Damping standard prefabricated trave-type floor structure system convenient to construct

A technology of prefabricated wells and slabs, which is applied in the direction of floors, earthquake resistance, building components, etc., can solve the problems of difficulty in popularization and high cost, and achieve the effects of convenient construction, improved structural stability, and meeting rigidity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A detailed description will be given below in conjunction with the accompanying drawings.

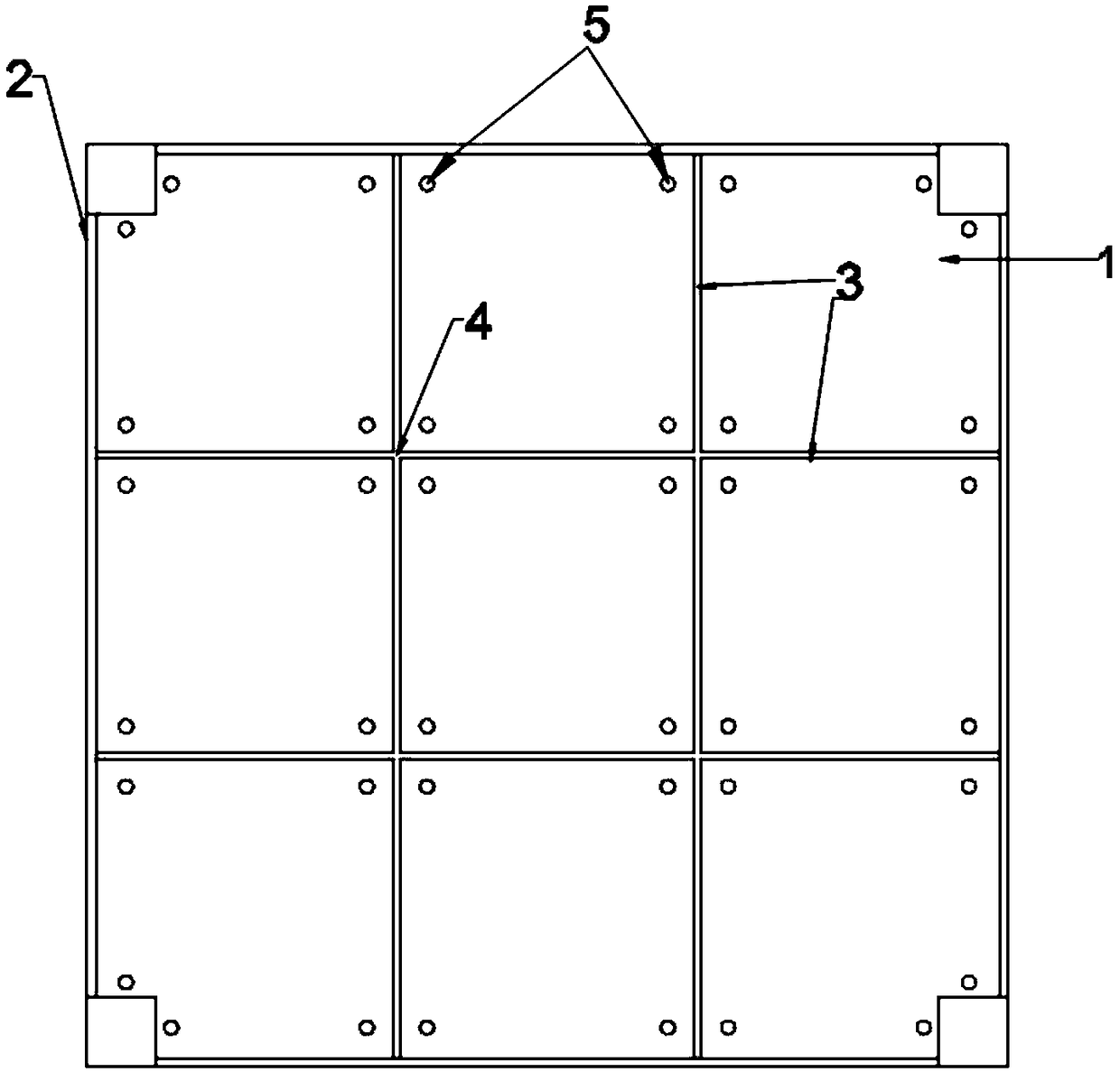

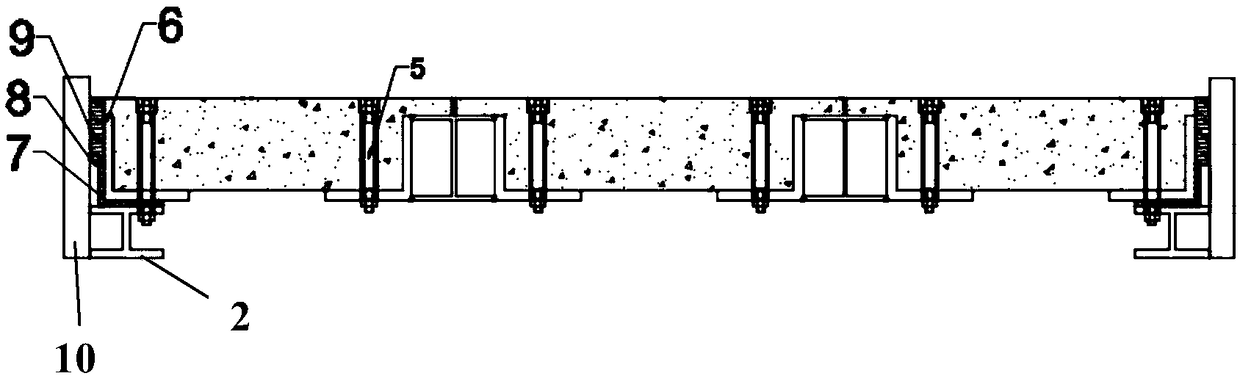

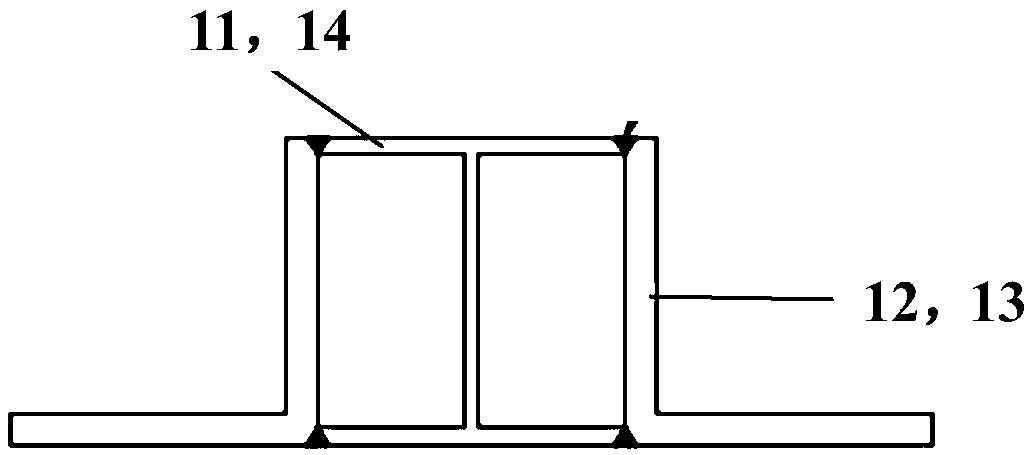

[0020] Such as figure 1 , figure 2 and Figure 6 As shown, the shock-absorbing standard prefabricated well format floor structure system provided by the present invention includes a prefabricated concrete floor 1, a main beam 2, a steel structure frame 3, a shock-isolation and energy-dissipating layer 7, a steel block 8 and a flexible material filling layer. 9; wherein the main beam 2 is arranged horizontally along the inner side of the wall 10, and is made of I-shaped steel; the steel structure frame 3 is a well-shaped structure, and the edges are placed on different main beams 2, and each grid is equipped with a prefabricated The concrete floor 1; the contact part between the main beam 2 and the steel structure frame 3 is provided with an L-shaped seismic isolation and energy dissipation layer 7; the top surface of the main beam 2 is located between the wall 10 and the seis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com