Main pipe construction method for laying tunnel structure and construction structure therof

A technology for tunnel structures and construction methods, which is applied in tunnels, tunnel linings, and infrastructure engineering, and can solve problems such as inconvenient operations, laying and connecting main pipelines, and difficult completion of tunnels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

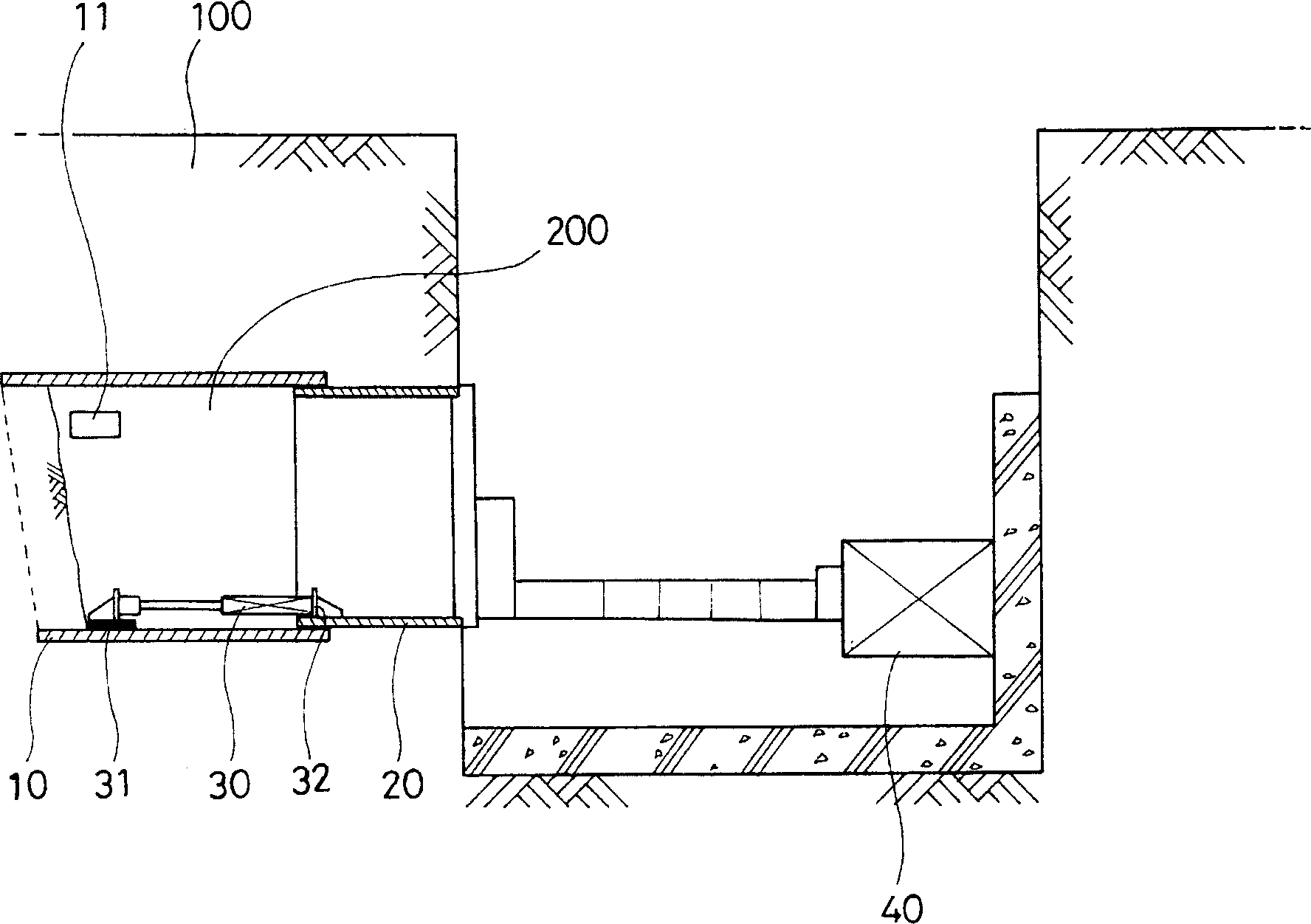

[0024] Embodiment 1 of the present invention will refer to Figure 1a to Figure 3 Be explained. mainly includes:

[0025] In order to lay various types of tunnel structures suitable for the topography and stratum conditions, wooden pipes 300 formed by combining a plurality of wooden boards 320 are laid for a long distance between both sides of steel pipes truncated at a certain length or between H beams 310 in the underground 100 round or angular main pipes. For this, as Figure 1a As shown, a certain number of reaction tables 31, 32 corresponding to each other are arranged at a certain interval on the inner side of the transmission pipe 10 and the main pipe 20, and the rod of the hydraulic / pneumatic cylinder 30 arranged between the reaction tables 31, 32 is advanced to utilize the hydraulic pressure. The jack 40 presses the transmission pipe 10 and the main pipeline 20 into the process A of the underground 100;

[0026] Such as Figure 1a Shown, in above-mentioned transfer...

Embodiment approach 2

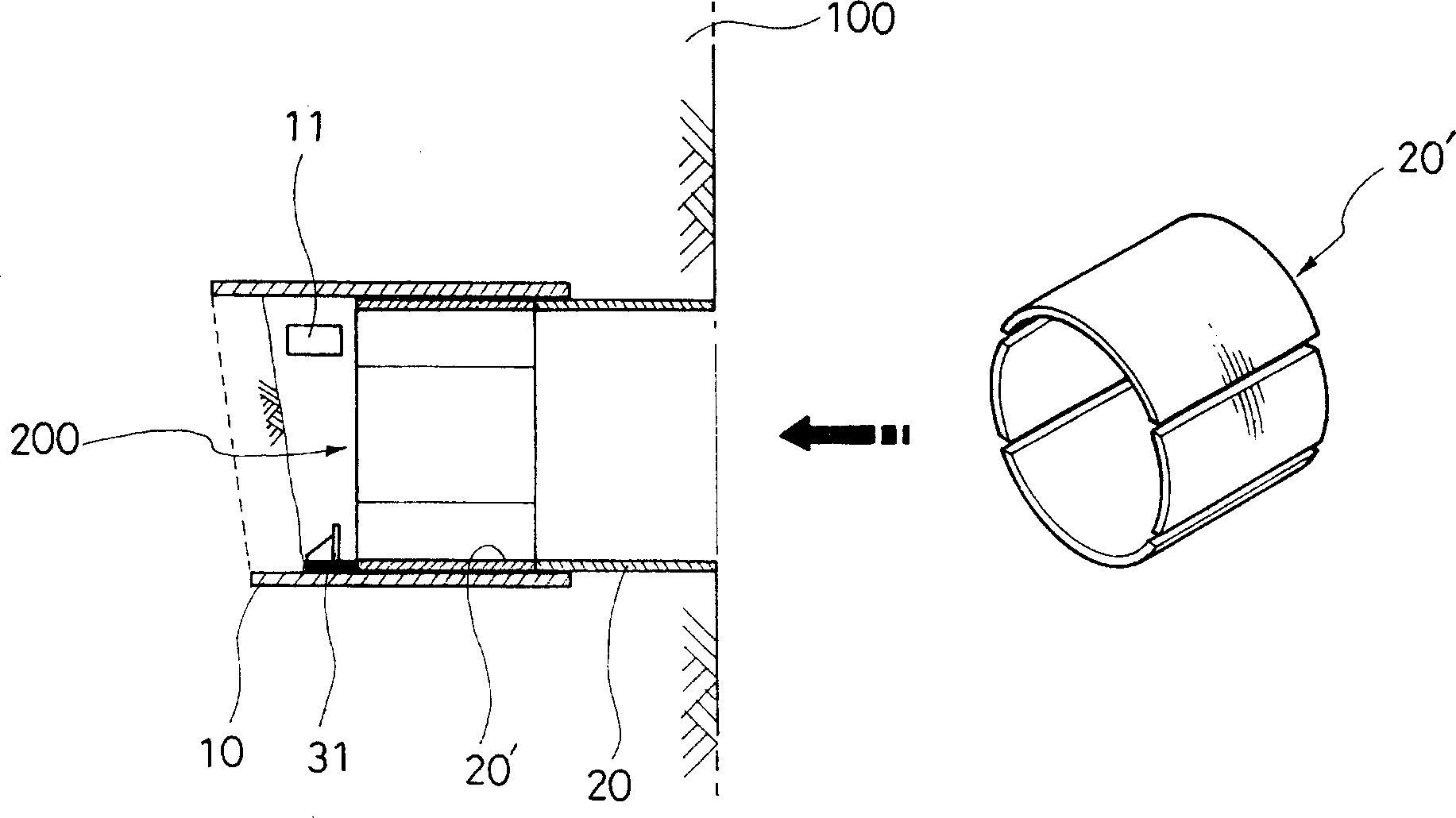

[0031] Embodiment 2 of the present invention will refer to Figure 4 , other techniques will refer to figure 2 b to image 3 Be explained. mainly includes:

[0032] In order to lay a variety of tunnel structures suitable for terrain and stratum conditions, such as Figure 4 As shown, a certain number of reaction platforms 31, 32 corresponding to each other are arranged at a certain interval on the inner side of the transmission pipe 10 and the main pipeline 20, and the rod of the hydraulic / pneumatic cylinder 30 arranged between the reaction platforms 31, 32 is retreated. The hydraulic jack 40 presses the transmission pipe 10 and the main pipeline 20 into the underground 100 process A';

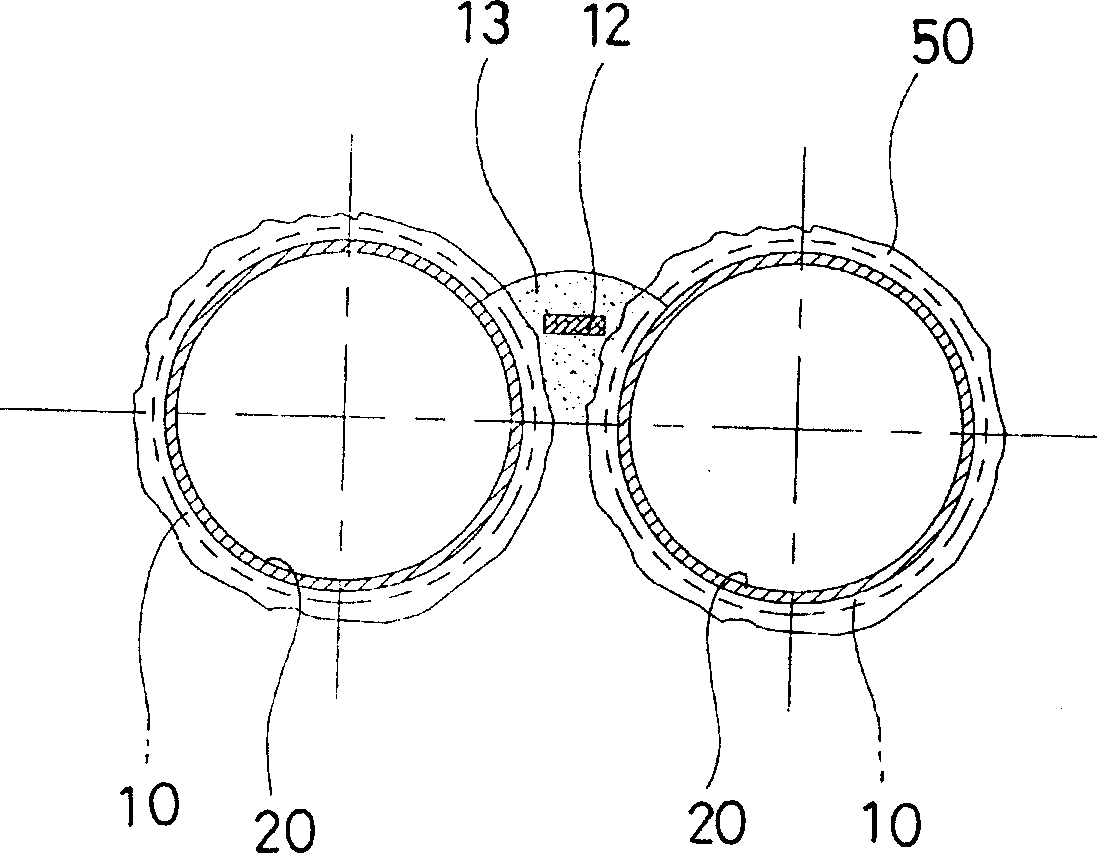

[0033] use Figure 1a Shown method, in above-mentioned transfer pipe 10 and main pipeline 20 press-in process, as Figure 1b As shown, through the input port 11 of the anti-collapse plate formed on the transmission pipe 10, the surrounding soil is dug out, and then the anti-collapse plat...

Embodiment approach 3

[0038] Embodiment 3 of the present invention will refer to Figure 5 , other techniques will refer to figure 2 b to image 3 Be explained. mainly includes:

[0039] In order to lay a variety of tunnel structures suitable for terrain and stratum conditions, such as Figure 5 As shown, the front reaction platform 31 is set inside the transmission pipe 10, so that the front end of the main pipe 20 is stuck here, and the transmission pipe 10 and the main pipe 20 are pressed into the underground 100 by the hydraulic jack 40. Process A";

[0040] use Figure 1a Shown method, in above-mentioned transfer pipe 10 and main pipeline 20 press-in process, as Figure 1b As shown, through the input port 11 of the anti-collapse plate formed on the transmission pipe 10, the surrounding soil is dug out, and then the anti-collapse plate 12 is sequentially input and connected, and the mud is poured on the anti-collapse plate 12 to form a mud pouring part 13 to prevent the process of collapse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com