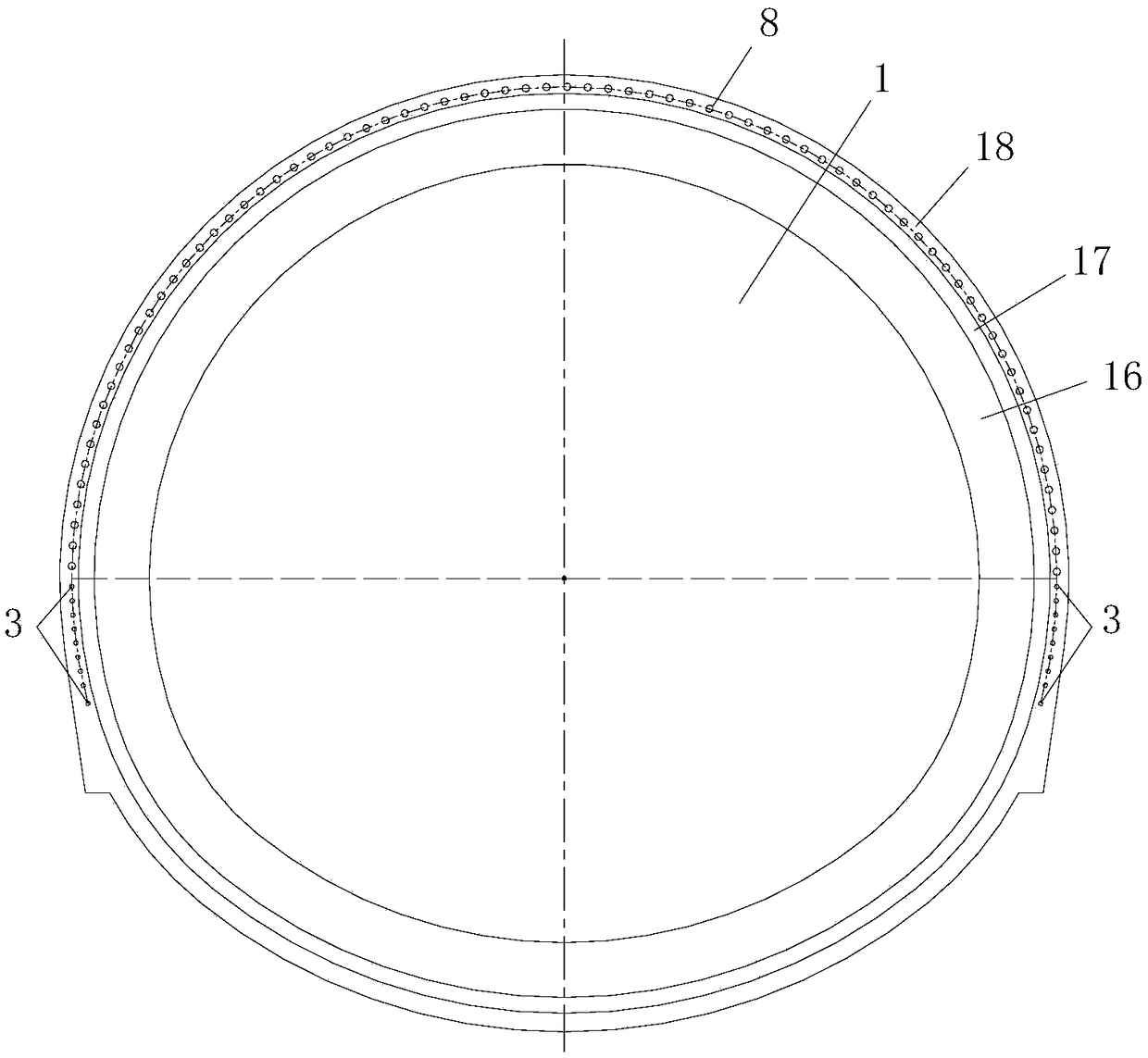

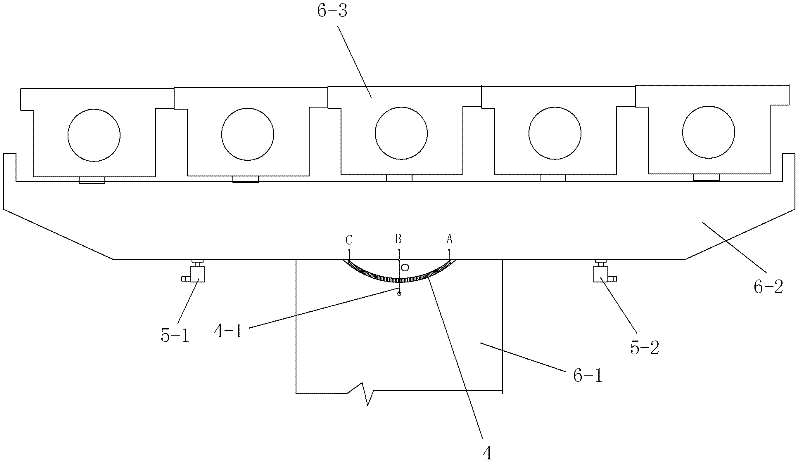

Shield tunneling machine for tunnel connecting passageway and connecting passageway tunneling method of shield tunneling machine

ActiveCN106437735AReaction support enoughCompact and reasonable structure designTunnelsShield tunnelingUltimate tensile strength

The invention belongs to the technical field of tunnel construction equipment, and relates to a shield tunneling machine for a tunnel connecting passageway and a connecting passageway tunneling method of the shield tunneling machine. The shield tunneling machine comprises a start end supporting walking platform and a receiving end supporting walking platform which are respectively arranged on material transportation rails in two main tunnels, a shield tunneling machine main unit, a counterforce supporting frame and a main tunnel supporting assembly which are respectively arranged on the start end supporting walking platform and a corresponding main tunnel duct piece, and a start end socket sealing assembly and a receiving end socket sealing assembly which are respectively arranged at the start end and the receiving end of the connecting passageway, wherein a duct piece hanging assembly is arranged on the start end supporting walking platform; a jacking tunneling assembly is arranged between the counterforce supporting frame and the shield tunneling machine main unit. The shield tunneling machine can realize automatically mechanical excavation; the labor intensity is greatly reduced, the energy consumption is reduced, and the cost is reduced; meanwhile, equipment construction is stable, and the efficiency is high; settling of the ground is effectively controlled, and the construction risk is reduced.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

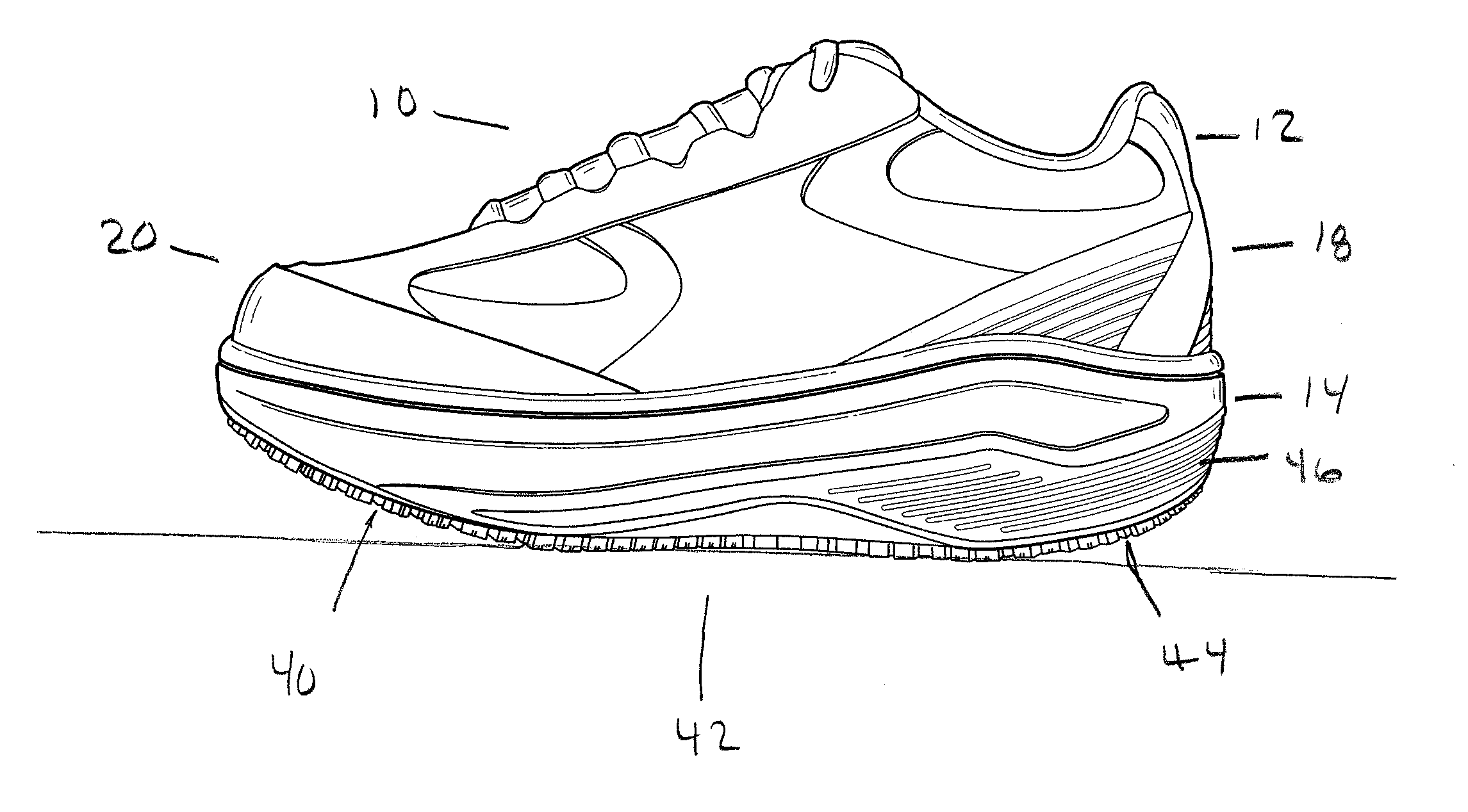

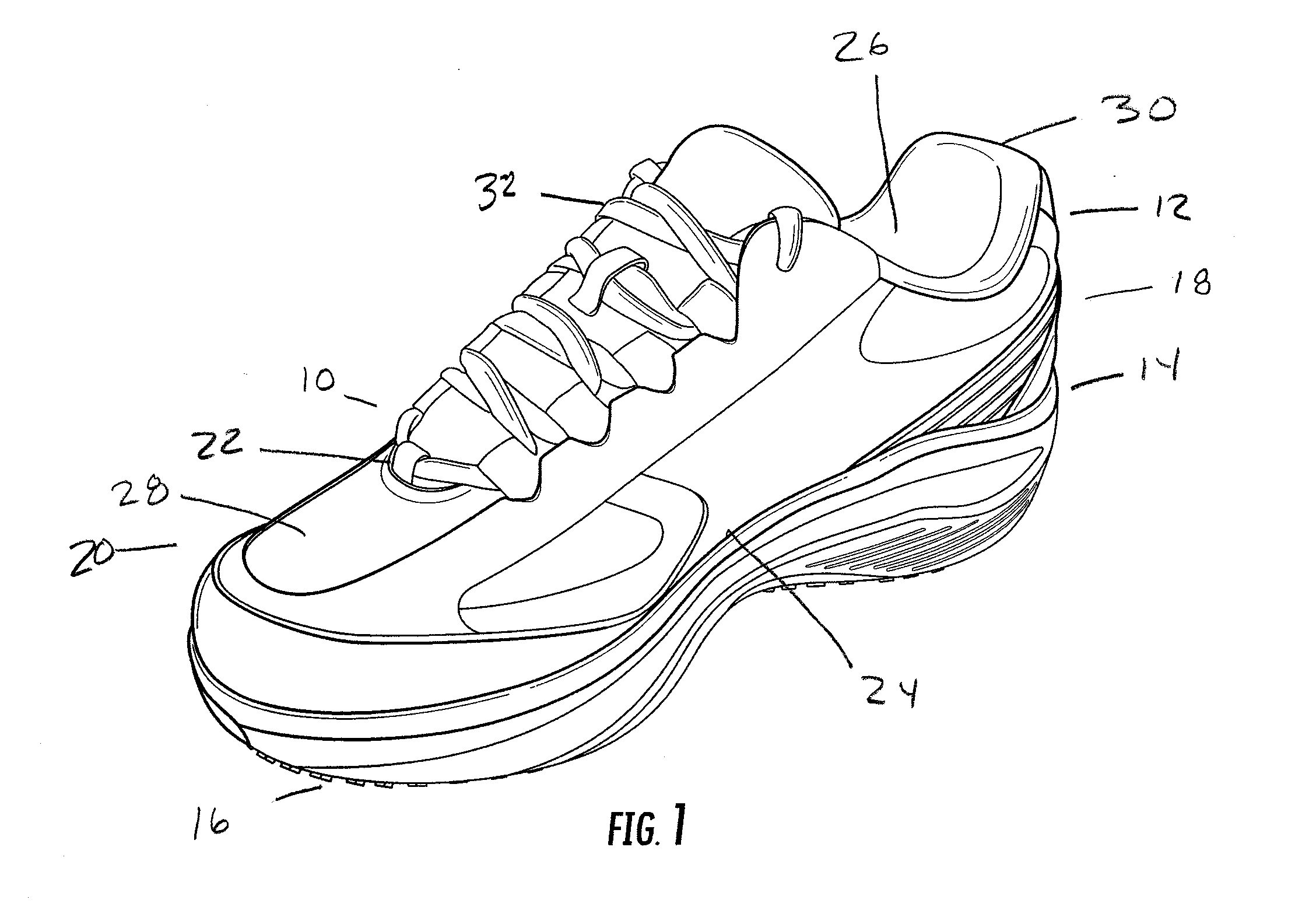

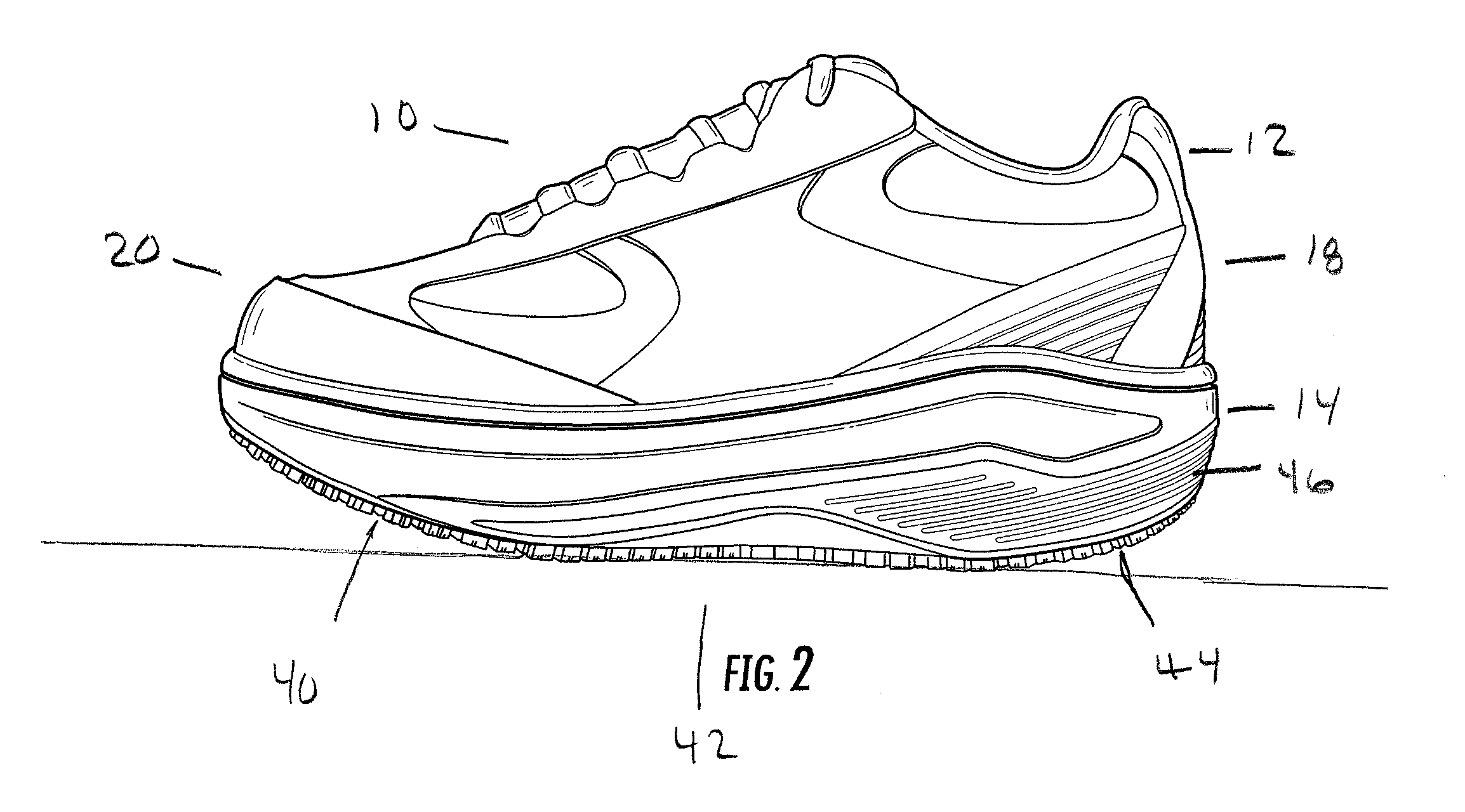

Shoe Construction Having A Rocker Shaped Bottom And Integral Stabilizer

ActiveUS20110067267A1Stabilizing shoe constructionHigh durometer materialSolesUpperTorsion springWedge shape

A shoe construction comprising an outsole constructed from a slip resistant material and a wedge shaped cushion member having a rounded and beveled shaped lower surface bonded to the outsole. A midsole body member is bonded to the cushion member having a torsion spring member secured to the midsole body member. The torsion member assists in stabilizing the shoe construction by directing an outer surface of the outsole to a preferred position, while the lower surface is constructed and arranged to provide a curved rocker-like surface whereby the outsole remains in contact with the ground, and requires muscle control, throughout a walking step.

Owner:SHOES FOR CREWS INC

Tunnel fireproof paint

InactiveCN101747675AGood construction performanceConstruction stabilityFireproof paintsCalcium formateToxic material

The invention relates to fireproof paint, in particular to tunnel fireproof paint, which is prepared from the following ingredients: a major bonding agent (ordinary Portland cement), inorganic heat insulation filling materials (expanded perlite, expanded vermiculite, meerschaum, kaoline and wollastonite powder) and addition agents (calcium formate, starch ether, redispersible latex powder, methyl cellulose ether and polypropylene fiber). Through the unique addition agent combination and the prescription mixture ratio, the tunnel fireproof paint has the advantages that the construction performance is obviously improved, at the same time, the integral overall performance of the tunnel fireproof paint is greatly improved, and the tunnel fireproof paint has the characteristics of stable fireproof performance, high adhesion intensity and stable physicochemical performance. Simultaneously, the product per se generates no toxic substance in the construction and burning processes, has the effects of environment protection and high practicability, and can be widely used for the fireproof protection of buildings such as highways, railways, subway tunnels and the like.

Owner:江西三星气龙新材料有限公司

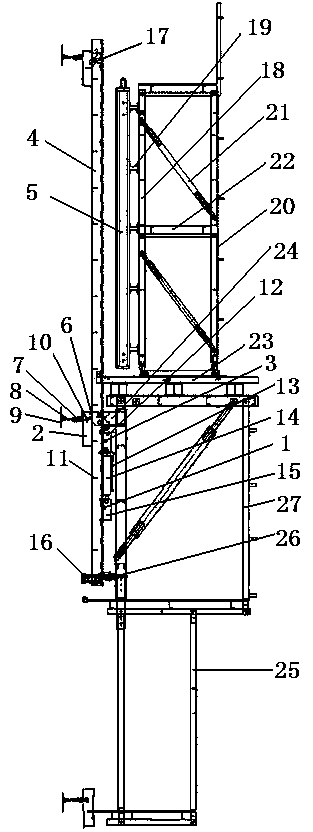

Full Casing Azimuth Drilling Rig

InactiveCN102287132AImprove rigidityHigh output torqueConstructionsDerricks/mastsHydraulic motorGear drive

The invention discloses a full-casing full-rotation drilling rig, which relates to engineering machinery. Including power station, working device and auxiliary drilling tools. The power station is external, and the working device includes a base, a power support platform, a column, a lifting platform and a casing clamping device, and there is an outrigger cylinder in the base for leveling. Drawing cylinders, hydraulic motors, gearboxes, clamping cylinders and gear transmissions are the main devices that transmit power to the casing, driving the casing to rotate, rise and fall. Auxiliary drilling tools include casings of various specifications, grabs, multi-head grippers, etc. The full-casing full-rotary drilling rig has four main actions: leveling, clamping, turning, pressing and pulling. The engine in the power station drives a number of hydraulic pumps, which are connected to the working device through hydraulic hoses and transmit the power to the corresponding actuators.

Owner:徐州盾安重工机械制造有限公司

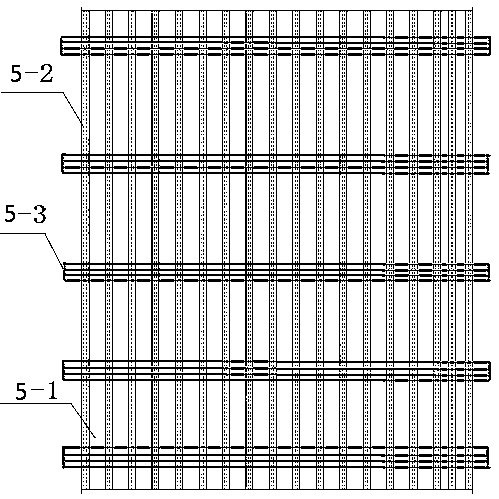

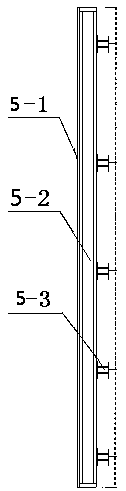

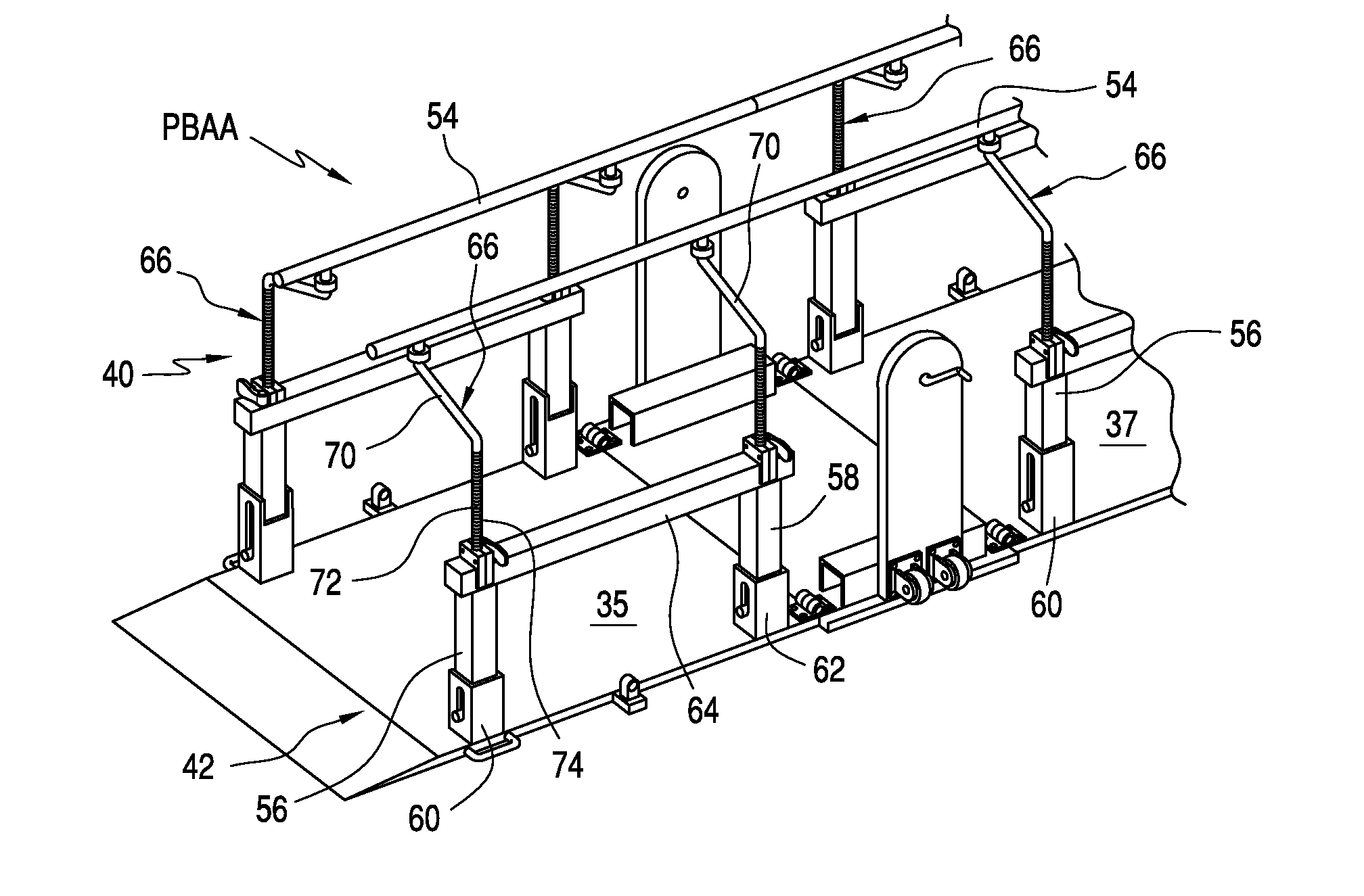

Display rack construction

InactiveUS20050263466A1Stable display rack constructionEasy to installFolding cabinetsDismountable cabinetsMesh gridLateral movement

A display rack construction includes at least first and second grid assemblies in combination with a removable bracket assembly. The bracket assembly is designed to functionally join the grid assemblies and simultaneously act to support items for purposes of display. The combination of grid assemblies and bracket assembly provides a self-positioning display rack construction that is generally stable with respect to lateral movement of the individual grid assemblies.

Owner:LIBMAN

Ultra-deep foundation pit supporting method

ActiveCN105089061AGuaranteed continuitySafe and reliable structureExcavationsPurlinReinforced concrete

The invention relates to an ultra-deep foundation pit supporting method which comprises a single-row triaxial deep-mixing pile water-stop curtain, bored piles and upright steel posts, wherein the single-row triaxial deep-mixing pile water-stop curtain is lower than natural ground and is arranged along the periphery of a foundation pit in an enclosing way; the bored piles are sequentially arranged at intervals in the foundation pit and located on the inner side of the single-row triaxial deep-mixing pile water-stop curtain; the upright steel posts are arranged in the foundation pit and located on the inner sides of the bored piles; the tops of the bored piles are sequentially connected via reinforced concrete crown beams in a pulling way; reinforced concrete enclosing purlins along the periphery of the foundation pit are arranged in positions, which are not the height positions of floor slabs of underground floors, on the inner sides of the bored piles; the inner sides of the reinforced concrete enclosing purlins are connected in a pulling way via reinforced concrete enclosing purlin beams supported on the upright steel posts; the reinforced concrete enclosing purlin beams are in latticed pulling connection with the reinforced concrete enclosing purlins via a plurality of groups of inner reinforced concrete supports; filling plain concrete is arranged inwards at the bottoms of the bored piles; a baseplate is laid on the foundation pit and enclosed by the filling plain concrete; and more than one post-cast strip with support replacement pieces is arranged on the baseplate.

Owner:TAIXING FIRST CONSTR INSTALLATION

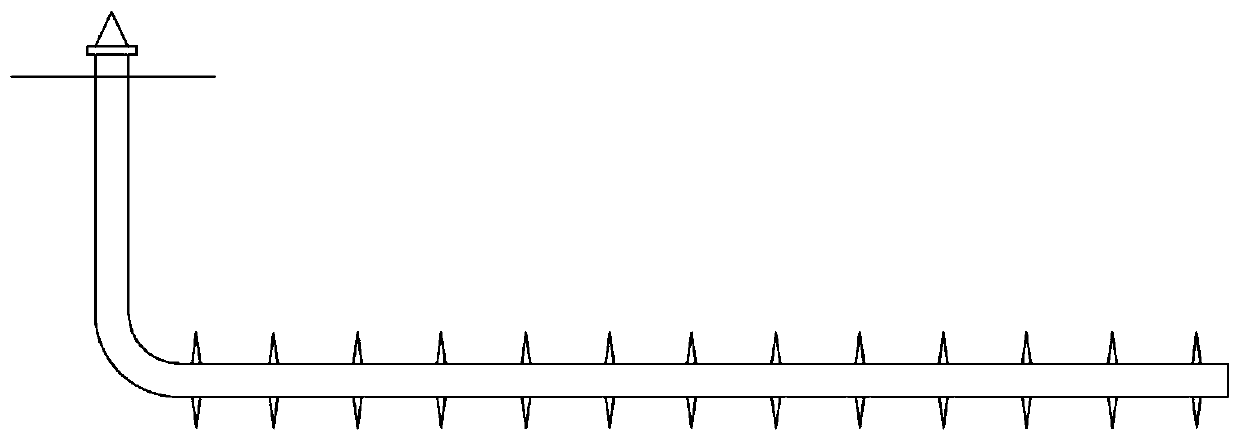

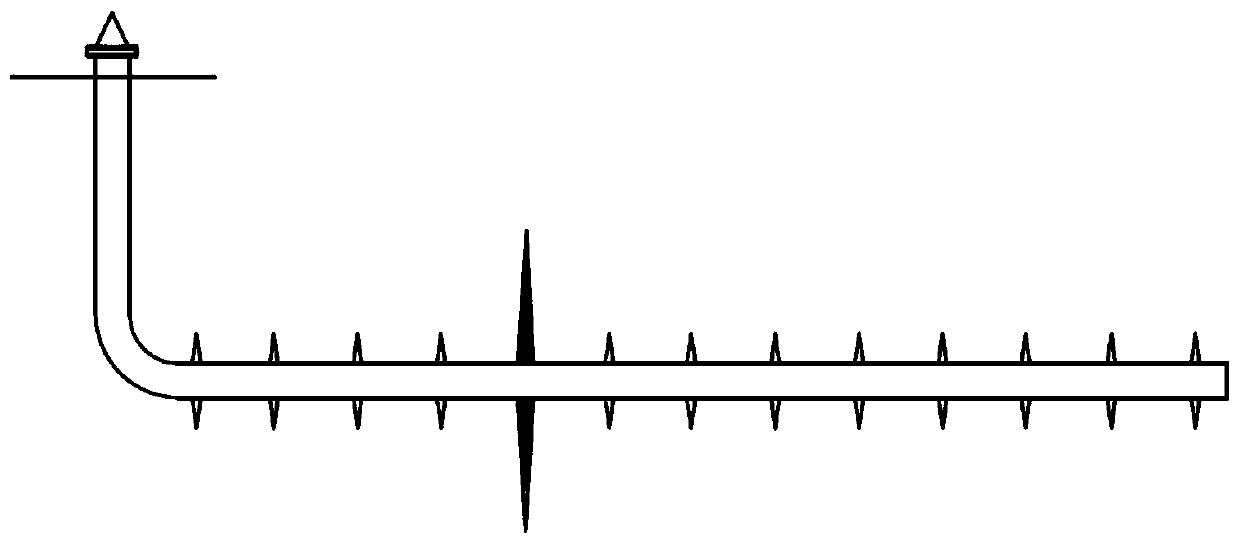

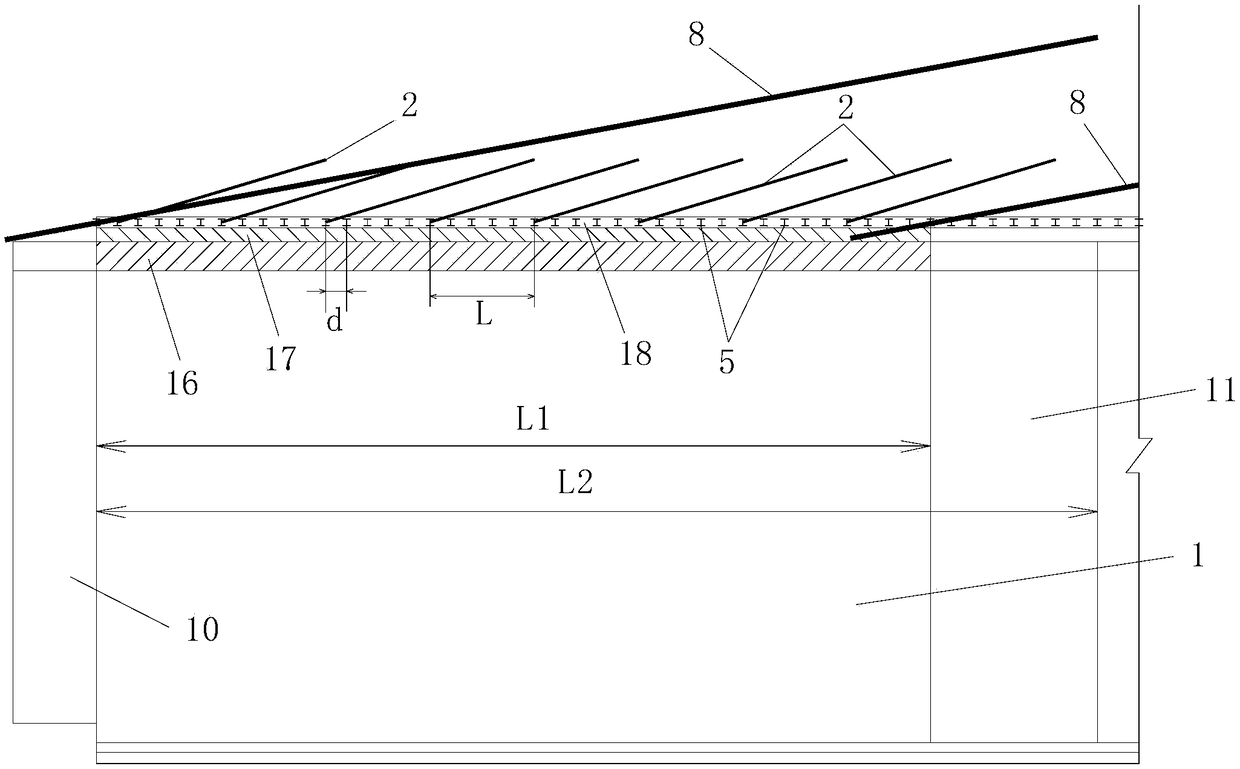

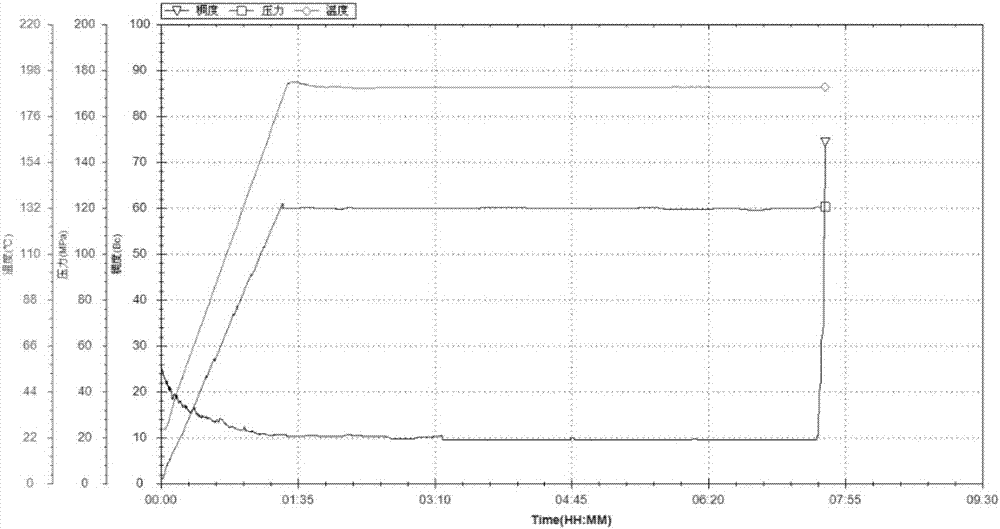

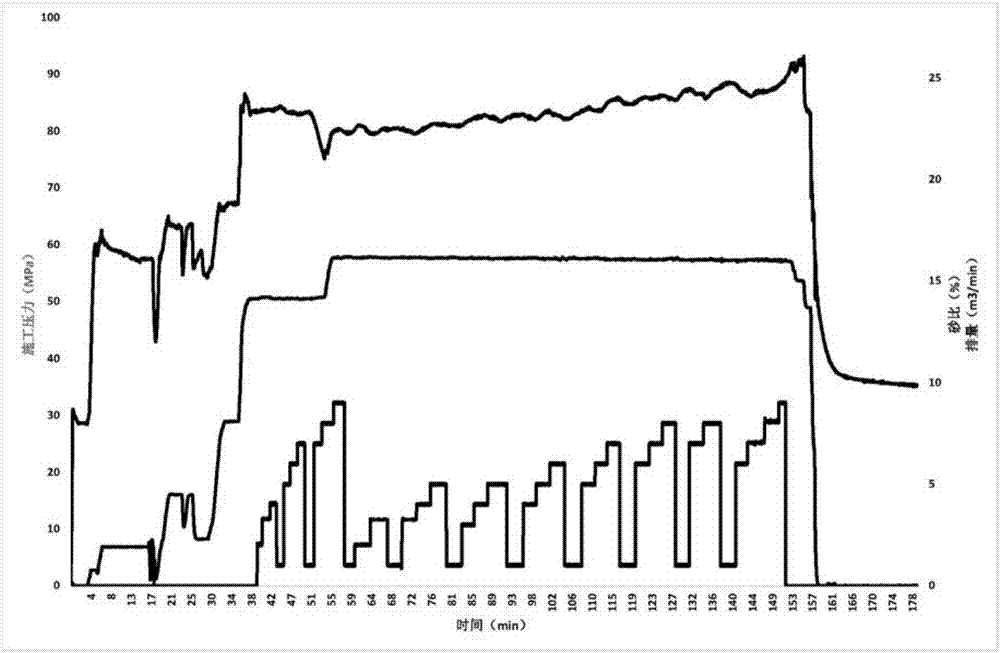

Horizontal well segmented temporary blockage fracturing method

ActiveCN109763804AComplex seam structureRealize infinite continuous fracturingFluid removalFracturing fluidHydraulic fracturing

The invention relates to a horizontal well segmented temporary blockage fracturing method and belongs to the technical field of hydraulic fracturing of oil and gas field development. The method comprises the steps of: carrying out temporary blockage on a perforation of a horizontal well; forming a new crack around the temporary blocked perforation; and repeating the process above. The horizontal well segmented temporary blockage fracturing method achieves a segmented fracturing effect on a well section of a horizontal well and provides a more effective, rapider and more convenient mode for development of the horizontal well. Meanwhile, after a temporary blockage agent is degraded, a crack end port also can be supported so as to improve a fracturing success rate; the temporary blockage agent cannot be left in a shaft, meanwhile, has a very high degradation rate in fracturing fluid, and cannot generate pollution to the stratum, so that the transformation effect is greatly promoted.

Owner:PEKING UNIV

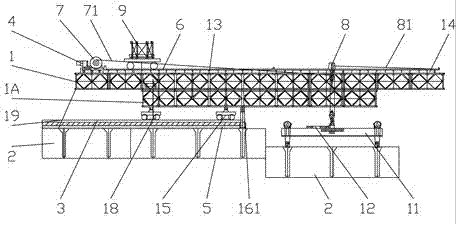

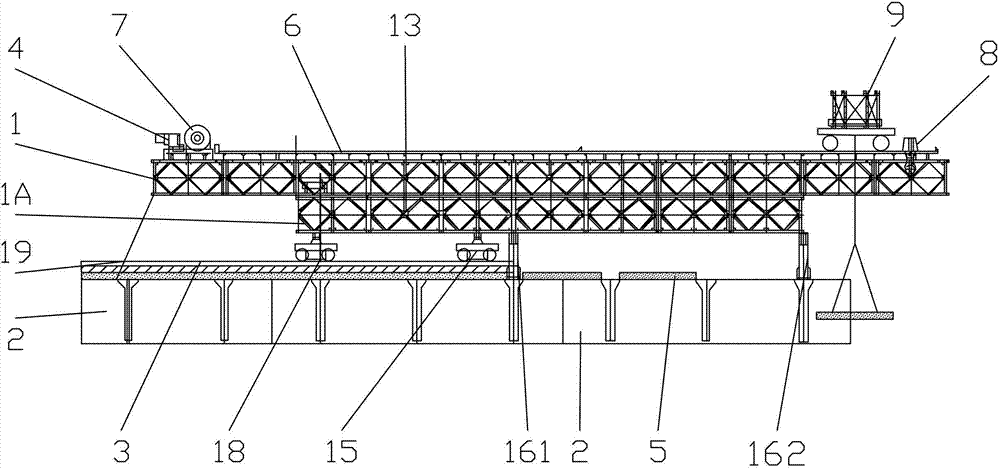

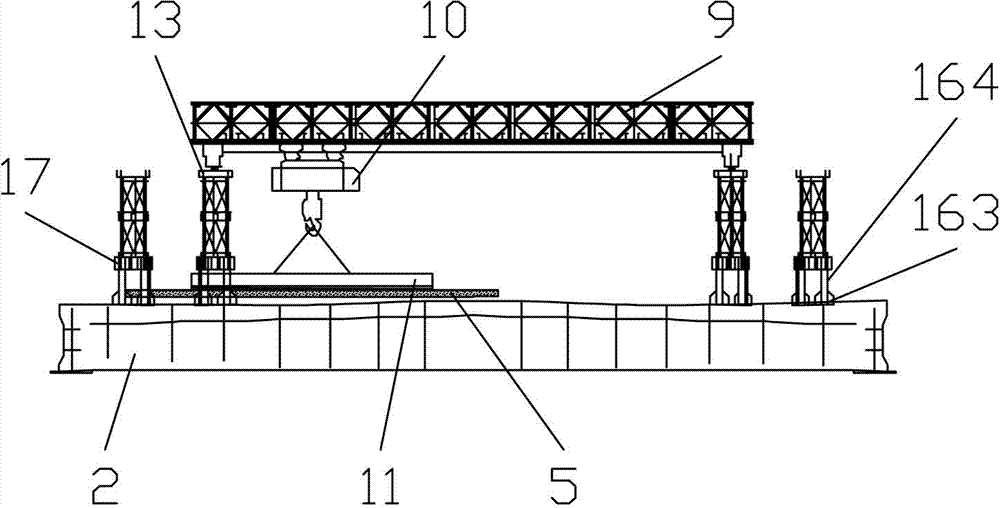

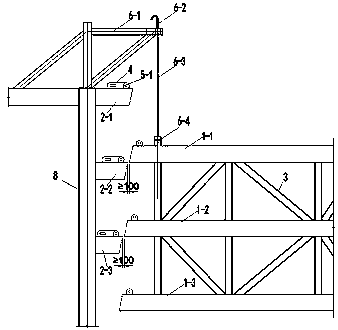

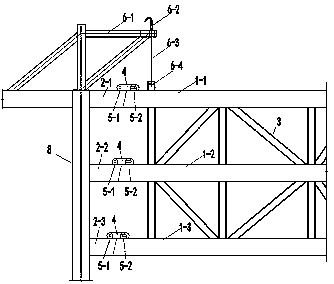

Bridge floor crane for cable-stayed bridge

InactiveCN103882811AGuaranteed stabilityImprove stabilityBase supporting structuresBraking devices for hoisting equipmentsSupporting systemArchitectural engineering

The invention relates to a construction device for a cable-stayed bridge, in particular to a bridge floor crane for the cable-stayed bridge. The bridge floor crane for the cable-stayed bridge comprises two sets of main trusses arranged oppositely, a craning system arranged above the main trusses and a walking system arranged below the main trusses, wherein the walking system comprises a main track laid on a mounted steel beam and a walking device in sliding fit with the main track, and an upper layer and lower layer structure is adopted by the main trusses. The bridge floor crane for the cable-stayed bridge further comprises a supporting system arranged on the lower portions of the main trusses, a rear anchoring system arranged on the outer sides of the two sets of the main trusses, a balance weight device and a safety device, the balance weight device and the safety device are arranged at the rear ends of the main trusses, and the supporting system comprises a middle supporting device arranged in the middles of the main trusses and a temporary supporting device arranged at the front ends of the main trusses. Through the adoption of the technical scheme, the bridge floor crane for the cable-stayed bridge has the advantages of being proper in craning height, strong in bearing capacity, good in construction stability, high in construction efficiency and high in safety.

Owner:CHONGQING CONSTR BRIDGE ENG +2

Vitrified microbead heat-preserving mortar

The invention discloses vitrified microbead heat-preserving mortar. The vitrified microbead heat-preserving mortar comprises the following substances in mass percentage: 60-65% of cementing material, 30-35% of heat-preserving aggregate, 0.5-1% of redispersible latex powder and 1-1.5% of functional material. The vitrified microbead heat-preserving mortar is short in solidification time, good in fire-proof performance and heat-preserving effect and stable in construction performance.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

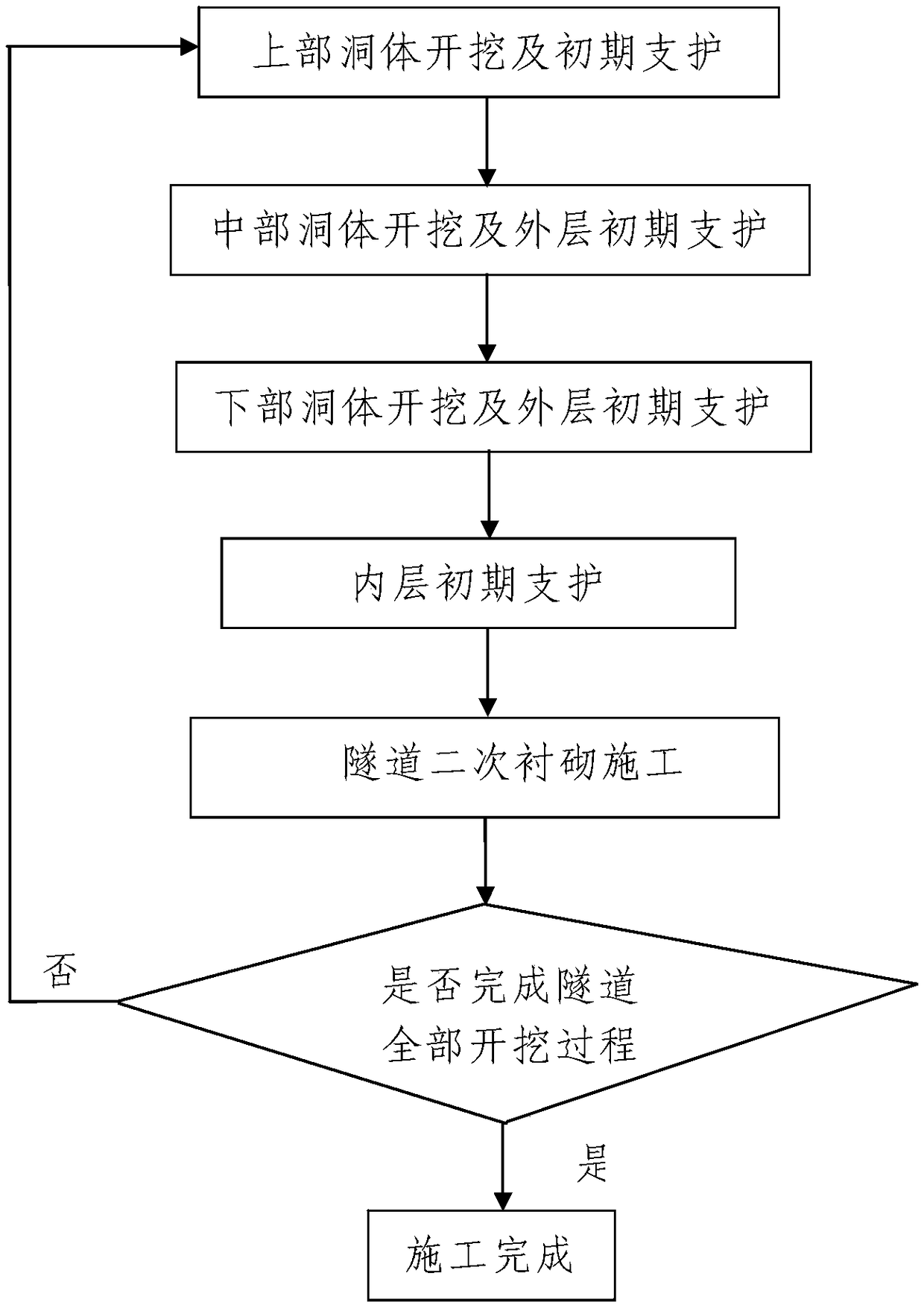

Excavation method for tunnel passing through high-angle thrust water-rich and sand-rich fault

ActiveCN109209398ASimple structureReasonable designUnderground chambersTunnel liningHigh angleStep method

The invention discloses an excavation method for a tunnel passing through a high-angle thrust water-rich and sand-rich fault. A construction tunnel hole is divided from the top to the bottom into an upper hole body, a central hole body, and a lower hole body, wherein the upper hole body is divided into a left guide hole and a right guide hole. A primary support structure of the tunnel hole is a double-layer primary support structure. During the excavation of the construction tunnel, the construction tunnel is divided into a plurality of tunnel segments from the back to the front for excavation. During the excavation of any one tunnel segment, the method comprises the steps: 1, performing the excavation of the upper hole body and the primary supporting; 2, performing the excavation of the central hole body and the primary supporting of an outer layer; 3, performing the excavation of the lower hole body and the primary supporting of the outer layer; 4, performing the primary supporting of an inner layer; 5, repeatedly performing the steps 1-4 for many times, and completing the excavation of the tunnel. The method is simple in step, is reasonable in design, is convenient for construction, is good in use effect, employs a three-step method for the excavation of the tunnel hole, employs double primary support structure for the full-section support of the tunnel hole after excavation, and can guarantee the safety of the tunnel structure later.

Owner:CHINA RAILWAY 20 BUREAU GRP

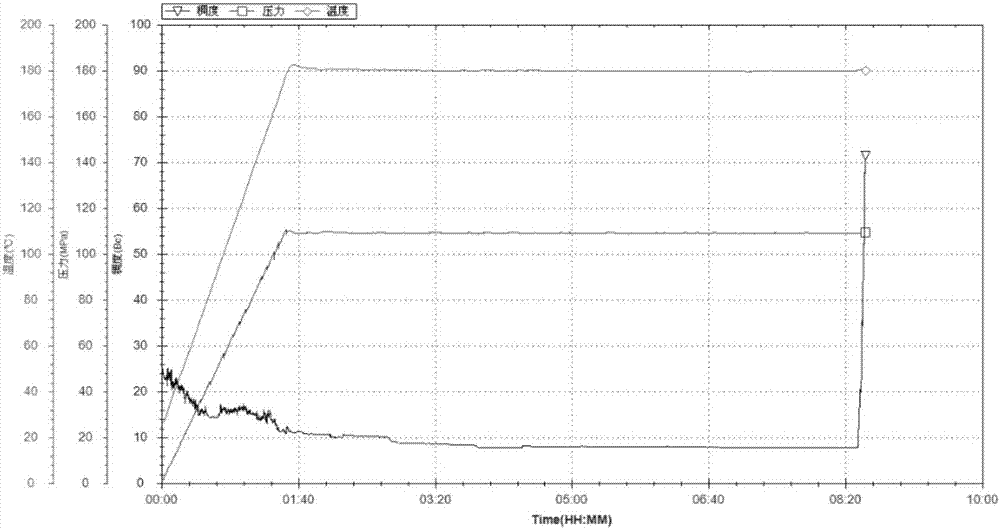

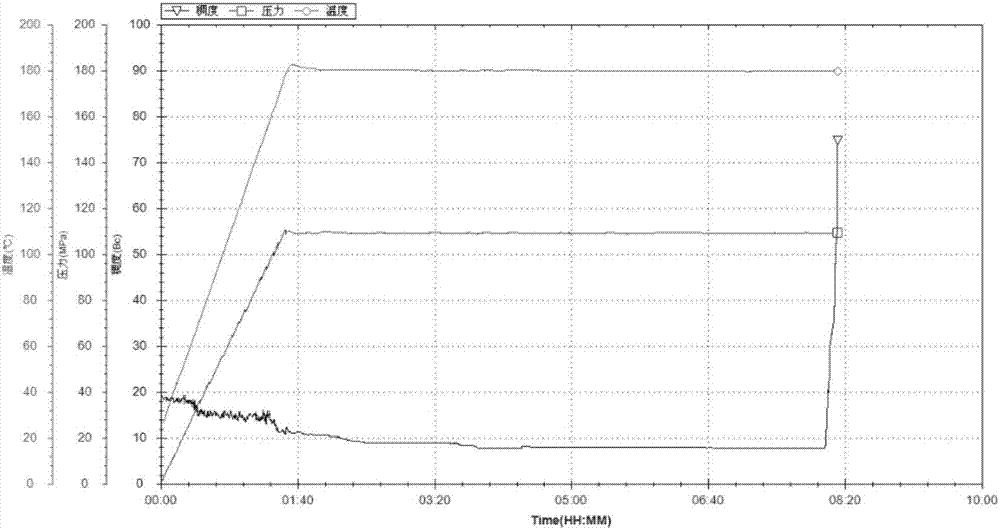

High-temperature-resisting, anti-fluid-channeling and high-density well cementing slurry and its preparation method

InactiveCN107418536AHigh compressive strengthTechnical Issues to Prevent Stability DeteriorationDrilling compositionHigh densityPhysical chemistry

The invention discloses a high-temperature-resisting, anti-fluid-channeling and high-density well cementing slurry and its preparation method, wherein the well cementing slurry is prepared from, by weight, 100 parts of oil well cement, 80-120 parts of weighting agent, 30-35 parts of silica powder, 3-6 parts of silica fume, 2-4 parts of suspension stabilizer, 6-10 parts of high-temperature fluid loss agent, 6-10 parts of high-temperature retarder, 1-2 parts of dispersing agent, 3-5 parts of anti-fluid-channeling agent, 1-2 parts of defoaming agent, and 55-65 parts of water. The high temperature resistance can reach 180-200DEG C, and the well cementing slurry is featured by good flowing property, low filter loss, good sedimentary stability, and strong anti-fluid-channeling performance, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

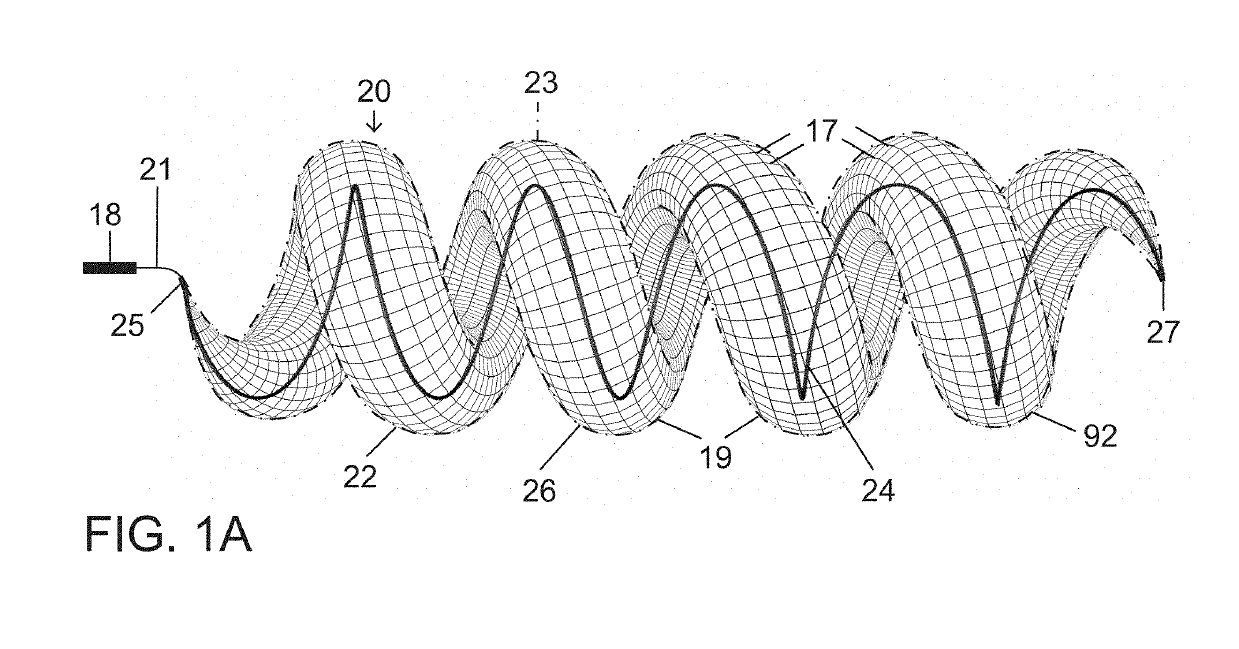

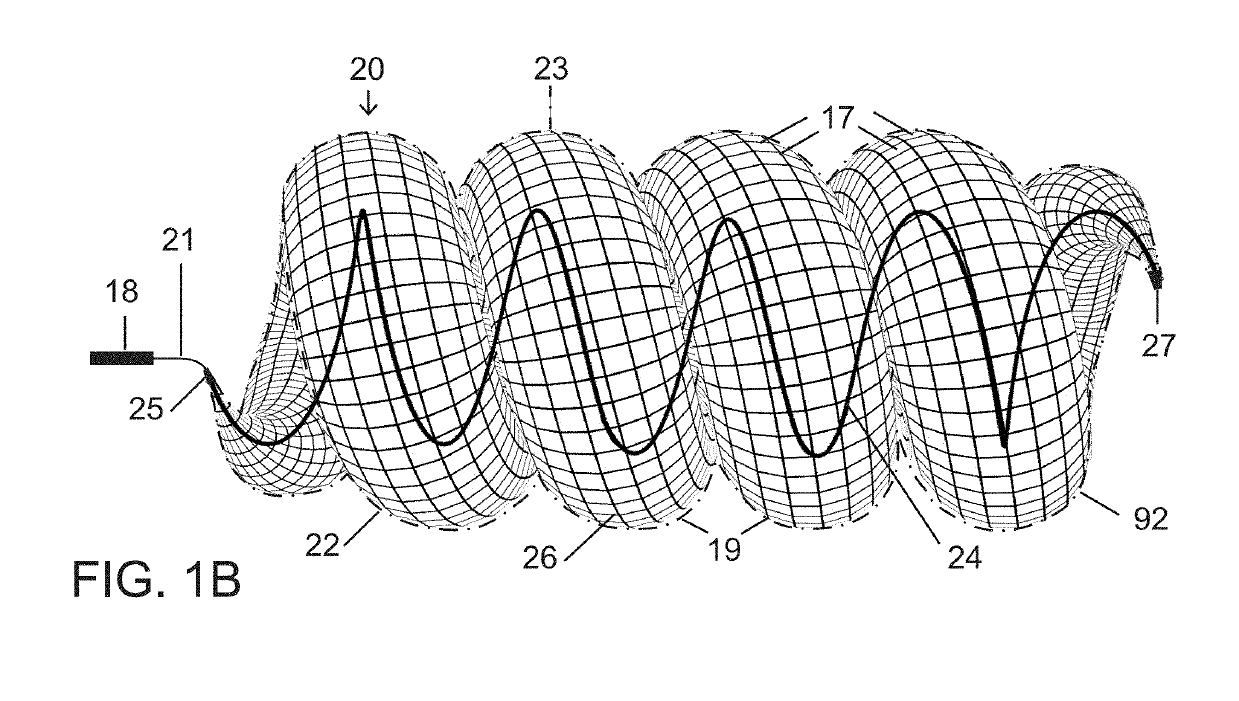

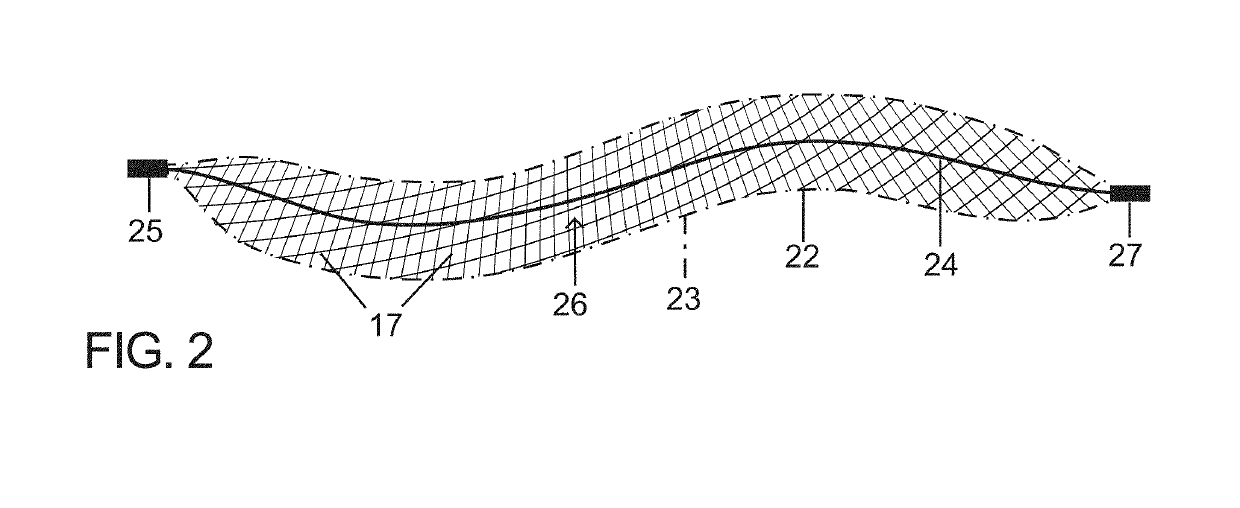

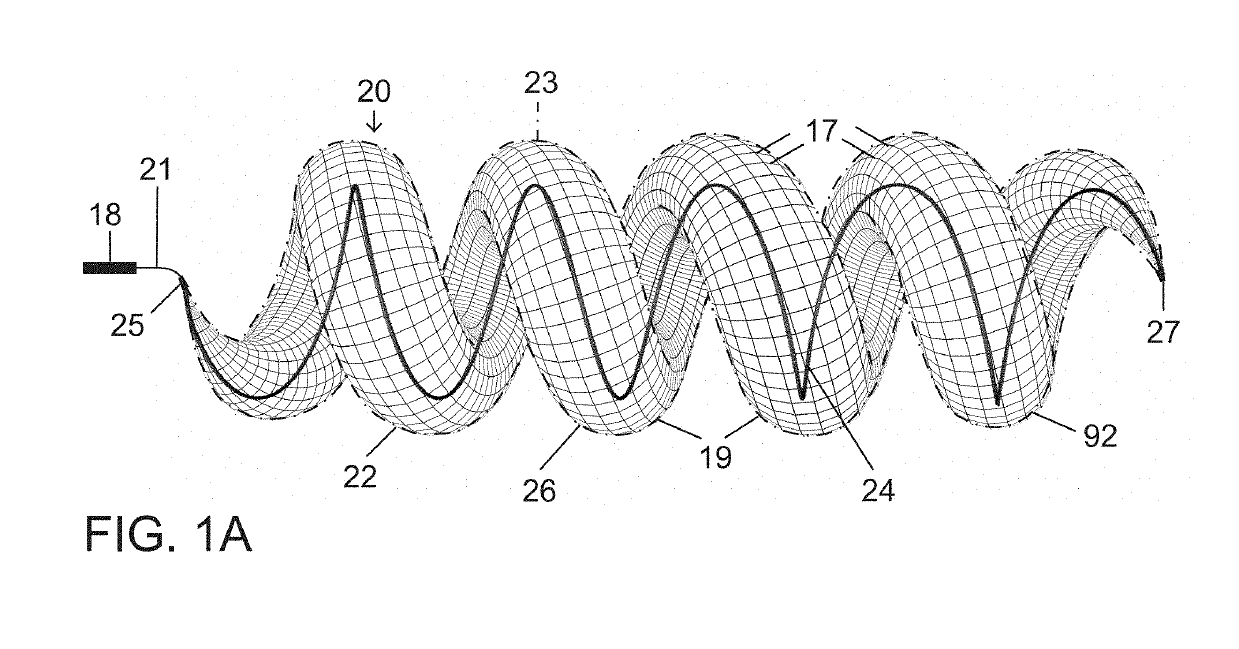

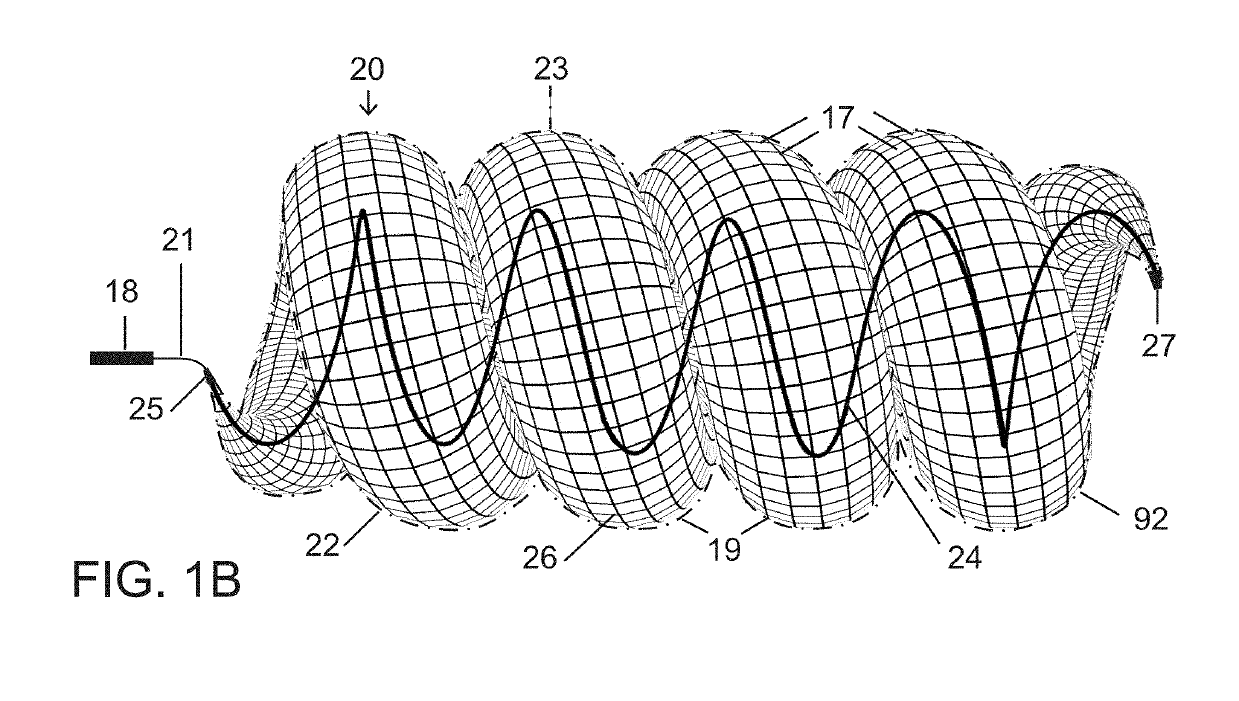

Micro-macro endovascular occlusion device and methodology

ActiveUS10299799B1Large filling capacitySubstantial and total occlusionOcculdersEndovascular occlusionThree dimensional shape

A vascular plug comprises a superstructure expandable from a collapsed percutaneous insertion configuration to an expanded deployment or use configuration. The superstructure is comprised of both primary and secondary three-dimensional shapes allowing for the occlusion of a wide range of vessel sizes from small to large through a disproportionately small delivery catheter. The plug includes a shape memory element for the generation of radial force and the creation of the larger secondary three-dimensional twisting or helical superstructure as is needed for target vessel occlusion.

Owner:DEMERITT JOHN S

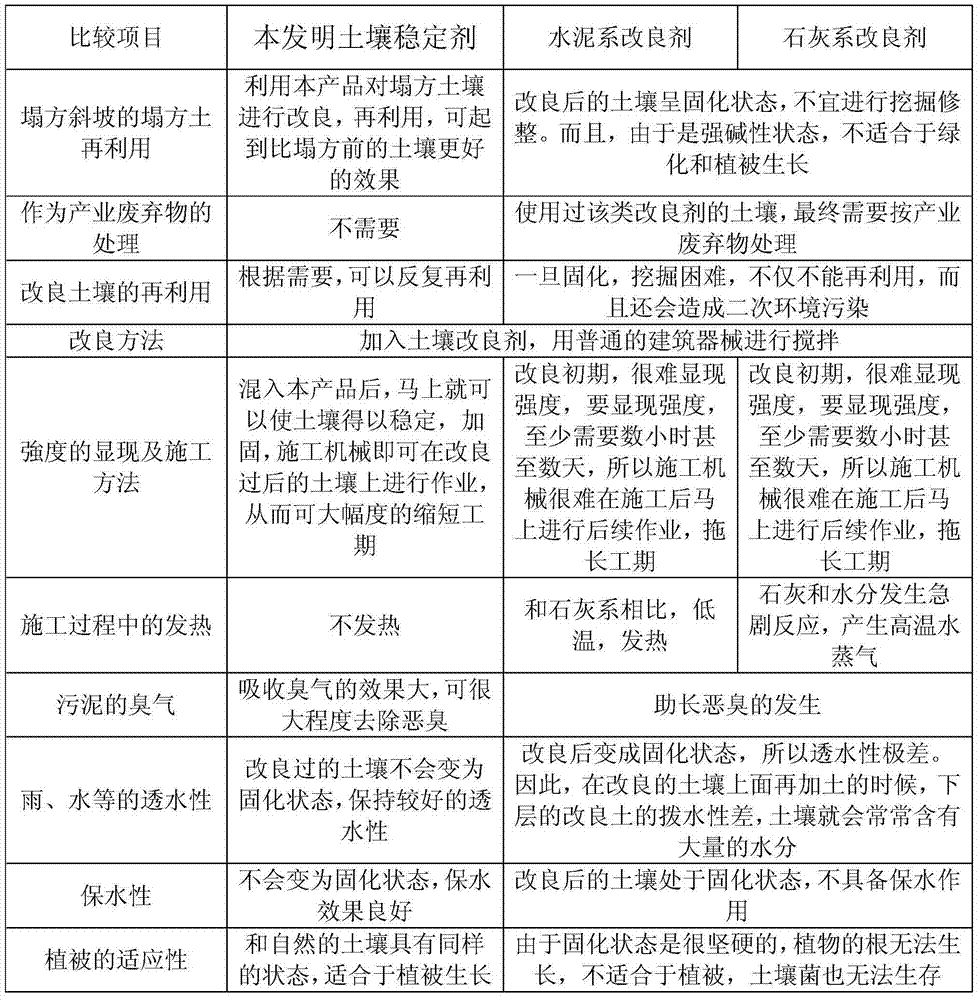

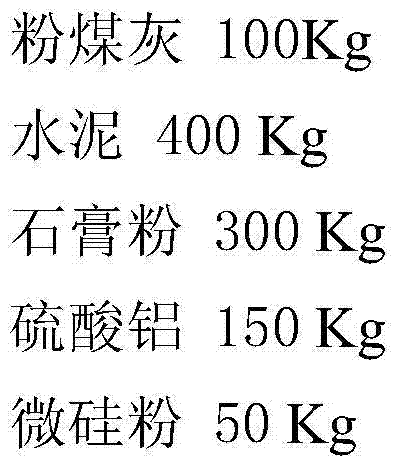

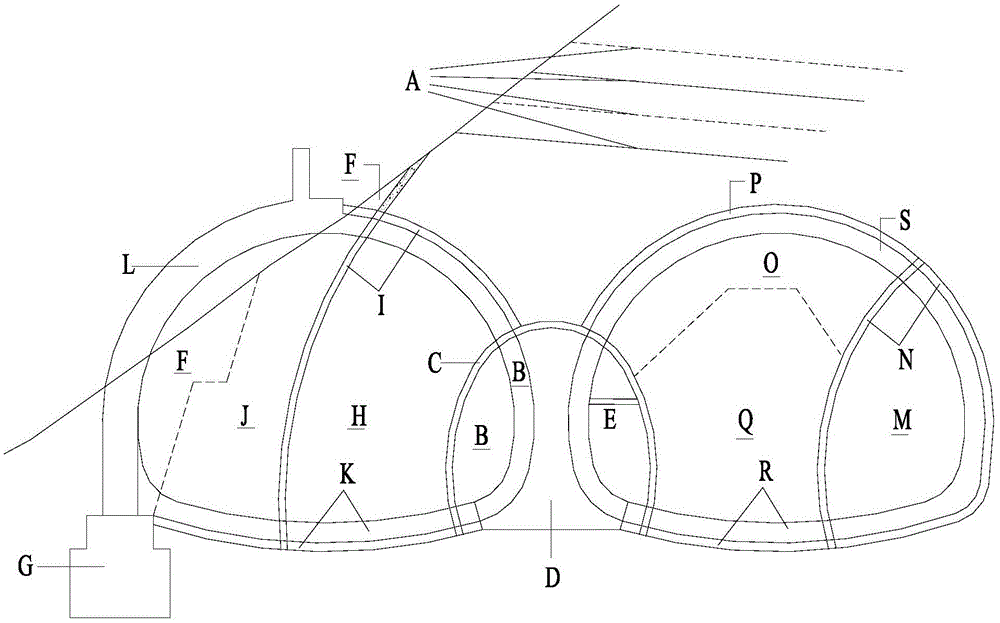

Efficient soil stabilizer

ActiveCN103864391AImprove stabilityConstruction stabilitySolid waste managementGypsumAluminium salts

The invention relates to an efficient soil stabilizer. The efficient soil stabilizer comprises the following materials in parts by weight: 10-70 parts of coal ashes, 10-50 parts of cement, 10-30 parts of gypsum powder, 1-20 parts of aluminum sulfate and 1-5 parts of micro silicon powder. The soil stabilizer disclosed by the invention can be widely applied to clearing silt for river-lake bottom mud, paving a park walking road and a rural soil road, improving soil, and the like, has very strong soil stabilizing capacity, soil strengthening capacity, super-strong bad smell adsorbing capacity, excellent water-retaining property and water permeability, and is suitable for vegetation growing.

Owner:刘洪军

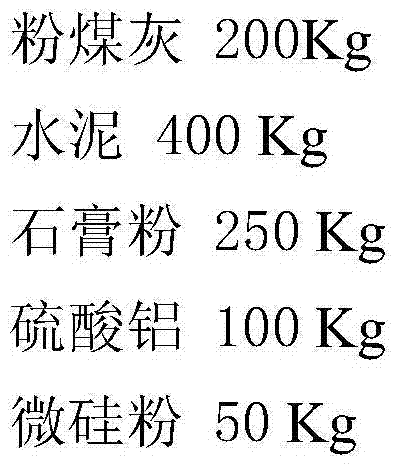

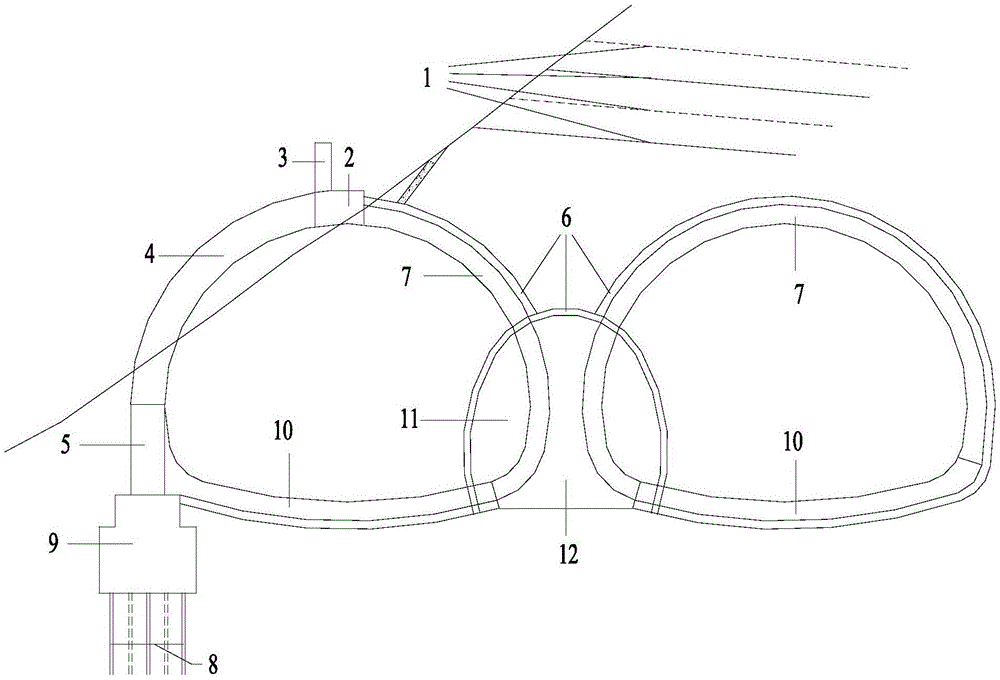

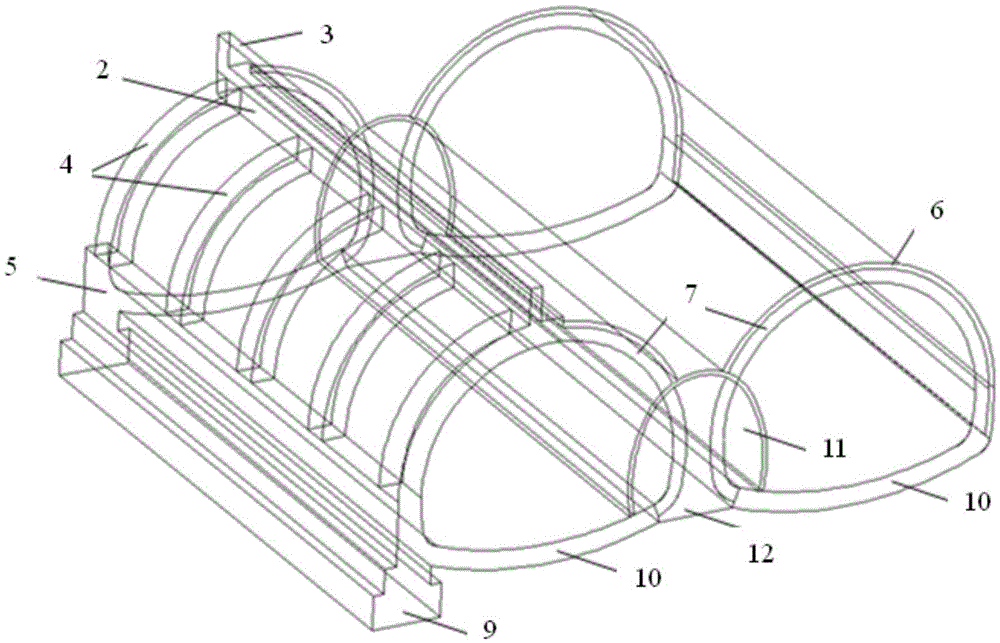

Construction method for permeable ribbed multiple-arch tunnel

InactiveCN105626083AReduce distortionReduce stress levelsUnderground chambersTunnel liningSteel tubeClerestory

The invention discloses a construction method for a permeable ribbed multiple-arch tunnel. The construction method specifically comprises the following steps: firstly reinforcing a vault slope with grouting steel tubes, and joining with anchor rods of a tunnel body system to form a continuous reinforced system; carrying out middle pilot heading excavation and then constructing an integral mid-partition; excavating tunnel chambers by adopting a procedure of a left tunnel first, and a right tunnel later; carrying out integral molding on a left tunnel ribbed arched beam with a vault longitudinal beam, an anticollision wall and an anticollision wall, and forming an annular force-bearing system with the mid-partition and an inverted arch; carrying out cyclic construction at an excavation progress being 12 to 14m according to a longitudinal construction spacing being 6 to 8m and a construction spacing of the left tunnel and the right tunnel being 30m. The construction method disclosed by the invention is a set of integral construction method aiming to the permeable ribbed multiple-arch tunnel; construction procedures, a supporting system and construction control parameters are adapted to the construction mechanical behavior time-space evolution regularity of the permeable ribbed multiple-arch tunnel, such that the safety of the construction process and the stability of a tunnel structure are effectively ensured, and a set of practical and operable construction technology is provided for promotion and application of the novel environment-friendly tunnel.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

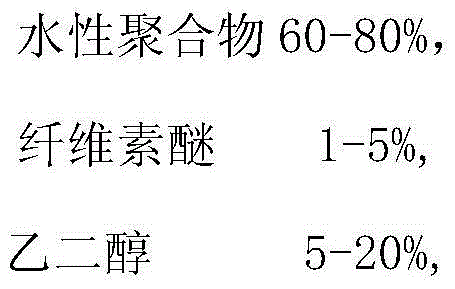

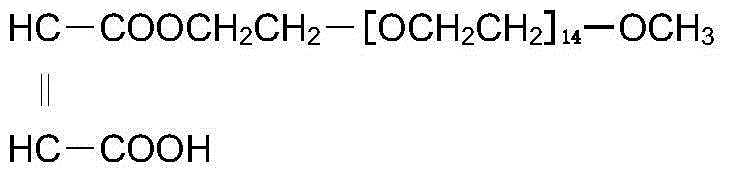

Cement grinding aid for masonry cement

The invention discloses a cement grinding aid for masonry cement. The cement grinding aid comprises the following components in percentage by weight: 60-80% of an aqueous polymer, 1-5% of cellulose ether, 5-20% of ethanediol and 10-15% of a sucrose ester. Compared with the frequently-used cement grinding aid in the market, the cement grinding aid disclosed by the invention has a good milling effect. The cement grinding aid has the effect of helping milling, besides, an appropriate amount of bubbles are added in the masonry cement, and the bubbles are maintained stable during construction; therefore, mortar or concrete prepared from cement produced by using the cement grinding aid has a good construction property.

Owner:SOUTHEAST UNIV

Micro-Macro Endovascular Occlusion Device and Methodology

ActiveUS20190142435A1Low porosityIncrease it throbogenicityOcculdersThree dimensional shapeVascular plug

A vascular plug comprises a superstructure expandable from a collapsed percutaneous insertion configuration to an expanded deployment or use configuration. The superstructure is comprised of both primary and secondary three-dimensional shapes allowing for the occlusion of a wide range of vessel sizes from small to large through a disproportionately small delivery catheter. The plug includes a shape memory element for the generation of radial force and the creation of the larger secondary three-dimensional twisting or helical superstructure as is needed for target vessel occlusion.

Owner:DEMERITT JOHN S

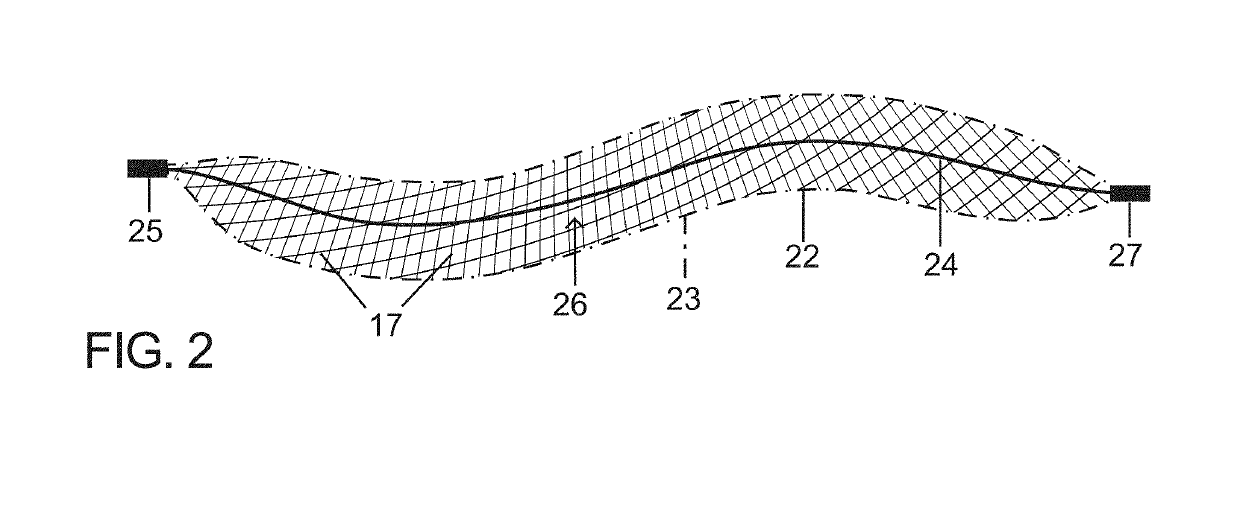

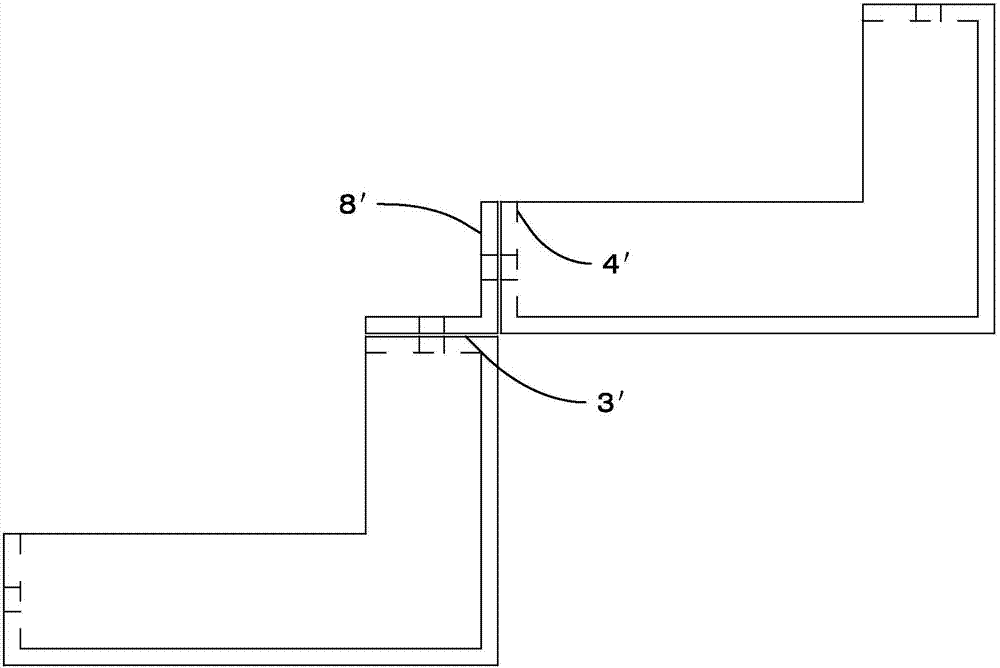

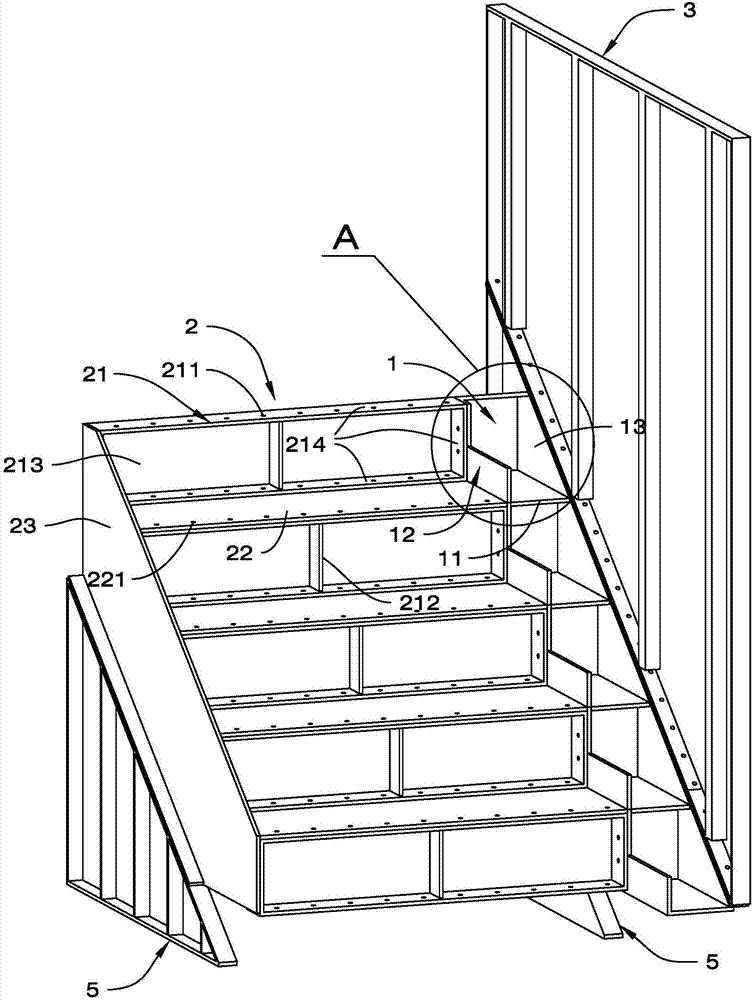

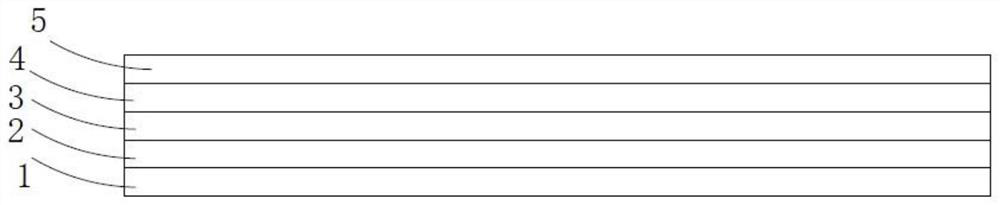

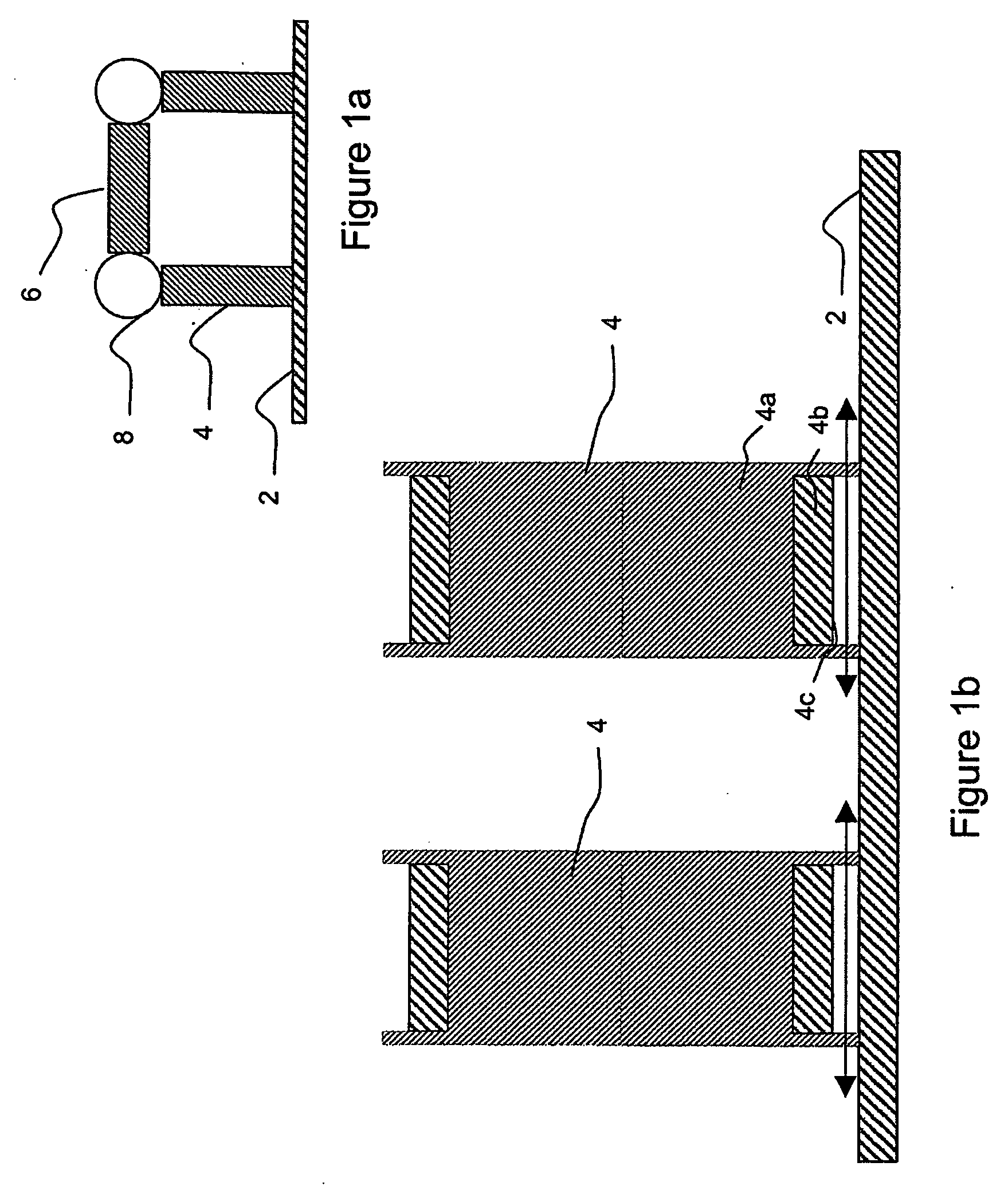

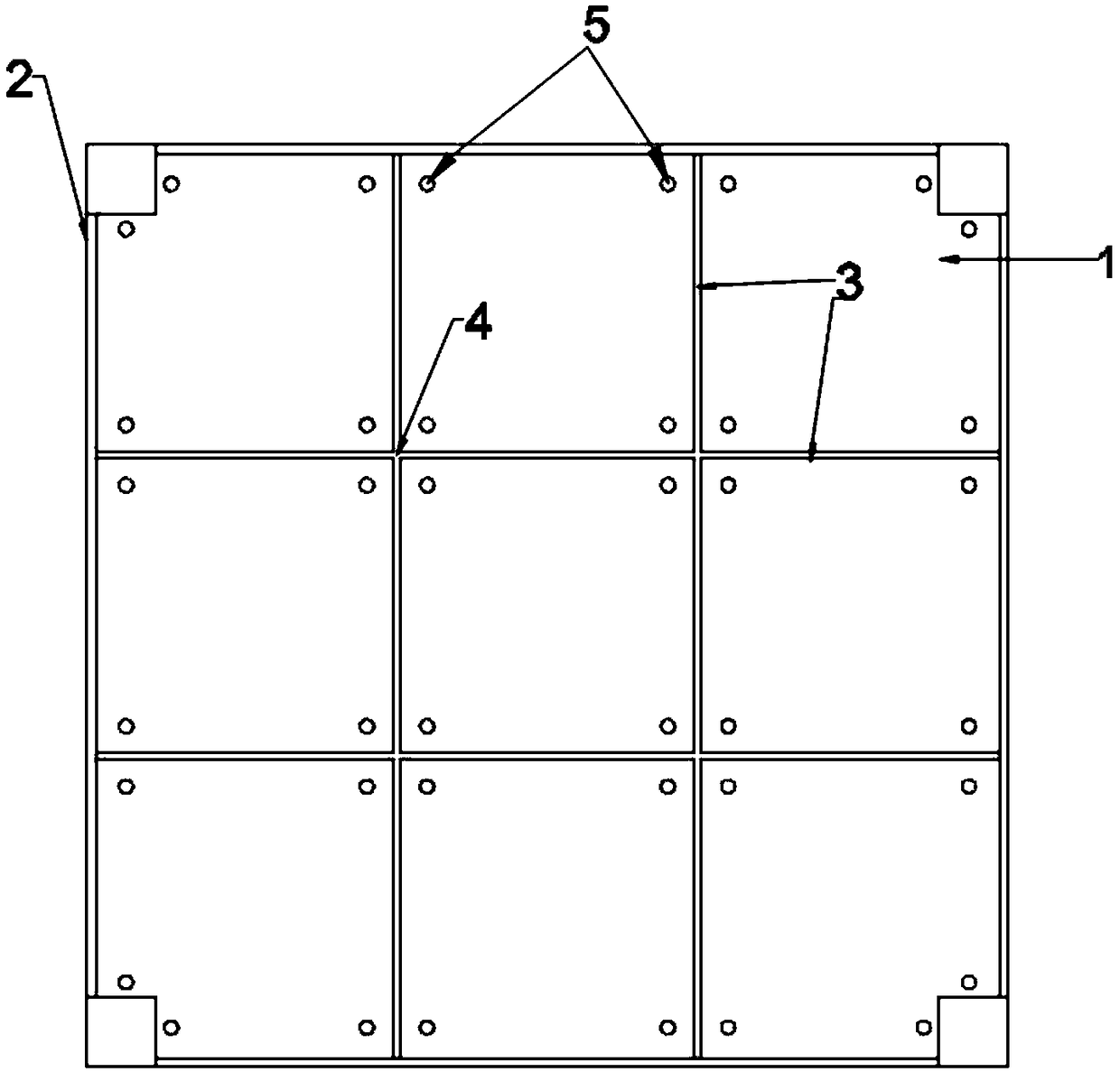

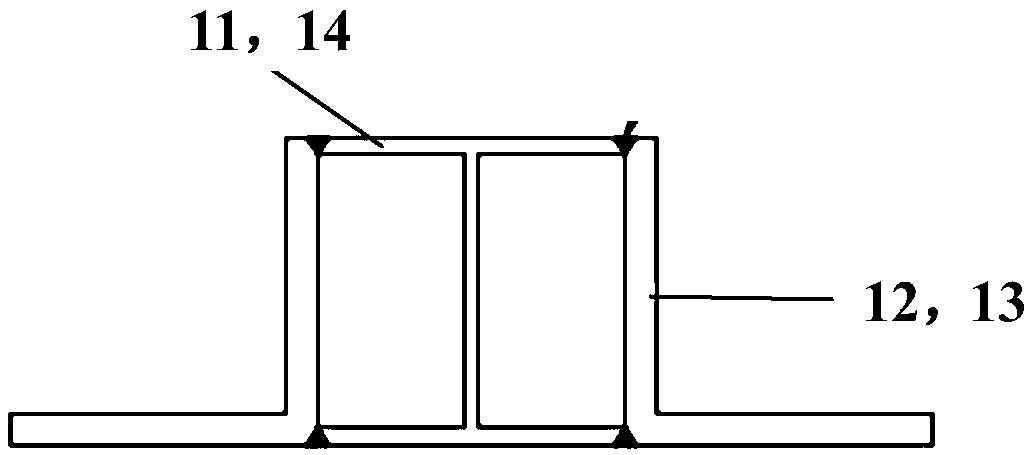

Stair connecting piece, manufacturing method, aluminum formwork system utilizing stair connecting pieces and stair construction method

PendingCN107165286ASimple structureStable structureForms/shuttering/falseworksBuilding material handlingMechanical engineeringManufacturing engineering

The invention provides a stair connecting piece, a manufacturing method, an aluminum formwork system utilizing the stair connecting pieces and a stair construction method. The stair connecting piece comprises a stepped main body, wherein side plates perpendicular to a step surface are arranged on two sides of each step of the main body, pin holes A are formed in the side plates, connecting plates perpendicular to the side plates are fixedly arranged on the corresponding side plates, and pin holes are formed in the connecting plates. The aluminum formwork system comprises stair aluminum formworks and wall aluminum formworks, each stair aluminum formwork is connected with the corresponding wall aluminum formwork through the corresponding stair connecting piece. During stair construction, the wall aluminum formworks are arranged firstly, then the stair connecting pieces are arranged and connected with the wall aluminum formworks, then the stair aluminum formworks are built and connected with the stair connecting pieces, concrete is poured, and the equipment is disassembled after the concrete is set. The stair connecting piece which is simple in structure, low in cost and simple and convenient to operate, facilitates splicing of the stair aluminum formworks and the wall aluminum formworks and provides great convenience for construction, the manufacturing method of the stair connecting piece, the aluminum formwork system utilizing the connecting pieces and the stair construction method utilizing the system are provided.

Owner:SHANDONG XINHUOXIN MATERIAL TECH CO LTD

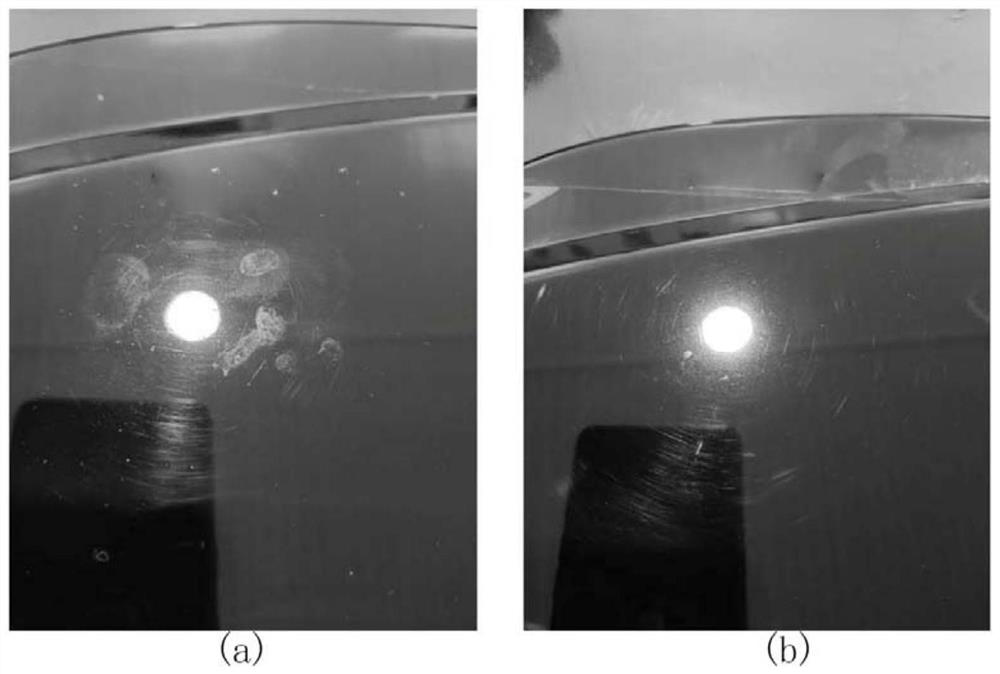

Self-repairing yellowing-resistant paint surface protective film and preparation method thereof

InactiveCN113072890AIncrease stickinessImprove protectionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceFunctional monomer

The invention discloses a self-repairing yellowing-resistant paint surface protective film and a preparation method thereof. The paint surface protective film is sequentially composed of a release film layer I, a pressure-sensitive adhesive layer, a TPU base material, a self-repairing coating and a release film layer II from bottom to top. The self-repairing coating is made of thermocuring functional polyurethane acrylate resin and comprises 20-50% of functional monomer modified acrylic resin, 10-30% of polymer polyol, 40-60% of a diluting solvent, 10-20% of a curing agent, 0.2-0.5% of a catalyst and 0.5-2% of an auxiliary agent, the TPU base material is optical-grade aliphatic TPU, the pressure-sensitive adhesive is an acrylate adhesive, and the release film layer is a PET silicone oil release film. The paint surface protective film prepared by the invention not only has excellent yellowing resistance and self-repairing performance, but also has high transparency, high glossiness, excellent scratch resistance, acid and alkali resistance, rain spot resistance and the like, so that the self-repairing yellowing-resistant paint surface protective film is suitable for the fields of automobile, furniture films and the like.

Owner:南阳金牛彩印集团有限公司 +1

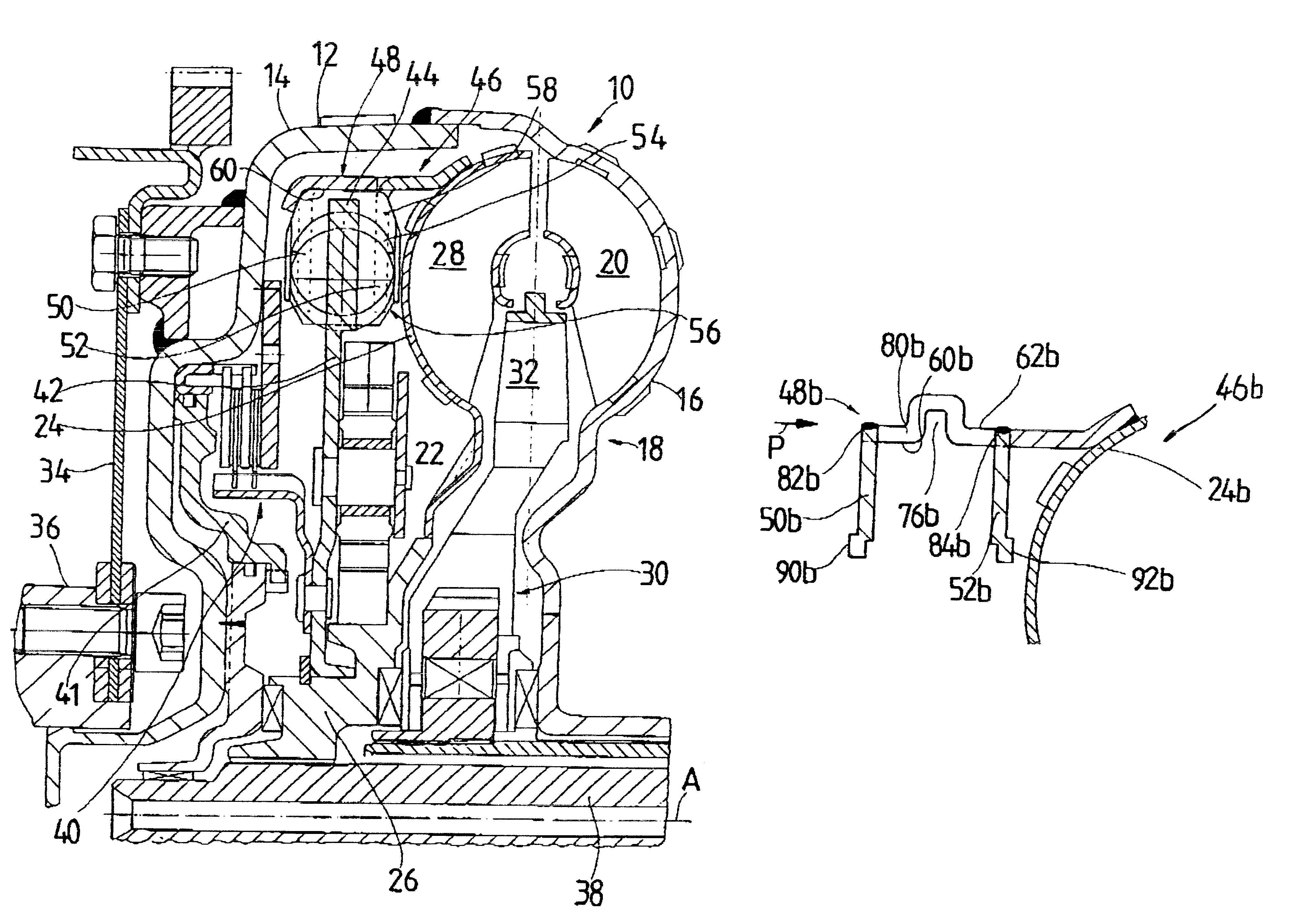

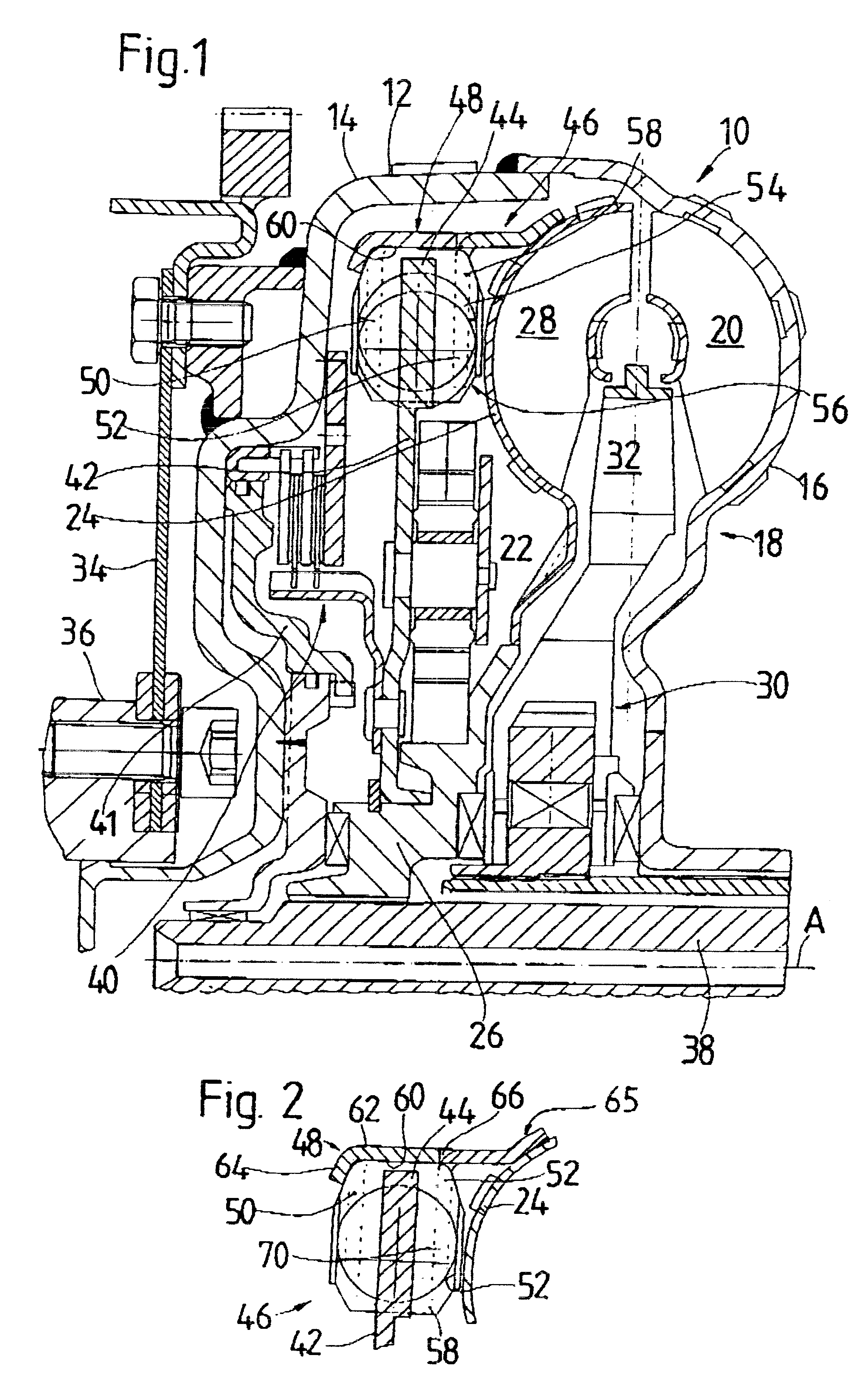

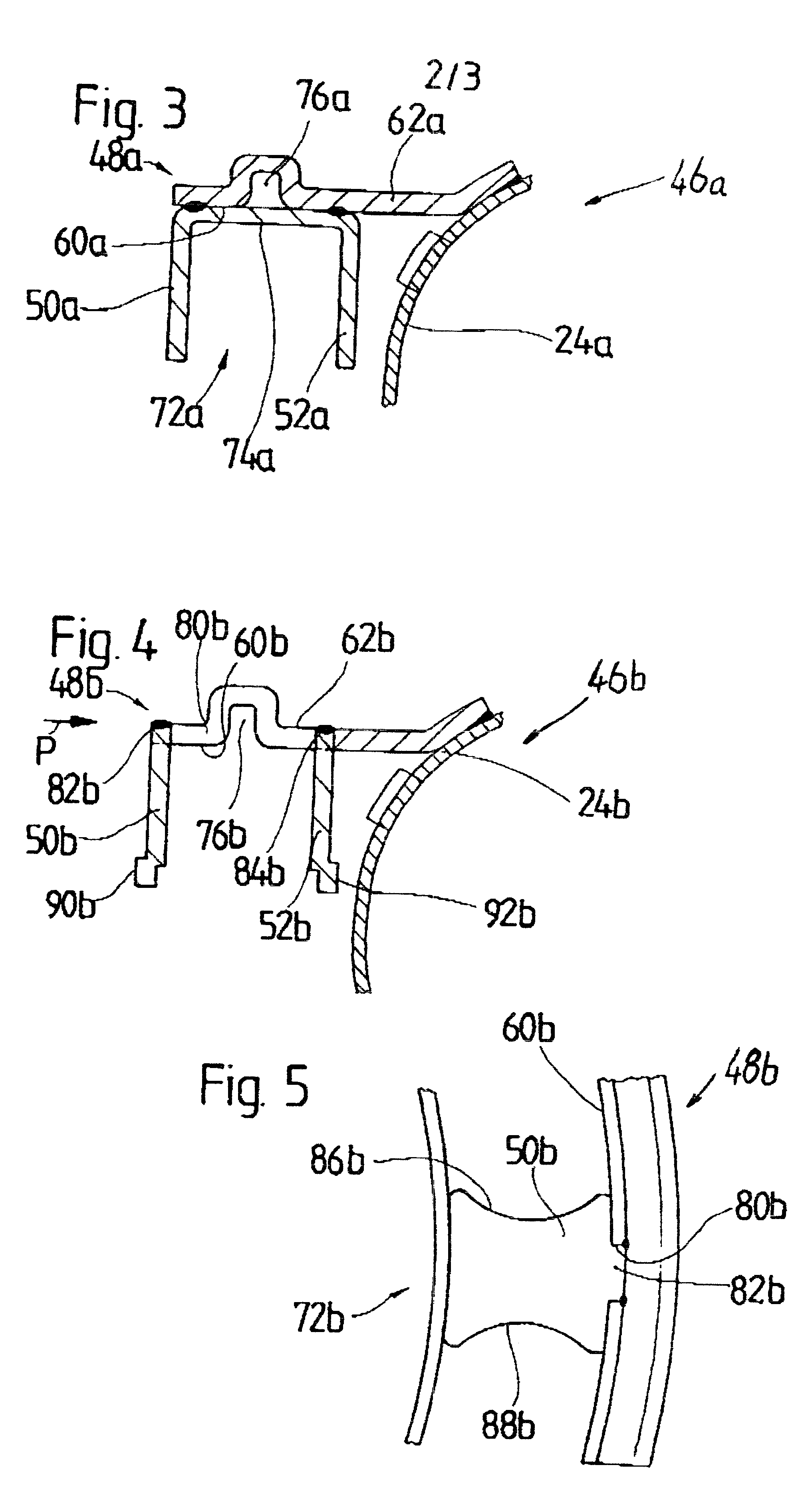

Torsional vibration damper

InactiveUS6334816B1Stable structureConstruction stabilityRotating vibration suppressionClutchesEngineeringTorsional vibration

A torsional vibration damper, especially for transmission of torque in a hydrodynamic torque converter, includes a primary side, a secondary side, and a plurality of damper spring arrangements arranged between the primary side and the secondary side such that the primary side is rotatable relative to the secondary side against an urgency of the damper spring arrangement. Each damper spring arrangement has at least one spring and is supported in each circumferential end area at a supporting area of the secondary side and at a first and a second supporting area of the primary side which are arranged on both axial sides of the associated supporting area of the secondary side. The primary side has a substantially annular carrier part and at least one of the first and second supporting areas of the primary side are constructed as separate parts that are connected for rotation with the primary side.

Owner:ZF FRIEDRICHSHAFEN AG

Coastal environment high pier hydraulic self-creeping formwork construction method

PendingCN111119060AEasy to operateImprove securityBridge structural detailsBridge erection/assemblyPurlinShaped beam

The invention discloses a coastal environment high pier hydraulic self-creeping formwork construction method. The method comprises the steps of tower column starting section construction, tower columnfirst section construction, hydraulic creeping formwork installation, tower column second section construction, tower column remaining section construction and creeping formwork removal, the hydraulic creeping formwork comprises an embedded part mechanism embedded in a high pier wall, and a frame body mechanism comprises a lower hanging bracket and a bearing frame; the formwork installation comprises a formwork consisting of a panel, a woodworking I-shaped beam and a steel enclosing purlin, a movable template bracket and a backward moving device; a hydraulic power mechanism comprises an upperreversing box, a lower reversing box, a hydraulic pump and a hydraulic oil cylinder which are connected with the guide rail in a sliding manner; the guide rail is composed of two steel channels and guide rail stair stops, and the upper reversing pawl of the upper reversing box and the lower reversing pawl of the lower reversing box are arranged between the guide rail stair stops. The constructionmethod is convenient to operate, high in safety and convenient to construct, working hours and construction sites are saved, and formwork bumping damage is reduced; and the formwork is recycled, theworkload of hoisting machinery is greatly reduced, and the construction process is stable, synchronous and safe.

Owner:YANJIAN GRP CO LTD +1

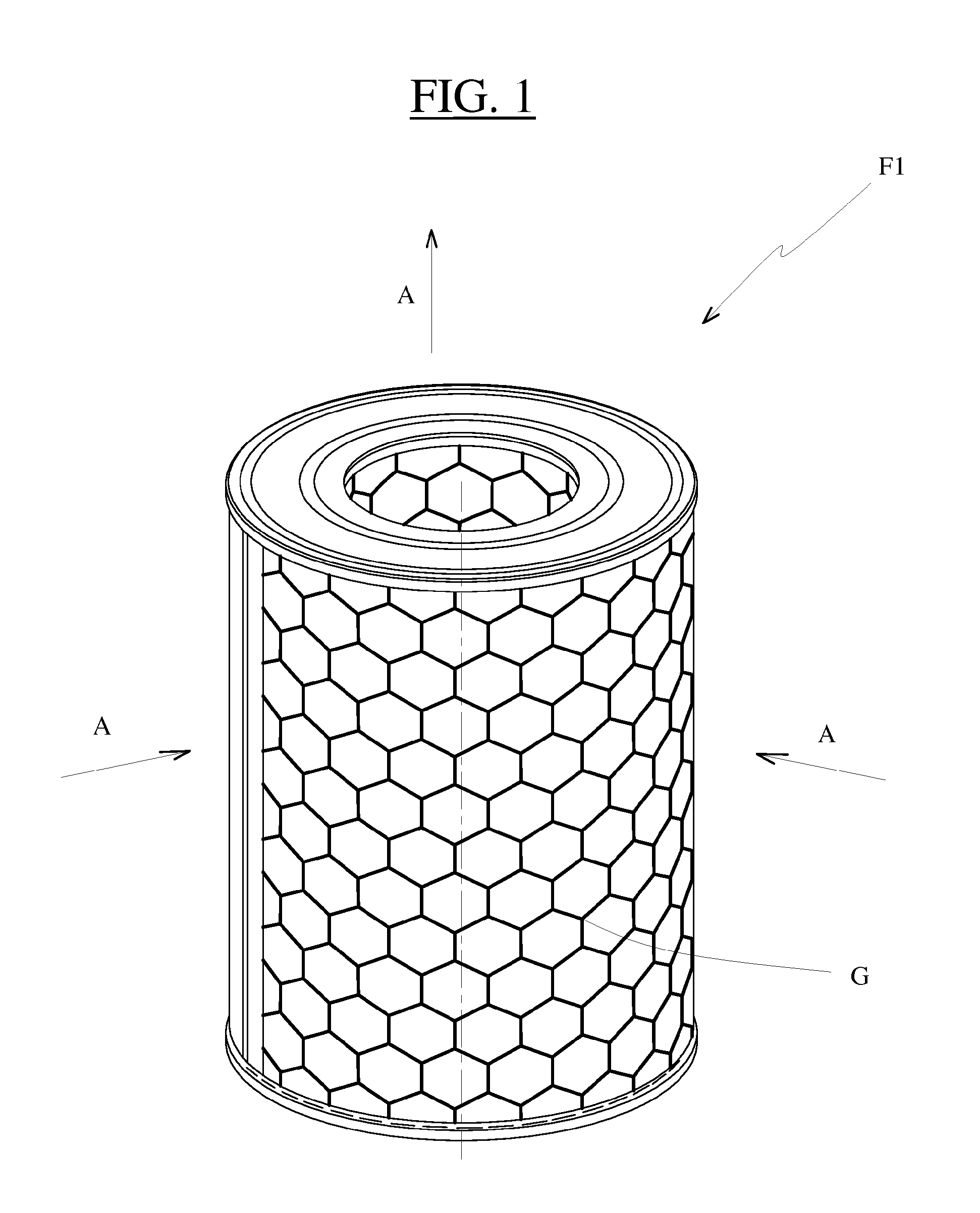

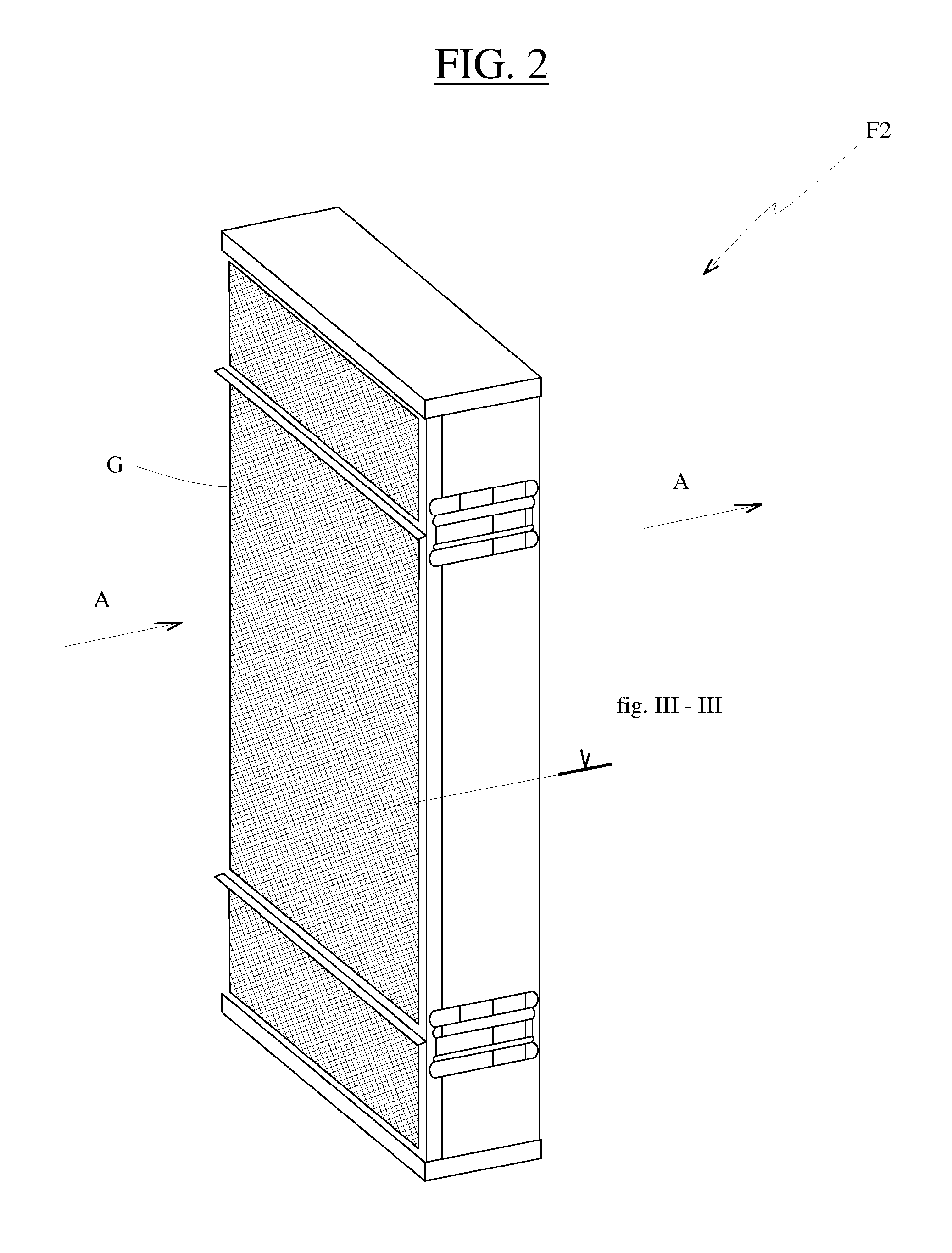

Microbicidal filter and filtration cartridge incorporating such a filter

InactiveUS9266048B2Construction stabilityLow costCombination devicesAuxillary pretreatmentFiltrationAirflow

A microbicidal filter for treating air, includes, in the allocated direction of flow of the air stream capable of passing therethrough, a filtration layer and a HEPA filter. The filtration layer contains a bactericidal and / or fungicidal agent, and the HEPA filter is pleated while being applied against a second pleated filtration layer that is arranged downstream, so as to prevent the mutual contacting of its pleats. The combination of the action of the impregnated layer and of the HEPA filter inhibits or kills by contact all the living particles that penetrate into the microbicidal filter. The HEPA filter is held in stable application in the pleated shape thereof against the second filtration layer, so that filtering performance deteriorates only gradually.

Owner:LIND DU PONANT

Foldable Parallel Bar Apparatus

InactiveUS20140087920A1CompactingAdjustable lengthSpace saving gamesParallel barsEngineeringHandrail

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE DEPT OF VETERANS AFFAIRS

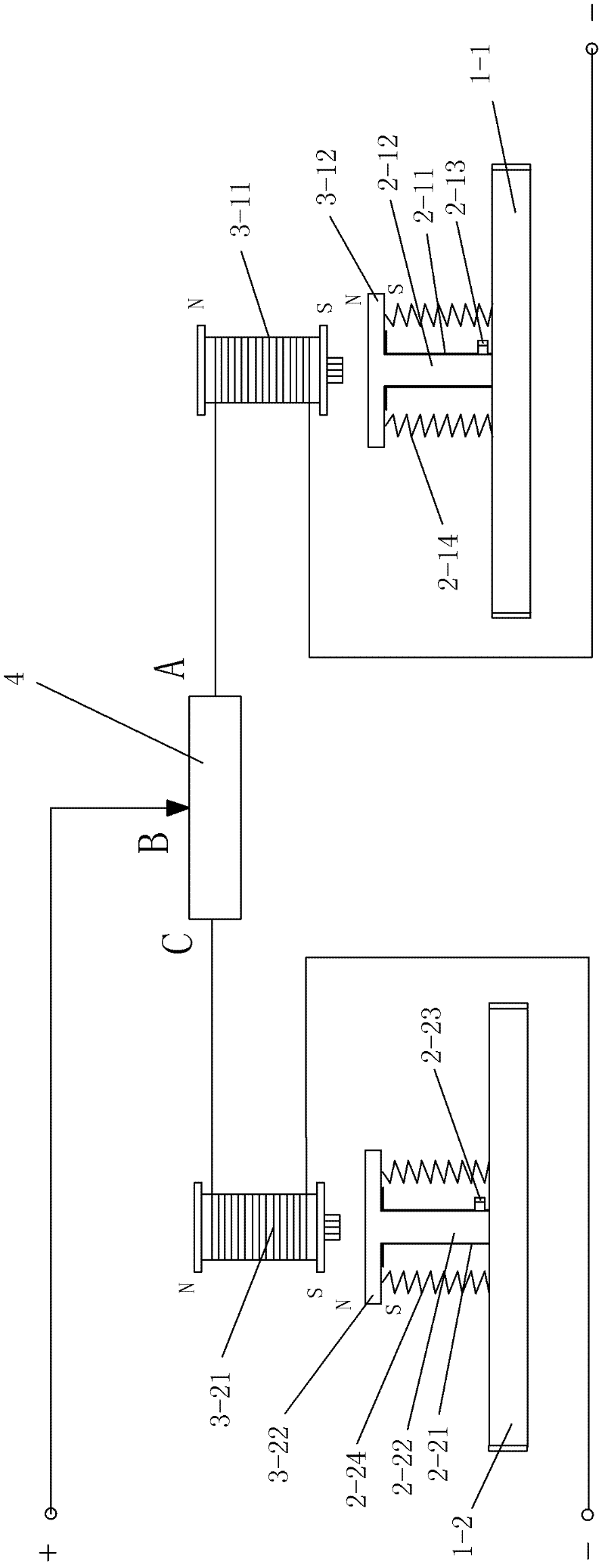

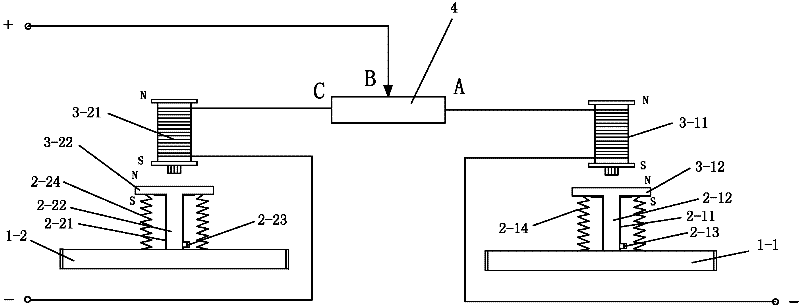

Control system for integrated synchronous jacking of cut pier and control method

ActiveCN102505642AReasonable designLow input costBridge erection/assemblyBridge strengtheningAutomatic controlControl system

The invention discloses a control system for integrated synchronous jacking of a cut pier and a control method. The control system comprises two hydraulic jacking devices for providing jacking power, two hydraulic circuits connected with the two hydraulic jacking devices respectively, two oil feeding amount adjusting devices and a jacking balancing state monitoring device, wherein the two oil feeding amount adjusting devices are installed on the two hydraulic circuits respectively, and the jacking balancing state monitoring device performs real-time monitoring to a balancing state of a structure needing to be jacked in the jacking process and controls the two oil feeding amount adjusting devices according to monitoring results. The control method comprises the steps of jacking preparation and jacking, upward jacking is performed to the structure through the two hydraulic jacking devices in actual jacking until the structure is jacked to a preset height, and timely dynamic deviation rectification is carried out to the structure. The control system for integrated synchronous jacking of the cut pier and the control method are reasonable in design, high in automation, good in coordinating performance and safety performance and simple and convenient to control, enables the jacking process to be smooth and efficient, and can effectively solve the construction problem that unbalanced elevation discrepancy limitation in the pier cutting integration jacking process cannot be automatically controlled.

Owner:CHINA RAILWAY FIRST GRP CO LTD

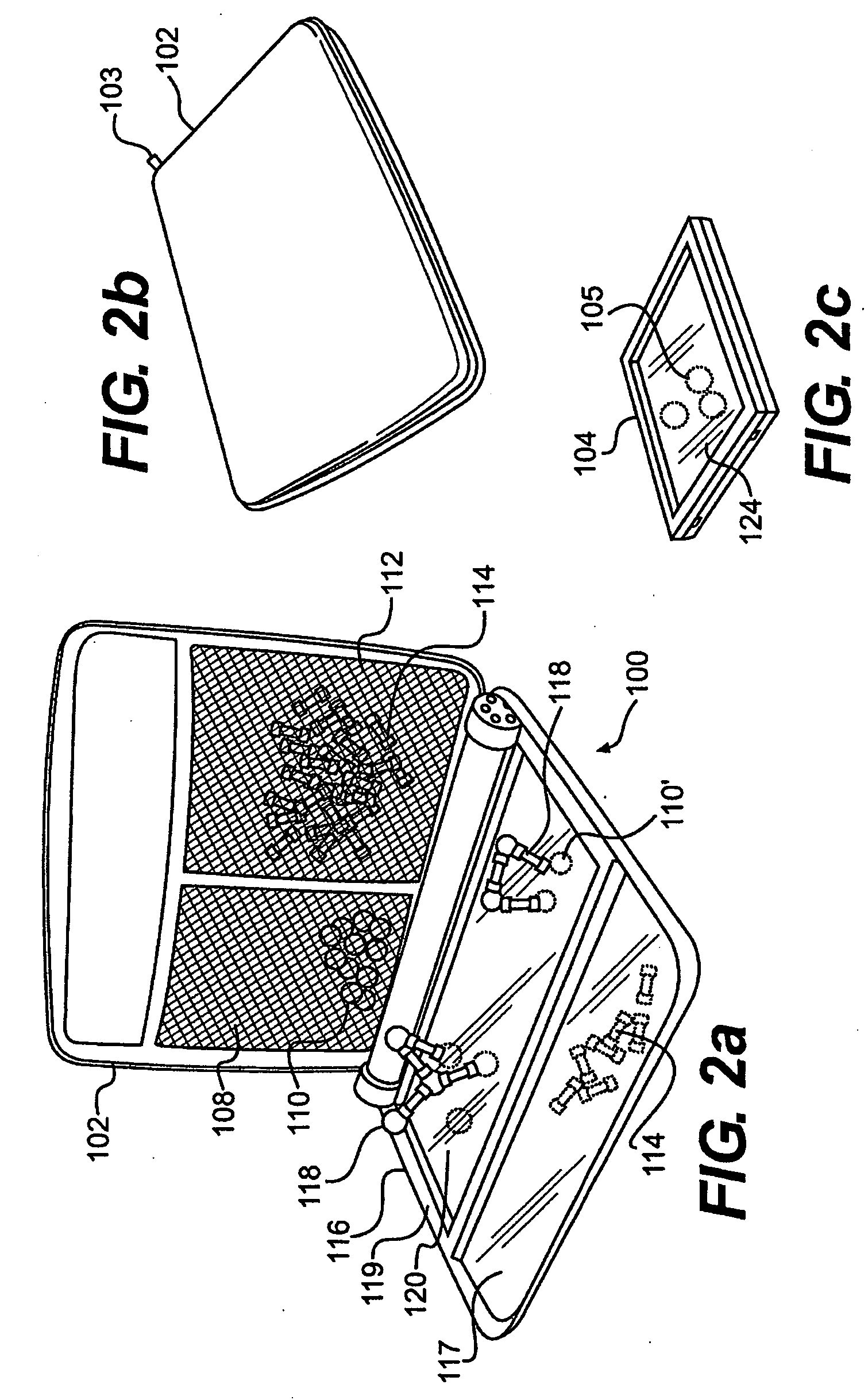

Portable magnetic toy construction kit

An embodiment of the present invention provides portable magnetic toy construction system having a base plate upon which to build magnetic toy constructions, the base plate configured to accept and hold in position ferromagnetic or magnetic base elements, such as ferromagnetic balls. The base plate comprises at least one flexible membrane that stretches around a base element and holds the base element in position. The membrane exerts a force that holds the base element in position resisting lateral movement, although the elasticity of the flexible membrane still allows a user to manipulate the base element through the membrane to move the base element laterally. In one configuration, the base plate forms part of a travel case that can additionally include compartments to store magnetic building components. Further embodiments provide a magnetic toy construction, and a method for building the construction, that incorporate the base plate.

Owner:MEGA BRANDS INT R L LUXEMBOURG ZUG BRANCH

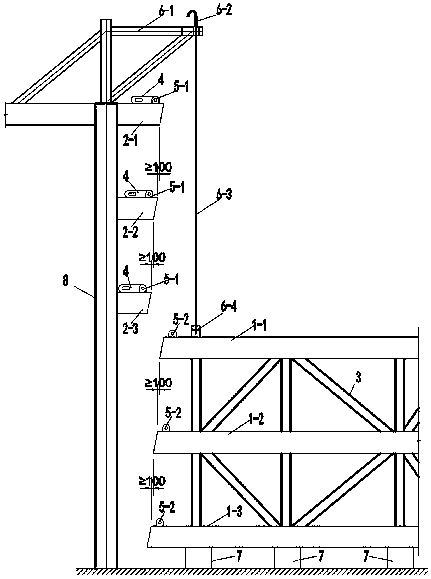

In-situ assembling and lifting construction in-position butt joint method for multi-layer steel truss

InactiveCN110778127AFast and stable in placePlace stableBuilding material handlingButt jointEngineering

The invention discloses an in-situ assembling and lifting construction in-position butt joint method for a multi-layer steel truss. The method is characterized in that multi-layer steel truss chord rods and corbels both adopt an oblique joint mode, all layers of chord rods are cut off in a staggered mode, the projection distance between the upper layer of chord rod and the adjacent lower layer ofchord rod is staggered by 100 mm or above so as to ensure that the truss is not interfered all the time in the lifting process, adjustment is carried out again when in-position butt joint is achieved,during in-position operation, the truss is ensured to be quickly and stably in place through quick connection joints, the whole construction process is safe and efficient, the practicability is veryhigh, the construction process is improved, the interference is less, the construction efficiency is high, the performance is stable, and the effects of being safe and reliable are achieved. The in-situ assembling and lifting construction in-position butt joint method has a wide application prospect in the multi-layer steel truss in-situ assembling and lifting construction.

Owner:SHANGHAI BAOYE GRP CORP

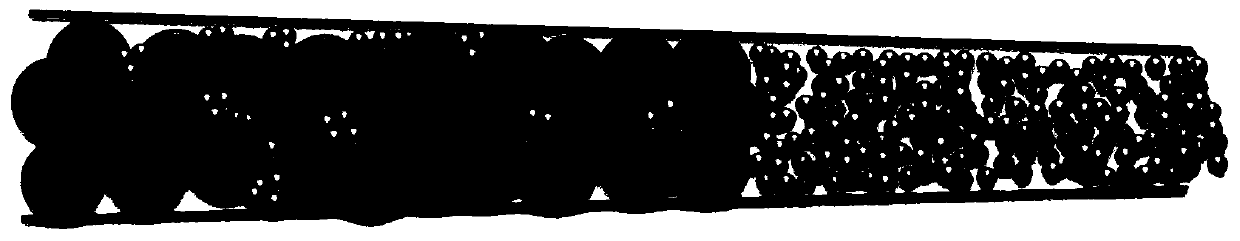

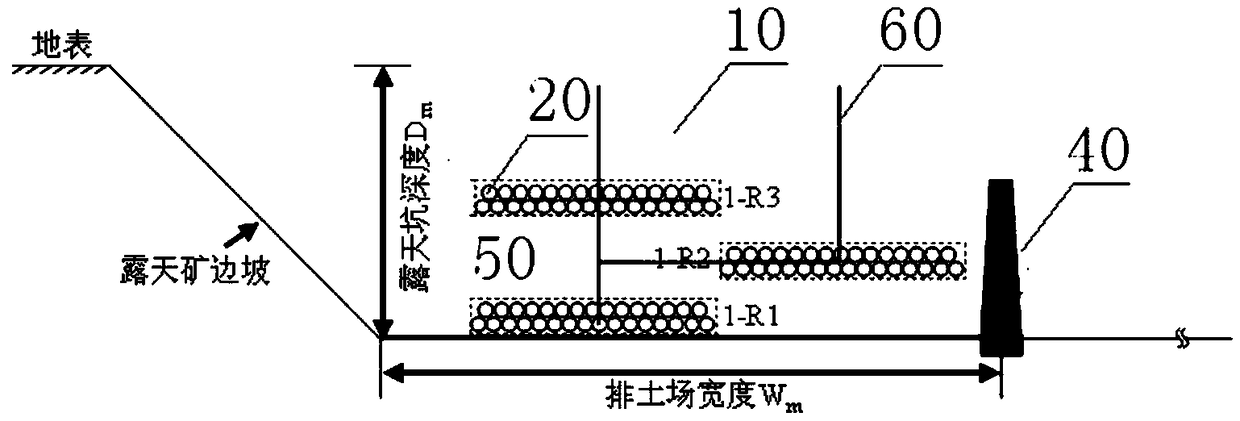

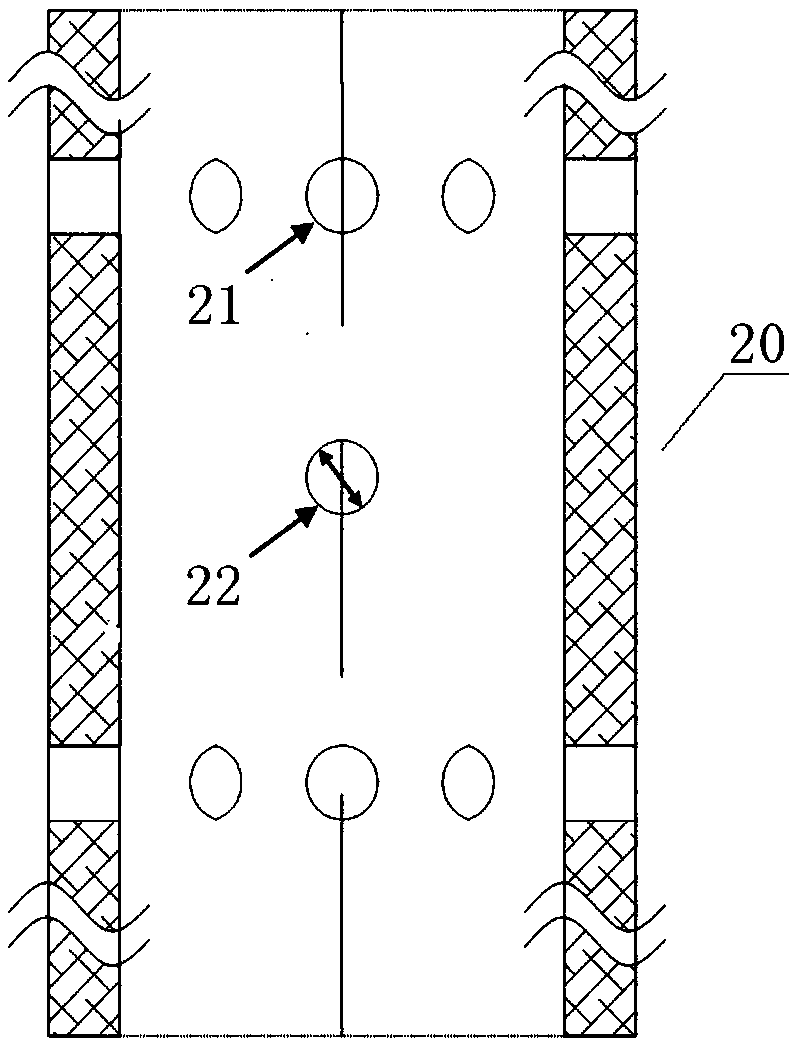

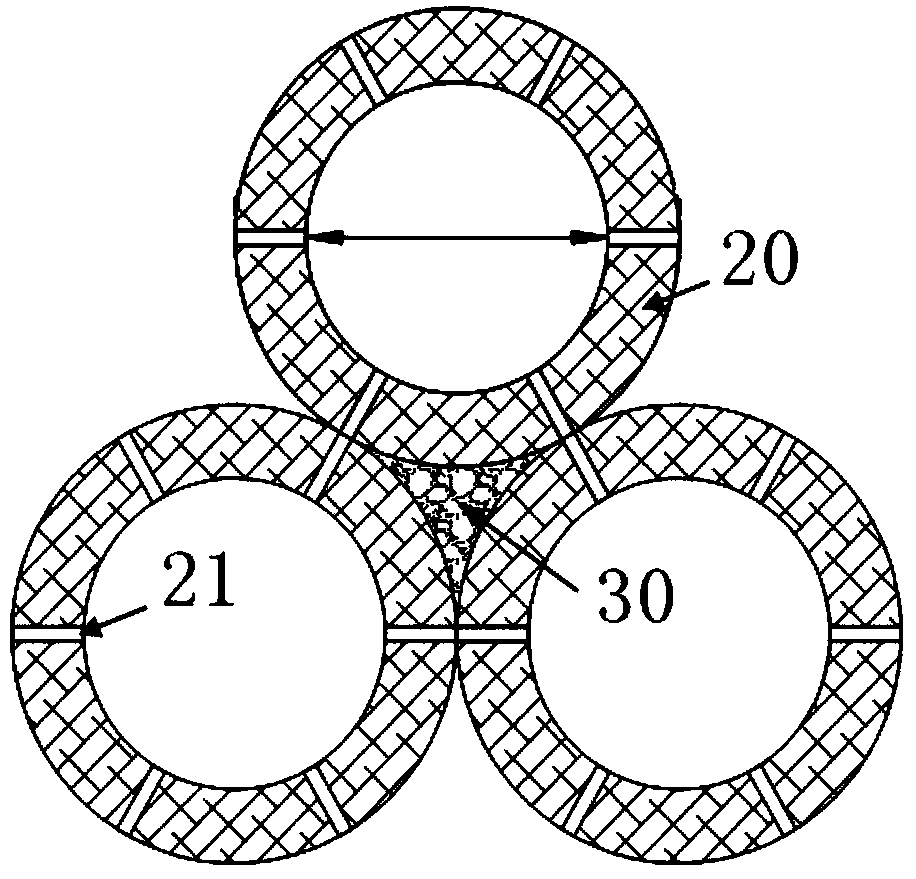

Open-pit coal mine underground reservoir, reservoir water storage body and reservoir storage capacity calculation method

The invention provides an open-pit coal mine underground reservoir water storage body. The water storage body is formed by stacking 2-6 rows of prefabricated pipe culverts from the reservoir bottom ofan underground reservoir to the top in a staggered mode, stacking gaps among the prefabricated pipe culverts are filled with gravels or rubble, a plurality of rows of culvert holes are formed in theprefabricated pipe culverts, and 4-8 culvert holes are formed in each row and uniformly formed in the same circumference of the corresponding prefabricated pipe culvert, a center hole is formed in every two culvert hole rows, water diversion among all the prefabricated pipe culverts is facilitated, and the outer walls of the prefabricated pipe culverts located at the peripheral boundary of the underground reservoir are not provided with culvert holes to ensure the effective water storage of the underground reservoir. The invention further provides the open-pit coal mine underground reservoir with the prefabricated pipe culverts as the water storage body and a storage capacity calculation method of the underground reservoir. The open-pit coal mine underground reservoir with the prefabricated pipe culverts as the water storage body is large in storage capacity and stable in structure, and the storage capacity is convenient and accurate to calculate.

Owner:TSINGHUA UNIV

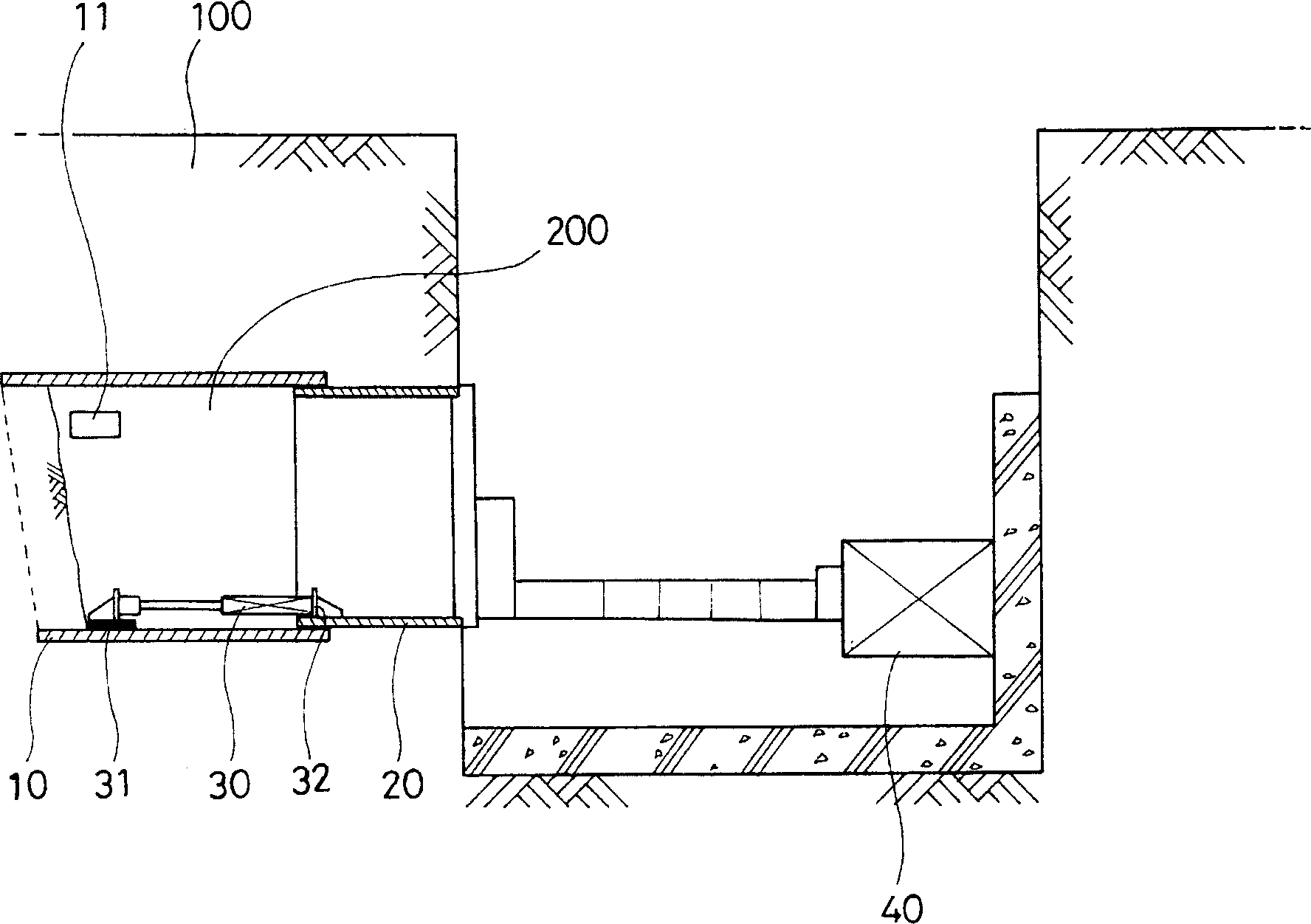

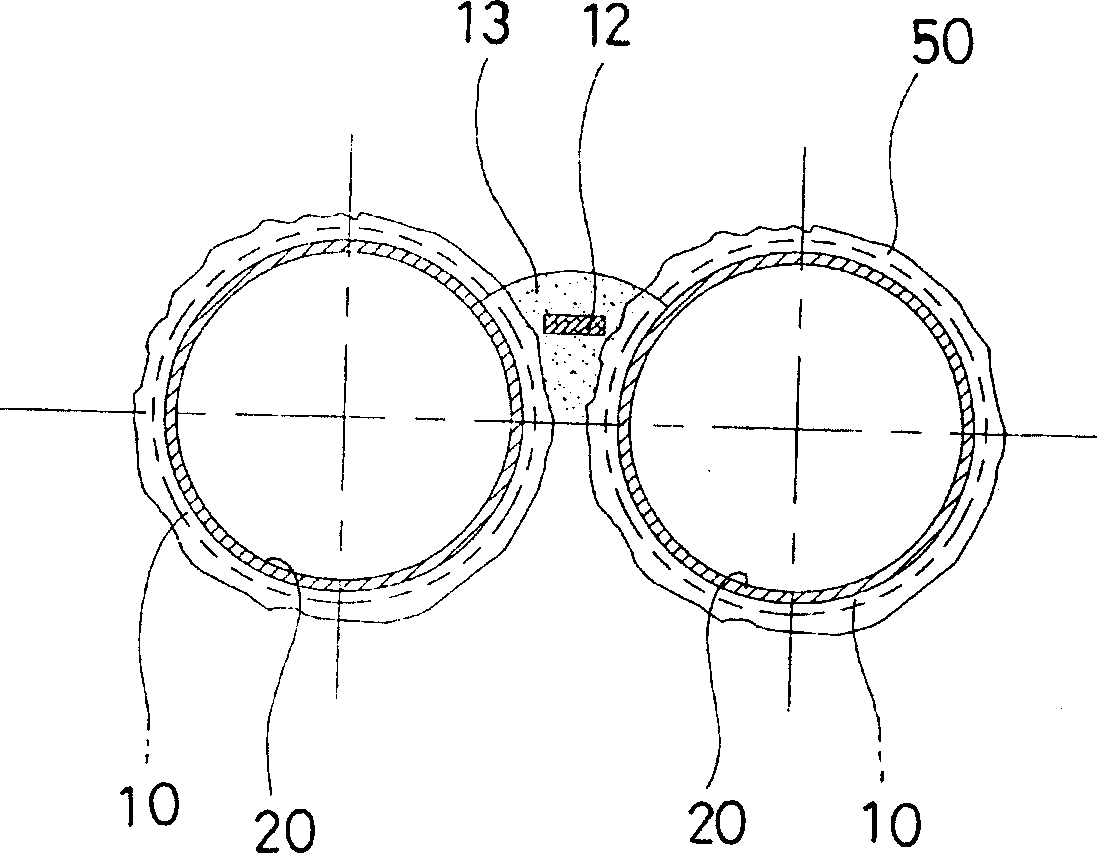

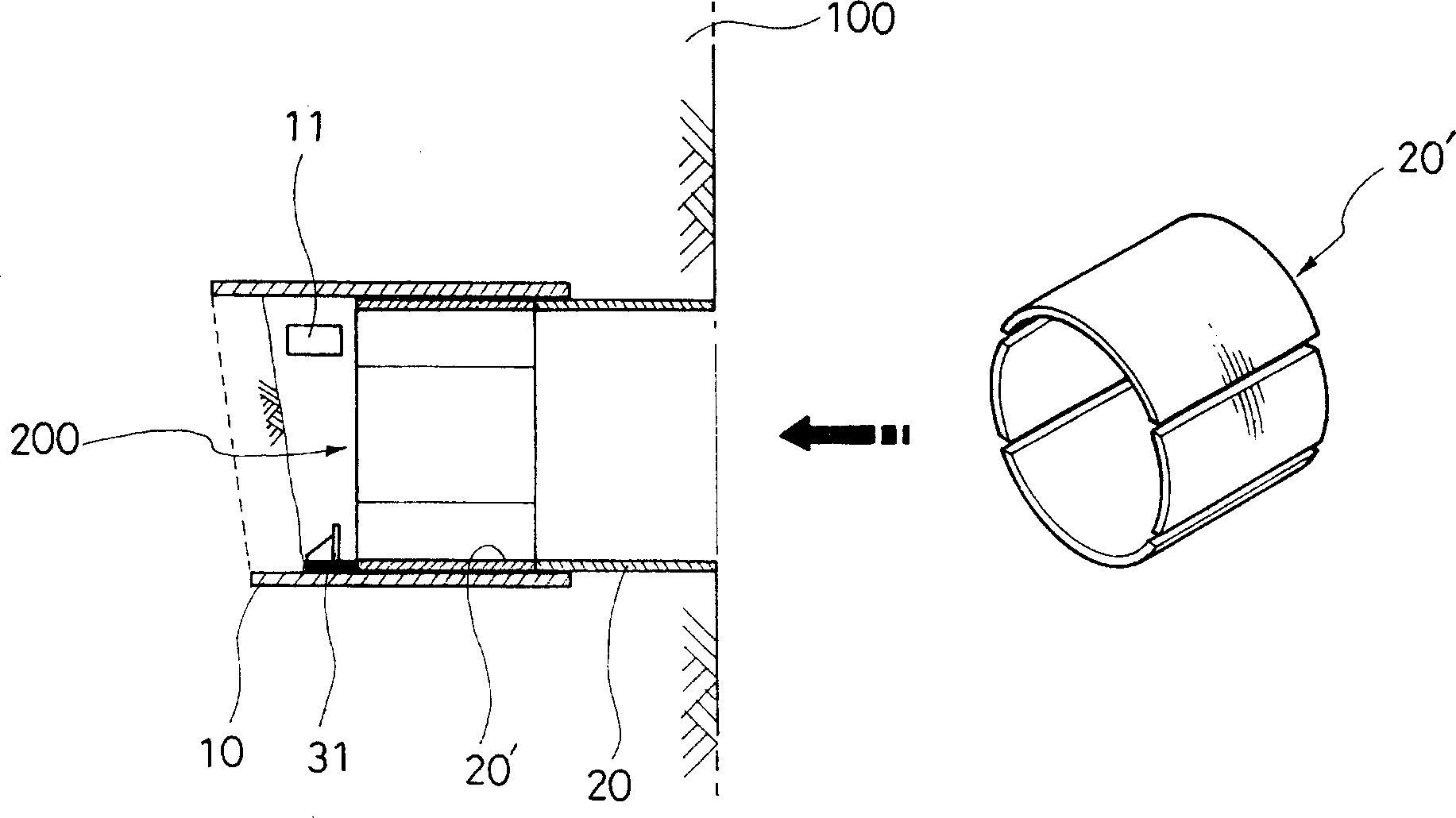

Main pipe construction method for laying tunnel structure and construction structure therof

InactiveCN1766285ASimple Tunnel FormConstruction stabilityUnderground chambersTunnel liningTunnel constructionBuilding construction

A method and a structure for constructing a main pipe installing a tunnel structure forming a tunnel are provided to quickly, easily, safely construct a number of main pipes under ground in straight or curved form. Using the said method and structure, the tunnel structure can bear tunnel external stress to the tunnel designed based on topography and stratum regardless of straight or curved tunnels, so that the designed tunnel can be easily and firmly constructed at short time using few manpower, equipment and facilities. The said method is composed of steps for press-fitting the guidance pipeand the main pipe under the ground; preventing landsliding; welding and connecting the main pipe in turn; propelling forward the guidance pipe; repeatedly the working of the main pipe and finally accomplishing tunnel construction.

Owner:NTS ENC

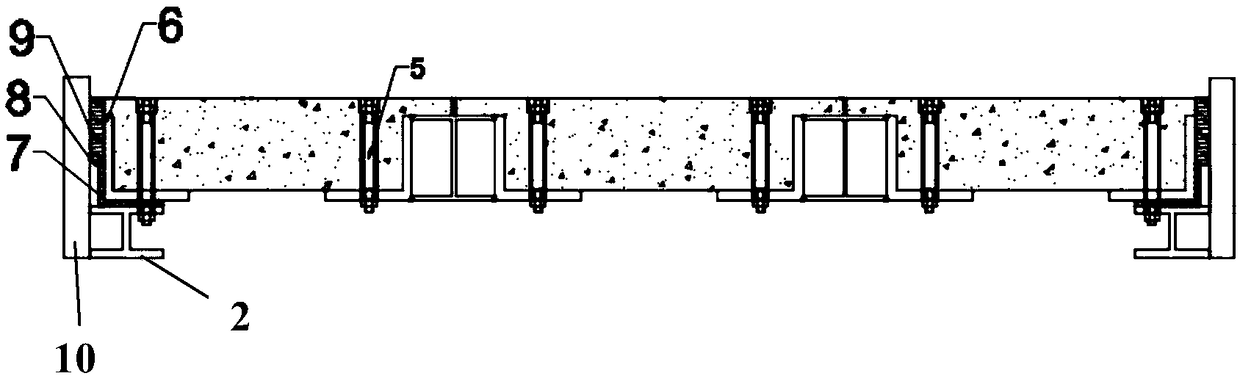

Damping standard prefabricated trave-type floor structure system convenient to construct

InactiveCN109339321AMeet the stiffness requirementsImprove structural stabilityFloorsProtective buildings/sheltersBending momentStructural stability

The invention discloses a damping standard prefabricated trave-type floor structure system convenient to construct. The damping standard prefabricated trave-type floor structure system comprises prefabricated concrete floors, a main beam, a steel structure frame, a shock insulation and energy dissipation layer, steel check blocks and a flexible material filling layer. The multiple prefabricated concrete floors are connected into a whole in the modes such as welding and bolting, and integrity and continuity of the floor structure system are ensured; the trave-type steel structure frame bears and transmits the bending moment and shearing force, thus a floor structure has the enough strength, and meanwhile the stiffness requirement of the floor structure is met; wing plates are arranged on the prefabricated concrete floors and are in lap joint with H-shaped beams, and thus structural stability is improved; when a building is under the effect of an earthquake or meets the needs of certainshocking equipment, the arranged shock insulation and energy dissipation layer achieves the effects of shock insulation and energy dissipation, and transmitting of vibration form parts of structures to the other parts of structures is blocked; and the trave-type steel structure grid frame is fixed through bolts and the steel check blocks, and it is ensured that under the effect of vibration, the situation that the floor structure generates large displacement and then loses stability is avoided.

Owner:河北水利电力学院

Shale gas pool hydraulic fracturing sand-adding technology

InactiveCN107023285AEliminates clogging effectsReduce construction pressureFluid removalSoil scienceVolumetric Mass Density

The invention discloses a shale gas pool hydraulic fracturing sand-adding technology, and belongs to the field of hydraulic fracturing. The shale gas pool hydraulic fracturing sand-adding technology comprises the following steps that (1) acid-pickling is conducted, and acid-pickling is conducted to an perforating area and a near-wellbore zone to remove blockages on perforations and the periphery of the near-wellbore zone; (2) silt is fractured, and sand-carrying fluid carries the silt to form fissure; (3) medium sand is fractured, and the sand-carrying fluid carries the medium sand to form the fissure; (4) coarse sand is fractured, and the sand-carrying fluid carries the coarse sand to fill the fissure of the near-wellbore zone; (5) the sand-carrying fluid is replaced, and ground high pressure pipe joints and the sand-carrying fluid in the wellbore are replaced into stratum to clear out the remaining sand in the wellbore; and (6) ending operation is conducted, a pressure dropping test is conducted, and the construction comes to an end. According to the shale gas pool hydraulic fracturing sand-adding technology, the whole sand-adding amount is improved, the construction pressure is smoother and steadier, the density of sand-paving is evener, and the fissure flow conductivity is effectively improved.

Owner:华美孚泰油气增产技术服务有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com